Microfluid drive unit based on infiltration

A technology of driving device and osmosis, which is applied in the field of microfluidic driving device based on osmosis, can solve the problems of huge micropump driver, complex processing technology, difficult to replace liquid flow, etc., and achieve low cost, simple overall structure and high liquid flow rate. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

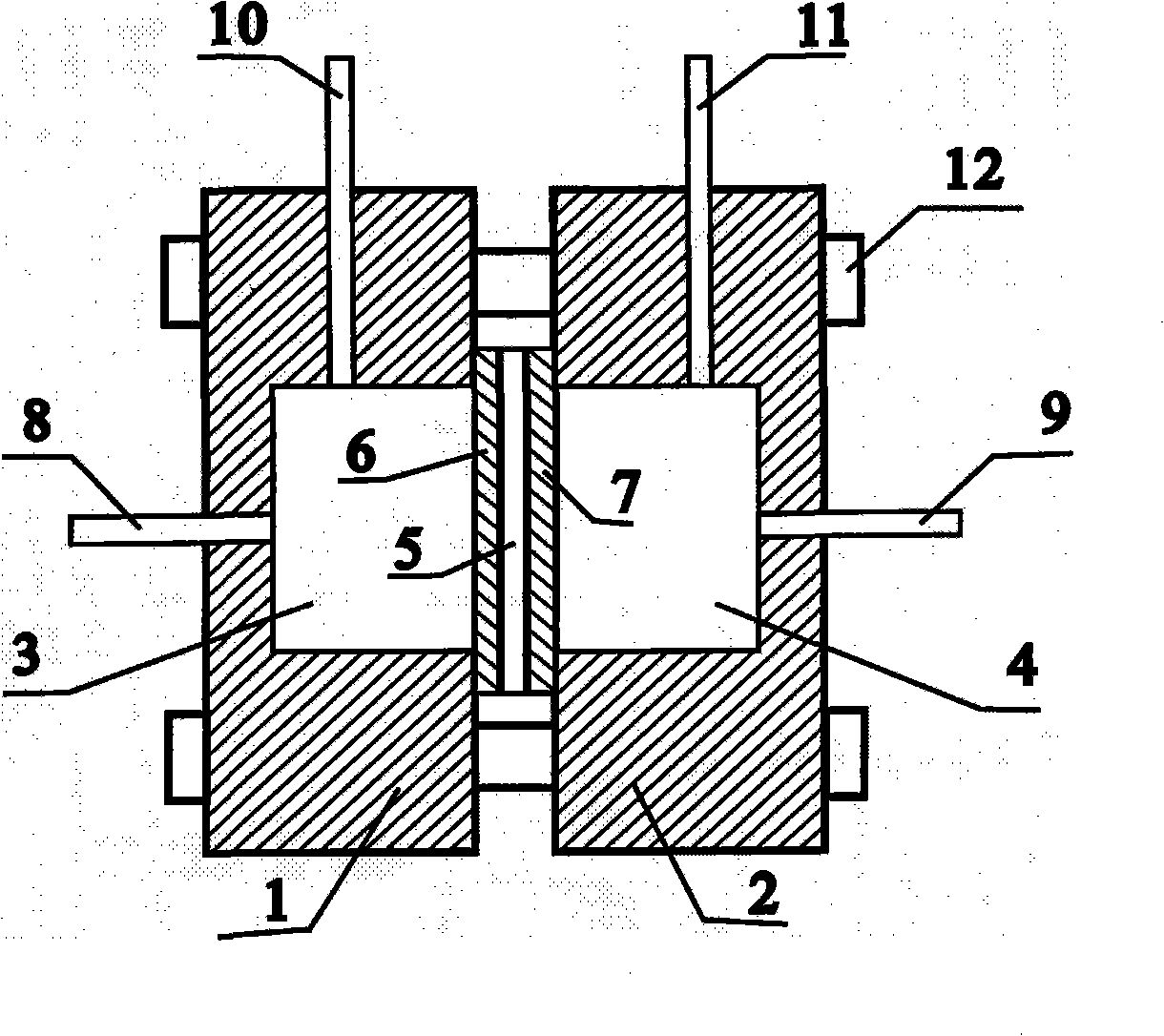

[0016] Example 1: The structure of the microfluid drive device of the present invention is as attached figure 1 As shown, there is a first pool body 1 with a first liquid storage tank 3 and a second pool body 2 with a second liquid storage tank 4, all of which are made of polymethyl methacrylate (purchased in the market), The volumes of the first liquid storage tank 3 and the second liquid storage tank 4 are equal, and on the inner side walls corresponding to each other of the first tank body 1 and the second tank body 2, there is a The opening of the liquid storage pool 4 communicates with the cavity. There is an inlet 8 of the first liquid storage pool 3 on the outer wall of the first pool body 1, and an outlet of the second liquid storage pool 4 on the outer wall of the second pool body 2. 9. There is an exhaust port 10 of the first liquid storage tank 3 on the first pool body 1, and an exhaust port 11 of the second liquid storage tank on the second pool body 2. The semi-p...

