Patents

Literature

589results about How to "Prevent excessive deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

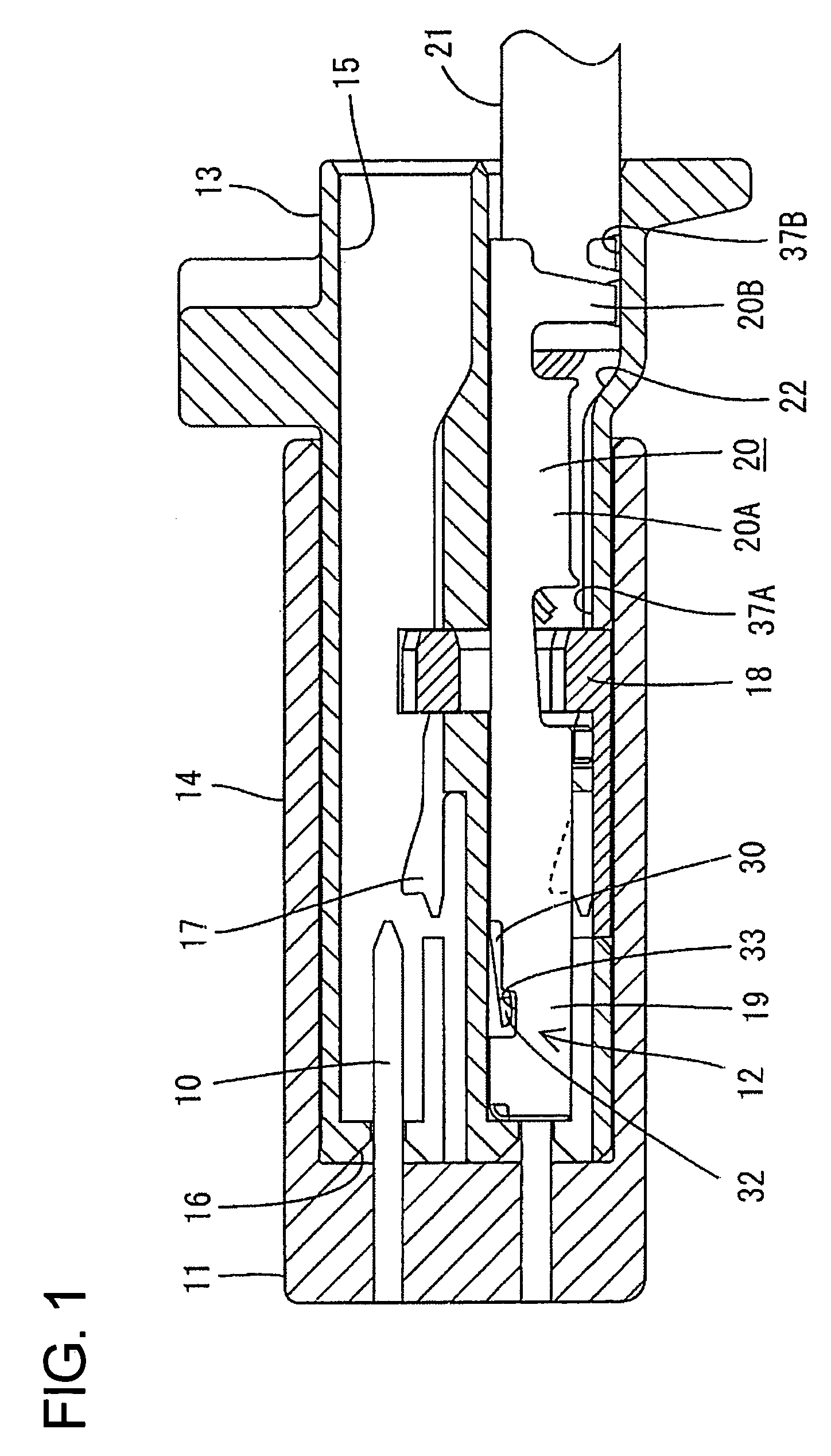

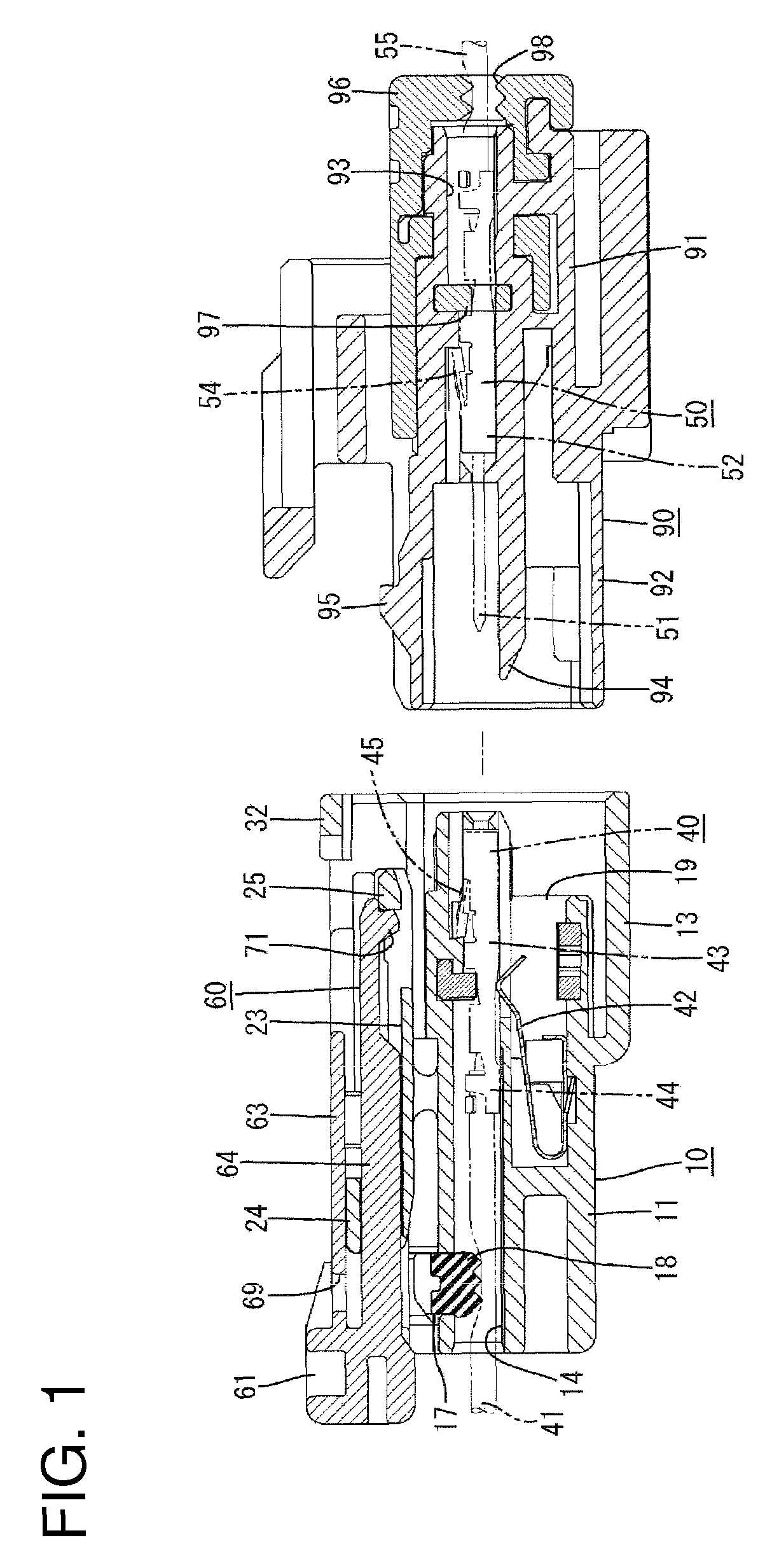

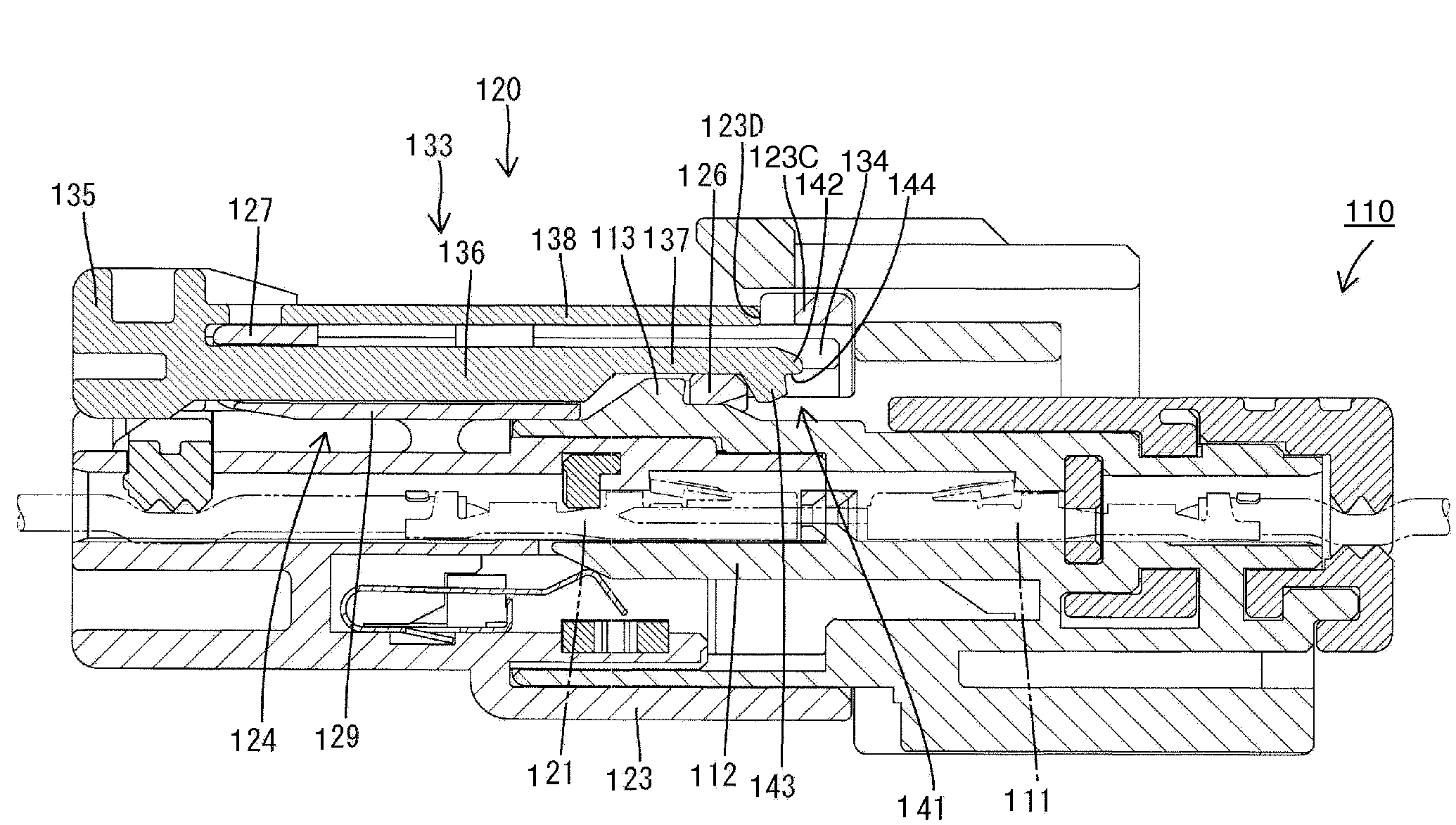

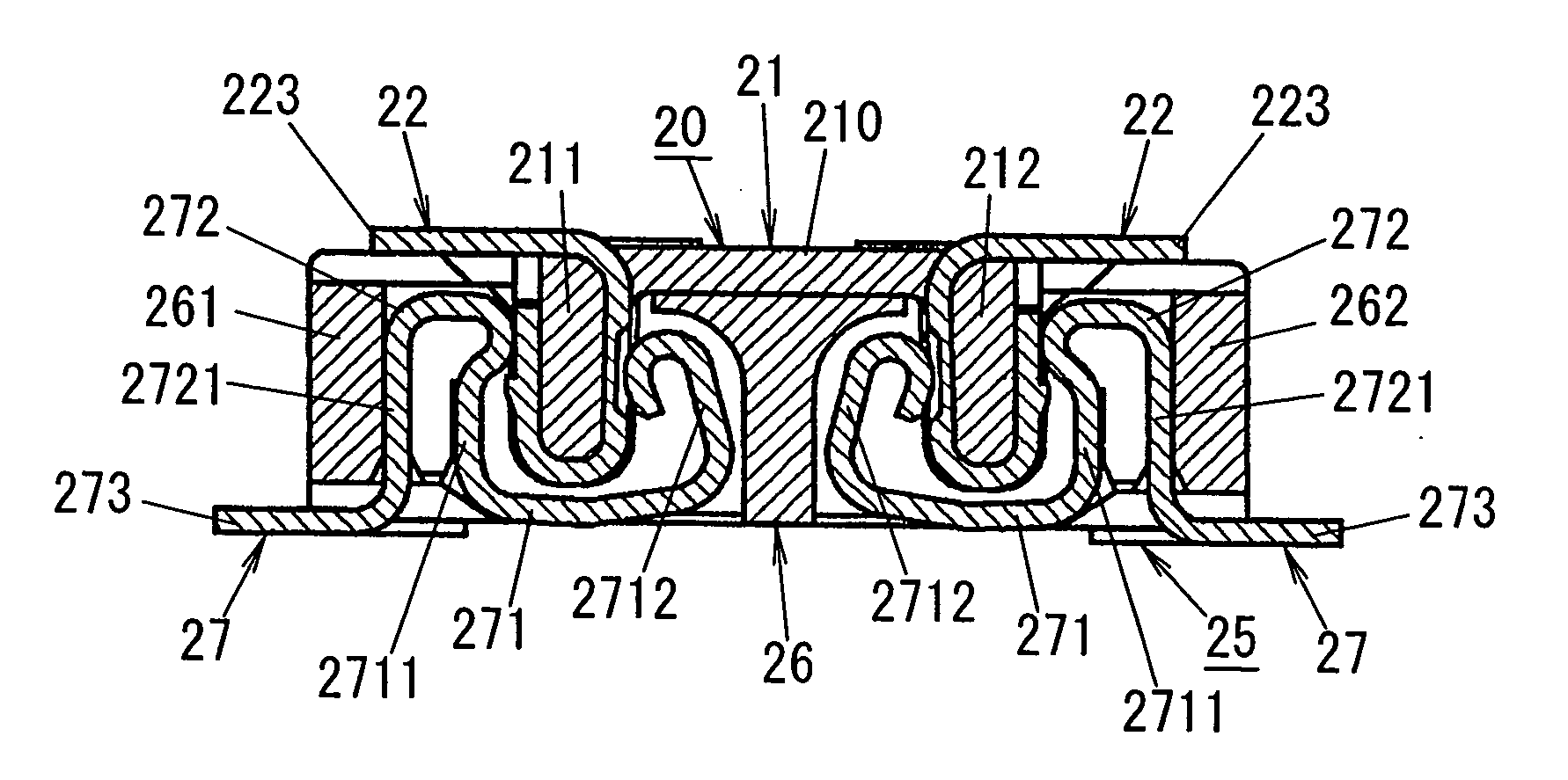

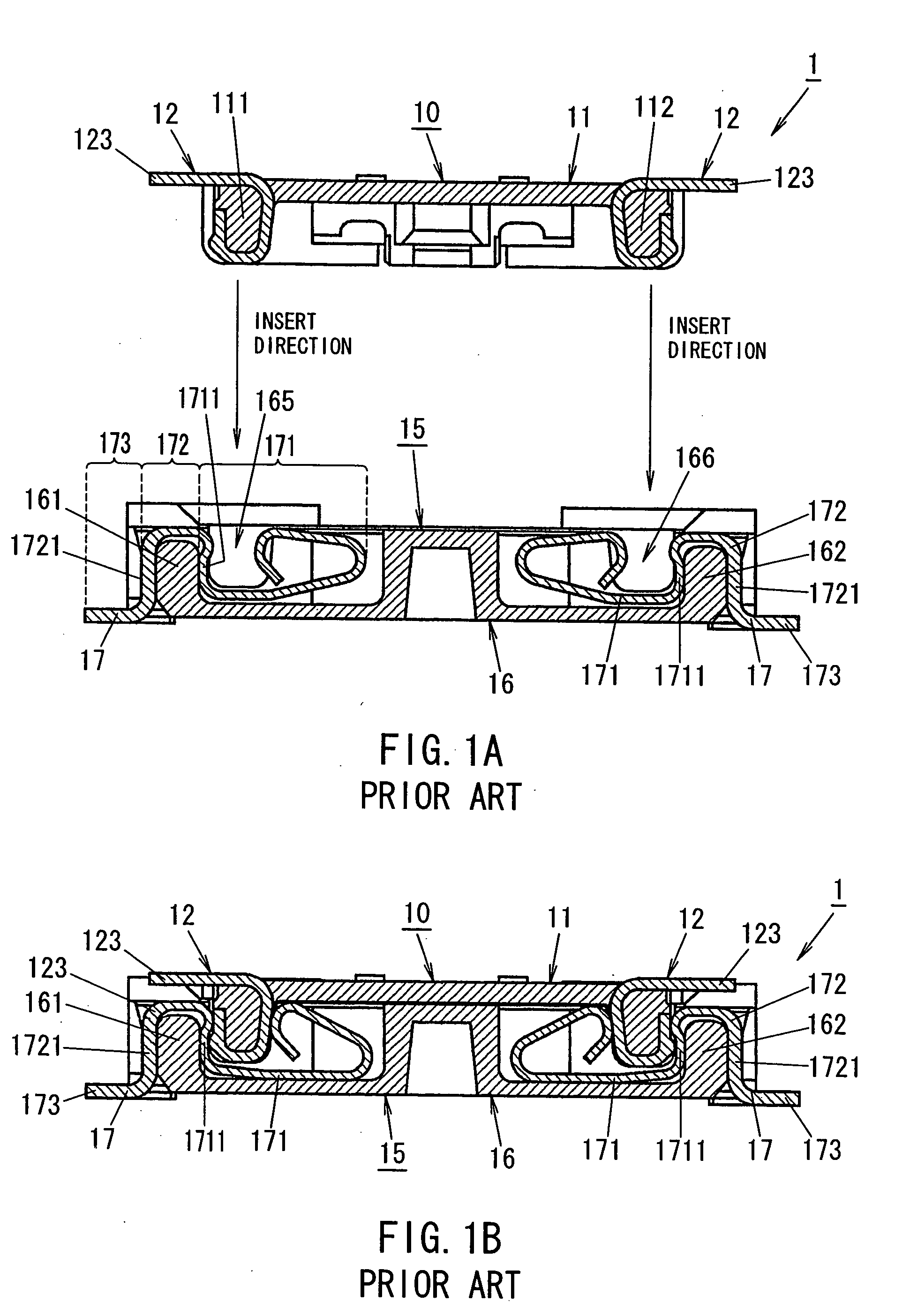

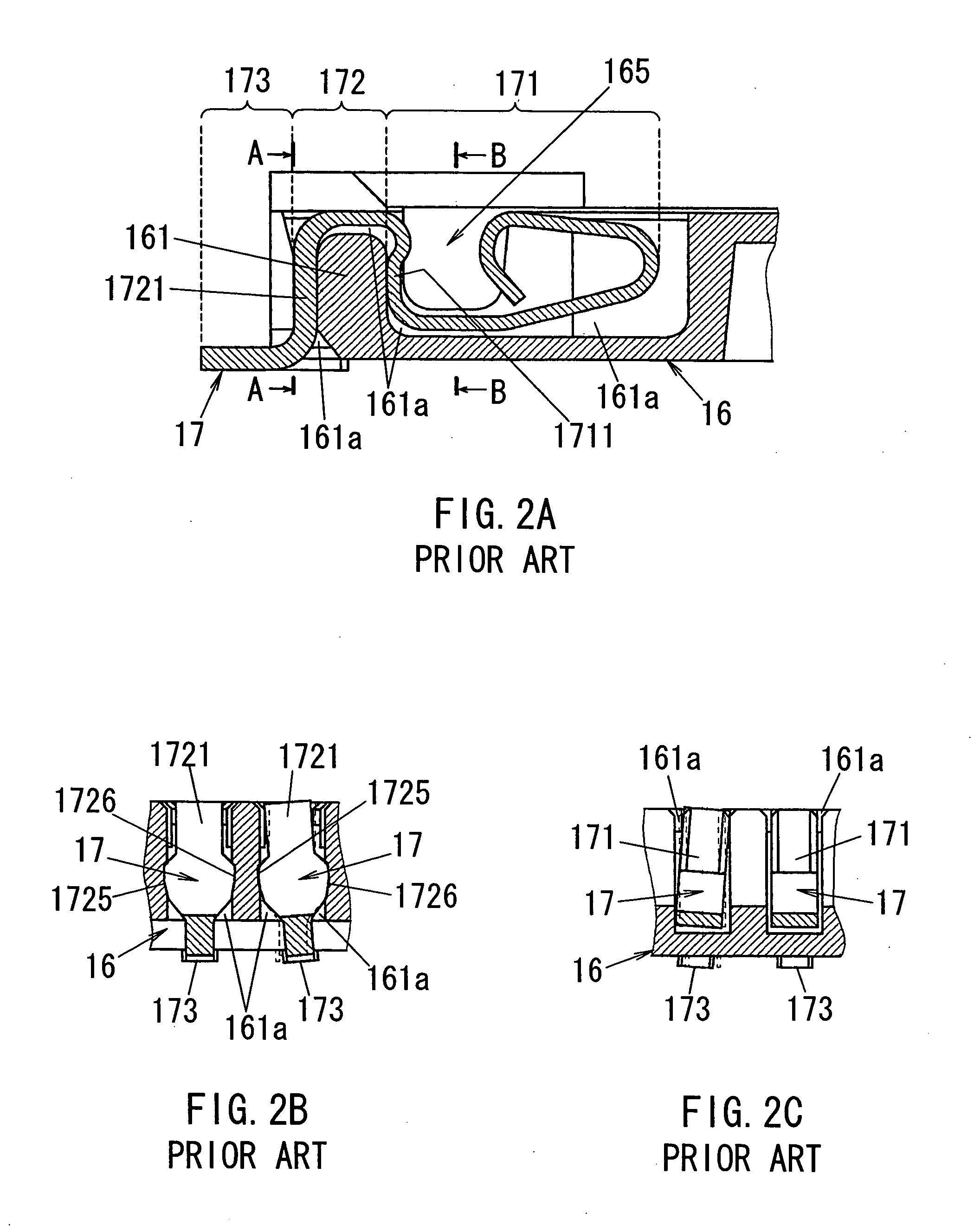

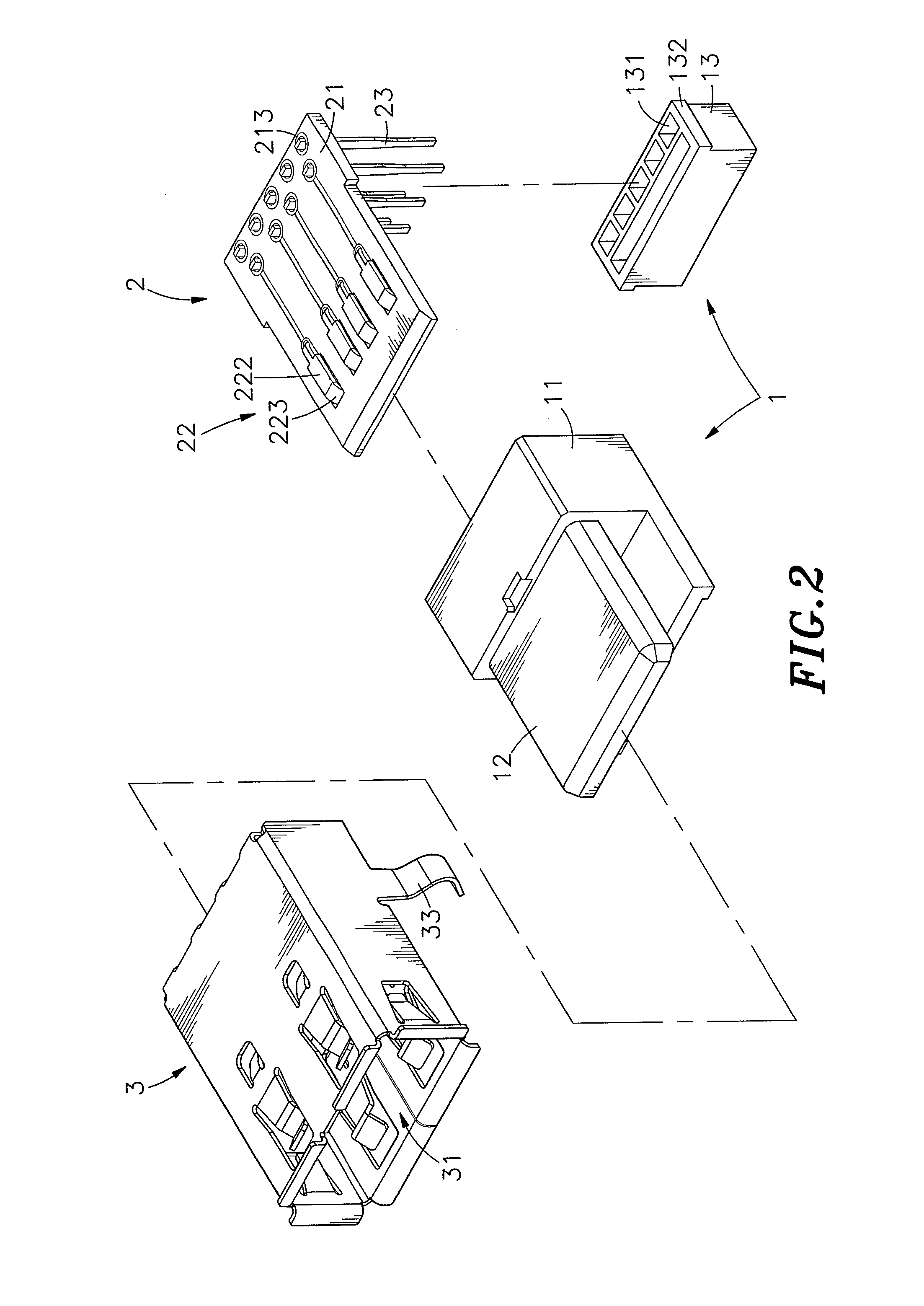

Connector with header connector and socket connector that are mechanically and electrically connected with each other

