Patents

Literature

143results about How to "Fixed fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

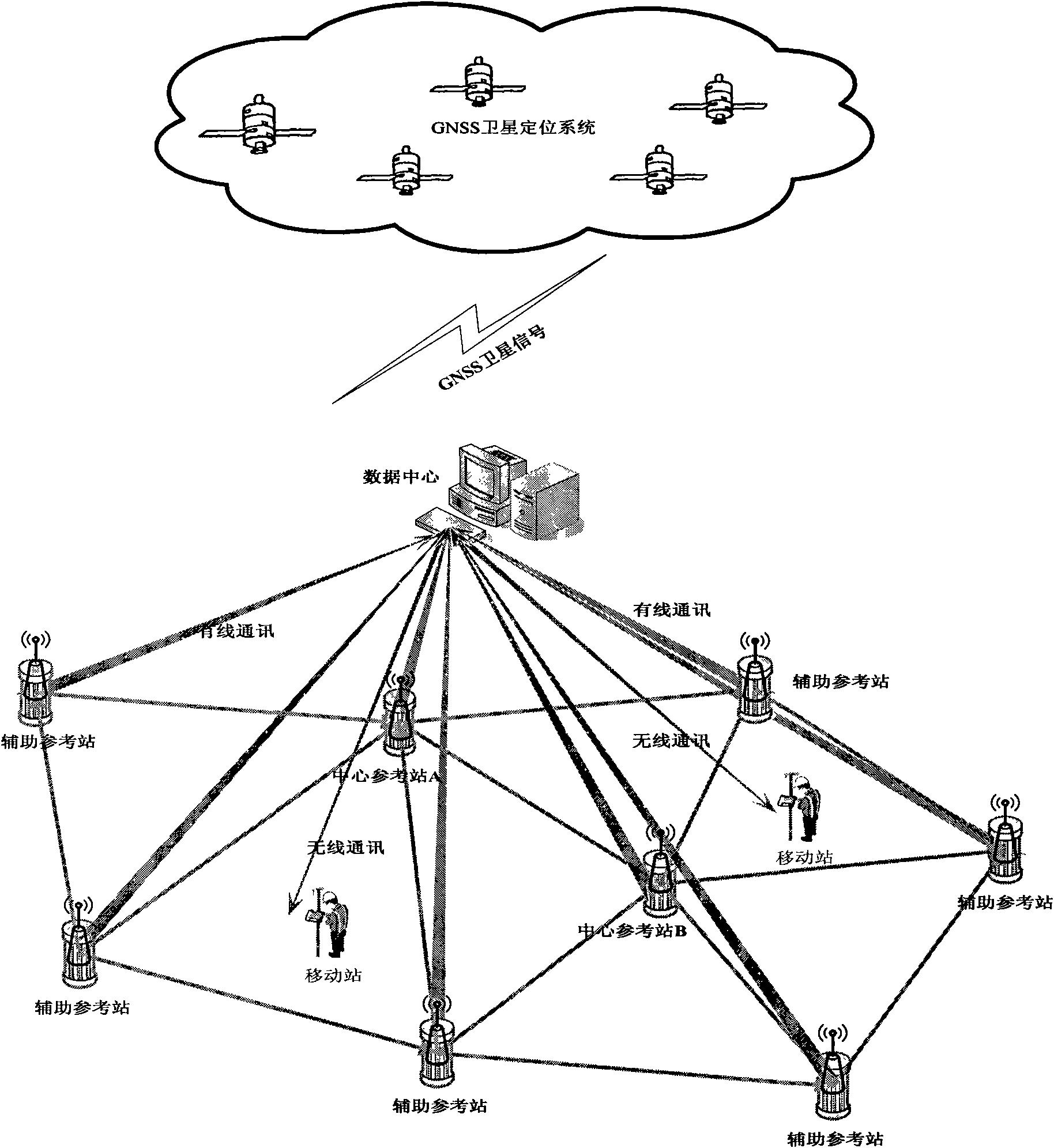

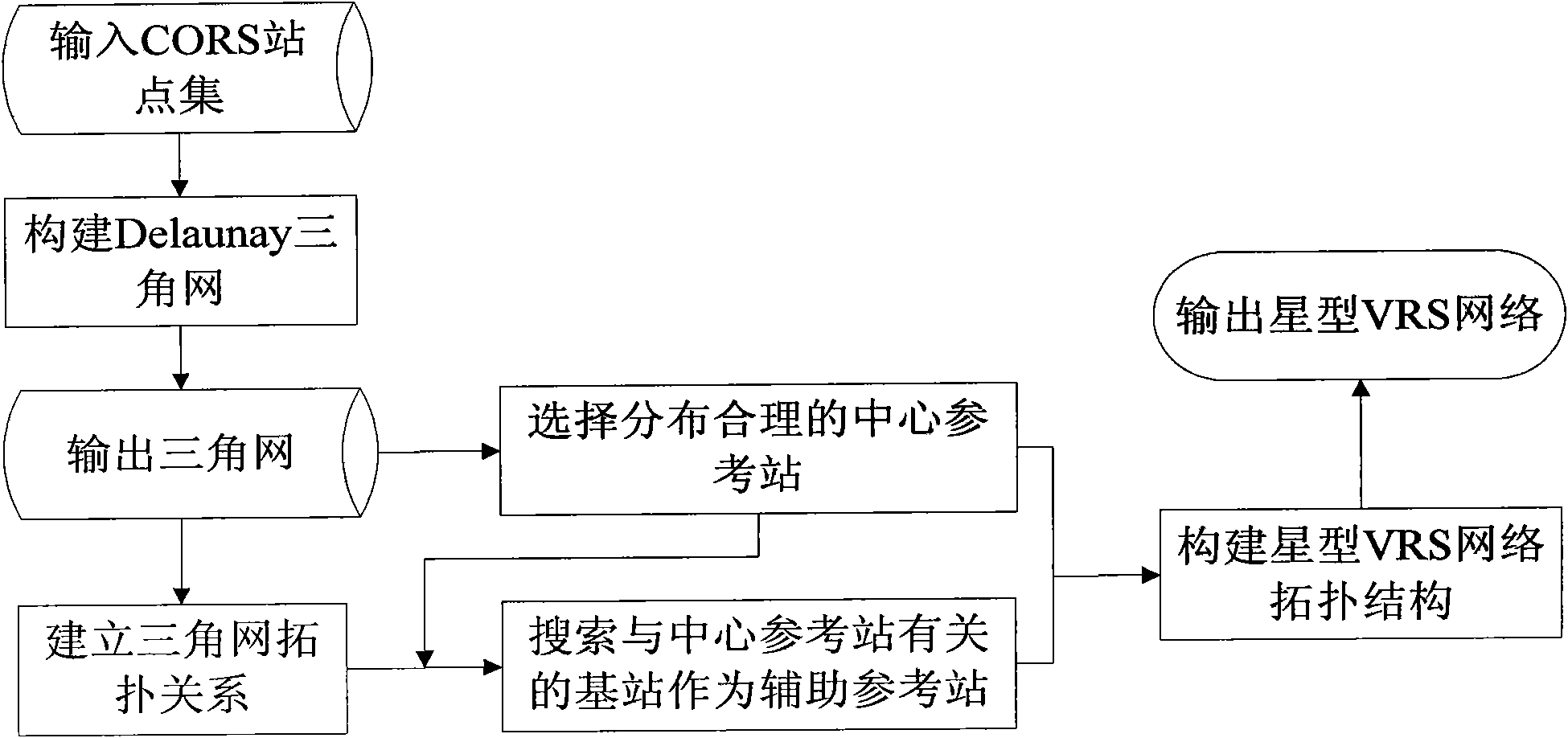

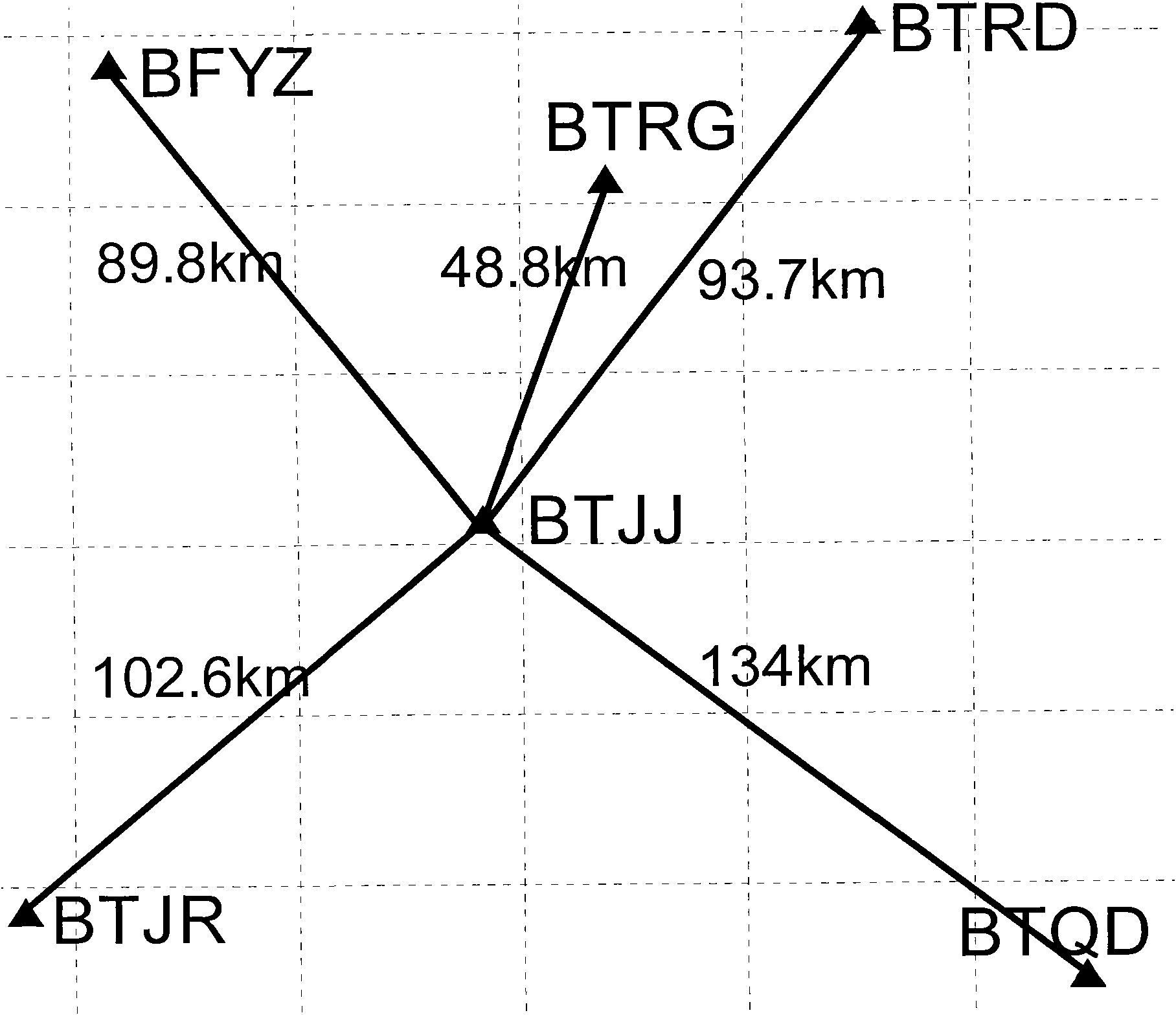

Method for positioning network RTK based on star-shaped virtual reference station

InactiveCN101943749AFixed fastHigh precisionPosition fixationSatellite radio beaconingTroposphereIonosphere

The invention discloses a method for positioning a network RTK based on a star-shaped virtual reference station, which comprises the steps of: firstly, establishing a star-shaped basic calculation unit, constructing a baseline calculation way for a star-shaped VRS network RTK and proposing an ambiguity calculation method suitable for the star-shaped VRS network RTK; and then studying the algorithm of the corrections of the ionosphere and the troposphere in the VRS network RTK aiming at the star shape. The method markedly increases the calculation speed on the network ambiguity by about 50% and has higher accuracy and reliability of the generated network correction.

Owner:SOUTHEAST UNIV

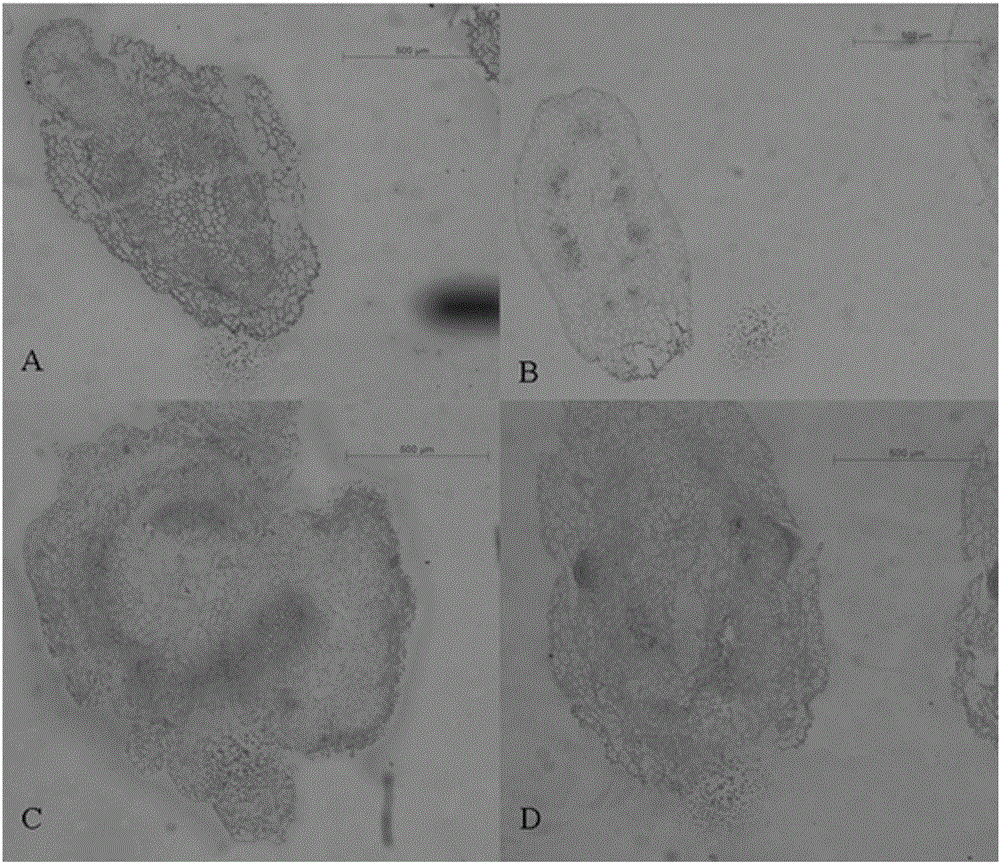

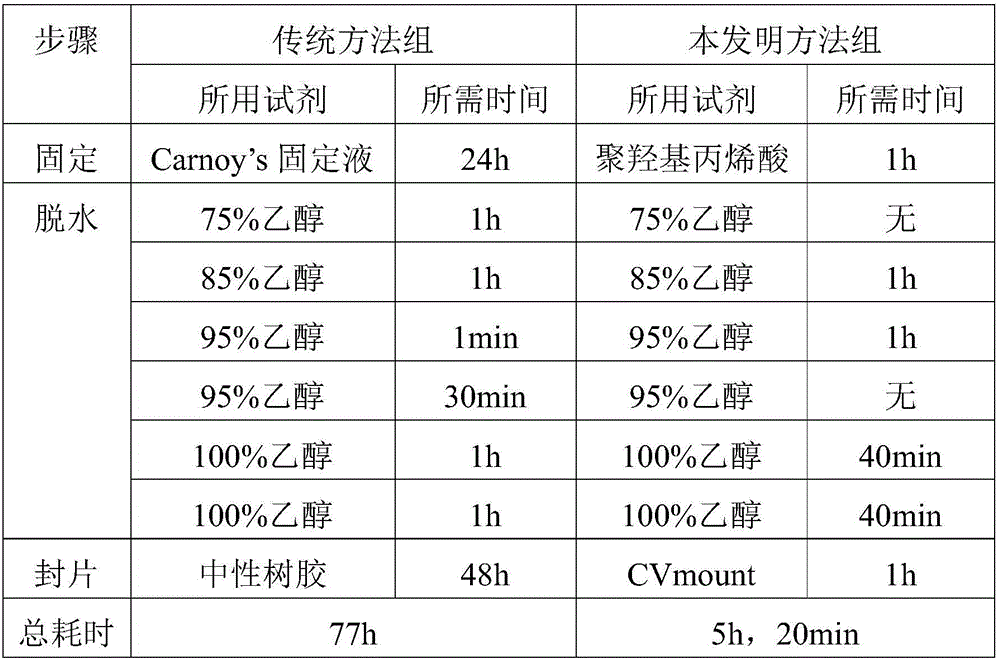

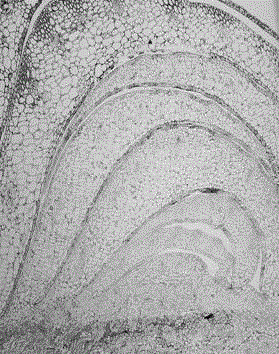

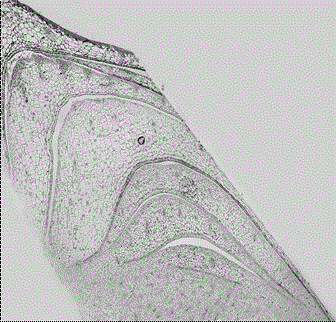

Paraffin sectioning method for eucalyptus tissue

InactiveCN105973673AStrong penetrationFixed fastPreparing sample for investigationParaffin waxDyeing

The invention belongs to the technical field of plant microscopic observation and discloses a paraffin sectioning method for eucalyptus tissue. The method comprises the steps of preparing materials, fixing, washing, dehydrating, performing a transparency treatment, waxing, embedding, sectioning, displaying the sections, adhering the sections, roasting the sections, dewaxing and rehydrating, dyeing, dehydrating, redyeing and enclosing the sections. According to the paraffin sectioning method for the eucalyptus tissue, utilized novel stationary liquid polyhydroxyl acrylic acid has high speed, can largely shorten the fixing time and can balance the fixing; meanwhile, xylene replaces with a safe and nontoxic TO transparent reagent, the TO transparent agent can be solved with alcohol of 95% at 25 DEG C or above, can solve paraffin and sealed vegetable glue, has excellent volatility without bad influence on dyeing of common biological dye, and has relatively better transparency and dewaxing effects, and after the transparency treatment is performed, the tissue is unlikely to embrittle, the sections can keep complete; furthermore, neutral vegetable glue replaces with a section sealing agent CVmount. After the fixing, dehydrating and section sealing steps during optimization of paraffin sections are performed, the section production cycle is shortened by at least 72 hours on the premise of ensuring the sectioning effect.

