Patents

Literature

164results about "Boiler flue tubes/fire tubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

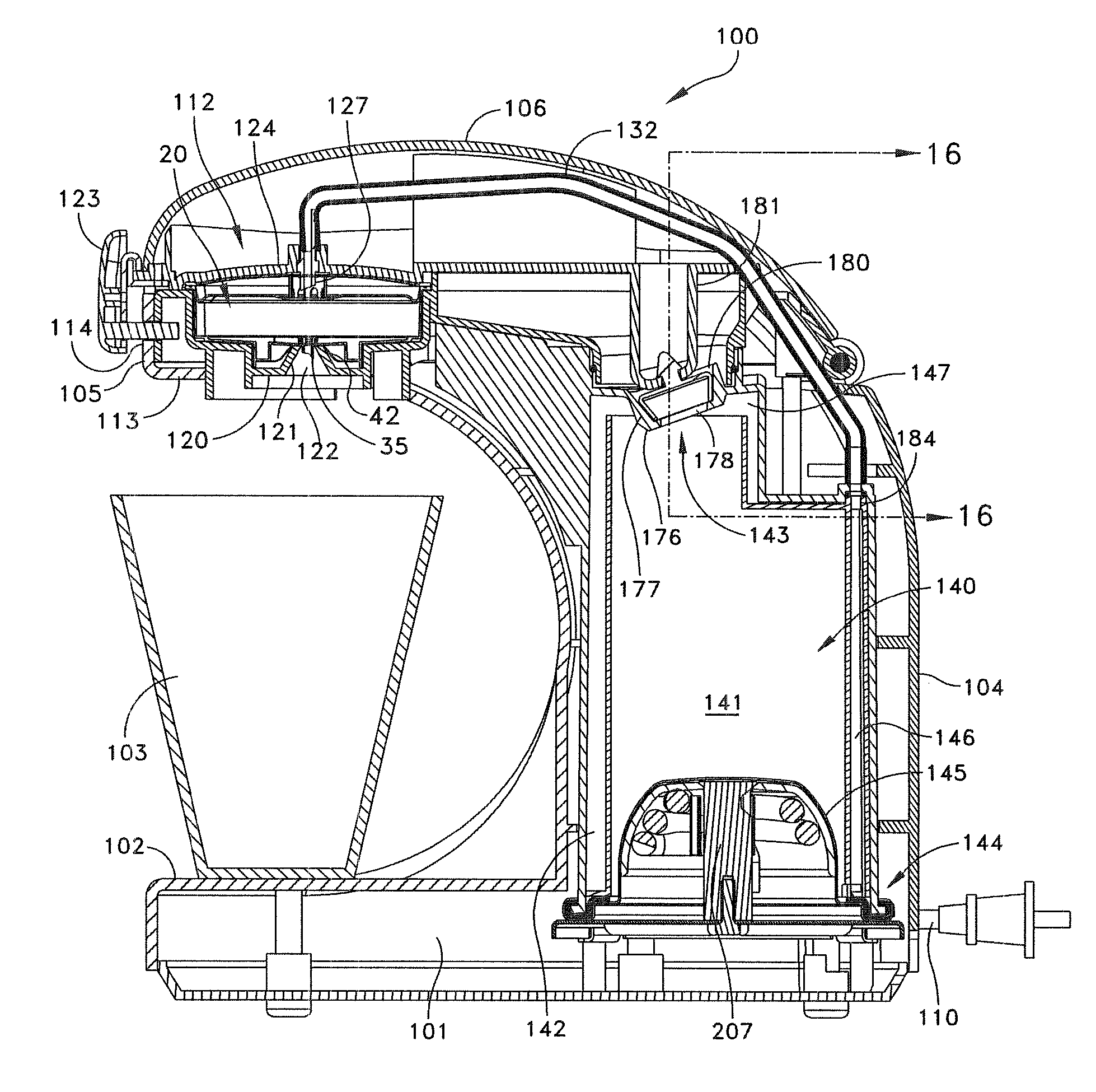

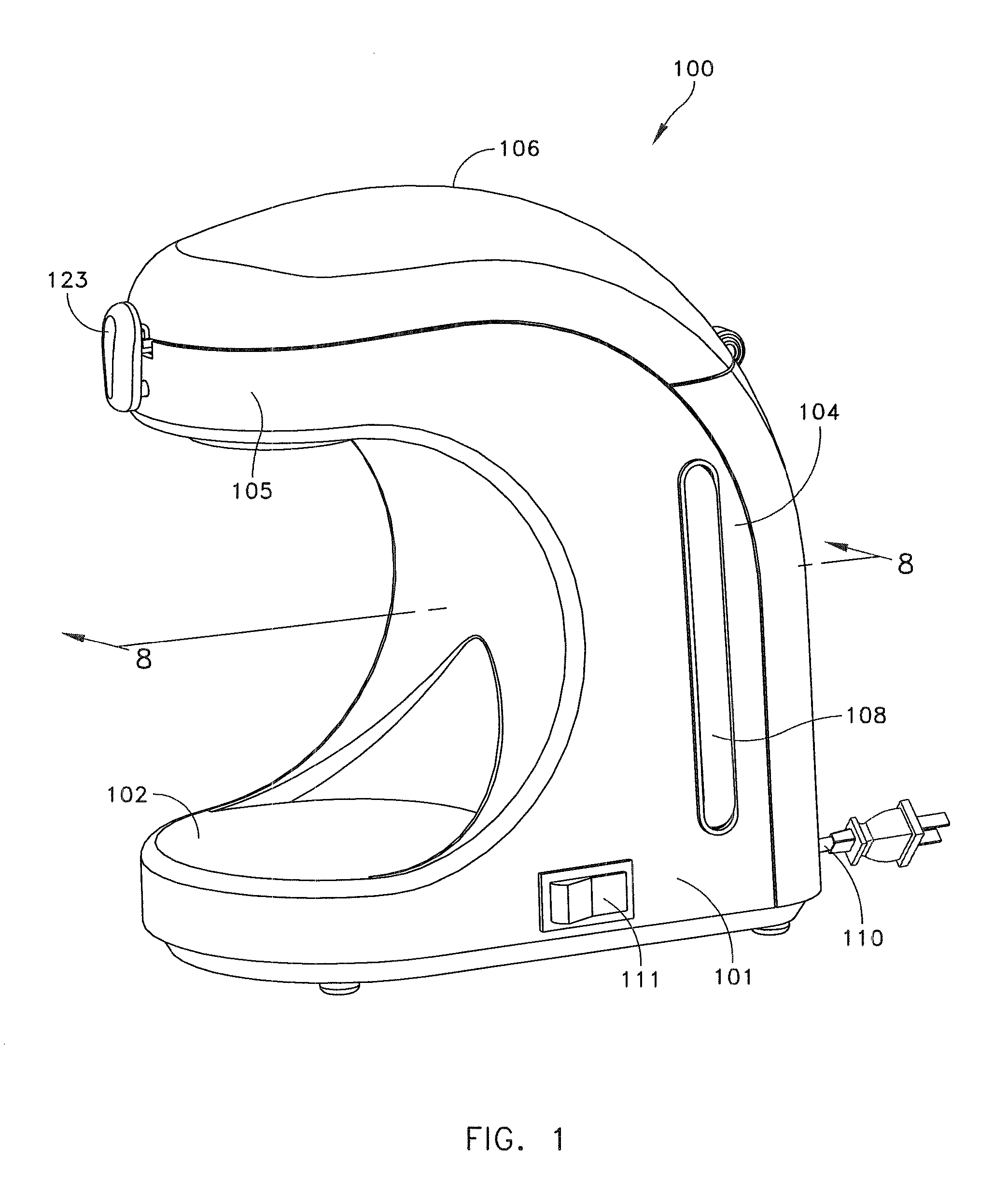

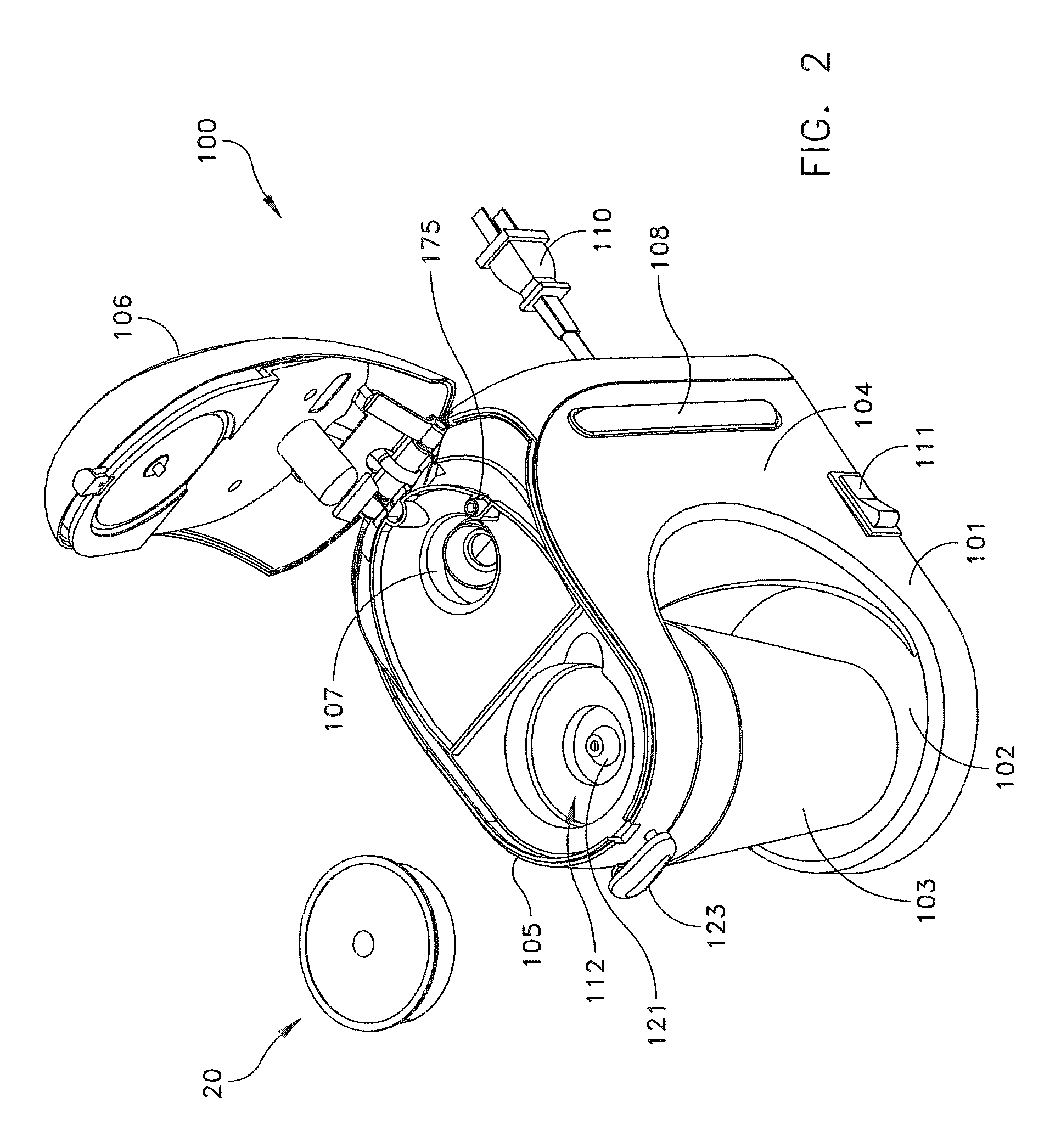

Hot beverage brewing apparatus

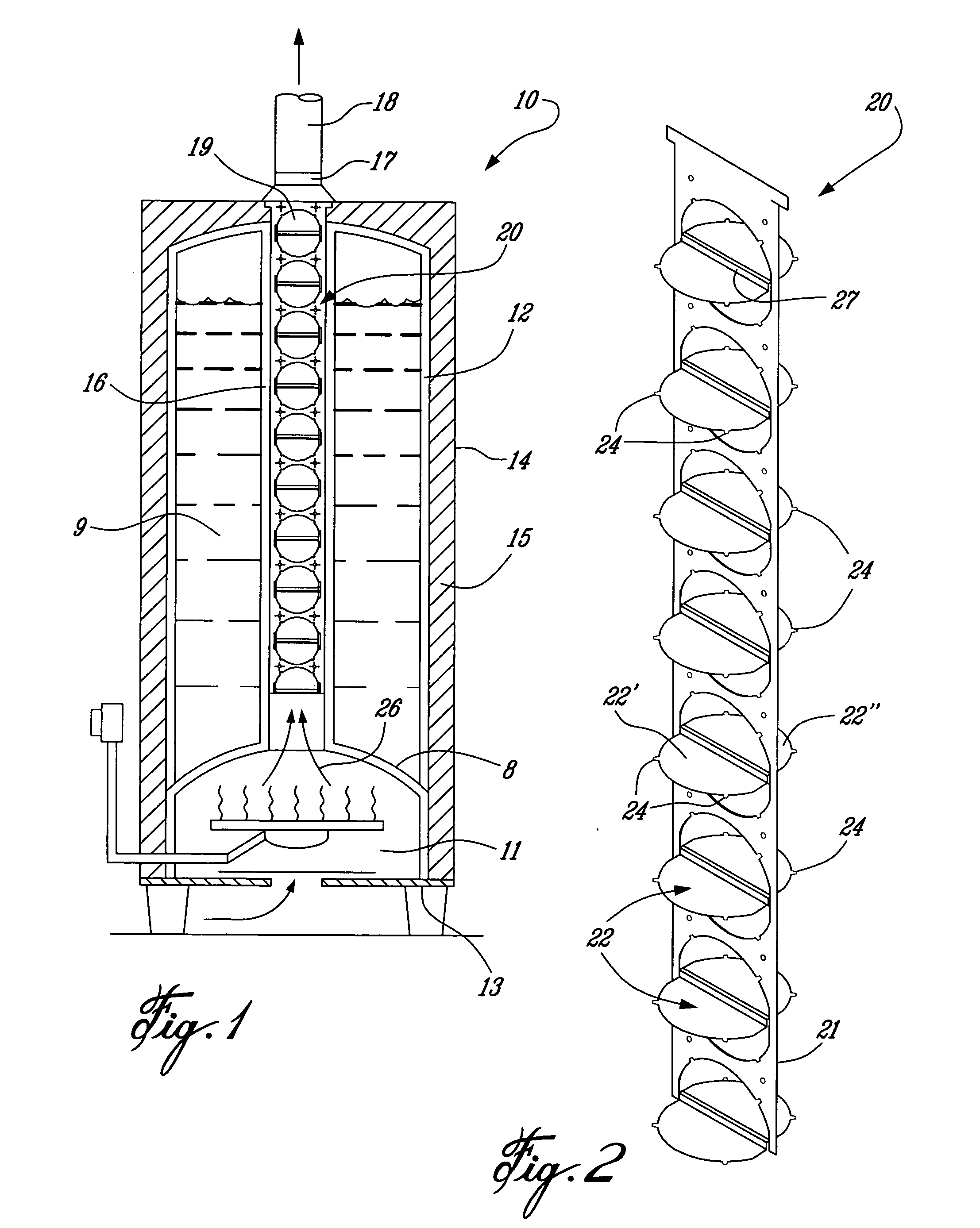

ActiveUS20090007792A1Easy to controlCompact and reliable and inexpensive to manufactureSteam generation heating methodsBoiler flue tubes/fire tubesProcess engineeringHot liquids

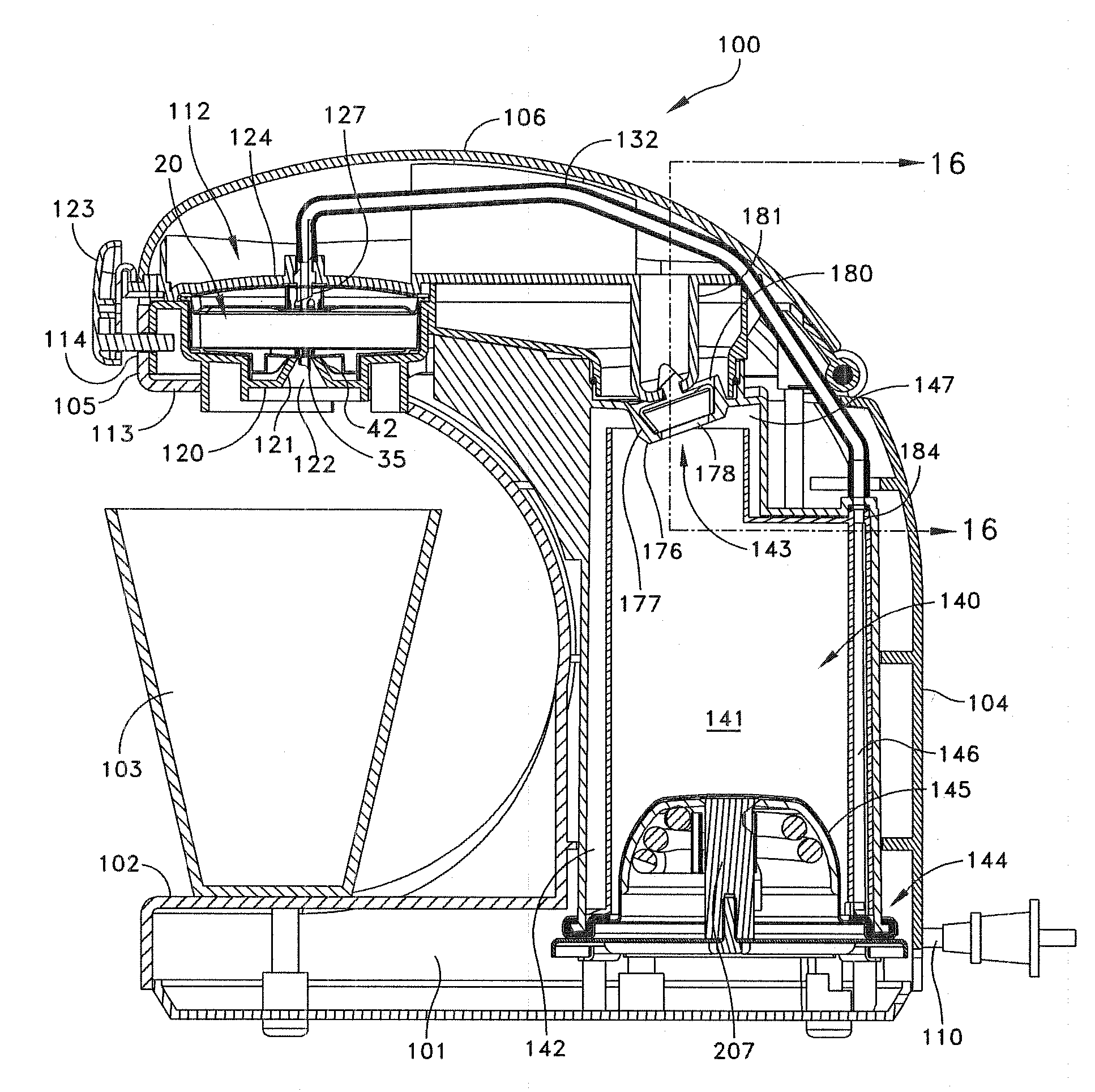

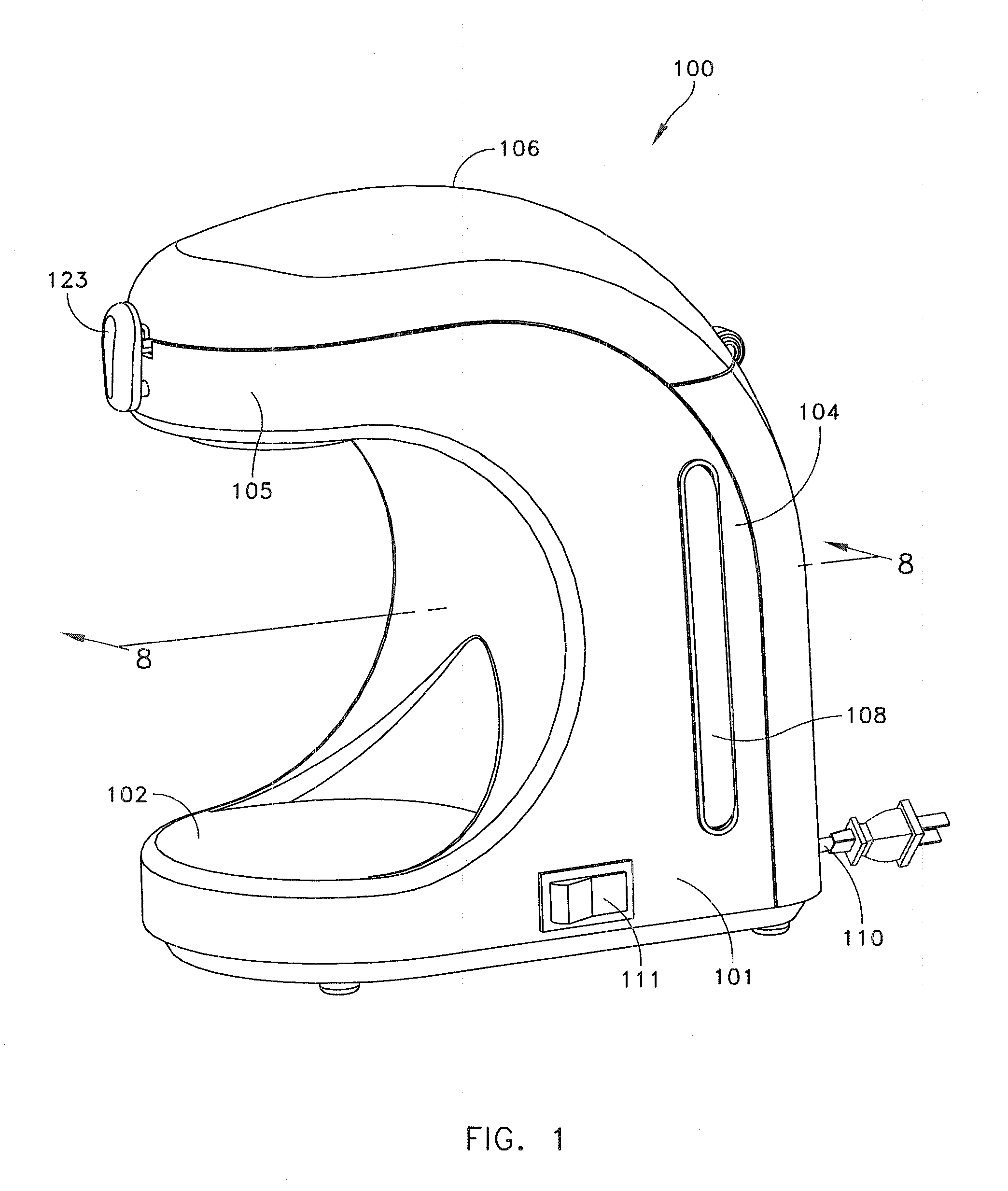

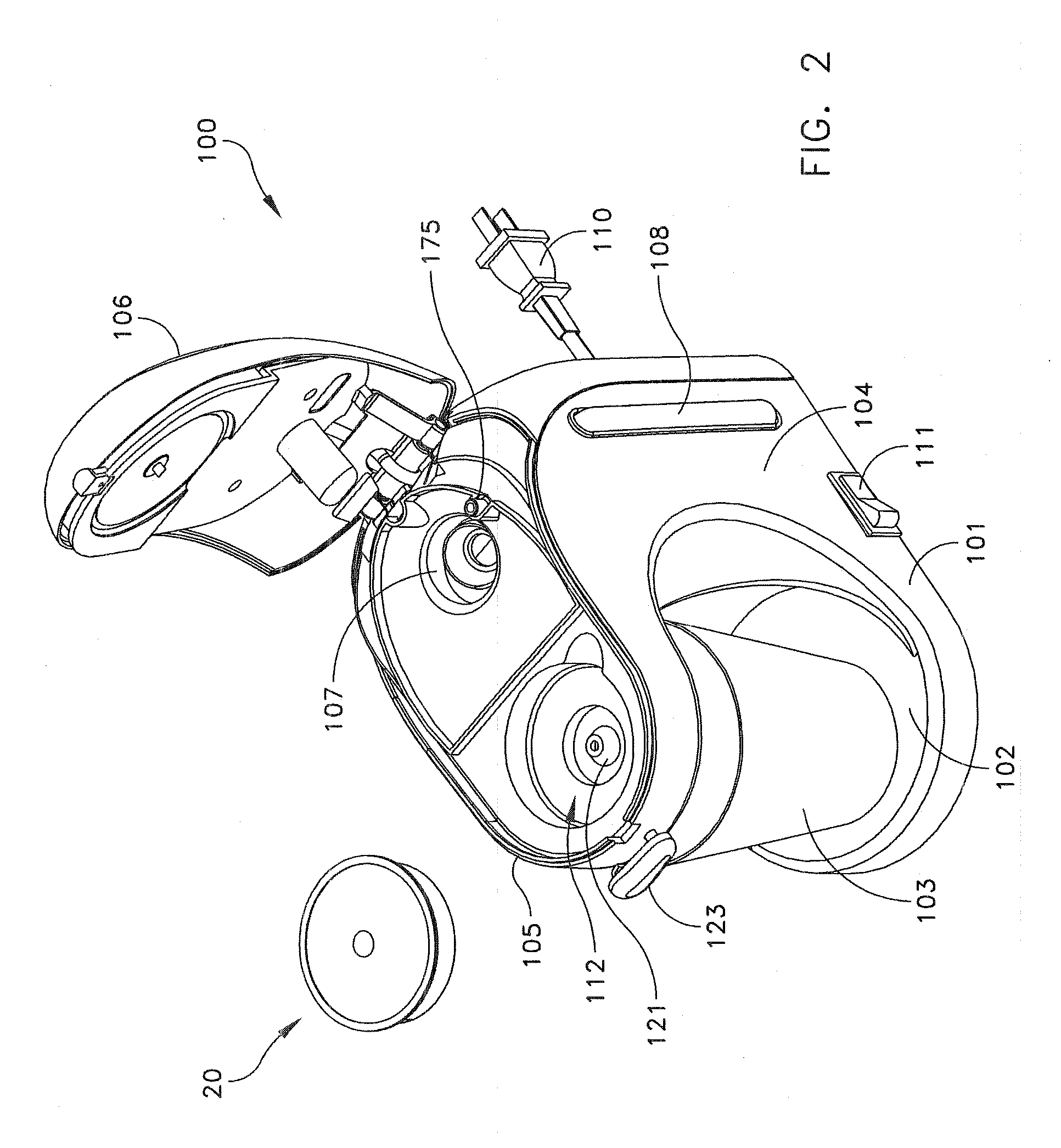

A hot beverage brewing apparatus. A pressurized hot liquid delivery system provides liquid under pressure within a range of acceptable brewing temperatures without any mechanical pump. Water is apportioned into sealable tank volumes, one of which is heated to boil the liquid and produce steam under pressure. The pressurized steam displaces the liquid from the tank volumes in proportion and at a temperature that is within the acceptable brewing range. The hot liquid under pressure is directed to a capsule receiving station to infuse a material in a capsule. The capsule dispenses the brewed beverage without contacting the brewing apparatus.

Owner:SOLABEV

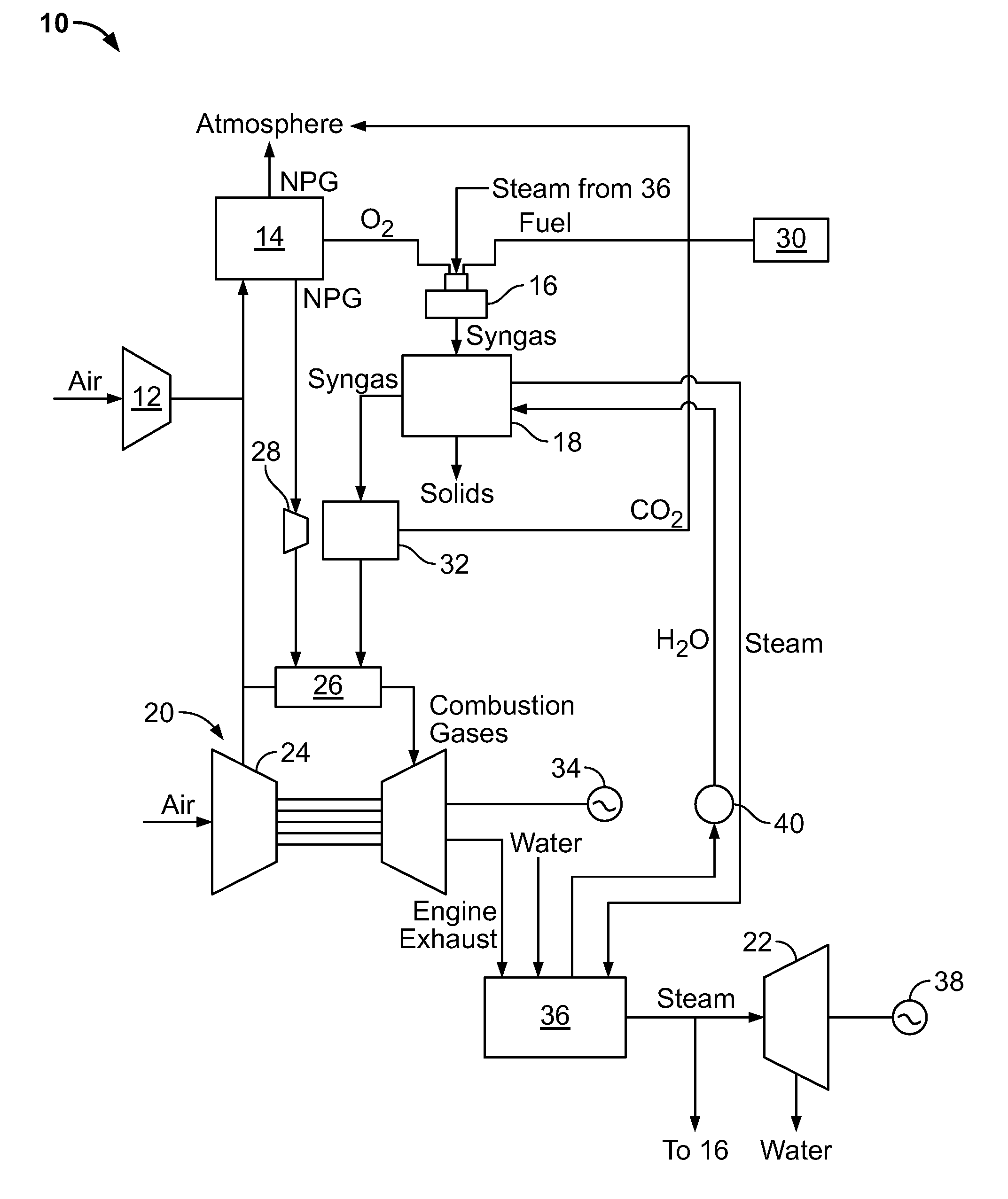

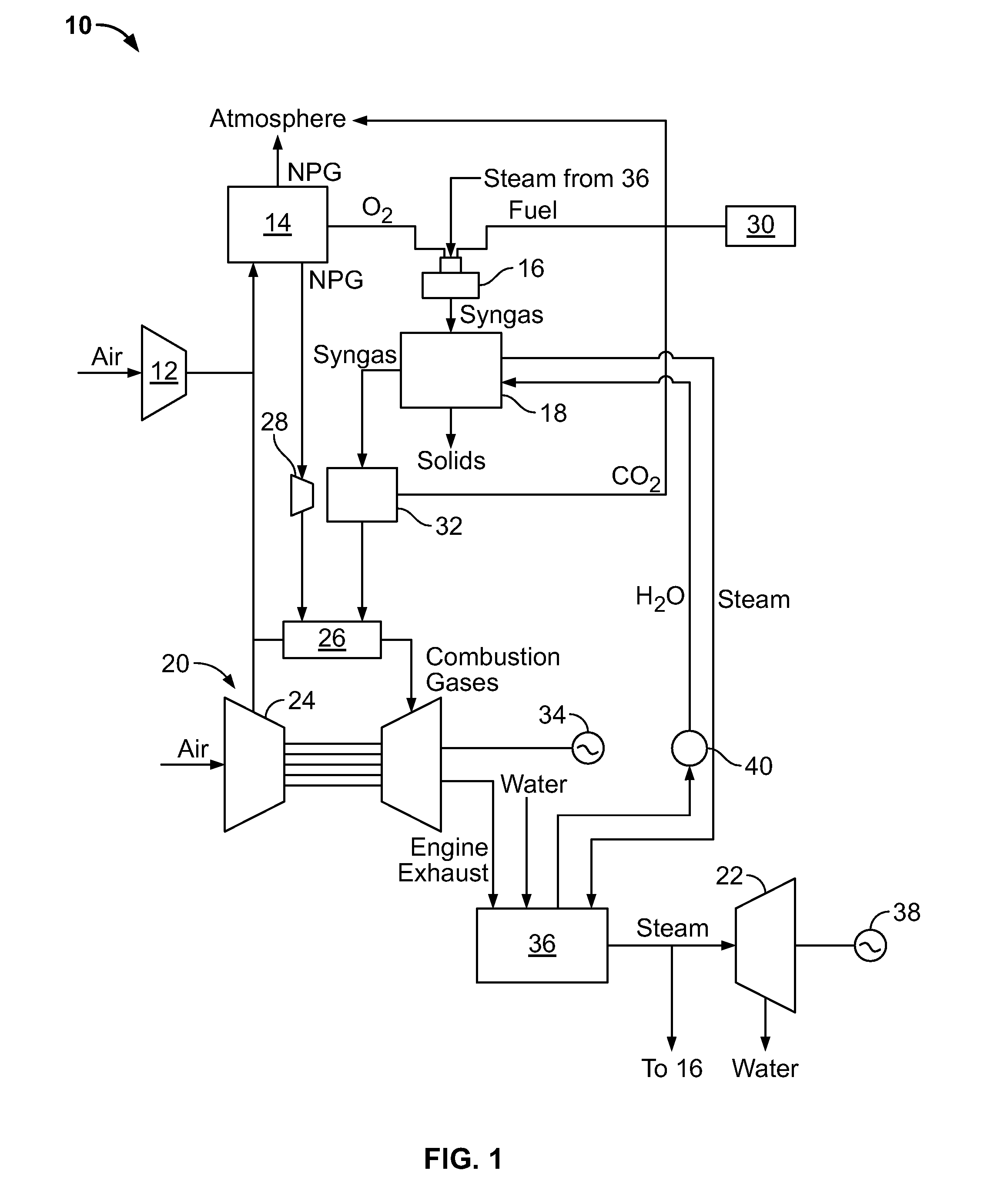

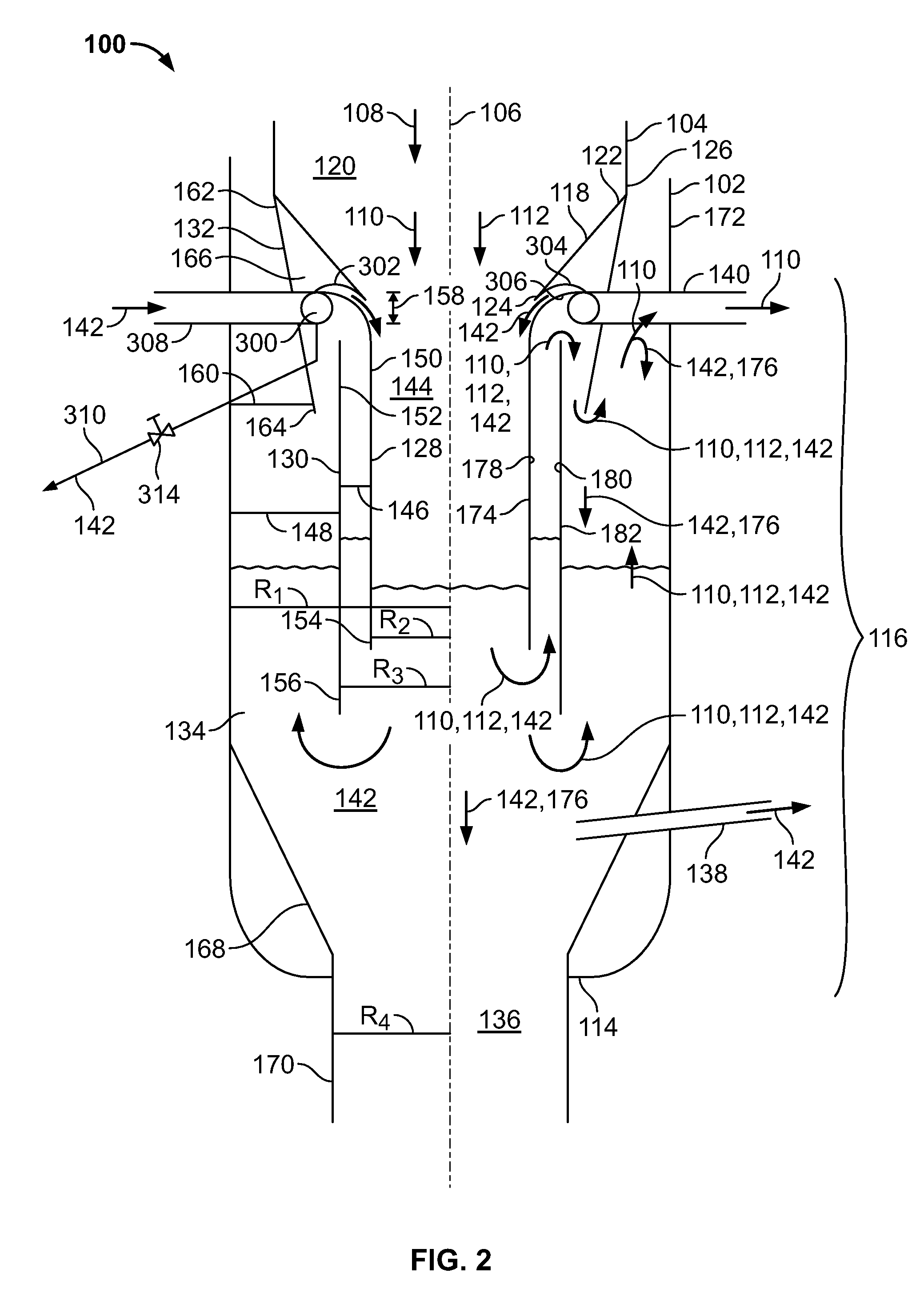

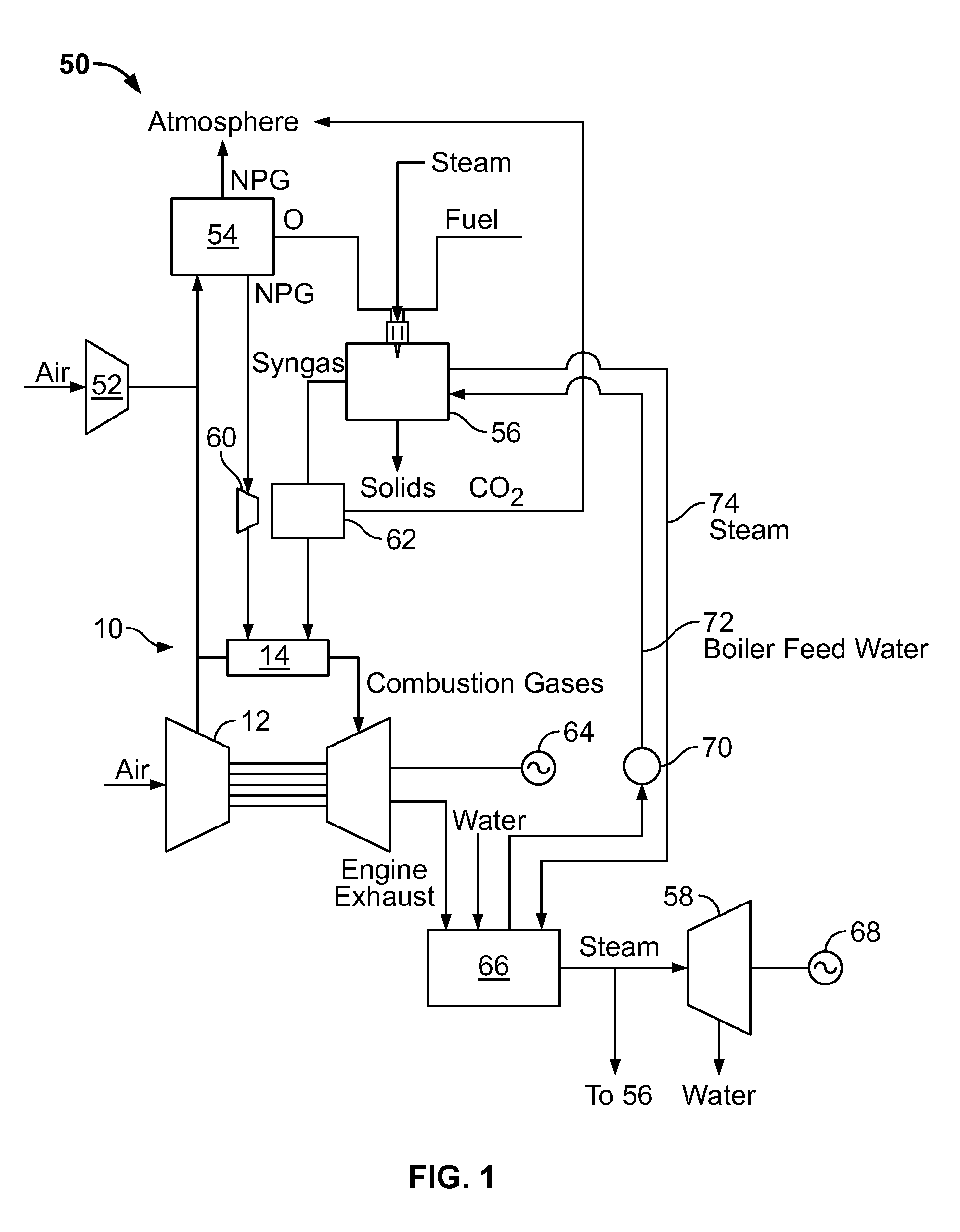

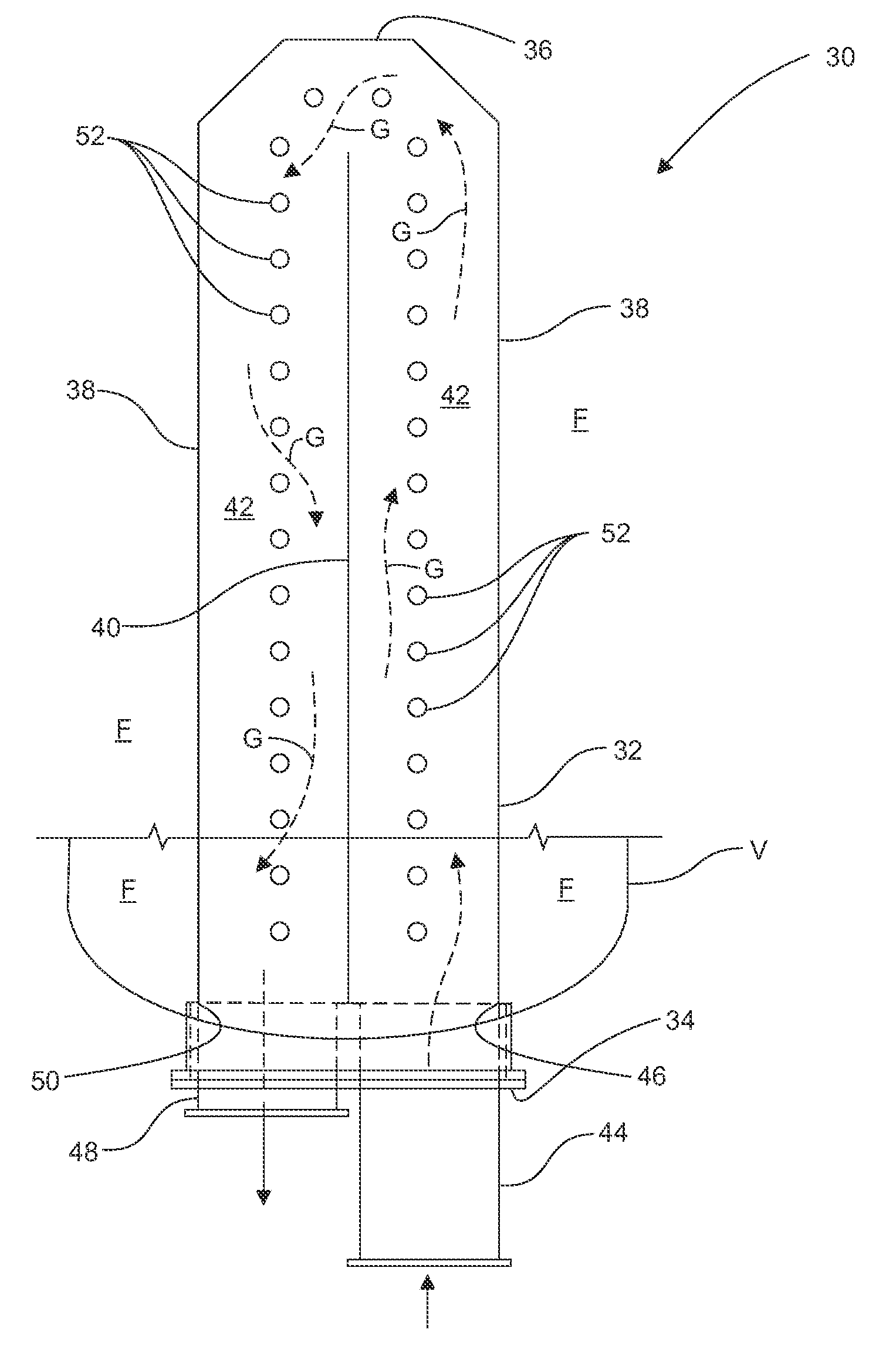

Methods and apparatus for cooling syngas within a gasifier system

A method for operating a syngas cooler is provided. The method includes channeling a flow of syngas into an annular cooling chamber having a longitudinal axis, injecting a cooling fluid into a manifold such that the cooling fluid is channeled substantially circumferentially about the annular cooling chamber, and discharging the cooling fluid from the manifold such that the cooling fluid contacts a surface of the cooling chamber at a predetermined angle relative to the axis of the cooling chamber.

