Patents

Literature

876 results about "Hydrogen oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Oxidation state of Hydrogen is 1+ when in a regular compound. However, when the Hydrogen is bonded to a metal (LiH or NaH for example) then the charge is 1-.

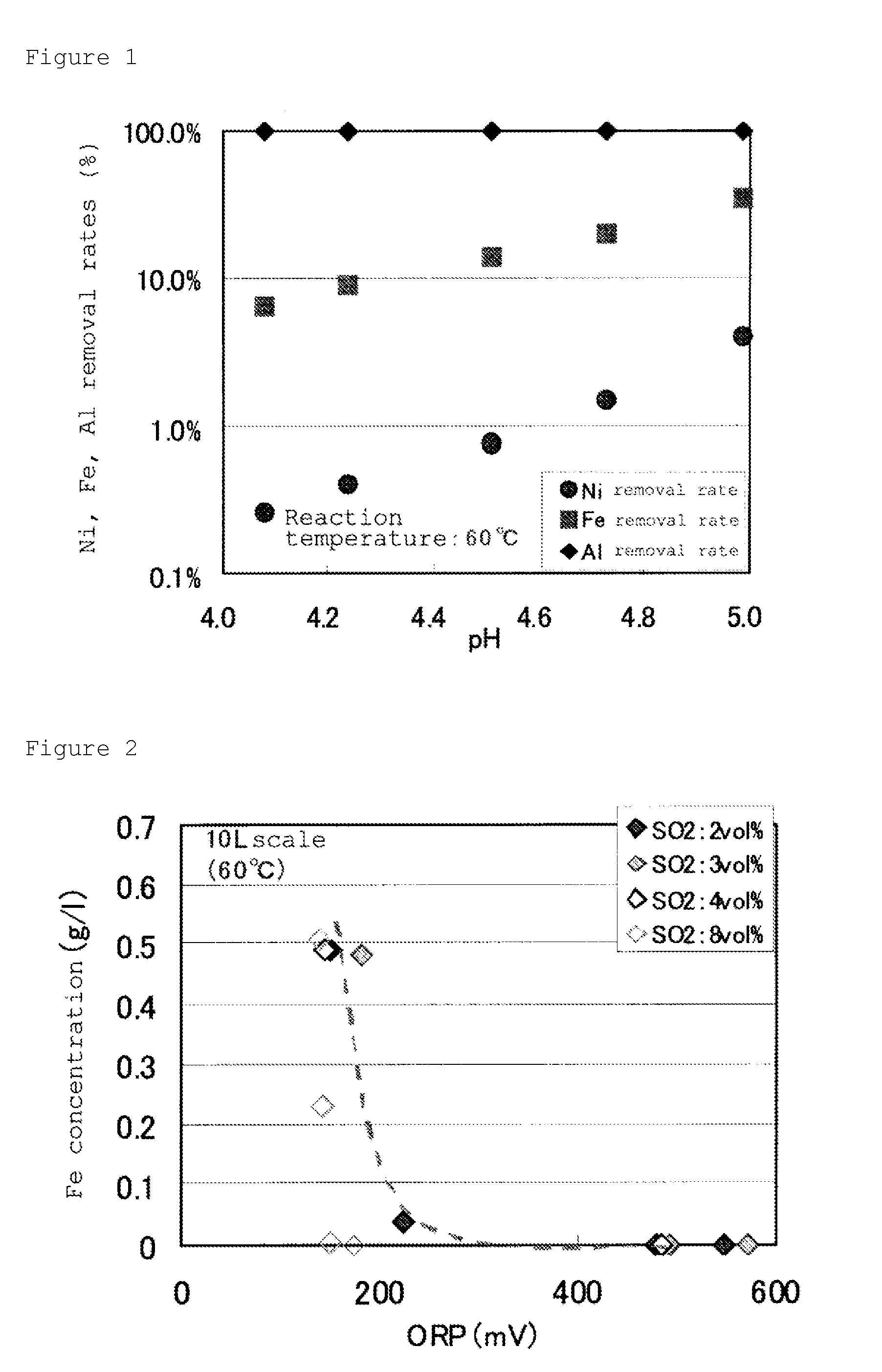

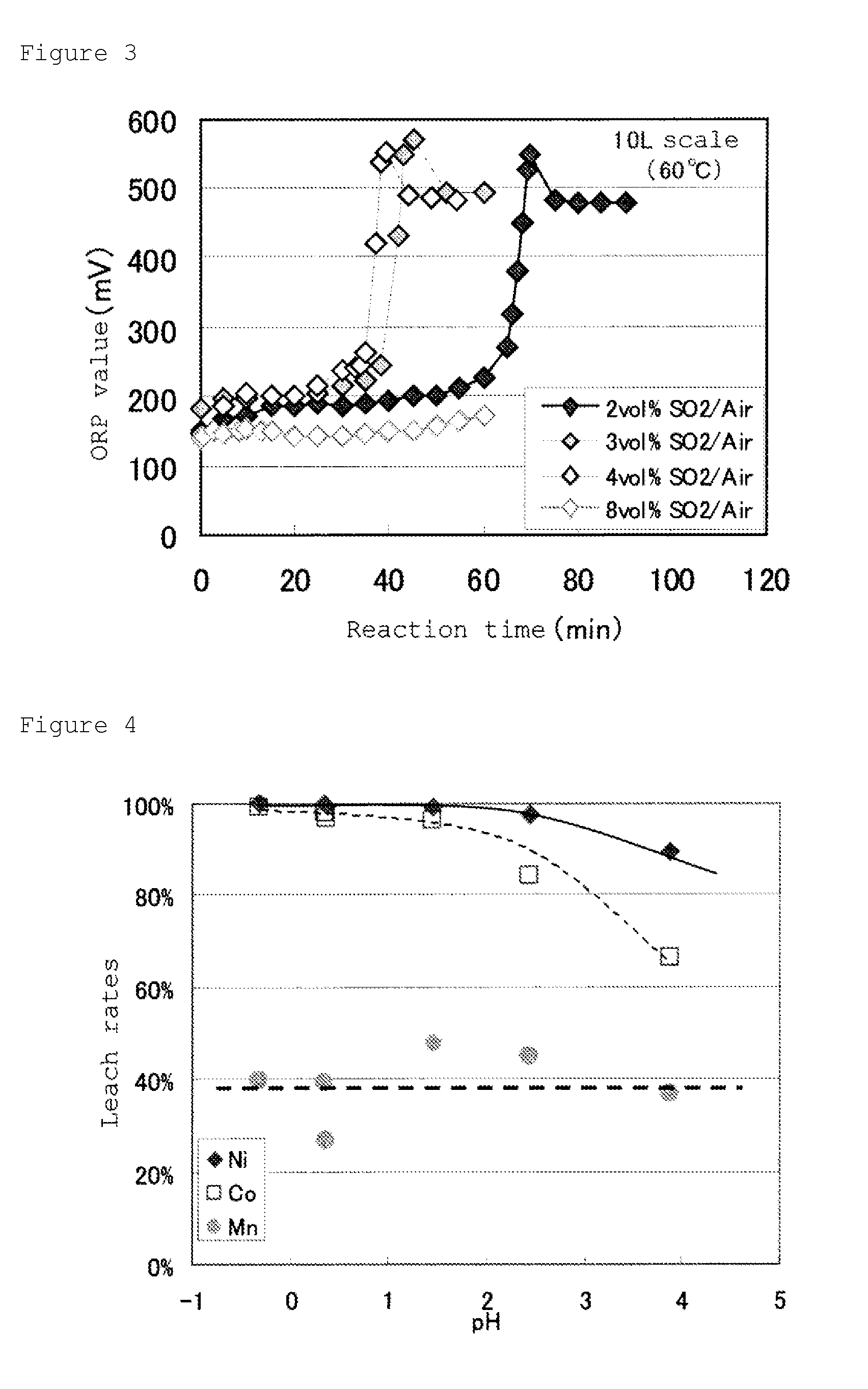

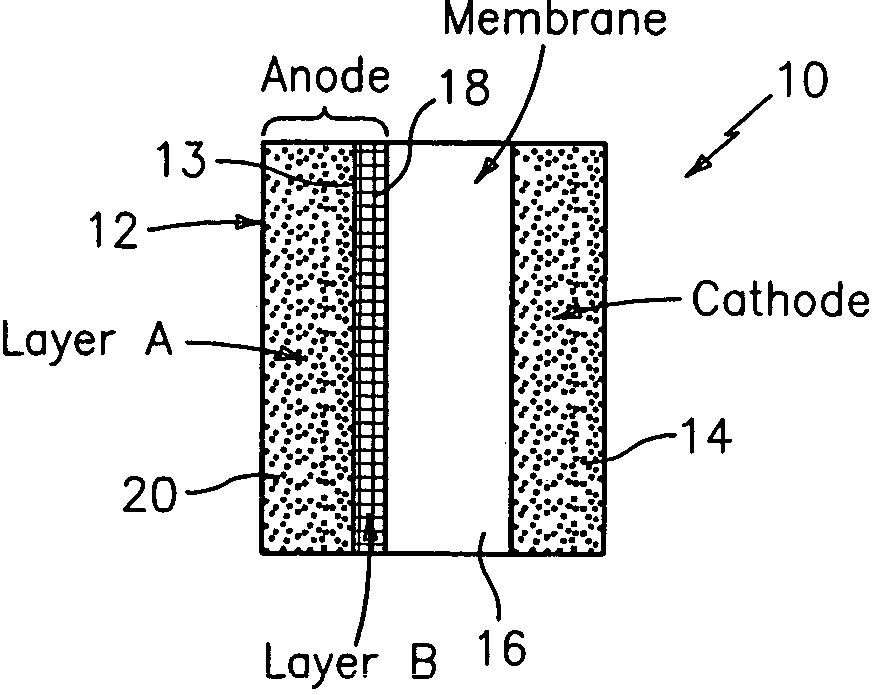

Method for recovering nickel from sulfuric acid aqueous solution

ActiveUS20110135547A1High industrial valueEasy to useSolvent extractionNickel compounds preparationSolventAluminium

A method for recovering nickel from an sulfuric acid aqueous solution, for recovering nickel in an effectively utilizable form as a raw material of nickel industry material, by separating efficiently impurity elements of iron, aluminum, manganese and the like, from the sulfuric acid aqueous solution containing nickel and cobalt, and the impurity elements, iron, aluminum, manganese and the like.The method is characterized by comprising the following steps (1) to (5).step (1): to subject the sulfuric acid aqueous solution to oxidation neutralization treatment.step (2): then, to subject the solution to neutralization treatment, and to separate and recover mixed hydroxides containing nickel and cobalt.step (3): to subject the mixed hydroxides to dissolution treatment in a sulfuric acid solution having a concentration of equal to or higher than 50% by mass.step (4): to subject the concentrated solution to solvent extraction treatment, using a phosphate ester-based acidic extraction agent.step (5): by adding a neutralizing agent to the resultant extraction residual liquid, to subject the solution to the neutralization treatment, and to separate and recover nickel hydroxide generated.

Owner:SUMITOMO METAL MINING CO LTD

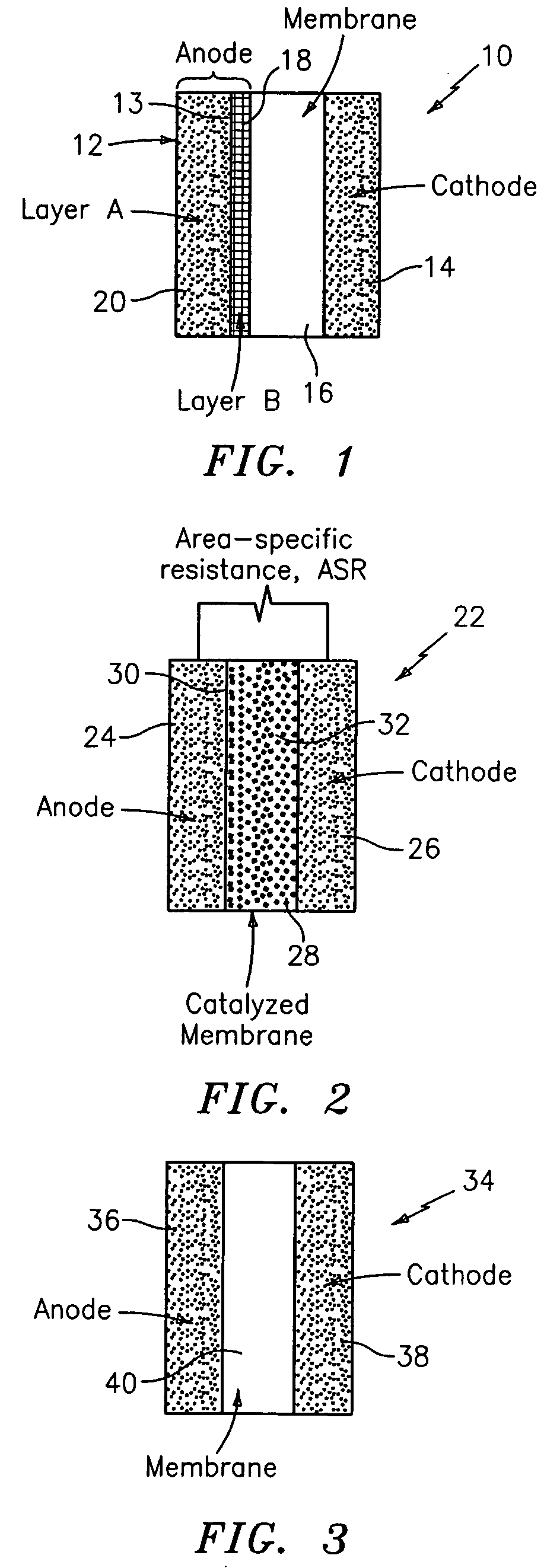

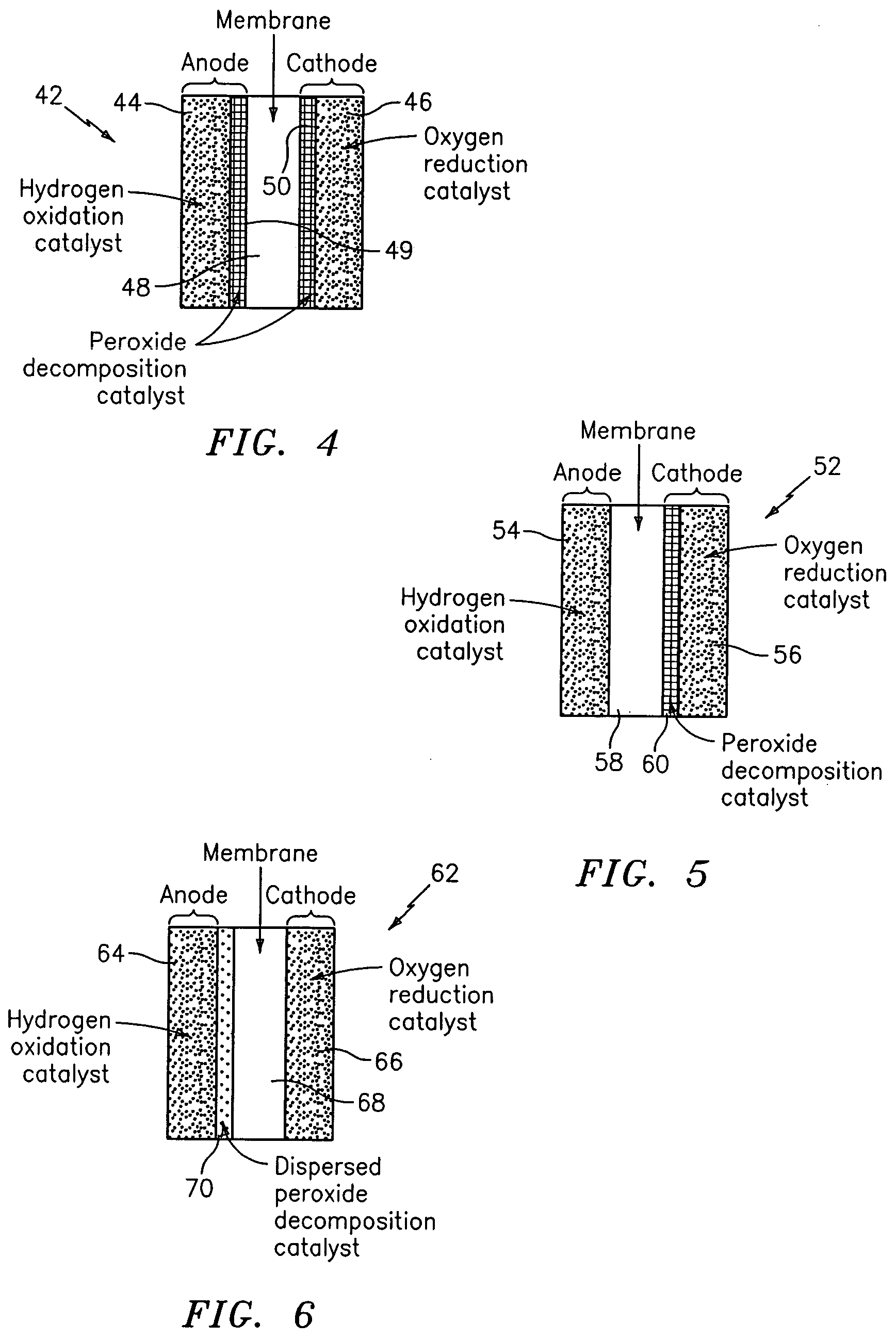

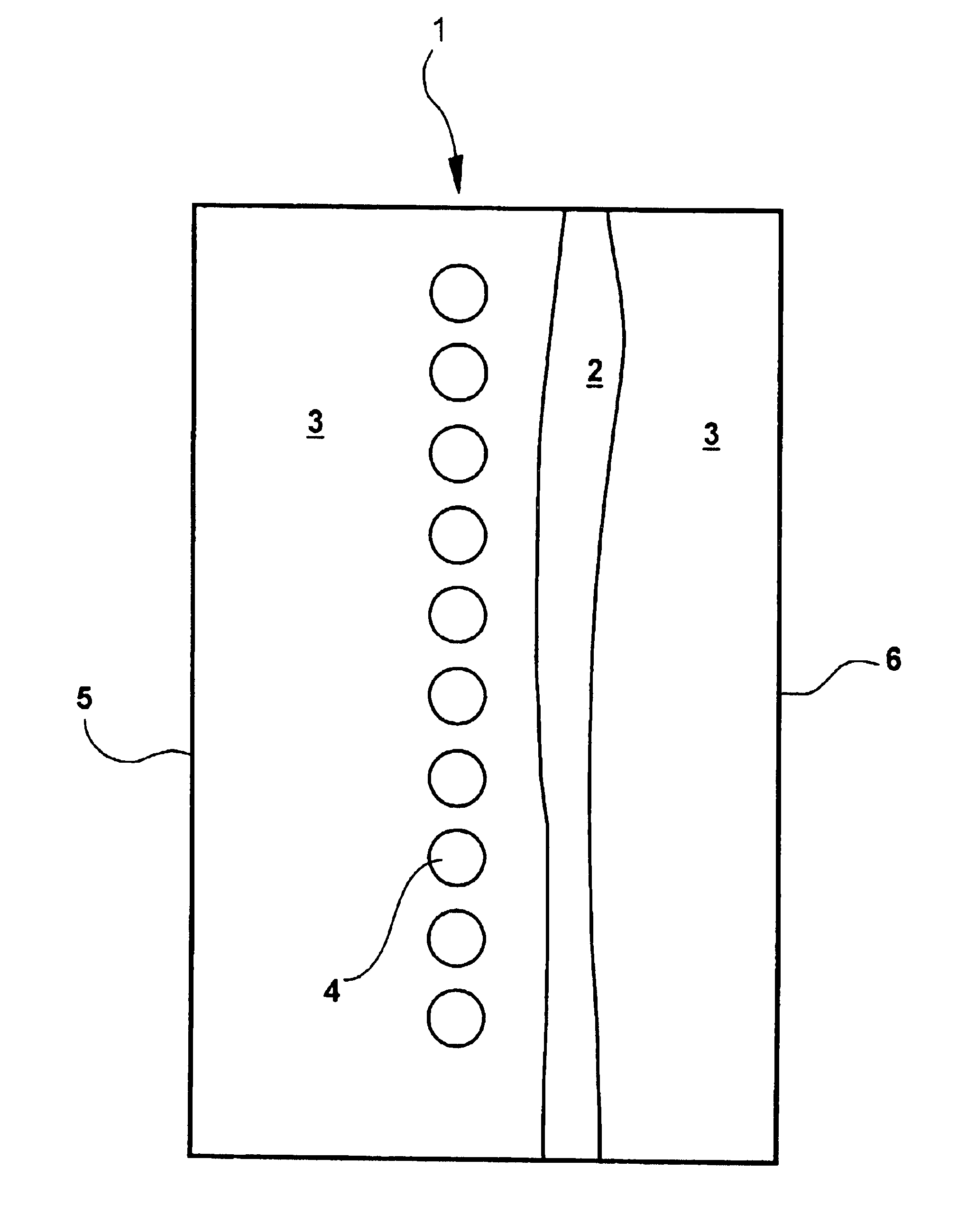

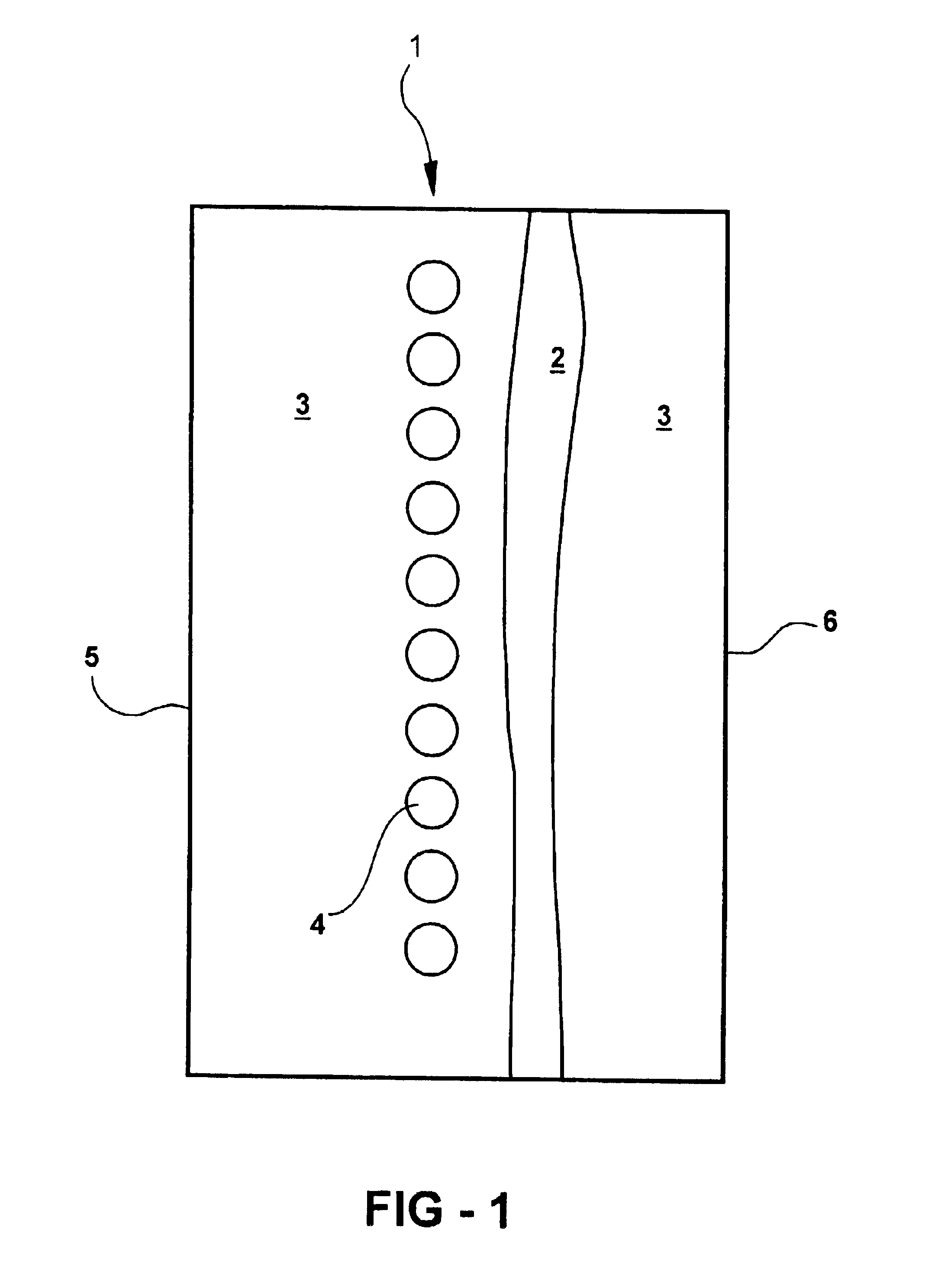

Method for preparing membranes and membrane electrode assemblies with hydrogen peroxide decomposition catalyst

ActiveUS20050095355A1Easy to reachCell electrodesFinal product manufactureHydrogen peroxide breakdownFuel cells

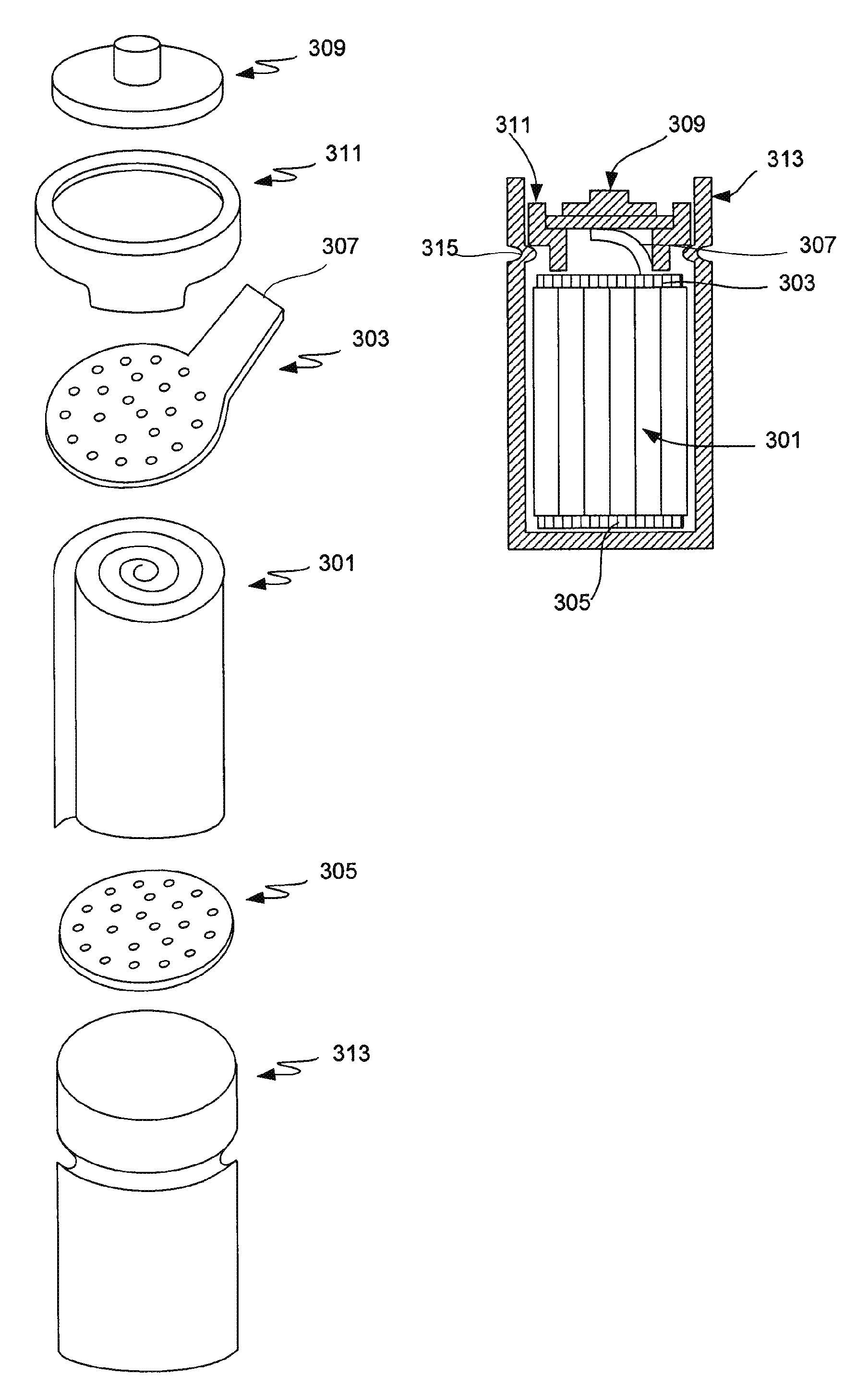

A method for making a membrane electrode assembly includes the steps of providing a membrane electrode assembly including an anode including a hydrogen oxidation catalyst; a cathode; a membrane disposed between the anode and the cathode; and depositing a peroxide decomposition catalyst in at least one position selected from the group consisting of the anode, the cathode, a layer between the anode and the membrane and a layer between the cathode and the membrane wherein the peroxide decomposition catalyst has selectivity when exposed to hydrogen peroxide toward reactions which form benign products from the hydrogen peroxide. The peroxide decomposition catalyst can also be positioned within the membrane. Also disclosed is a power-generating fuel cell system including such a membrane electrode assembly, and a process for operating such a fuel cell system.

