Ion source sputtering target material device with high utilization rate and using method thereof

A sputtering target and ion source technology, applied in the field of ion source sputtering, can solve the problems of polluted film, waste, large swing range of the target, etc., to ensure no pollution, reduce production costs, and reduce space area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

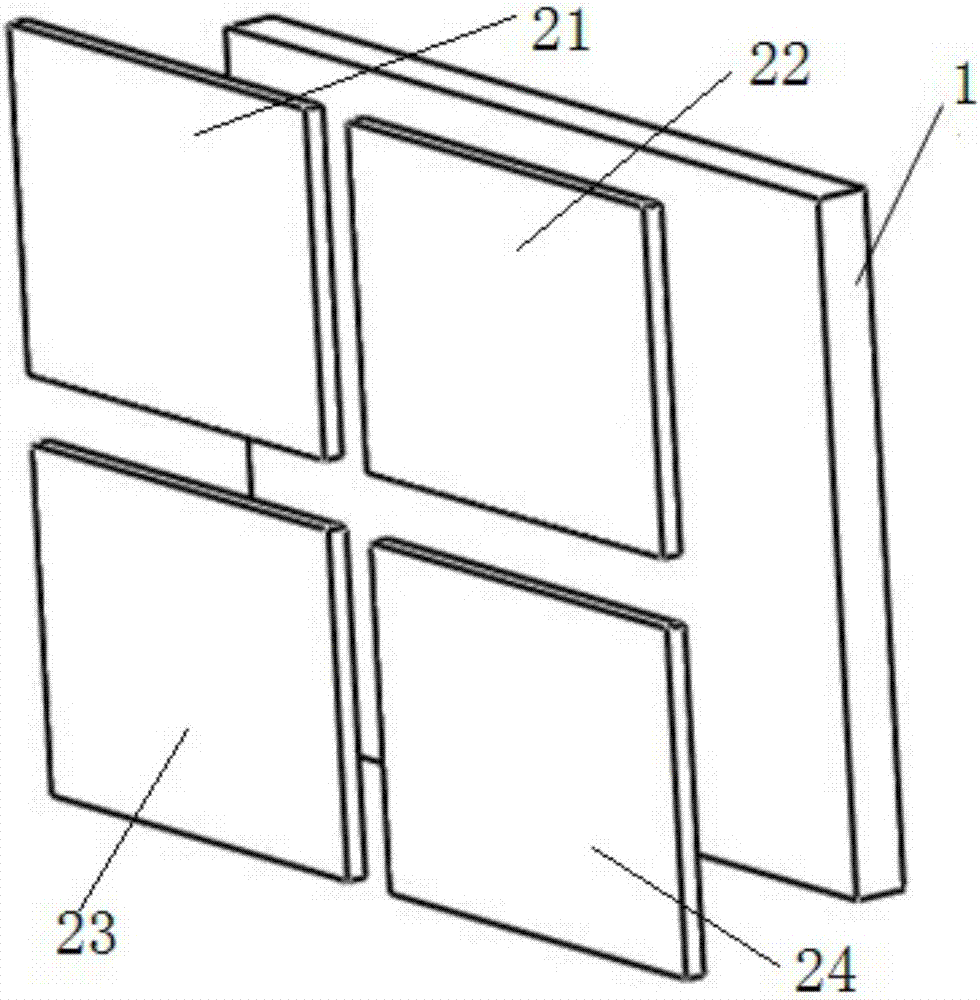

[0030] A schematic diagram of an ion source sputtering target device with high utilization rate in this embodiment is as follows figure 1 As shown, it includes a backboard 1 and a first target 21, a second target 22, a third target 23 and a fourth target 24 detachably arranged on the backboard 1; the four targets They are all rectangular structures, and the four targets are spliced together in a cross-shaped structure.

