Patents

Literature

30results about How to "Save aluminum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-counterfeiting transfer printing technology

InactiveCN101618630APromote degradationNo pollutionTransfer printingVacuum evaporation coatingVacuum pumpingCompanion animal

The invention relates to an anti-counterfeiting transfer printing technology which comprises the following steps: preparing a laser plate; coating a layer of mold release agent or imaging paint on a PET base film; carrying out vacuum pumping on the PET base film and an aluminum material device in a vacuum plating evaporator; then heating the aluminum material and depositing gaseous aluminum particles on the surface of the moving PET base film and / or the surface of the mold release agent or the imaging paint; stamping an embossing pattern on the laser plate on a mold release agent layer or an imaging paint layer and / or an aluminum layer so as to make a holographic transfer film for transfer; bonding the holographic transfer film and backing paper together; separating the PET base film from the paper, wherein the stripped PET base film can be repeatedly used for a coated base film; and coating a layer of aqueous varnish on the surface of the transferred paint layer and / or the aluminum layer. The technology can combine an anti-counterfeiting printing technology with a transfer printing technology, and an aluminum plating layer transferred on the paper can be made to be thin, thereby saving the aluminum material; in addition, the base film used in transfer printing can be repeatedly utilized and does not pollute the environment.

Owner:江苏中印印务集团有限公司

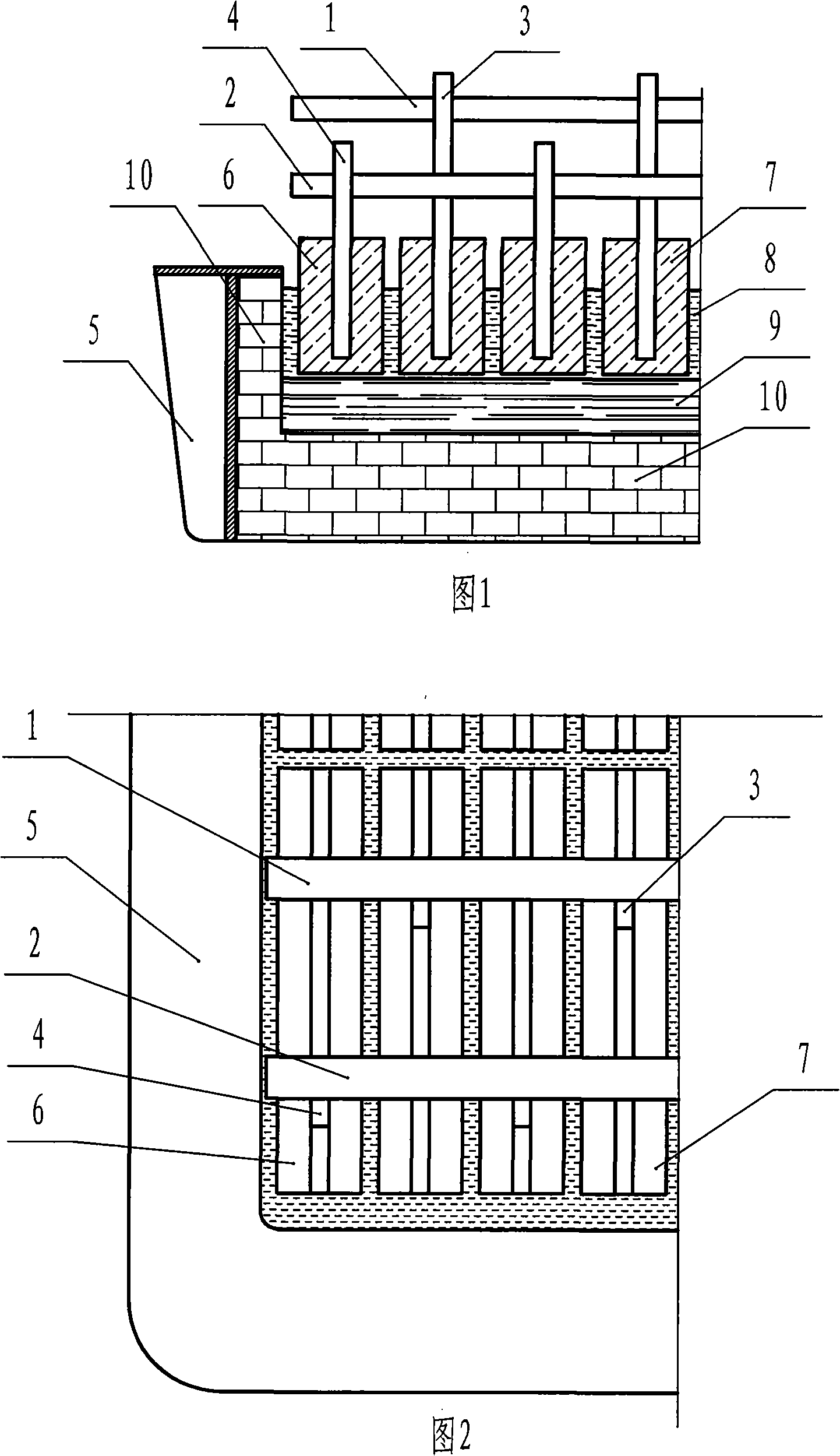

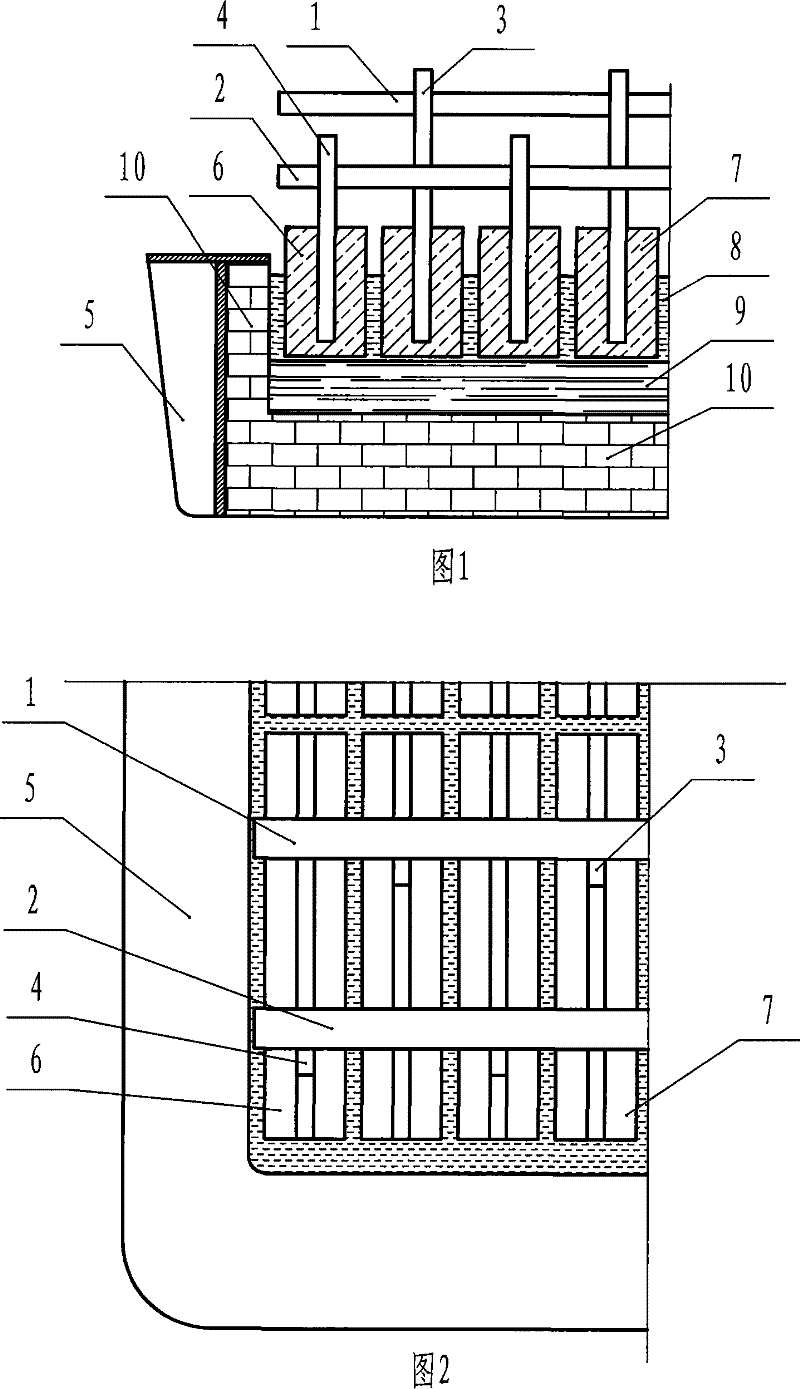

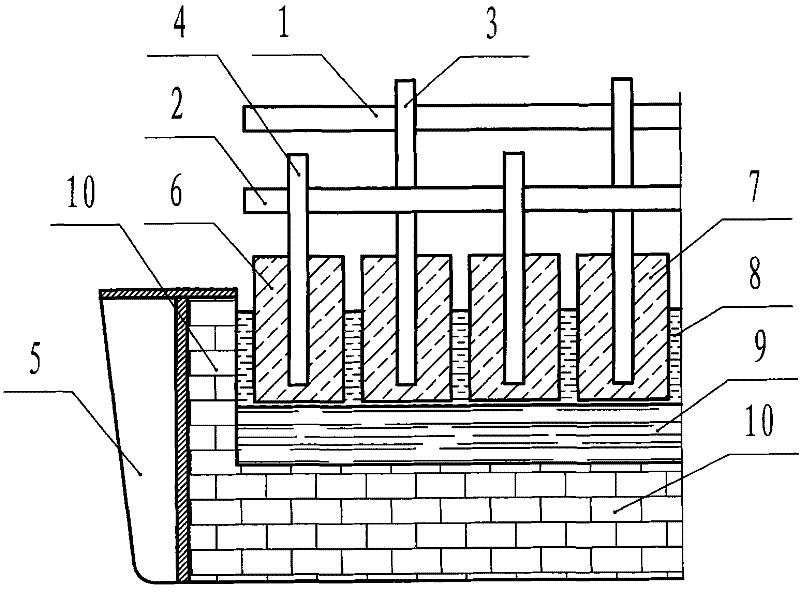

Horizontal current aluminium cell

The invention discloses a horizontal current aluminum electrolytic bath. The aluminum electrolytic bath comprises a melting bath part and an electrode part, wherein the melting bath part consists of a steel bath shell(5) and fire proof and heat proof materials(10); the upper end of the bath shell(5) adopts an open type structure; while the electrode part consists of a cathode electrode part and an anode electrode part, wherein the cathode electrode part consists of a cathode electrode(6), a cathode electrically conductive pole(4) and a cathode bus(2) applied to discharge electric current, and the anode electrode part consists of an anode electrode(7), an anode electrically conductive pole(3) and an anode bus(1) applied to charge electric current; the electrode part are hanged in the bath shell(5) by a support steel beam, and a liquid electrolyte layer (8) is arranged between the cathode electrode(6) and the anode electrode(7); electrolytic currents horizontally enter the corresponding side face of the cathode electrode(6) from the side face of the anode electrode(7). The aluminum electrolytic bath has the advantages that the design is novel, no electric current pass through the melting bath, no electrochemical reaction happens, the aluminum electrolytic bath does not need to be drilled around, along with long service life and good social and economic benefits.

Owner:HENAN ZHONGFU IND

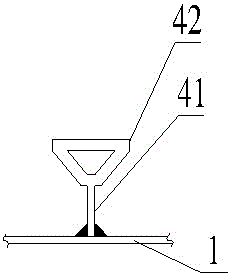

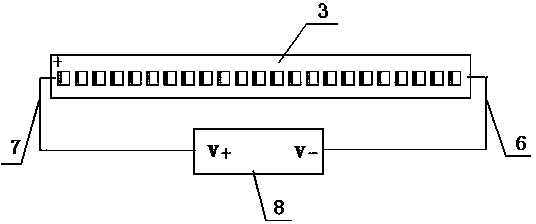

Heat dissipation fault warning method of LED lamp and heat dissipating device

InactiveCN101790263ARepair in timeReduce the temperaturePoint-like light sourceElectric circuit arrangementsEffect lightEngineering

The invention relates to a heat dissipation fault warning method of an LED lamp. The substrate of an LED lamp module is provided with a heat dissipating device; the temperature of the substrate of the LED lamp module is detected by using a temperature sensor; when the temperature of the substrate is higher than the maximum temperature, a control circuit cuts off the power supply of an LED lamp; when the temperature of the substrate drops to be lower than the maximum temperature, the control circuit switches on the power supply of the LED lamp; when the temperature of the substrate raises again to be higher than the maximum temperature, the control circuit cuts off the power supply of the LED lamp again; by repeating in such a manner, the discontinuous lighting of the LED lamp is utilized to warn that the LED lamp generates a heat dissipation fault; street lamp managers know that the heat dissipating device of the LED lamp generates fault when finding the discontinuous lighting of the LED lamp, and the maximum temperature is smaller than the light attenuation temperature of the LED lamp. The method can enable the LED lamp with the heat dissipation fault to be very easily found by the street lamp managers, thereby, the LED lamp is maintained in time. Meanwhile, the temperature of the LED lamp can be controlled to be lower than the light attenuation temperature, thereby achievingthe goal of protecting the LED lamp.

Owner:陈鸿 +1

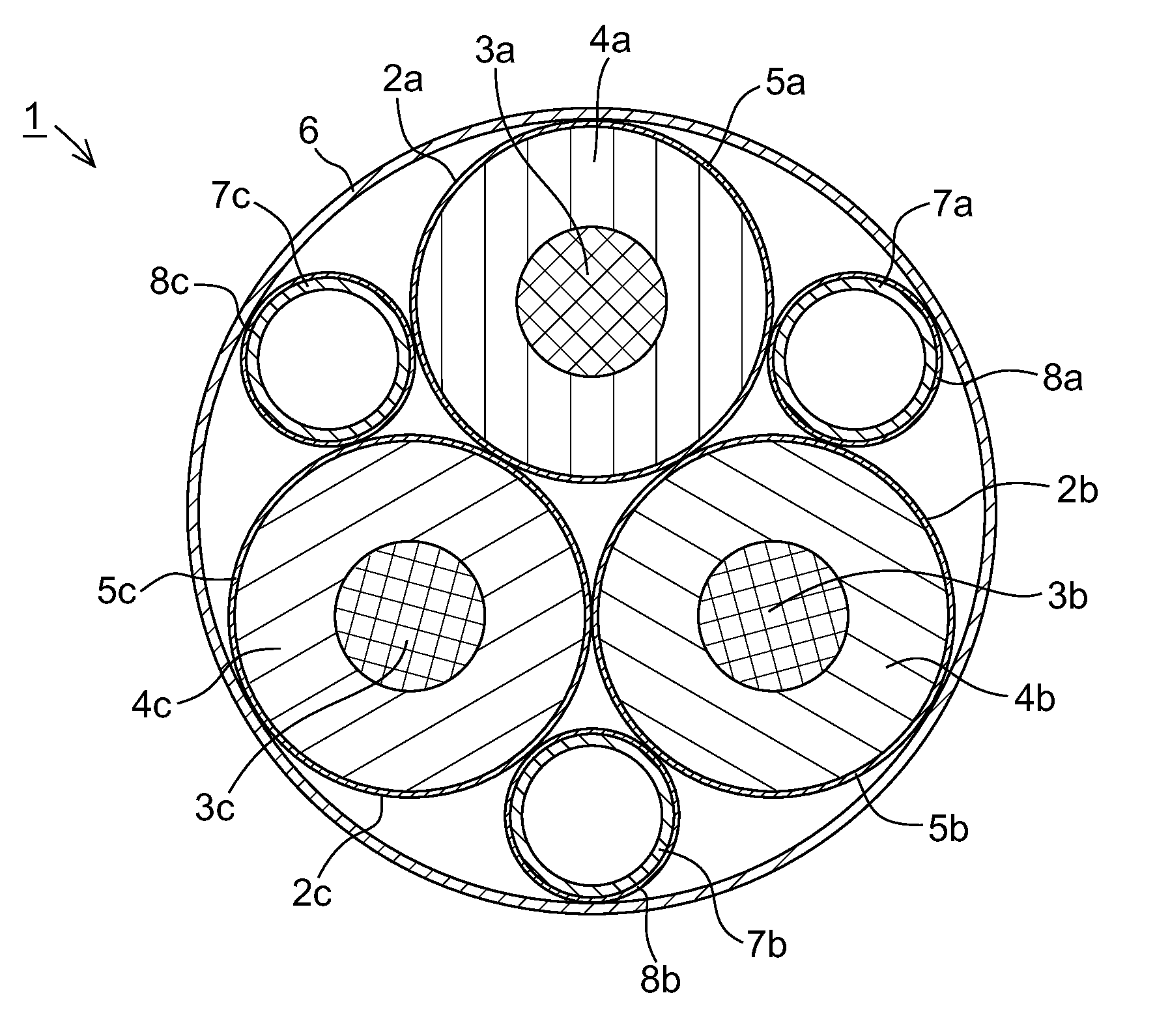

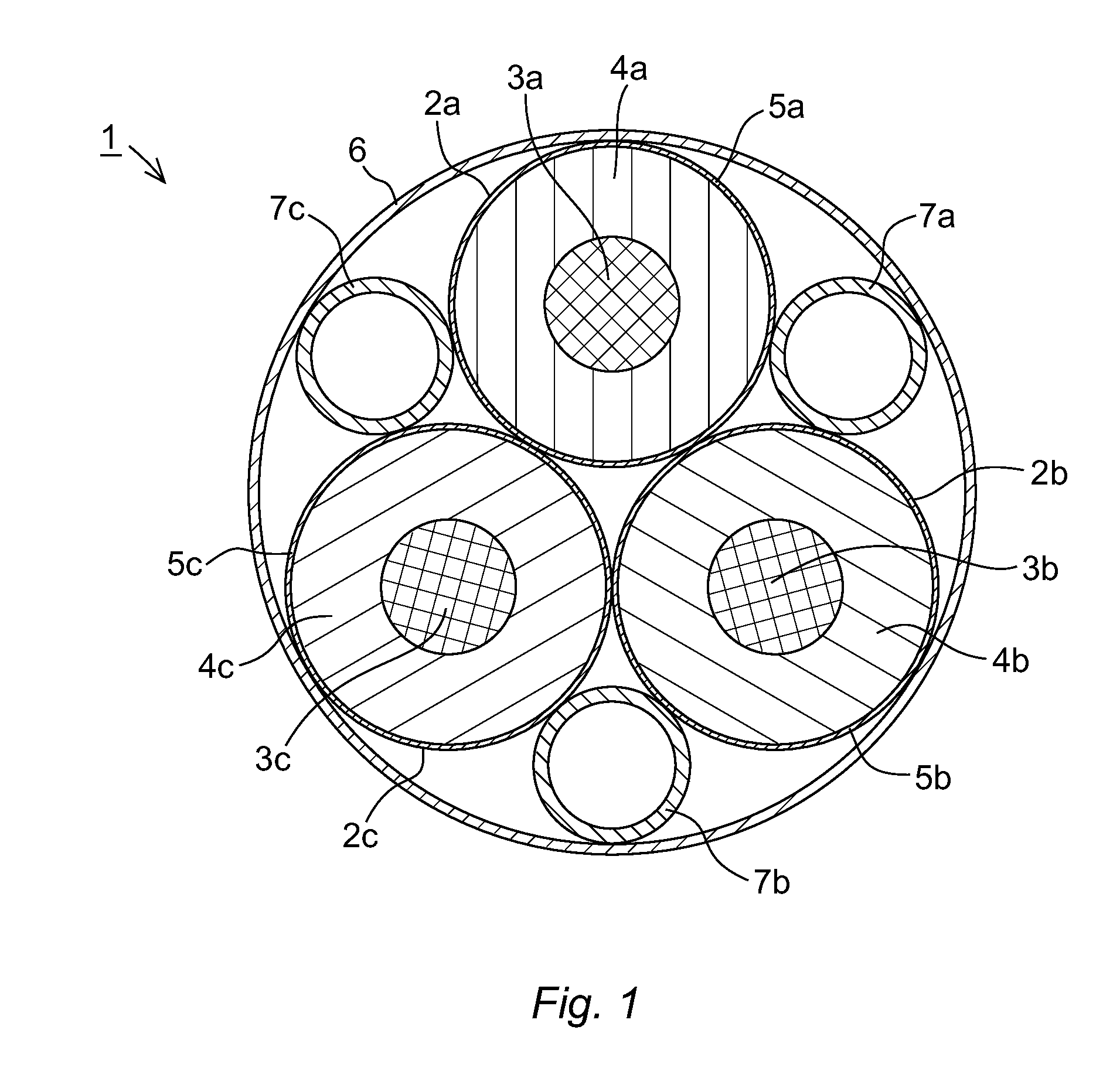

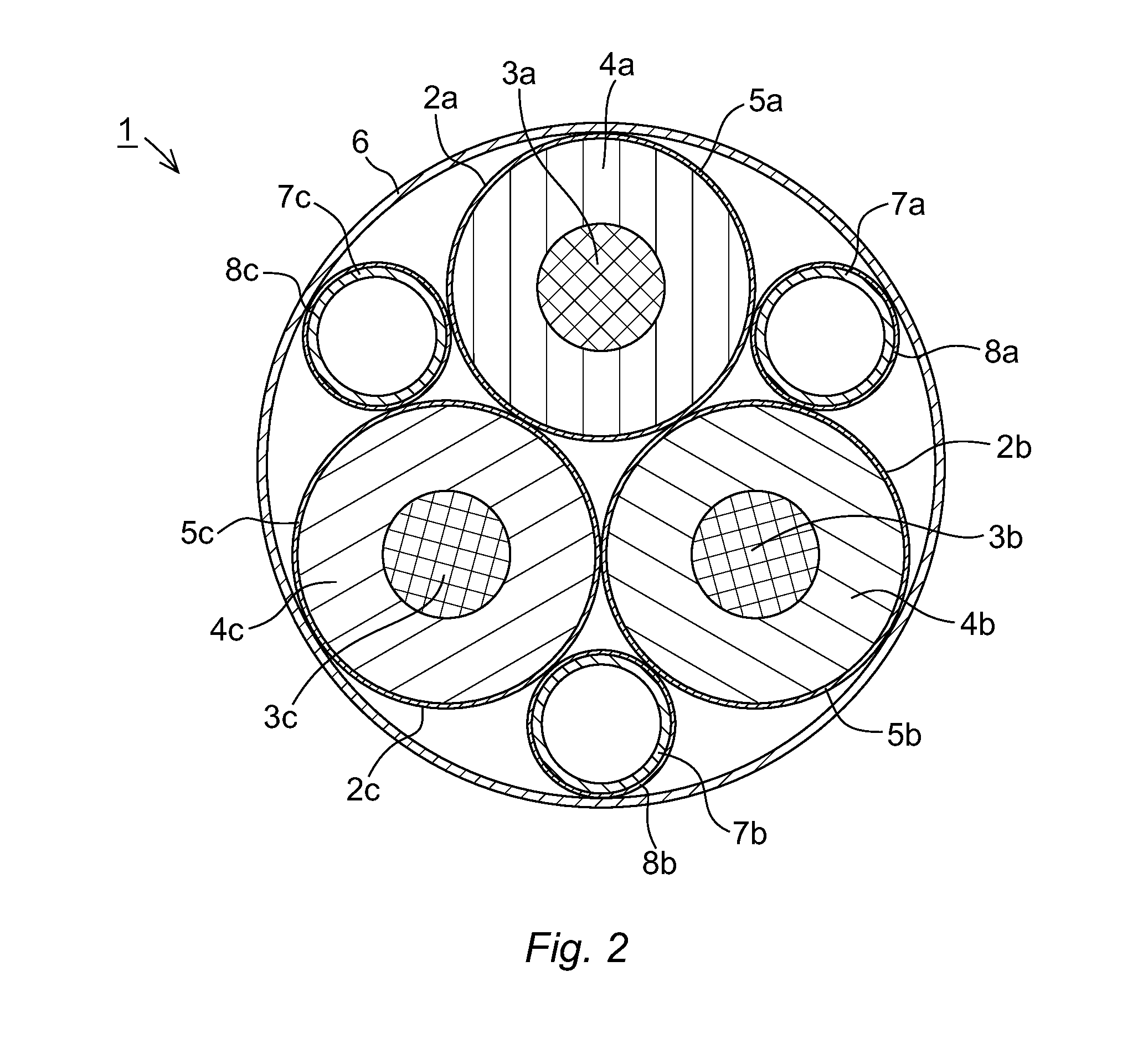

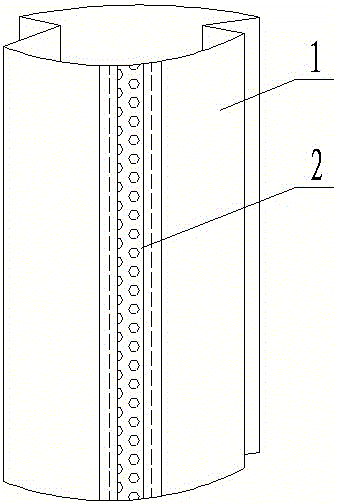

High voltage electric cable

ActiveUS8847069B2Easy to integrateEasy to manufactureElectrically conductive connectionsInsulated cablesHeat conductingEngineering

A high voltage electric cable including a cable core, a cooling pipe for cooling the cable core including a polymer and adapted for carrying a cooling fluid, and a cable covering enclosing the cable core and the cooling pipe. The electric cable further includes a heat conducting element surrounding the cable core, and being arranged in thermal contact with the cable core and the cooling pipe.

