Patents

Literature

96 results about "Volume body" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

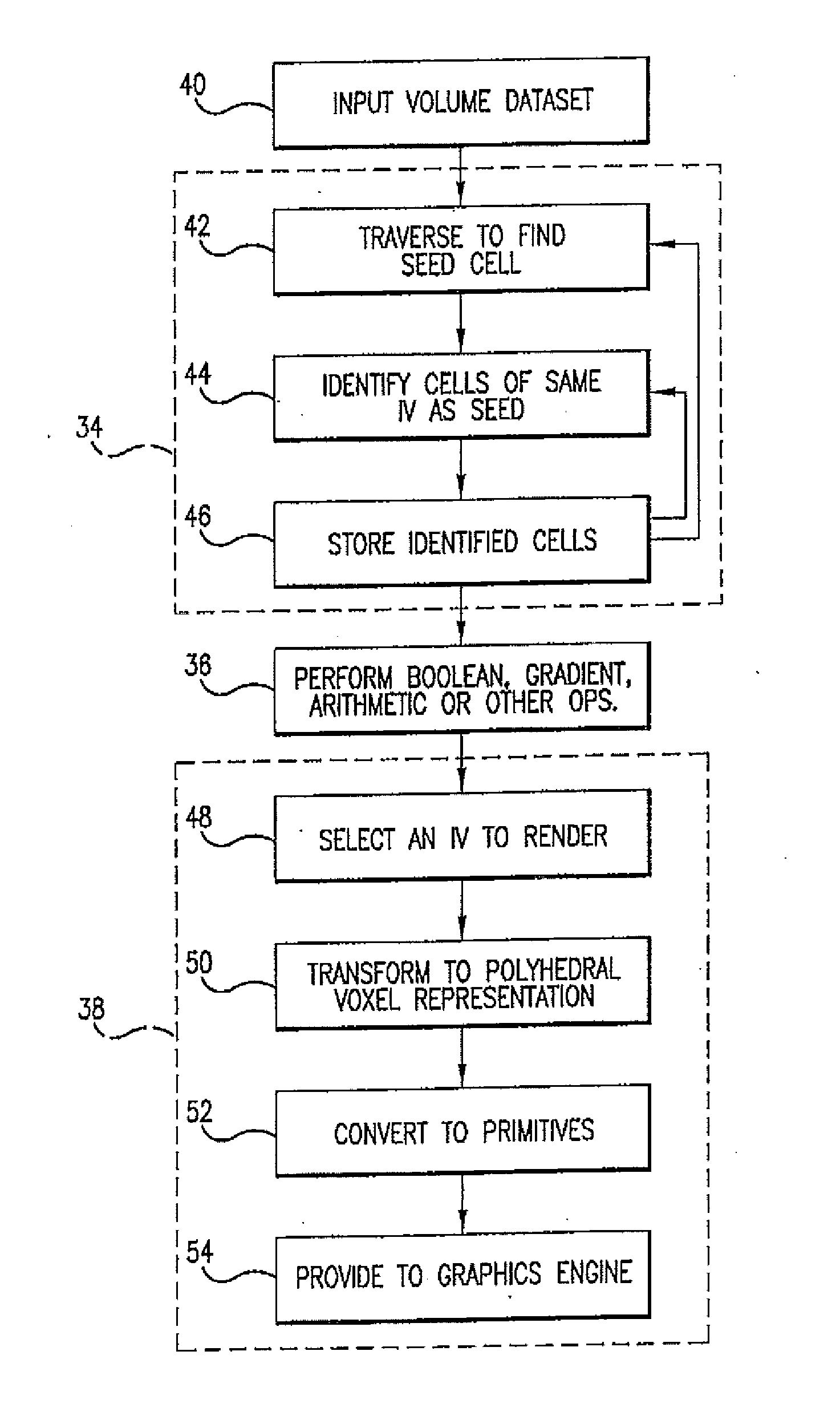

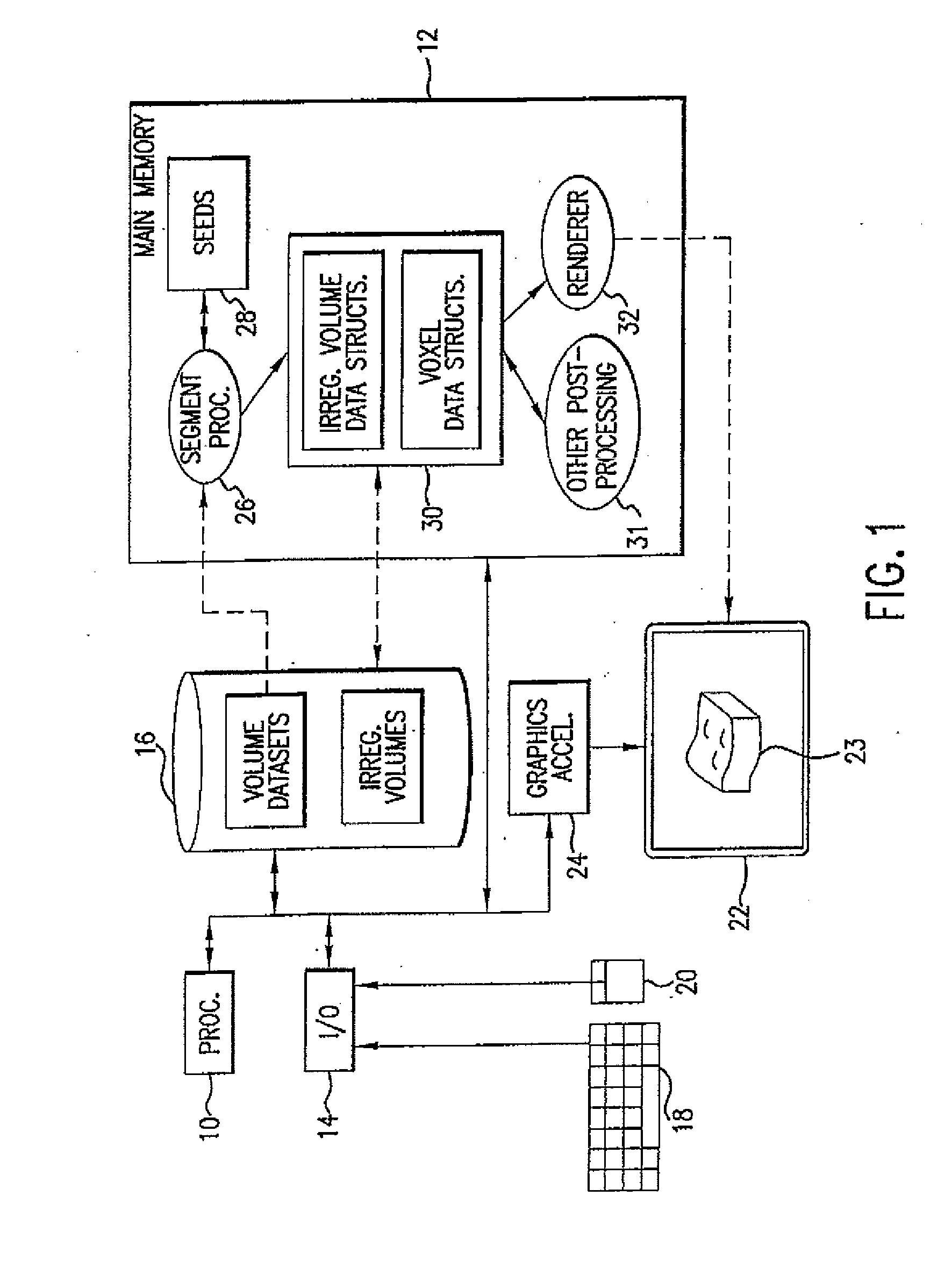

Volume body renderer

ActiveUS7412363B2Less computationally complexPerformed rapidly and efficientlyImage enhancementImage analysisVoxelData set

