Battery case, battery cell, battery and assembly method thereof

An assembly method and battery technology, which is applied to large-size batteries/battery packs, small-size batteries/battery packs, battery boxes/coats, etc., can solve the problems of potential safety hazards, difficulties, and scratches on cores, etc. Achieve the effects of eliminating potential safety hazards, simplifying the assembly process, and reducing material thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

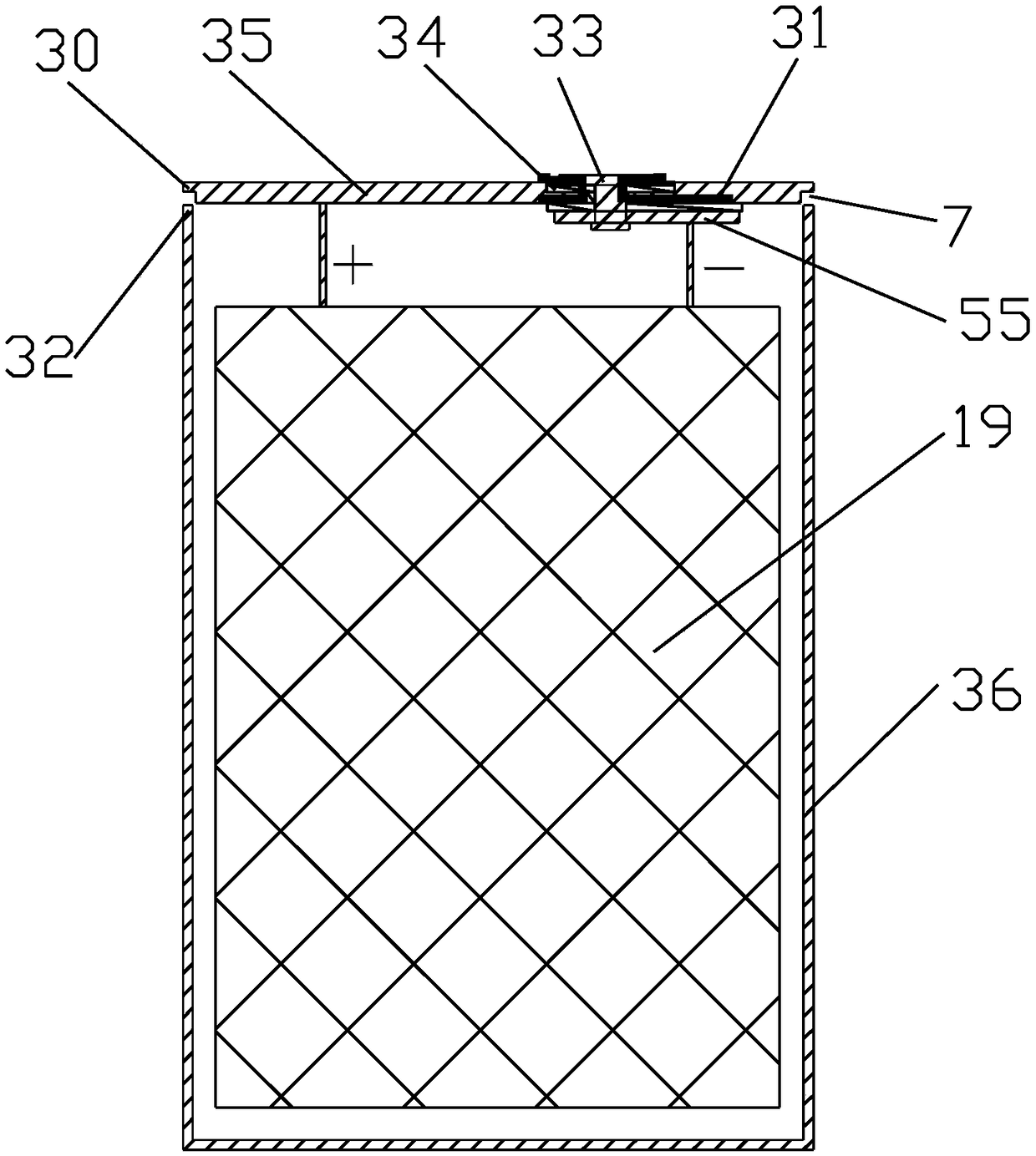

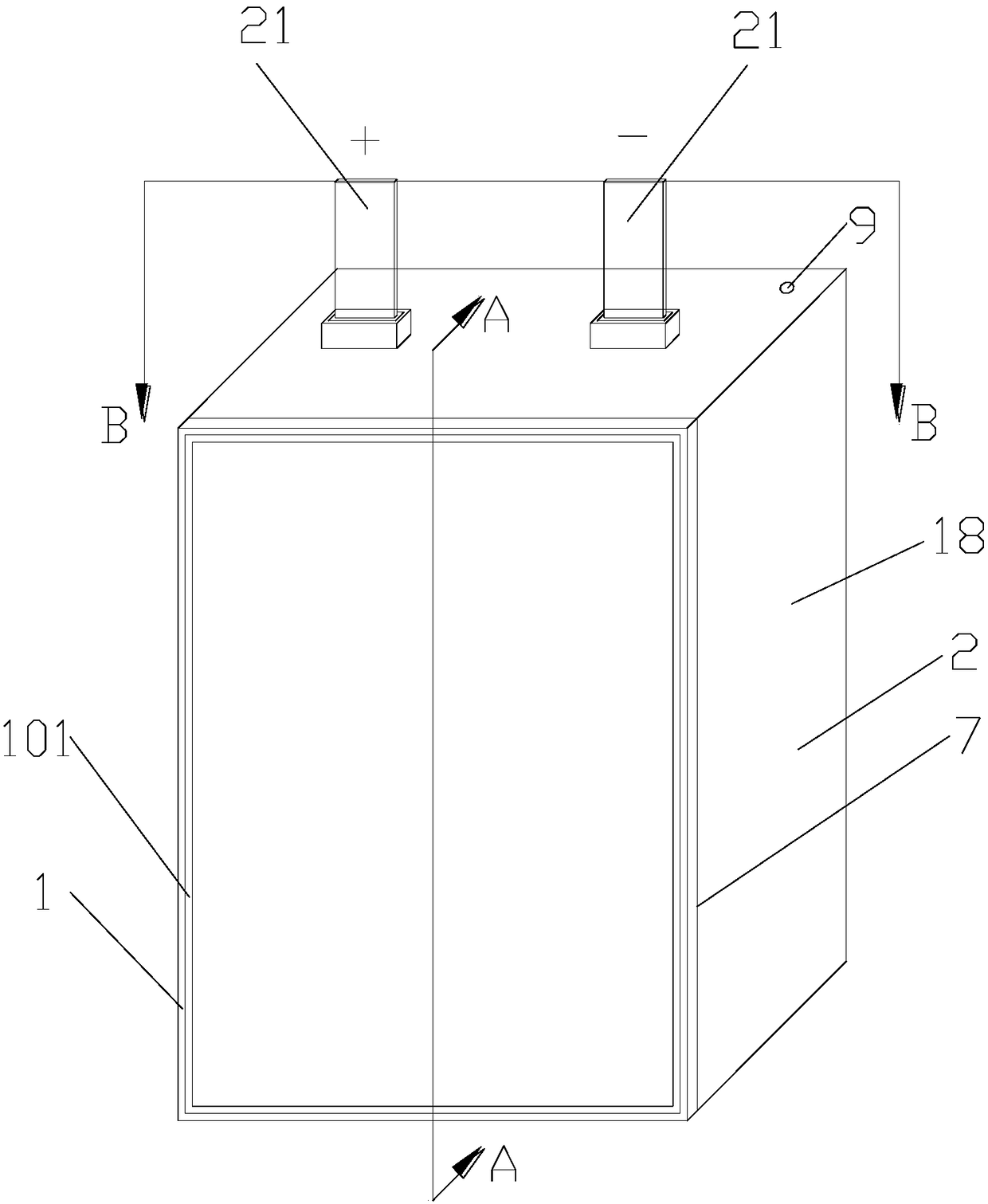

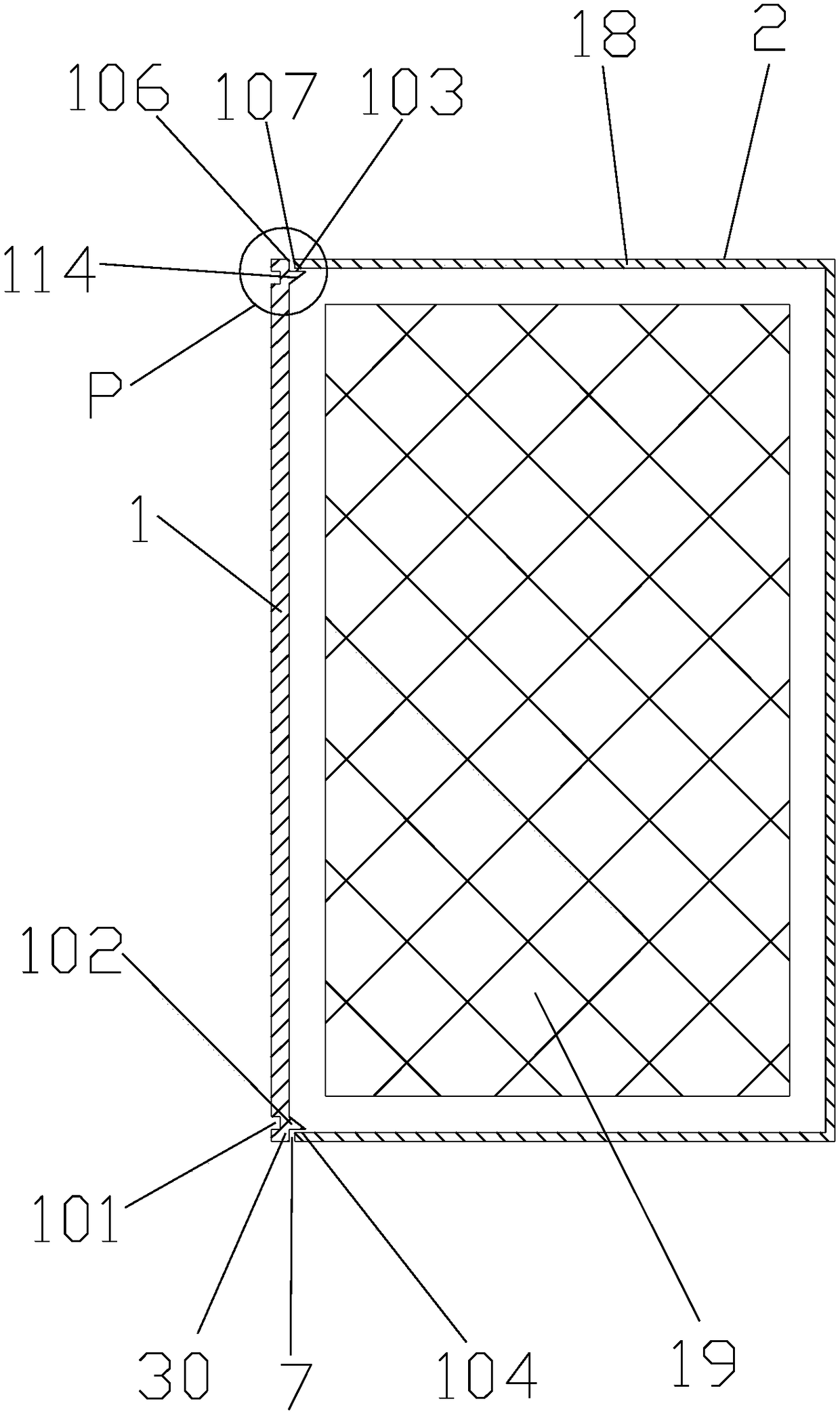

[0050] Such as Figure 2 to Figure 4 and Figure 16 As shown, a battery case 18 includes an upper case 1 and a lower case 2 . The lower casing 2 is a volume body with a certain volume (the inside and the outside are opposite to each other) with a seal on the inside and an opening on the outside. figure 2 in terms of). The upper shell 1 is to stamp out an annular groove 101 on the upper surface 200 of the thin plate of a specific size along the four edges slightly inward, and form an annular boss 102 on the lower surface 201 of the thin plate correspondingly, and the outer surface 103 of the boss 102 is The first mating surface is matched with the inner surface 104 of the opening of the lower case 2. Naturally, the outermost side of the thin plate is the upper case step 30. After the upper case 1 and the lower case 2 are in pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com