Expansion bolt

A technology of expansion bolts and expansion tubes, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems affecting the appearance, etc., and achieve fast fixing speed, high firmness, and good stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

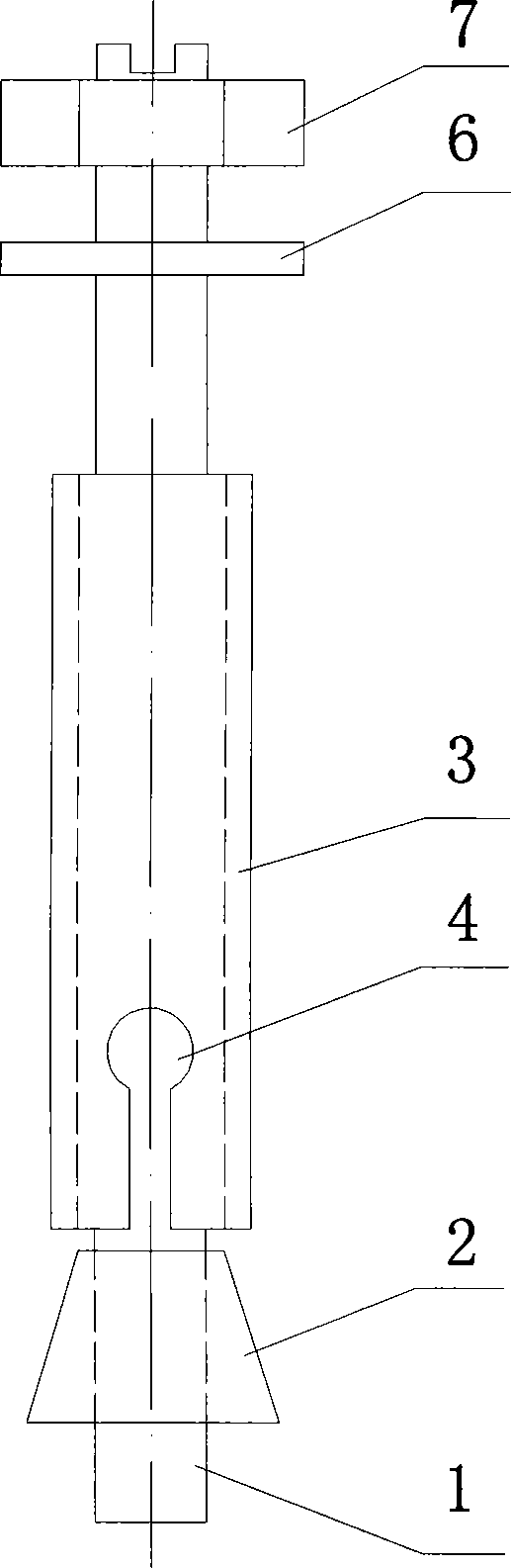

Embodiment 1

[0016] like figure 1 As shown, the expansion bolt includes a screw rod 1, a lower tapered nut 2, an expansion tube 3, a washer 6, and a nut 7. The lower end of the expansion tube 3 is provided with an equally divided opening groove 4, and the screw rod 1 is provided with an external thread , the lower end of the screw 1 passes through the expansion tube 3; the upper end of the screw 1 is welded with a nut 7 (the nut 7 and the screw 1 can also be an integral structure), and the nut 7 is located above the expansion tube 3; the screw 1 is covered with The washer 6, the washer 6 is located above the expansion tube 3; the lower end of the screw 1 is screwed with a lower conical nut 2, the lower conical nut 2 is located below the expansion tube 3, the small end of the lower conical nut 2 faces upwards, and the lower end of the lower conical nut 2 faces upwards. The outer diameter of the small end of the conical nut 2 is less than or equal to the inner diameter of the expansion tube ...