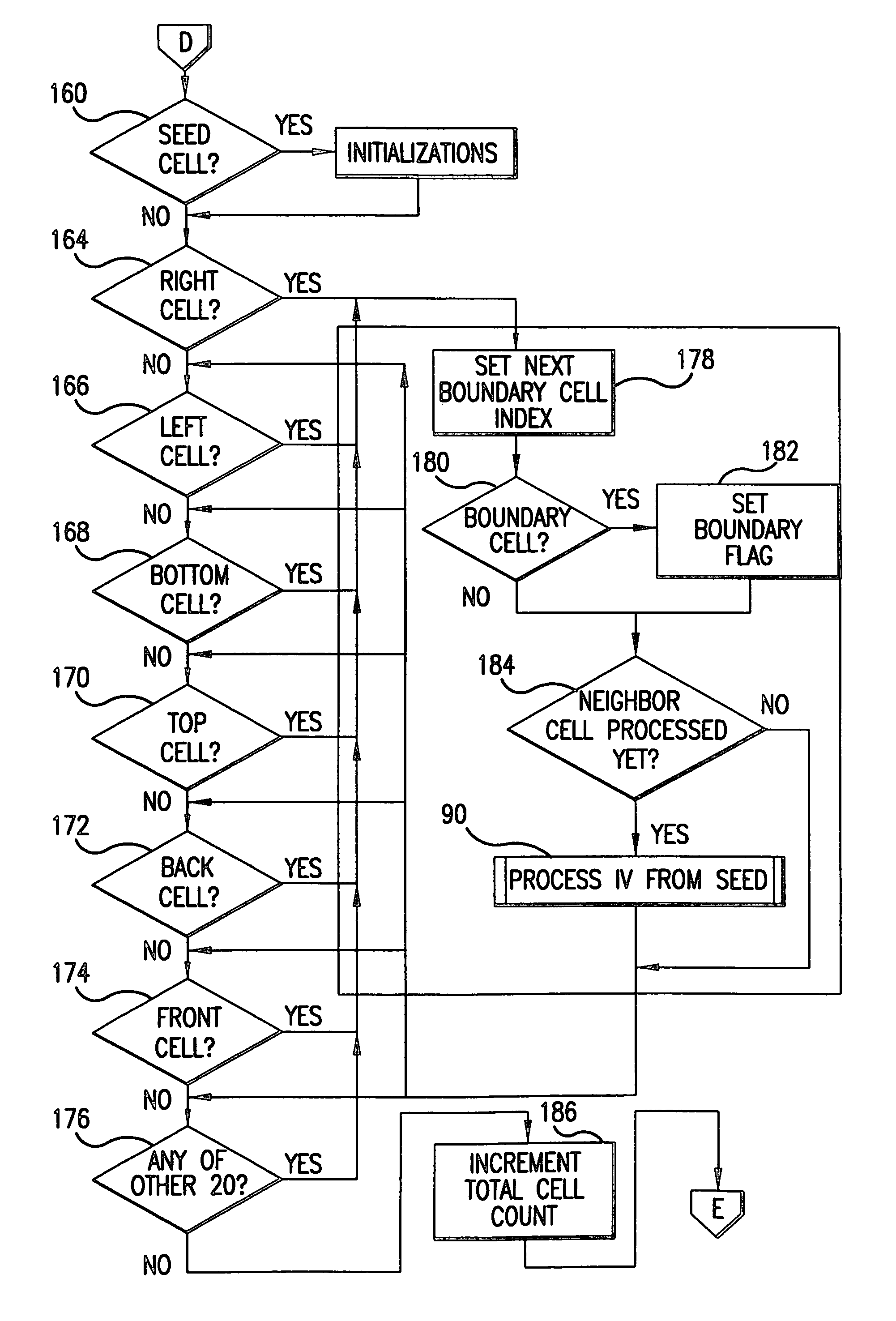

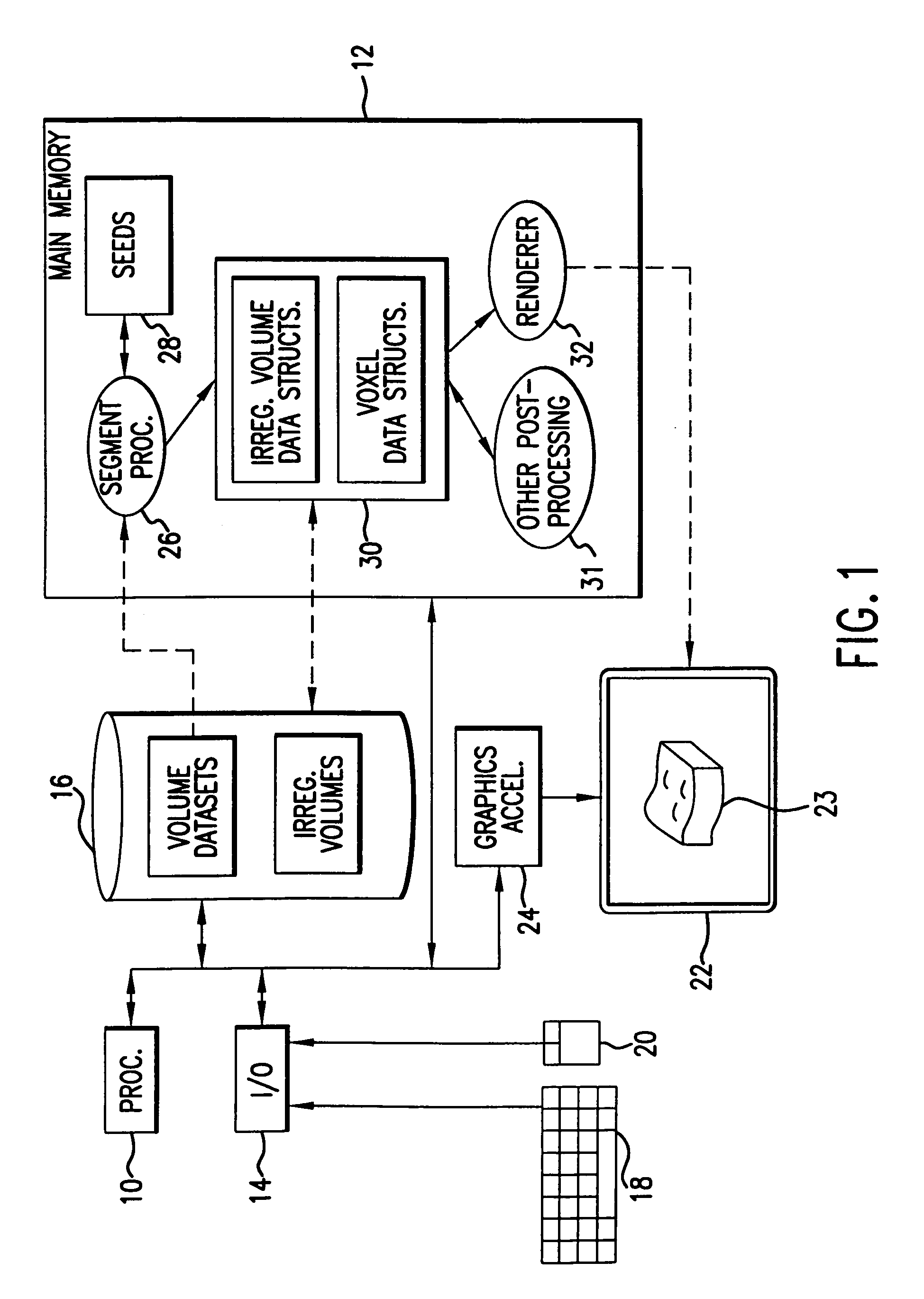

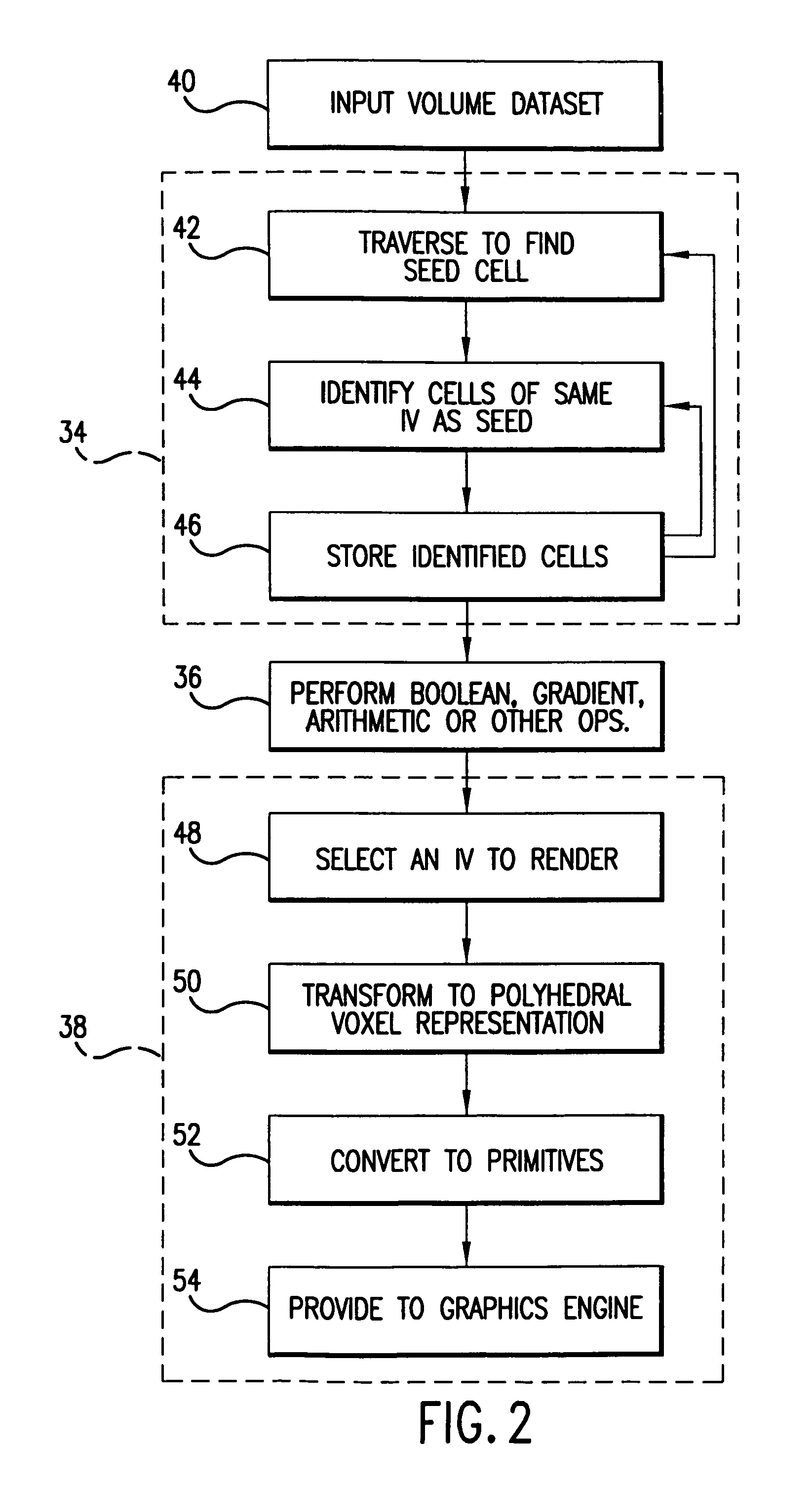

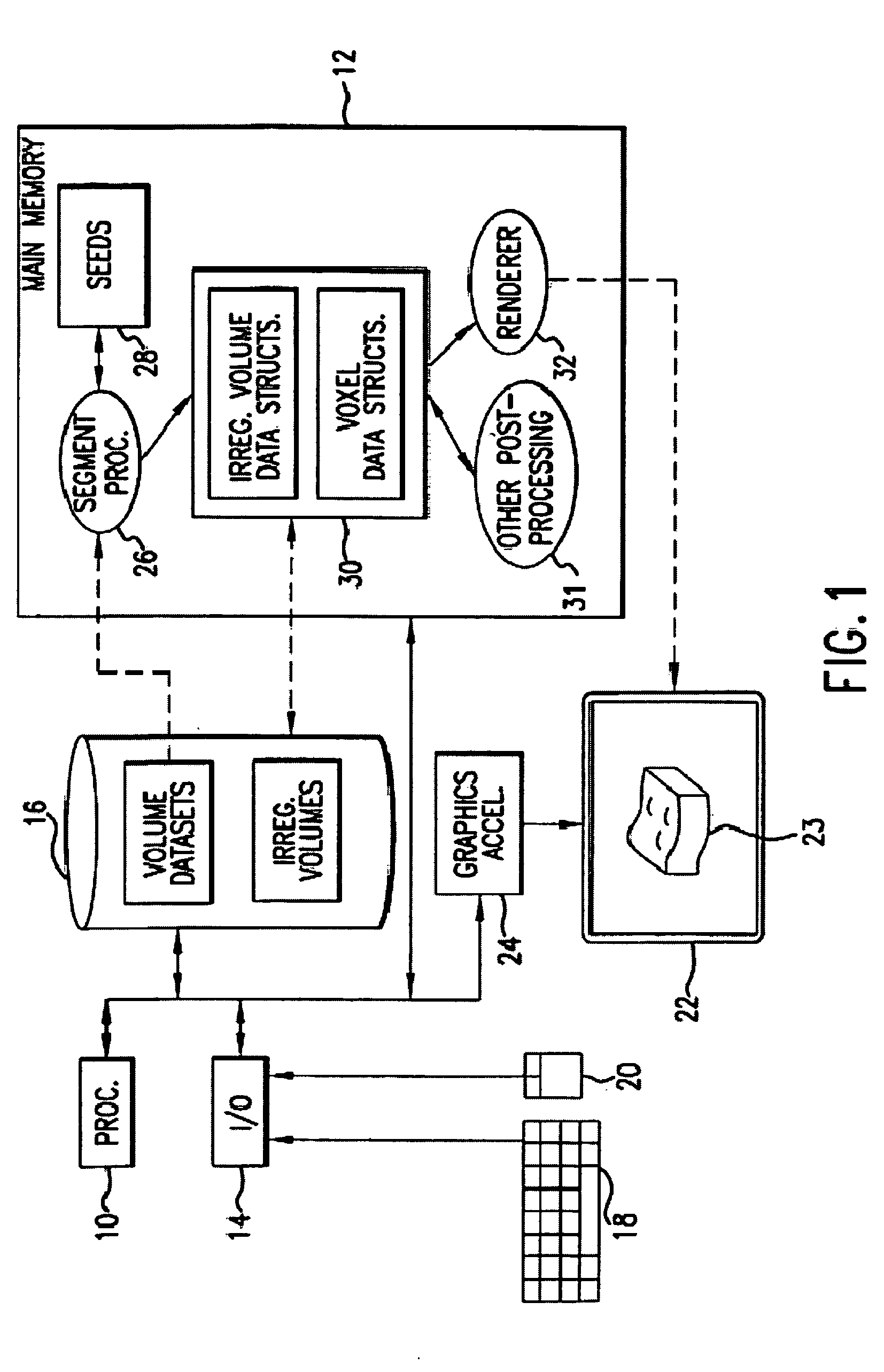

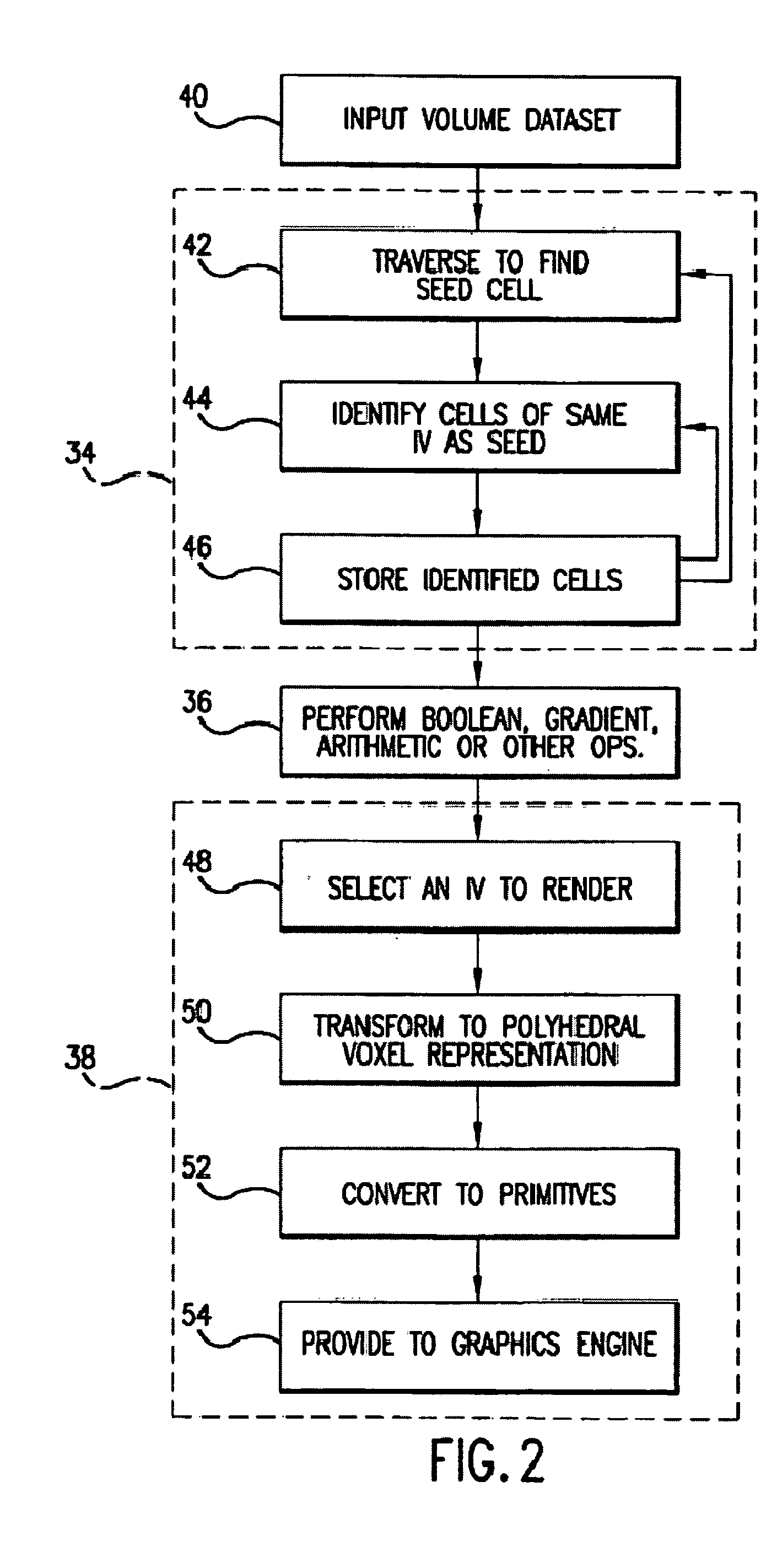

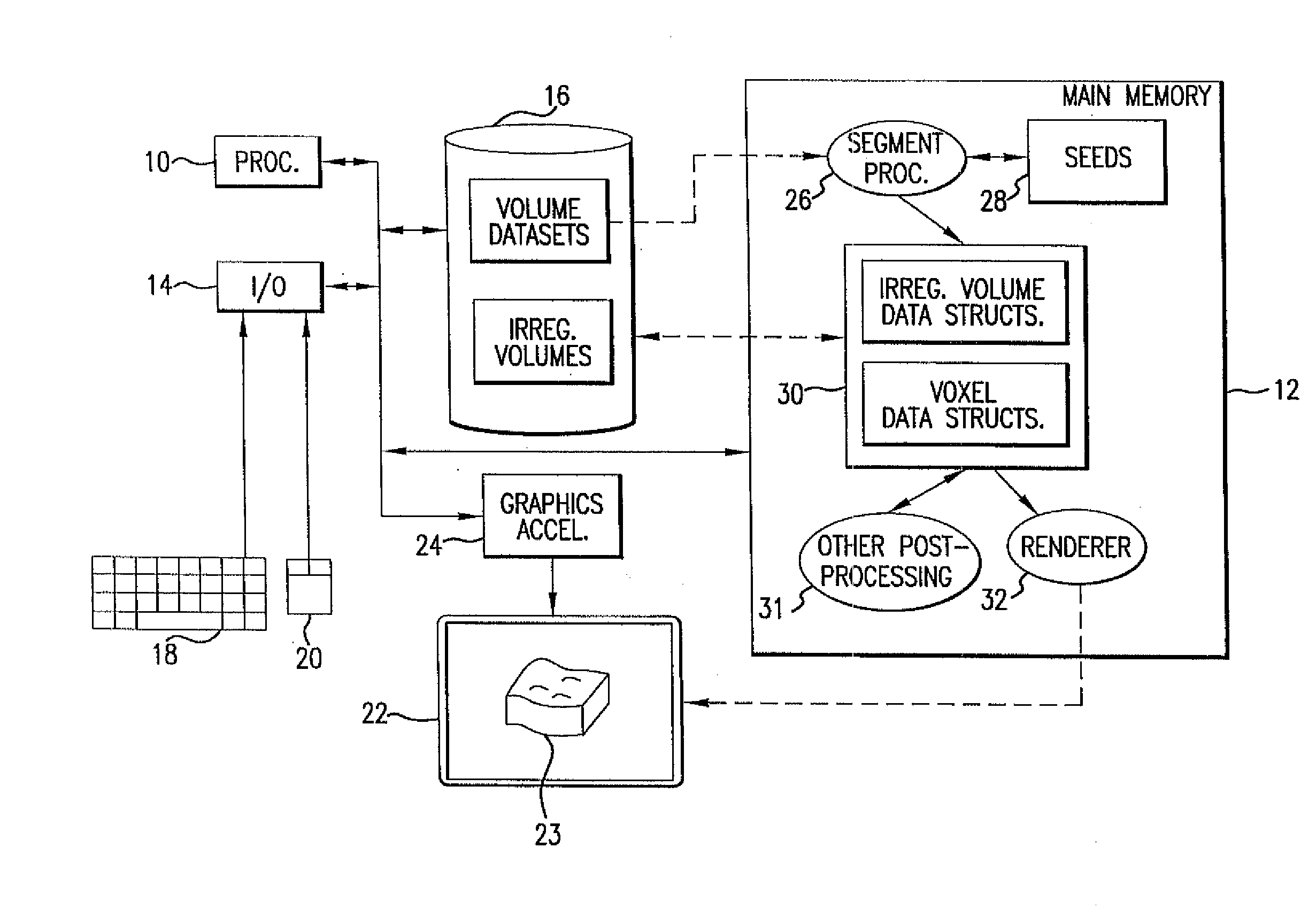

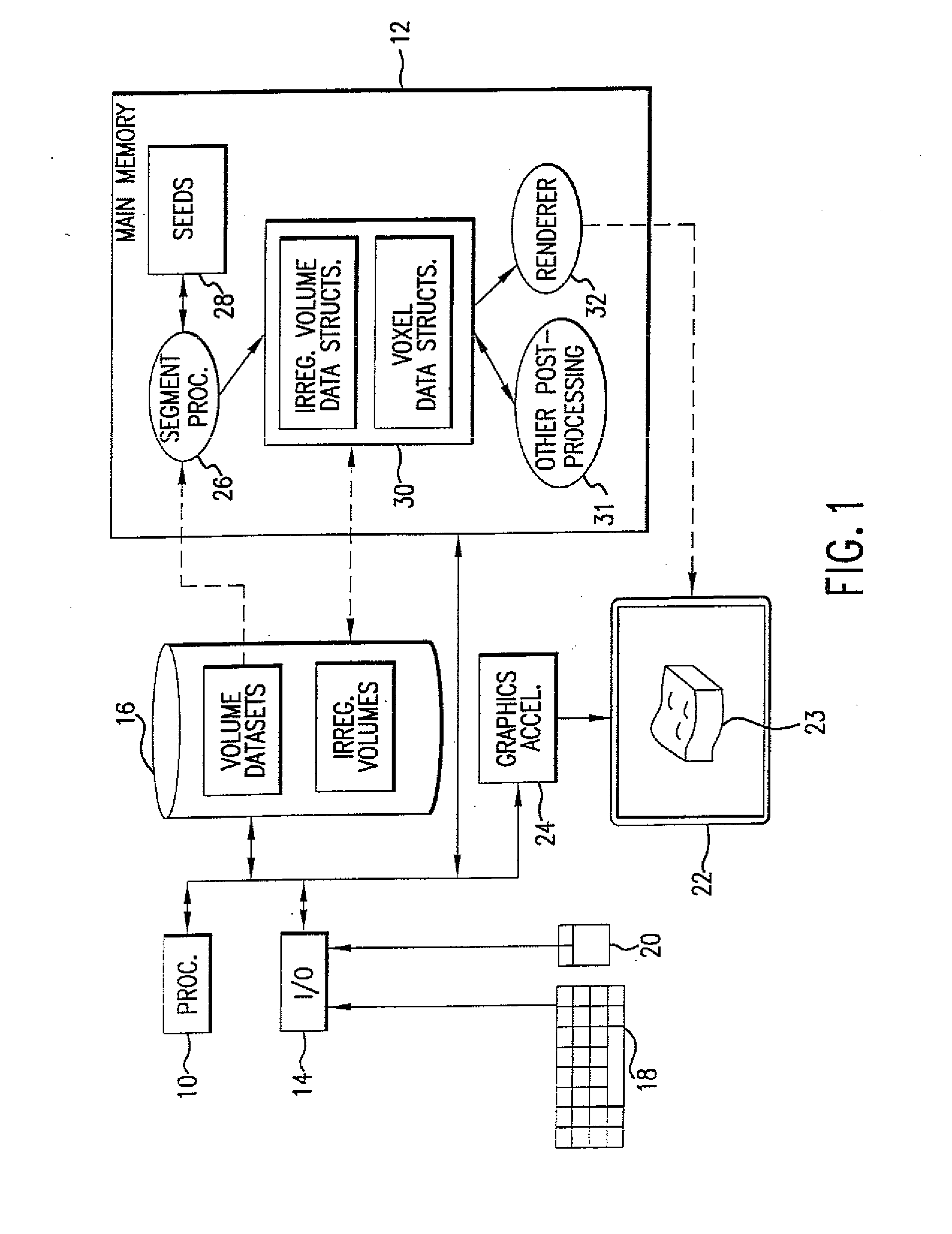

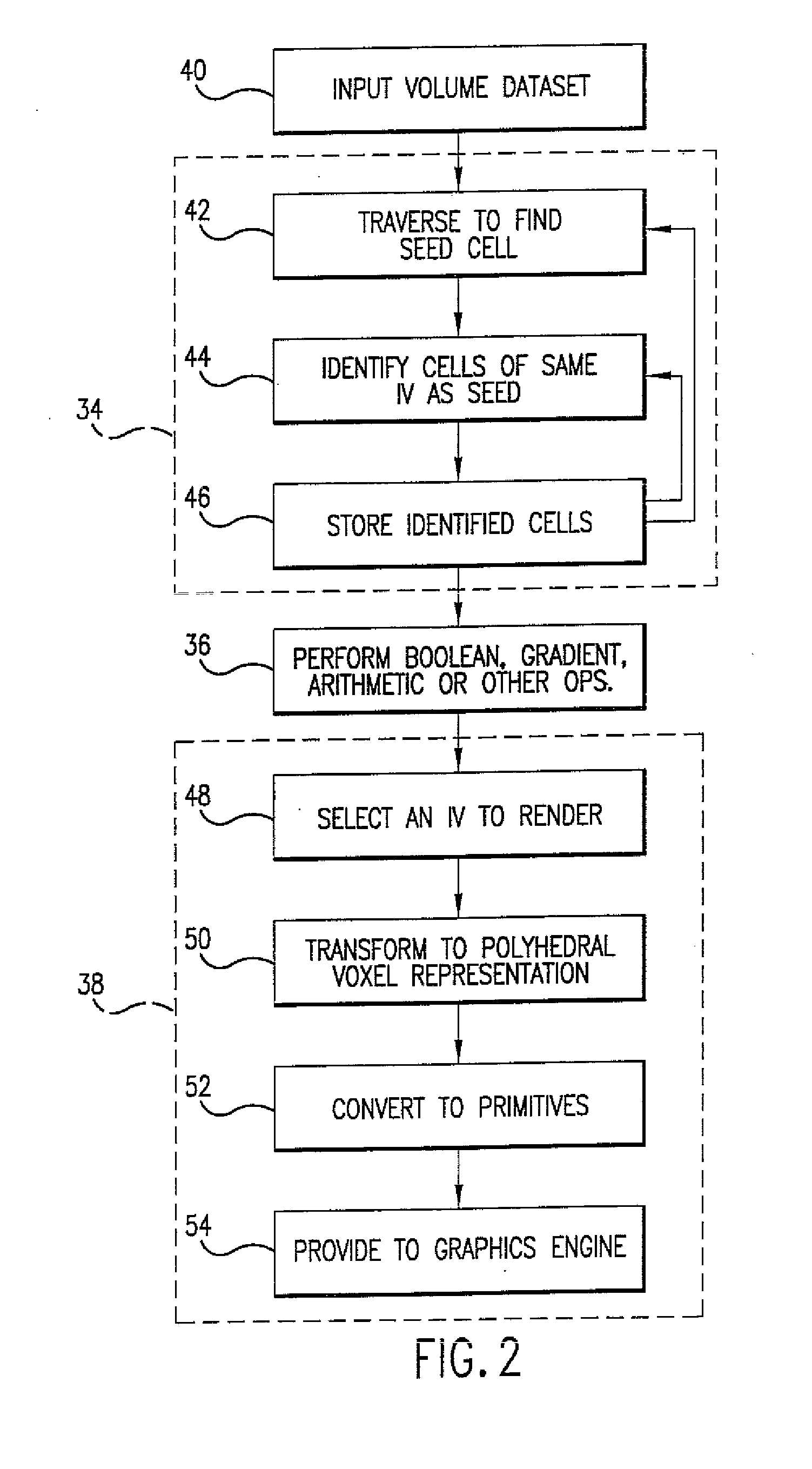

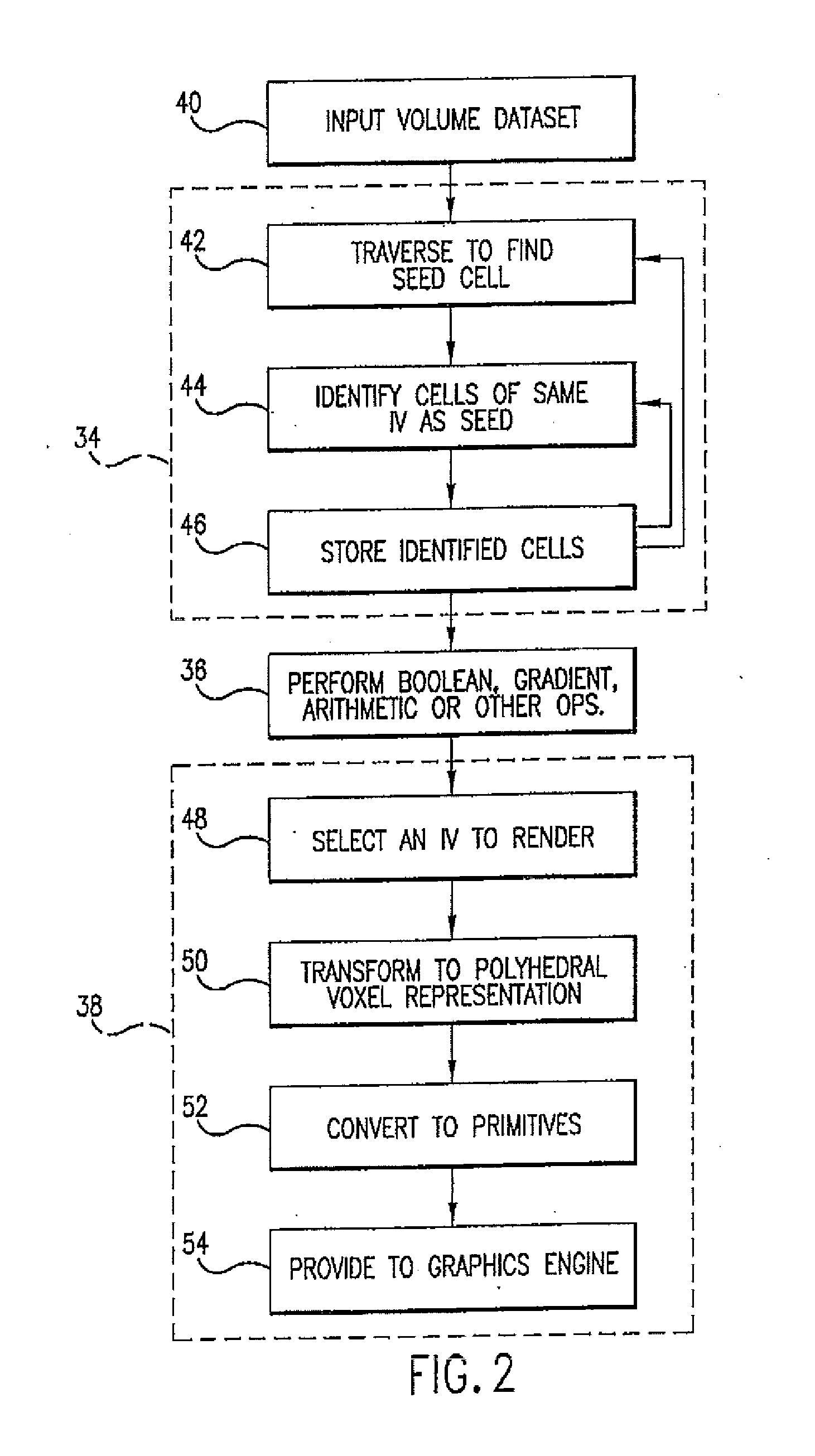

Irregular volumes within one or more three-dimensional volume datasets are identified and extracted in response to criteria. The processing involves automatically finding a seed voxel or seed cell that meets the criteria and thus belongs to an irregular volume of interest, and then identifying cells related to the seed cell by one or more predetermined relationships that are therefore also to be grouped into that irregular volume. Information, which can be of any suitable type, identifying each such cell as being related to other cells and belonging to an irregular volume is stored in a suitable data structure. The location or similar neighborhood information and other data describing properties or attributes of the identified cell are also stored. Because the irregular volumes are extracted and pre-processed in this manner, operations including rendering them on a display and performing Boolean and arithmetic operations on them can readily be performed.

Owner:LANDMARK GRAPHICS

Volume body renderer

InactiveUS20050114831A1Less computationally complexPerformed rapidly and efficientlyDigital computer detailsSeismic signal processingGraphicsVoxel

Irregular volumes within one or more three-dimensional volume datasets are identified and extracted in response to criteria. The processing involves automatically finding a seed voxel or seed cell that meets the criteria and thus belongs to an irregular volume of interest, and then identifying cells related to the seed cell by one or more predetermined relationships that are therefore also to be grouped into that irregular volume. Information, which can be of any suitable type, identifying each such cell as being related to other cells and belonging to an irregular volume is stored in a suitable data structure. The location or similar neighborhood information and other data describing properties or attributes of the identified cell are also stored. A graphical user interface that includes an irregular volume presentation area may be used to display a set of attributes associated with each of the identified irregular volumes.

Owner:LANDMARK GRAPHICS

Toner composition, developer comprising the toner composition, and method in connection with the production of a volume body

ActiveUS20110117485A1Easy to recycleNo wearAdditive manufacturing apparatusDevelopersVolume bodyEngineering

The present invention relates to a toner composition for forming a masking pattern for use e.g. in connection with a method of building up a three-dimensional body from a large number of mutually connected layers of powder particles that are bonded to each other using radiant heat. The toner composition consists of powder particles that arc able to withstand a temperature of at least 200° C. without sticking together. It also relates to a developer that comprises the toner composition and carrier particles and a method in connection with the production of a volume body by using a toner composition or a developer according to the invention.

Owner:SINTERMASK

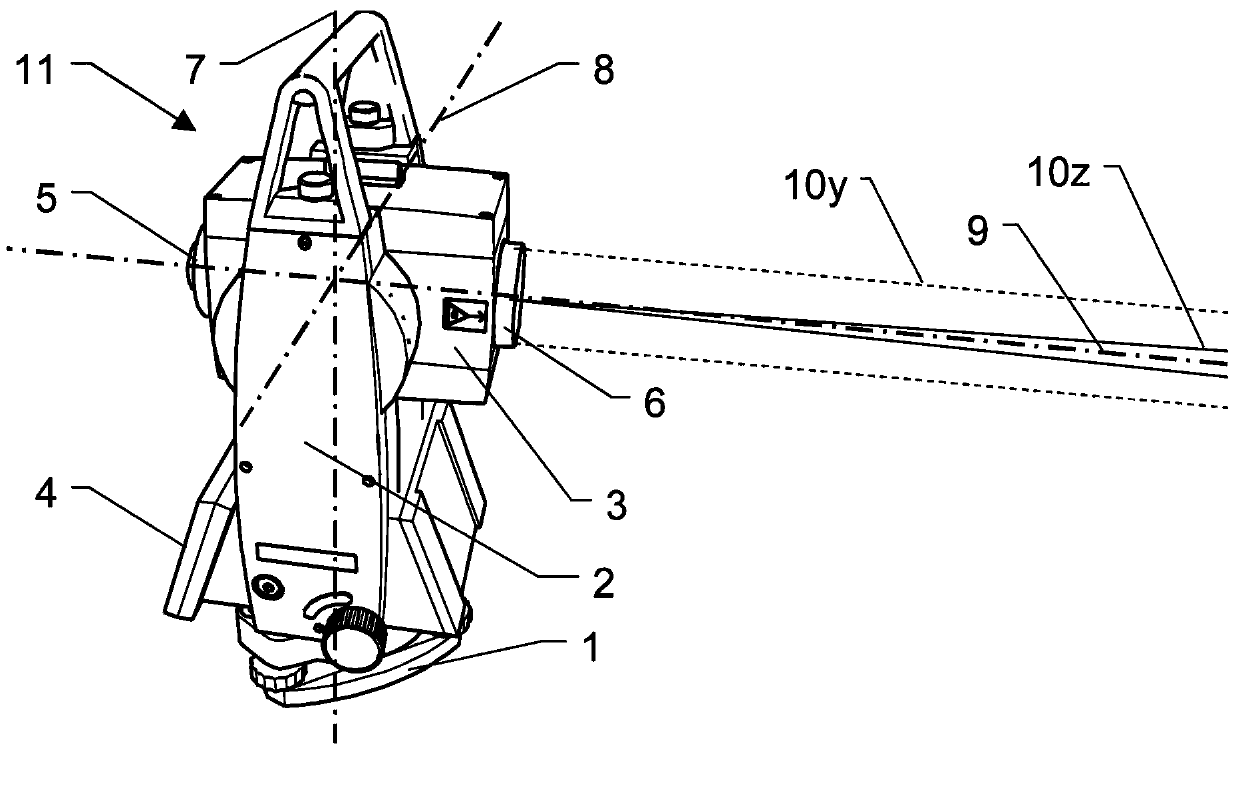

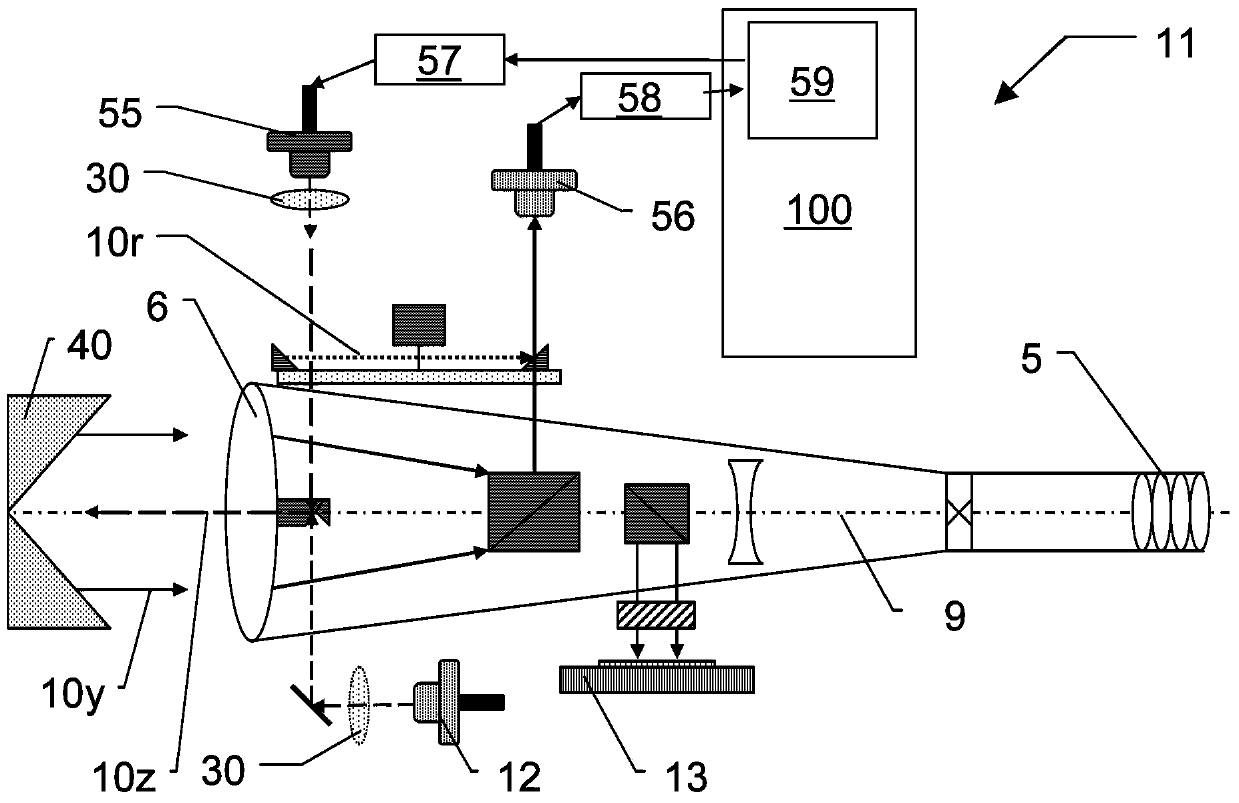

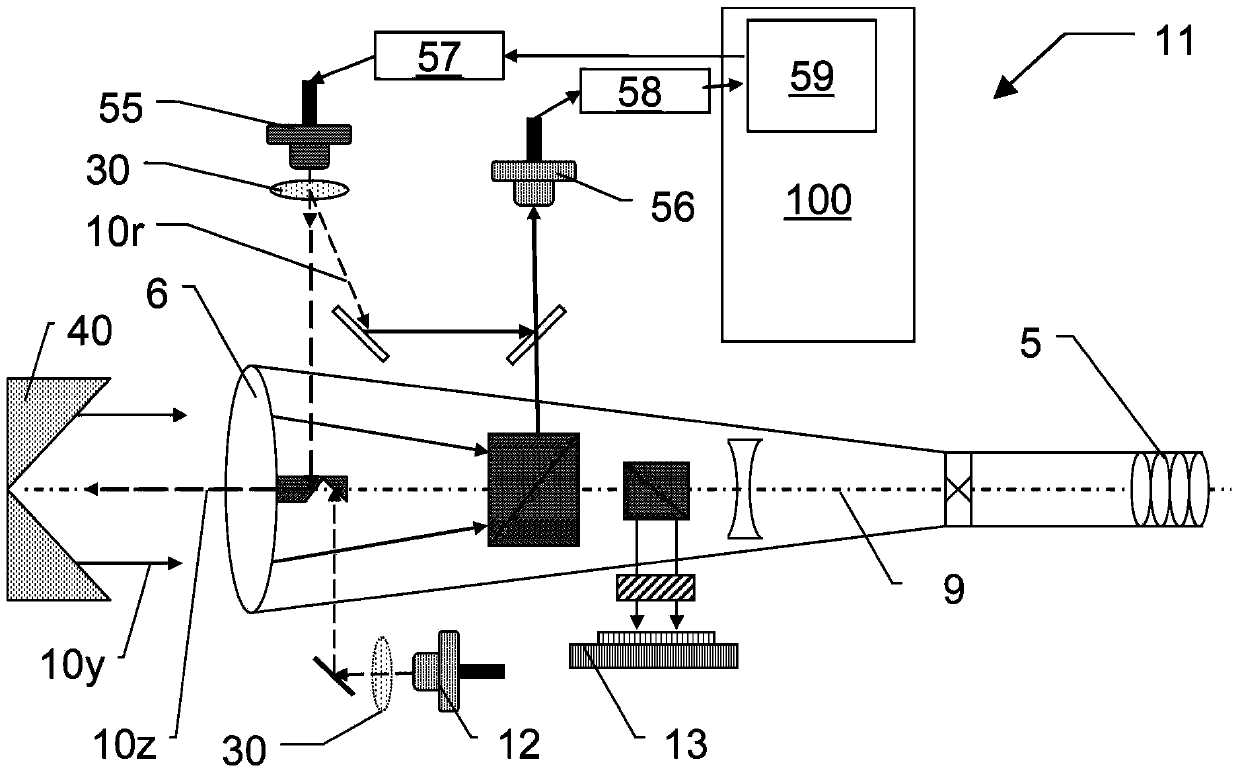

Surveying device, method for surveying target object with the survey device and computer program product

ActiveCN104101335AReference line/planes/sectorsElectromagnetic wave reradiationElectricityOptical radiation

The invention relates to a surveying device, a method for surveying a target object with the survey device and a computer program product. The surveying device has a base for setting up the surveying device and a targeting unit, which is rotatable in relation to the base about two axes, and which defines a target axis or targeting a target object to be surveyed. The targeting unit has a first beam path for emitting optical radiation in the direction of the target object to be surveyed and a second beam path for receiving a component of the optical radiation, which is reflected from the target object, by way of an optoelectronic receiving element. In some embodiments, at least one of the beam paths, has an optical element, which is implemented having an optically transparent, deformable volume body, and which has at least one interface toward a medium having an optical index of refraction deviating from the volume body. The interface makes the optical reflective performance changes on at least two different directions by deformation of a plurality of electrical activation signals.

Owner:HEXAGON TECH CENT GMBH

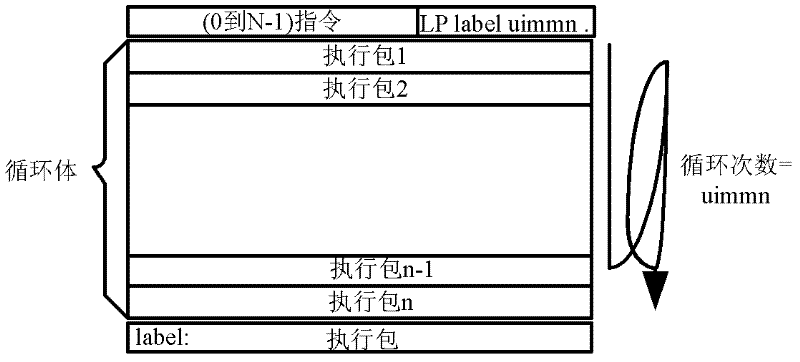

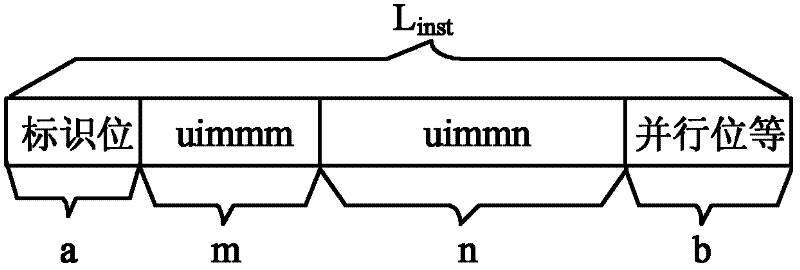

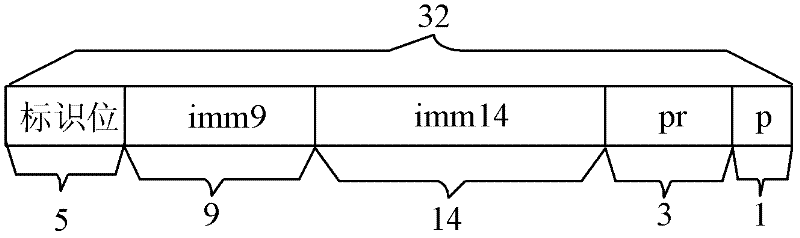

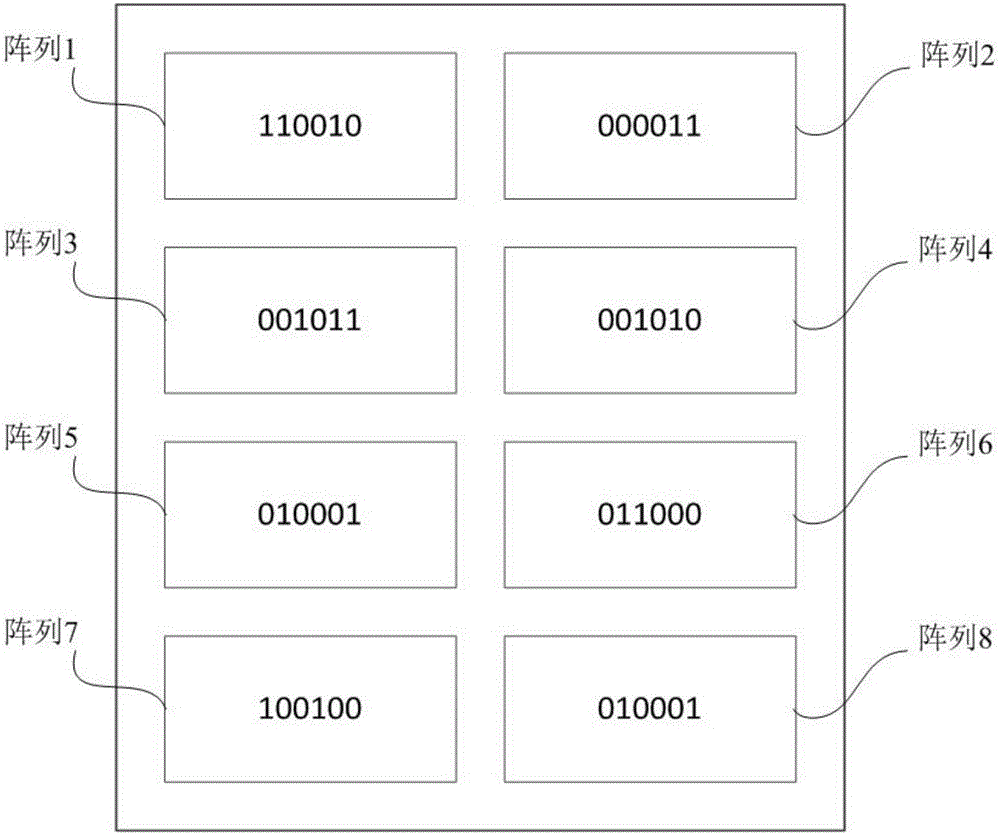

Processor device and loop processing method thereof

InactiveCN102508635AAchieving Zero Overhead for LoopsImprove performanceMachine execution arrangementsLoop controlVolume body

The invention discloses a VLIW (Very Long Instruction Word) processor device and a loop processing method thereof. The VLIW processor device comprises a loop unit, an address sending unit and an instruction decoding unit, wherein the loop unit comprises a loop volume data calculating module, a loop counting module, a memory module and an instruction fetching address calculating module. The loop processing method comprises the following steps of: obtaining a loop mark instruction; extracting a loop parameter carried in the loop mark (LP) instruction; obtaining and storing loop volume data according to the address of the loop mark instruction and the loop parameter; taking the stored loop volume body data as current loop volume data; obtaining and executing the instruction according to a current instruction fetching address; and obtaining a next instruction fetching address according to the current instruction fetching address, and obtaining the current instruction fetching address by comparing the next instruction fetching address with the loop volume data. The problems that the loop control of a VLIW processor cannot be completely realized by hardware and the loop execution expense is high are solved, therefore, the performance of the VLIW processor is greatly increased.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Volume Body Renderer

Irregular volumes within one or more three-dimensional volume datasets are identified and extracted in response to criteria. The processing involves automatically finding a seed voxel or seed cell that0 meets the criteria and thus belongs to an irregular volume of interest, and then identifying cells related to the seed cell by one or more predetermined relationships that are therefore also to be grouped into that irregular volume. Information, which can be of any suitable type, identifying each such cell as being related to other cells and belonging to an irregular volume is stored in a suitable data structure. The location or similar neighborhood information and other data describing properties or attributes of the identified cell are also stored. Because the irregular volumes are extracted and pre-processed in this manner, operations including rendering them on a display and performing Boolean and arithmetic operations on them can readily be performed.