Owner:NKT HV CABLES AB

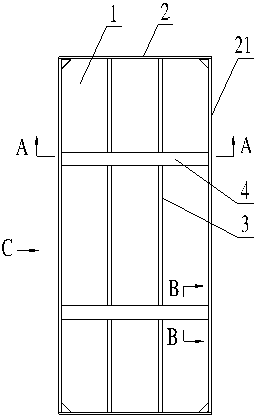

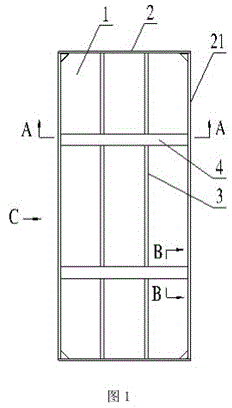

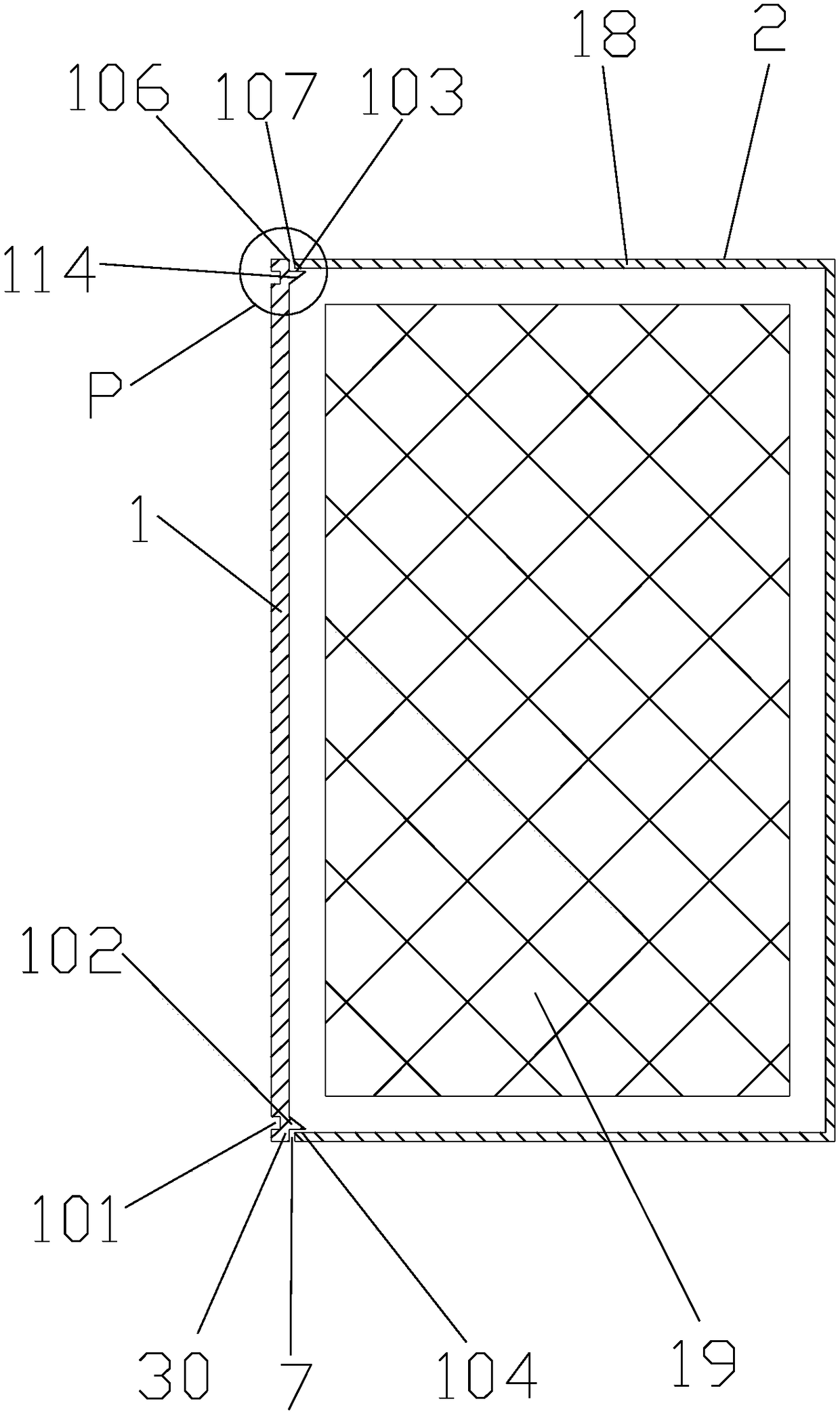

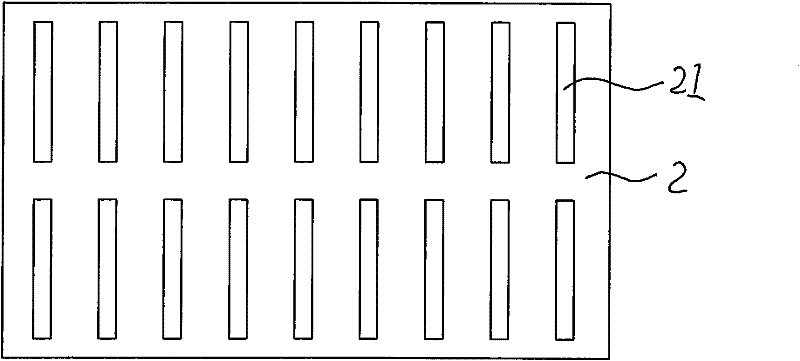

Aluminum template

ActiveCN103437547AHigh compressive strengthNot easy to seepAuxillary members of forms/shuttering/falseworksForming/stuttering elementsSlurryUltimate tensile strength

The invention relates to an aluminum template which has higher use efficiency and saves more materials. The aluminum template comprises a panel and connection plates at the periphery of the inner side of the panel, wherein a plurality of vertical reinforcing ribs and transverse reinforcing ribs are arranged on the inner side of the panel, and the two ends of the vertical reinforcing ribs and the transverse reinforcing ribs are fixedly connected with the connection plates respectively; notches are formed in one sides of the transverse reinforcing ribs, which are contacted with the panel; the vertical reinforcing ribs are inserted into the notches. According to the aluminum template, a manner of arranging the reinforcing ribs vertically and transversely is adopted so that the panel with a template area of 0.5 square meters is divided into a plurality of small stresses faces, so that the template is not easy to deform and the strength and the bearing capability of the template are enhanced greatly; convex shoulder strip inner bolts are arranged on the connection plates for connection so that the occlusion of the templates is more tight and slurry is not easy to seep, and furthermore, the slurry is saved and a construction site is prevented from being polluted by the slurry; a pin sheet is set to be a radian plate so that the pin sheet is not easy to fall off, is convenient to mount and dismount and is convenient to pick up when falling down to the ground; the construction cost is reduced effectively to a certain extent.

Owner:镇江科顺高新材料有限公司

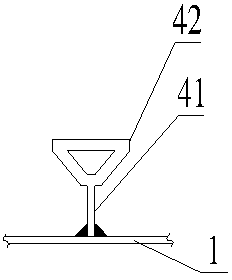

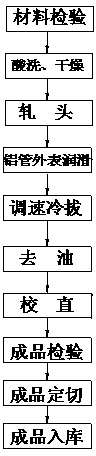

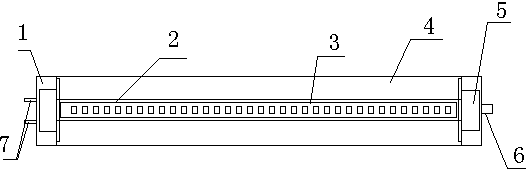

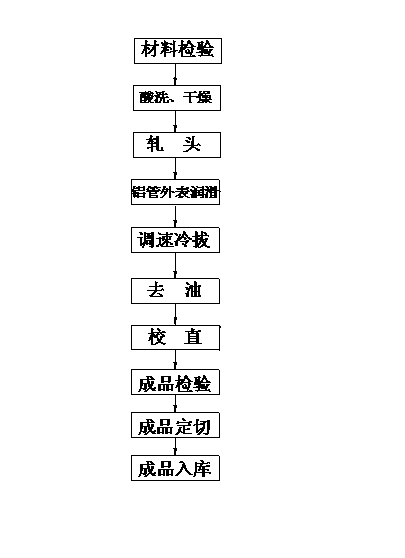

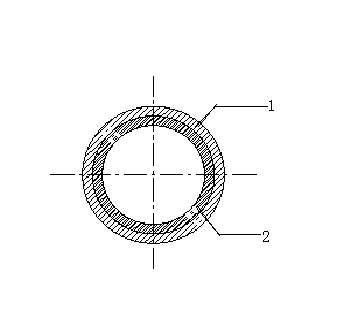

Manufacturing process of aluminum-steel composite pipe with high thermal conductivity for petrochemical

InactiveCN103372579AImprove structural rigidityExtend your lifeWire straightening devicesHeat conductingPetrochemical

The invention discloses a manufacturing process of an aluminum-steel composite pipe with high thermal conductivity for petrochemical. The adopted raw materials comprise an aluminum pipe and a steel pipe. The manufacturing process comprises the following steps: firstly, pickling and drying the aluminum pipe and the steel pipe; then, sleeving the aluminum pipe at the outside of the steel pipe, reserving a gap of 0.3-0.4 mm between the inside diameter of the aluminum pipe and the outside diameter of the steel pipe, simultaneously heating the aluminum pipe and the steel pipe through super audio induction coils, and firmly compounding the heads of the aluminum pipe and the steel pipe through a special head rolling machine; lubricating the aluminum pipe; finally, performing cold drawing through a speed drawing machine. Therefore, the produced aluminum-steel composite pipe not only has excellent heat conducting performance, and the rigidity is improved, meanwhile, the aluminum material is greatly saved and the heat dissipation efficiency is enhanced.

Owner:常熟市异型钢管有限公司

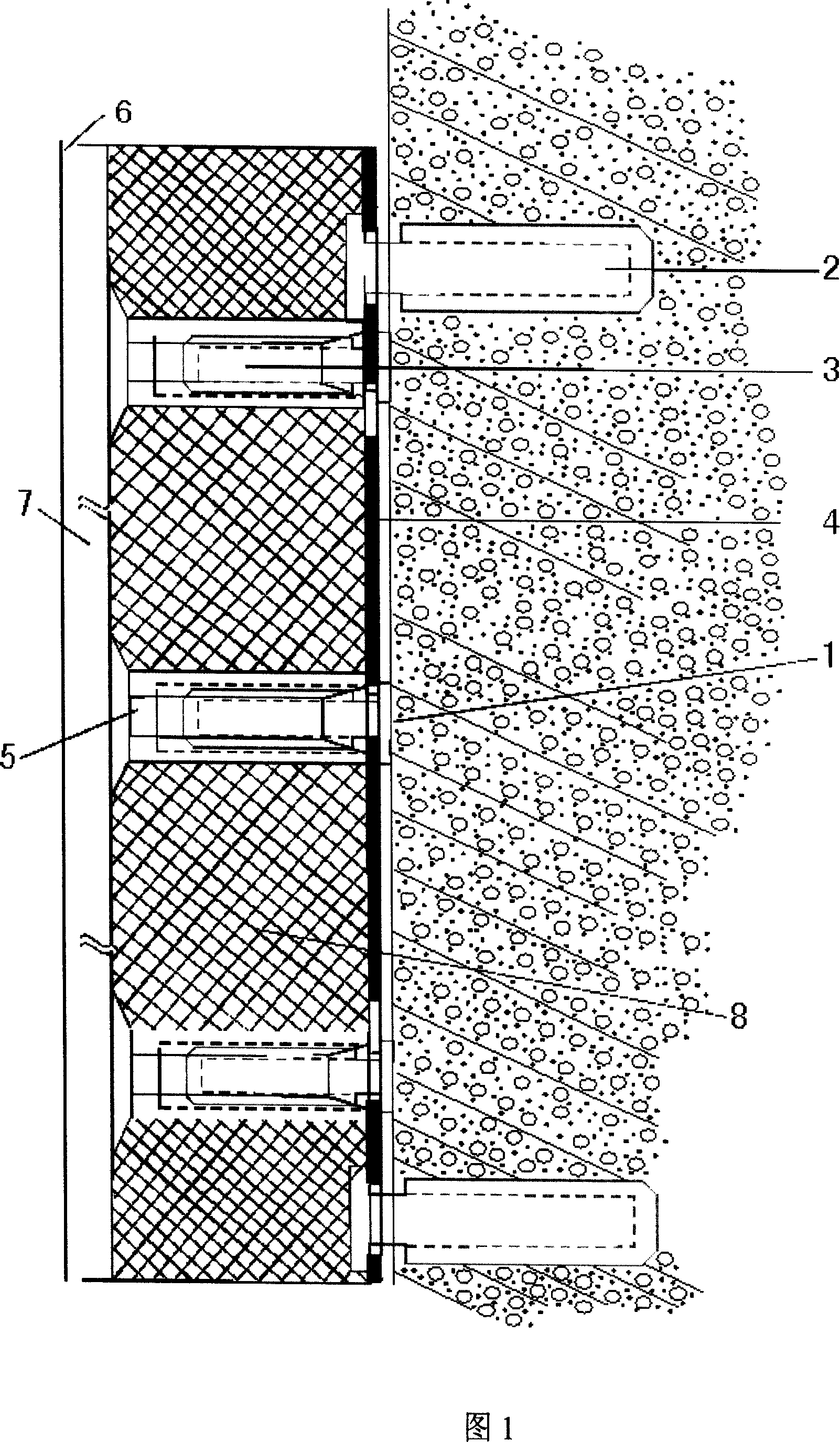

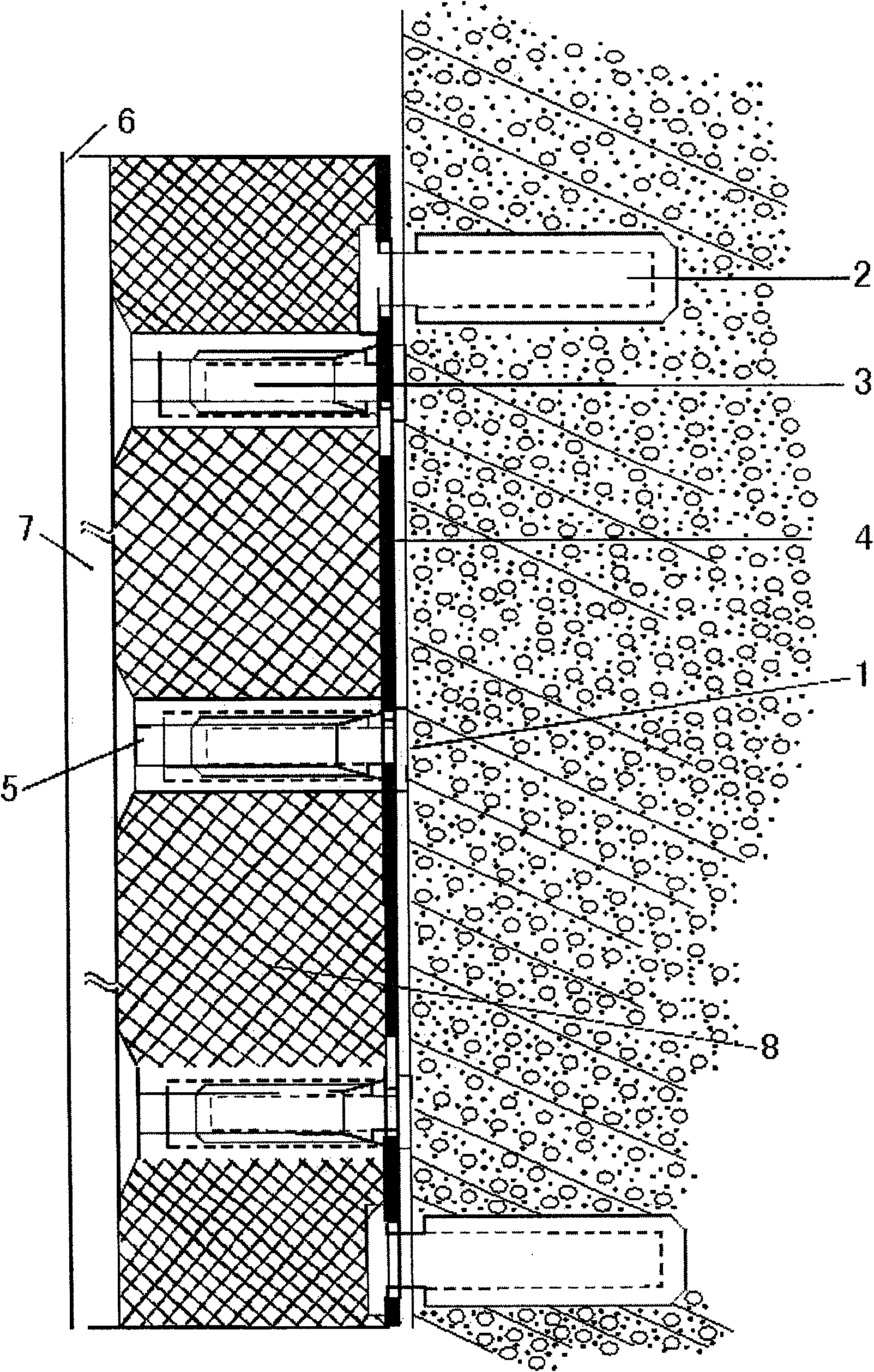

Insulation curtain wall and its construction method

InactiveCN101008195ASave aluminumWith clean airCovering/liningsWallsArchitectural engineeringPre embedding

The invention discloses a thermal-insulated curtain wall, comprising an expanding bolt embedded in the outer wall, a suspending plate mounted at the face of outer wall via the expanding bolt which is pre-embedded with bolt, a clamping plate with decorate face plate, and a thermal-insulated plate between the clamping plate and the suspending plate. The suspending plate is preset with reverse-clamping bolt. The clamping plate via sink lock clamping bolt is engaged with the reverse-clamping bolt to be fixed at the outside of suspending plate. The thermal-insulated plate is preset a through hole engaged with the reverse-clamping bolt. The through hole sheathes the reverse-clamping bolt. The thermal-insulated plate is arranged between the clamping plate and the suspending plate. The invention also discloses relative construction. The invention can save aluminum support, purify air and insulate heat.

