Nano-composite film bag capable of realizing one-way venting and high obstruction

A nano-composite, one-way exhaust technology, applied in the field of packaging composite film bags, can solve the problems of difficult adoption by small and medium-sized enterprises, large equipment investment, and high equipment requirements, and achieve the effect of good barrier property, simplified process and smooth appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

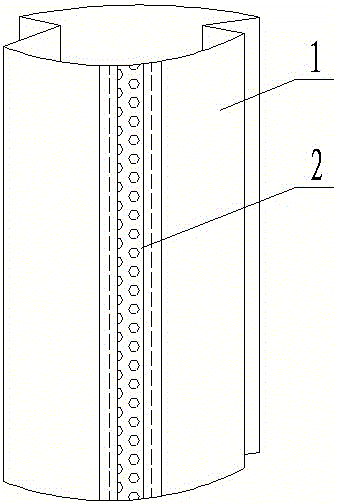

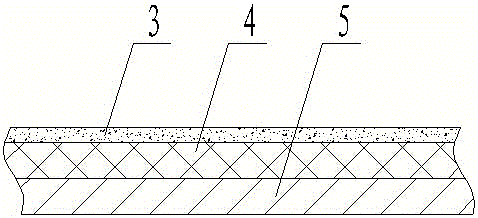

[0014] Such as Figure 1~2 As shown: the composite film bag of the present invention is composed of a bag body 1 and a non-woven fabric 2 lapped at the seam of the bag body, and a number of air-permeable micropores (not shown in the figure) are distributed on the non-woven fabric. The bag body 1 is made of a heat-sealing base film 4, the outer surface of which is coated with a nano-modified PVA slurry film layer 3; the heat-sealing base film 4 can be a PE film, It can also be CPP film.

[0015] In order to further improve the barrier performance of the packaging bag, a layer of printed base film 5 is compounded on the inner surface of the heat-sealing base film 4 . When the package is an item that does not need shading, the printed base film 5 can choose BOPP film or PET film; when the package is an item that needs shading treatment (such as tea, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com