Owner:RES INST OF TROPICAL FORESTRY CHINESE ACAD OF FORESTRY

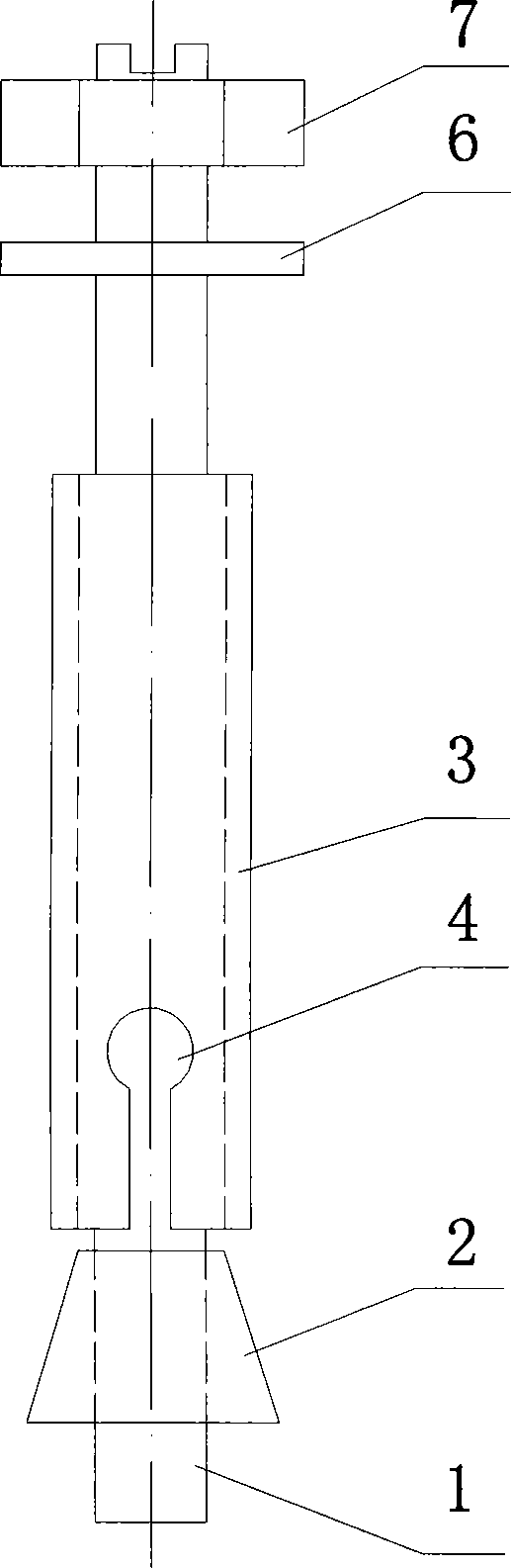

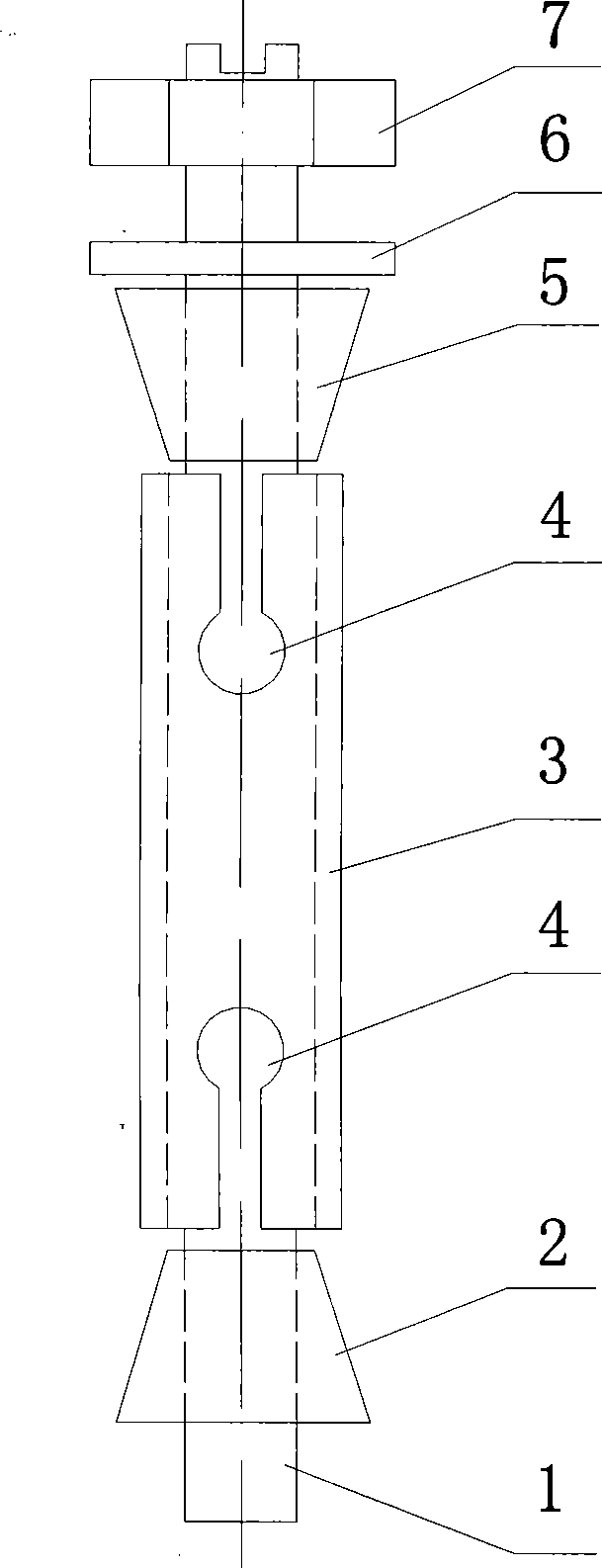

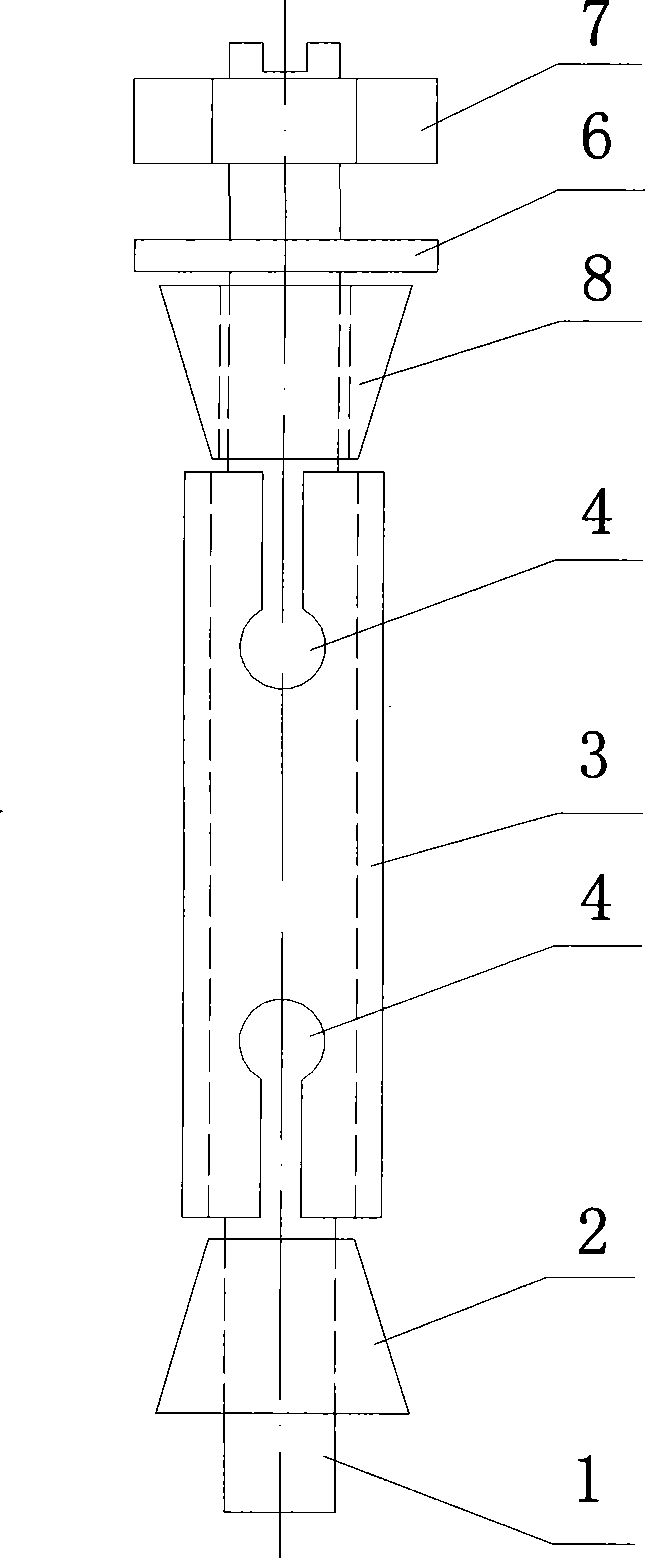

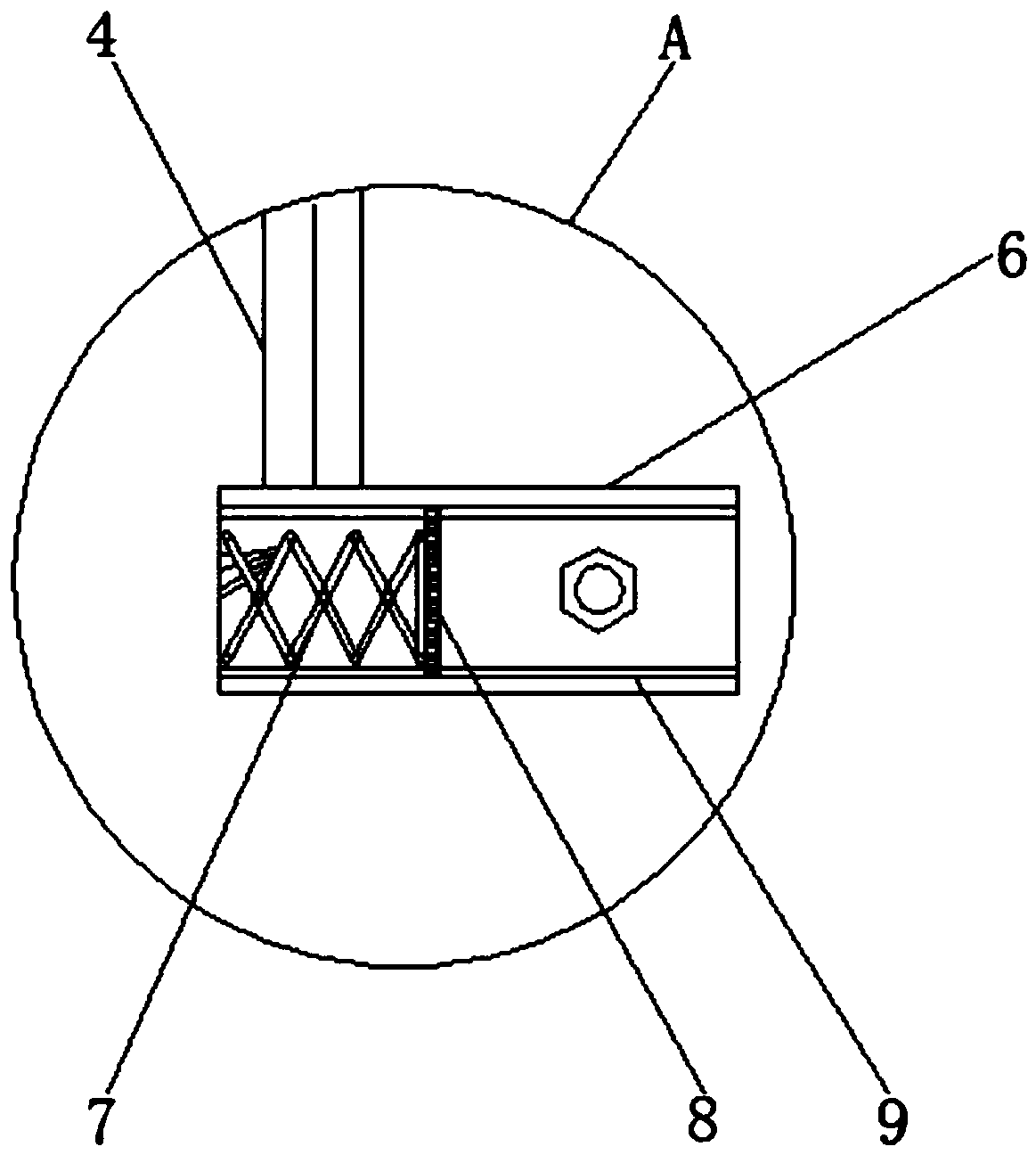

Expansion bolt

The invention relates to an expansion bolt, which comprises a threaded rod and an expansion tube, wherein the lower end part of the expansion tube is provided with equant open slots, the threaded rod is provided with outside threads, and the lower end part of the threaded rod passes through the expansion tube. The expansion bolt is characterized in that a screw cap is welded on the upper end of the threaded rod and is positioned on the expansion tube; a lower tapered nut is screwed on the lower end part of the threaded rod and is positioned under the expansion tube, the small head end of the lower tapered nut faces upwards, the outer diameter of the small head end of the lower tapered nut is less than or equal to the inner diameter of the expansion tube, and the outer diameter of the big head end of the lower tapered nut is larger than the inner diameter of the expansion tube. When the expansion bolt is used, the threaded rod is exposed little and the expansion bolt is beautiful.

Owner:HUBEI WENBANG PLASTICS

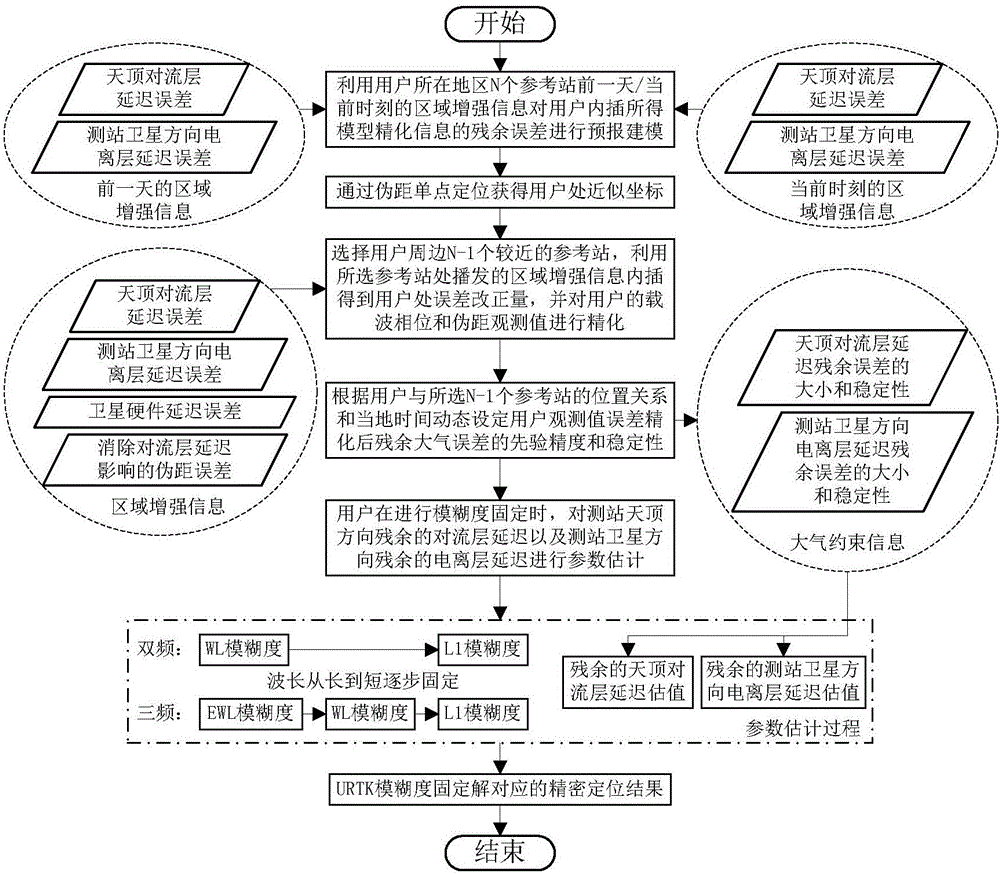

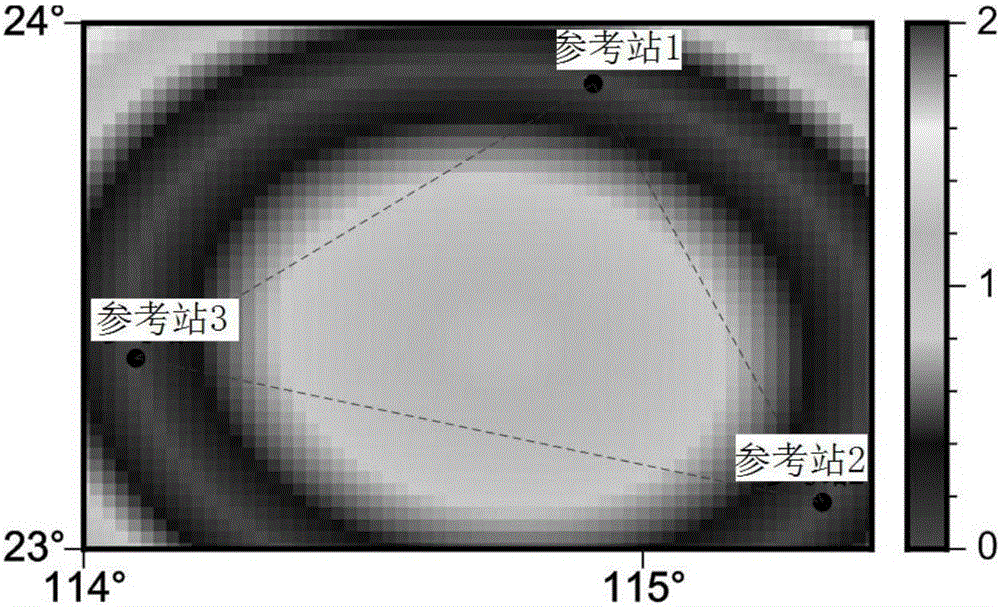

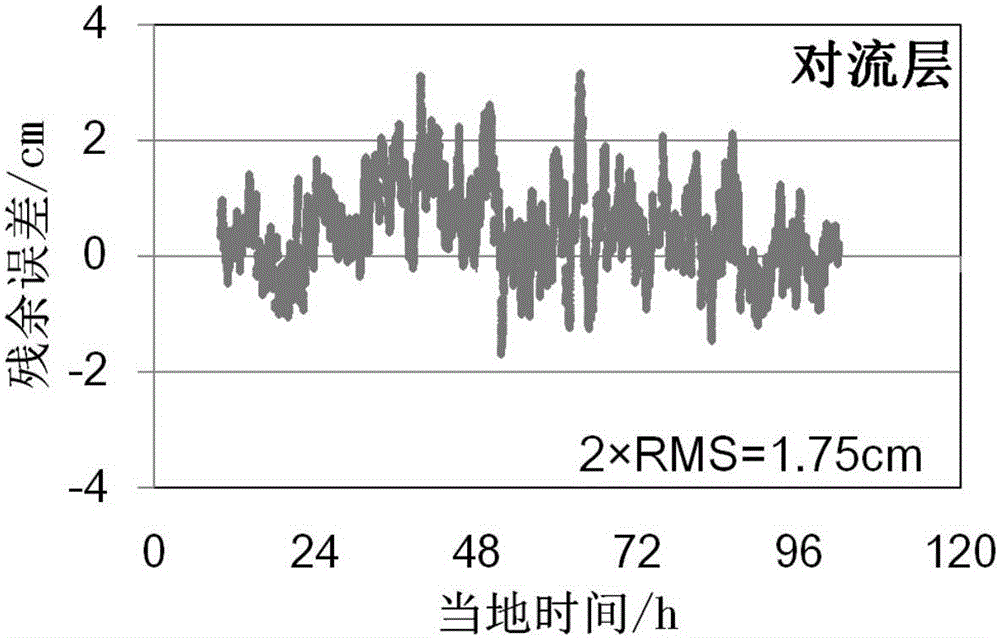

Un-differenced real-time kinematic (URTK) fuzziness rapid fixing method with additional atmosphere information dynamic constraint

InactiveCN105738934AImproved ambiguity resolutionEffectively fixedSatellite radio beaconingTropospherePrior information

The present invention discloses a URTK fuzziness rapid fixing method with additional atmosphere information dynamic constraint. The method comprises the steps of dynamically setting the prior information of the zenith direction tropospheric delay and the observation station satellite direction ionosphere delay at the position of a user by utilizing the position relationship of the user and a reference station, the validity of an atmosphere delay interpolation result at the region of the user and the change of the atmosphere delay along with the local time, taking the residual tropospheric delay and the ionosphere delay as the random walk to-be-evaluated parameters to evaluate, and improving the URTK fuzziness resolution by considering the atmosphere constraint information, such as the space-time change characteristics of a troposphere and an ionosphere. At the URTK fuzziness resolution, and by utilizing the characteristic that the extra wide lane (EWL) / WL observation value wavelength is longer, the fuzziness rapid and effective fixing is convenient, the fuzziness fixing speed of the user can be accelerated effectively.

Owner:WUHAN UNIV

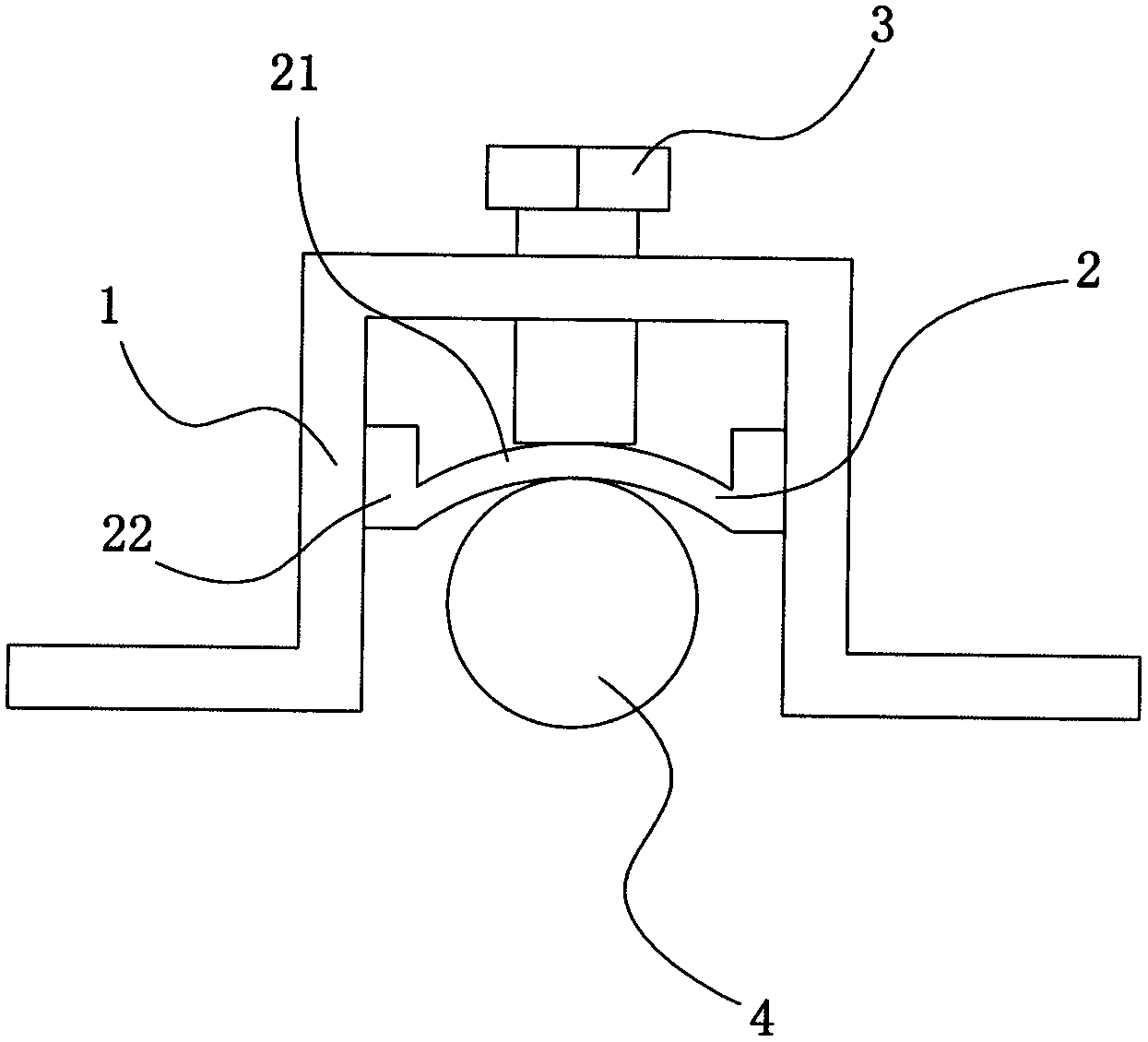

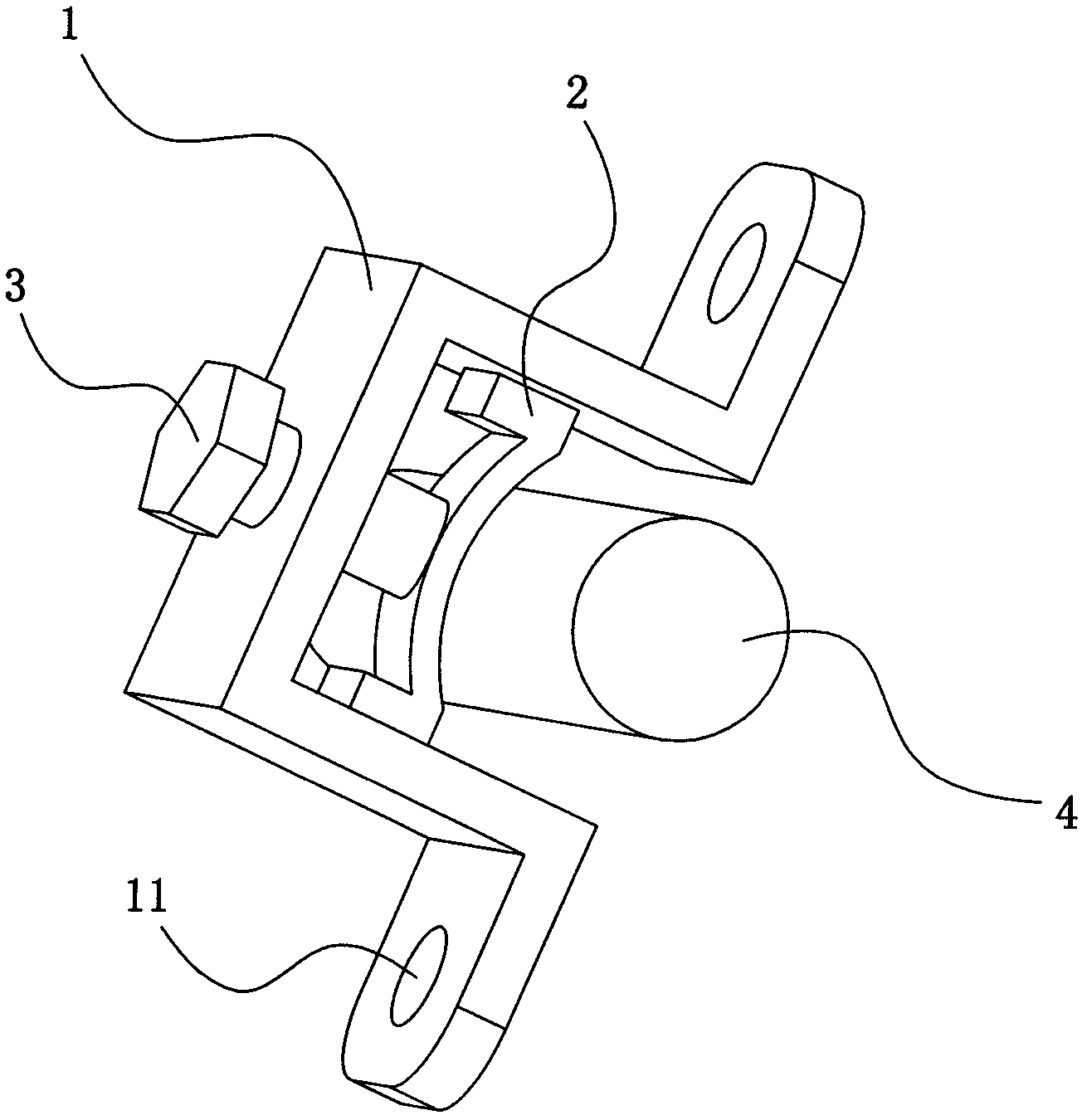

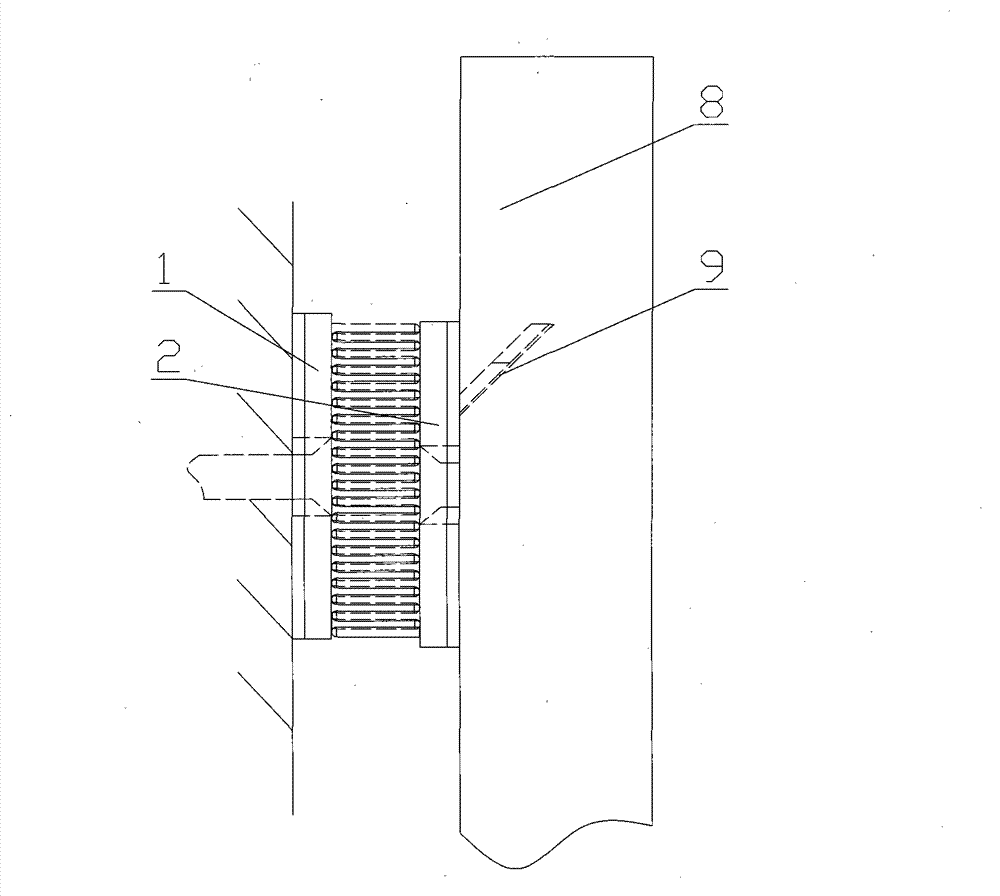

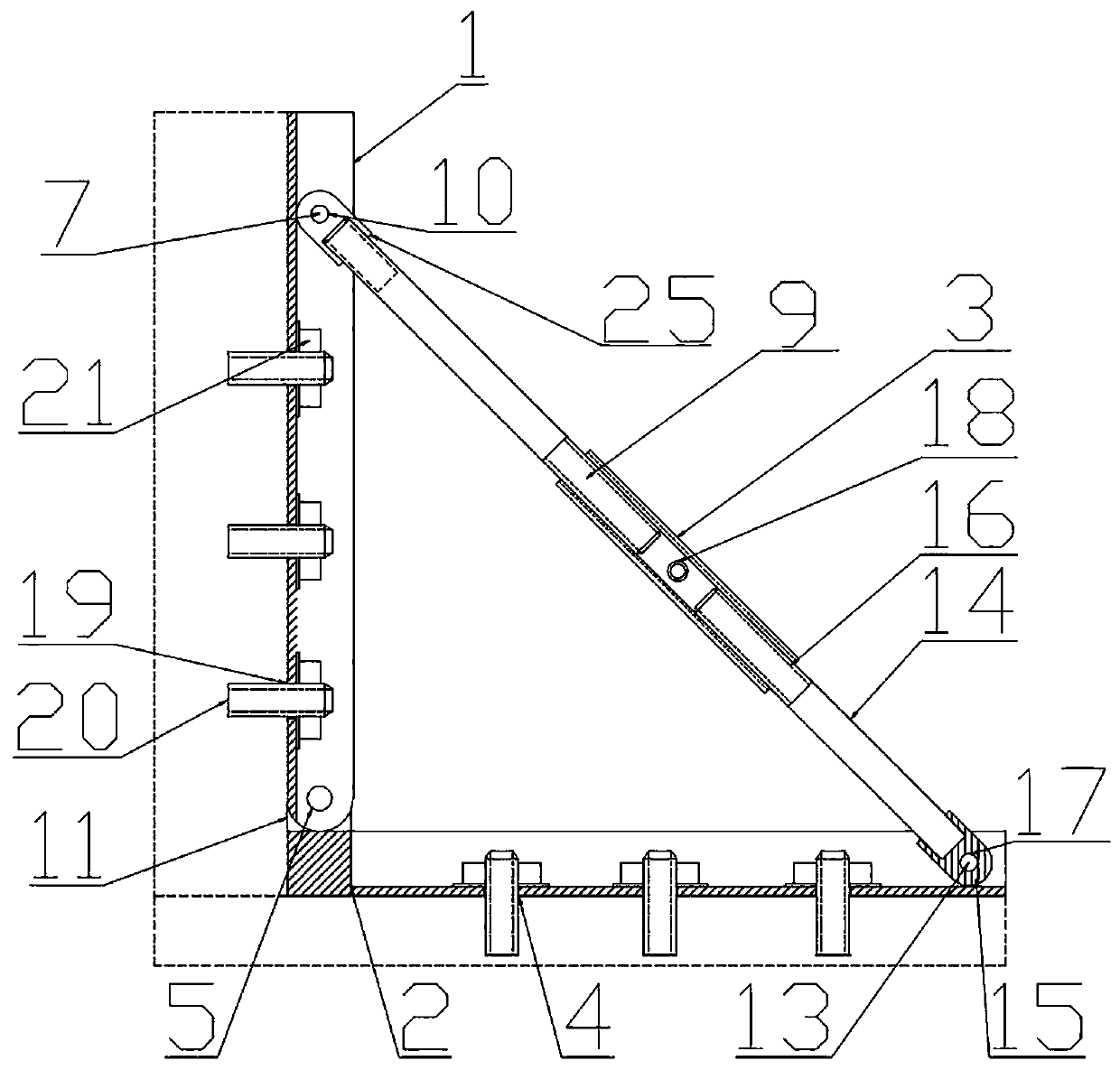

Fast fixing device for cable

InactiveCN103515894ASimple structureEasy to fixElectrical apparatusChinese charactersMechanical engineering

The invention relates to a fast fixing device for a cable. The fast fixing device comprises a frame body of a structure in a shape of a Chinese character 'ji'. A fixed through is formed in the frame body, an elastic sheet is fixed in the frame body, the elastic sheet comprises an arc sheet, the two ends of the arc sheet are respectively provided with an attachment plate, and the attachment plates cling to the inner wall of the frame body. The inner side of the arc sheet is next to the cable, the outer side of the arc sheet is next to the tail end of a screw connected to the frame body in a spiral mode. The fast fixing device for the cable is simple in structure, and the cable is fixed in a pressed mode by fastening the elastic sheet through the screw. The fast fixing device has the advantages of being convenient to control and fast in fixing speed, and the cable is convenient and simple to fix.