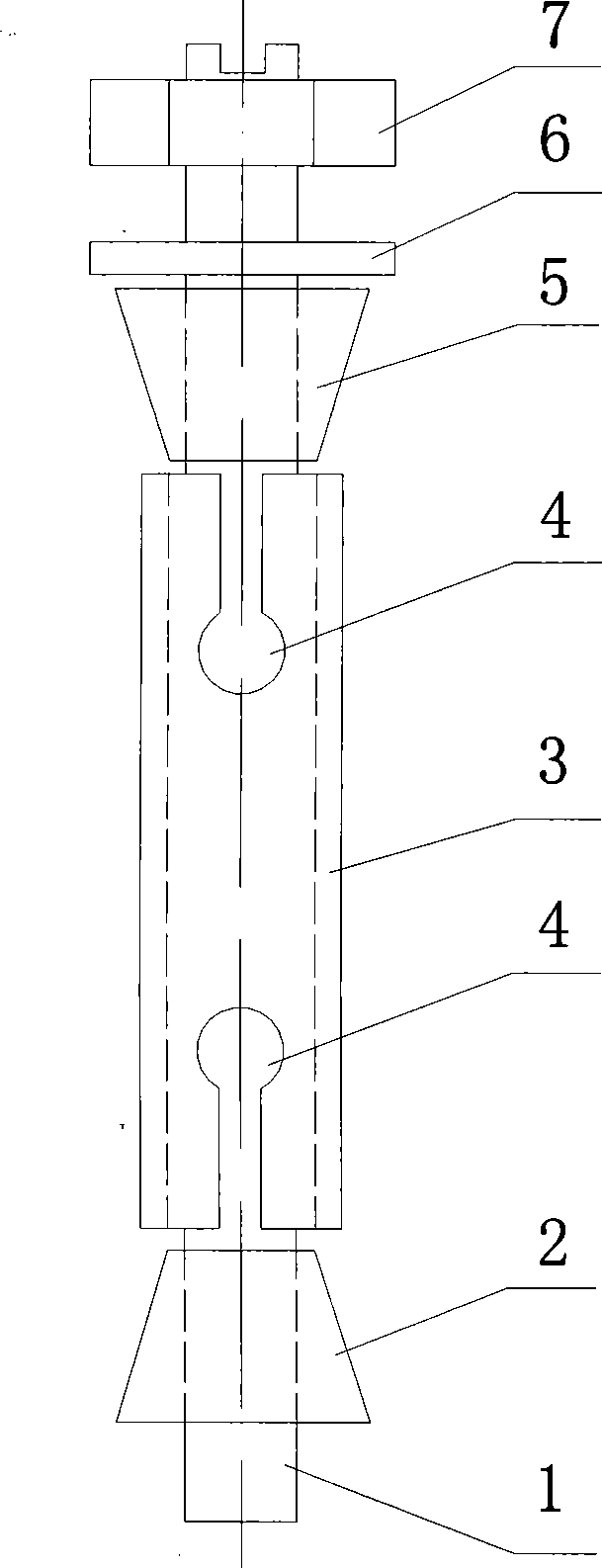

Embodiment 2

[0018] like figure 2 As shown, the expansion bolt includes a screw rod 1, a lower conical nut 2, an expansion tube 3, an upper conical nut 5, a washer 6, and a nut 7; both ends of the expansion tube 3 are provided with equally divided opening grooves 4 The upper and lower parts of the screw rod 1 are respectively provided with external threads, and the lower external threads of the screw rod 1 are opposite to the upper external threads; the screw rod 1 is covered with a gasket 6, and the gasket 6 is located above the expansion tube 3; the upper part of the screw rod 1 is screwed with an upper Conical nut 5, the upper conical nut 5 is located between the washer 6 and the expansion tube 3 (the upper conical nut 5 is located above the expansion tube 3), and the upper end of the screw rod 1 is welded with a nut 7 (the nut 7 and the screw rod 1 are also Can be an integral structure), the nut 7 is positioned above the expansion tube 3; the small end of the upper tapered nut 5 faces...

