System and Method for Zero Emissions, Hydrogen Fueled Steam Generator

a technology of hydrogen fueled steam generator and system, which is applied in the field of system and method of generating steam, can solve the problems of not being able to produce carbon monoxide or carbon dioxide like previous fuels such as natural gas, methane, cellulose based, etc., and achieves the effects of reducing mechanical components, reducing the stress on mechanical components, and reducing the temperature of the reaction chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

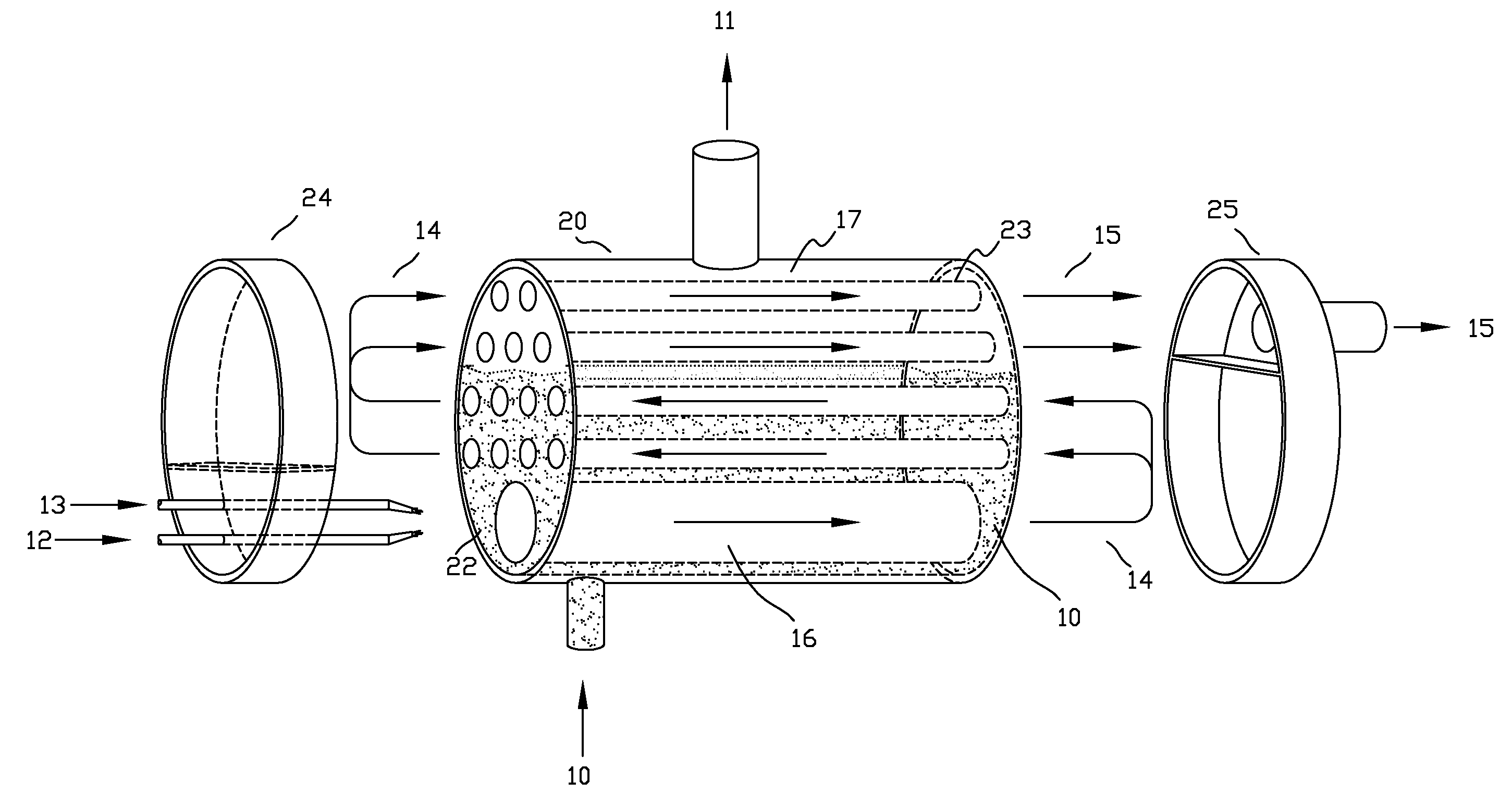

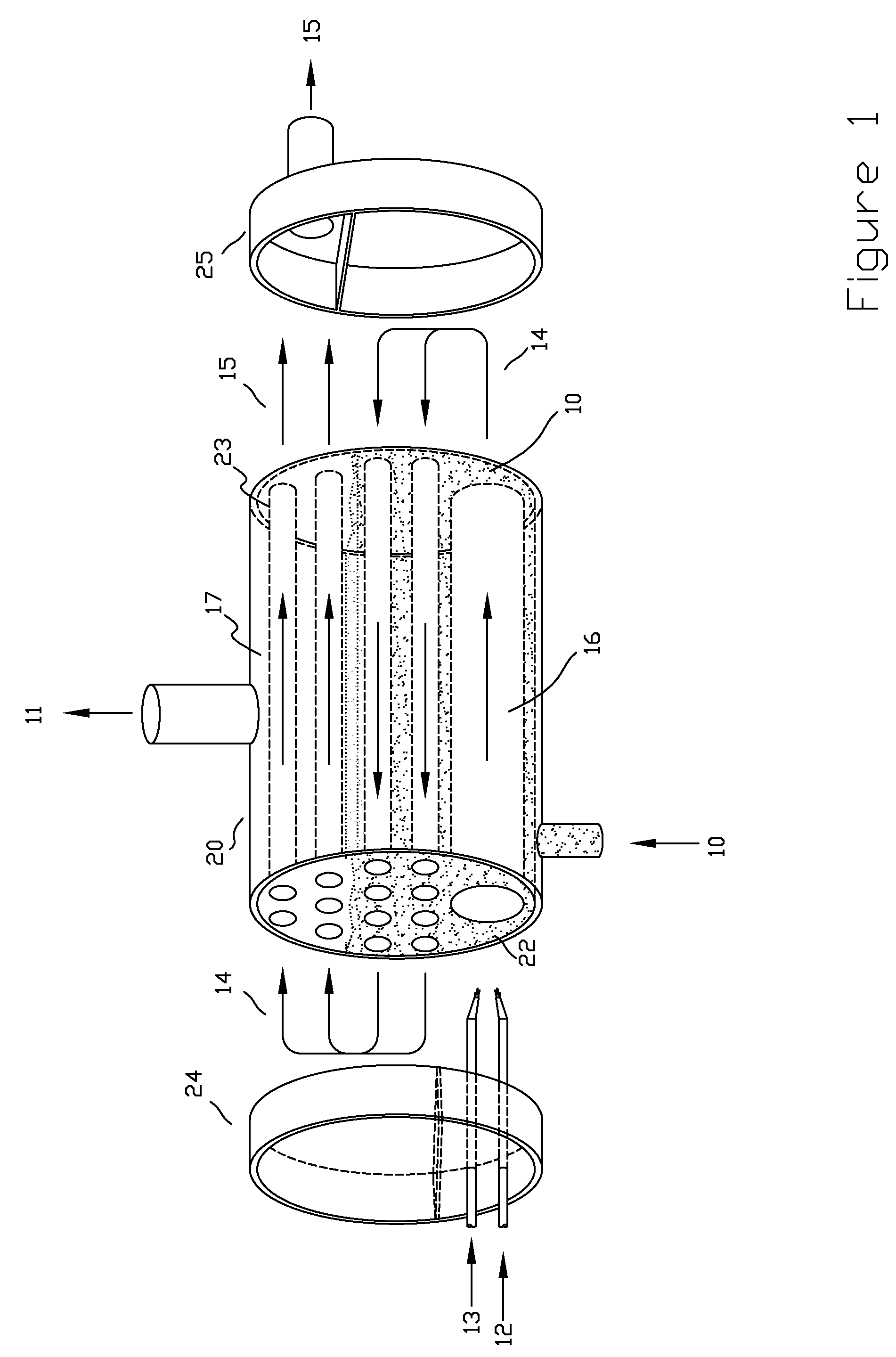

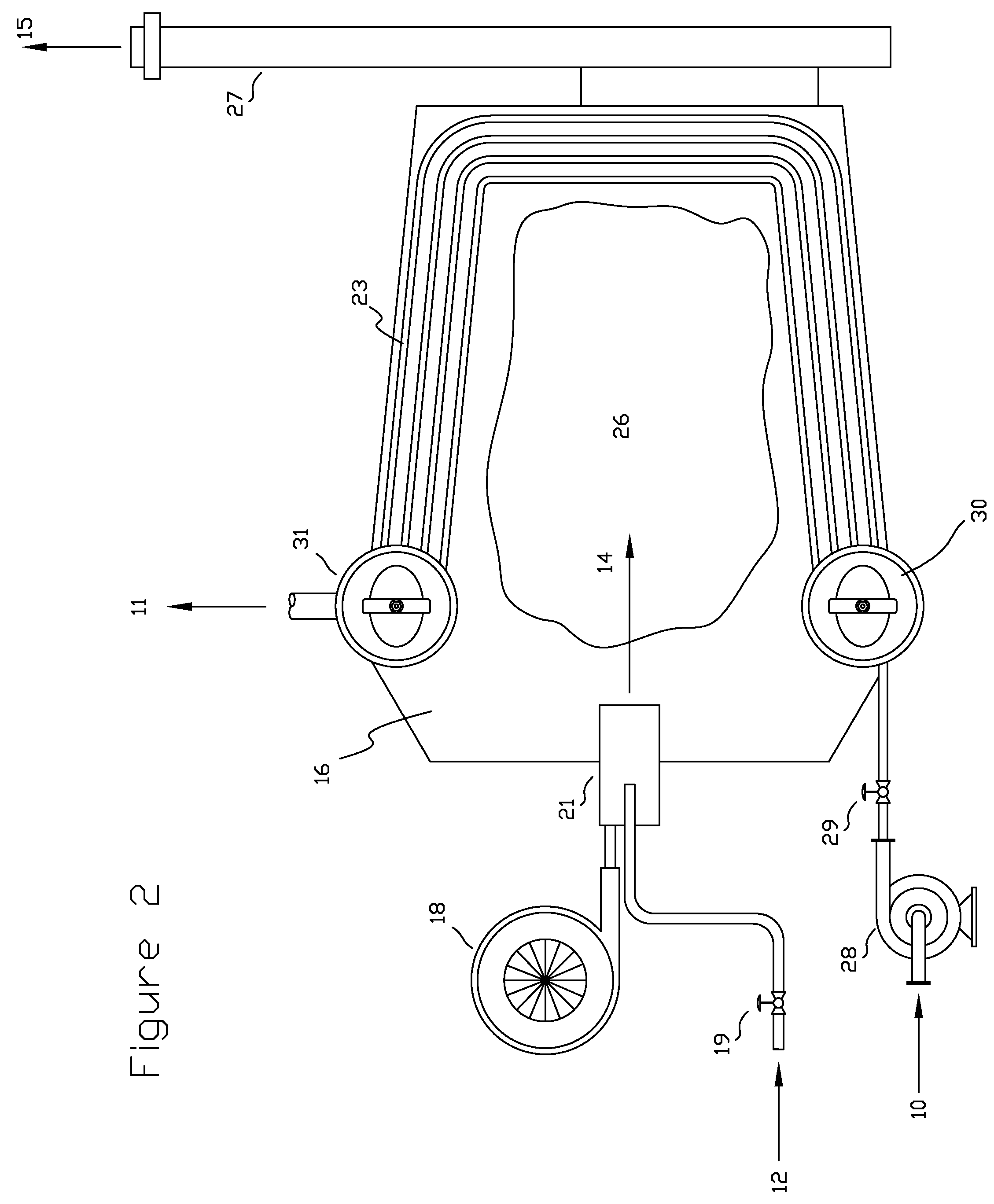

[0022]FIG. 1 illustrates one preferred embodiment of this invention wherein the steam generator is operates within a shell 20 with one head 24 fixed on the left end and the other head 25 fixed on the right end. The heads 24 and 25 are shown separated from the shell 20 for illustration purposes, so the path of the gasses and the divider plate within the heads can be more clearly understood. In operation the heads are affixed to the shell. The boiler tubes 23 are fixed at each end to the tube sheets 22.

[0023]In operation, water 10 enters the shell through the nozzle at the bottom of the shell. The controller maintains a fixed water level within the shell 20. Hydrogen 12 and oxygen 13 enter through conduits penetrating the left head 24. The hydrogen 12 and oxygen 13 react together in the reaction chamber 16. As these reaction gasses 14 combine together they move down the path shown by the arrows. The heat generated by the reaction, passes through the tube walls causing the water 10 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com