Owner:AUDI AG

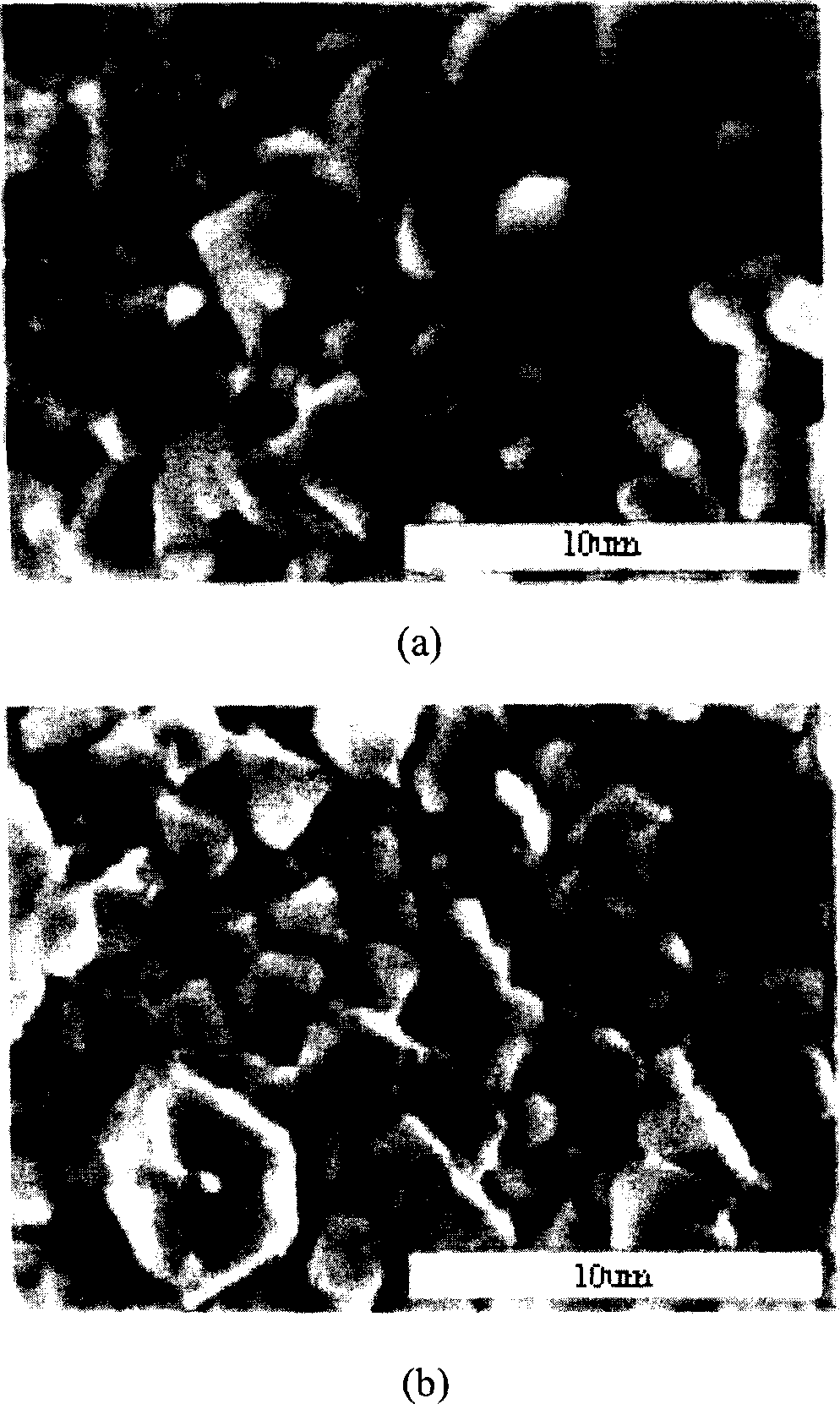

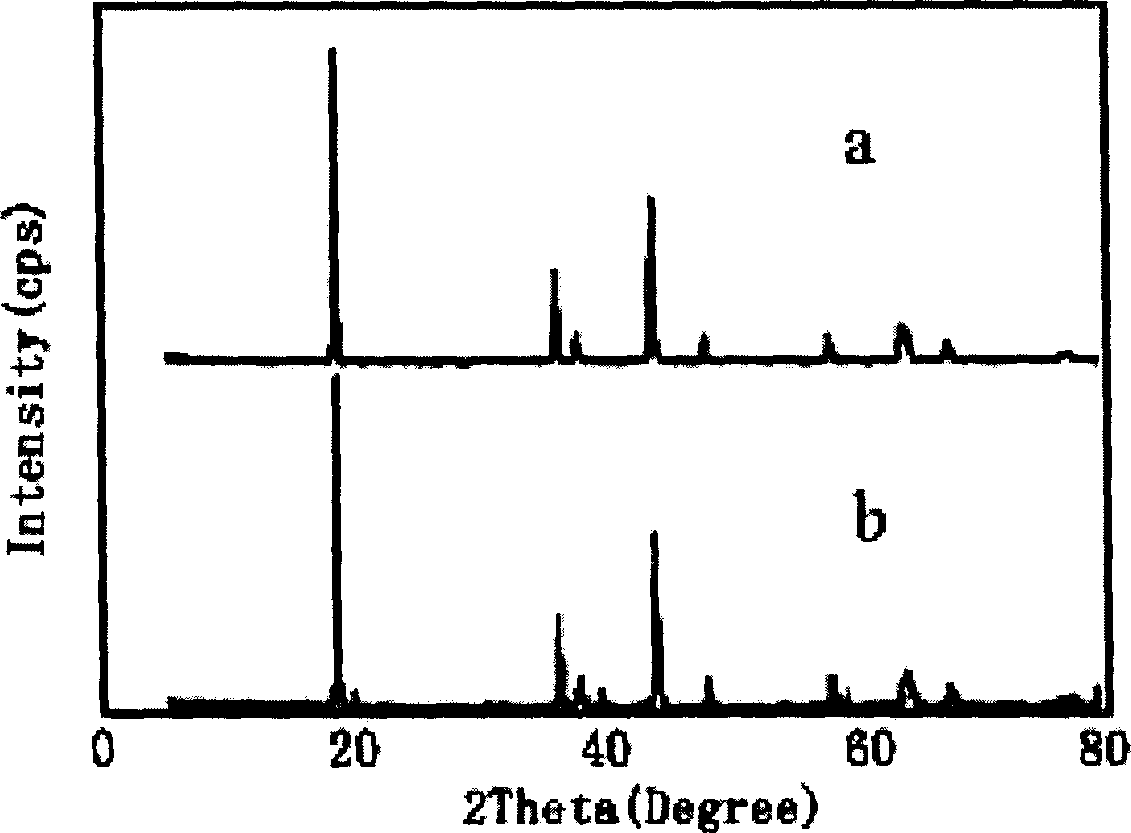

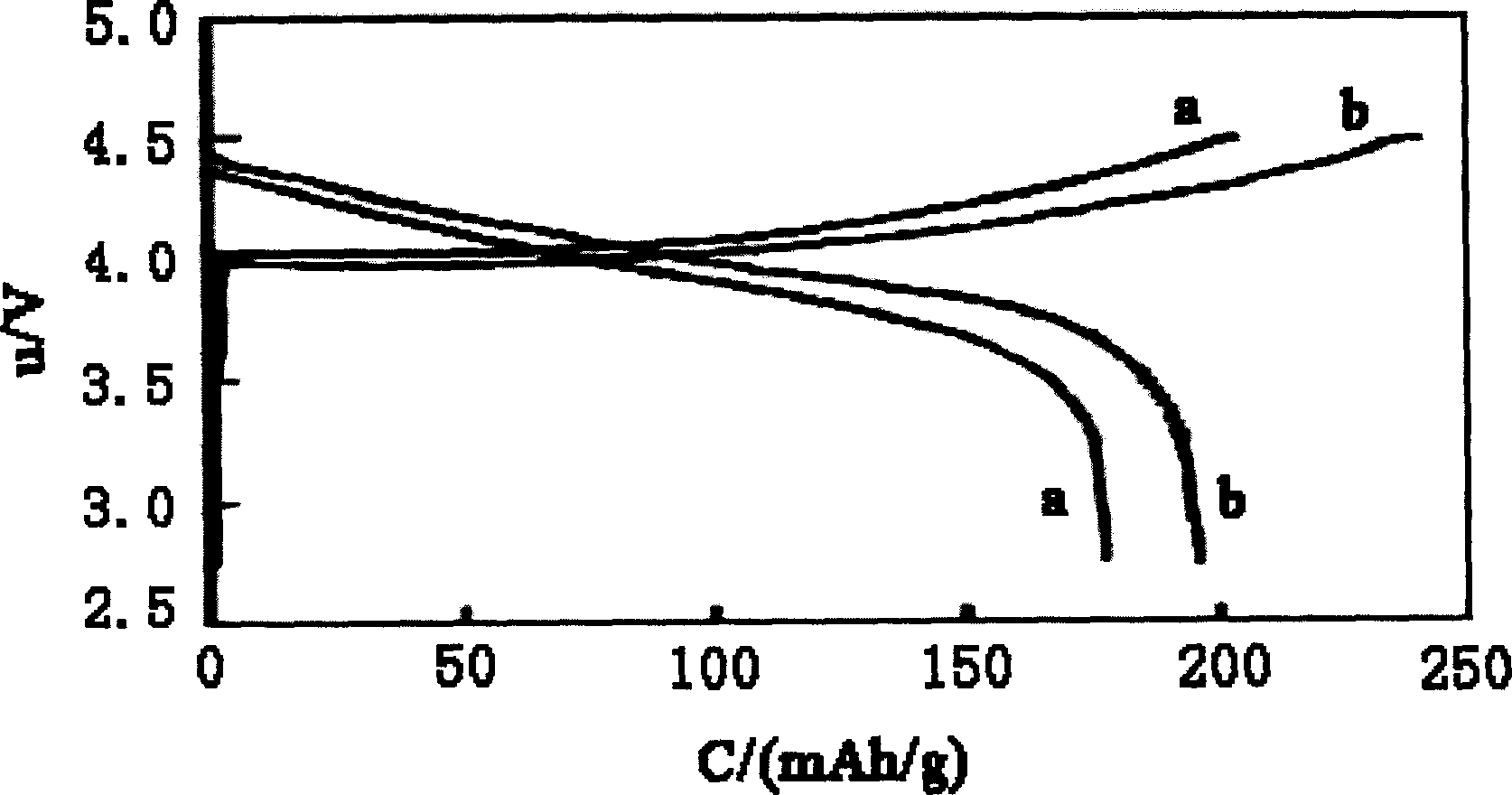

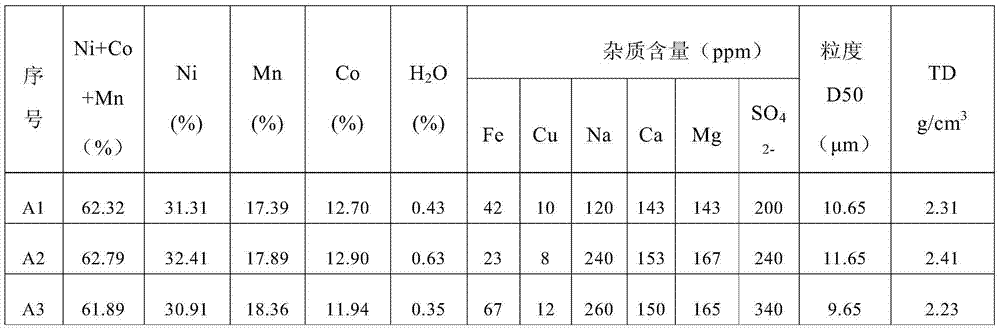

Manganese-included multi-element metal oxide, lithium ion secondary battery anode material and its preparing method

ActiveCN1770513AImprove cycle performanceUniform particle sizeCell electrodesSecondary cellsNickel saltLithium hydroxide

This invention relates to one multi-element metal oxidation and discloses The process method, which comprises the following steps: a, in nitrogen or inertance gas depositing the mixture of cobalt salt, nickel salt and maganism salt to generate Ni-Co-Mn compound hydrogen oxidation to process front drive after drying and grinding; b, adding lithium hydrate into the front drive grinding and processing mixture to remove absorbed water and structure water; c, processing products under degrees of 650 to 850 degrees; d, using high polymer as assistant agent to process surface covering on product; e, processing the product to remove solvent to process multi-metal oxidation.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

Preparation method for photocatalytic material with strong adsorption and high visible light degradation of performance

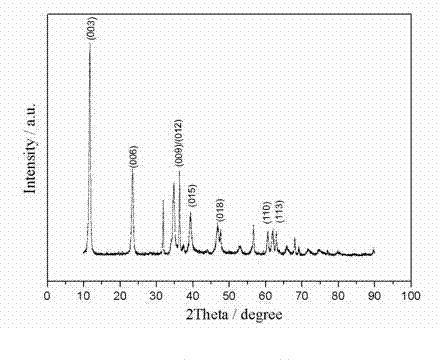

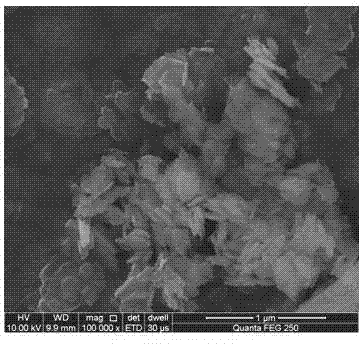

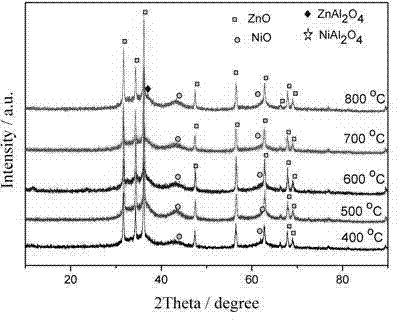

The invention discloses a gahnitem, zinc oxide and nickel zinc nano-composite photocatalytic material which has a high specific surface area and a mesoporous structure and is prepared by roasting at high temperature by taking ternary hydrotalcite as a precursor. The material is used for the adsorption and the degradation of organic pollutants. The photocatalytic material is prepared by taking zinc nitrate, nickel nitrate, aluminum nitrate, sodium carbonate, sodium hydroxide and the like as raw materials; preparing the raw materials into salt solutions and alkali solutions respectively; mixing the solutions by using a constant-flow pump at the temperature of 80 DEGC with magnetic stirring, transferring the mixed solution into a hydrothermal reaction kettle; performing hydrothermal treatment at 130 to 180 DEG C; performing suction filtration, washing and drying to the precursor; roasting the precursor in Muffle furnace for 2 to 6 hours at the temperature of 400 to 600 DEG C to obtain the product, wherein the specific surface area is greater than 150 m<2>.g<-1>. The photocatalyst disclosed by the invention has regular shape, large specific surface area, and super-high capacity for adsorbing and degrading organics, and can be reused; the raw materials for preparing the composite photocatalyst are abundant, the cost is low, and the process is simple.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

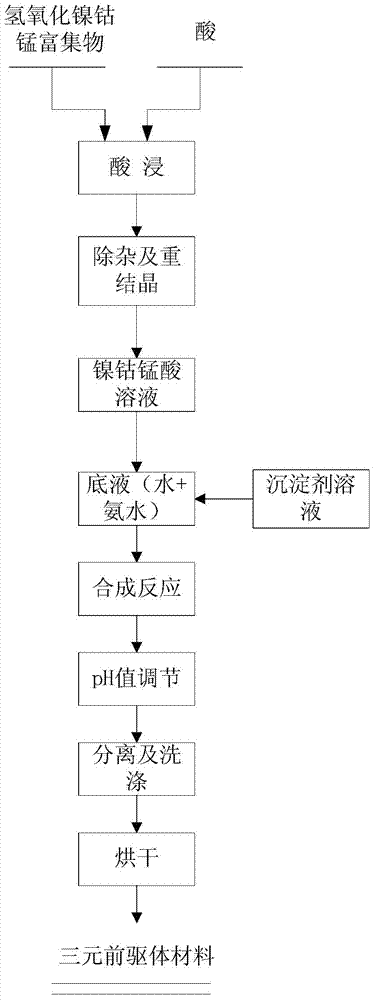

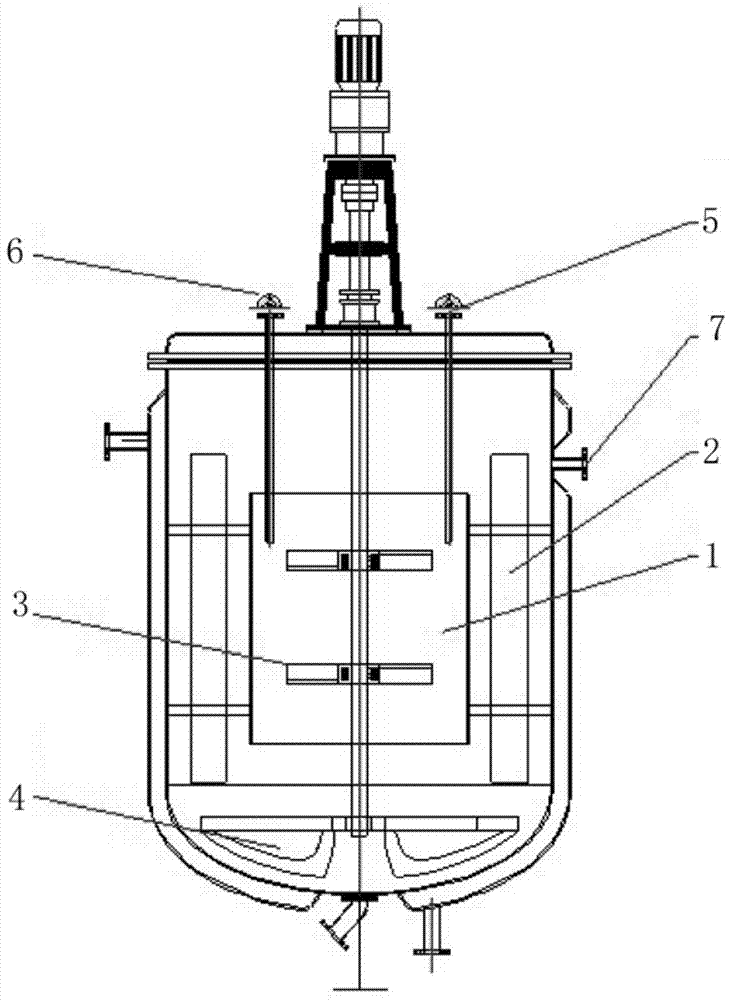

Preparation method of ternary anode material precursor

ActiveCN103545504AReduce manufacturing costLow costCell electrodesSecondary cellsNickel oxide hydroxideManganese

The invention discloses a preparation method of a ternary anode material precursor. According to the preparation method, an intermediate product namely nickel-manganese-cobalt hydroxide concentrate generated by producing electrolytic nickel from laterite, and the preparation process comprises the following process flows: A, acid leaching; B, impurity removal and recrystallization; C, preparation of a mixed salt; D, preparation of a precipitant; E, synthetic reaction; F, adjustment of the pH value; G, separation and washing; H, drying. The ternary anode material precursor prepared by the preparation method disclosed by the invention is uniform in particle size distribution, high in activity, high in density, high in specific capacity and low in cost.

Owner:江西赣锋循环科技有限公司

Catalytic hydrogen storage composite material and fuel cell employing same

InactiveUS6875536B2High catalytic activityImprove corrosion resistanceWater management in fuel cellsElectrode carriers/collectorsFuel cellsPhysical chemistry

A composite hydrogen storage material including 1) an active material having hydrogen storage capacity; and 2) a catalytic material having greater catalytic activity toward the dissociation of molecular hydrogen and / or oxidation of hydrogen than that of said active material having hydrogen storage capacity. Also, a fuel cell employing anodes formed from the composite hydrogen storage material. The fuel cell has the ability to start up instantly and can accept recaptured energy such as that of regenerative braking by operating in reverse as an electrolyzer.