ActiveUS7410364B2Increase in sizeIncrease the lengthSubstation/switching arrangement detailsElectric discharge tubesEngineeringMechanical engineering

Owner:MATSUSHITA ELECTRIC WORKS LTD

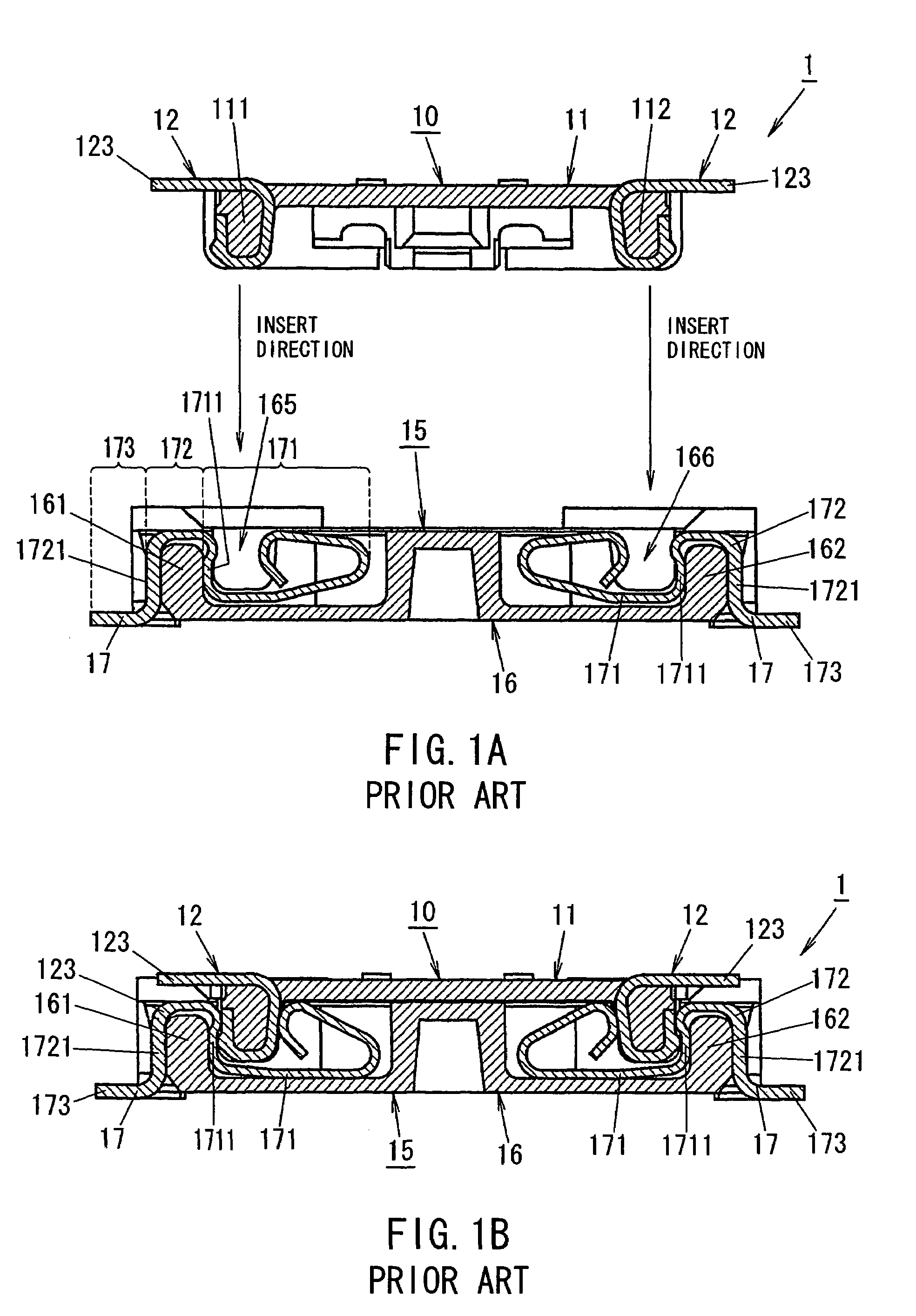

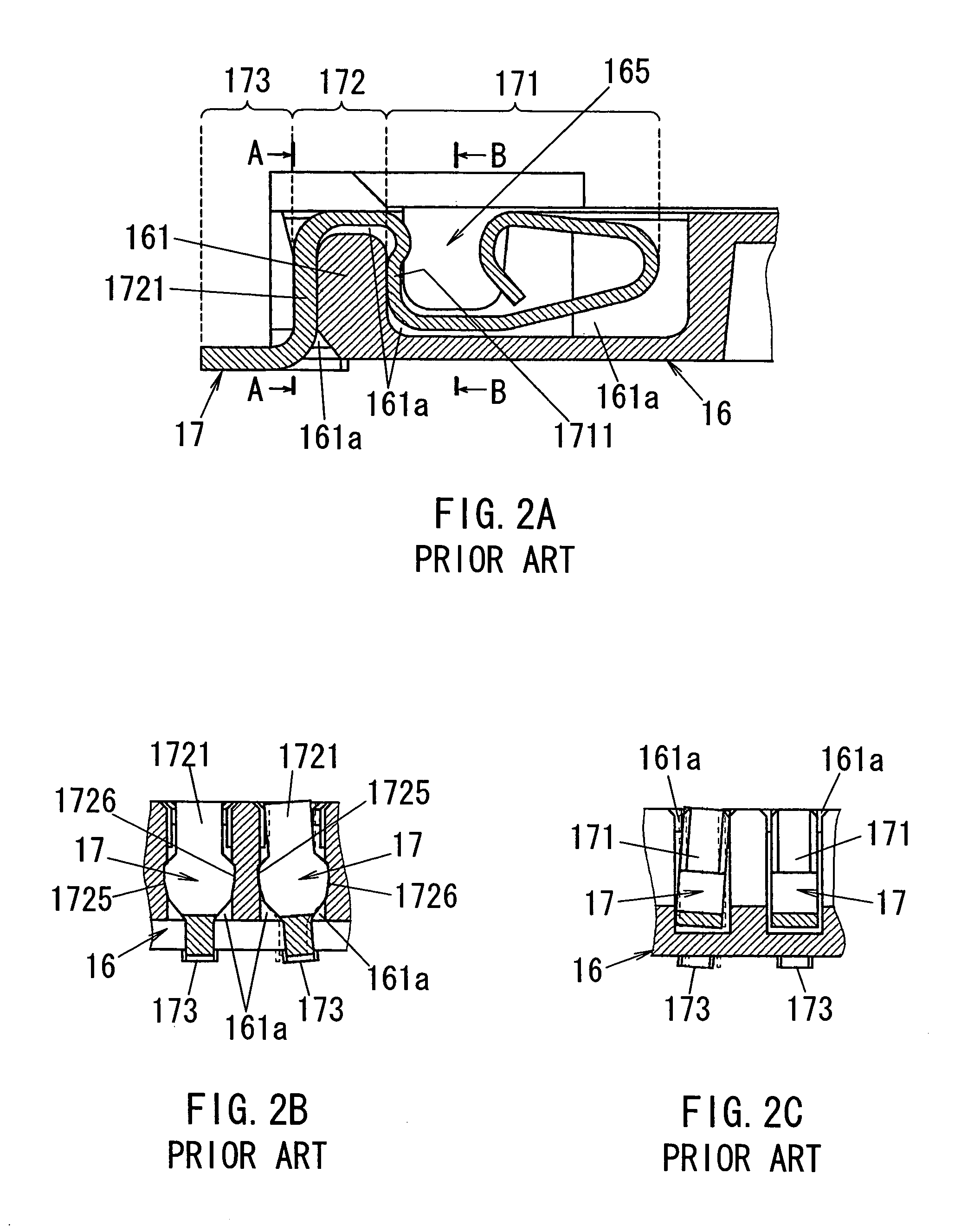

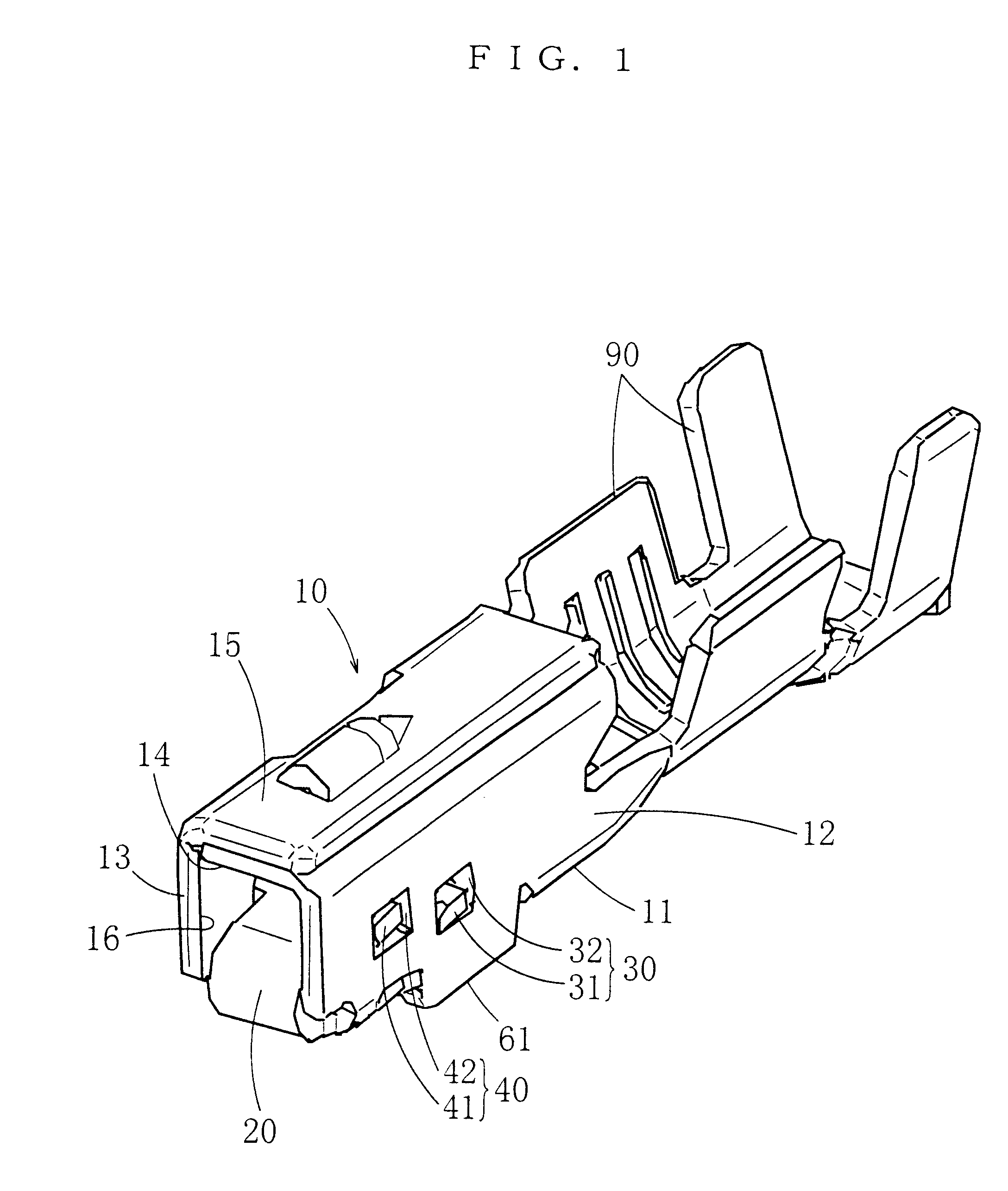

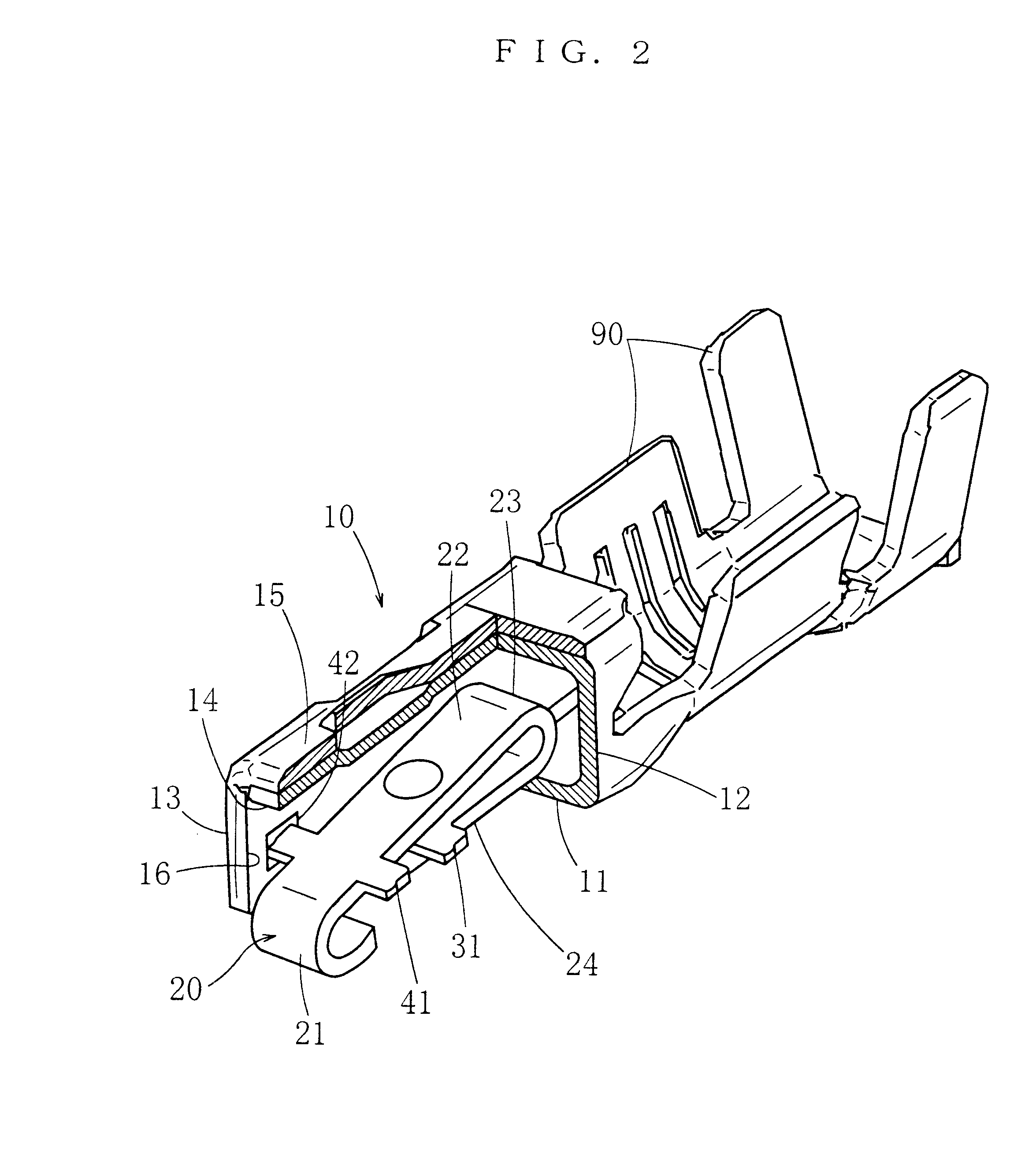

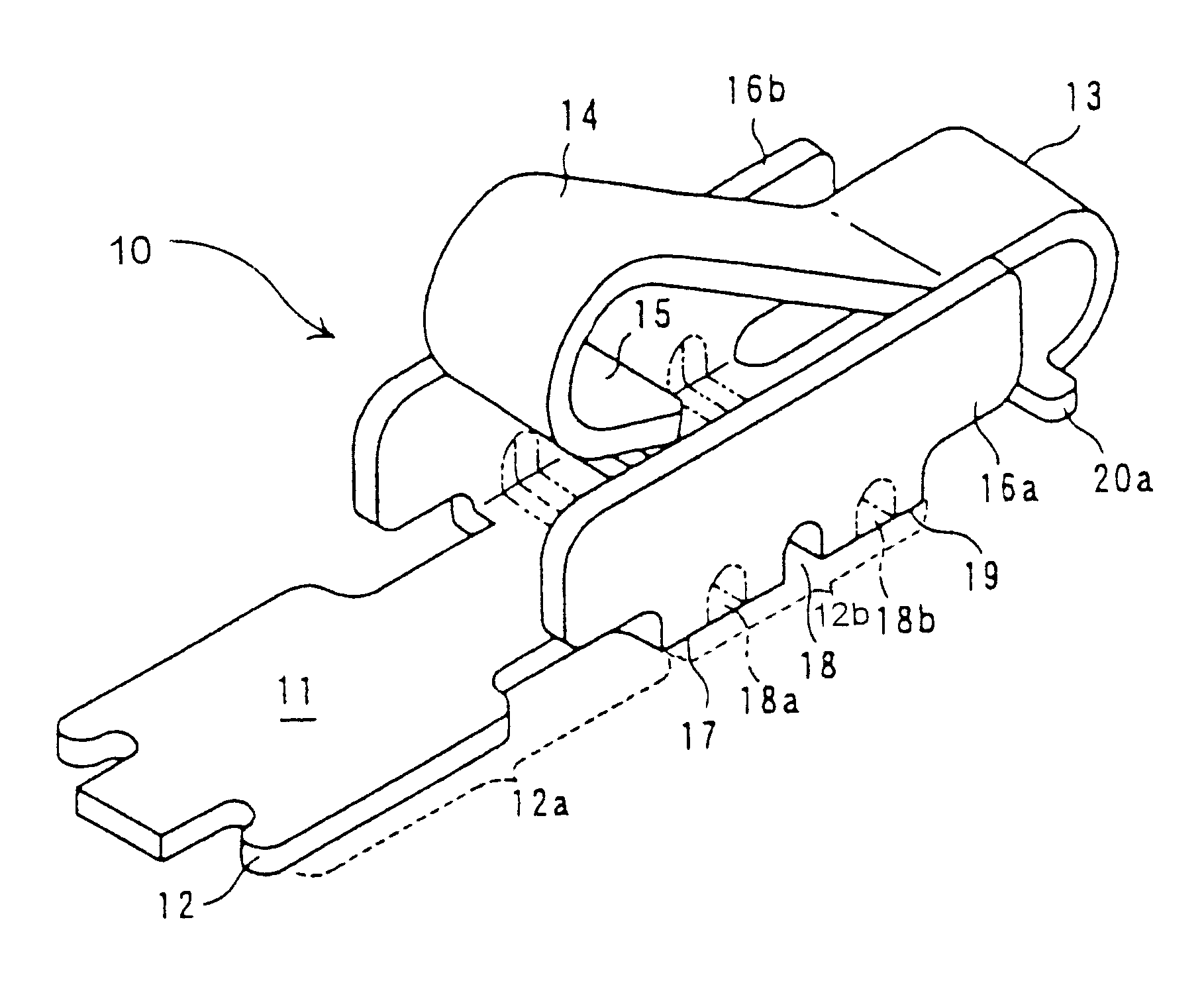

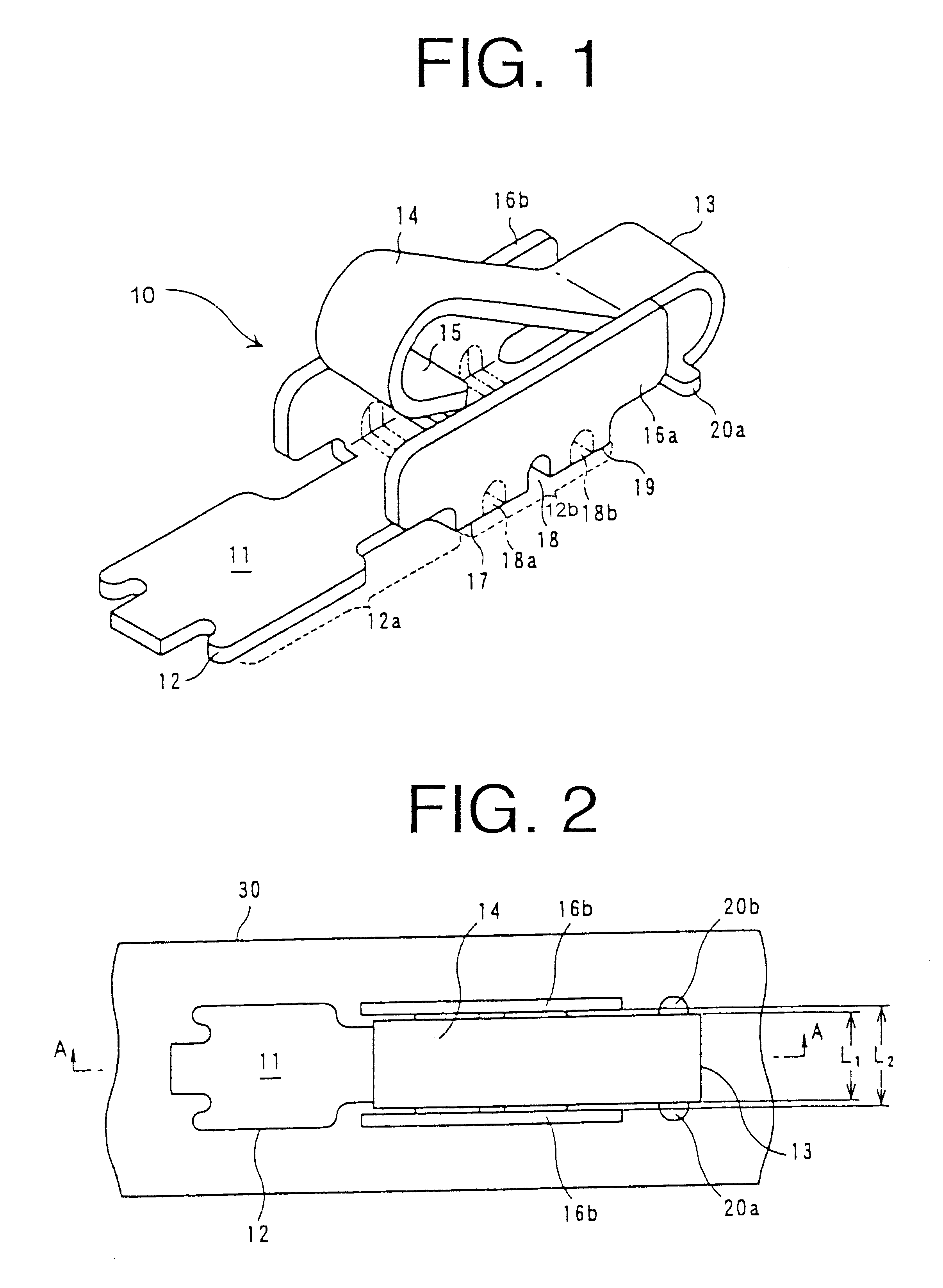

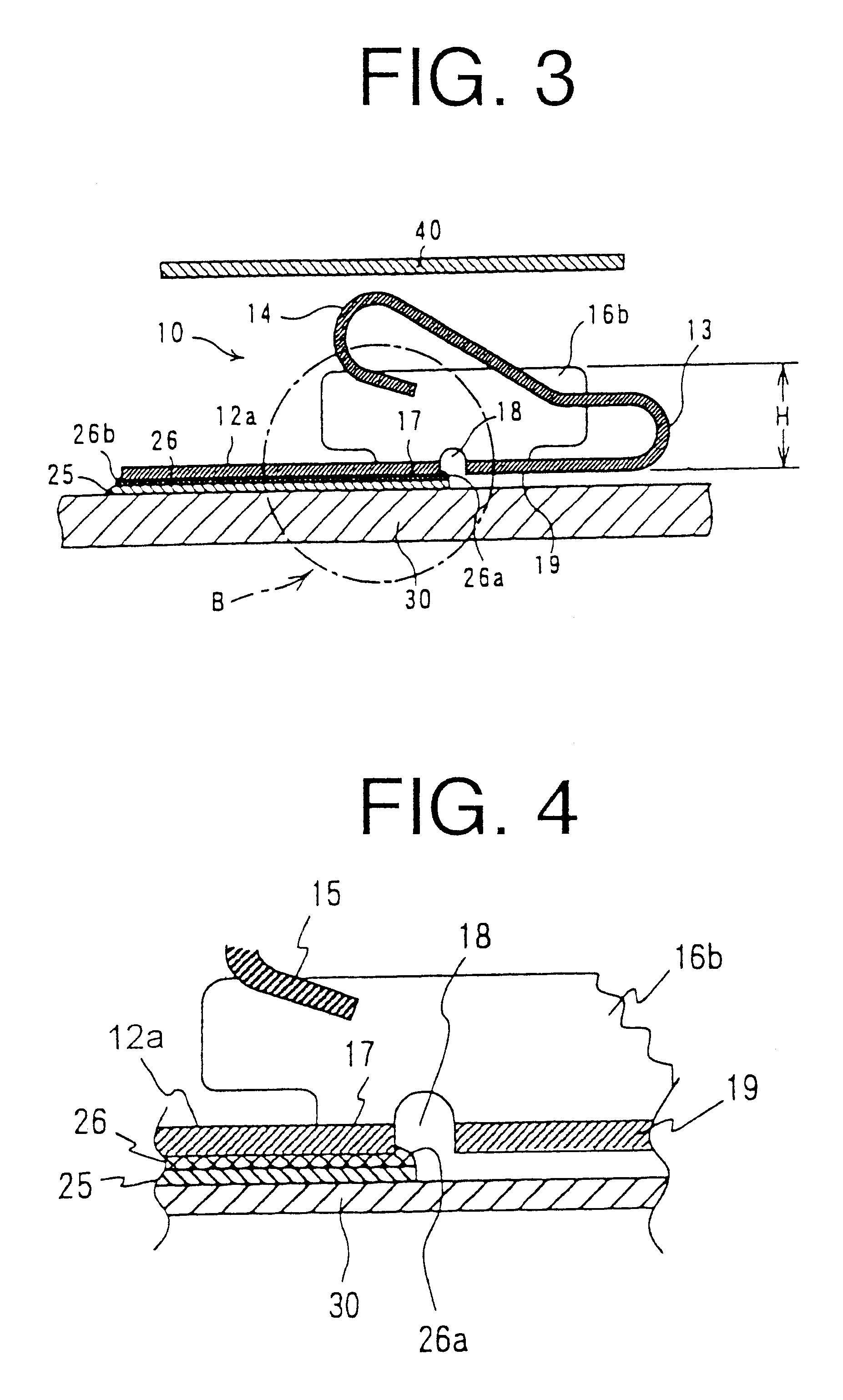

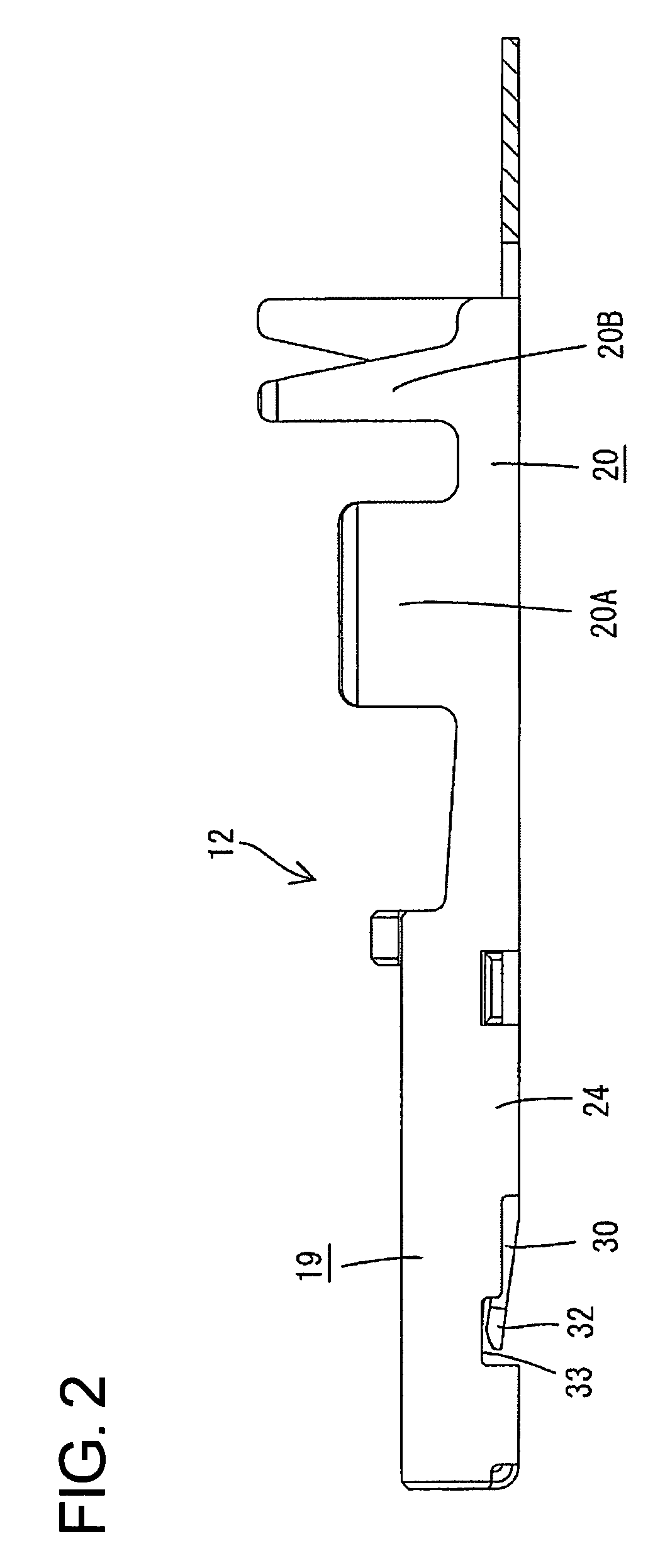

Female terminal

InactiveUS6527601B2Prevent excessive deformationPrevent the leaf spring from being deformed excessivelyCoupling contact membersElectric connection basesLeaf springEngineering

A female terminal includes: a tubular body; a leaf spring inside the body having a first bent part bent upward and rearward from the front end of the bottom wall of the body, an intermediate part extending rearward from the first bent part, a second bent part bent downward and forward from the rear end of the intermediate part, and a top end part extending forward from the second bent part and spaced away from the intermediate part; a first fitting means for fitting the front end of the top end part onto the side walls; a second fitting means, which allows the intermediate part to be displaced downward to contact the top end part of the leaf spring, and a part ahead thereof to be displaced downward until the intermediate part fits onto the side walls at the bottom dead point; and a flexible-piece-receiving hole in the bottom wall ahead of a part at which the leaf spring will contact the bottom wall.

Owner:JST MFG CO LTD

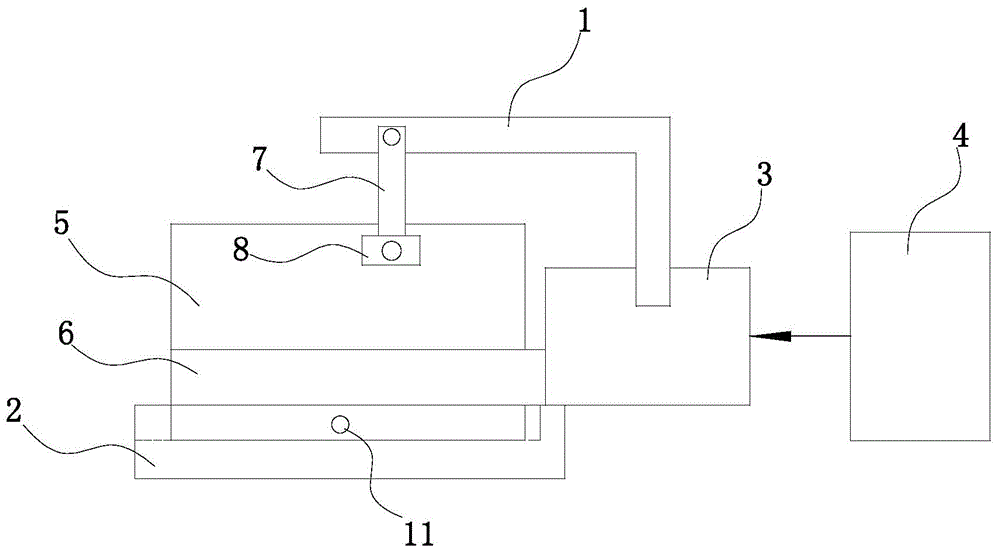

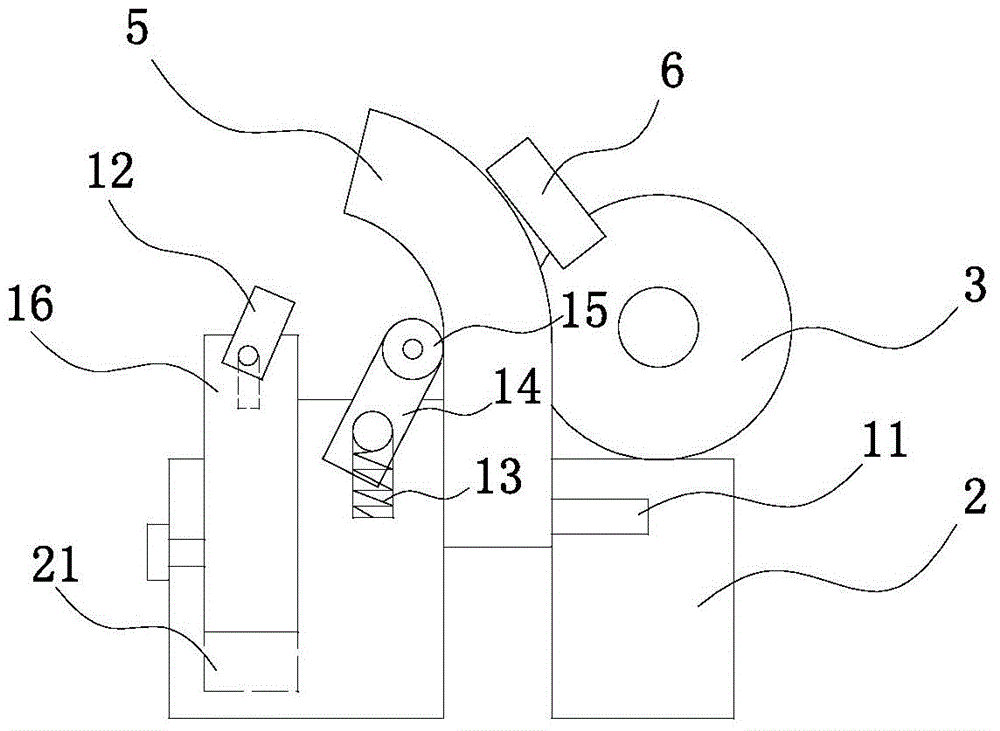

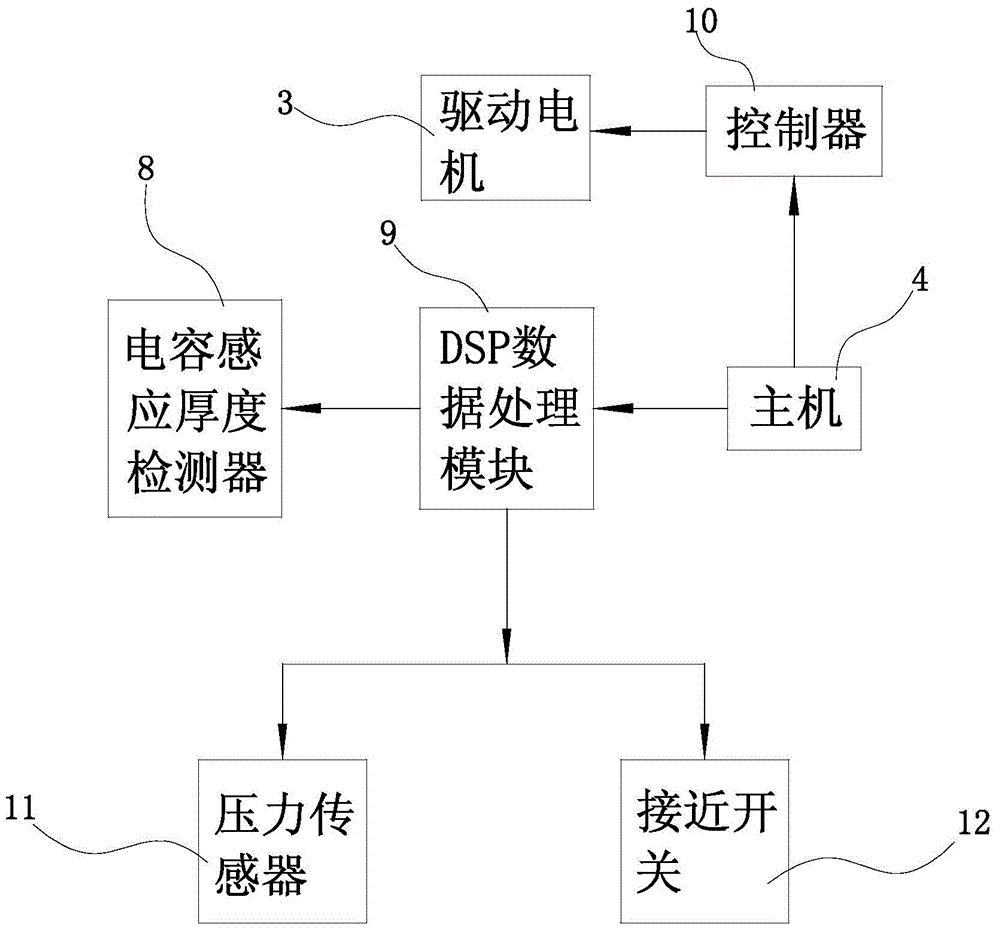

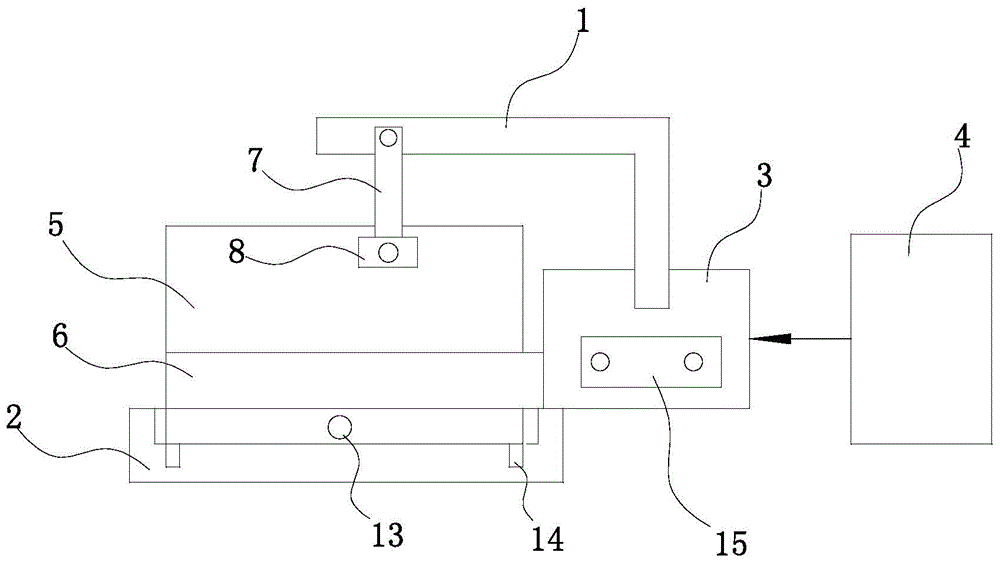

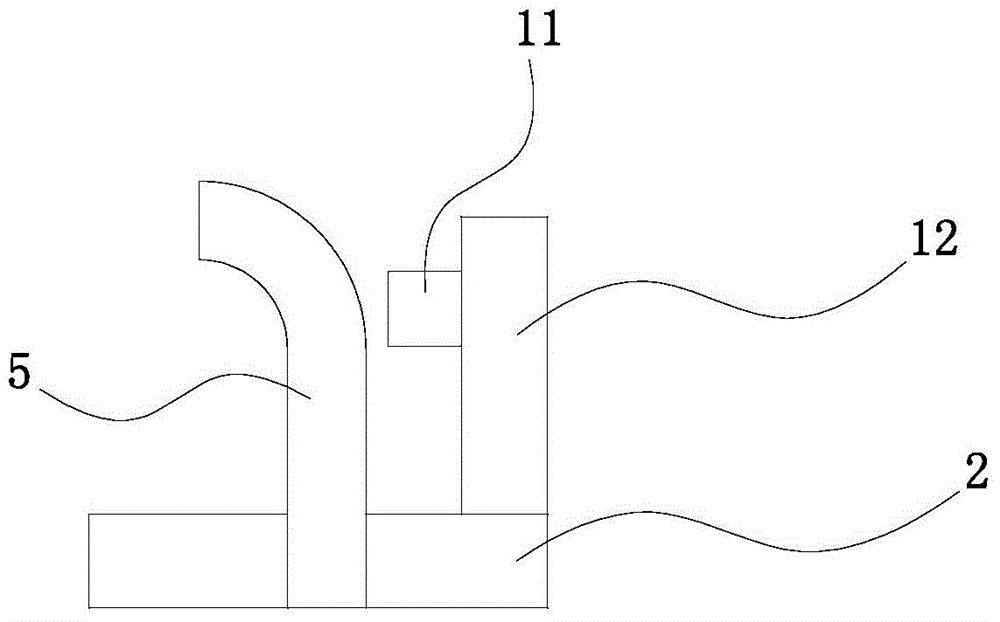

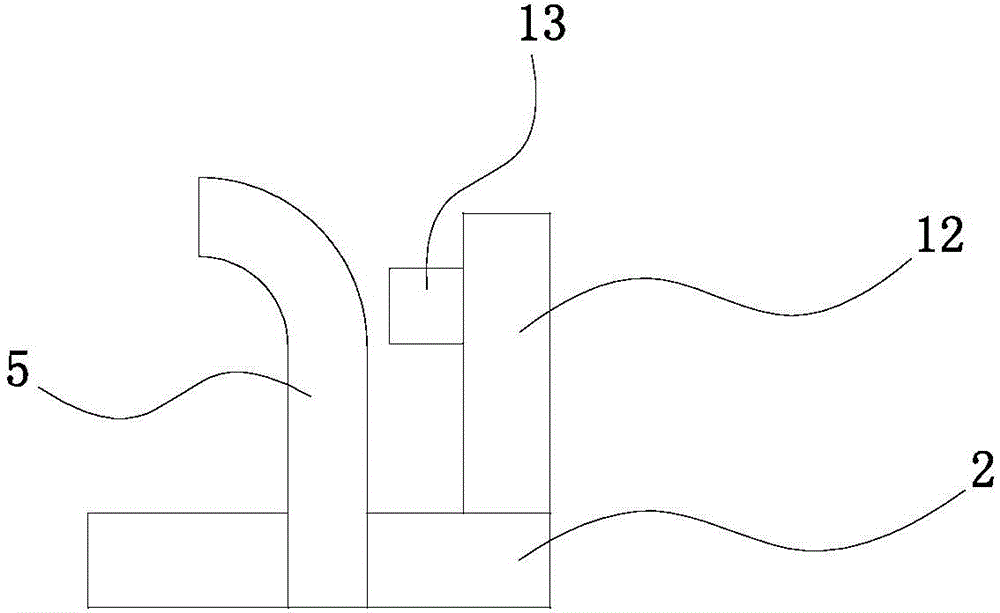

Bending machine controlling torque adjustment and roll bending through PLC and method

InactiveCN104624737APrevent looseningPrevent excessive deformationMetal-working feeding devicesMetal working apparatusCapacitanceAutomatic control

The invention relates to a bending machine controlling torque adjustment and roll bending through a PLC and a method. The bending machine comprises a driving motor, a clamping-fixing seat and a PLC mainframe, wherein the driving motor, the clamping-fixing seat and the PLC mainframe are arranged on a machine frame, a bending shaft is installed on the driving motor, and a machined part is arranged on the clamping-fixing seat. The bending machine further comprises a capacitive sensing thickness detector