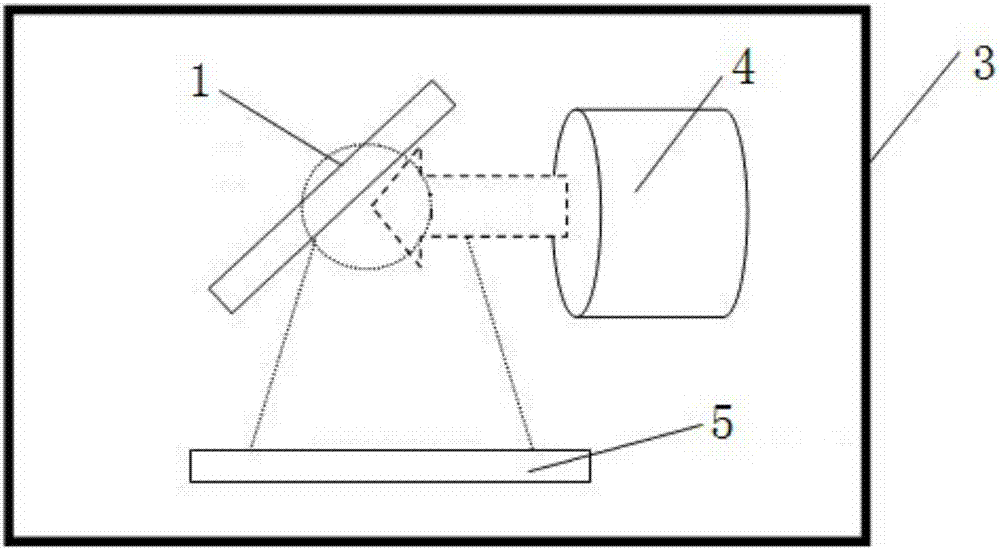

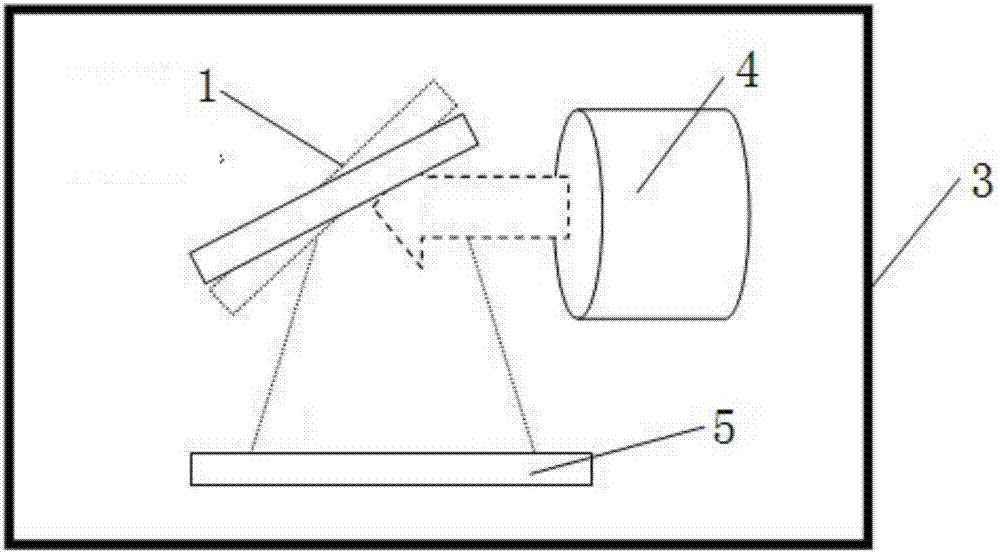

[0031] The schematic diagram of using the ion source to sputter the target device to produce thin films is shown in figure 2As shown, the ion source 4, the target device and the product platform 5 are placed in the vacuum chamber 3, and the four targets are detachably spliced on the back plate 1 in a cross-shaped structure, and the ion source 4 is used for four The target is sputtered for the first time, and the target material is deposited on the product platform 5; then, the relative positions of the four targets when spliced are readjusted, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com