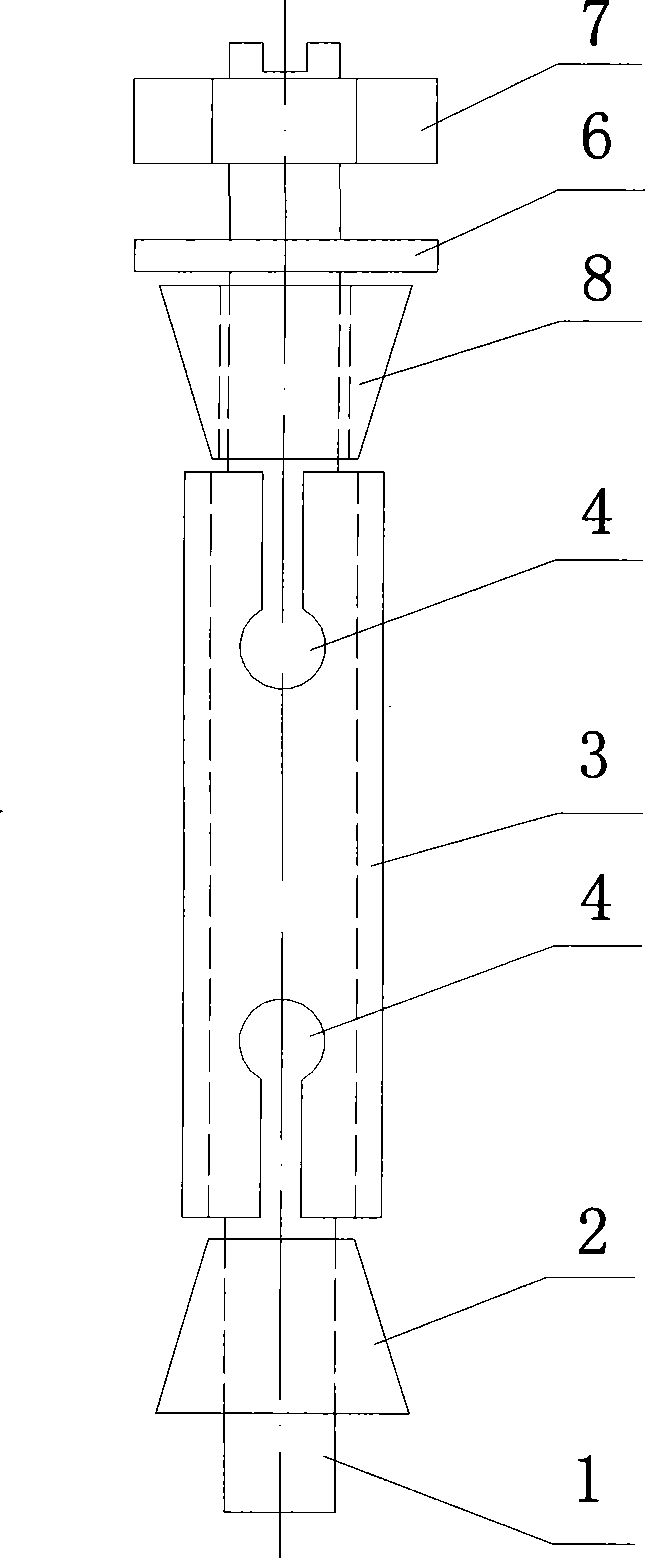

Embodiment 3

[0020] like image 3 As shown, it is basically the same as Embodiment 1, the difference is that: the screw rod 1 is covered with an upper cone body 8, the upper cone body 8 is provided with a screw through hole, and the screw rod 1 passes through the screw rod of the upper cone body 8 Through hole, the upper cone 8 is located above the expansion tube 3; the upper end of the expansion tube 3 is provided with equally divided opening grooves; the small end of the upper cone 8 faces downward, and the outer diameter of the small end of the upper cone 8 is less than Or equal to the inner diameter of the expansion tube 3, the outer diameter of the big end of the upper cone 8 is greater than the inner diameter of the expansion tube 3. When rotating, the nut 7 presses the upper cone 8 into the expansion tube 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com