Owner:LANDMARK GRAPHICS CORP

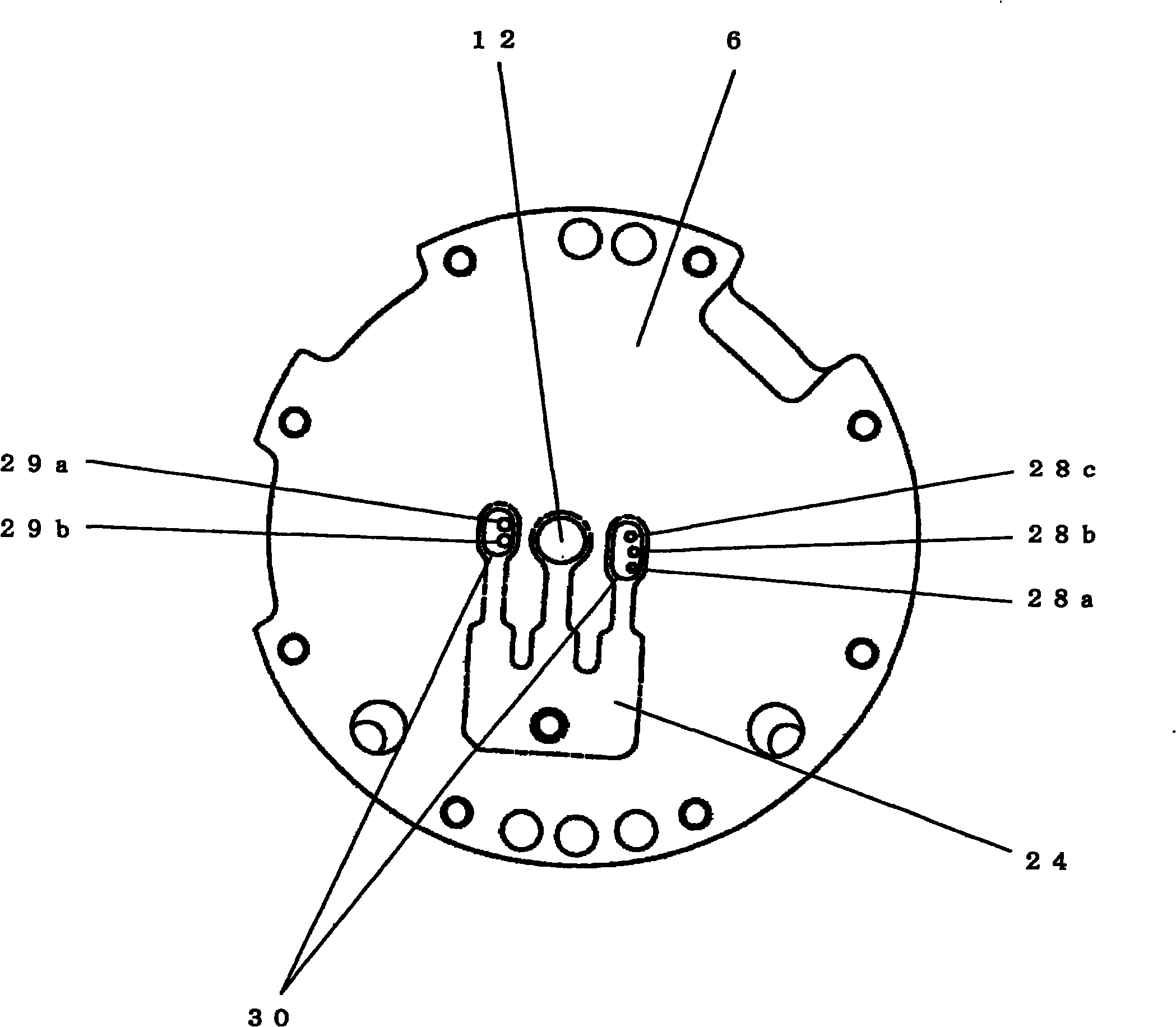

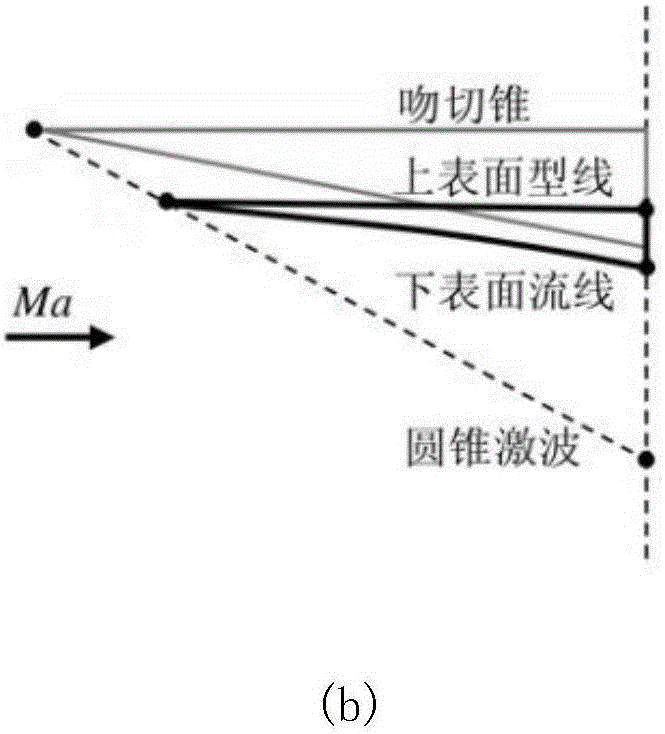

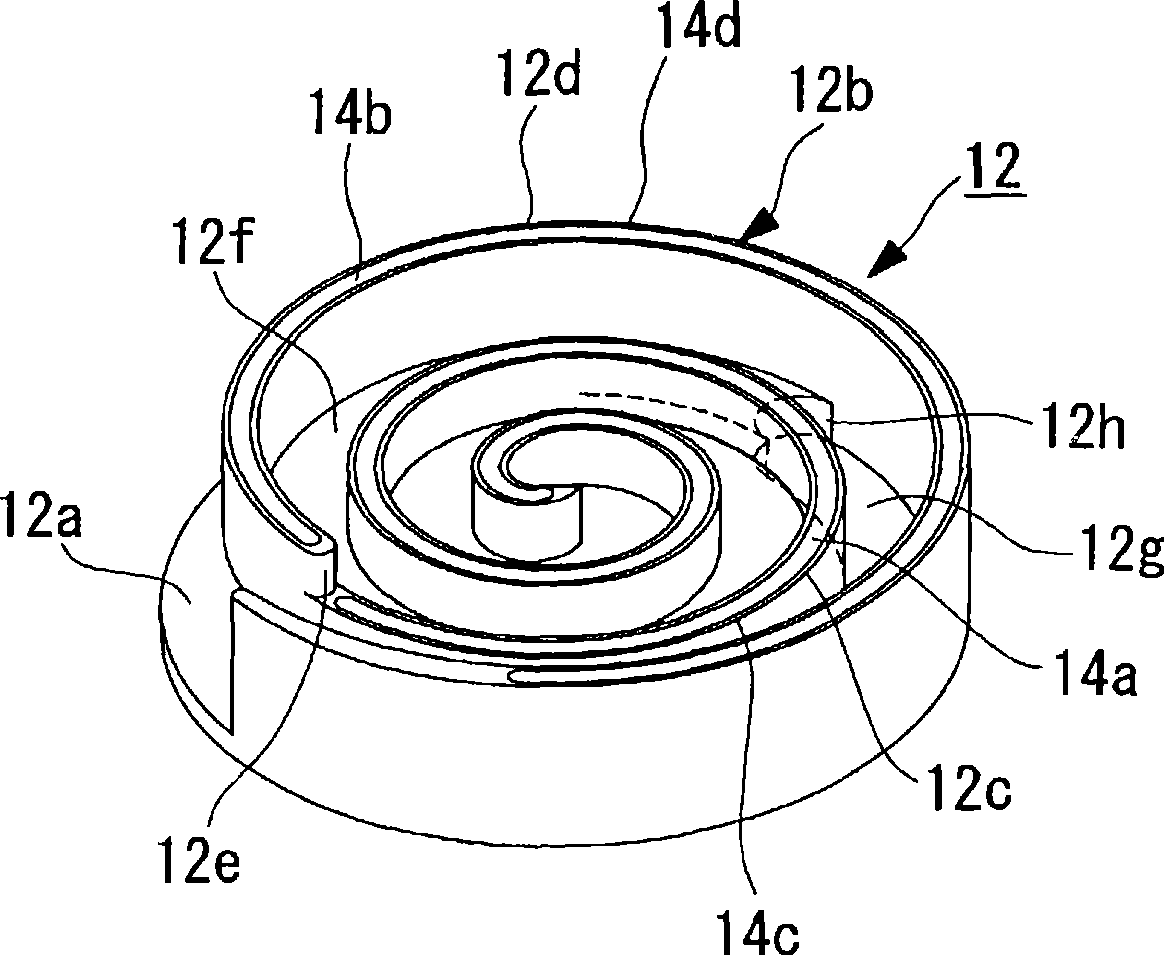

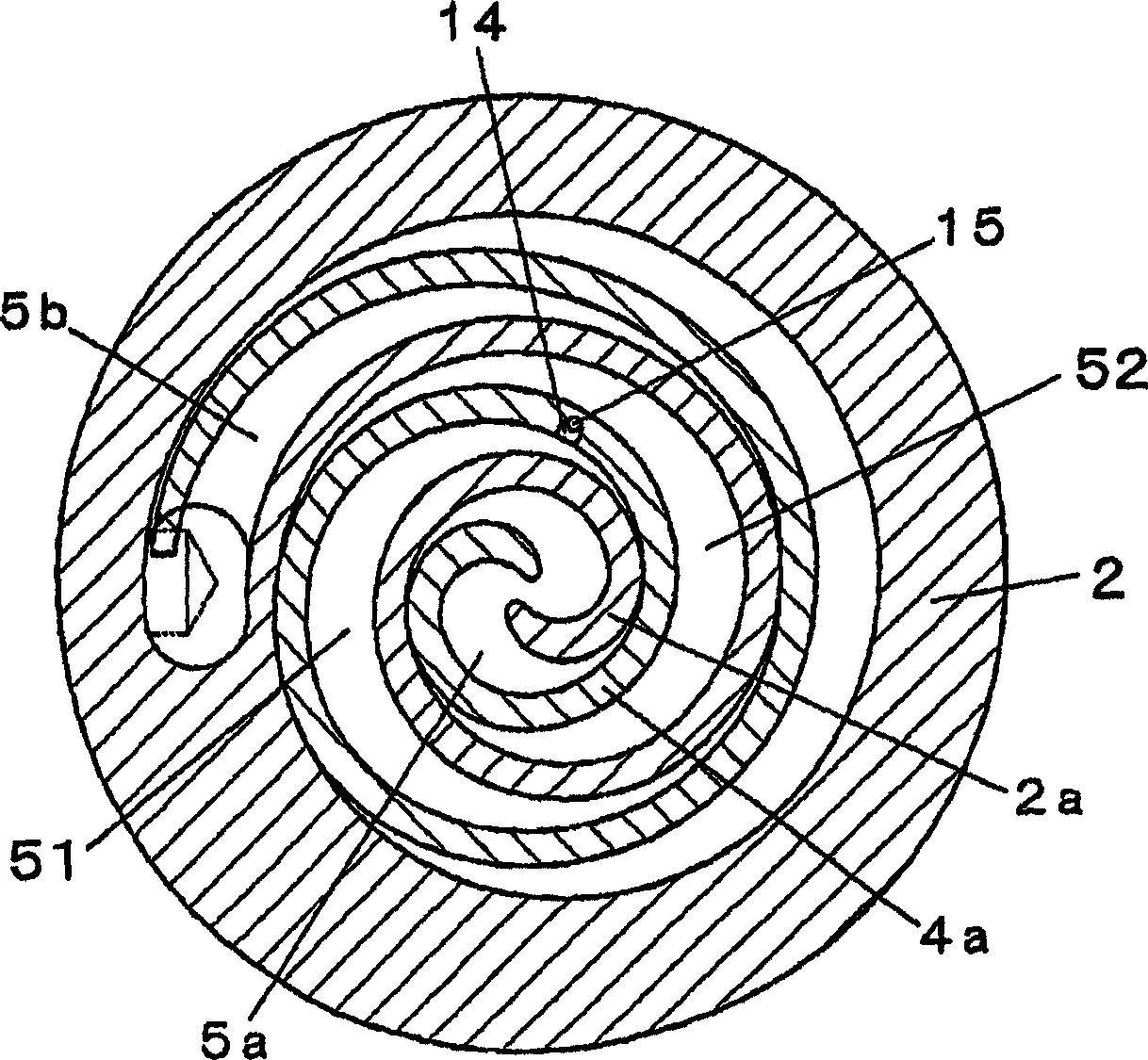

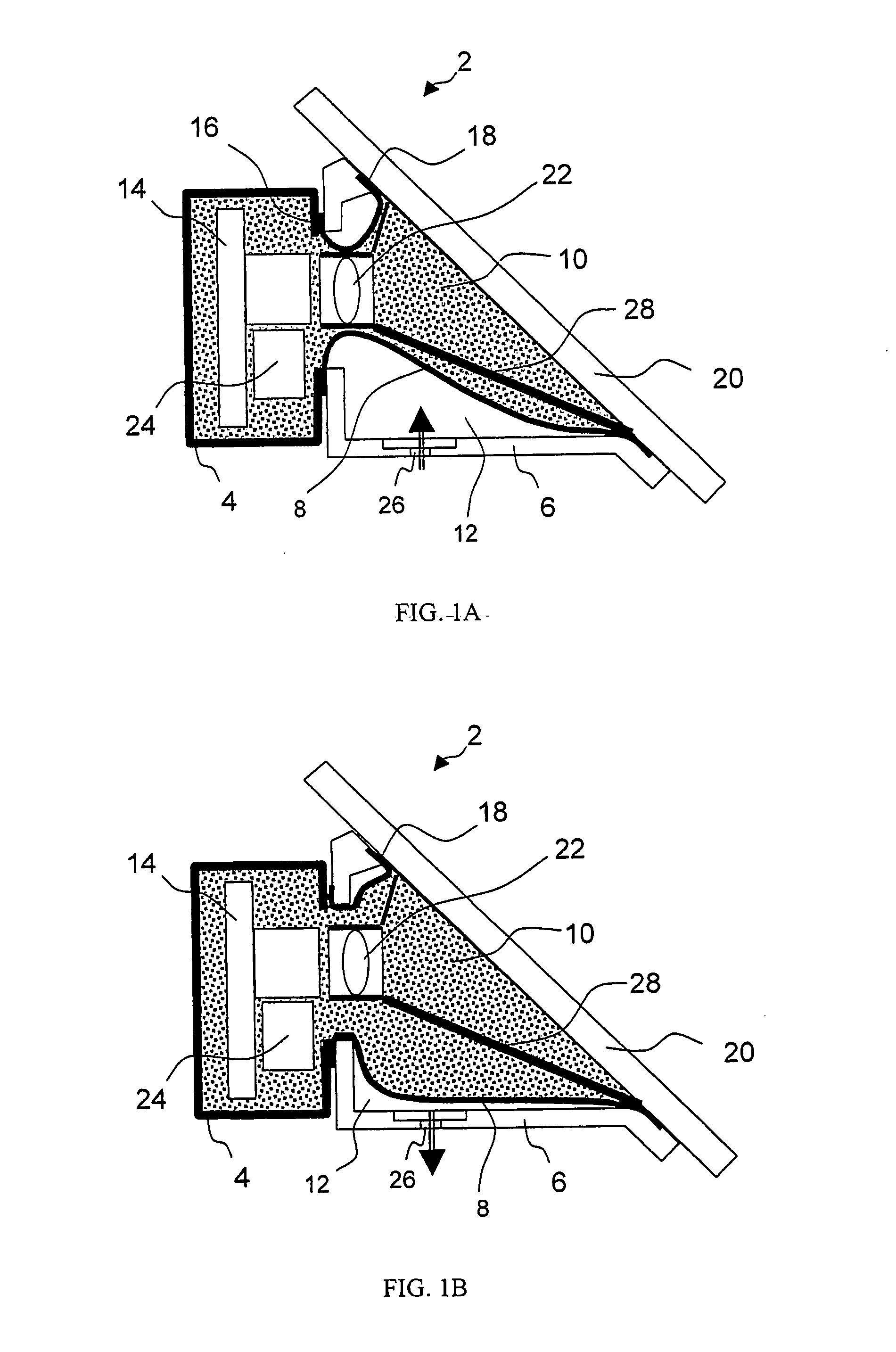

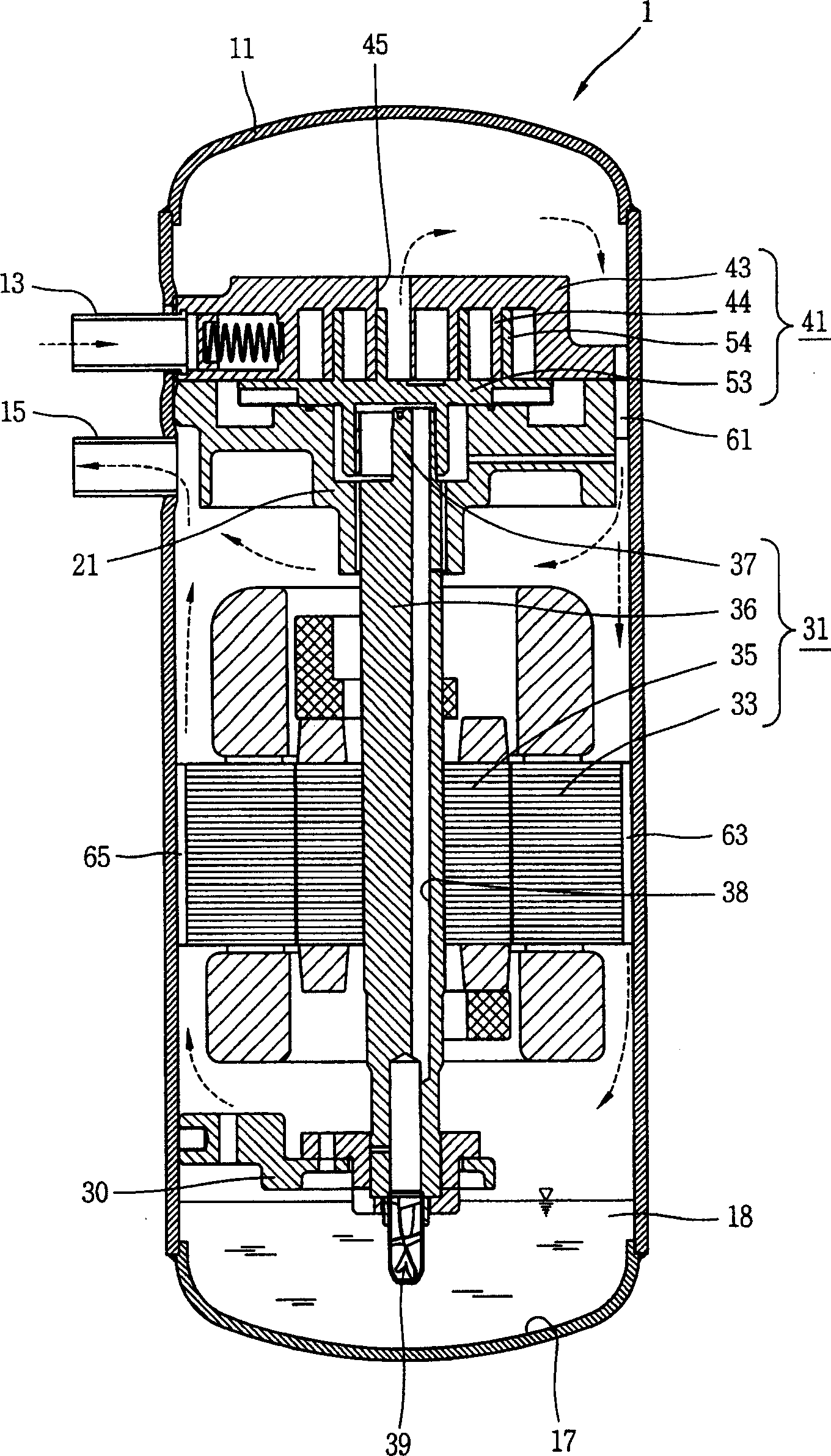

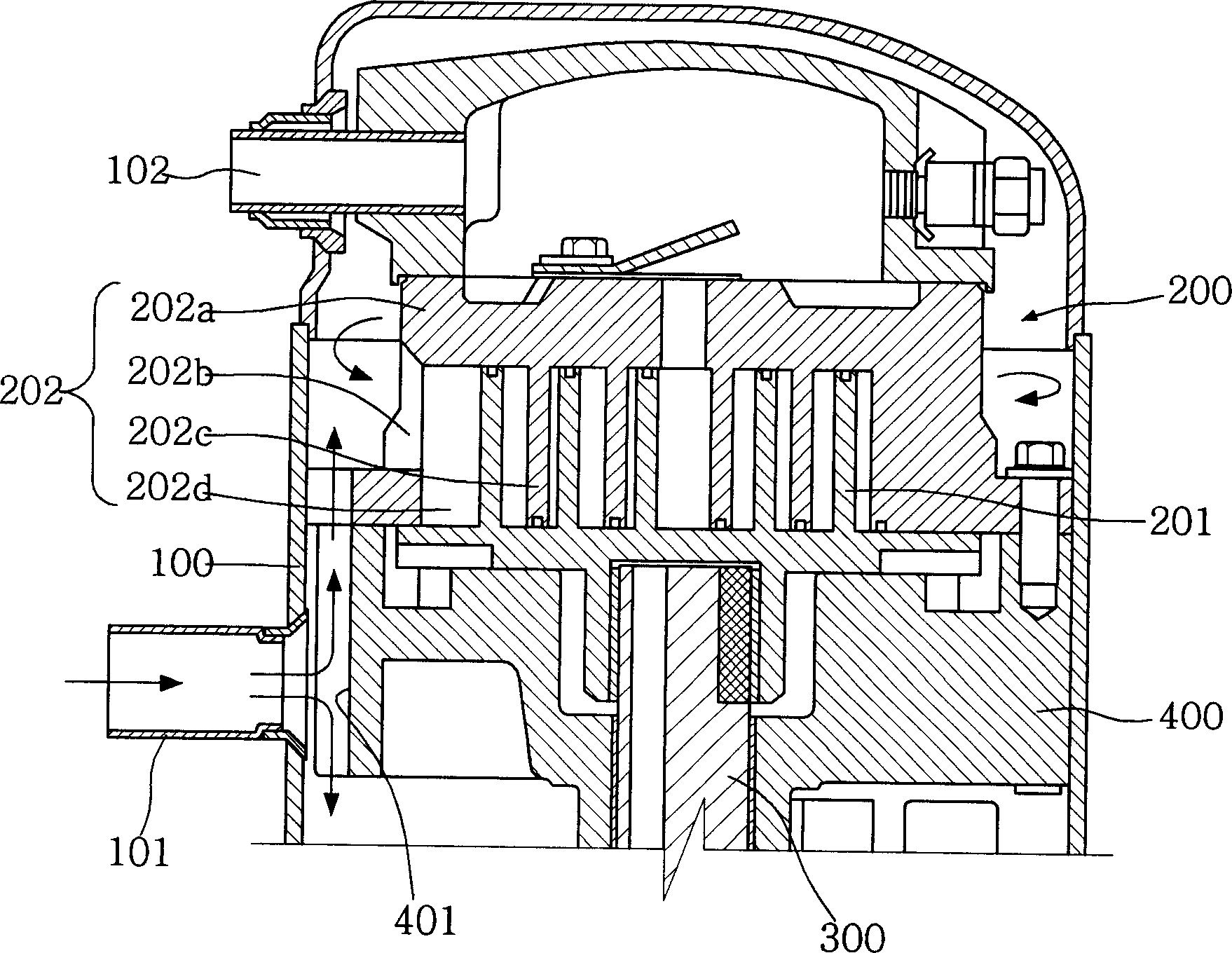

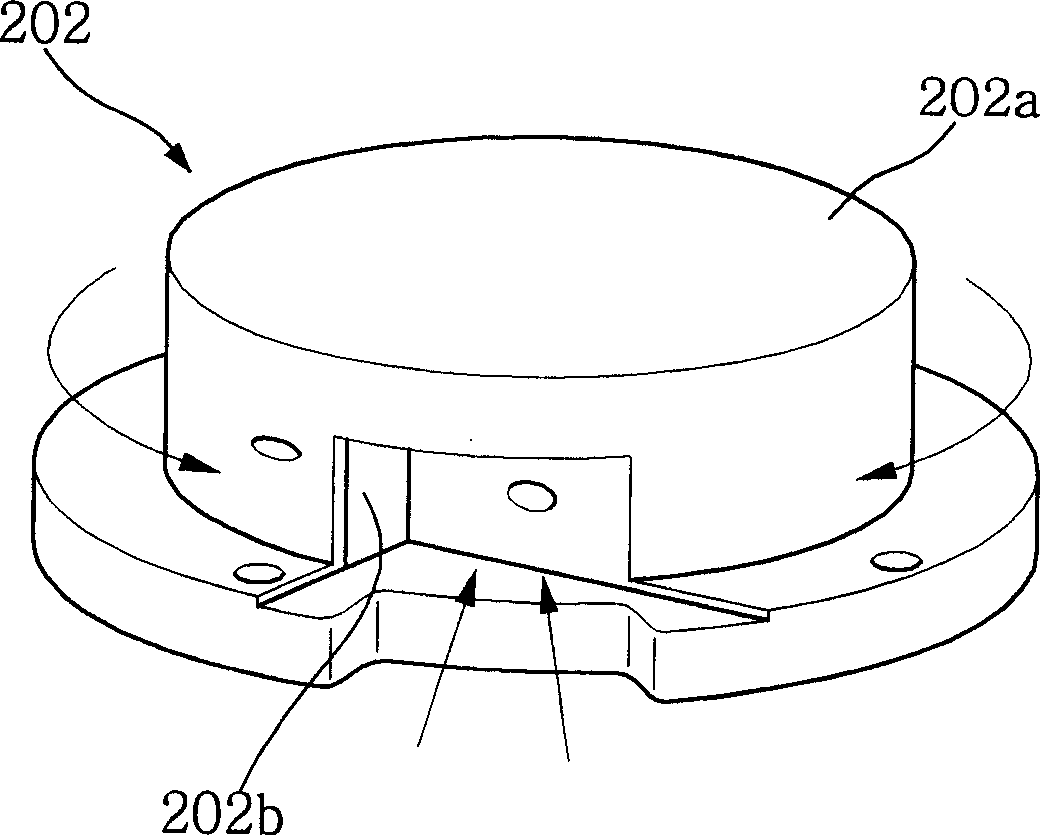

Scroll compressor

InactiveCN102042224ANeat dischargeOrderly rowsRotary piston pumpsRotary piston liquid enginesVolume bodyMiniaturization

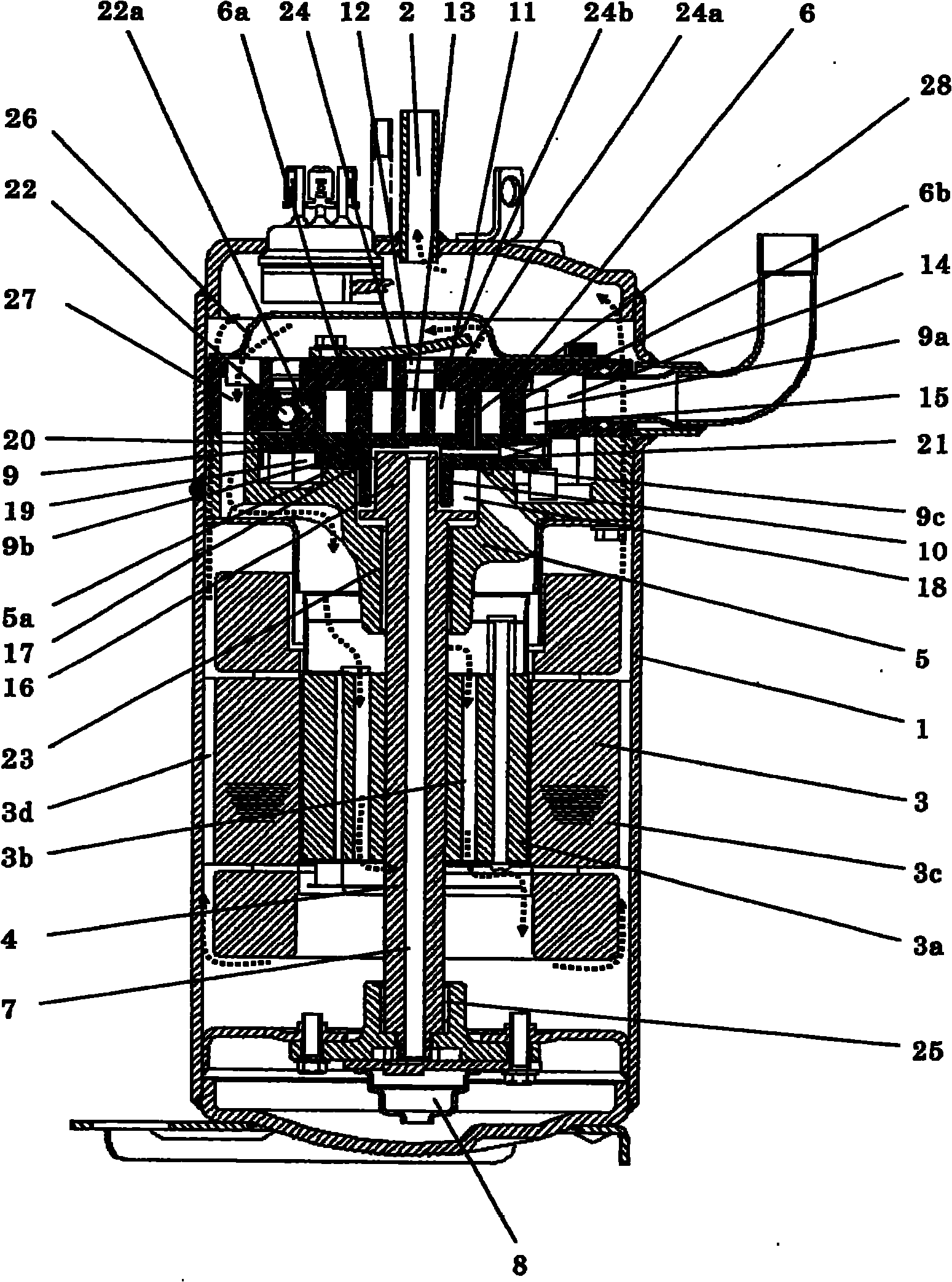

The present invention provides a scroll compressor in which check valves are arranged neatly and miniaturized for realizing high efficiency and low cost. In the scroll compressor, a central part is provided with an exhaust path which is communicated with an exhaust chamber (13); a first compression chamber (11a) and a second compression chamber (11b) are respectively provided with a first bypass path (28) and a second bypass path (29) which are communicated with the exhaust chamber in the middle part of compression. The first bypass path and the second bypass path are respectively composed of at least one hole. The exhaust path and each bypass path are respectively provided with a check valve (24). The bypass path of the compression chamber at the outer wall side of a scroll has a smaller number of the holes and larger area of the hole compared with a bypass path of the compression chamber at the inner wall side of the scroll. The holes on the first bypass path and the second bypass path are set parallelly as possible. The check valves are arranged neatly for obtaining high compactness, small size and cost reduction. The coexistence of high efficiency and low cost is obtained.

Owner:PANASONIC CORP

Volume Body Renderer

Irregular volumes within one or more three-dimensional volume datasets are identified and extracted in response to criteria. The processing involves automatically finding a seed voxel or seed cell that meets the criteria and thus belongs to an irregular volume of interest, and then identifying cells related to the seed cell by one or more predetermined relationships that are therefore also to be grouped into that irregular volume. Information, which can be of any suitable type, identifying each such cell as being related to other cells and belonging to an irregular volume is stored in a suitable data structure. The location or similar neighborhood information and other data describing properties or attributes of the identified cell are also stored. Because the irregular volumes are extracted and pre-processed in this manner, operations including rendering them on a display and performing Boolean and arithmetic operations on them can readily be performed.

Owner:LANDMARK GRAPHICS CORP

Continuous sheet processing apparatus and method of setting a roll body in the continuous sheet processing apparatus

InactiveUS7975955B2Transport stableEasy to set upFilament handlingOther printing apparatusVolume bodyEngineering

A continuous sheet processing apparatus has a frame, a roll body accommodating portion disposed inside of the frame for accommodating a roll body formed of a wound continuous sheet, and a cover mounted for undergoing pivotal movement between open and closed positions relative to the frame so as to allow the insertion of the wound continuous sheet into the roll body accommodating portion in the open position of the cover. A processing portion has a processing head and a platen roller confronting the processing head. The processing head performs a processing operation with respect to the continuous sheet drawn out from the roll body accommodating portion in a state in which the cover is in the closed position. The platen roller transports the continuous sheet in a state in which the cover is in the closed position.