Owner:TACTICAL FUEL CELLS

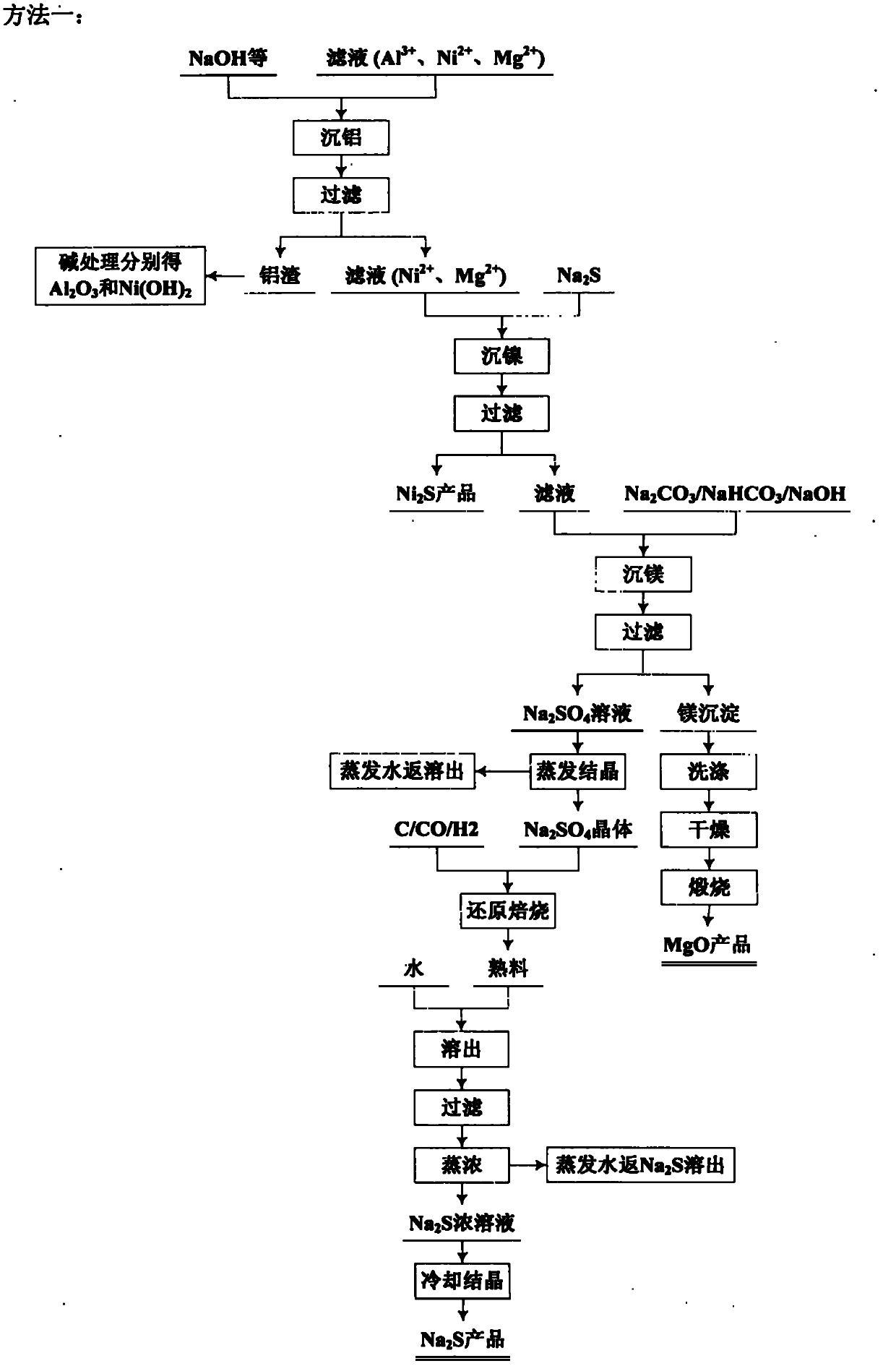

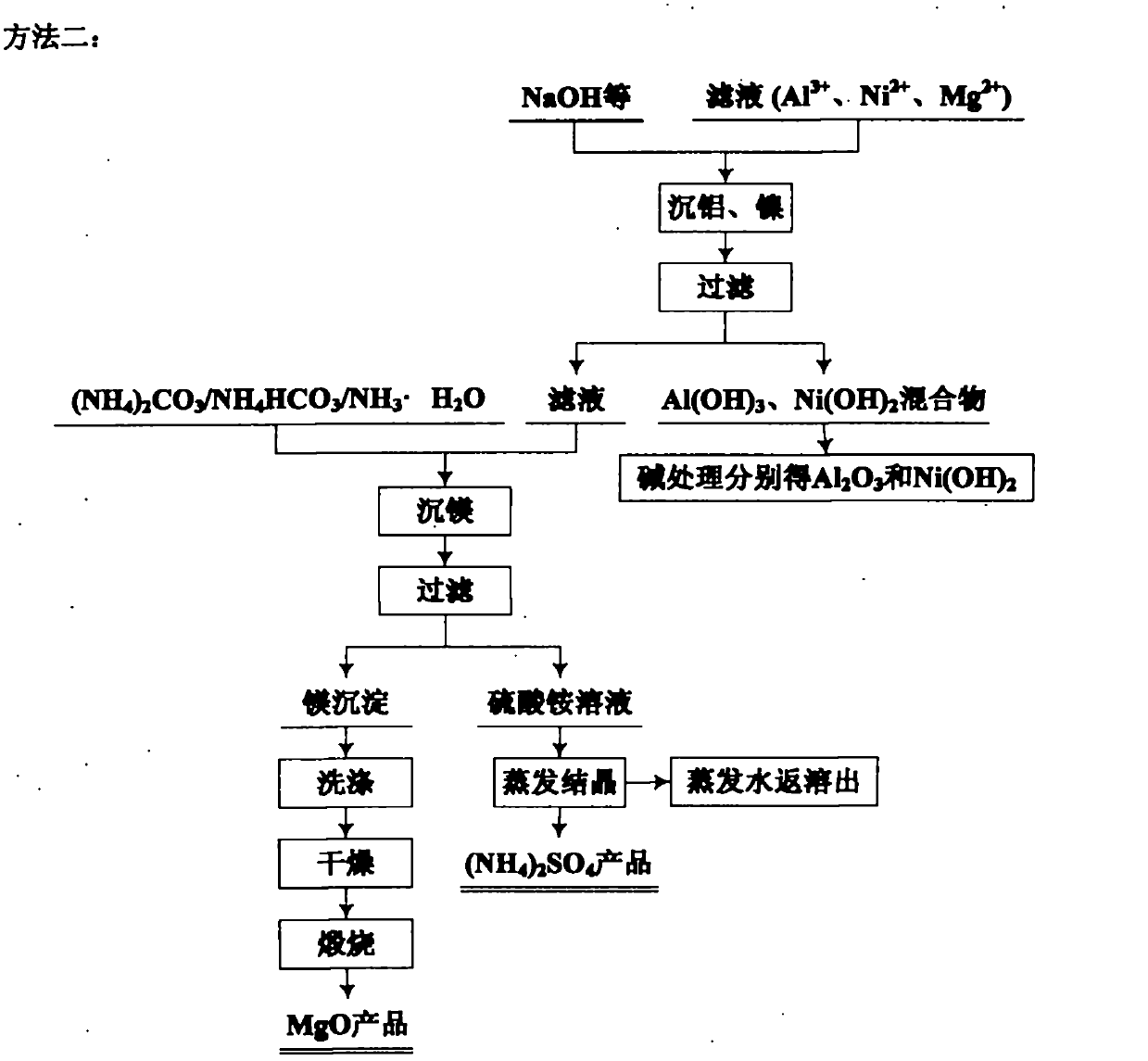

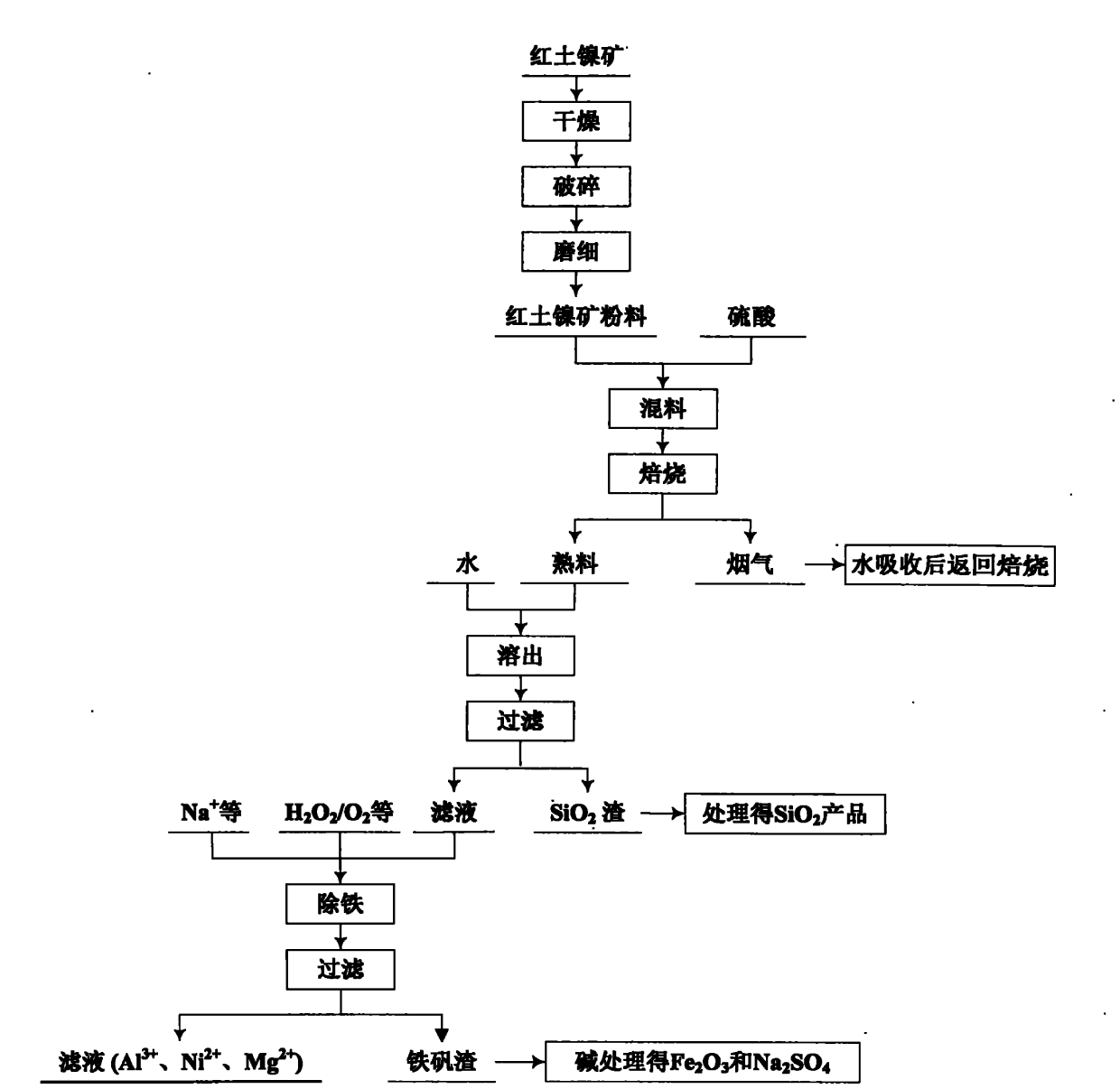

Comprehensive utilization method for laterite-nickel ore

The invention relates to an environmental-friendly comprehensive utilization method for a laterite-nickel ore, which comprises the following steps of: (1) grinding the laterite-nickel ore, mixing with sulfuric acid, roasting, dissolving out roasted clinker and filtering to obtain silicon dioxide and dissolution liquid; (2) deironing the dissolution liquid to obtain liquid No.2 and filter residue (iron compounds), wherein the liquid No.2 comprises aluminum, nickel and magnesium and can be treated by the step (3) or (4); (3) precipitating the aluminum in the liquid No.2 by using alkali, filtering, precipitating the nickel in filtrate by using sodium sulfide, filtering, precipitating the magnesium by using the alkali, and treating filter residue to obtain aluminum oxide, nickel hydroxide, nickel sulfide and magnesium oxide respectively; and (4) precipitating the aluminum and the nickel in the liquid No.2 by using the alkali, treating mixed slag containing the aluminum and the nickel by using the alkali to obtain aluminum hydroxide and nickel hydroxide products, and precipitating the magnesium in filtrate subjected to aluminum and nickel precipitation by using ammonia or ammonium saltto obtain a magnesium oxide product. The method is suitable for treating various laterite-nickel ores, three wastes (waste gas, waste water and waste residue) are not generated, and valuable components magnesium, nickel, iron, aluminum and silicon in the laterite-nickel ore are separated and extracted.

Owner:NORTHEASTERN UNIV

Fuel additive containing lattice engineered cerium dioxide nanoparticles

ActiveUS20120124899A1Material nanotechnologyHeterogenous catalyst chemical elementsKinetic diameterNanoparticle

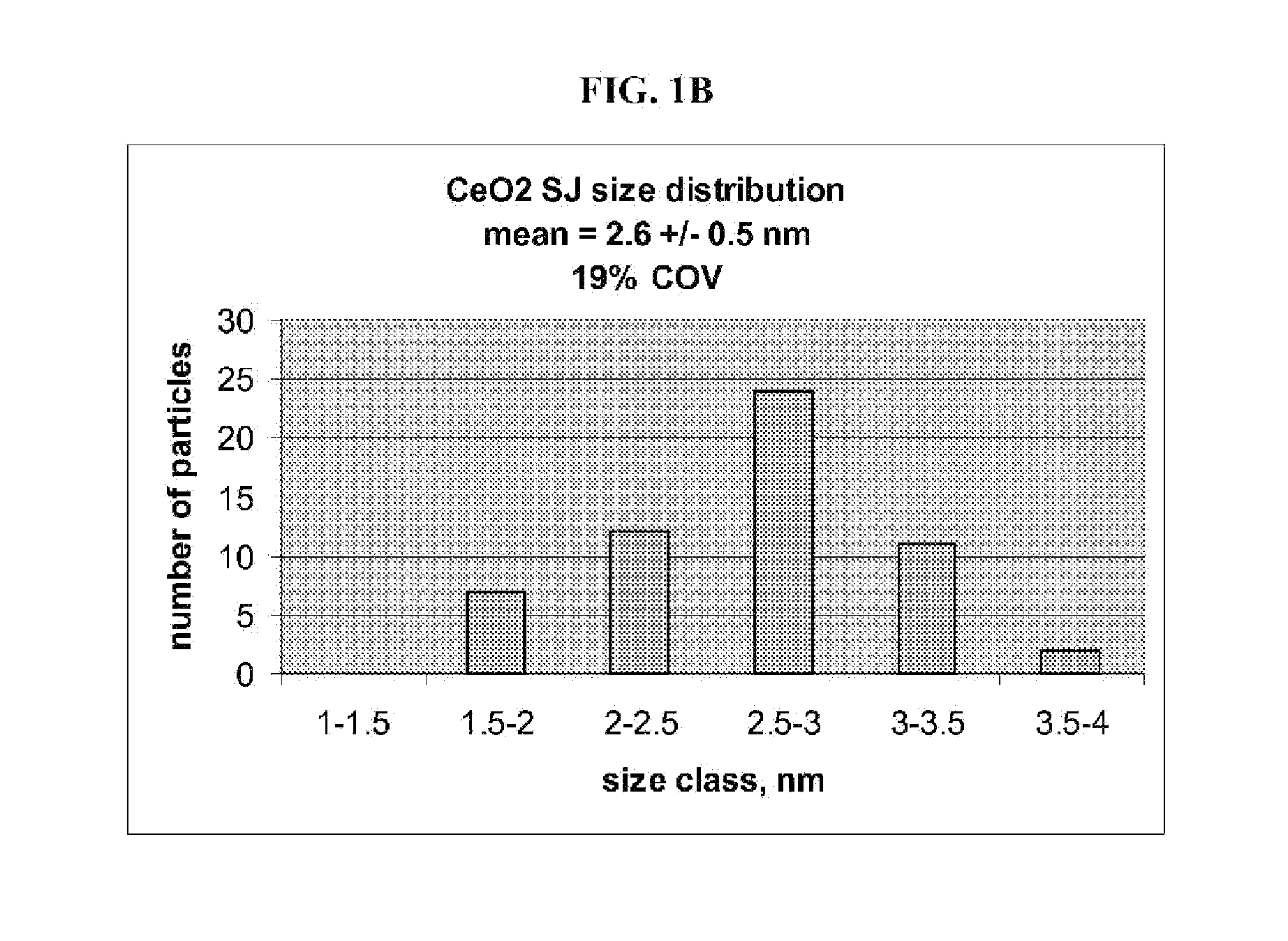

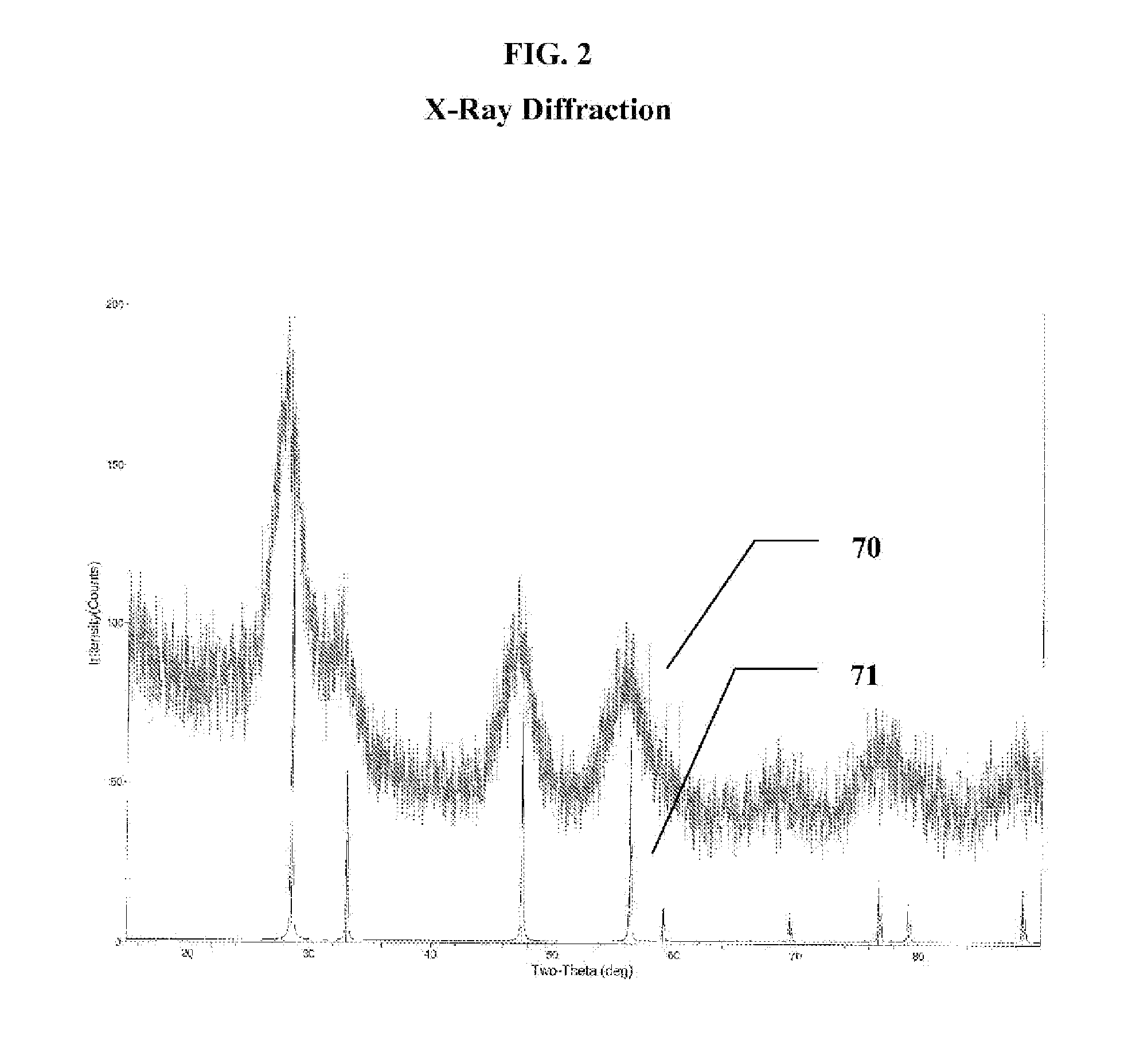

A process for making cerium dioxide nanoparticles containing at least one transition metal (M) utilizes a suspension of cerium hydroxide nanoparticles prepared by mechanical shearing of an aqueous mixture containing an oxidant in an amount effective to enable oxidation of cerous ion to ceric ion, thereby forming a product stream that contains transition metal-containing cerium dioxide nanoparticles, Ce1-xMxO2, wherein “x” has a value from about 0.3 to about 0.8. The nanoparticles thus obtained have a cubic fluorite structure, a mean hydrodynamic diameter in the range of about 1 nm to about 10 nm, and a geometric diameter of less than about 4 nm. The transition metal-containing crystalline cerium dioxide nanoparticles can be used to prepare a dispersion of the particles in a nonpolar medium.

Owner:CERION

Nickel hydroxide electrode for rechargeable batteries

ActiveUS20090208839A1Facilitate interface reactionImprove reliabilityMaterial nanotechnologyHybrid capacitor electrodesPotassium persulfateNickel oxide hydroxide

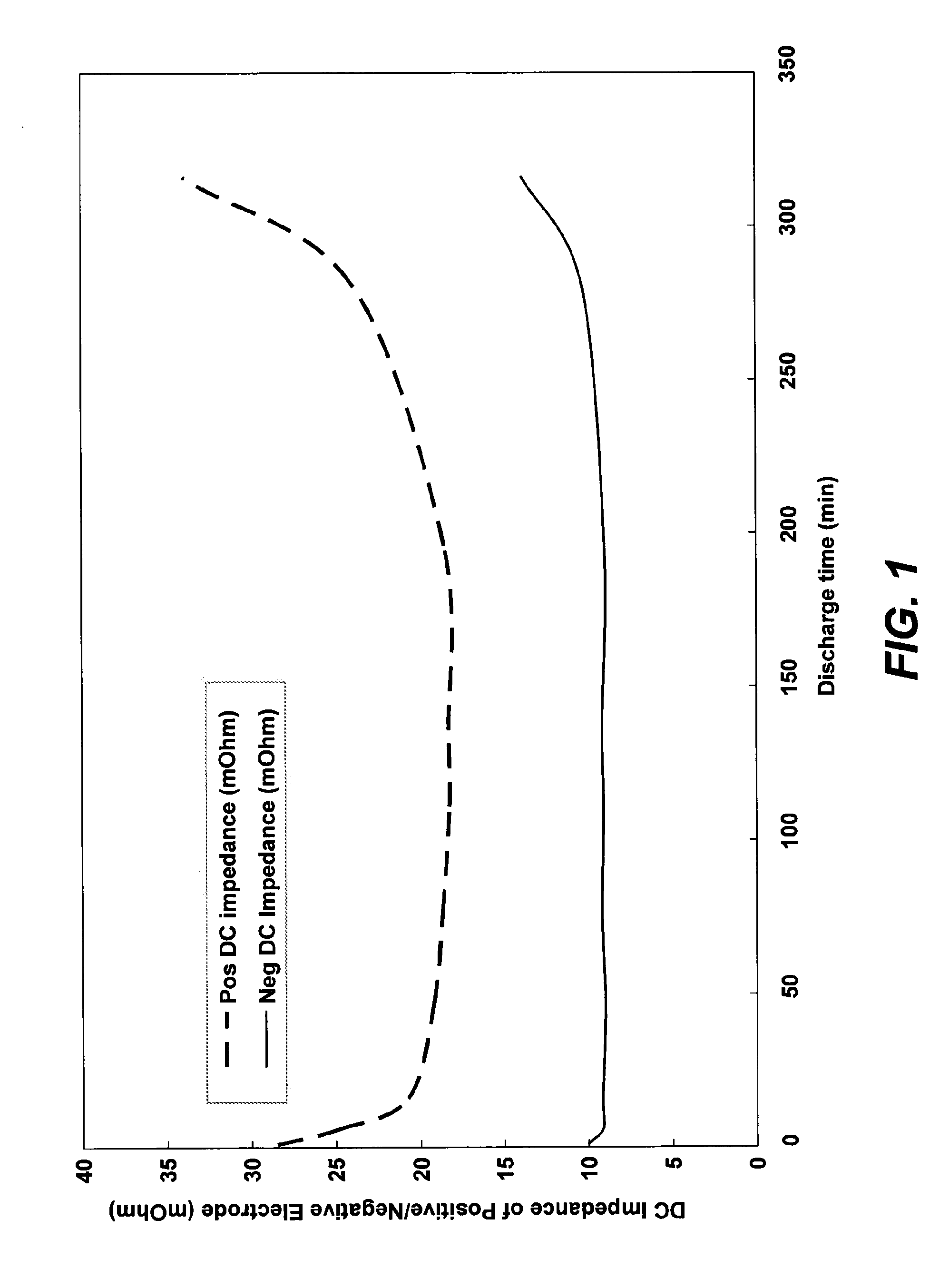

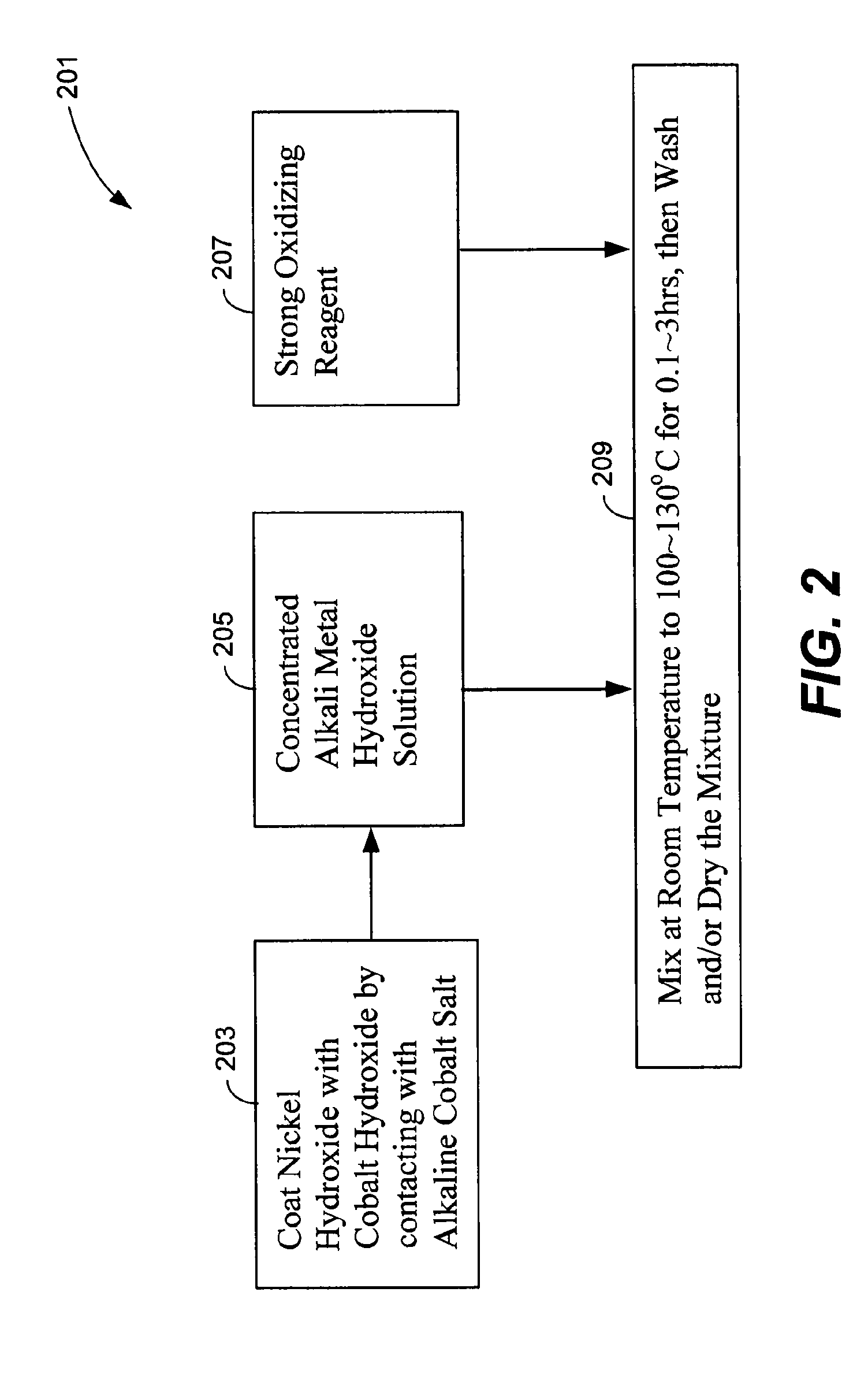

The nickel hydroxide particles for a nickel hydroxide electrode may be treated using an alkaline solution of a strong oxidizing agent such as sodium or potassium persulfate to modify the surface nickel hydroxide structure. The resulting modified surface structure has been found to impart various benefits to electrodes formed from the nickel hydroxide. It is believed that the oxidation of cobalt compounds at the surface of the nickel hydroxide particles results in a highly conductive cobalt compound that plays an important role in the high reliability, high stability and high capacity utilization of nickel electrodes as described herein.

Owner:ZINCFIVE POWER INC

Preparation method of thin shell shaped noble metal catalyst

InactiveCN101491778AExtended service lifeGood dispersionMolecular sieve catalystsCatalyst activation/preparationAlkaneThin shells

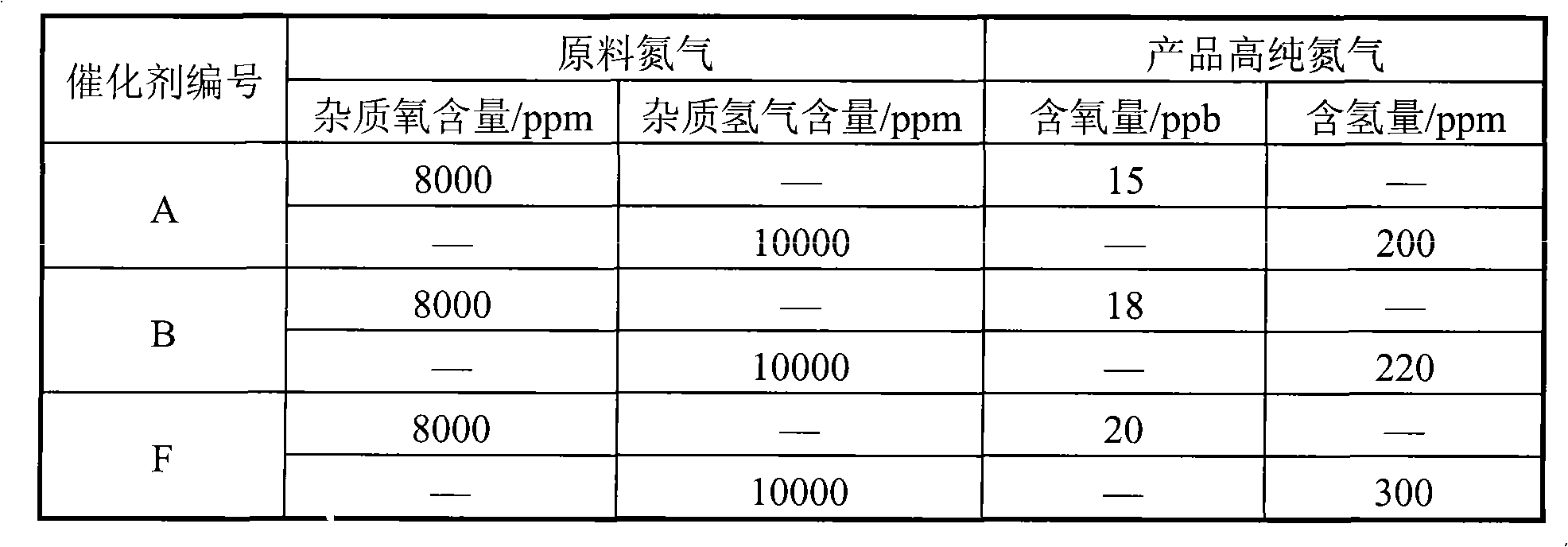

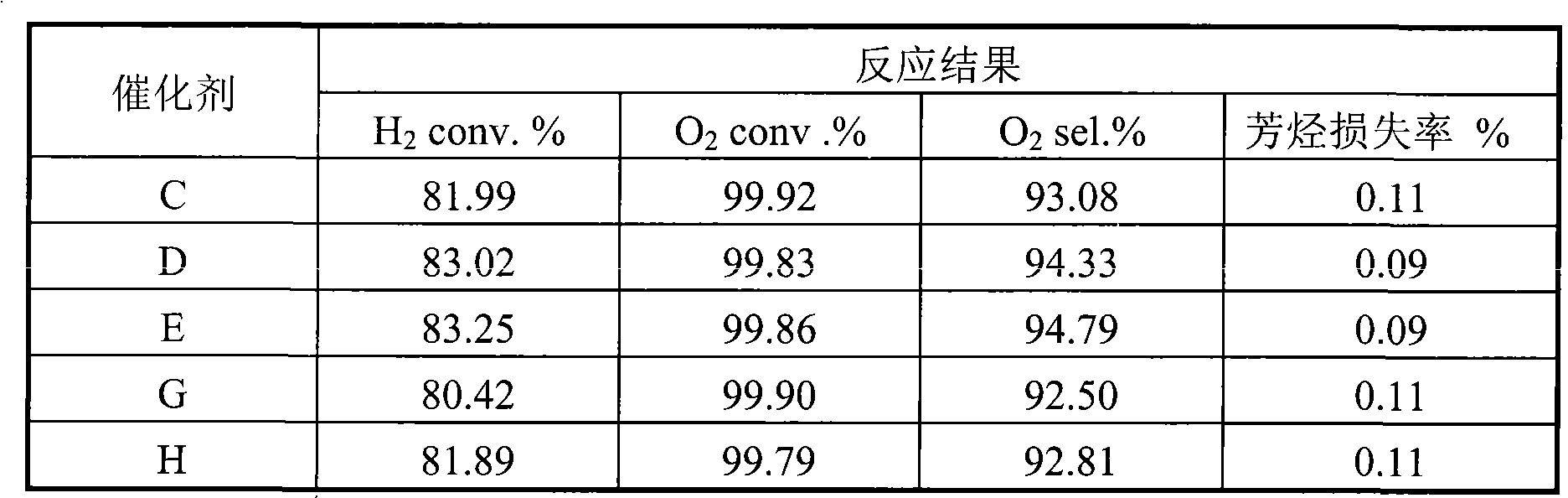

The invention relates to a preparation method of thin-shelled noble metal catalyst, and mainly solves the problems of the prior art of high dosage, poor selectivity and short service life of noble metal. The preparation method better solves the technical problems of the prior art by adopting the technical proposal comprising the following steps of: (a) coating the slurry of a coat porous material on the inner core of an inert carrier, drying the slurry coating and baking the slurry coating at a temperature of between 700 and 1,200 DEG C for 0.5 to 10 hours to obtain a laminar composite carrier; (b) impregnating the surface of the laminar composite carrier with a solution containing noble metal and cocatalyst components, drying the laminar composite carrier, and baking the laminar composite carrier in the air at a temperature of between 200 and 700 DEG C for 1 to 24 hours to obtain a thin-shelled catalyst precursor; and (c) reducing the thin-shelled catalyst precursor in a reducing atmosphere at a temperature between 300 and 800 DEG C for 1 to 24 hours to obtain the thin-shelled noble metal catalyst. The preparation method can be used in the industrial production of gas purification materials which are dehydrogenation-deoxidization catalysts, alkanes and aromatic hydrocarbons for selective hydrogen oxidation in a dehydrogenation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for large-grained spherical cobalt oxyhydroxide

