Preparation method of nitrogen-doped carbon-supported low-platinum metal spherical nanoparticle electrocatalyst with uniform particle size and application

A nitrogen-doped carbon, nanoparticle technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the complex synthesis steps, nitrogen-doped porous carbon synthesis steps, and harm the environment. and other problems, to achieve the effect of simple and easy preparation process, easy large-scale production, and high electrocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Platinum acetylacetonate (0.08mmol), ruthenium chloride (0.16mmol), 4,4'-dipyridine (80mg) were dispersed in ethanol (10ml), and a homogeneous solution was obtained by ultrasonication for 30min; the homogeneous solution was placed in a water bath, and the At 80°C, stirring promotes the Pt 2+ 、Ru 3+ Coordinate with 4,4'-bipyridine; then, add activated carbon (180mg) dispersed in ethanol (10ml) and ultrasonicate for 30min; stir and evaporate ethanol to dryness at 85°C to obtain a black mixture; after vacuum drying, After grinding, carbonize in an Ar atmosphere at 700 °C for 1 h; then switch the inert gas to ammonia to remove the precipitates attached to the surface of the metal particles, and finally obtain PtRu with uniform particle size of nitrogen-doped carbon 2 Metal spherical nanoparticle electrocatalysts;

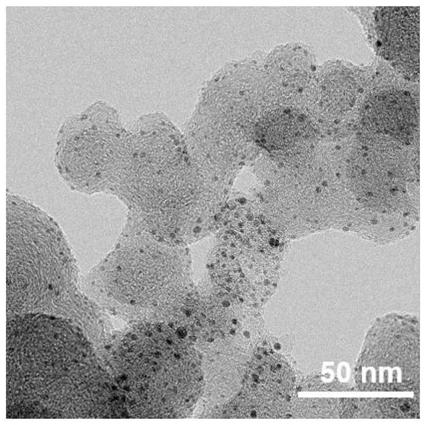

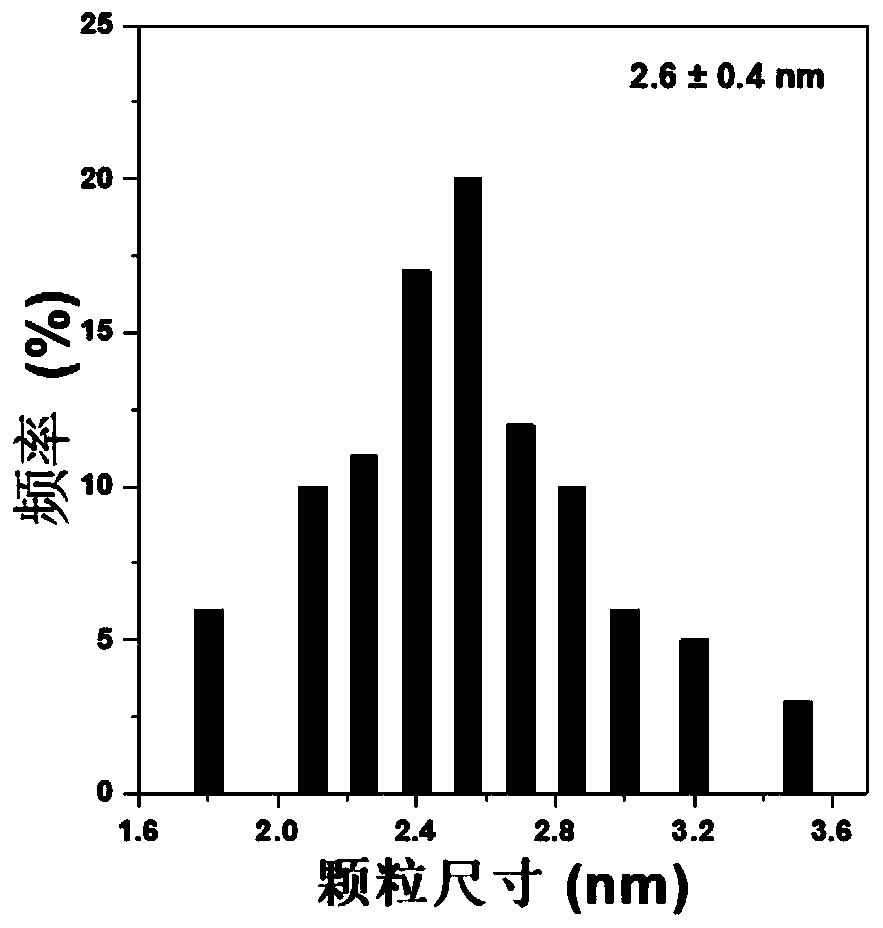

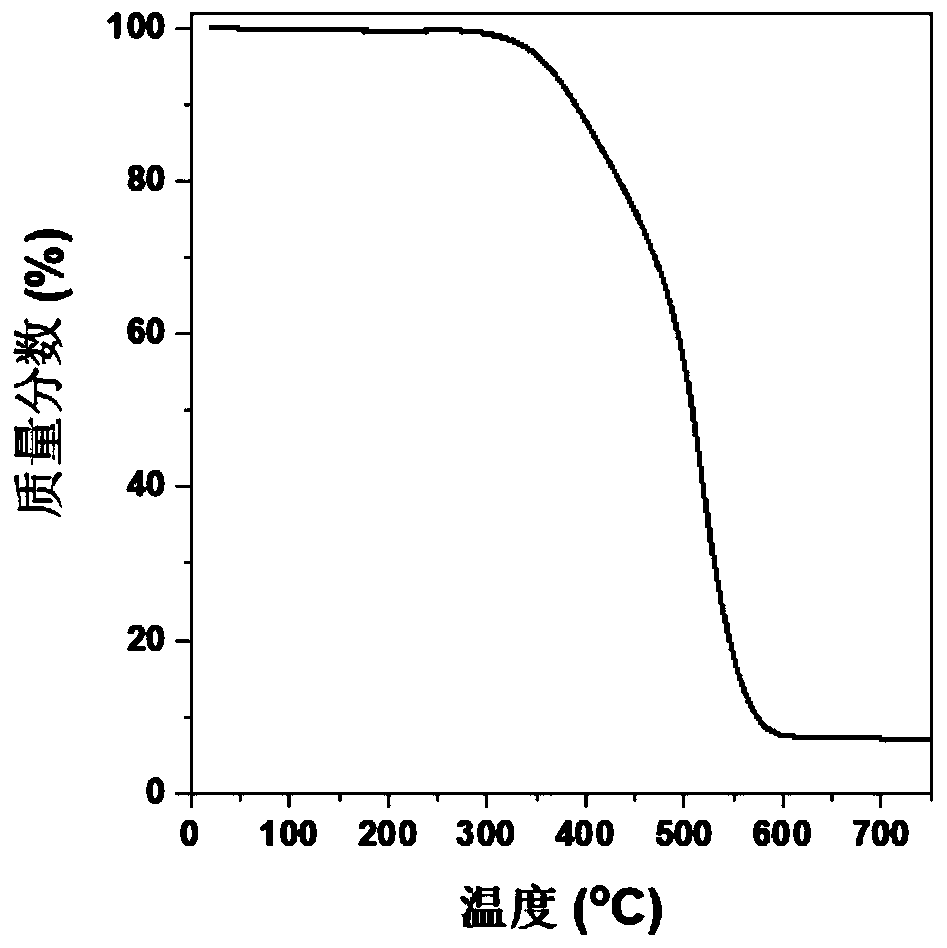

[0035] Such as figure 1 , TEM results show that the obtained product is PtRu with uniform particle size supported by nitrogen-doped carbon 2 Nanospherical par...

Embodiment 2