Owner:AIR PROD & CHEM INC

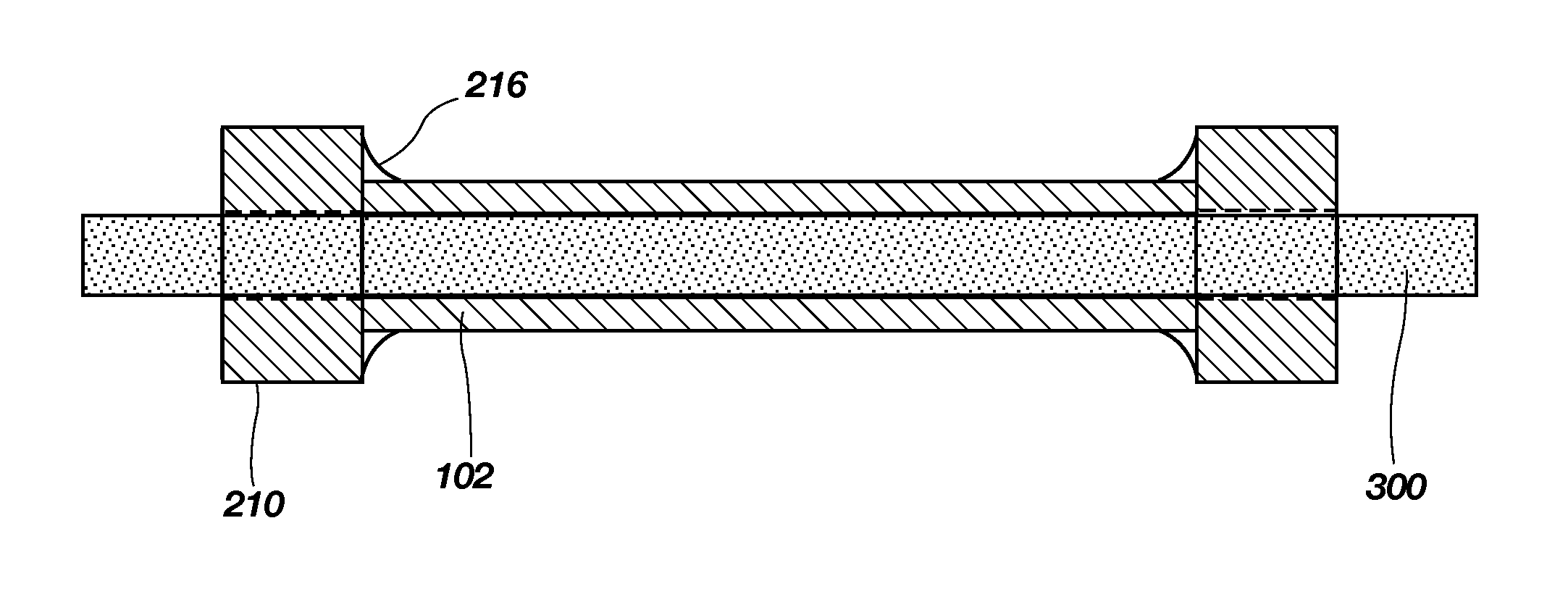

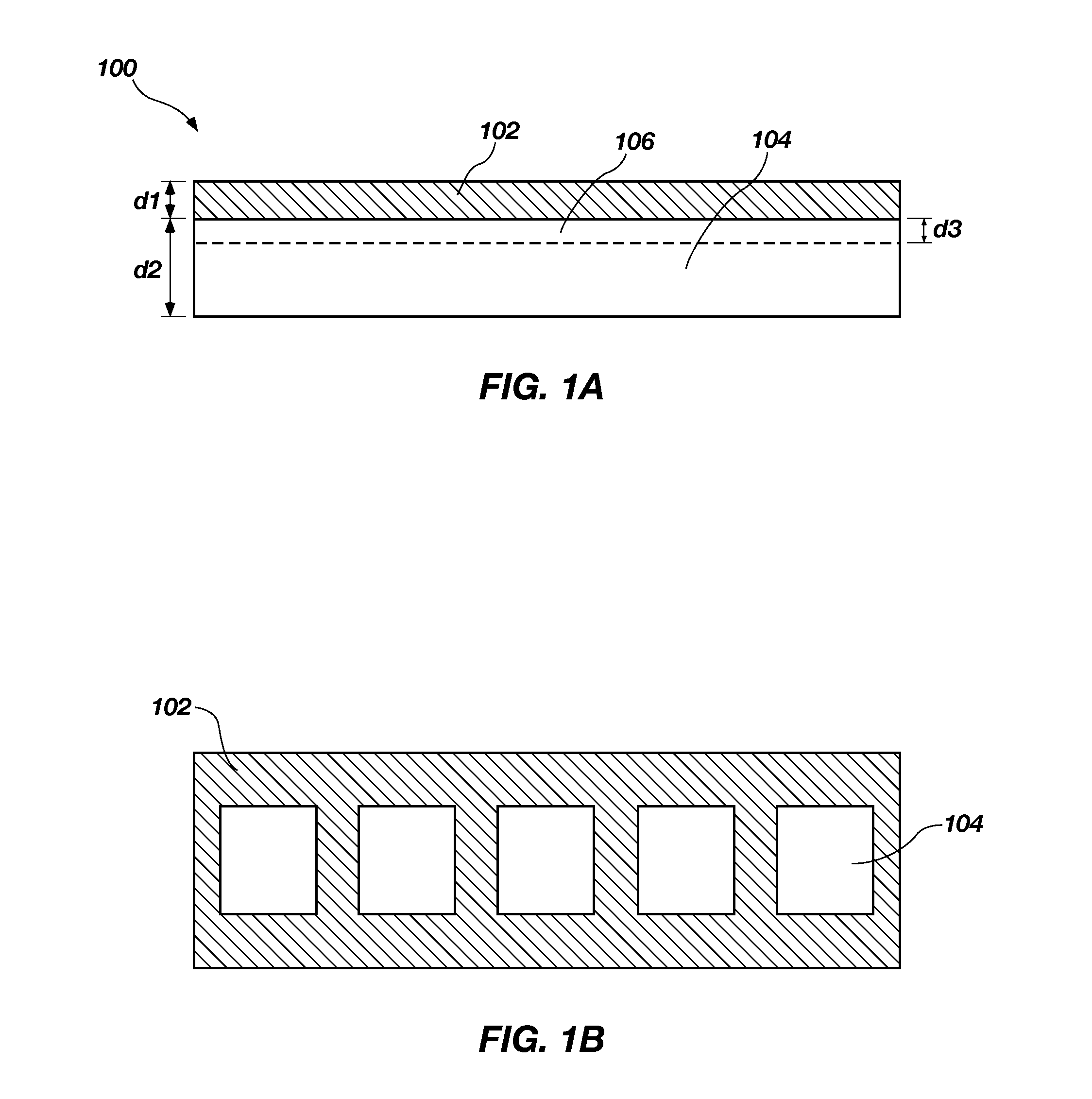

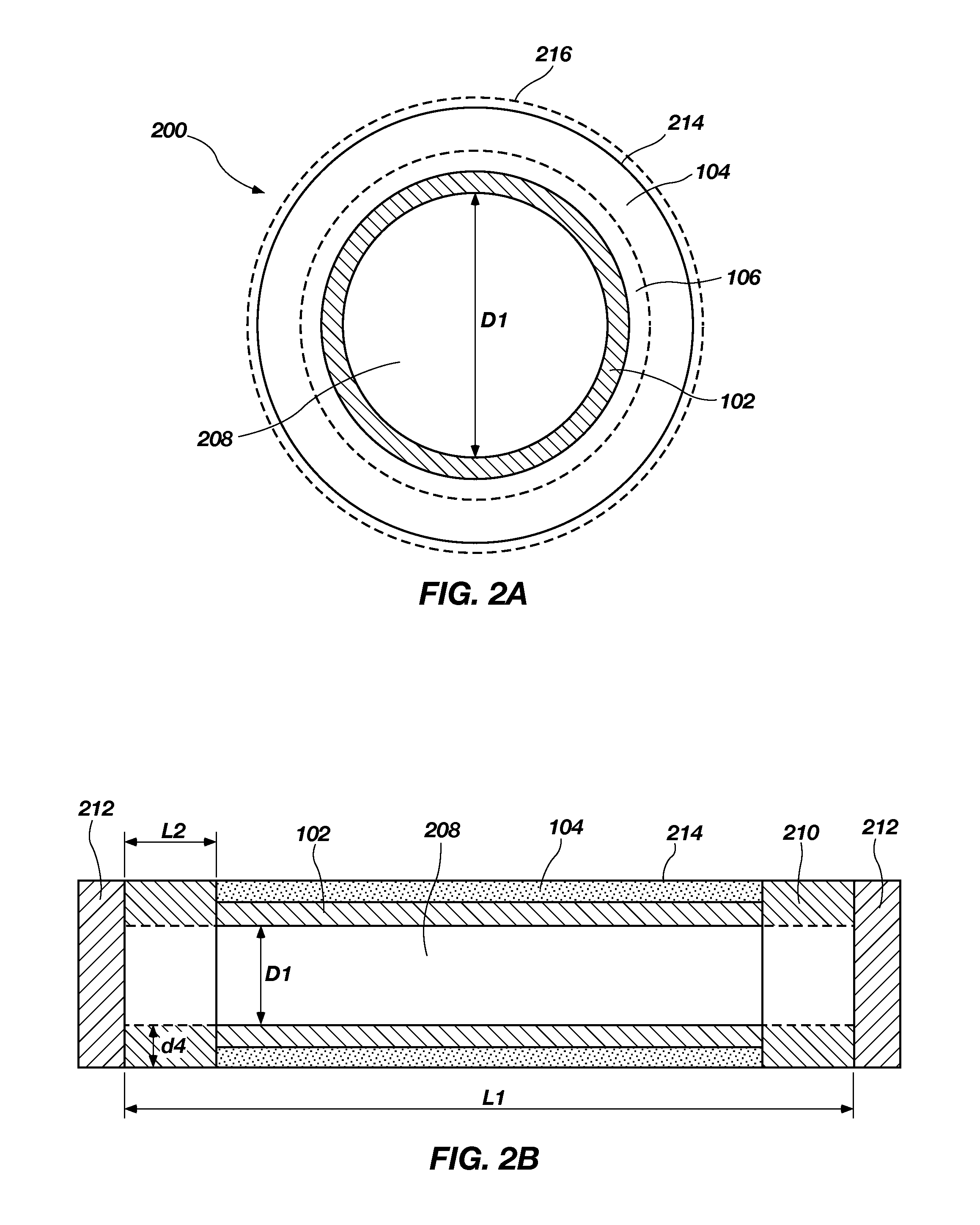

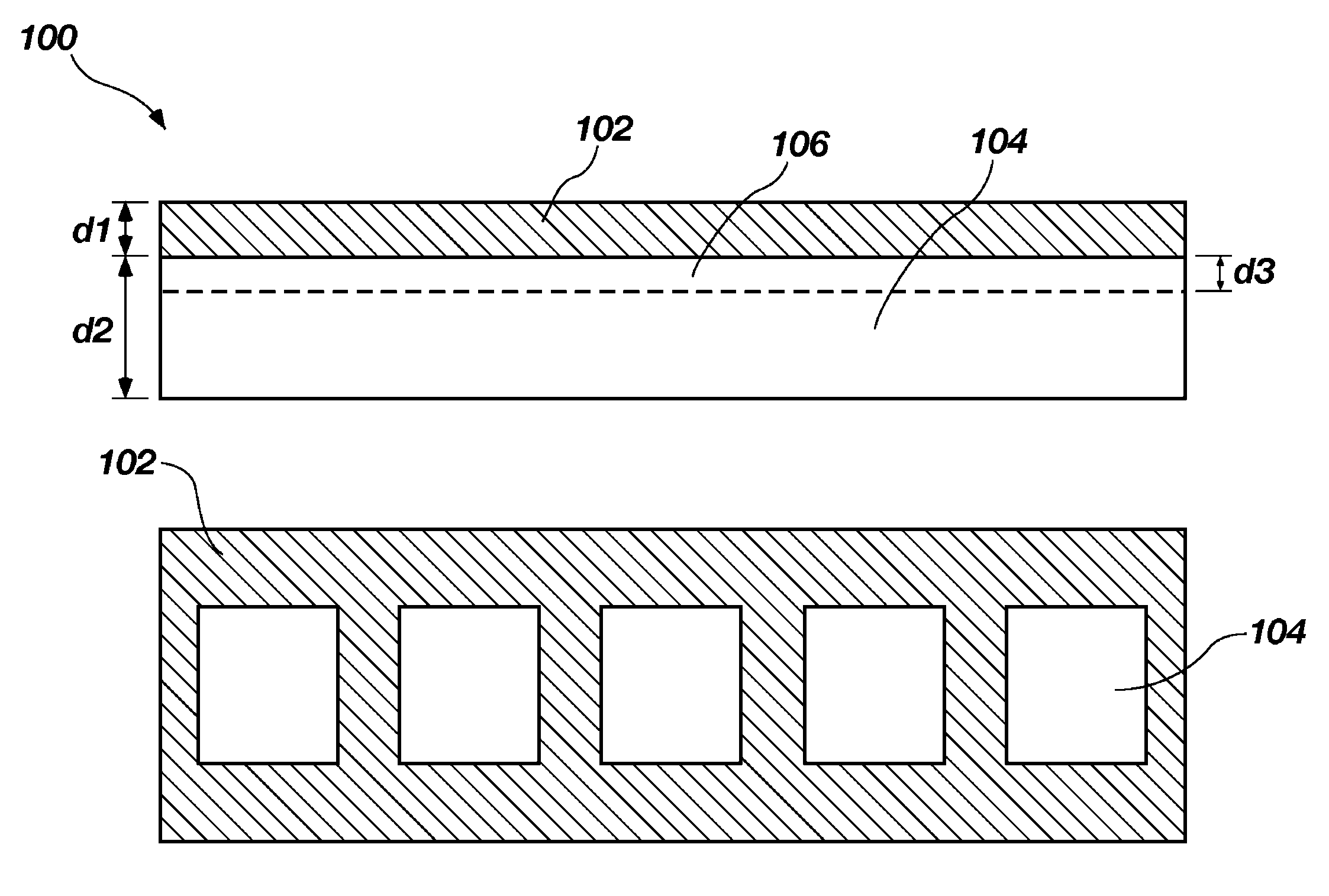

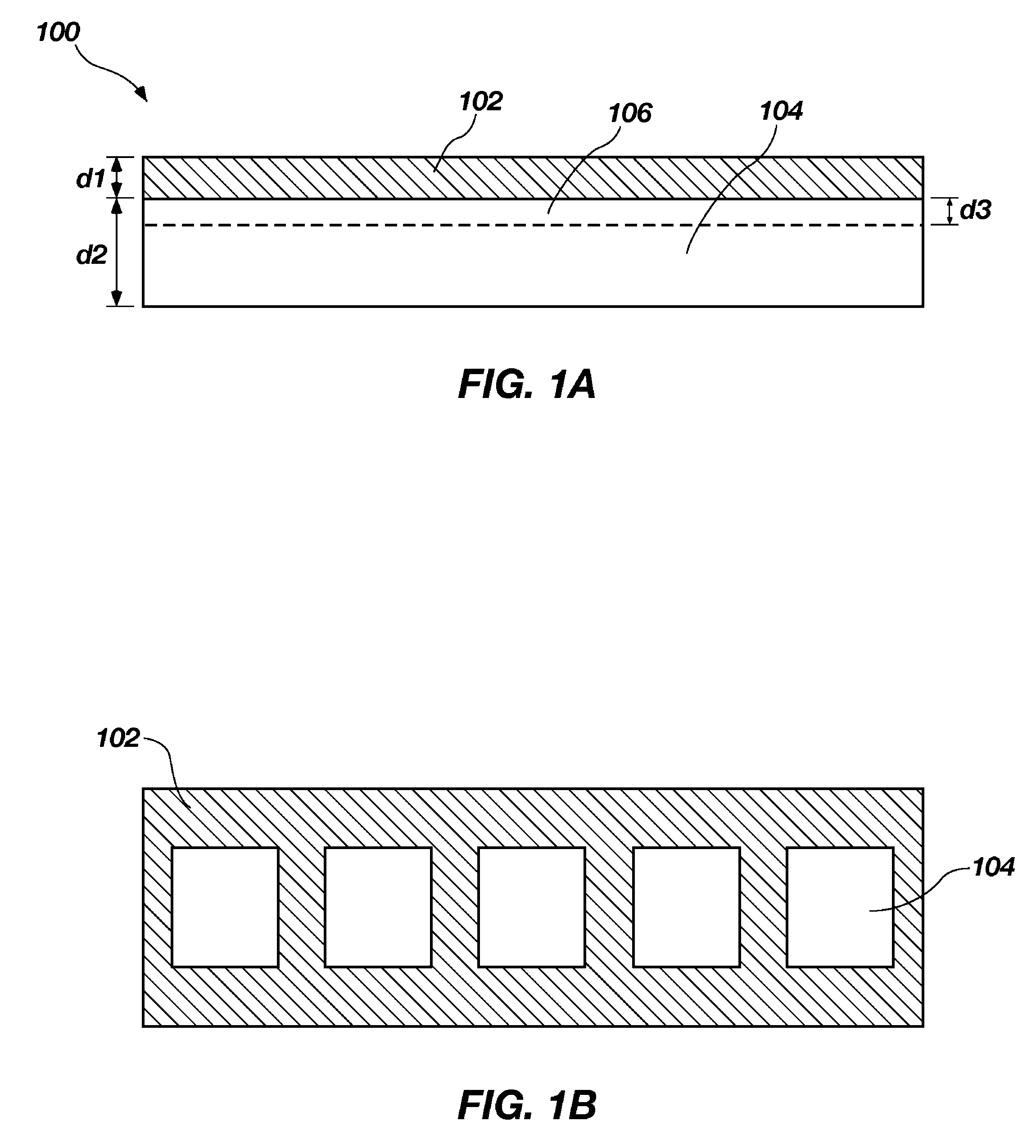

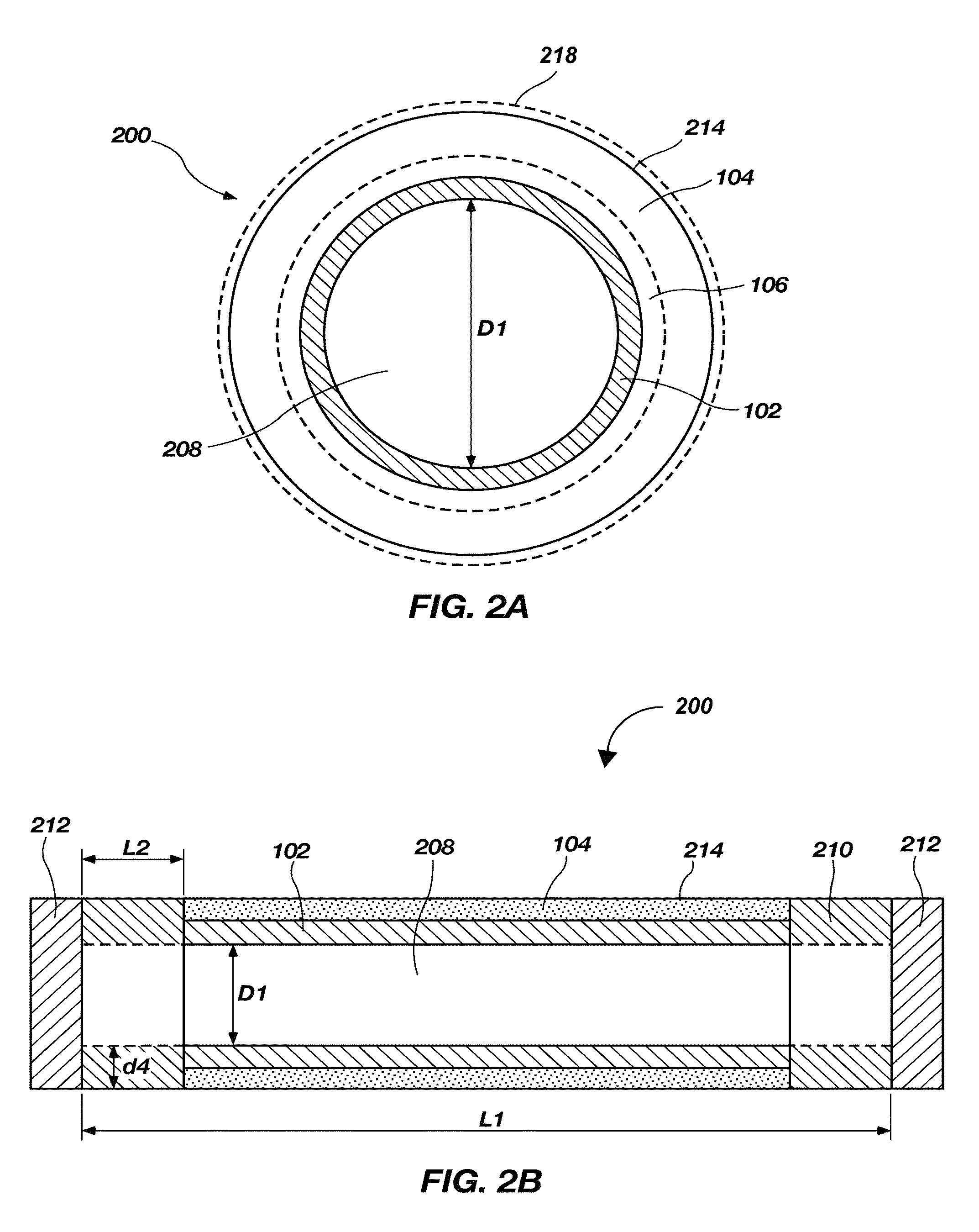

Cladding material, tube including such cladding material and methods of forming the same

ActiveUS20120087457A1Reduce operating costsImprove securityBoiler flue tubes/fire tubesNuclear energy generationThermal shockMetallic materials

A multi-layered cladding material including a ceramic matrix composite and a metallic material, and a tube formed from the cladding material. The metallic material forms an inner liner of the tube and enables hermetic sealing of thereof. The metallic material at ends of the tube may be exposed and have an increased thickness enabling end cap welding. The metallic material may, optionally, be formed to infiltrate voids in the ceramic matrix composite, the ceramic matrix composite encapsulated by the metallic material. The ceramic matrix composite includes a fiber reinforcement and provides increased mechanical strength, stiffness, thermal shock resistance and high temperature load capacity to the metallic material of the inner liner. The tube may be used as a containment vessel for nuclear fuel used in a nuclear power plant or other reactor. Methods for forming the tube comprising the ceramic matrix composite and the metallic material are also disclosed.