Owner:WUXI SHENLI COMM ENG

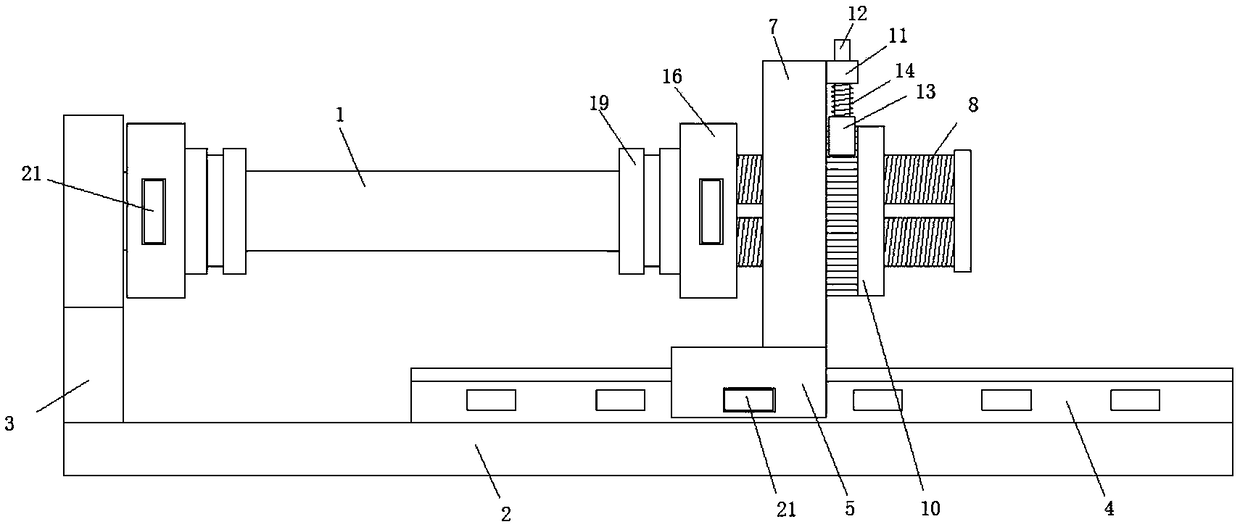

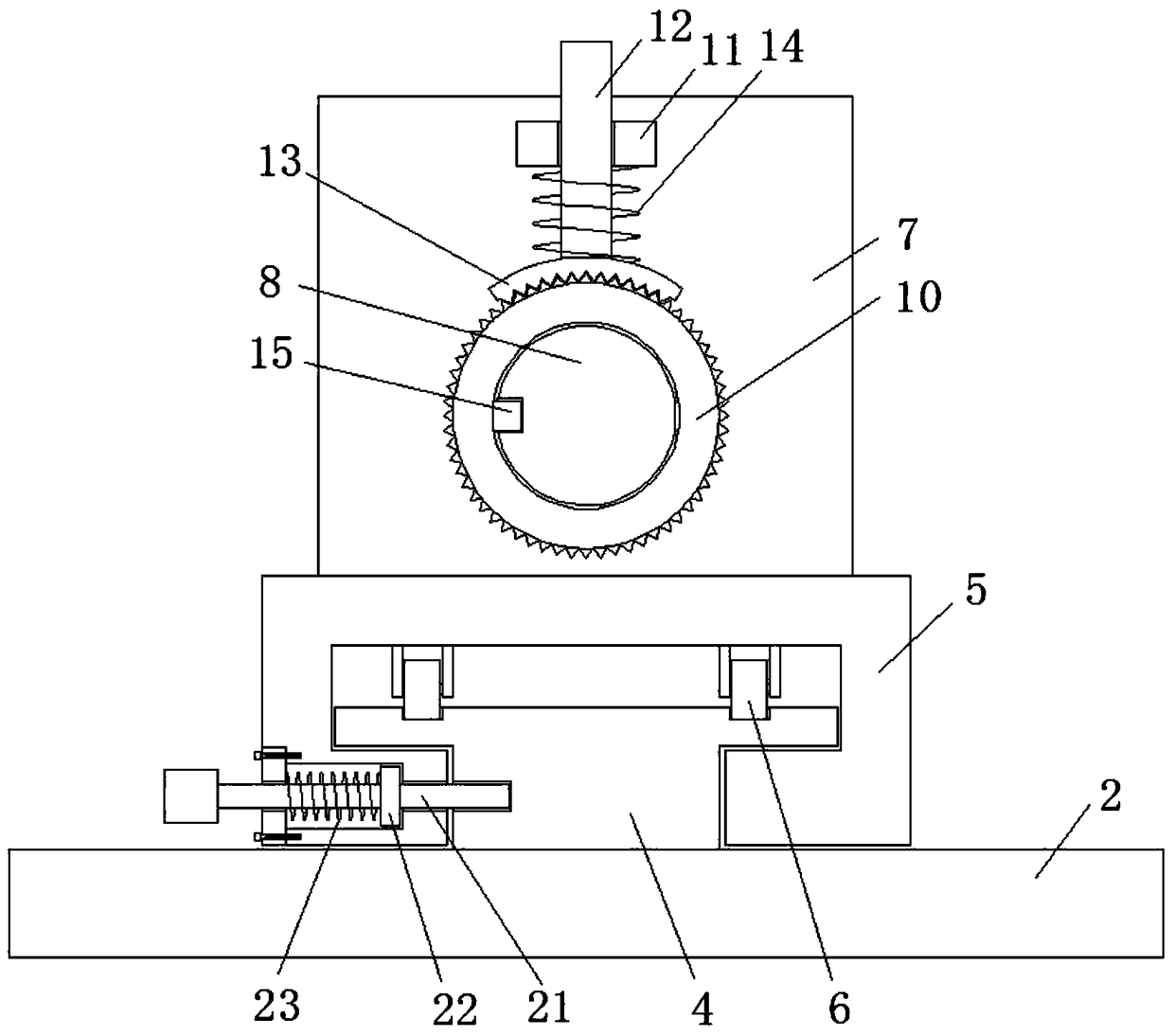

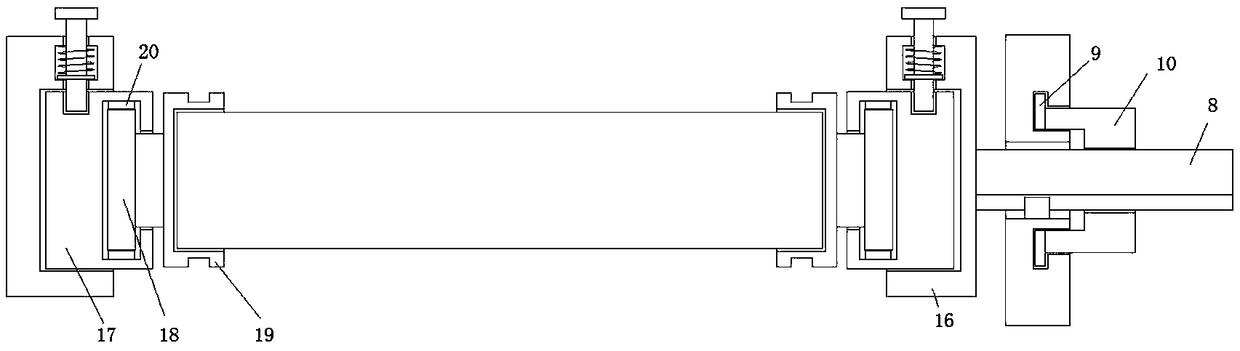

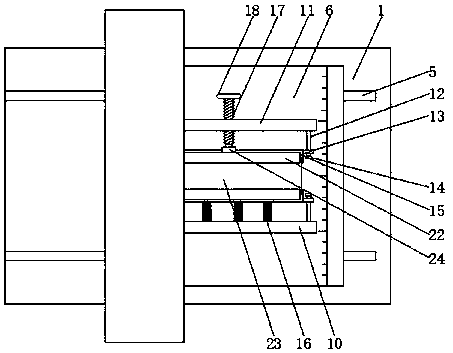

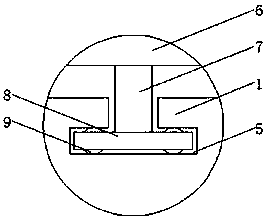

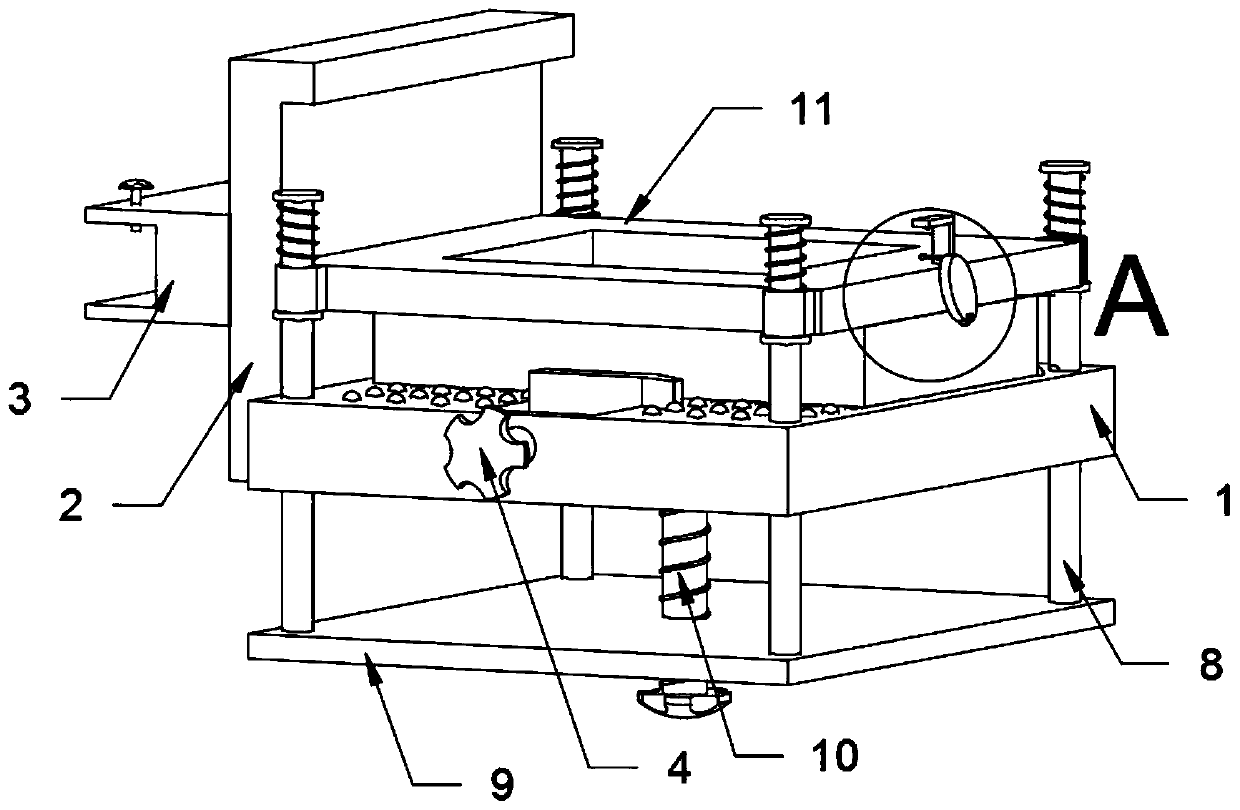

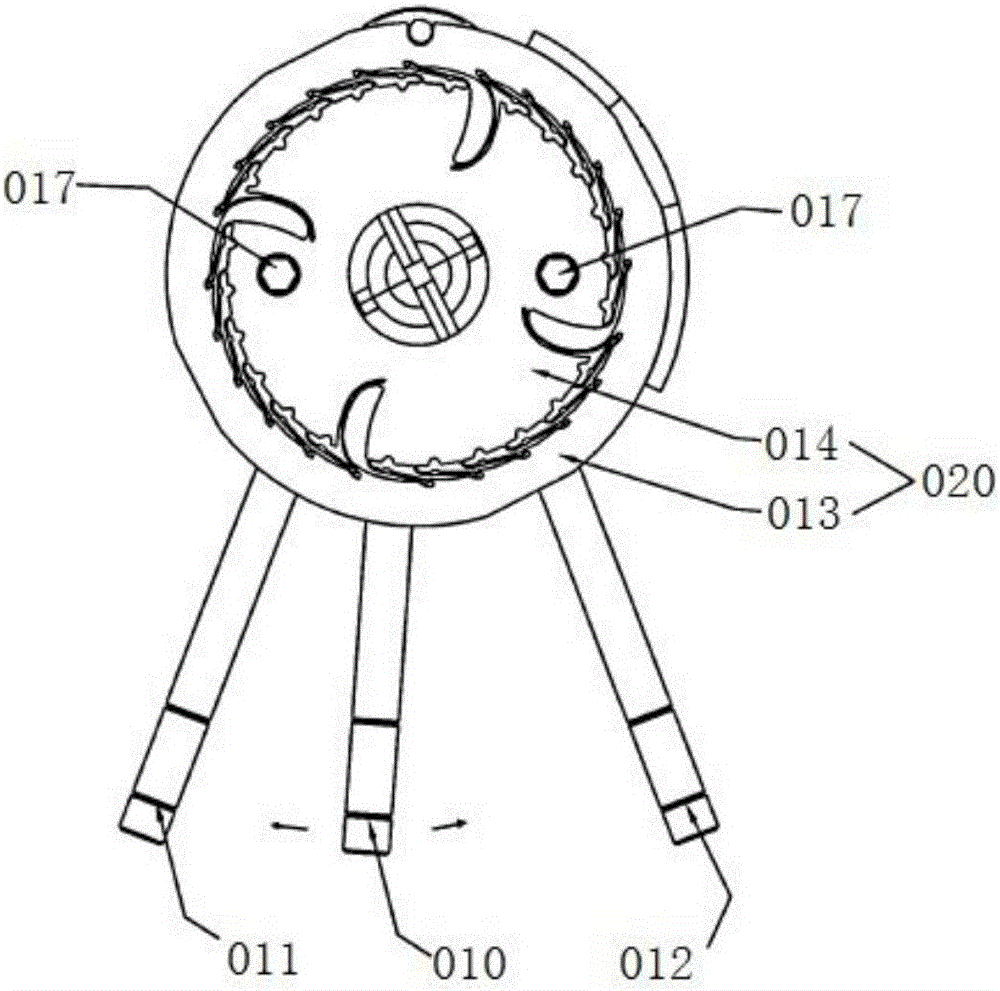

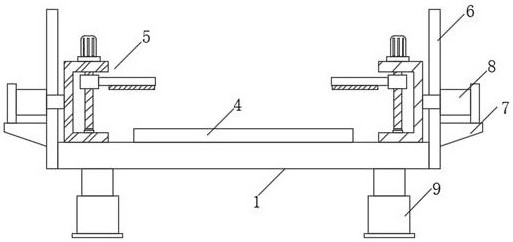

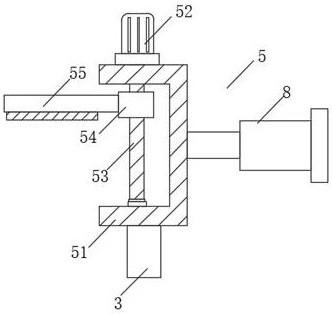

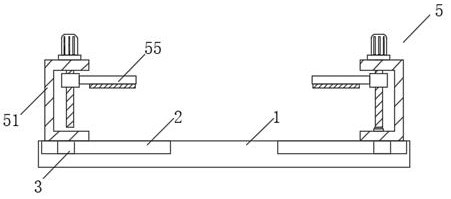

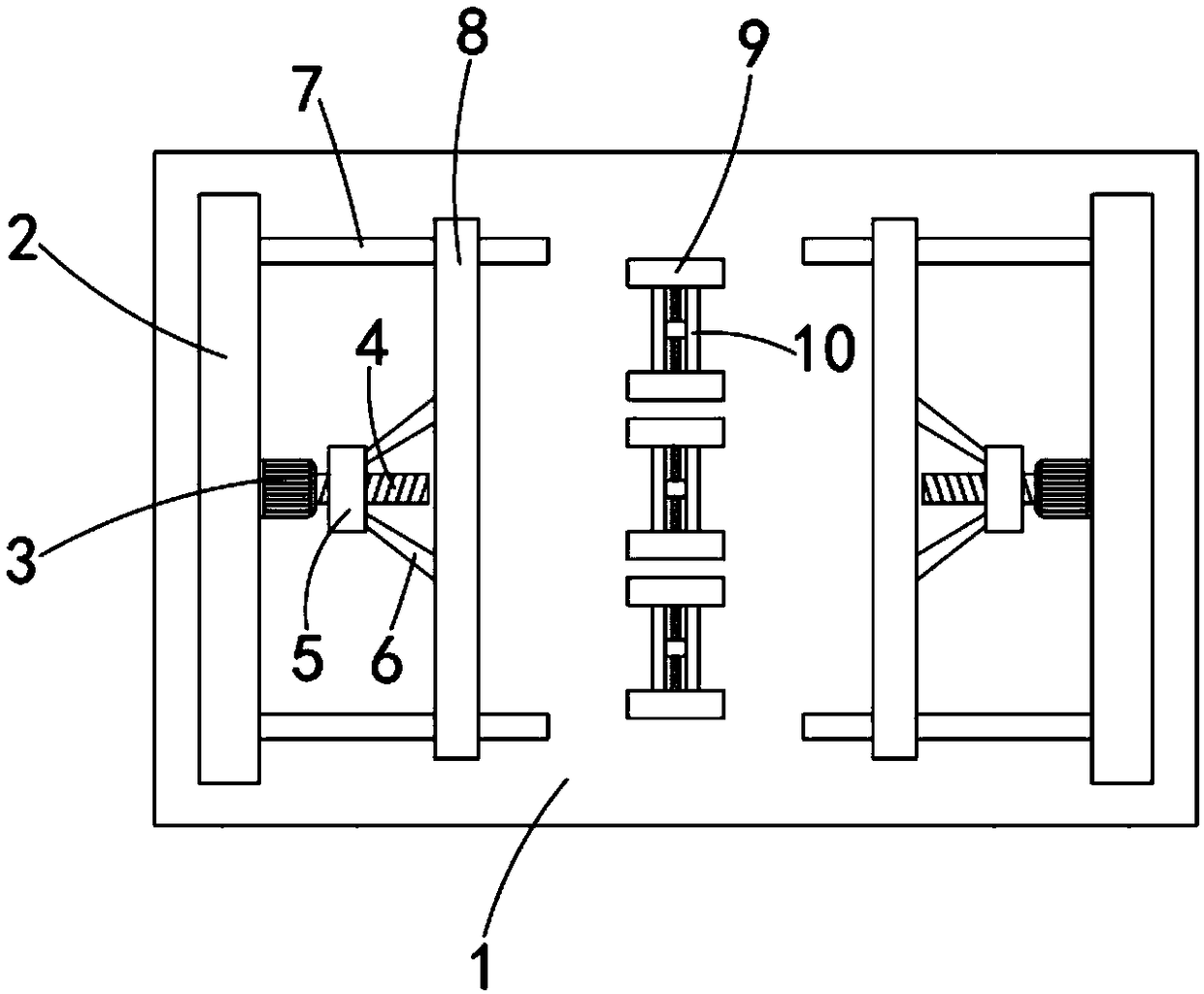

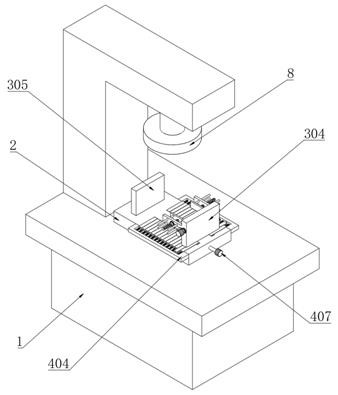

Multipurpose fixing device for automobile axle type component machining

InactiveCN108838712AGood compatibilityEasy to fixPositioning apparatusGrinding work supportsEngineeringMachining

The invention discloses a multipurpose fixing device for automobile axle type component machining. The multipurpose fixing device comprises a transverse shaft. A bottom plate is vertically arranged below the transverse shaft. A side plate and a T-shaped stand column are fixedly welded to the top of the bottom plate. The top of the T-shaped stand column is sleeved with a sliding sleeve in a slidingmanner. A T-shaped groove is formed in the bottom side of the sliding sleeve. A track groove is formed in the top side of the T-shaped stand column. Track wheels are fixedly arranged on the inner wall of the top side of the T-shaped groove and are in sliding connection into the track groove. A vertical plate is fixedly welded to the top side of the sliding sleeve, a horizontal through hole is formed in a plate body of the vertical plate and internally provided with a threaded transverse column, a limiting sliding groove is formed in one side of a column body of the threaded transverse column,a limiting transverse rod is fixedly welded to the inner wall of one side of the horizontal through hole, the limiting transverse rod is horizontally arranged and is in sliding connection into the limiting sliding groove. According to the multipurpose fixing device for automobile axle type component machining, the automobile axle type component fixing effect is better, precision is higher, the application range is wider, operation is convenient, and the usage requirements of people in production and life are met.

Owner:ANQING JIAN AUTO PART FORGING & ROLLING

Embedding and slice making method of lateral buds at different node positions of sugarcane

ActiveCN106546473ASolve the slicing problemReduce breakage ratePreparing sample for investigationPlant tissueBud

The invention relates to an embedding and slice making method of lateral buds at different node positions of sugarcane, and belongs to the technical field of the embedding and slicing of plant tissue. The method comprises the following steps of (1), taking and fixation of a sample, (2), softening, (3), dehydration, (4), displacement, (5), infiltration, (6), embedding, (7), trimming of a block, (8), slicing, (9), spreading of a slice, and adhesion of the slice, (10), dyeing, and the like. According to the method, the characteristics of two embedding and slicing methods of paraffin embedding and slicing and resin infiltrating and embedding are synthesized; the application is integrated; weak points are compensated by learning from strong points; the novel method is searched and developed to systematically solve the slicing problem of the cytological study of the lateral buds of the sugarcane; further, the made slice is intact and is almost not broken; slicing and embedding effects of giving consideration to a whole and a detail can be achieved.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI

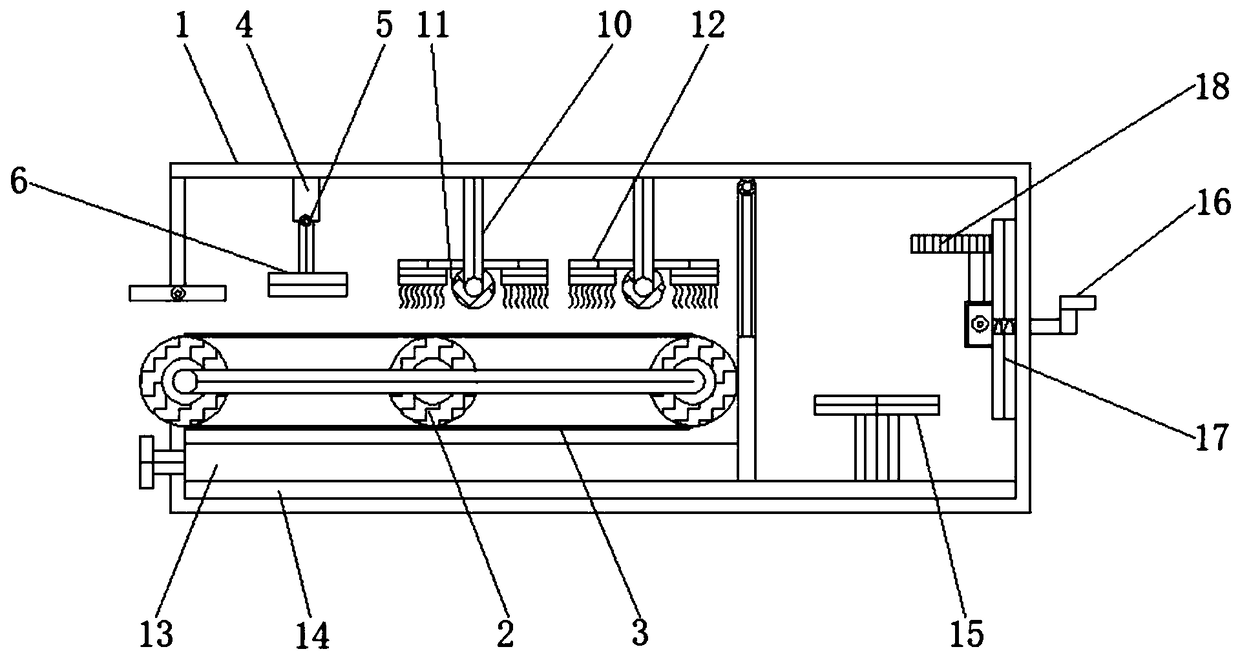

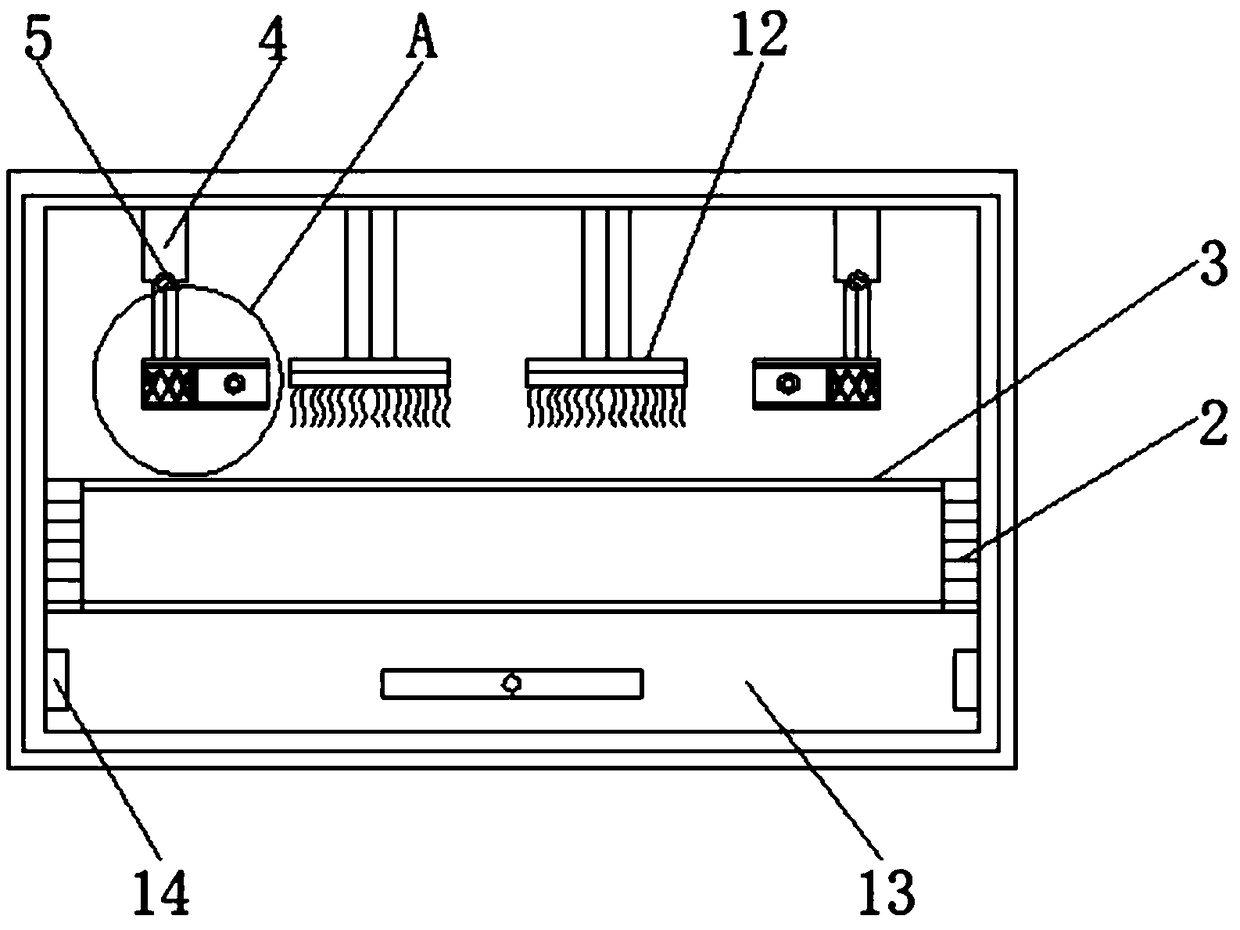

Carton binding equipment capable of using for online production

The invention discloses carton binding equipment capable of using for online production. The carton binding equipment comprises a main body, a telescopic rod and connecting rods. The main body is internally provided with electric motors, a conveyor belt is arranged on the electric motors, the telescopic rod is mounted above the conveyor belt, and a bolt is arranged in the telescopic rod in a penetrating mode. A binding box is disposed under the telescopic rod, a hydraulic rod is disposed inside the binding box, a pushing plate is disposed on the right side of the hydraulic rod, and sliding rails are disposed on the upper and lower sides of the pushing plate. According to the carton binding equipment capable of using for the online production, the telescopic rod is arranged, and the lengthof the telescopic rod can be adjusted by the bolt so that the binding box fixed under the telescopic rod can reach the suitable position so as to be suitable for the binding of cartons with differentthicknesses to make the binding of the cartons more firm.