example 2

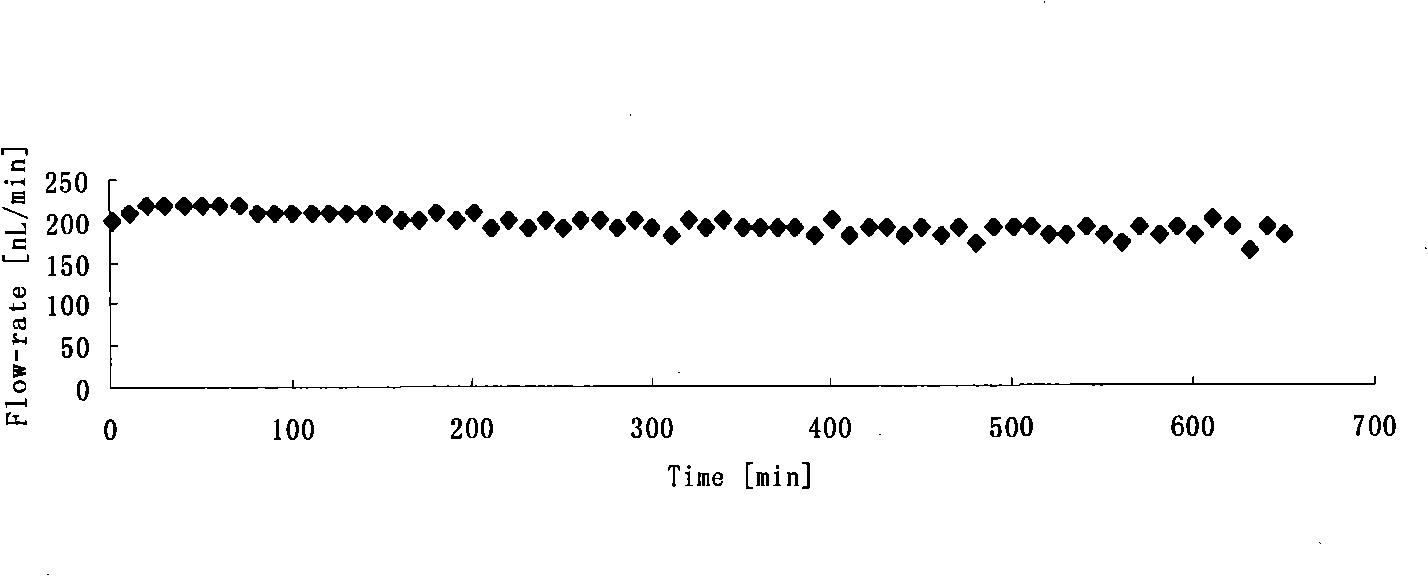

[0018] Example 2: The device structure and operation steps are the same as Example 1, the difference is that the osmotic driving reagent is selected as 40 mg mL -1 Polyvinylpyrrolidone (PVPK17, molecular weight 8000, pharmaceutical grade, purchased from Henan Boai Xinkaiyuan Pharmaceutical Co., Ltd.) solution, the test result is that the average flow rate in 650min is 195nLmi n- 1, RSD is 7.0% (n=66), such as image 3 .

example 3

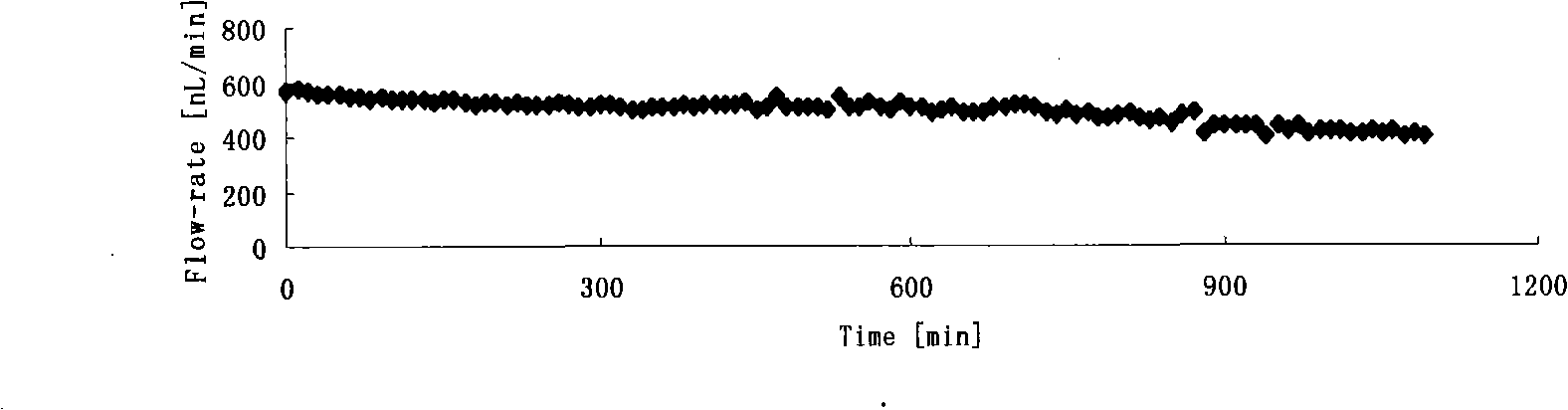

[0019] Example 3: The device structure and operation steps are the same as Example 1, the difference is that the osmotic driving reagent is selected as 200 mg mL -1 The PVPK25 (molecular weight 34000, pharmaceutical grade, purchased from Henan Boai Xinkaiyuan Pharmaceutical Co., Ltd.) achieved a record of continuous work within 294 hours. Flow rate from 650nL min -1 down to 120nL min -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com