Aluminum alloy hub core pulling casting mold and process thereof

A technology of aluminum alloy wheels and casting molds, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of large amount of car chips, waste of materials, and excessive thickness of materials, so as to reduce weight, reduce damage, meet lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

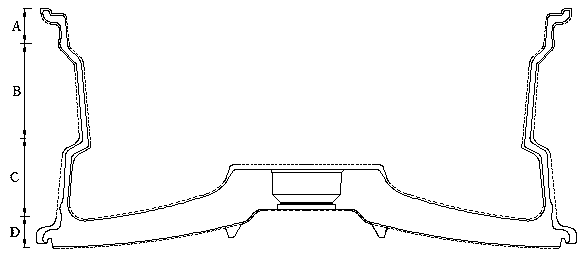

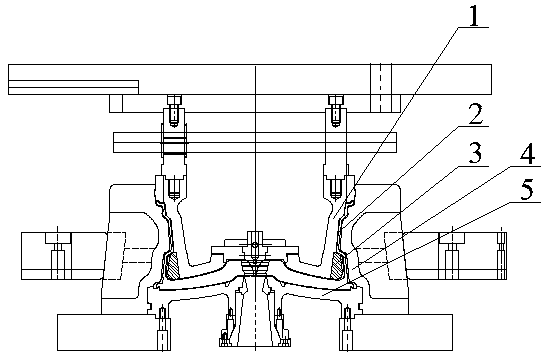

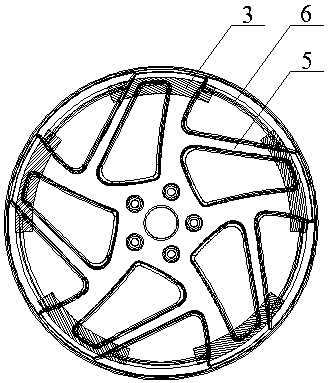

[0015] refer to Figure 1 to Figure 3 , a core-pulling casting mold for an aluminum alloy wheel hub, comprising a lower mold 5, a side mold 4 and an upper mold 1 that are combined to form a wheel hub casting cavity, and any adjacent two rib window elevation slopes 6 of the lower mold 5 are provided An insert 3 is arranged, and the insert 3 is in an arc-shaped structure, which just matches the inner surface of the formed C-ring of the hub.

[0016] A core-pulling casting process for an aluminum alloy wheel hub. The casting process includes: in the early stage of casting, placing a set of preheated inserts 3 on the corresponding position of the lower mold 5, and then closing the mold to start casting; the demoulding stage: when the mold is opened, The insert 3 is taken up by the upper mold 1 together with the wheel hub, and after demolding, the insert 3 is rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com