Owner:LIAONING TAIFENG ALUMINUM ENG

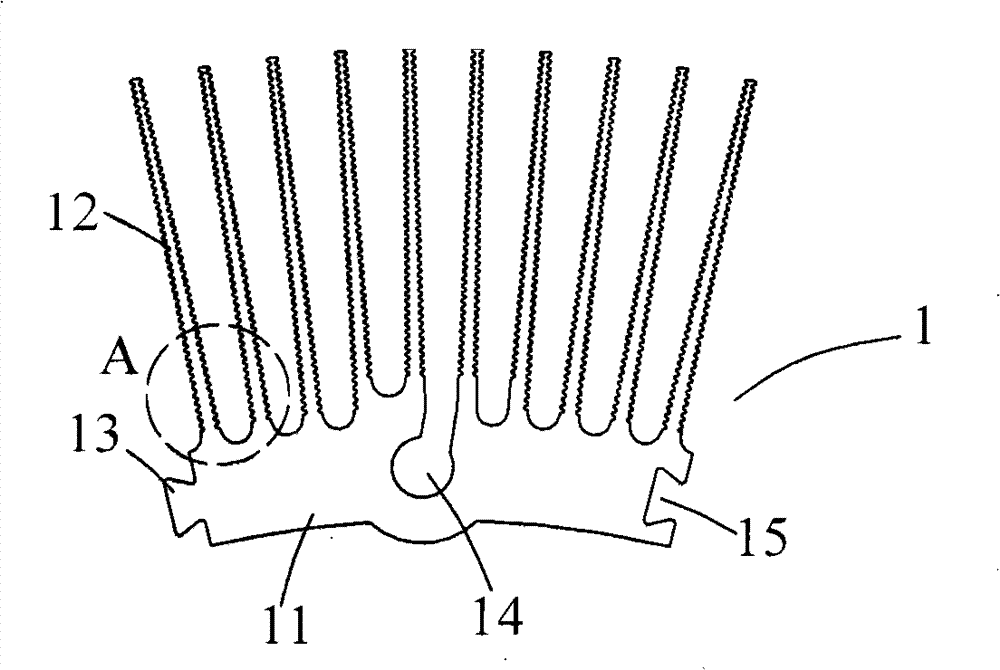

Novel aluminum formwork

InactiveCN104088459AHigh compressive strengthNo leakageAuxillary members of forms/shuttering/falseworksForming/stuttering elementsUltimate tensile strengthBolt connection

The invention relates to a novel aluminum formwork which is high in use efficiency, capable of saving materials and capable of being circulated and used 300 times. The novel aluminum formwork comprises a face plate and connecting plates located on the circumference inside the face plate. A plurality of longitudinal reinforcement ribs and a plurality of transverse reinforcement ribs are arranged inside the spliced face plate. The two ends of each longitudinal reinforcement rib are fixedly connected with connecting plates respectively. The two ends of each transverse reinforcement rib are connected with connecting plates respectively. A notch is formed in one side of the contact face between each transverse reinforcement rib and the face plate. The longitudinal reinforcement ribs are inserted into the notches. By means of the method that the reinforcement ribs are arranged in the longitudinal direction and the transverse direction, the one-square-meter formwork area of the face plate is divided into a plurality of small force-bearing faces, deformation does not easily occur, and strength and bearing capacity of the aluminum formwork are greatly enhanced; by means of the connecting plates, bolted connection formworks inside protruding shoulder strips are more tightly meshed, concrete can not easily leak, the formwork can not easily explode, concrete is saved, contamination to the construction site is avoided, and splicing convenience is achieved; radian plates serve as connecting pin pieces, and therefore the pin pieces can not easily fall and can be conveniently installed and detached and can be conveniently picked up after falling onto the ground, and construction cost is reduced to a certain degree.

Owner:云南亚千科技有限公司

Intelligent steelmaking system based on converter fume and gas analysis technology

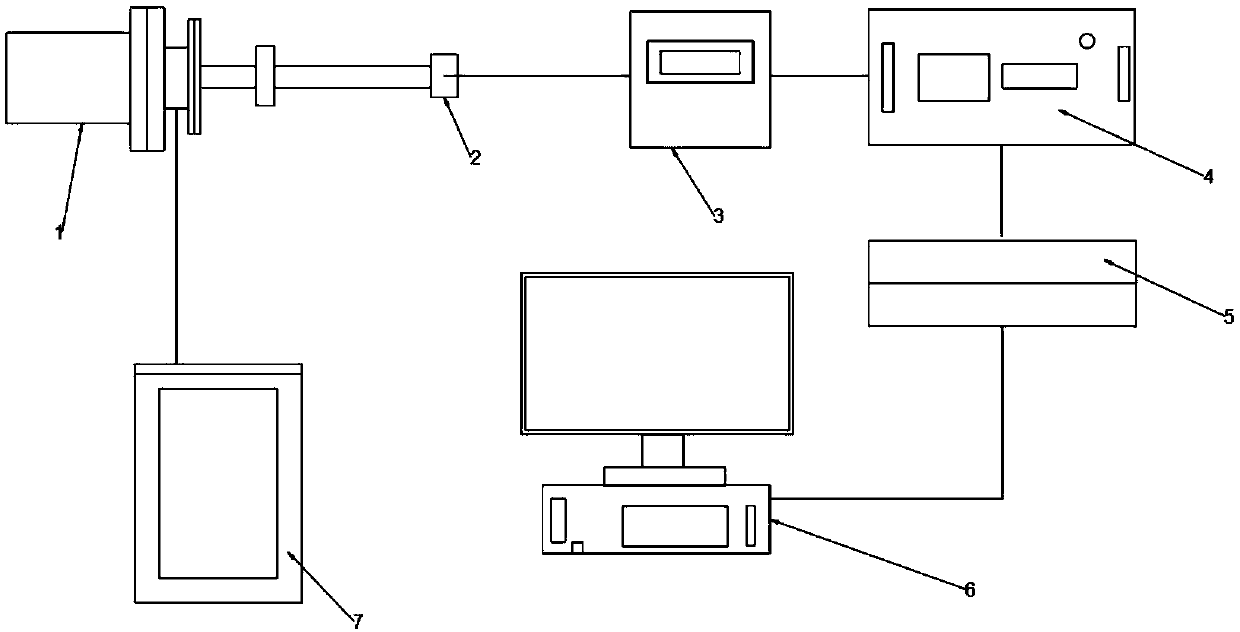

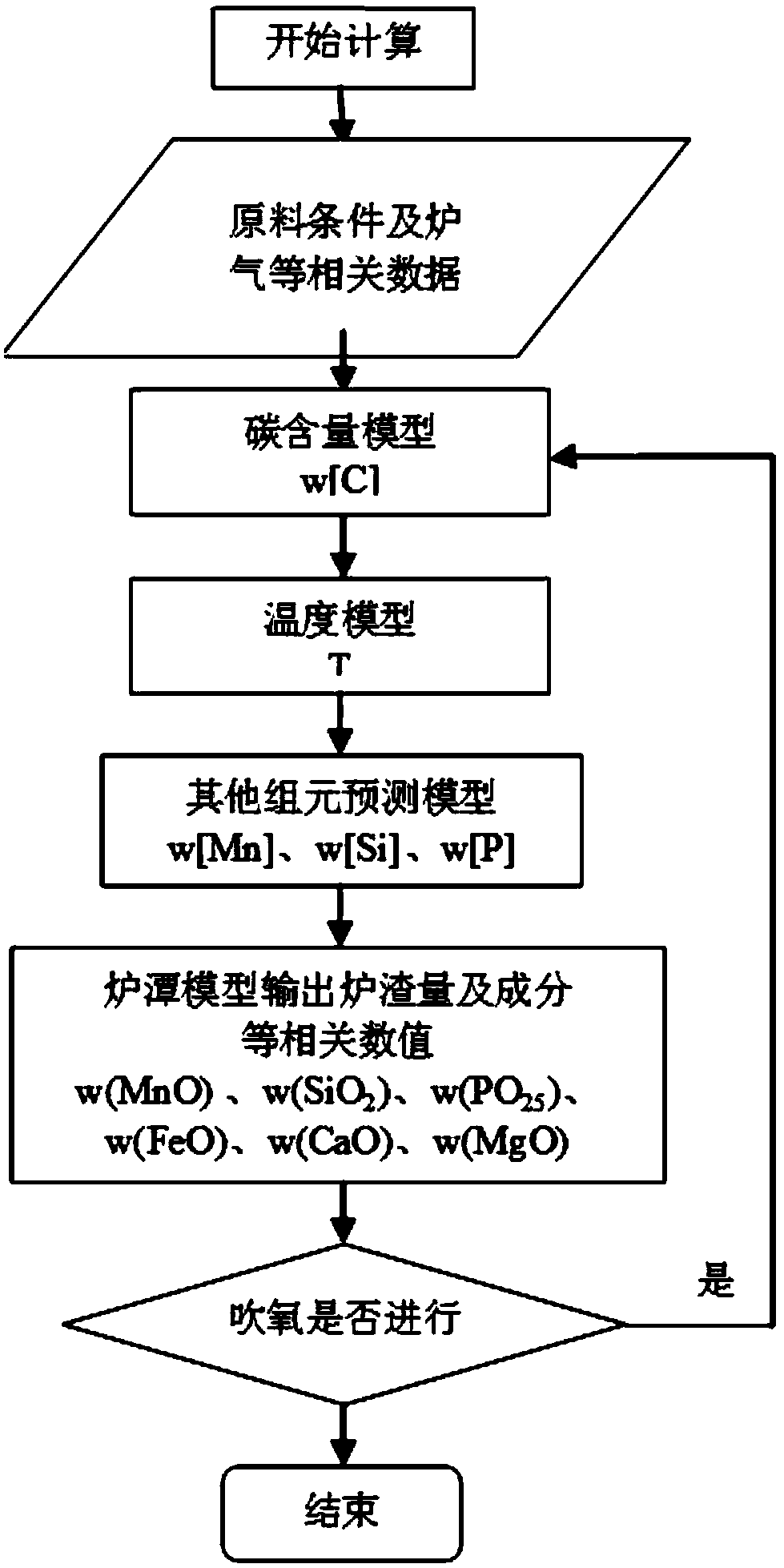

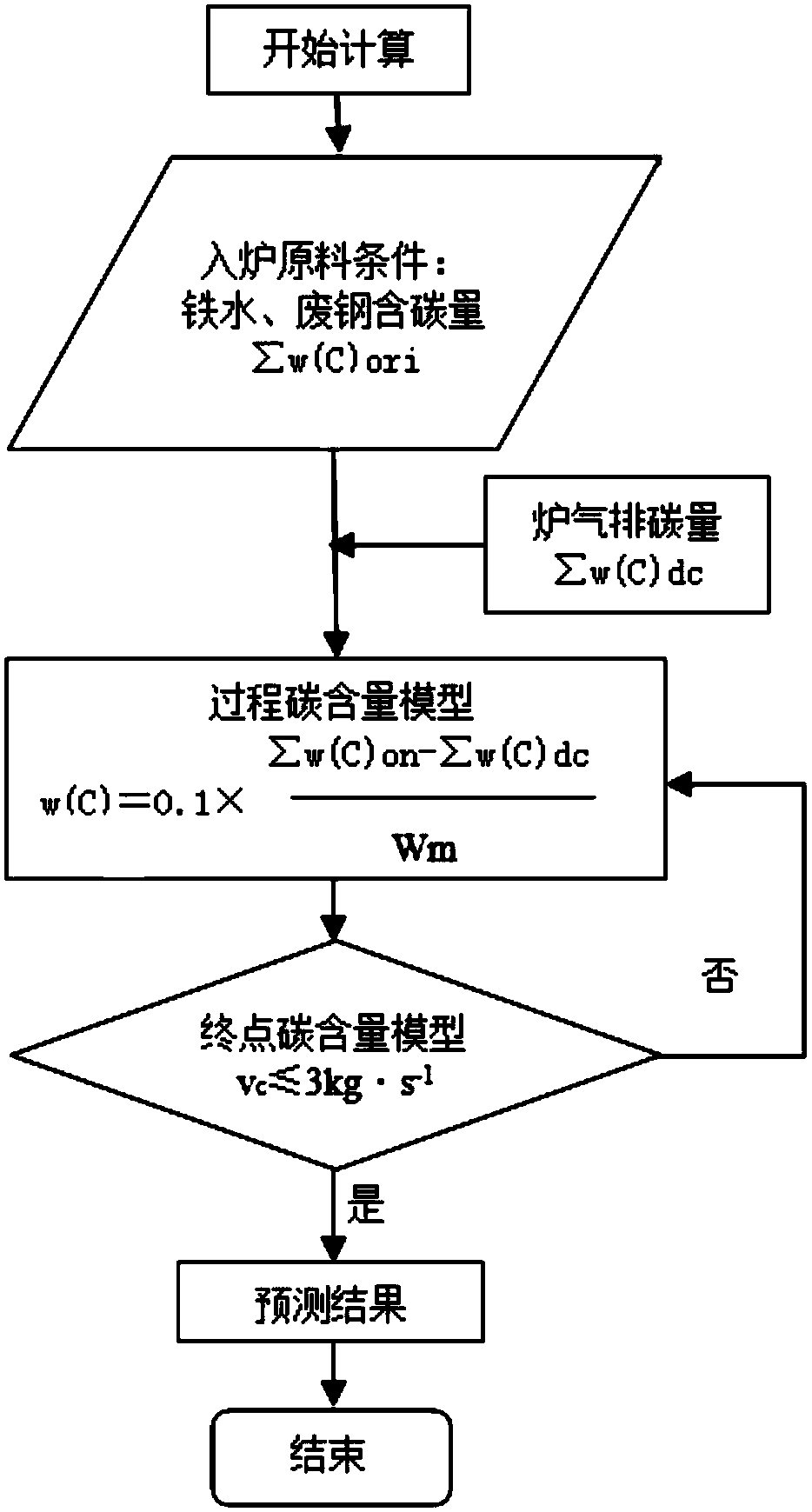

PendingCN109581988AAutomatically and accurately record statisticsMeet the needs of converter intelligent steelmakingSteel manufacturing process aspectsIncreasing energy efficiencySteelmakingGas analysis

The invention discloses a professional detection instrument for fume and gas analysis, and relates to the technical field of ferrous metallurgy. The professional detection instrument for fume and gasanalysis mainly solves the problems of automation and intelligence during steel-making and smelting operations of a converter. The professional detection instrument for the fume and gas analysis comprises a fume and gas analyzer, and a converter audio frequency slag melting monitoring system; the converter audio frequency slag melting monitoring system comprises a converter, and the upper part ofthe right side of the converter is sequentially provided with a water inlet, an audio sampling device, and a nitrogen inlet from left to right. The invention further discloses an intelligent steelmaking system, a main program of the intelligent steelmaking system, and an implementing method of the intelligent steelmaking system which are based on the converter fume and gas analysis technology of the professional detection instrument for the fume and gas analysis. According to the professional detection instrument for the fume and gas analysis, precision of endpoint control and the hit rate areincreased, thus stability and reliability of production are improved, production efficiency is improved, cleanliness of molten steel and quality of steel are improved, and full-automatic steelmakingis realized.