installed on the machine frame through a support, a proximity switch installed on the clamping-fixing seat, a pressure sensor and a rolling shaft, wherein the rolling shaft is connected to the upper end face of an adjusting plate, and the lower end face of the adjusting plate is installed in an installing groove formed in the clamping-fixing seat by means of a rotary shaft and a spring. The bending machine adopts the pressure sensor to control clamping force, and excessive deformation and looseness of boards are avoided. Bending is performed by utilizing most suitable torque, and machining quality is improved. The bending machine automatically controls a bending angle through the arranged proximity switch and prevents excessive bending. The inner concave face of the machined part is rolled through the rolling shaft, and cracks and burrs at the position of the concave face are decreased.

Owner:DONGGUAN ZHENGQIANG HARDWARE ELECTRONICS

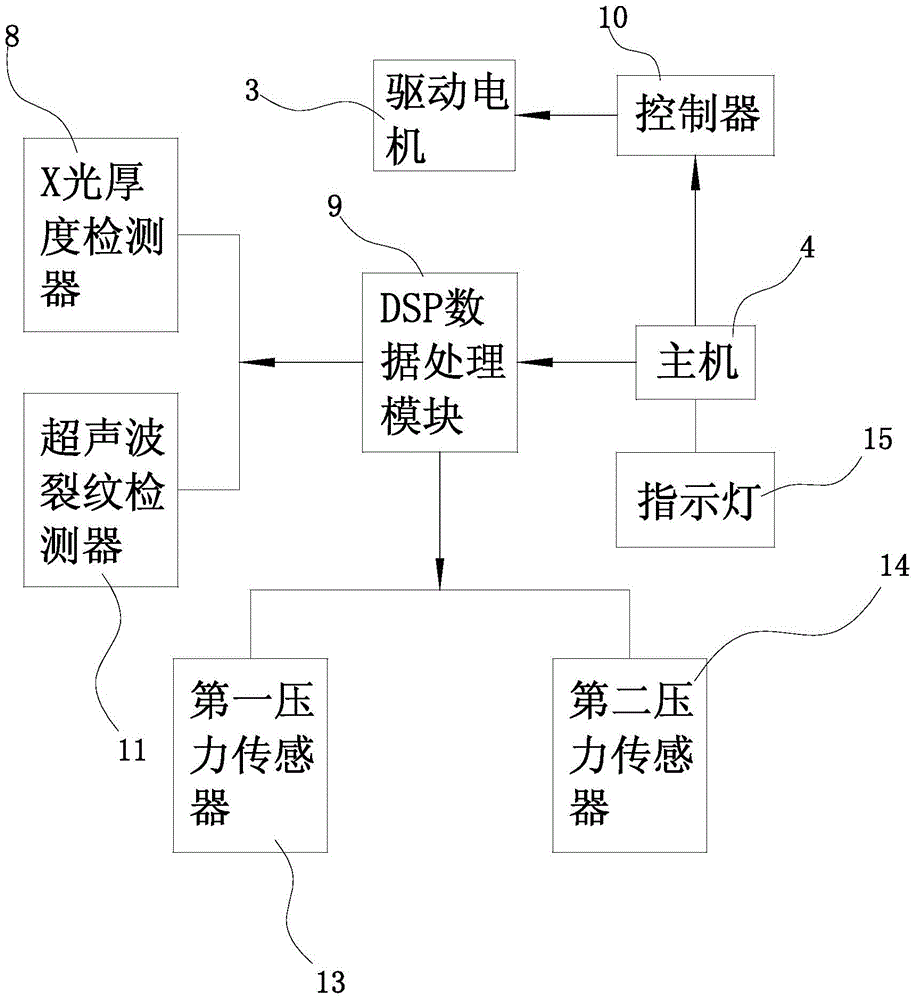

X-ray thickness detection and bending speed adjusting bending machine based on PLC

ActiveCN104624726AAvoid bendingAvoid empty foldsMetal-working feeding devicesShaping safety devicesX-rayDrive motor

The invention relates to an X-ray thickness detection and bending speed adjusting bending machine based on a PLC. The X-ray thickness detection and bending speed adjusting bending machine comprises a driving motor, a clamping fixing base, a main machine as well as an X-ray thickness detector, a first pressure sensor, a second pressure sensor and a detection feedback device, wherein the driving motor is arranged on a rack; the main machine is used for controlling the driving motor; a bending shaft is mounted on a motor shaft of the driving motor; a processed workpiece is arranged on the clamping fixing base; the X-ray thickness detector is mounted on the rack through a first bracket; the first pressure sensor and the second pressure sensor are arranged on the clamping fixing base; the detection feedback device comprises an ultrasonic crack detector which is arranged on the clamping fixing base through a second bracket. The invention further provides a bending processing method adopting the bending machine. Due to PLC controlled sectional processing and positioning detection, the phenomenon of bending deviation or bending omission can be avoided, and the processing reliability can be improved; the processed workpiece can be bent according to most appropriate torque, so that the processed workpiece is prevented from being affected by too large or too small torque, bending cracks can be reduced, and the processing quality can be improved.

