Grinding clamp and jig thereof

A technology for grinding jigs and jigs, which is applied in the direction of grinding devices, grinding machine tools, manufacturing tools, etc., to achieve the effects of prolonging service life, reducing force, and fast fixing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

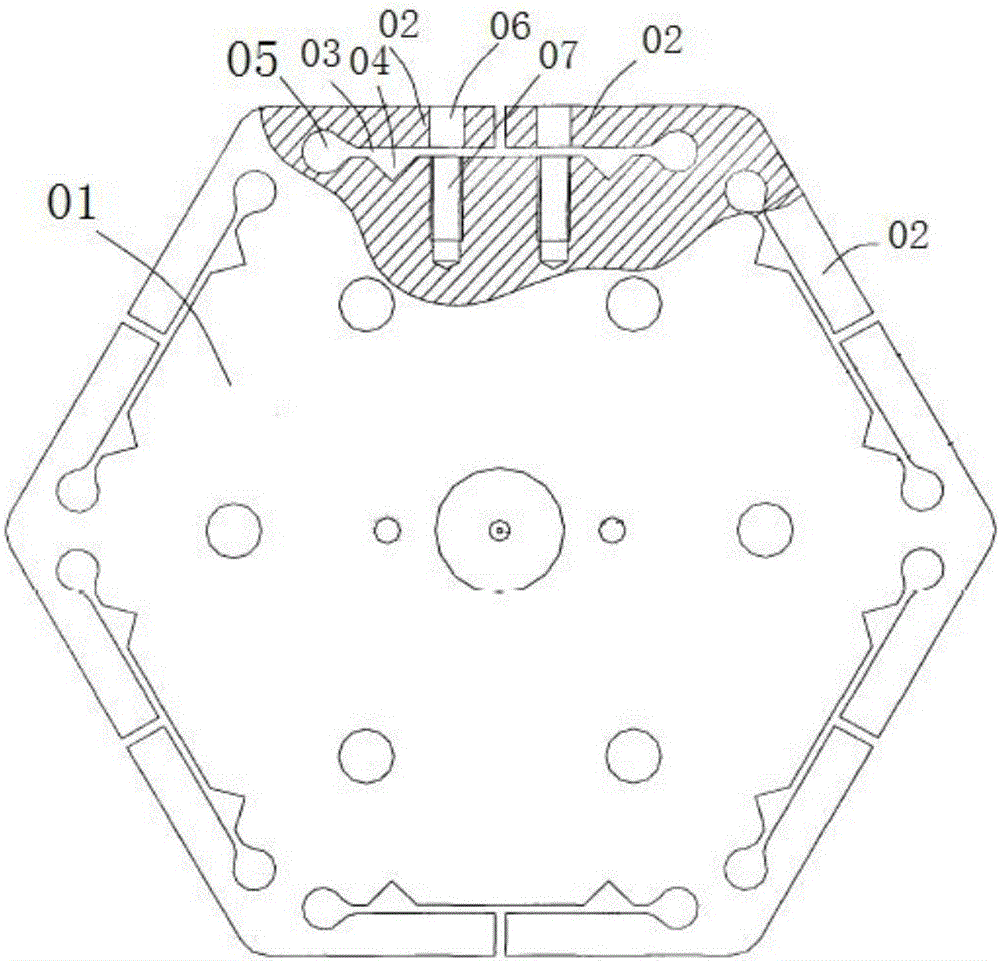

[0067] This embodiment provides a grinding fixture, such as Figure 4-5 As shown, it includes a disc-shaped clamp body 1; elastic positioning arms 2 have free ends and connecting ends, and the connecting ends of a plurality of elastic positioning arms 2 are uniformly fixed on the circumferential outer wall of the clamping body 1; the first extruding The surface 21 is arranged on the outer wall of one elastic positioning arm 2; the second extrusion surface 22, opposite to the first extrusion surface 21, is arranged on the inner wall of the other elastic positioning arm 2; the other elastic positioning arm 2 It is close to the one elastic positioning arm 2 under the action of its own elastic force, so that the first extrusion surface 21 and the second extrusion surface 22 are connected close to each other, so as to squeeze the first position of the positioning ferrule 3; and Under the action of external force, overcome its own elastic force and set a distance away from the elast...

