Ceramic electronic device

A technology of electronic components and ceramics, applied in the field of ceramic electronic components, can solve the problems of inability to meet thermal shock resistance or high temperature load life, and achieve the effects of good thermal shock resistance, improved installation reliability, and good high temperature load life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0130] Hereinafter, the present invention will be described based on more detailed examples, but the present invention is not limited to these examples.

[0131] (Experiment 1)

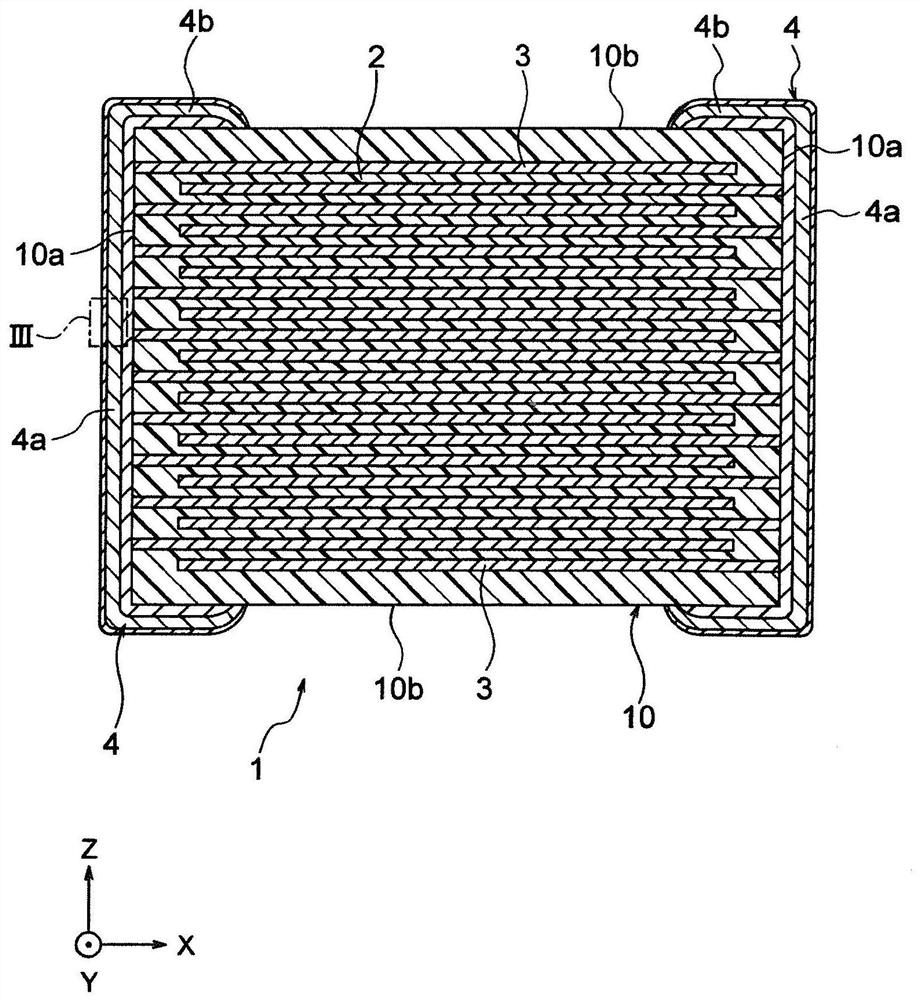

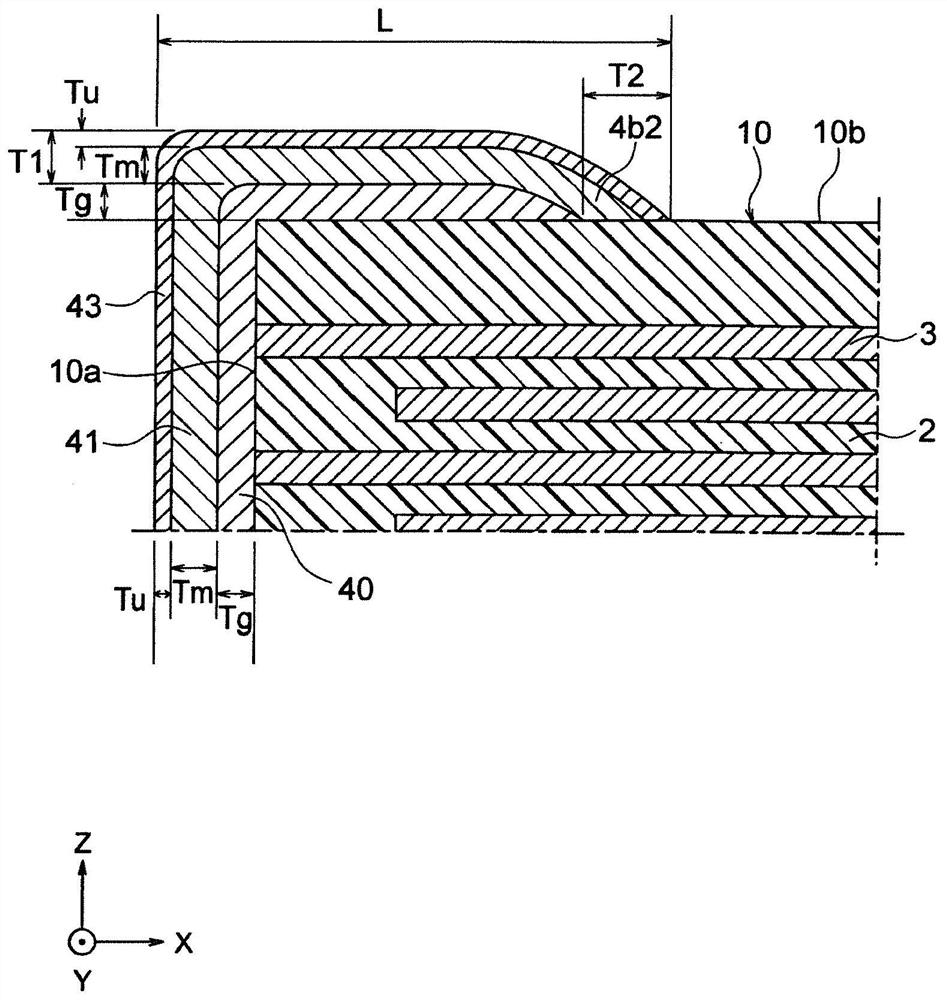

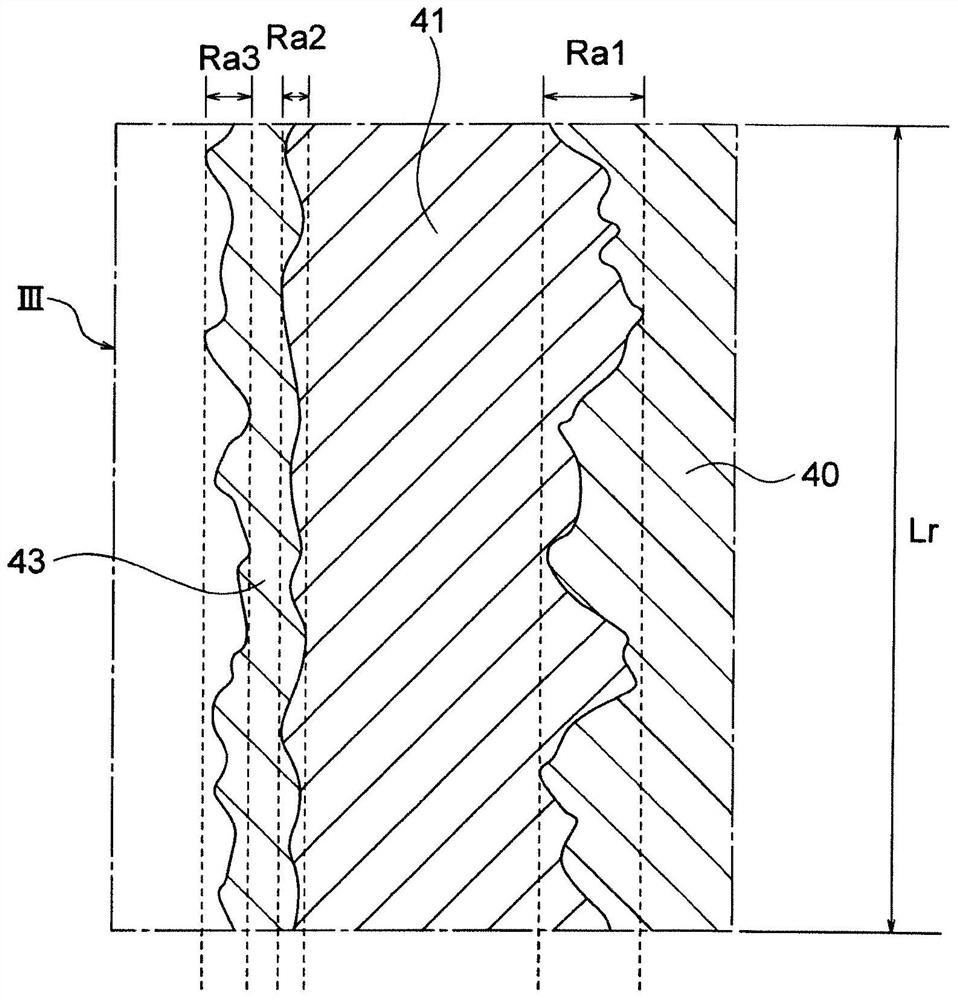

[0132] In Experiment 1, capacitor samples according to Examples 1 to 20 were produced. As the ceramic body 10 of each capacitor sample, CaZrO laminated with CaZrO 3 A sintered body sample of the ceramic layer 2 as the main component and the internal electrode layer 3 containing Ni. Then, with respect to this sintered body sample, a pair of external electrodes 4 were formed in the following procedure.

[0133] First, a metal paste to be a raw material of the base electrode layer 40 is prepared. This metal paste is obtained by preparing and kneading a metal powder, a glass component, and a vehicle at a predetermined ratio. The glass components used at this time use ZnO, B 2 o 3 , SiO 2 、Al 2 o 3 As a raw material, additionally, a mixture selected from BaCO 3 , CaCO 3 , SrCO 3 , MgCO 3 , or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com