Owner:安徽徽之润纸业有限公司

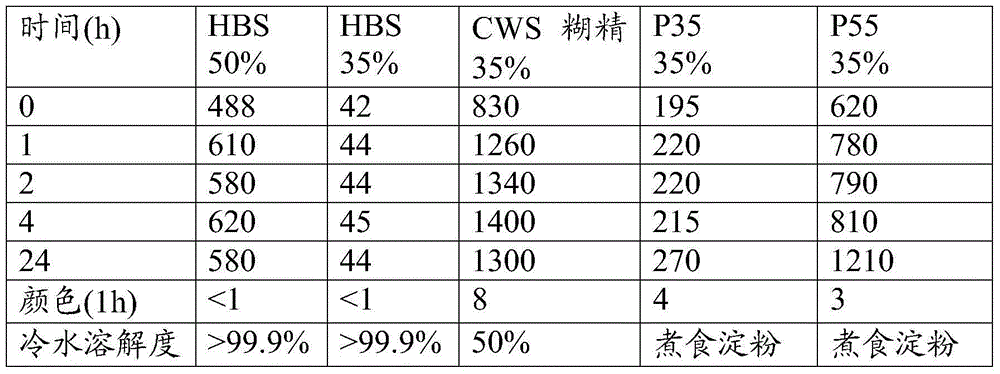

Methods and means for coating paper by film coating

ActiveCN104411885AImprove surface strengthIncrease brightnessNon-fibrous pulp additionStarch dervative coatingsGlycogen branching enzymeFilm-coated tablet

This invention relates to the field of paper coating, more in particular to means and methods for providing paper with at least one layer of pigment using film coating to obtain a well printable surface. Provided is a method for preparing coated paper comprising the steps of: a) providing a pigmented wet coating formulation comprising water, 2-20 parts of a binder and 100 parts of pigment, wherein at least 50% of the binder is highly branched starch (HBS) characterized by a molecular weight of between 0.5* 105 and 1*106 Daltons and having a molecular branching degree of at least 8% and which is obtained by treatment of gelatinized starch or starch derivative with a glycogen branching enzyme (EC 2.4.1.18); and wherein at least 70% of the pigment is calcium carbonate; and b) applying the pigmented wet coating formulation to paper by film coating and drying the coated paper.

Owner:艾维贝皇家合作公司

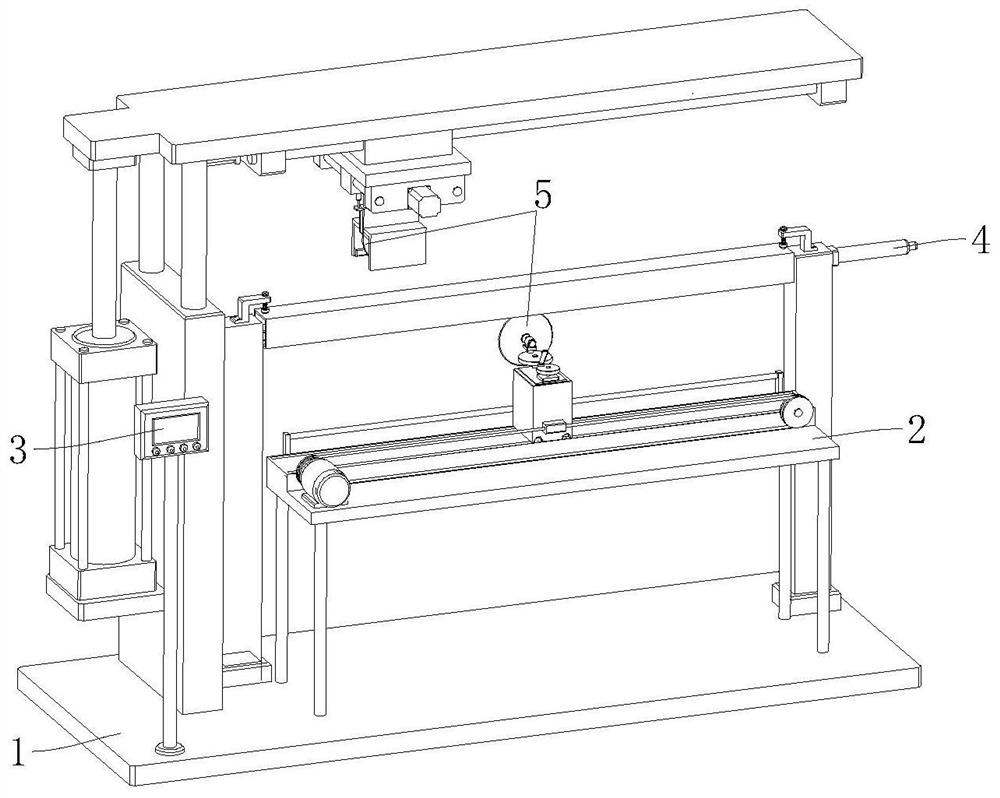

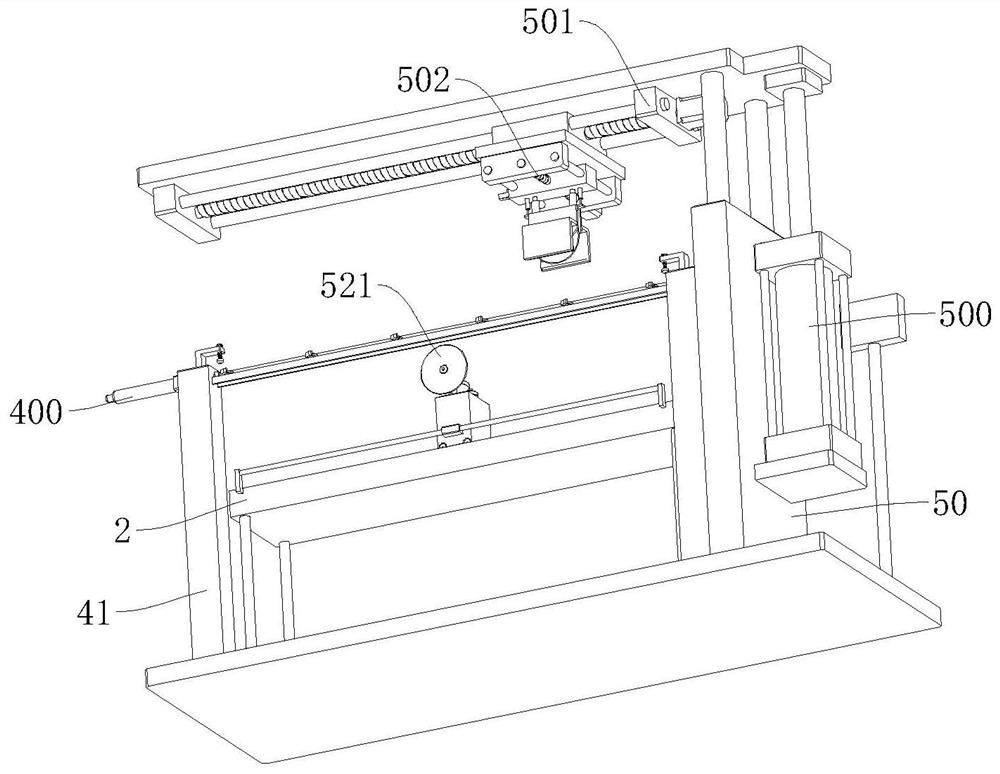

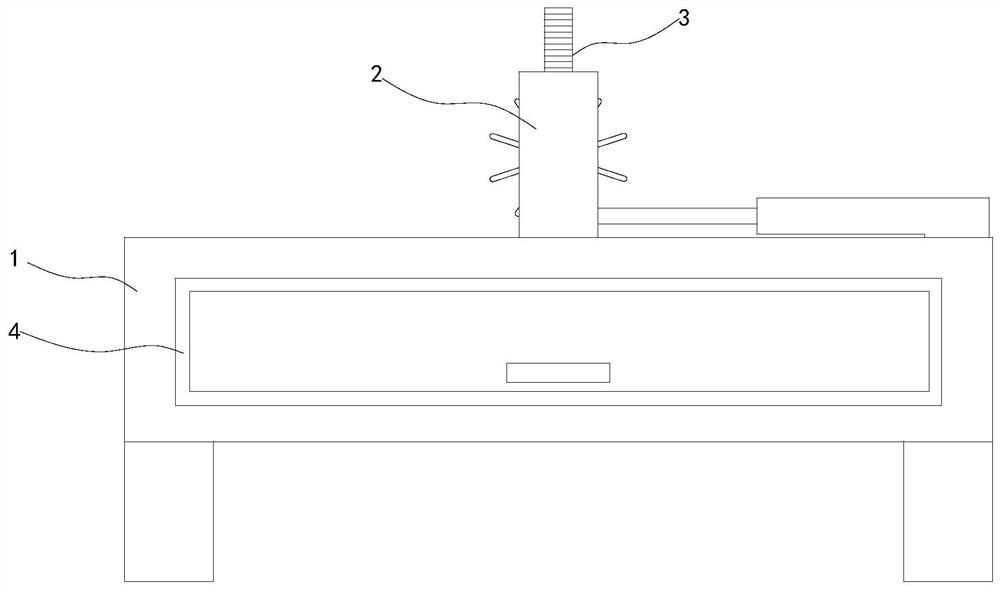

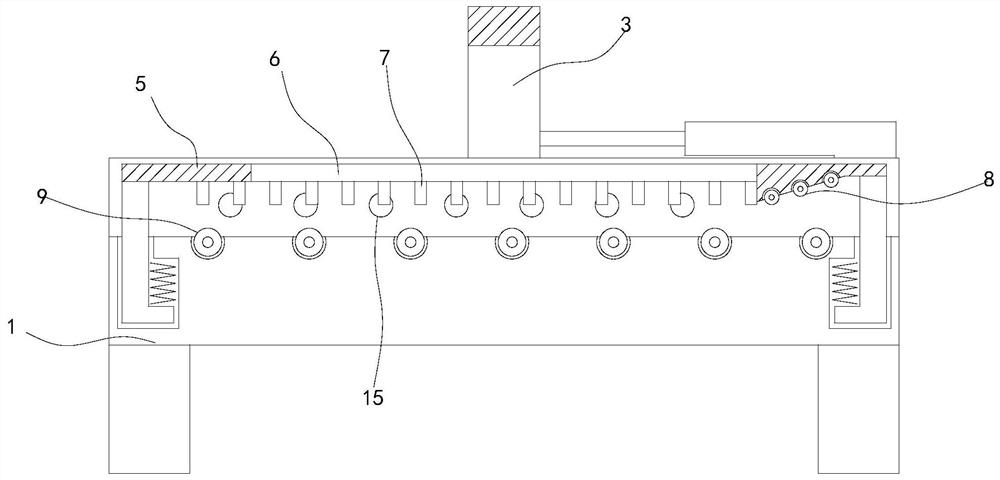

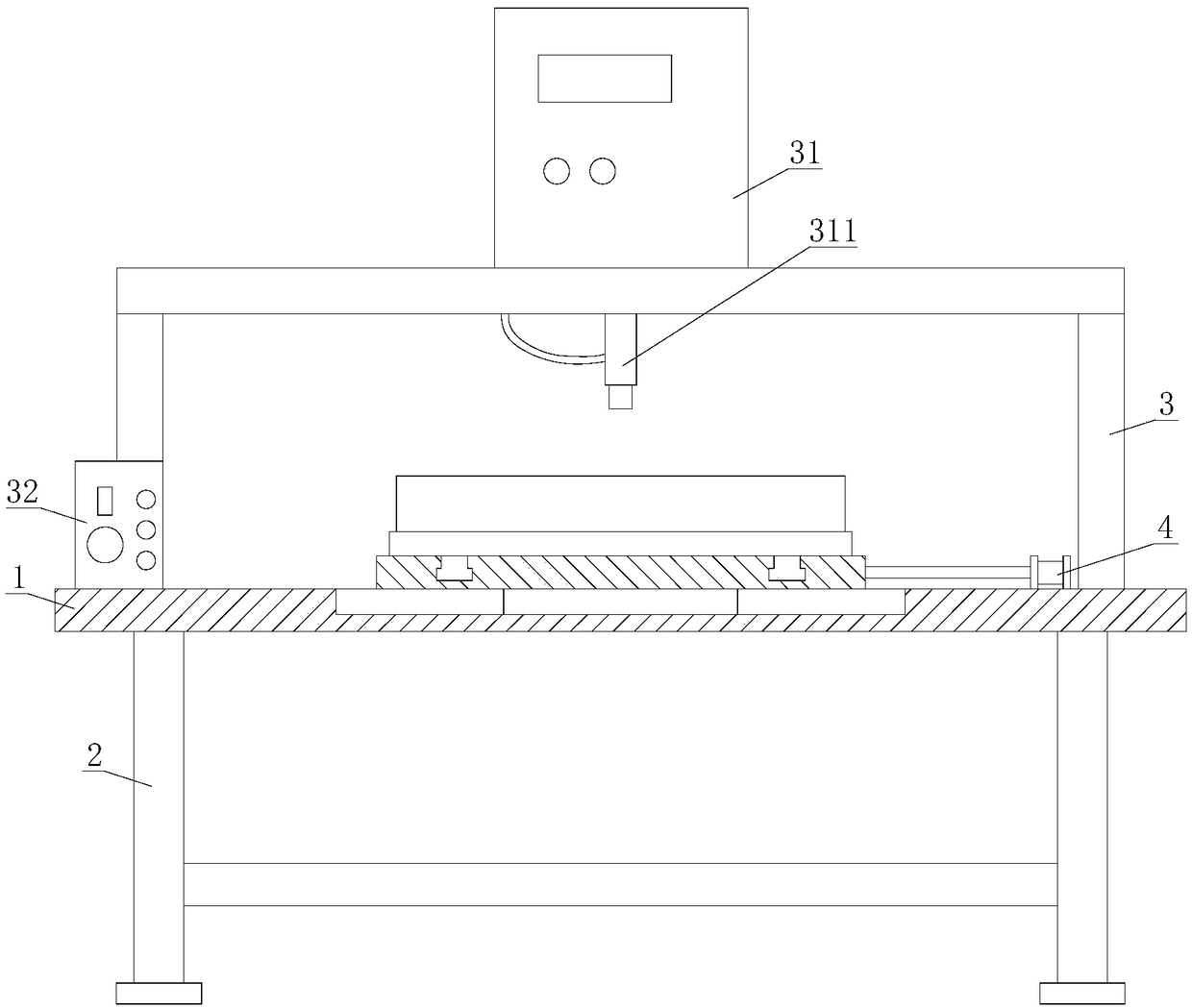

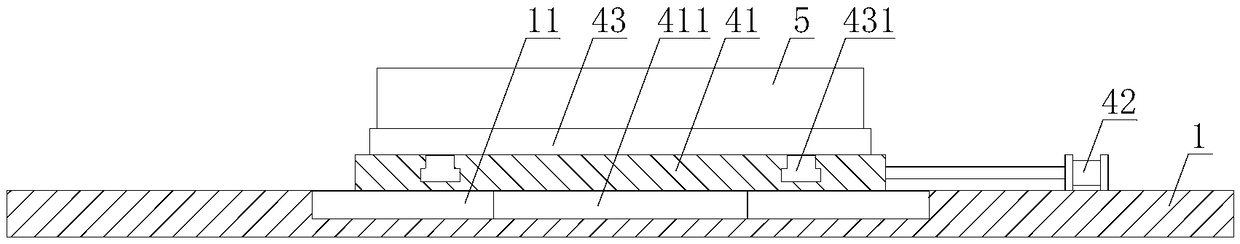

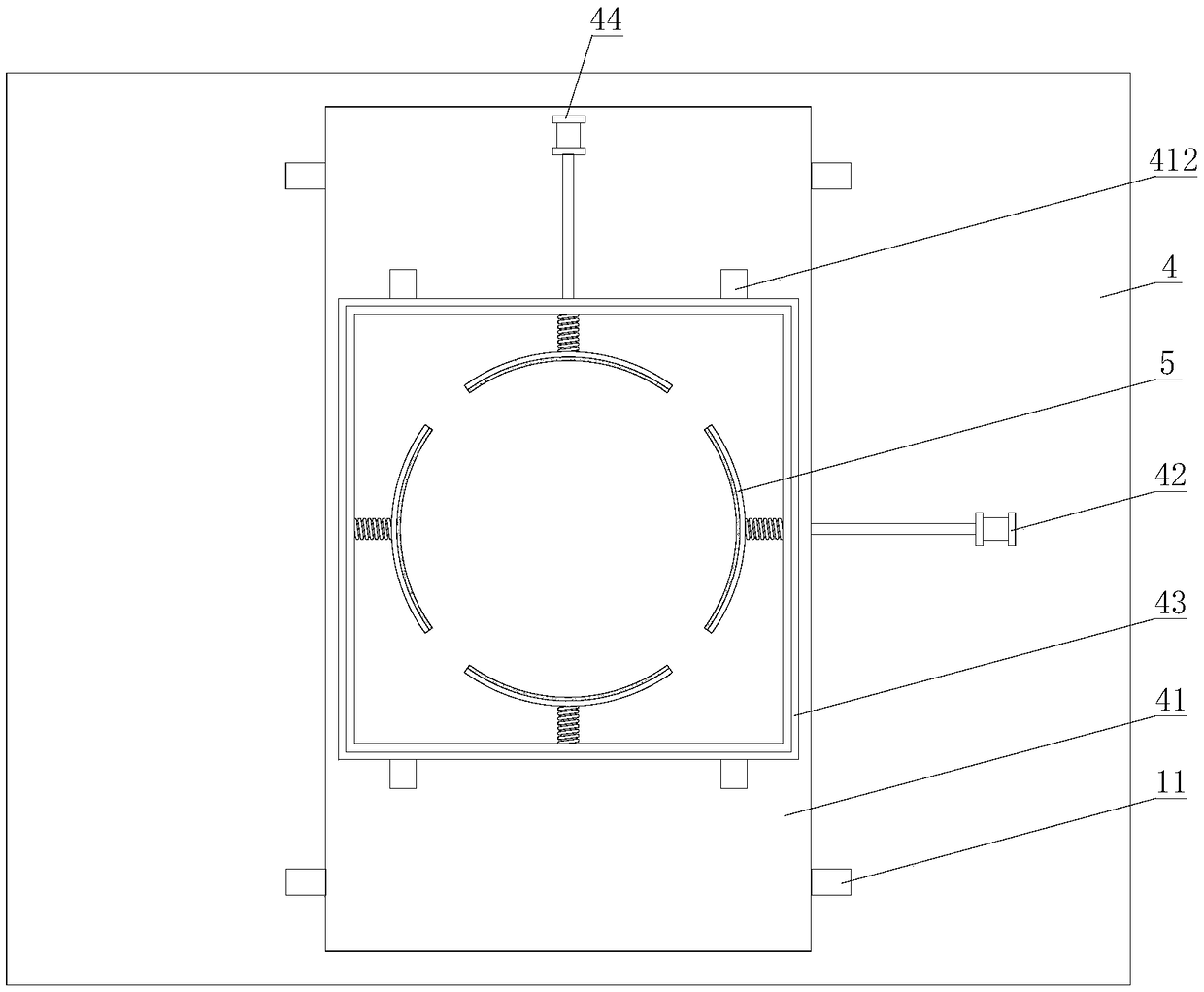

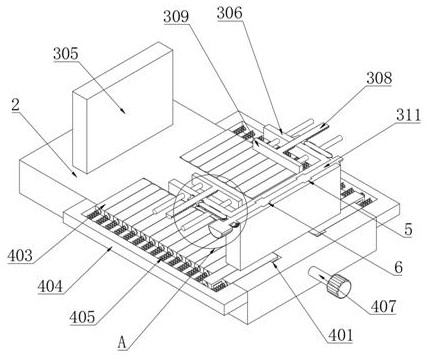

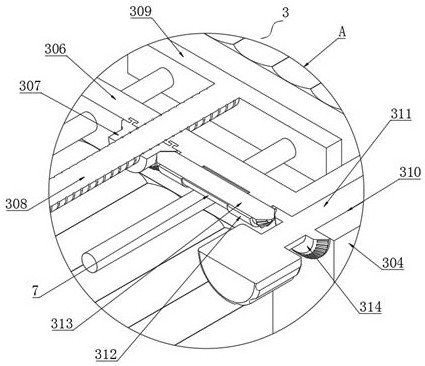

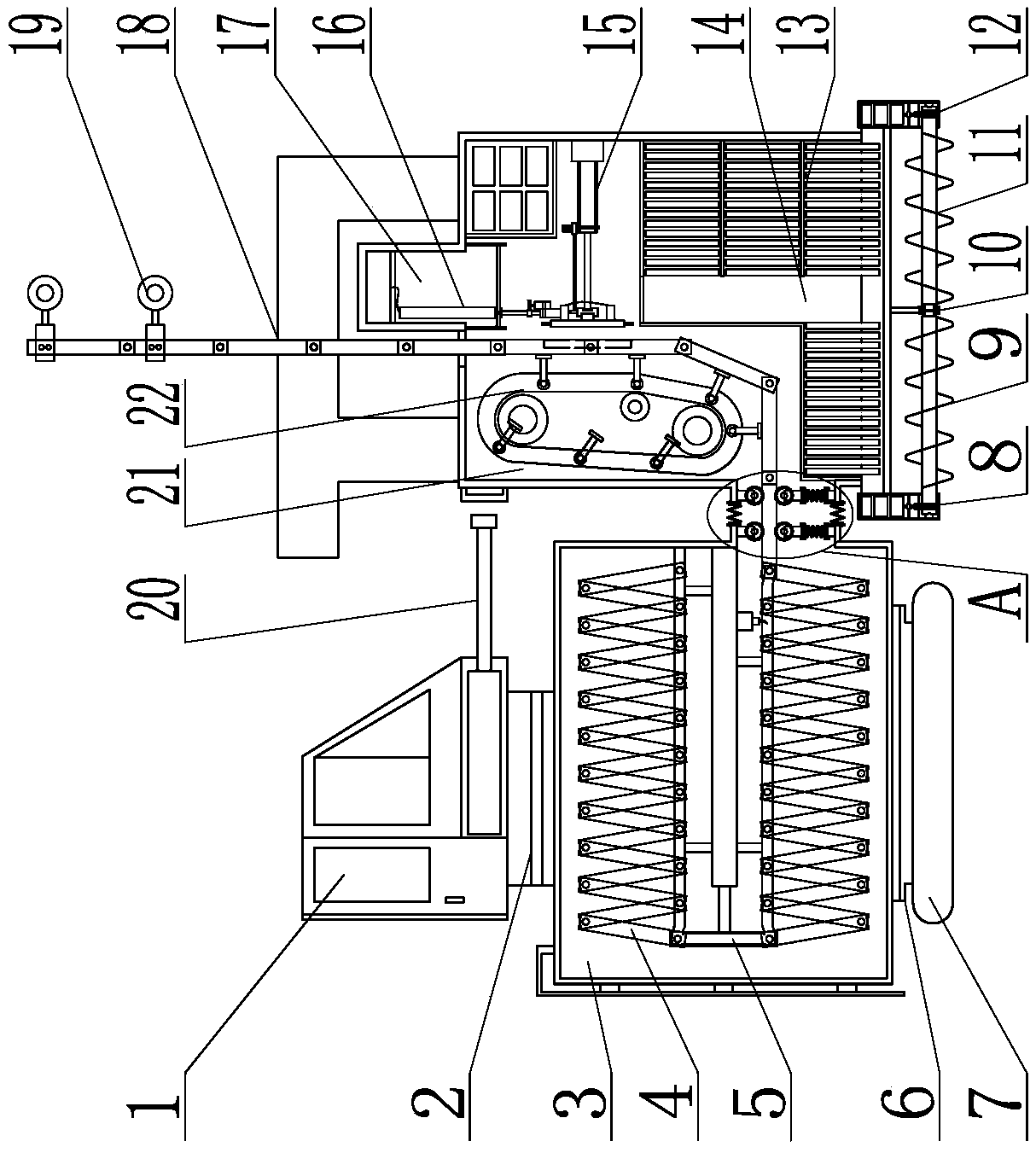

C-shaped steel structure automatic processing equipment

ActiveCN111673164ARealize automatic resetGuaranteed smoothShearing machinesShearing machine accessoriesEngineeringAutomatic processing

The invention relates to the technical field of steel structure processing, in particular to C-shaped steel structure automatic processing equipment. The equipment comprises a base and a supporting platform, and further comprises a controller, a fixing mechanism and a cutting mechanism; the controller is fixedly arranged at the top of the base; the fixing mechanism is arranged at the top of the base and is used for fixing C-shaped steel; the fixing mechanism comprises a bearing assembly, two supporting pillars and two pressing assemblies; the cutting mechanism is arranged on the base and is used for cutting the C-shaped steel; the cutting mechanism comprises a vertical plate, an upper cutting assembly and a lower cutting assembly; and the bearing assembly, the upper cutting assembly and the lower cutting assembly are electrically connected with the controller. The C-shaped steel structure automatic processing equipment and an operation method can conduct automatic adjustment based on offset deviation when position deviation of a cutting tool occurs, realize resetting of the cutting tool, and always maintain that the cutting tool meets the cutting requirements; at the same time, when the C-shaped steel is fixed, the speed is fast, the operation is convenient and processing efficiency can be effectively improved.

Owner:永盟绿建科技(南通)有限公司

Mechanical automatic cutting device with dust cage

InactiveCN108274259AImprove cutting efficiencyImprove collection efficiencyFeeding apparatusPositioning apparatusEngineeringGuide tube

The invention discloses a mechanical automatic cutting device with a dust cage. The mechanical automatic cutting device comprises a dust cage body and a clamping plate, and the dust cage body is fixedto a cutting table; the dust cage body is fixedly provided with a dust suction inlet connected to an air inlet of a fan through a tube, and an air outlet of the fan is provided with a cloth bag filter; the interior of the dust cage body is rotatably connected to a first screw rod which is in threaded connection with a first sliding block, and the first sliding block is provided with a cutting machine; the clamping plate is movably connected to the cutting table, and the bottom end of the clamping plate is fixed to a second sliding block which is in threaded connection with a second screw rod;and the second screw rod is rotatably connected to the lower surface of the cutting table. According to the mechanical automatic cutting device, the fixing speed of workpieces is increased through the second screw rod, and the cutting of the workpieces can be finished in the moving process of the cutting machine; the cutting efficiency of the cutting machine is improved, and the collection efficiency of chippings and spark is high; and the mechanical automatic cutting device is environmentally friendly, and the harm to workers is reduced.