The present invention provides a preparation method for large-grained spherical cobalt oxyhydroxide. The specific method is as follows: (1) preparing a 0.5-2.0mol / L cobalt salt solution and a 5-10mol / L sodium hydroxide solution, and adding a complexing agent and a reducing agent in the sodium hydroxide solution; (2) under the protection of nitrogen, simultaneously pumping the cobalt salt solution and the sodium hydroxide solution prepared in the step (1) into a reaction vessel for a continuous reaction, wherein a pH value is controlled to be in a range of 10-12 by adjusting the flow rate of the sodium hydroxide solution, and a slurry particle size is controlled to be in a range of 15-20 microns; (3) obtaining cobalt hydroxide with good sphericity and crystallinity, washing and filtering, controlling a water content in a range of 10-30%, transferring into an oxidation reactor, and blowing air in for oxidation; and (4) placing the oxidized slurry into a blast oven for drying to obtain the large-grained spherical cobalt oxyhydroxide.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

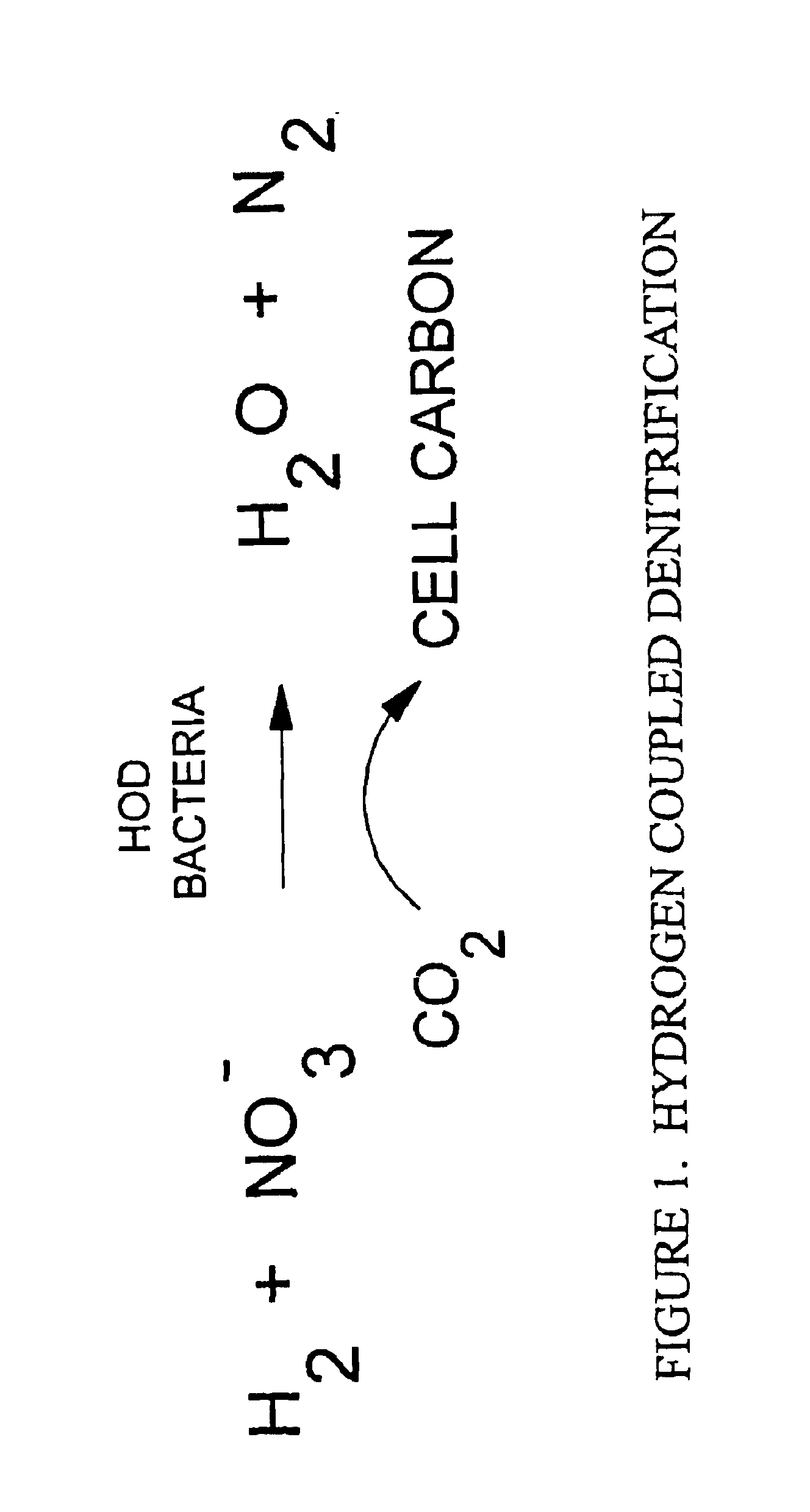

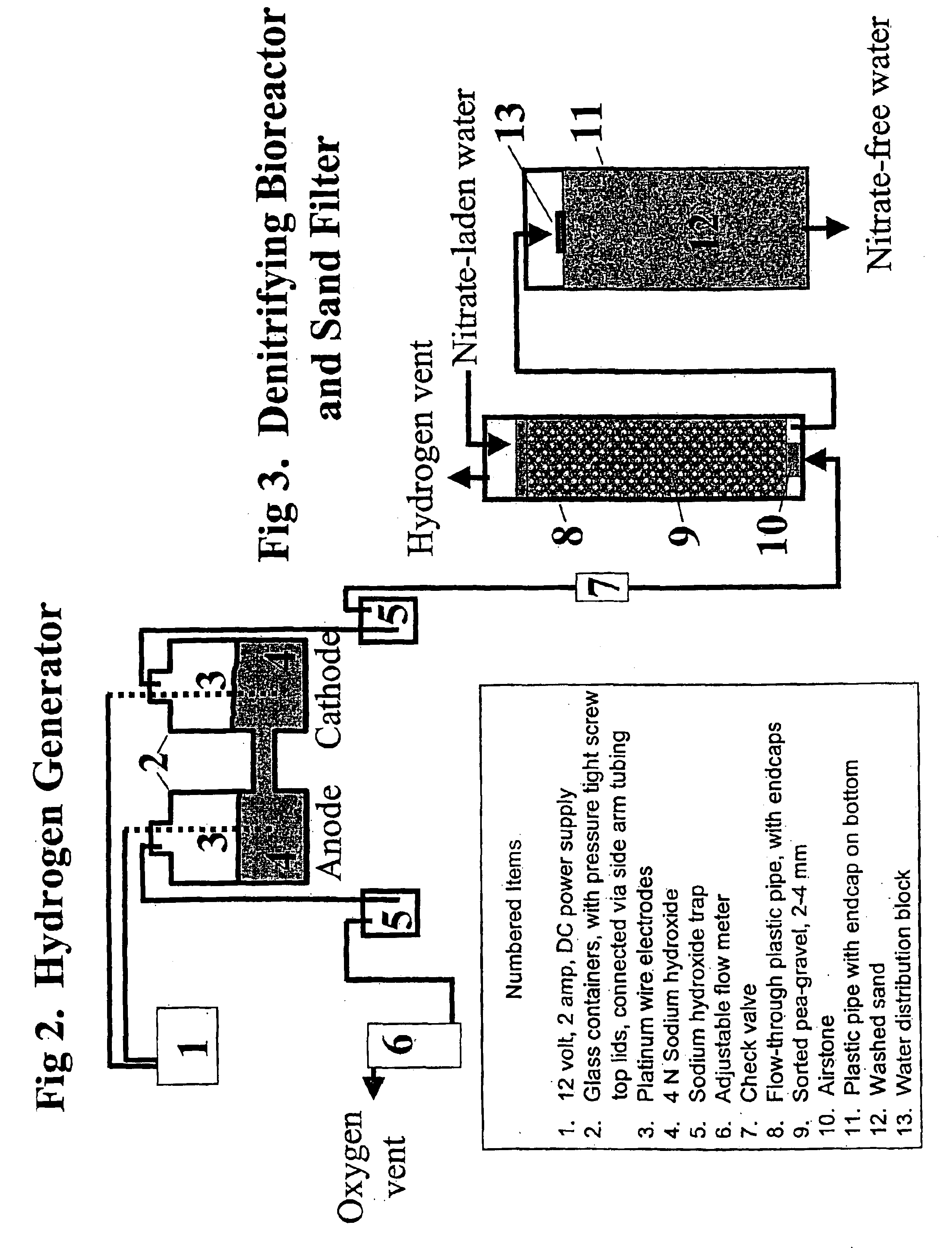

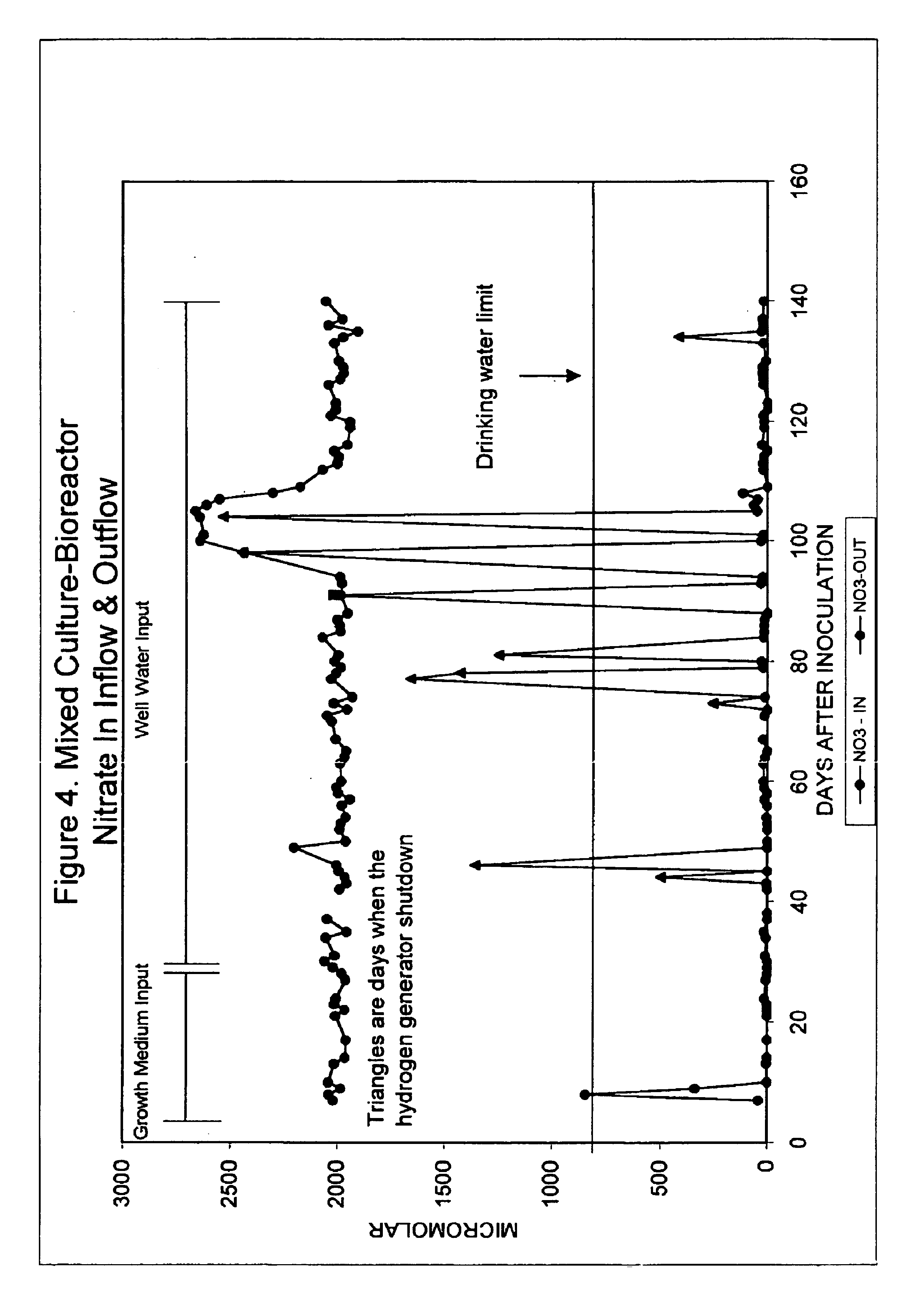

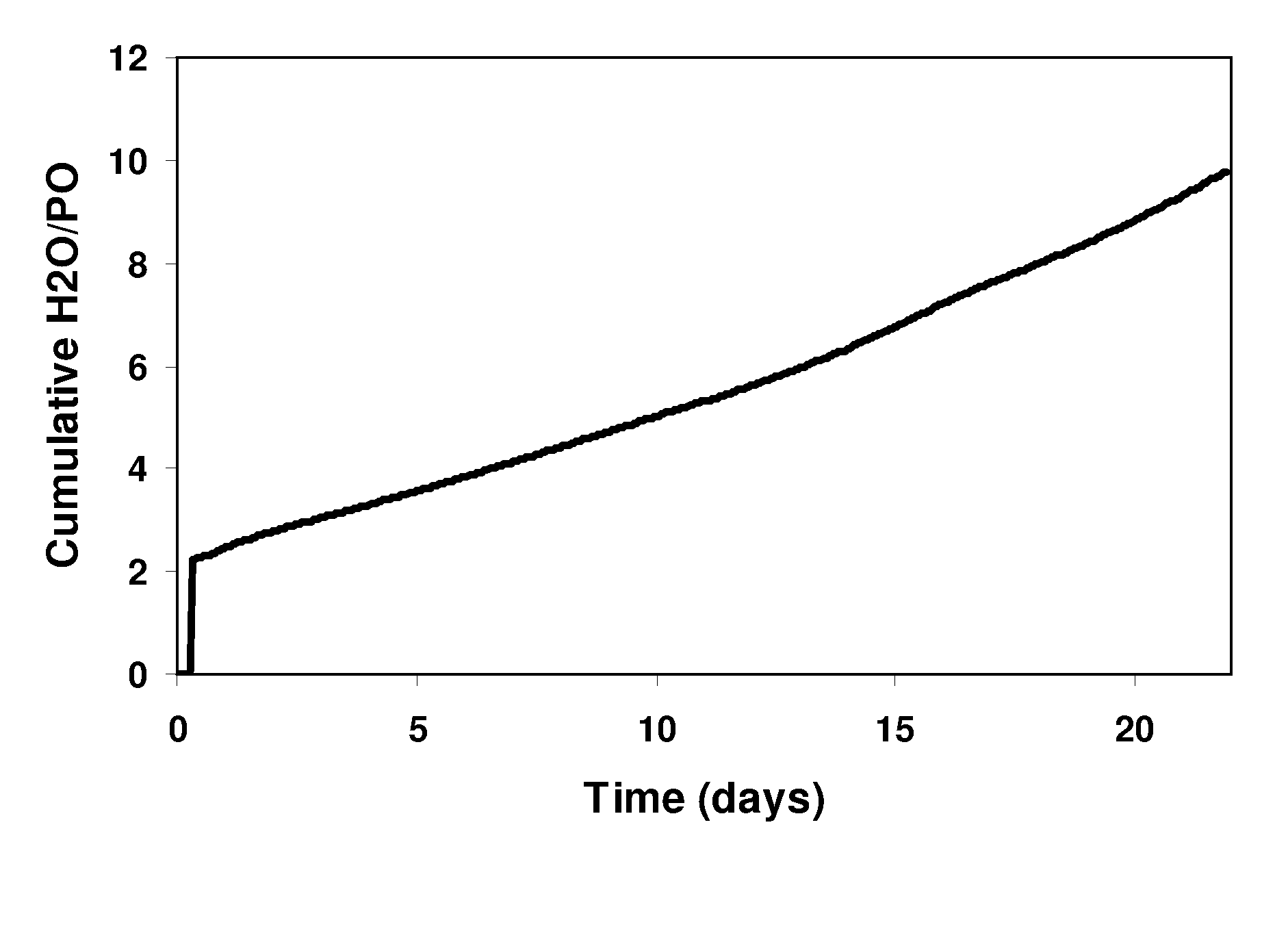

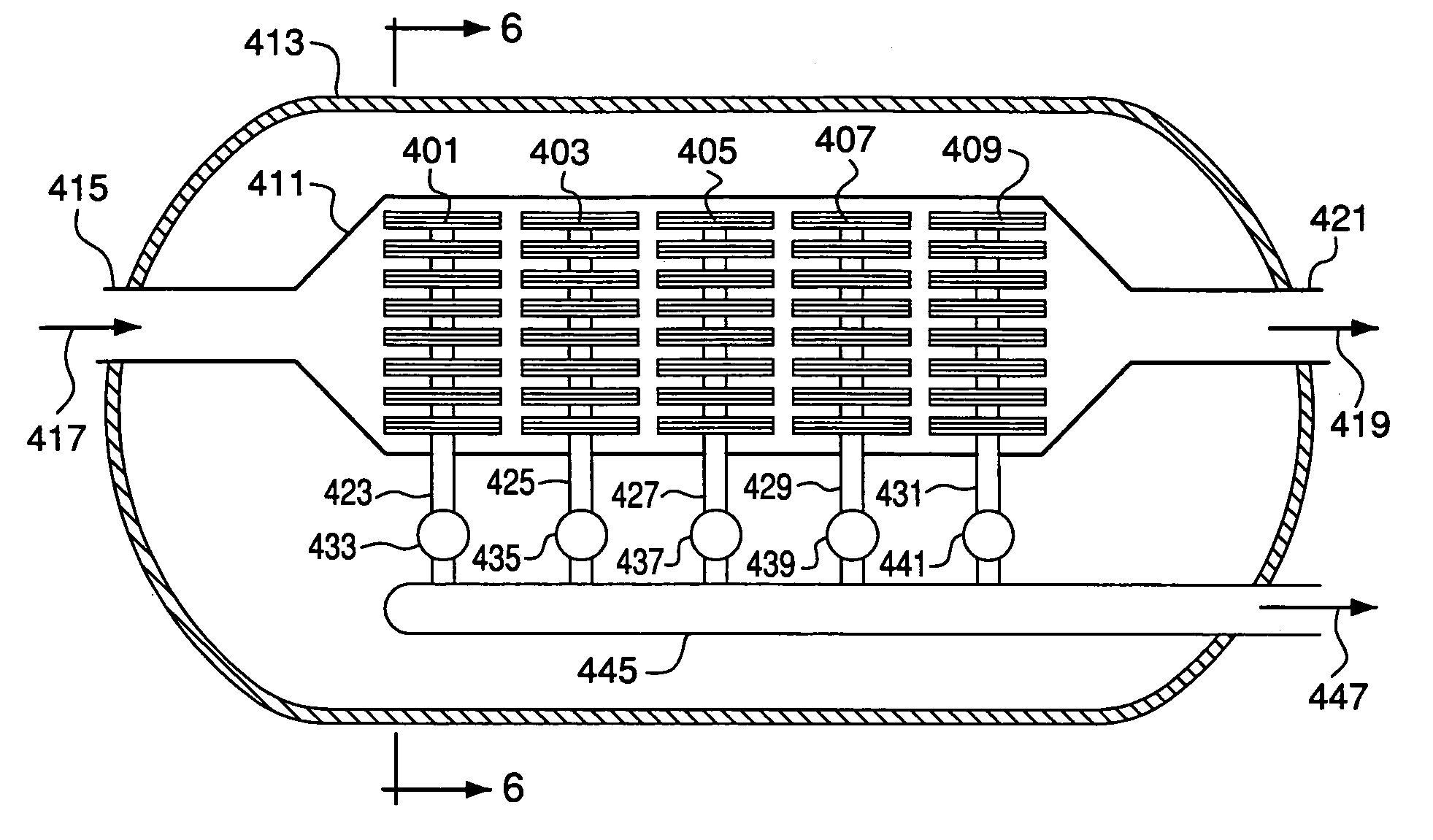

Small-scale hydrogen-oxidizing-denitrifying bioreactor

InactiveUS6863815B1Maximizing abilityLow costWater cleaningWater contaminantsNitrateDenitrifying bacteria

A method for treating nitrate-contaminated water comprising treating said water with hydrogen-oxidizing denitrifying bacteria in the presence of hydrogen. The apparatus for use in this method preferably comprises:(a) a pure culture of autotrophic, hydrogen-oxidizing denitrifying bacteria;(b) a hydrogen generator;(c) a flow-through bioreactor; and(d) a filtration unit.