Owner:重庆布鲁斯格智能科技有限公司

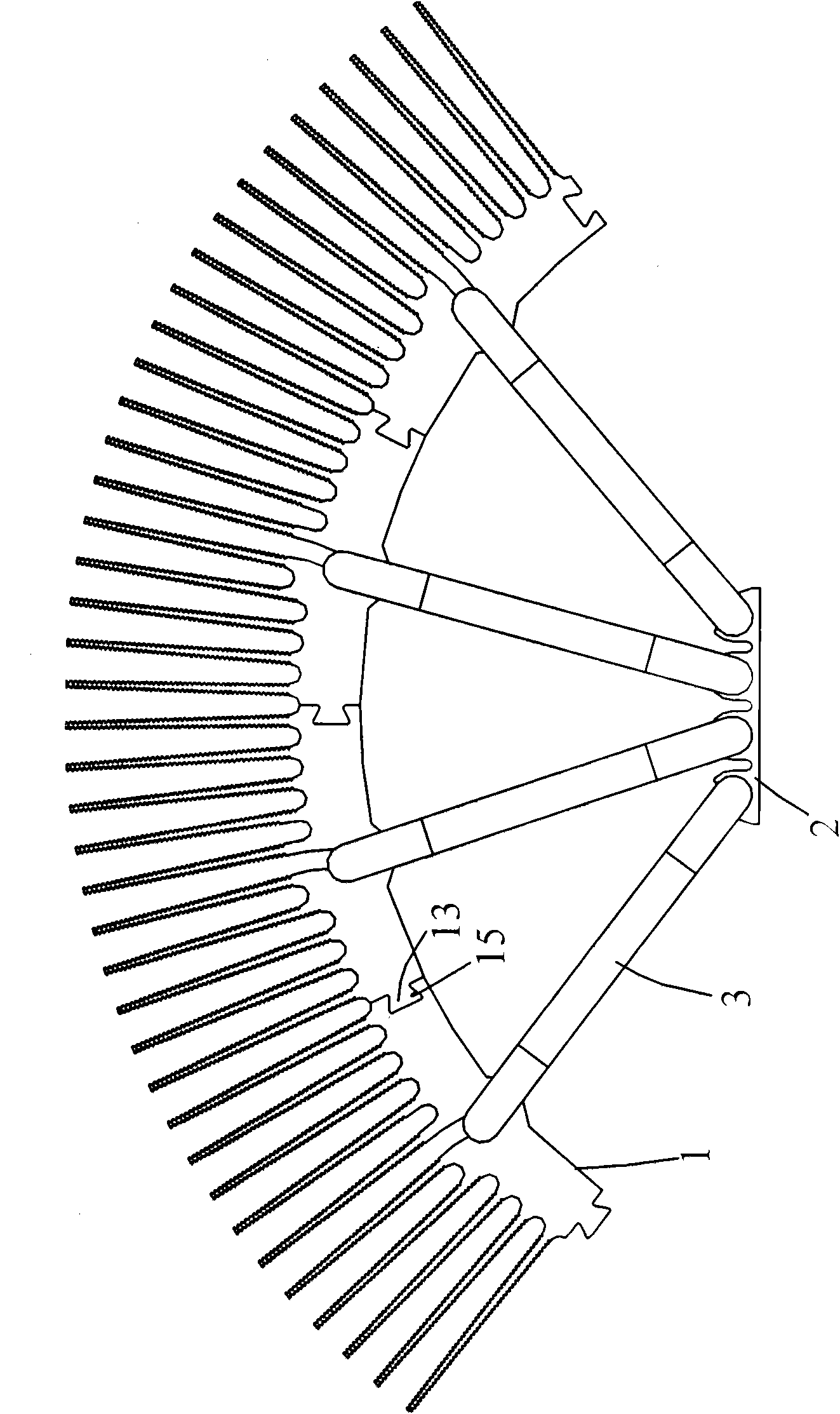

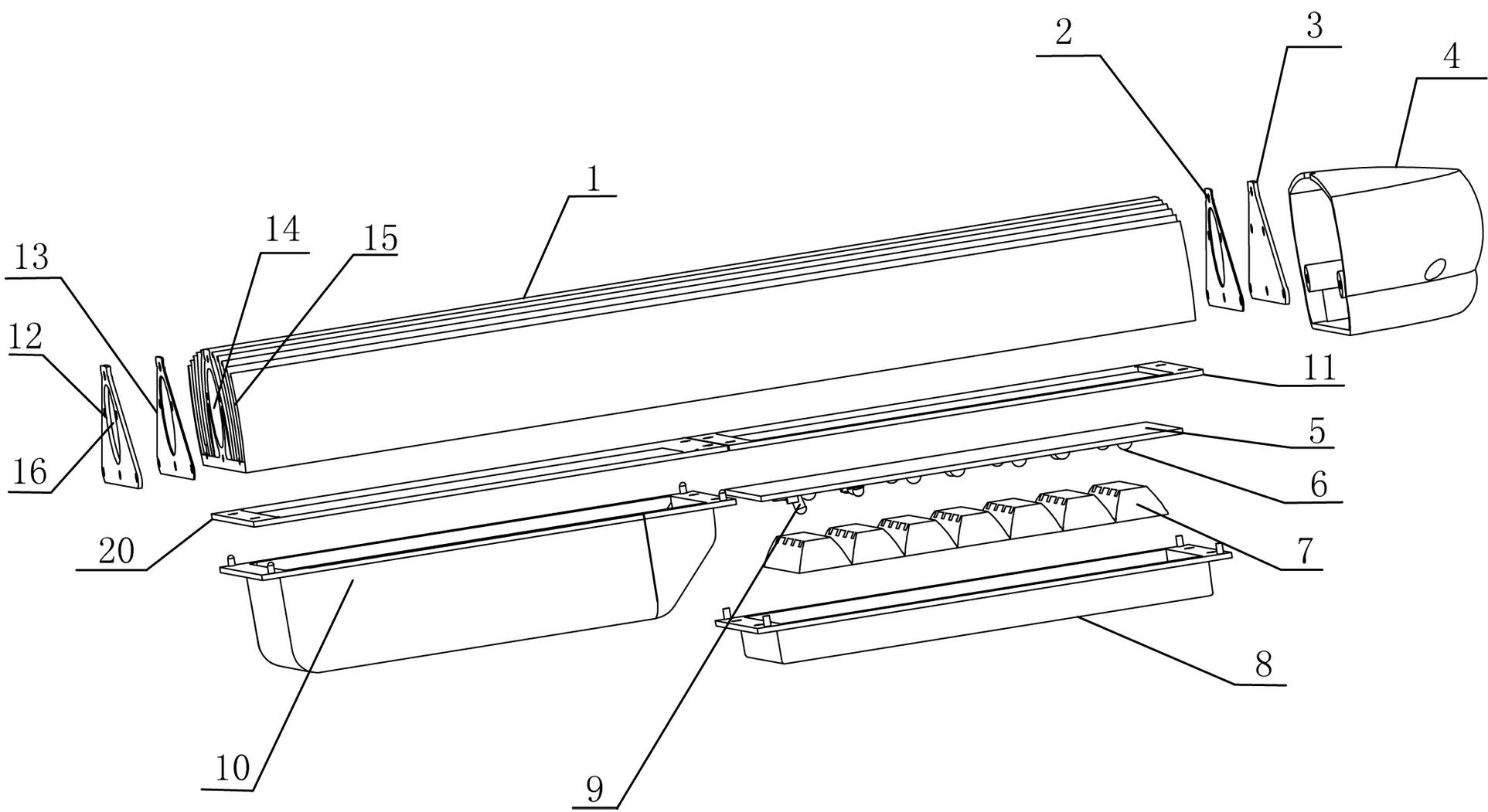

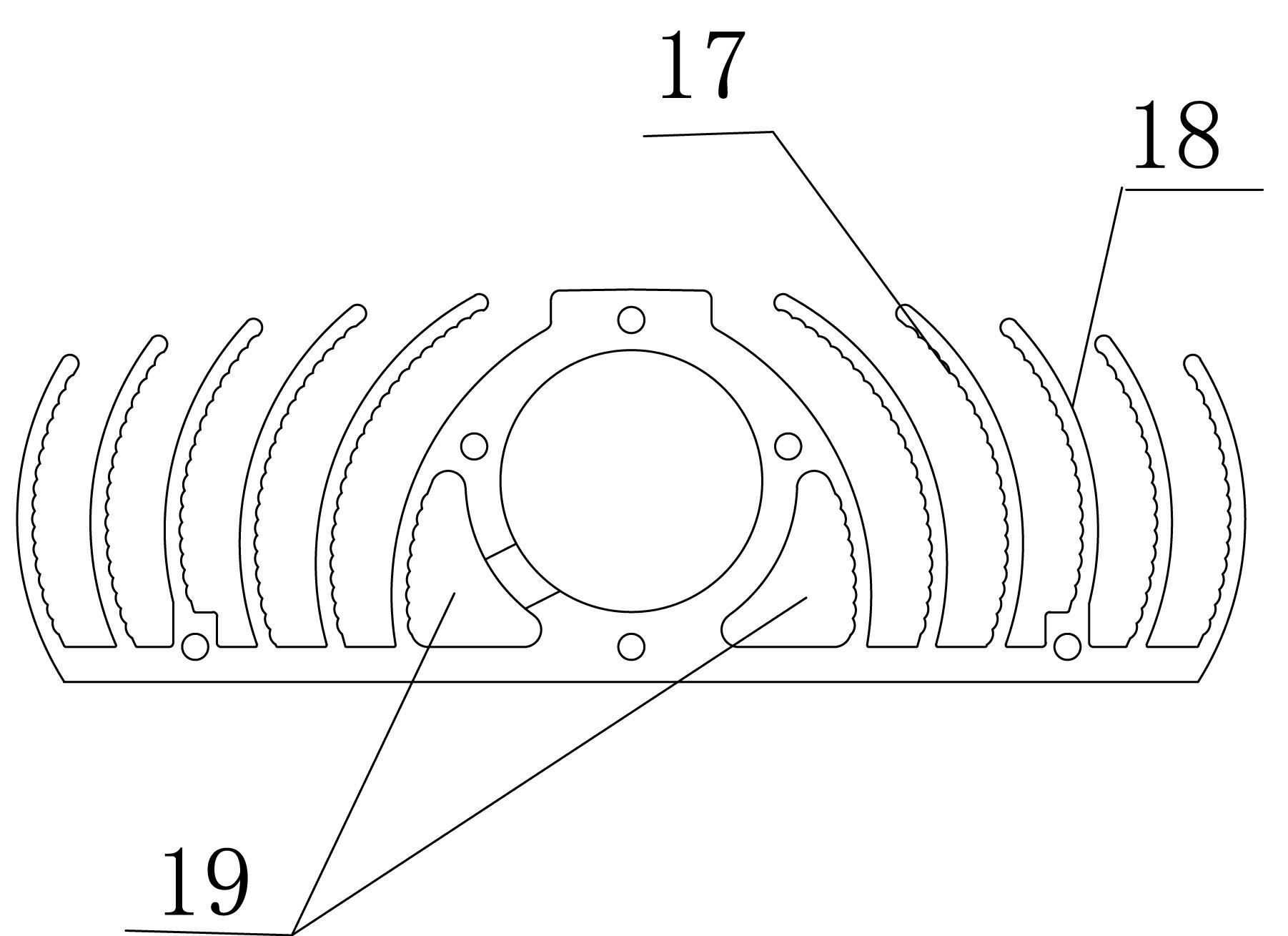

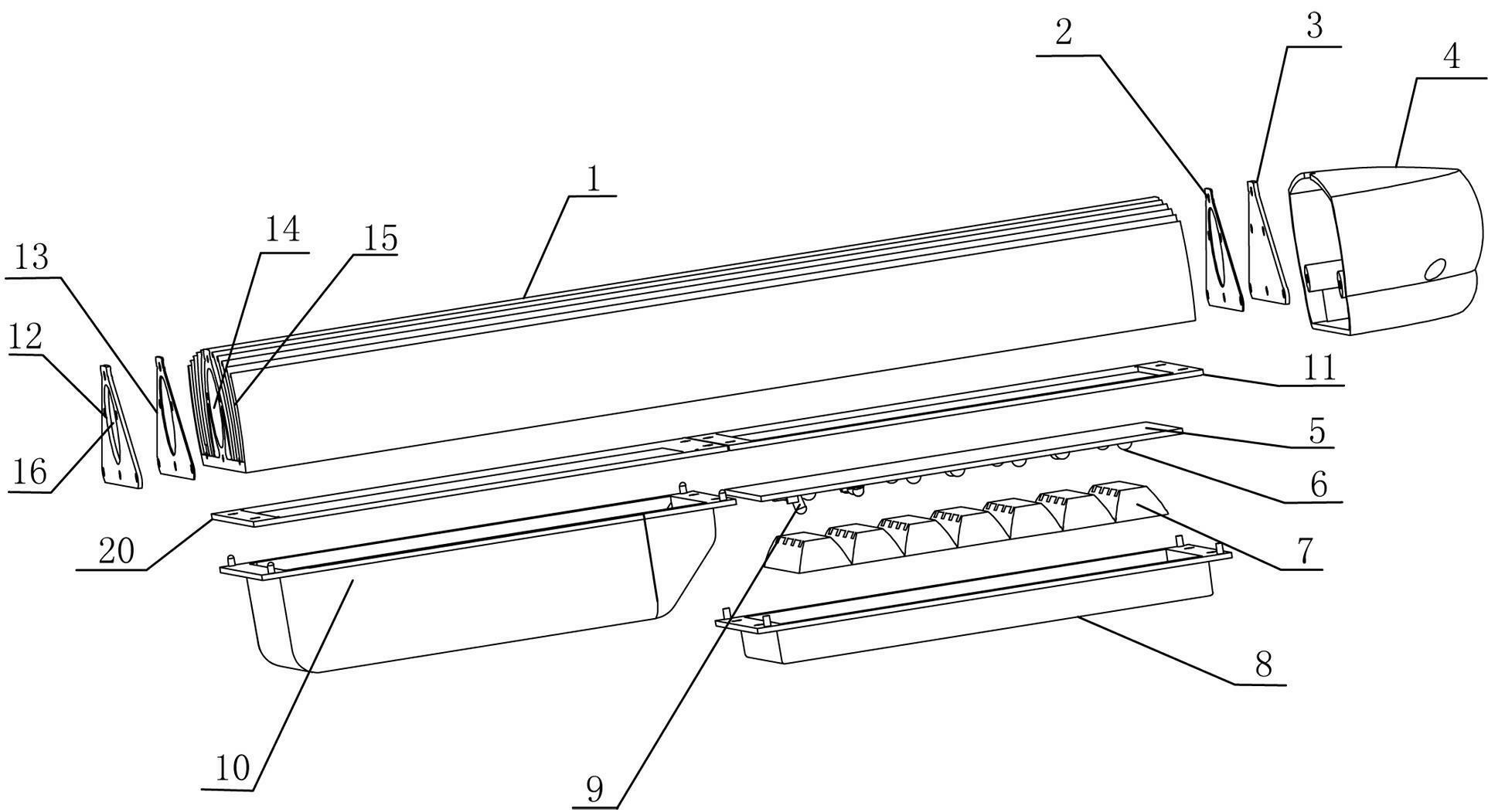

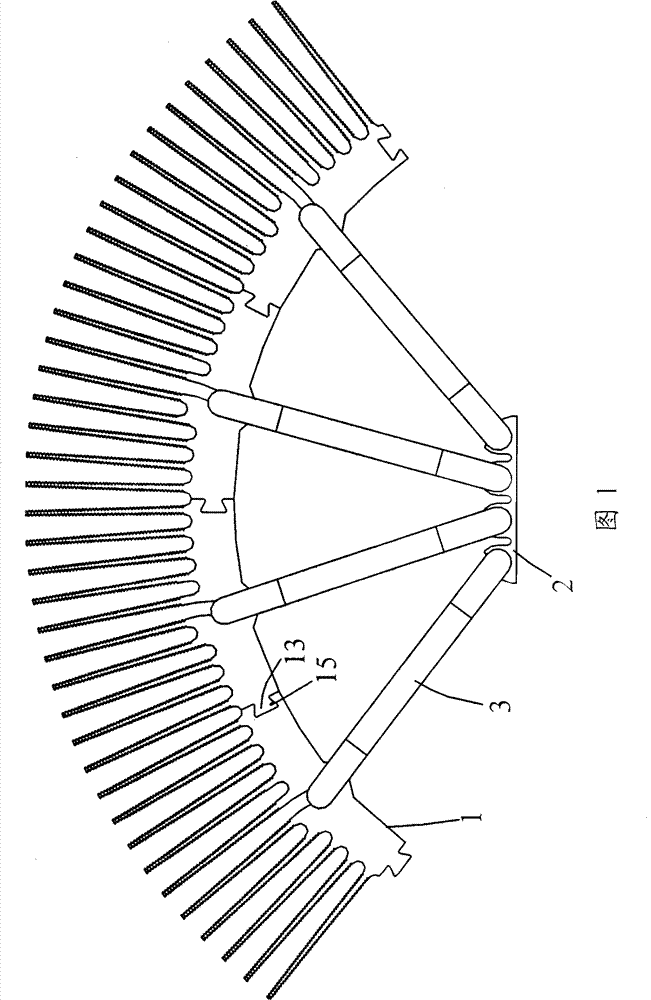

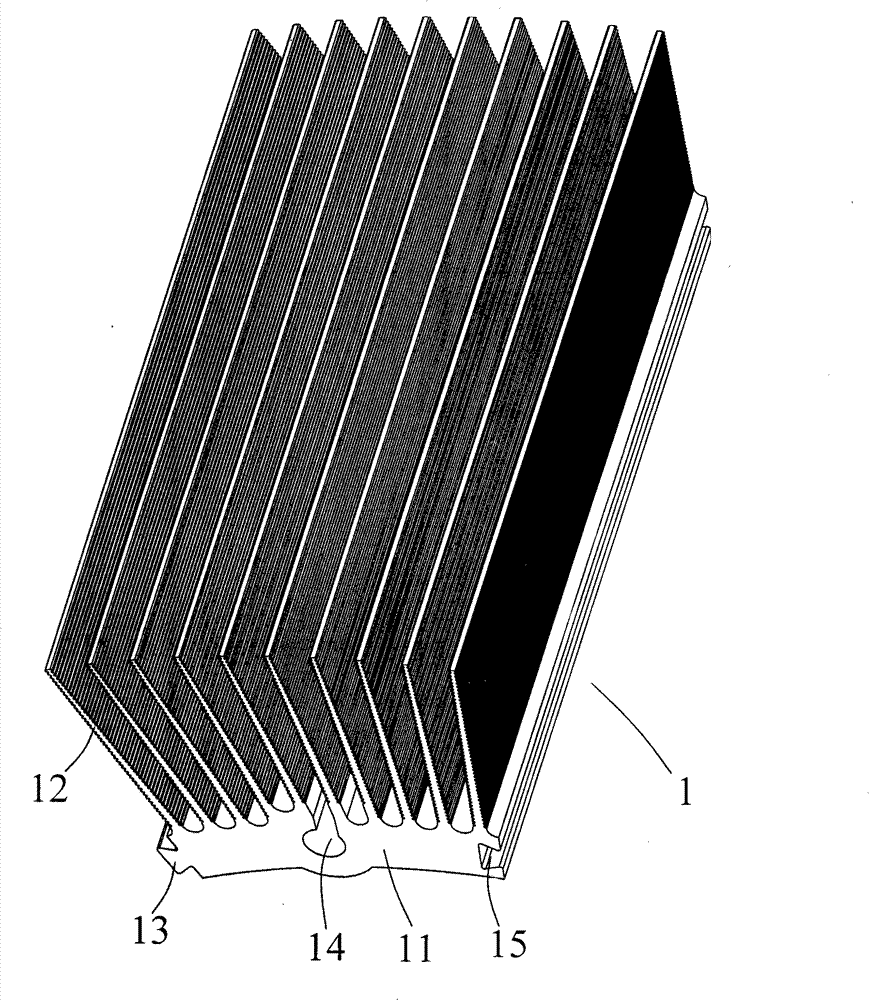

Solar modular LED street lamp

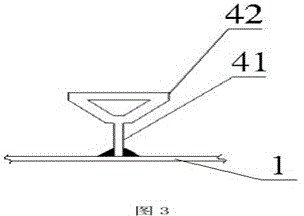

InactiveCN102563504AImprove cooling efficiencyReduced strength requirementsPoint-like light sourceLighting heating/cooling arrangementsElectricityModularity

The present invention discloses a solar modular LED street lamp. A bottom surface of a heat radiator is provided with a thin plate. The central part of the upper end of the bottom surface of the thin plate is provided with a lamp stand hole for mounting the lamp stand, and the two ends are provided with arc-shaped fins which are bent to the lamp stand hole. An LED module is composed of the following components: a plurality of large-power LEDs, an aluminum base circuit board which fixes and electrically connects each LED, a constant-current power supply which is fixed and electrically connected with the aluminum base circuit board, a reflection cup and a flat transparent cover. A front baffle plate and a back baffle plate are respectively fixed at two ends of the heat radiator. The front baffle plate is provided with mounting holes for mounting the lamp stand. The solar modular LED street lamp has the following advantages: small volume of the radiator, high heat radiation effect, small weight, reduced aluminum material, low cost, high convenience in outdoor overhead mounting, low strength requirement for the lamp stand; small light decay of the LED lamp, long service life and high light emitting efficiency of the LED lamp; high self-cleaning capability, high sealing effect and high protection performance. Particularly a variable-power control controller is adopted for furthermore prolonging service life and improving light emitting efficiency of the LED lamp.

Owner:保定市大正太阳能光电设备制造有限公司

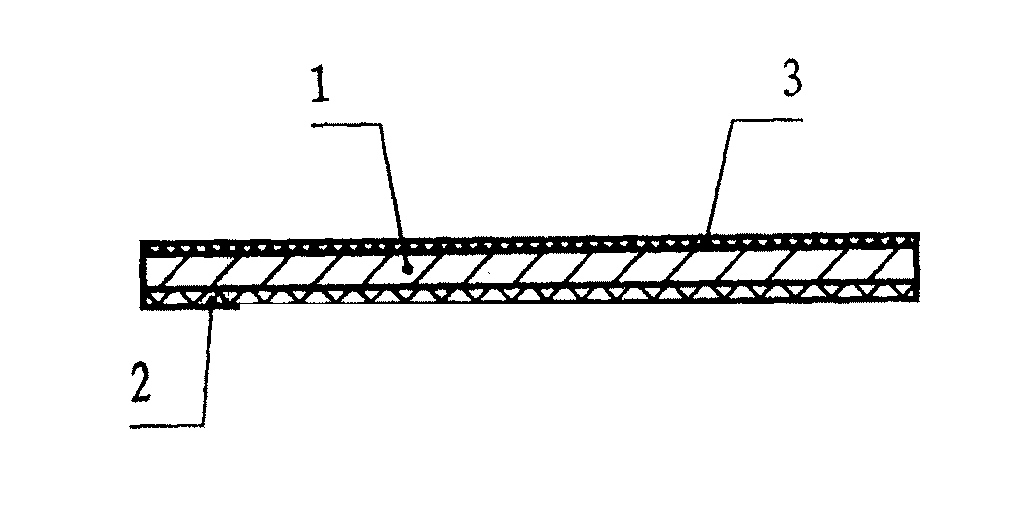

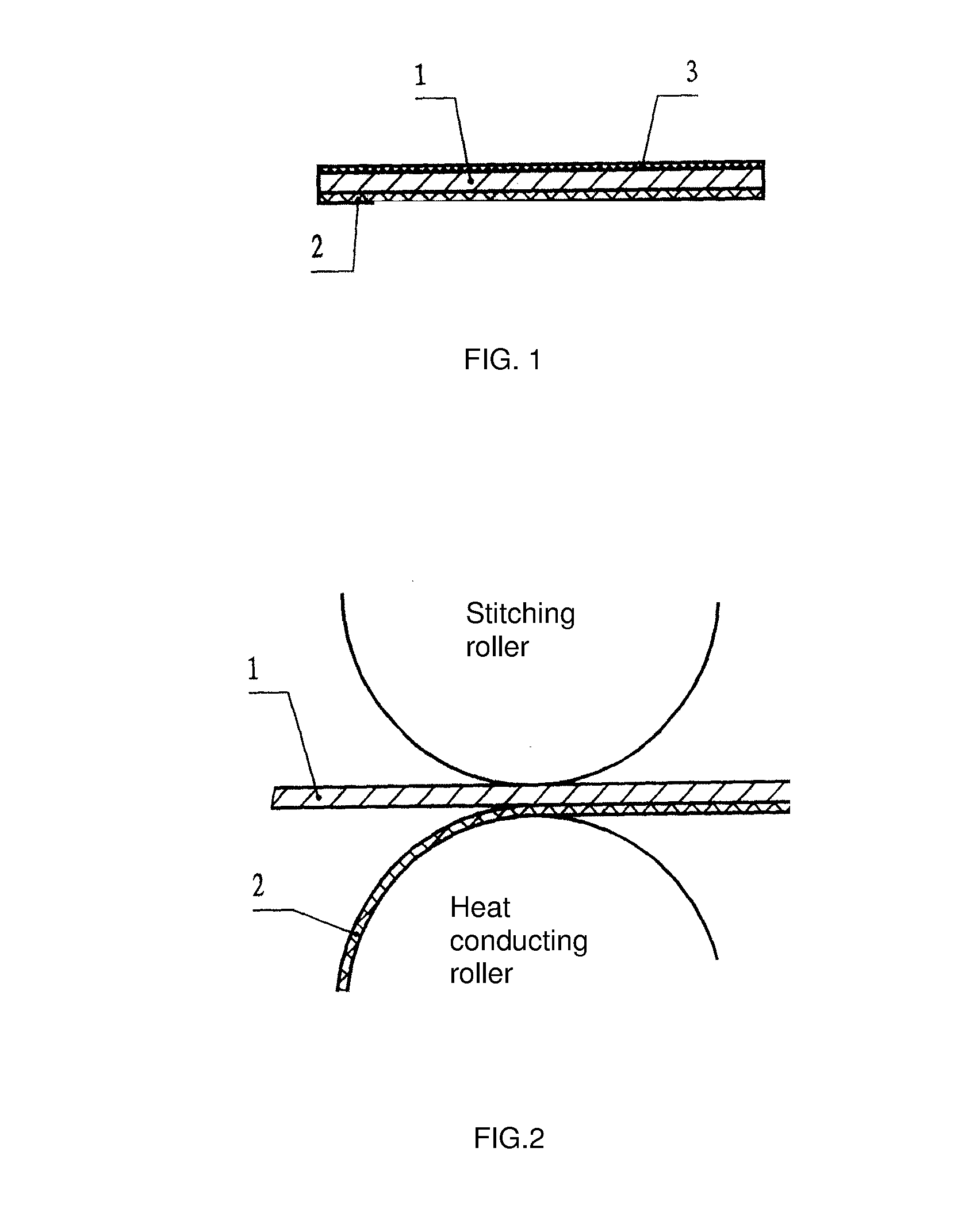

Offset PS Plate with Compound Support and Its Manufacturing Process

InactiveUS20080107895A1Save aluminumImprove performanceSynthetic resin layered productsRecord information storageVolumetric Mass DensityAluminum substrate

This invention involves with a kind of offset PS plate with compound support and its manufacturing process. PS plate has sensitization imaging layer set up on the front side of its aluminum substrate, and has a membrane of polymer materials covered on the back side of the substrate, which form the structure of compound support. The manufacturing process firstly deoils and cleans the aluminum substrate, and covers a membrane of polymer materials on the back side of plate substrate; then conducts electrochemical corrosion and roughening, generates oxidation layer through the oxidization of anode, carries out sealing or hydrophilic treatment for the oxidation layer, and coats sensitization liquid onto this oxidation layer; finally, dries and cuts the plates into finished products. This invention may use relatively thin aluminum materials to keep relatively high quality, greatly reduce the consumption of aluminum, and decrease the cost. The mentioned membrane is featured by strong toughness; after compounding, the substrate enjoys great tensile strength, so the plate is not easy to break during printing; and also, the substrate has lower density, which could lighten the weight of finished plates. Polymer membranes have extremely smooth surface, so multiple sheets of PS plates overlapped won't scratch the sensitization layer, and will require no interleaving paper. What's more, the manufacturing process of PS plate with compound support is basically accordant with the original one, and the compounding of membrane is simple and quick.