Owner:乐清市宏牛电气科技有限公司

Multi-column-shaped inserting type multipurpose hanging piece

InactiveCN103088987AAccurate and quick installationFirmly connectedCovering/liningsPicture framesBrickKeel

The invention discloses a multi-column-shaped inserting type multipurpose hanging piece, and relates to plate-shaped materials (marble, granite, artificial stones, porcelain plates, vitrified tiles, ceramic plates and glass) of building wall bodies and installation hanging pieces of indoor handiwork hanging pieces (mirror frames and photo frames). The multi-column-shaped inserting type multipurpose hanging piece is structurally composed of wall body hanging pieces and brick body hanging pieces. The brick body hanging pieces are installed on four corner portions of the inner side of a to-be-hanged brick body. The wall body hanging pieces are fixedly arranged on a wall body or a joist. The positions of the wall body hanging pieces correspond to the positions of the brick body hanging pieces on the to-be-hanged brick body. The brick body hanging pieces are inserted into the wall body hanging pieces, and the brick body is hanged on a wall. The multi-column-shaped inserting type multipurpose hanging piece has the advantages of being novel in structure, simple and convenient to process, low in cost, convenient to install, good in stability, easy to adjust, not prone to dropping and the like, thereby being a novel multi-column-shaped inserting type multipurpose hanging piece which integrates economy and practicability.

Owner:王建海

Template machining cutting machine capable of conveniently fixing template

InactiveCN108080849AEasy to fixSimple structureWelding/cutting auxillary devicesAuxillary welding devicesPulp and paper industryMachining

The invention provides a cutting machine capable of conveniently fixing a template, and relates to the field of cutting machines. The template machining cutting machine capable of conveniently fixingthe template comprises a cutting table and a supporting plate, supporting columns are fixedly connected to the two sides of the cutting table, and the two sides of the bottom of a supporting plate arefixedly connected with the tops of the two supporting columns correspondingly; a cutting machine is fixedly arranged at the bottom of the supporting plate, two sliding grooves are symmetrically formed in the top of the cutting table, and a placing plate is arranged above the cutting table and located below the cutting machine; and supporting blocks are fixedly connected to the positions, correspond to the positions of the two sliding grooves correspondingly, of the bottom of the placing plate, the bottoms of the supporting blocks penetrate through the cutting table to be fixedly connected with sliding blocks arranged inside the sliding grooves, and two balls are arranged on each sliding block. The template machining cutting machine capable of conveniently fixing the template is simple instructure and convenient to use, when a to-be-machined plate is fixed, the operation is very convenient, the fixing speed is high, time and labor are saved, and the fixing effect is good.

Owner:镇江亚昆机械有限公司

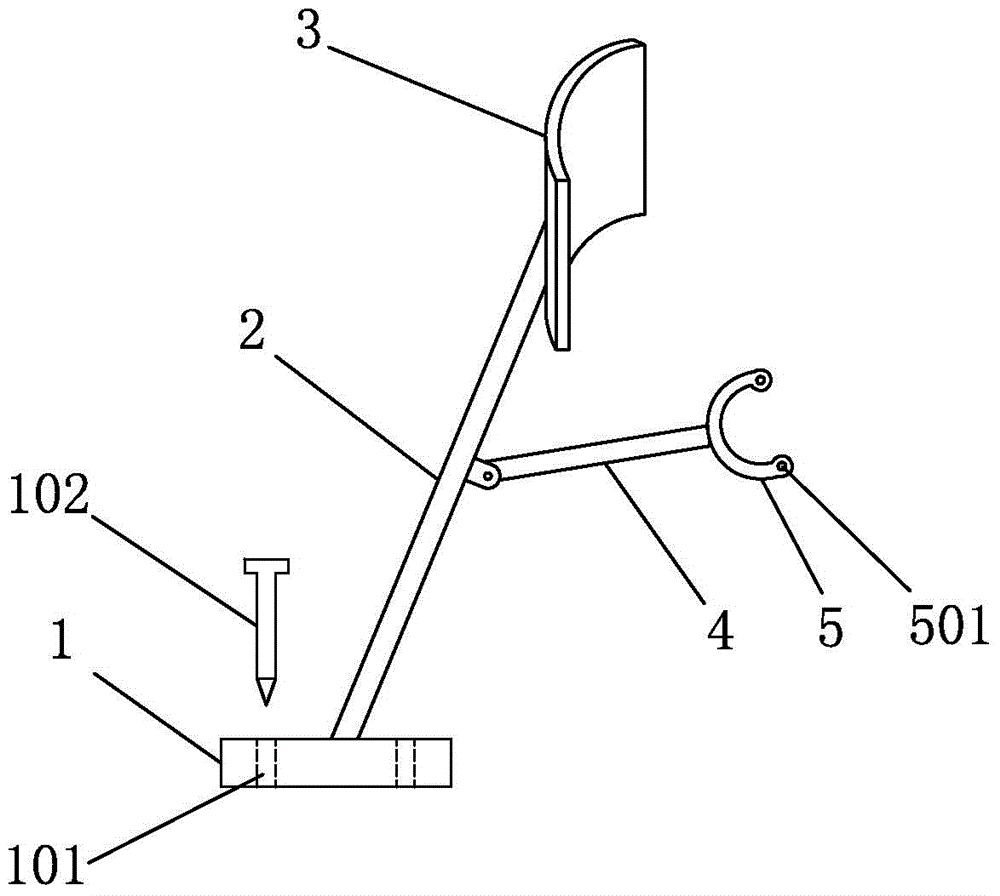

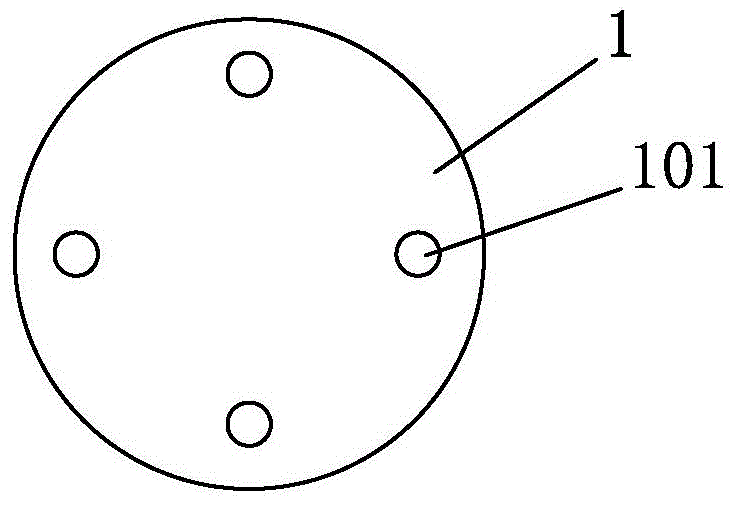

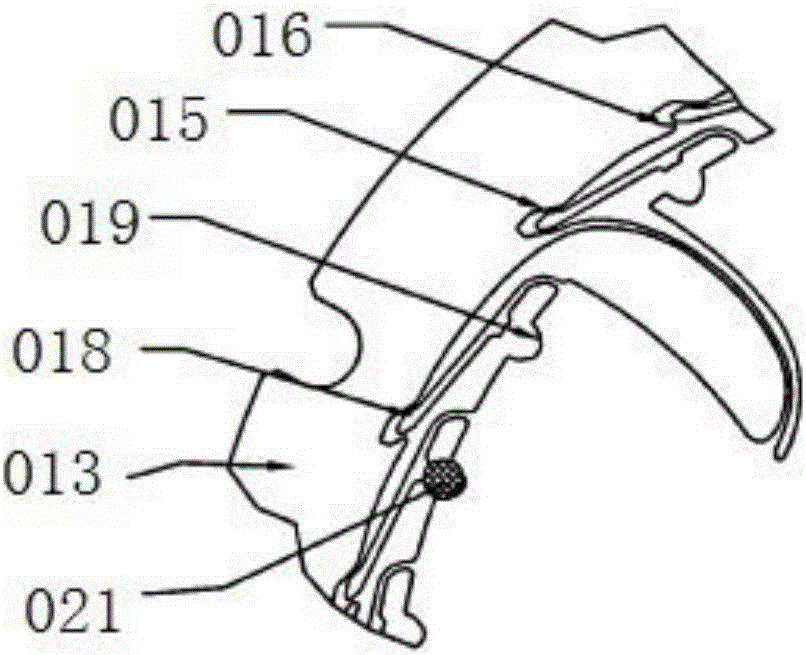

Nursery stock fixing device

The invention discloses a nursery stock fixing device, comprising a baseplate; the baseplate is fixedly connected to one end of a connecting rod; the other end of the connecting rod is connected with an elastic sheet capable of being adhered to a tree trunk; the rod body of the connecting rod is hinged with one end of a support rod; the other end of the support rod is connected with an arc-shaped rod; through-holes are respectively formed at two ends of the arc-shaped rod; fixing holes are formed on the baseplate; the nursery stock fixing device further comprises steel nails capable of penetrating the fixing holes to enable the baseplate to be fixedly connected with the ground. The nursery stock fixing device is simpler and faster to install, is capable of simplifying the nursery stock fixing process and is reduced in cost.

Owner:长兴泗安科林植保专业合作社

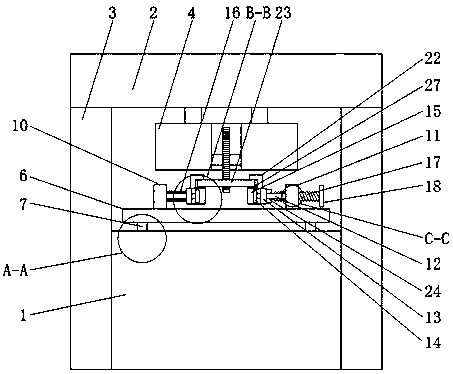

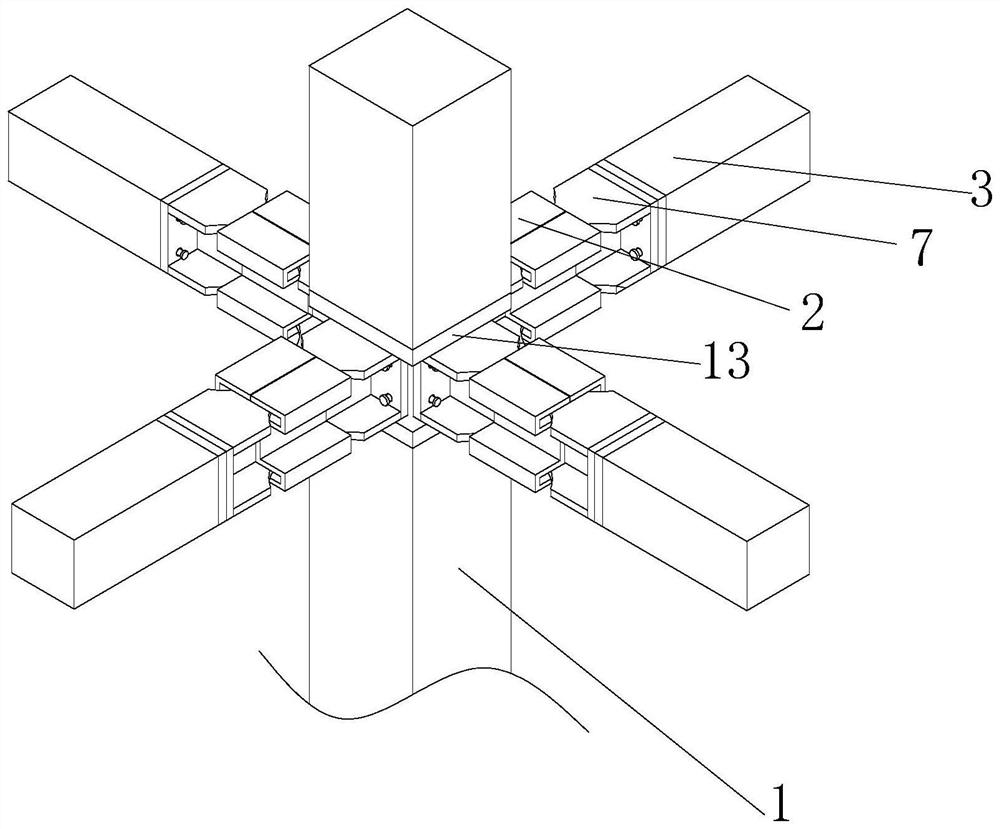

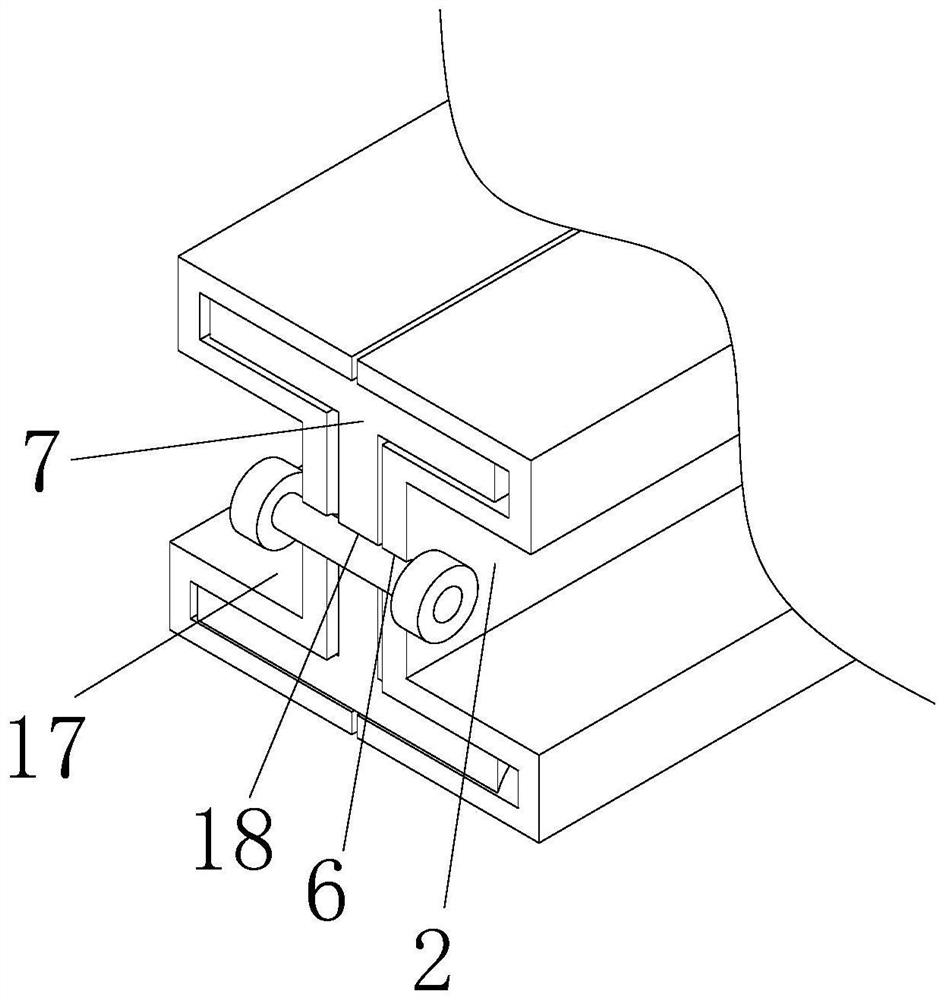

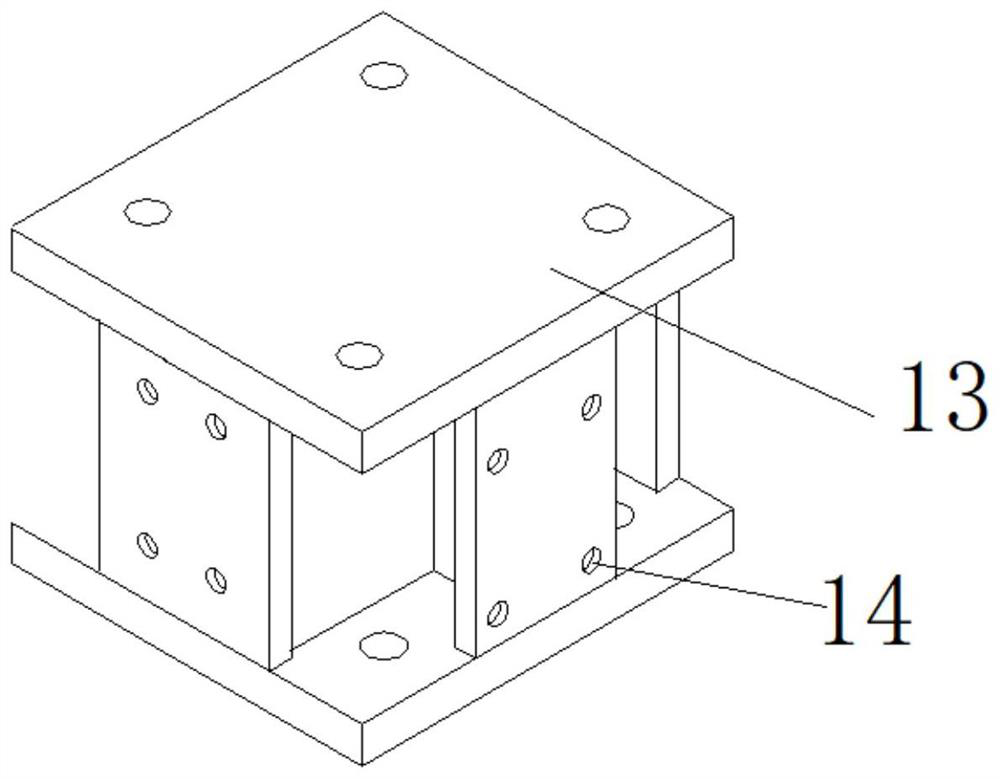

Concrete-filled steel tube beam column connecting joint capable of being replaced after earthquake

ActiveCN113323488AEasy to replaceExtended service lifeProtective buildings/sheltersShock proofingConcrete beamsClassical mechanics

The invention relates to a concrete-filled steel tube beam column connecting joint capable of being replaced after an earthquake. The concrete-filled steel tube beam column connecting joint comprises a prefabricated joint frame with threaded holes formed in the upper side, the lower side and the peripheral end face, the upper side and the lower side of the prefabricated joint frame are connected with an upper steel tube concrete column and a lower steel tube concrete column through bolts, the periphery of the prefabricated joint frame is connected with steel beams through bolts, the vertical section of the steel beams is I-shaped, arc-shaped stress grooves are formed in the front side and the rear side of a steel beam flange plate, the end, away from the prefabricated joint frame, of the steel beam is connected with a steel tube concrete beam through bolts, the surface of the steel beam is slidably connected with a first arch-shaped connecting piece and a second arch-shaped connecting piece which are spliced with each other, the first arch-shaped connecting piece, the second arch-shaped connecting piece and the steel beam are fixedly connected through fasteners, the dog-bone type steel beam can be prevented from buckling through the arch-shaped connecting pieces, the strength of the steel beam is enhanced to a certain degree, the energy dissipation capacity is enhanced, the ductility is improved, meanwhile, the steel beam is protected to a certain degree, and the service life of the steel beam is prolonged to a certain degree.

Owner:CHONGQING UNIV

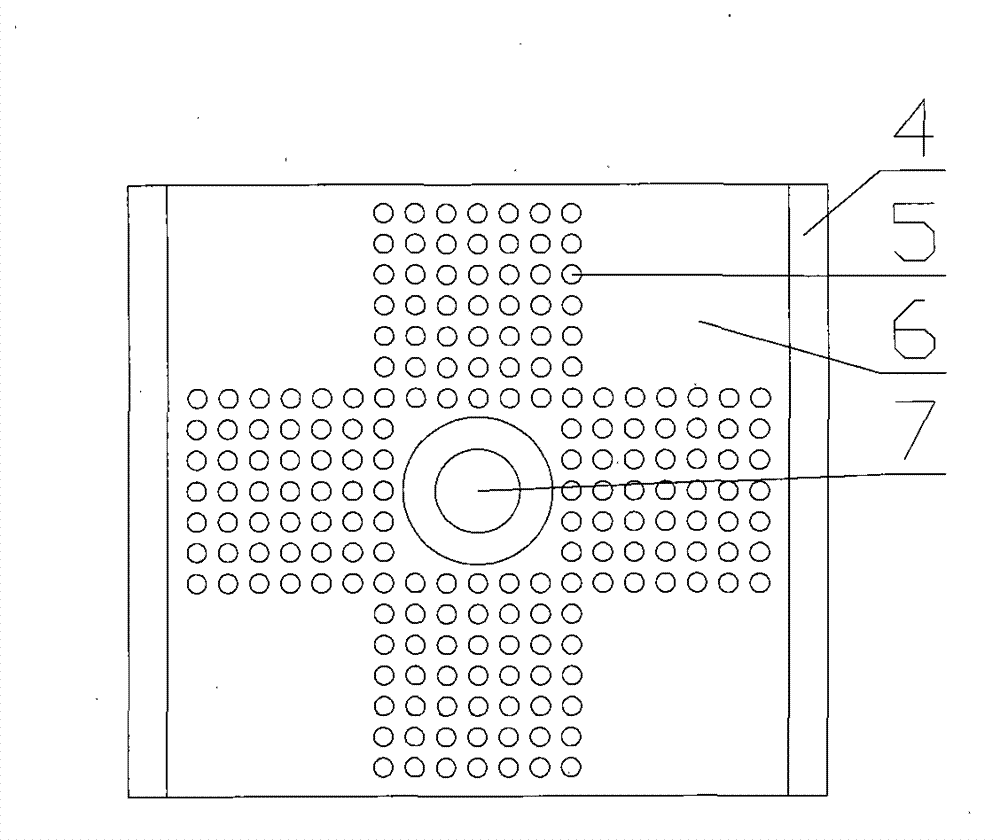

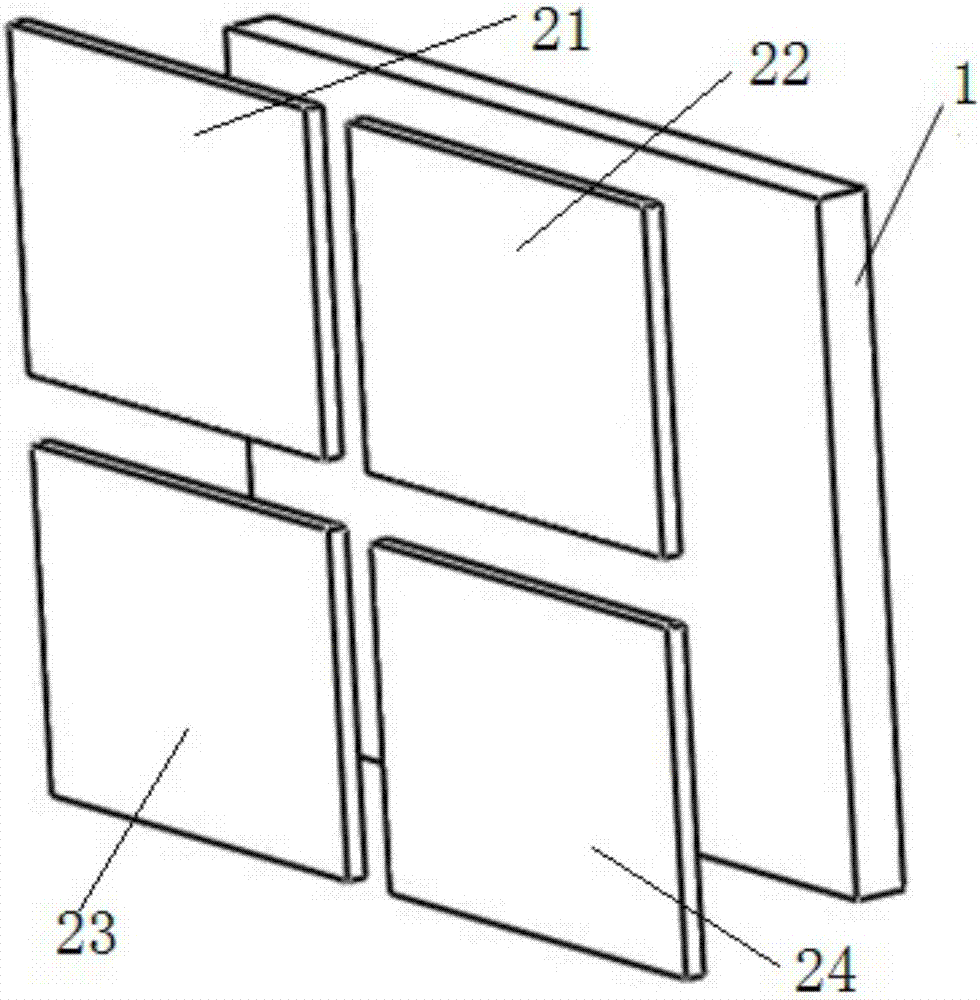

Ion source sputtering target material device with high utilization rate and using method thereof

InactiveCN106884147AIncrease profitEasy to splice at willVacuum evaporation coatingSputtering coatingSputteringMaterials science

The invention relates to the technical field of ion source sputtering, more particular to an ion source sputtering target material device with high utilization rate and a using method thereof. The device comprises a back plate, and a first target material, a second target material, a third target material and a fourth target material which are detachably arranged on the back plate; the four target materials are all of rectangular structures, and the four target materials are spliced together in a grid-shaped structure. According to the ion source sputtering target material device with the high utilization rate, the four target materials are arranged, and the four target materials are detachably spliced on the back plate in a grid-shaped structure, so that the relative positions when the four target materials are spliced can be re-adjusted after first sputtering of an ion source, and sputtering is performed again by using the ion source; the operations of target material position adjustment and ion source sputtering are repeated until the four corners of each target material are used; the device can greatly improve the utilization rate of the target materials, reduce the production cost, ensure the stability of target material deposition rate and prevent a manufactured thin film from being polluted.

