Seven-layer co-extrusion transparent high-isolation film and preparation method thereof

A high-resistance, transparent technology, applied in the field of packaging materials, can solve problems such as high production costs and environmental pollution, and achieve the effects of preventing oxygen infiltration, high mechanical strength, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of a transparent high barrier film, comprising the following steps:

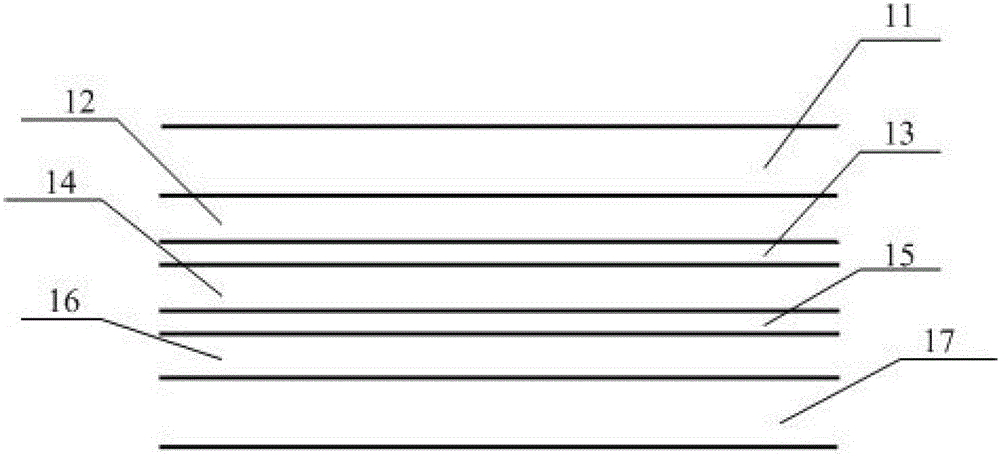

[0037] Polyamide, linear low-density polyethylene, ethylene-vinyl alcohol copolymer and polyethylene are co-extruded to obtain a first polyamide layer, a first linear low-density polyethylene layer, and a second polyamide layer in sequential contact. Heat-melt pipe of amide layer, ethylene-vinyl alcohol copolymer layer, third polyamide layer, second linear low density polyethylene layer and polyethylene layer;

[0038] Blow molding the hot-melt pipe into a film, cooling and setting;

[0039] The outer surface of the film after cooling and setting is subjected to corona treatment to obtain a transparent high-barrier film.

[0040] The invention adopts a co-extrusion blow molding process to prepare a transparent high-barrier film, and the production process is relatively simple.

[0041] First, the first polyamide layer, the first linear low-den...

Embodiment 1~5

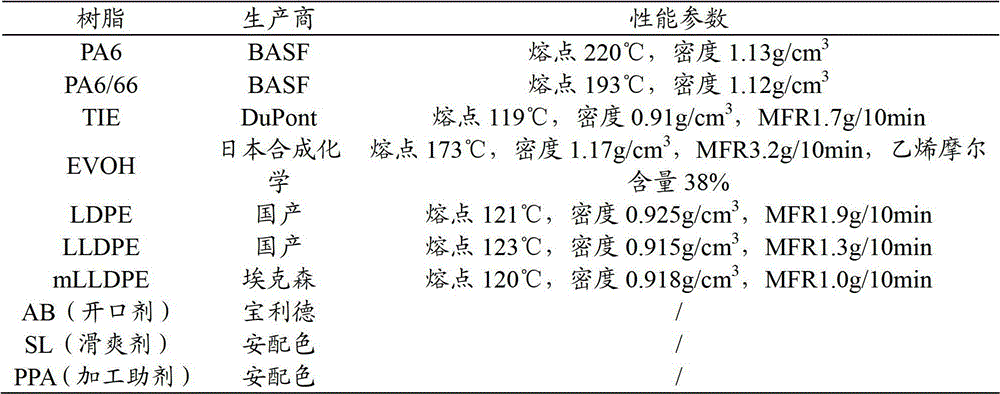

[0055] The transparent high-barrier film was prepared with a seven-layer co-extrusion upper blow molding equipment of the model VAREX produced by W&H in Germany:

