Cloth cutting bed

A cloth cutting and outer surface technology, which is applied in the field of cutting bed, can solve the problems that thin threads are easily inhaled into the body, the area of the cutting bed is large, and the effect of cutting cloth is affected, so as to prevent the cloth cutting effect from being good and avoid the body Discomfort, the effect of ensuring physical health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

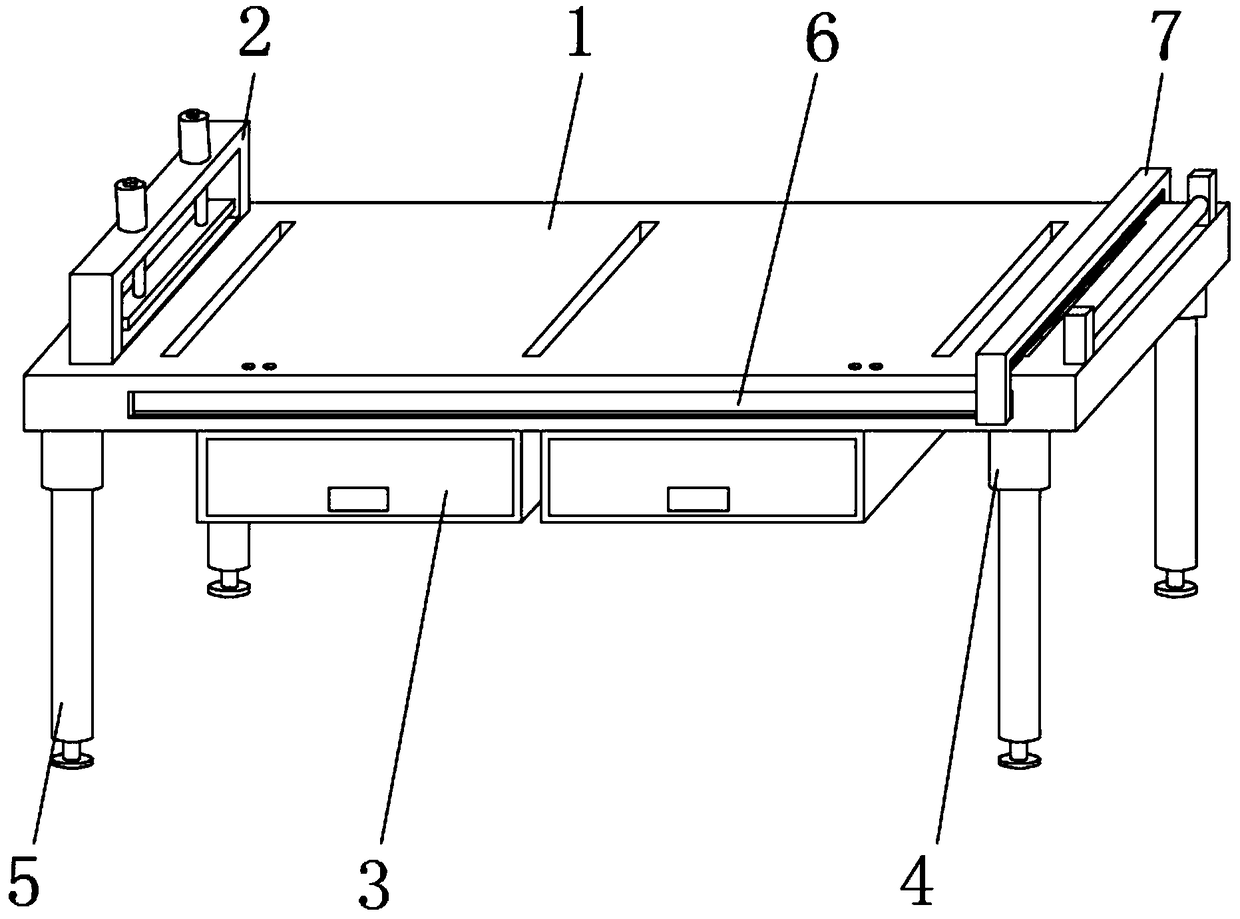

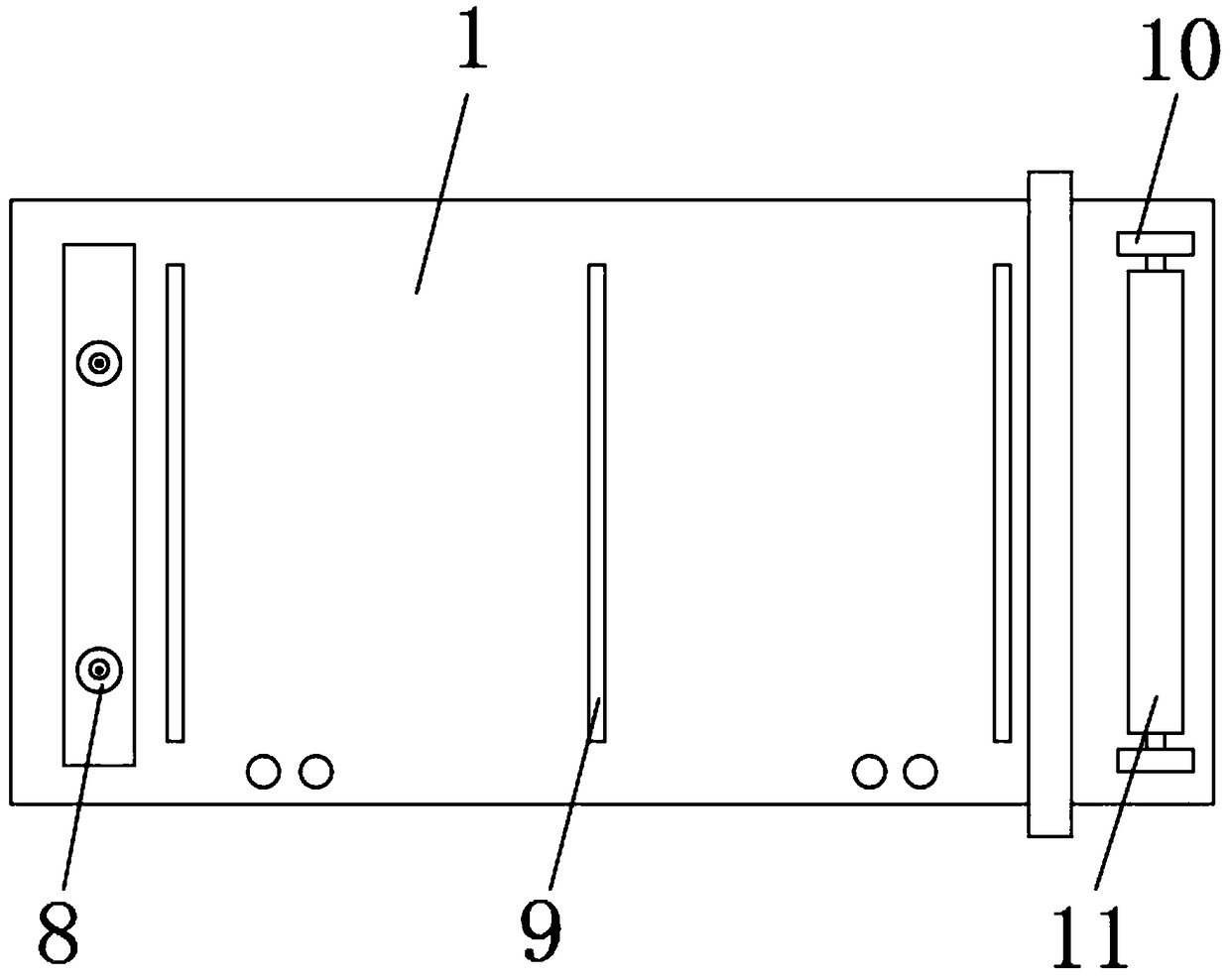

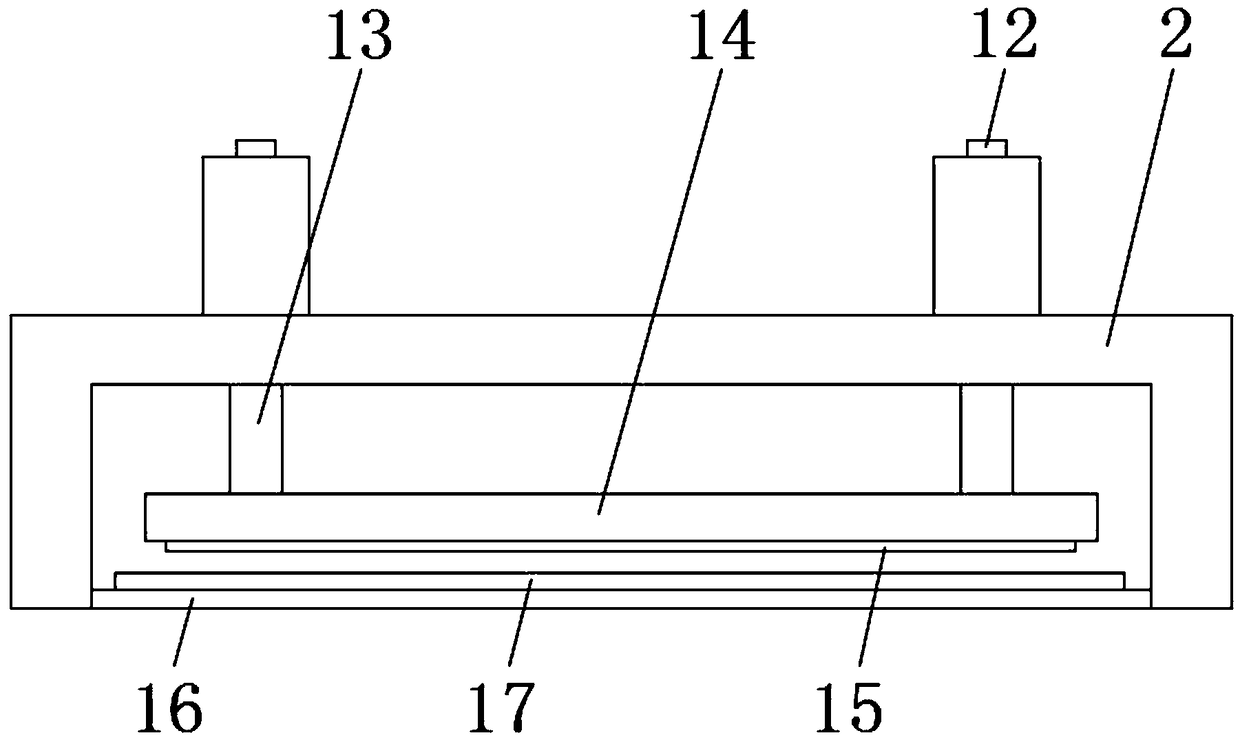

[0028] Such as Figure 1-5 As shown, a cutting bed includes a main body 1 of the cutting bed. A fixing frame 2 is fixedly installed on the outer surface of the upper end of the main body 1 of the cutting bed near one side. A set of drawers 3, a shock absorber 4 is fixedly installed on the outer surface of the lower end of the main body of the cutting bed 1 close to the four corners, and a support column 5 is fixedly installed on the outer surface of the lower end of the shock absorber 4. The surfaces are all provided with sliding grooves 6, and the outer surface of the front end of the main body of the cutting bed 1 is provided