Owner:ZHONGSHAN IBD TECH CO LTD

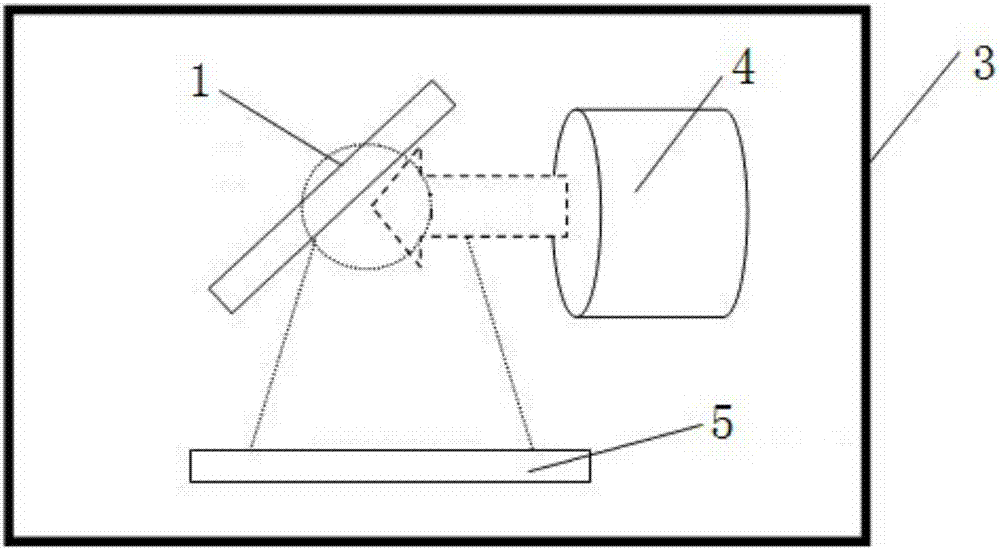

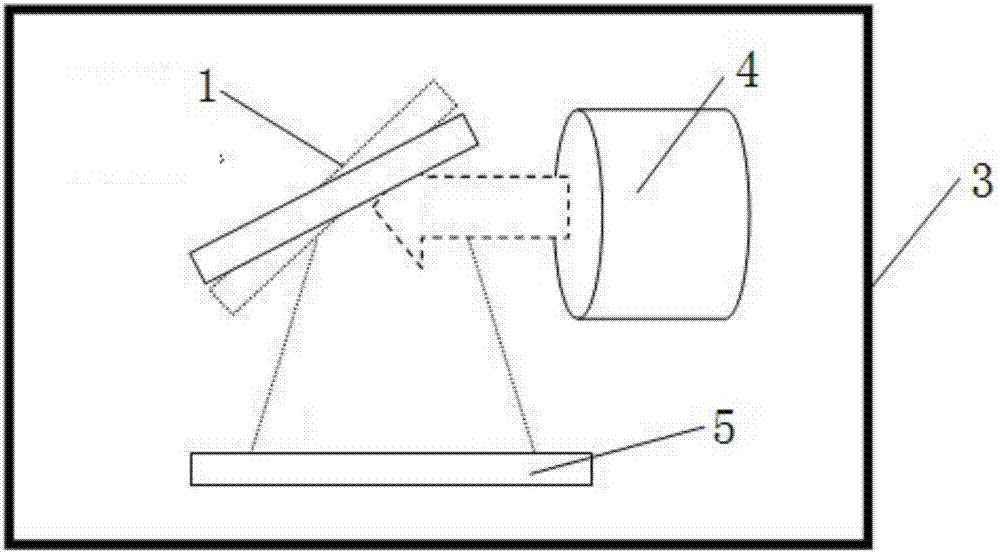

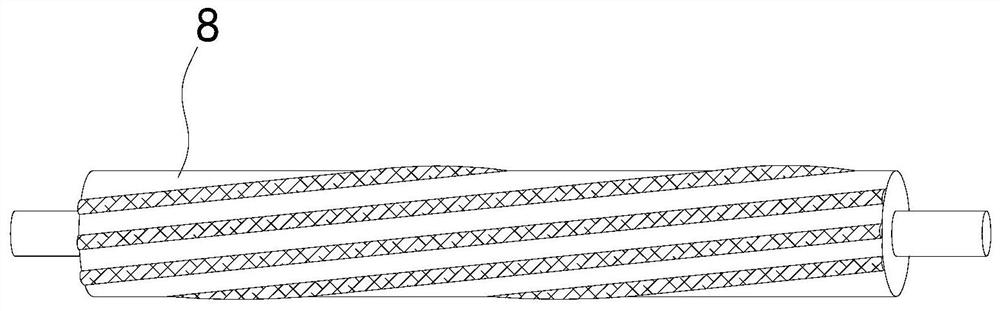

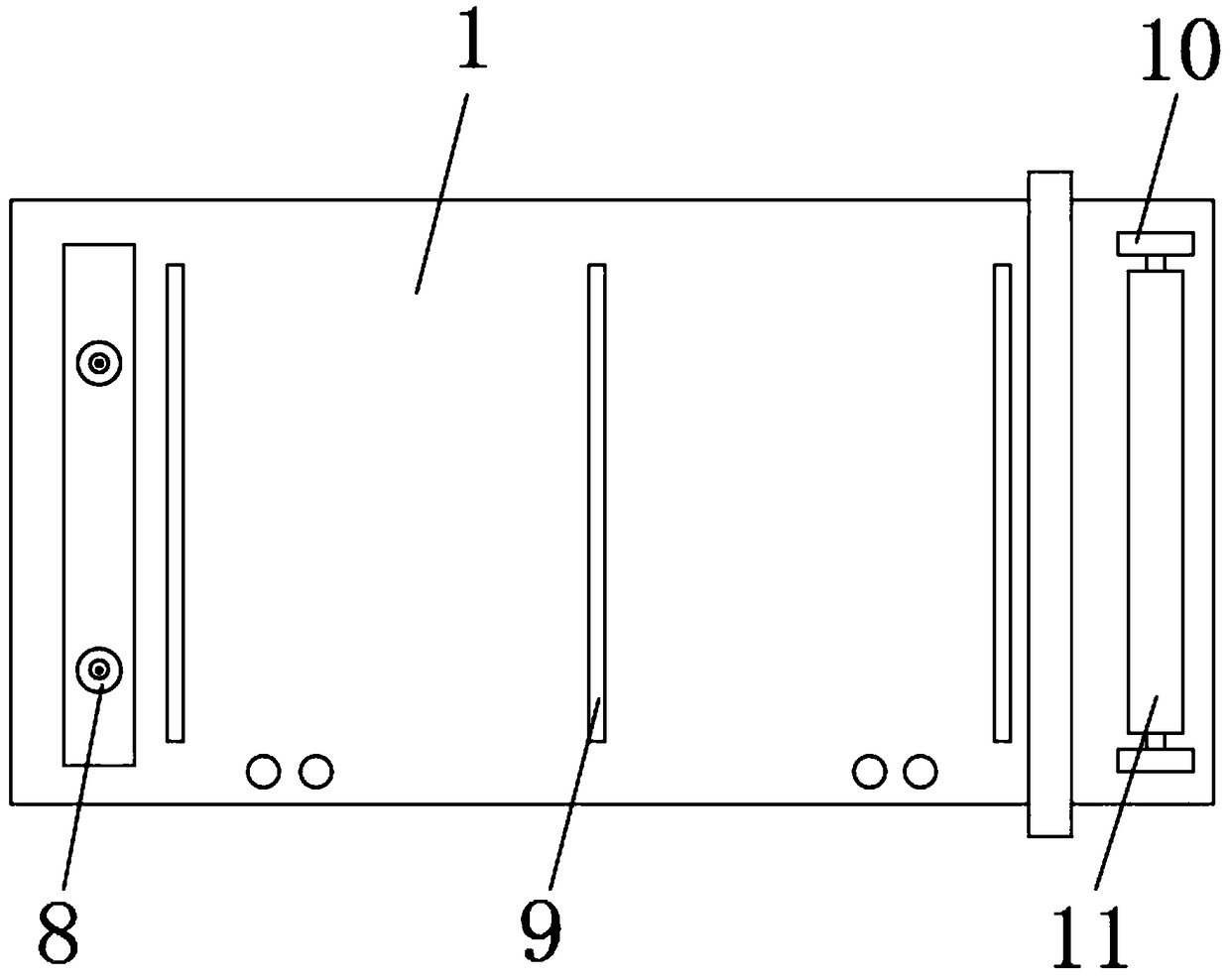

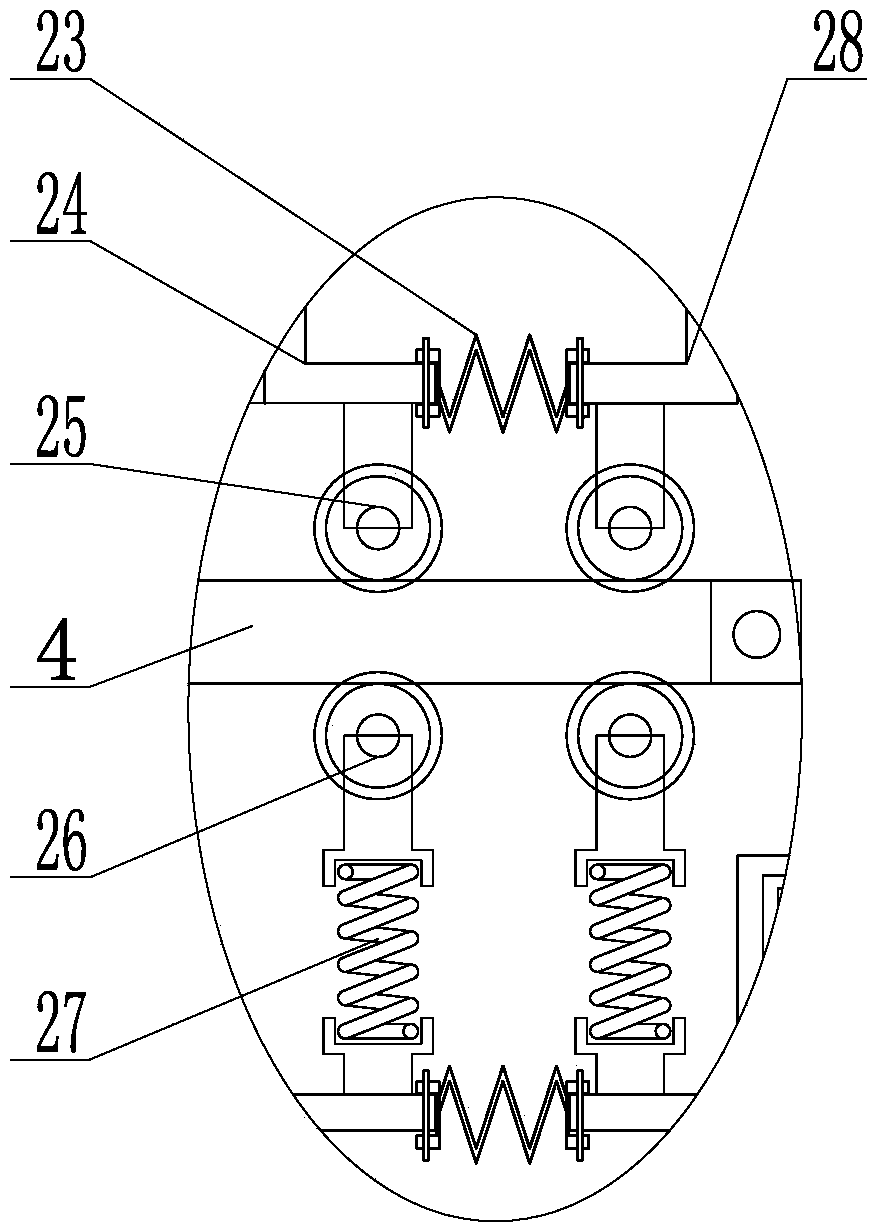

Flexible clamp for performance testing of solar cell

ActiveCN110718500AAvoid breakingAvoid crackingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSolar cellIdler-wheel

The invention provides a flexible clamp for performance testing of a solar cell. The flexible clamp comprises a rectangular plate A, an L-shaped frame and a reset spring. The rectangular hole A is formed in the center of the top end face of the rectangular plate A, and a rectangular hole B is formed in the position, located on the rear side of the rectangular hole A, of the top end face of the rectangular plate A; an elastic stop block structure is composed of an oval baffle, an oval idler wheel, the L-shaped frame and the reset spring. The oval baffle is rotationally connected to the center of the front end face of a pressing plate. The clamp is higher in flexibility and adjustability; due to the matched arrangement of the threaded transmission rod and the stop blocks A, on one hand, thethreaded directions of the threaded rod A and the threaded rod B are opposite, so that when the threaded transmission rod is rotated, the two stop blocks A can move in opposite directions along the rectangular hole A at the same time, and the adjustment time of the stop blocks A is saved; on the other hand, the stop block A is of a convergent structure, so that the smoothness can be improved whenthe solar panel is pushed into the device.

Owner:JIAXING UNIV

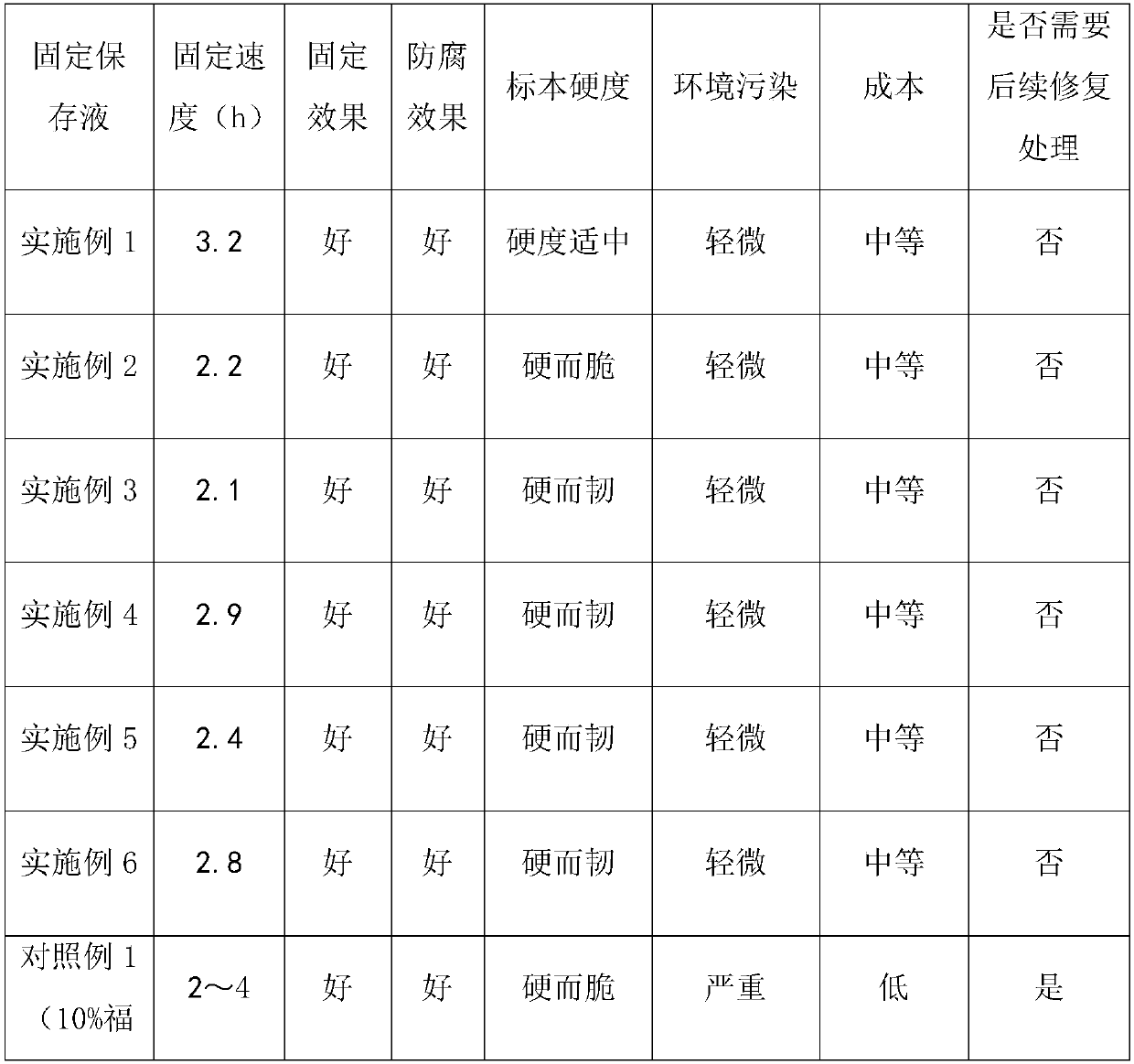

Formaldehyde-free tissue fixing preservative liquid and preparation method thereof

ActiveCN109805001AAvoid health threatsImprove work efficiencyDead animal preservationAntioxidantPreservative

The invention discloses formaldehyde-free tissue fixing preservative liquid and a preparation method thereof, and belongs to the technical field of tissue fixing liquid. The fixing preservative liquidis prepared from the following components in parts by weight: 41-83 parts of a protein fixing agent, 0.04-0.12 part of a preservative, 0.9-3.6 parts of an osmotic pressure adjusting agent, 9-39 partsof a humectant, 0.1-0.5 part of an antioxidant and 8-30 parts of water, wherein the protein fixing agent is composed of 2-methyl-1,2-benzisothiazolin-3-one, dimethyl sulfoxide and ethanol; and the preservative is composed of 5-chloro-2-methyl-4-isothiazoline-3-ketone and 2-methyl-4-isothiazoline-3-ketone. The fixing preservative liquid has the advantages of good fixation performance, strong preservative ability, no formaldehyde, and safty and no toxicity, and is suitable for tissue or specimen preservation, specimen fixation before pathological analysis and fixed storage of samples collectedby surgery.