Owner:ADVANCED CERAMIC FIBERS

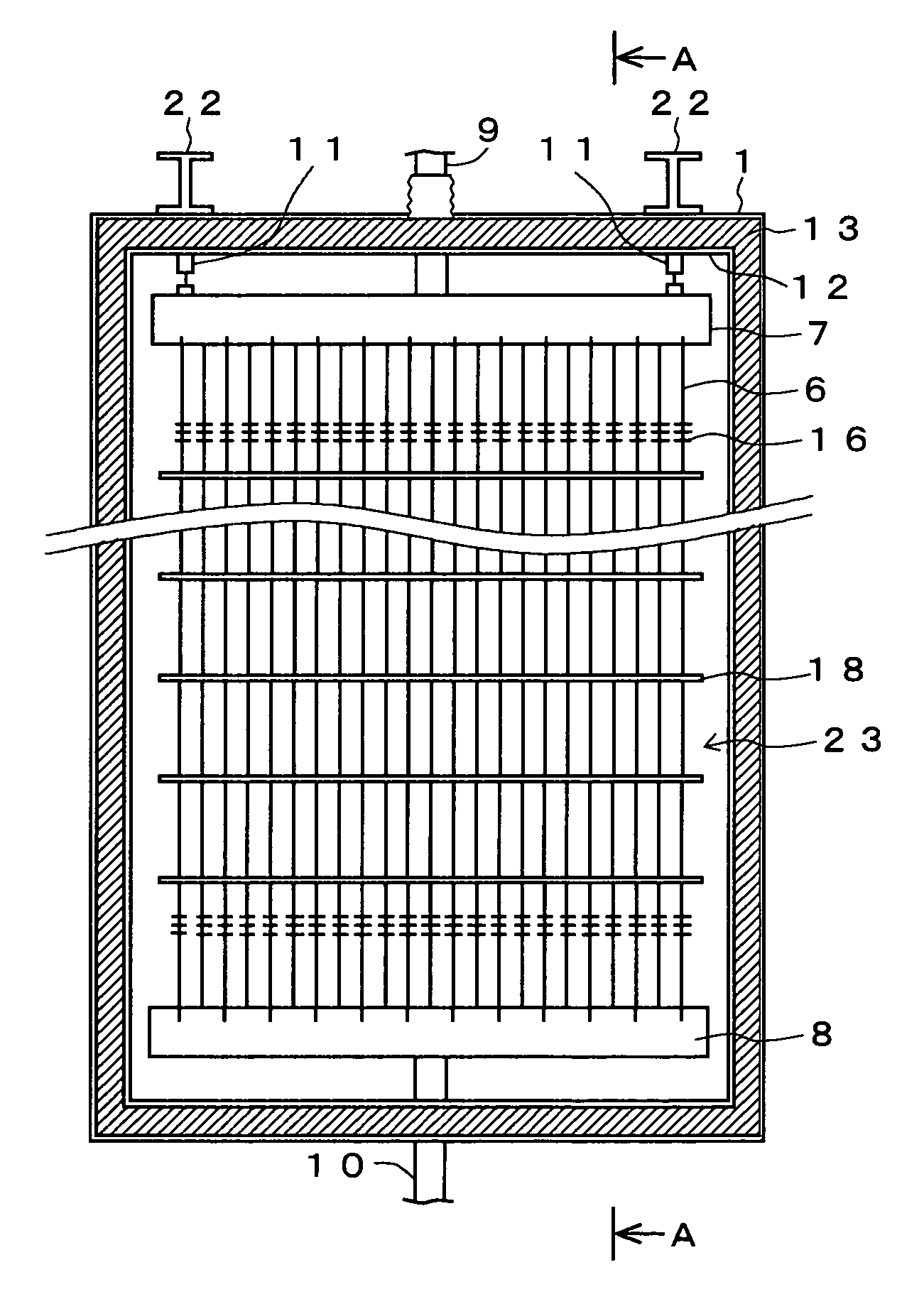

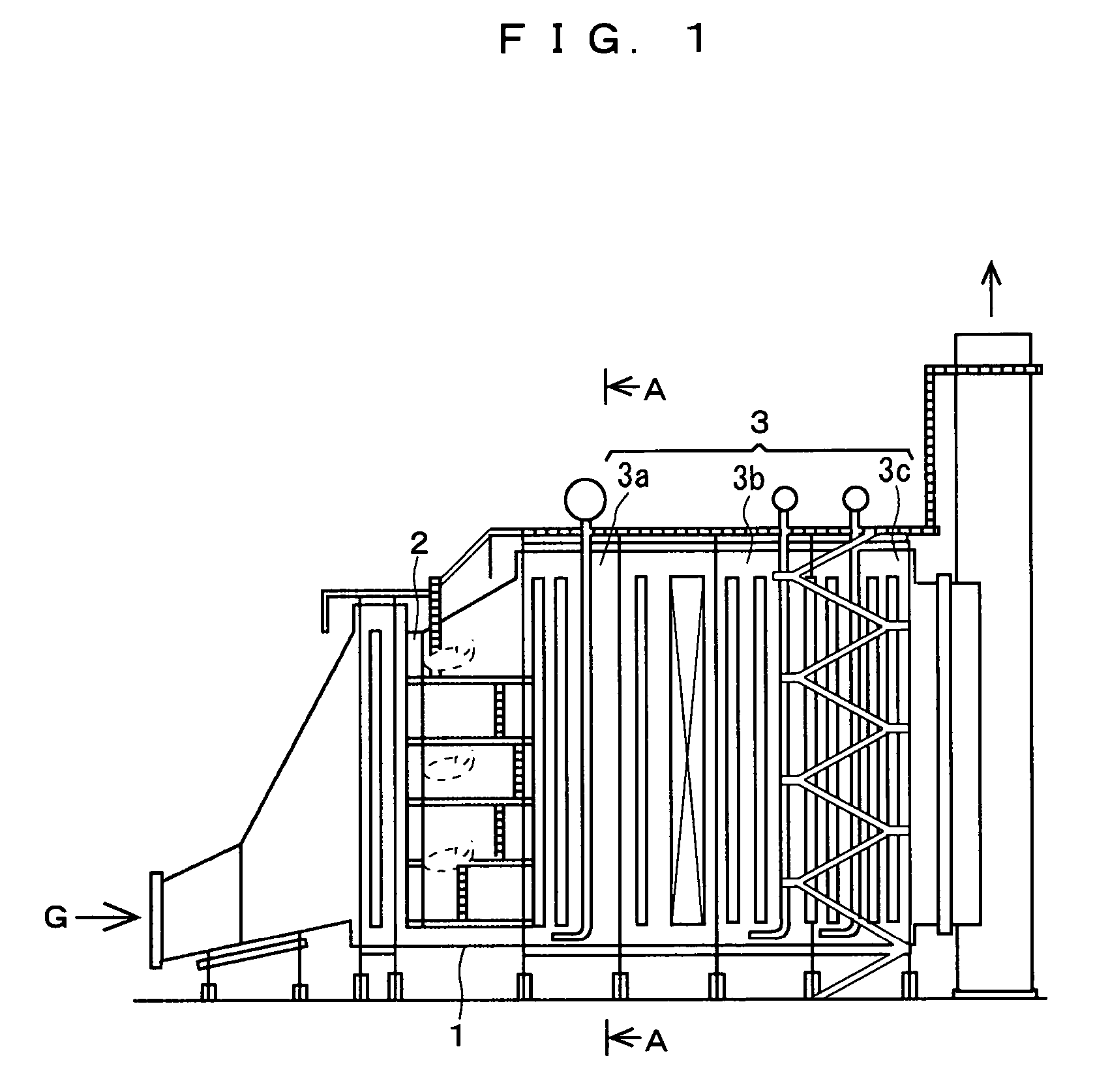

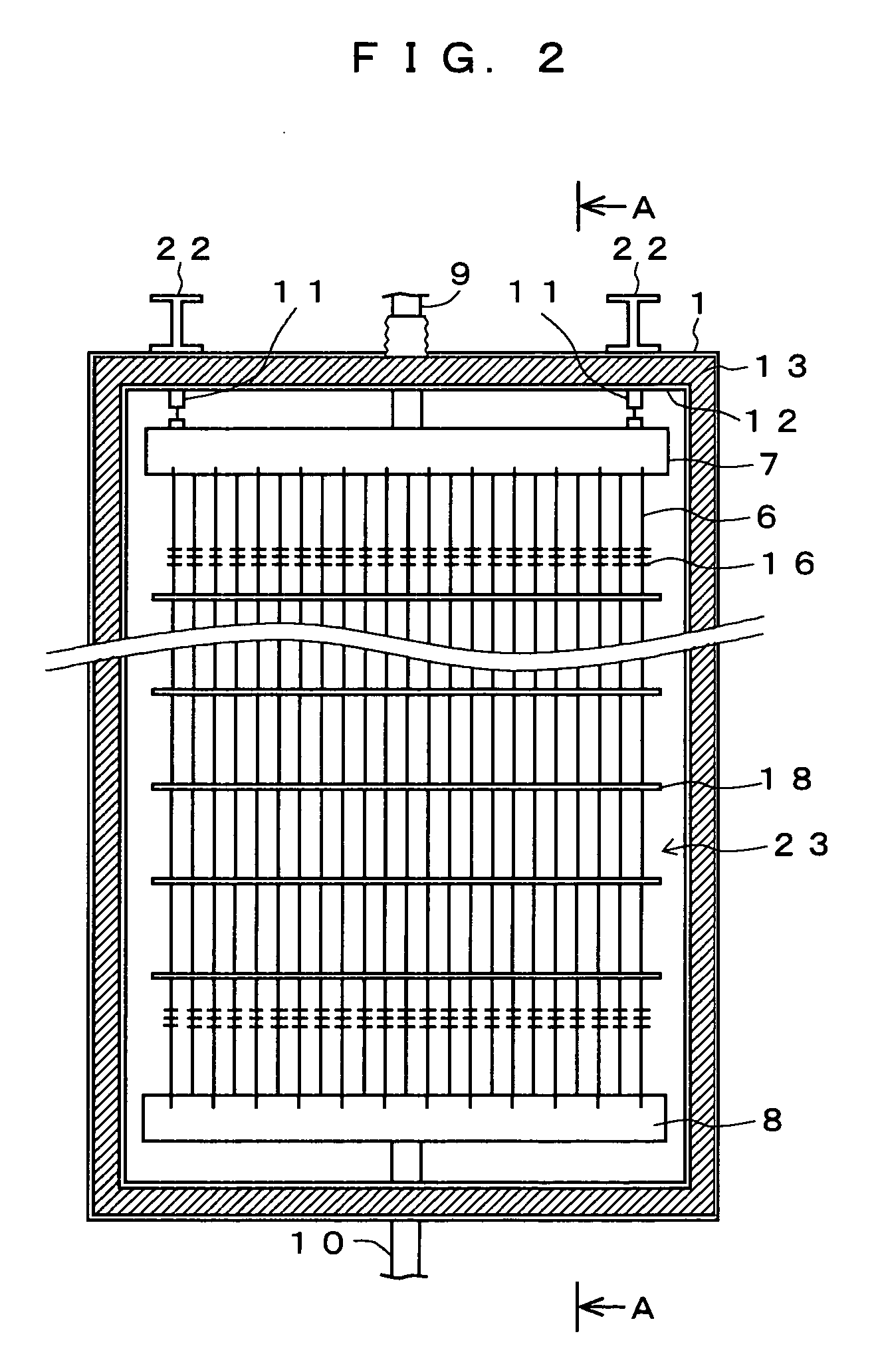

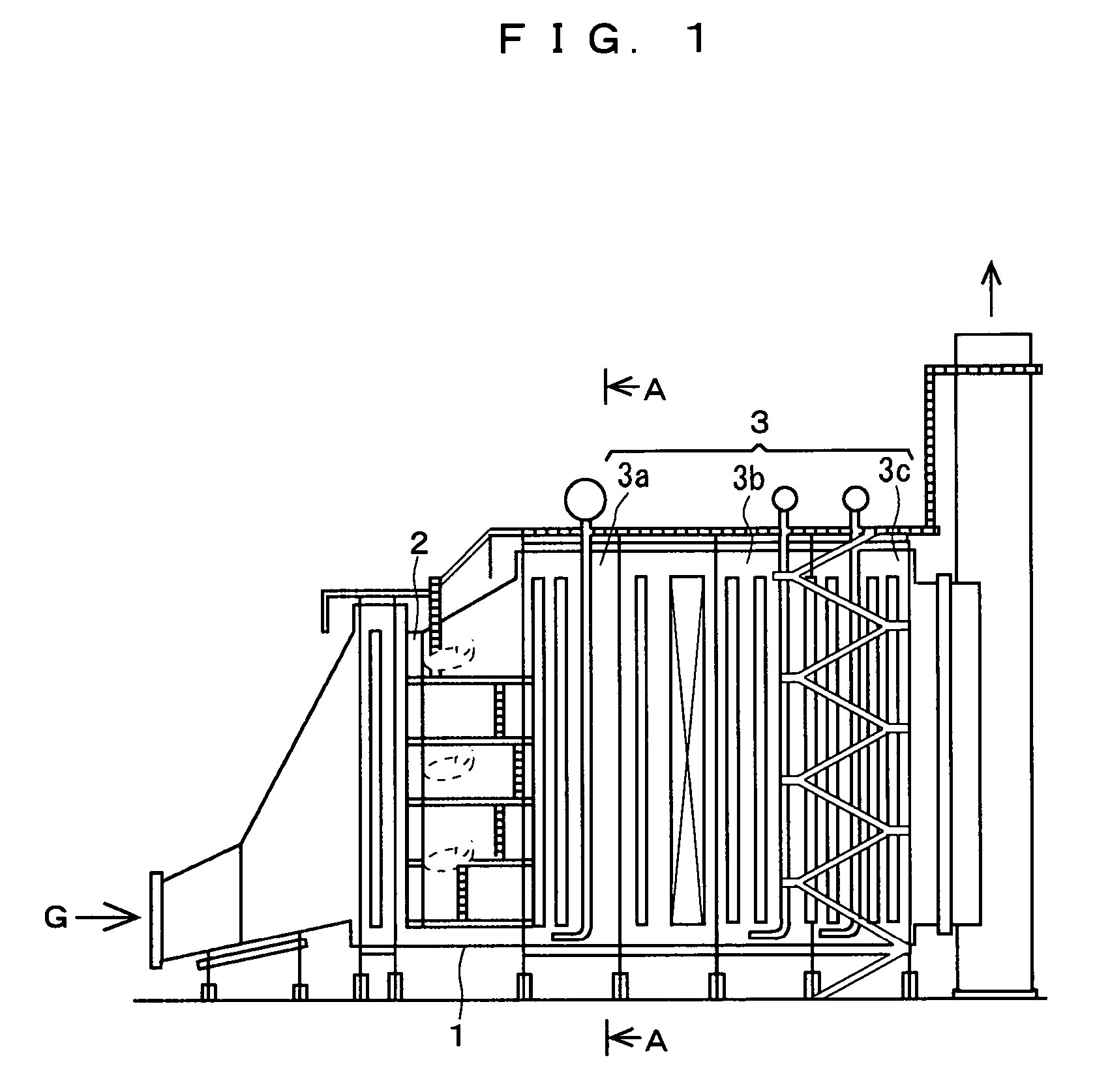

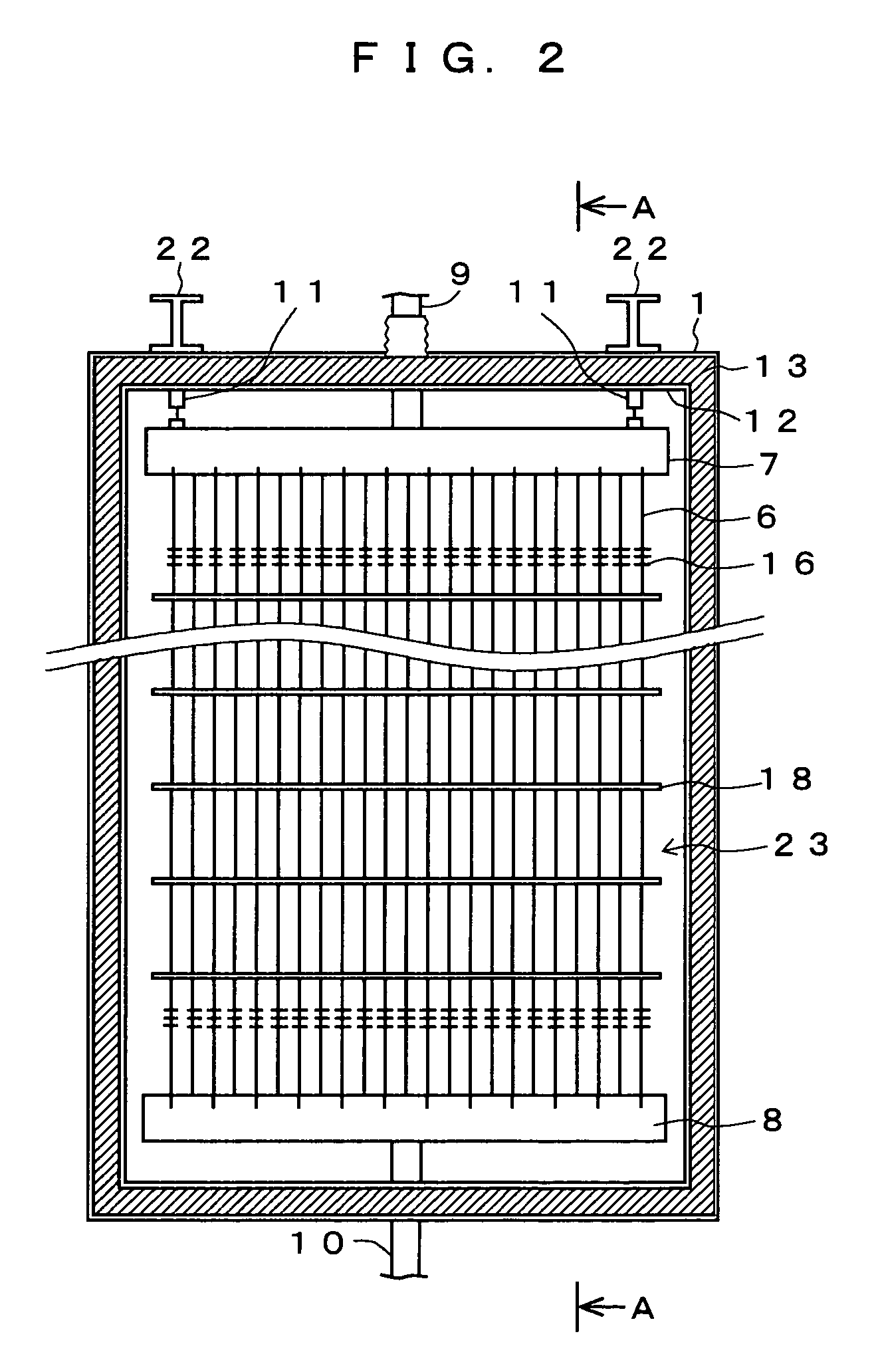

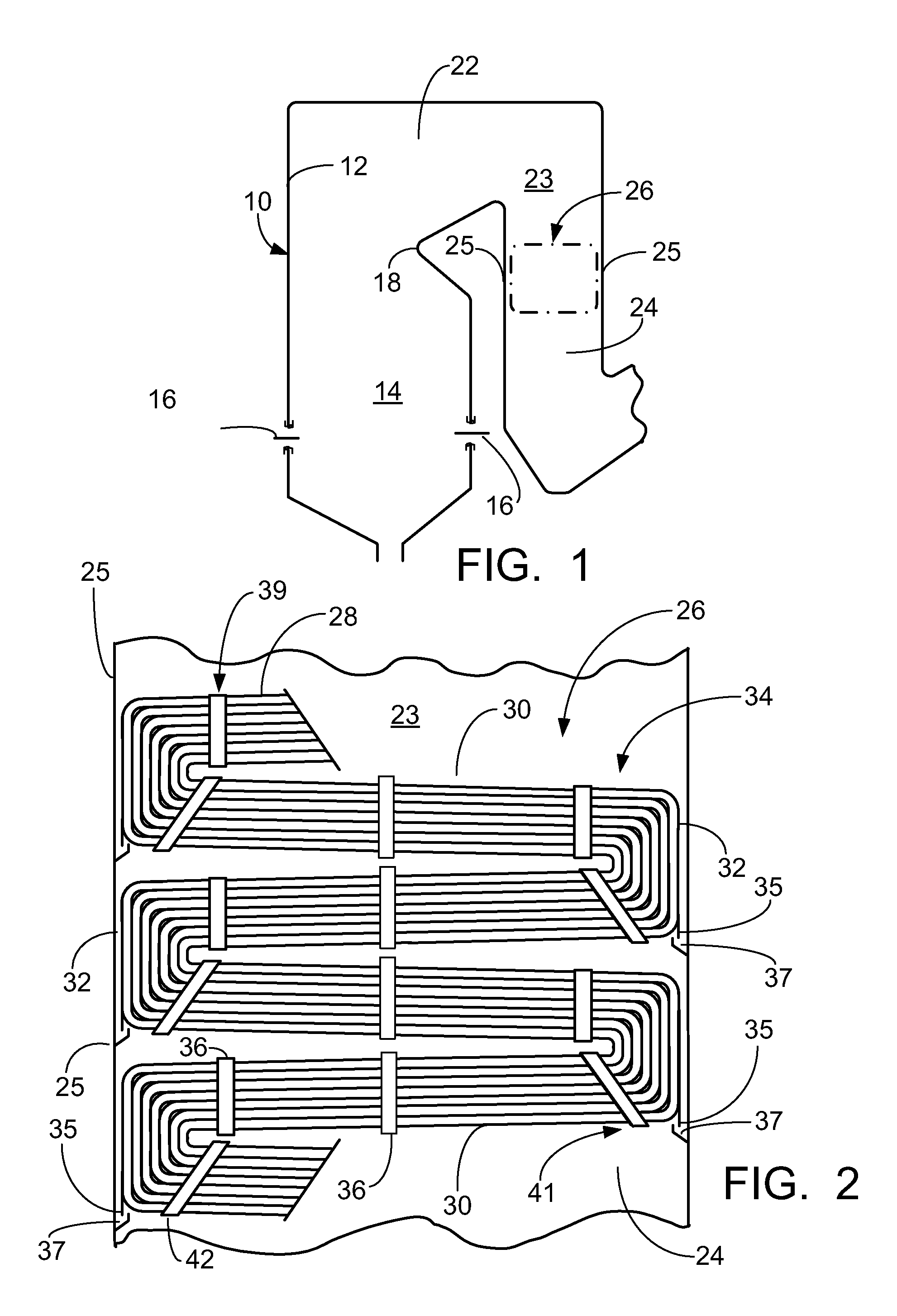

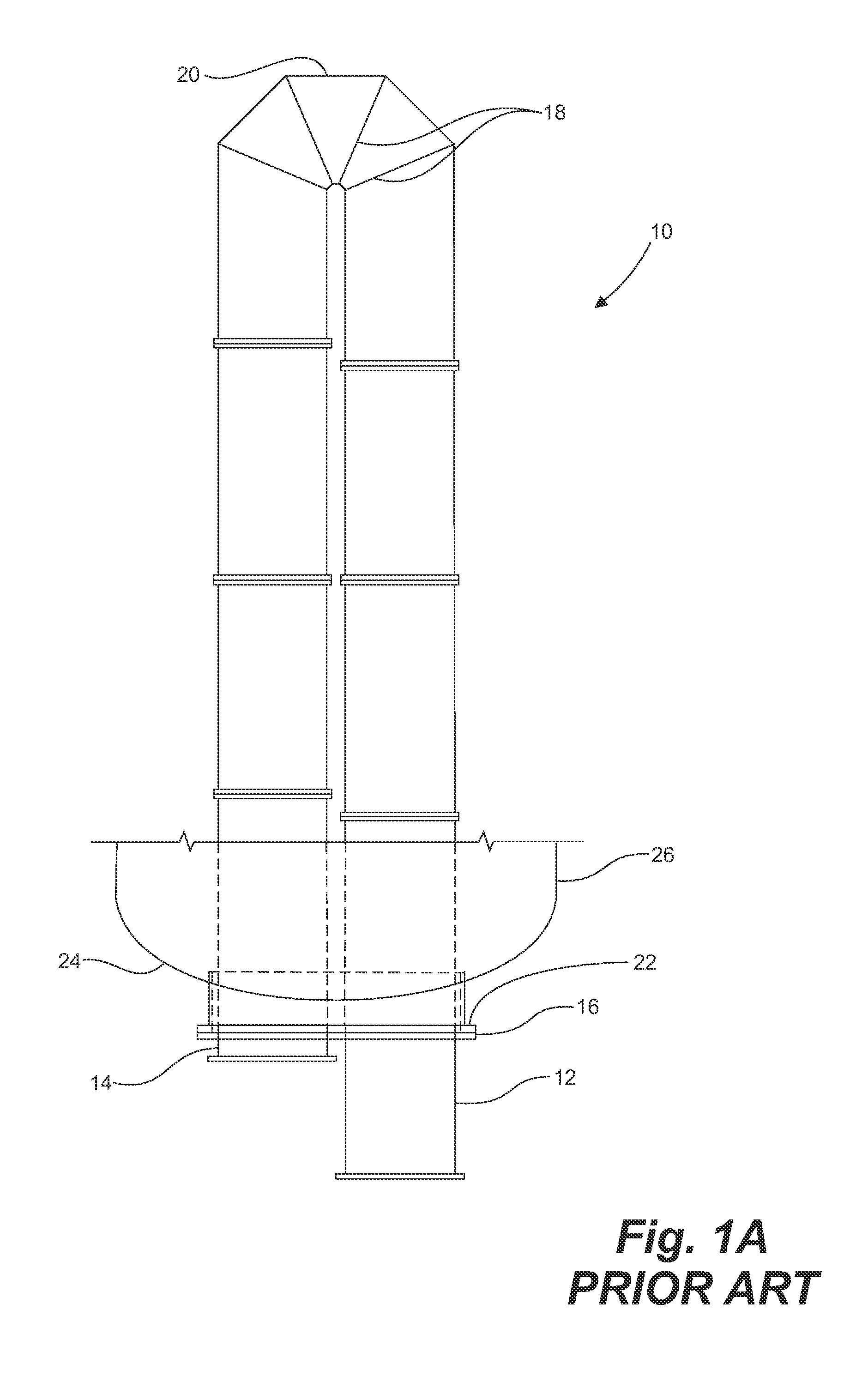

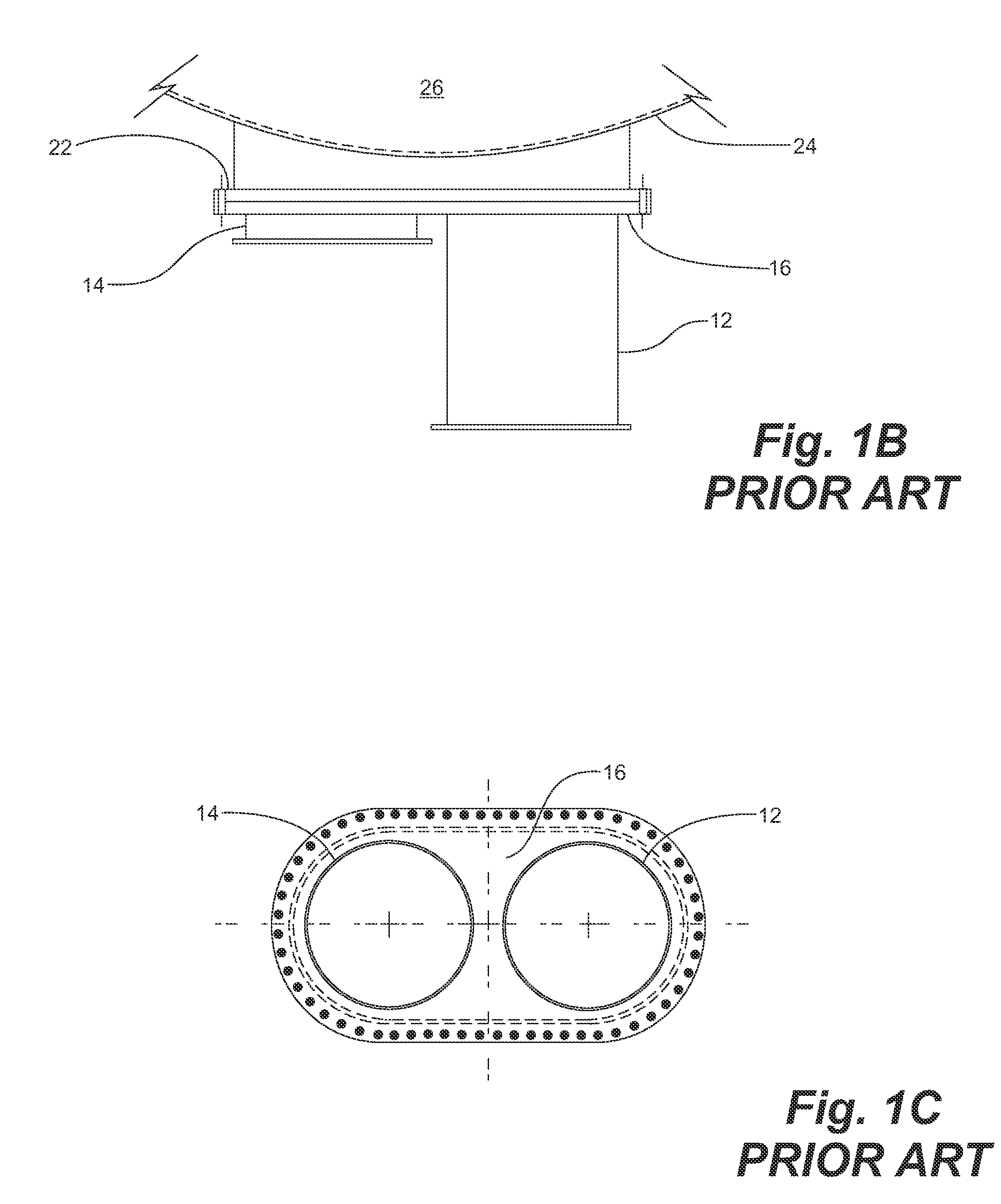

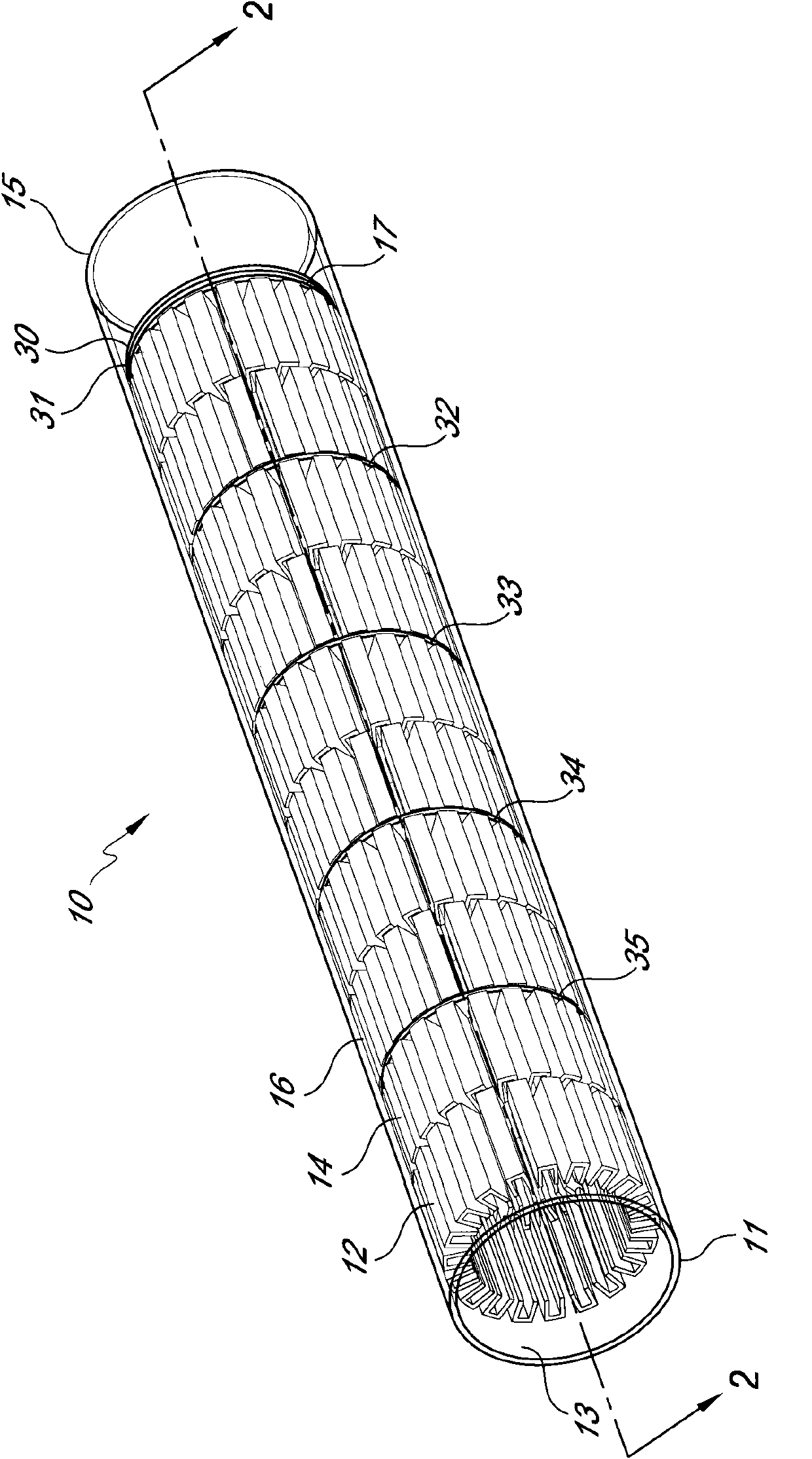

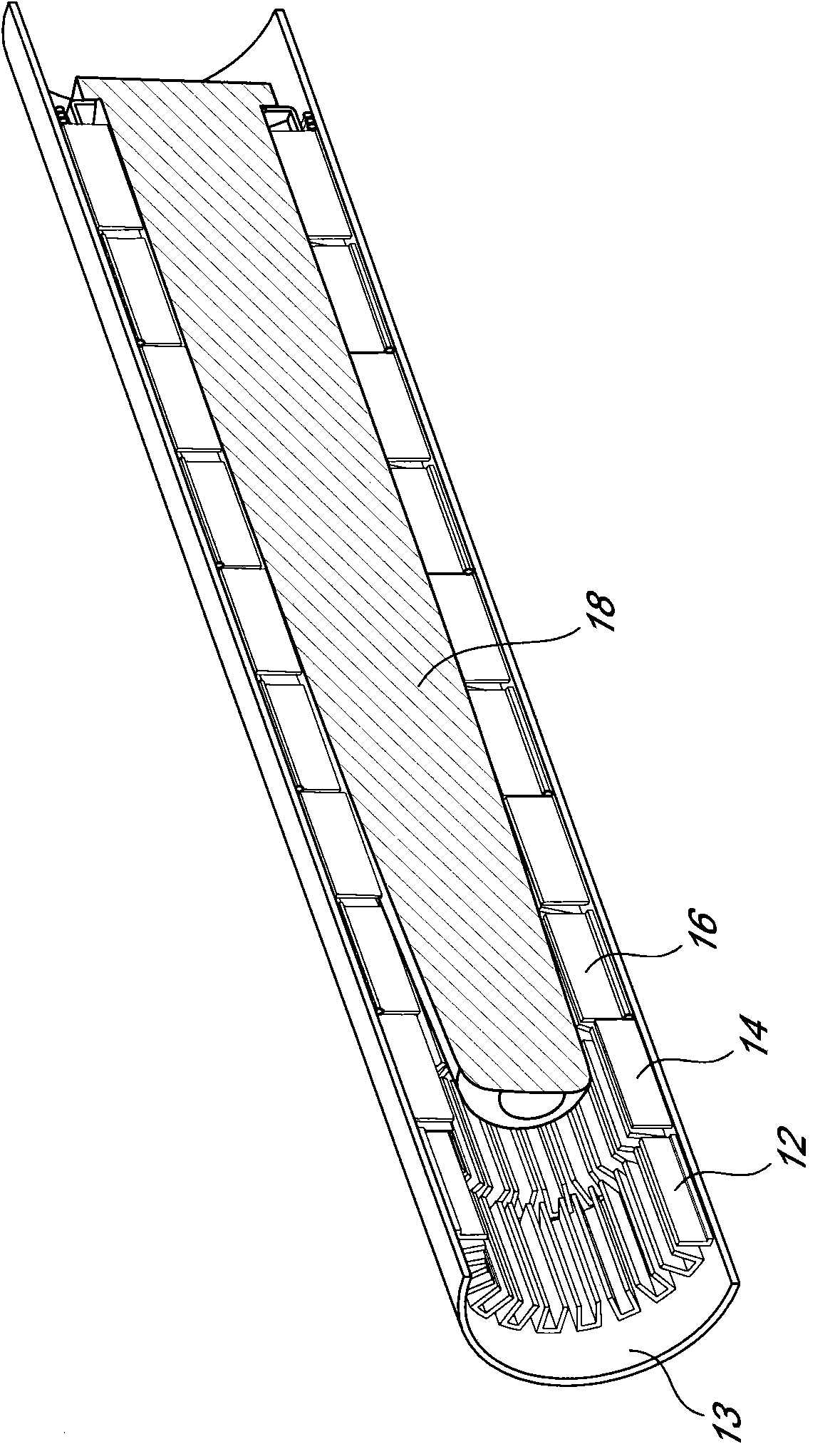

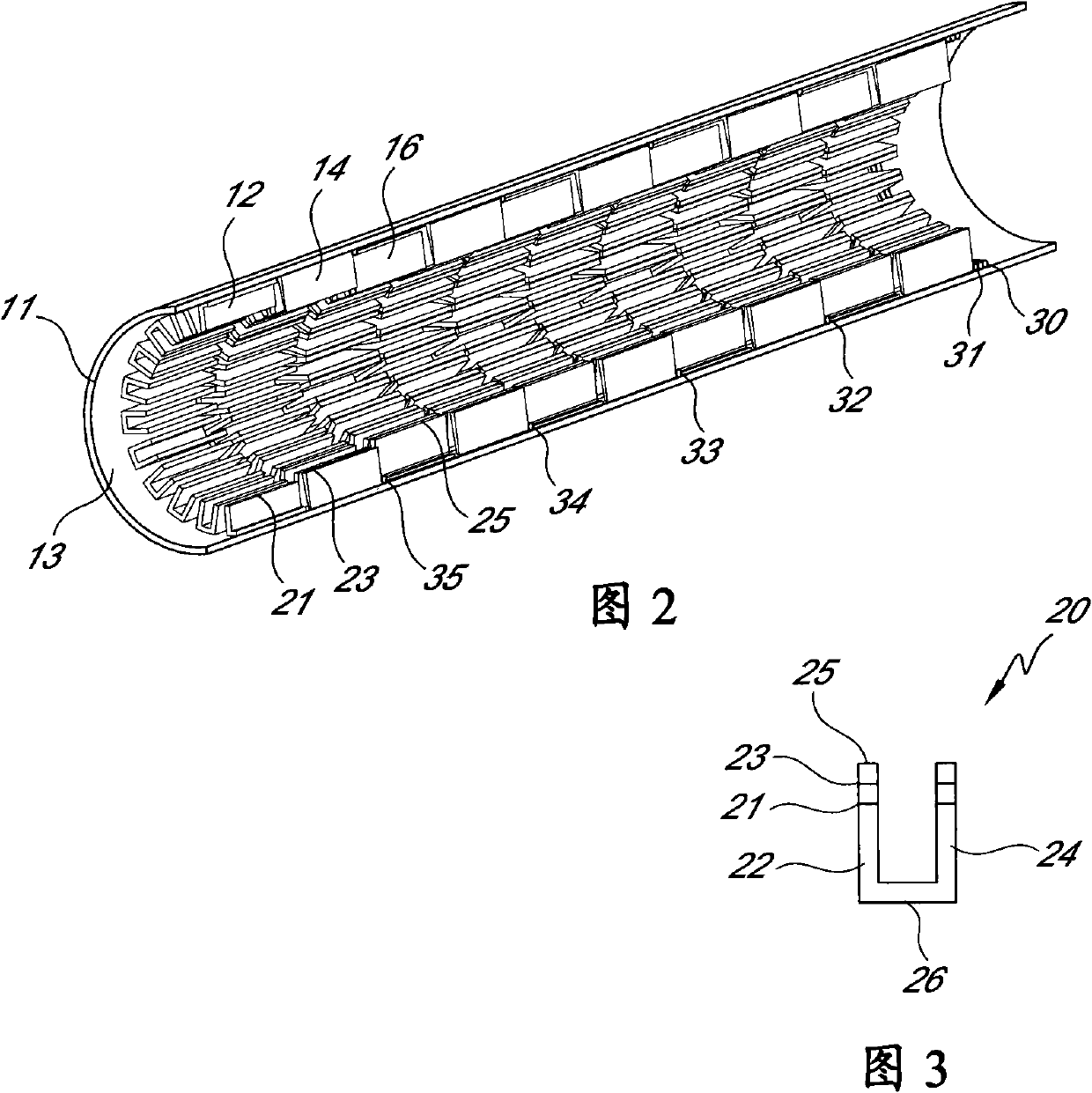

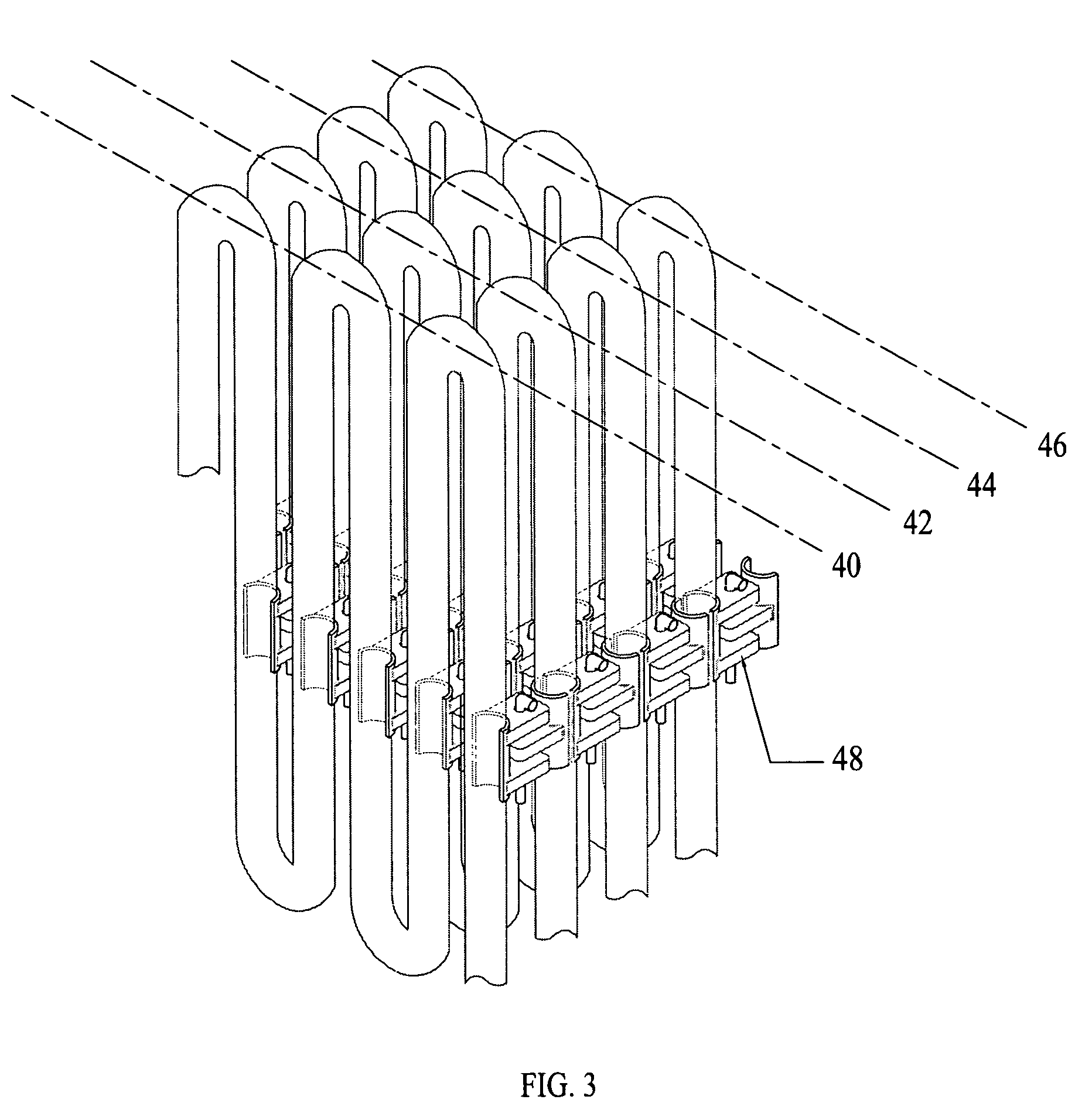

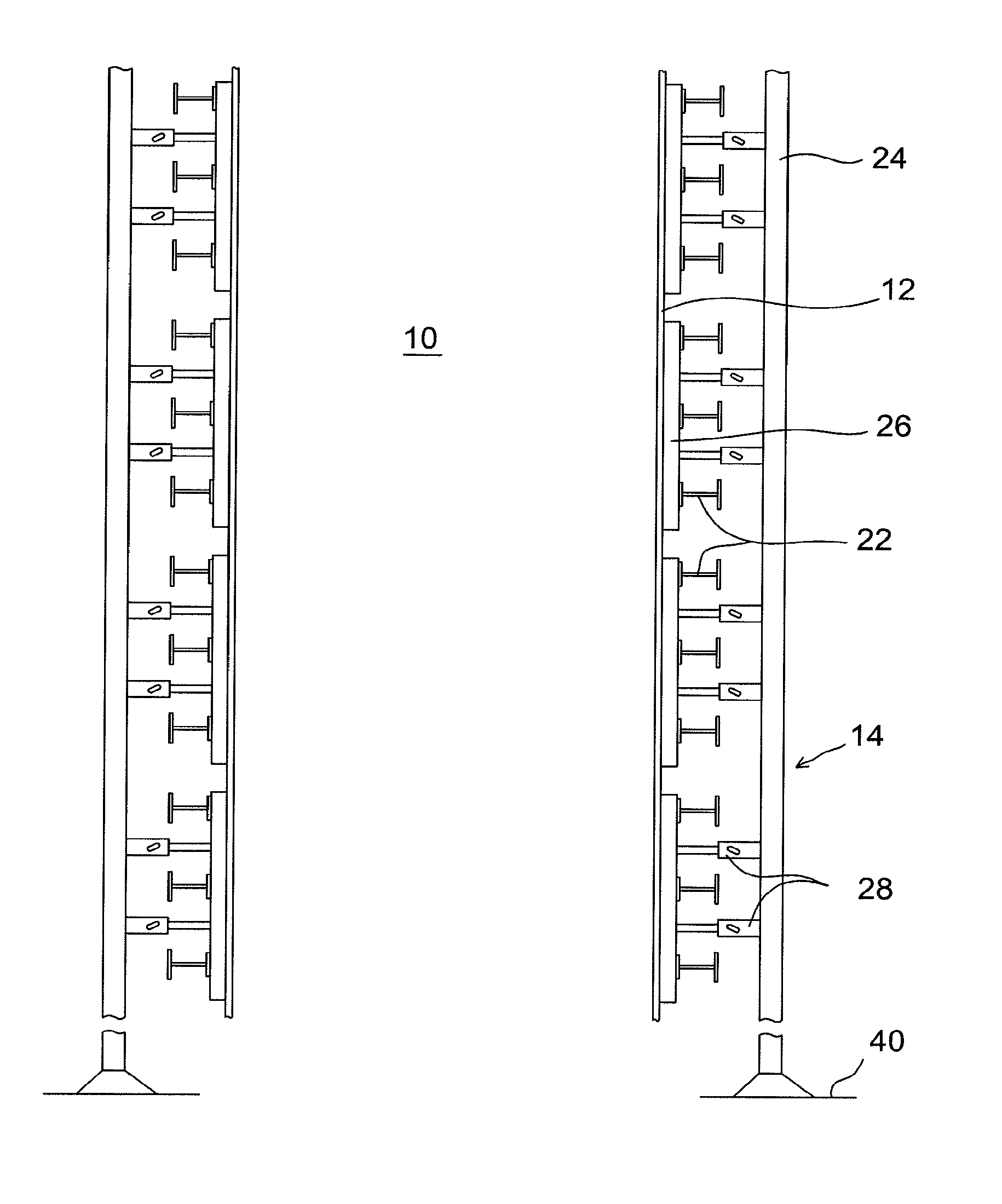

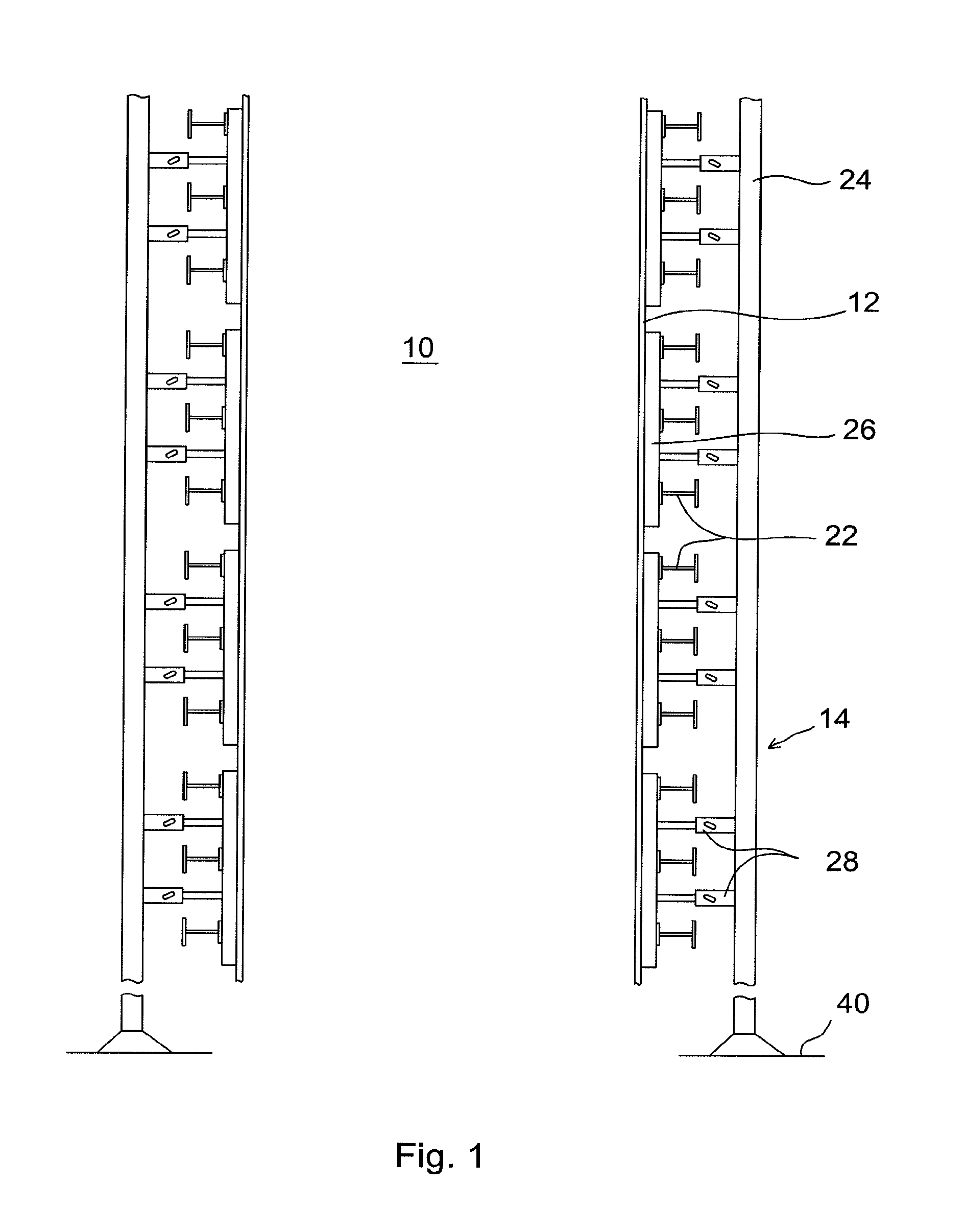

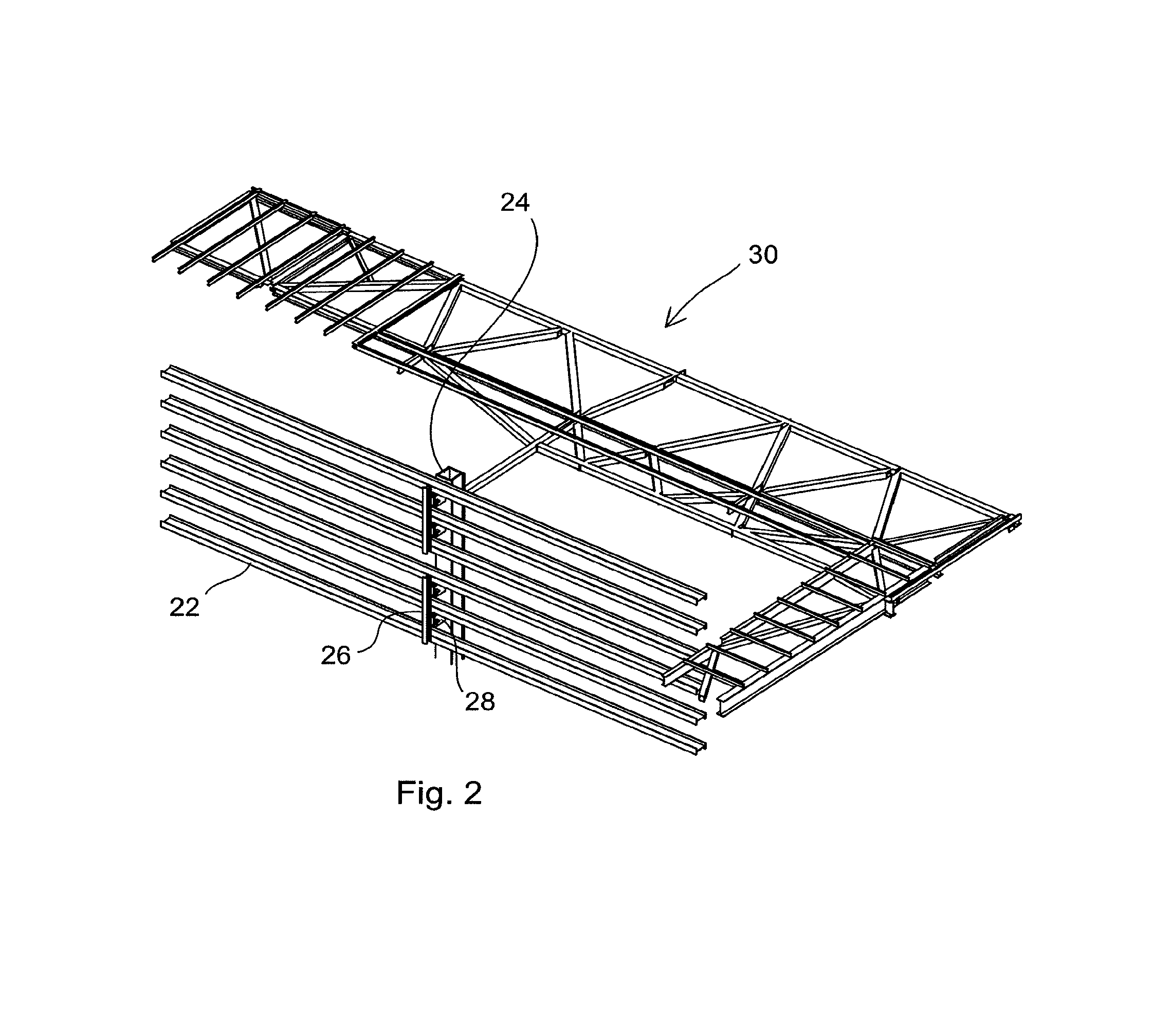

Heat exchanger tube panel module, and method of constructing exhaust heat recovery boiler using the same

InactiveUS20070119388A1Easy to installShort timeBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesEngineeringRecovery boiler

A necessary size and number of modules each obtained by housing a member including heat exchanger tube panels each comprising a heat exchanger tube bundle and headers for the heat exchanger tube bundle, an upper casing of an exhaust heat recovery boiler (HRSG), provided above the heat exchanger tube panels, heat insulators, and heat exchanger tube panel support beams provided on the upper surface of the upper casing into a transportation frame, are prepared according to design specifications of the HRSG, and side casings and a bottom casing except for the ceiling part casing are constructed in advance at a construction site of the HRSG, and the modules are suspended from above between adjacent support beams of the ceiling part to dispose the heat exchanger tube panel support beams of the modules at the set heights of the ceiling part support beams, and the support beams and the ceiling part support beams are connected and fixed via connecting steel plates, whereby the respective modules are transported to the HRSG construction site and can be easily constructed.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Tower-type boiler with primary reheater and secondary reheater

ActiveCN102889570AImprove heat transfer characteristicsImprove heat transfer efficiencySuperheating controlBoiler flue tubes/fire tubesEngineeringSuperheater

The invention discloses a tower-type boiler with a primary reheater and a secondary reheater. A superheater of the boiler comprises a low-temperature superheater and a high-temperature superheater; a technological process of a main steam system comprises the following steps that: feeding water enters a front flue coal economizer and a rear flue coal economizer which are arranged in parallel; water from outlets of the coal economizers enters water-cooling walls from the lower part of a hearth; outlets of the water-cooling walls are connected with a separator; and steam of an outlet of the separator enters the low-temperature superheater and the high-temperature superheater sequentially. According to a low-to-high flow direction of temperatures on a steam side, the primary reheater sequentially comprises primary reheating low-temperature reheaters and a primary reheating high-temperature reheater, the secondary reheater sequentially comprises secondary reheating low-temperature reheaters and a secondary reheating high-temperature reheater, and the primary reheater and the secondary reheater are connected with each other in parallel in a perpendicular flue.