Owner:U S GEOLOGICAL SURVEY +1

Hydro-oxidation process using a catalyst prepared from a gold cluster complex

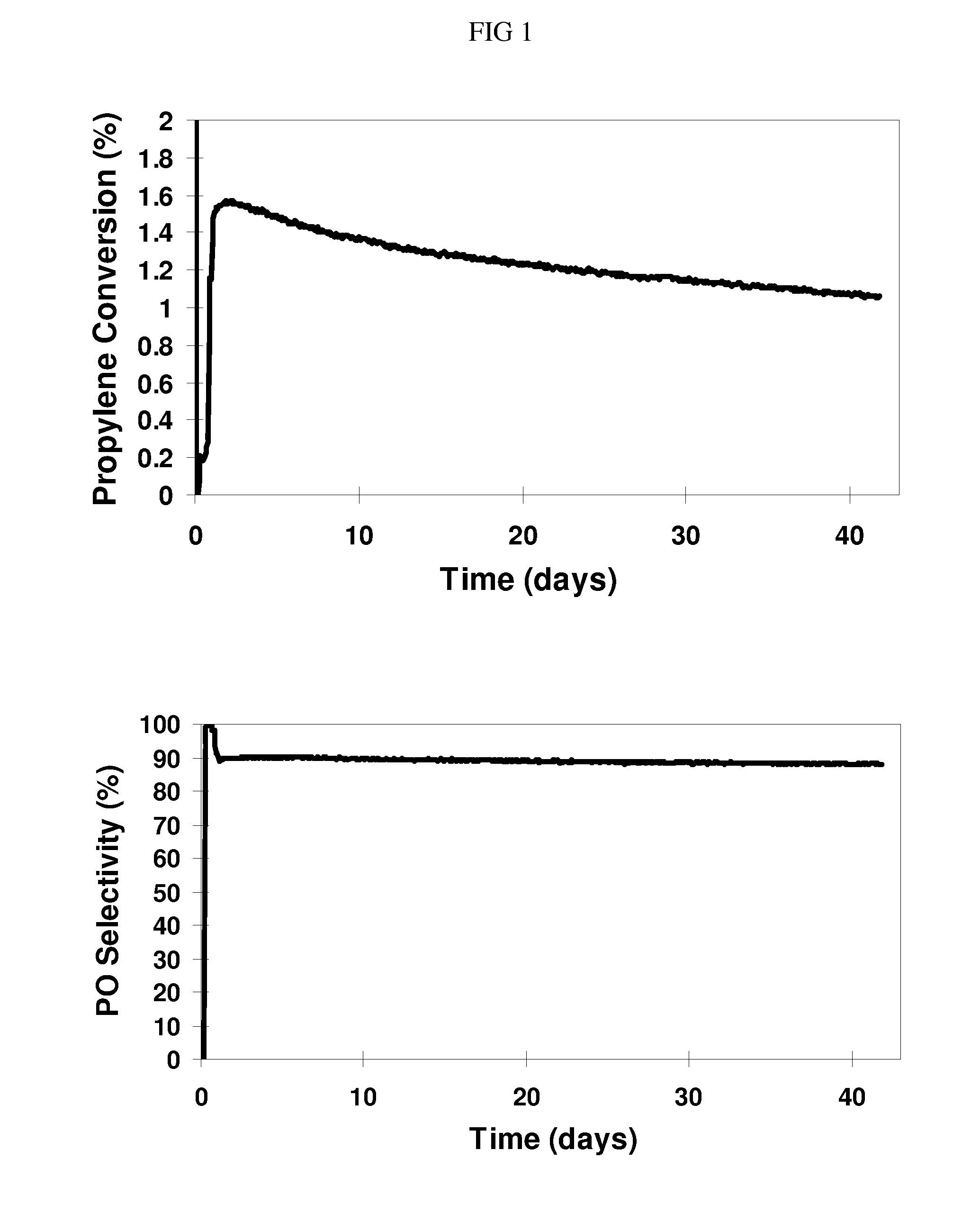

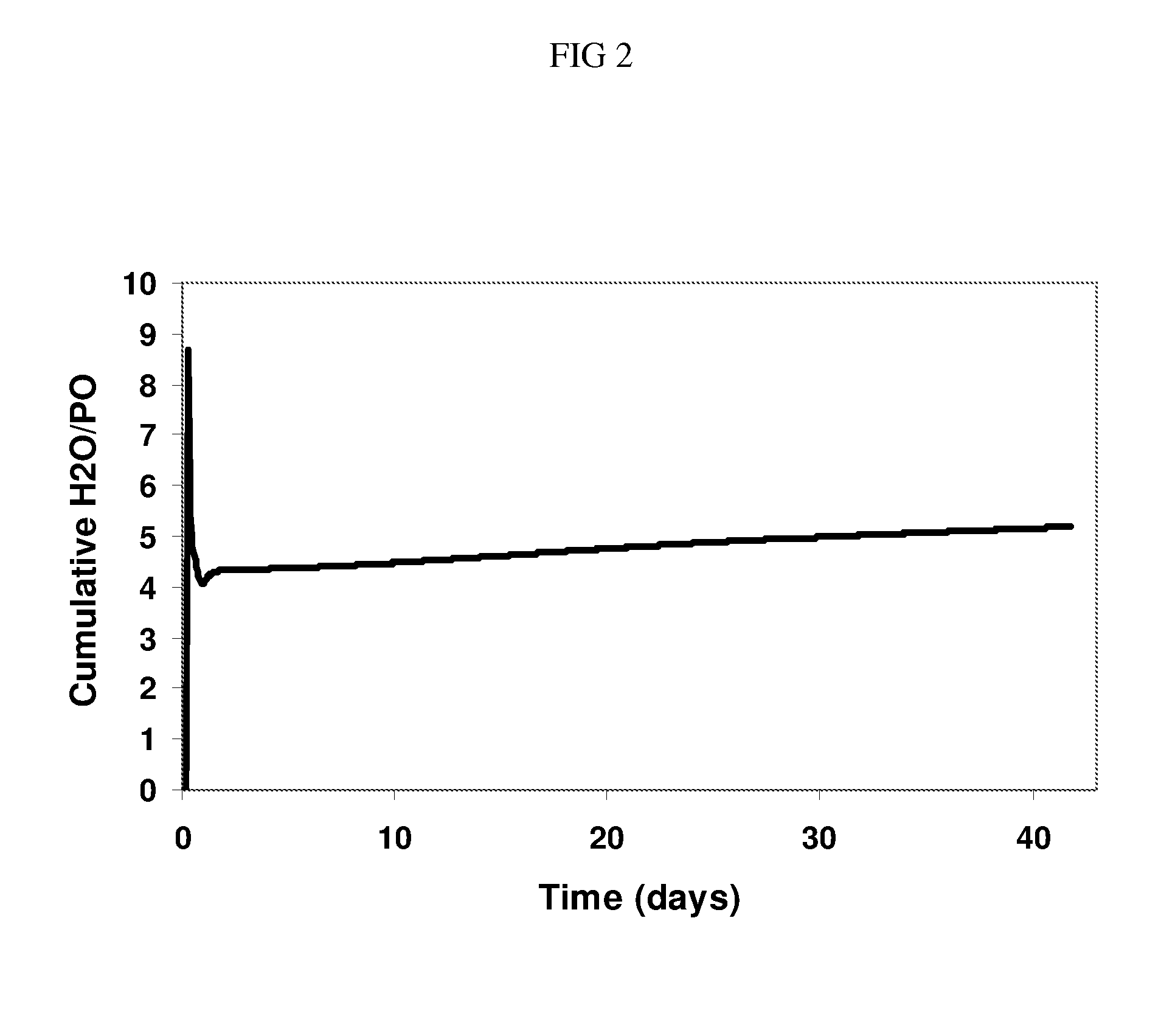

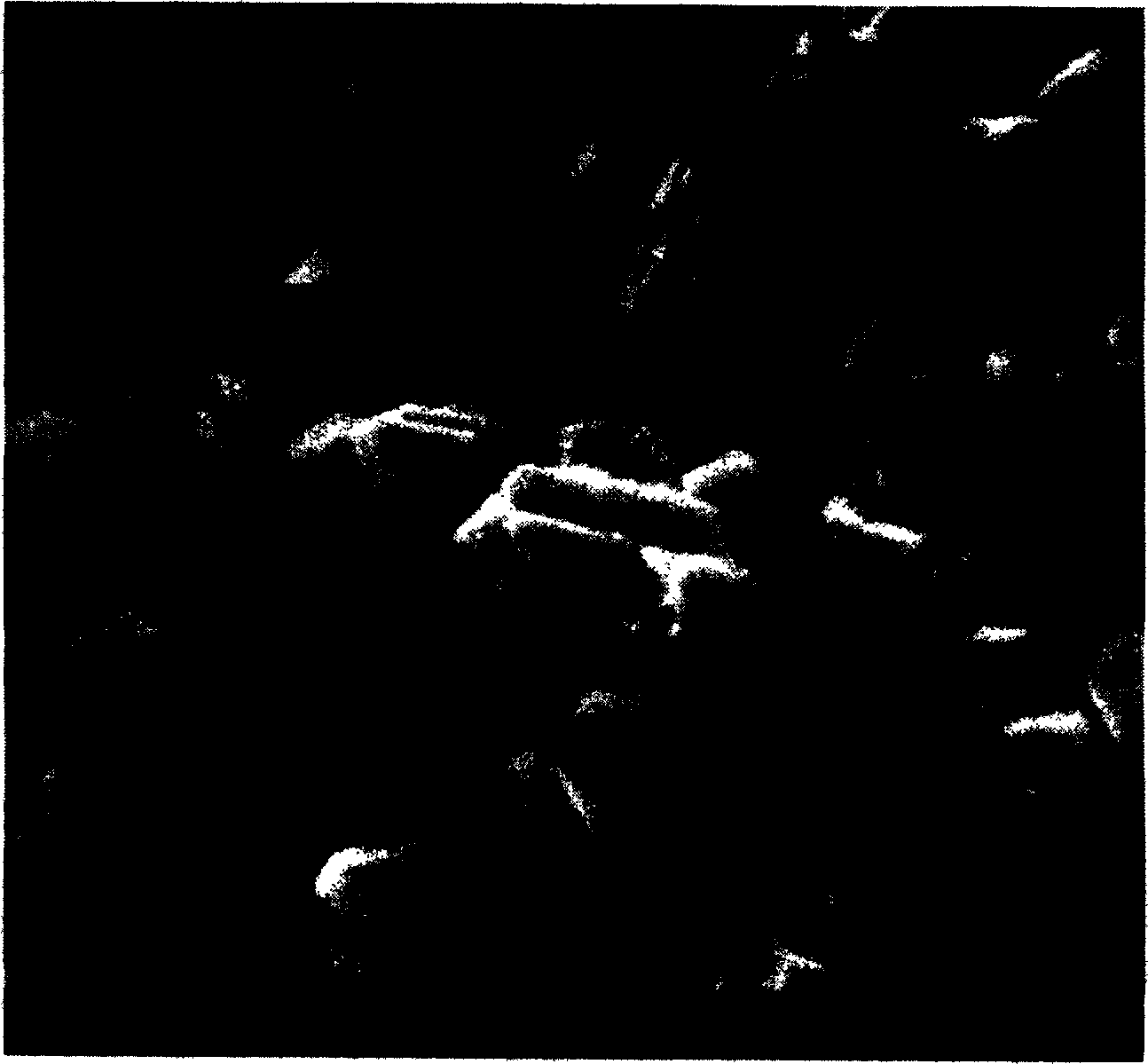

InactiveUS20100076208A1No decrease in olefin oxide selectivityIncrease the number ofOrganic chemistryMolecular sieve catalystsChemical treatmentGold cluster

A process and catalyst for the hydro-oxidation of an olefin having three or more carbon atoms, such as propylene, to form an olefin oxide, such as propylene oxide. The process involves contacting the olefin with oxygen in the presence of hydrogen and a hydro-oxidation catalyst under reaction conditions; the catalyst comprising gold nanoparticles deposited on a nanoporous titanium-containing support, prepared by depositing a gold-ligand cluster complex onto the support to form a catalyst precursor, and then heating and / or chemically treating the catalyst precursor to form the hydro-oxidation catalyst composition. The hydro-oxidation catalyst exhibits stabilized catalyst activity, enhanced lifetime, and improved hydrogen efficiency.

Owner:DOW GLOBAL TECH LLC

Process for preparing high purity cobalto-cobaltic oxide

InactiveCN1587069AImprove electrochemical performanceWide variety of sourcesCobalt oxides/hydroxidesCobalt(II,III) oxideCobalt salt

The present invention relates to the preparation process of high purity cobalto-cobaltic oxide. Water solution of two-valent cobalt salt and sodium hydroxide solution are reacted in strong stirring and in the conditions of pH 4.5-13.5, 50-100 deg.c and existence of reductant to obtain cobaltous hydroxide precipitate. Where, the weight ratio between cobalt, sodium hydroxide and reductant is 1.00 to 2.0-3.0 to 0.01-0.1. The precipitate is filtered and washed, and the filter cake is dried at 80-125 deg.c, crushed, roasted and calcined at 200-950 deg.c in a calcining furnace for 0.5-14 hr, re-crushed and graded into the high purity cobalto-cobaltic oxide powder.

Owner:曾福兴

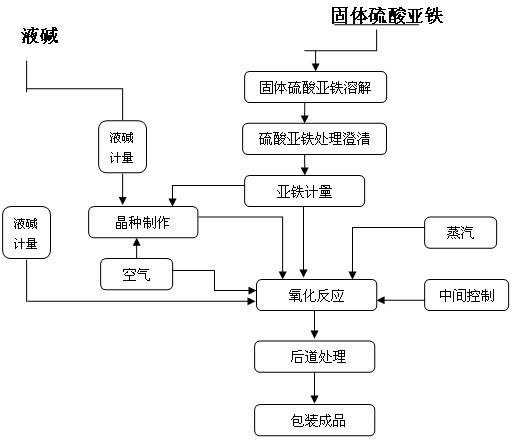

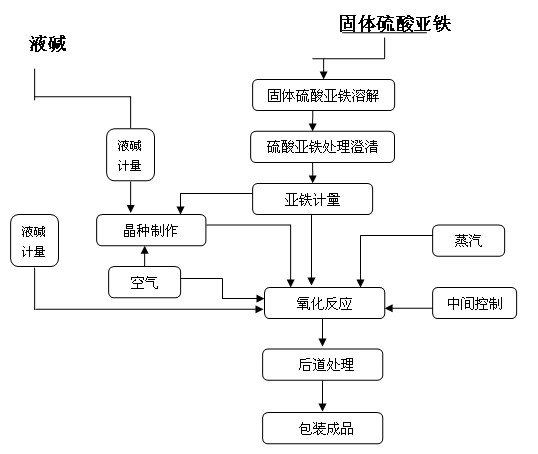

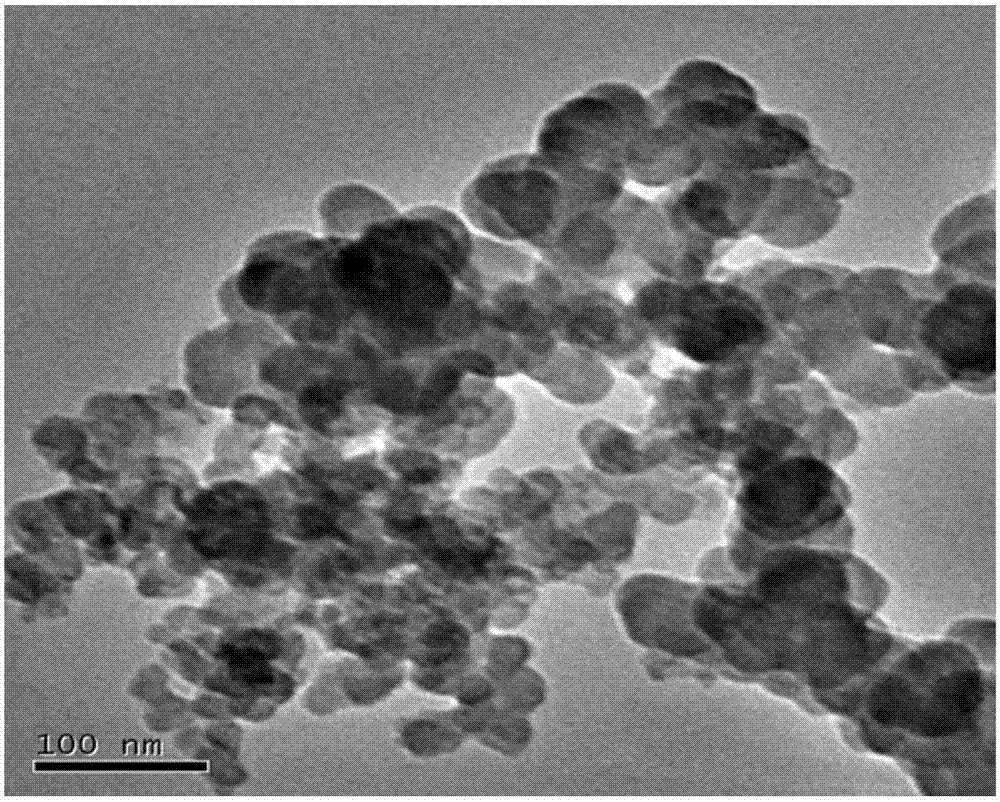

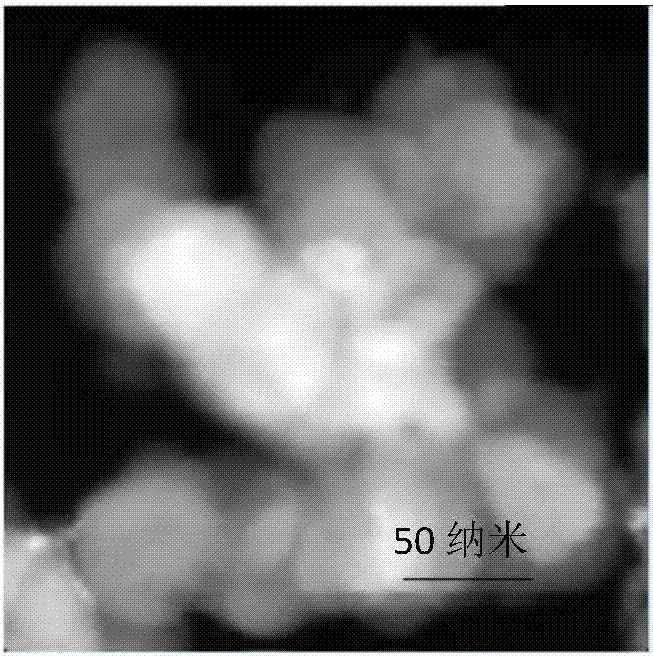

High-purity iron oxide black pigment and production method thereof

ActiveCN102139927AHeavy metal content controlHigh purityFerroso-ferric oxidesIron(II) oxideIron oxide black

The invention relates to a high-purity iron oxide black pigment and a production method thereof. The production method comprises the following steps of: with a crystal seed as a carrier in a liquid phase method production process, carrying out reaction on ferrous sulphate and sodium hydroxide in an oxidation barrel, immediately generating ferrous hydroxide sol under the alkali condition, introducing steam and warming for reaction, introducing air for oxidation after a specified temperature is reached, and reacting for a period of time to obtain the high-purity iron oxide black pigment. The granules of the product obtained by the method are small and uniform compared with a synthetic method, and the yield is high and the coloured light is good; meanwhile, the purity of the product is controlled, thus the operating requirement in the industry is met. The invention also aims at providing the high-purity iron oxide black pigment prepared by adopting the method.

Owner:SHENGHUA GROUP DEQING HUAYUAN PIGMENT

Composite electrode materials, preparation method thereof, and application thereof

ActiveCN107359054AIncrease profitSmall sizeHybrid capacitor electrodesCell electrodesComposite electrodeNickel oxide hydroxide

The present invention relates to composite electrode materials, a preparation method thereof, and an application thereof. The method comprises: metallic oxide and / or hydroxide solution through coordination solution are mixed with carbon materials, the metallic oxide and / or metal hydroxide are grown in situ at the surface of the carbon materials through evaporation of a ligand solution, and the composite electrode materials are obtained. The method provided by the invention is simple to operate, low in cost, green and environmentally friendly without postprocessing, and provides possibility for industrialization large-scale production of the electrode materials. The composite electrode materials prepared by the method are good in electric energy storage. For example, the 5% capacity nickelous hydroxide-active carbon composite electrode materials are prepared by the method, the full electrode quality specific capacity thereof can reach 294F / g, and the active substance specific capacity thereof can reach 4917F / g.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