Owner:SEIKO INSTR INC

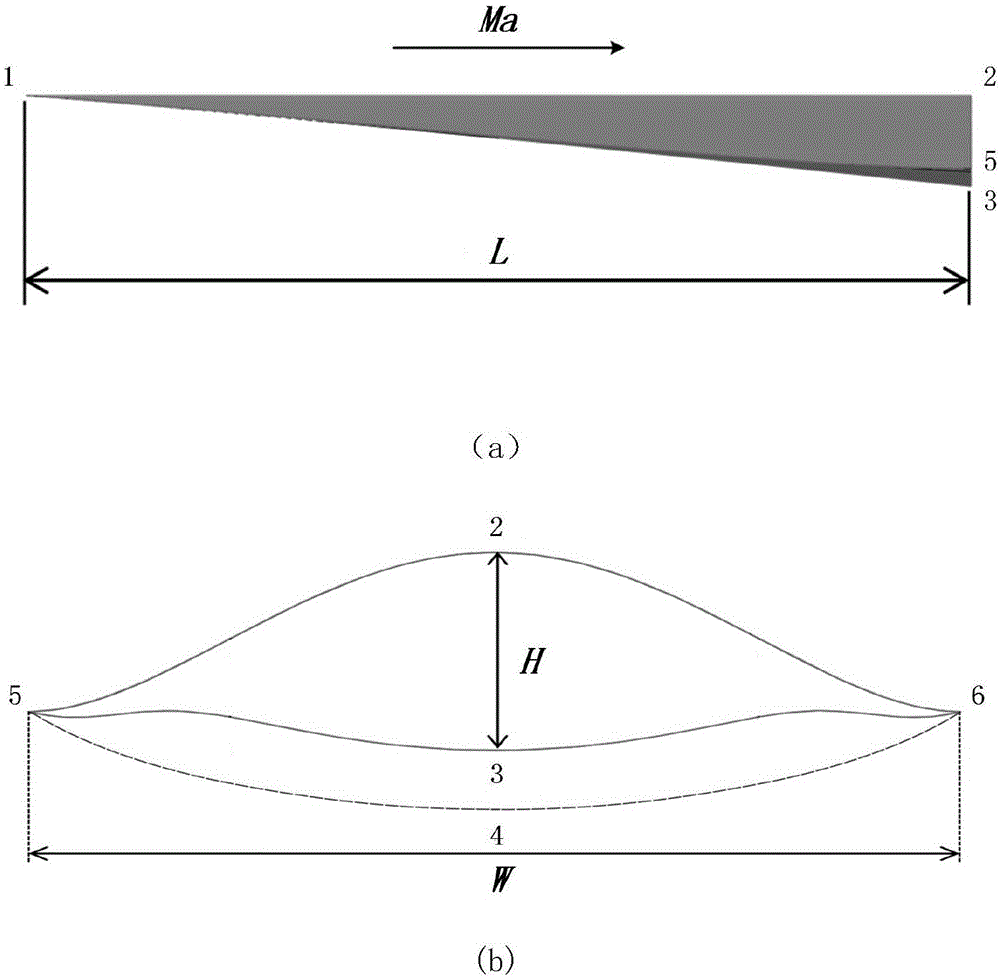

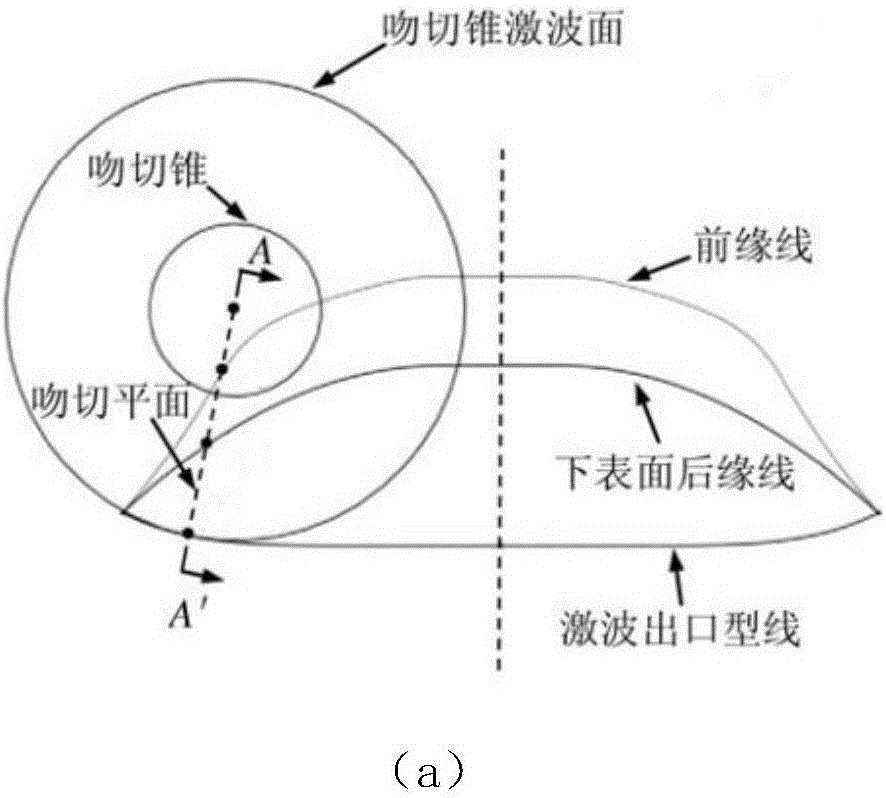

Design method of ridge-shaped osculating-cone wave-rider with large capacity and high lift-to-drag ratio

ActiveCN106428620ASolve the problem of lift-to-drag ratio lossGround installationsVolume bodyEngineering

The invention provides a design method of a ridge-shaped osculating-cone wave-rider with a large capacity and a high lift-to-drag ratio. Firstly, flight conditions, dimension constraints and performance requirements of a wave-rider are given, and an osculating-cone wave-rider is designed according to an osculating-cone theory and the dimension constraints; then, a volume body is designed according to the dimension constraints; finally, a standard wave-rider is combined with the volume body, wing-body fusing operation is conducted to design the upper surface of the wave-rider again, and the finished ridge-shaped osculating-cone wave-rider is obtained. According to the design method, the ridge-shaped wave-rider which meets volume index requirements can be designed according to a task requirement; under the condition of an incidence angle, the wave-rider has high-lift-to-drag-ratio aerodynamic performance, and the problem that the lift-to-drag ratio of the wave-rider is reduced due to a volume requirement is effectively solved.

Owner:NAT UNIV OF DEFENSE TECH

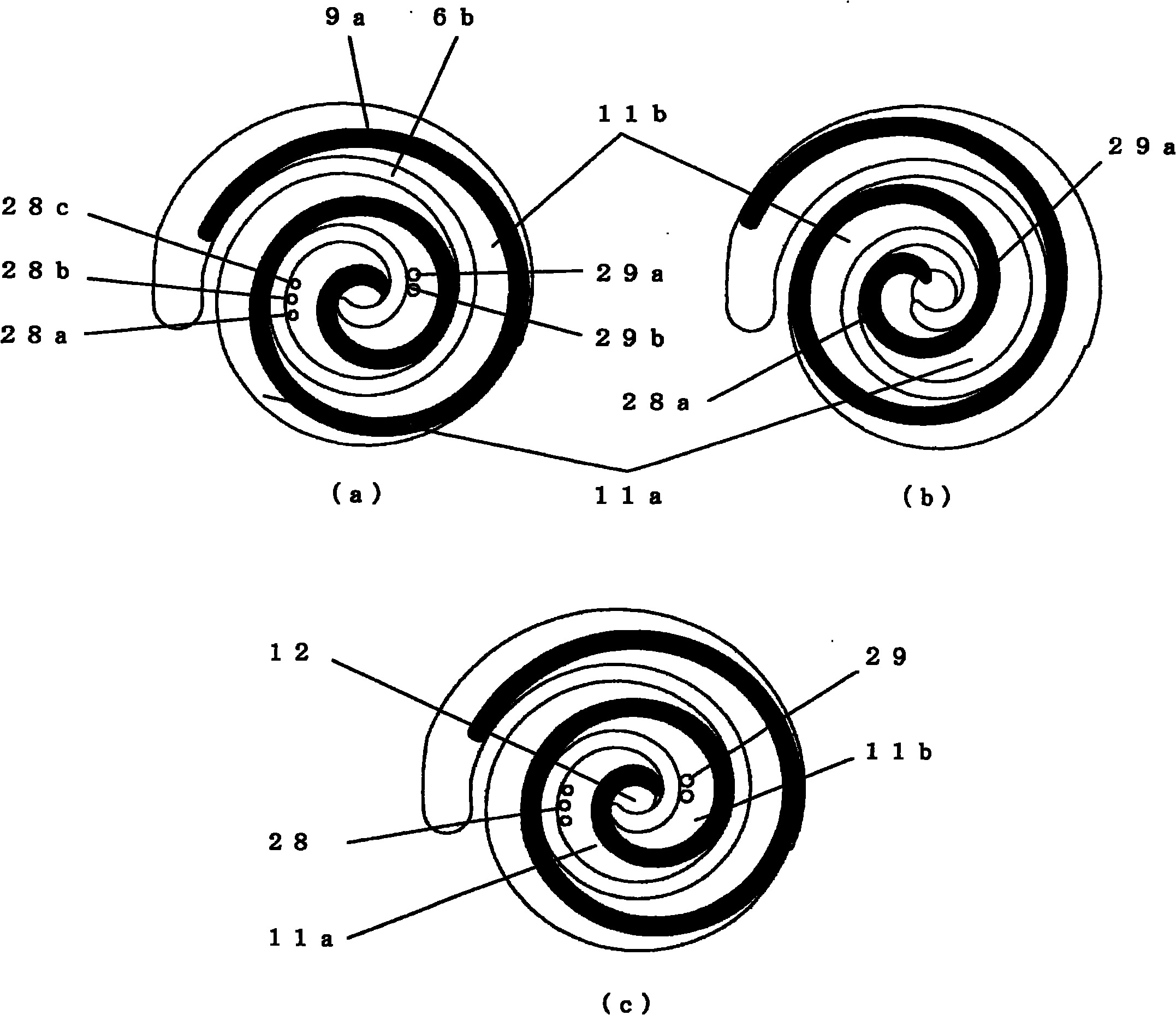

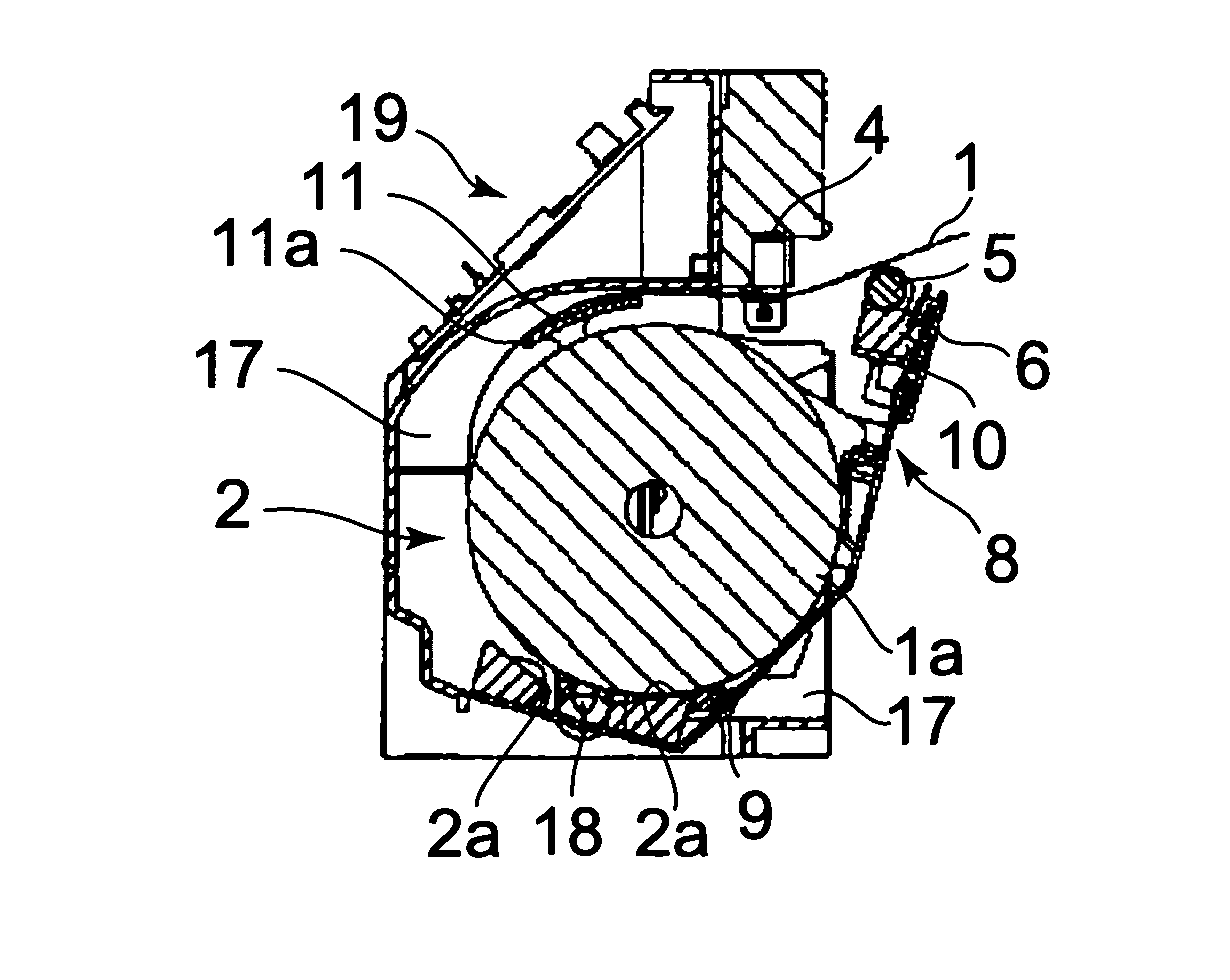

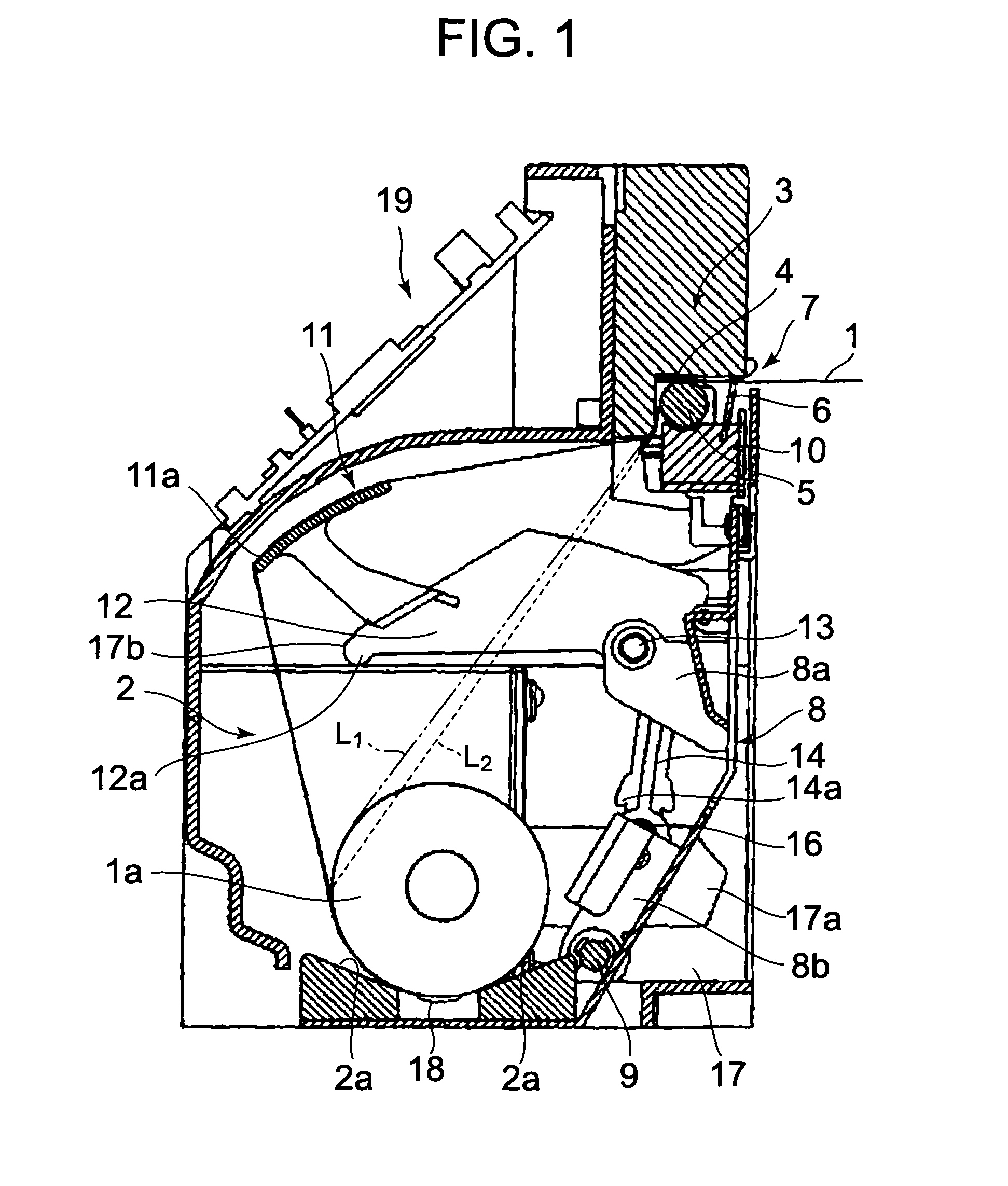

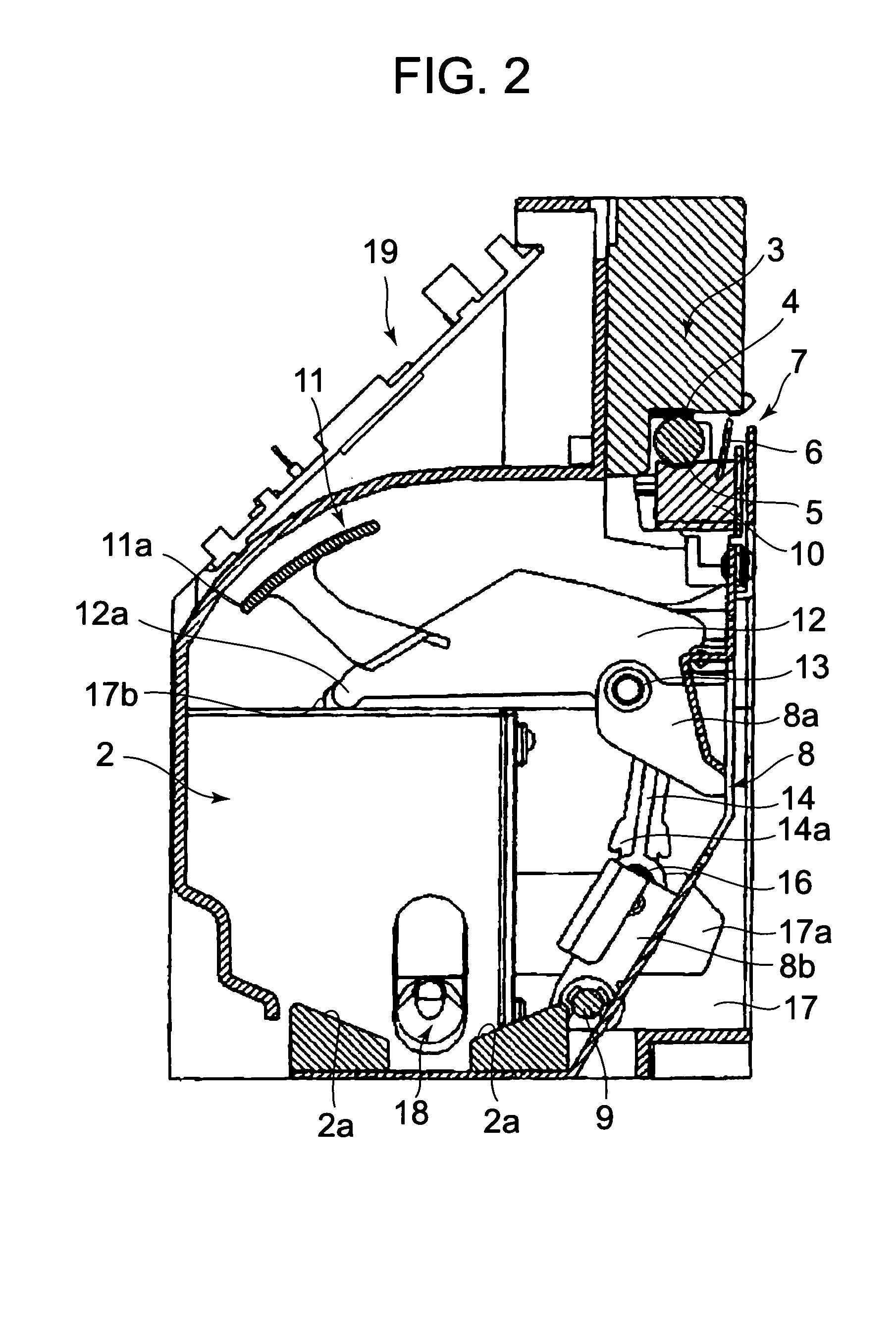

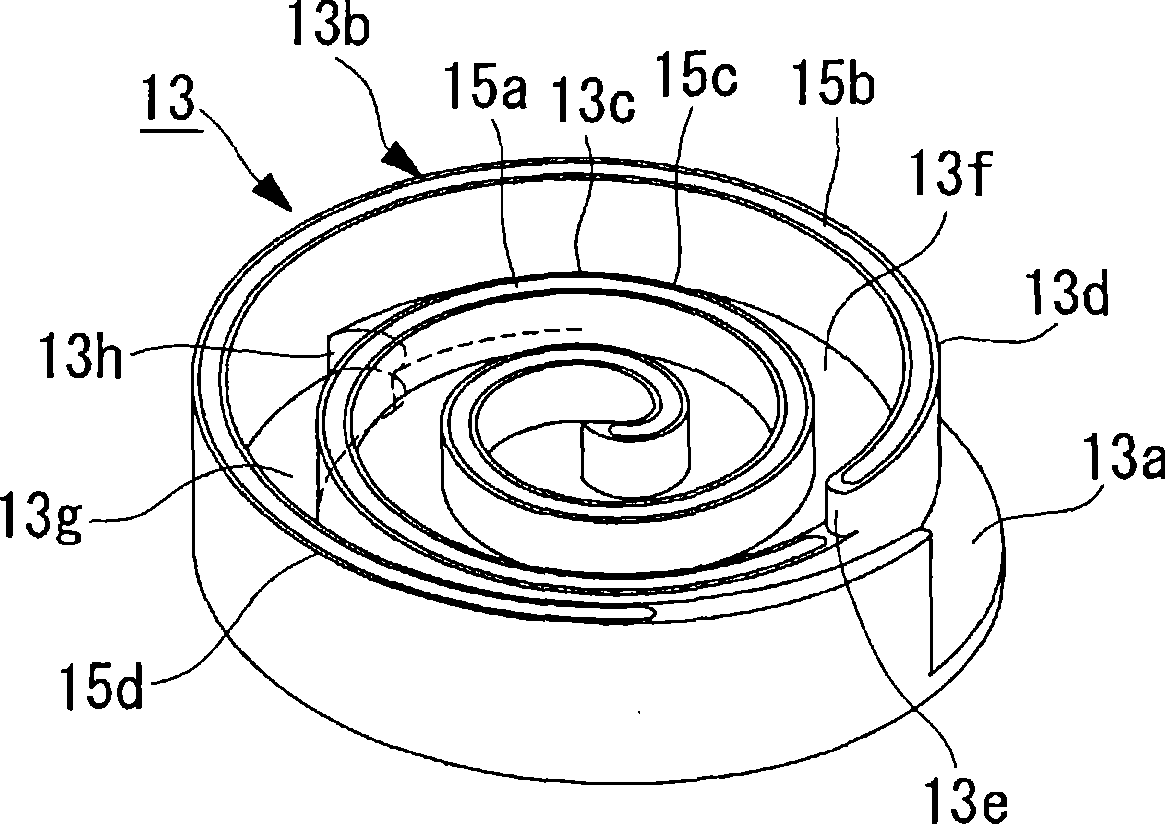

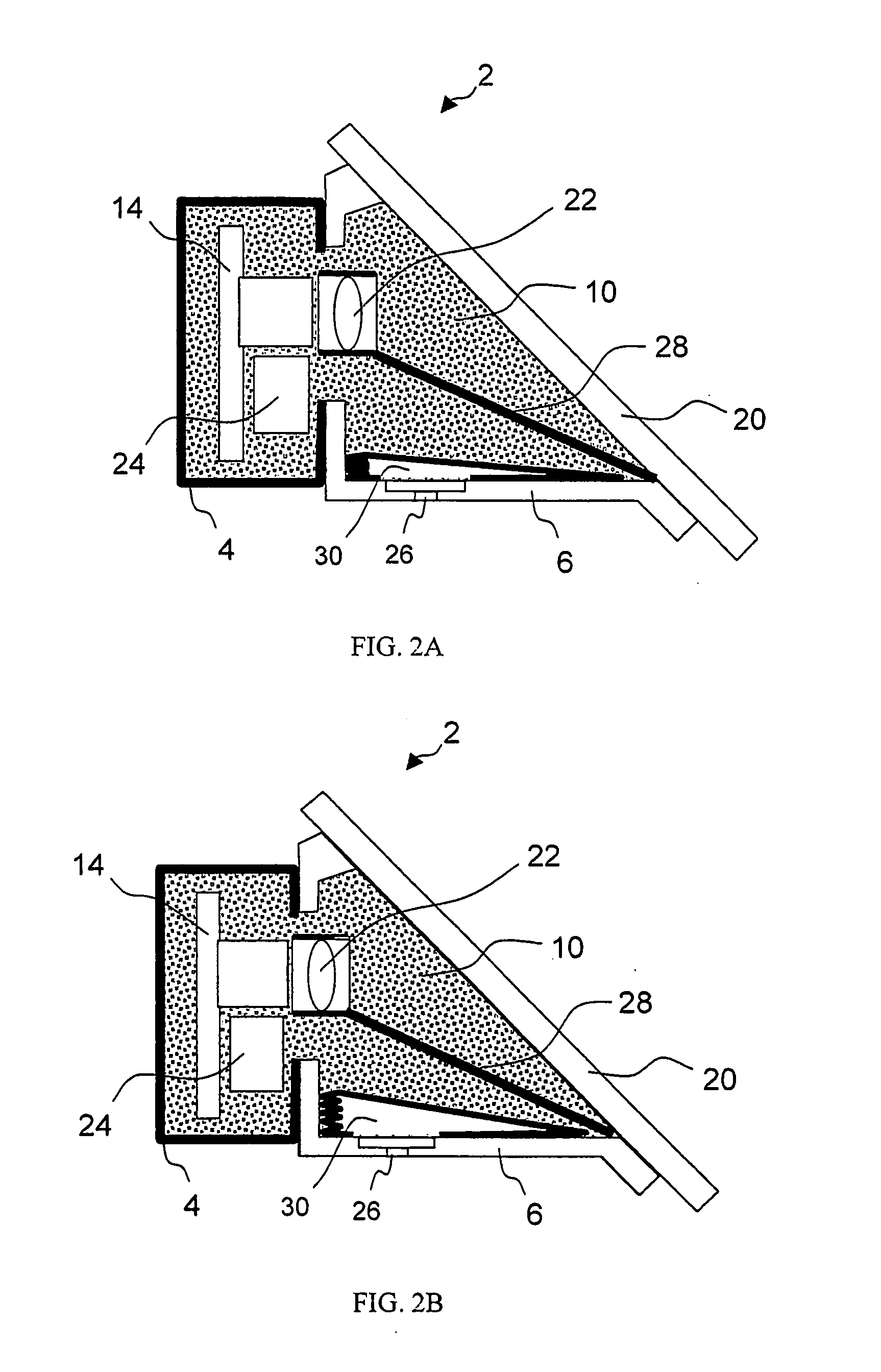

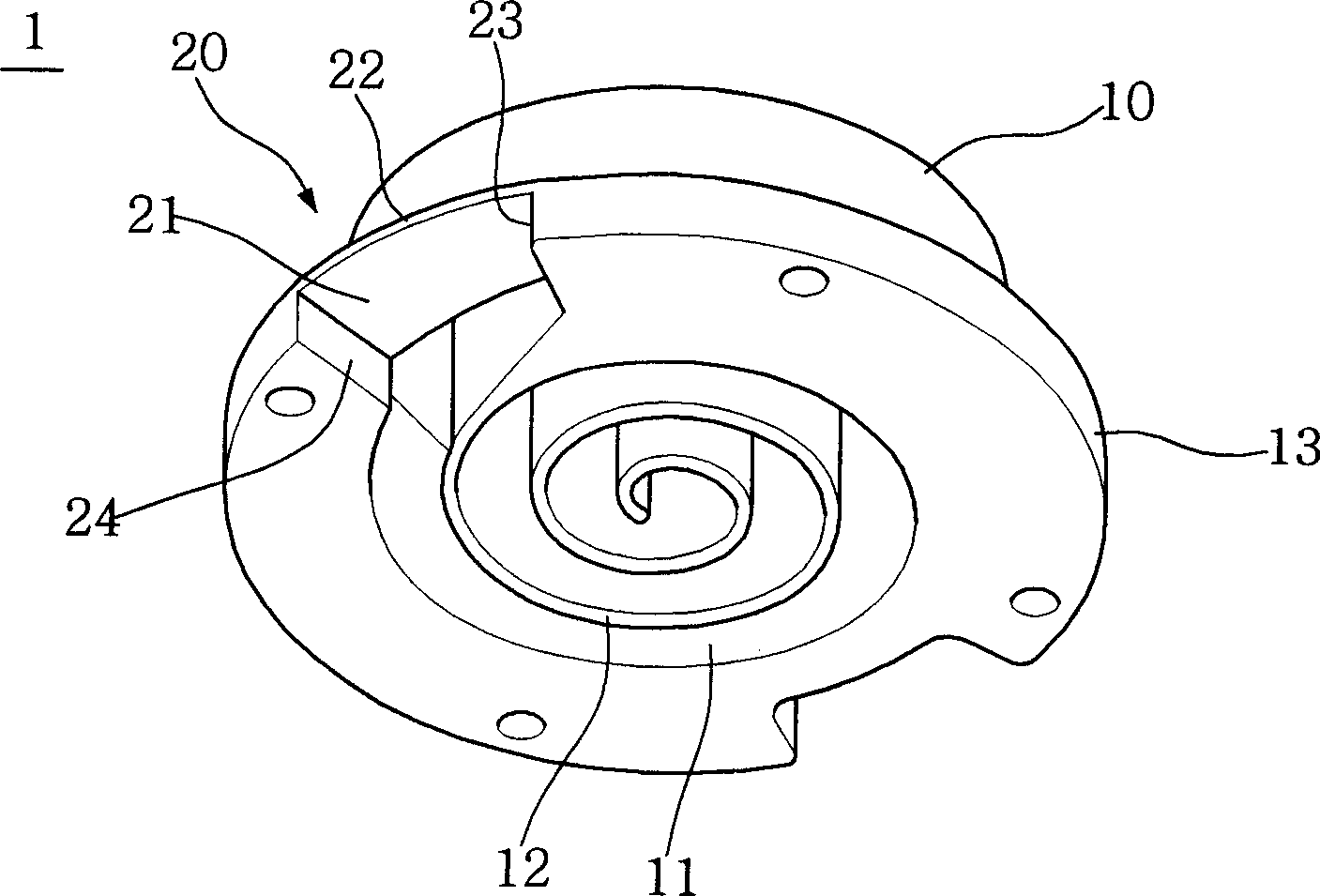

Scroll compressor

ActiveCN101449061AReduce leakageReduced blade tip clearanceRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsVolume bodyThermal expansion

The present invention is to provide a scroll compressor capable of three-dimensional compression in which high performance can be achieved by optimizing a tip clearance during an operation while taking account of thermal expansion and pressure deformation, and reducing compression leakage thereby enhancing compression efficiency. The three-dimensional compression enabled scroll compressor in which a level difference (13e) is provided between the distal end faces (13c, 13d) and the bottom face of a spiral lap (13b), a lap height is set larger on the outer circumferential side of the spiral lap (13b) than on the inner circumferential side, and compression in the circumferential direction and the lap height direction of the spiral lap (13b) is possible, wherein the height of the spiral lap (13b) on the inner circumferential side of the level difference (13e); is reduced stepwise or continuously and gradually toward the central side of the spiral lap (13b), and the tip clearance (delta) of the spiral lap is increased gradually toward the central side of the spiral lap (13b) on the inner circumferential side of the level difference (13e).