with a movable frame 7 on the side away from the fixed frame 2, and the outer surface of the upper end of the main body of the cutting bed 1 is provided with three sets of strip grooves 9. The outer surface of the upper end of the main body 1 is provided with two sets of fixed plates 10 on the side close to the movable frame 7. Bearings are fixedly inst...

Embodiment 2

[0032] Such as Figure 1-5 As shown, a cutting bed includes a main body 1 of the cutting bed. A fixing frame 2 is fixedly installed on the outer surface of the upper end of the main body 1 of the cutting bed near one side. A set of drawers 3, a shock absorber 4 is fixedly installed on the outer surface of the lower end of the main body of the cutting bed 1 close to the four corners, and a support column 5 is fixedly installed on the outer surface of the lower end of the shock absorber 4. The surfaces are all provided with sliding grooves 6, and the outer surface of the front end of the main body of the cutting bed 1 is provided with a movable frame 7 on the side away from the fixed frame 2, and the outer surface of the upper end of the main body of the cutting bed 1 is provided with three sets of strip grooves 9. The outer surface of the upper end of the main body 1 is provided with two sets of fixed plates 10 on the side close to the movable frame 7. Bearings are fixedly inst...

Embodiment 3

[0037] Such as Figure 1-5 As shown, a cutting bed includes a main body 1 of the cutting bed. A fixing frame 2 is fixedly installed on the outer surface of the upper end of the main body 1 of the cutting bed near one side. A set of drawers 3, a shock absorber 4 is fixedly installed on the outer surface of the lower end of the main body of the cutting bed 1 close to the four corners, and a support column 5 is fixedly installed on the outer surface of the lower end of the shock absorber 4. The surfaces are all provided with sliding grooves 6, and the outer surface of the front end of the main body of the cutting bed 1 is provided with a movable frame 7 on the side away from the fixed frame 2, and the outer surface of the upper end of the main body of the cutting bed 1 is provided with three sets of strip grooves 9. The outer surface of the upper end of the main body 1 is provided with two sets of fixed plates 10 on the side close to the movable frame 7. Bearings are fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com