Owner:SHANGHAI BOILER WORKS

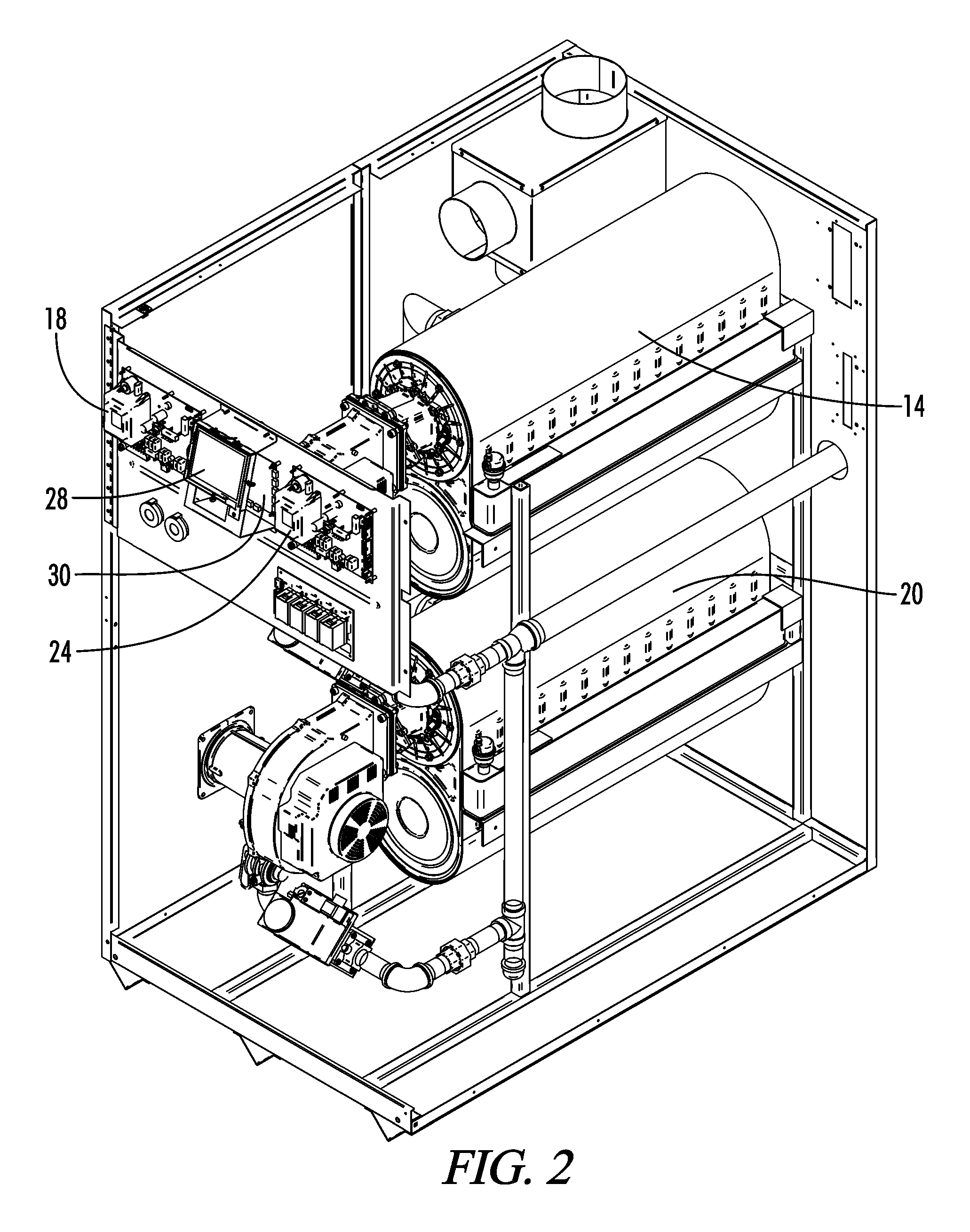

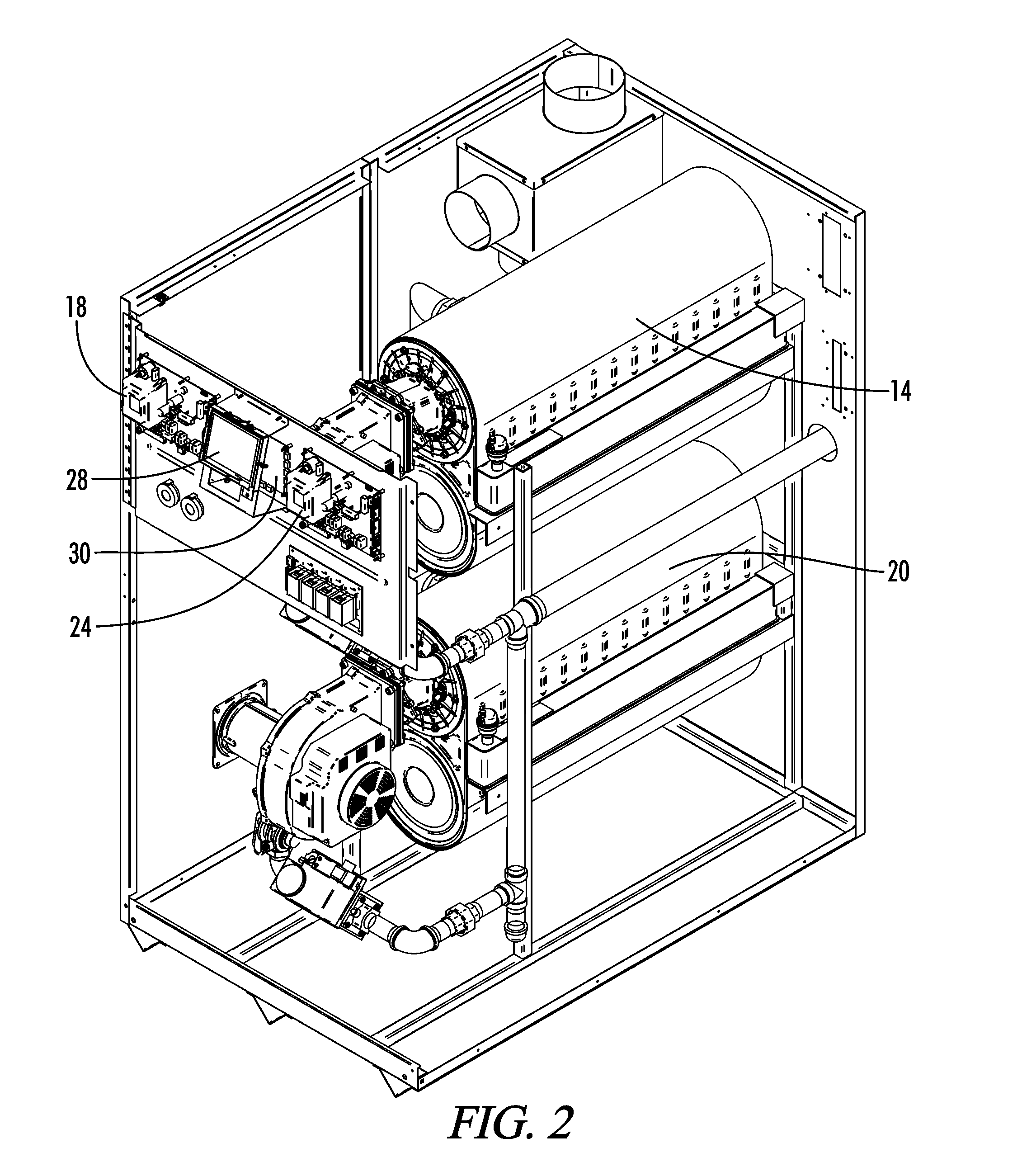

Control system for a boiler assembly

ActiveUS8371252B1Minimize occurrenceEasy to igniteFluid heatersBoiler flue tubes/fire tubesFlueWater heater

A control system for managing and interfacing a plurality of water heaters, e.g. boilers. The control system includes a first boiler unit controlled by a first boiler control unit and a second boiler unit controlled by a second boiler control unit. The first boiler control unit is operable to coordinate the operation of the first and second boiler units in response to changes in output demand. The flues of the first and second boiler units are connected to a common flue. The control system further includes an interface and an interface control system. The interface control system communicates requests from the interface, to report and / or alter the operating parameters of the first and second boiler units, to the first and second boiler control units and communicates the request outcome(s) back to the interface.

Owner:LOCHINVAR

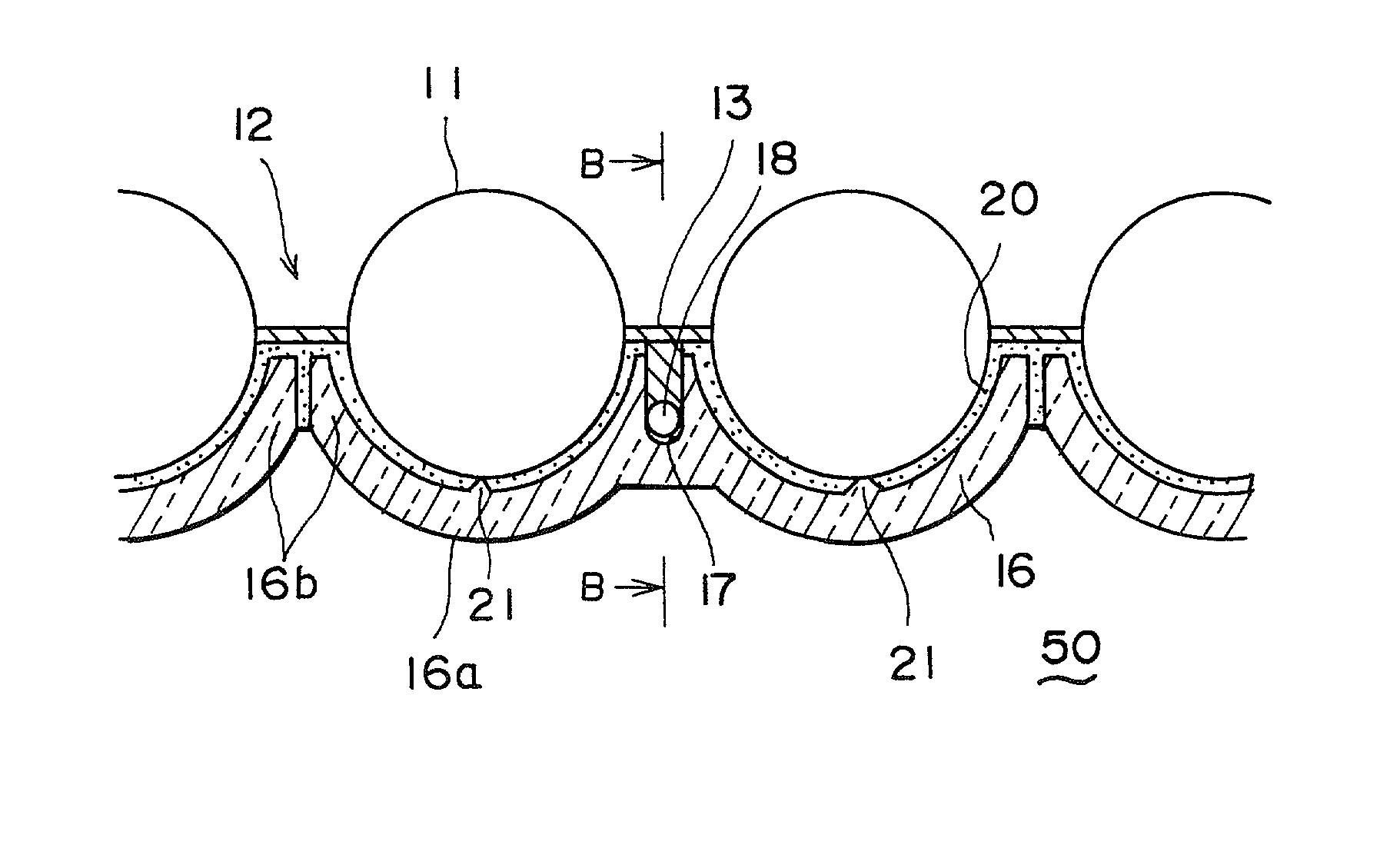

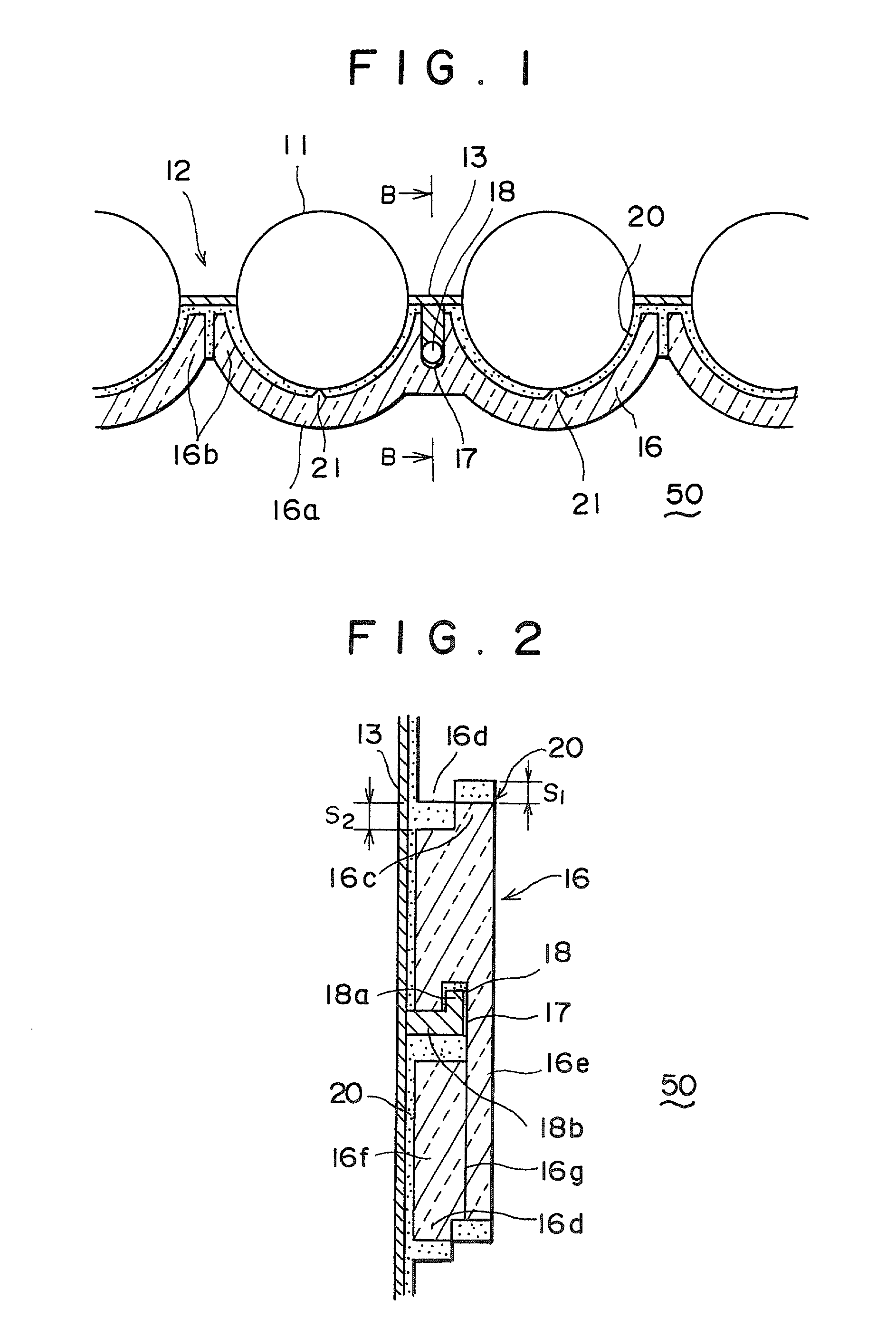

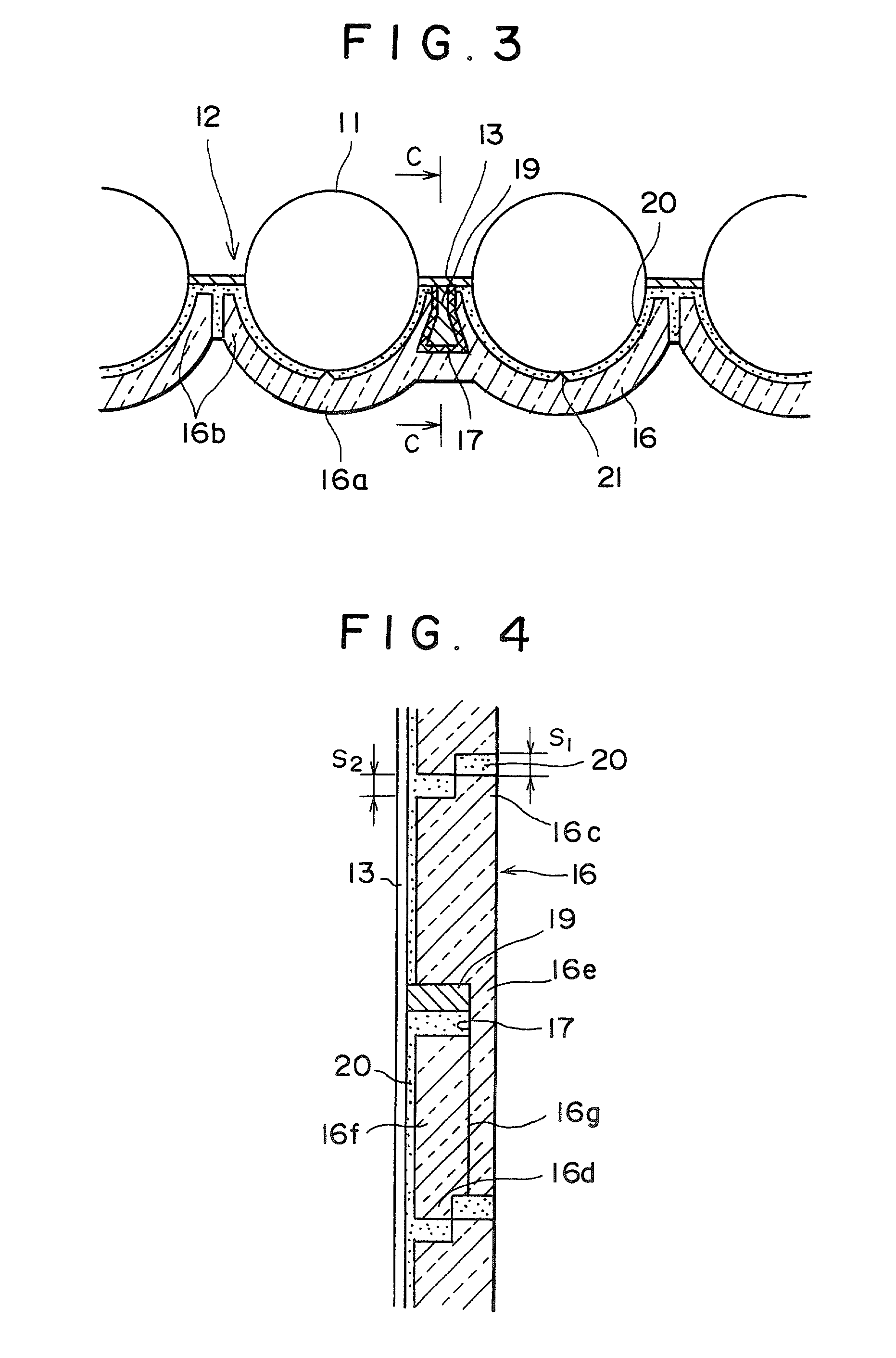

Heat-resistant assembly for protecting boiler tubes and method of assembling same

InactiveUS20020077767A1Thermometer detailsBoiler supporting/setting arrangementsEngineeringMechanical engineering

This invention concerns a heat-resistant assembly having a heat-resistant block conformed to the contours of boiler tubes and the surface of their connecting rib. The heat-resistant assembly has an arm which protrudes from the surface of the rib toward the heat-resistant block and which has a catch on the end. The block has an indentation in which the catch on the arm engages. The block can be hung on or removed from the tube assembly by means of the arms and indentations. The heat-resistant assembly is further distinguished by the fact that a space is created between the end of the arm and the indentation of the block. A fusible substance, which will melt when the temperature of the arm exceeds a given value, is placed in the space. The heat-resistant assembly is further distinguished by the fact that an indentation is formed in the block in which a heat-resistant sleeve is adhered to engage the arm. This arrangement makes it possible to manufacture the heat-resistant block using press molding.

Owner:MITSUBISHI HEAVY IND LTD

Heat exchanger tube panel module, and method of constructing exhaust heat recovery boiler using the same

InactiveUS7357100B2Avoid damageEffect of preventing damage due to shaking during transportation is increasedBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesEngineeringRecovery boiler

A necessary size and number of modules each obtained by housing a member including heat exchanger tube panels each comprising a heat exchanger tube bundle and headers for the heat exchanger tube bundle, an upper casing of an exhaust heat recovery boiler (HRSG), provided above the heat exchanger tube panels, heat insulators, and heat exchanger tube panel support beams provided on the upper surface of the upper casing into a transportation frame, are prepared according to design specifications of the HRSG, and side casings and a bottom casing except for the ceiling part casing are constructed in advance at a construction site of the HRSG, and the modules are suspended from above between adjacent support beams of the ceiling part to dispose the heat exchanger tube panel support beams of the modules at the set heights of the ceiling part support beams, and the support beams and the ceiling part support beams are connected and fixed via connecting steel plates, whereby the respective modules are transported to the HRSG construction site and can be easily constructed.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Hot beverage brewing apparatus

ActiveUS8180204B2Easy to controlMinimization requirementsSteam generation heating methodsBoiler flue tubes/fire tubesProcess engineeringEngineering

A hot beverage brewing apparatus. A pressurized hot liquid delivery system provides liquid under pressure within a range of acceptable brewing temperatures without any mechanical pump. Water is apportioned into sealable tank volumes, one of which is heated to boil the liquid and produce steam under pressure. The pressurized steam displaces the liquid from the tank volumes in proportion and at a temperature that is within the acceptable brewing range. The hot liquid under pressure is directed to a capsule receiving station to infuse a material in a capsule. The capsule dispenses the brewed beverage without contacting the brewing apparatus.

Owner:SOLABEV

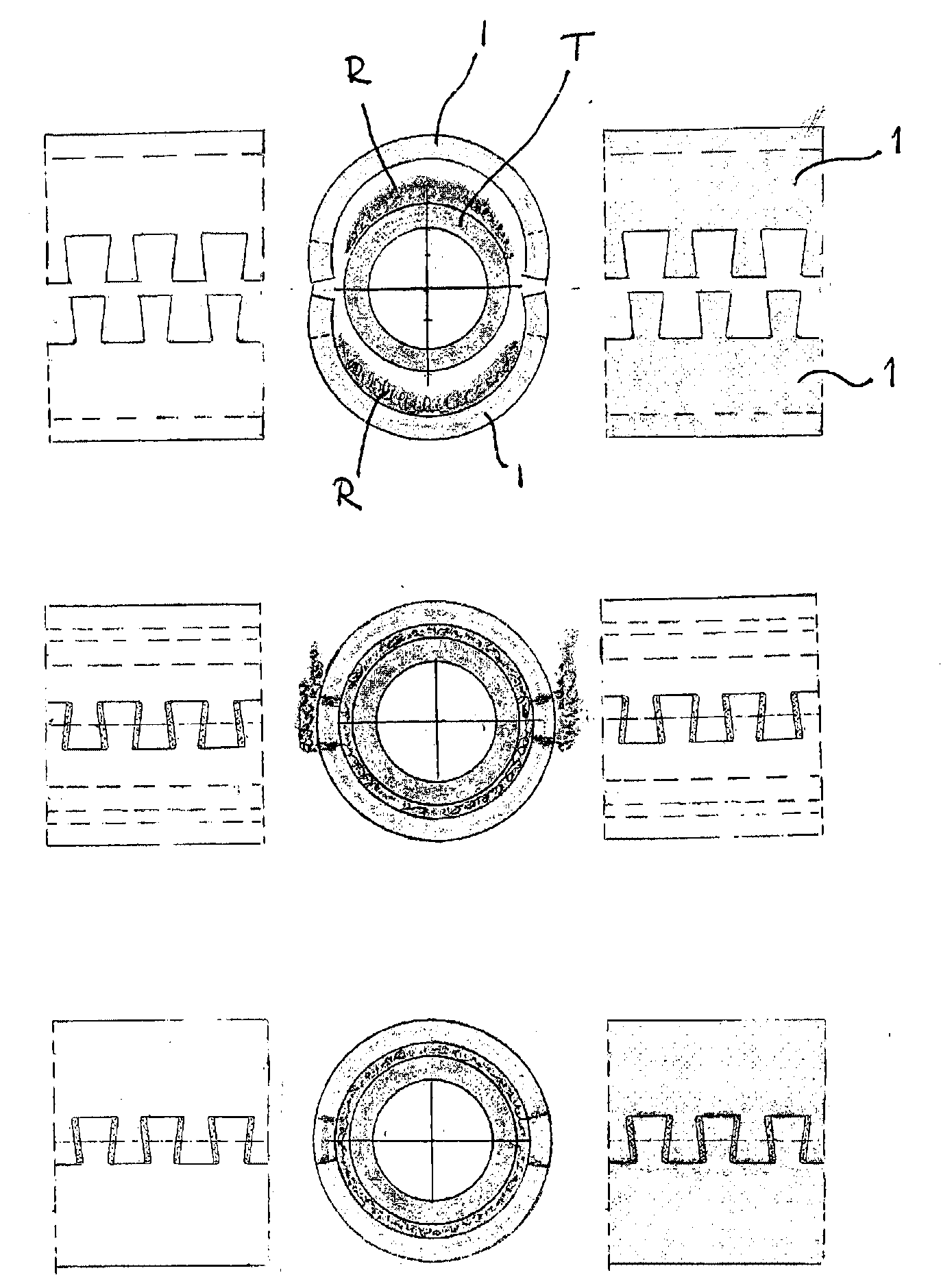

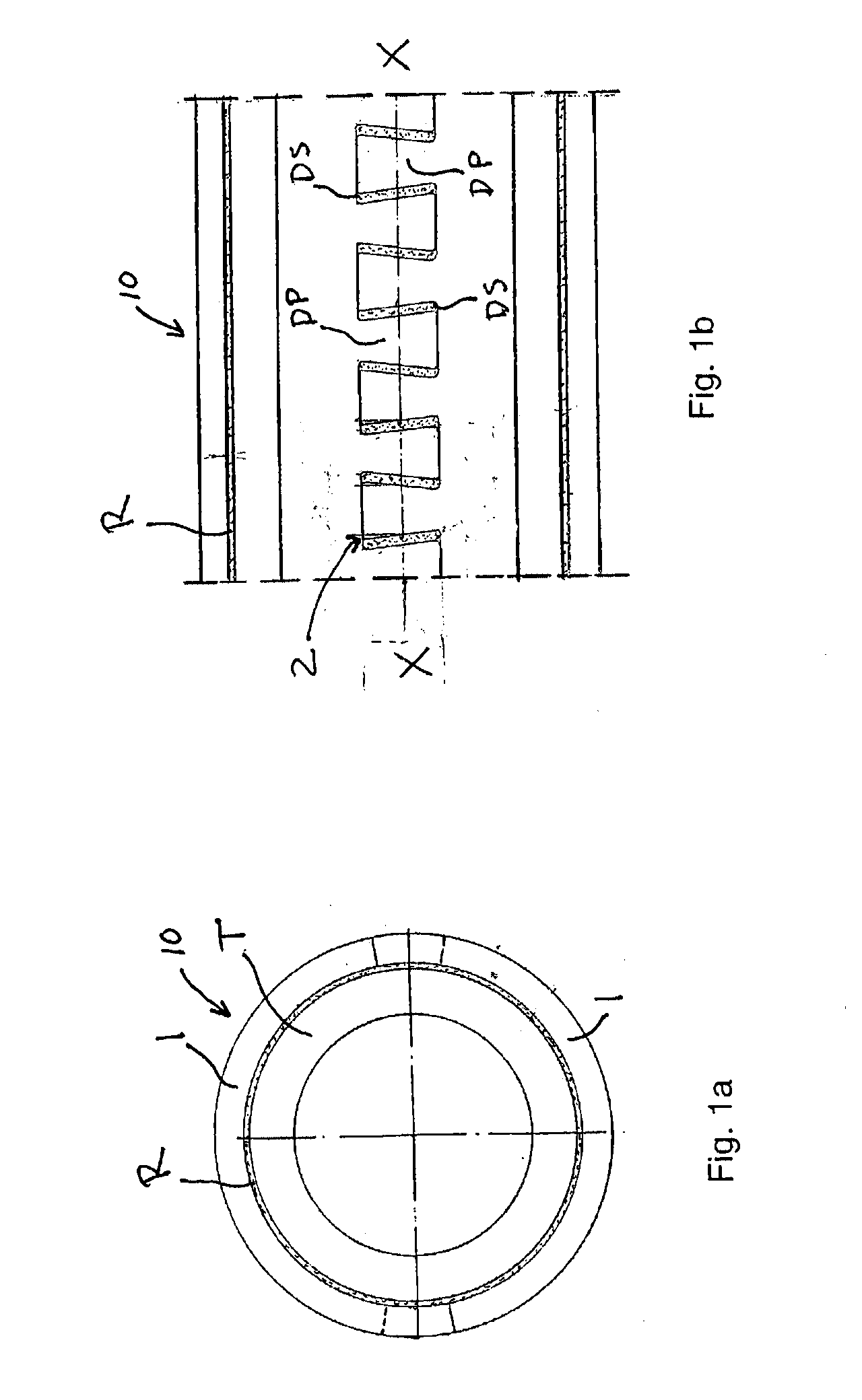

Tube shield and a method for attaching such shield to a boiler tube

InactiveUS20100101511A1Less cumbersome to installPipe supportsBoiler flue tubes/fire tubesEngineeringMechanical engineering

A tube shield has a cylindrical shape and adapted to be attached with refractory cement (R) around an outer peripheral surface of a boiler tube (T). The tube shield has at least two tube shield parts for surrounding the boiler tube (T). The shield parts has complimentary parting surfaces for defining a gap between abutting complimentary parting surfaces of adjacent shield parts when the shield parts are attached with refractory cement (R) around the boiler tube (T). Each shield part encloses 140-220° of the total circumference of the boiler tube (T). Each complimentary parting surface is configured in a dovetail form such that one shield part is locking into the other shield part with dovetail protrusions (DP) located in dovetail slots (DS) in the other shield part.