Owner:MITSUBISHI HEAVY IND LTD

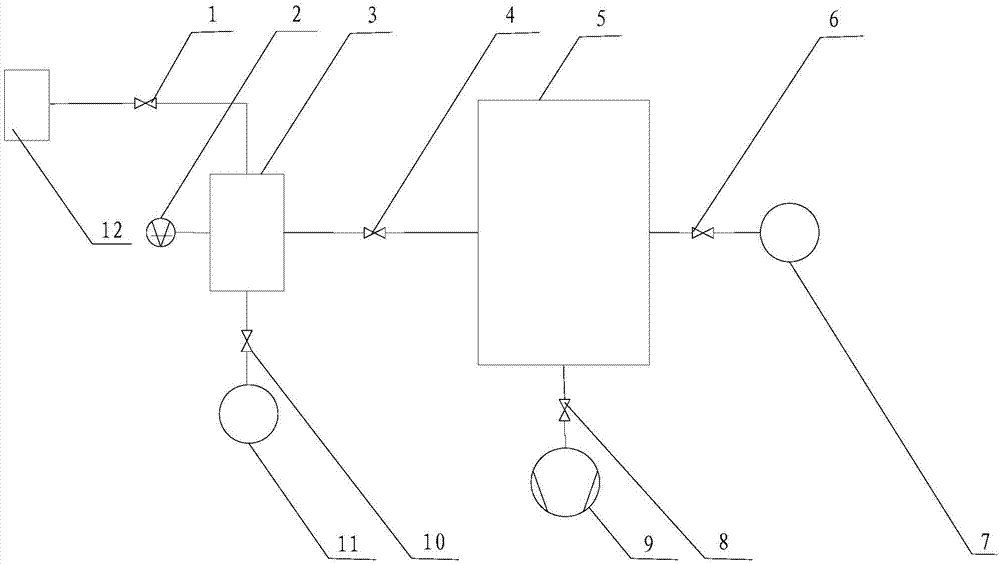

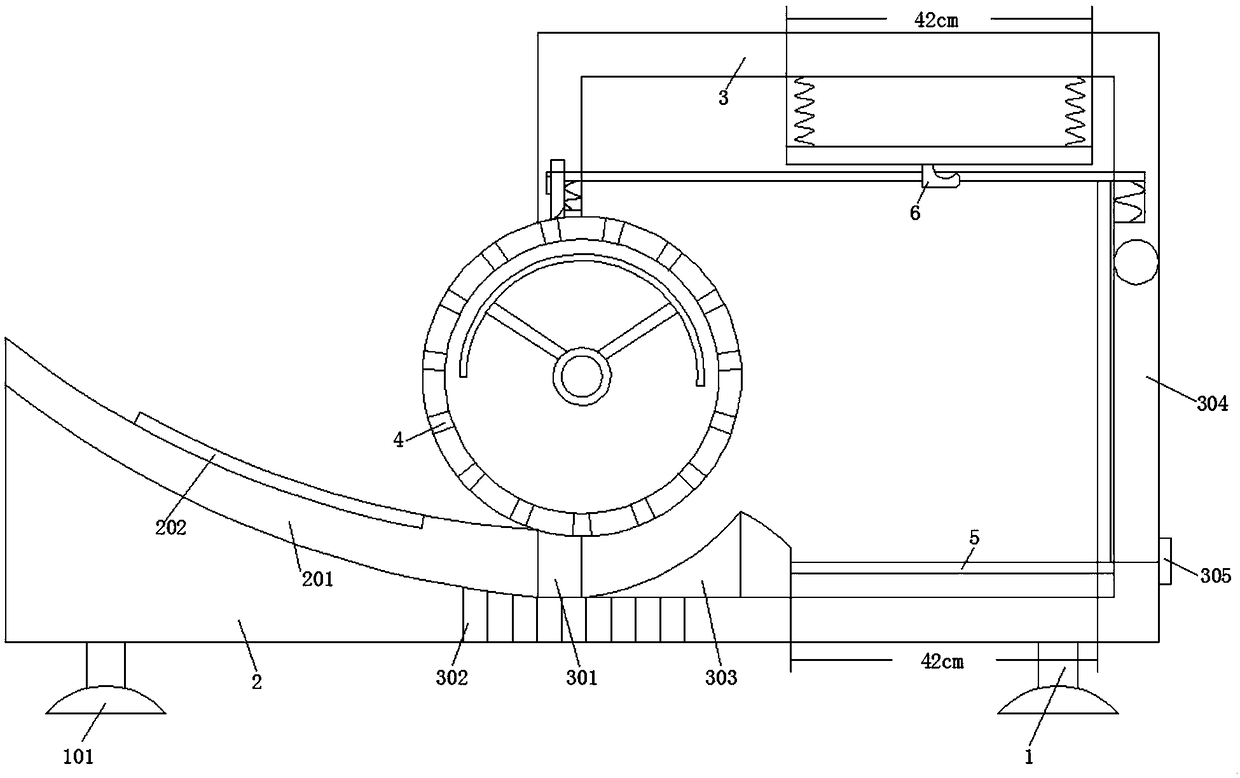

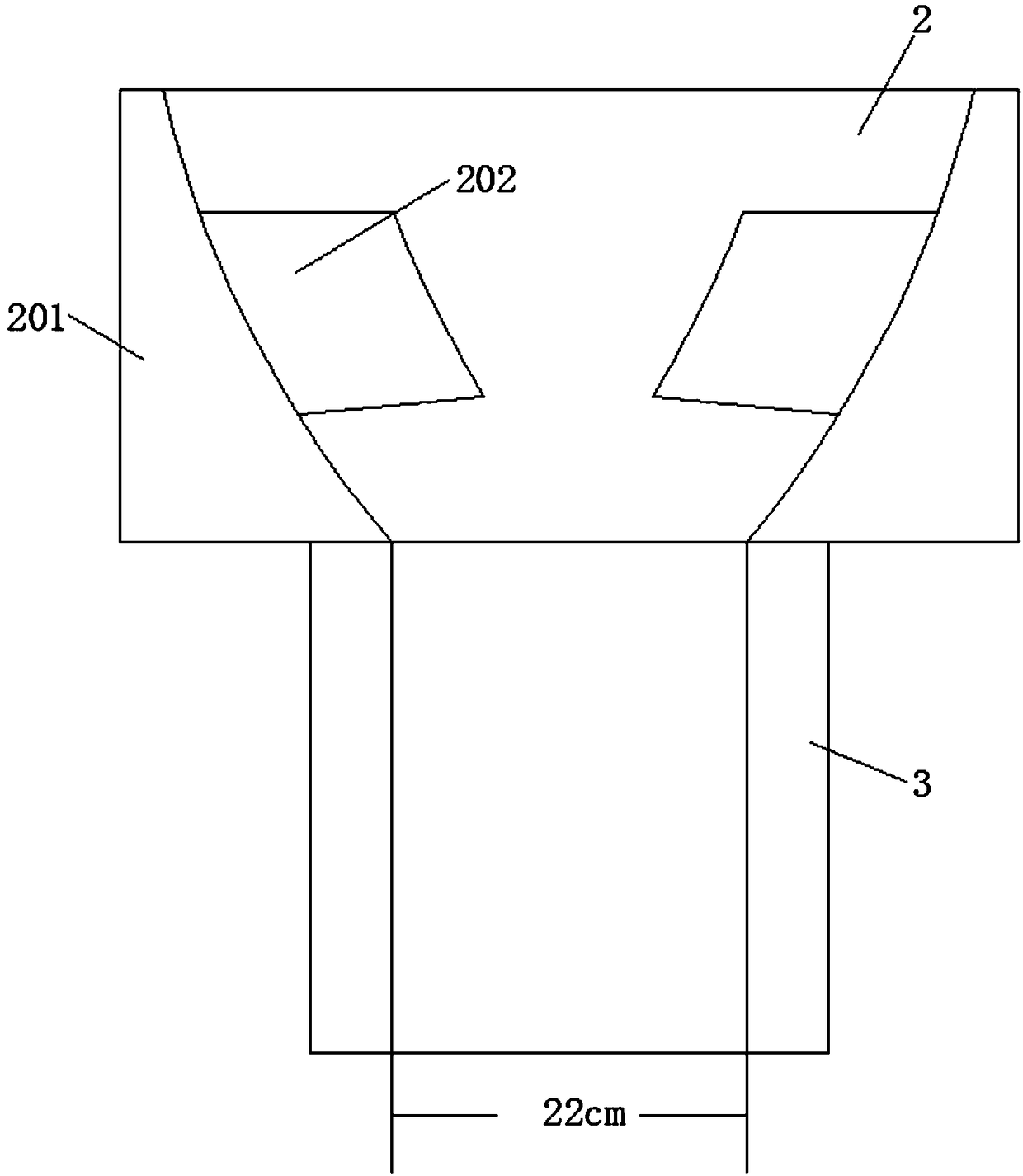

Heat exchange device of air inlet and outlet pipe system

InactiveCN103195618AReasonable designSimple structureInternal combustion piston enginesThermal treatment of fuelVolume bodyTurbocharger

The invention provides a heat exchange device of an air inlet and outlet pipe system and belongs to the technical field of mechanical design. The heat exchange device of the air inlet and outlet pipe system comprises an air inlet pipe, an engine, an air outlet pipe, an air compressor, a turbine, connecting pipes, a volume cavity, a moving body and a spring. The moving body is installed in the volume cavity and contacted with the inner wall surface of the volume cavity in sealing mode, a penetrating pipe penetrates through the upper wall surface and the lower wall surface of the moving body, and two ends of the spring are respectively connected with a left wall surface of the moving body and the left wall surface of the volume cavity. When the engine is at a low-speed working condition, the moving body moves rightward in the volume cavity, a second connecting pipe is communicated with a fifth connecting pipe, outlet air waste heat is used for heating inlet air, cold starting performance of the engine is good; and when the engine is at a high-speed working condition, the moving body moves leftward in the volume body, and the second connecting pipe is separated from the fifth connecting pipe. The heat exchange device of the air inlet and outlet pipe system is reasonable in design, simple in structure and suitable for an engine inlet air heating system with a turbocharger.

Owner:SHANGHAI JIAO TONG UNIV

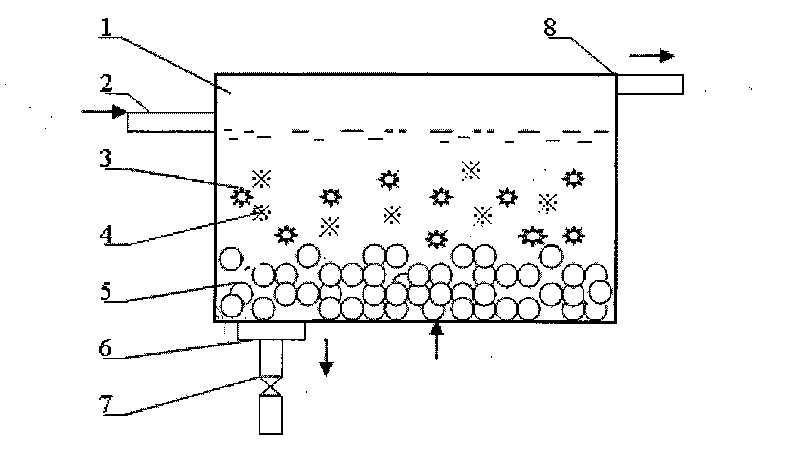

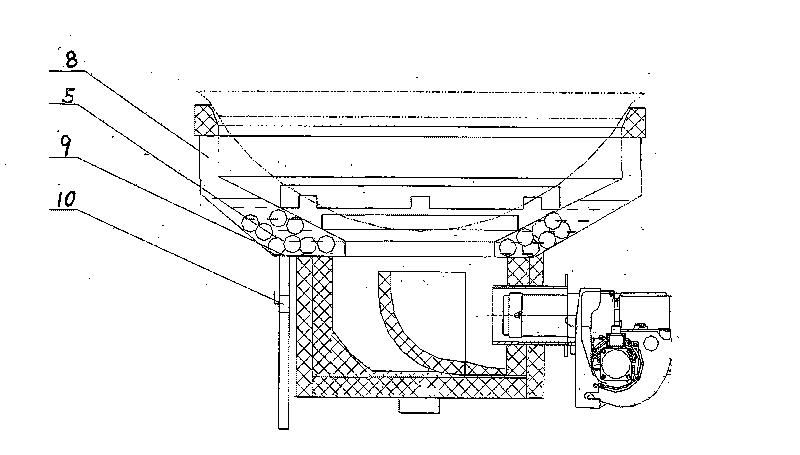

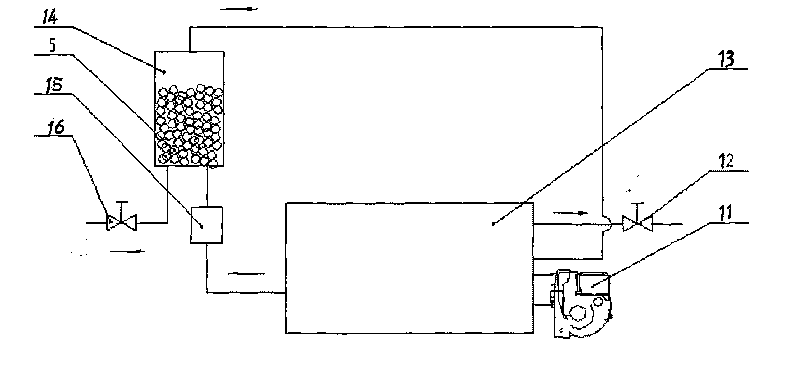

Antiscaling compound and method for preventing and removing scale

ActiveCN101691259APrevent and remove scalingAvoid churnBoiler cleaning apparatusTreatment using complexing/solubilising chemicalsVolume bodyAdditive ingredient

The invention relates to an antiscaling compound and a method for preventing and removing scales; the ingredients of the antiscaling compound comprises: 20-50 percent of natural zeolite, 25-20 percent of TiO, 10-40 percent of V2O5, 20-40 percent of SiO2, and 5-20 percent of NdFeB; the antiscaling compound is an ensemble of regular or irregular solid fine particles or an ensemble of solid porous particles; the average diameter of the fine particles of the antiscaling compound is 0.5-15mm; when the average diameter of the particles of the antiscaling compound is more than 15mm, porous particles are adopted, the pore diameter of the particle is more than 20mum and penetrates through the particle; the density of the antiscaling compound is 1.2-5g / cm<3>; the method for preventing and removing scales is that: the antiscaling compound is placed in water of a heating jacket of a water system freely for preventing and removing the scales in the water system, a filter screen is arranged at the outlet of the water jacket to prevent the antiscaling compound particles from being drained; or the antiscaling compound is placed in a volume body with meshes to form a water processor, the processor is placed nearby the heater and is arranged at the water charging port of the water system to processing charged water. The invention can process the scales efficiently for a long time without secondary pollution, the water treatment is safe, real-time on-line scale removal can be carried out, and the installation and usage are convenient and rapid.

Owner:昆明博远中菱科技有限公司

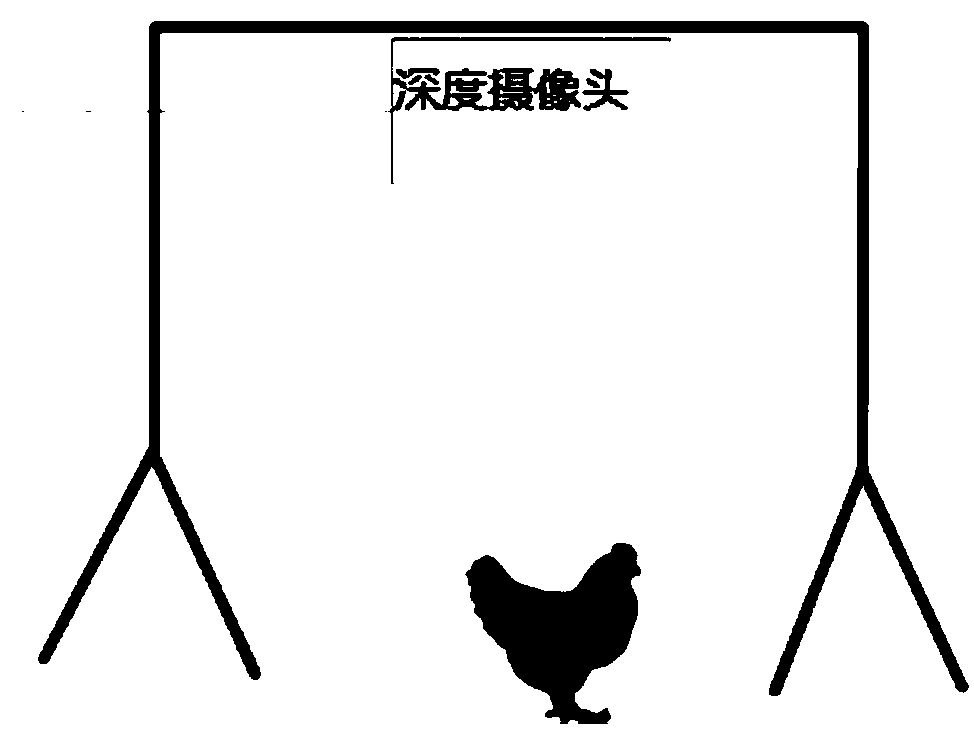

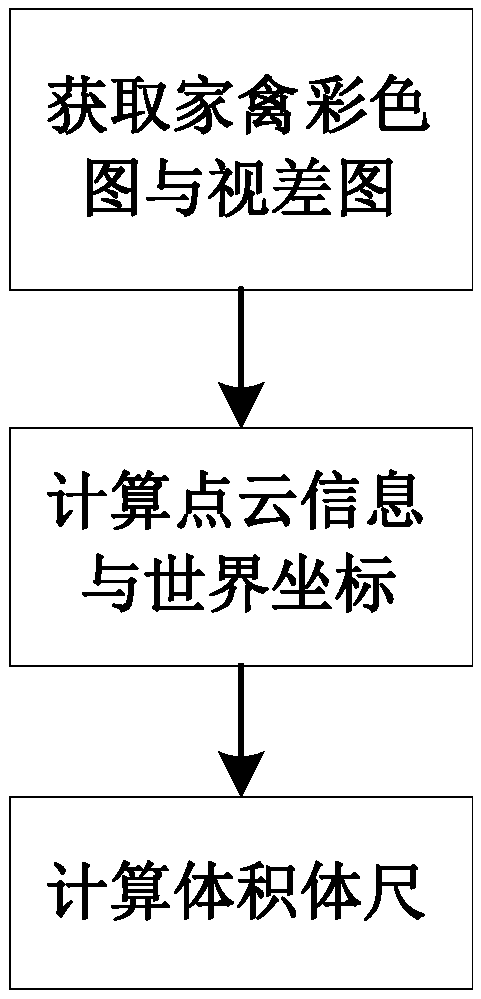

Method and device for identifying poultry volume scale and storage medium

ActiveCN109636779AImprove adaptabilityHigh measurement accuracyImage enhancementImage analysisParallaxVolume body

The invention discloses a method and a device for identifying a poultry volume scale and a storage medium. The method comprises: obtaining a chicken color map and a disparity map, calculating point cloud information and world coordinates, and calculating the volume scale. According to the method, the image information of the measurement scene is acquired by using the depth camera, the chicken is quickly segmented through an algorithm, an external clamping device is not needed to fix the measured chicken, and the volume body size information of the chicken is simply and effectively extracted byusing the computer vision while the normal activity of the chicken is not influenced. The depth camera is not influenced by the light intensity and has good adaptability to a scene with unstable light rays in a chicken farm, the measurement precision can be well improved through algorithm processing, chicken size and body size information is measured through visual non-contact, measurement is easy and convenient, and healthy growth of chickens is facilitated.

Owner:SOUTH CHINA AGRI UNIV

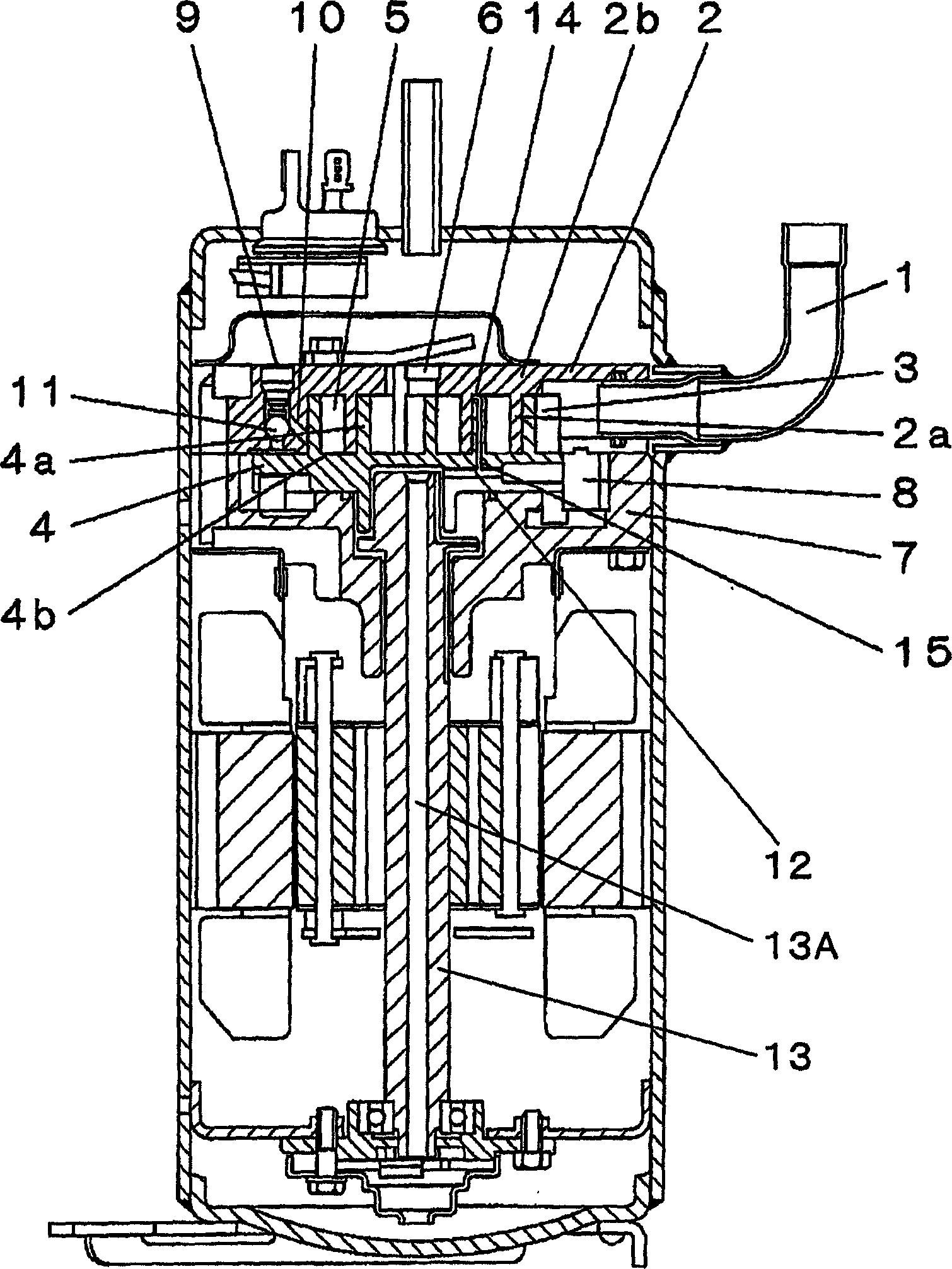

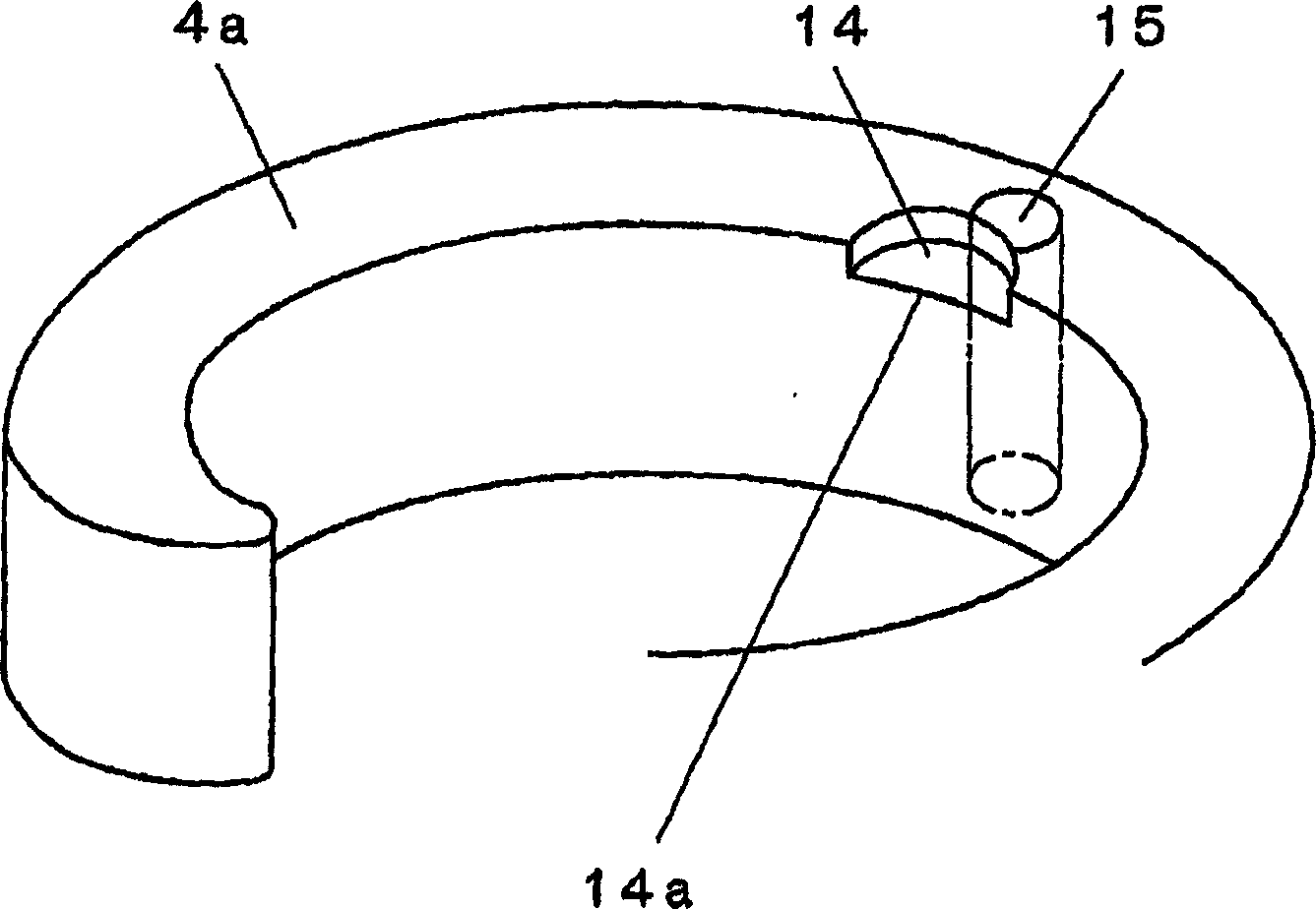

Scroll compressor

InactiveCN1829861ANo increase in varietyReduce leakageRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsVolume bodyEngineering

In a scroll compressor, a stationary scroll part (2) and an orbiting scroll part (4) that have scroll wraps rising from end plates are engaged with each other to form a compression chamber (5) between the parts. The compressor performs suction, compression, and discharge when the compression chamber (5) moves while varying its volume, the movement occurring when the orbiting scroll part (4) orbits along a circular path while being restrained for rotation by a rotation restraining mechanism. A recess (14) is provided in an end face of a wrap (4a), on the opposite side of the end plate (4b). A connection path (15) for connecting the recess (14) and an end plate (4b) rear face is formed.

Owner:PANASONIC CORP

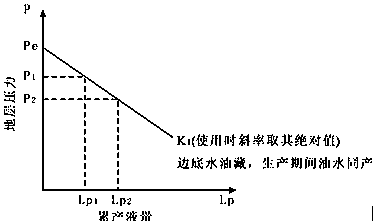

Carbonate rock reservoir karst cave type-constant volume body capacity indication curve interpretation model

The invention discloses a karst cave type-carbonate reservoir. The invention discloses a constant volume physical capacity indication curve interpretation model, and relates to the technical field ofreservoir geology and development. Establishment method comprises the following steps according to the constant volume body model, cracks only play a role in diversion, the storage performance of thecracks is ignored, elastic energy of an original formation water body is considered, and karst caves and caves are ignored. The volume change of the constant volume body and the rock compressibility are achieved; Karst cave type device The constant volume body model serves as a research target, and for oil reservoirs with different elastic energy, the influence of the energy provided by the same oil reservoir in different exploitation stages on the energy indication curve can be distinguished. Through the newly established energy indication curve model, the expression of formation pressure andcumulative liquid production can be derived, the driving energy of different elastic energy reservoirs can be qualitatively distinguished, and the geological reserves of different elastic energy reservoirs can be quantitatively calculated.