Owner:南京比泰数控机械设备有限公司

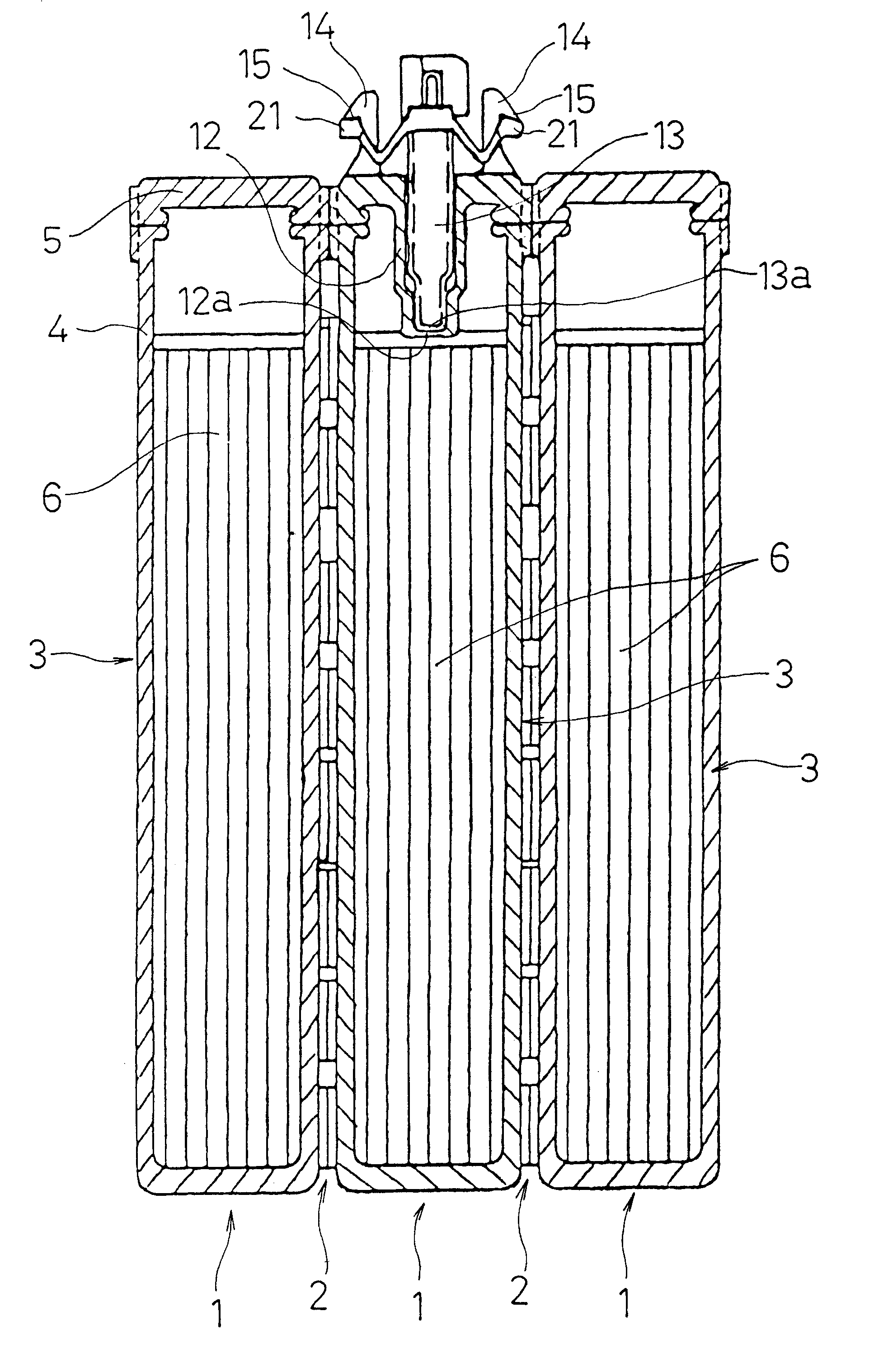

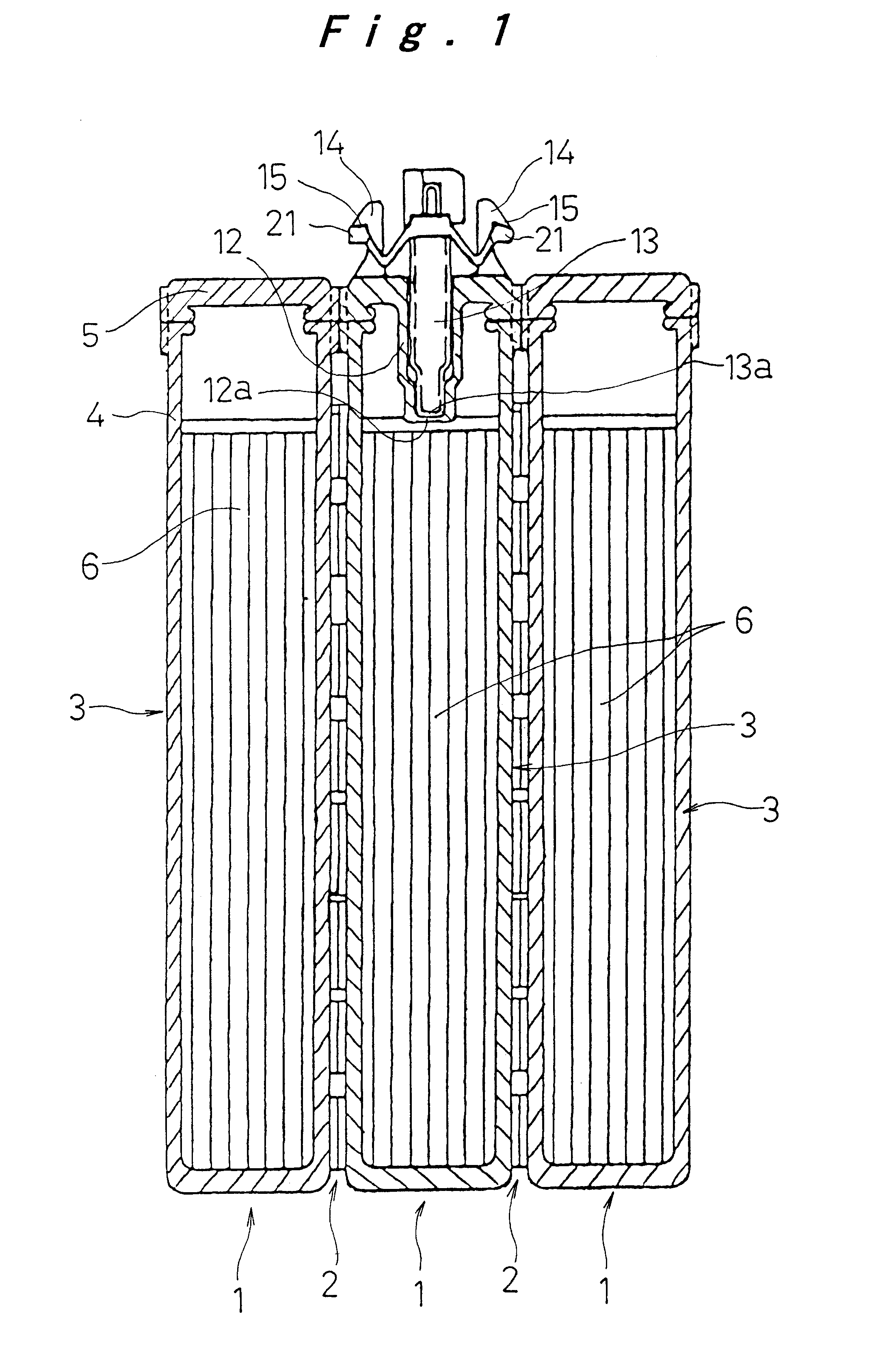

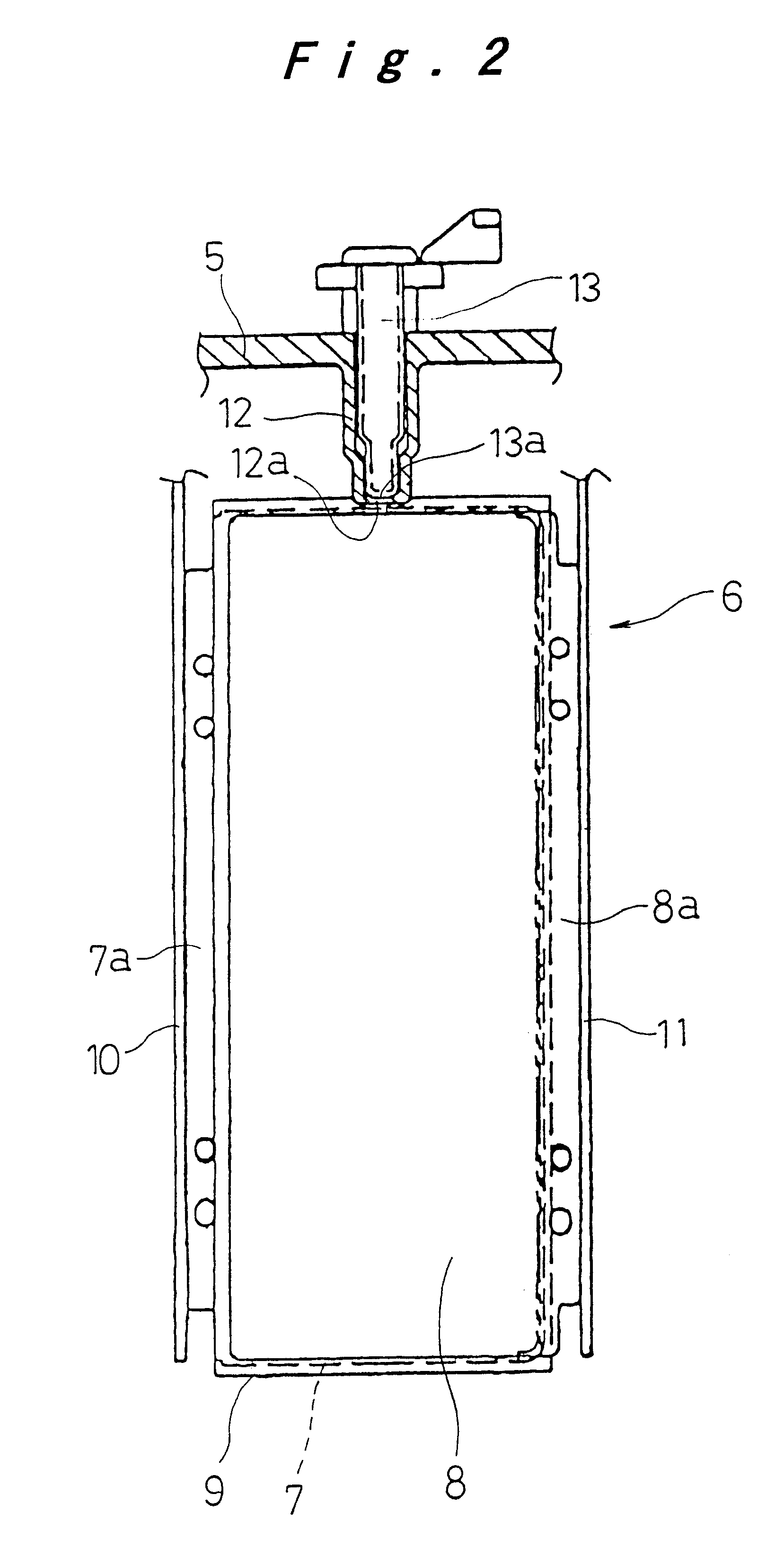

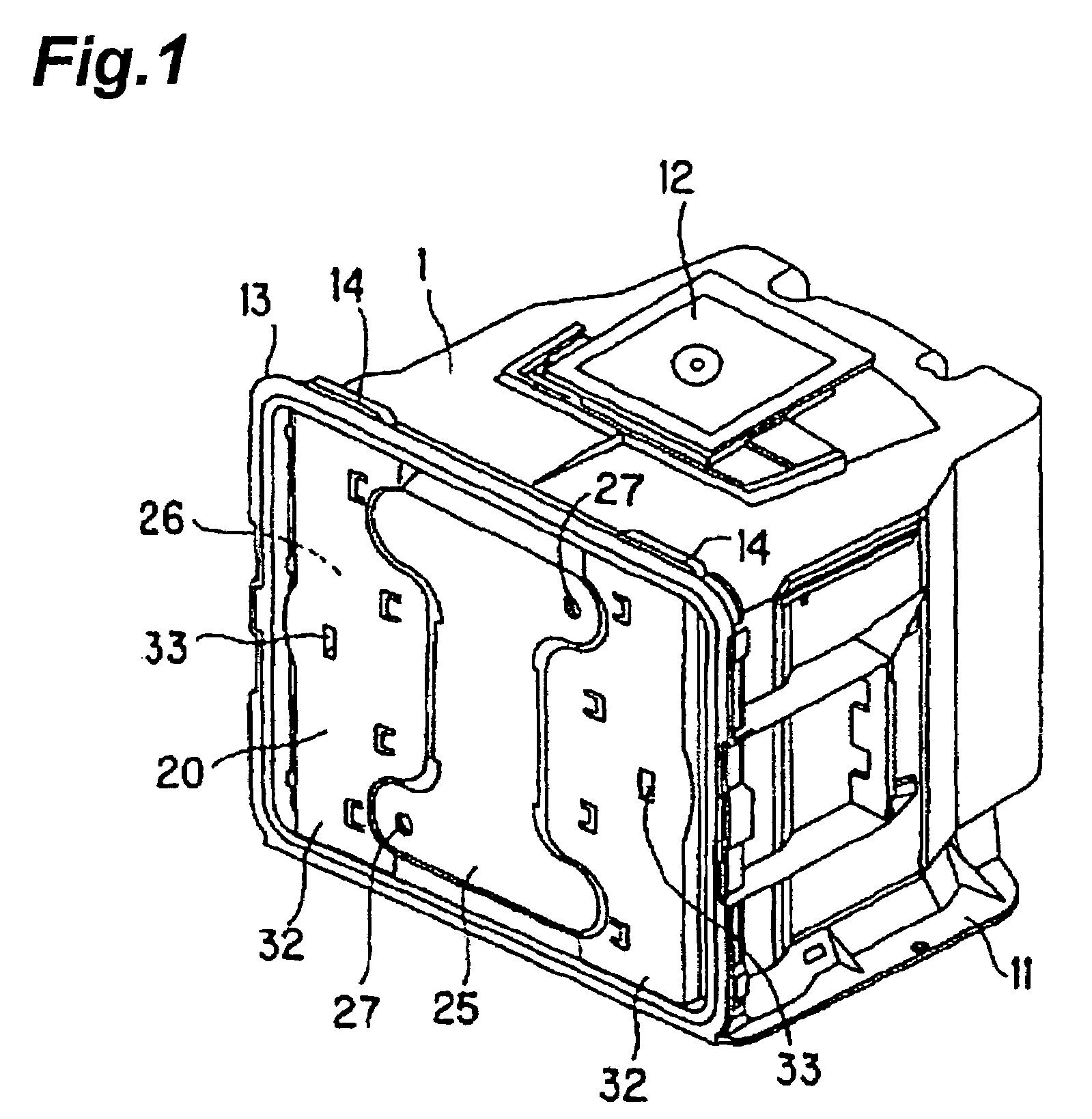

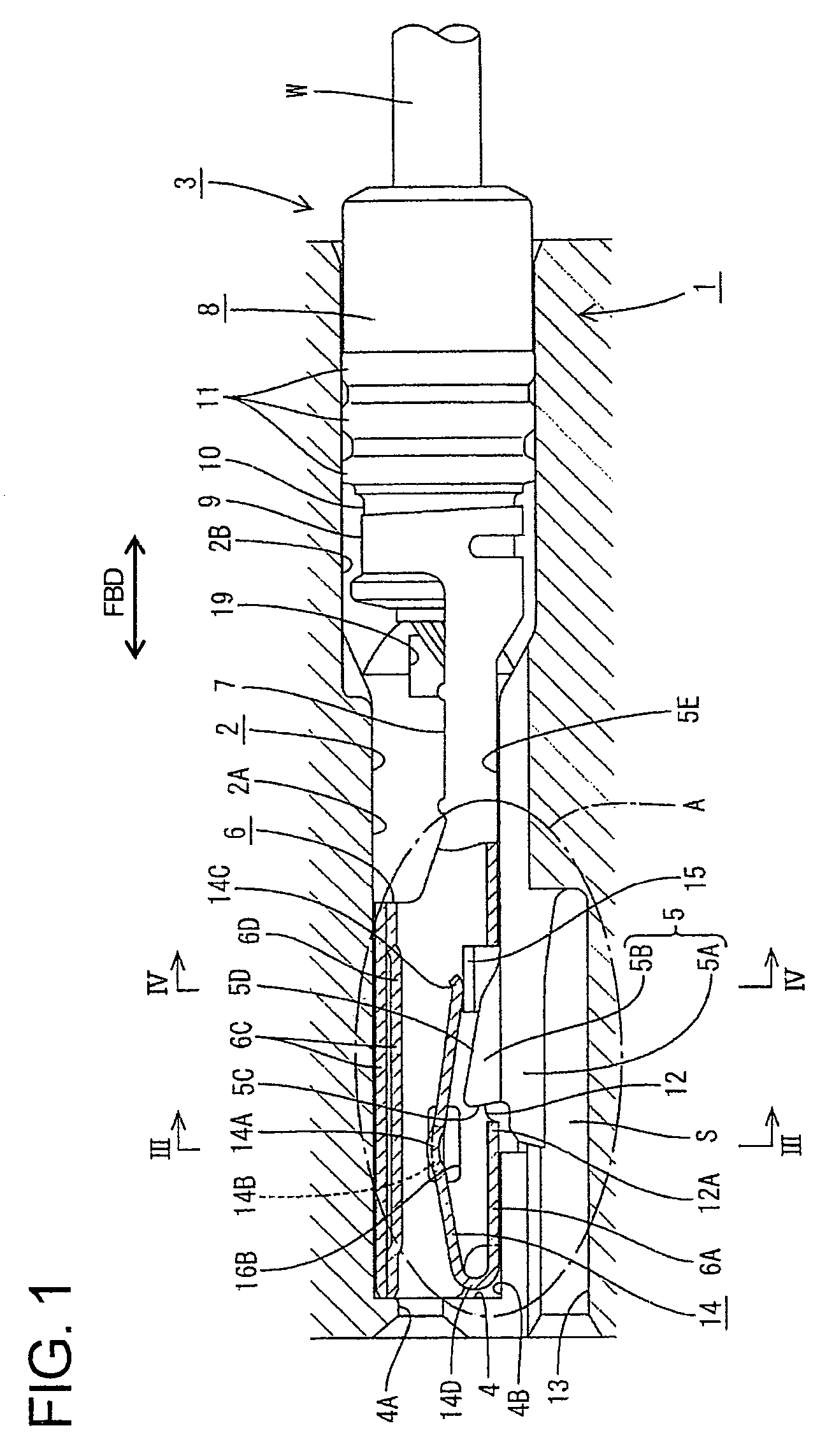

Mounting structure for temperature detecting member in rechargeable battery

InactiveUS6610439B1High precisionImprove responseThermometer detailsCell temperature controlEngineeringRechargeable cell

A temperature detection hole 12 having a bottom, which is sealed against the inside of the battery case 3 while being open to the outside, is formed in the battery case. The bottom wall 12a of the temperature detection hole is in contact with or in close proximity to the elements for electromotive force. Engaging hooks 14 are formed on lateral portions of the temperature detection hole 12 of the battery case 3, while a temperature sensor 13 is provided with elastically deformable engaging flanges 21. When the temperature sensor 13 is mounted removably in the temperature detection hole 12, the elastic restorative force of the engaging flanges 21 that are engaged in elastic deformation with the engaging hooks 14 is applied to the temperature sensor 13. The sensor end 13a of the temperature sensor 13 is thereby pressed against the bottom wall 12a of the temperature detection hole 12.

Owner:PANASONIC CORP +1

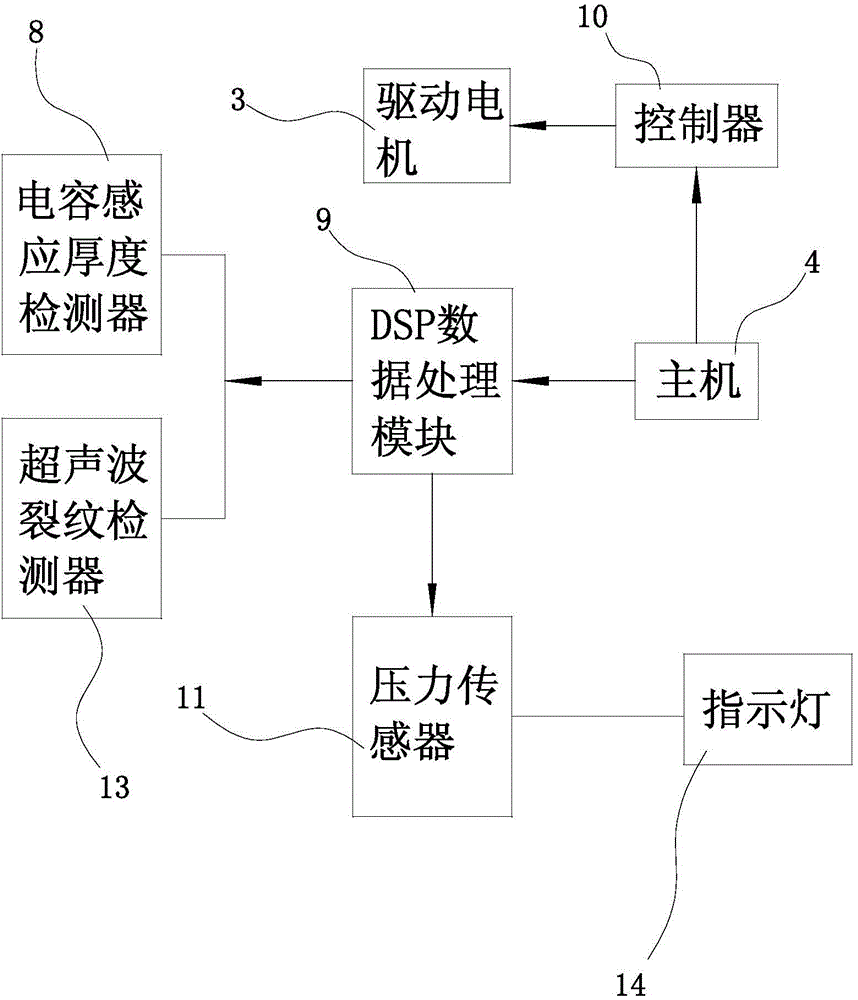

Capacitor thickness detection and crack feedback plate bending machine based on PLC

ActiveCN104624739APerformance impactPrevent excessive deformationMetal working apparatusCapacitanceEngineering

The invention relates to a capacitor thickness detection and crack feedback plate bending machine based on a PLC. The capacitor thickness detection and crack feedback plate bending machine comprises a driving motor, a clamping fixing base and a PLC host machine for controlling the driving motor. A bending shaft is installed on a motor shaft of the driving motor, and a machined piece is arranged on the clamping fixing base. The capacitor thickness detection and crack feedback plate bending machine further comprises a capacitor induction thickness detector installed on a machine frame, a pressure sensor arranged on the lateral side of a clamping groove of the clamping fixing base, a detection feedback device and a controller connected with the PLC host machine. The detection feedback device comprises an ultrasonic crack detector arranged on the clamping fixing base. The capacitor induction thickness detector, the ultrasonic crack detector and the pressure sensor are connected with the PLC host machine through a DSP module. The invention further provides a bending method. According to the capacitor thickness detection and crack feedback plate bending machine and method, sectioned machining is controlled through the PLC, the machined piece is bent at the most proper rotating speed, influences of the excessively-high or excessively-low rotating speed on the machined piece are avoided, bending cracks are reduced, and the machining quality is improved.