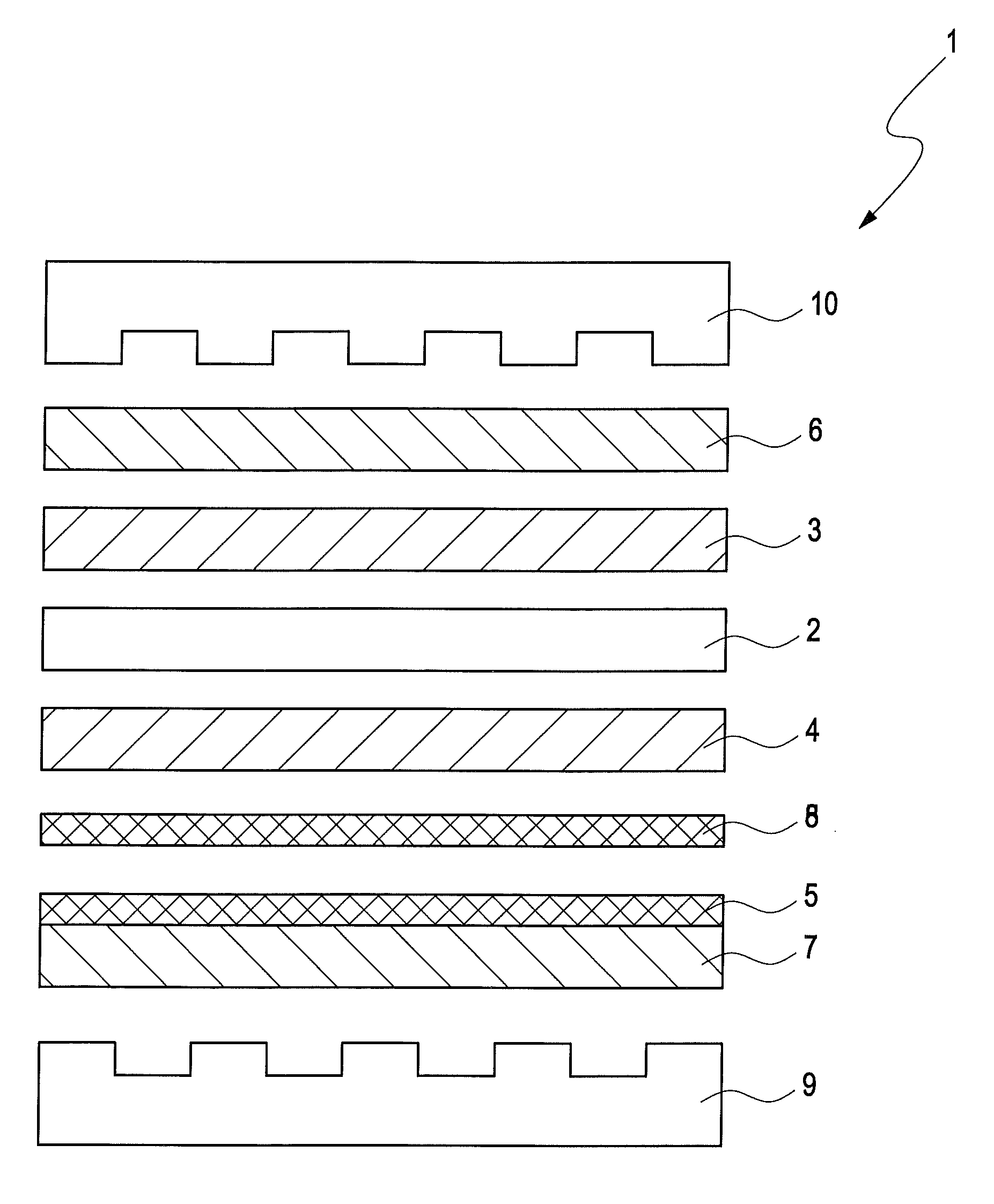

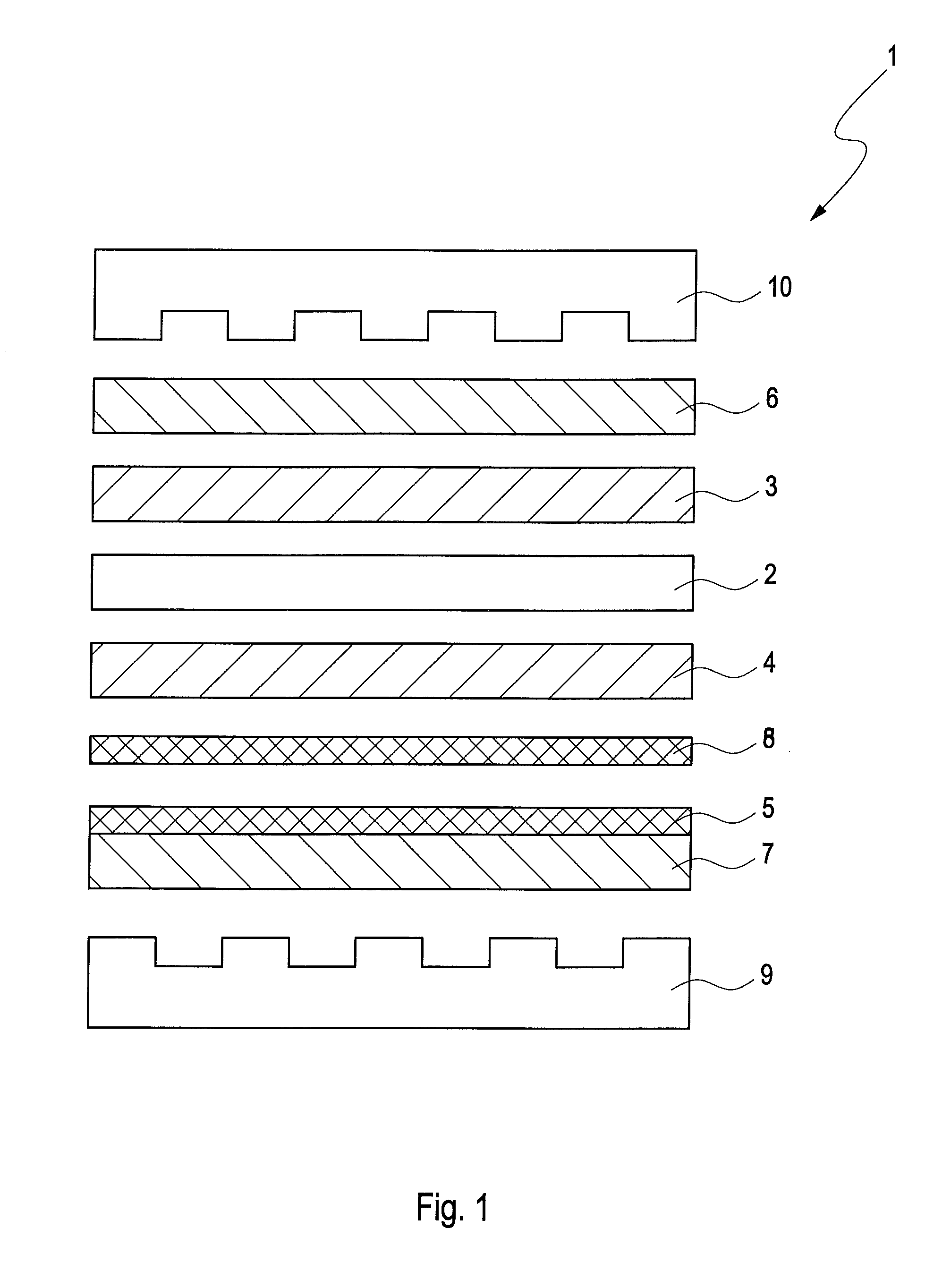

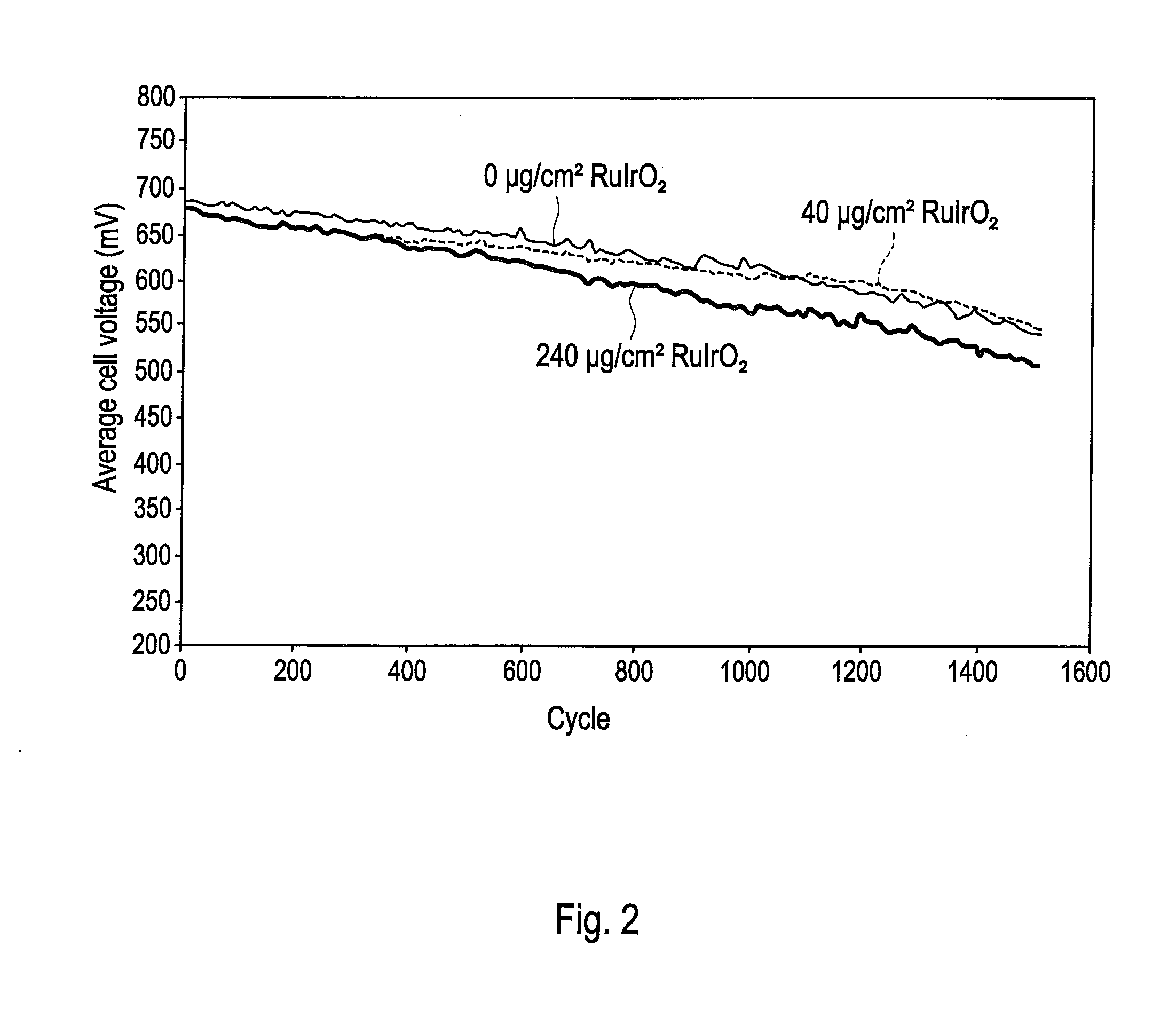

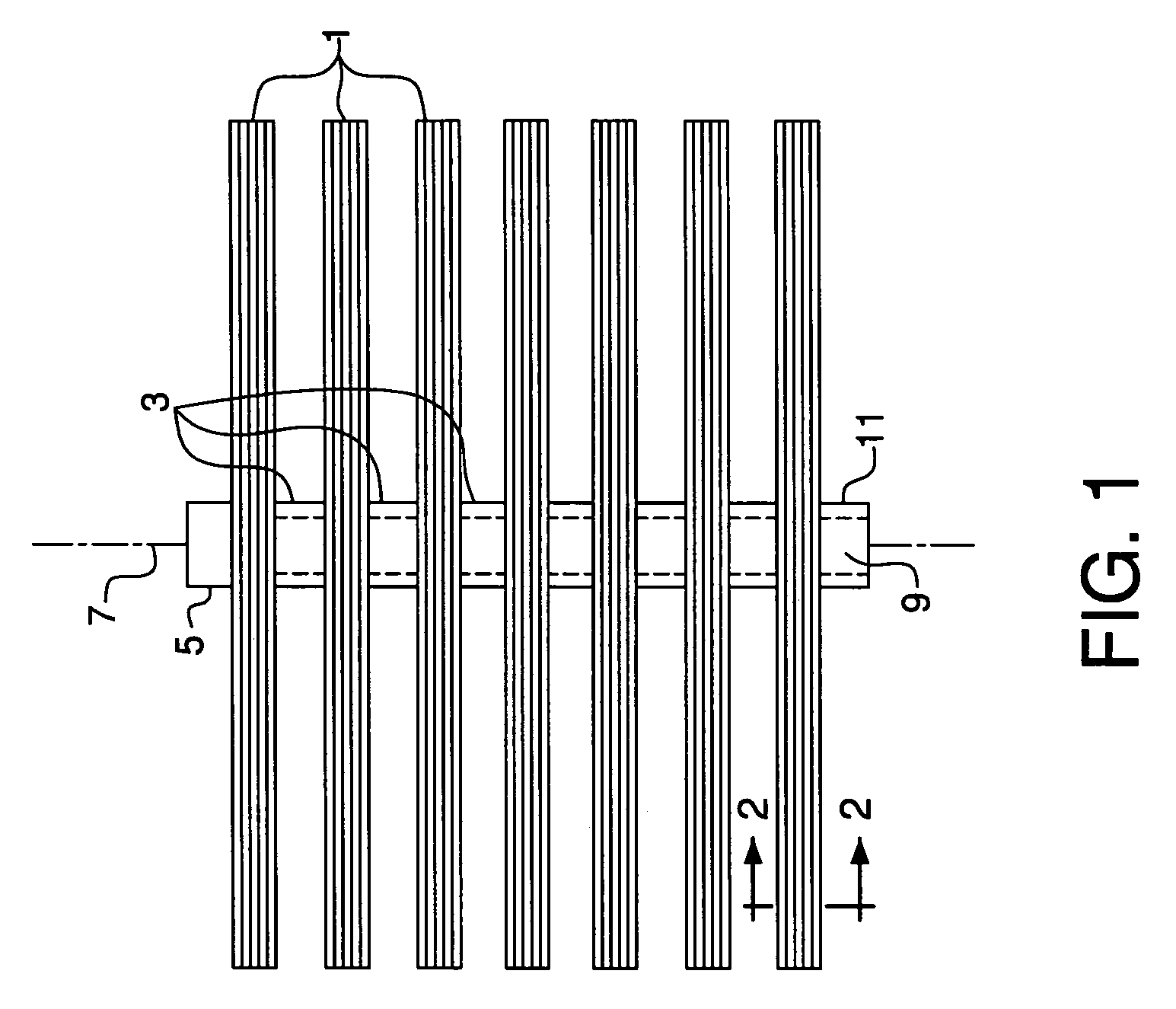

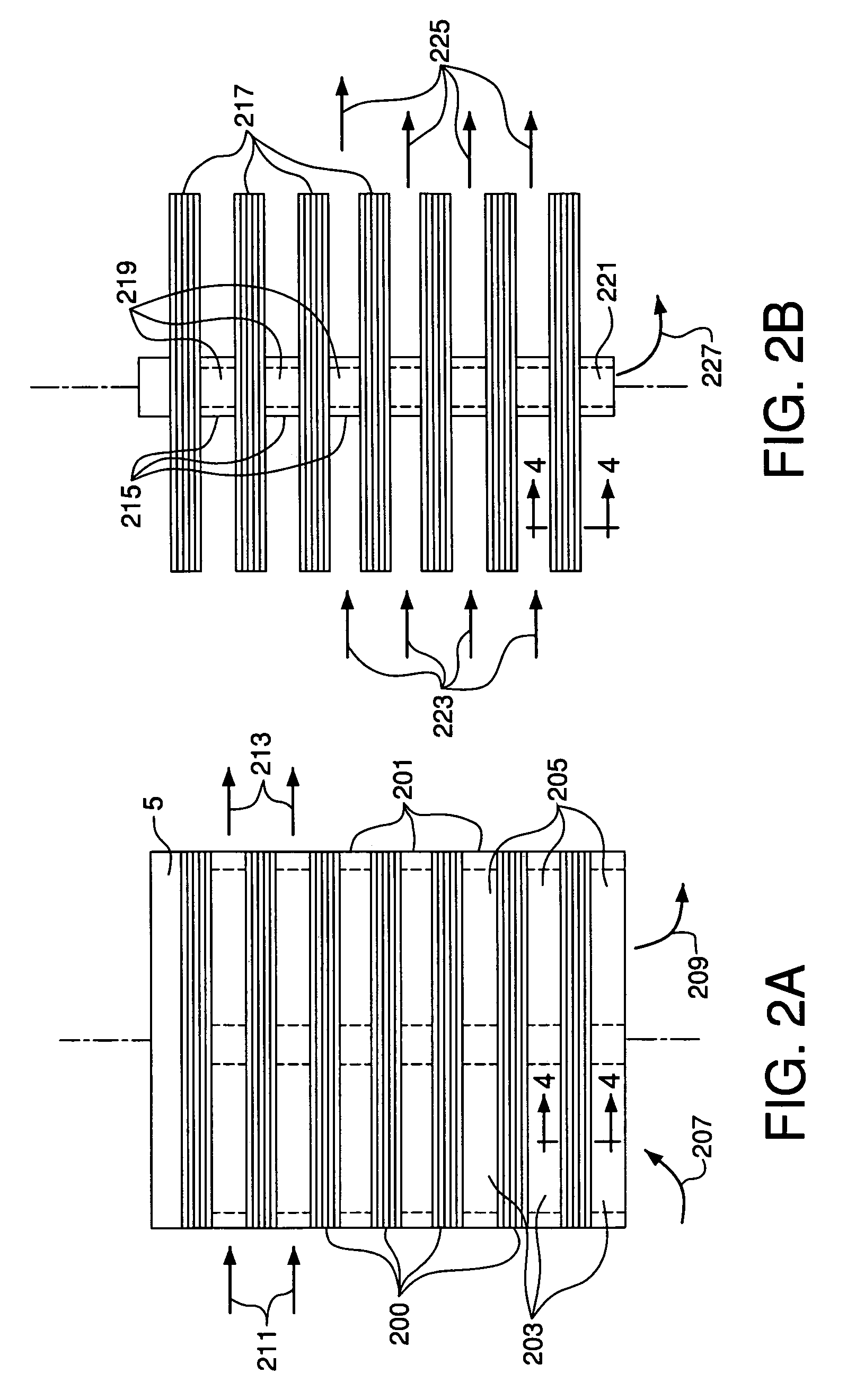

Solid polymer electrolyte fuel cell with improved voltage reversal tolerance

InactiveUS20130022890A1Increased durabilityImprovement in reversal toleranceCell electrodesSolid electrolyte fuel cellsOxygenOxygen evolution

In solid polymer electrolyte fuel cells, an oxygen evolution reaction (OER) catalyst may be incorporated at the anode along with the primary hydrogen oxidation catalyst for purposes of tolerance to voltage reversal. Incorporating this OER catalyst in a layer at the interface between the anode's primary hydrogen oxidation anode catalyst and its gas diffusion layer can provide greatly improved tolerance to voltage reversal for a given amount of OER catalyst. Further, this improvement can be gained without sacrificing cell performance.

Owner:FORD MOTOR CO +1

Feed gas contaminant removal in ion transport membrane systems

Owner:AIR PROD & CHEM INC

Titanium dioxide-aluminum oxide composite carrier and preparation method thereof

The invention discloses a titanium dioxide-aluminum oxide composite carrier and a preparation method thereof. Titanium hydroxide-aluminum hydroxide gel prepared by supersolubility micelles is used as a raw material, and the gel contains a surfactant and a hydrocarbon substance, so after the gel is molded and roasted, nanometer titanium dioxide and aluminum oxide particles formed by removing water from polymerized titanium hydroxide and aluminum hydroxide still have a rodlike basic structure and accumulate unorderly to form a frame structure. The composite carrier has the advantages of large pore volume, large pore diameter, high porosity, large orifices on the external surface, and high penetrability of pore channel; and particularly for macromolecules, a catalyst does not have ink bottle-shaped orifices, so the orifices cannot be blocked so as not to inactivate the catalyst. The composite carrier is favorable for increasing the sediment accumulation of impurities and prolonging the running period of the catalyst. The composite carrier can be used for catalytic reaction of macromolecular reactants or products.

Owner:CHINA PETROLEUM & CHEM CORP +1

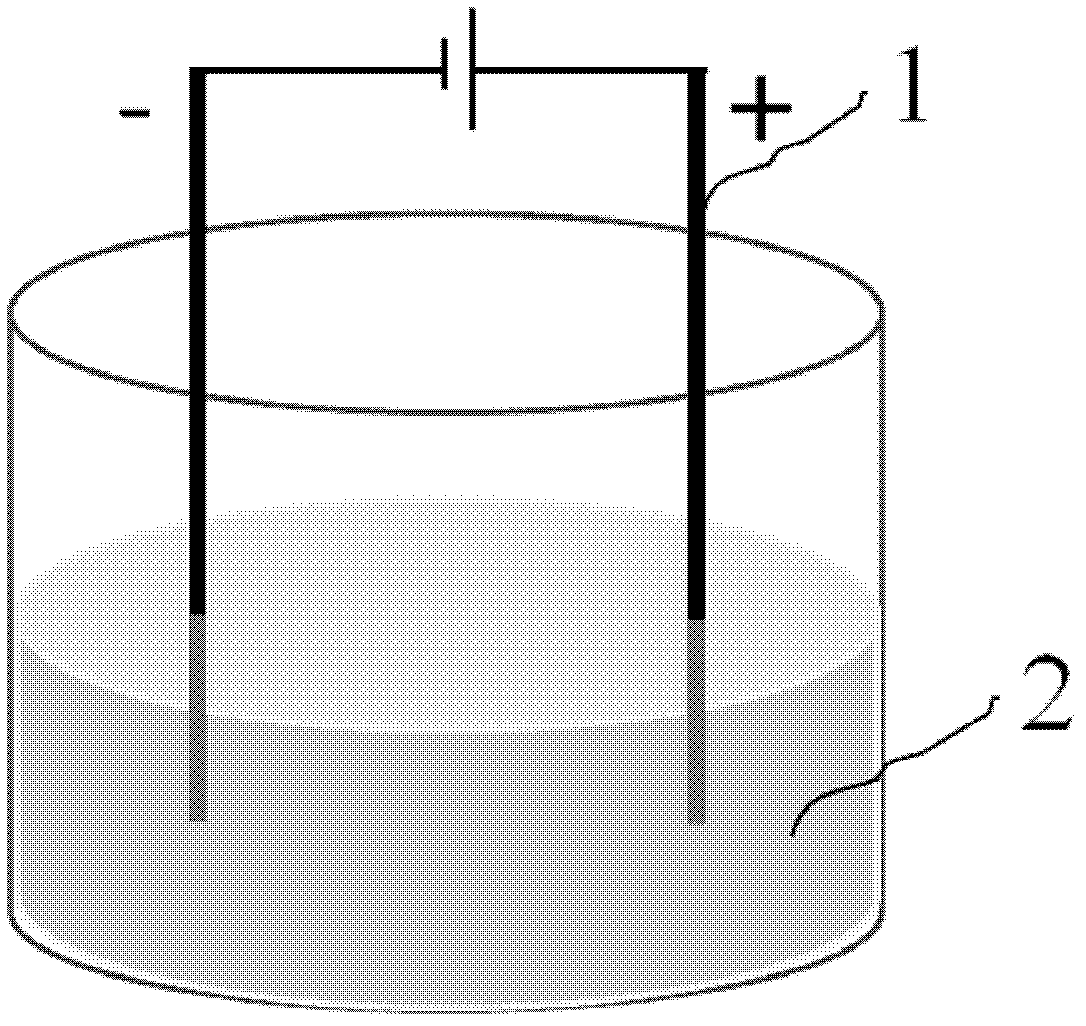

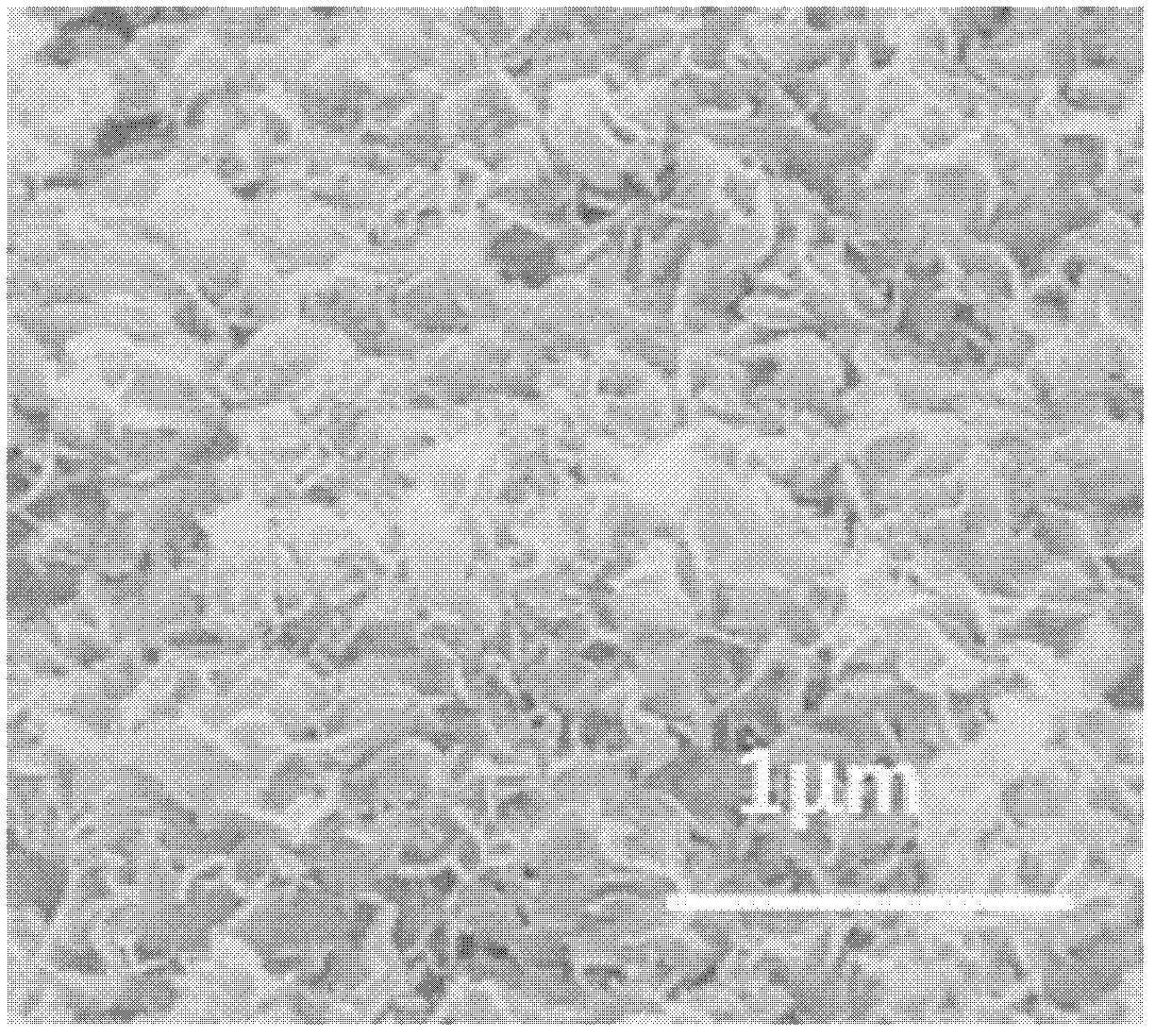

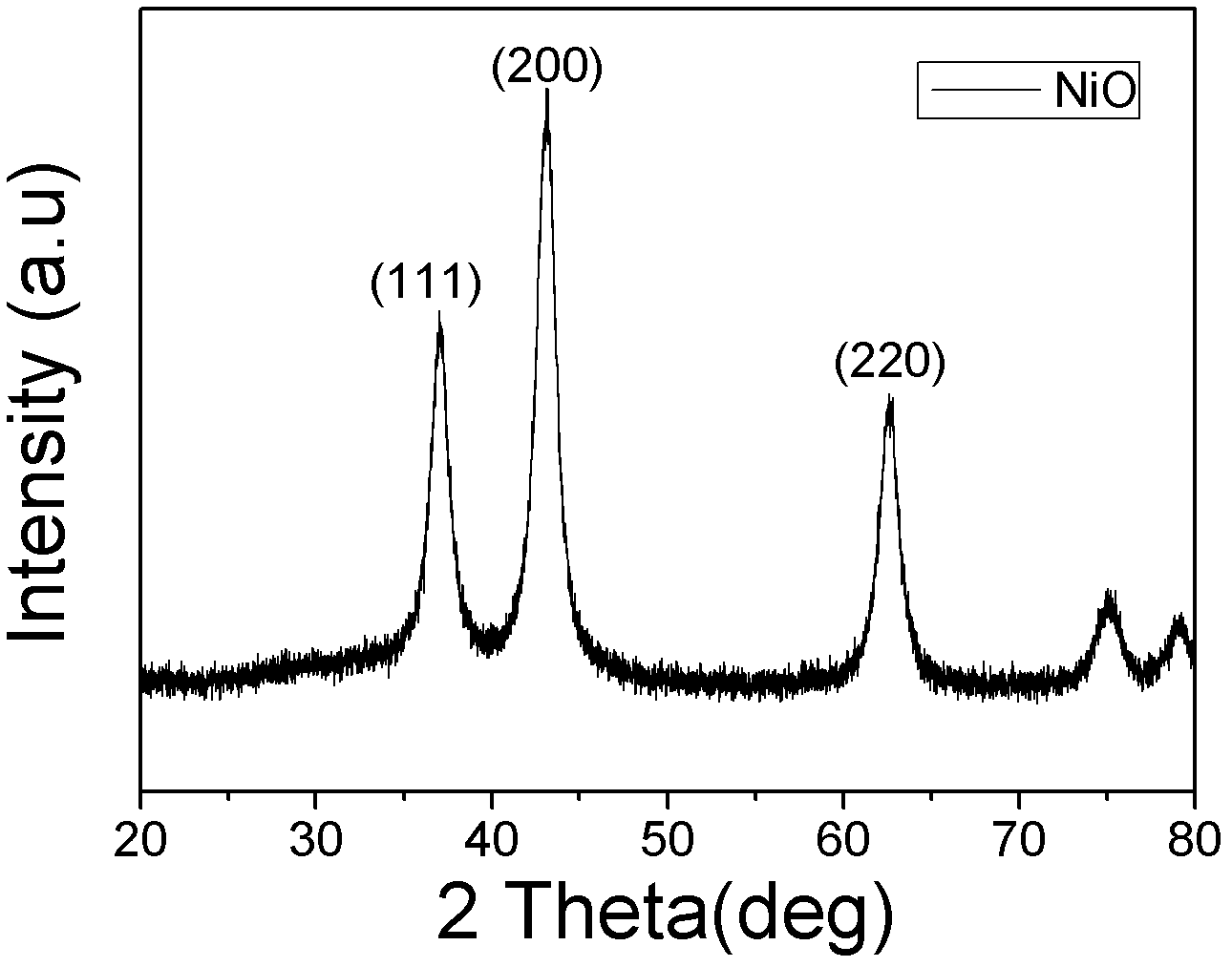

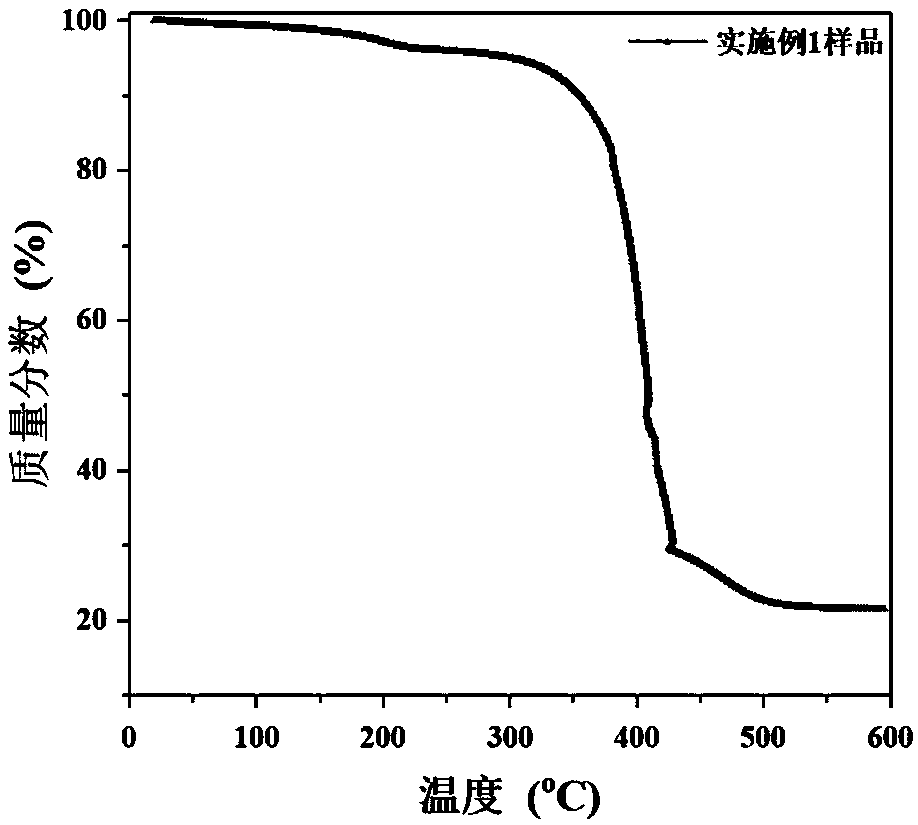

Method for preparing nanometer nickel oxide and application of method

InactiveCN102603016ASimple processEasy to operateNickel oxides/hydroxidesMaterial electrochemical variablesElectrolytic agentElectrochemistry

The invention discloses a method for preparing nanometer nickel oxide and application of the method. The method includes adding a certain quantity of inorganic salt and organic liquor into aqueous liquor to be used as electrolyte; using metal nickel as an electrode; applying voltage to two ends of the electrode; forming nickel hydroxide nano-particles by means of regulating the concentration of the electrolyte, the amplitude of the voltage, the reaction time and the stirring speed; then annealing the nickel hydroxide nano-particles at the temperature of 300 DEG C; and obtaining the nickel hydroxide nano-particles. A formaldehyde sensor built on the basis of the nanometer nickel oxide can be used for detecting formaldehyde gases with different concentrations. The method has the advantages that the nanometer nickel oxide is prepared in the electro-chemical method the nanometer nickel oxide is used for building the formaldehyde sensor, a process is simple, operation is convenient, environmental pollution is prevented, the cost of a product is low, repeatability is good, and the method is applicable to large-scale industrial production.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