Owner:HARBIN INST OF PETROLEUM

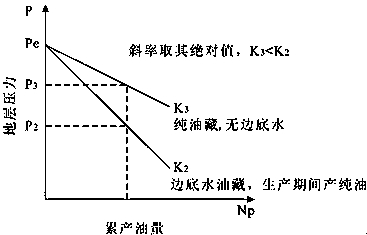

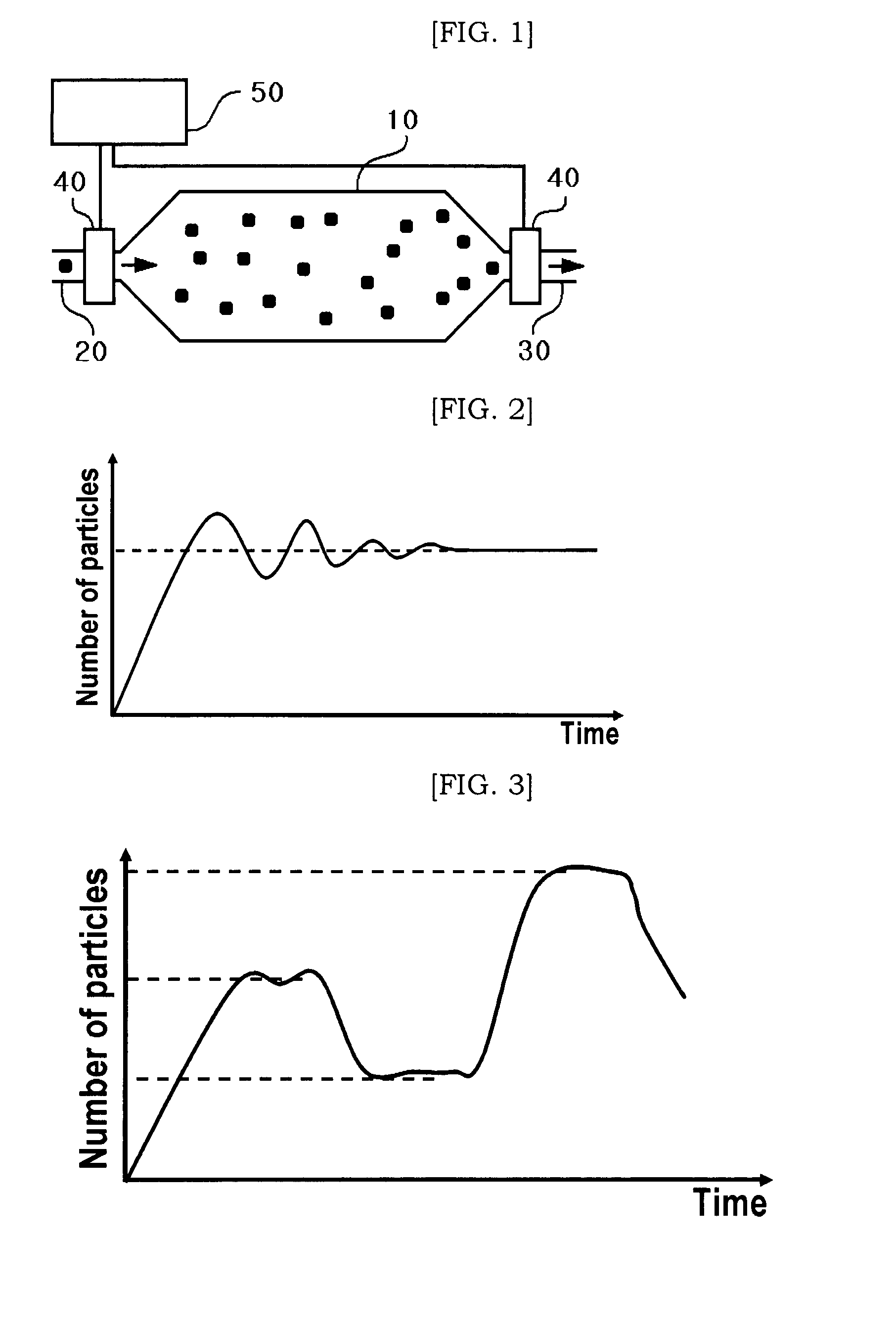

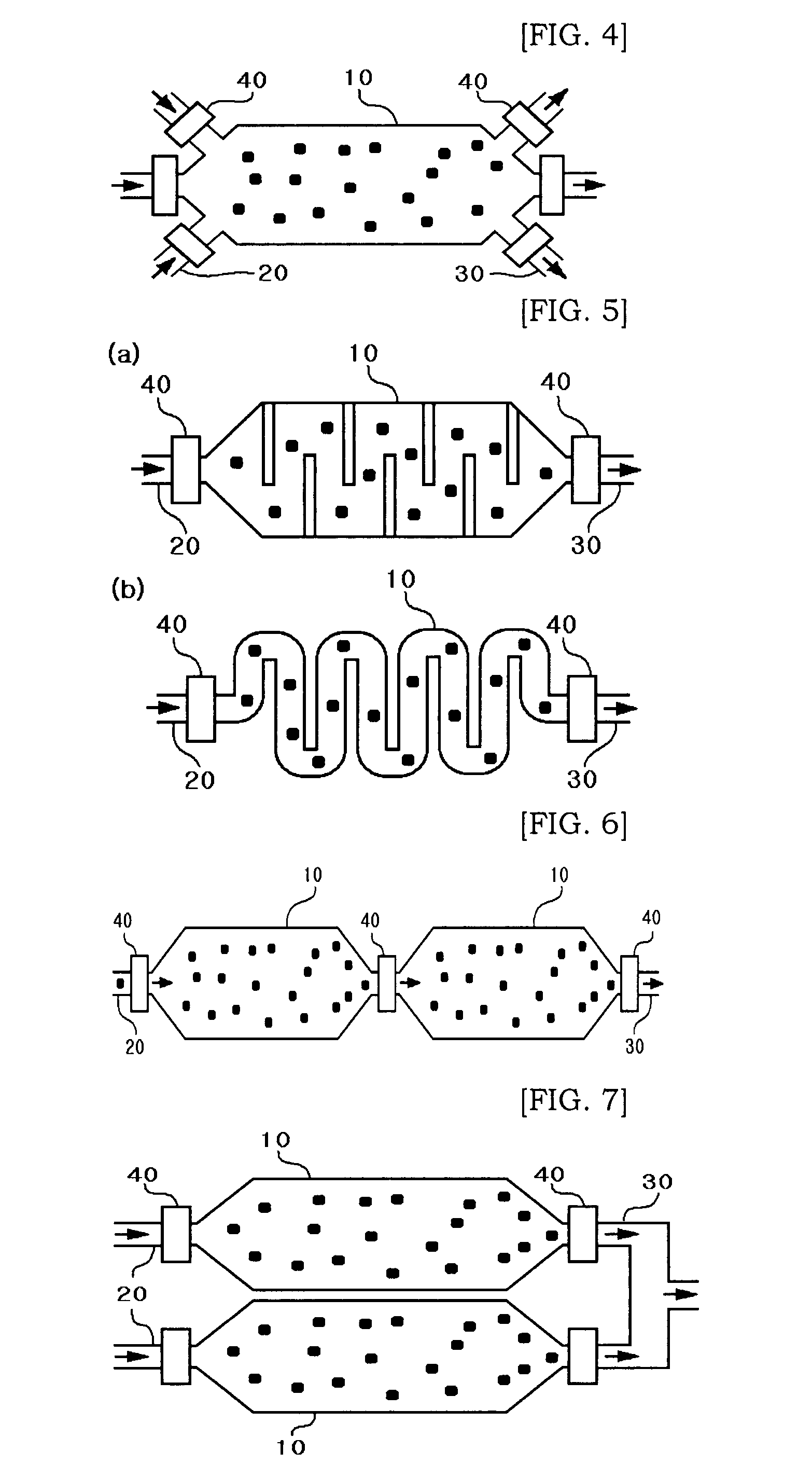

Device and method for measuring fine particle concentration

ActiveUS7784332B2Precisely and rapidly measureSmall sizeMaterial analysis by electric/magnetic meansIndividual particle analysisEngineeringVolume body

Disclosed is a device for measuring the concentration of the particles contained in a fluid. The device comprises a control volume body having a predetermined effective volume. An inlet path is formed at an end of the control volume body to feed the fluid into the control volume body therethrough. An outlet path is formed at another end of the control volume body to discharge the fluid from the control volume body therethrough. Measuring instruments are provided at the inlet path and the outlet path to emit electrical signals when the fine particles pass through the inlet path and the outlet path. A computing machine receives the electrical signals transmitted from the measuring instruments, and then computes the number and the concentration of fine particles contained in the control volume body. The device is easily integrated with Micro-TAS (Total analysis System).

Owner:KOREA ADVANCED INST OF SCI & TECH

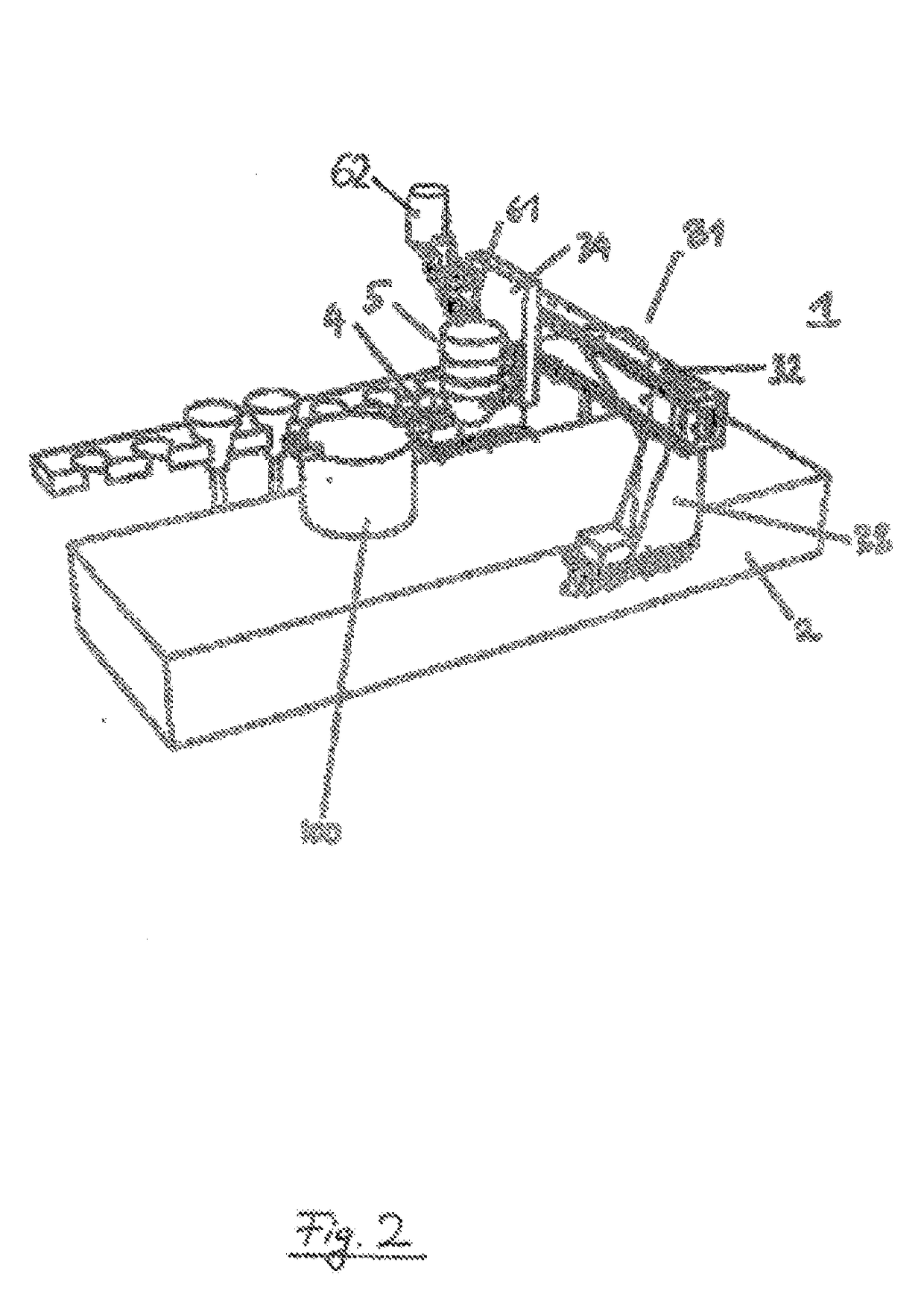

Device for forming 3D bodies

A device for forming 3D bodies, in particular pieces of furniture, by additive material application. In particular, the device has a support, on which the volume body is formed, an application unit, for building up the 3D body on the support by additive application of material, and a tool carrier with a tool holder, in which the application unit is mounted. The tool carrier is in this case designed in such a way that the application unit mounted in the tool holder can be aligned in five directions by moving the tool holder with respect to the support.

Owner:HOMAG BOHRSYST GMBH

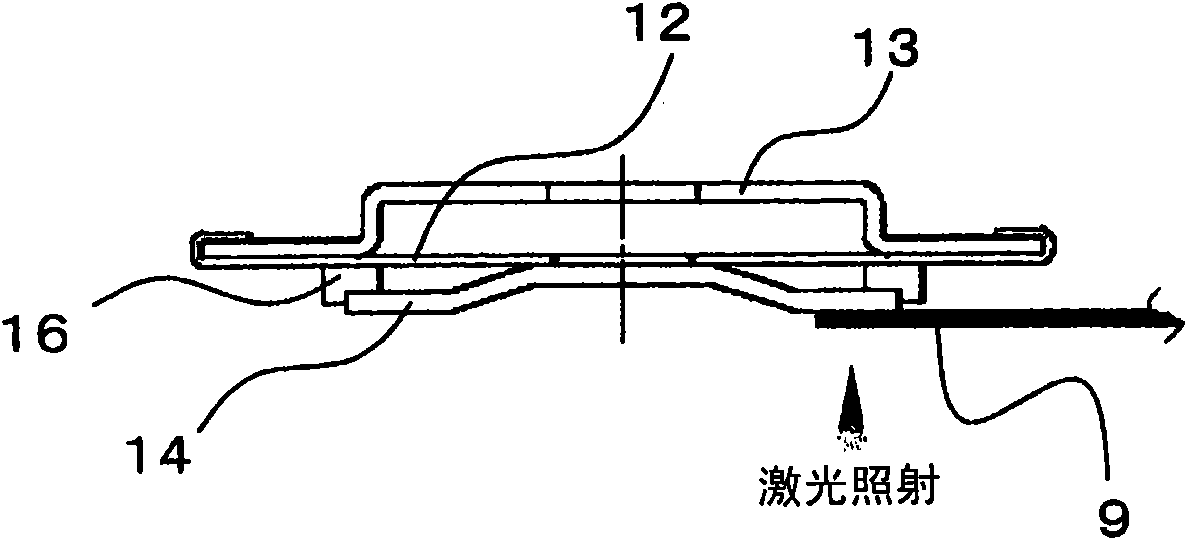

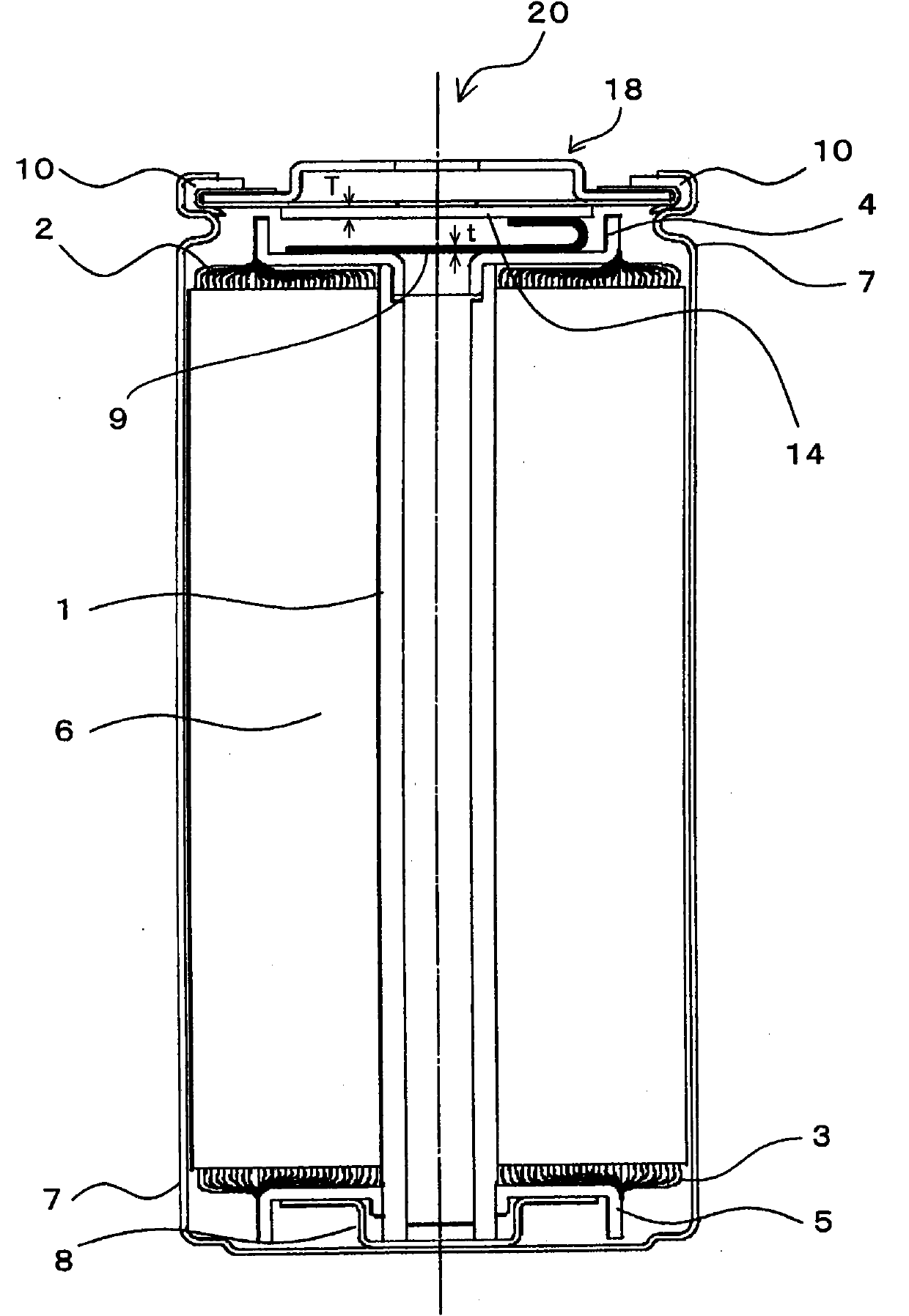

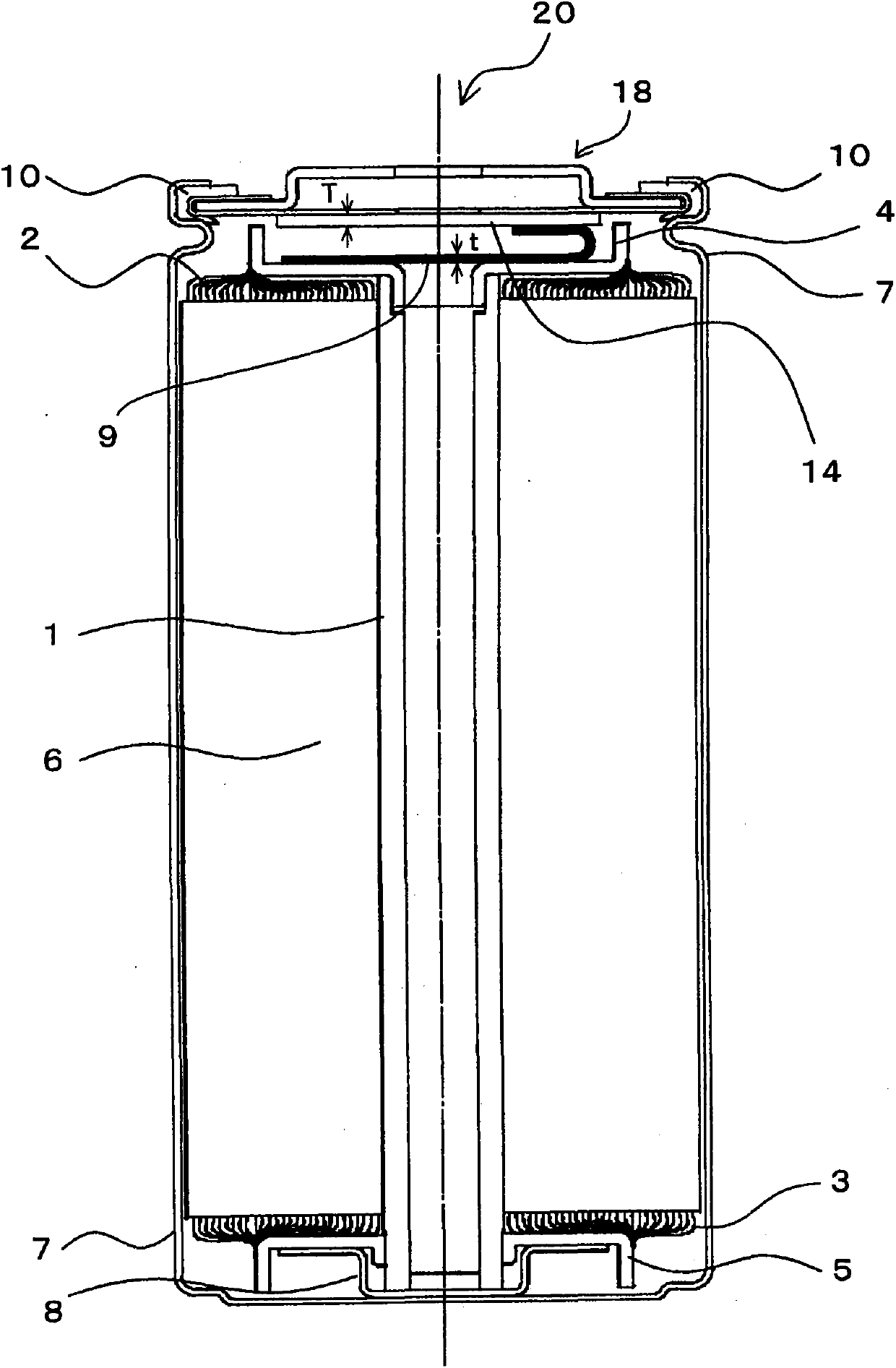

Sealed battery and producing method therefor

ActiveCN101908652AEnsure electrical continuityCompact containmentCell sealing materialsGastight accumulatorsLithiumVolume body

The invention provides a sealed battery which can guarantee conduction between a power generator and a cover body without generating a welding defect. A lithium ion secondary battery includes a battery container (7). The battery container (7) houses an electrode winding body, on which positive and negative electrode plates are wound via separators, together with a non-aqueous electrolytic solution. A positive electrode tab is bonded to a positive current collector ring (4) arranged at an upper side of the electrode winding body. A battery lid (18) to be a positive electrode external terminal is crimped and fixed to the battery container (7). The battery lid (18) has a diaphragm in which a cleaving valve (12) is formed. A coupling part is bonded to the diaphragm, and a stack lead (9) with a plurality of thin plates being laminated is bonded to the coupling part. In the stack lead (9), a total sum t of thicknesses of the thin plates is not more than a thickness T of the coupling part. Melting from the stack lead (9) to the coupling part by laser irradiation is optimized.

Owner:日本汽车能源株式会社

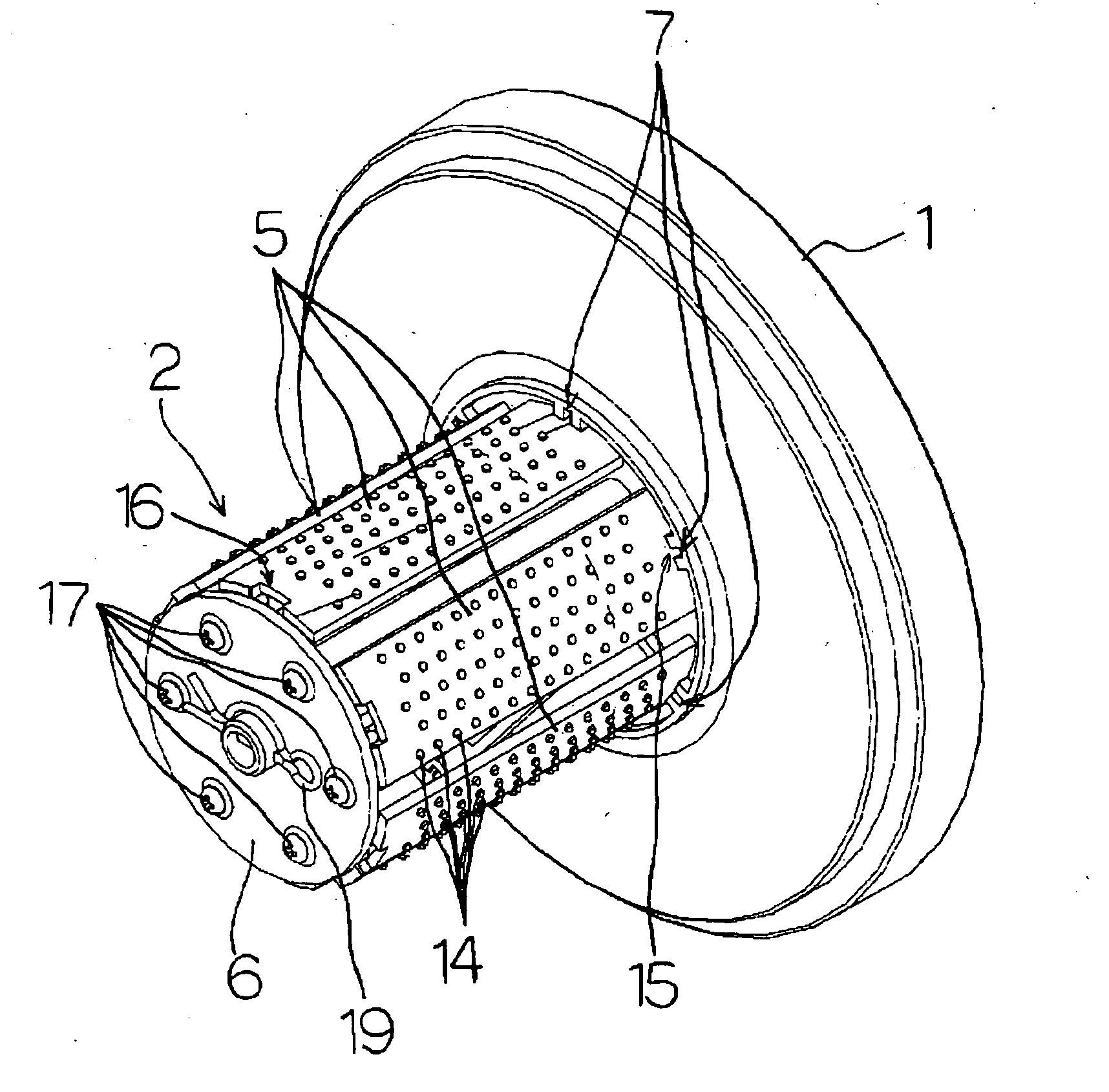

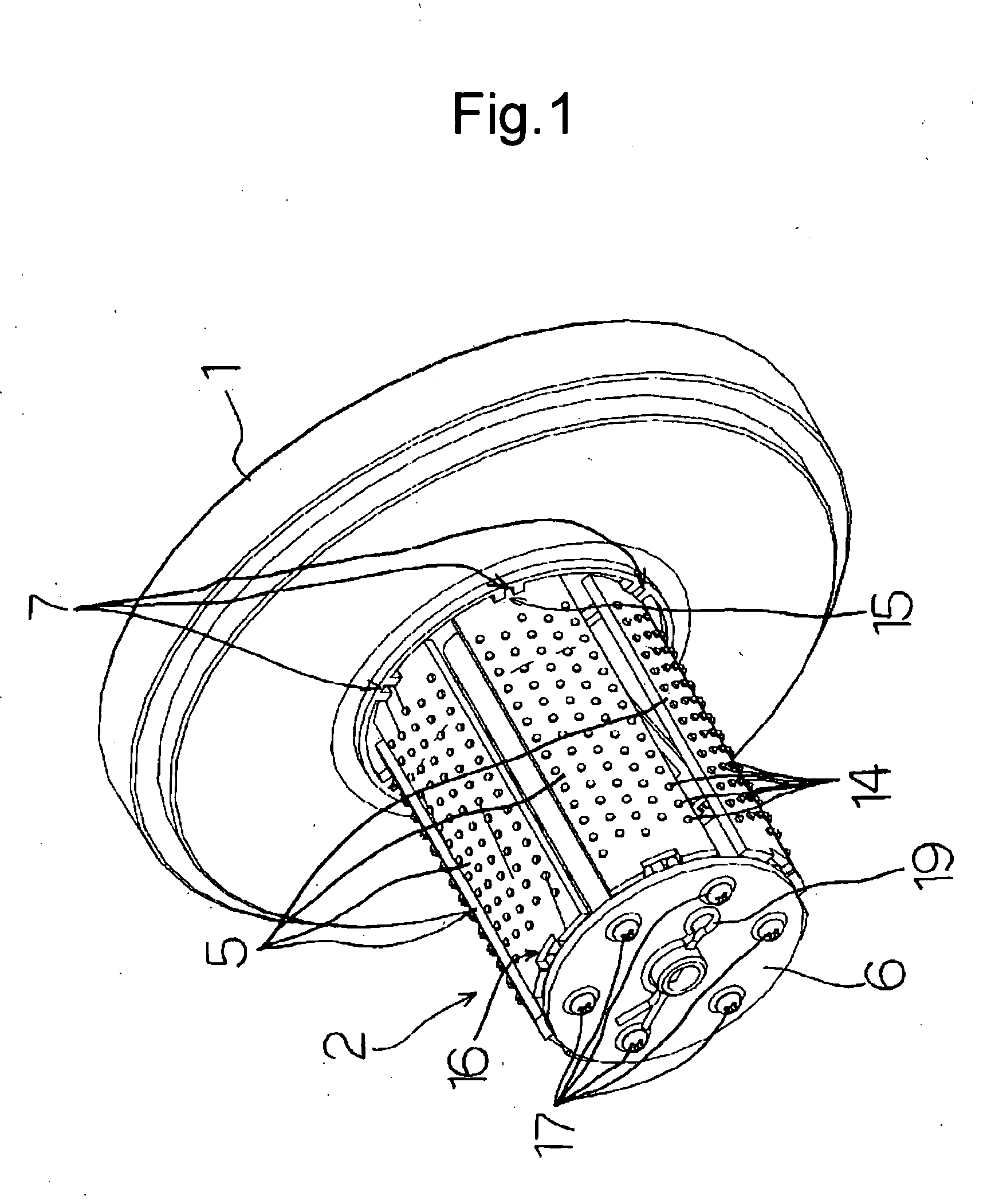

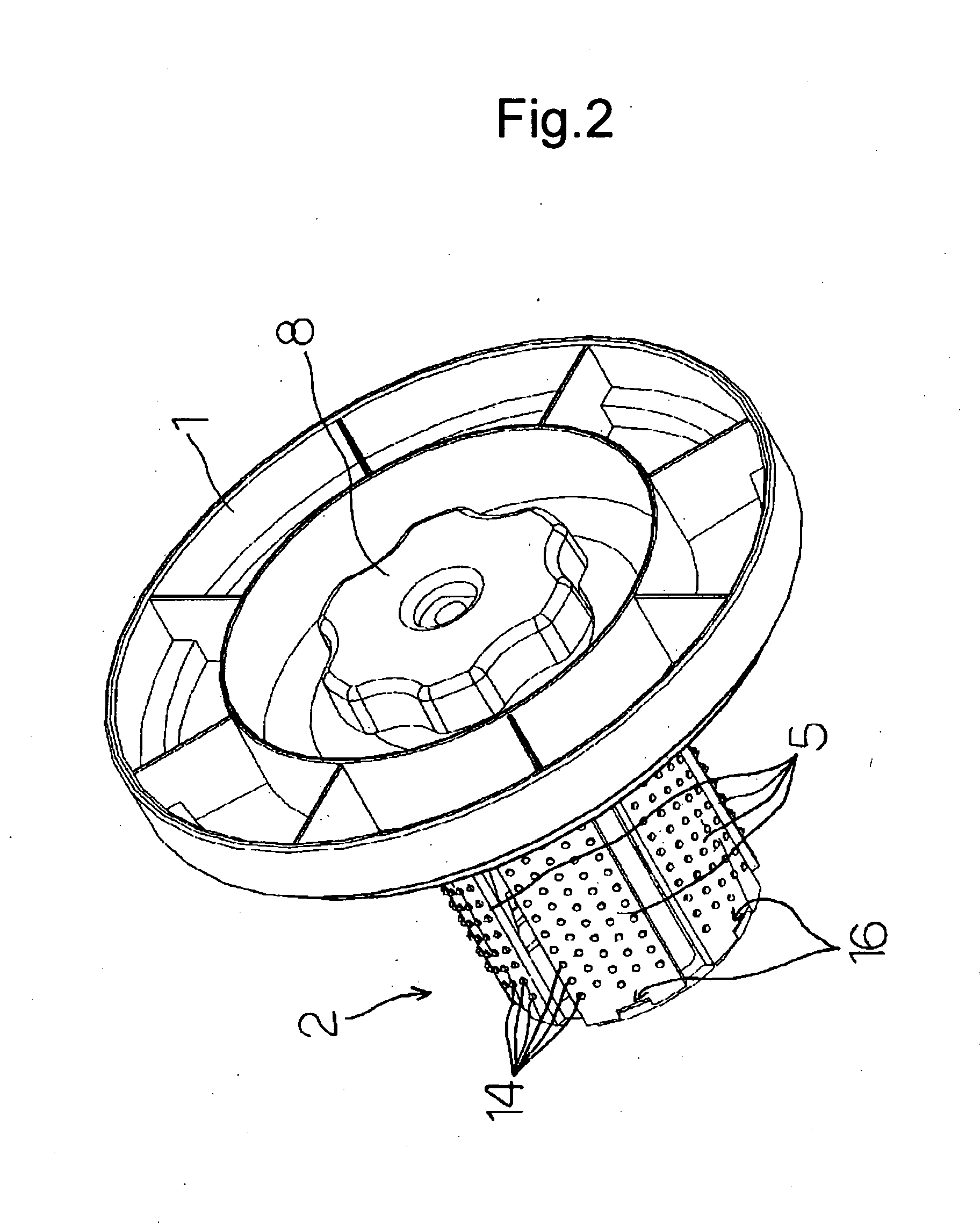

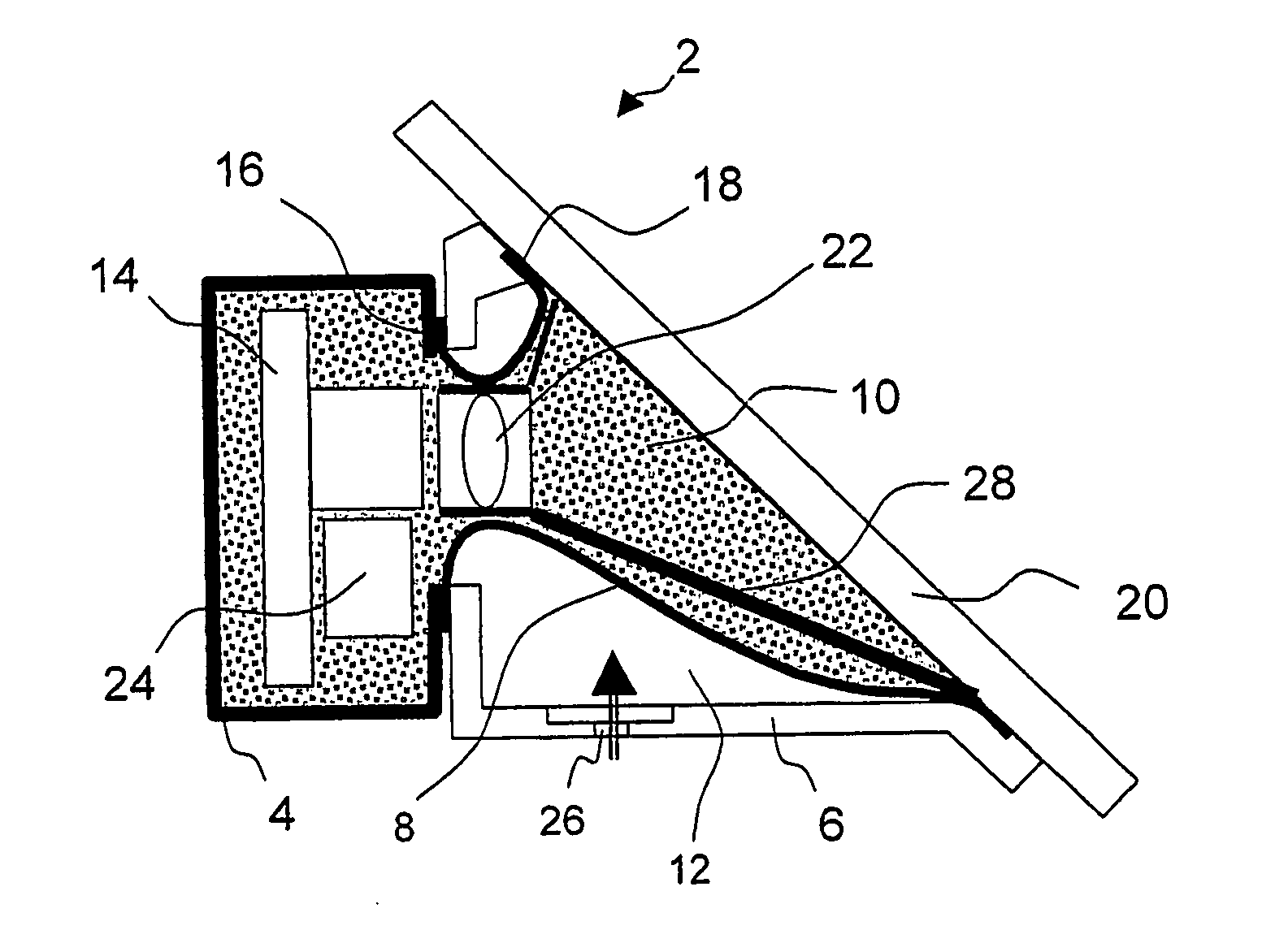

Rolled body holder and recording apparatus

A rolled body holder includes a center shaft member serving as a lead screw connected to a handle, a cam member screwed to the center shaft member, and a plurality of segments which form a cylindrical body covering the center shaft member and the cam member. The cam member includes a plurality of rails, and each of the rails includes a cam surface with a radially varying height. Each of the segments includes a follower part fitted to the rail and relatively slidable along the cam surface and an outer surface part on which multiple projections are formed. When the cylindrical body is inserted into a paper tube of a rolled body and the handle is rotated, the center shaft member is rotated to move the cam member in the longitudinal direction. Then, a portion of the cam surface, which is higher in the radial direction, is brought into contact with the follower part, and each of the segments extends in the radial direction so that the projections bite into an inner surface of the paper tube. As a result, the rolled body can be easily and securely held with a simple structure.