Embodiment 2

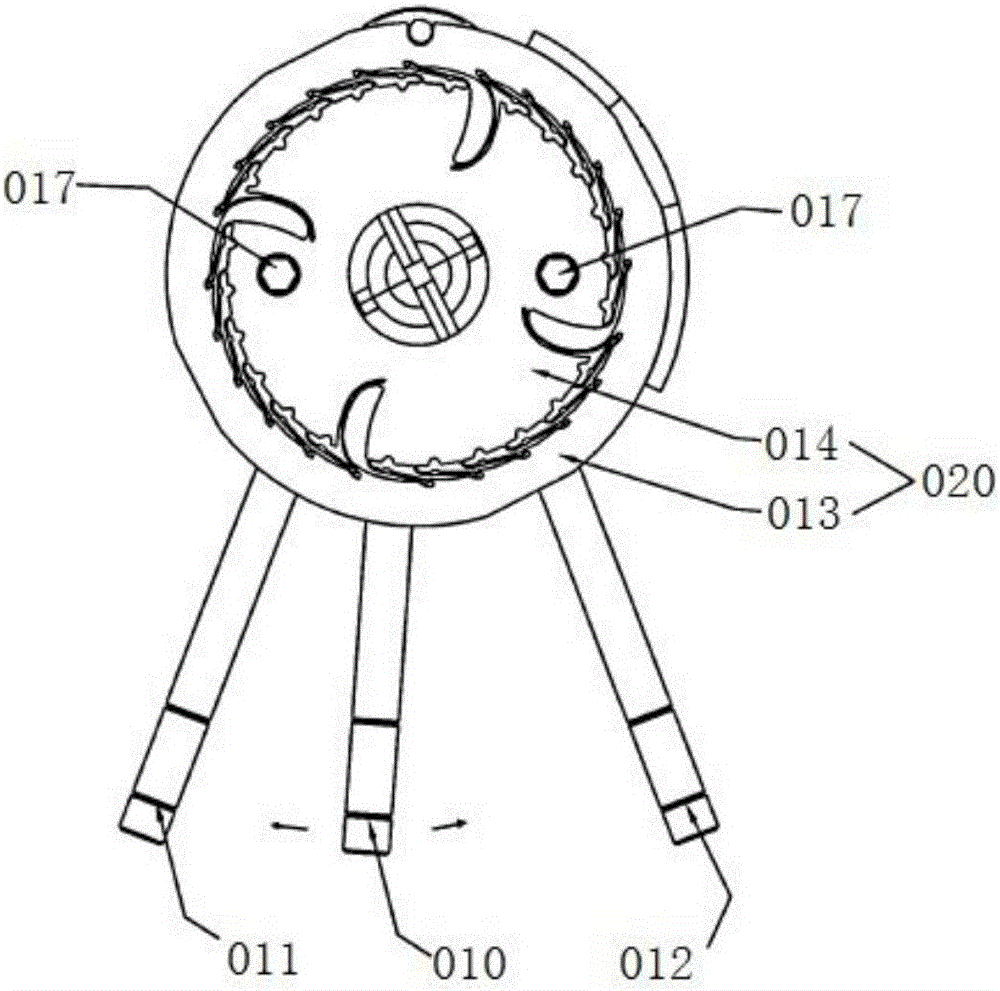

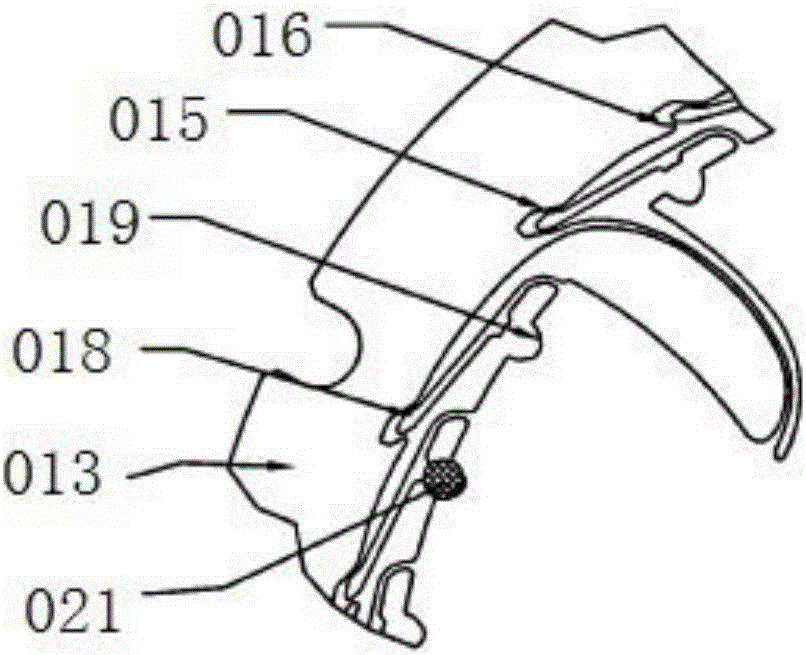

[0075] This embodiment provides a jig, which is used to cooperate with the jig in Embodiment 1, such as Figure 6-7 shown, including:

[0076] The base 5 includes a base 51, the base 51 has a bearing surface 52, a positioning plate 53 is fixed on the bearing surface 52, and a circular through hole 54 is provided on the positioning plate 53, and after the positioning plate 53 is fixed on the bearing surface 52, the circle A circular groove 50 is formed at the position of the shaped through hole 54;

[0077] The jig body 6 is rotatably installed inside the circular groove 50, the middle part is provided with an installation space 61 suitable for the installation of the grinding fixture, and the inner side is provided with a free end (insert part 25) suitable for the elastic positioning arm 2. ) cooperate with the jig groove 62 inserted, and the jig groove 62 corresponds to the free end of the elastic positioning arm 2 one by one;

[0078] Under the action of external force, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com