Owner:HARBIN GREEN SPECIMEN TECH DEV

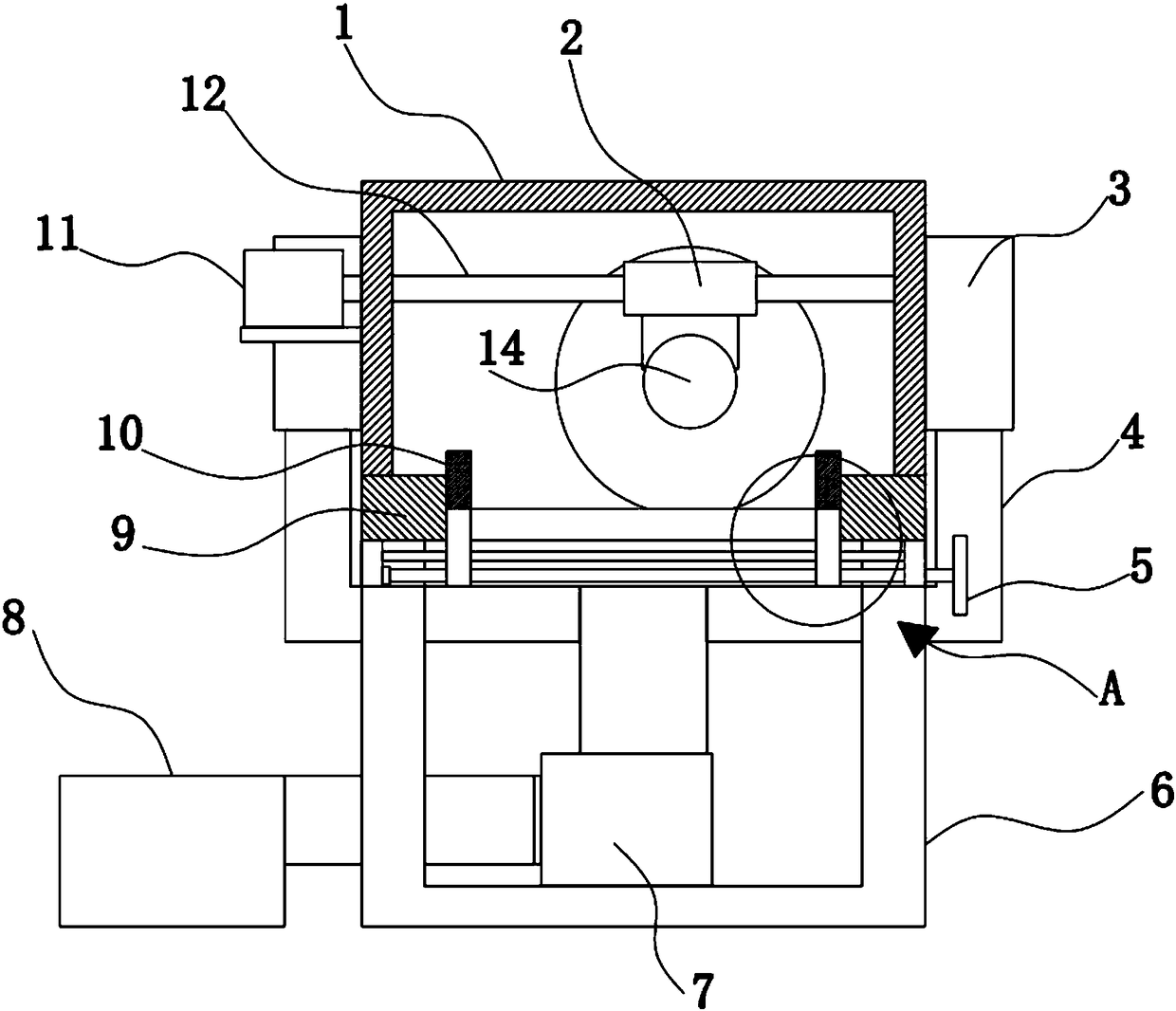

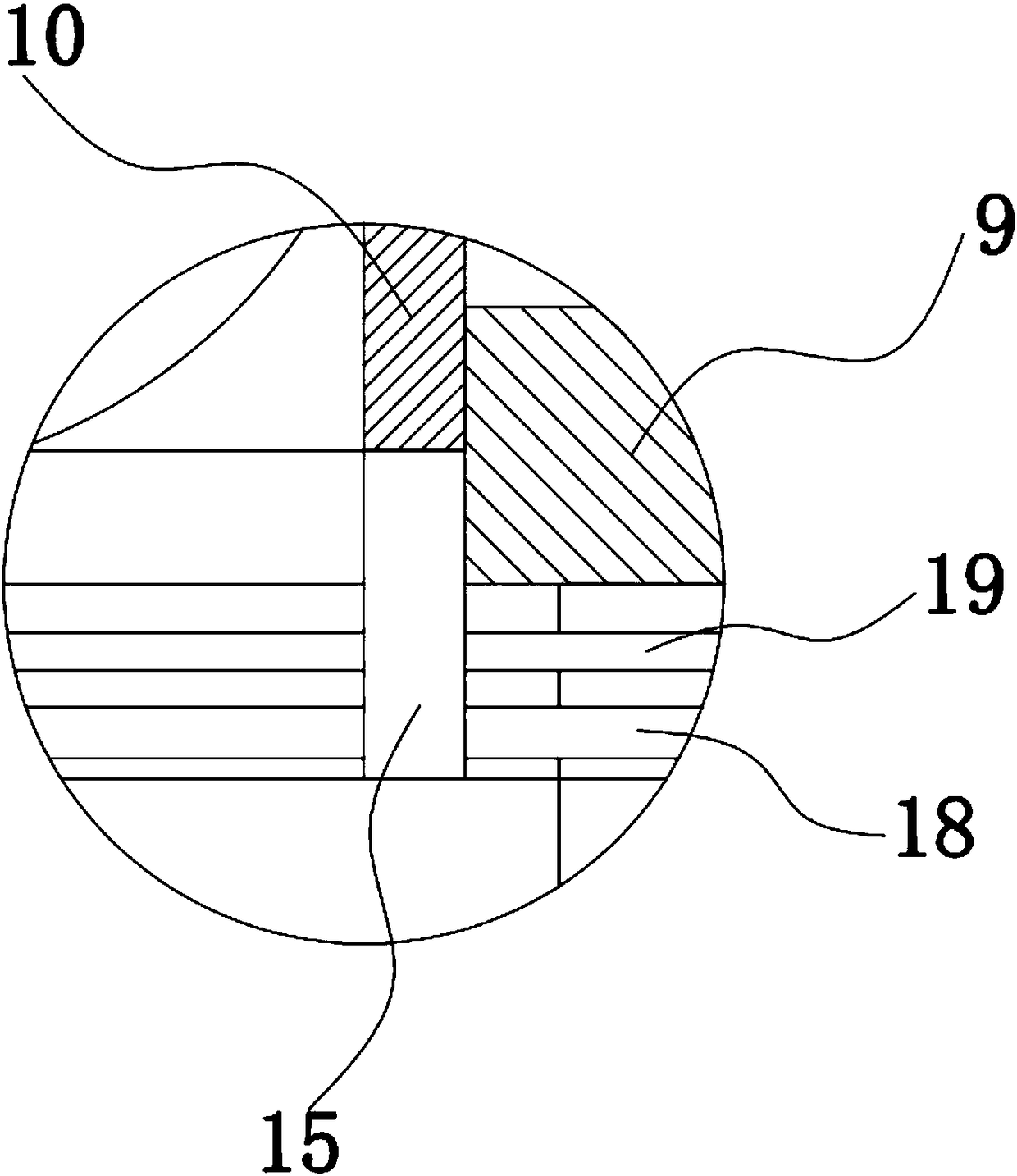

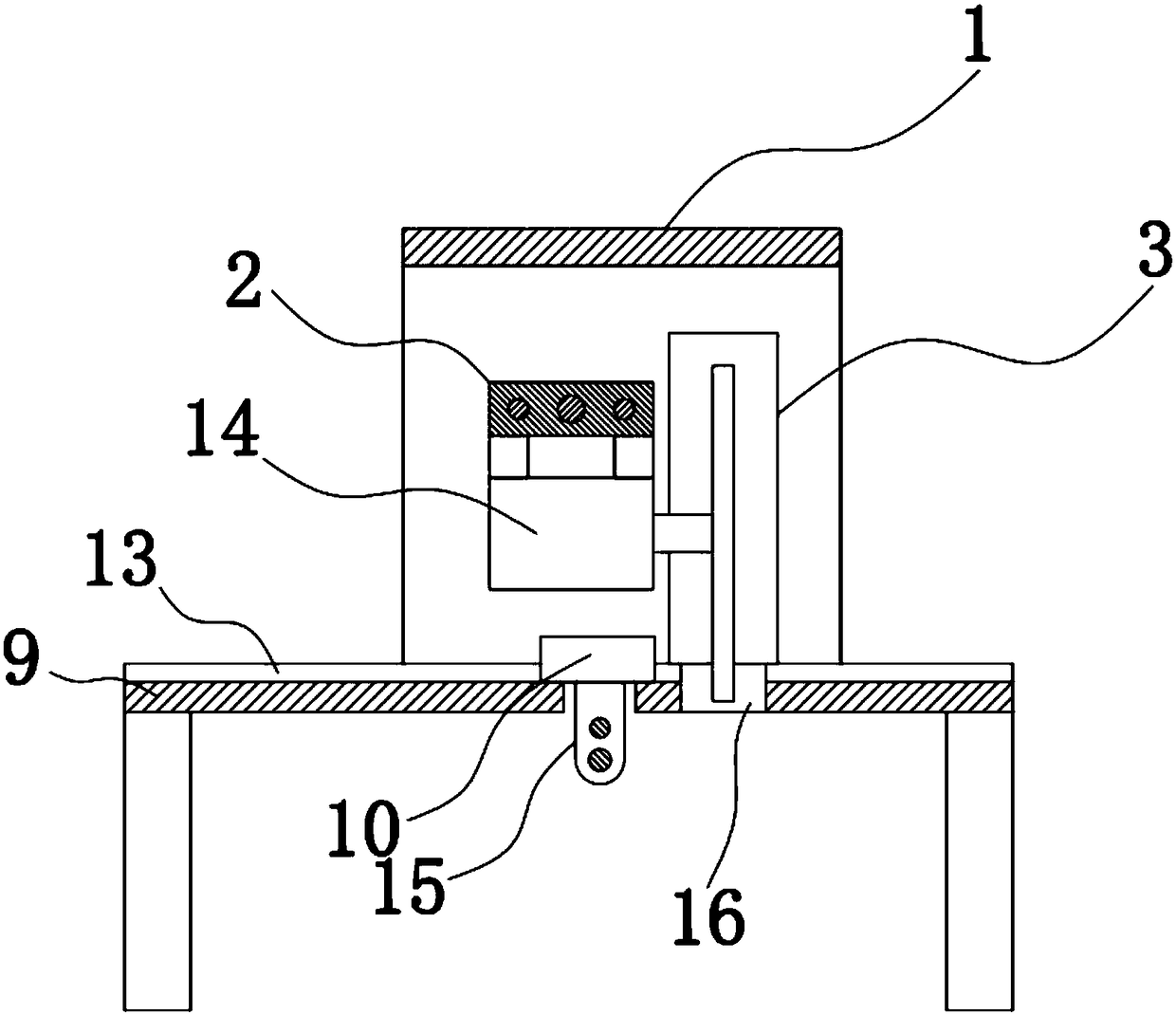

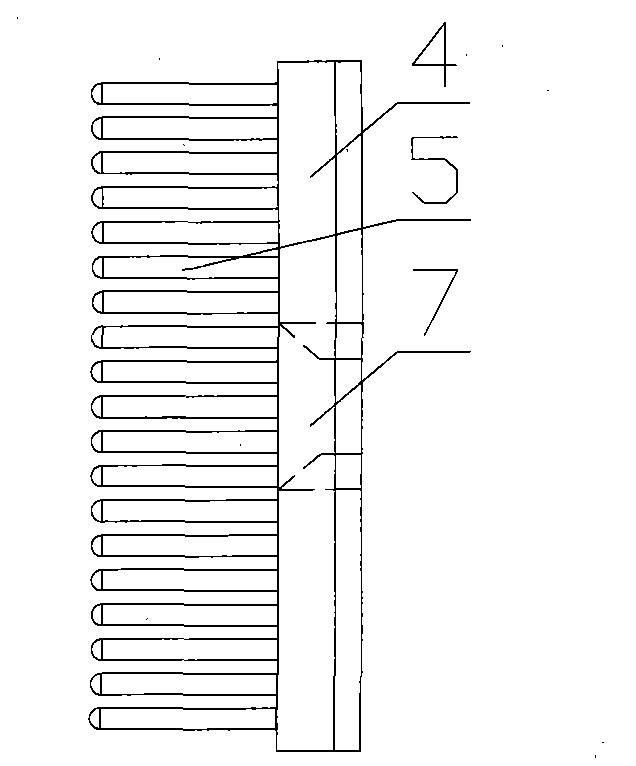

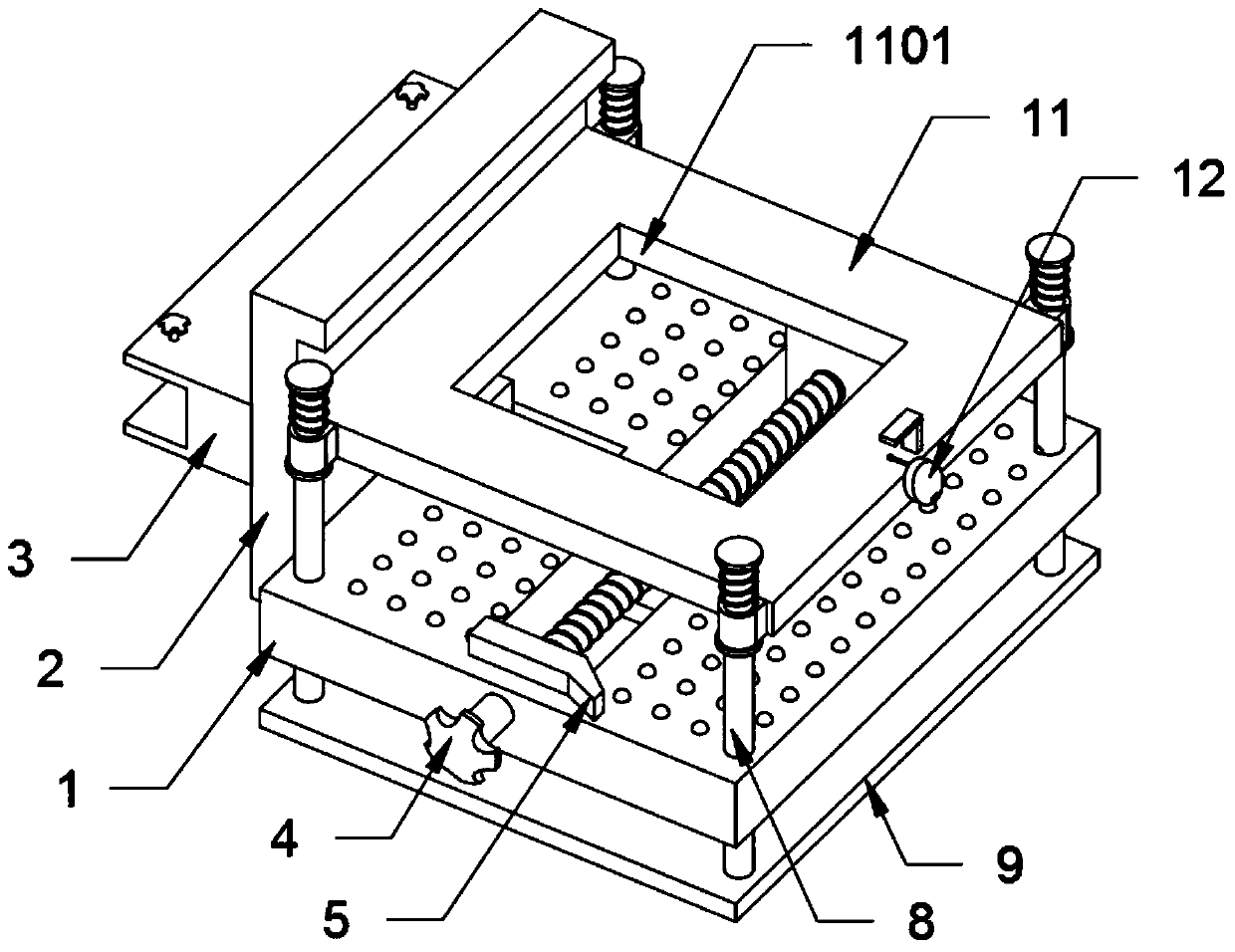

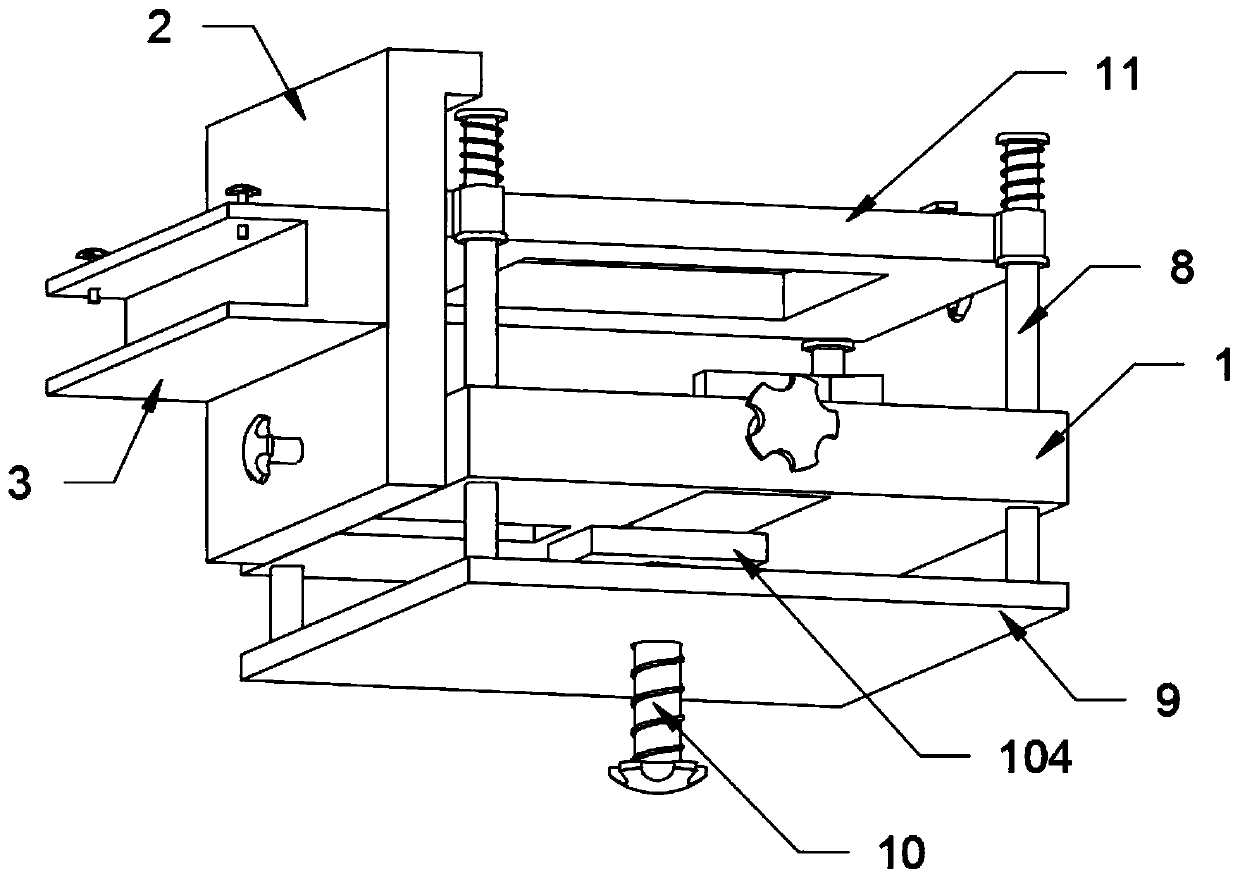

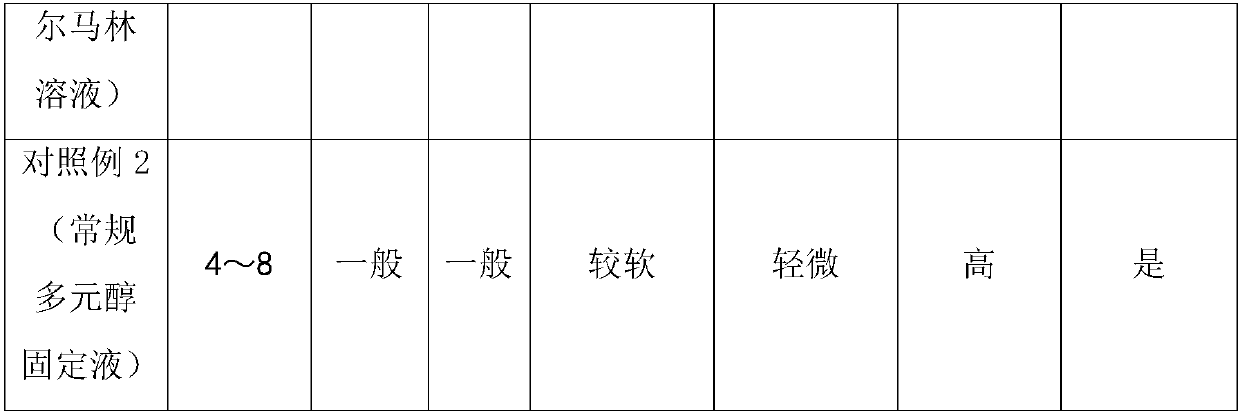

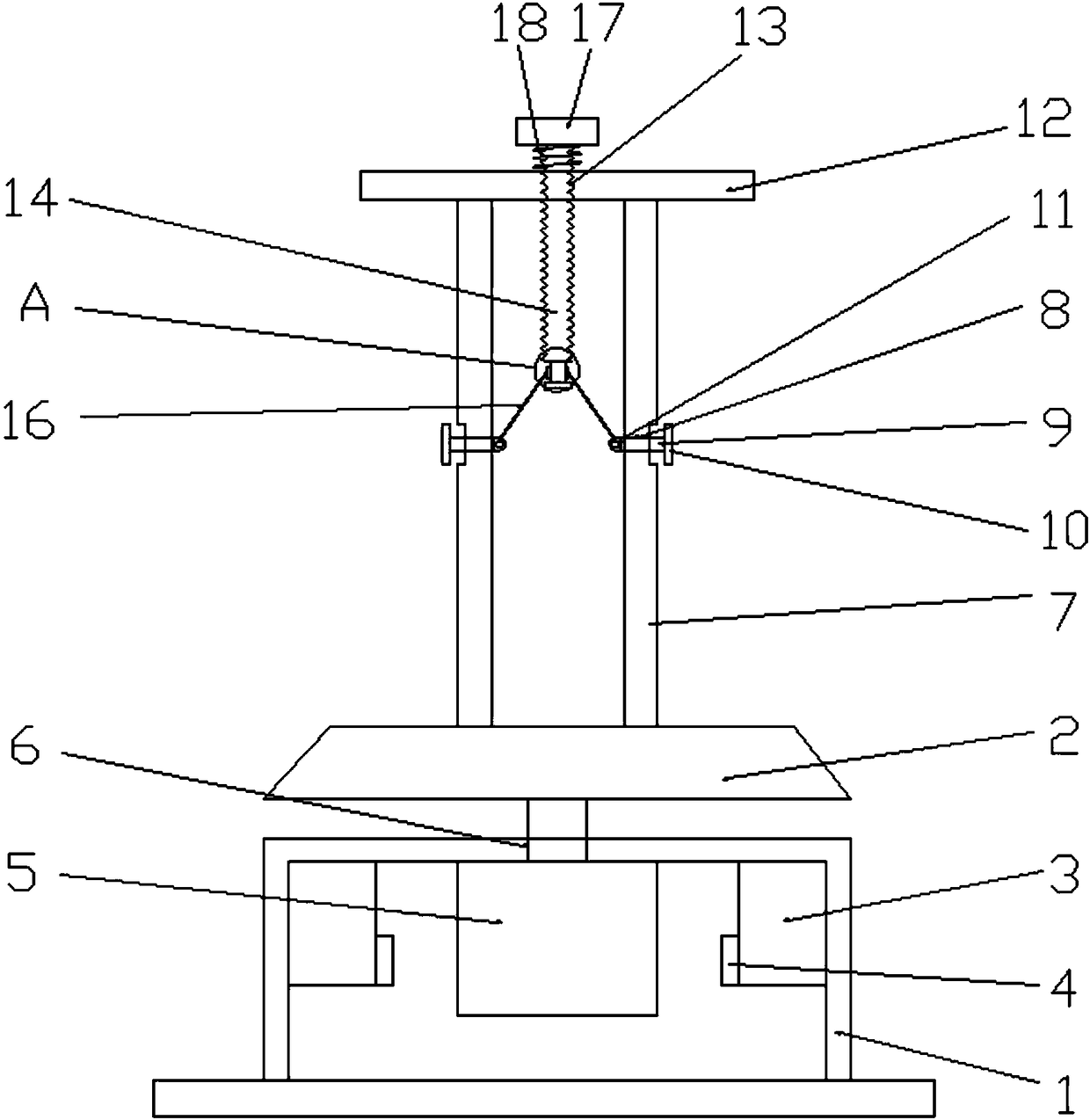

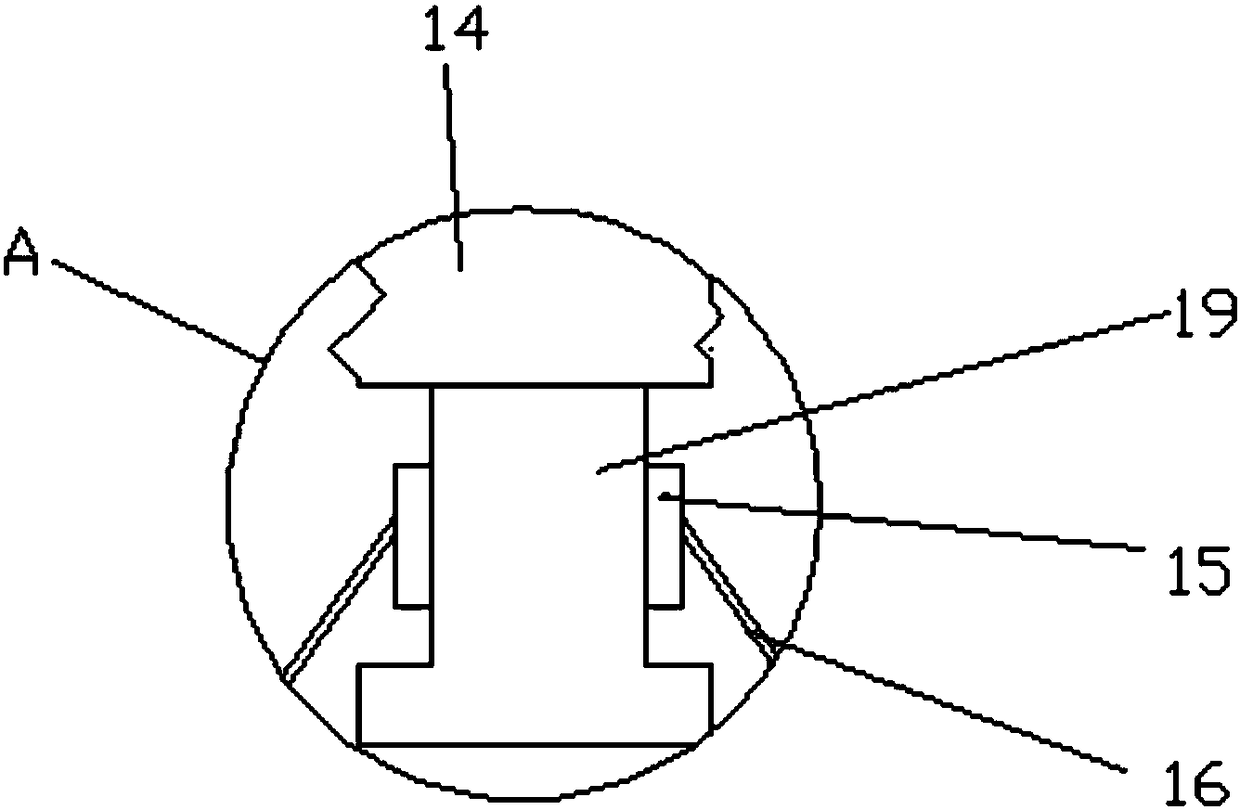

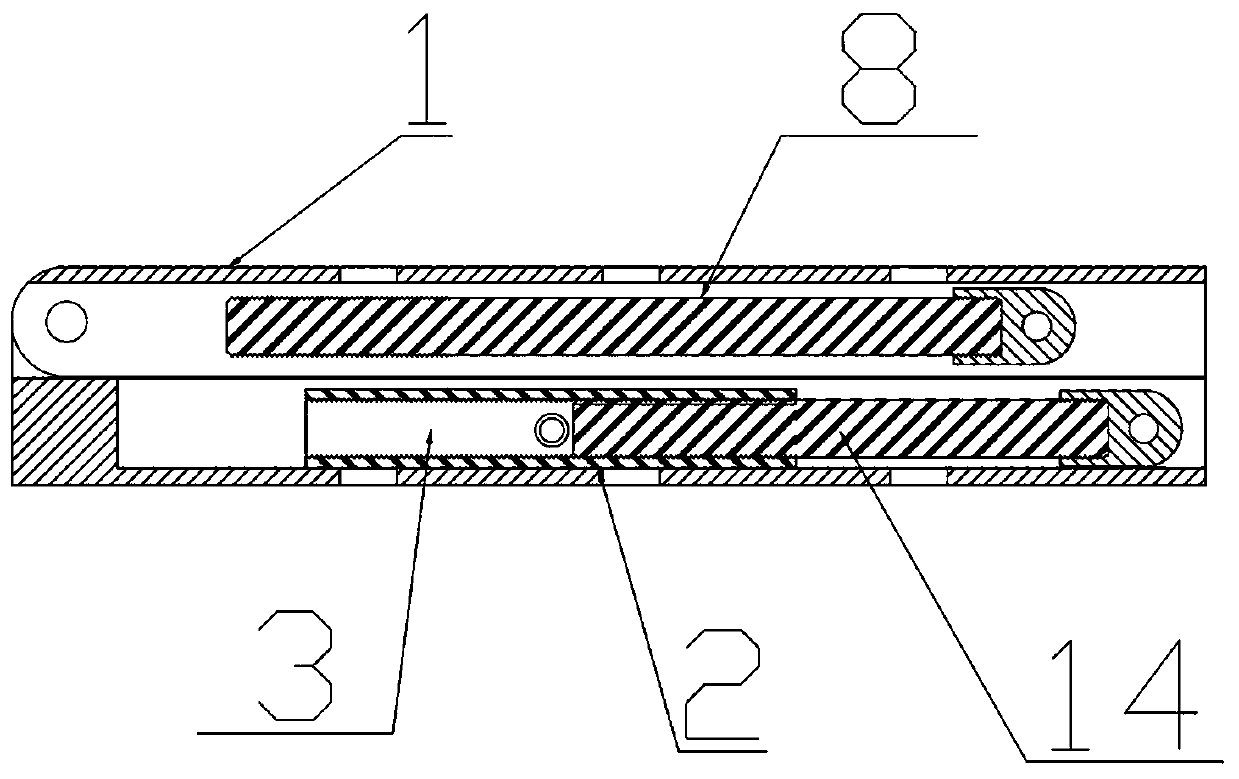

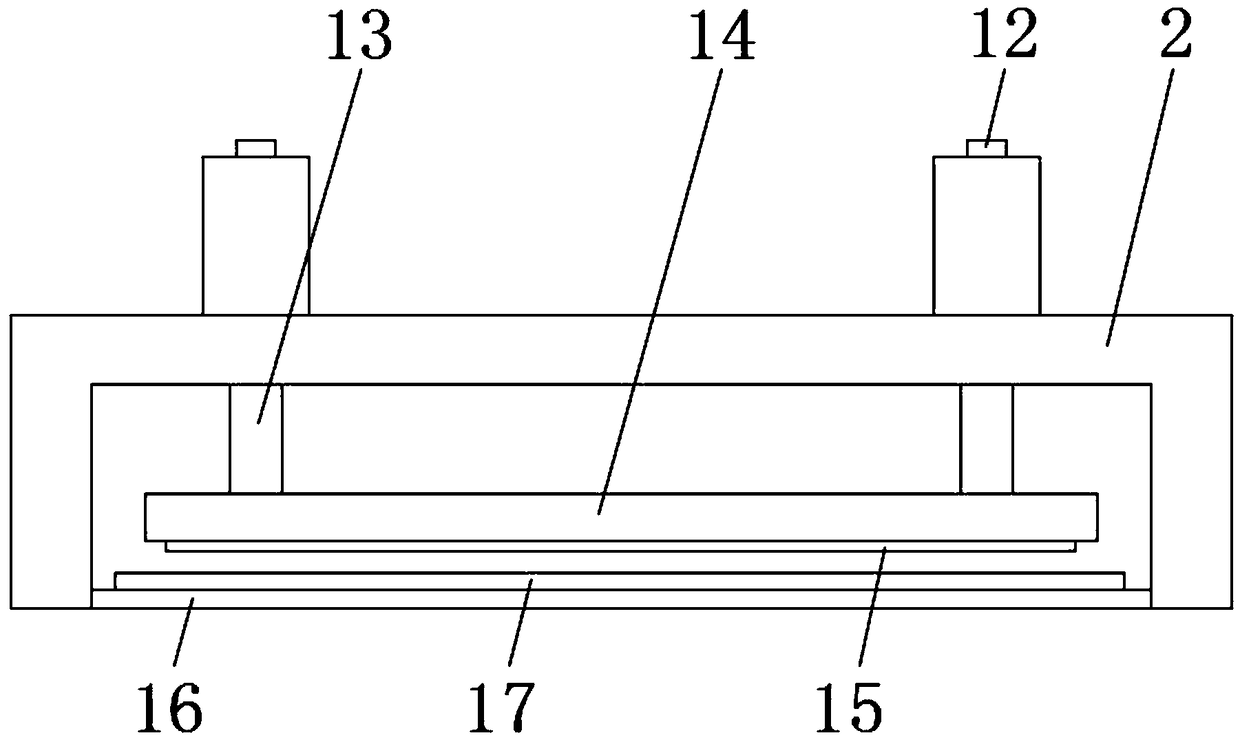

Grinding clamp and jig thereof

ActiveCN105108638AFixed fastThere will be no problems with small displacementsLapping machinesWork carriersEngineeringIliac screw

The invention provides a grinding clamp and a jig thereof. When an insertion core needs to be located and fixed, only the free end of the jig needs to be pulled towards the side away from a clamp body to enable a first extrusion face to be separated from a second extrusion face by a certain distance; then the insertion core is put between the first extrusion face and the second extrusion face, an elastic locating arm is loosened and restores to the original position under the action of elasticity of the elastic locating arm, and accordingly the insertion core can be fixed between the first extrusion face and the second extrusion face rapidly and firmly, and the fixing speed is high. As the insertion core is fixed at a time, the process of gradual extrusion of a screw is avoided in the process of fixing, small displacement due to gradual extrusion can be prevented, and the insertion core does not move any more once being extruded and fixed, so that the locating is accurate; besides, the elasticity of the elastic locating arm is large, so that the insertion core is extruded and fixed quite firmly, and position changing or falling of the insertion core due to external slight impact is prevented.

Owner:SUZHOU TFC OPTICAL COMM CO LTD

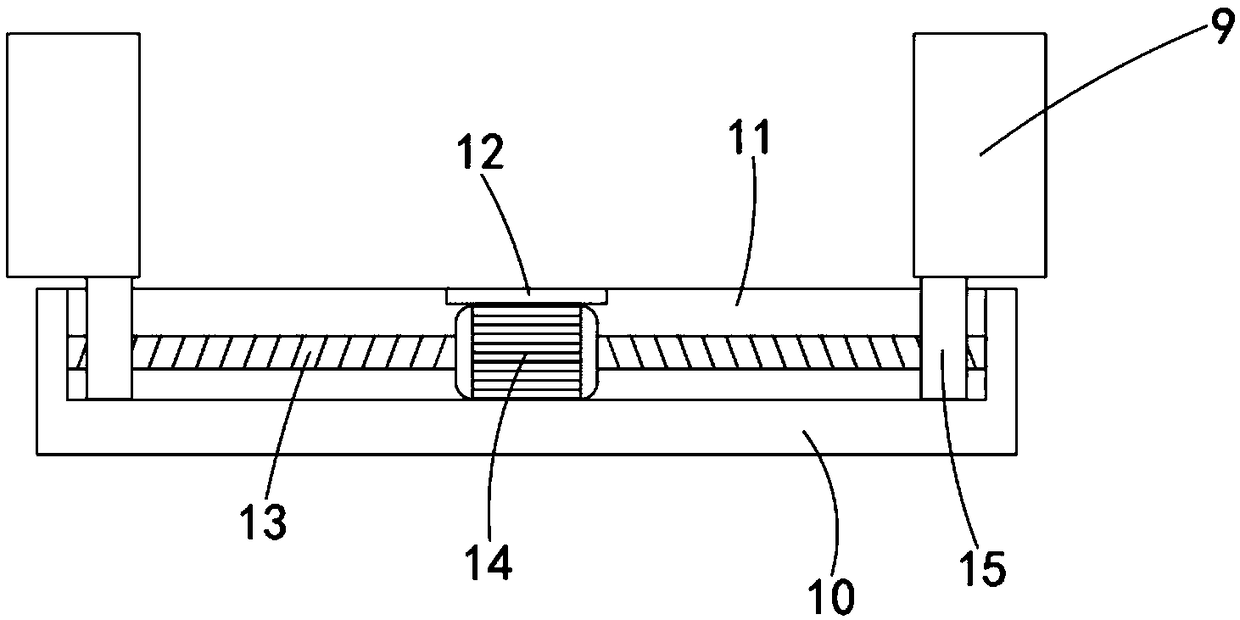

Doubling thread rolling device

The invention discloses a doubling thread rolling device which comprises a supporting frame. Draught fans are symmetrically arranged on the two sides of the inner wall of the supporting frame, a motoris arranged in the supporting frame, a disc is arranged at an output shaft of the motor, a barrel is arranged at the top of the disc, through holes horizontally penetrate the two sides of the barrel,connecting rods in movable connection are arranged in the through holes in a matched manner, a fastening plate is arranged on one side of the connecting rod, and the other side of each connecting rodis provided with a ring; a limiting disc is arranged at the top of the barrel, a screw hole penetrates the limiting disc, a screw is arranged in the screw hole in a matched manner, a winding column is arranged at the bottom of the screw, a screw cap is arranged at the top of the screw, clamps are symmetrically arranged on the two sides of the winding column, and steel wire ropes are arranged between the clamps and the rings. By means of the doubling thread rolling device, doubling threads can be automatically rolled, the draught fans can cool the motor, the service life is prolonged, the thread head fixing speed is high, the stability is high, the clamping effect is good, and the working efficiency is high.