Owner:METSO POWER AB

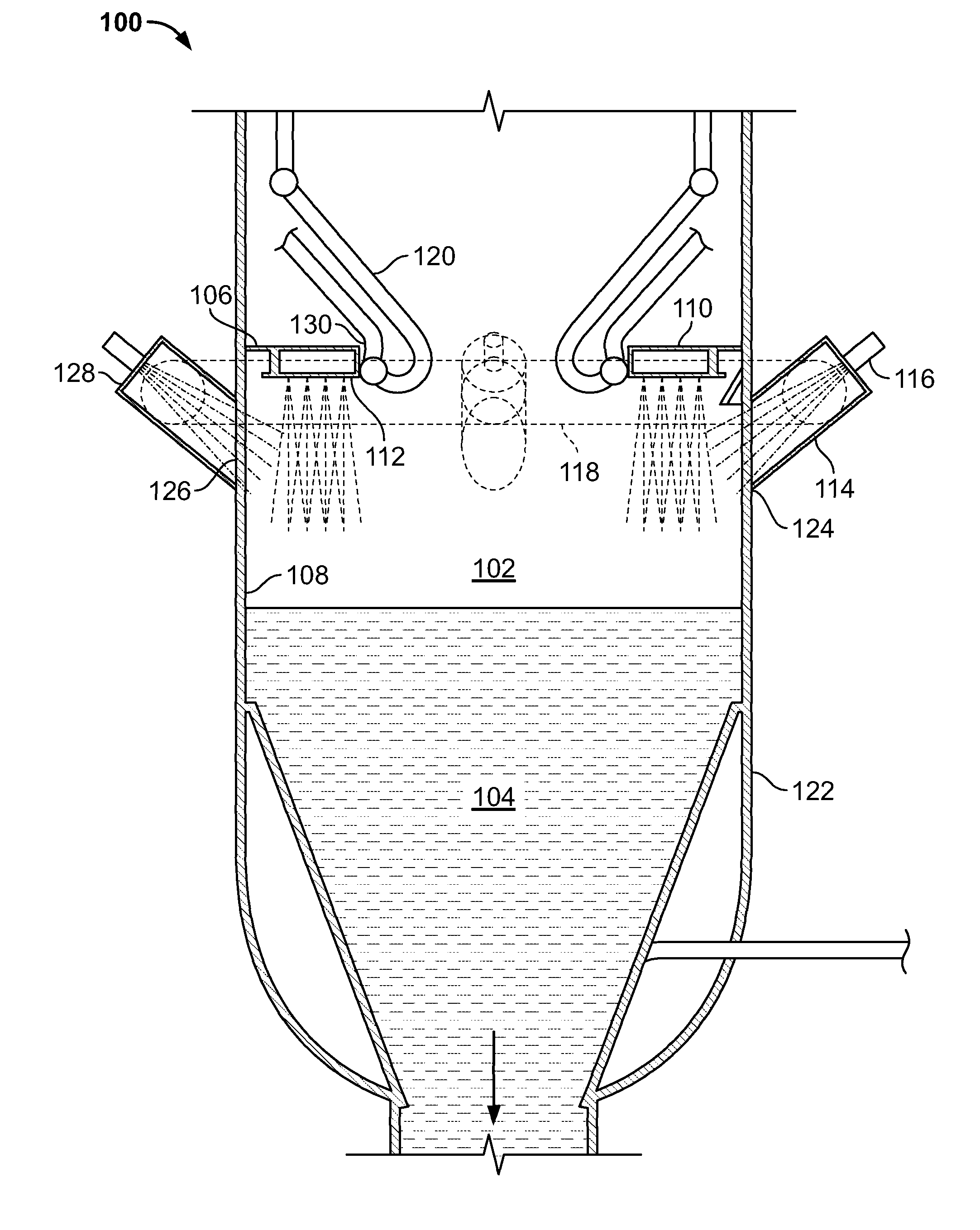

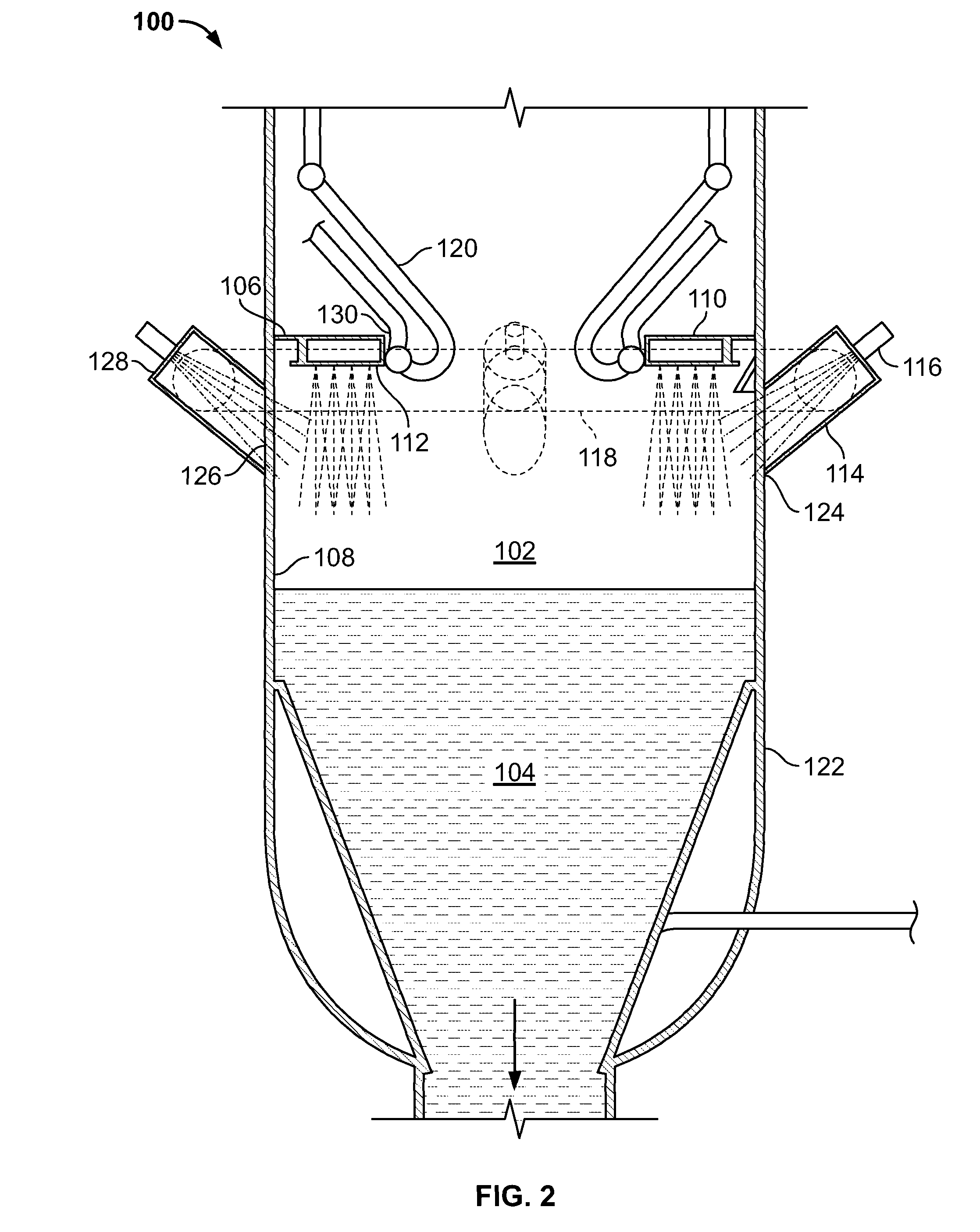

Apparatus for cooling and scrubbing a flow of syngas and method of assembling

Owner:AIR PROD & CHEM INC

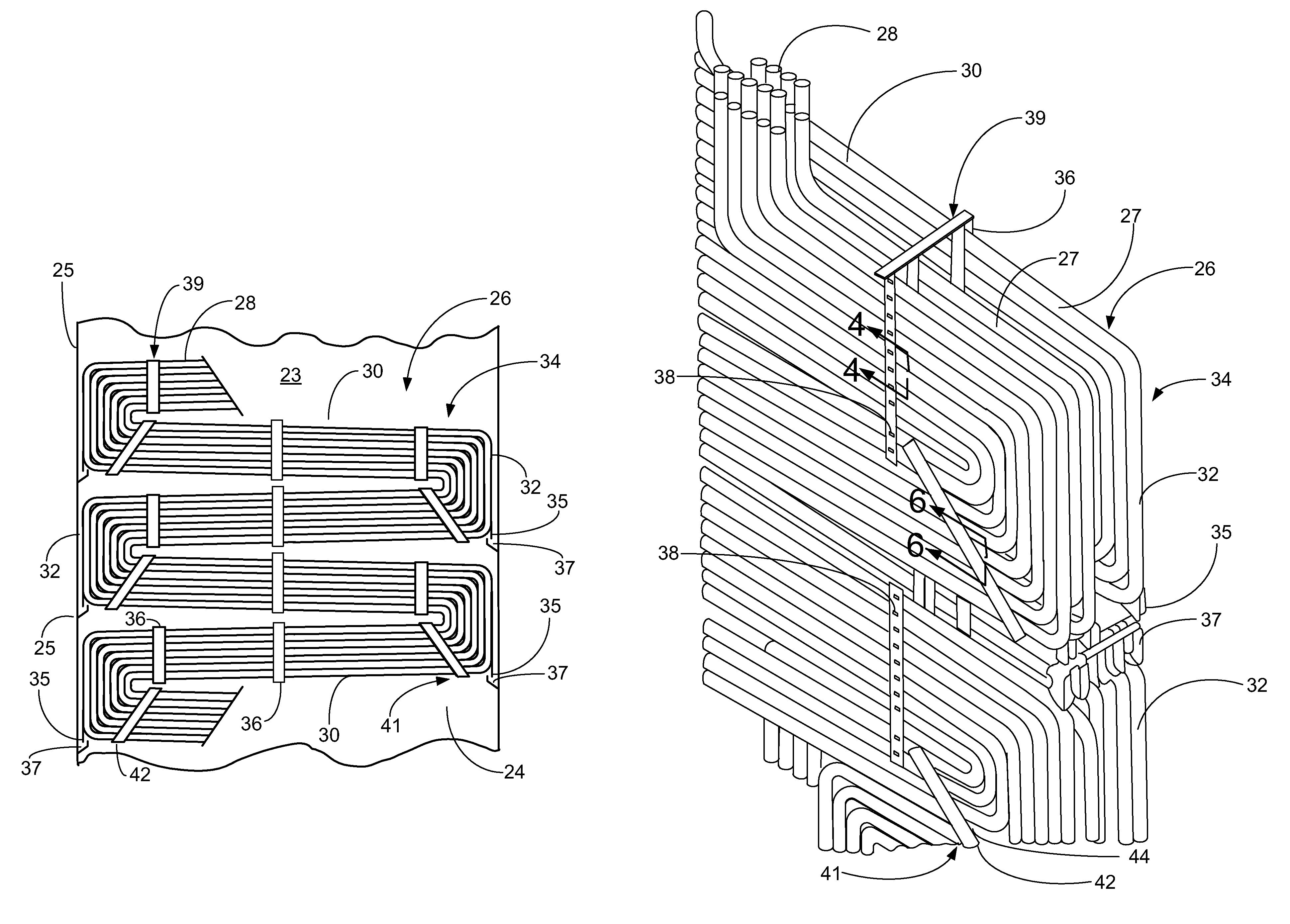

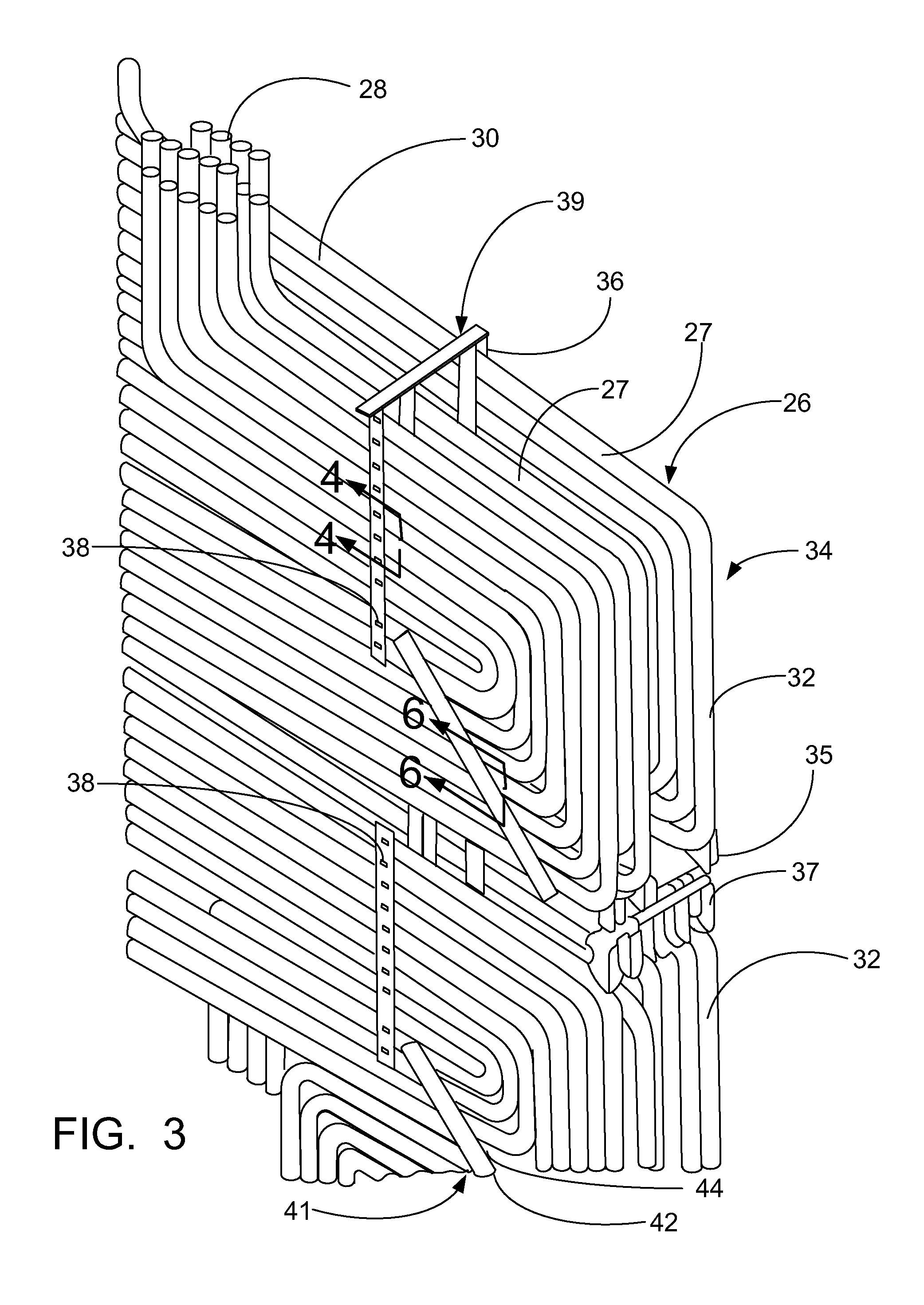

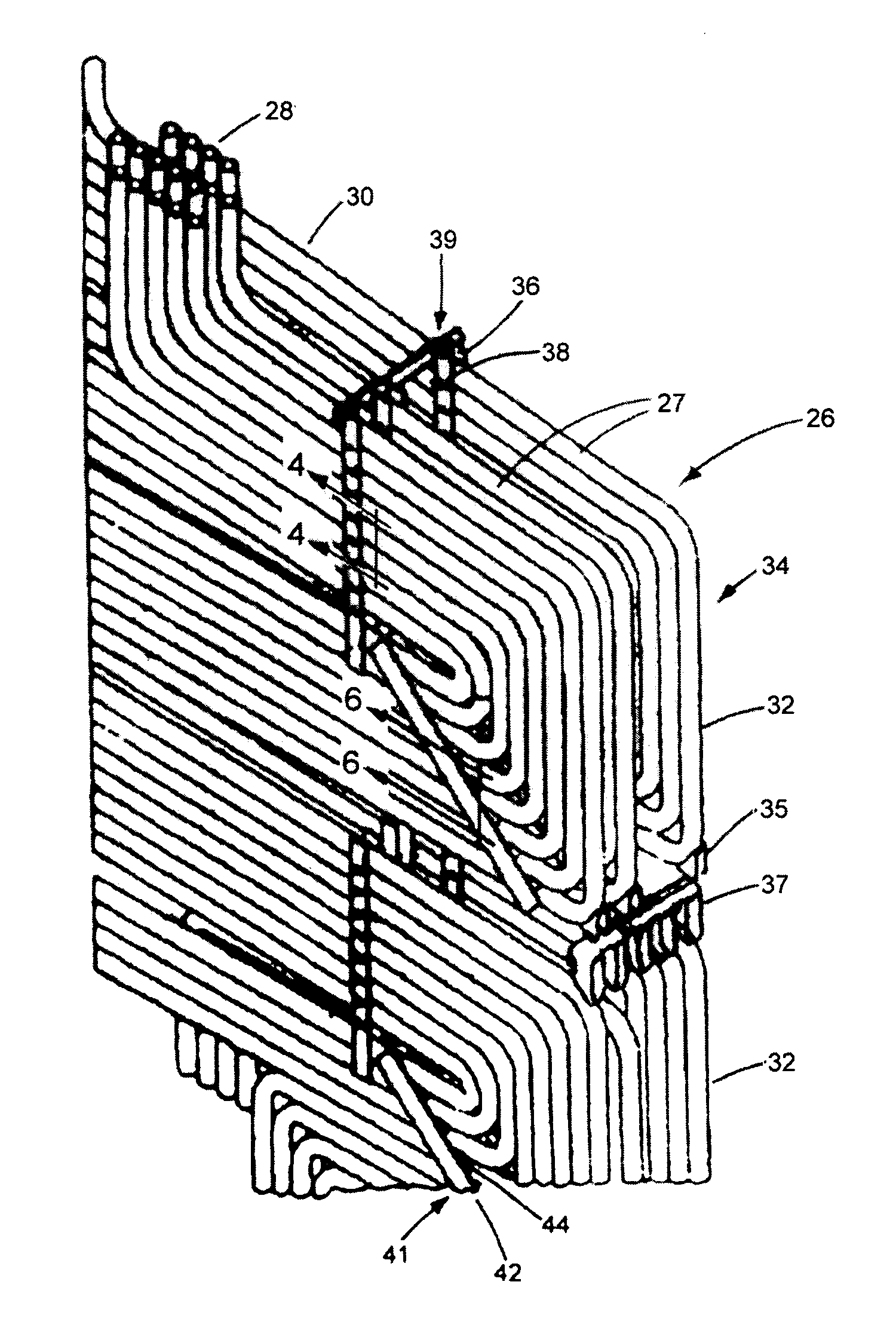

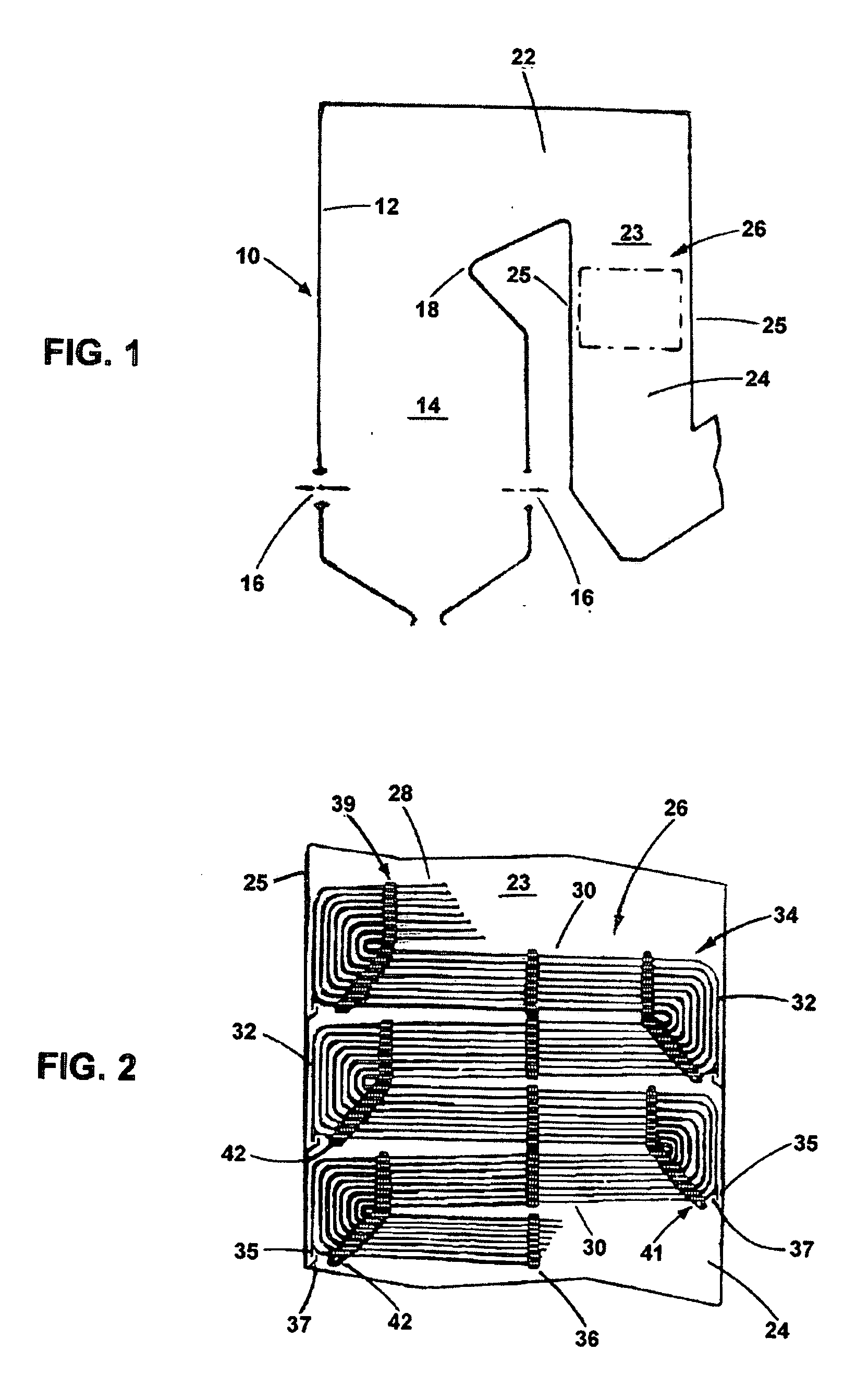

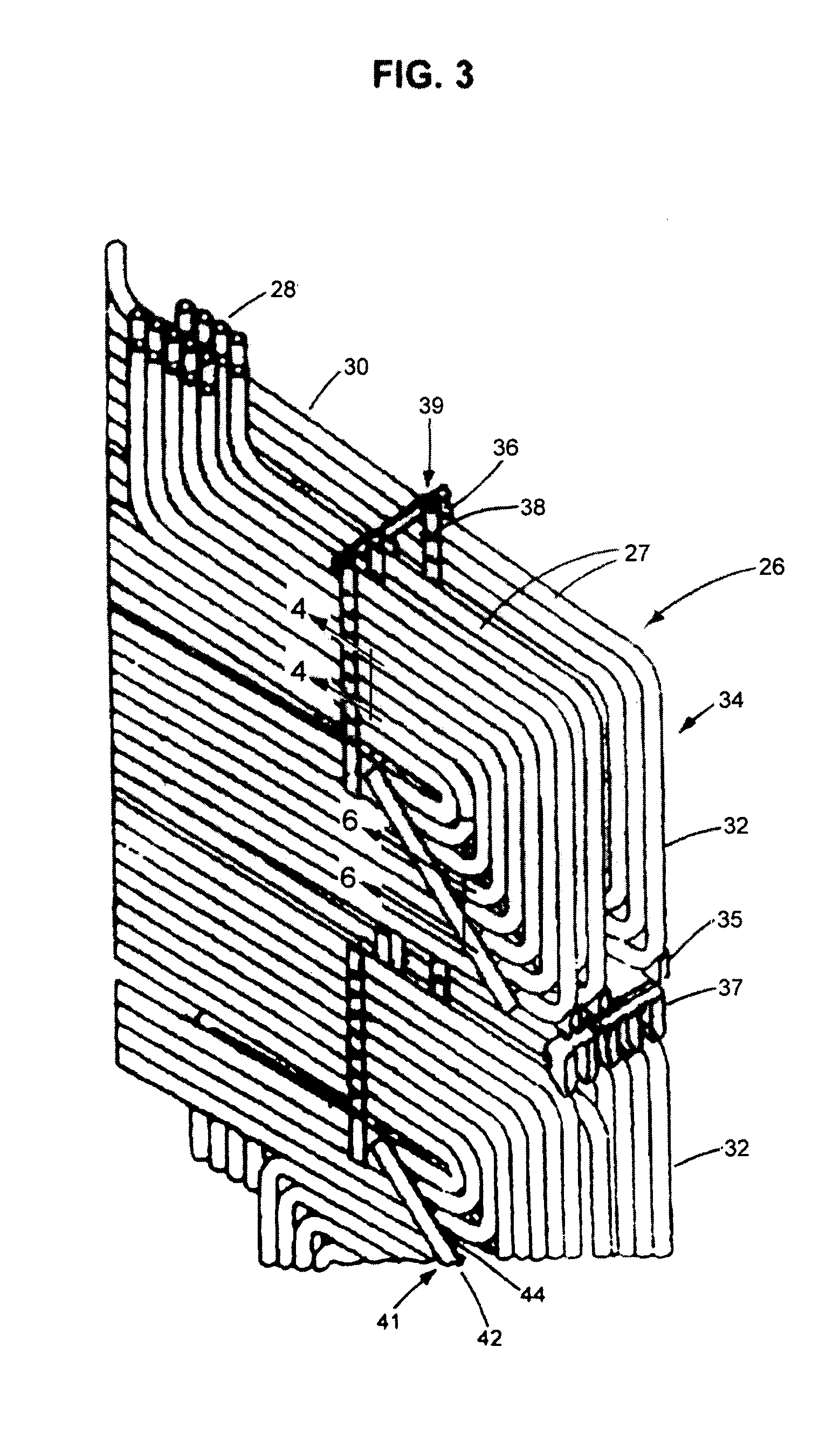

Heat exchanger framework

InactiveUS7464671B2Easy to drainAvoid distortionBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesEngineeringStructural framework

A structural framework for supporting the heat exchanger of a steam generator, the former being comprised of serpentine tubes having sloped segments to facilitate the drainage of water from the heat exchanger when the steam generator is shutdown. The structural framework includes paired groups of vertically and diagonally extending first support members contiguously straddling the sloped-tube segments. The paired first support members are rigidly connected by second support members which extend between adjacent sloped-tube segments. The structural framework preserves the spacing between the sloped-tube segments and prevents direct contact between adjoining tube surfaces, but is not attached to the straddled tube segments and, thus, provides a tube supporting fit that is loose enough to permit the tubes to move freely due to expansion and contraction at different rates from that of the structural framework.

Owner:THE BABCOCK & WILCOX CO

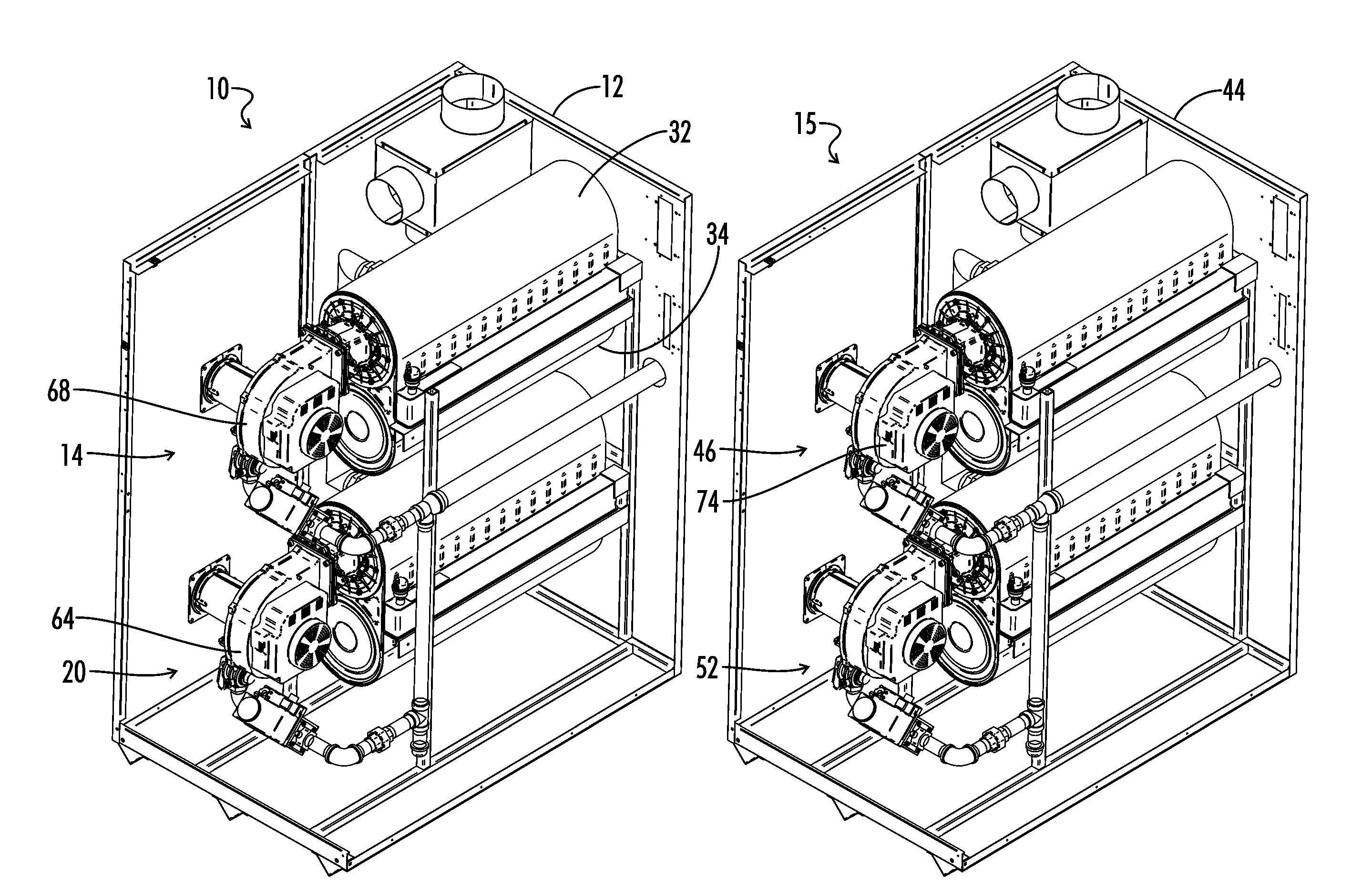

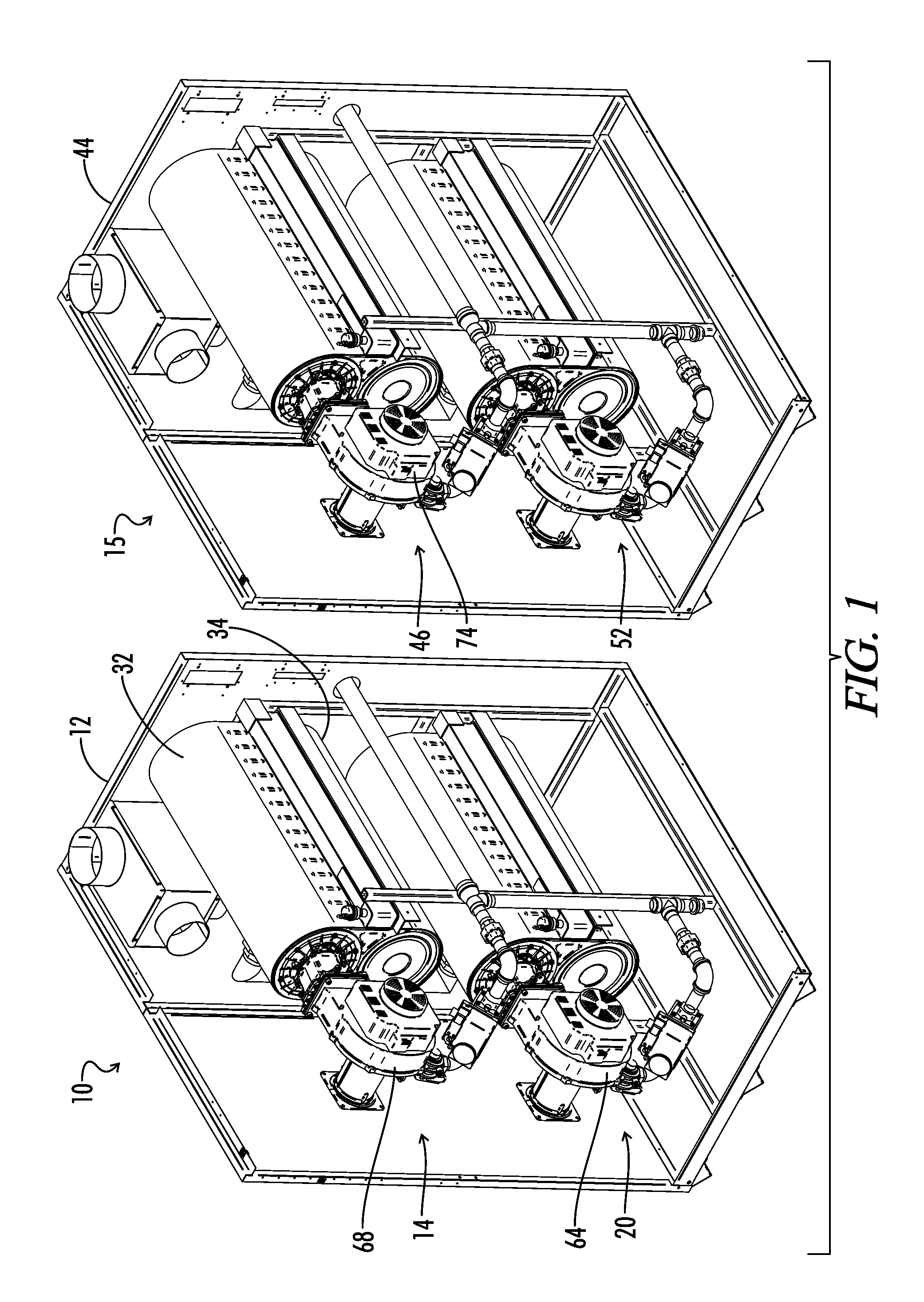

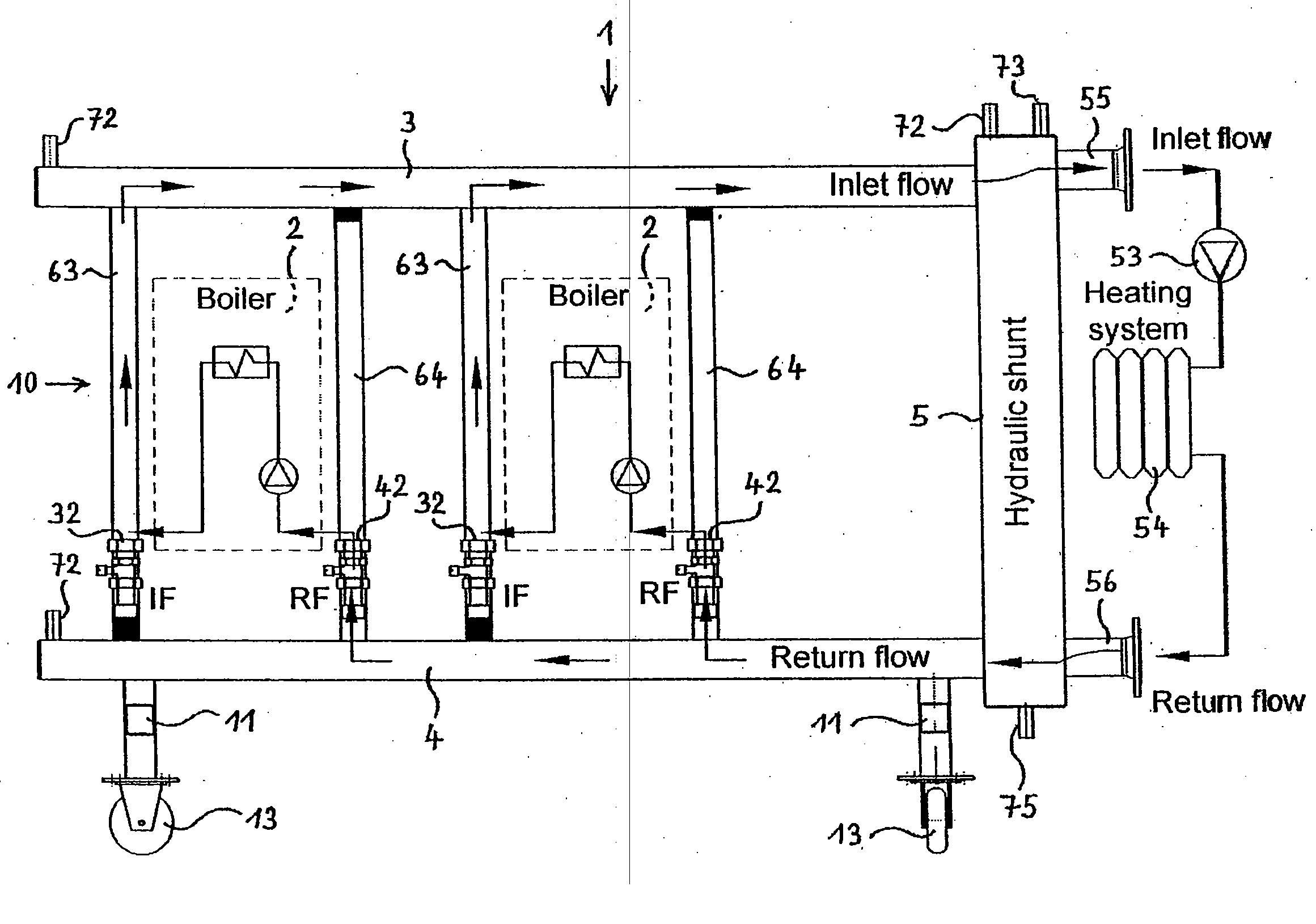

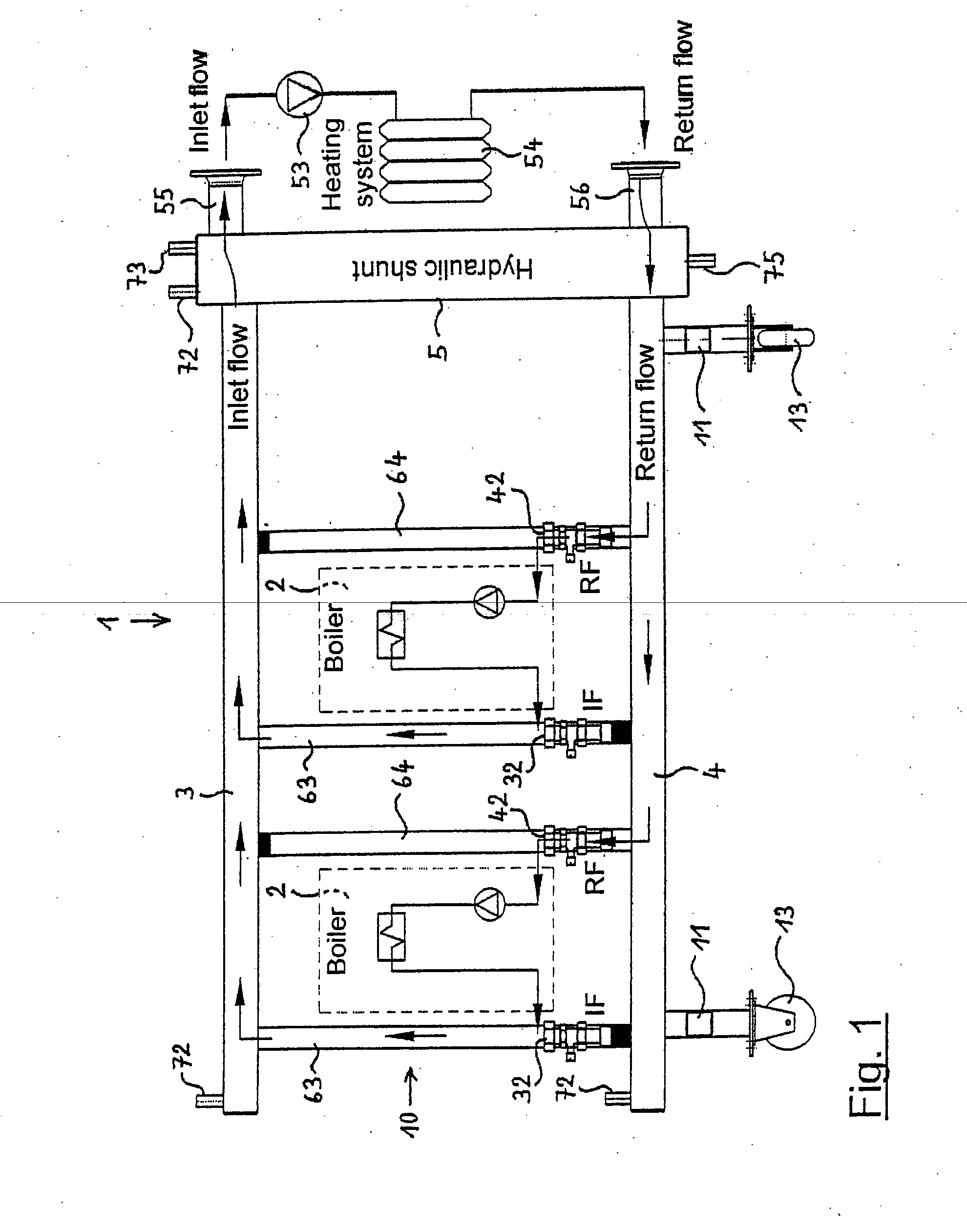

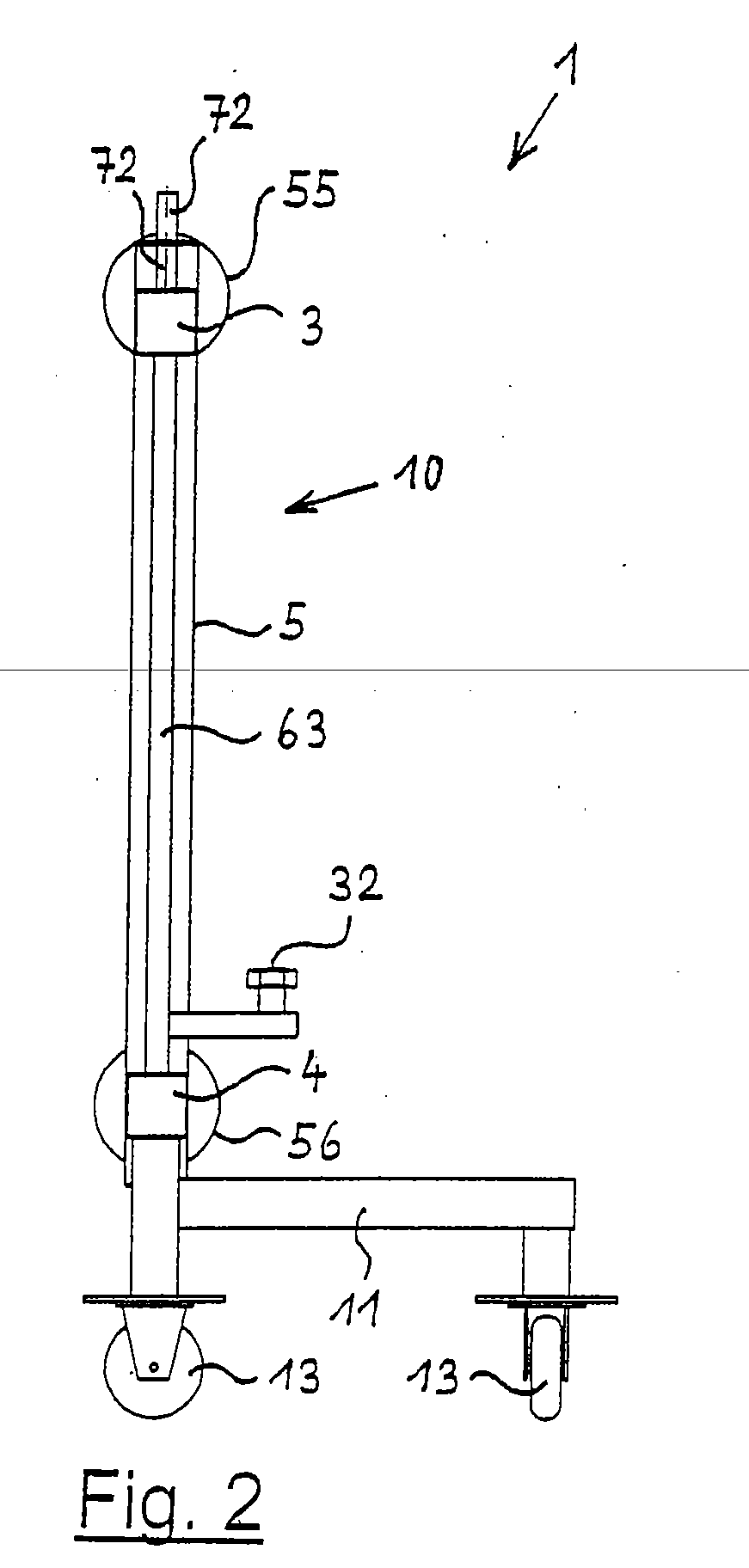

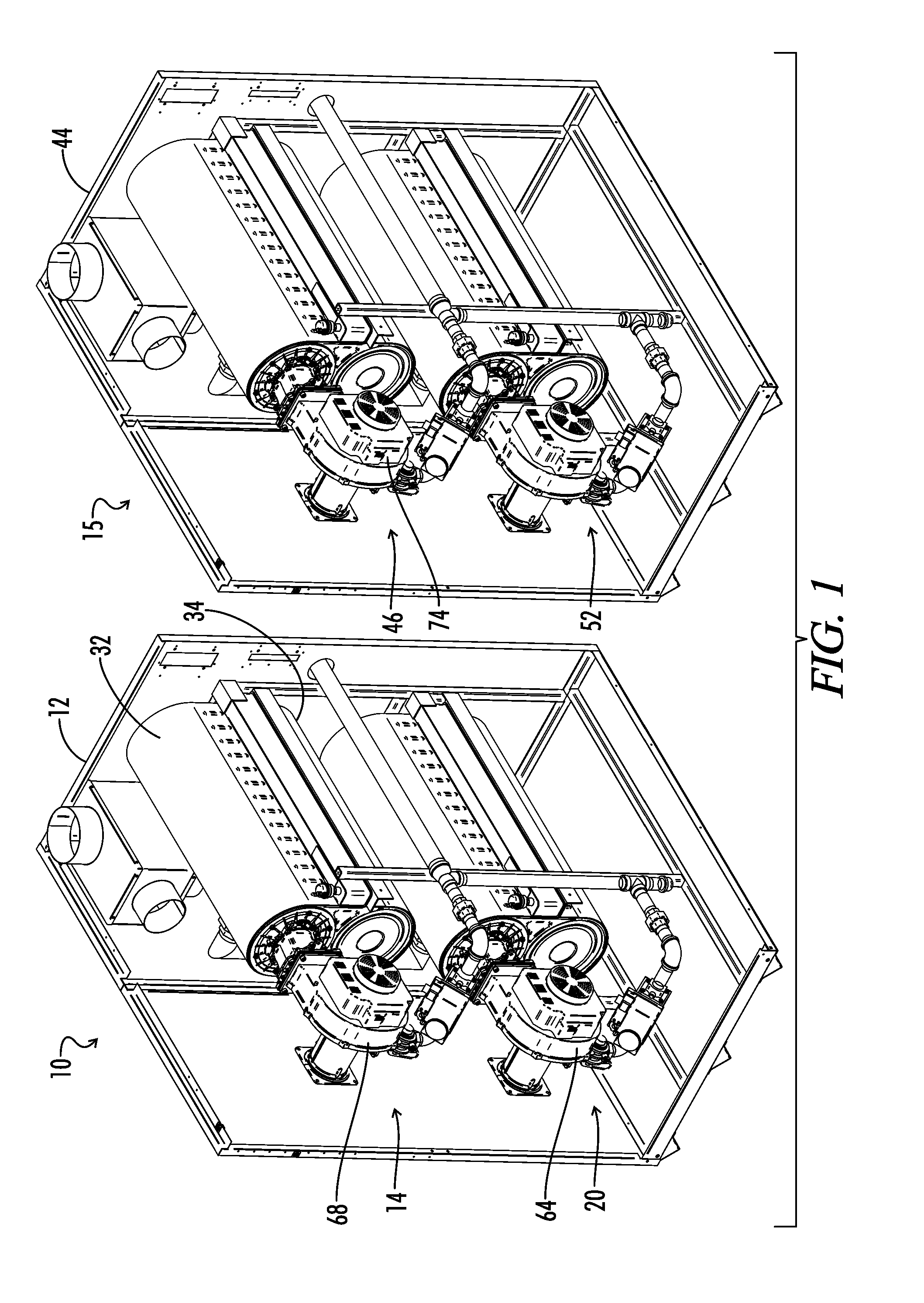

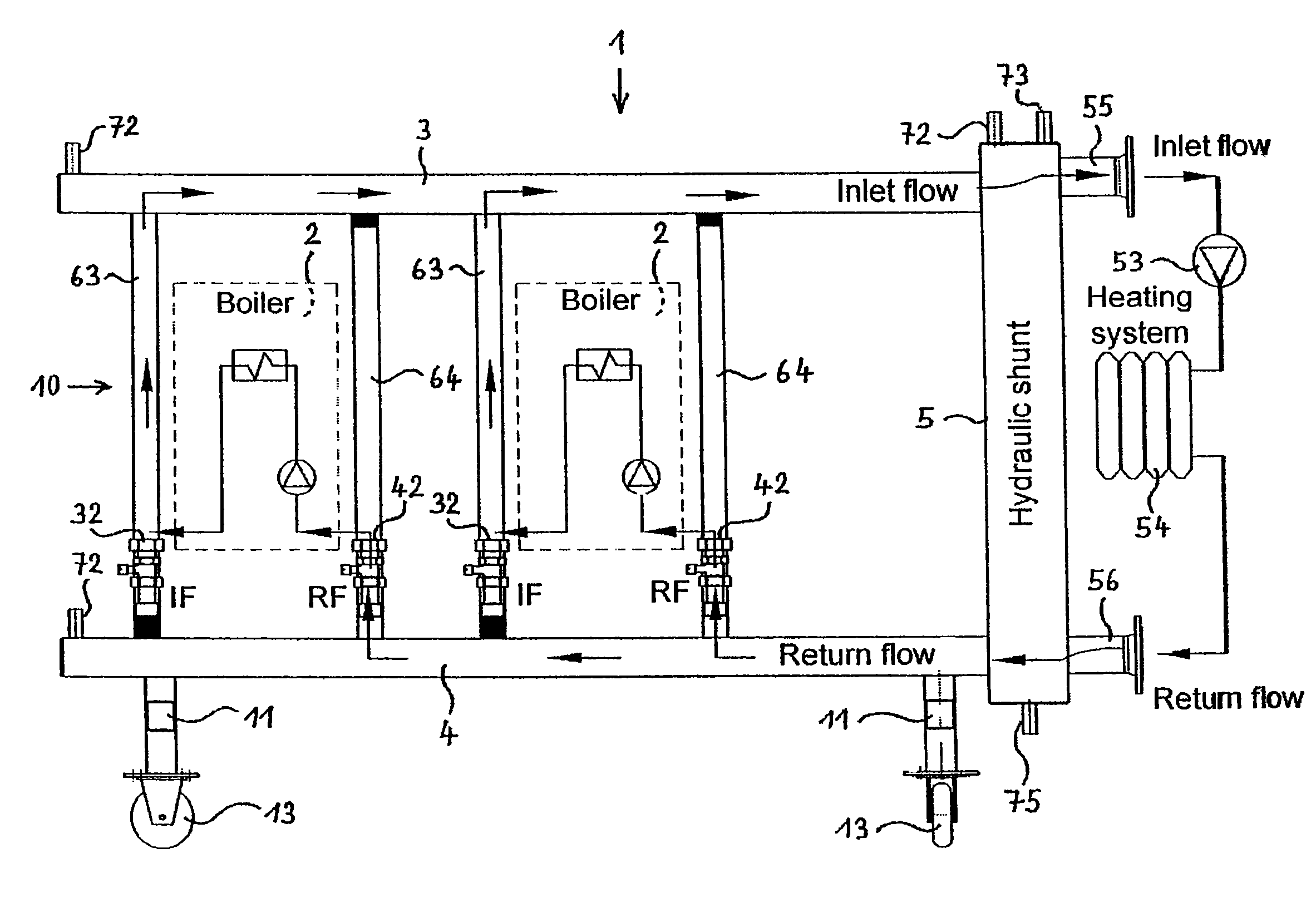

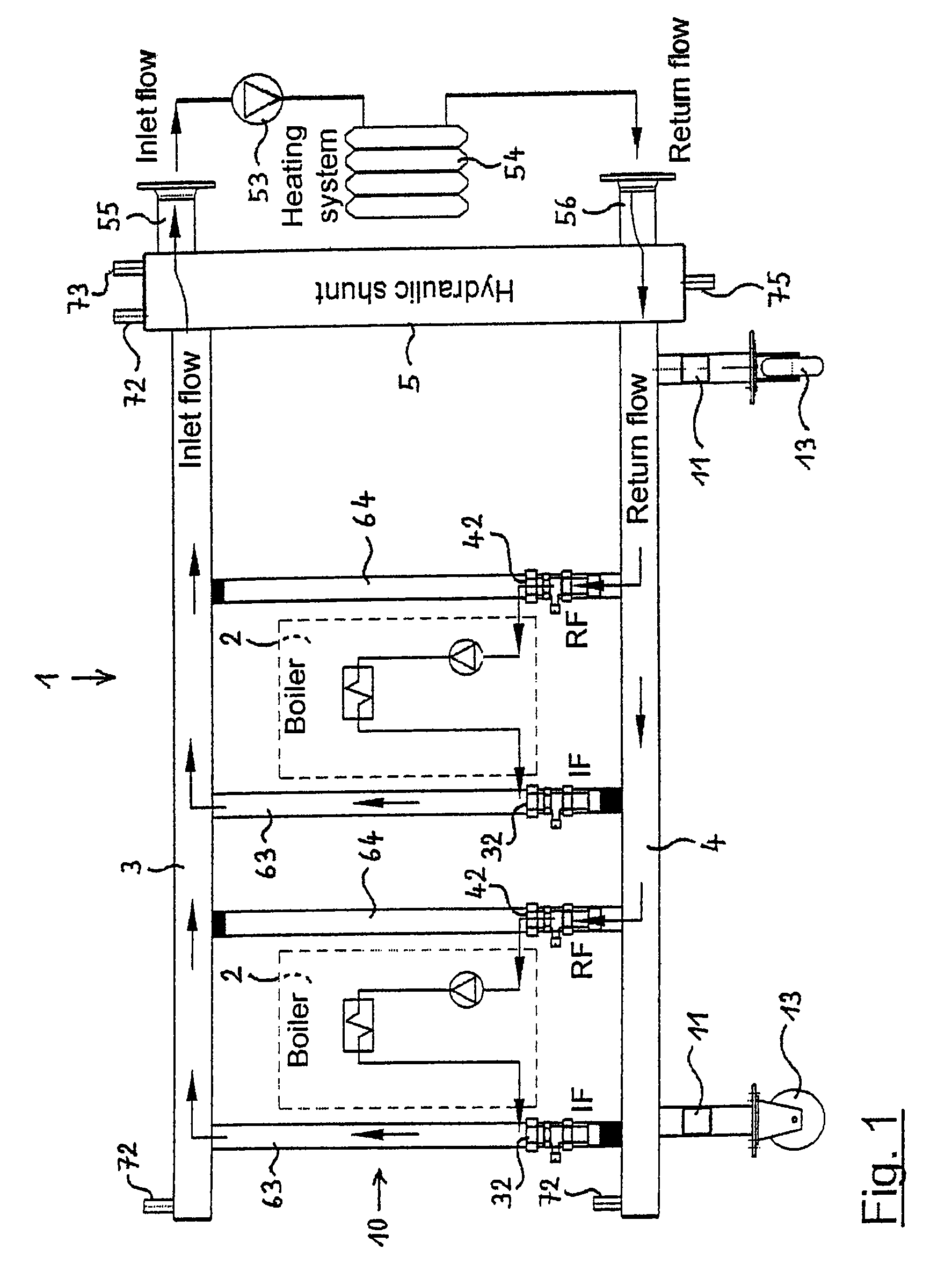

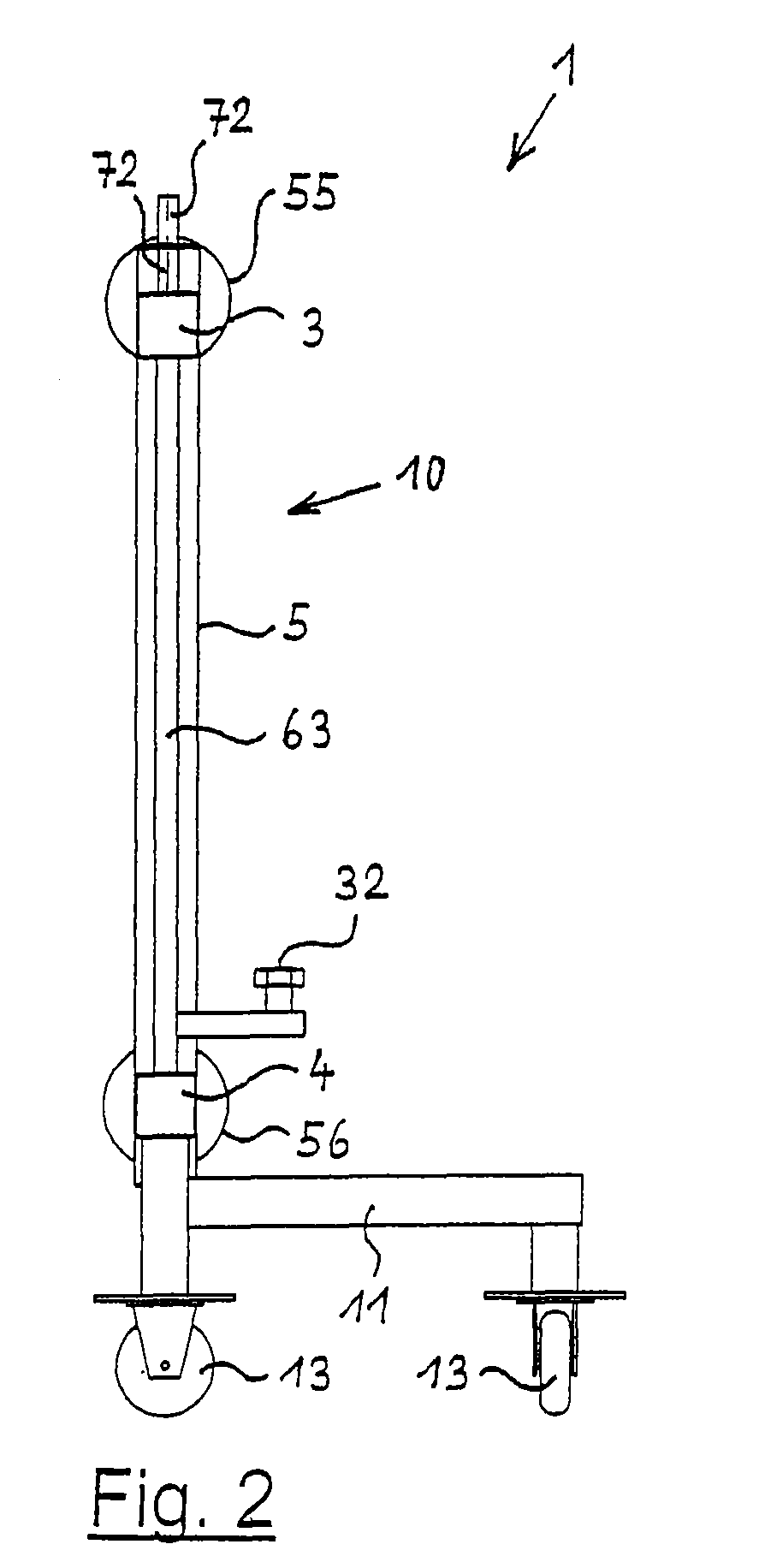

Cascade unit for a heating system with two or more heating boilers

ActiveUS20070144458A1Lower assembly costsExtensive and thus cost-saving prefabricationFluid heatersHeating fuelEngineeringInlet flow