Owner:宿州市徽腾知识产权咨询有限公司

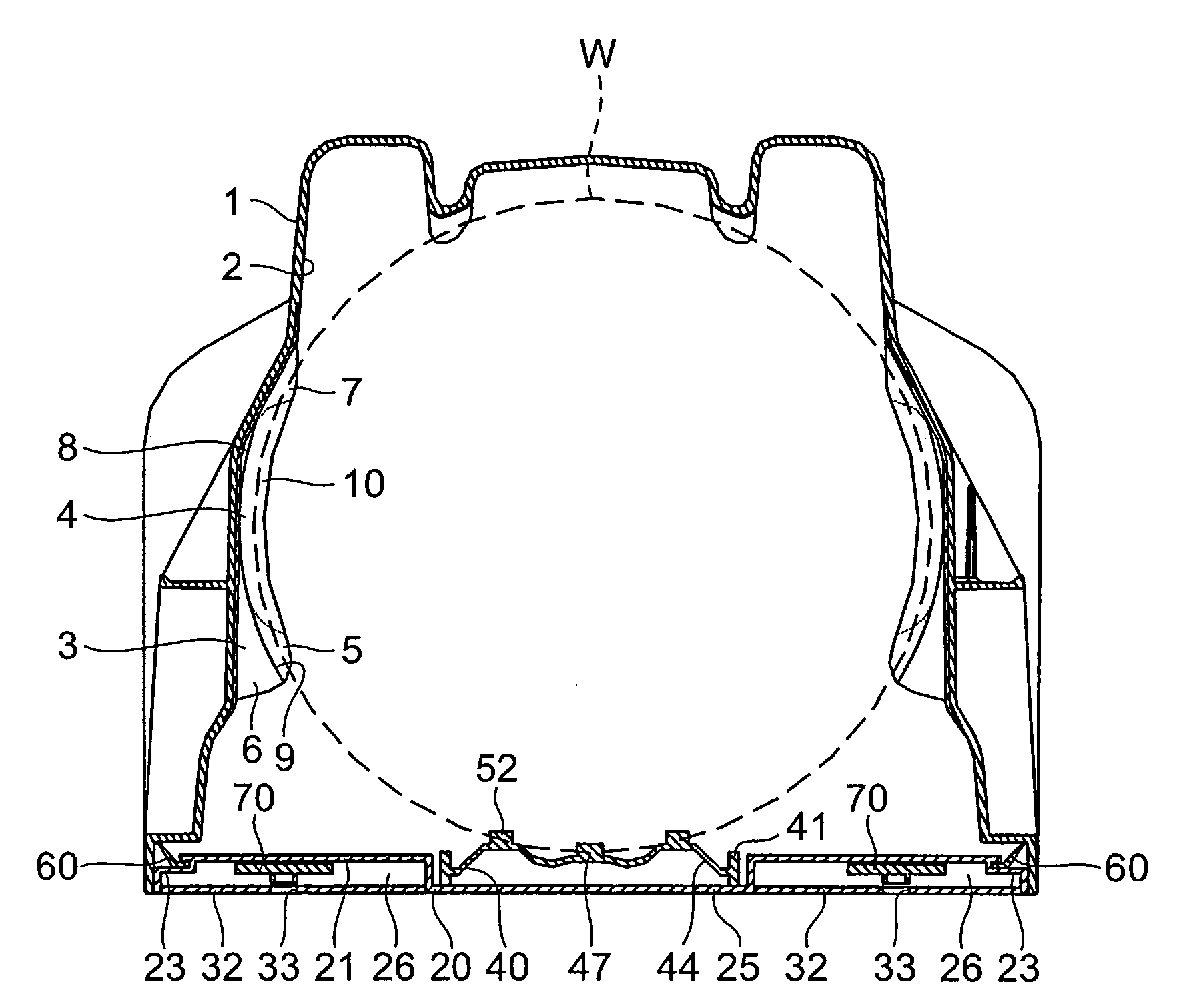

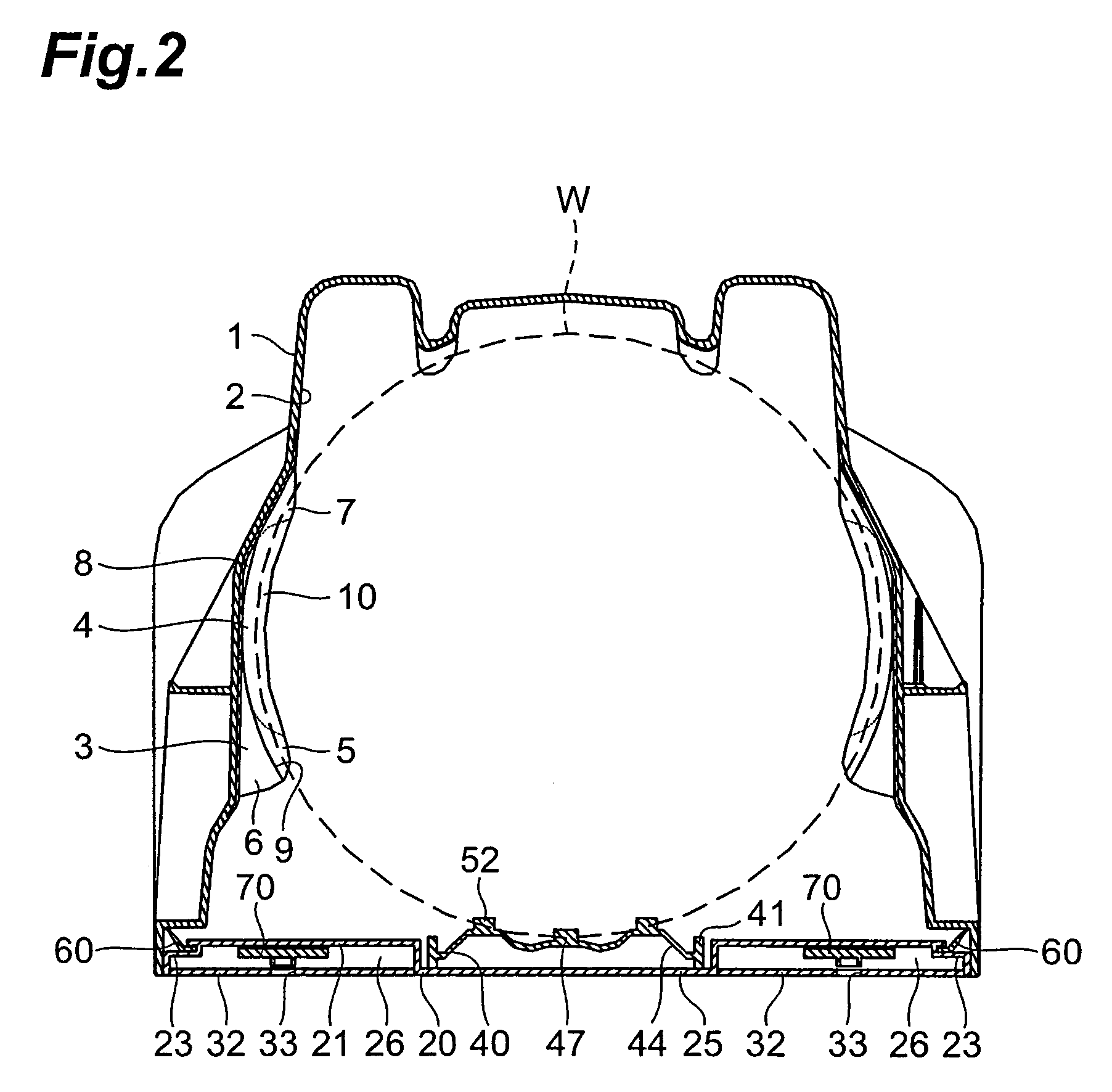

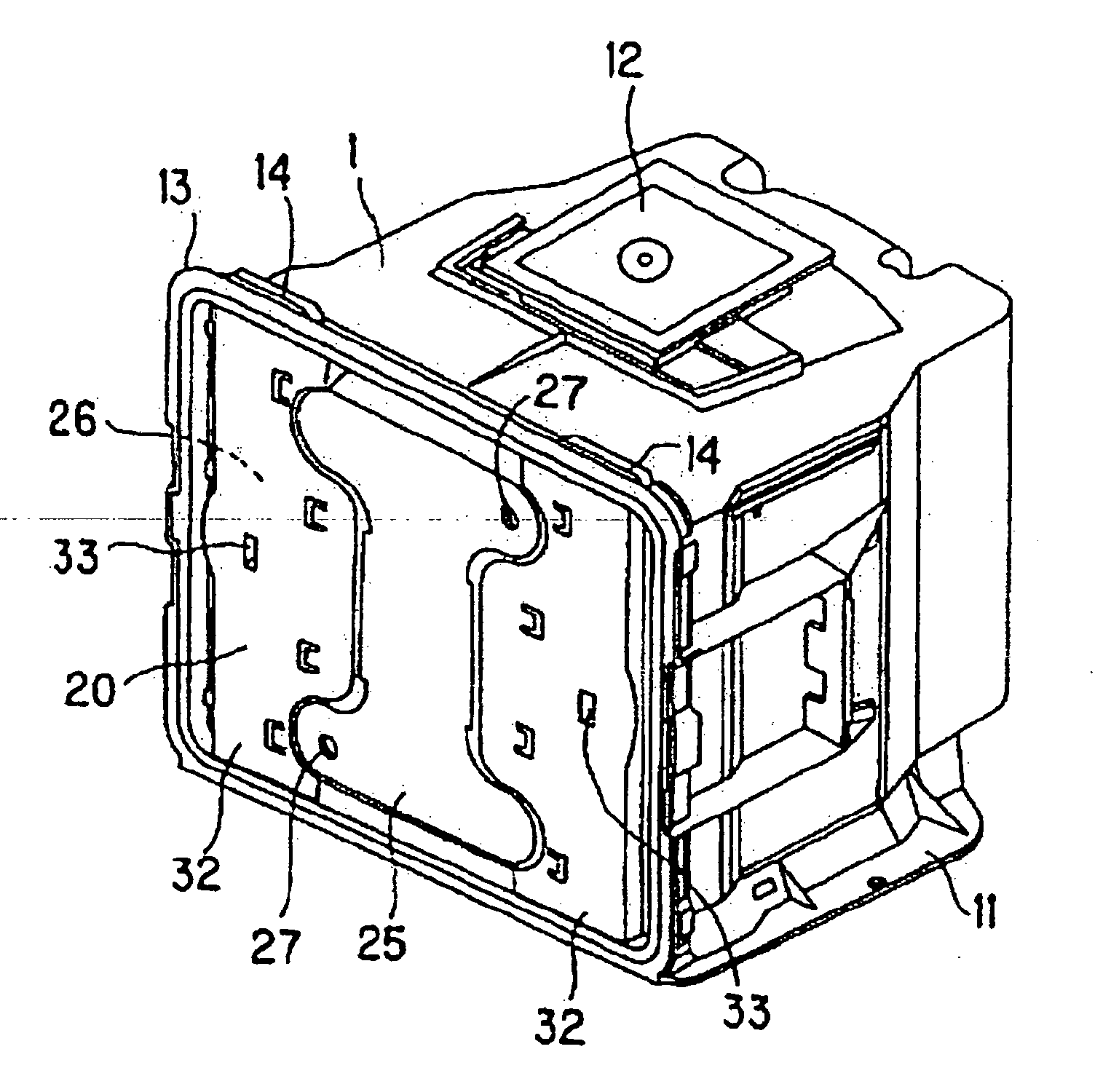

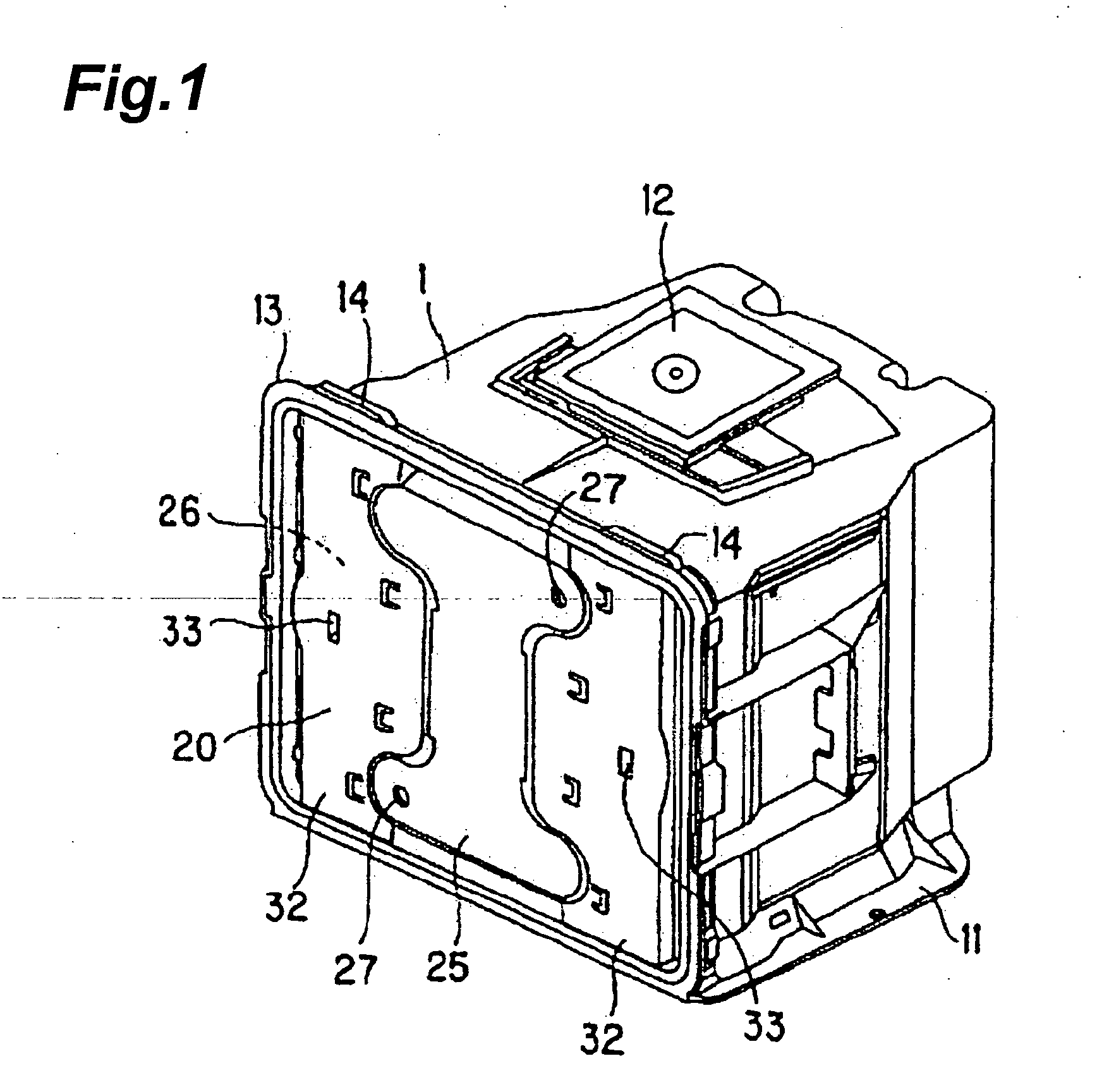

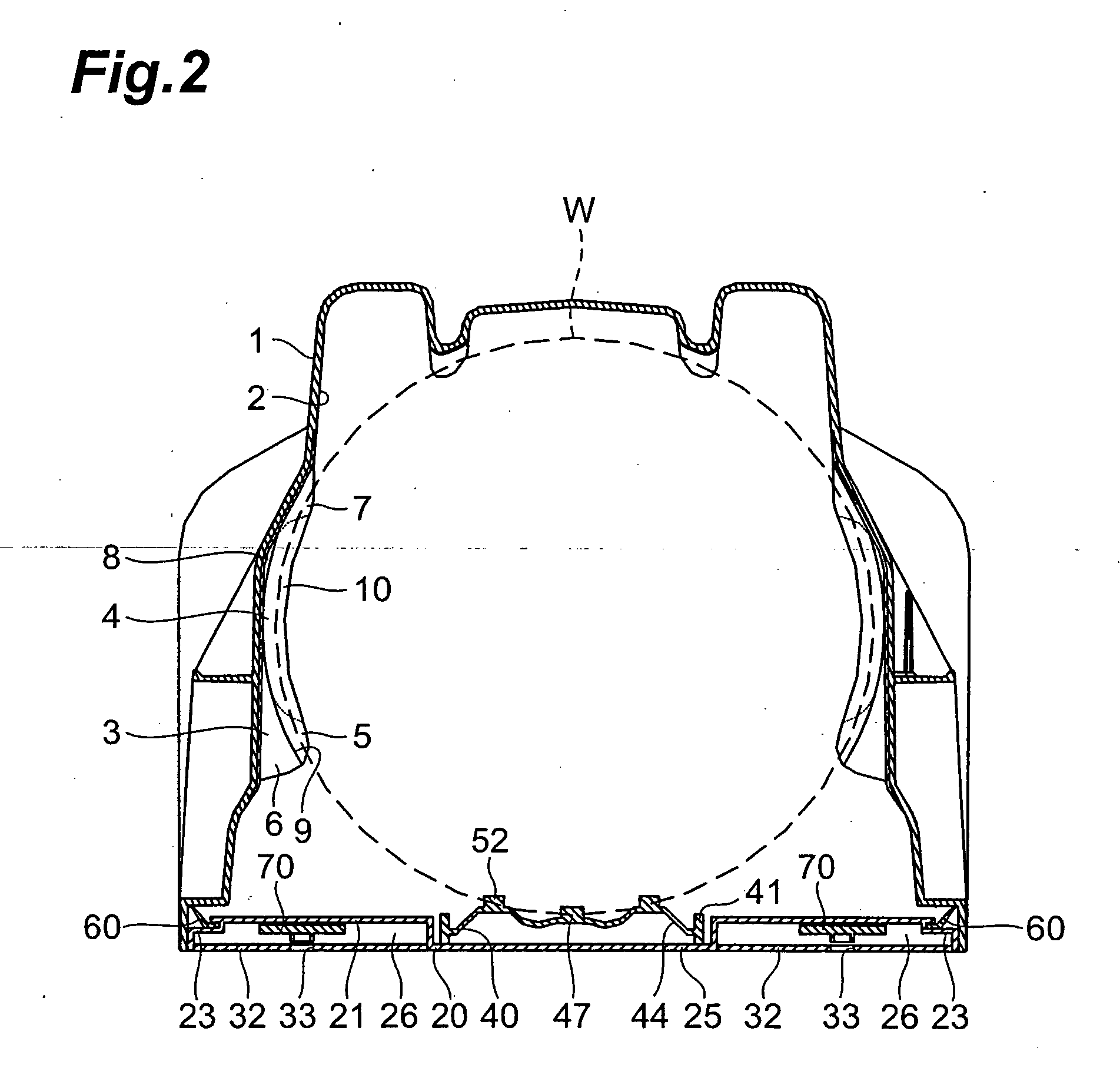

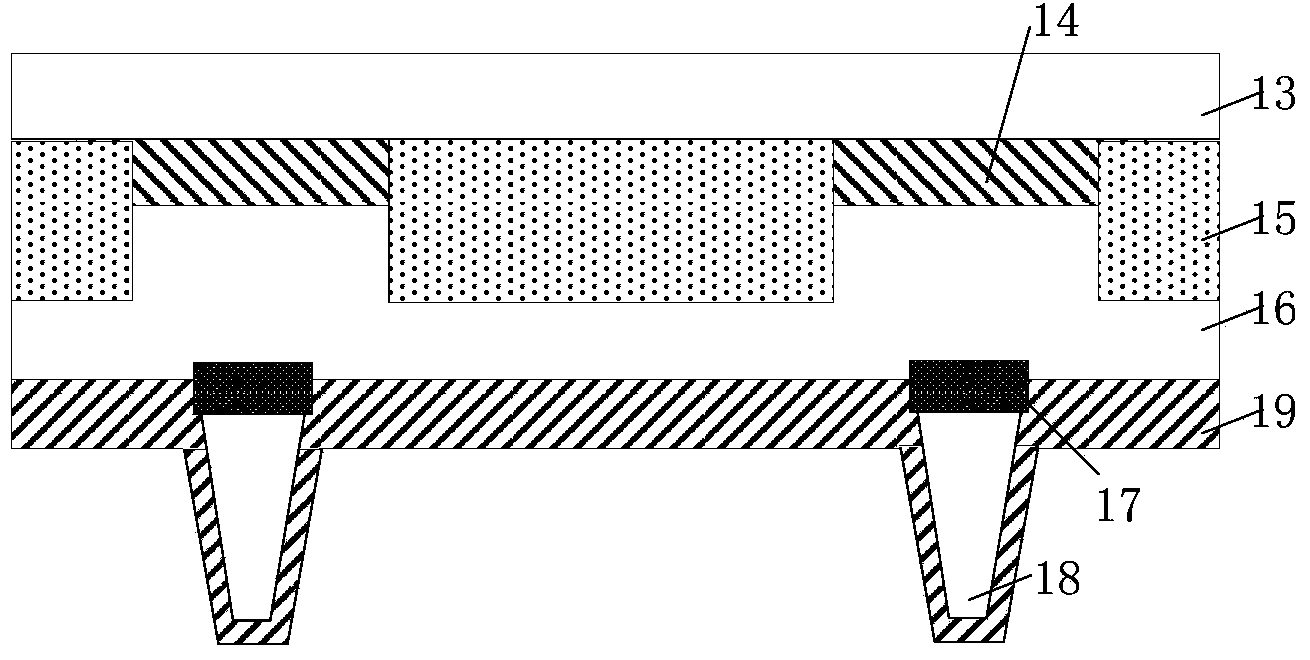

Substrate storage container

ActiveUS7344031B2Damage can be suppressedPrevent particle generationSemiconductor/solid-state device manufacturingOther accessoriesEngineeringGasket

A substrate storage container comprises: a container casing having an aperture through which a plurality of substrates are placed in or taken out; a cover adapted to fit into the aperture of the container casing; a sealing gasket capable of elastic deformation provided between the container casing and the cover; and a retainer, mounted on the cover, capable of retaining the periphery of the substrates. The retainer has: a supporting body mounted on the inside face of the cover; a plurality of elastic pieces provided in elastically deformable fashion on the supporting body; and a block provided on each of the elastic pieces, the block retaining the periphery of one of the substrates. A relation 10.8×w<y<34.3×w is satisfied when a substrate retaining force of each of the elastic pieces is y [unit: N] and a weight per the substrate is w [unit: kg].