Owner:OKI DATA CORP

Quick-freezing pork vegetable roll food and preparation thereof

InactiveCN101317671AReasonable and strict processImprove qualityFood preparationQuick FreezeVolume body

The invention relates to a quick-frozen pork-vegetable roll food and the making method thereof. Serving as raw materials, crushed pork, pig fat, cubed onions and scalded, crushed and dehydrated pickled cabbage powder are added and stirred with an adhesive, a seasoning agent, a color fixative and water in proper amount to form fillings; the fillings are then moulded into filling balls which are steamed, cooled and shaped; the outer surfaces of the balls are wrapped with a plurality of pickled cabbage bodies which have curves and are scalded and then cooled previously; the outer layer of the pickled cabbage body is fixed with a fastening band so that a green roll food which is externally provided with a fastening fixation band and a plurality of curves and internally a filling ball. After being quick-frozen, the roll food can then become the quick-frozen pork-vegetable roll food. The quick-frozen pork-vegetable roll food of the invention has beautiful shape, bright color and pure taste, combines the nutrients of the pork and various vegetables and is easy to be stored and convenient to be eaten. The making method of the food of the invention has reasonable and strict technology, strong operability and high making efficiency and is suitable for the industrial production. The food made is safe and healthy and has stable quality.

Owner:RONGCHENG BODELONG FOODSTUFF

Pressure Equalizing Housing Device

There is provided a pressure-equalizing housing device, including a rigid housing having a coupling end and configured to contain at least one instrument. The coupling end of the housing is adapted to be sealable to a radiation transmittable surface. An opening made in a wall of the housing enables fluid to pass therethrough, and the housing and surface delimit an interior space communicating with the exterior of the housing via the opening. There is also provided a pressure-influenced member forming an expandable and retractable volume body, a portion of which member is located adjacent to, or the interior of which member communicates with, the opening, for equalizing the pressure inside and outside the housing.

Owner:KERETH YEFIM

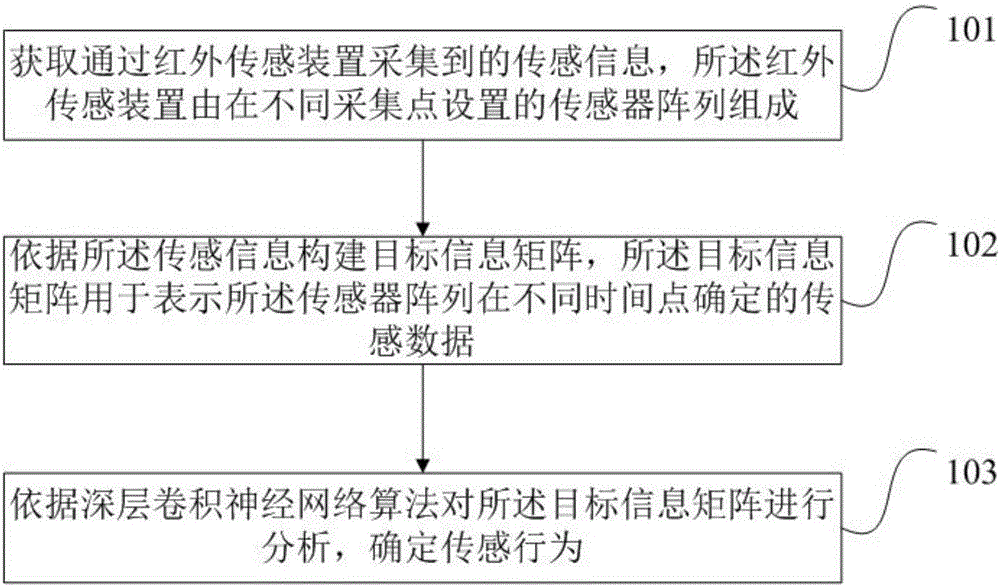

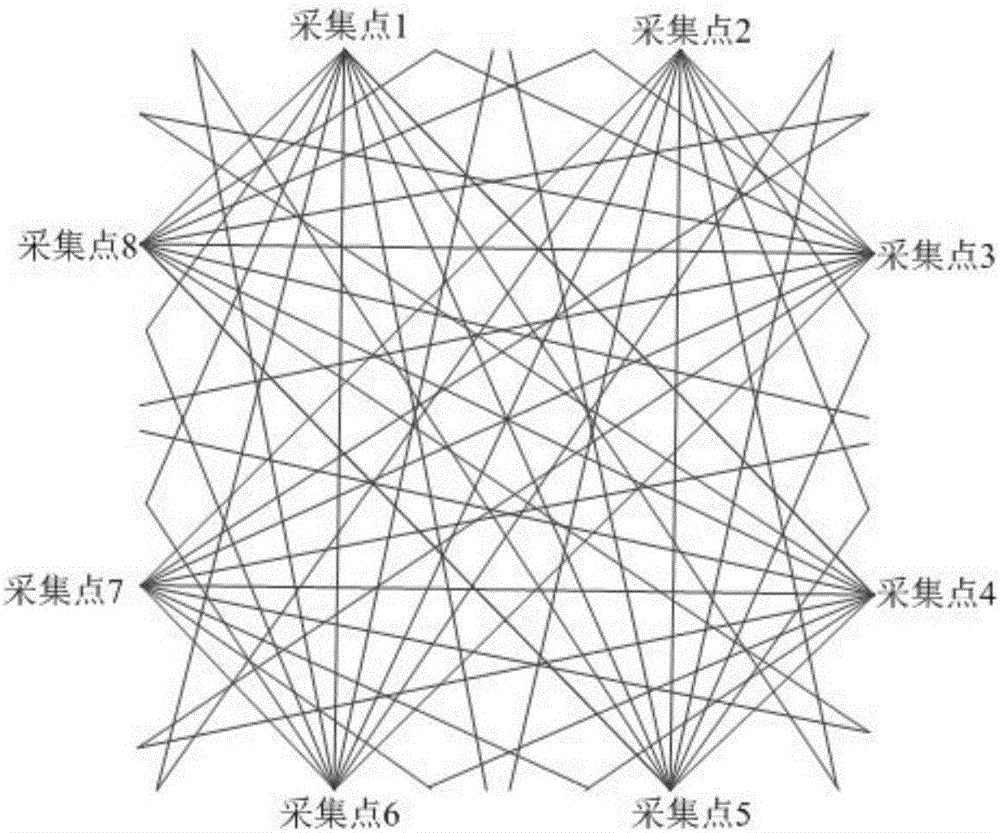

Sensing behavior recognition method and device

The invention discloses a sensing behavior recognition method and a sensing behavior recognition device. The sensing behavior recognition method comprises the following steps: acquiring sensing information acquired by an infrared sensing device, wherein the infrared sensing device consists of sensor arrays arranged at different acquisition points; according to the sensing information, establishing a target information matrix, wherein the target information matrix is used for showing sensing data determined by the sensor arrays at different time points; according to a deep convolution neural network algorithm, analyzing the target information matrix to determine a sensing behavior. Through the sensing behavior recognition method and the sensing behavior recognition device, small-calculation data amount, non-invasive, low-cost and small-volume body behavior recognition is achieved and the recognition accuracy rate is improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

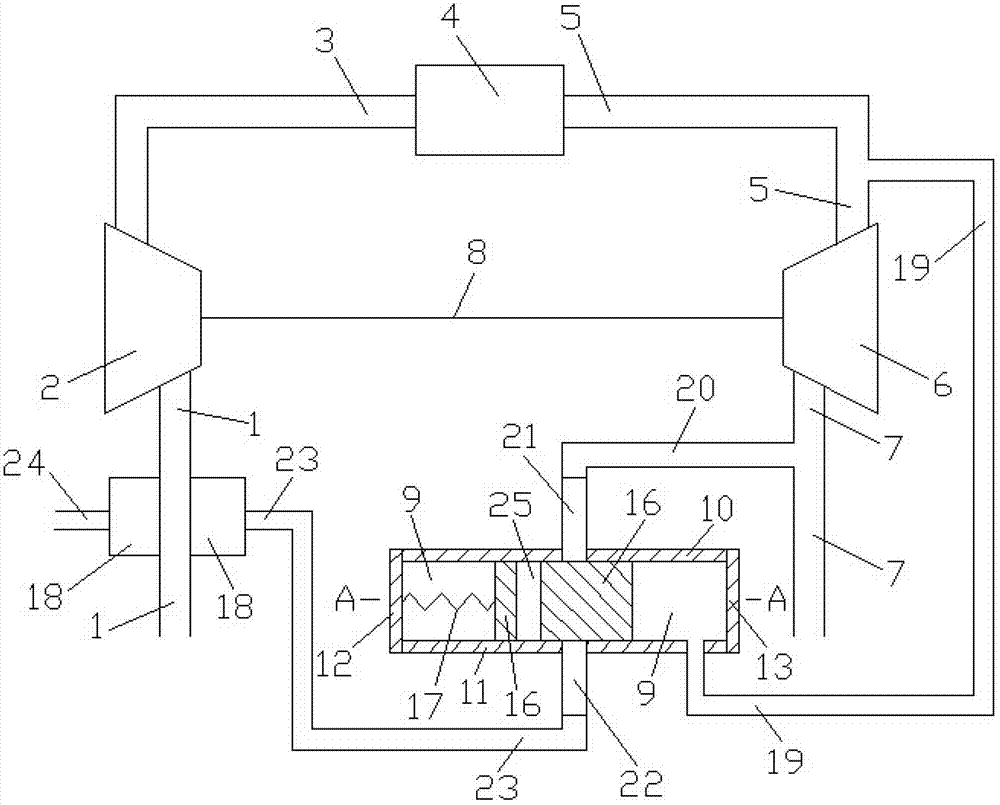

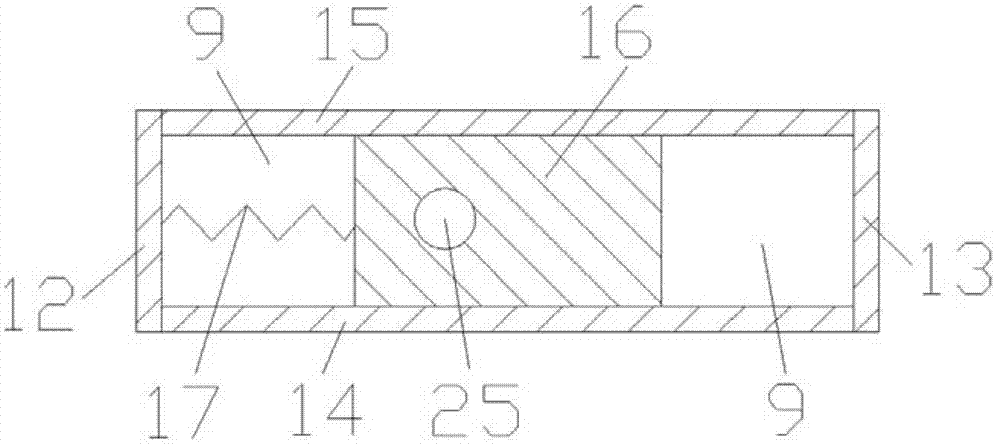

Working volume measuring device and method for reducing device wall air outlet error

InactiveCN103808383AImprove volume measurement accuracyMaintain static pressureTesting/calibration apparatusContainer/cavity capacity measurementVolume bodyMeasurement device

The invention provides a working volume measuring device and method for reducing a device wall air outlet error. The device comprises a working volume body and a reference volume body which are connected through a first valve, the reference volume body is connected with a first non-evapotranspiration getter pump through a second valve, the reference volume body is connected with an air exhausting system through a third valve, the working volume body is connected with a second non-evapotranspiration getter pump through a fourth valve, and the working volume body is connected with a vacuum meter. According to the scheme, the active gases separating from absorbing on the wall of the working volume body and the wall of the reference volume body are correspondingly and selectively pumped through the first non-evapotranspiration getter pump and the second non-evapotranspiration getter pump, the static pressure inside the working volume body and the static pressure inside the reference volume body are kept, and the volume measuring precision of the working volume body is further improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

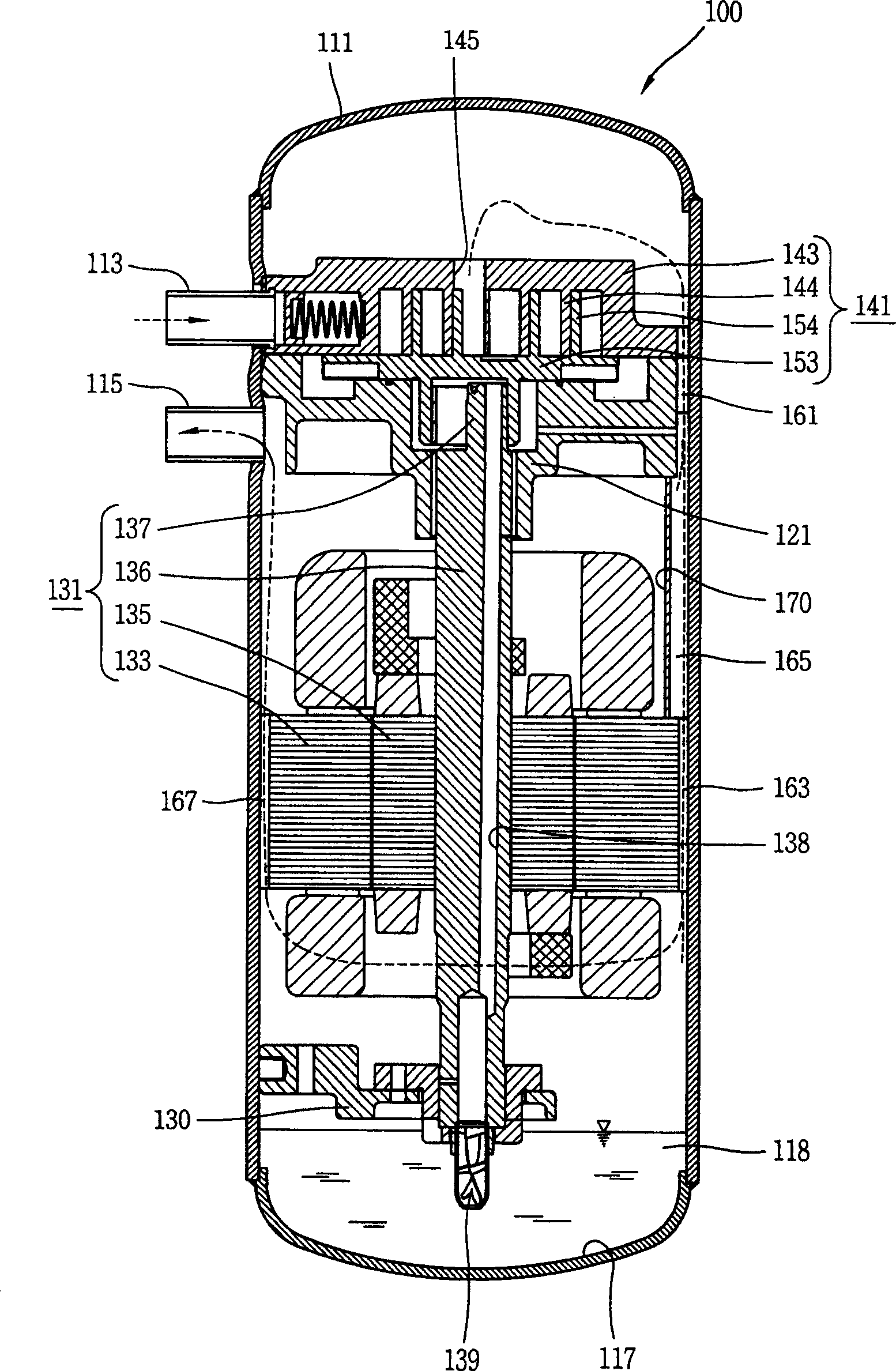

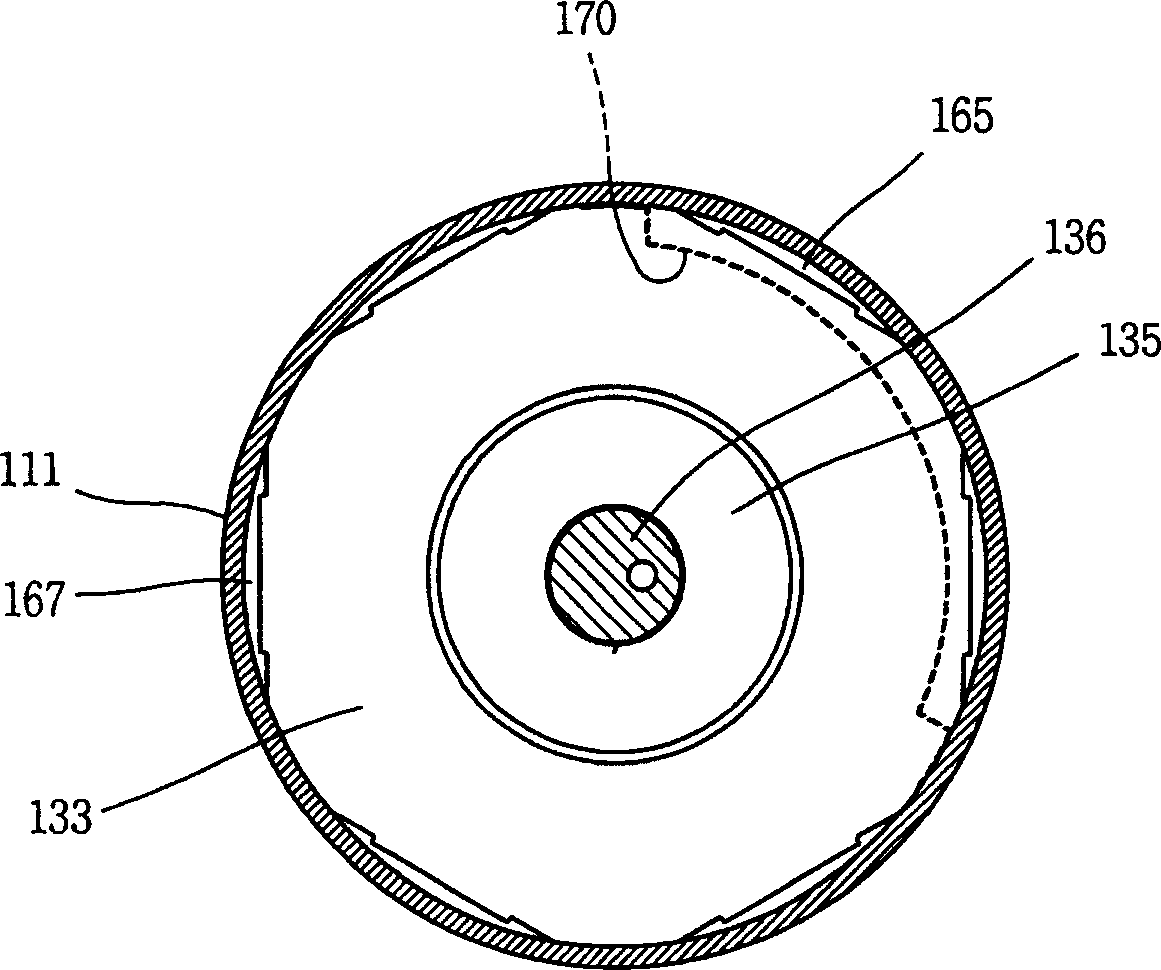

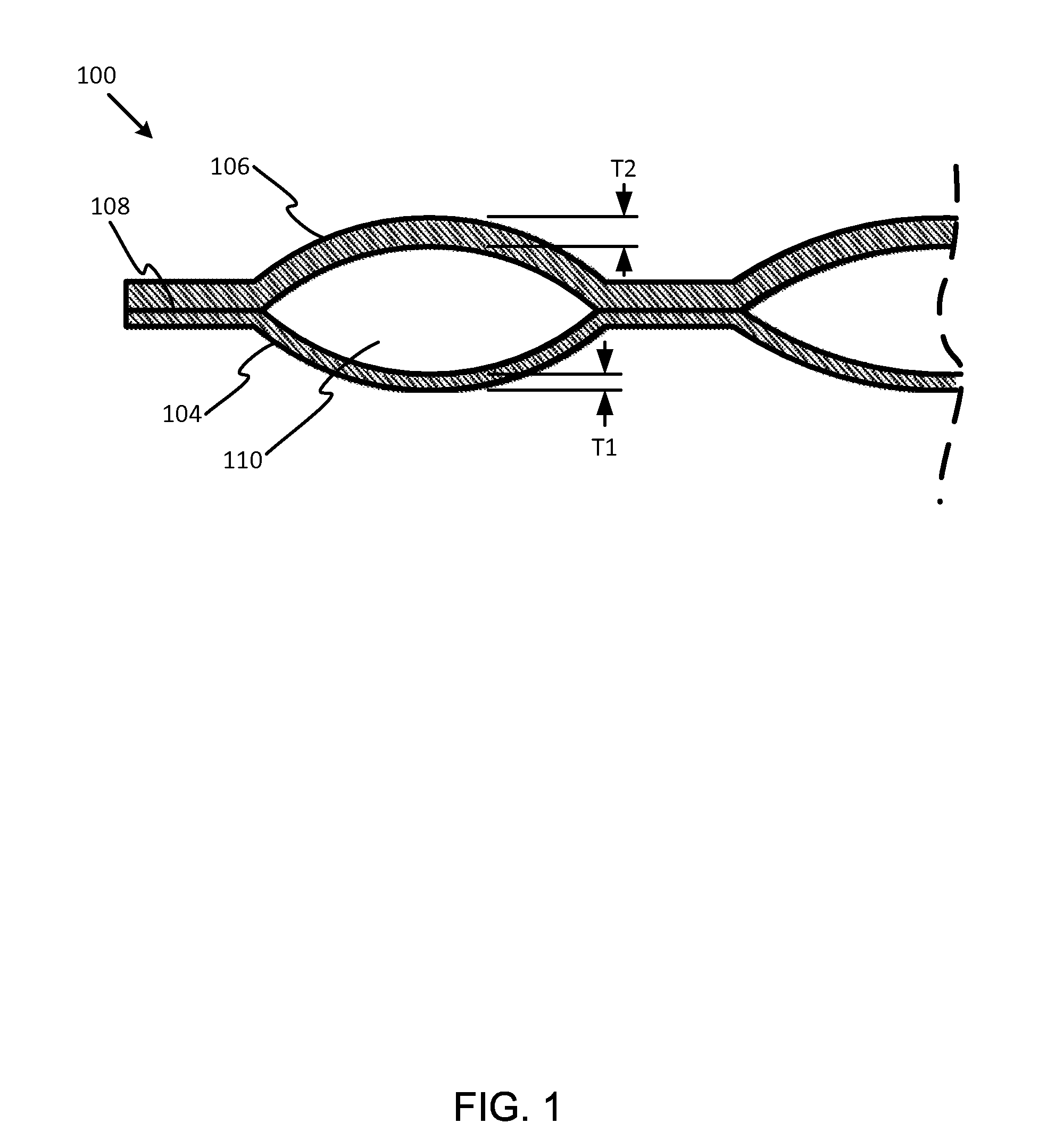

Scroll compressor having refrigerant gas guiding structure

InactiveCN1752447AGood compressibilityPrevent overflowRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsVolume bodyEngineering

To provide a scroll compressor having a refrigerant gas guiding structure. This scroll compressor includes a casing 111 having a storage space inside it and provided with a suction pipe for sucking refrigerant gas and a discharge pipe for discharging refrigerant gas, a fixed scroll provided with a lap having an involute shape and a discharge port for discharging compressed refrigerant gas and arranged inside the casing, a turning scroll provided with a lap having an involute shape and connected so as to turn and move relatively to the fixed scroll, and a gas guiding member provided inside the casing to guide refrigerant gas discharged through the discharge port.