The invention relates to a cascade unit for a heating system with two or more heating boilers, in particular condensing boilers, with a hydraulic shunt which is connected on the one hand with the inlet flows and return flows of all heating boilers and on the other hand with at least one heating circuit inlet flow and heating circuit return flow each, with the cascade unit furthermore comprising one each of the essentially horizontally extending boiler inlet flow header and boiler return flow manifold, the header and the manifold being connected with the hydraulic shunt, and the header and the manifold each being designed with prepared connecting nozzles fittingly placed for a group of two or more heating boilers the connection of the heating boiler inlet flows and the heating boiler return flows. The cascade unit forms at least one self-supporting support frame on which at least one of the heating boilers is mountable.

Owner:COMFORT SINUSVERTEILER

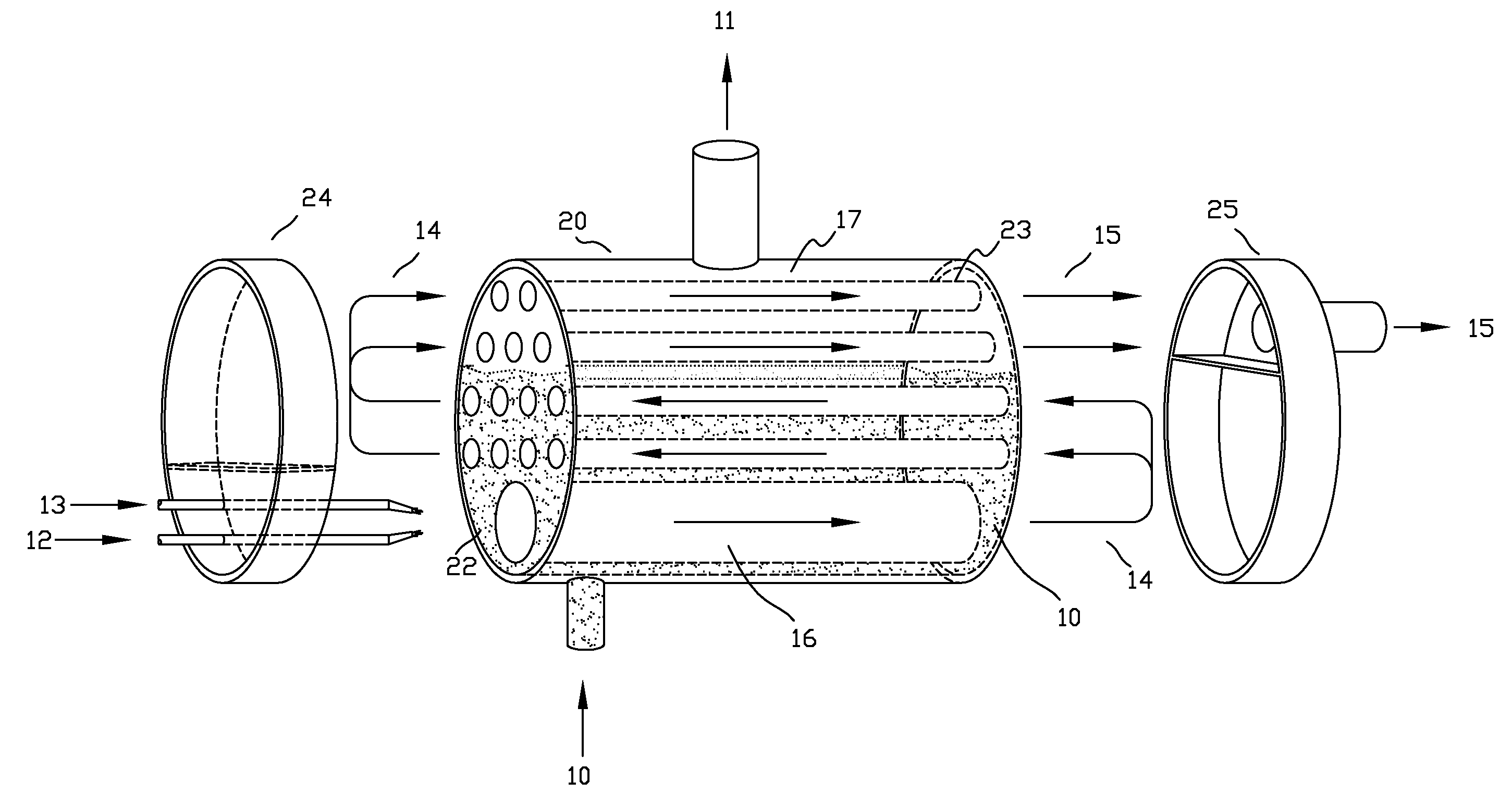

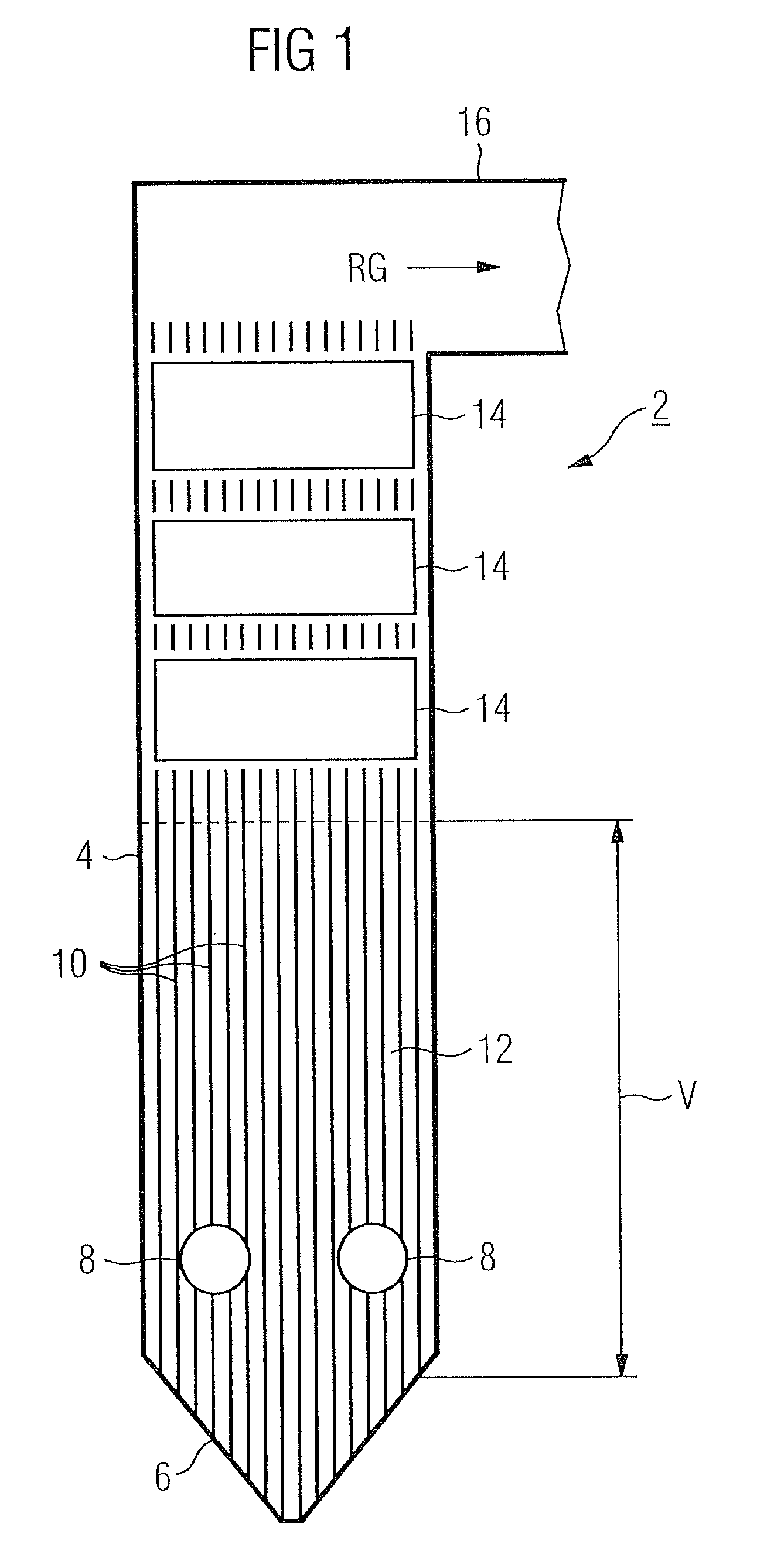

System and Method for Zero Emissions, Hydrogen Fueled Steam Generator

InactiveUS20080223315A1Easy to completeEfficient heatingBoiler flue tubes/fire tubesSteam superheatersOxygenCarbon-based fuel

As we move towards a hydrogen economy or use hydrogen as an energy carrier, the need to get heat energy and steam out of the hydrogen is arising more frequently. This invention addresses that need without the atmospheric pollutants which would result from burning carbon based fuels or hydrogen freely in the air. Presented is an invention which has very high overall efficiency and generates no oxides of carbon and nearly zero nitrogen oxide compounds. The generated steam can be used for comfort heating, process heating, electric generation and other common applications requiring steam. The invention can also be used for generation of hot water. The process of steam generation is accomplished by precisely metering the mixing and oxidation of hydrogen and oxygen under controlled conditions. The result of this oxidation reaction is simply only water and heat, which are used to generate steam.

Owner:DOLAND GEORGE

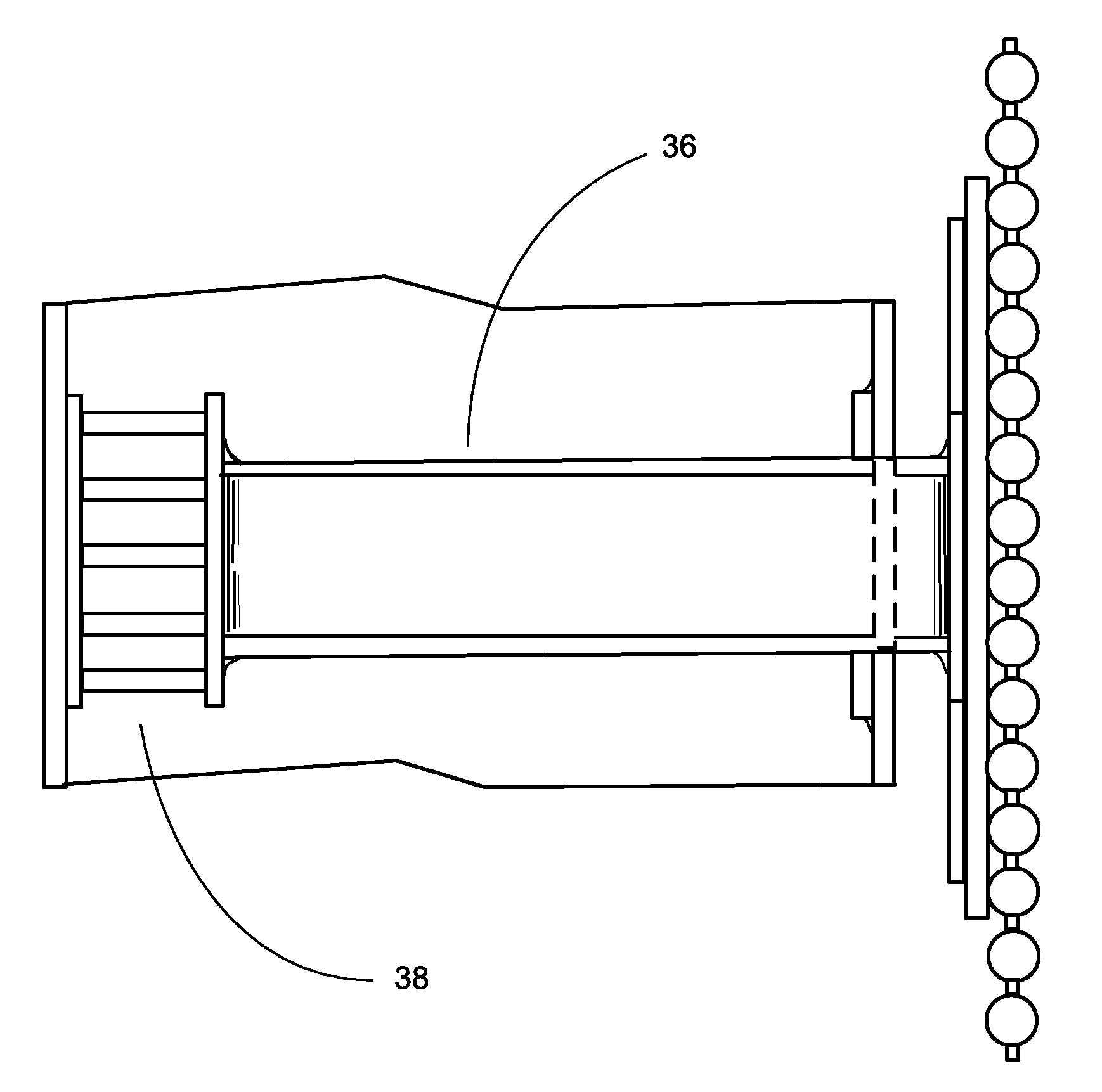

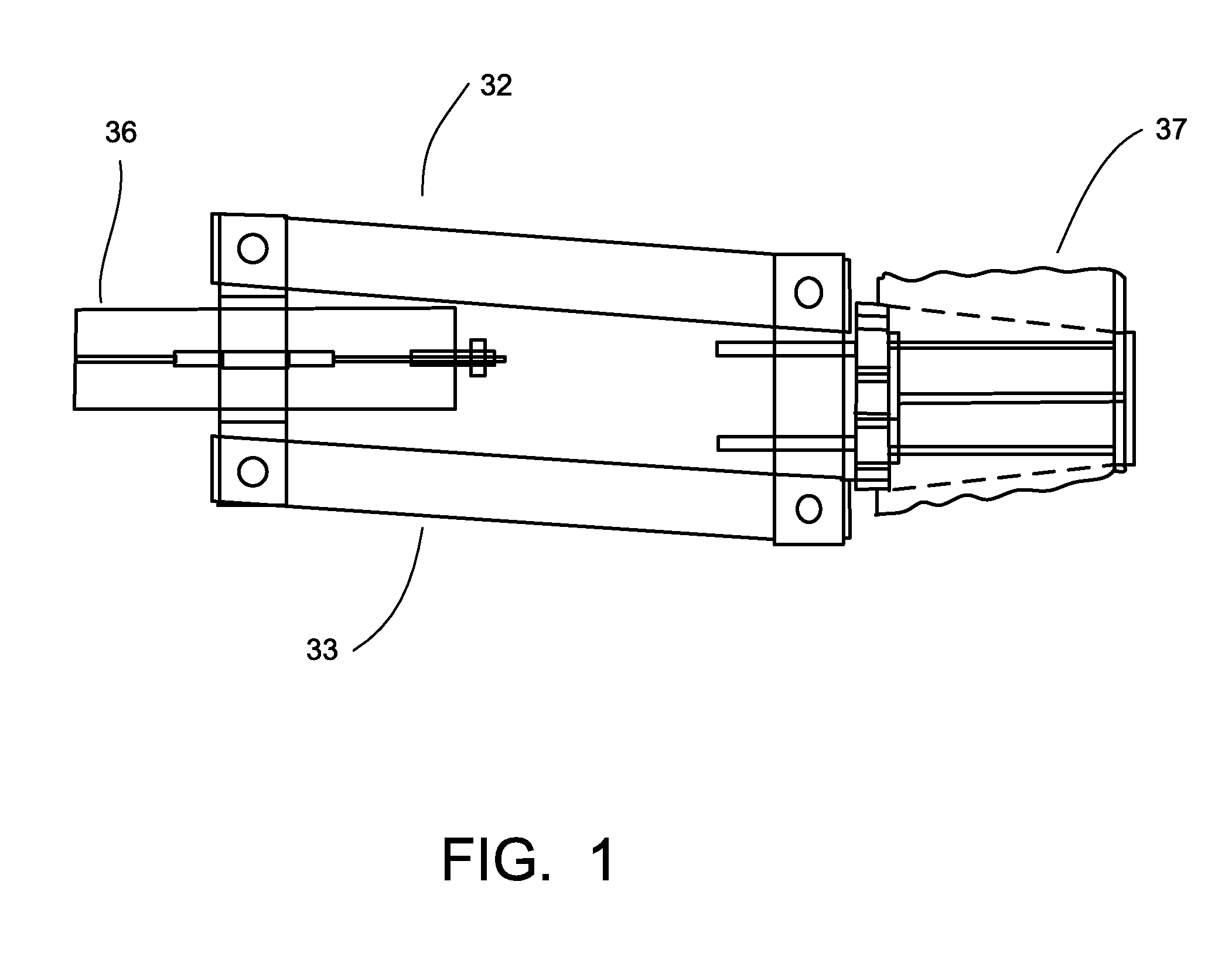

Firetube having thermal conducting passageways

InactiveUS20120145373A1Boiler flue tubes/fire tubesRecuperative heat exchangersEngineeringHeat exchanger

A firetube is immersed in a fluid to be heated and transfers heat from hot gases flowing through the firetube to the fluid surrounding the firetube. The firetube has a plurality of thermally conductive passageways which extend through the firetube for increasing the surface area available for heat transfer. Fluid is conducted through the passageways by a thermosiphon effect resulting from a temperature differential in the vessel, the fluid below the firetube being cooler and denser than fluid above the heat exchanger.

Owner:CHADWICK ENERGY SERVICES

Cladding material, tube including such cladding material and methods of forming the same

A multi-layered cladding material including a ceramic matrix composite and a metallic material, and a tube formed from the cladding material. The metallic material forms an inner liner of the tube and enables hermetic sealing of thereof. The metallic material at ends of the tube may be exposed and have an increased thickness enabling end cap welding. The metallic material may, optionally, be formed to infiltrate voids in the ceramic matrix composite, the ceramic matrix composite encapsulated by the metallic material. The ceramic matrix composite includes a fiber reinforcement and provides increased mechanical strength, stiffness, thermal shock resistance and high temperature load capacity to the metallic material of the inner liner. The tube may be used as a containment vessel for nuclear fuel used in a nuclear power plant or other reactor. Methods for forming the tube comprising the ceramic matrix composite and the metallic material are also disclosed.

Owner:ADVANCED CERAMIC FIBERS

Link Type Seismic Tie For Boilers

InactiveUS20080271686A1Avoid displacementMore dampingPipe supportsBoiler supporting/setting arrangementsGusset plateMechanical engineering

A link-type seismic tie is provided between a steel structural support and a buckstay, and includes two horizontally arranged, parallel, and spaced apart link members, which are connected at their ends to large vertical pins. Each of the link members includes two horizontally arranged and parallel longitudinal outboard stringers and a horizontally arranged and parallel longitudinal center stringer centered between the two outboard stringers. Each link member further includes finger plates standing upright and spaced apart from each other relatively perpendicular to the longitudinal stringers. The finger plates are held between each of the outboard stringers and the longitudinal center stringer. A gusset plate connects the outboard stringers to a pin plate, which is connected to a large pin at the buckstay. The other end of the link members is connected to a large pin at the steel structural support via the ends of the outboard stringers.

Owner:THE BABCOCK & WILCOX CO

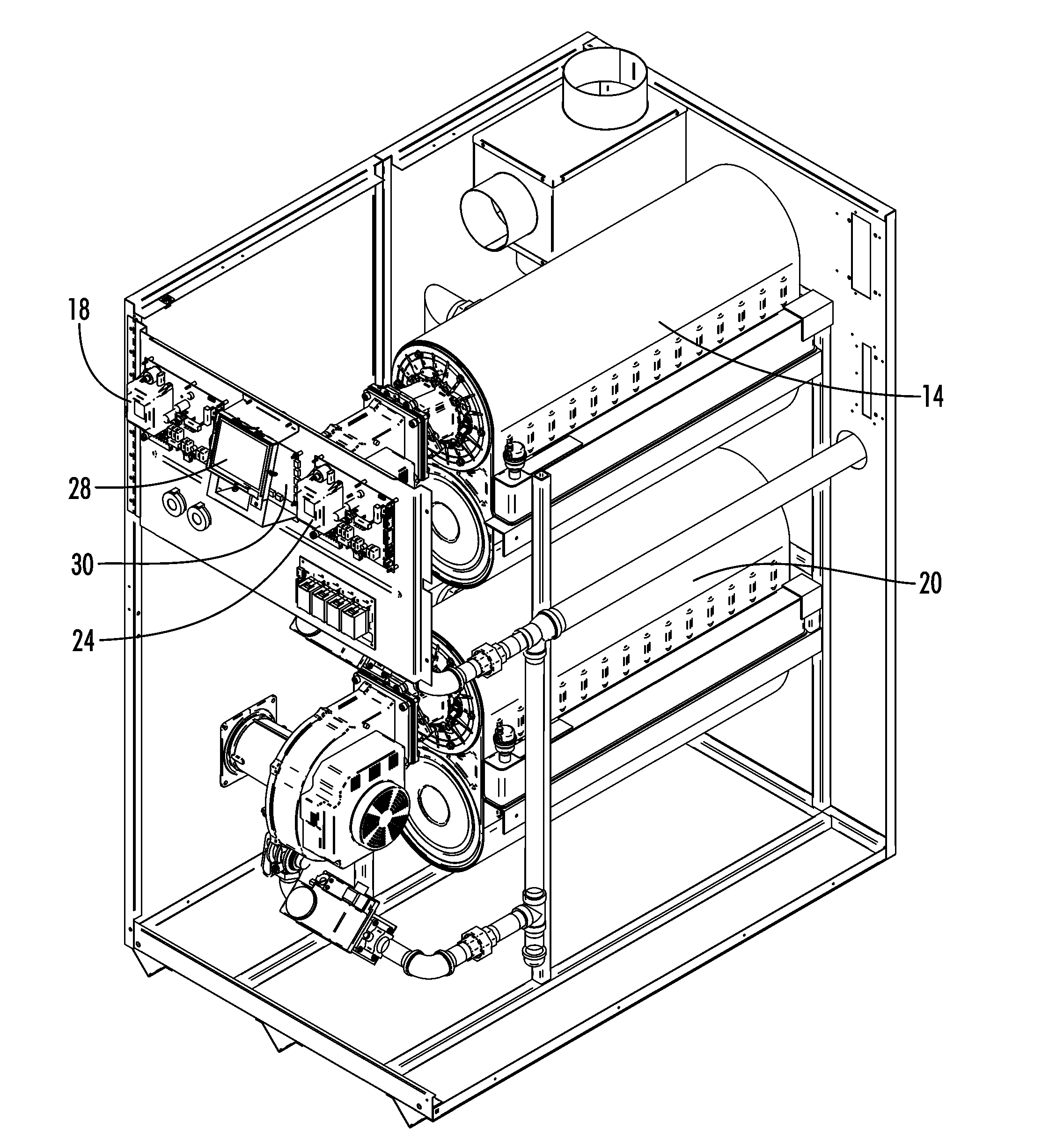

Control System For A Boiler Assembly

ActiveUS20130126627A1Modulated outputMinimize occurrenceBoiler flue tubes/fire tubesBoiler controlEngineeringControl theory

A control system for managing and interfacing a plurality of water heaters, e.g. boilers. The control system includes a first boiler unit controlled by a first boiler control unit and a second boiler unit controlled by a second boiler control unit. The first boiler control unit is operable to coordinate the operation of the first and second boiler units in response to changes in output demand. The flues of the first and second boiler units are connected to a common flue. The control system further includes an interface and an interface control system. The interface control system communicates requests from the interface, to report and / or alter the operating parameters of the first and second boiler units, to the first and second boiler control units and communicates the request outcome(s) back to the interface.

