Resource utilization method for saponification waste water producing epoxypropane by chlorohydrination process

A method of propylene oxide and saponification wastewater technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to support sustainable development, good economic benefits, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

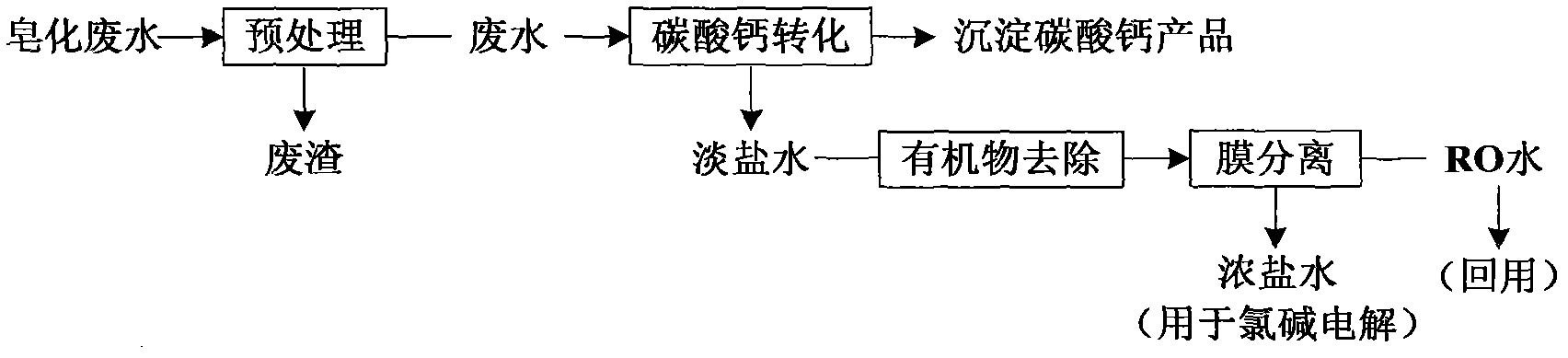

Method used

Image

Examples

Embodiment 1

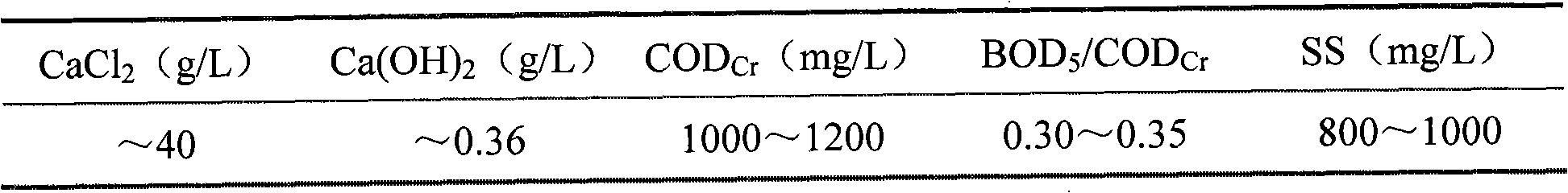

[0030] Step 1. Put a certain amount of saponification wastewater shown in Table 1 in the reactor, feed carbon dioxide, stop the ventilation when the pH value drops below 7, and then add 0.4mol / L of Sodium carbonate solution until the calcium ion removal rate reaches 99%, and the reaction temperature is controlled at 25°C. After solid-liquid separation, the precipitated calcium carbonate is washed and dried to obtain nano-scale calcium carbonate with a particle size of 80-100nm, calcite crystal form, and spherical shape.

[0031] Step 2. Take the filtrate after the above solid-liquid separation and put it in an electrolytic cell without a diaphragm. The anode of the electrolytic cell is a mesh flat Ti / PbO 2 Oxide-coated electrode, stainless steel as the cathode, the anode and cathode have the same area, adjust the pH value to 6-7, perform constant current electrolysis at room temperature, and the current density is 50mA / cm -2 , take samples at regular intervals, monitor COD, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com