Small environment-friendly incinerator for garbage disposal

A technology for garbage disposal and incinerator, which is applied in incinerators, combustion methods, combustion types, etc., and can solve the problems of less space for incineration, complex structure, easy generation of garbage residue or incineration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

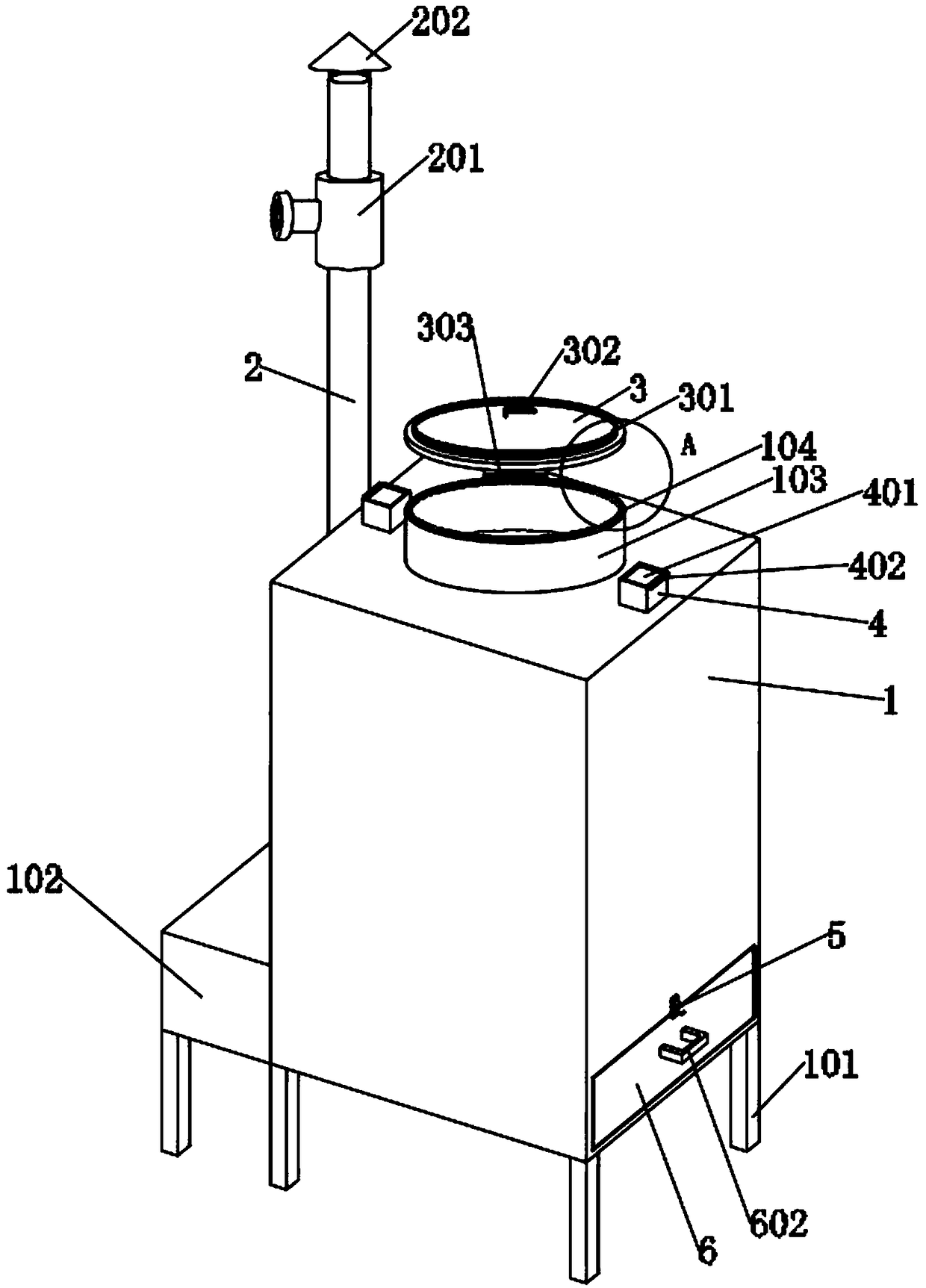

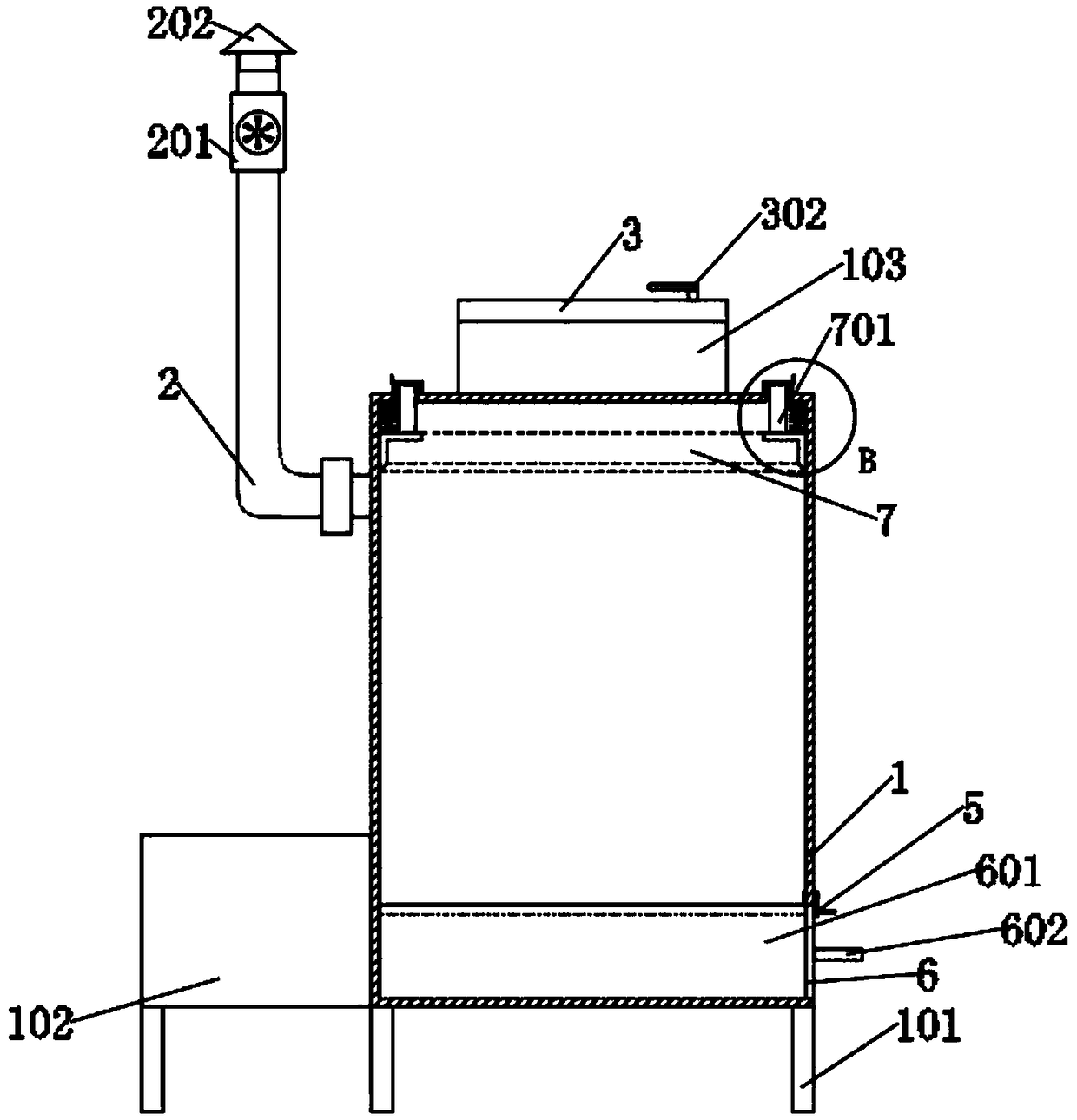

[0035] as attached figure 1 to attach Figure 10 Shown:

[0036] The invention provides a small environment-friendly incinerator for garbage disposal,

[0037] The invention provides a small heating furnace device, a temperature sensor, a conveyor belt, an internal heat insulation layer,