Owner:YANCHENG JUNLONG YARN CO LTD

Fixing device for arc processing of acrylic plate

The invention discloses a fixing device for arc processing of an acrylic plate. The fixing device comprises a base, a sliding chute, a sliding block and a working table; support rods are fixedly connected with the two ends of the base; electric push rods are fixedly mounted on the outer side walls of the support rods through mounting bases; the end parts of the electric push rods penetrate throughthe support rods to be fixedly connected with clamping fixing mechanisms; the working table is fixedly mounted in the middle of the upper surface of the base; the sliding chute is formed in the base;the sliding block is mounted on the sliding chute in a sliding manner; and the electric push rods control the sliding block to move left and right on the sliding chute, so that the space between thetwo clamping fixing mechanisms is adjusted to fix plates with different sizes, application is facilitated, the working strength of a working staff is lowered, and at the same time, the plate fixing speed and the plate processing efficiency are improved.

Owner:魏苒

Automatic welding device capable of efficiently replacing filler rods

InactiveCN112975213AReduce the frequency of electrode replacementImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryStructural engineering

The invention relates to the field of automatic welding, in particular to an automatic welding device capable of efficiently replacing filler rods. The device comprises a device main body, a moving frame is movably mounted at the upper end of the device main body, a welding rod is movably mounted at the inner side of the moving frame, and a filler rod replacing device is fixedly mounted at the inner side of the moving frame; and fixing blocks are fixedly installed in the filler rod replacing device at equal intervals along the edge, standby filler rods can be placed between the fixing blocks, after the filler rods at the lower end of the welding rod are used up, the filler rod replacing device can be driven by a motor to rotate, so that the filler rod replacing device uses a driving plate arranged in an annular wavy manner and located at the left side of the filler rod replacing device, rotation in a driving groove of a propelling block is achieved, when the driving block abuts against the driving plate in an attached manner through a spring at one side of a connecting rod, the propelling block can move left and right along the track of the driving plate, and therefore the standby filler rods at the outer side of the propelling block are pushed into welding tongs at the lower end of the welding rod along with rotation of the filler rod replacing device, and replacement is completed. Therefore, the frequency of filler rod replacement through device pause is greatly reduced.

Owner:新余山海企业服务有限公司

Bioengineering latex paint

The invention discloses bioengineering latex paint, which is prepared from the following ingredients in parts by weight: 350 to 380 parts of hydroxyl acrylic emulsion, 20 to 25 parts of glue material, 15 to 30 parts of film forming auxiliary agents, 50 to 100 parts of toughening agents, 3 to 4 parts of dispersants, 0.2 to 0.5 part of antifoaming agents, 65 to 75 parts of filling agent, 70 to 75 parts of accelerants and 100 to 600 parts of water, wherein the glue material is an ultraviolet curing adhesive; the filling agent is glass short fiber. By adopting the mode, after the bioengineering latex paint is used to coat a wall surface, and when the surface is irradiated by sunlight, the ultraviolet curing adhesive on a paint surface is fast cured; the ultraviolet curing adhesive inside the paint receives ultraviolet irradiation through the light guide effect of the glass short fiber; the whole fixing speed is accelerated; the construction is fast; the requirement on fine weather is lowered; the construction is convenient; the durability is high.

Owner:CHANGSHU RES INST OF DALIAN UNIV OF TECH CO LTD

SMT tray piece component welding location tool

The invention discloses an SMT tray piece component welding location tool which comprises a base, wherein a plurality of location mechanisms are sequentially arranged on the surface of the front sideof the base from top to bottom, every two adjacent location mechanisms in the plurality of the location mechanisms are evenly distributed on the base at equal intervals, two abutting mechanisms are symmetrically arranged on the two sides of each location mechanism, and the two abutting mechanisms are arranged on the surface of the front side of the base. According to the SMT tray piece component welding location tool disclosed by the invention, the location mechanisms and the abutting mechanisms are matched to achieve the purpose of fixing the positions of a plurality of PCB boards in one time, the speed for operators to fix the PCB boards is improved, and convenience is brought to the operators to weld SMT tray piece components.

Owner:WEIKE ELECTRONICS MODULES SHENZHEN

Nano coating device for ore milling

The invention belongs to the technical field of ore milling equipment, and discloses a nano coating device for ore milling. The nano coating device comprises an ore fixing table, an ore adjusting mechanism is arranged on the upper surface of the ore fixing table, and comprises a first sliding plate, a first air cylinder, a second sliding plate and a second air cylinder, and an ore fixing mechanismis arranged on the upper surface of the second sliding plate, and comprises a fixed outer frame, an electric telescopic rod, a spring, an arc-shaped clamping plate and an anti-extruding rubber pad. According to the nano coating device for ore milling, the electric telescopic rod is adopted for controlling the arc-shaped clamping plate to move, ore can be fast fixed, the consumed time is short, the fixing speed is high, the ore of different sizes can be fixed, and high practicality is achieved; spraying of the ore in the X-axis direction and the Y-axis direction can be achieved through the oreadjusting mechanism, the ore can be coated evenly through the spraying head, and the spraying effect is good.

Owner:安徽捷运矿山机械有限公司

New energy battery integral press-down assembling device

ActiveCN113725456AEasy to movePrecise positioningPrimary cell manufactureAssembling battery machinesNew energyStructural engineering

The invention discloses a new energy battery integral press-down assembling device, and the device comprises an assembling device body used for fixing a battery box so as to realize integral press-down assembling of a battery body into the battery box, and the assembling device body comprises a sliding seat and a camera visual judgment system arranged above the sliding seat. The camera visual judgment system can judge whether the battery box is fixed at a preset position or not and whether the posture is right or not; a positioning assembly is arranged on the sliding seat, and comprises a fixed plate fixed to the position, close to one end, of the sliding seat, a sliding plate arranged to the position, close to the other end, of the sliding seat and oppositely spaced from the fixed plate, and clamping plates symmetrically arranged to the positions, close to the two sides, of the sliding seat. The sliding plate can horizontally move against or away from the fixed plate; the two clamping plates can synchronously and horizontally move in a manner of abutting against or leaving away from each other; the fixed plate, the sliding plate and the two clamping plates jointly clamp and fix the battery box. Therefore, the speed and accuracy of fixing the battery box can be effectively improved, the positioning is firm, and the fixing posture of the battery box is correct.

Owner:厦门微亚智能科技股份有限公司

A method for embedding side buds at different nodes of sugarcane and making tablets

ActiveCN106546473BSolve the slicing problemReduce breakage ratePreparing sample for investigationPlant tissueBud

The invention relates to an embedding and slice making method of lateral buds at different node positions of sugarcane, and belongs to the technical field of the embedding and slicing of plant tissue. The method comprises the following steps of (1), taking and fixation of a sample, (2), softening, (3), dehydration, (4), displacement, (5), infiltration, (6), embedding, (7), trimming of a block, (8), slicing, (9), spreading of a slice, and adhesion of the slice, (10), dyeing, and the like. According to the method, the characteristics of two embedding and slicing methods of paraffin embedding and slicing and resin infiltrating and embedding are synthesized; the application is integrated; weak points are compensated by learning from strong points; the novel method is searched and developed to systematically solve the slicing problem of the cytological study of the lateral buds of the sugarcane; further, the made slice is intact and is almost not broken; slicing and embedding effects of giving consideration to a whole and a detail can be achieved.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI

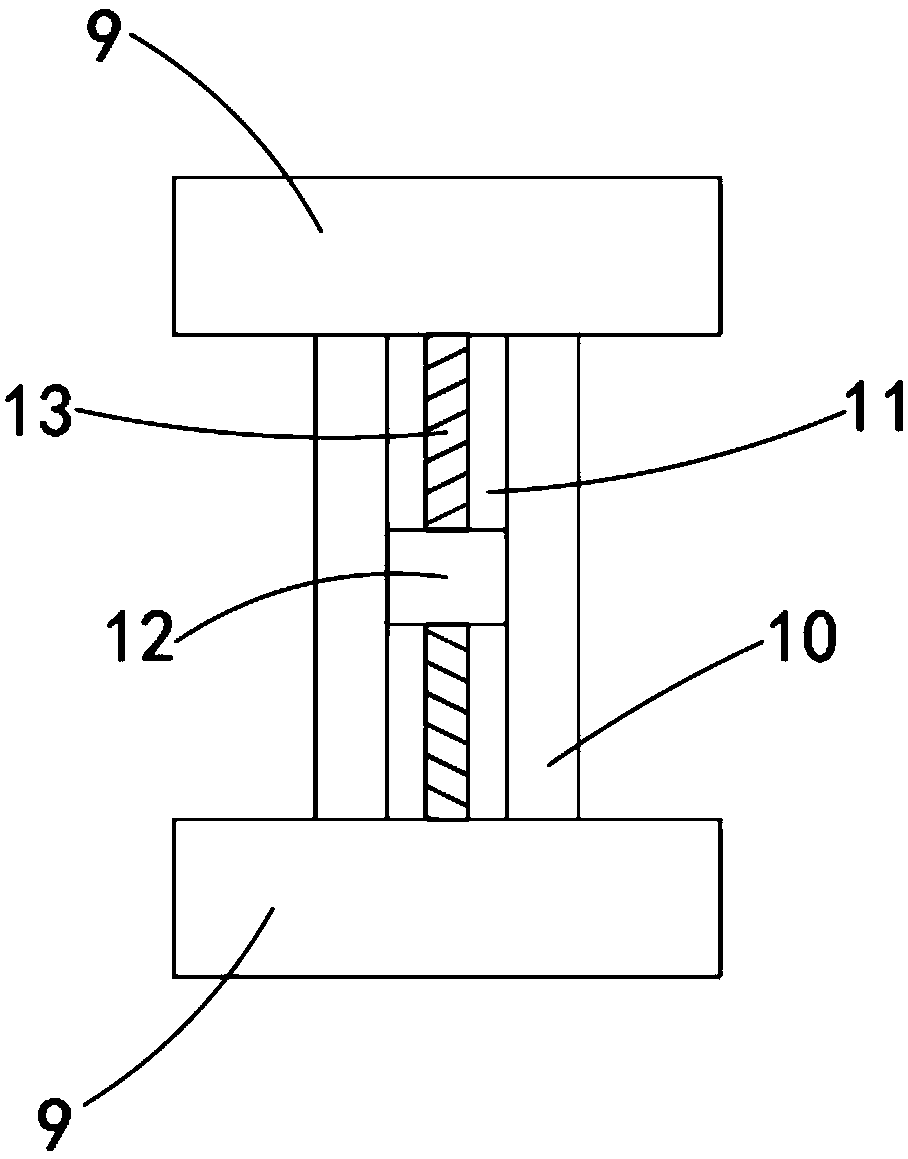

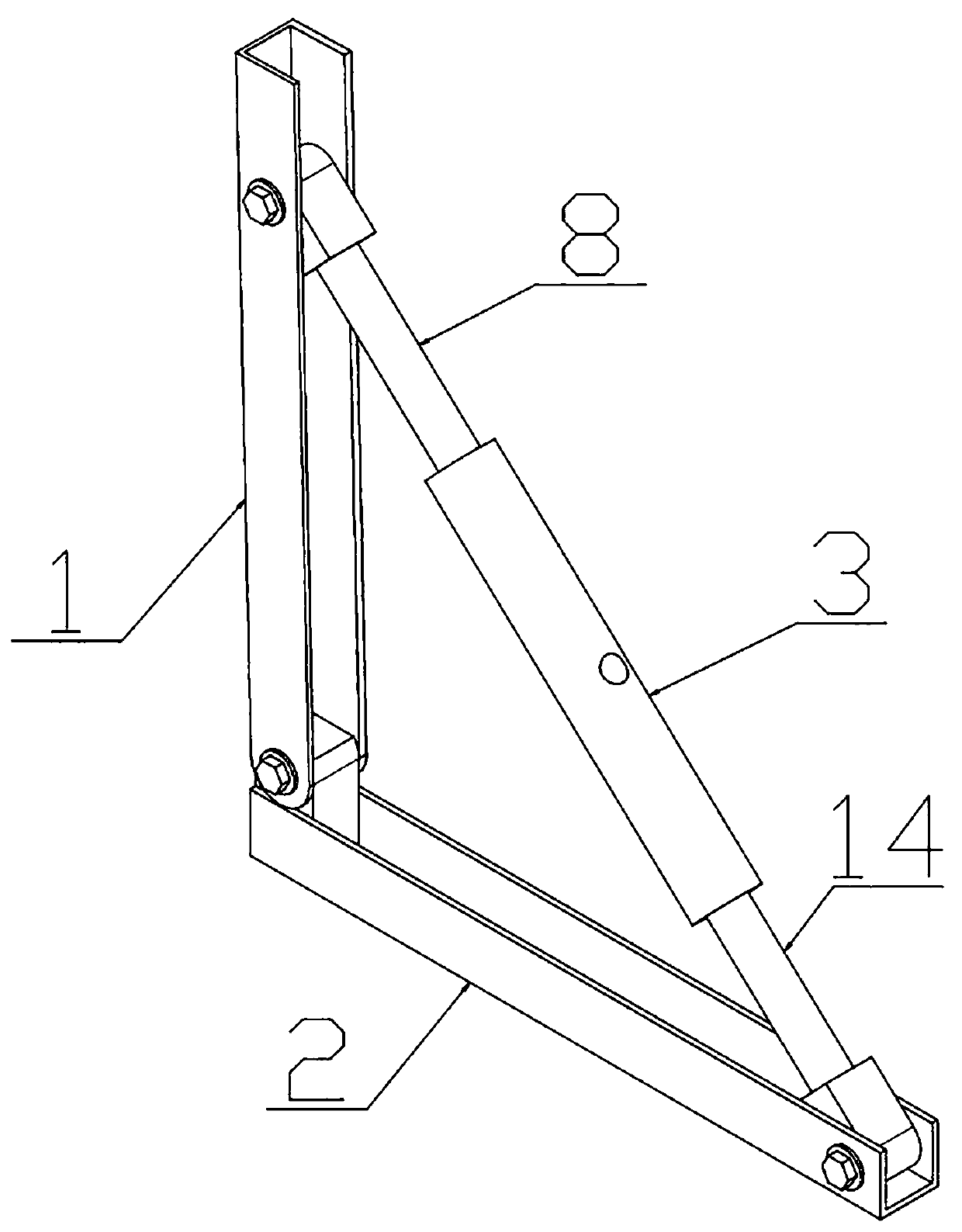

PC assembling type inner wall module fixing device for building

InactiveCN110388075AFixed fastImprove fixation efficiencyBuilding material handlingStructural engineeringComputer module

The invention relates to a PC assembling type inner wall module fixing device for building. The inner wall module fixing device comprises an upper supporting plate, a lower supporting plate and an adjusting pipe. Fixing holes are formed in the upper supporting plate and the lower supporting plate correspondingly. The upper supporting plate is provided with a hinge shaft, an upper fixing hole, an upper hinge shaft and an upper supporting rod. The upper supporting rod comprises an upper hinge block and an upper screw rod arranged on the upper hinge block. The upper hinge block is provided with an upper hinge hole. The upper hinge shaft is connected with the upper fixing hole and the upper hinge hole in a matched manner. The lower supporting plate is provided with a hinge block, a lower fixing hole, a lower hinge shaft and a lower supporting rod. The hinge block is provided with a hinge hole. The hinge shaft is connected with the hinge hole in a matched manner. The lower supporting rod comprises a lower hinge block and a lower screw rod arranged on the lower hinge block. A lower hinge hole is formed in the lower hinge block. A control pipe is arranged on the middle portion of an adjusting pipe. Threads matched with the upper screw rod and the lower screw rod are arranged at the two ends of the inner wall of the adjusting pipe. The fixing device improves the fixing efficiency, canbe adjusted, and can be folded when not being used.

Owner:HUNAN CITY UNIV

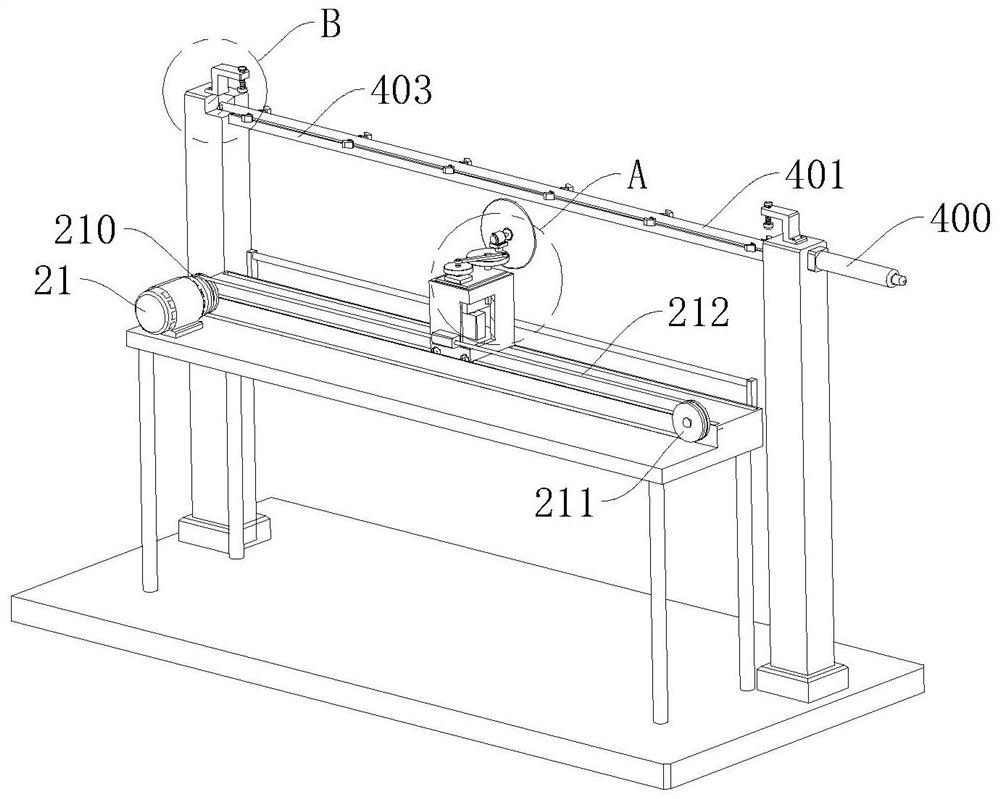

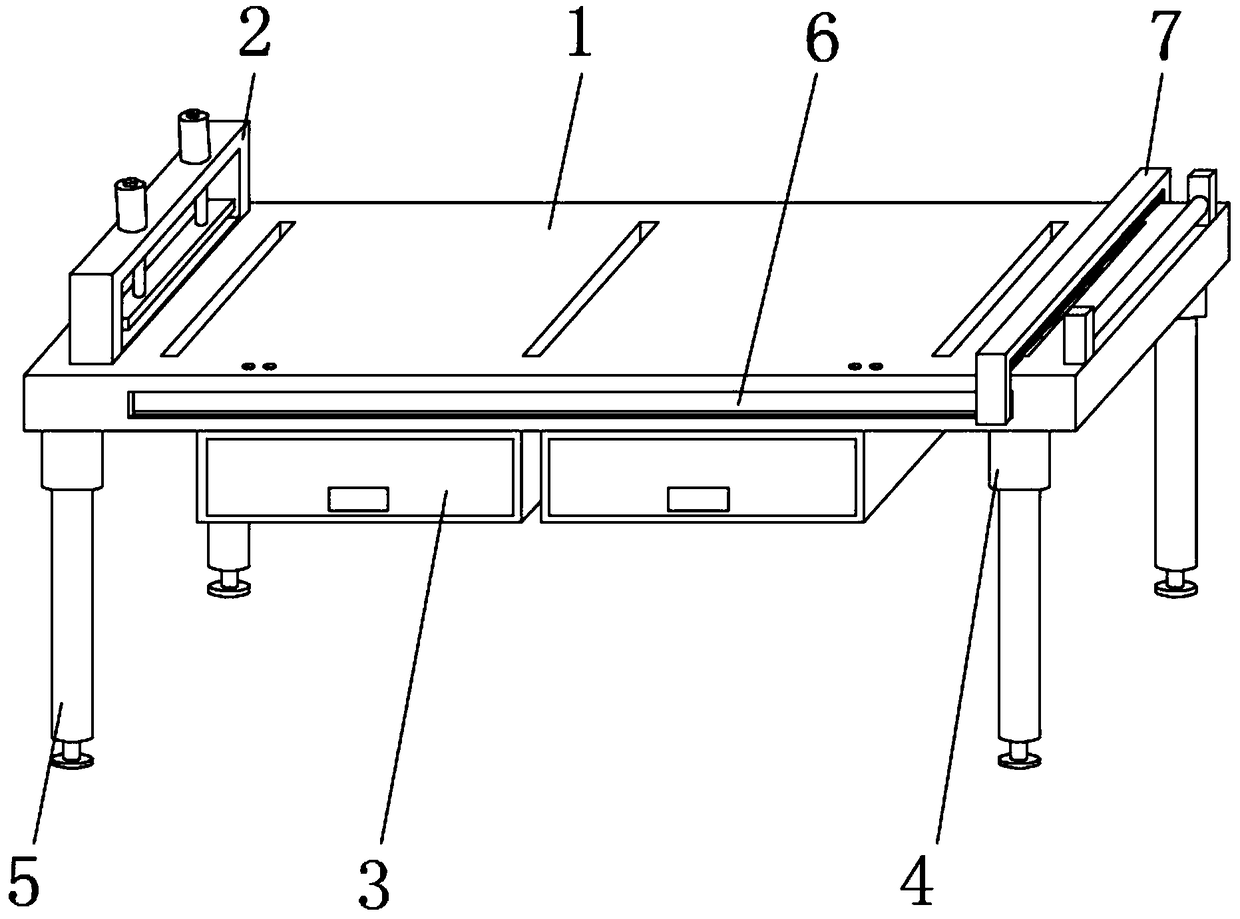

Cloth cutting bed

InactiveCN109281148AImprove efficiencyEven strengthSevering textilesCleaning using toolsBody discomfortFixed frame

The invention discloses a cloth cutting bed which comprises a cloth cutting bed body. A fixing frame is fixedly arranged at the position, close to one side, of the outer surface of the upper end of the cloth cutting bed body; two sets of drawers are arranged in the middle of the outer surface of the lower end of the cloth cutting bed body, and shock absorbers are fixedly installed at the positions, close to the four corners, of the outer surface of the lower end of the cloth cutting bed body; the outer surfaces of the lower ends of the shock absorbers are fixedly provided with supporting columns. According to the cloth cutting bed, cloth can be conveniently fixed by people, the speed for fixing the cloth is relatively high, and the cloth cutting efficiency is improved; people can conveniently clean away dust on the surface of the cloth cutting bed, and the cleaning effect is good; finally, tiny substances such as cloth and fluff which are caused by cutting the cloth can be sucked intoan ash storage box, so that the body discomfort caused when an operator inhales the micro cloth is avoided, the body health of the operator is guaranteed, and better application prospects are brought.

Owner:阜阳鑫合服饰有限公司

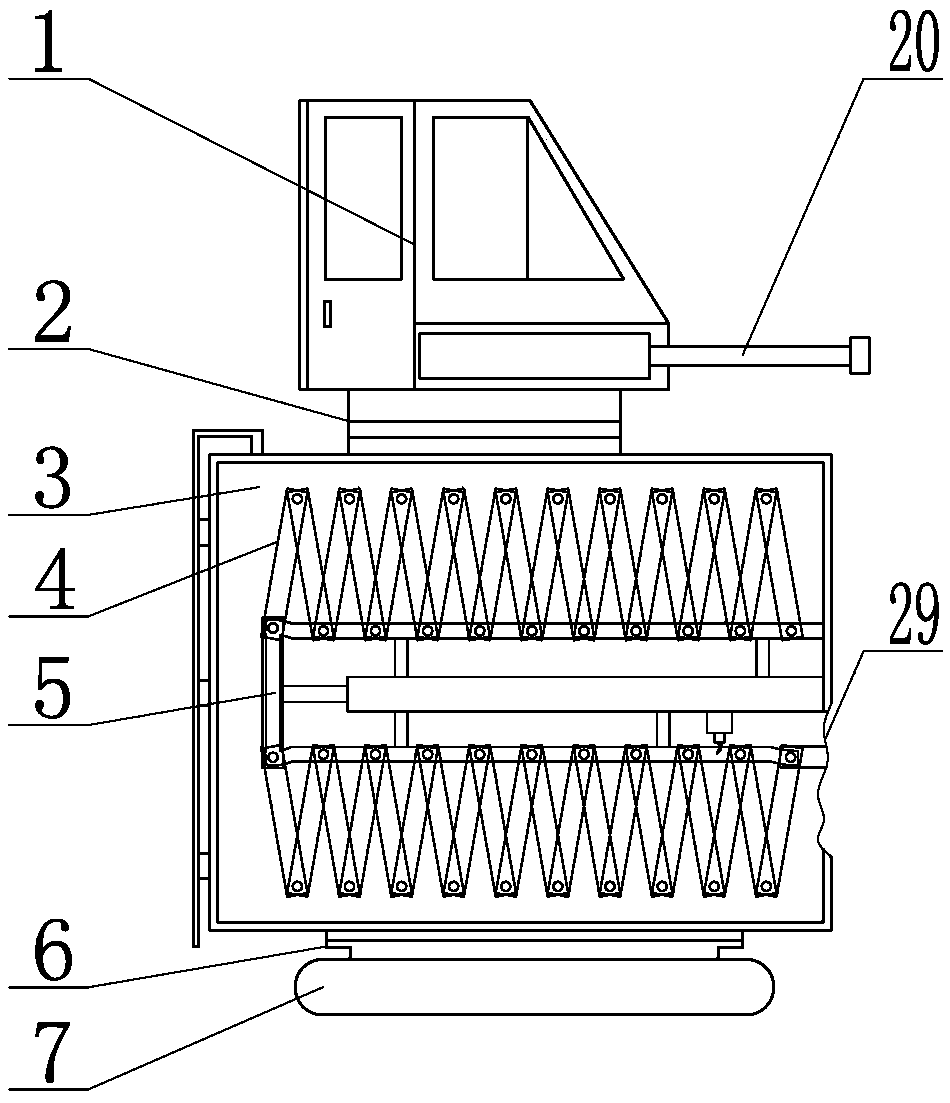

Fast conveying equipment for solidification-resisting type refractory castable

ActiveCN107892187AMake up for the phenomenon of gravity decompositionIncrease the amount of storageConveyorsStorage devicesDecompositionRefractory

The invention provides fast conveying equipment for solidification-resisting type refractory castable and belongs to the field of refractory material construction equipment. The equipment is characterized by comprising a material mixing device, a feeding device, a material conveying device and a material transferring device. According to the equipment, at first, the material mixing device and thefeeding device carry out pretreatment on materials needing to be conveyed, and then the material conveying device and the material transferring device sequentially convey the materials to the construction operation face of a boiler body. The material mixing device carries out pre-machining on the castable on site firstly through a material mixing support and a material mixing hopper, then the feeding device transfers the materials transversely and then carries out material lifting operation from bottom to top, when the high-altitude conveying link is carried out finally, at first, double helixes in a feeding cylinder carry out gap type high-speed material mixing, thus, the phenomenon of material macromolecule gravity decomposition possibly generated in the material lifting process is avoided, and finally the materials are conveyed to the high-altitude operation construction face through the material conveying device.

Owner:SHANDONG YAOHUA REFRACTORY MATERIAL SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com