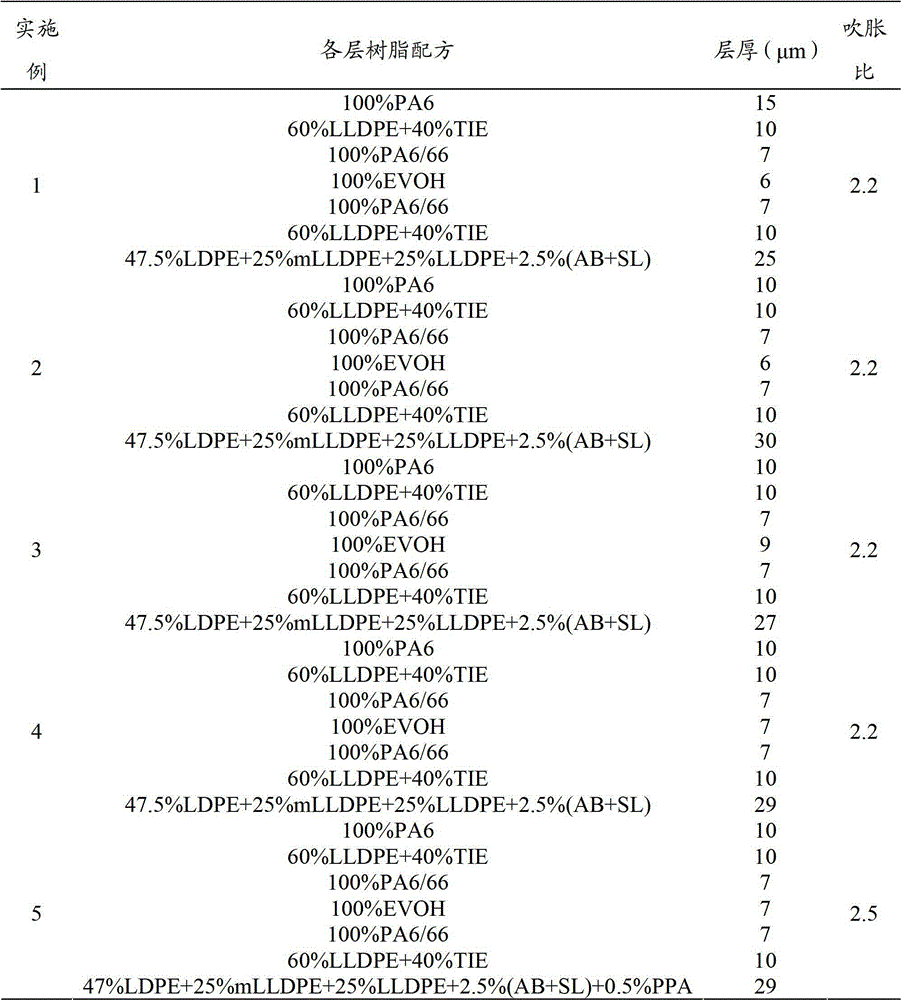

[0056] Add the first polyamide layer raw material (denoted as Y1), the first linear low-density polyethylene layer raw material (denoted as Y2), the second polyamide layer Raw materials (denoted as Y3), raw materials for ethylene-vinyl alcohol copolymer layer (denoted as Y4), raw materials for the third polyamide layer (denoted as Y5), raw materials for the second linear low-density polyethylene layer (denoted as Y6) and polyethylene Layer raw materials (denoted as Y7), the specific formula of each raw material is shown in Table 2.

[0057] The raw materials in the 7 barrels were co-extruded and then blow molded. The inflation ratios were 2.2, 2.2, 2.2, 2.2 and 2.5 respectively, and the thickness of each layer was controlled. The thickness of each layer is shown in Table 2.

[0058] Table 2 The formula of raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com