Owner:LOCHINVAR

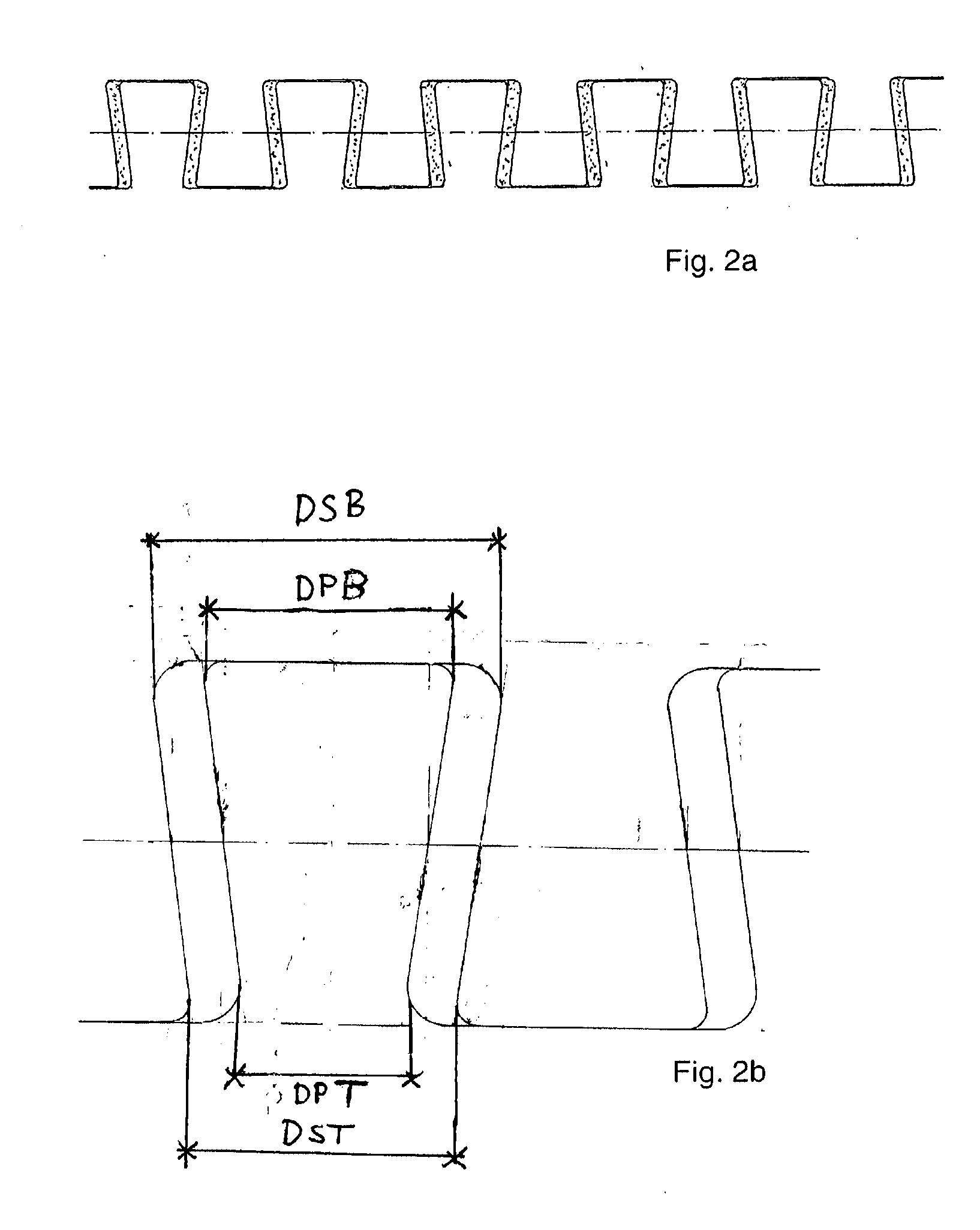

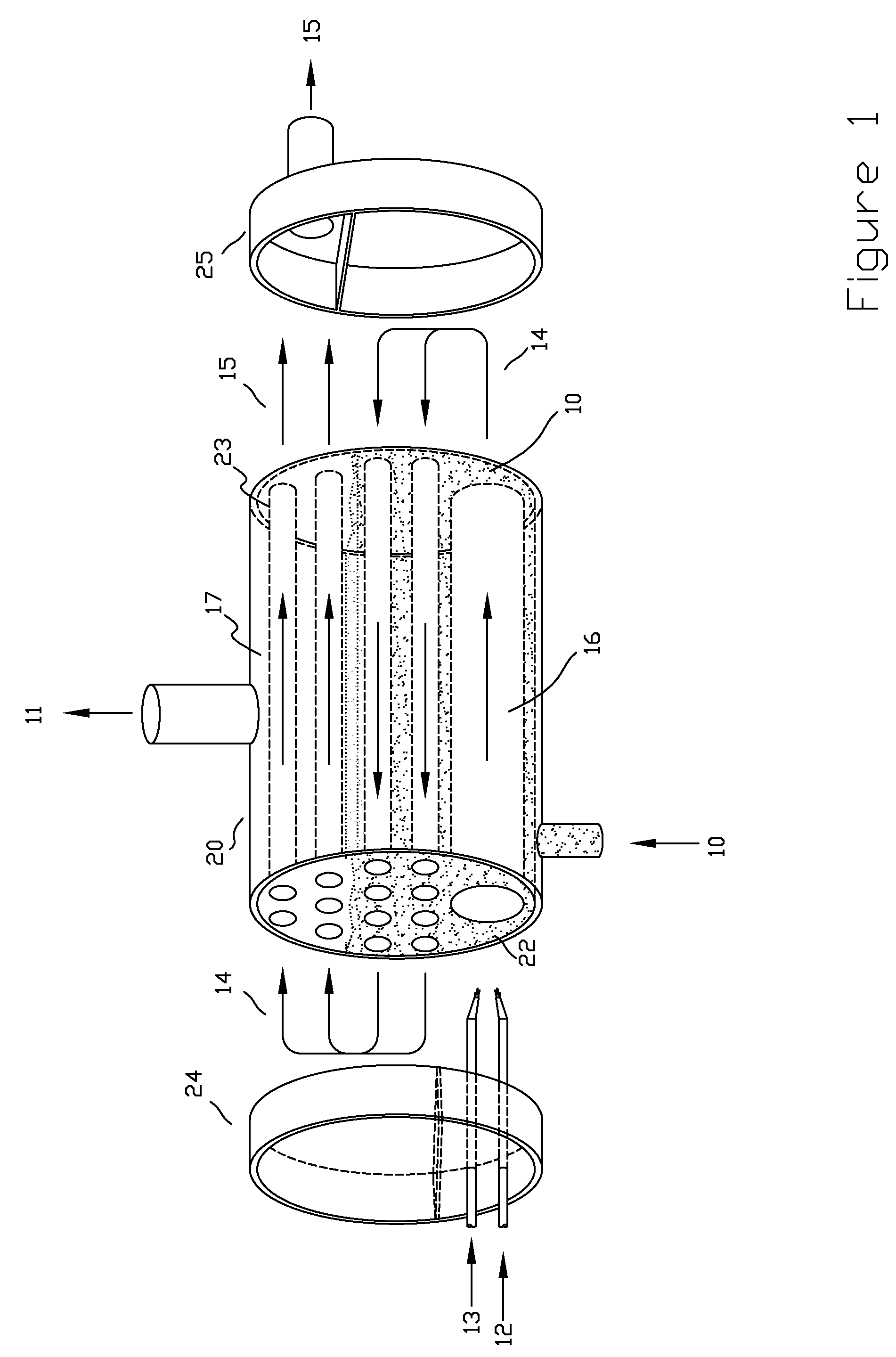

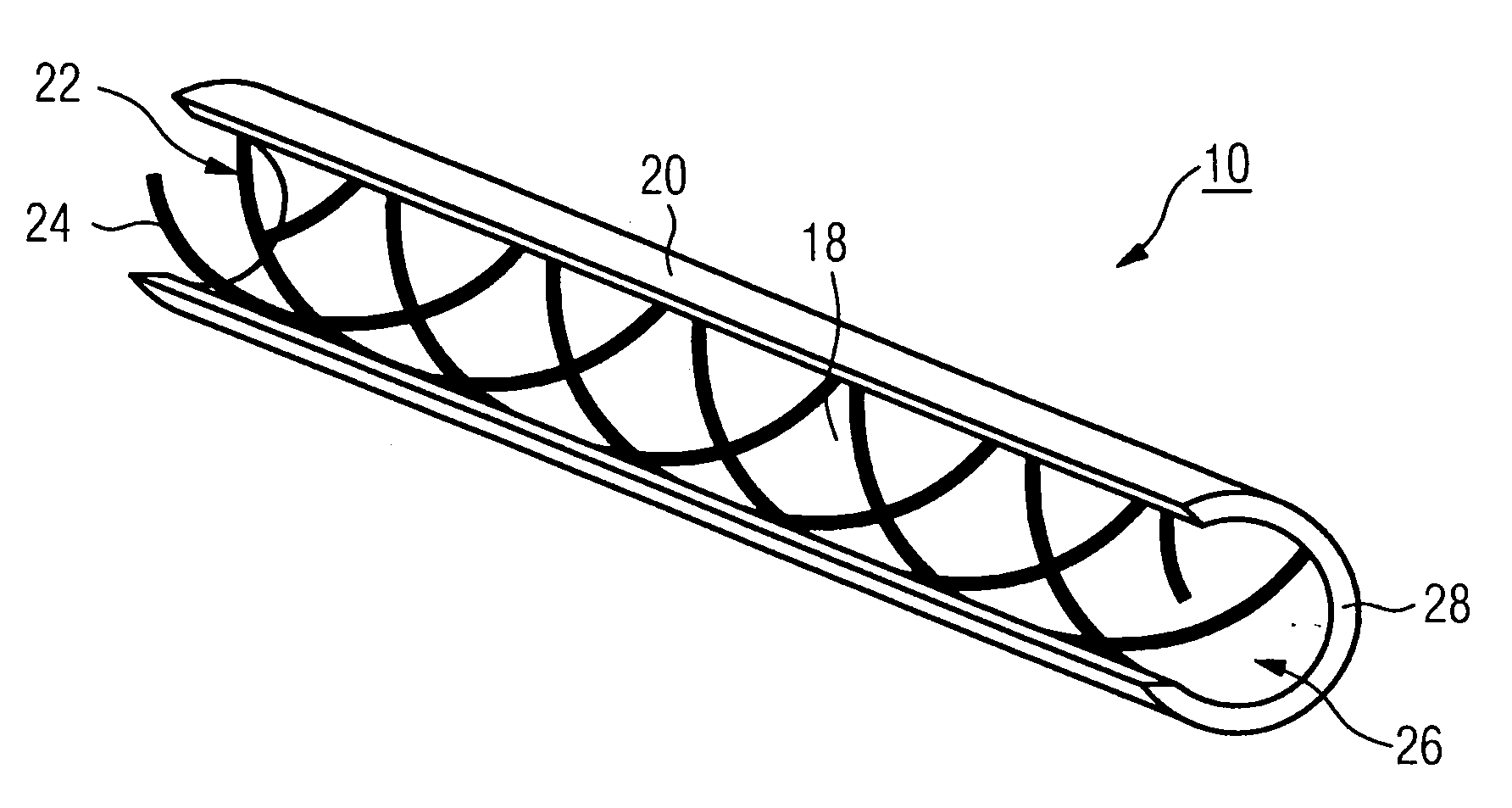

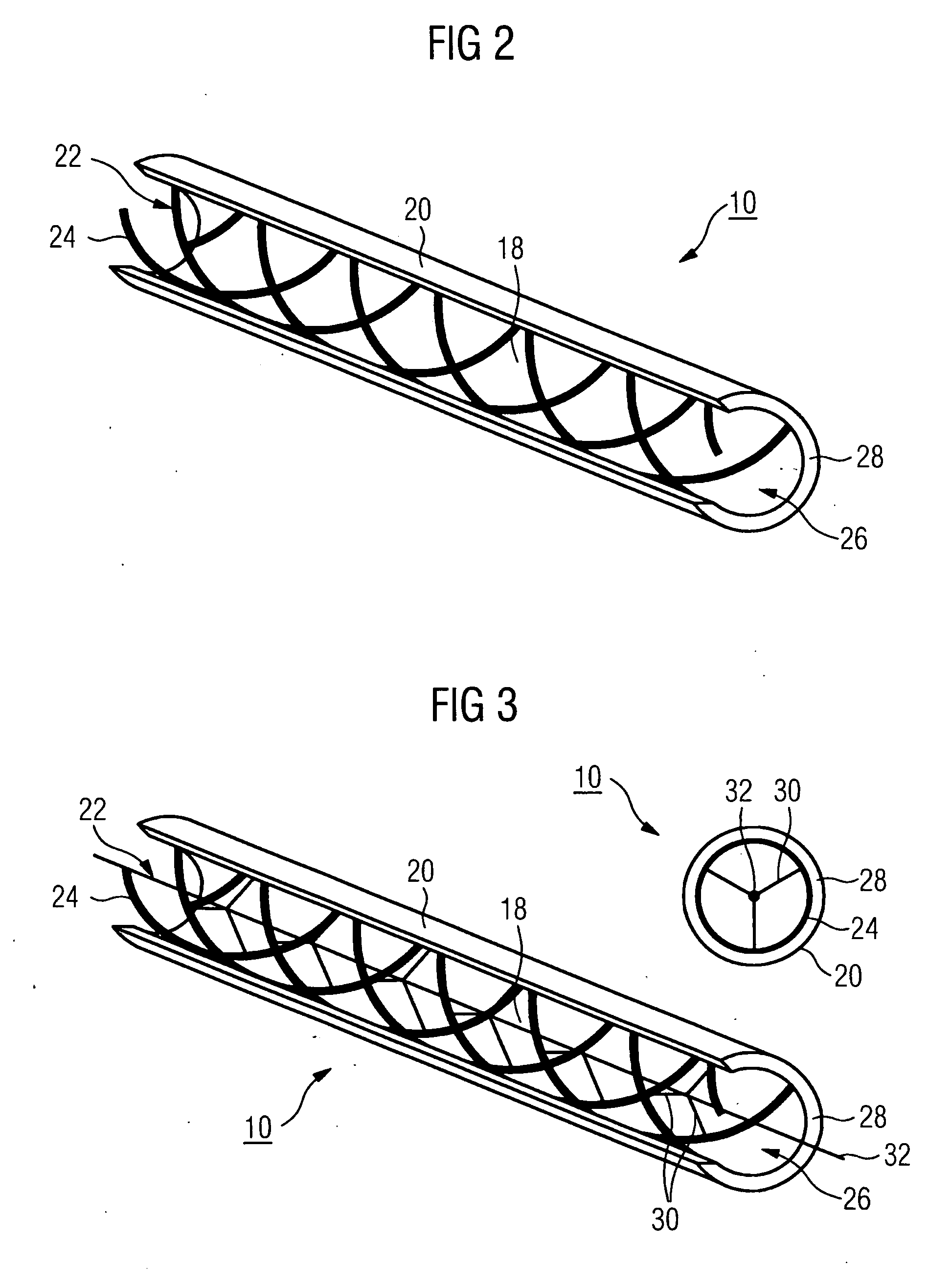

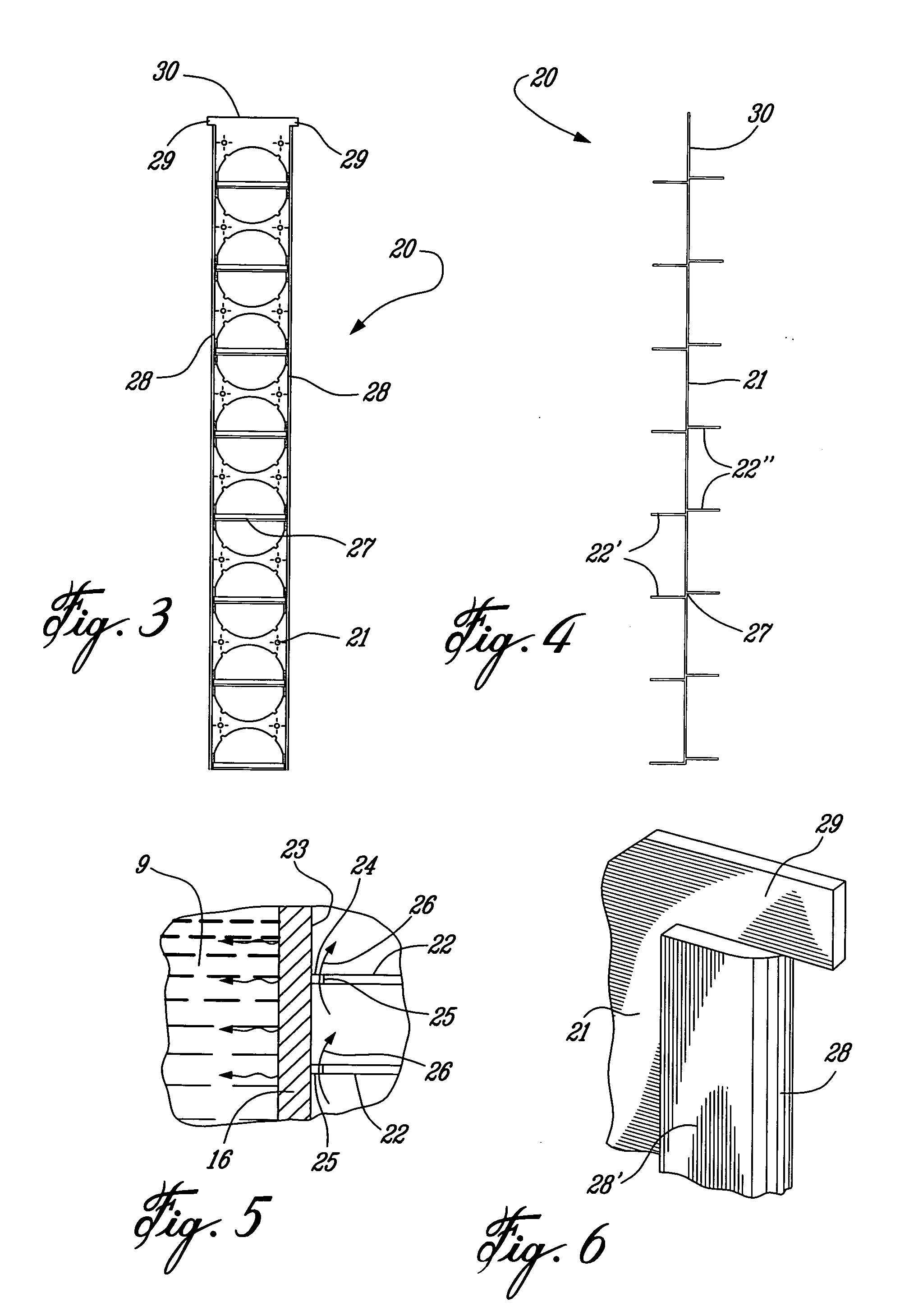

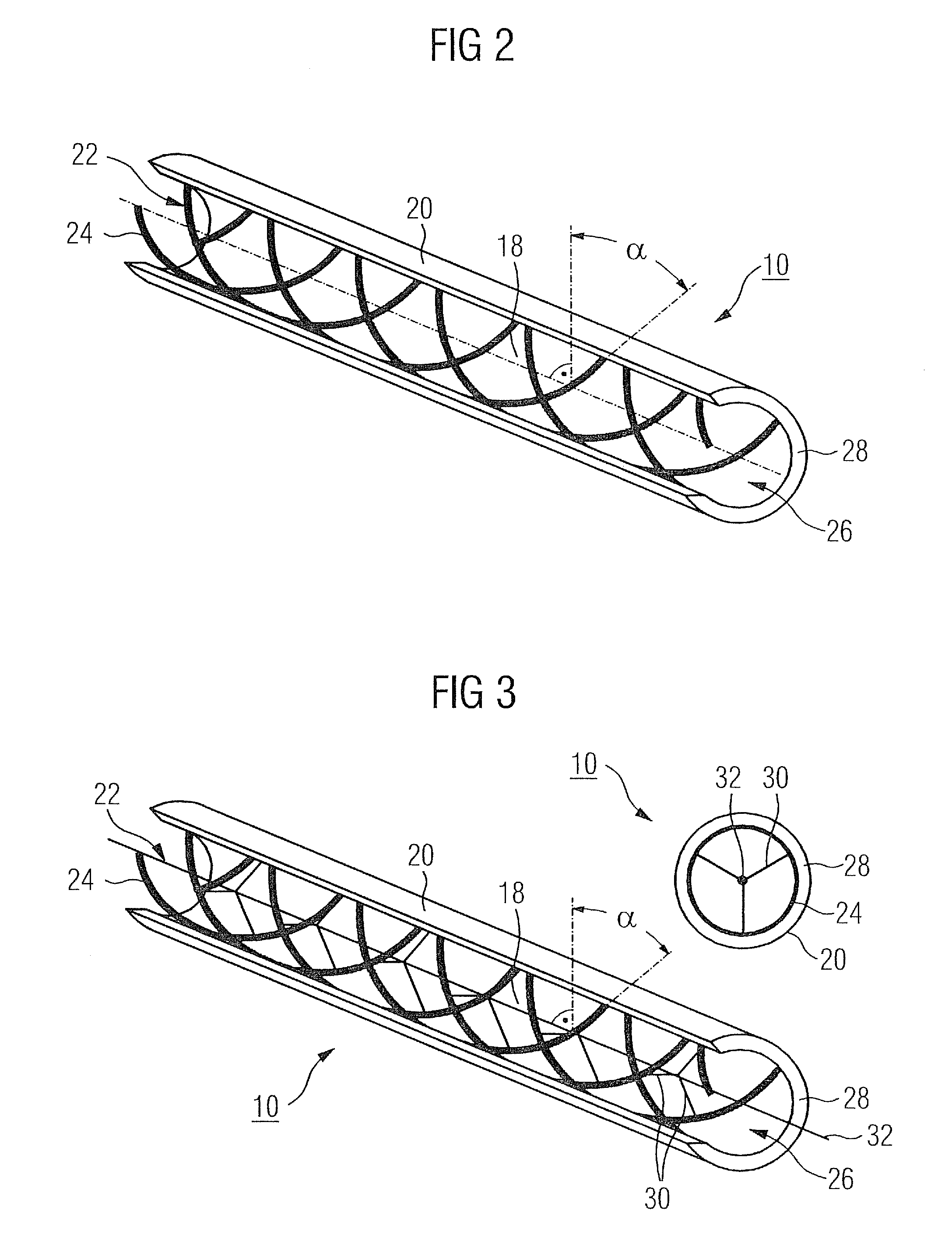

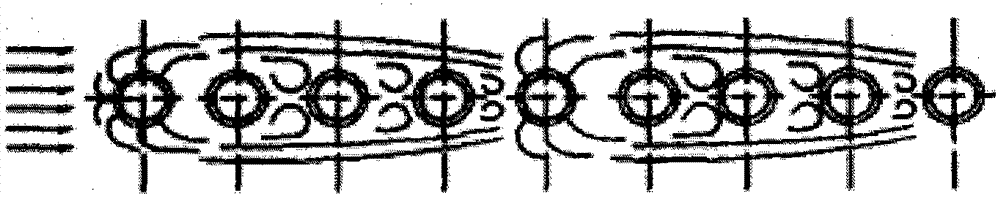

Steam Generator Pipe, Associated Production Method and Continuous Steam Generator

InactiveUS20090095236A1Favorable heat transition behaviorEasy to manufactureBoiler flue tubes/fire tubesBoiler water tubesEngineeringScrew thread

Disclosed is a steam generator pipe which can be produced in a simple and economical manner and which has a particularly good heat transitional behavior having a large band width with various operational conditions. According to the invention, at least one insert is arranged in the inner chamber of the pipe in order to form a swirl-generating inner profile. The insert comprises a plurality of wires which wind, in a screw-like manner, along the inner wall of the pipe in the form of a multi-path thread.

Owner:SIEMENS AG

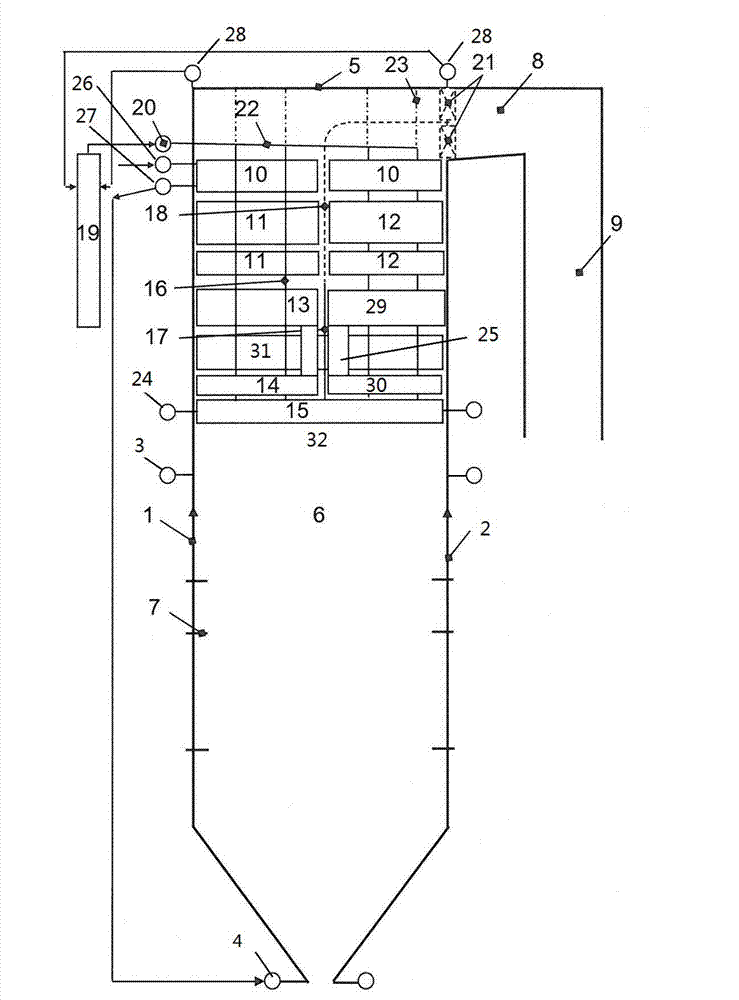

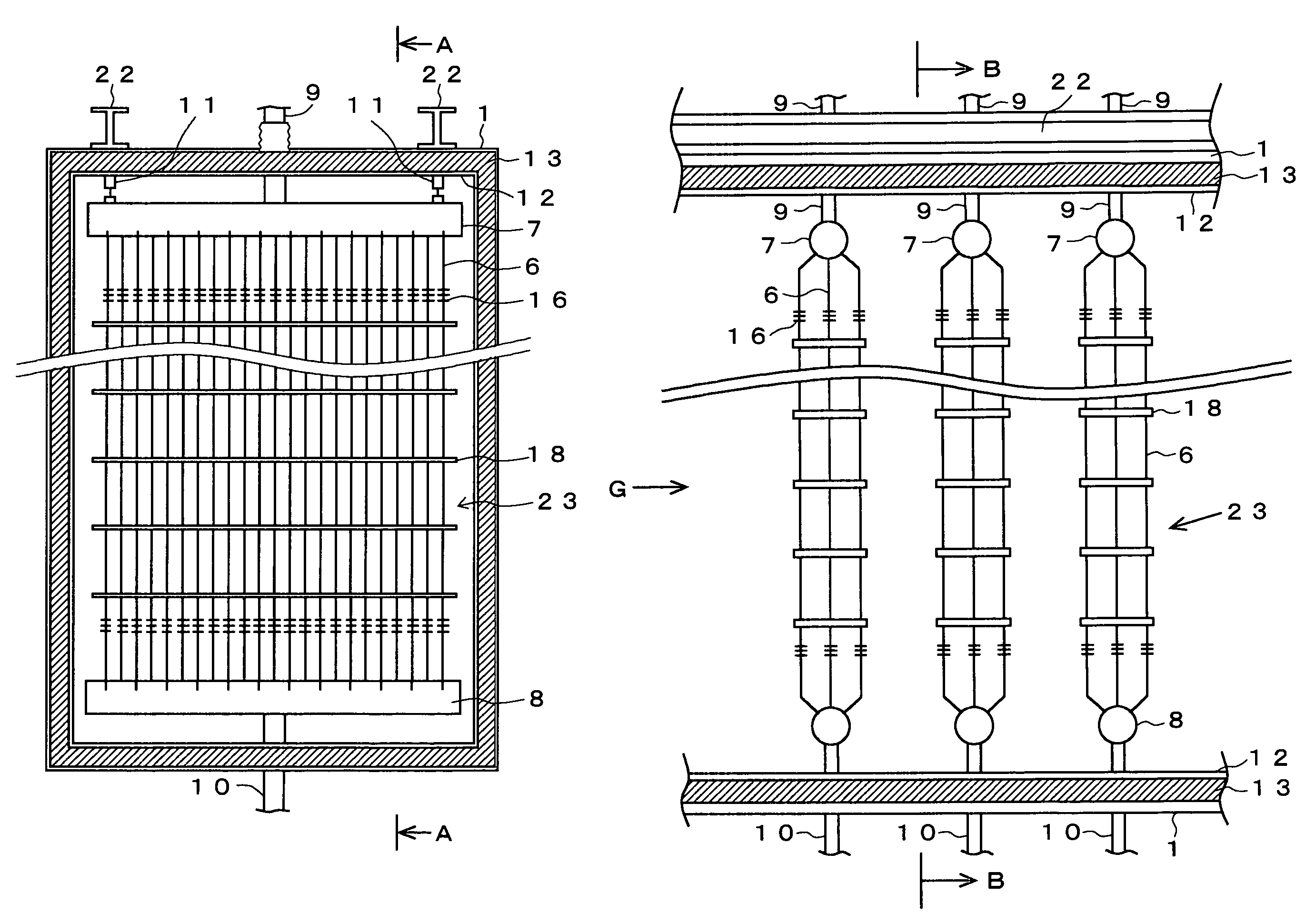

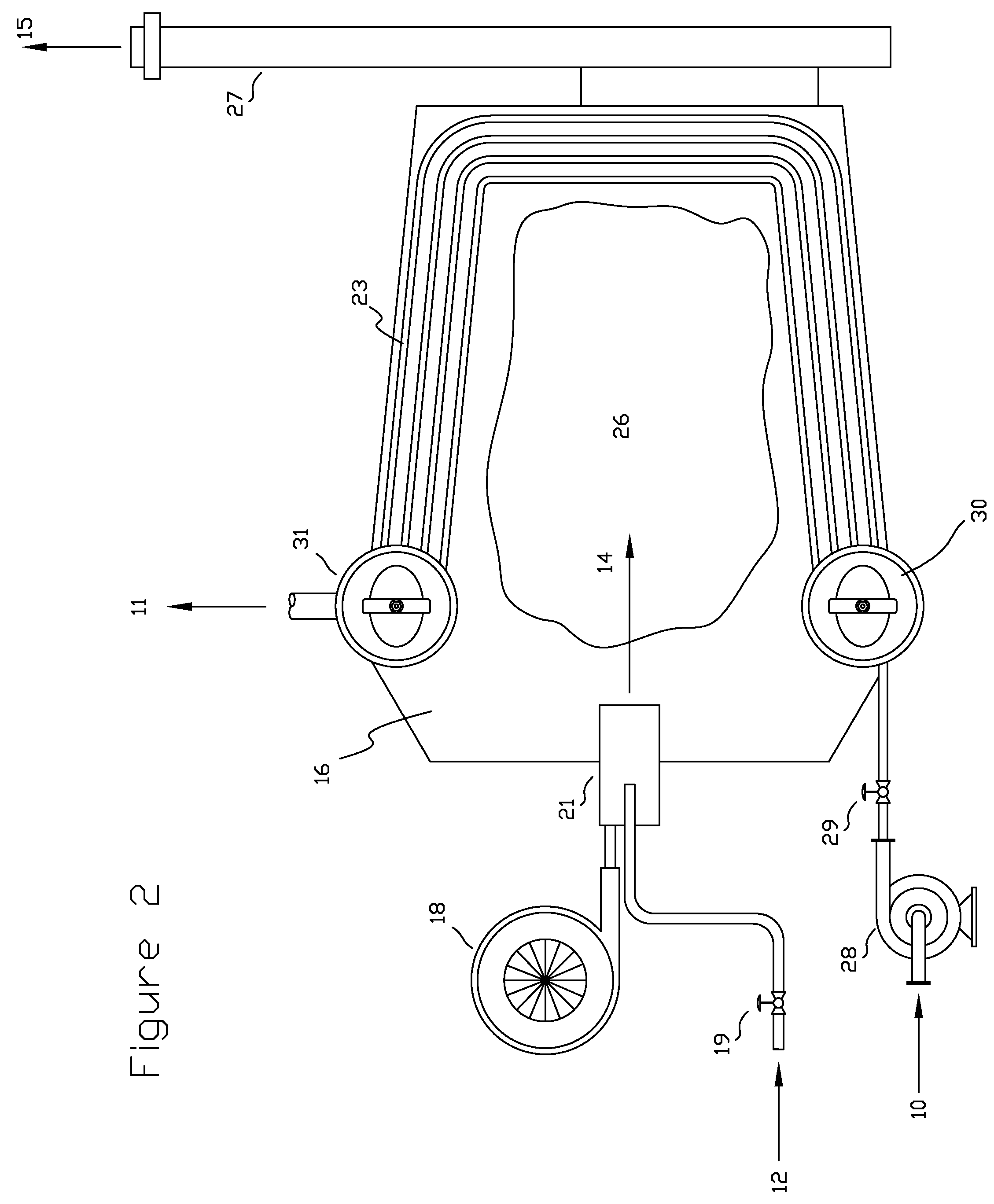

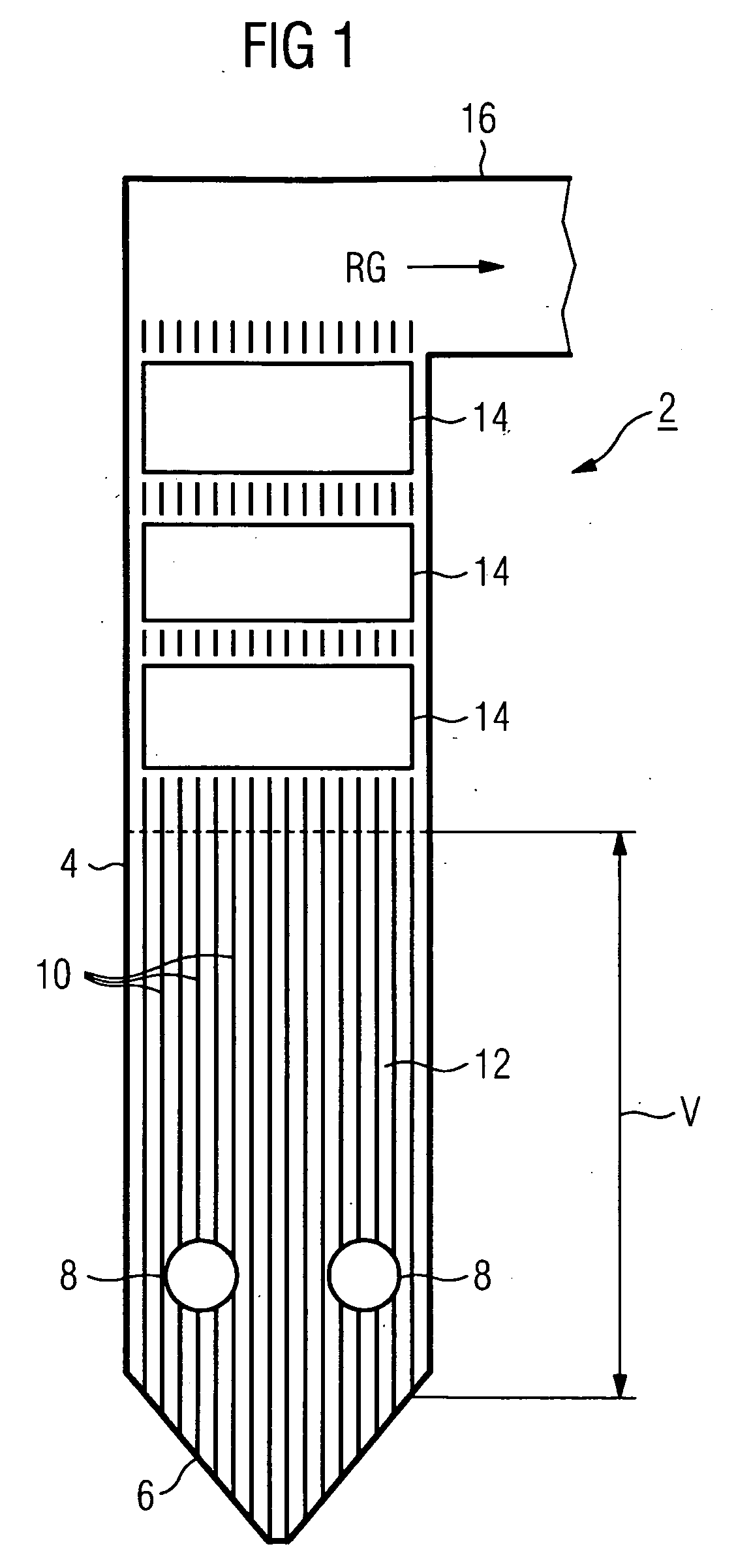

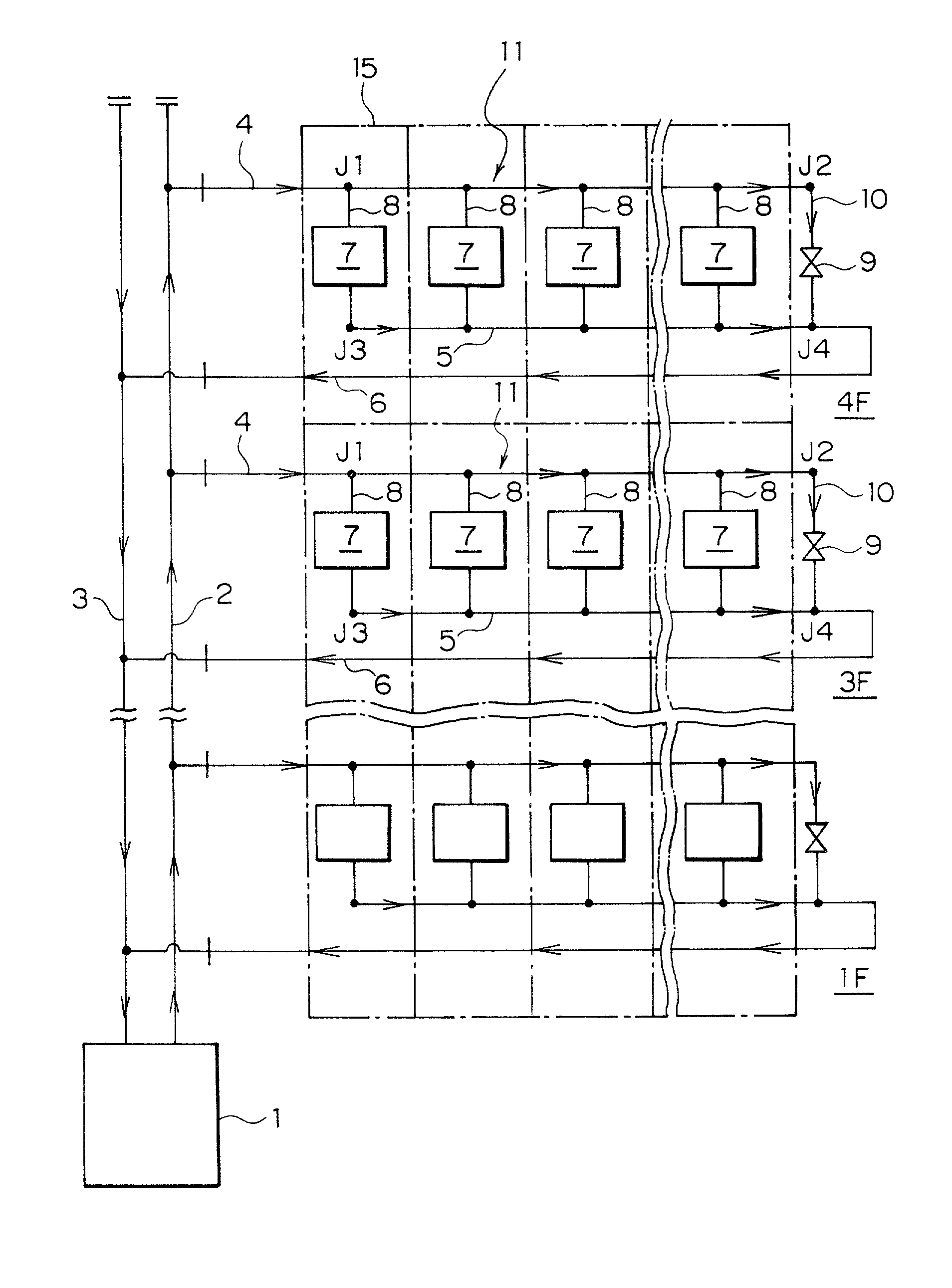

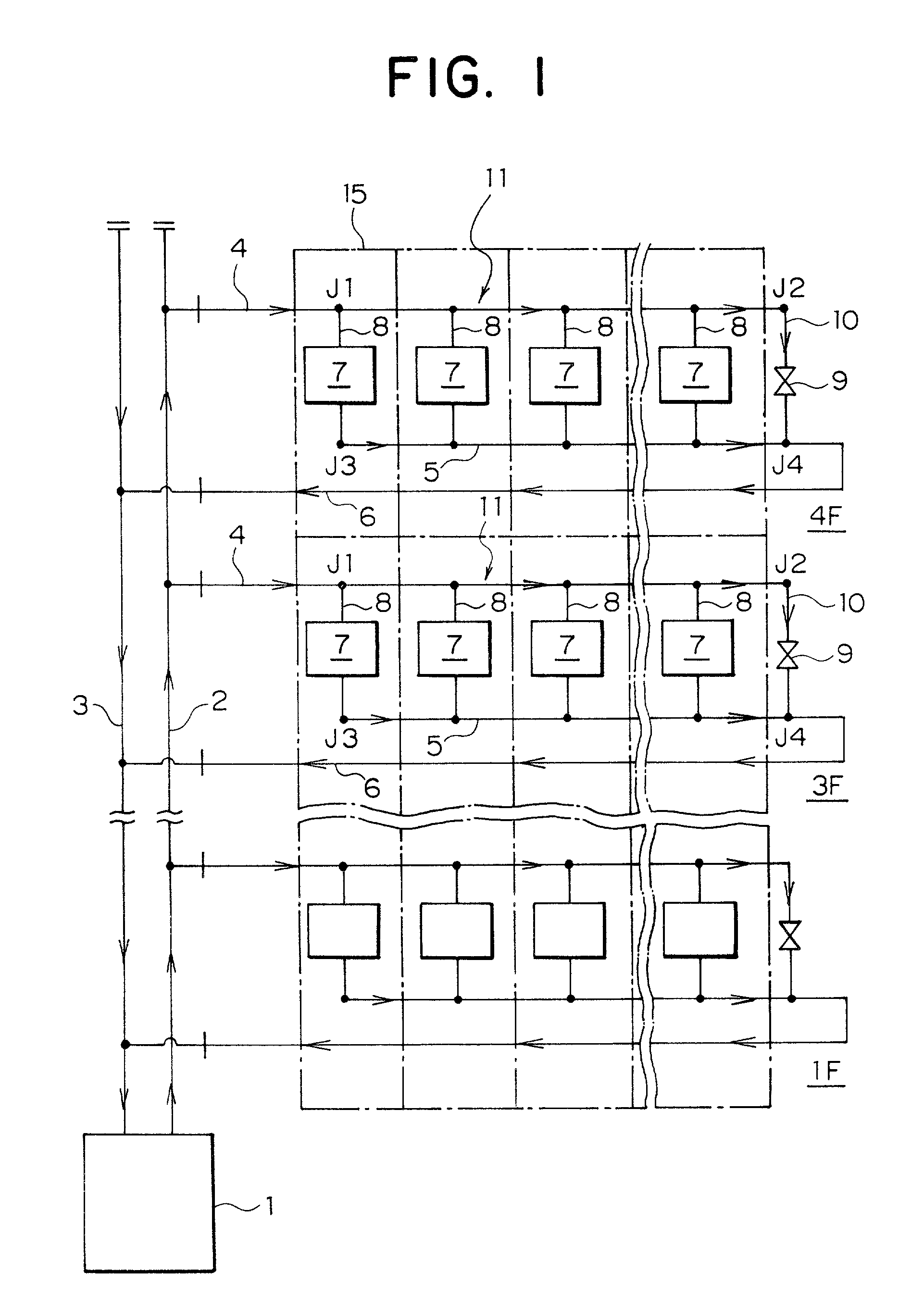

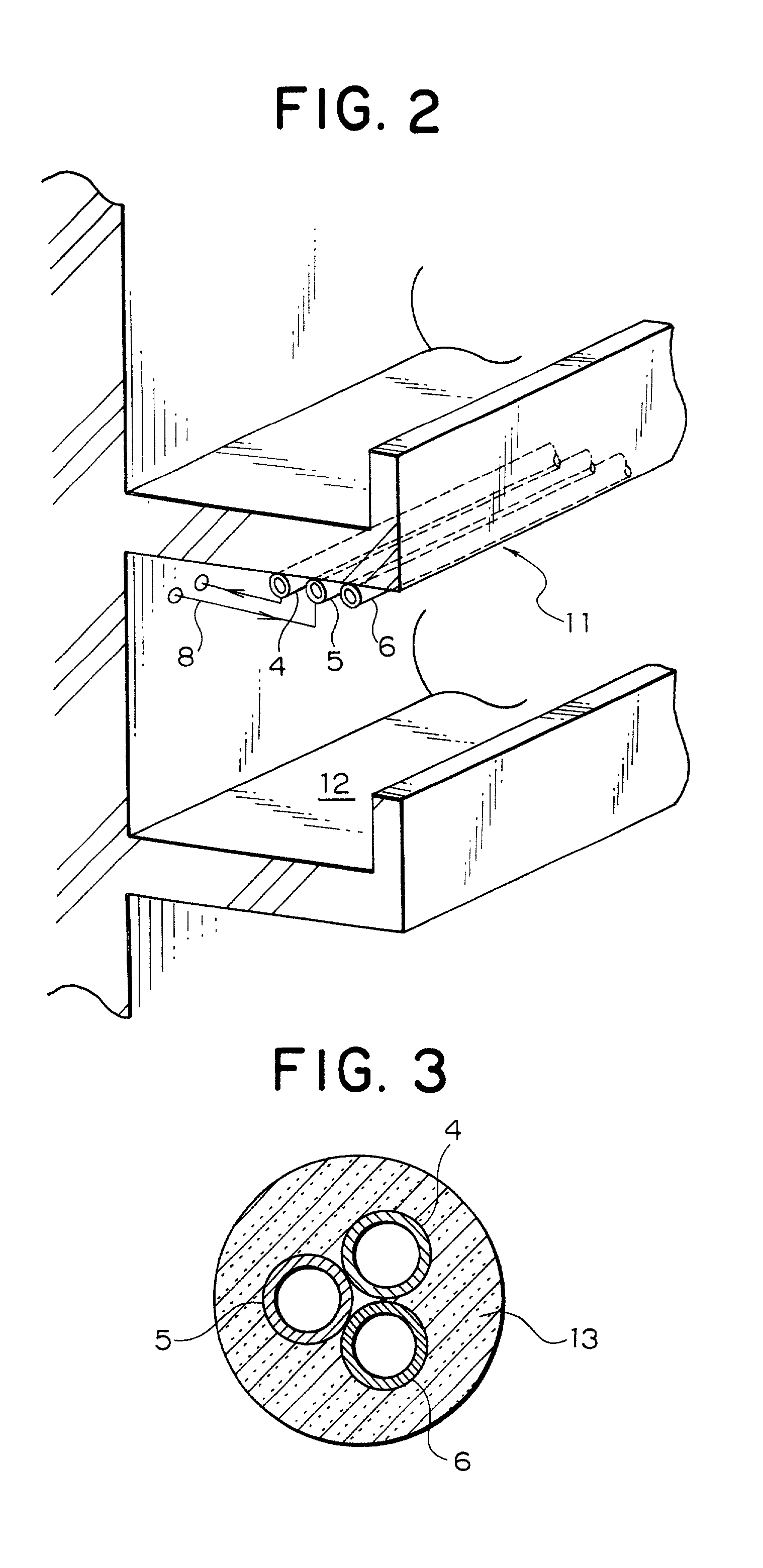

Heat supply system

InactiveUS20020026904A1Equally distributedBoiler flue tubes/fire tubesBoiler water tubesProcess engineeringHeat exchanger

A heat supply system is provided which enables use of small pipes with the same diameter for both feed branch pipes and return branch pipes, thus reducing the initial cost and also suppressing heat emission loss. The heat supply system comprises a heat exchanger 1, a feed main pipe 2, a return main pipe 3, a feed branch pipe 4 connected to the feed main pipe 2, a first return branch pipe 5 for directing the flow of a heat medium to an edge section in the downstream side of the feed branch pipe 4, a plurality of load pipes connected in parallel to a section between the feed branch pipe 4 and the first return branch pipe 5 each having a load member 7 provided thereon, and a second return branch pipe 6 connected to a section between an edge section in the downstream side of the first return branch pipe 5 and the return main pipe 3, said heat supply system having a plurality of branch pipe paths 11 including therein the feed branch pipe 4, first return branch pipe 5, load pipe 8, and second branch pipe 6.

