Aluminum template

An aluminum formwork and panel technology, which is applied to formwork/formwork components, formwork/formwork/work frame connectors, and on-site preparation of building components, can solve the problem of high use cost of aluminum formwork, difficulty in promoting aluminum formwork, problems such as major safety hazards, to achieve the effect of reducing construction costs, avoiding slurry pollution, and increasing compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

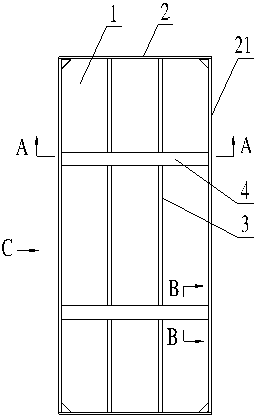

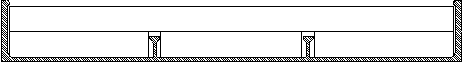

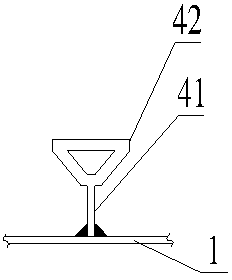

[0025] After multiple aluminum formworks are connected during construction work (such as Figure 8 shown) in contact with the slurry, the specific structure of the aluminum formwork is as follows Figure 1-Figure 6 As shown, it includes a panel 1 and a connecting plate 2 located around the inner side of the panel. The inner side of the panel 1 is provided with several longitudinal ribs 3 and transverse ribs 4 that are fixedly connected to the connecting plate at both ends, and the transverse ribs 4 include fixedly connected The notch strip 41 and the stressed rib 42, the side where the transverse reinforcing rib 4 is in contact with the panel, that is, the side where the notch strip 41 is in contact with the panel, is provided with a notch 43, and the longitudinal reinforcing rib 3 is inserted into the notch 43, The tensile capacity of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com