Owner:WENZHOU KONITA PRINTING EQUIP

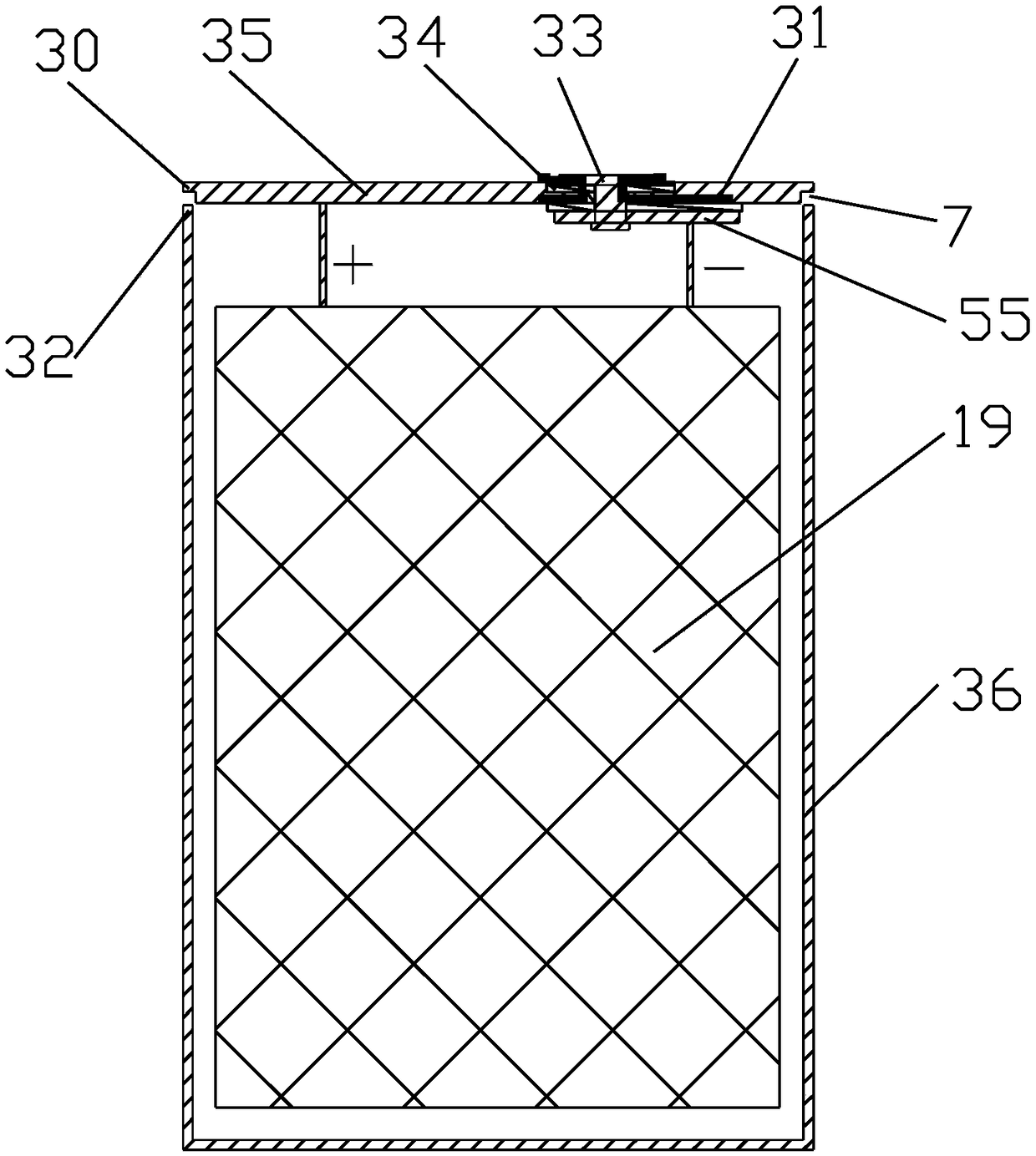

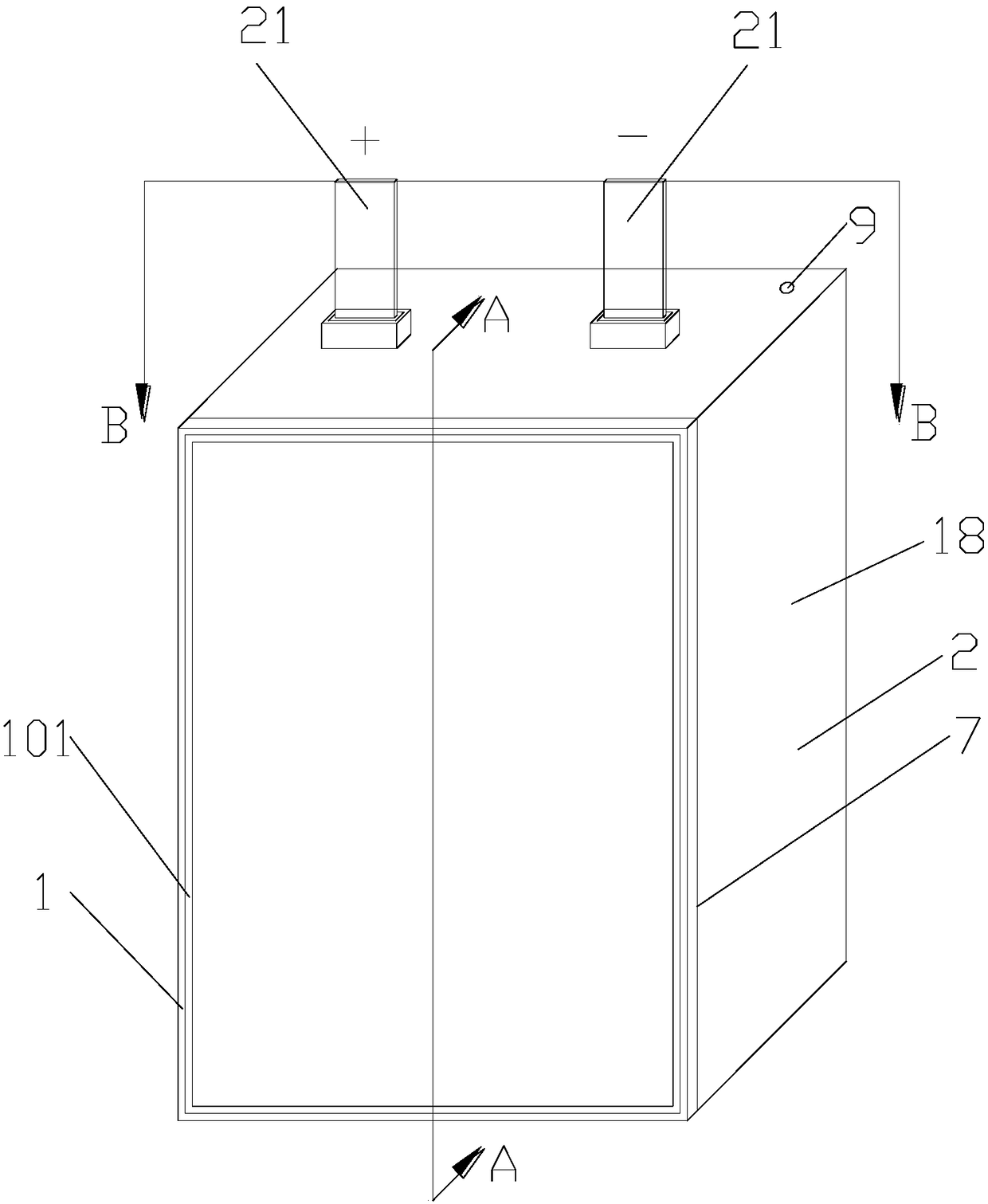

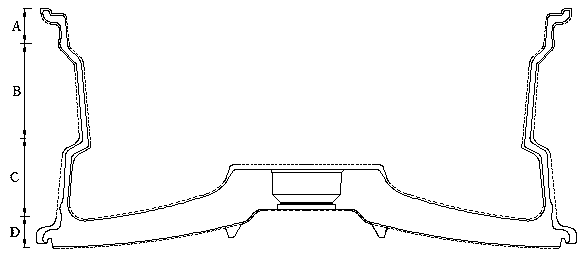

Battery case, battery cell, battery and assembly method thereof

ActiveCN105977408BSimplify the assembly processReduce or eliminate safety hazardsFinal product manufactureSmall-sized cells cases/jacketsMechanical engineeringBattery cell

The invention discloses a battery case, a battery cell, a battery and an assembly method thereof. The battery case is a flat body with opposite upper and lower surfaces. The upper surface is stamped and formed with an annular groove, and the lower surface corresponds to An annular boss is formed, and a step is correspondingly formed on the edge of the upper shell, and the boss and the groove are located on the inside of the step, the outer side of the boss is the first mating surface, and the edge of the step The lower surface is the second mating surface. In the case of saving the battery cap, the assembly process of the battery is simplified, reducing or eliminating the potential safety hazard of the battery; material thickness.

Owner:ANHUI QUANCHAI TIANHE MACHINERY

Anti-counterfeiting transfer printing technology

InactiveCN101618630BPromote degradationNo pollutionTransfer printingVacuum evaporation coatingVacuum pumpingEmbossing

The invention relates to an anti-counterfeiting transfer printing technology which comprises the following steps: preparing a laser plate; coating a layer of mold release agent or imaging paint on a PET base film; carrying out vacuum pumping on the PET base film and an aluminum material device in a vacuum plating evaporator; then heating the aluminum material and depositing gaseous aluminum particles on the surface of the moving PET base film and / or the surface of the mold release agent or the imaging paint; stamping an embossing pattern on the laser plate on a mold release agent layer or an imaging paint layer and / or an aluminum layer so as to make a holographic transfer film for transfer; bonding the holographic transfer film and backing paper together; separating the PET base film fromthe paper, wherein the stripped PET base film can be repeatedly used for a coated base film; and coating a layer of aqueous varnish on the surface of the transferred paint layer and / or the aluminum layer. The technology can combine an anti-counterfeiting printing technology with a transfer printing technology, and an aluminum plating layer transferred on the paper can be made to be thin, thereby saving the aluminum material; in addition, the base film used in transfer printing can be repeatedly utilized and does not pollute the environment.

Owner:江苏中印印务集团有限公司

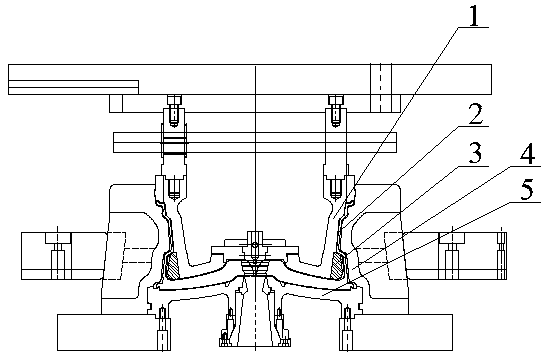

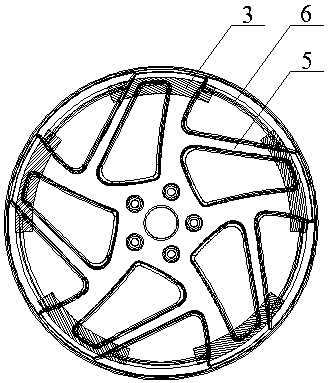

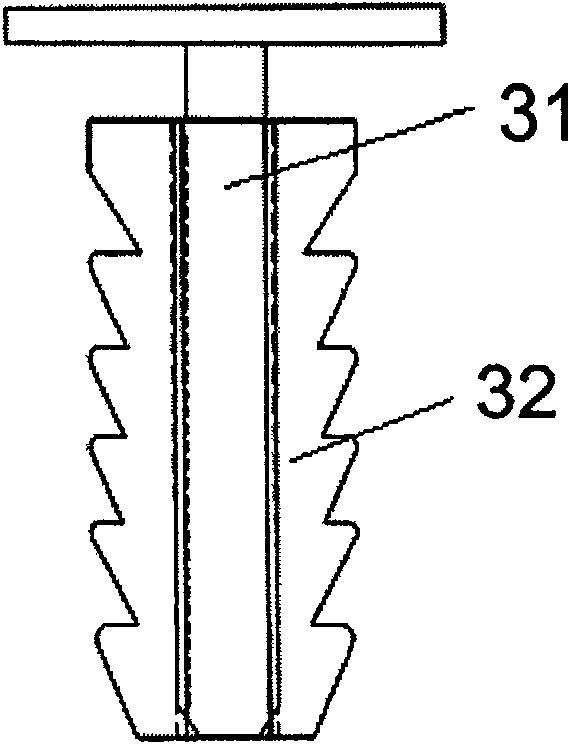

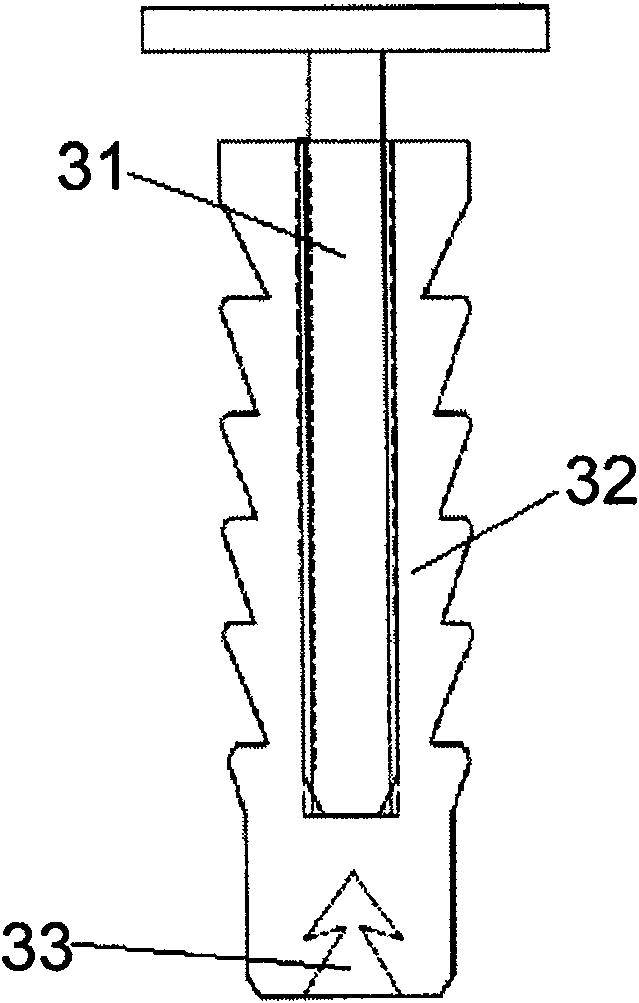

Aluminum alloy hub core pulling casting mold and process thereof

InactiveCN108296453AReduce weightAvoid damageFoundry mouldsFoundry coresManufacturing technologyEconomic benefits

The invention relates to the technical field of hub manufacturing, in particular to an aluminum alloy hub core pulling casting mold and a process thereof. The mold comprises a lower mold, a side moldand an upper mold which are combined to form a hub casting mold cavity; an insert is arranged between two adjacent rib window backward slanting faces of the lower mold, and is of an arc structure, andthe insert is right matched with the inner side face of a hub C ring. The insert is arranged on the lower mold of the hub, the insert is used for replacing an aluminum profile added newly in a C ringin the prior art, the demolding angle is ensured, demolding is facilitated, meanwhile, the weight of a hub rough material is reduced by about 5.3 kg, the aluminum material for casting a workblank issaved, cost is saved, damage of a machining tool is reduced, meanwhile, market needs of light weight and individuation are met, and the excellent market value and economic benefits are achieved.