Owner:SHIN-ETSU POLYMER CO LTD

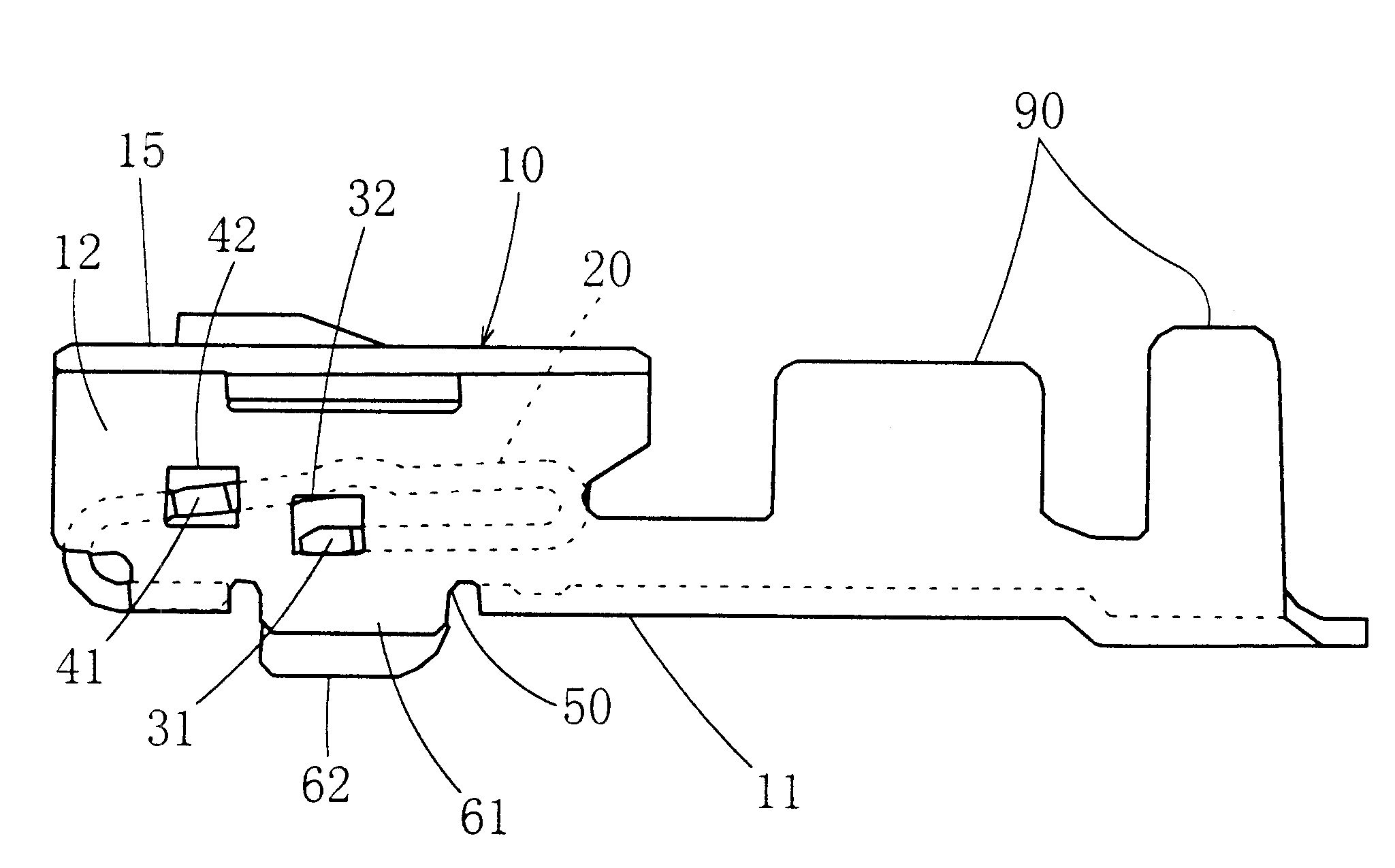

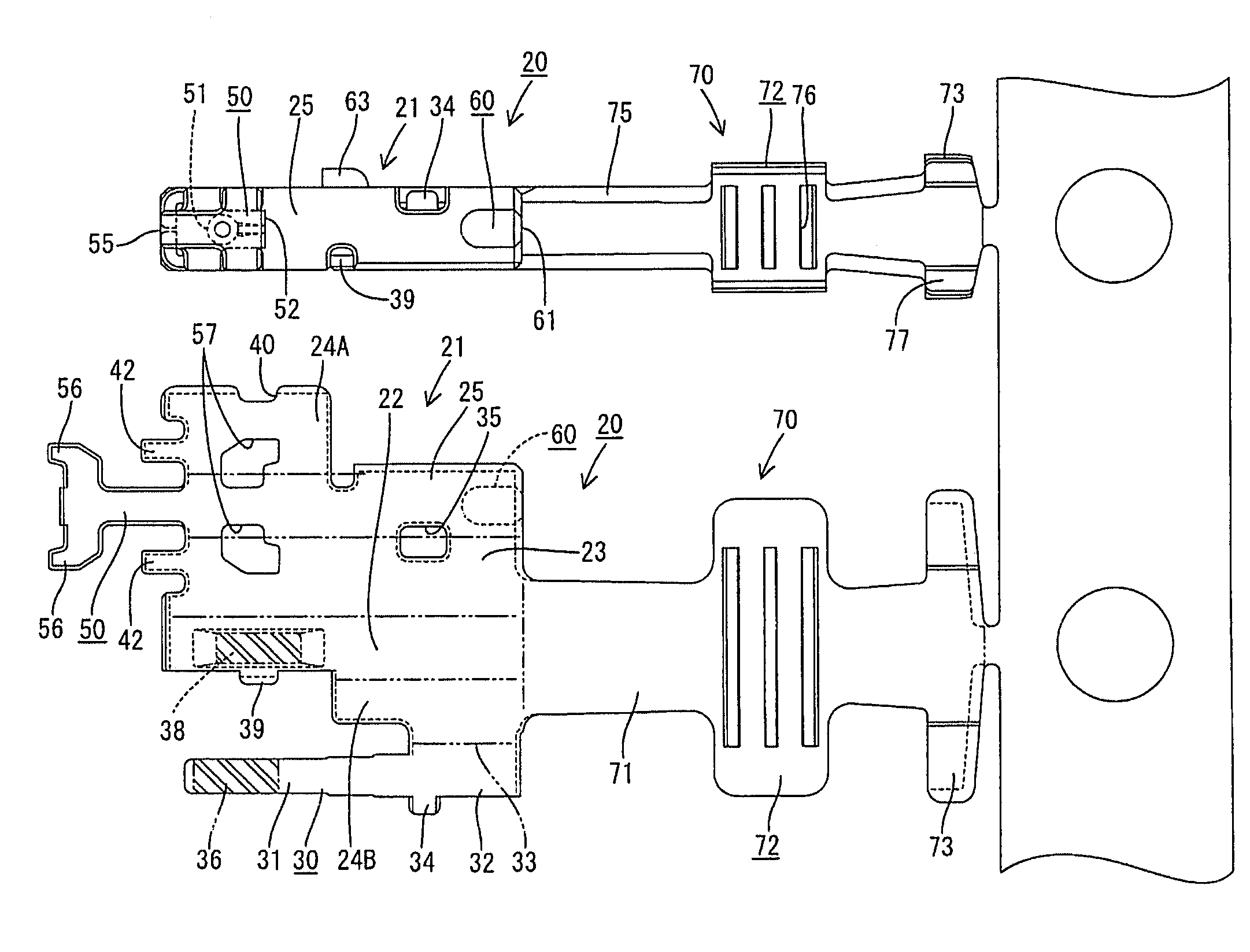

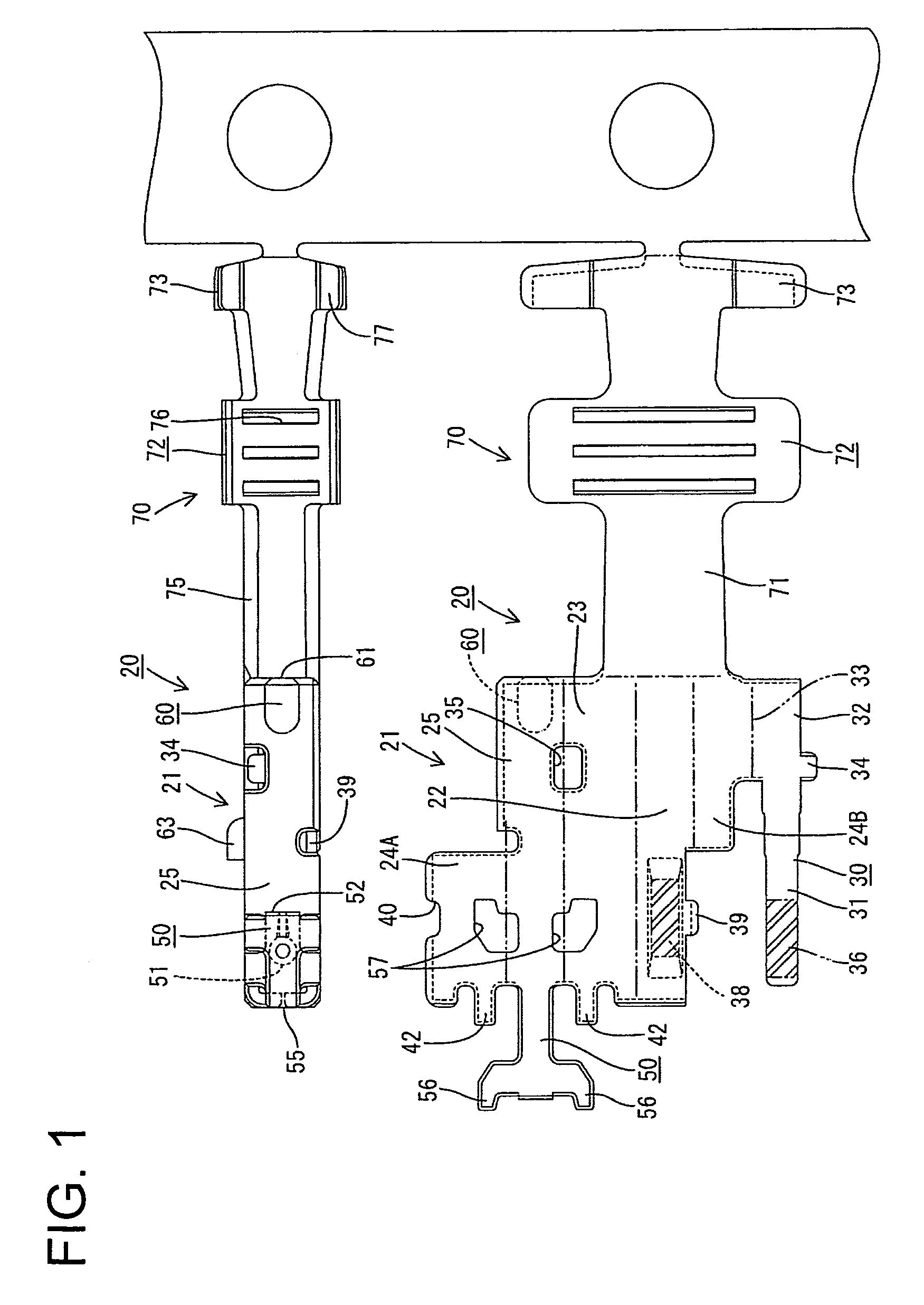

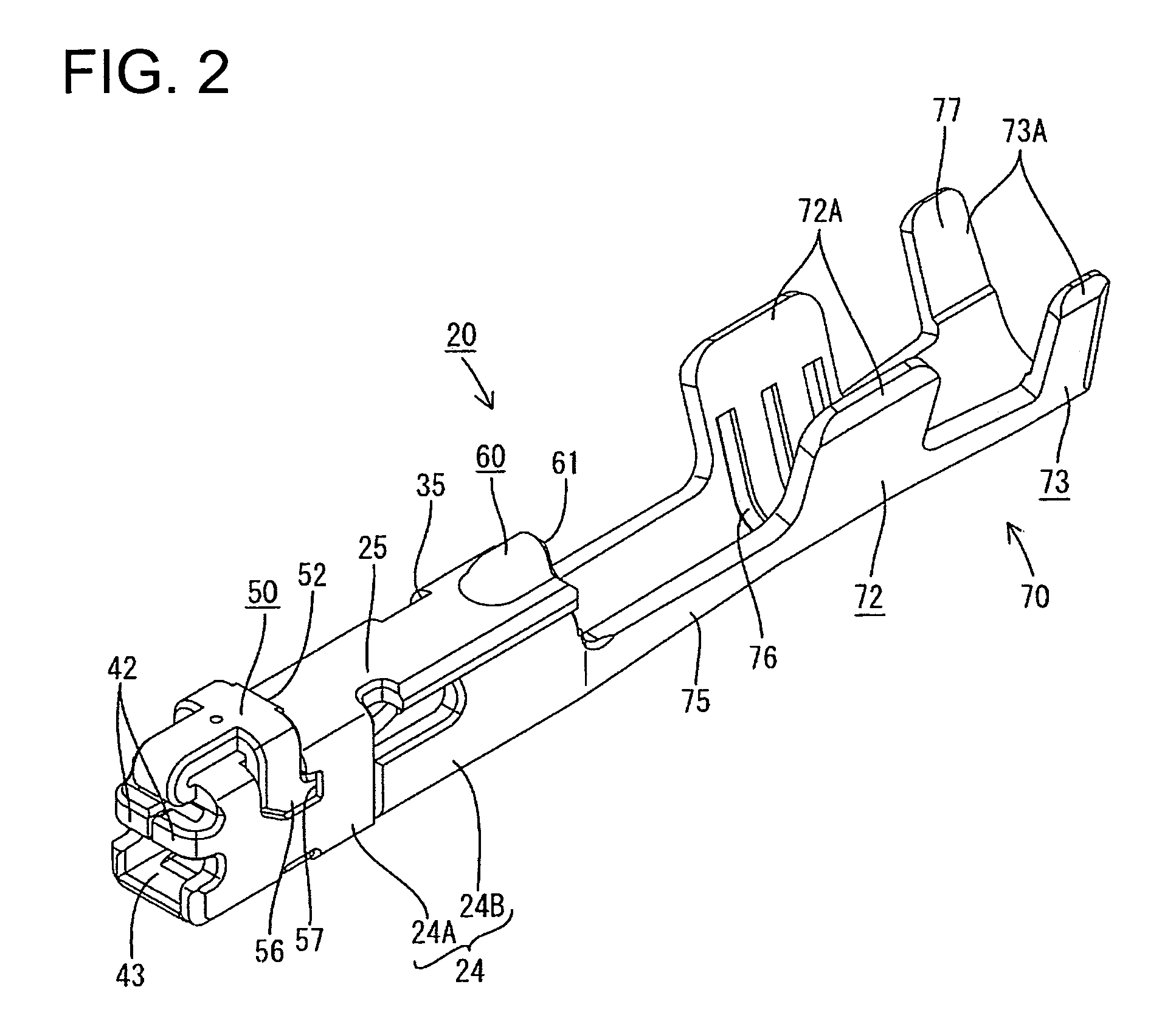

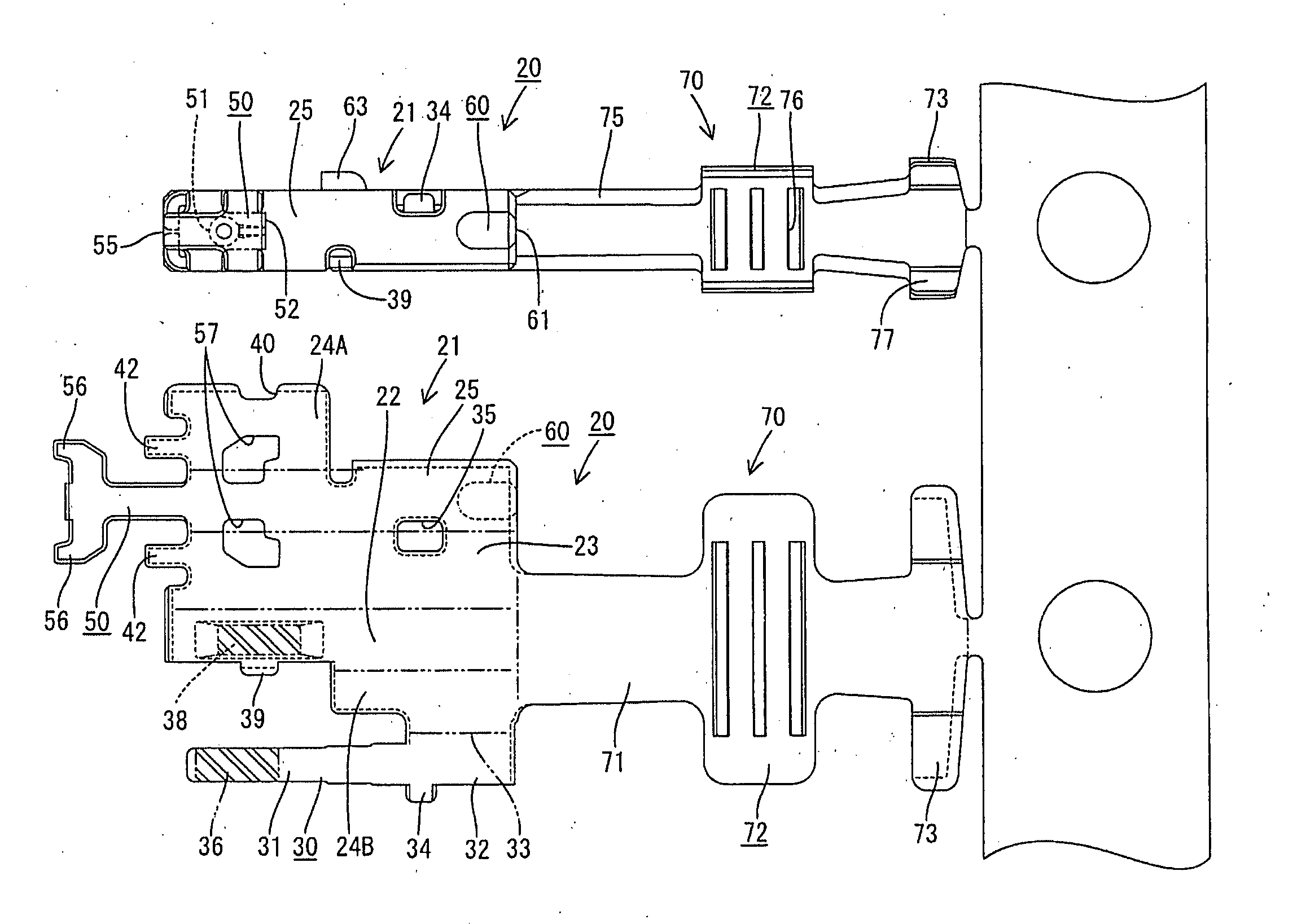

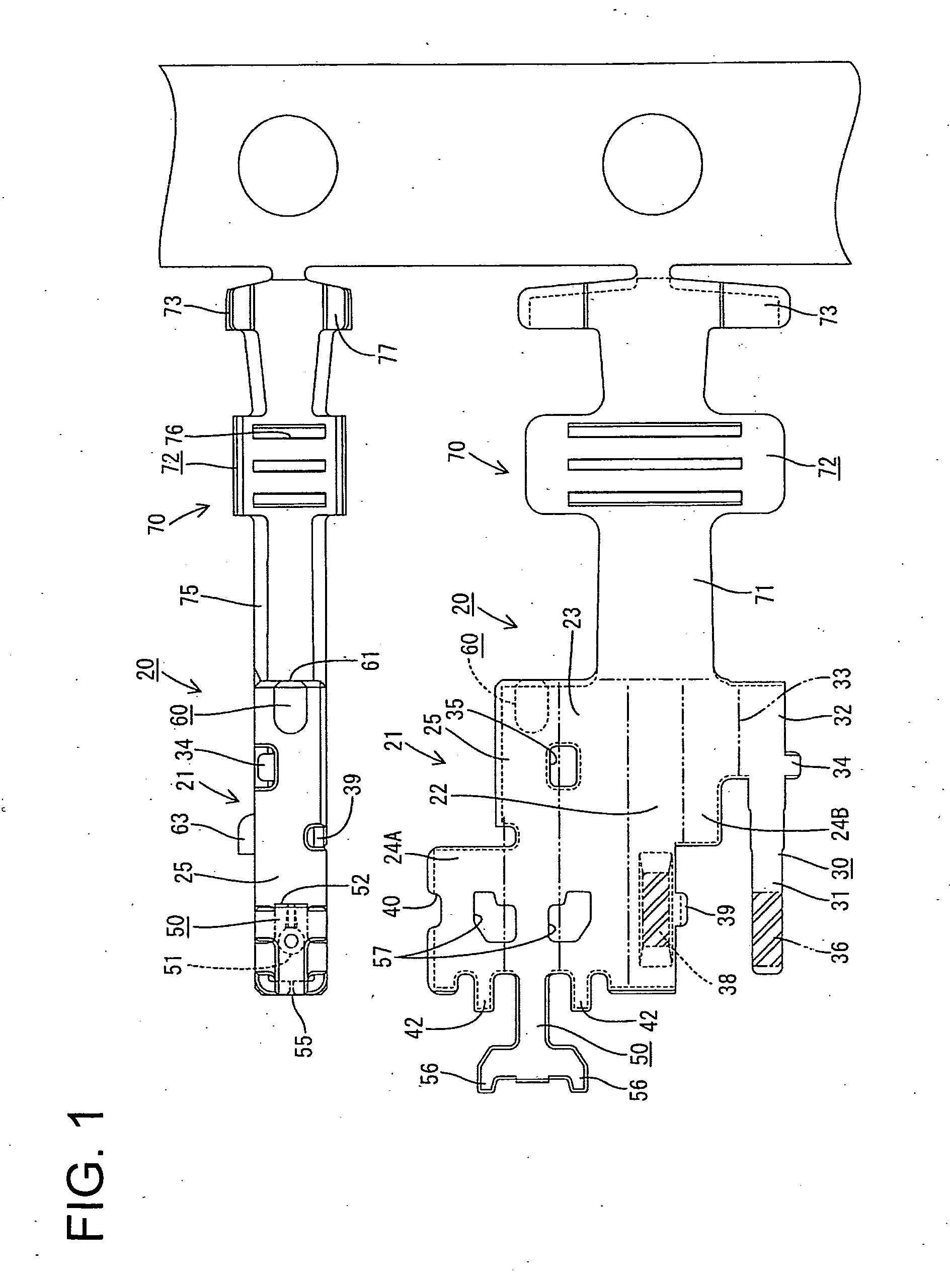

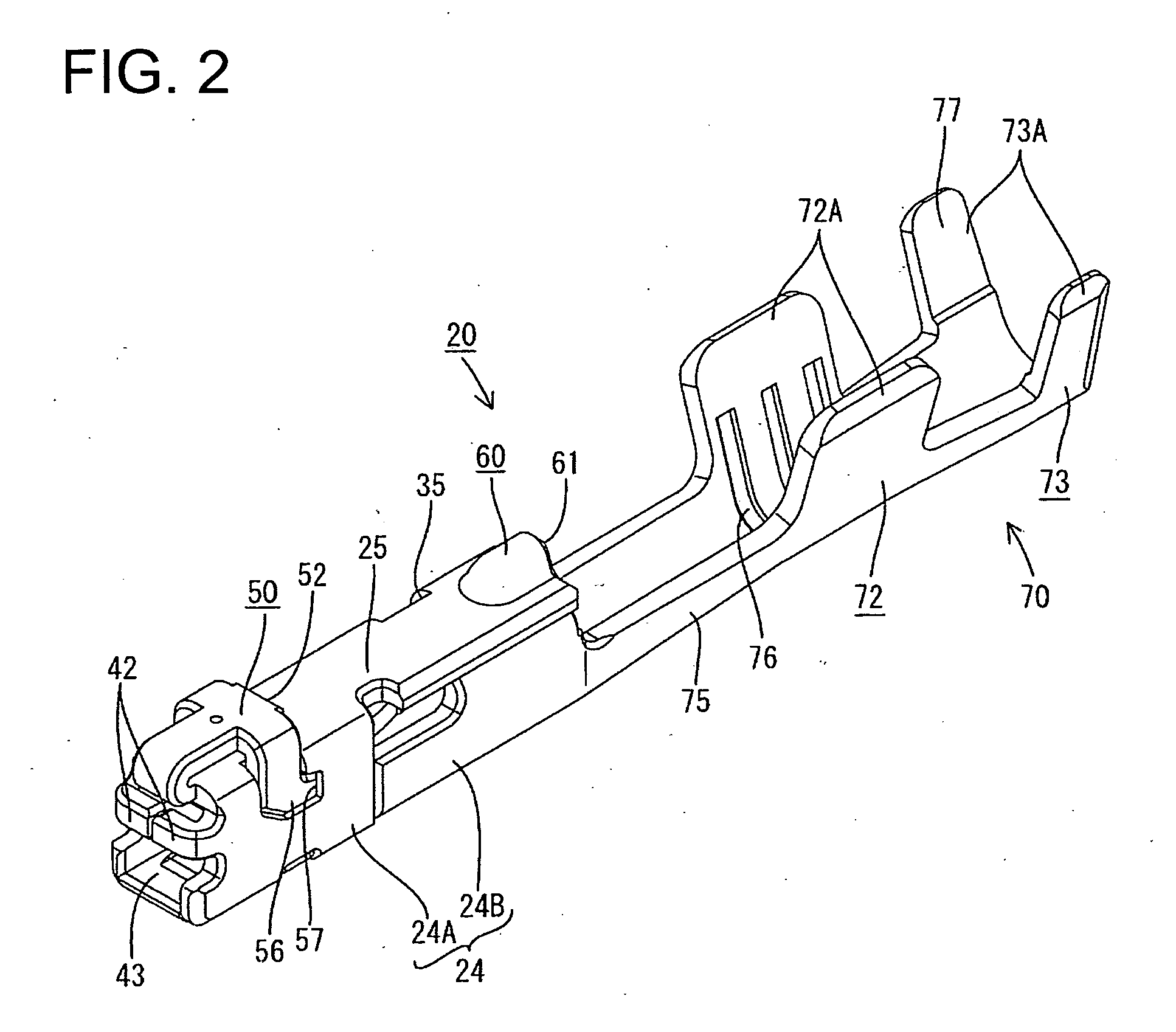

Female terminal fitting and connector provided therewith

InactiveUS7048582B2Increase the areaSufficient locking forceContact member manufacturingSecuring/insulating coupling contact membersEngineeringMechanical engineering

A female terminal fitting (20) has a main portion (21) that can be inserted into a cavity. An engaging portion (50) for engaging a lock (17) in the cavity is folded back from the front of the main portion (21). The fold (55) is rounded and contacts the lock (17) when the terminal fitting (20) is inserted into a cavity. Thus, resistance to insertion is low. The engaging portion (50) is distanced from an opposed surface (25) of the main portion (21) by an embossment (51). Thus, a large area of engagement with the lock (17) exists. A slanted surface (53) is formed at a corner of a locking surface (52) closer to the ceiling plate (25). Thus, the leading end of the lock (17) intrudes at the inner side of the slanted surface (53) to prevent the lock (17) from escaping.

