Method and apparatus for preparing palladium carbon catalyst

A palladium-carbon catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high labor intensity, complicated operation process, and centrifuge vibration Large and other problems, to achieve the effect of reducing labor intensity, simple process operation, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

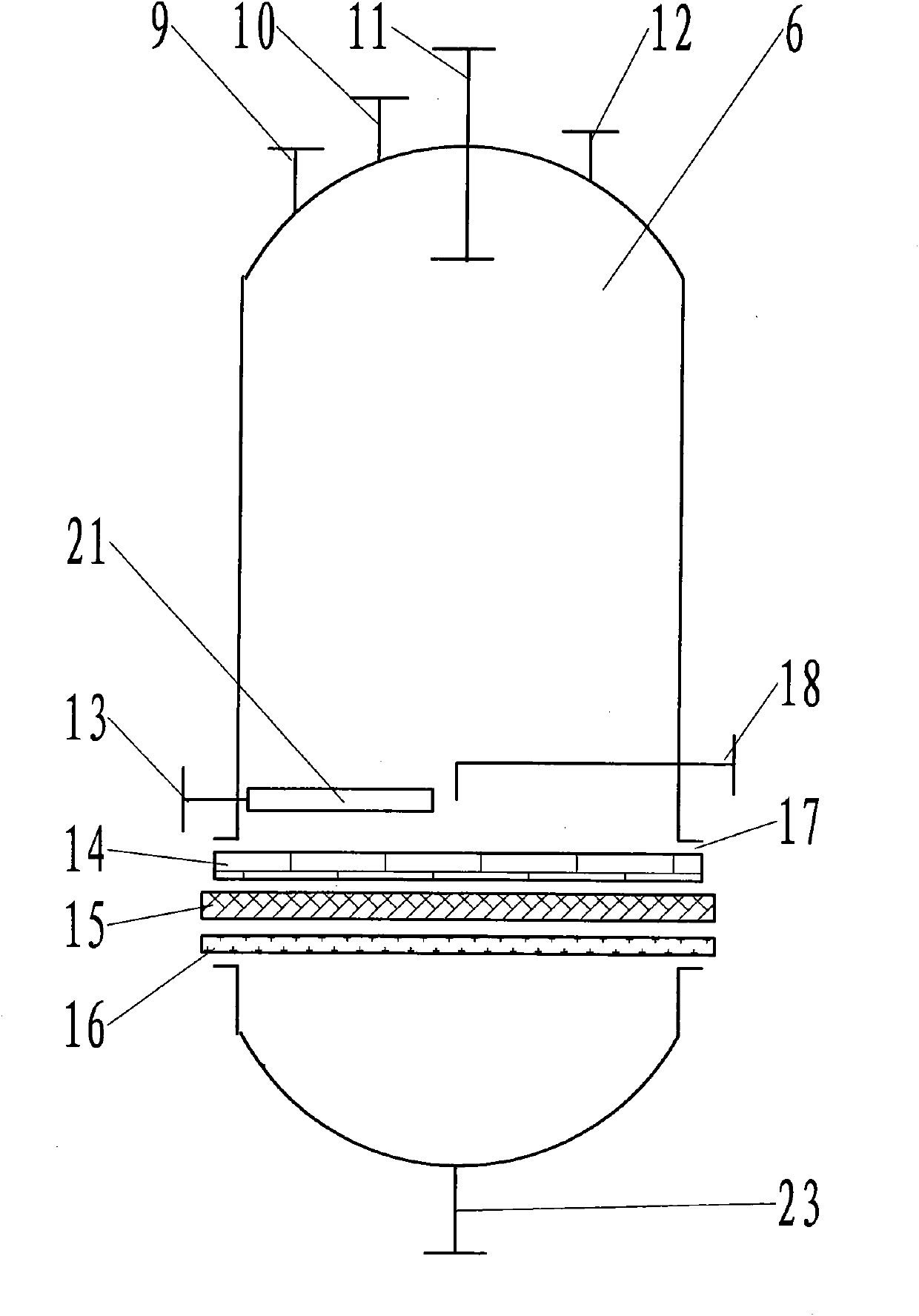

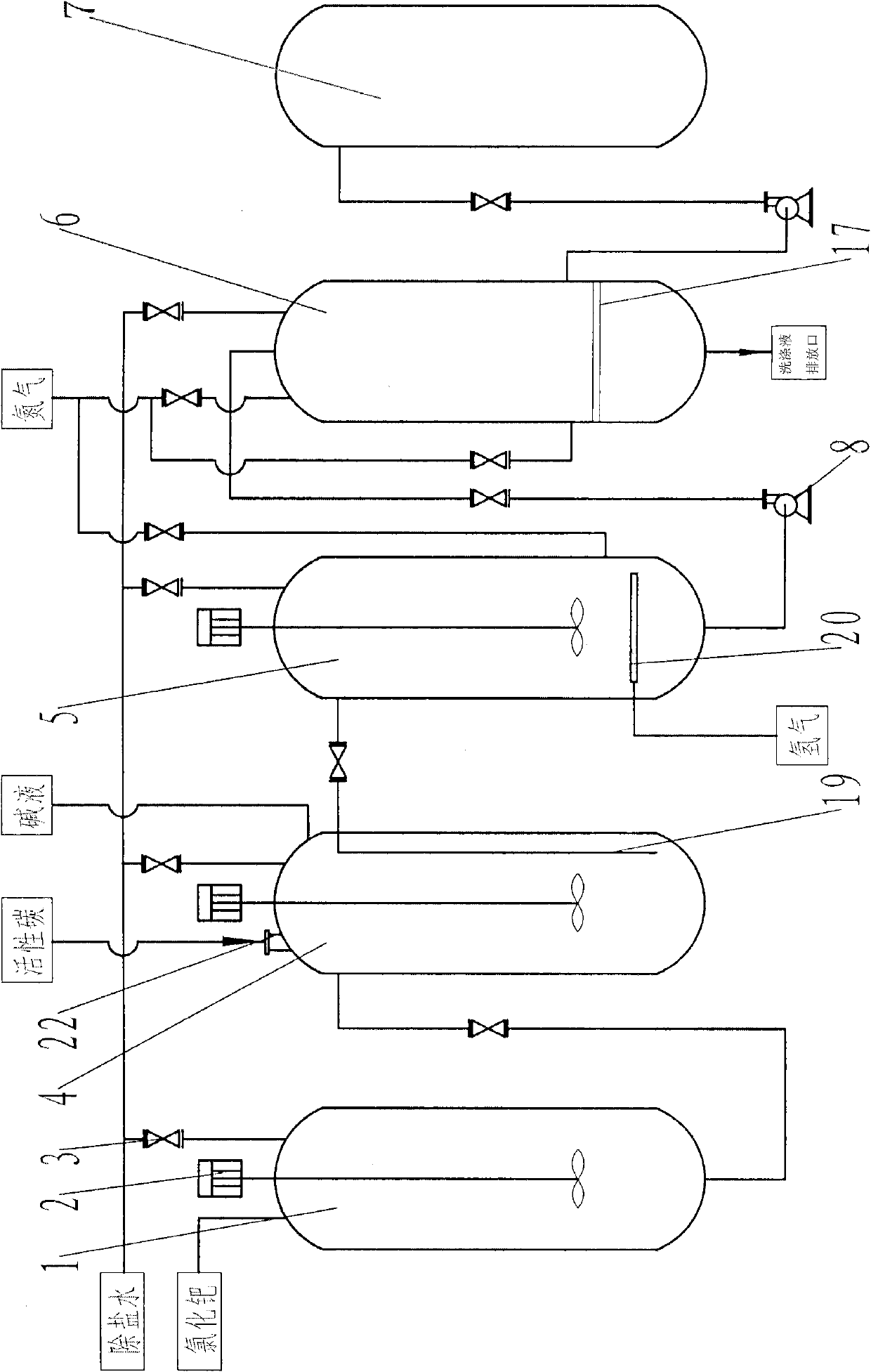

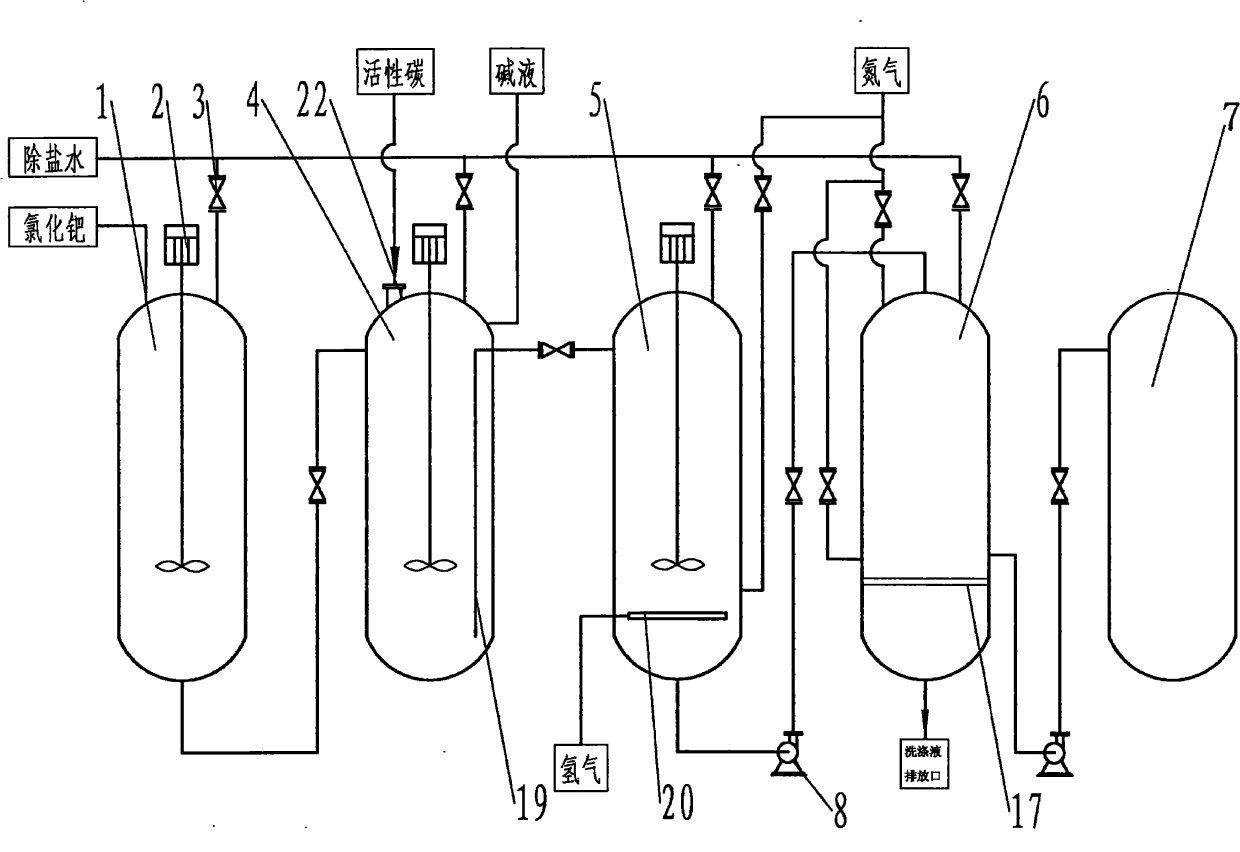

[0022] The present invention prepares palladium carbon catalyst device, as figure 1 As shown, it is mainly composed of palladium chloride dissolution reactor 1, activated carbon slurry preparation reactor 4, hydrogenation reactor 5, catalyst scrubber 6, catalyst storage tank 7 and supporting pipeline, pump 8 and valve 3. The palladium chloride dissolution reactor, the activated carbon slurry preparation reactor and the hydrogenation reactor are equipped with a stirrer 2 . The material outlet of the palladium chloride dissolution reactor is connected to the palladium chloride solution inlet of the activated carbon slurry preparation reactor. The activated carbon slurry preparation reactor is provided with an activated carbon feeding port 22 and an alkali liquor inlet. The activated carbon slurry preparation reactor is provided with a siphon tube 19, the siphon tube is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com