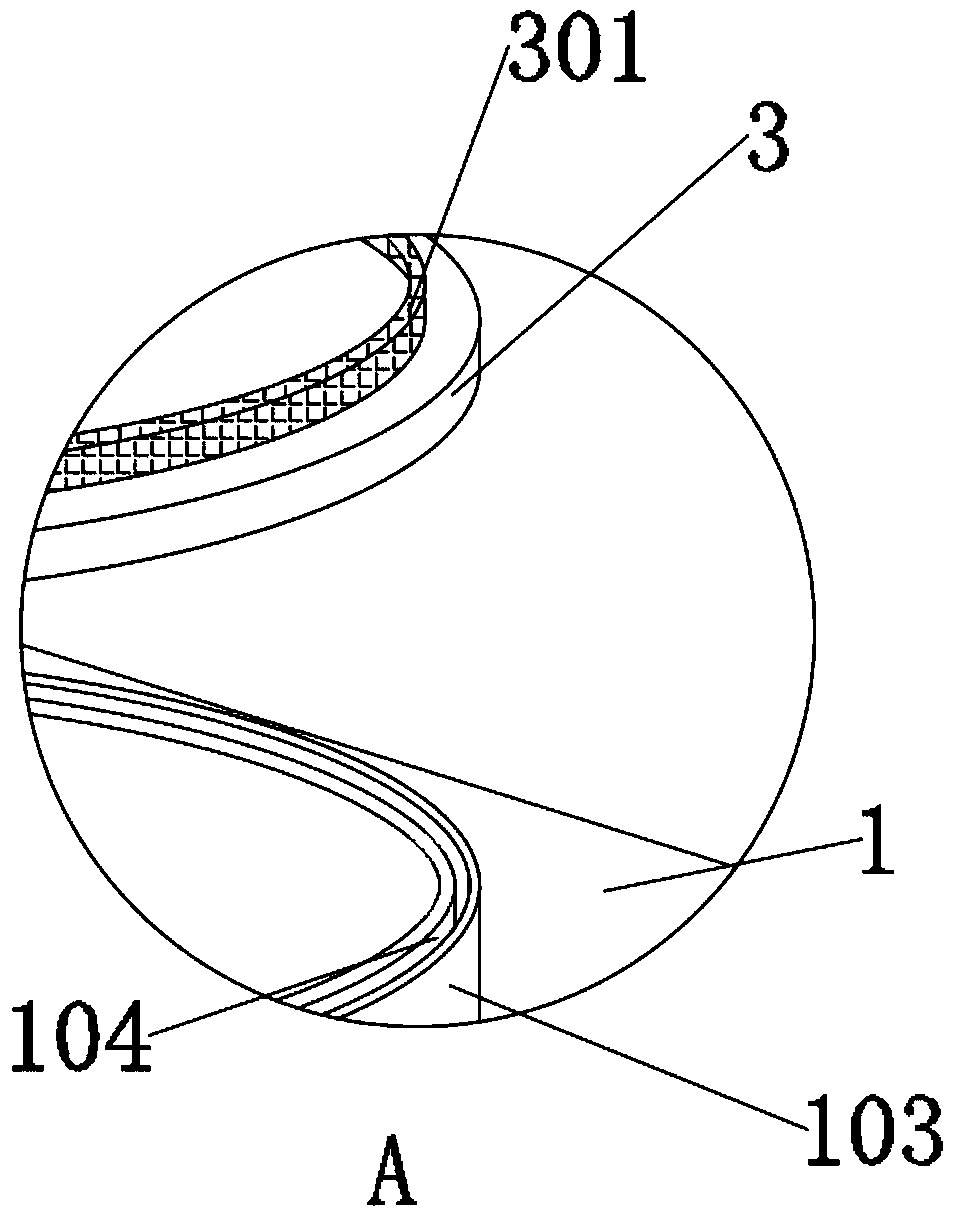

[0038] Including main body 1, support foot 101, burner 102, feed port 103, sealing groove 104, discharge pipe 2, smoke and dust purifier 201, rain cover 202, sealing cover 3, sealing strip 301, rotary switch 302, connecting shaft 303, Sealing port 4, sealing plate 401, sealing handle 402, rotating baffle 5, rotating member 501, rotating shaft 502, rotating stopper 503, drawing panel 6, drawing inner part 601, handle 602, slide rail 603, moving parts 7. Connecting piece 701, connecting thread 702, retractable spring 703, mounting piece 8, threaded head 801, hand piece 802, temperature sensor, conveyor belt, internal heat insulation layer,

[0039] The main body 1 is a rectangular internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com