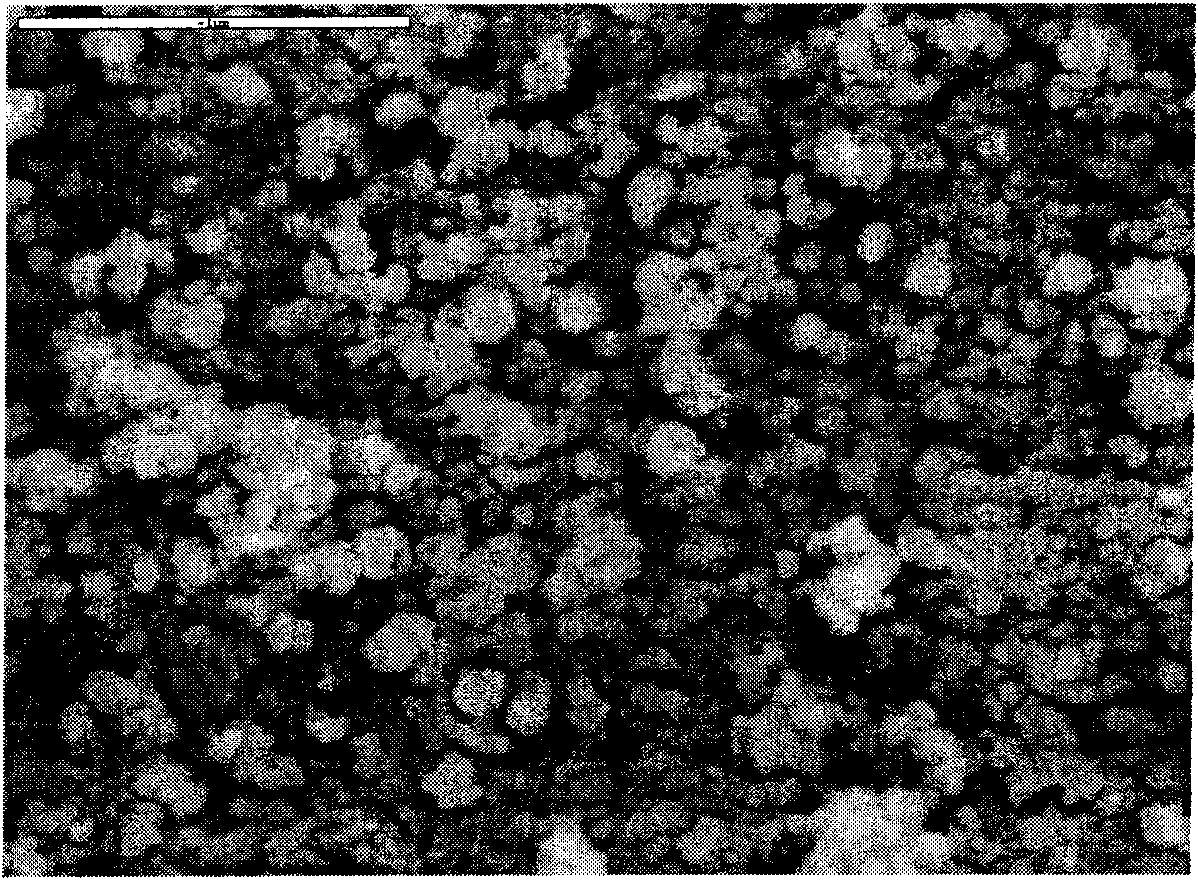

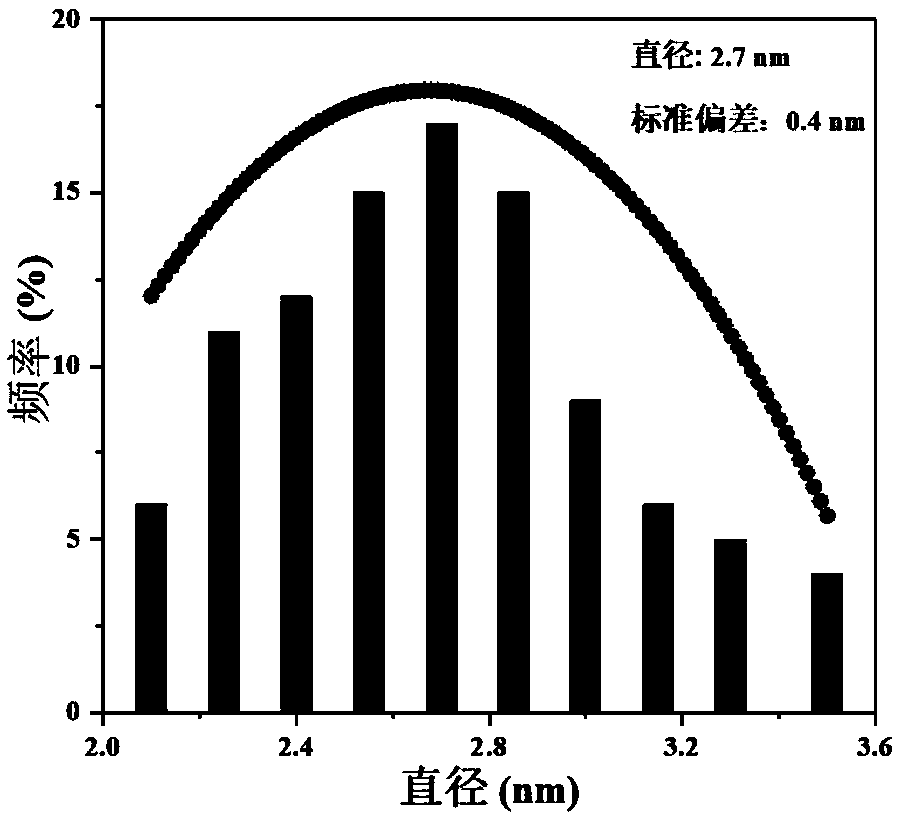

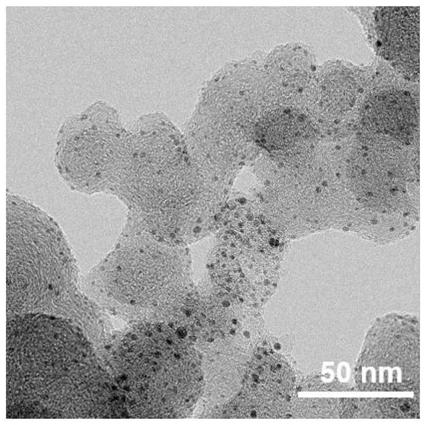

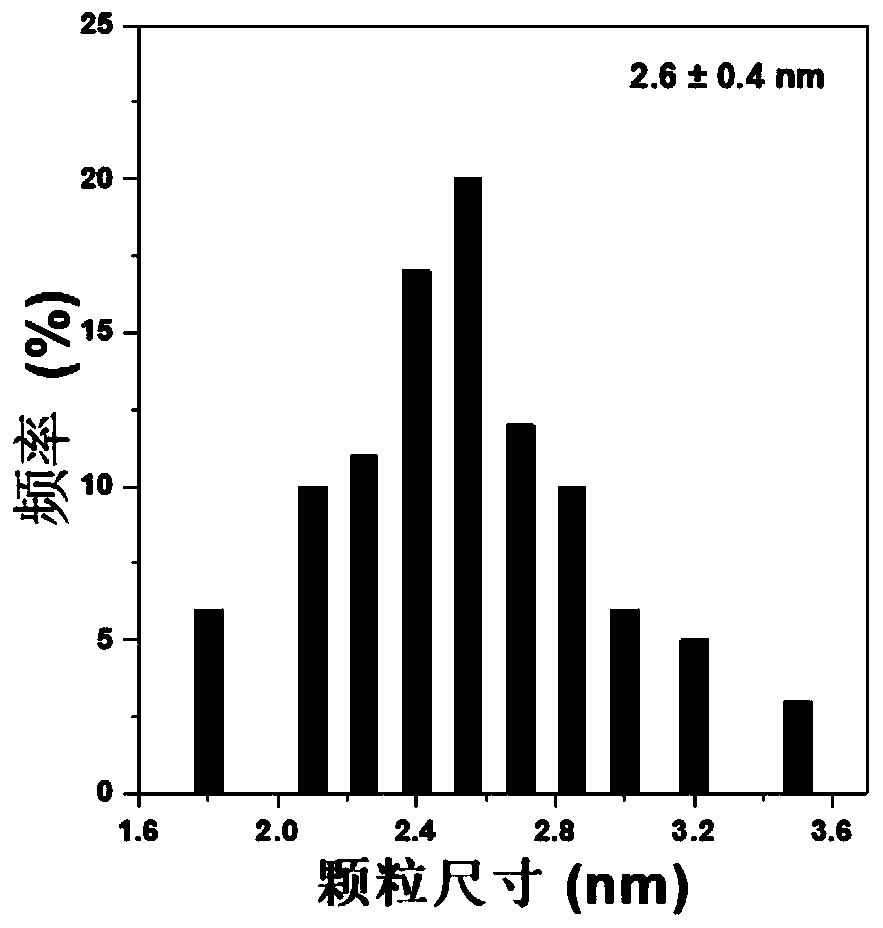

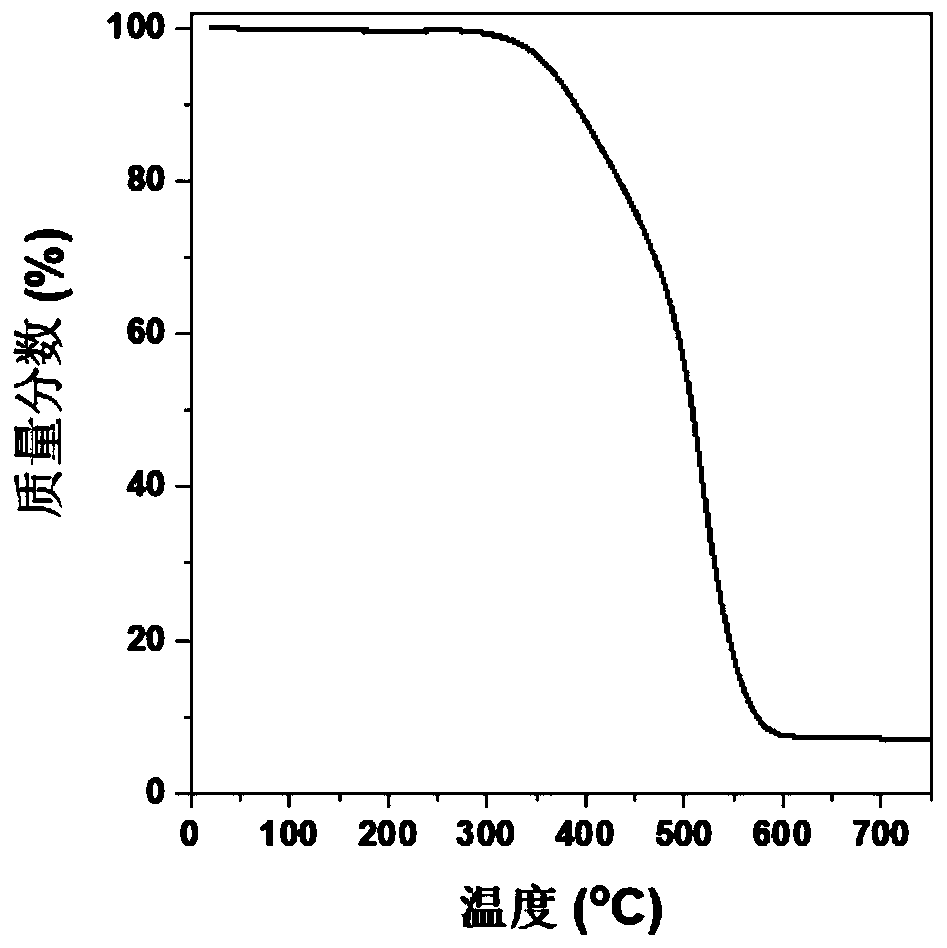

Preparation method and application of nitrogen-doped carbon supported metal nanoparticles electrocatalyst with uniform particle size for alkaline hydroxidation reaction

InactiveCN109103473AImprove electrocatalytic activityEasy to manufactureMaterial nanotechnologyCell electrodesPtru catalystActive agent

The invention belongs to the technical field of metal electrocatalysts, and provides a preparation method and application of a nitrogen-doped carbon-supported metal nano-particle electrocatalyst withuniform particle size for alkaline hydroxidation reaction. The nitrogen-containing ligand and the carbon material are used as the nitrogen source and the carbon source, the nitrogen-doped carbon carrier contains more metal nanoparticle attachment sites is simply and quickly prepared through carbonization. As the metal salt is adsorbed in advance and the reduction temperature of the metal salt is controlled, the purpose of control the reduction rate of the metal salt is achieved, and the metal nanoparticles are uniformly dispersed on the carrier. A surfactant is not used in the invention, and the reagent used is safe and harmless. The preparation process of the invention is simple and easy, the synthesis cost is low, and the large-scale production is easy. The supported highly dispersed nano-electrocatalyst prepared by the invention has high electrocatalytic activity and is suitable for alkaline fuel cell anodic hydrogenation reaction.

Owner:DALIAN UNIV OF TECH

Preparation method of nitrogen-doped carbon-supported low-platinum metal spherical nanoparticle electrocatalyst with uniform particle size and application

ActiveCN111129513ASimple manufacturing processEase of mass productionMaterial nanotechnologyCell electrodesPtru catalystActive agent

The invention belongs to the technical field of metal electrocatalysts, and relates to a preparation method of a low-platinum metal spherical nanoparticle electrocatalyst with uniform nitrogen-doped carbon supported particle size and an application. The method comprises the following steps: dispersing platinum metal salt, M metal salt and a nitrogen-containing ligand into a solvent, and performingultrasonic treatment to obtain a uniform solution; putting the uniform solution into a water bath, and performing stirring at 20-90 DEG C; adding a carbon carrier dispersed in the solvent, carrying out ultrasonic treatment, performing stirring at 20-120 DEG C, and evaporating the solvent to dryness to obtain a black mixture; after drying and grinding, performing carbonizing for 0.1-3 hours at thetemperature of 200-1100 DEG C in an inert atmosphere; changing inert gas into reducing gas, and etching precipitates attached to the surfaces of the metal particles. According to the preparation method disclosed by the invention, a surfactant does not need to be used, and the prepared nitrogen-doped carbon-supported low-platinum metal spherical nanoparticle electrocatalyst with uniform particle size has higher electrocatalytic activity and is suitable for an anodic hydrogen oxidation reaction of a hydroxyl exchange membrane fuel cell.

Owner:DALIAN UNIV OF TECH

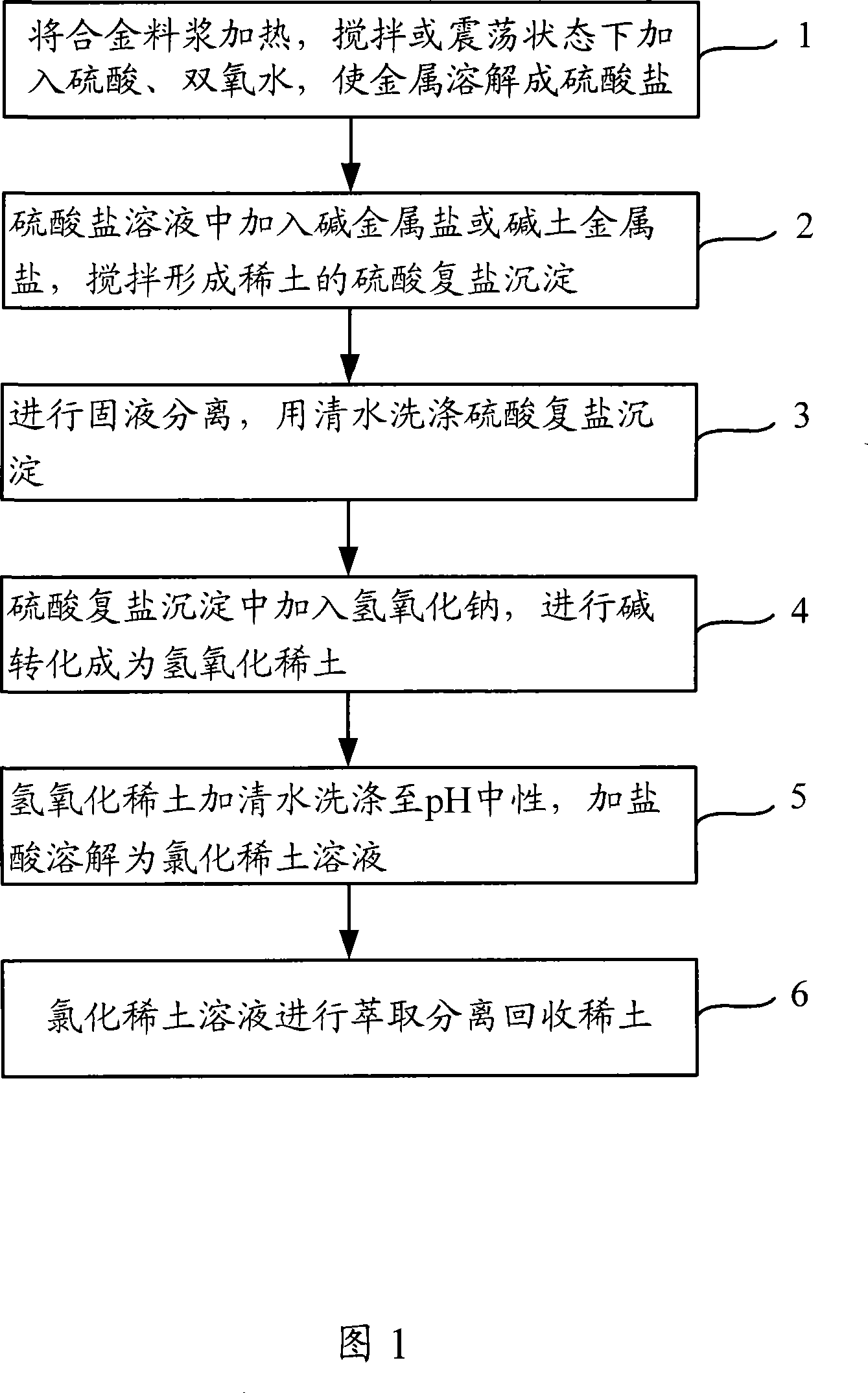

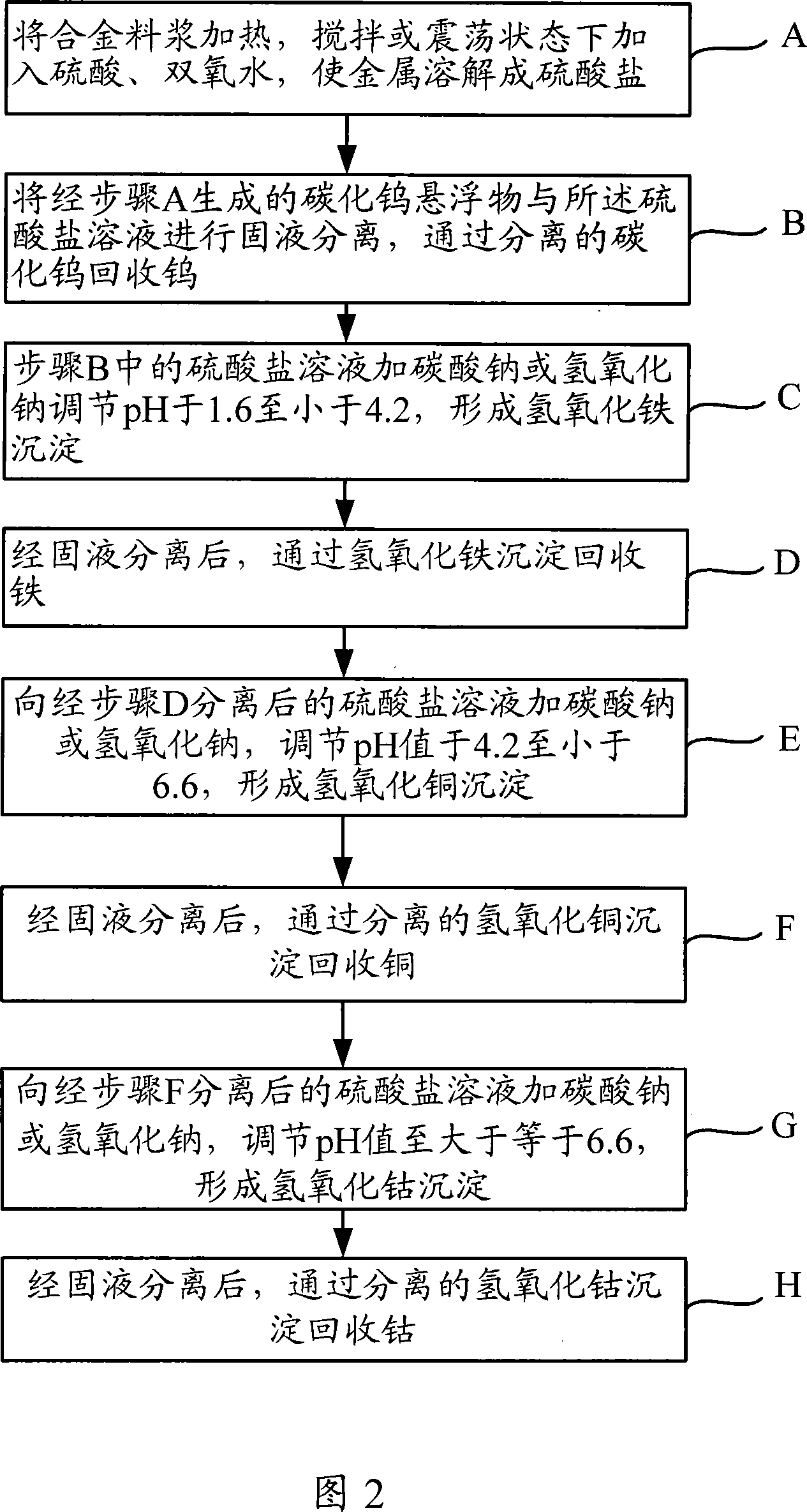

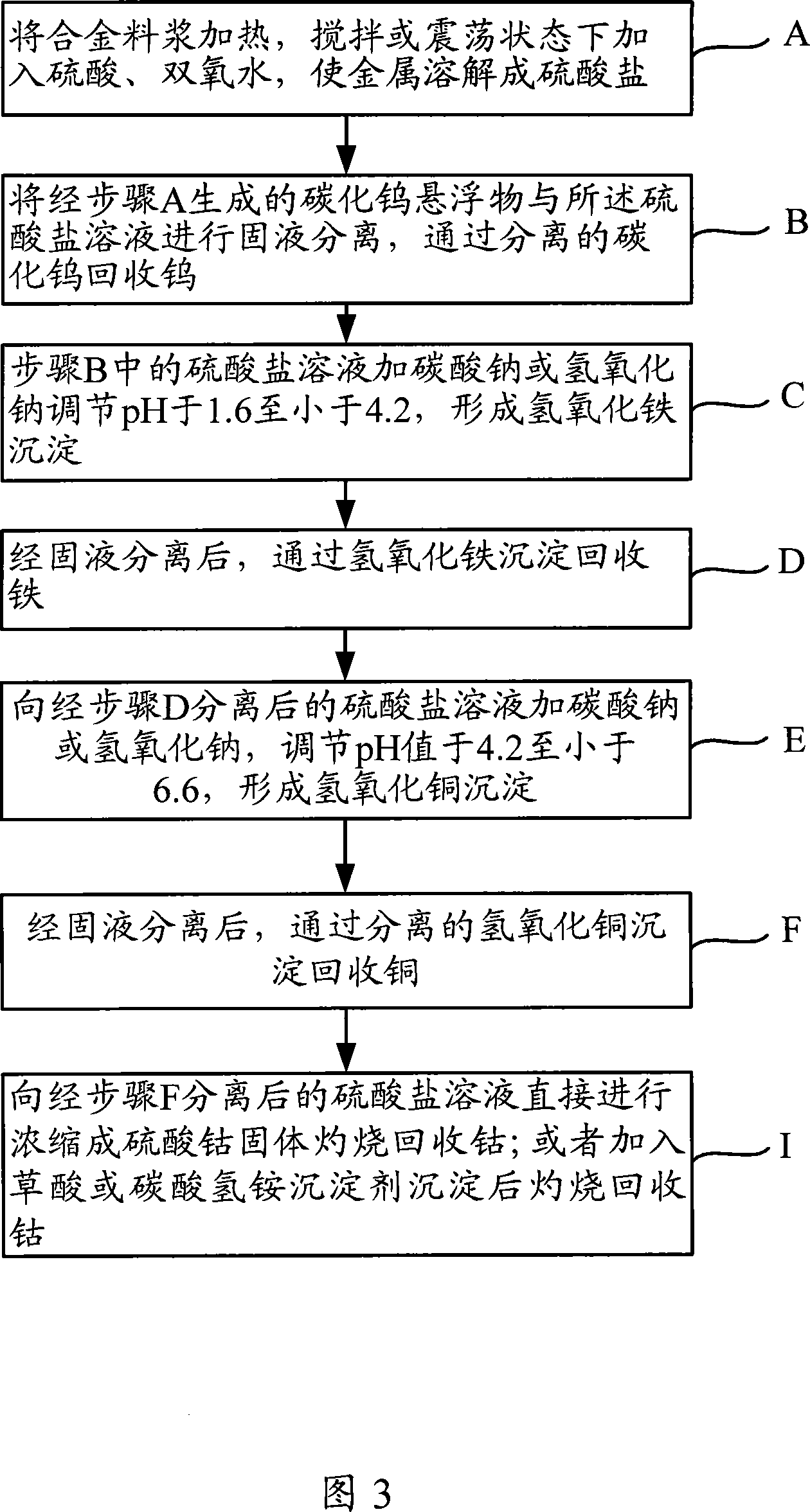

Method for separating rare earth, iron, copper, cobalt and tungsten from alloy

InactiveCN101186969ALow equipment requirementsSimple processProcess efficiency improvementDouble saltTungsten

The invention discloses a process for separating rare earth, copper, iron, cobalt, and tungsten from alloys. The treating process of the separation of the rare earth is that sulphuric acid and hydrogen dioxide solution are added to the alloy, the alloy is quickly dissolved to sulphate solution, and alkali metal salt or alkaline earth metal salt is added to the sulphate solution to generate sulfuric double salt precipitation of the rare earth, the sulfuric double salt precipitation is added with alkali and is converted to rare earth hydrate, and the rare earth hydrate is treated and rare earth is recycled. The treating process of the separation of copper, iron, cobalt, and tungsten is that sulphuric acid and hydrogen dioxide solution are added to the alloy, the alloy is quickly dissolved to sulphate solution, and the precipitation of tungsten carbide is simultaneously separated out, alkali is added to the sulphate solution after the solid-liquid separation, the precipitations corresponding to iron, copper and cobalt are respectively separated out by adjusting pH values of different ranges, and copper, iron, cobalt, and tungsten are recycled through the separated precipitations. The invention has low level of facility request, and the whole technology process is simpler, cleaner and safer, and the recovery ratio is high and the energy consumption is low.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

Mesoporous manganese oxide nano granule and preparation method thereof

InactiveCN101597085AImprove protectionSimple preparation processManganese oxides/hydroxidesMANGANESE ACETATESesquioxide

The invention relates to a mesoporous manganese oxide nano material and a preparation method thereof. In the invention, a uniformly distributed mesopore with the aperture of 2 to 10 nanometers and a mixture of oxyhydrogen manganese oxide and manganic manganous oxide or a mangano-manganic octoxide monocrystal granule or a manganese sesquioxide monocrystal granule with the granule particle diameter controlled within the range of 20 to 80 nanometers are prepared by the hydrothermal function of manganese metal, manganese acetate and ammonia and the subsequent calcination control, and the uniformly distributed mesoporous, the mixture of oxyhydrogen manganese oxide and manganic manganous oxide, the mangano-manganic octoxide monocrystal granule and the manganese sesquioxide monocrystal granule play a catalytic action to a toluene combustion reaction. The invention has simple preparation method, loose synthesizing condition, easy repetition and cheap raw materials and can carry out large-scale production.

Owner:HEBEI UNIV OF TECH

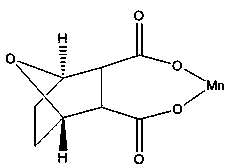

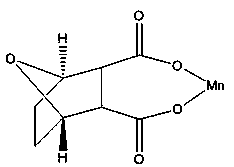

Preparation of demethylated manganese cantharidate

InactiveCN103910744AHigh purityGood water solubilityOrganic chemistryAntineoplastic agentsPhysical chemistryManganese

The invention discloses a demethylated manganese cantharidate of which the structural formula (I) is disclosed in the specification. The preparation method comprises the following steps: heating a certain volume of deionized water to 70-80 DEG C, and adding a certain amount of demethylated cantharidin until the end concentration is 12.5 mmol / L; adding a certain amount of manganous hydroxide until the mole ratio of the demethylated cantharidin to the manganous hydroxide is 1:2-1:5; heating while magnetically stirring to react for 30-60 minutes, centrifuging at 10000g for 30 minutes, and discarding the precipitate to reserve the supernatant; and drying the supernatant at 60 DEG C under reduced pressure to obtain the colorless random crystal. The demethylated manganese cantharidate has the characteristics of higher anticancer activity, simple technique, favorable safety, stable finished product performance and high purity, and the preparation method is easy to operate.

