Dehydrogenation catalyst and preparation method thereof

A technology for dehydrogenation catalysts and hydrogen storage materials, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor stability, low activity, and easy coking, and achieve high dispersion and high activity , to avoid the effect of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

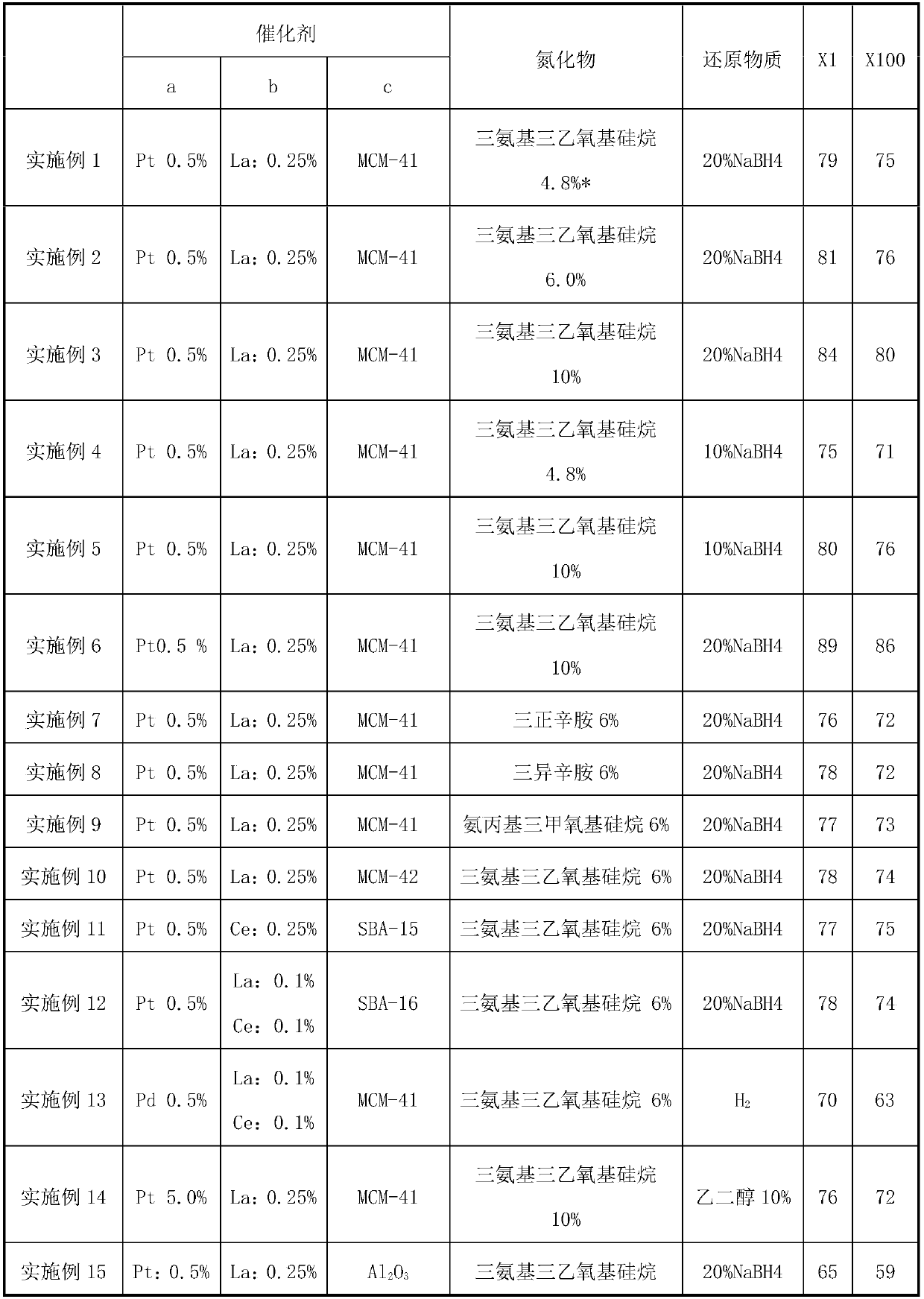

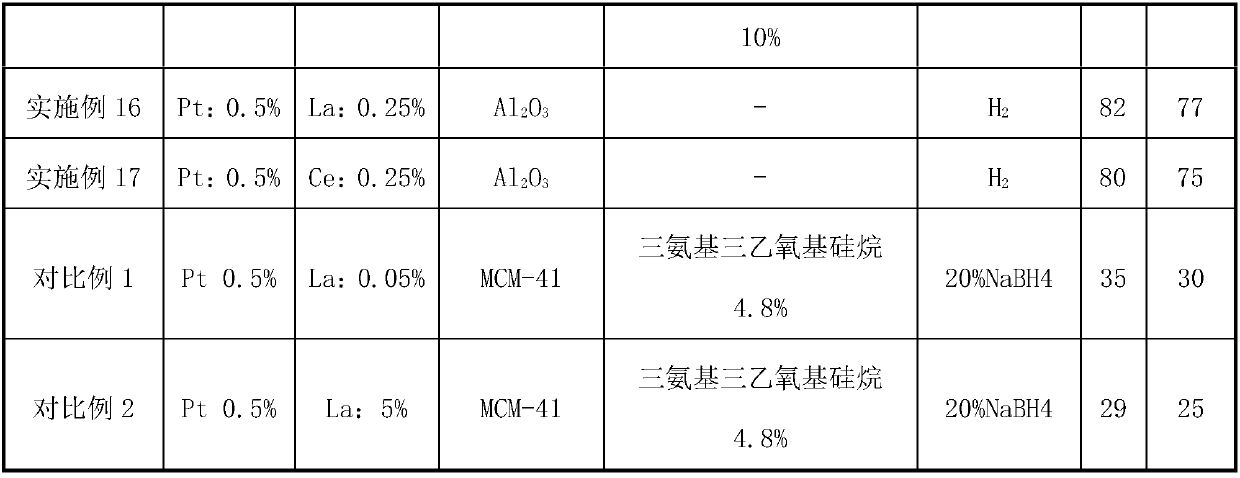

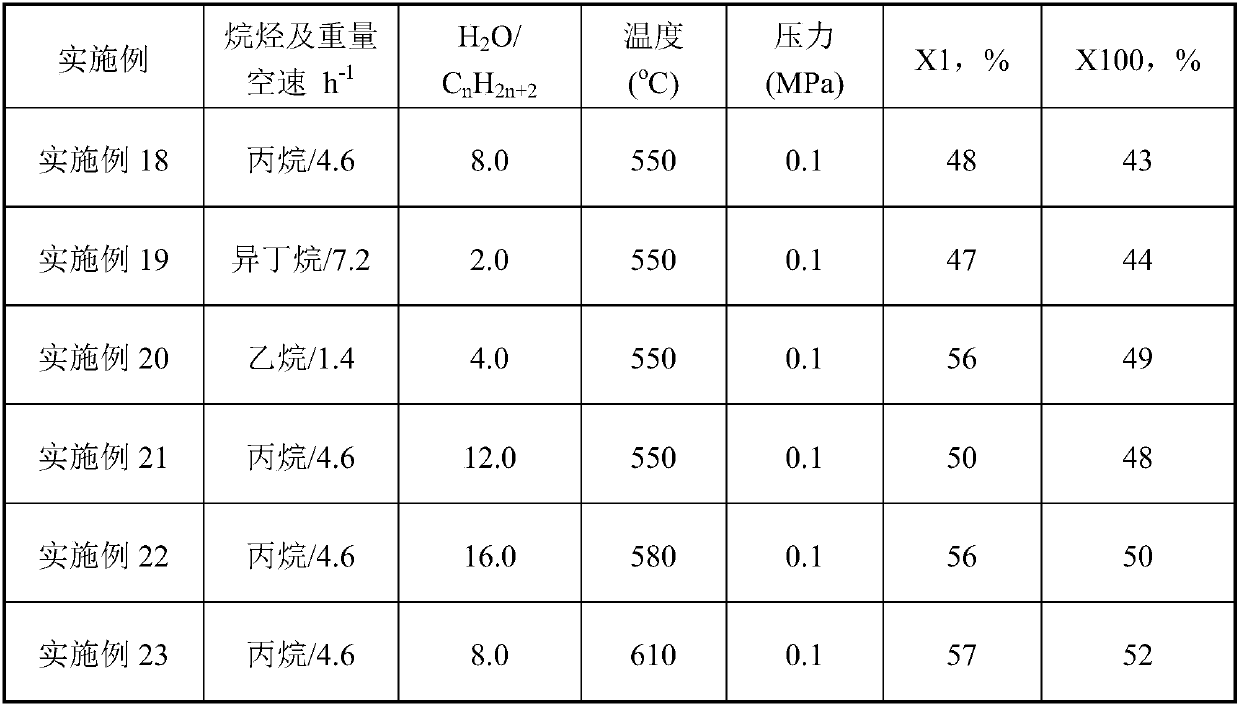

Examples

Embodiment 1

[0050] Weigh 2 grams of molded MCM-41 molecular sieves into a 500ml round bottom flask, add 300ml of toluene, add 15ml of triaminotriethoxysilane, reflux in a water bath at 100°C for 6h, cool, filter, and vacuum dry to obtain organic The modified MCM-41 was measured to have a water absorption rate of 3.0.

[0051] Take 0.622mL of a mixed solution of 16.14mL / L chloroplatinic acid and 1.42ml / L lanthanum chloride, add 5.578mL of water to prepare a solution, add 2g of organic MCM-41 to this solution, stir, and place at room temperature for 2h , and then placed in a vacuum drying oven, dried at 100° C. for 4 hours under a pressure of 0 MPa to