Device and method for preventing coking, pollution and corrosion on pipeline wall surface of boiler heating surface

A heating surface tube and heating surface technology, which is used in the field of contamination and corrosion devices to prevent coking on the wall surface of boiler heating surface pipes, and can solve problems such as limiting the output of the unit, shutting down the unit, and destroying the heat transfer characteristics of each heating surface of the boiler.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

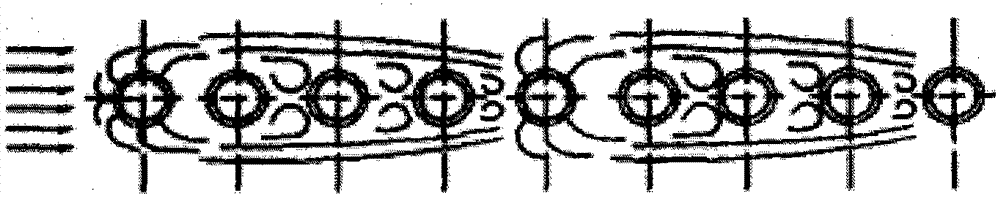

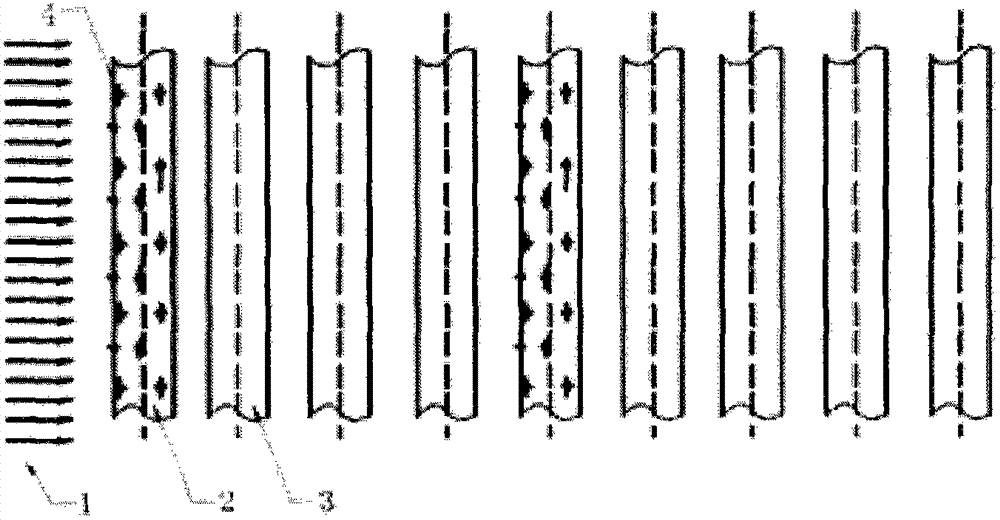

[0010] Such as figure 1 As shown, a tubular cavity 2 is installed in front of and in the middle of the protected boiler heating surface tube row 3 facing the incoming flow direction of the flue gas 1, and a hole connected to the outside is opened on the surface of the cavity 2 along the length and circumferential direction as the nozzle 4, and the cavity 2 is provided with the interface for filling gas. Gas is charged from the interface, and then continuously ejected from the nozzle 4 to form a gas film around the cavity 2. The boiler heating surface tube row 3 arranged in sequence behind the cavity 2 is placed in its effective projected area or the effective area of the gas film isolation and protection. The gas film on the windward side of the cavity 2 itself blocks the direct impact on the surface of the cavity 2. The ash particles prevent the self from being polluted, and also prevent the ash particles from directly scouring the tube row 3 on the heating surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com