Owner:SUMITOMO WIRING SYST LTD

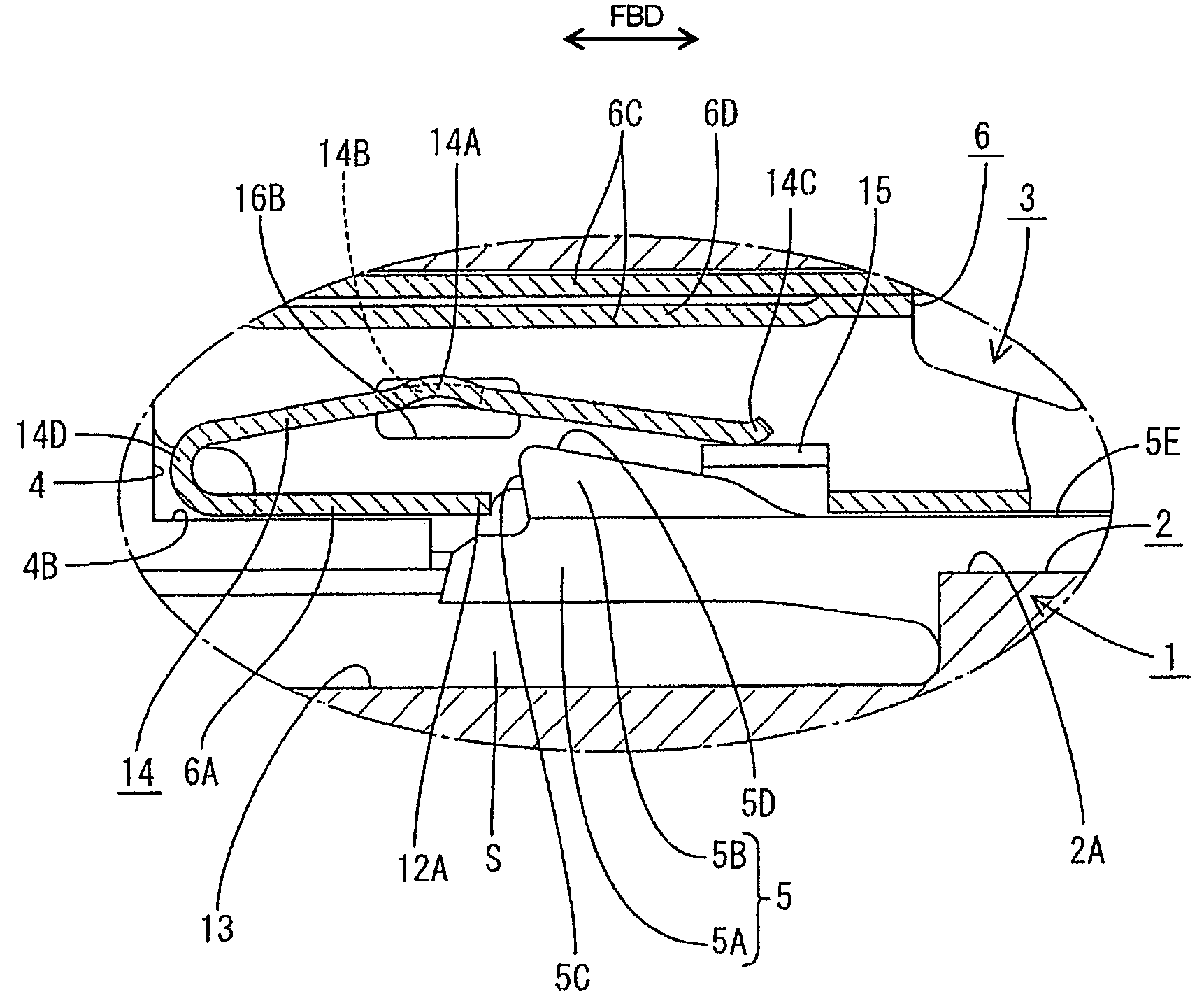

Female terminal

InactiveUS20020076999A1Prevent excessive deformationPrevent the leaf spring from being deformed excessivelyCoupling contact membersElectric connection basesContact forceLeaf spring

A flexible-piece-receiving hole is opened in the bottom wall while ensuring an adequate contact force is obtained between the leaf spring and a male terminal and preventing the leaf spring from excessive deformation, and in turn, the workability of operation of disengaging the flexible piece from the female terminal is enhanced. A female terminal comprising a tubular body, a leaf spring being provided inside the body and having a first bent part being bent upward and rearward from the front end of the bottom wall of the body, an intermediate part extending rearward from the first bent part, a second bent part being bent downward and forward from the rear end of the intermediate part, and a top end part extending forward from the second bent part and keeping itself away from the intermediate part, a first fitting means for fitting the front end of the top end part of the leaf spring onto the side walls, a second fitting means, which allows, when the intermediate part of the leaf spring is displaced downward to contact the top end part of the leaf spring, a part ahead of said contacting part of the intermediate part of the leaf spring to be displaced downward by a certain length, and fits the part onto the side walls at the bottom dead point, and a flexible-piece-receiving hole being opened in the bottom wall ahead of a part at which the second bent part or the rear end of the top end part of the leaf spring being displaced downward contacts the bottom wall.

Owner:JST MFG CO LTD

Female terminal fitting and connector provided therewith

InactiveUS20050227551A1Enhance locking forcePrevent from escapeContact member manufacturingSecuring/insulating coupling contact membersEngineeringMechanical engineering

A female terminal fitting (20) has a main portion (21) that can be inserted into a cavity. An engaging portion (50) for engaging a lock (17) in the cavity is folded back from the front of the main portion (21). The fold (55) is rounded and contacts the lock (17) when the terminal fitting (20) is inserted into a cavity. Thus, resistance to insertion is low. The engaging portion (50) is distanced from an opposed surface (25) of the main portion (21) by an embossment (51). Thus, a large area of engagement with the lock (17) exists. A slanted surface (53) is formed at a corner of a locking surface (52) closer to the ceiling plate (25). Thus, the leading end of the lock (17) intrudes at the inner side of the slanted surface (53) to prevent the lock (17) from escaping.

Owner:SUMITOMO WIRING SYST LTD

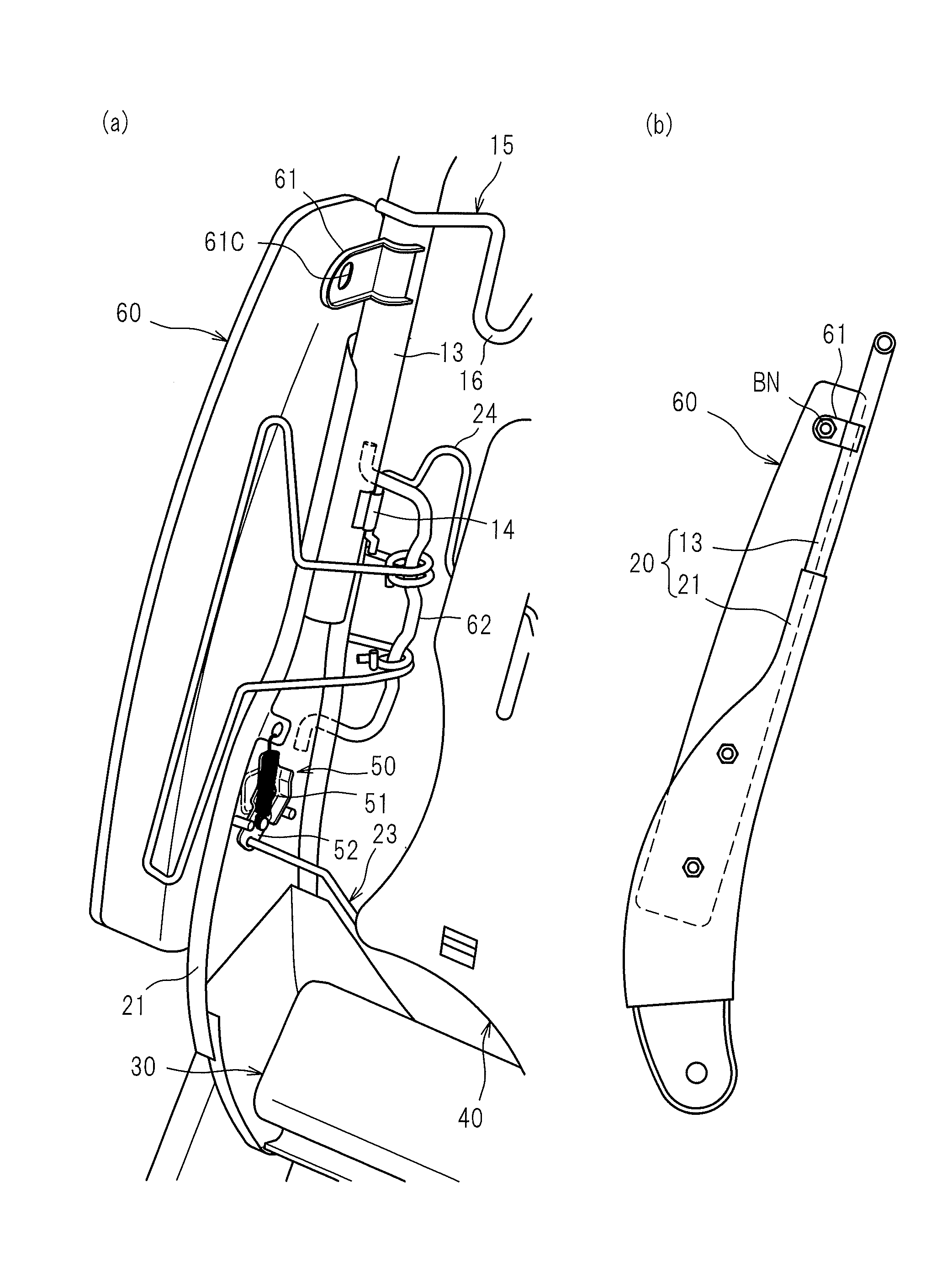

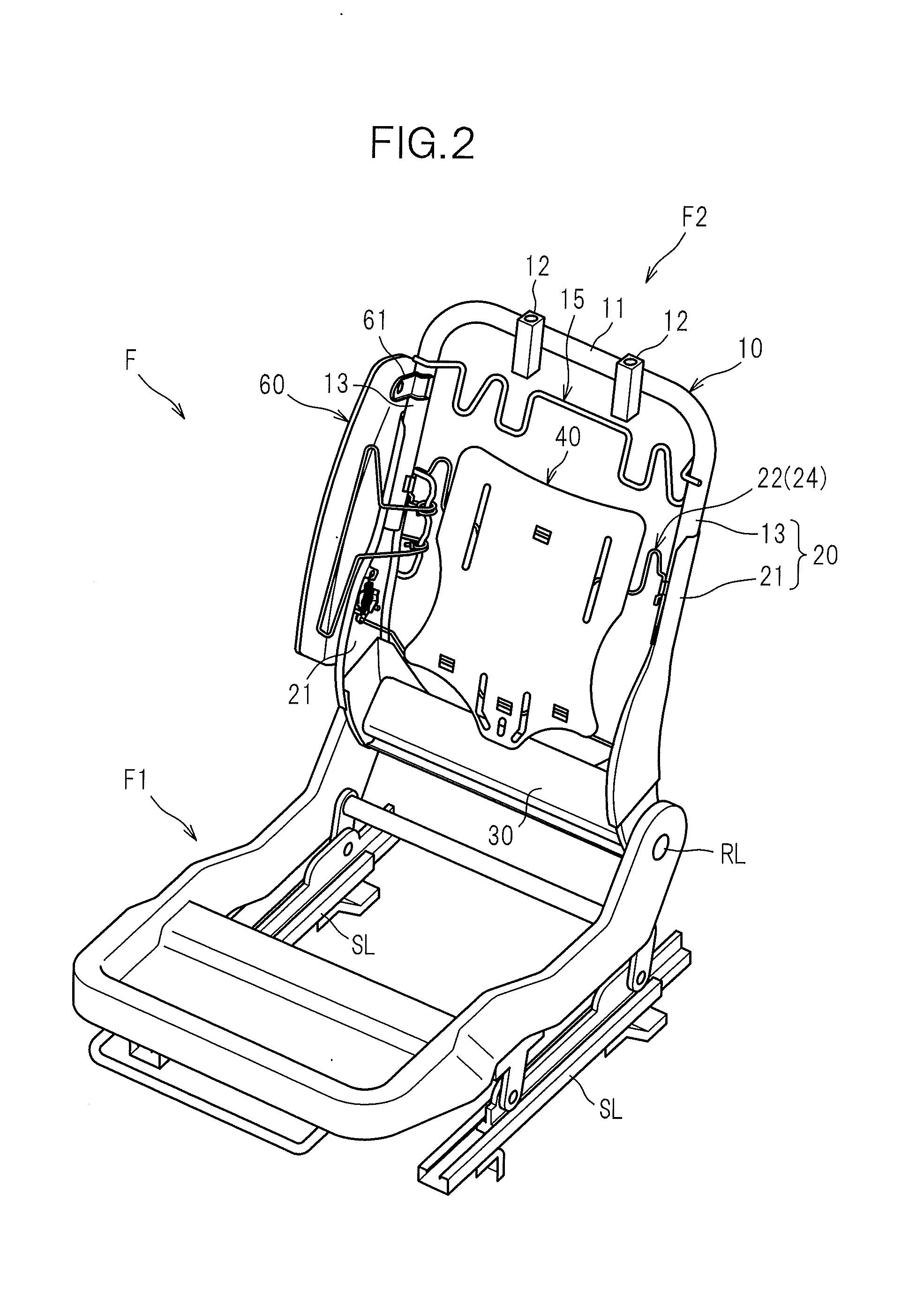

Vehicle seat

ActiveUS20130270878A1Prevent excessive deformationAdhesionBack restsPedestrian/occupant safety arrangementEngineeringRear-end collision

A seat back pad 70 has a groove 73 for tucking a skin material therein, formed at borders between a central portion 71 and side portions 72. A hole (slot hole 74) is formed in a bottom of the groove 73 along the groove 73. A tuck-in wire 76 for tucking the skin material in includes a plurality of tuck-in portions 76A provided along the groove 73, and a connecting portion (detour portion 76B) detouring around the hole and connecting the tuck-in portions 76A. With this configuration, when an upper body of an occupant P subsides into a seat back S2 in a rear-end collision of a vehicle, the central portion 71, defined by the groove 73 as a border, is easily and sufficiently moved rearward relative to the left and right side portions 72. Furthermore, the tuck-in wire 76 is not exposed through the hole, and thus adhesion between the seat back pad 70 and the tuck-in wire 76 can be improved.

Owner:TS TECH CO LTD

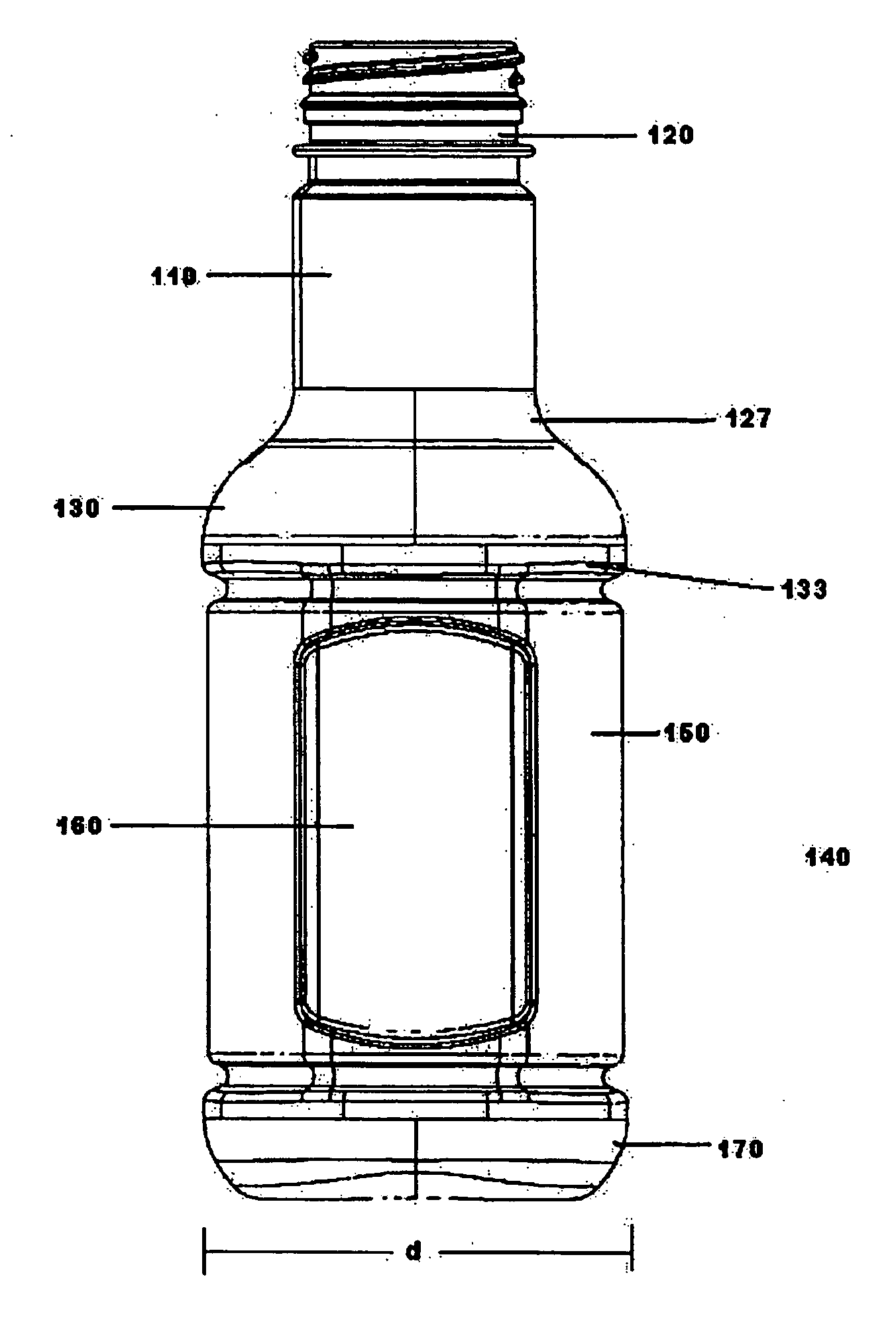

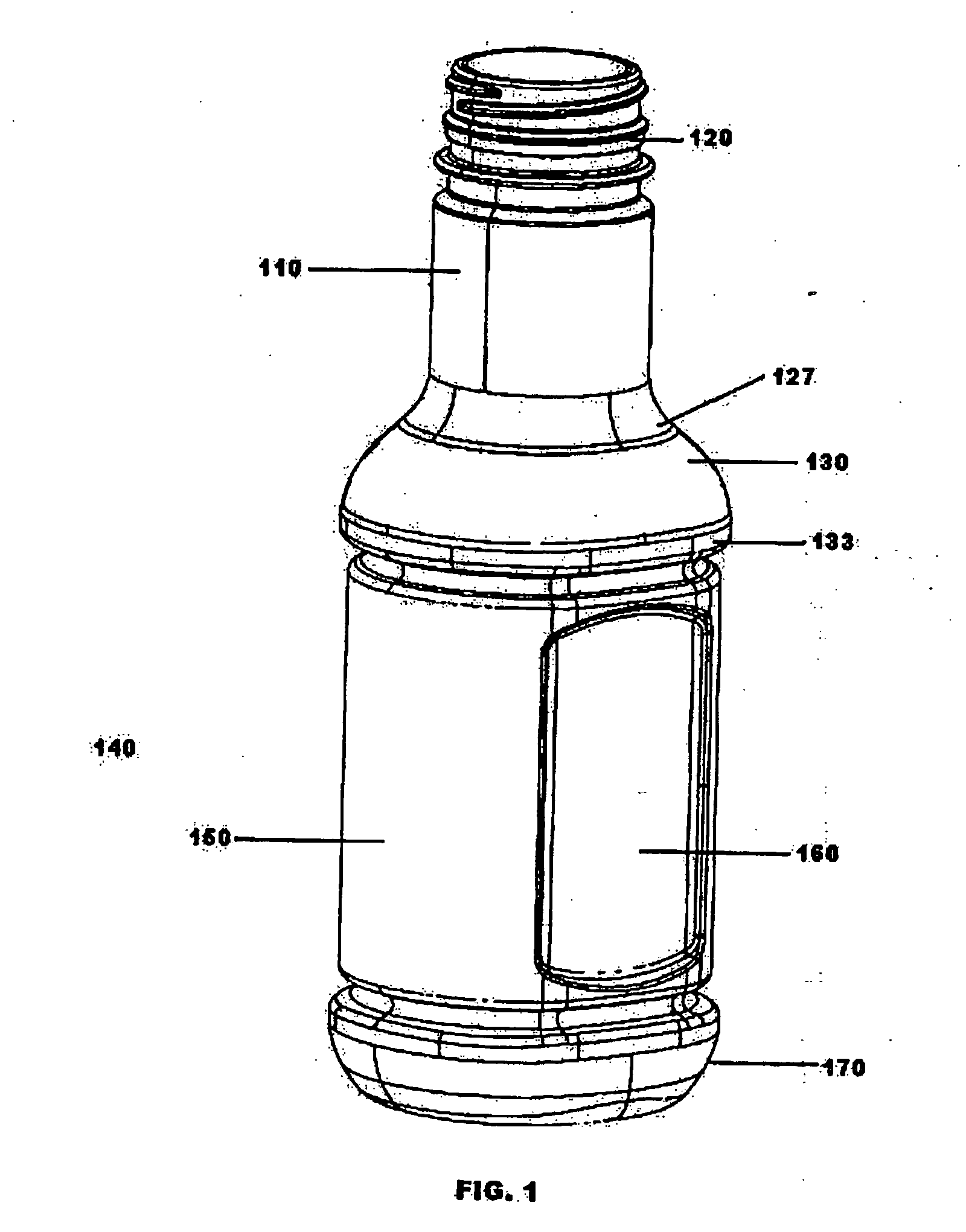

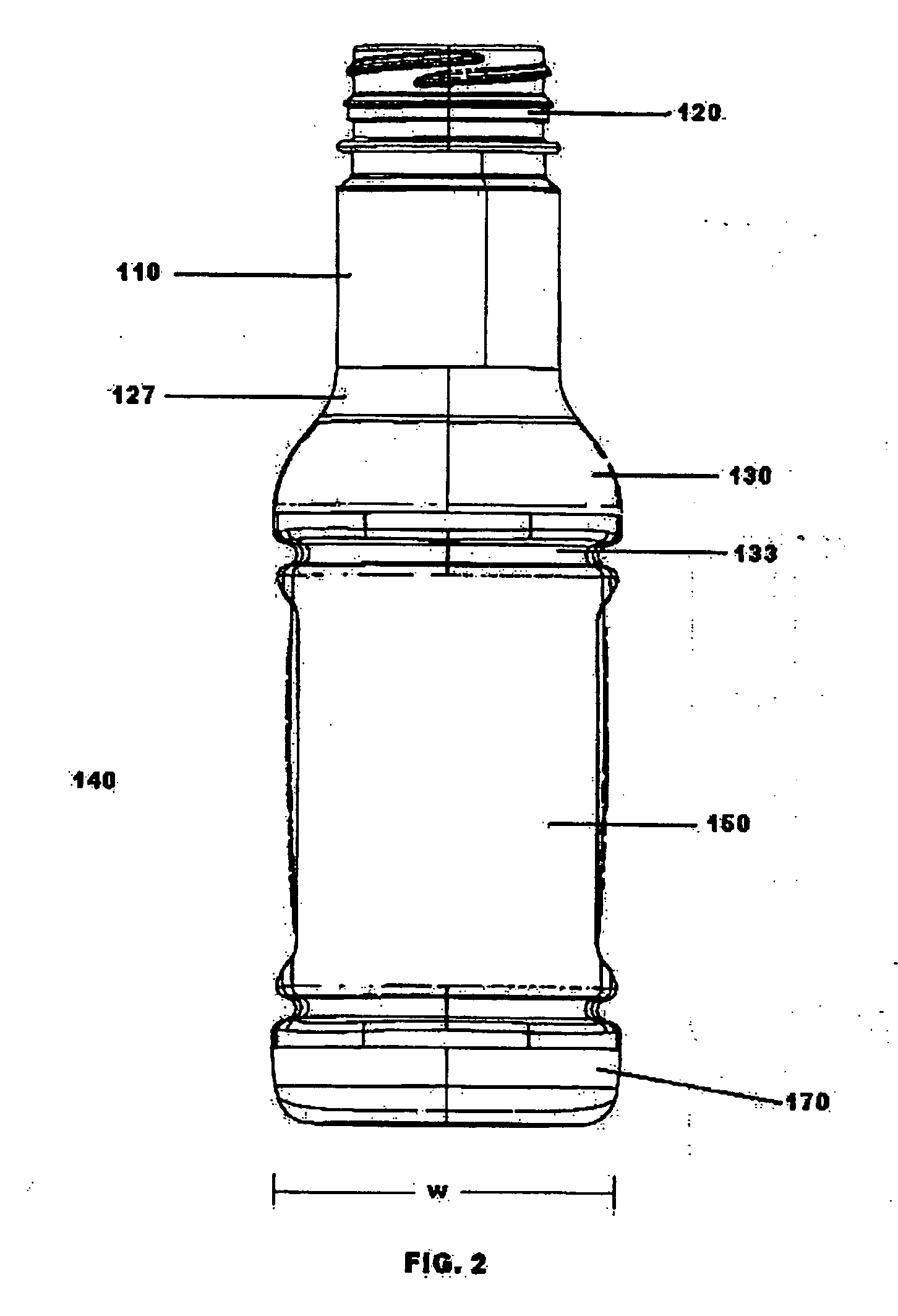

Oval container

InactiveUS20060070977A1Prevent excessive deformationPrevent bucklingLarge containersRigid containersPressure sensitiveEllipse

An oval plastic container. A cross-section of the container, taken perpendicular to the height of the container shows an oval or elliptical shape. Such a container has front and back sides. The container also has a left side and a right side. Given the oval shape of the body, the width of the container as measured from the left side to the right side, is less than the depth of the container, measured from front to back. The front and back of the container therefore have a relatively small radius of curvature, compared to the left and right sides. The front and / or the back of the container includes a relatively featureless panel. Such a panel is flat, apart from the curvature that results from the oval shape of the body. Such an area can be used for the application of a pressure-sensitive label. The oval shape of the body prevents the labeled surface from buckling during the cooling process. The left and right sides of the container may include structure such as ribbing, to prevent buckling or excessive deformation during cooling. Alternatively, the left and right sides of the container may include vacuum panels that may be drawn inward during cooling, without excessive deformation or buckling.