Owner:MARUYAMA NOBORU

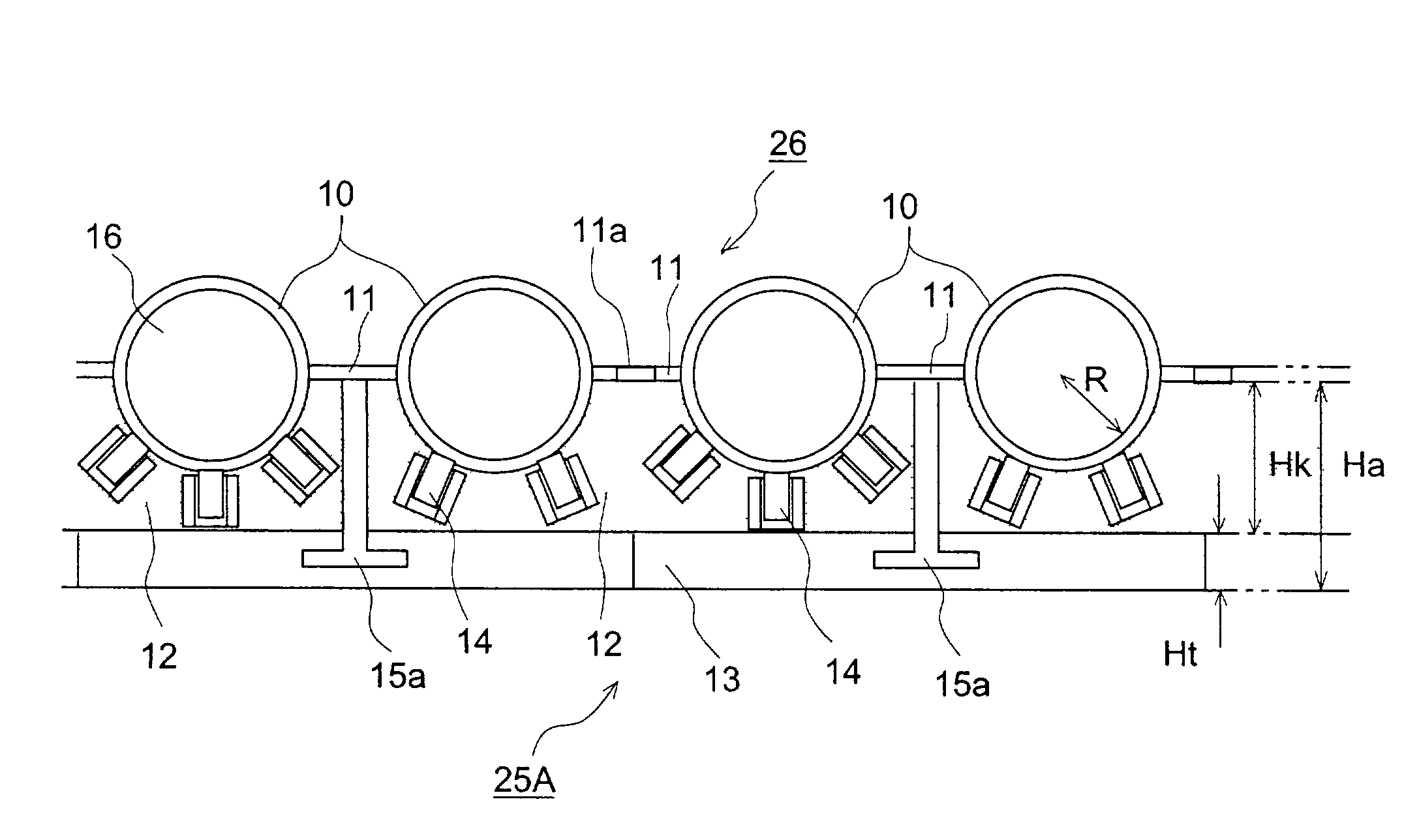

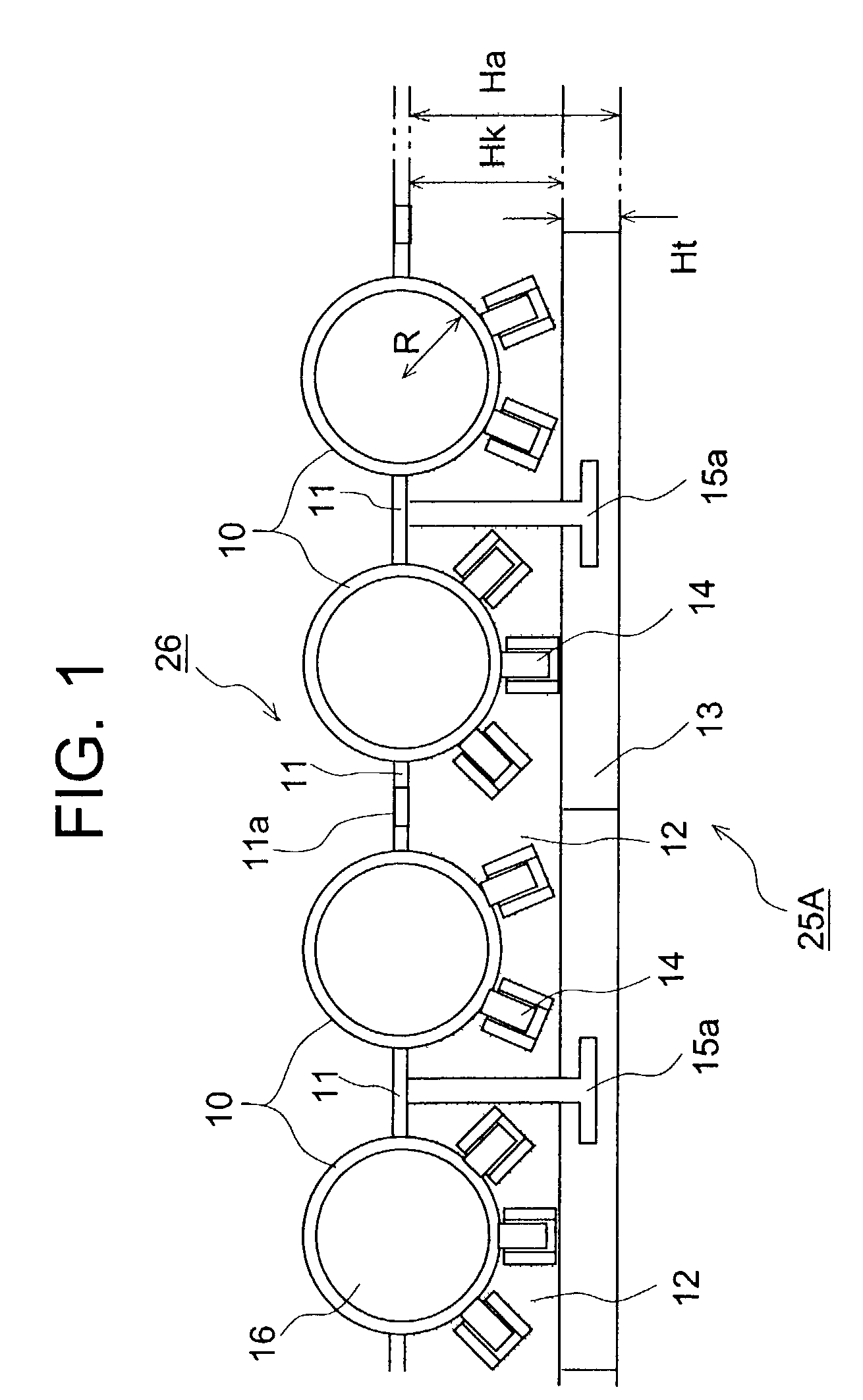

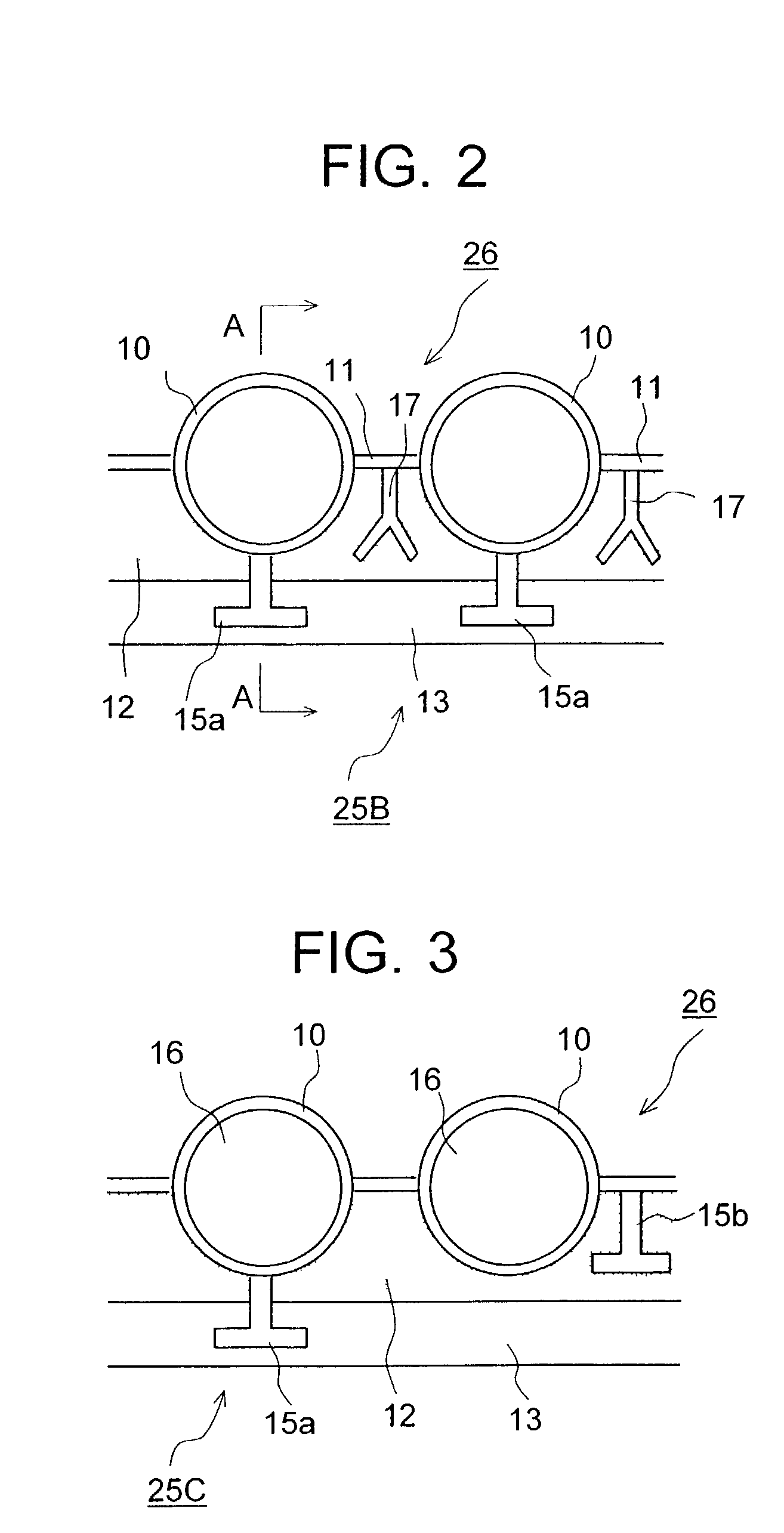

Fireproof structure and installation method for protecting water pipes

A fireproof structure protects water pipes with stable durability even in a high temperature gas environment. Even in a case where it falls off, it does not leave the water pipes suddenly exposed. The fireproof structure for protecting water pipes 25B installed on water pipe walls of a combustion gas side is configured by a double-layered structure made up of an outer layer water pipe protective structure facing towards the combustion gas side, which is fireproof tile 13, and an inner layer water pipe protective structure provided between the outer layer water pipe protective structure and the water pipes, which is fireproof castable 12. The thickness ratio between the castable 12 and the tiles 13 lies within the range of about 2:1 to 3:1, and the ratio between the thickness of the fireproof castable and the radius of the water pipe is set to 1+α:1, wherein the value of α ranges from approximately 0.1 to 0.3. The water pipes are equipped with hanging hooks 15a for tiles 13.

Owner:MITSUBISHI HEAVY IND LTD

Firetube heat exchanger

The invention discloses a firetube heat exchanger. A firetube having an elongated cylindrical shell is characterized by a plurality of circular rows of elongated U-shaped fins, each having a bottom surface, preferably curved along a radius or flat, secured to the inner surface of the cylindrical shell and two flat, planar, preferably parallel sides extending upwardly from the bottom surface, with the fins in each row aligned substantially parallel along the axis of the cylindrical shell.

Owner:ROCKY RES INC

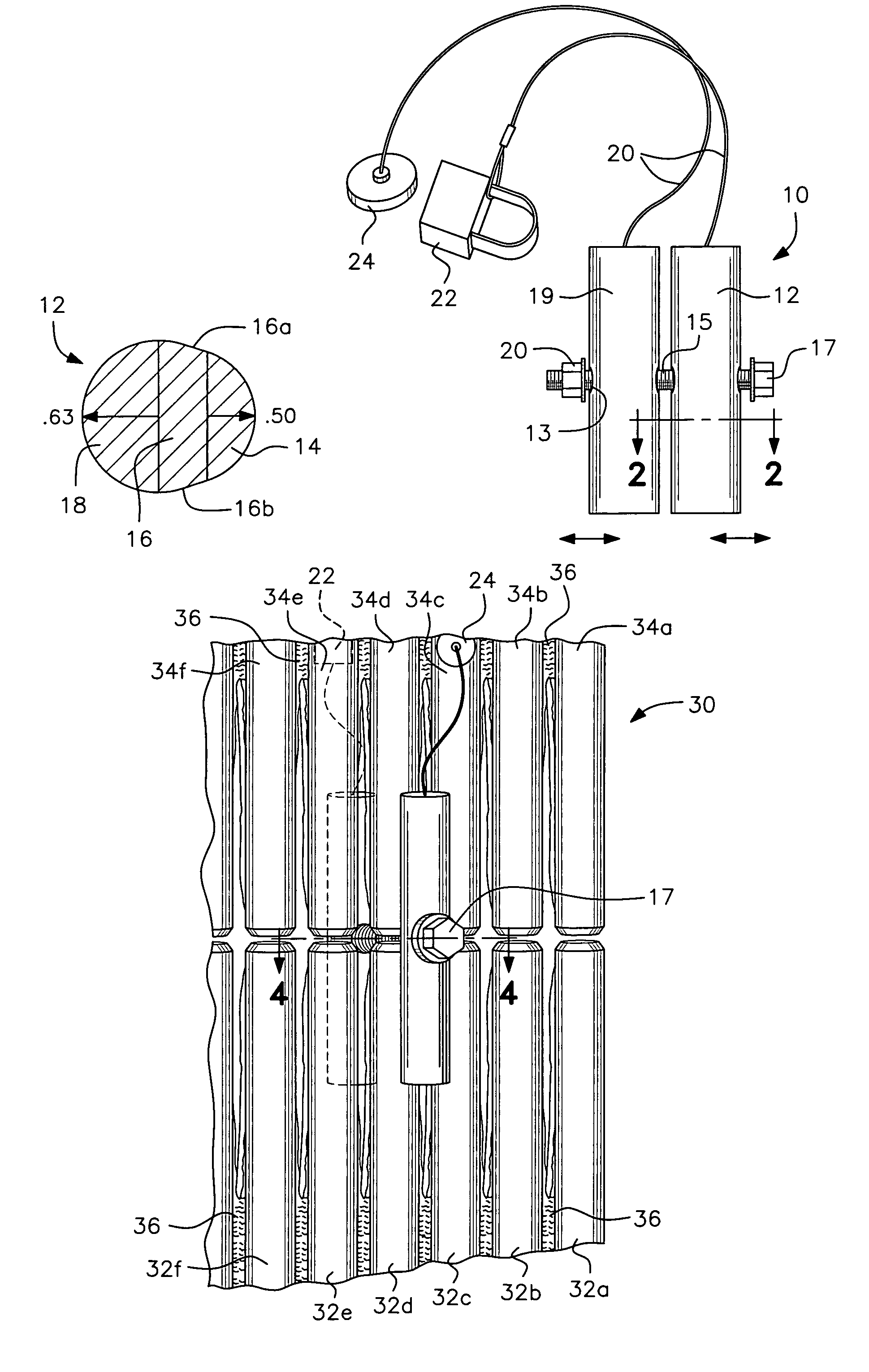

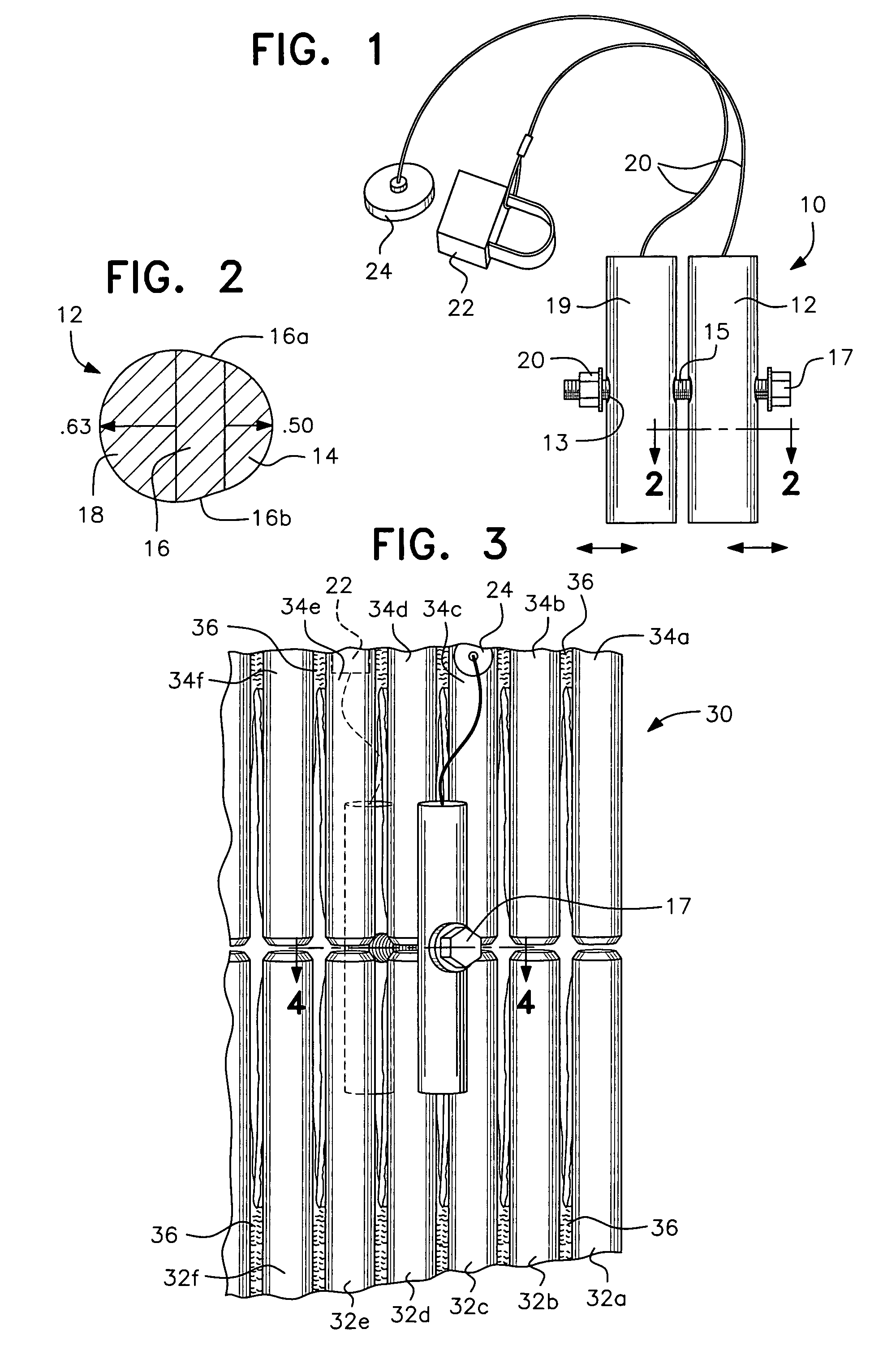

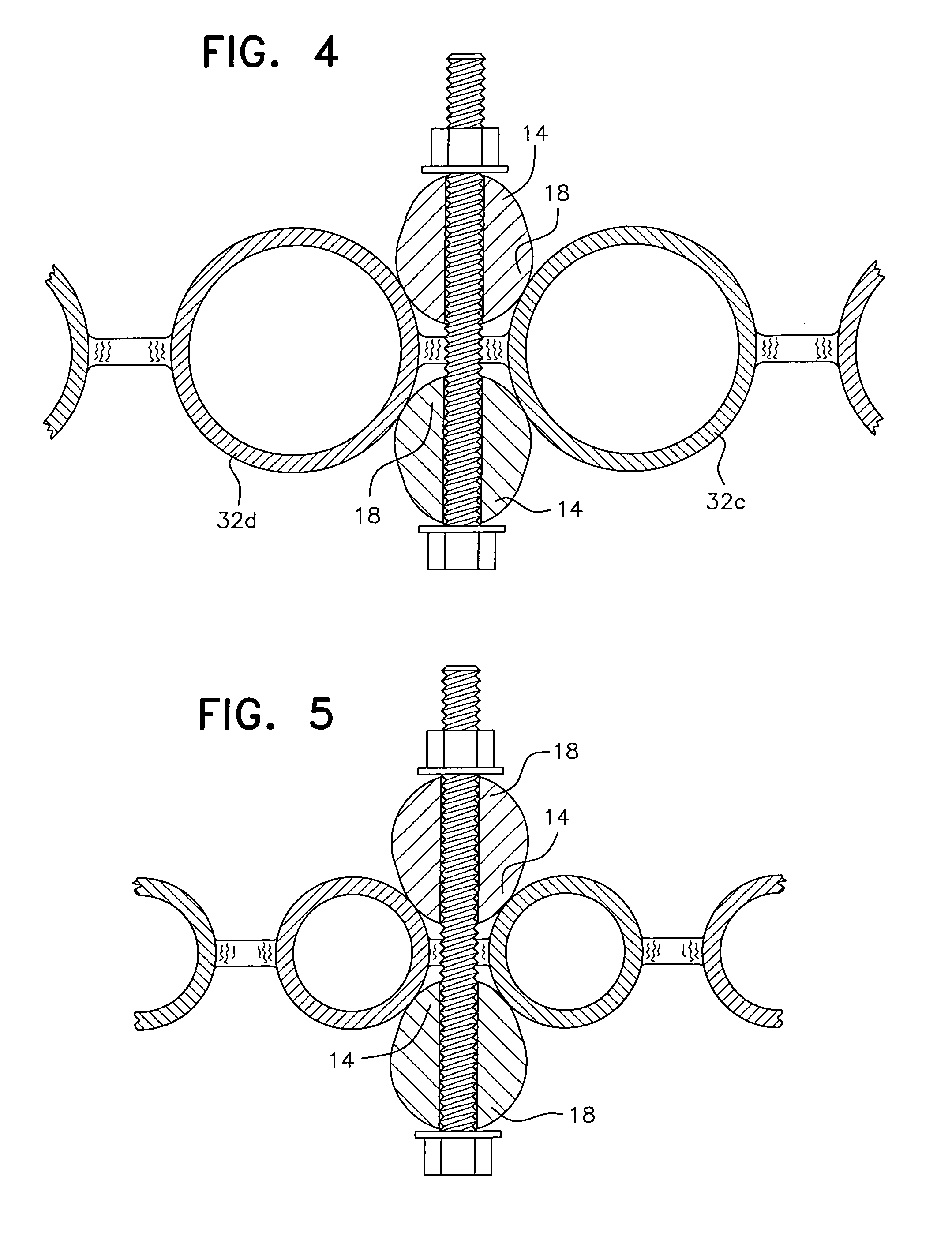

Water wall fit up tool

ActiveUS7089887B1Easy to useCheap manufacturingBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesMembrane configurationBiomedical engineering

Owner:MCCLURE MARK W

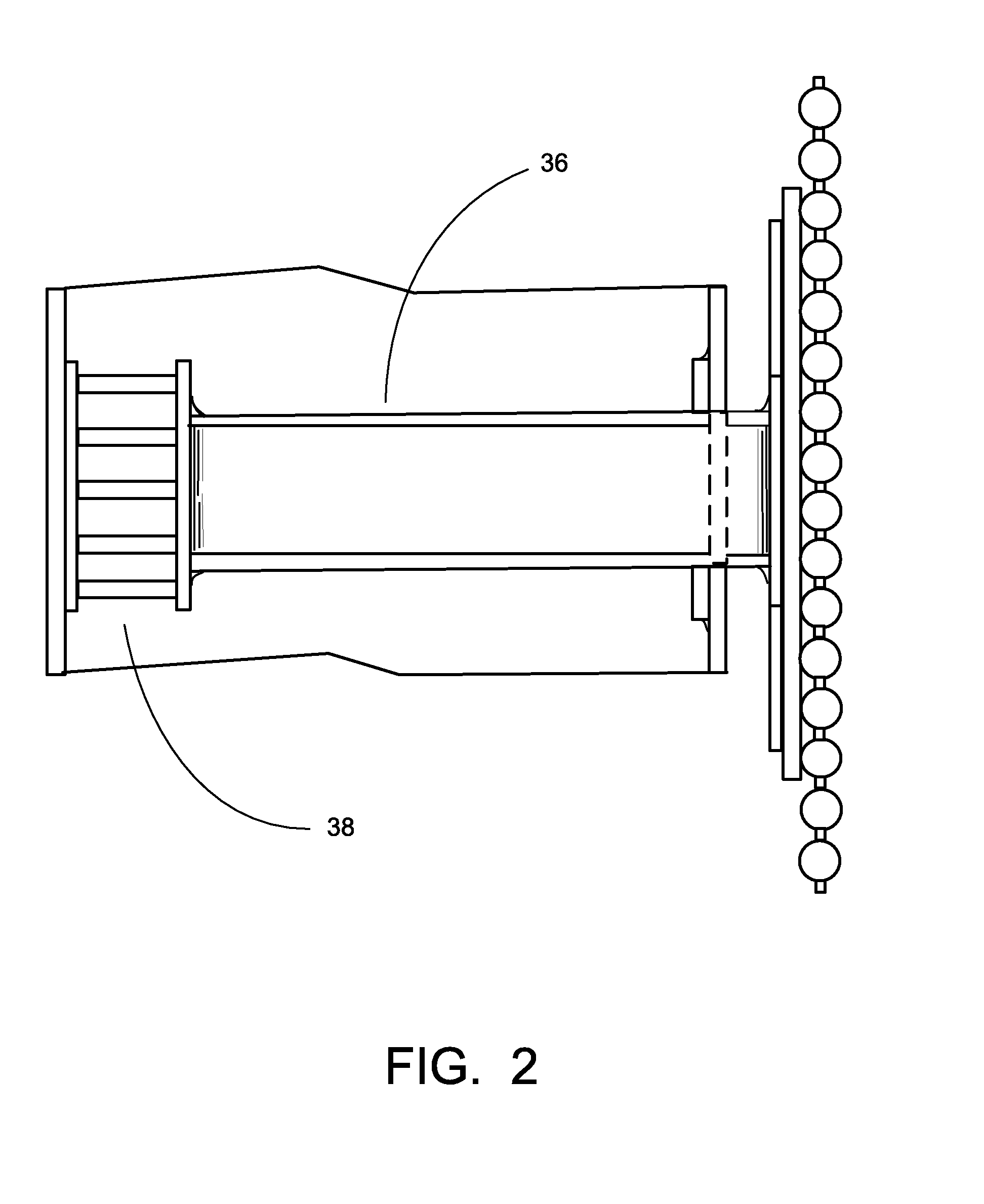

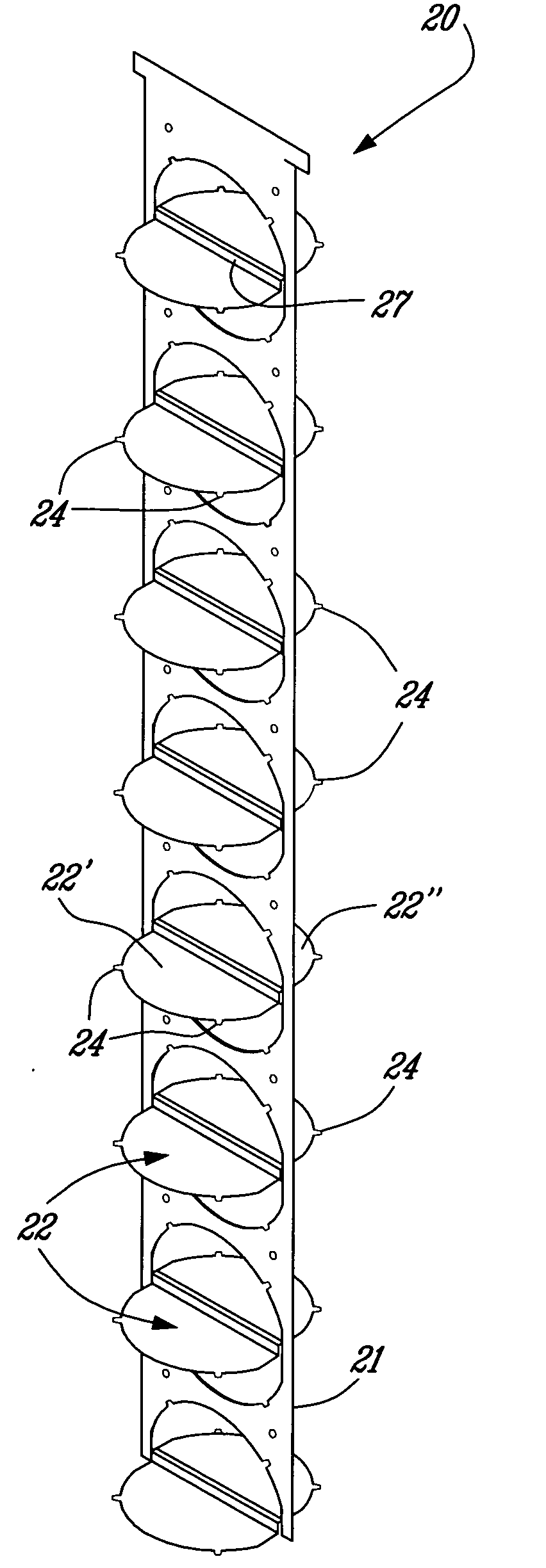

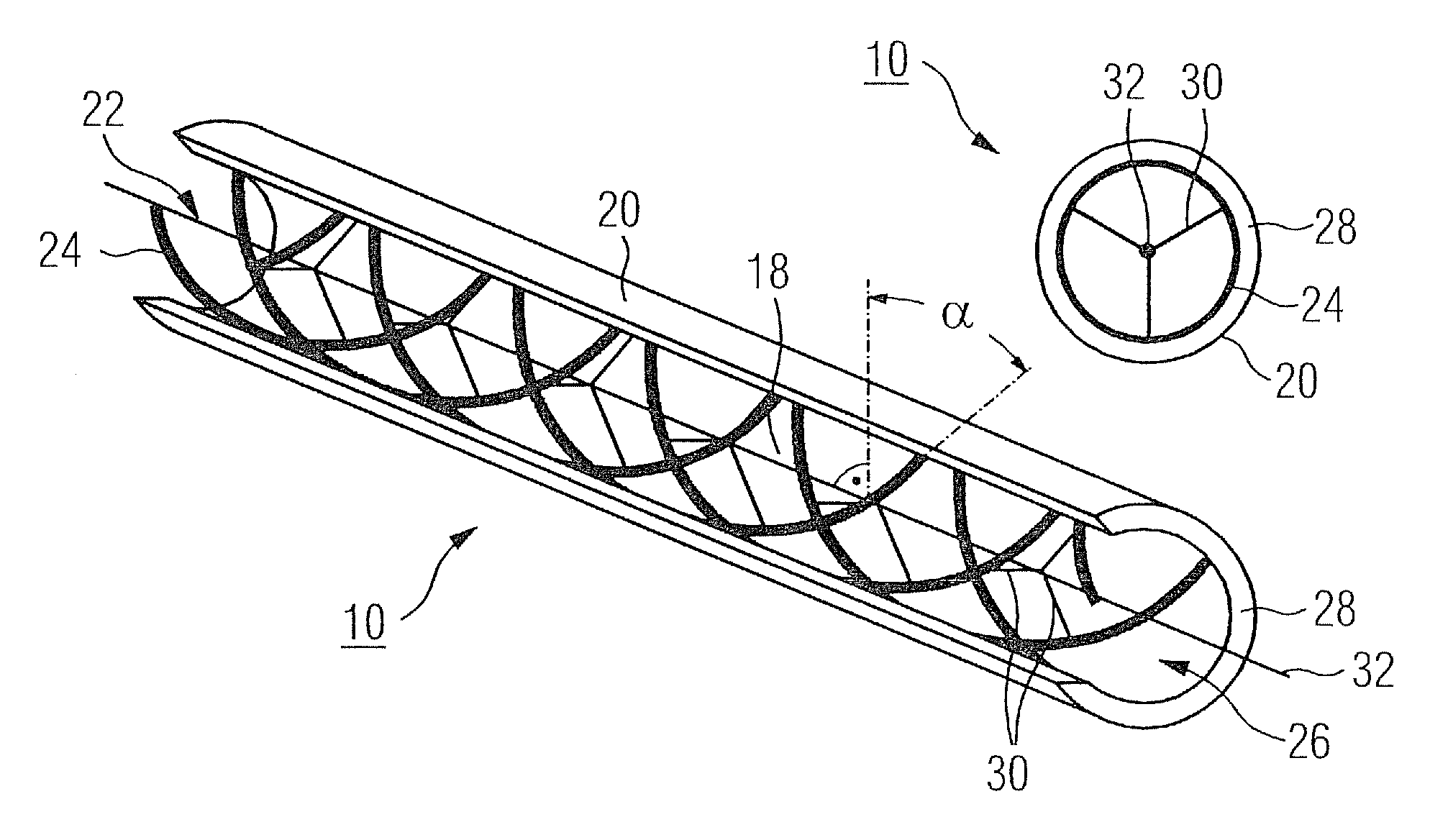

Flue baffle for gas-fired hot water tanks

InactiveUS20090199788A1Reduce manufacturing costBoiler flue tubes/fire tubesFurnace-tube steam boilersMetal stripsCombustion chamber

A flue baffle for use in a hot water tank flue pipe which is disposed to be in contact with water contained in an inner tank of the hot water heater. A burner chamber is provided at a lower end of the inner tank. The flue baffle is comprised of an elongated rectangular metal strip which has a plurality of spaced circular metal discs disposed substantially transverse to the strip and to the longitudinal axis of the flue pipe. The metal discs are dimensioned to be spaced from an inner surface of the flue pipe. Two or more spacing nipples protrude from a circumferential outer edge of the circular metal discs and are spaced apart from one another for slight frictional engagement with the inner surface of the flue pipe to maintain a substantially constant circumferential passage between the circumferential outer edge of the discs and the inner surface of the flue pipe.

Owner:LESAGE CLAUDE

Steam generator pipe, associated production method and continuous steam generator

InactiveUS8122856B2Favorable heat transition behaviorEasy to manufactureBoiler flue tubes/fire tubesBoiler water tubesEngineeringMulti path

Disclosed is a steam generator pipe which can be produced in a simple and economical manner and which has a particularly good heat transitional behavior having a large band width with various operational conditions. According to the invention, at least one insert is arranged in the inner chamber of the pipe in order to form a swirl-generating inner profile. The insert comprises a plurality of wires which wind, in a screw-like manner, along the inner wall of the pipe in the form of a multi-path thread.

Owner:SIEMENS AG

Cascade unit for a heating system with two or more heating boilers

ActiveUS7806346B2Lower assembly costsExtensive and thus cost-saving prefabricationBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesEngineeringInlet flow

A cascade unit for a heating system with two or more heating boilers, in particular condensing boilers, with a hydraulic shunt which is connected on the one hand with the inlet flows and return flows of all heating boilers and on the other hand with at least one heating circuit inlet flow and heating circuit return flow each, with the cascade unit furthermore comprising one each of the essentially horizontally extending boiler inlet flow header and boiler return flow manifold, the header and the manifold being connected with the hydraulic shunt, and the header and the manifold each being designed with prepared connecting nozzles fittingly placed for a group of two or more heating boilers for the connection of the heating boiler inlet flows and the heating boiler return flows. The cascade unit forms at least one self-supporting support frame on which at least one of the heating boilers is mountable.

Owner:COMFORT SINUSVERTEILER

Heat exchanger framework

InactiveUS20080022949A1Easy to drainAvoid distortionBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesEngineeringStructural framework

A structural framework for supporting the heat exchanger of a steam generator, the former being comprised of serpentine tubes having sloped segments to facilitate the drainage of water from the heat exchanger when the steam generator is shutdown. The structural framework includes paired groups of vertically and diagonally extending first support members contiguously straddling the sloped-tube segments. The paired first support members are rigidly connected by second support members which extend between adjacent sloped-tube segments. The structural framework preserves the spacing between the sloped-tube segments and prevents direct contact between adjoining tube surfaces, but is not attached to the straddled tube segments and, thus, provides a tube supporting fit that is loose enough to permit the tubes to move freely due to expansion and contraction at different rates from that of the structural framework.

Owner:THE BABCOCK & WILCOX CO

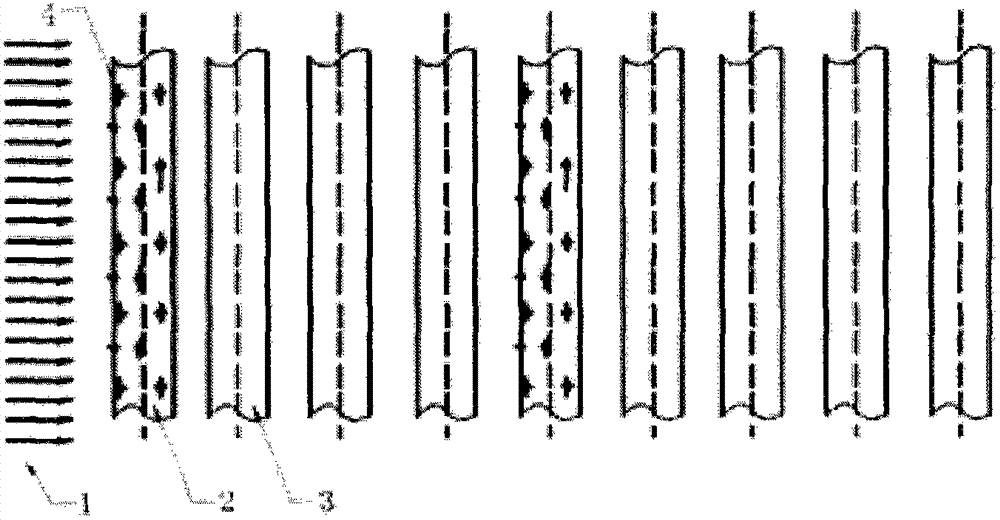

Device and method for preventing coking, pollution and corrosion on pipeline wall surface of boiler heating surface

InactiveCN102878546AAvoid cokingAvoid contaminationFluid heatersBoiler flue tubes/fire tubesFlue gasEngineering

The invention discloses a device and a method for preventing coking, pollution and corrosion on a pipeline wall surface of a boiler heating surface. According to the device, strip-type cavities are formed in the front, middle, two sides and rear of pipe bundle of the protected boiler heating surface along the smoke flow direction; holes communicated with the outside are formed in the surfaces of the cavities and serve as nozzles; the cavities are provided with joints; liquid and gas filled through the joints are ejected from the nozzles to form a gas film or liquid film at the peripheries of the cavities; the boiler heating surface pipe bundles which are sequentially arranged in the rear of the cavities are arranged in acting areas of the gas film and the liquid film for effective isolation and protection; ash particles which directly impact the surfaces of the cavities are blocked by the gas film or the liquid film, and the ash particles are prevented from directly washing the pipe bundles of the rear boiler heating surface; the surrounding ash particles are cooled through the gas film, and the adhesiveness of the ash particles is reduced; and moreover, an isolating layer is formed between the boiler heating surface and high-temperature flue gas through the gas film, the ash particles are prevented from being in direct contact with the boiler heating surface, and the adhesion possibility is reduced.

Owner:周丽琴

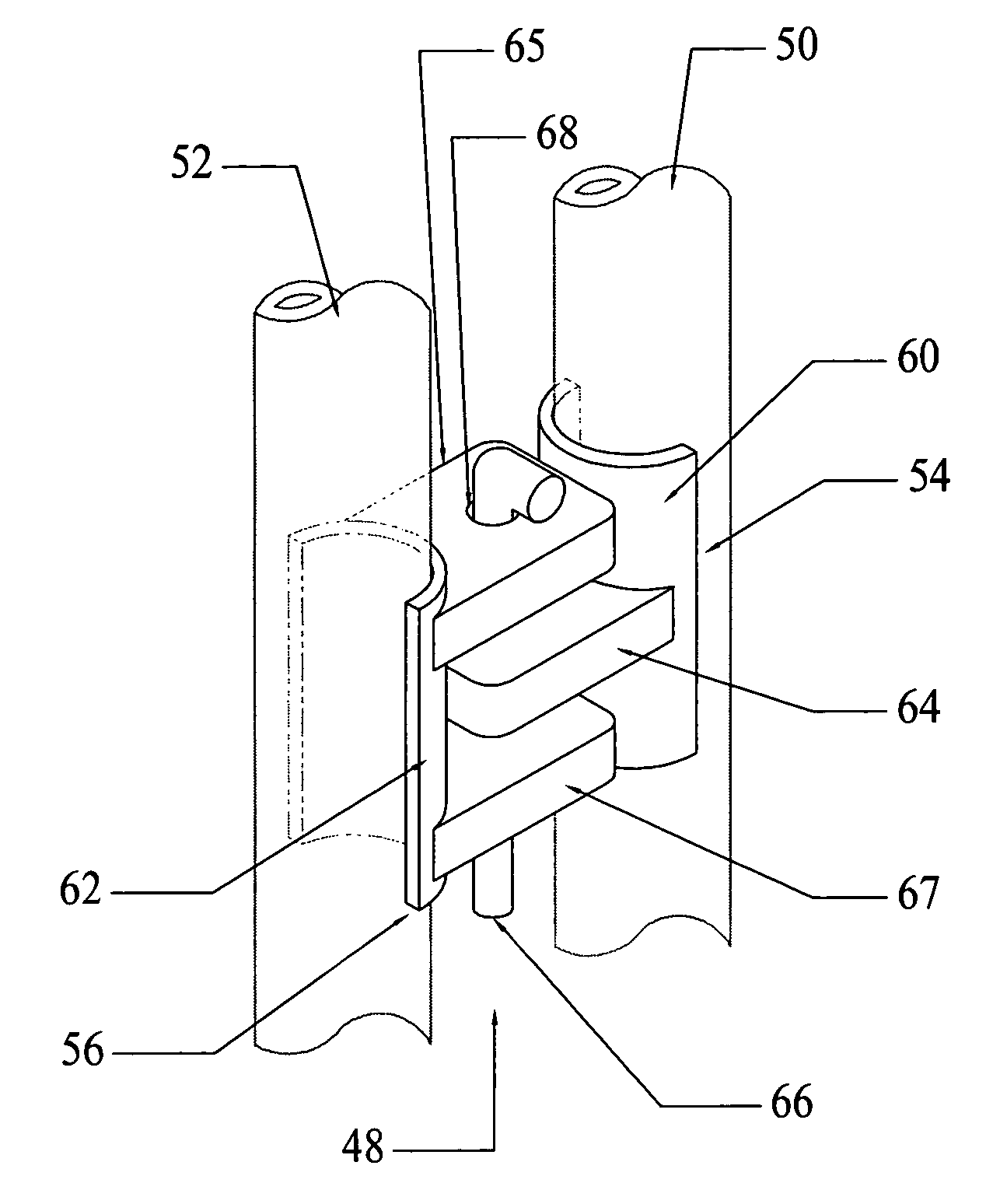

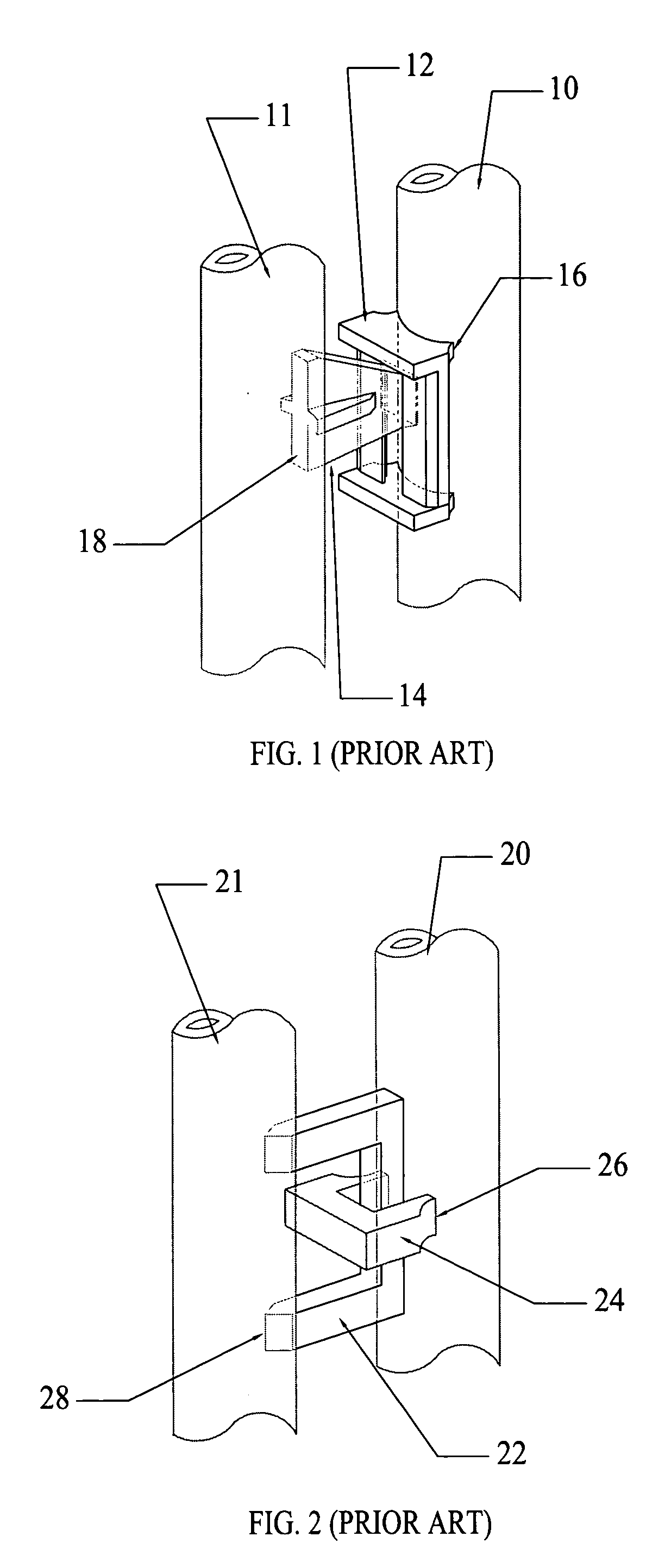

Boiler tube position retainer assembly

ActiveUS20060243223A1Heating fastBoiler supporting/setting arrangementsSteam generation heating methodsProduction rateEngineering

The tube assembly device of the present invention maintains spacing for proper heat transfer and avoids tubing wall removal should weld failure occur, thereby decreasing leakage of boiler tubes, shut down time and unscheduled down time for inspections and repairs. Productivity of the boilers is increased and maintenance costs are decreased. In the event of excess stress on the positioning assembly, the retainer assembly of the present invention allows for failure points to occur on the boiler tube position retainer assemblies rather than on the boiler tubes themselves.

Owner:RETTIG MARK +2

Method of and apparatus for supporting walls of a power boiler

ActiveUS8393304B2Boiler supporting/setting arrangementsBoiler flue tubes/fire tubesSupporting wallMethod of support

Owner:FOSTER WHEELER ENERGIA OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com