Owner:LG ELECTRONICS INC

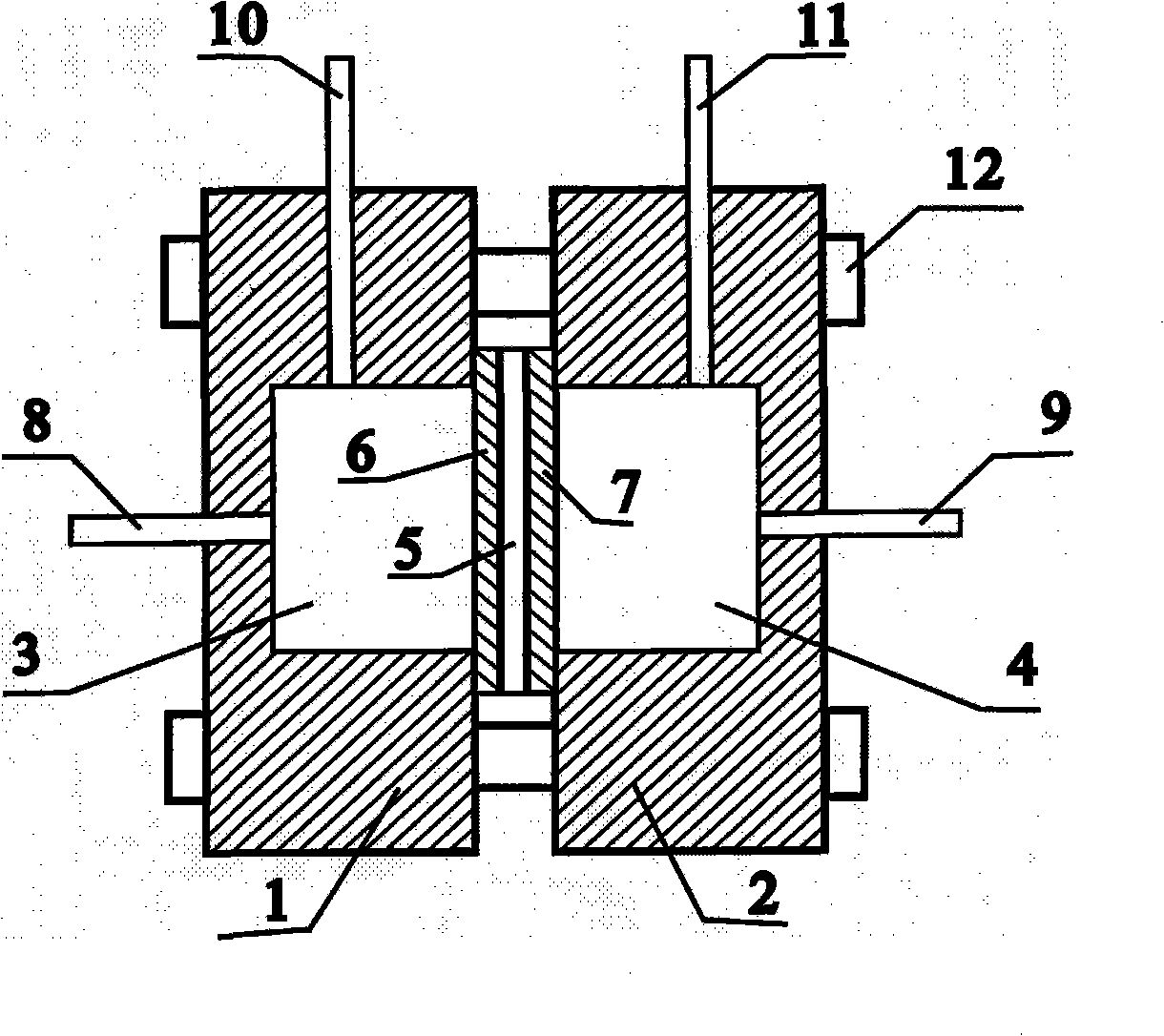

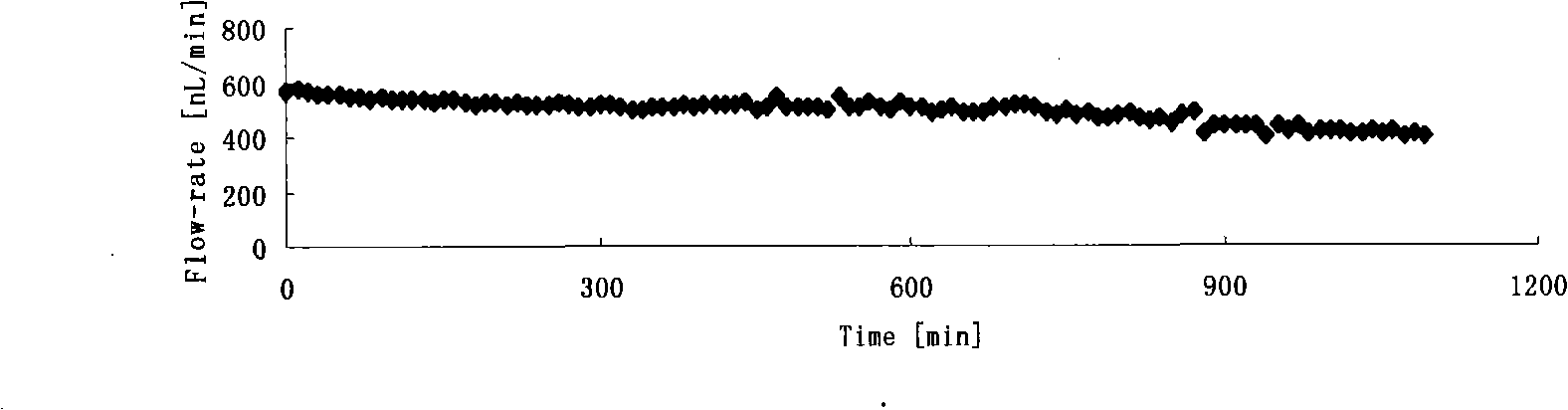

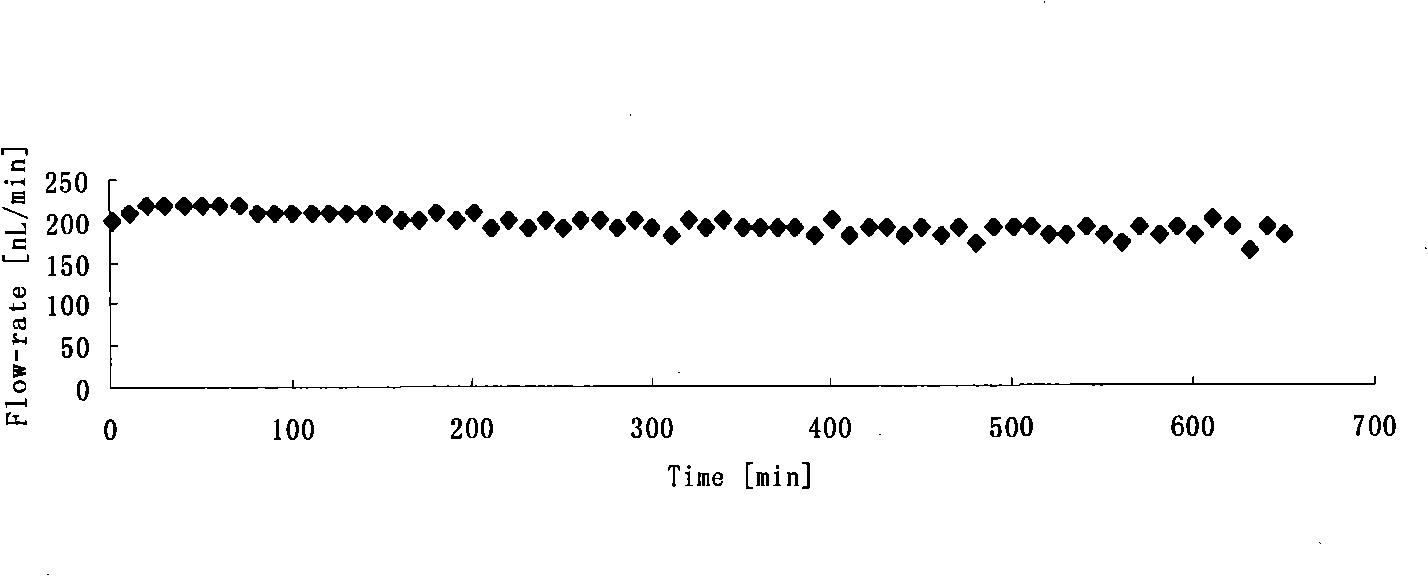

Microfluid drive unit based on infiltration

The invention relates to a microflow driving device based on osmosis. Two floor plates sandwiched by a semipermeable membrane and installed between two tank bodies of aqua storage tanks with constant volume body and connected by bolt and nut. Two tank bodies all have one vent of aqua storage tank. One inlet or outlet of one aqua storage tank is provided on the outer sidewalls of the two tank bodies and one opening communicated with the cavity for storing liquid is respectively on the corresponding point of the inner wall of the two tank bodies. The minipores are all dispersed on the two floor plates, wherein the aperture diameter of minipore is 0.4-2mm and the cutoff molecular weight of semipermeable membrane is less than the molecular weight of infiltration driving agent. On running, the aqua storage tank is filled with deionized water and another aqua storage tank is filled with infiltration driving agent, therefore the gas of the two aqua storage tanks are removed and the flow speed and stability of micropump can be measured after closing the vent. The whole structure is simple and the cost is low. The microflow driving device is convenient for carrying without external resource and continuously serves for many days and the liquid flow is stable, adjustable without pulse.

Owner:NORTHEASTERN UNIV

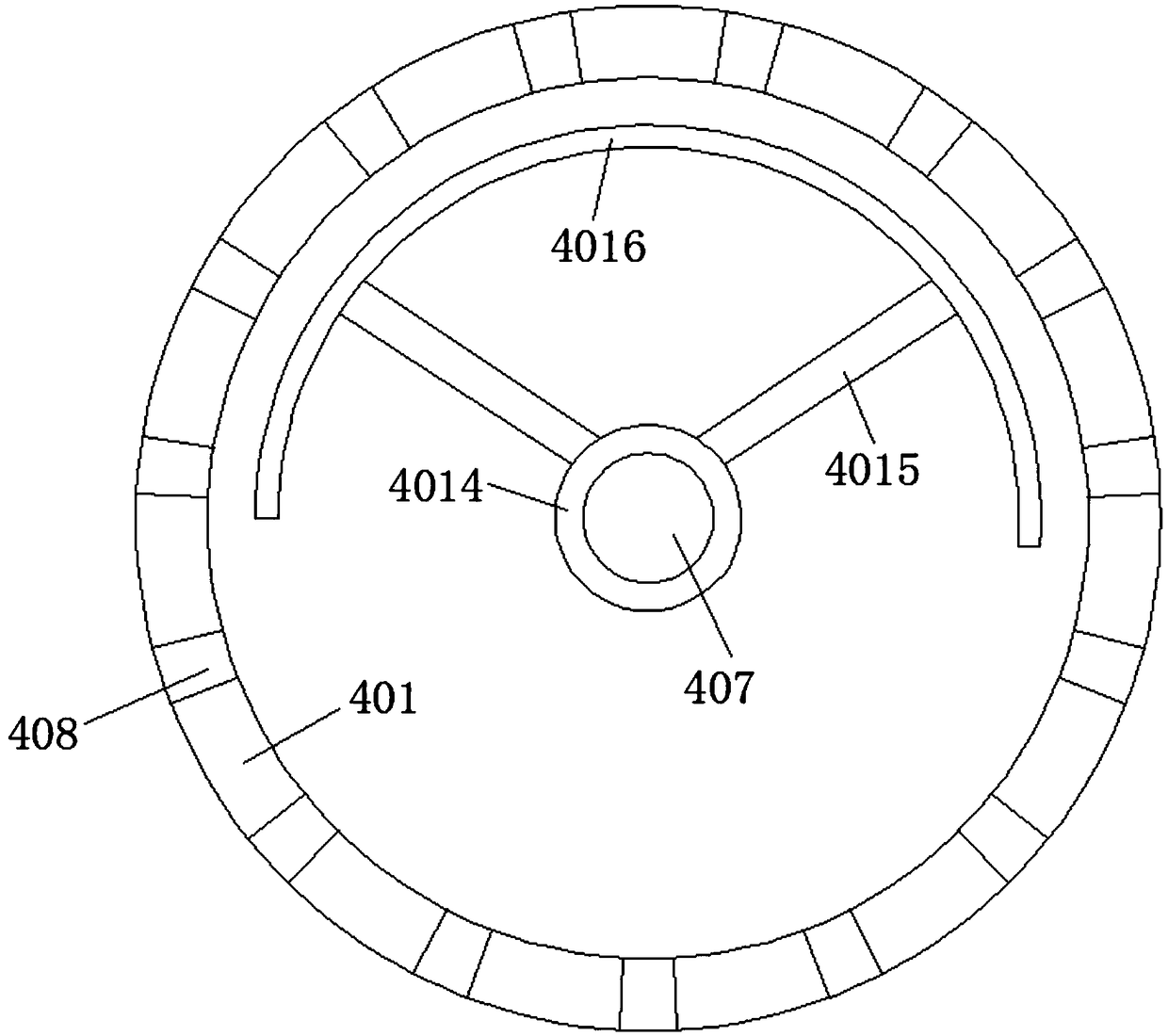

Test paper file cabinet

The invention provides a test paper file cabinet. The cabinet comprises supporting legs, an arc-shaped paper guiding body, a file cabinet body, a paper suction inward guiding mechanism, a synchronousvibration mechanism and a file storage mechanism, rubber suction plates are bonded to the surfaces of the supporting legs, the surfaces of the supporting legs are welded to the lower surface of the arc-shaped paper guiding body, the surfaces of the supporting legs are welded to the lower surface of the file cabinet body, the surface of the arc-shaped paper guiding body is welded to the surface ofthe file cabinet body, the paper suction inward guiding mechanism is arranged on the file cabinet body, the synchronous vibration mechanism is arranged in the file cabinet body, and the test paper file cabinet relates to the field of education. According to the test paper file cabinet, by arranging the rubber suction plates, the whole cabinet can be absorbed and stabilized through the rubber suction plates when the cabinet is used to prevent the shaking of the cabinet, the rubber suction plates have better silencing and shock-absorbing effects, and the problems that most of existing test paperfile cabinets are used for subsequent keeping of test paper failing to take the place of workers to sort out the test paper, the test paper sort-out operation is complicated, and test paper damage and omission are easily caused are solved.

Owner:刘树发

Fixed scroll of scroll compressor

InactiveCN1840913AValid importImport preventionRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsVolume bodyEngineering

Owner:LG ELECTRONICS INC

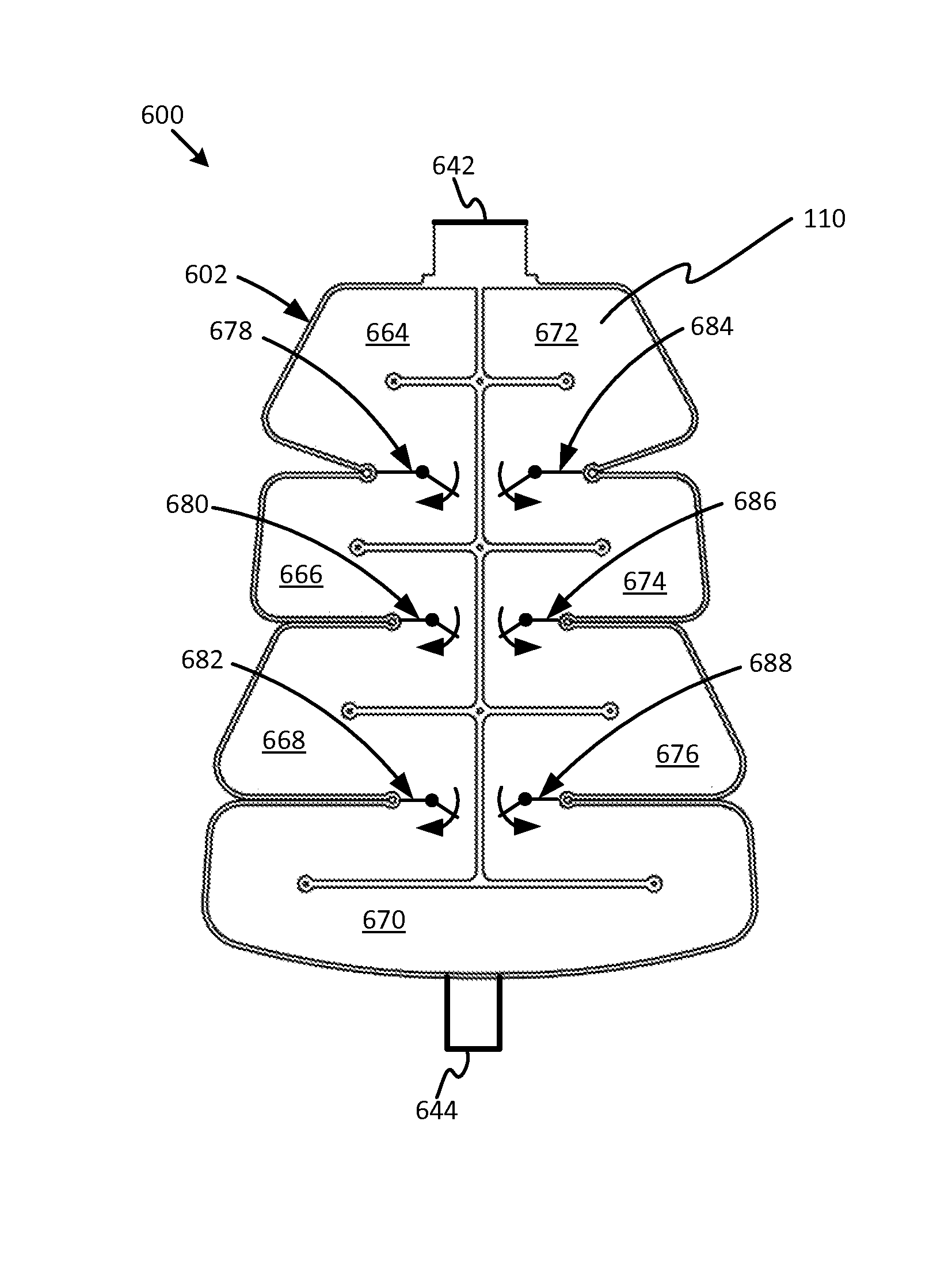

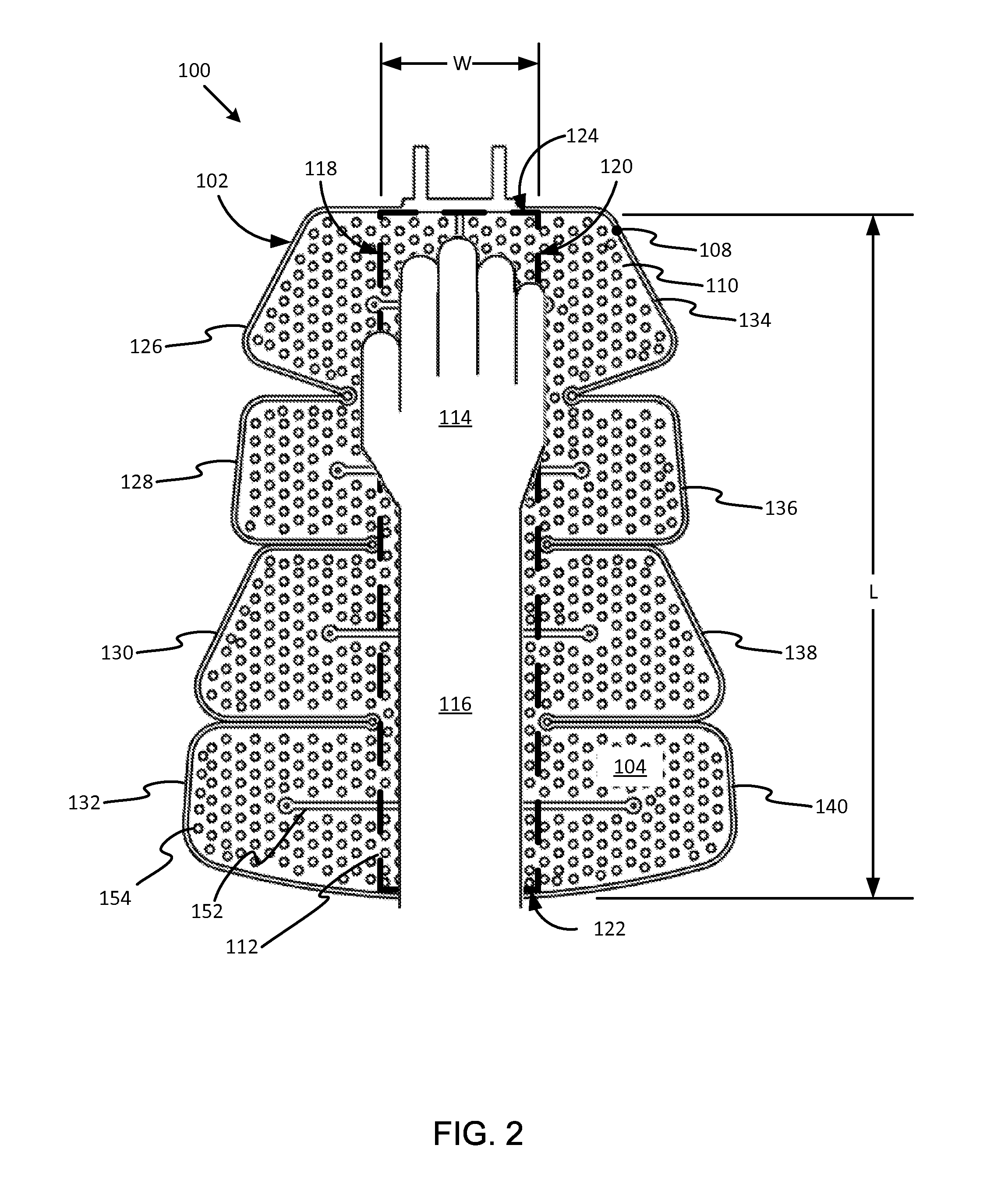

Patient warming device with patient access

A patient warming device with patient access for maintaining normothermia and / or treating hypothermia is provided. The device includes a first compliant layer and a second compliant layer sealed together around an outer border to contain a liquid between the two layers and to form a wrap that surrounds and conforms to a body portion of a patient. A plurality of flaps extends from opposite sides of a generally longitudinal central portion of the wrap, such that one or more flaps from the opposite sides fasten to each other to surround the body portion. The flaps are openable during functional use to provide access to an underlying patient body surface. A continuous fluid flow path extends between the first compliant layer and the second compliant layer between a fluid inlet and a fluid outlet to carry liquid and deliver heat through the wrap.

Owner:SUNMED GRP HLDG LLC

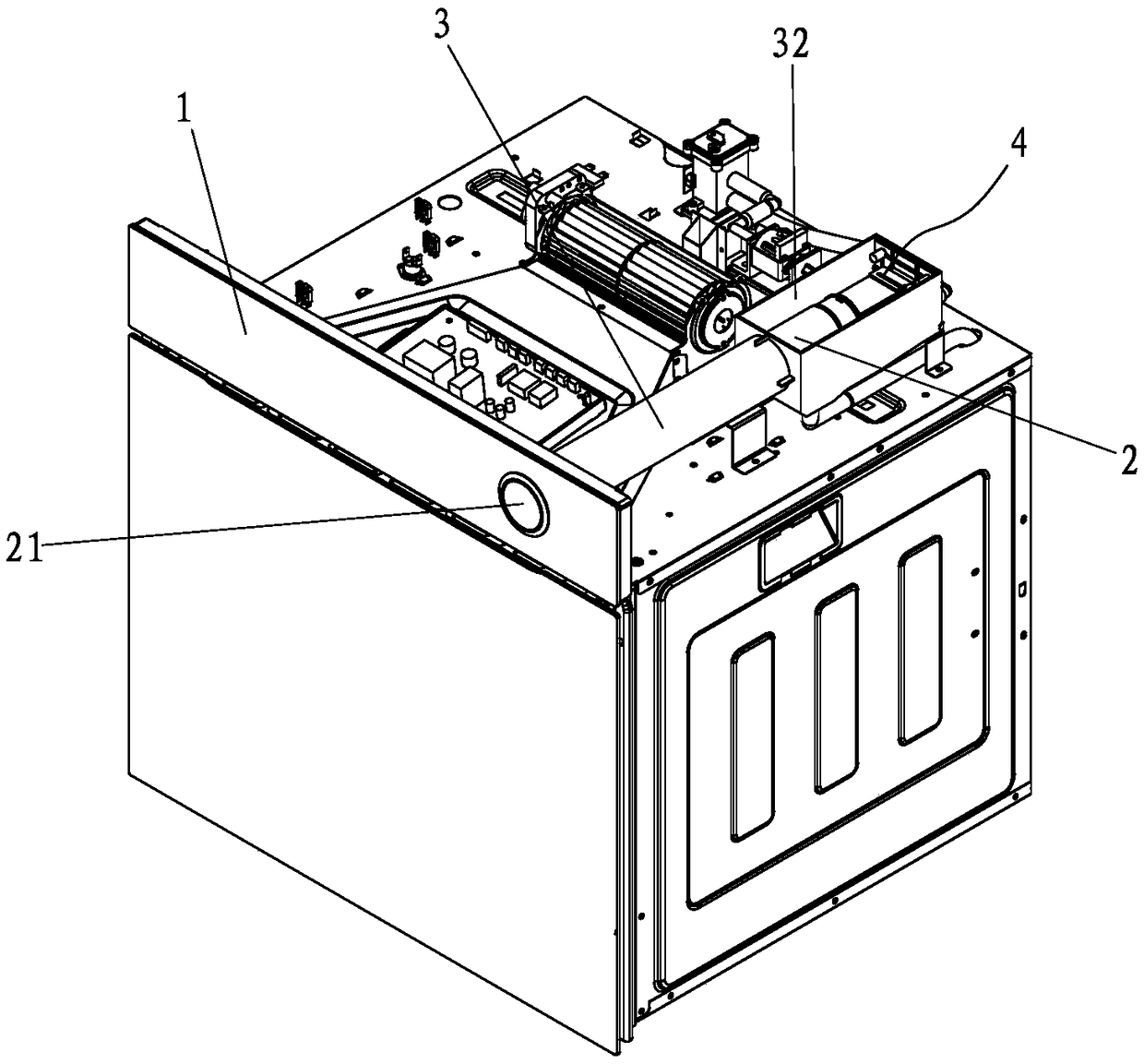

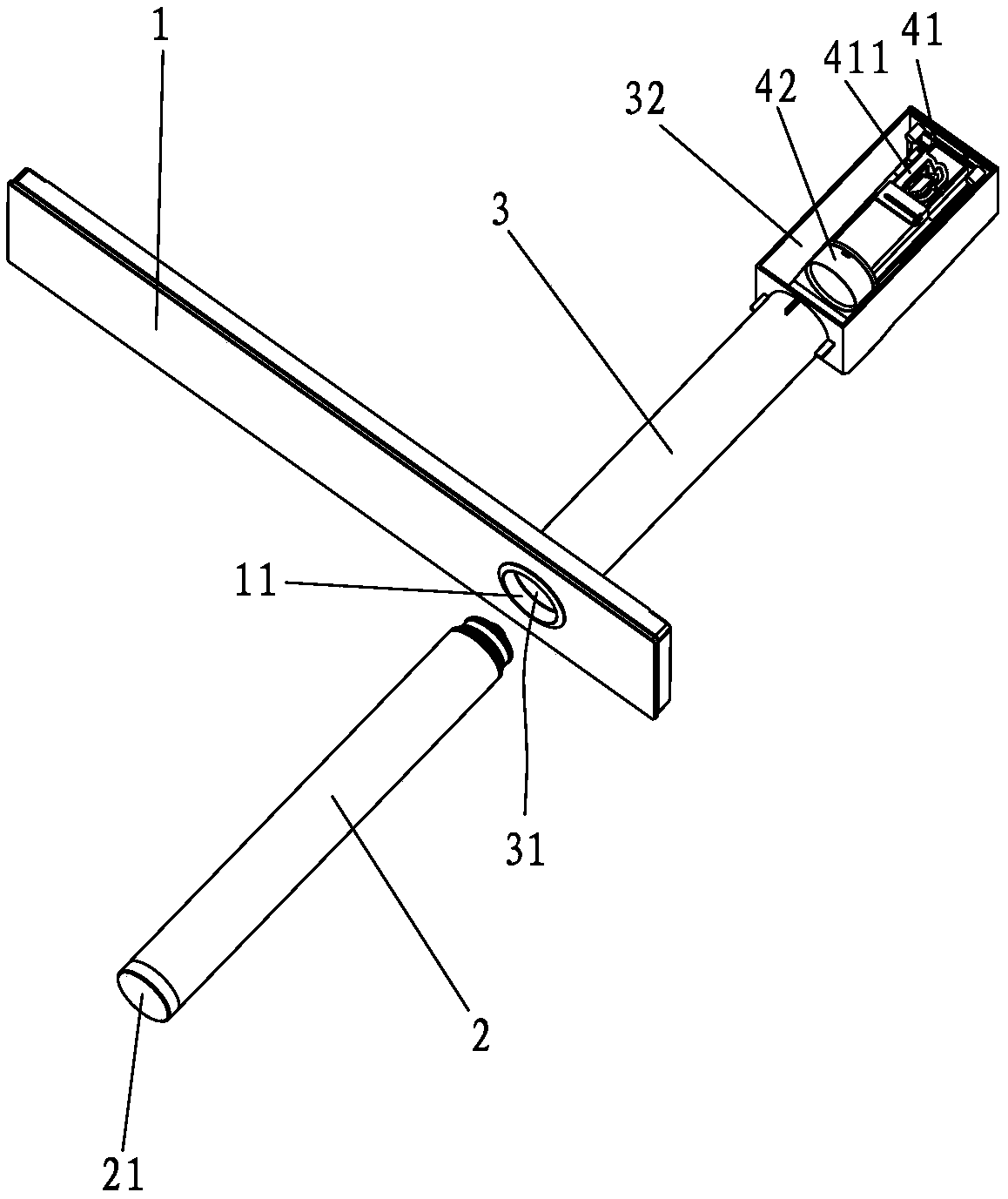

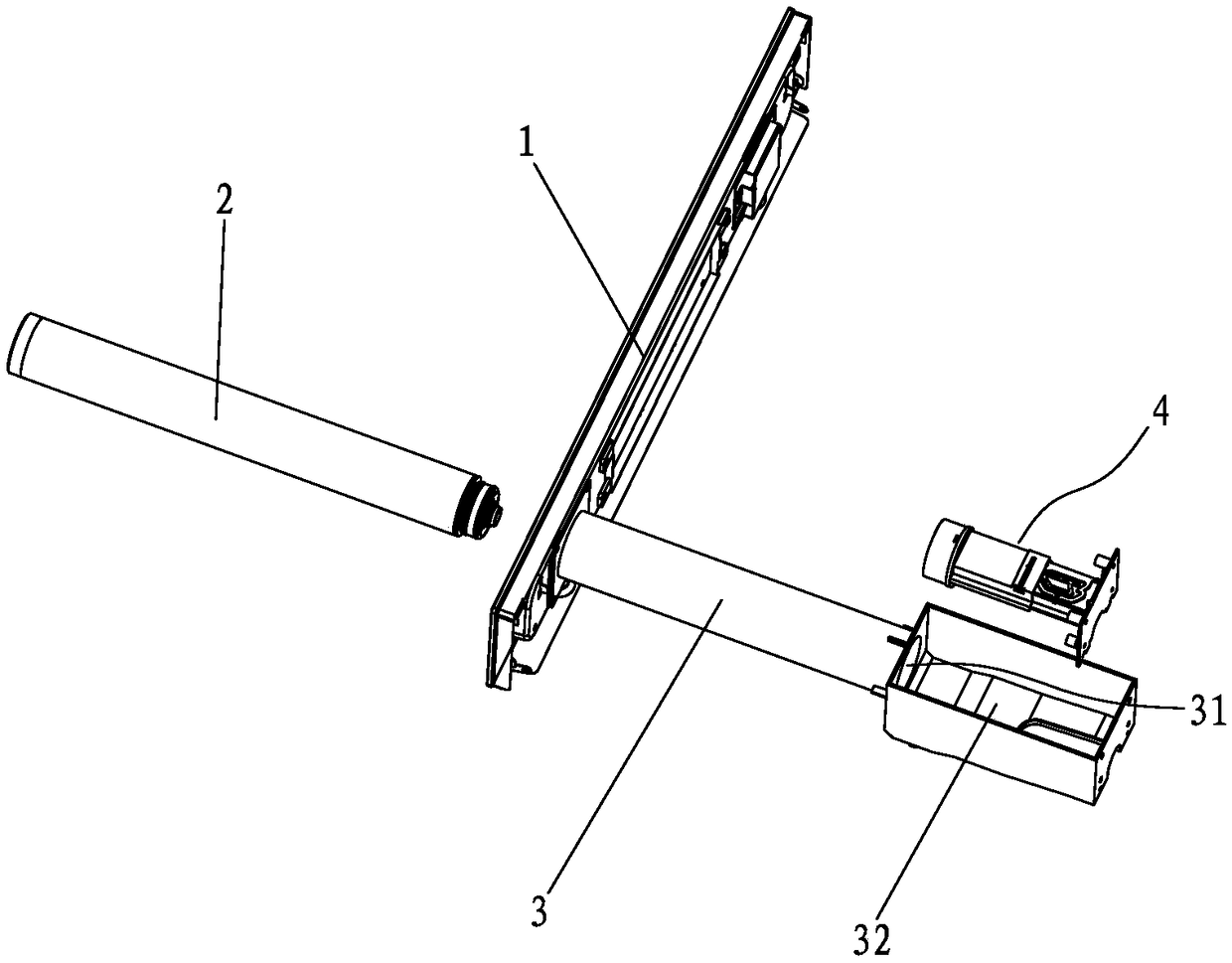

Embedding type and pulling type water tank mounting structure of electric oven

PendingCN108784404ASimple structureEasy to operateRoasters/grillsVolume bodyAgricultural engineering

The invention discloses an embedding type and pulling type water tank mounting structure of an electric oven. The embedding type and pulling type water tank mounting structure comprises a panel and awater tank which is a strip-shaped volume body, wherein a water tank fixing bracket used for fixing the water tank is arranged at the inner side of the panel, the water tank fixing bracket is providedwith an insertion hole for inserting of the water tank, the panel is provided with an insertion inlet corresponding to the insertion hole, the water tank is inserted into the insertion hole from theinsertion inlet, when the water tank is inserted at the water supply work position, a front end cover of the water tank is level with the front end of the panel, and the water tank fixing bracket is provided with an ejection mechanism capable of ejecting the water tank at the work position out of the front end of the panel. For the mounting structure provided by the invention, the water tank is detachably mounted in the electric oven in an embedding manner, meanwhile, the water tank can be taken out and mounted through the pulling and pushing methods for the water adding or drainage operation,the structure is simple, and the operation is convenient.

Owner:ZHONGSHAN HUANUO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com