Multipurpose fixing device for automobile axle type component machining

A part processing and fixing device technology, applied in the field of automobile parts processing, can solve the problems of low versatility and single use of the fixing device, and achieve the effects of good fixing effect, lower production cost and high matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

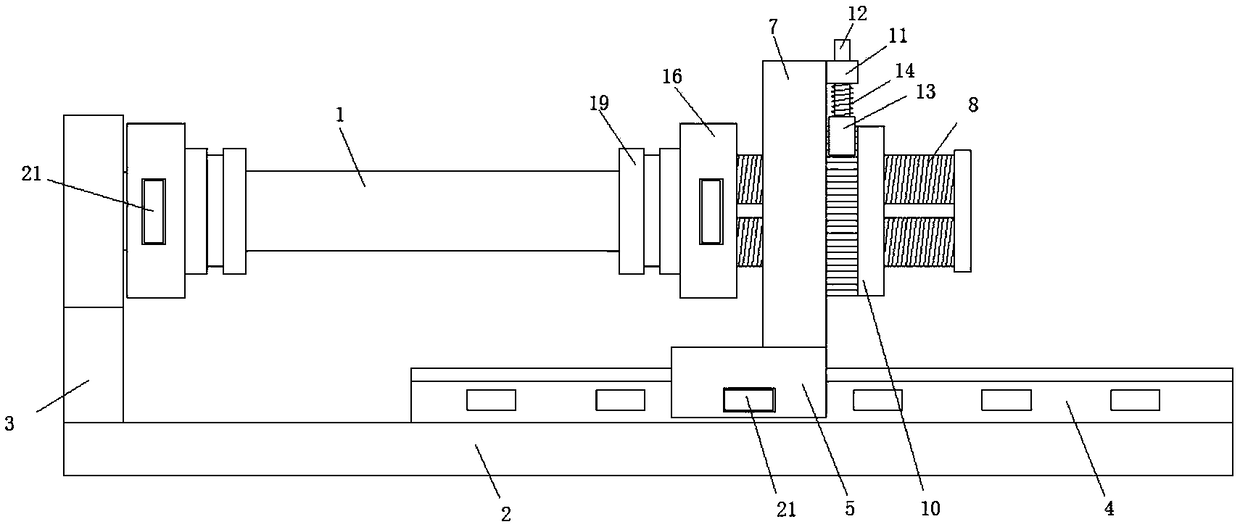

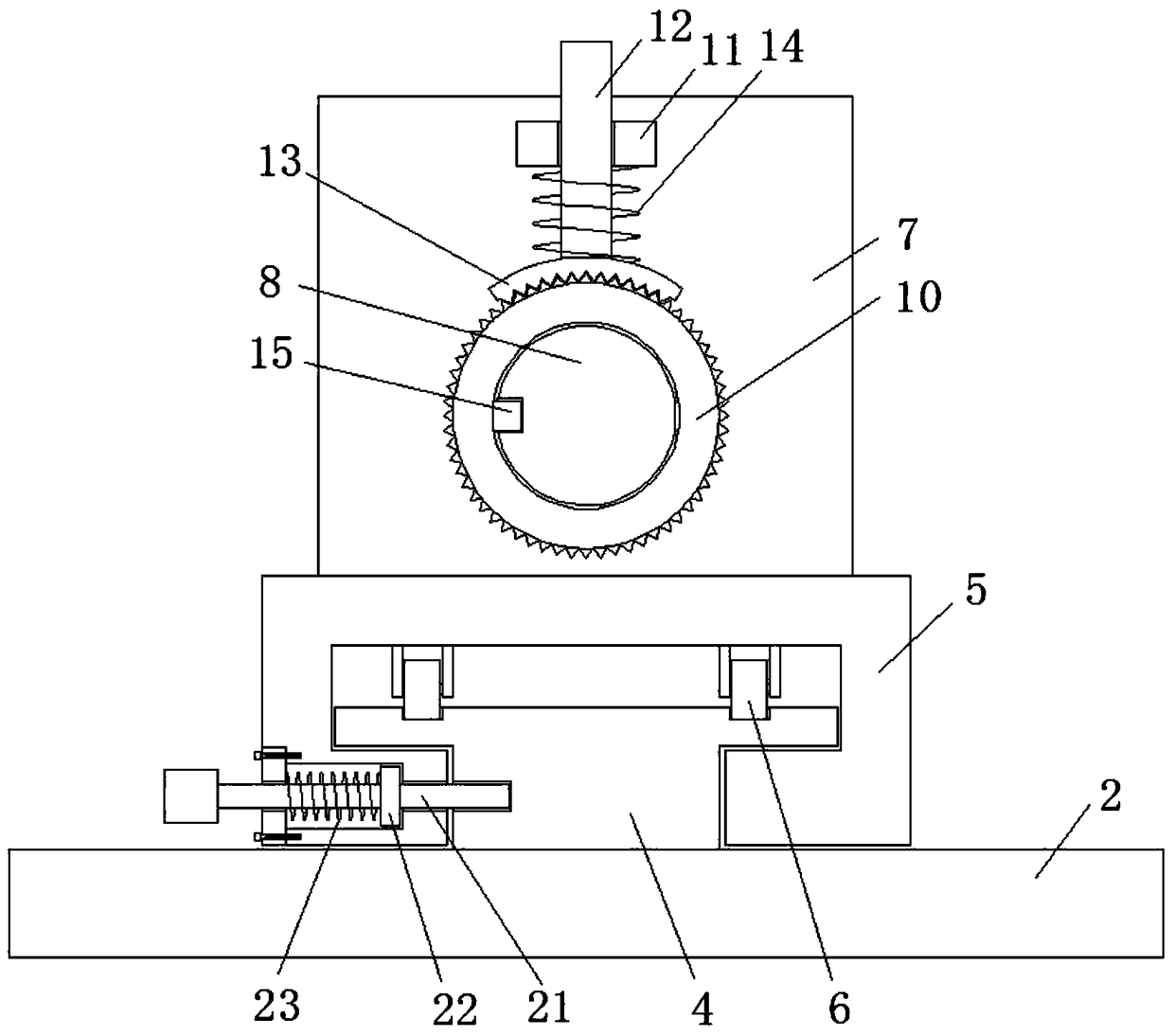

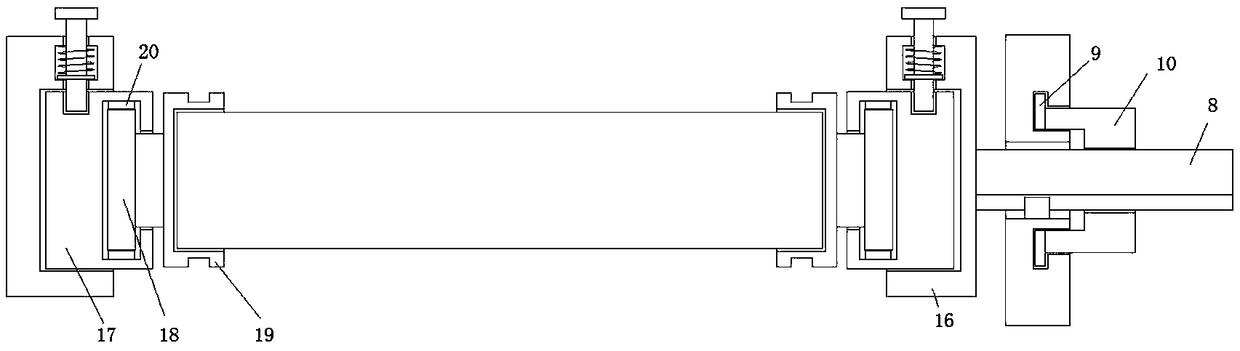

[0025] refer to Figure 1-4 , a multi-purpose fixing device for the processing of automobile shaft parts, comprising a horizontal shaft 1, a bottom plate 2 is arranged vertically below the horizontal shaft 1, a side plate 3 and a T-shaped column 4 are fixedly welded on the top of the bottom plate 2, and the T-shaped column The top sliding sleeve of 4 is provided with a sliding sleeve 5, the bottom side of the sliding sleeve 5 is provided with a T-shaped groove, the top side of the T-shaped column 4 is provided with a track groove, and the top side inner wall of the T-shaped groove is fixedly provided with a track wheel 6 And slidingly connected in the track groove, the top side of the sliding sleeve 5 is fixedly welded with a vertical plate 7, and the body of the vertical plate 7 is provided with a horizontal through hole, and the horizontal through hole is provided with a threaded horizontal column 8, and a threaded horizontal column 8 Limiting chute is set on one side of the...

Embodiment 2

[0028] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the adjustment mechanism includes a horizontal plate 11, a control rod 12, an arc gear plate 13 and a return spring one 14, and the horizontal plate 11 is fixedly welded on one side of the vertical plate 7 And offer vertical through hole, the bar body of control rod 12 passes through in vertical through hole, arc gear plate 13 is fixedly welded on the bottom of control rod 12, the outer wall of threaded ring 10 and the bottom of arc gear plate 13 The sides are provided with tooth grooves and meshed with each other.

[0029] In this embodiment, the setting of the adjustment mechanism enables the distance between the splints 19 to be adjusted in a small range, so that the precision of the device is higher and the fixing effect is better.

Embodiment 3

[0031] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 2. Preferably, the return spring one 14 is arranged between the horizontal plate 11 and the arc-shaped gear plate 13 and sleeved on the outside of the rod body of the control rod 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com