Owner:六和轻合金(昆山)有限公司 +1

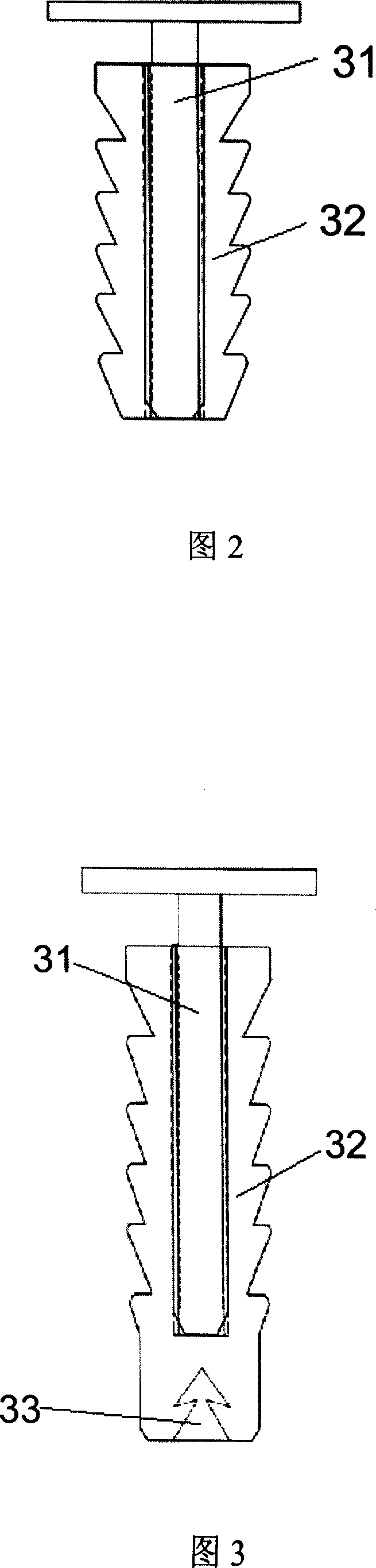

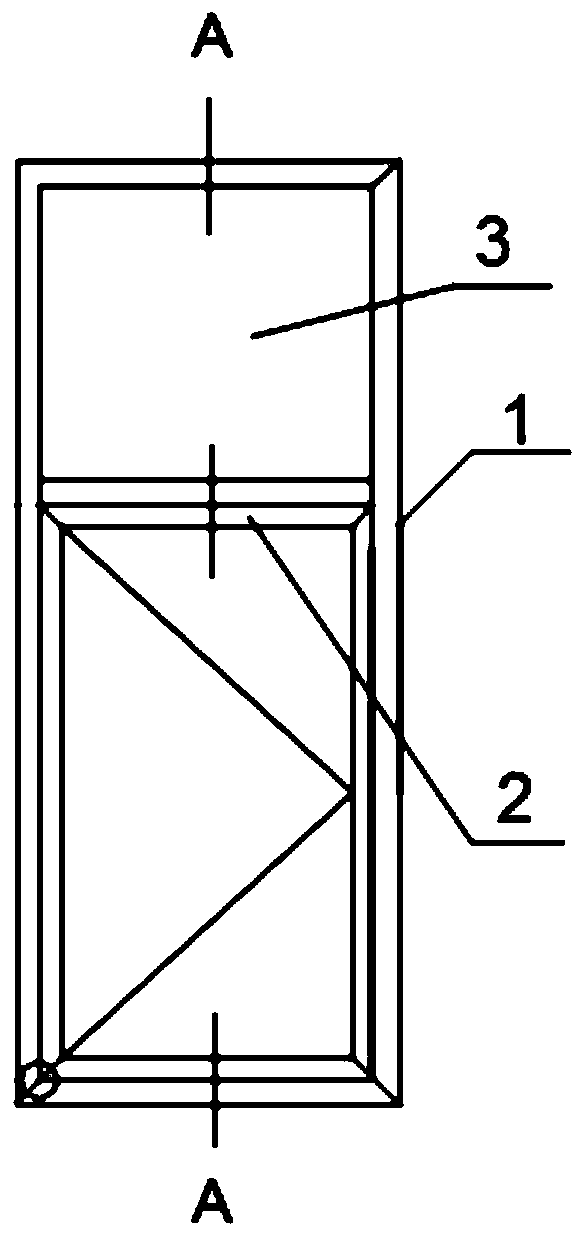

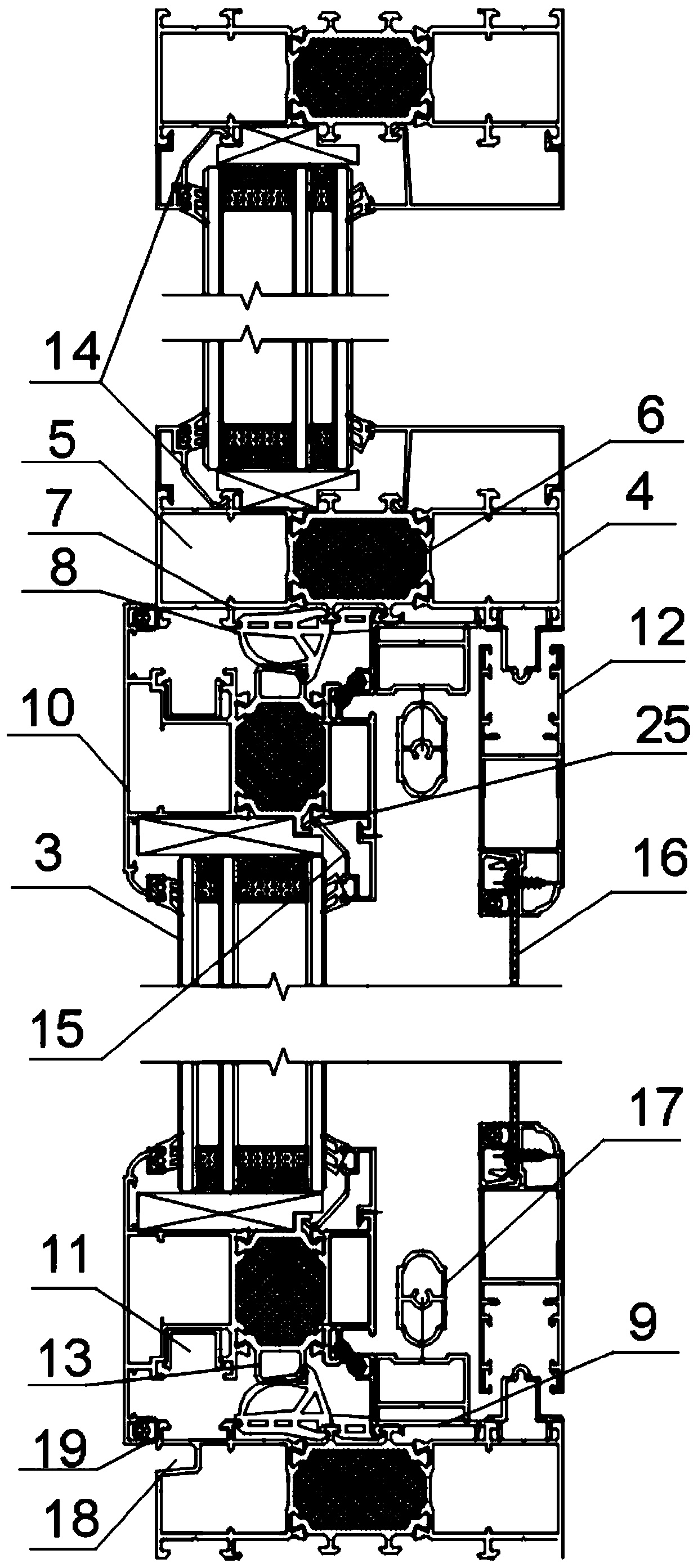

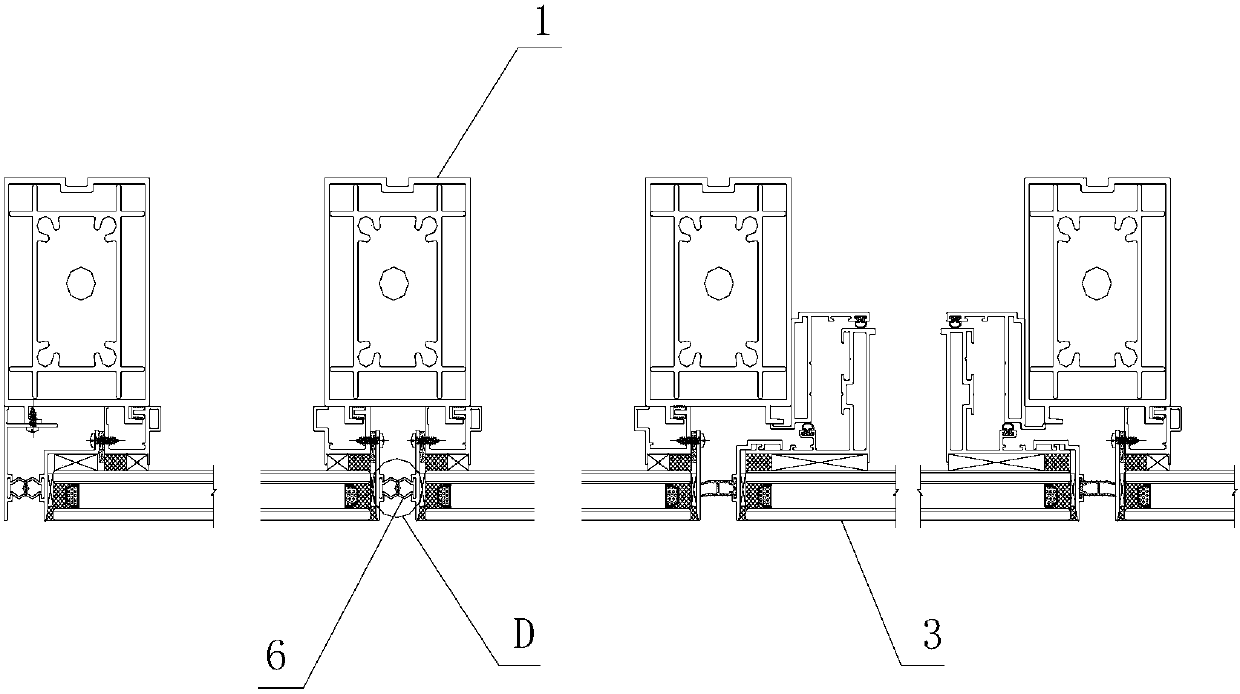

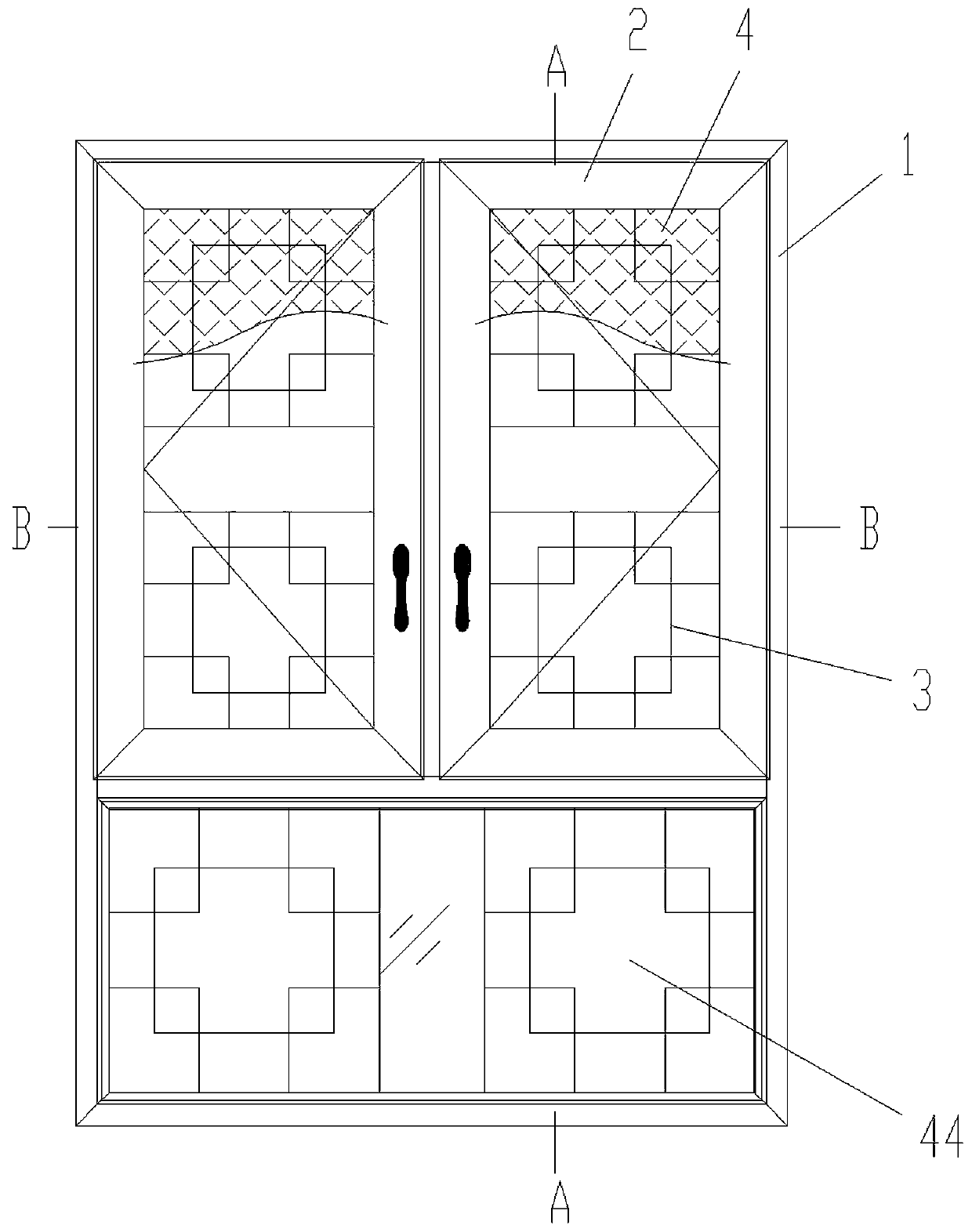

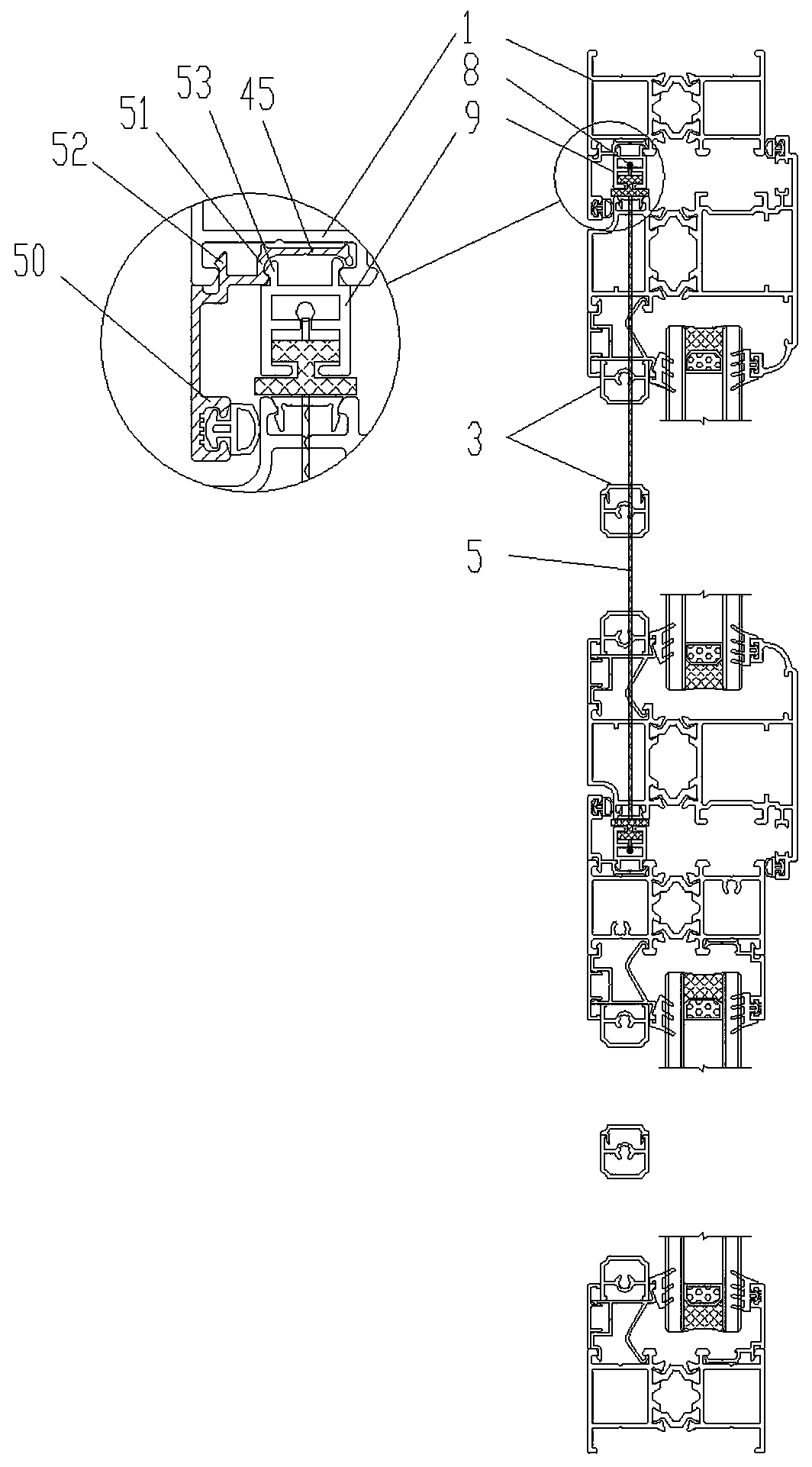

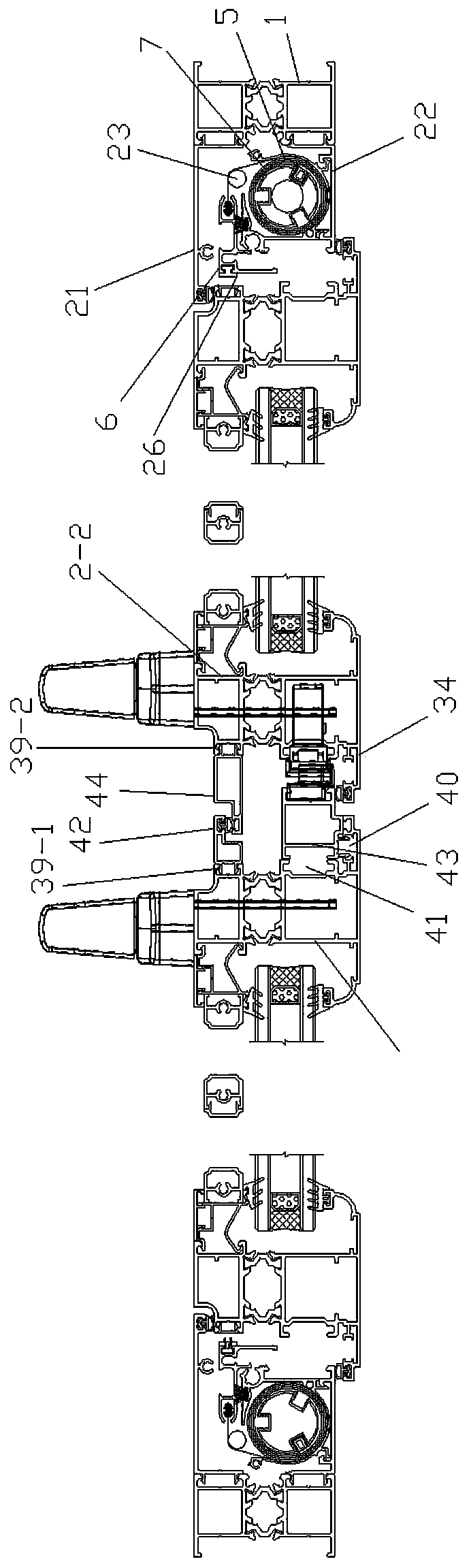

Inner/outer opening heat insulation broken bridge window screen integrated window

PendingCN110905345AImprove performanceSave aluminumInsect protectionNoise insulation doors/windowsEngineeringWindow screen

The invention discloses an inner / outer opening heat insulation broken bridge window screen integrated window. The window comprises a frame and a mullion, wherein the frame is defined by an upper frame, a lower frame, a left frame and a right frame, the mullion divides the frame into panes, one or more of glass, a window sash or a screen sash are respectively installed in the panes, the frame and the mullion are formed by splicing an inner frame section bar, an outer frame section bar and middle heat insulation strips, and isobaric rubber strips and inner-outer opening conversion pieces are arranged between clamping grooves of the inner frame section bar, the outer frame section bar and the middle heat insulation strips. According to the window, the centers of the inner frame section bar, the outer frame section bar, heat insulation strips and the middle heat insulation strips are horizontally symmetrical and vertically symmetrical with one another, the inner frame section bar and the outer frame section bar adopt the same section bar, so that flexible splicing of window is realized, the screen sash adopts a casement screen sash or a push-pull screen sash, the requirements of different consumers for different opening modes of a screen window can be met, and various screen window installation modes are realized.

Owner:连云港双源窗业有限公司

an aluminum formwork

ActiveCN103437547BHigh compressive strengthNot easy to seepAuxillary members of forms/shuttering/falseworksForming/stuttering elementsSlurryUltimate tensile strength

Owner:镇江科顺高新材料有限公司

Heat dissipation fault warning method of LED lamp and heat dissipating device

InactiveCN101790263BRepair in timeReduce the temperaturePoint-like light sourceElectric circuit arrangementsEffect lightEngineering

The invention relates to a heat dissipation fault warning method of an LED lamp. The substrate of an LED lamp module is provided with a heat dissipating device; the temperature of the substrate of the LED lamp module is detected by using a temperature sensor; when the temperature of the substrate is higher than the maximum temperature, a control circuit cuts off the power supply of an LED lamp; when the temperature of the substrate drops to be lower than the maximum temperature, the control circuit switches on the power supply of the LED lamp; when the temperature of the substrate raises again to be higher than the maximum temperature, the control circuit cuts off the power supply of the LED lamp again; by repeating in such a manner, the discontinuous lighting of the LED lamp is utilized to warn that the LED lamp generates a heat dissipation fault; street lamp managers know that the heat dissipating device of the LED lamp generates fault when finding the discontinuous lighting of the LED lamp, and the maximum temperature is smaller than the light attenuation temperature of the LED lamp. The method can enable the LED lamp with the heat dissipation fault to be very easily found by the street lamp managers, thereby, the LED lamp is maintained in time. Meanwhile, the temperature of the LED lamp can be controlled to be lower than the light attenuation temperature, thereby achieving the goal of protecting the LED lamp.

Owner:陈鸿 +1

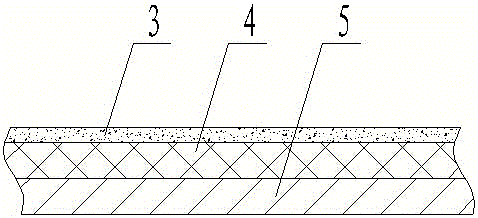

Nano-composite film bag capable of realizing one-way venting and high obstruction

The invention discloses a nano-composite film bag capable of realizing one-way venting and high obstruction, belongs to soft packing bags for food and medicines, and aims to provide a soft packing bag which is applied to the food and medicines, can vent gas inside the bag as well as prevent external gases such as oxygen, nitrogen, hydrogen, dioxides, water vapor and the like from entering the bag and is simple in production technology and low in cost. The nano-composite film bag comprises a bag body made of a heat-seal base material film and nonwoven fabric overlapped at a joint of the bag body, wherein the outer surface of the heat-seal base material film (4) is coated with a PVA film layer (3). The composite film bag is non-toxic and good in obstruction property, is an ideal environment-friendly packing material, and can replace existing high-obstruction packing materials for the food and medicines.

Owner:GUIZHOU RUILONG GRP PLASTIC PACKAGING CO LTD

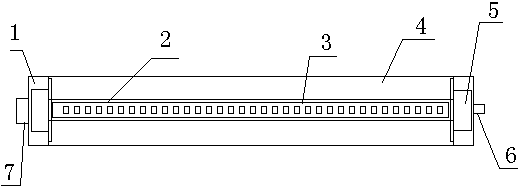

LED (Light-emitting diode) lamp tube electrode with easily determined LED polarity

InactiveCN104344376ASuitable designSuitable for productivityPoint-like light sourceElongate light sourcesEngineeringLED lamp

The invention relates to an LED lamp tube electrode with easily determined LED polarity. The LED lamp tube electrode at least comprises an LED lamp panel, a lamp panel heat dissipation rack, lamp holders at two ends and a lamp tube, wherein the LED lamp panel is fixed on the lamp panel heat dissipation rack; the LED lamp tube electrode is characterized in that the lamp tube is connected to the outer end of the lamp panel heat dissipation rack in a sleeving manner; the lamp holders at two ends are encapsulated at two ends of the lamp tube, and are used for enabling a left lamp tube electrode and a right lamp tube electrode which are connected with a power supply to extend out from two ends of the lamp holders; shapes or sizes the left lamp tube electrode and the right lamp tube electrode are different; the electrodes with different shapes or sizes form positive and negative electrodes, so that positive and negative electrodes are distinguished when the lamp tube is installed. The LED lamp tube electrode can greatly reduce the use quantity of aluminum heat dissipation racks, simplifies the production technology of LED lamp tubes, reduces labor cost, reduces the total cost of the LED lamp tube, does not need polarity conversion circuits, and has the characteristics of environment protection, efficiency saving and the like.

Owner:西安发威电子科技有限公司

Processing method for antiwear shaft sleeve pipe

InactiveCN103567254AImprove structural rigidityExtend your lifeUltimate tensile strengthThermal conductivity

The invention discloses a processing method for antiwear shaft sleeve pipe, wherein employed raw materials comprise an aluminium pipe and a steel pipe. The processing method comprises: performing acidpickling and drying on the aluminium pipe and the steel pipe; sleeving the steel pipe with the aluminium pipe, reserving 0.3 mm-0.4 mm of a gap between the aluminium pipe internal diameter and the steel pipe external diameter; employing a supersonic-frequency induction coil to heat the aluminium pipe and the steel pipe at the same time, tightly combining the heads of the aluminium pipe and the steel pipe by a special-purpose head rolling machine; lubricating the aluminium pipe and performing cold drawing by a speed-adjustable drawing machine. The shaft sleeve pipe produced by employing the processing method is not only excellent in thermal conductivity, but also improved in rigidity strength, and also aluminium material is substantially saved and the heat dissipation benefit is improved.

Owner:刘先艳

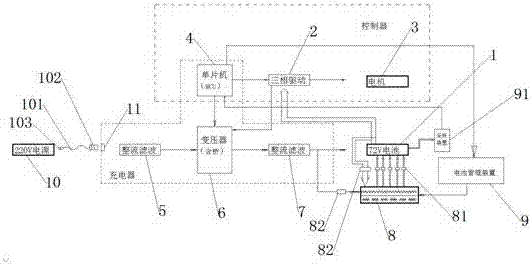

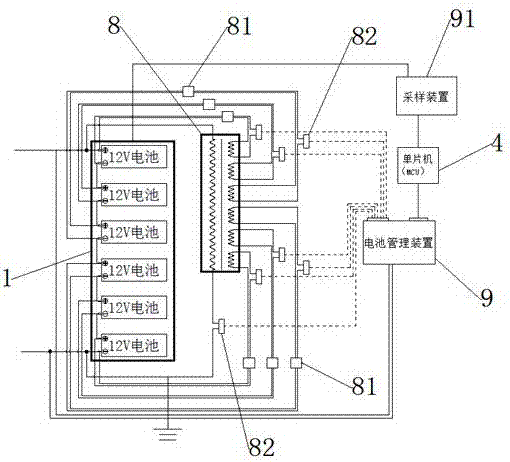

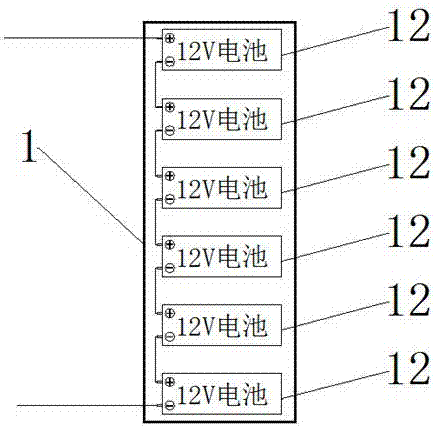

Charging type motor controller with battery management function

InactiveCN106981912AGuaranteed practical lifeSolve Compatibility IssuesCharge equalisation circuitParallel/serial switchingElectrical batteryTransformer

The invention relates to a charging type motor controller with a battery management function. The motor controller comprises a three-phase drive device, a single-chip microcomputer, a first rectifying and filtering device, a transformer, a second rectifying and filtering device, a charging interface, a multifunctional inverter, a battery management module and a battery residual capacity sampling device and is connected with a 72V power battery, a motor and a 220V external power supply. The charging type motor controller has the advantages that defects in the prior art are overcome, an electric vehicle motor controller and a charger are combined due to the fact that the electric vehicle motor controller and the charger do not work at the same time and have many identical parts such as the single-chip microcomputer and the three-phase drive device, the charging type motor controller is further integrated with a battery management system formed by the multifunctional inverter, the battery management device and the battery residual capacity sampling device, and battery pack service life is guaranteed.

Owner:合肥凯利科技投资有限公司

Insulation curtain wall and its construction method

The invention discloses a thermal insulation curtain wall, which includes expansion bolts pre-buried on the outer wall, and a hanging plate preset with undercut bolts installed on the surface of the outer wall through the expansion bolts, and also includes a gusset plate attached to a decorative panel, and the The insulation board between the buckle plate and the hanging plate, the hanging plate is preset with undercut bolts, and the gusset plate is fastened on the outside of the hanging plate through the countersunk head lock column and the undercut bolts; the insulation board is preset to match the undercut bolts The through hole of the insulation board is set on the outside of the undercut bolt, and the insulation board is arranged between the buckle plate and the hanging plate. The invention also discloses a construction method of the thermal insulation curtain wall. The thermal insulation curtain wall of the present invention has basically the same aesthetic effect as the aluminum-plastic composite board, but does not require a large number of aluminum brackets, saves aluminum materials, and also has the functions of air purification, self-cleaning, and heat insulation, and the construction method is simple and efficient, and can be used in Factory pre-processing, and then assembled on site, significantly reducing construction costs.