Owner:ZUNYI MEDICAL UNIVERSITY

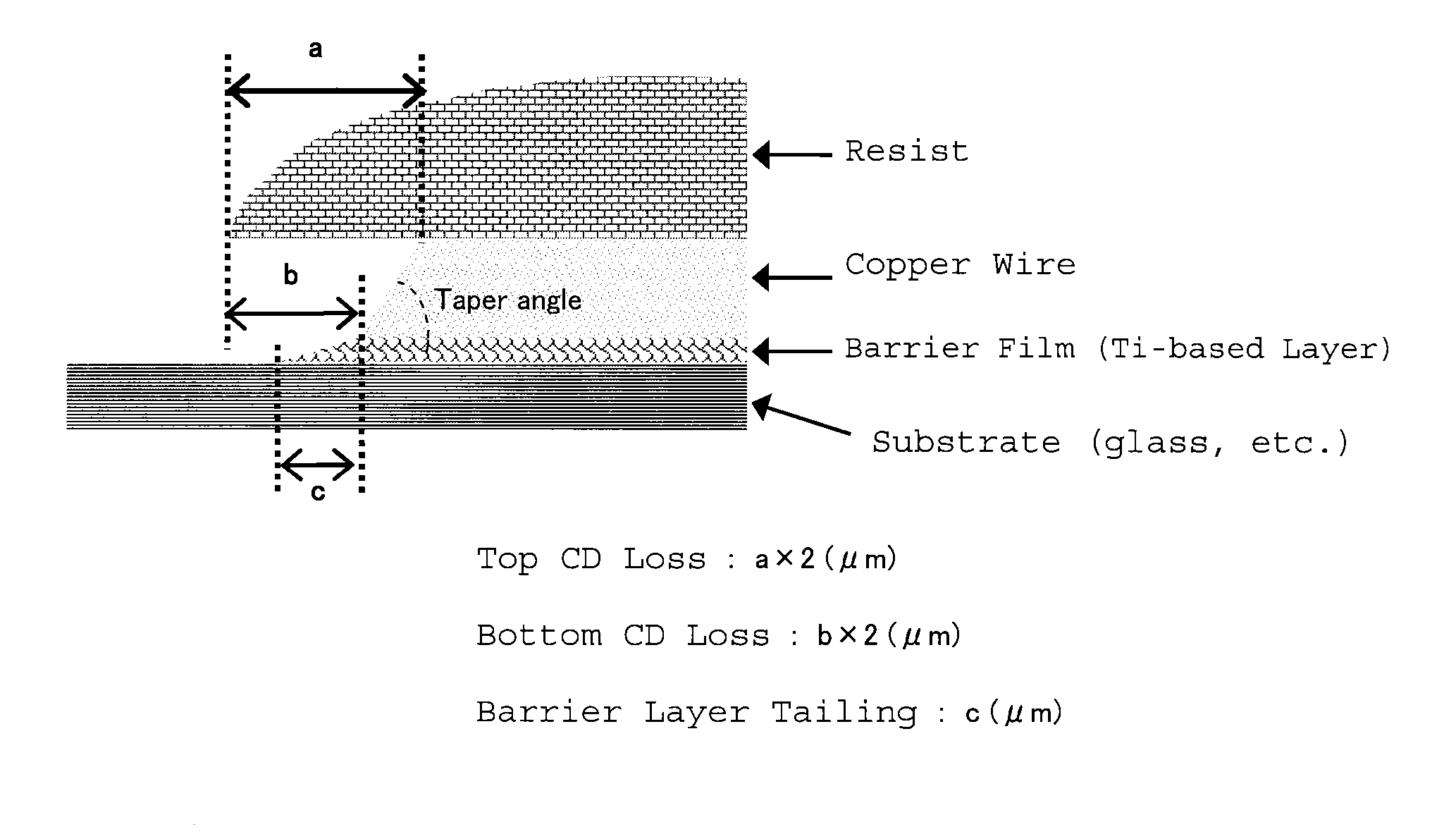

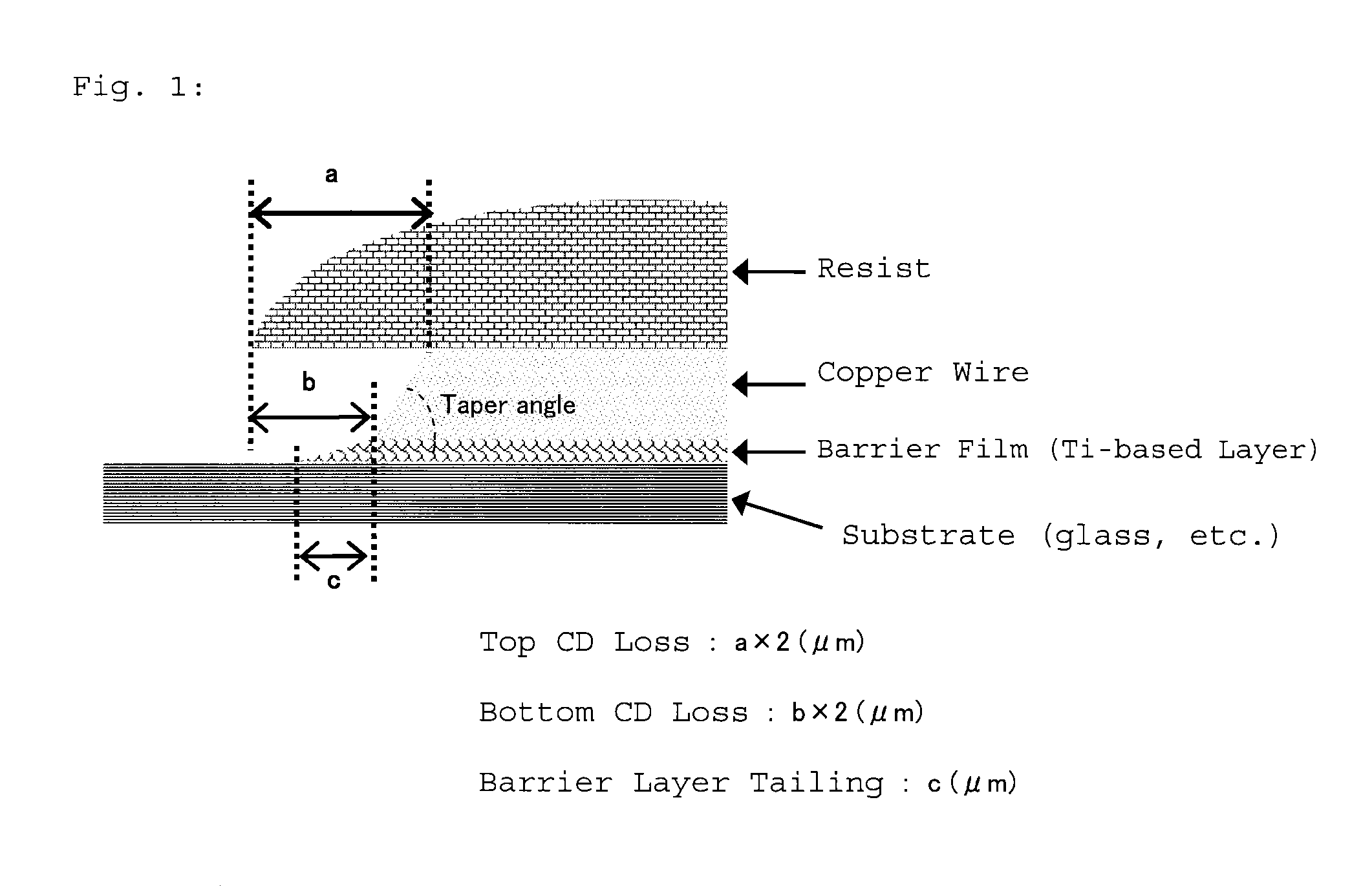

Etching liquid for a copper/titanium multilayer thin film

ActiveUS20130048904A1Improve processing accuracyLittle etching residueSemiconductor/solid-state device detailsSolid-state devicesChemistryAmmonium hydroxide

The present invention provides an etching liquid for a multilayer thin film containing a copper layer and a titanium layer, and a method of using it for etching a multilayer thin film containing a copper layer and a titanium layer, that is, an etching liquid for a multilayer thin film containing a copper layer and a titanium layer, which comprises (A) hydrogen peroxide, (B) nitric acid, (C) a fluoride ion source, (D) an azole, (E) a quaternary ammonium hydroxide and (F) a hydrogen peroxide stabilizer and has a pH of from 1.5 to 2.5, and a etching method of using it.

Owner:MITSUBISHI GAS CHEM CO INC +1

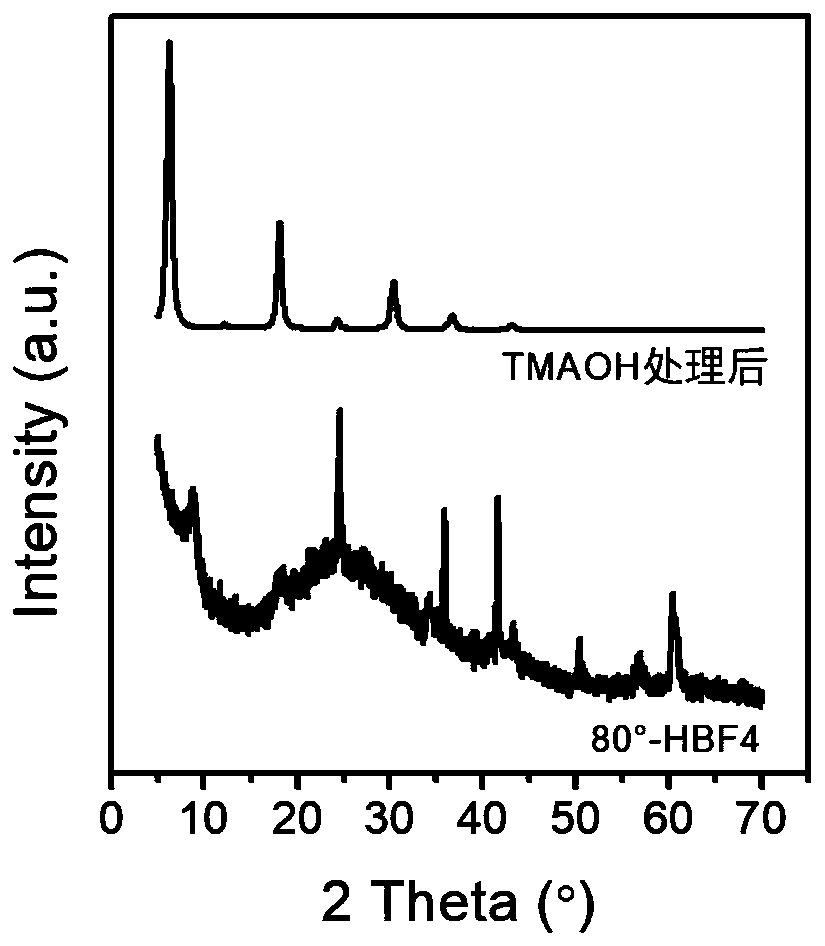

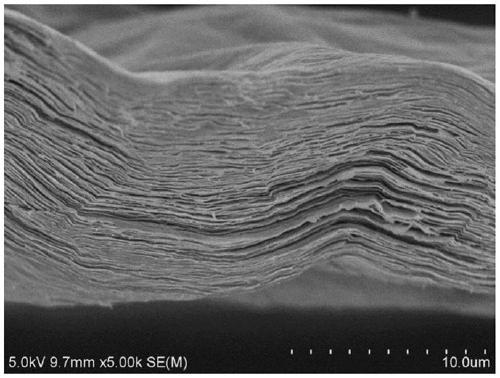

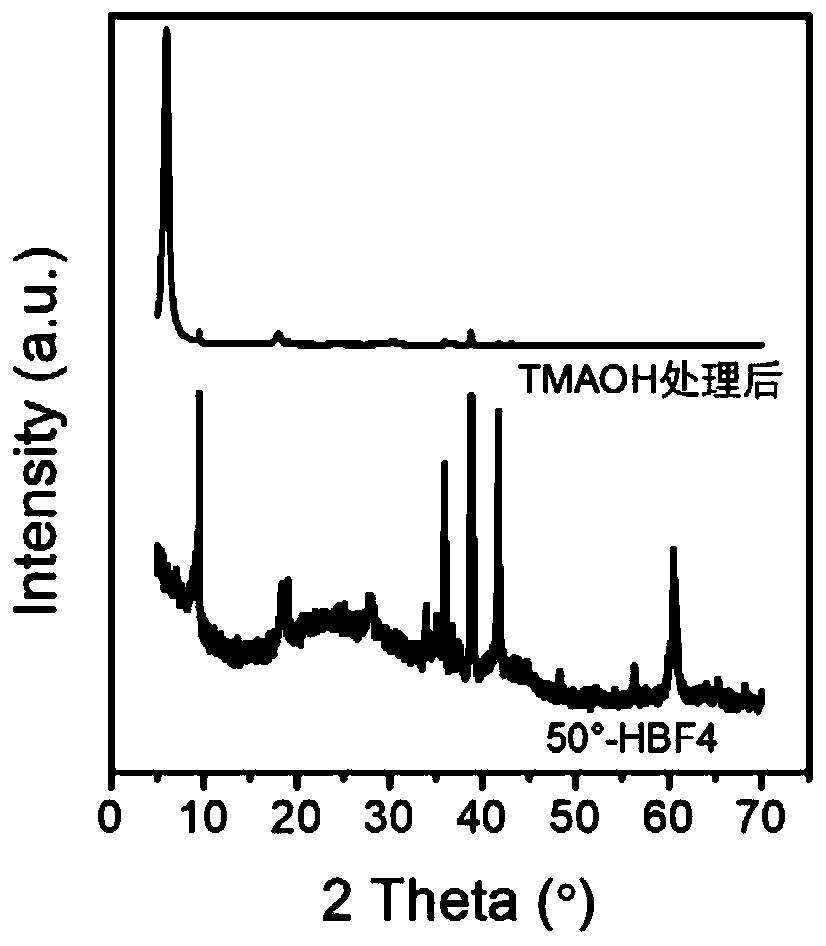

Two-dimensional transition metal carbonitride as well as preparation method and application thereof

ActiveCN111498850AEasy to filmHigh specific capacitanceNitrogen compoundsTitanium carbideEtchingFluoroboric acid

The invention discloses a two-dimensional transition metal carbonitride and a preparation method and application thereof, and belongs to the technical field of two-dimensional materials. The method comprises the following steps: adding an MAX phase material into a fluoroboric acid aqueous solution for normal-pressure etching; then washing and adding the MXene into an aqueous solution of tetraalkylammonium hydroxide for post-treatment, then washing a treatment product to obtain a two-dimensional transition metal carbonitride (MXene) material; and dispersing the material into water through handcranking, oscillation, stirring, high-speed dispersion or ultrasonic dispersion to form a stable dispersion liquid. According to the method, without use of hydrofluoric acid, the method is safer and more environmentally friendly compared with hydrofluoric acid etching; and the obtained MXene material has good application in the fields of supercapacitors, lithium ion batteries, electromagnetic shielding and electro-catalysis.

Owner:JIANGNAN UNIV

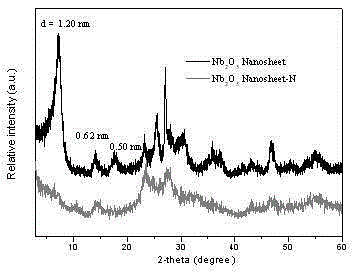

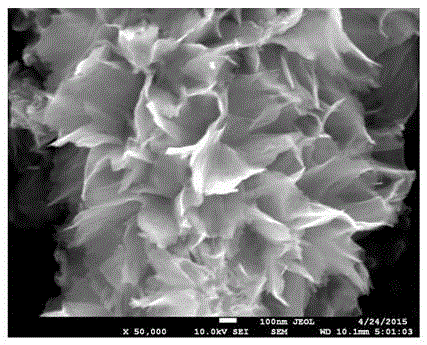

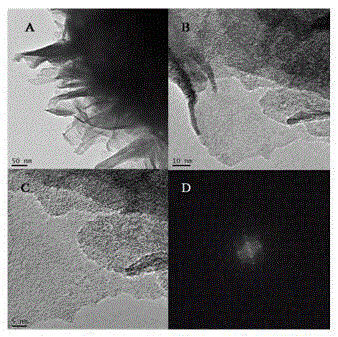

Preparation method of carbon and nitrogen doped niobium (V) pentoxide nano sheet and application of nano sheet as photocatalyst

ActiveCN105381813AGood lookingGood repeatabilityPhysical/chemical process catalystsOrganic compound preparationBenzaldehydeNitrogen gas

The invention discloses a preparation method of a carbon and nitrogen doped niobium (V) pentoxide nano sheet and an application of the nano sheet as a photocatalyst. The preparation method comprises the following steps: weighing soluble niobium salt at a room temperature, adding anhydrous ethanol to form an ethanol solution of niobium salt, dropwise adding an organic ammonium hydroxide solution into the ethanol solution of niobium salt, wherein in the initial phase, white turbidity appears, keeping on adding the organic ammonium hydroxide solution until the white turbidity disappears so as to form a clear and transparent solution; transferring the obtained solution to a hydrothermal reactor, wherein the solution accounts for 50 to 70% of the volume of the hydrothermal reactor, carrying out hydrothermal reactions at a temperature of 100 to 280 DEG C, after reactions, naturally cooling the reactor to the room temperature, washing and drying the reaction product to obtain white powder; and burning the white powder for 2 to 12 hours at a temperature of 400 to 1200 under the protection of nitrogen gas so as to obtain the carbon and nitrogen doped niobium (V) pentoxide nano sheet. The invention also discloses an application of the carbon and nitrogen doped niobium (V) pentoxide nano sheet as a photocatalyst. The photocatalyst can be applied to benzyl alcohol oxidation to prepare benzaldehyde.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Method for fractionating, extracting and separating zirconium and hafnium

The invention relates to a method for fractionating, extracting and separating zirconium and hafnium, in particular to a method for fractionating, extracting and separating zirconium and hafnium by using di(2-ethylhexyl)phosphorous acid as an extracting agent. The method comprises the following steps of: (1) extraction, using 50-300 parts by weight of di(2-ethylhexyl)phosphorous acid, 25-150 parts by weight of mixing alcohol with the carbon number of 7-9, and 550-925 parts by weight of sulfonated kerosene to prepare a di(2-ethylhexyl)phosphorous acid organic phase to extract; (2) washing, adding oxalic acid into a sulphuric acid solution to prepare a washing solution to wash; and (3) stripping, using a mixing solution of ammonia and carbonate as a strip liquor, stripping to obtain a strip liquor containing hafnium, slowly adding concentrated hydrochloric acid to adjust the solution into acidity, adding concentrated ammonia to obtain hafnium hydroxide precipitate, washing, filtering, calcining, and then obtaining hafnium oxide. The used chemical agents are difficult to volatilize, the toxicity is low, the corrosion is weak, the disposition is easy, and the discharged waste water can not cause the environments to be polluted. The technology has the advantages of quick phase separation, convenient operation, and high and stable product quality.

Owner:有研资源环境技术研究院(北京)有限公司

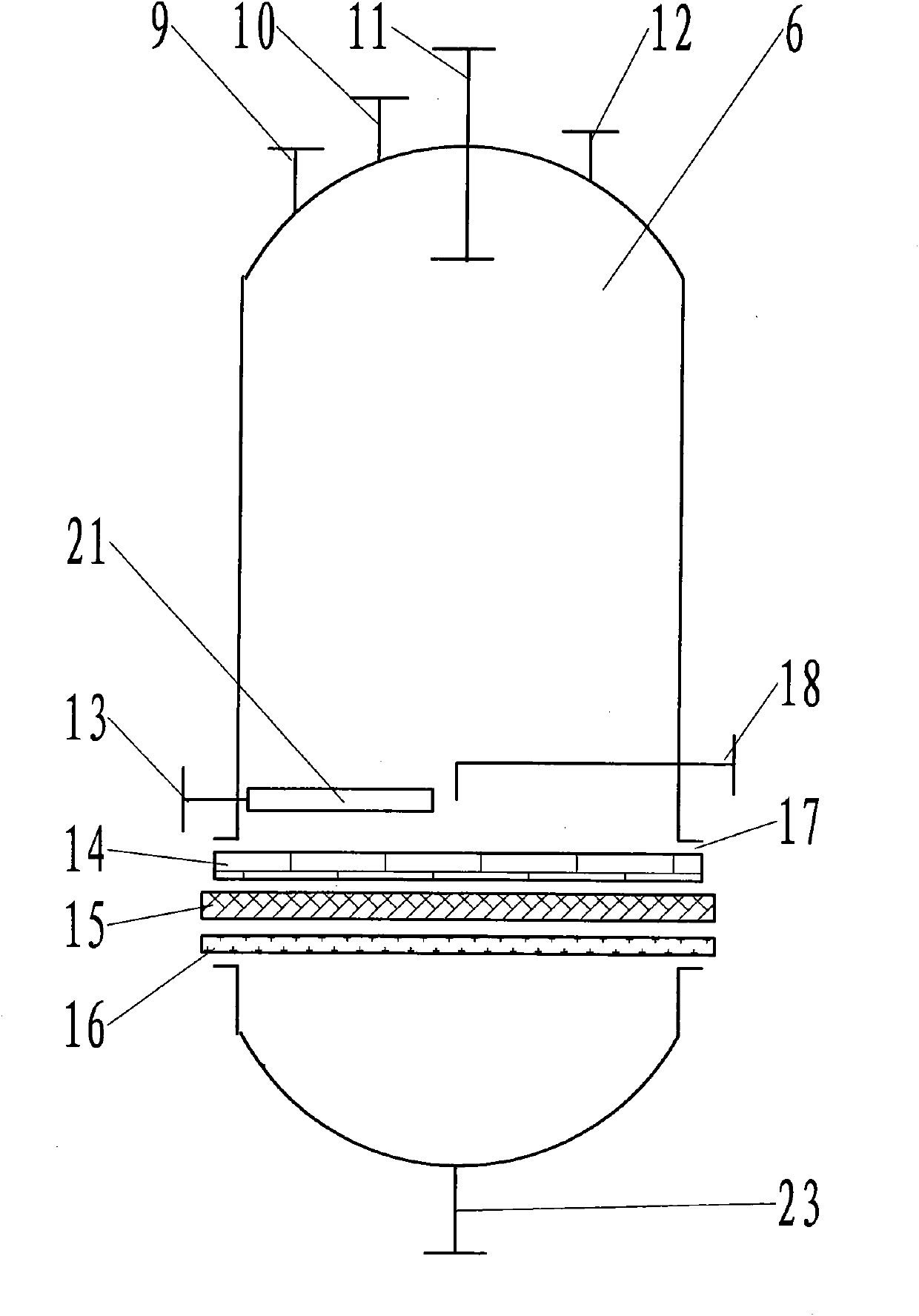

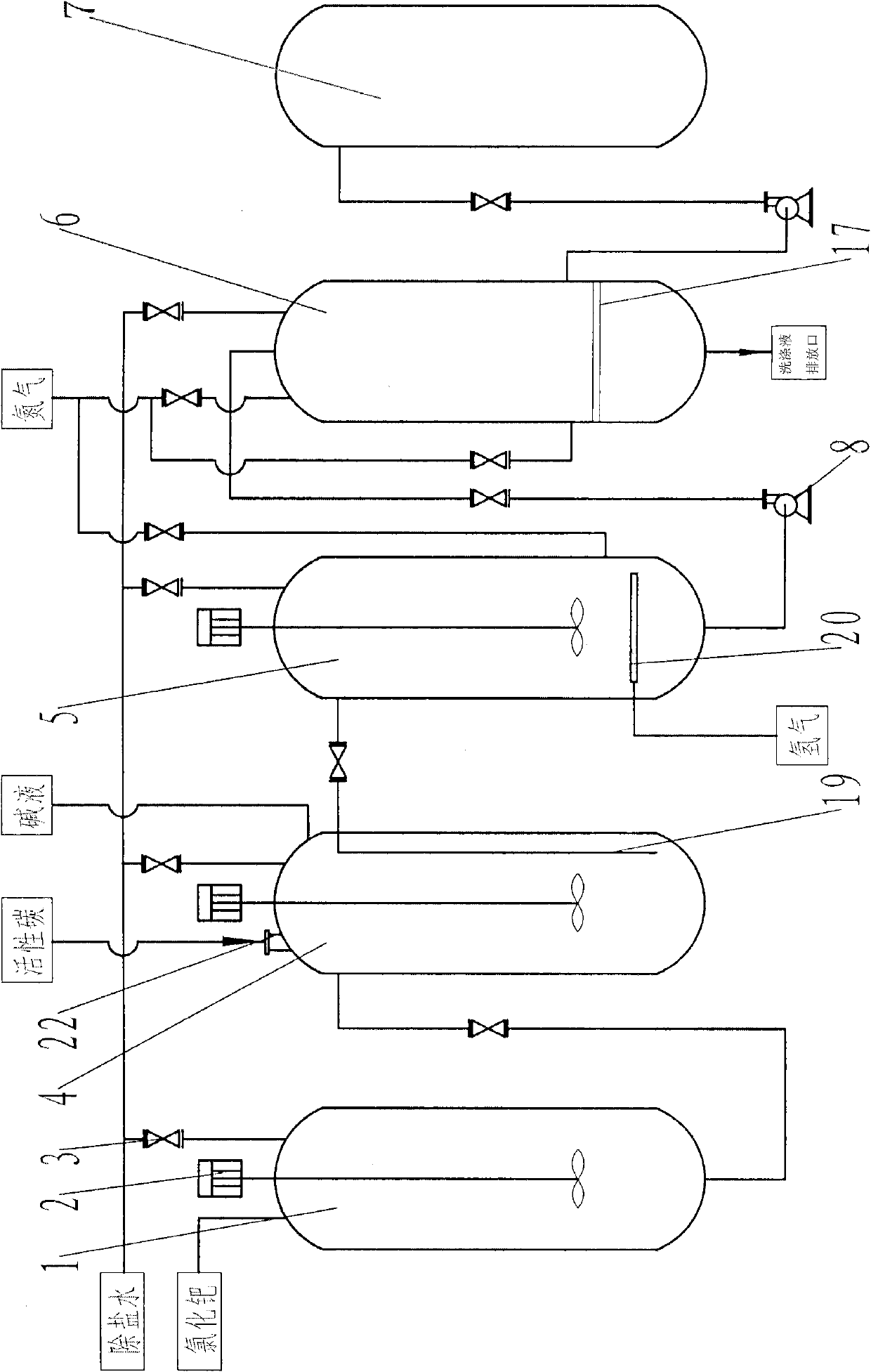

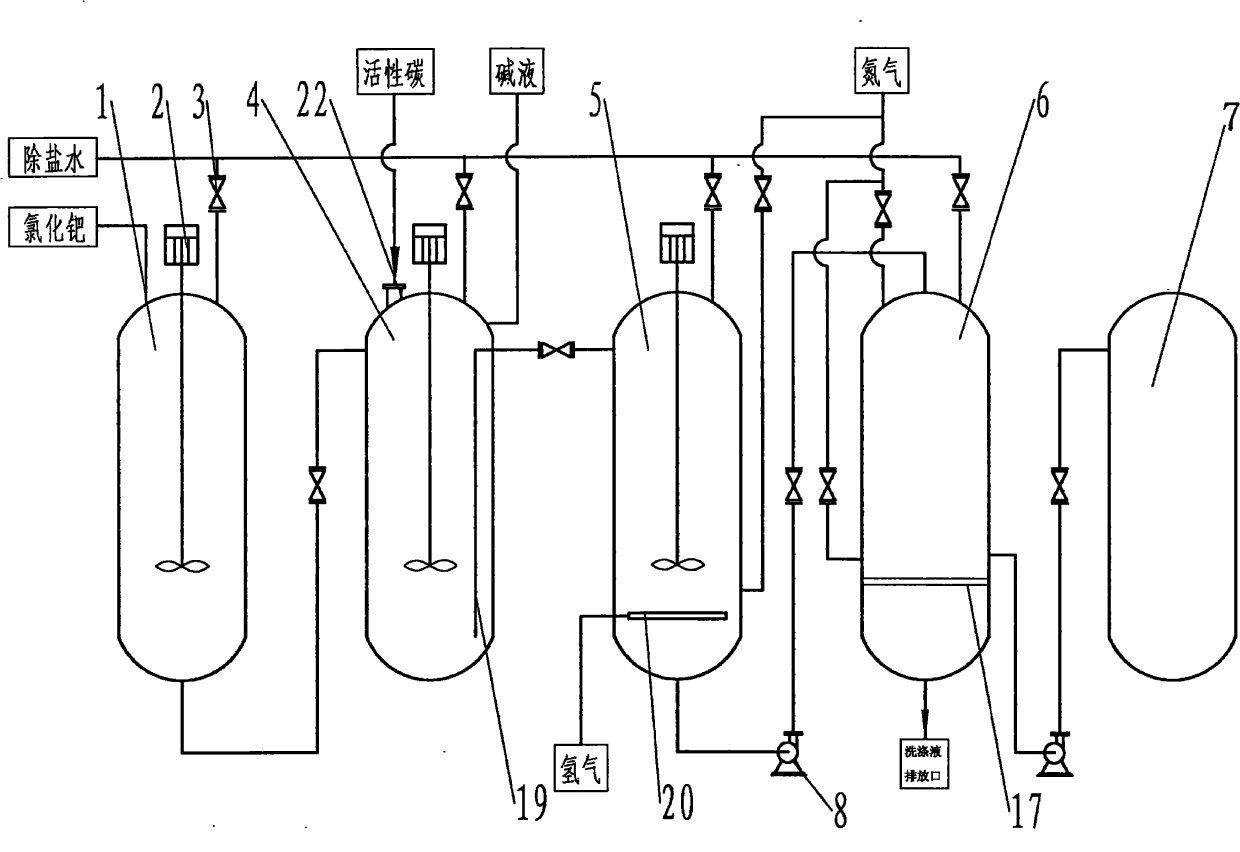

Method and apparatus for preparing palladium carbon catalyst

InactiveCN102397787AAvoid poisoningHigh activityMetal/metal-oxides/metal-hydroxide catalystsIon contentActivated carbon

The invention provides a method and an apparatus for preparing a palladium carbon catalyst. The apparatus comprises a palladium chloride dissolving reactor, an active carbon slurry preparing reactor, a hydrogenation reactor, a catalyst storage tank and a catalyst scrubber. The catalyst scrubber is provided with a top nitrogen inlet and a middle nitrogen inlet, and a filtering segment at a middle section. The preparation method comprises steps of: preparing a palladium chloride solution; adding water to prepare a active carbon slurry; adsorbing palladium chloride to active carbon; adding alkali to prepare palladium hydroxide; hydrogenating to reduce into a metal target; and preparing into a crude catalyst; washing the crude catalyst in the catalyst scrubber with stirring by nitrogen; filtering until a chloride ion content in a filtrate is qualified; sending the slurry to a storage tank for preservation. The invention increases catalyst activity by 0.2-0.3(Z0), reduces catalyst loss, lowers production cost, increases economic benefit and reduces labor intensity during catalyst preparation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com