[0040] Disperse platinum acetylacetonate (0.08mmol), ruthenium acetylacetonate (0.24mmol) and o-phenanthroline (150mg) in ethanol (8ml), and sonicate for 20min to obtain a homogeneous solution; Next, stirring prompts Pt 2+ 、Ru 3+ Coordinate with o-phenanthroline; then, add activated carbon (160mg) dispersed in ethanol (10ml), ultrasonic 30min; under the condition of 85°C, stir and evaporate the ethanol to obtain a black mixture; after vacuum drying and grinding, in N 2 Carbonization in the atmosphere at 600°C for 1.5h; then switch the inert gas to ammonia to remove the precipitates attached to the surface of the metal particles, and finally obtain PtRu with uniform particle size of nitrogen-doped carbon 3 Metal spherical nanoparticle electrocatalysts;

[0041] Such as Figure 5 , TEM results show that the obtained product is PtRu with uniform particle size supported by nitrogen-doped carbon 3 Spherical Nanoparticle Electrocatalysts.

[0042] Such as Figure 6 , accordin...

Embodiment 3

[0047] Platinum acetylacetonate (0.08mmol), nickel acetylacetonate (0.24mmol), and 2,2'-bipyridyl (300mg) were dispersed in ethanol (12ml), and a homogeneous solution was obtained by ultrasonication for 40min; the homogeneous solution was placed in a water bath, and the At 90°C, stirring promotes the Pt 2+ 、Ni 2+ Coordinate with 2,2'-bipyridine; then, add activated carbon (120mg) dispersed in ethanol (10ml), ultrasonicate for 30min; stir and evaporate ethanol to dryness at 90°C to obtain a black mixture; after vacuum drying, After grinding, at N 2 Carbonization in the atmosphere at 900°C for 20 minutes; then switch the inert gas to hydrogen to remove the precipitates attached to the surface of the metal particles, and finally obtain PtNi with uniform particle size supported by nitrogen-doped carbon 3 Metal spherical nanoparticle electrocatalysts;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com