Owner:LIAONING TAIFENG ALUMINUM ENG

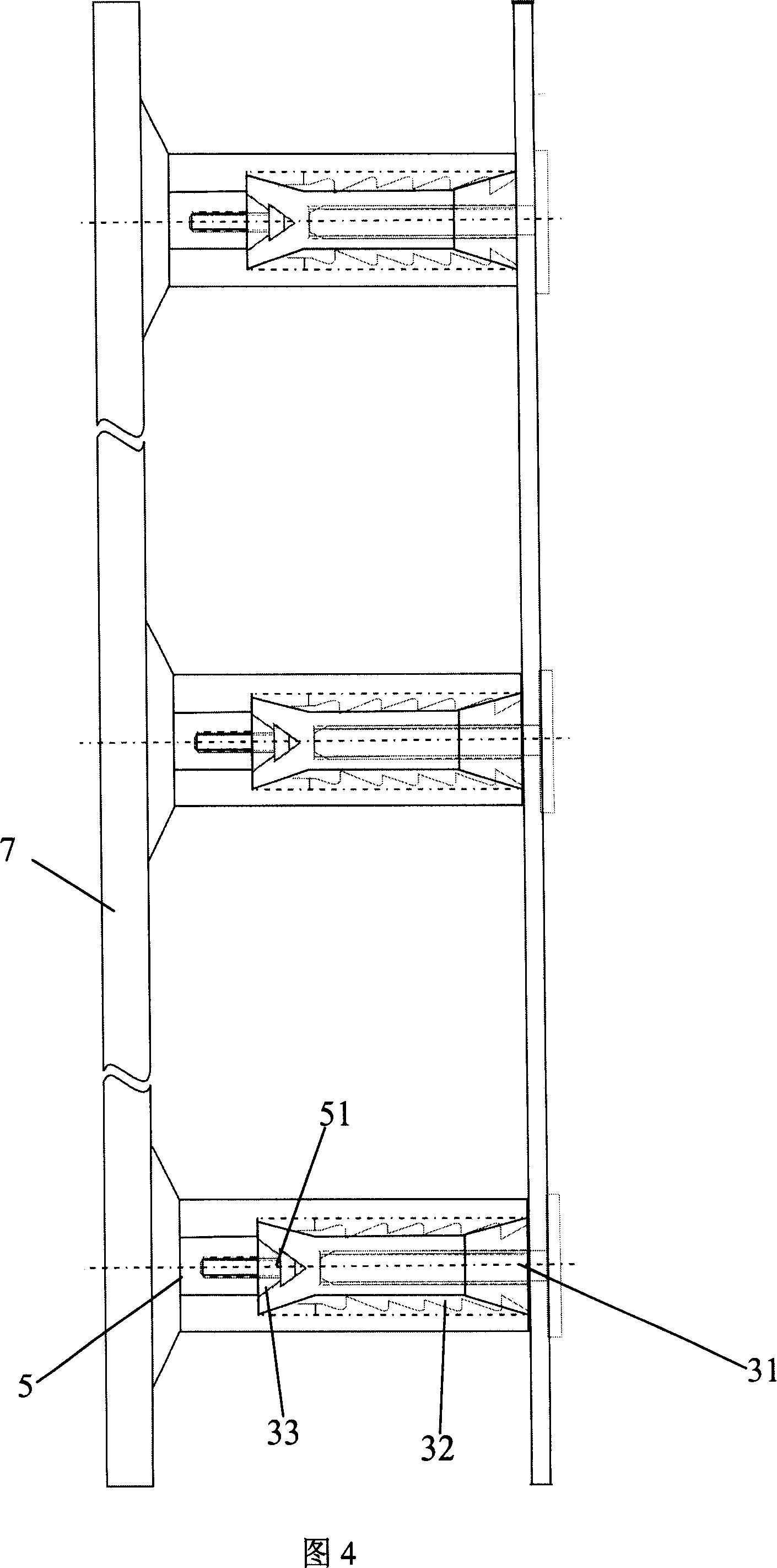

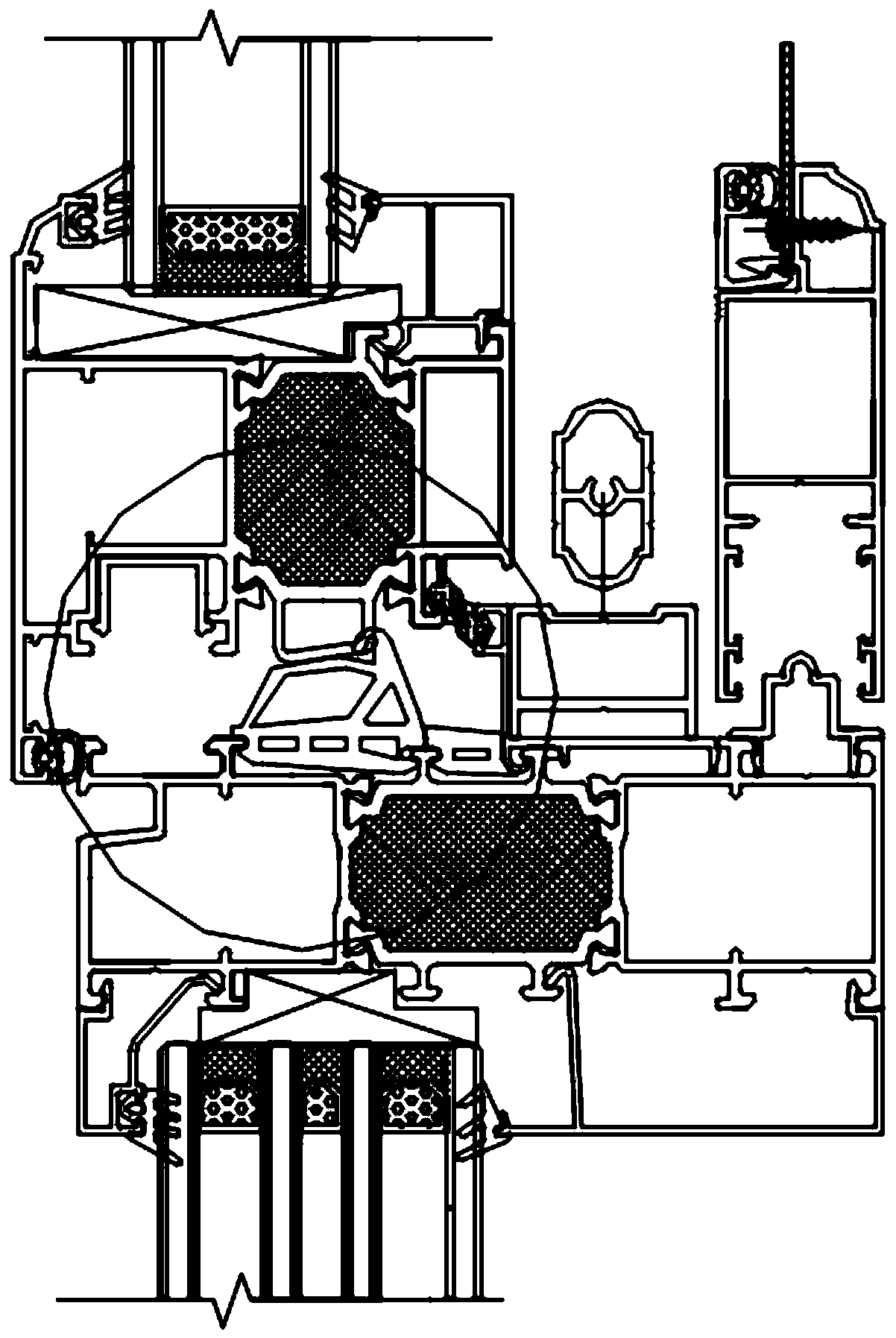

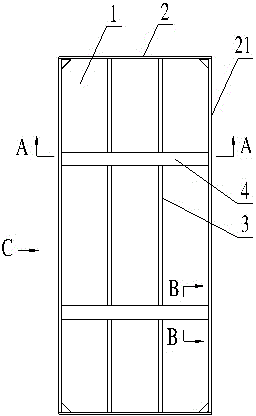

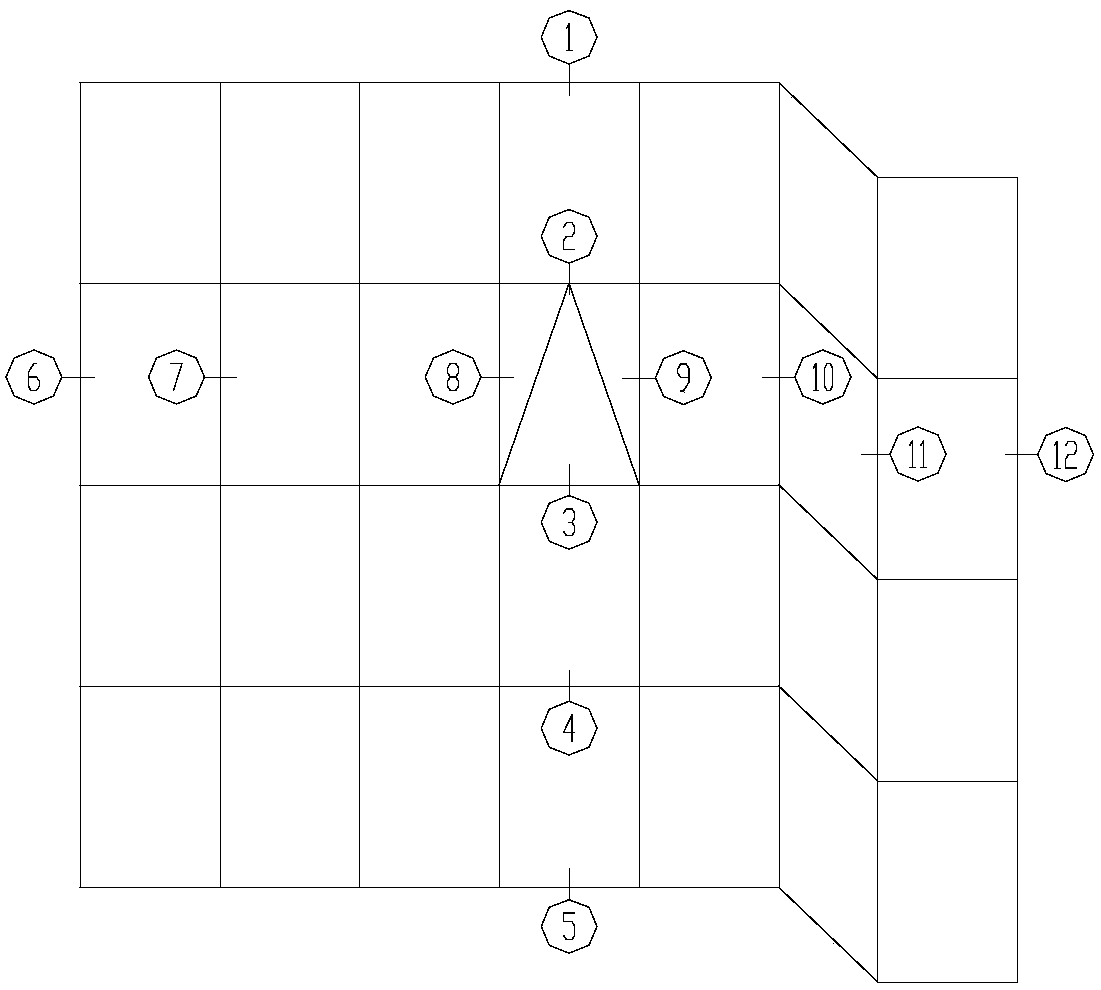

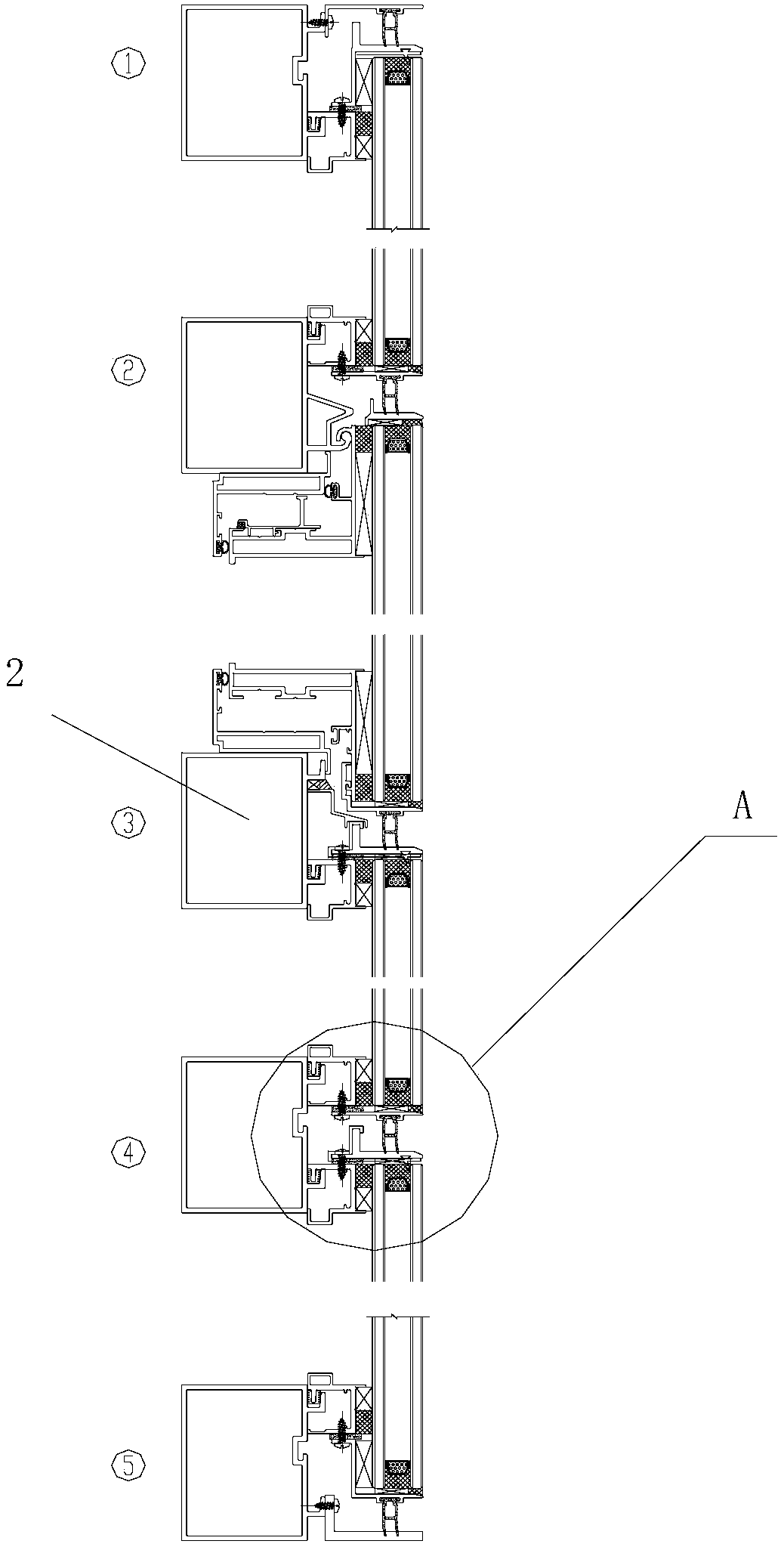

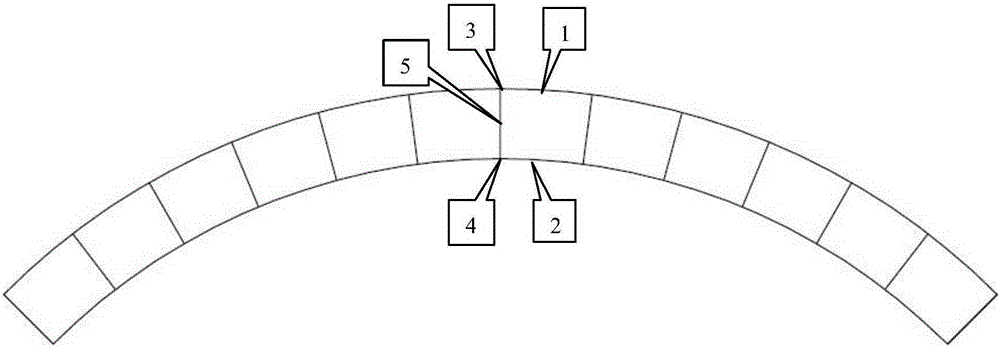

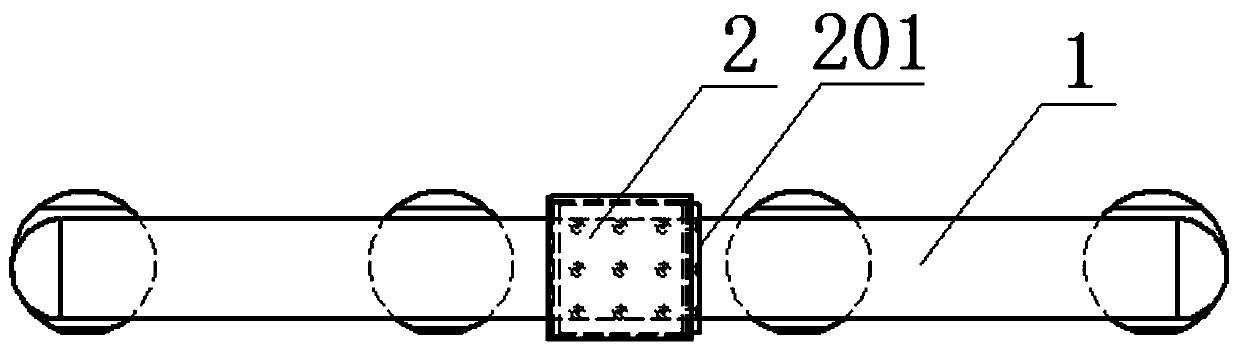

A Component Curtain Wall System Suitable for Dry Construction

ActiveCN105625617BChange the installation methodRealize dry constructionWallsBuilding insulationsWater leakageEngineering

A stick curtain wall system suitable for dry construction, comprising: mullions (1), transoms (2) connected to the mullions (1), and panels (3) mounted on the mullions (1) and the transoms (2). Several joint accessories (4) and several first sealing strips (6) are provided within vertical gaps formed by the panels (3); the first sealing strip (6) is mounted between two adjacent joint accessories (4); a waterstop strip (9) is provided on the top of each panel (3), and a second sealing strip (10) is provided at the bottom of each panel (3); the joint accessory (4) is horizontally mounted on the tops of two adjacent panels (3) to partition the vertical gaps; both ends of the joint accessory (4) are in engagement joint with the ends of the waterstop strip (9); a sealing layer (5) sealably connected with the ends of the waterstop strip (9) is further provided on the joint accessory (4). The mounting approach of the stick curtain wall is greatly changed. The joint accessories (4), the sealing layers (5), and the first sealing strips (6) are organically combined with the second sealing strips (10) and the waterstop strips (9) to form specific waterstop, flashing, and draining structures, thereby effectively solving the water leakage problem, and practically implementing the dry construction of a stick curtain wall.

Owner:杜军桦 +1

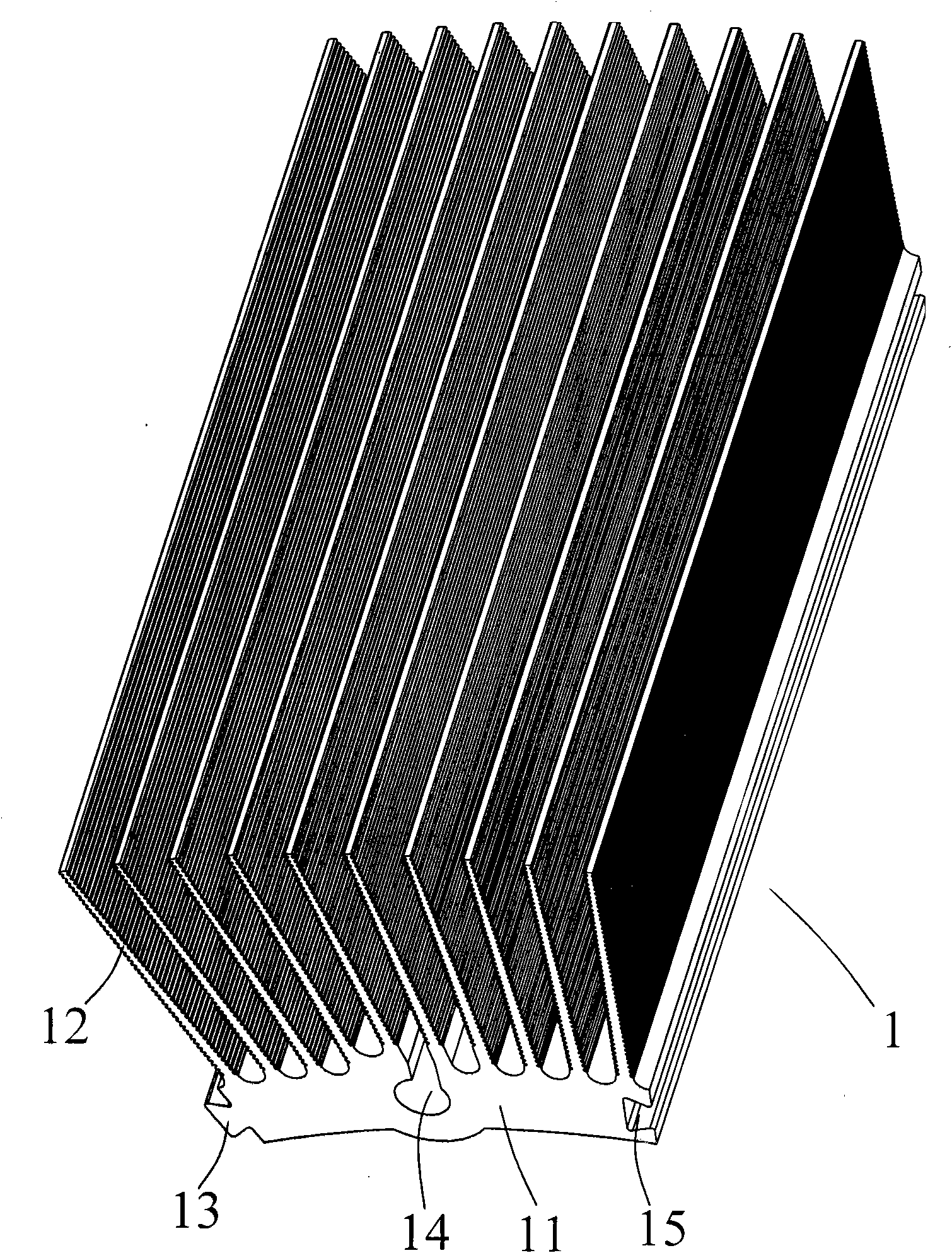

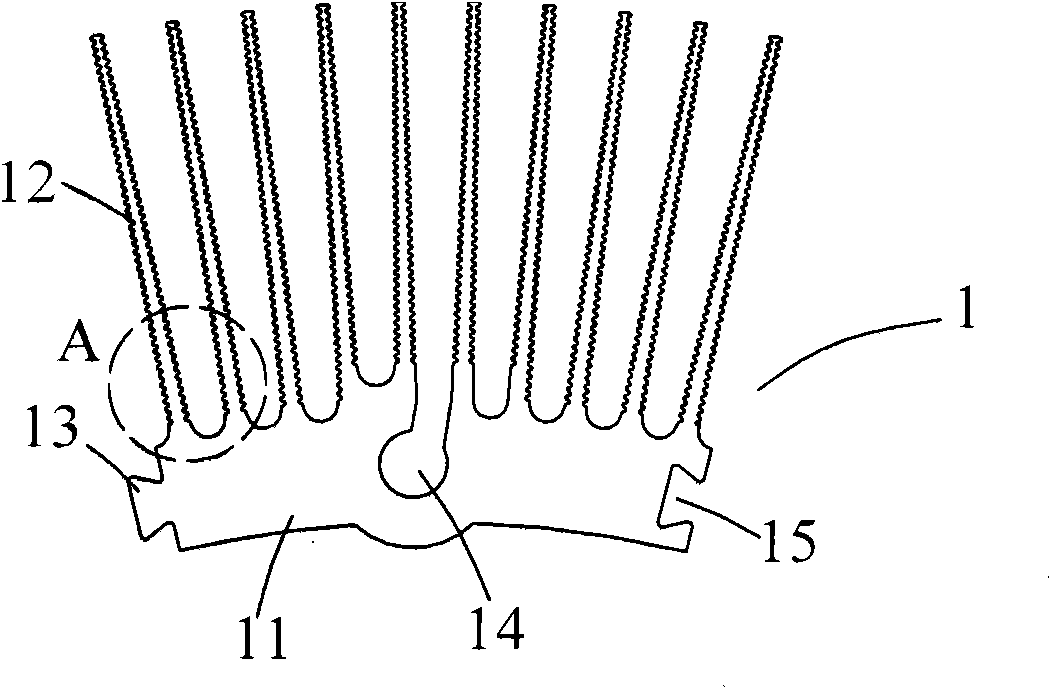

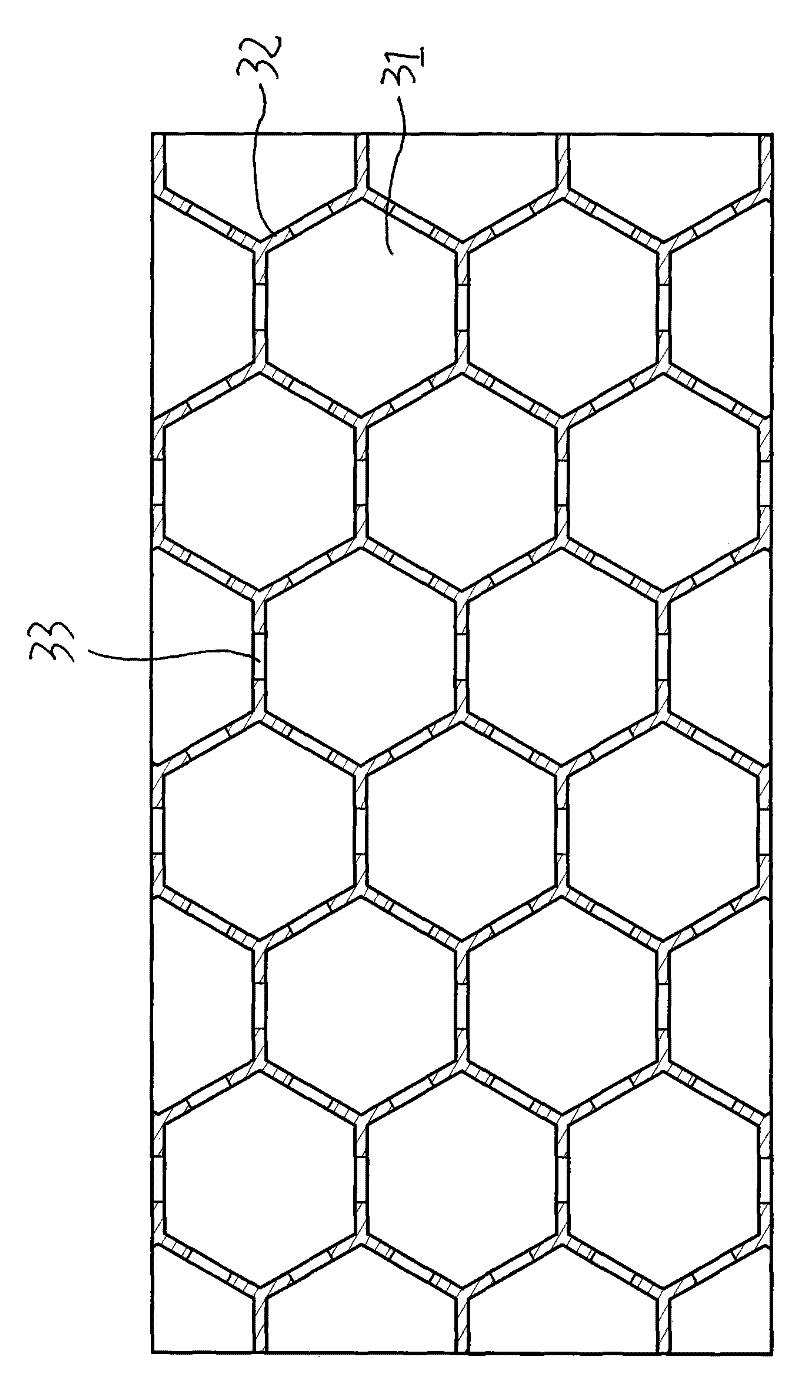

Heat-radiating device of electric component

InactiveCN101730455BReduce the temperatureExtended service lifePoint-like light sourceLighting heating/cooling arrangementsHoneycombHoneycomb Pattern