obtain a catalyst. The catalyst was put into 1.5 volumes of 20% NaBH4 solution for reduction for 4 hours, and then dried in a vacuum oven at 100° C. and a pressure of 0 MPa for 6 hours to obtain a dehydrogenation catalyst.

[0052] The obtained catalyst is ground into a particle size of 12-20 mesh, evaluated in an isothermal fixed-bed reactor...

Embodiment 2

[0056] Weigh 2 grams of molded MCM-41 molecular sieves into a 500ml round bottom flask, add 300ml of toluene, add 19ml of triaminotriethoxysilane, reflux in a water bath at 100°C for 6h, cool, filter, and vacuum dry to obtain organic The modified MCM-41 was measured to have a water absorption rate of 3.0.

[0057] Take 0.622mL of a mixed solution of 16.14mL / L chloroplatinic acid and 1.42ml / L lanthanum chloride, add 5.578mL of water to prepare a solution, add 2g of organic MCM-41 to this solution, stir, and place at room temperature for 2h , and then placed in a vacuum drying oven, dried at 100° C. for 4 hours under a pressure of 0 MPa to obtain a catalyst. The catalyst was put into 1.5 volumes of 20% NaBH4 solution for reduction for 4 hours, and then dried in a vacuum oven at 100° C. and a pressure of 0 MPa for 6 hours to obtain a dehydrogenation catalyst.

[0058] Evaluation conditions are the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0060] Weigh 2 grams of molded MCM-41 molecular sieves into a 500ml round bottom flask, add 300ml of toluene, add 33ml of triaminotriethoxysilane, reflux in a water bath at 100°C for 6h, cool, filter, and vacuum dry to obtain organic The modified MCM-41 was measured to have a water absorption rate of 3.0.

[0061] Take 0.622mL of a mixed solution of 16.14mL / L chloroplatinic acid and 1.42ml / L lanthanum chloride, add 5.578mL of water to prepare a solution, add 2g of organic MCM-41 to this solution, stir, and place at room temperature for 2h , and then placed in a vacuum drying oven, dried at 100° C. for 4 hours under a pressure of 0 MPa to obtain a catalyst. The catalyst was put into 1.5 volumes of 20% NaBH4 solution for reduction for 4 hours, and then dried in a vacuum oven at 100° C. and a pressure of 0 MPa for 6 hours to obtain a dehydrogenation catalyst.

[0062] Evaluation conditions are the same as in Example 1, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com