The present invention belongs to the technical field of heat-radiating devices, in particular to a heat-radiating device of an electric component. The heat-radiating device is mainly characterized by comprising a heat-radiating substrate and a heat-radiating plate which are closely contacted with the electric component, wherein the heat-radiating plate comprises a plurality of heat-radiating channels which are vertical to the heat-radiating substrate and heat-radiating walls encircling to form the heat-radiating channel; the section of each heat-radiating channel is in a shape of regular hexagon; the section of the heat-radiating plate is a shape of honeycomb; and the heat-radiating walls are aluminum foil boards and a plurality of air holes are arranged on the aluminum foil boards vertically arranged on the heat-radiating channels; a plurality of gas channels interlinked with the heat-radiating channels are arranged on the heat-radiating substrate. The heat-radiating mode is changed from giving the priority to the radiation into giving the priority to convection assisted by the radiation, thus the thermal impedance of the heat-radiating channel is greatly reduced and air convection is more unobstructed; in addition, the heat-radiating plate the section of which is in a shape of honeycomb ensures that the heat-radiating area reaches the maximum. The heat-radiating device of an electric component provided by the present invention solves the problem that the service life of the traditional electronic component is short caused by ineffective temperature reduction.

Owner:邢台绿时代光电科技有限公司

Holographic graphic gravure positioning printing method

ActiveCN104476935BPromote degradationSave aluminumOther printing apparatusThin membranePrinting press

The invention belongs to the field of printing, and in particular relates to a hologram text gravure positioning printing method. It includes a plate making process, a coating process, an aluminum plating process, a molding process, a composite process, a peeling process and a gravure printing process. In the present invention, the unpeeled reel transfer paper is directly unwound through the unwinder through the gravure printing on-line peeling, and the film of the transfer paper is peeled off through the in-line peeling unit first, and the paper material is directly introduced into the gravure printing unit for printing. It is of great significance to effectively solve the phenomenon of scratches caused by internal stress and improve the yield of production.

Owner:ANHUI SANLIAN WOODEN ART PACKAGE

Horizontal current aluminium cell

The invention discloses a horizontal current aluminum electrolytic bath. The aluminum electrolytic bath comprises a melting bath part and an electrode part, wherein the melting bath part consists of a steel bath shell(5) and fire proof and heat proof materials(10); the upper end of the bath shell(5) adopts an open type structure; while the electrode part consists of a cathode electrode part and an anode electrode part, wherein the cathode electrode part consists of a cathode electrode(6), a cathode electrically conductive pole(4) and a cathode bus(2) applied to discharge electric current, andthe anode electrode part consists of an anode electrode(7), an anode electrically conductive pole(3) and an anode bus(1) applied to charge electric current; the electrode part are hanged in the bath shell(5) by a support steel beam, and a liquid electrolyte layer (8) is arranged between the cathode electrode(6) and the anode electrode(7); electrolytic currents horizontally enter the correspondingside face of the cathode electrode(6) from the side face of the anode electrode(7). The aluminum electrolytic bath has the advantages that the design is novel, no electric current pass through the melting bath, no electrochemical reaction happens, the aluminum electrolytic bath does not need to be drilled around, along with long service life and good social and economic benefits.

Owner:HENAN ZHONGFU IND

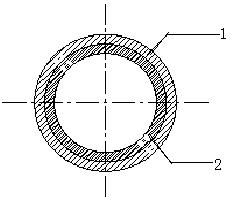

14AC-1825MPa-grade high-strength aluminum-clad steel wire and manufacturing method thereof

ActiveCN112427483AImprove carrying capacityGuaranteed conductivityHeat treatedHigh strength aluminium

The invention belongs to the field of high-strength aluminum-clad steel wire production processes, and relates to a 14AC1825MPa-grade high-strength aluminum-clad steel wire and a manufacturing methodthereof. The aluminum-clad steel wire comprises the following chemical components in percentage by mass: 0.70-0.74% of C, 0.10-0.30% of Si, 0.5-0.7% of Mn, less than or equal to 0.025% of S, less thanor equal to 0.020% of P, less than or equal to 0.10% of Cr, less than or equal to 0.10% of Ni and the balance of Fe and inevitable impurity elements. The specification of the aluminum-clad steel wireis phi 2 mm, the tensile strength is larger than or equal to 1970 MPa, and the 1% elongation stress is larger than or equal to 1720 MPa. The process comprises the following steps: 1, selecting a heattreatment line; 2, coating; 3, performing aluminum-clad steel wiredrawing; 4, wiping; and 5, performing shaft returning.

Owner:天津市新天钢中兴盛达有限公司

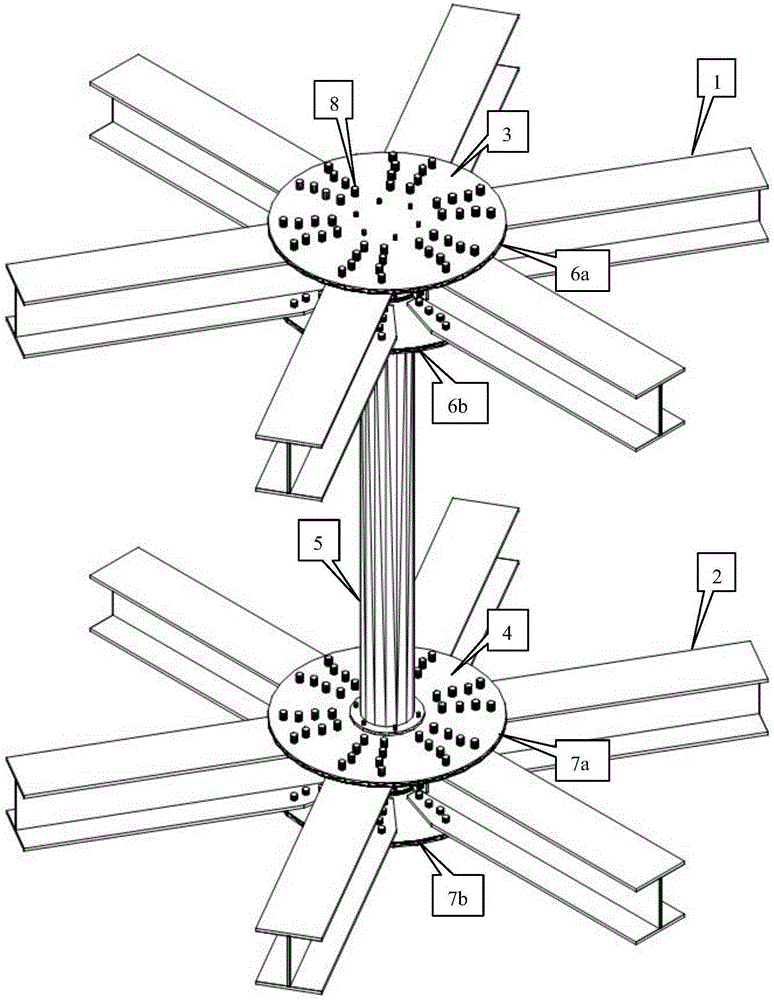

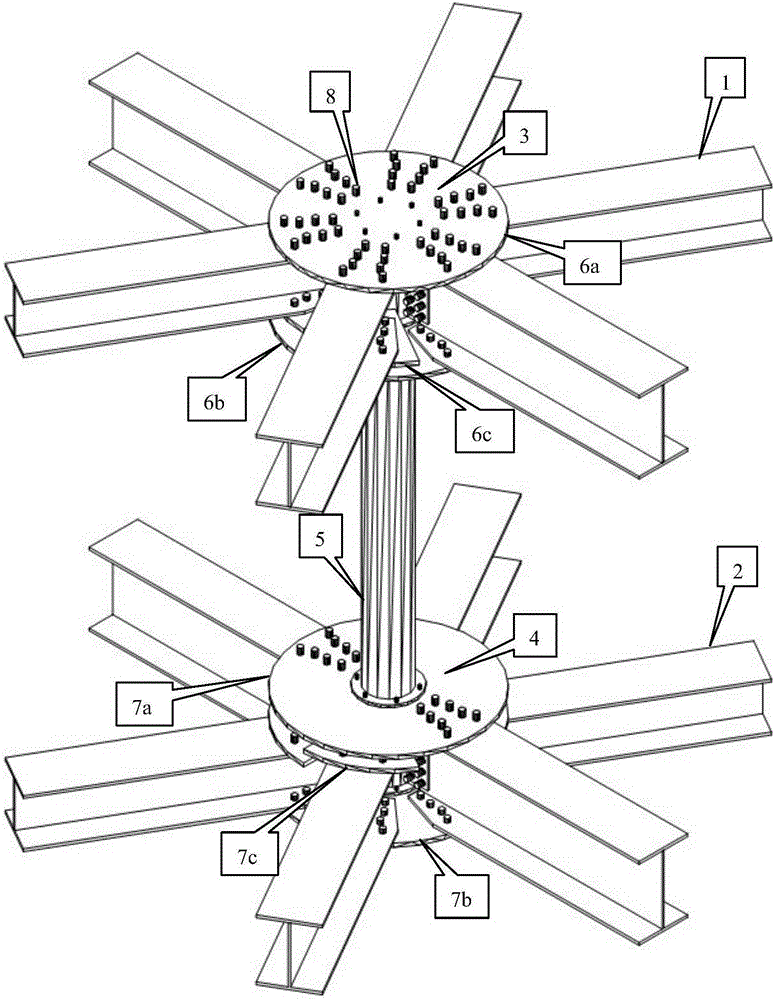

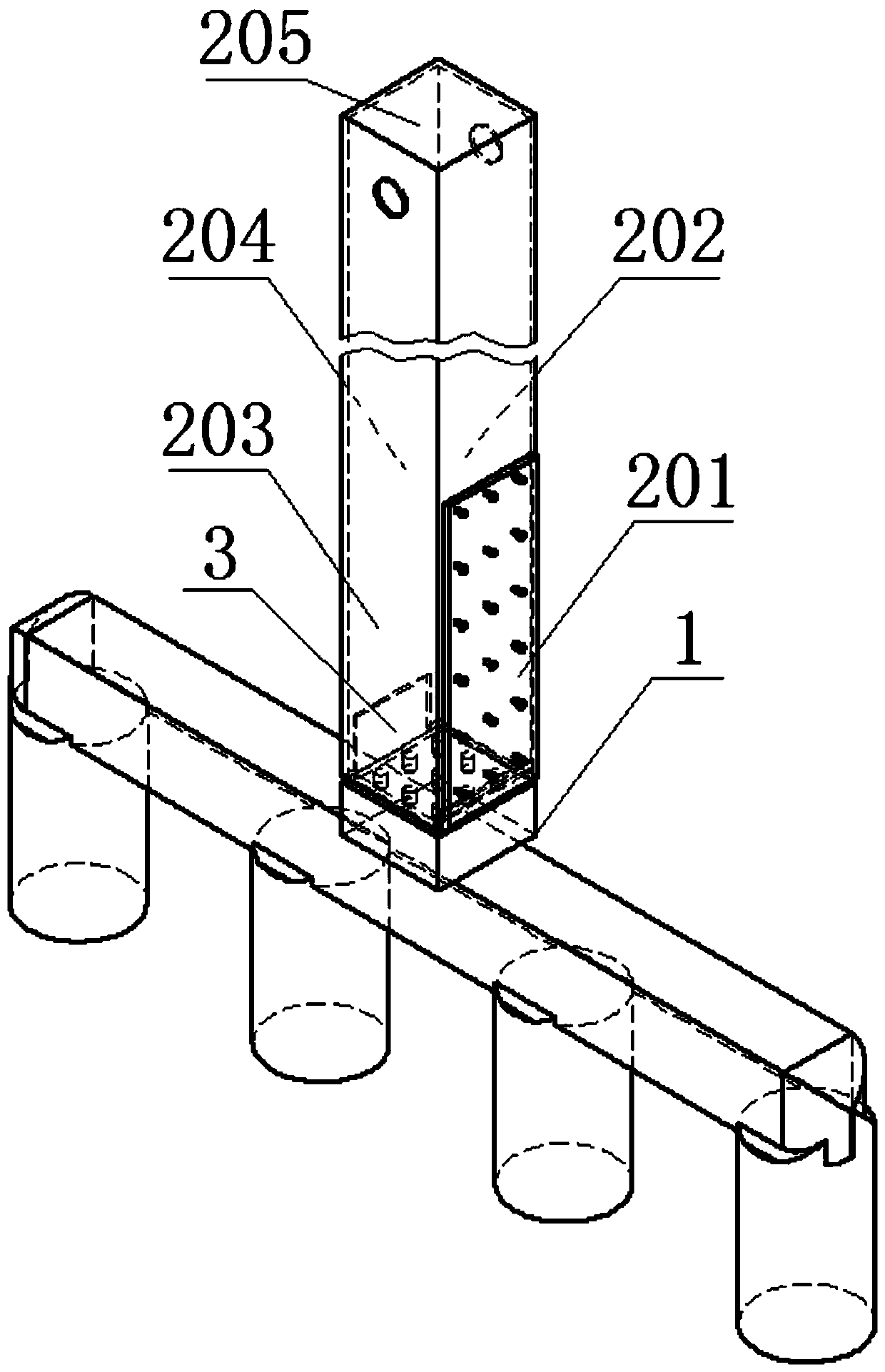

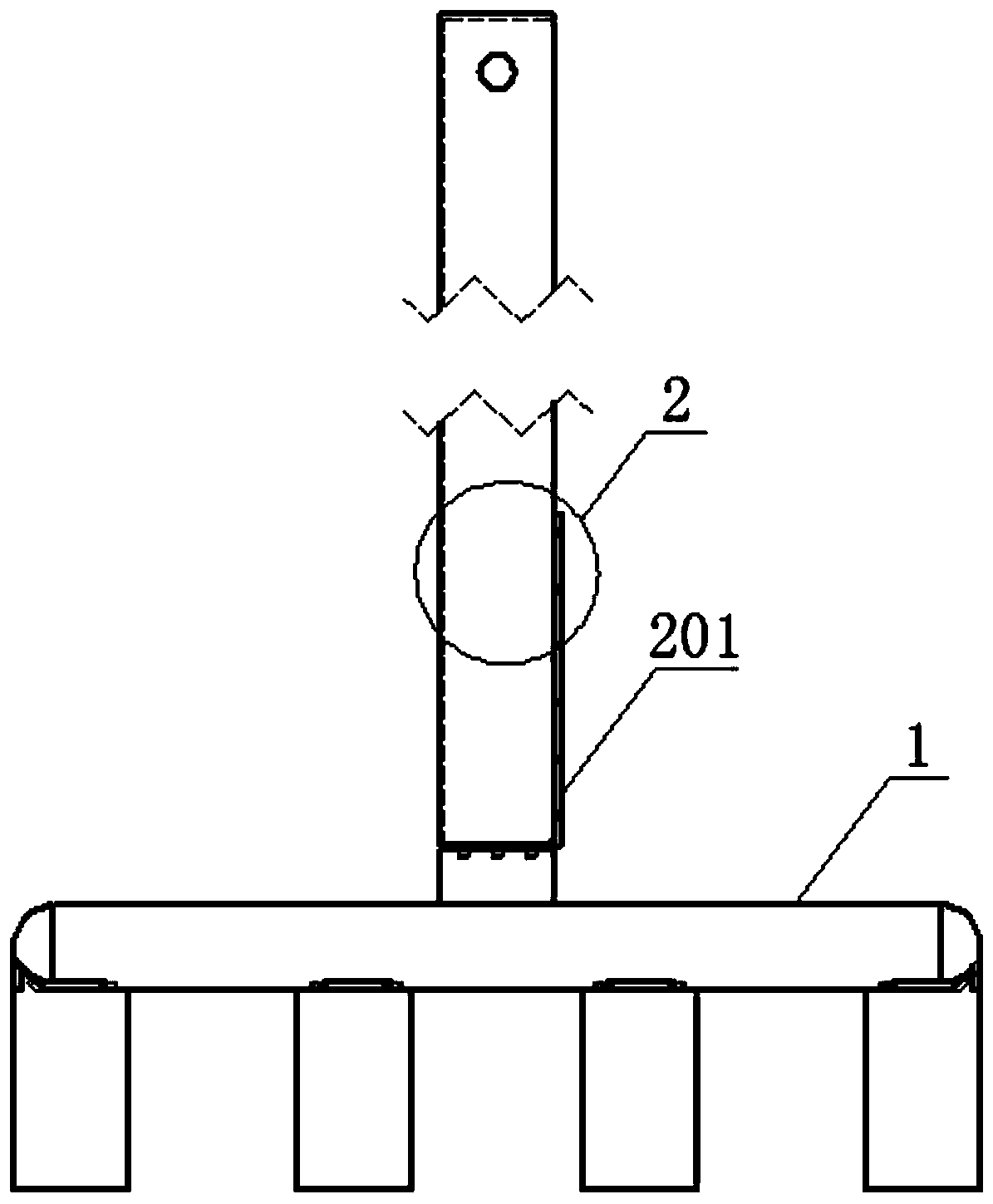

Bolt-assembled double-layer aluminum alloy reticulated shell structure

ActiveCN103590488BImprove stabilityIncrease profitArched structuresVaulted structuresStructural systemFlange

Owner:TIANJIN UNIV

A kind of anode steel claw guide rod group

ActiveCN108707929BReduce material costsReduce weightElectrical resistance and conductanceStructural engineering

The invention provides an anode steel claw guide rod set. The anode steel claw guide rod set comprises an anode steel claw guide rod and an anode steel claw. The anode steel claw guide rod is providedwith a hoisting part. A frame structure defined by a good conductor and steel plates meeting the strength requirement is adopted as the anode steel claw guide rod to be directly connected to the anode steel claw, and the good conductor plate is attached to one side face of the anode steel claw guide rod; and the anode steel claw guide rod is of the frame structure defined by the good conductor plate and the steel plates, wherein the bottom of the frame structure is hollow. The phenomenon of arc discharge cannot happen to the anode steel claw guide rod set, the service life is long, contact resistance is hardly achieved for the anode steel claw guide rod set, and electrical losses are few. The anode steel claw guide rod set is simple in structure, low in manufacturing cost and convenient to install. The anode steel claw guide rod set is adopted for aluminum electrolysis, and environment protection is facilitated; and connection between the anode steel claw guide rod and the anode steelclaw is firm and stable, the phenomena of falling-off and tearing cannot happen, aluminum materials can be greatly saved, and the material cost of the anode steel claw guide rod is greatly reduced.

Owner:重庆角鹿机械制造有限公司 +1

Building energy-saving out-swinging casement Chinese window structure with anti-mosquito function

PendingCN111140135AReduce occupancyIncrease profitWing handlesVentilation arrangementBuilding energyEngineering

The invention relates to a building energy-saving out-swinging casement Chinese window structure with an anti-mosquito function. The structure comprises a window frame and two glass window sashes which are arranged on the window frame and are opened opposite to each other, and Chinese carvings are arranged on the glass window sashes. The two ends of the window frame are provided with symmetrical detachable invisible screen windows. Each invisible screen window comprises a gauze screen, a gauze sash handle, a winding drum and sliding chains, wherein the gauze sash handle and the winding drum are arranged on the left and right sides of the gauze screen respectively, and the sliding chains are arranged on the upper and lower edges of the gauze screen respectively. Sliding rails correspondingto the sliding chains are arranged on the inner sides of the upper and lower edges of the window frame. Each glass sash comprises a sash frame and glass, wherein the sash frame comprises a first framematerial and a second frame material which are in embedded connection through connecting pieces. The window structure is provided with the detachable invisible screen windows, the gauze screens are stainless steel meshes and can prevent mosquitoes and biting of mice, opposite opening can be achieved, and a fixed mullion is not arranged, so that the view is wide and the ventilation effect is good.The Chinese carvings and a window are integrated, so that the window structure is attractive and elegant.

Owner:湖南梦同幕墙门窗有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com