Owner:GRAHAM PACKAGING CO LP

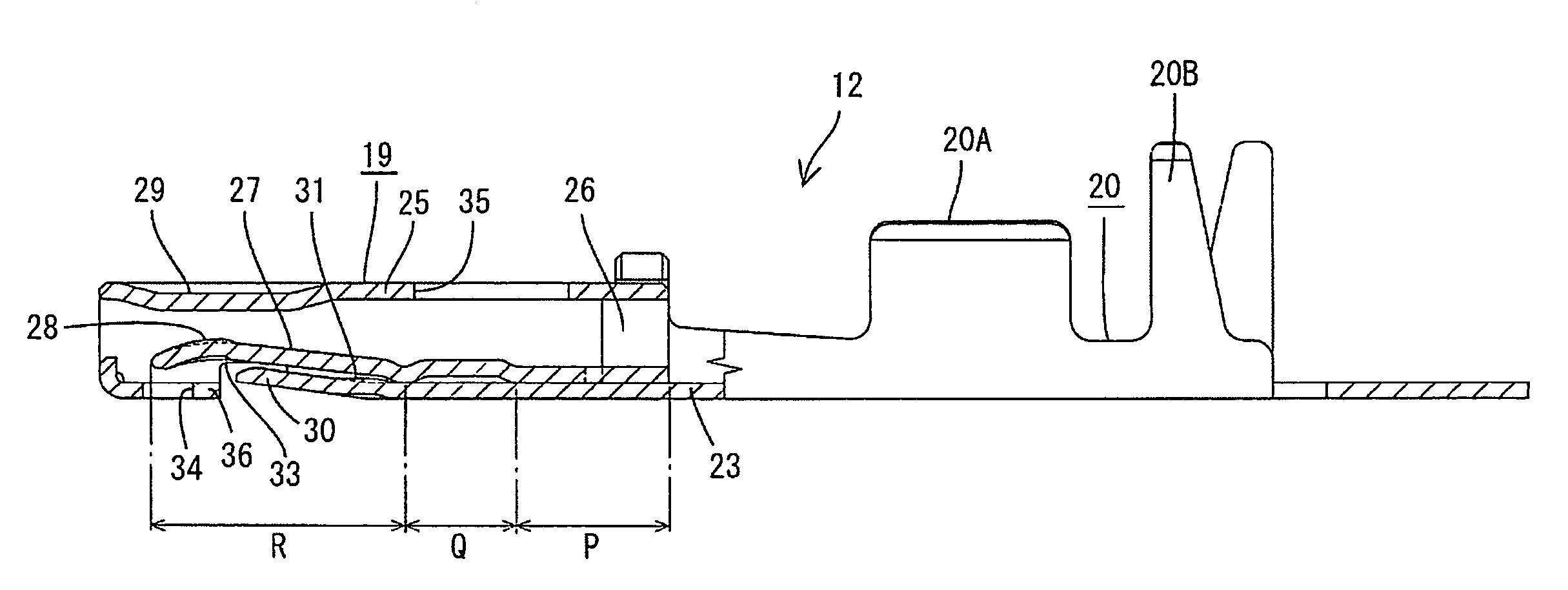

Connecting terminal and method of mounting the same onto a circuit board

InactiveUS6551149B2Prevent permanent deformationPrevent excessive deformationPrinted circuit assemblingSoldered/welded conductive connectionsElectrical conductorContact pressure

A connecting terminal for allowing a circuit board to come into compression contact with a flat conductor with certainty, particularly to a connecting terminal having a contact part which is not irregularly deformed even if the contact part comes into compression contact with the flat conductor oblique or in the lateral direction and which maintains an optimum contact pressure. The connecting terminal is made of a substantially strip conductive plate and comprises a fixed part provided at one end of the conductive plate to be mounted onto a circuit board, and a contact part extended from the fixed part and formed by bending the conductive plate toward the fixed part to form a curved part, wherein the contact part is elastically deformed about the curved part to come into compression contact with the substantially flat conductor, and the connecting terminal further comprises a pair of side wall parts formed by bending the conductive plate 11 at the fixed part in a width direction thereof, wherein the side wall parts have a height to an extent to restrict excessive deformation of the contact part when the contact part comes into compression contact with the flat conductor. Further, an interval between the pair of side wall parts is made larger than a width of the contact part, and both end sides of the contact part contact or approach inner surfaces of the side wall parts.

Owner:JST MFG CO LTD

Terminal fitting and a connector using such a terminal fitting

InactiveUS7156704B2Avoid displacementPrevent excessive deformationCoupling contact membersElectric connection basesEngineeringElectrical and Electronics engineering

Owner:SUMITOMO WIRING SYST LTD

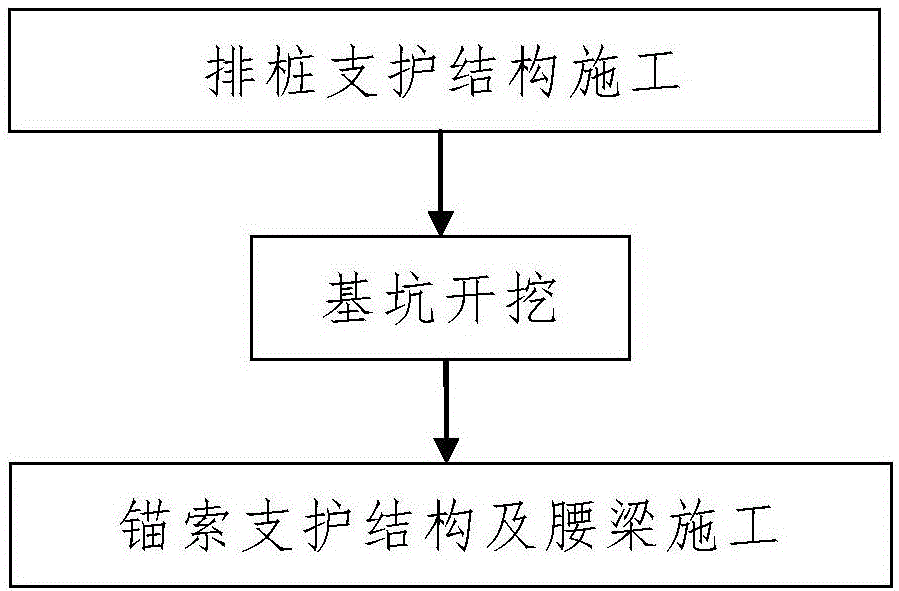

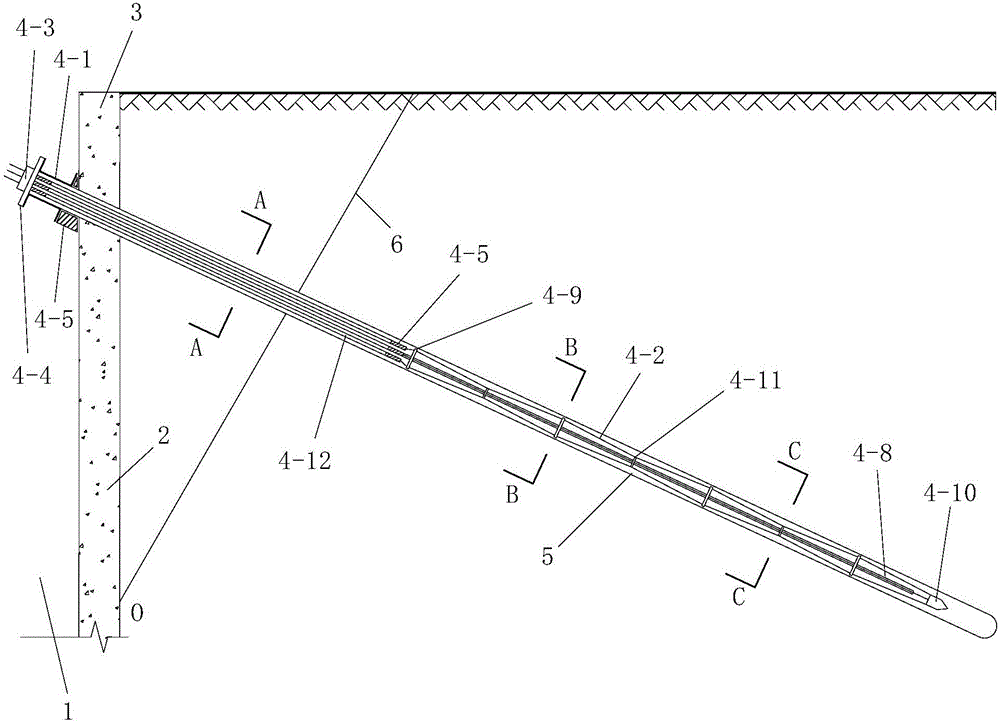

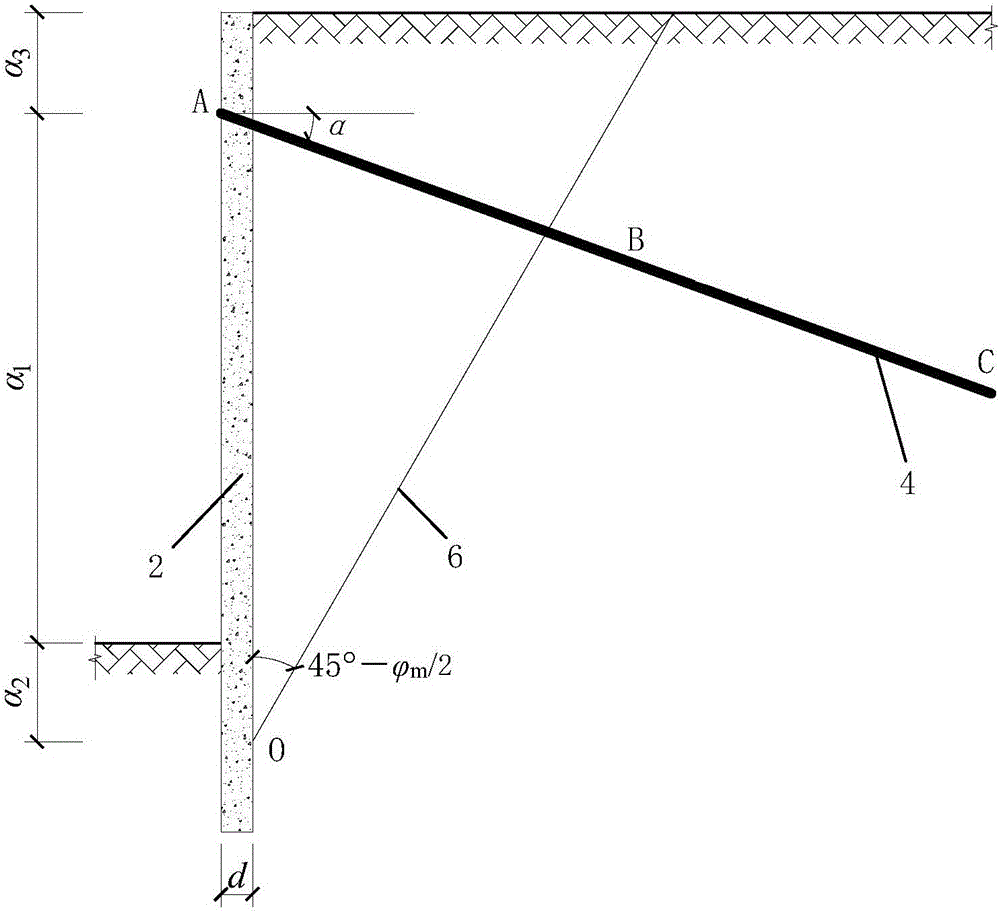

Construction method for supporting deep foundation pit through grouting after pile arrangement and anchor cable mounting

ActiveCN106320346AThe method steps are simpleReasonable designExcavationsBulkheads/pilesPre stressEngineering

The invention discloses a construction method for supporting a deep foundation pit through grouting after pile arrangement and anchor cable mounting. The construction method comprises the steps that firstly, pile arrangement supporting structure construction is performed, wherein a pile arrangement supporting structure comprises multiple slope protection piles which are arranged along the peripheral edge line of the constructed foundation pit from front to rear and a crown beam connected to the upper portions of the slope protection piles; secondly, foundation pit excavation is performed, wherein the constructed foundation pit is excavated from top to bottom; and thirdly, anchor cable supporting structure and waist beam construction is performed, wherein during excavation of the constructed foundation pit, the constructed foundation pit is excavated to the anchoring position of an anchor cable supporting structure, and the anchor cable supporting structure is constructed; and the anchor cable supporting structure comprises multiple prestress anchor cables, each prestress anchor cable comprises an anchor cable body, a primary grouting pipe and a secondary grouting pipe, and each anchor cable body comprises multiple steel strands. The method has the beneficial effects that the steps are simple, the design is reasonable, construction is easy and convenient, the use effect is good, the deep foundation pit supporting construction process can be completely easily, conveniently and quickly, the cost of the adopted prestress anchor cables is low, the anchoring force is high, and the deep foundation pit can be supported effectively.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

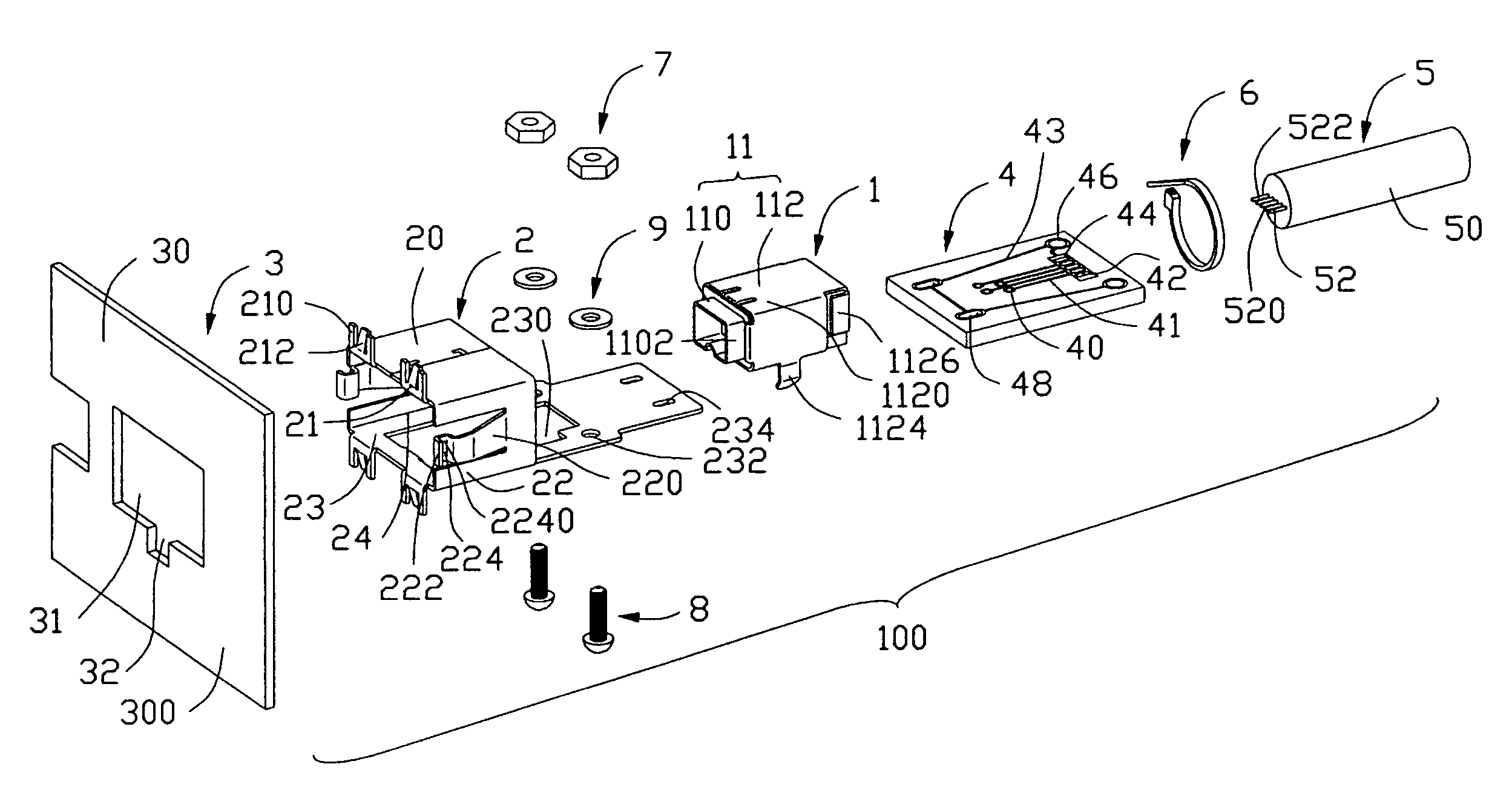

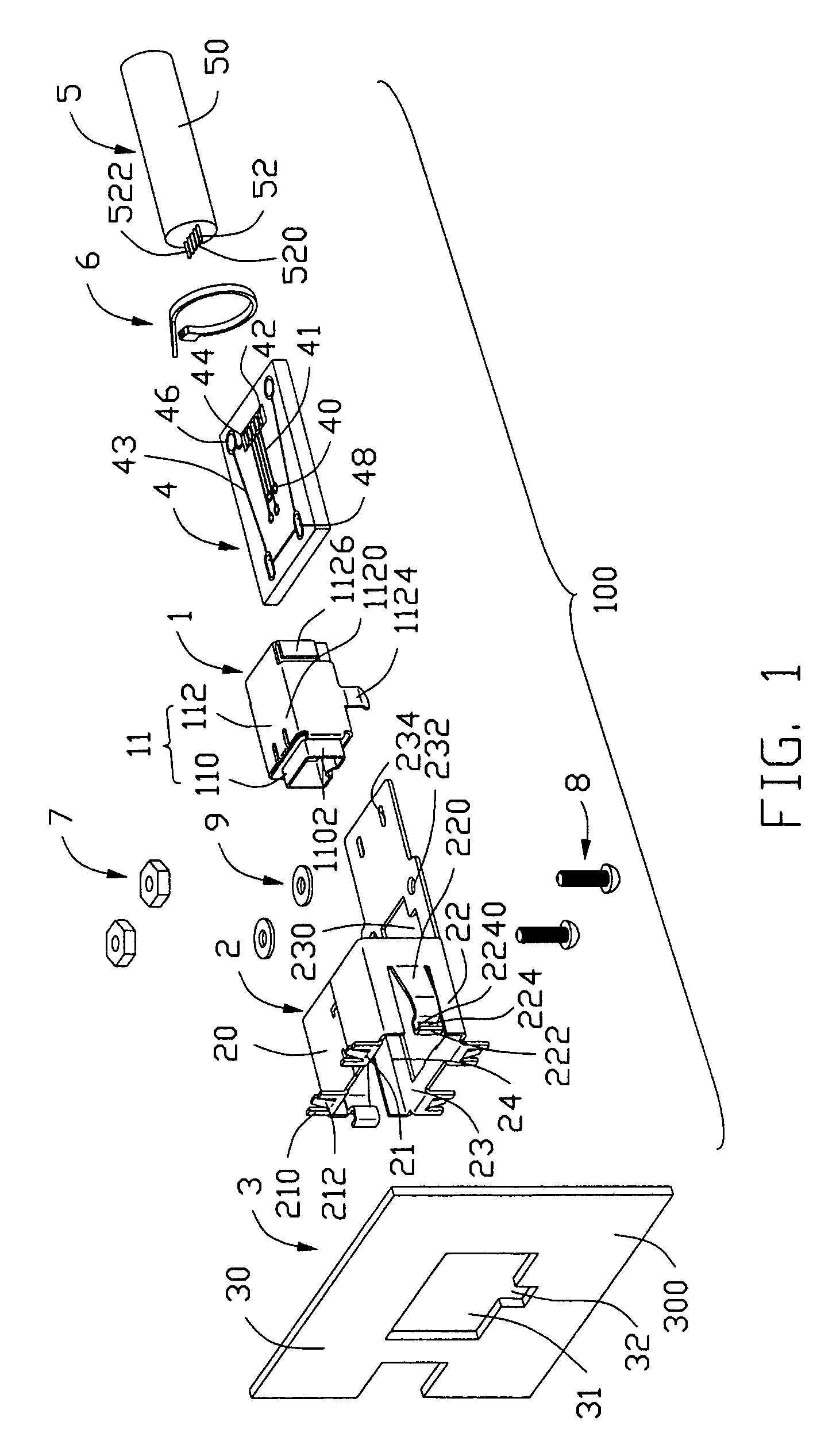

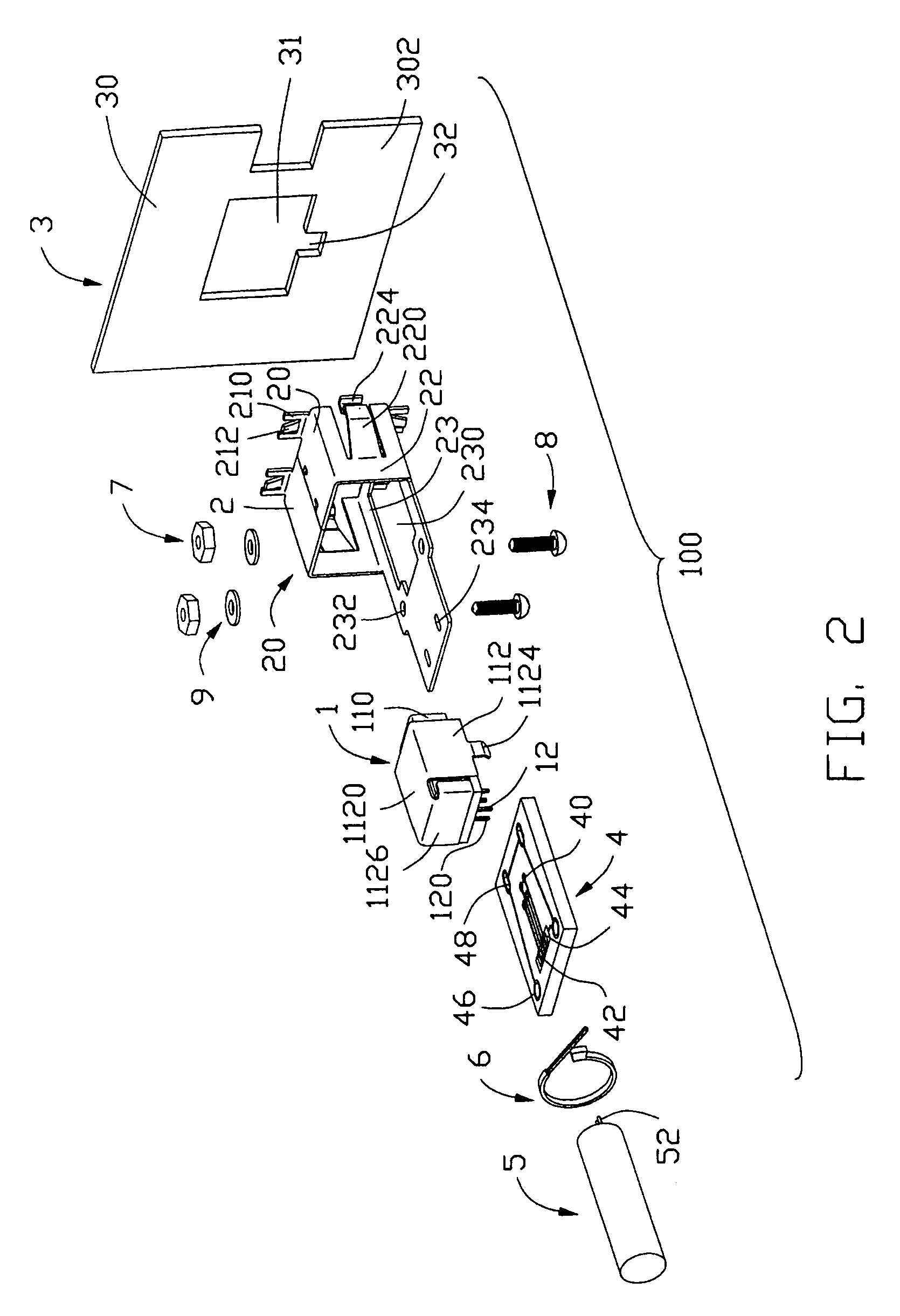

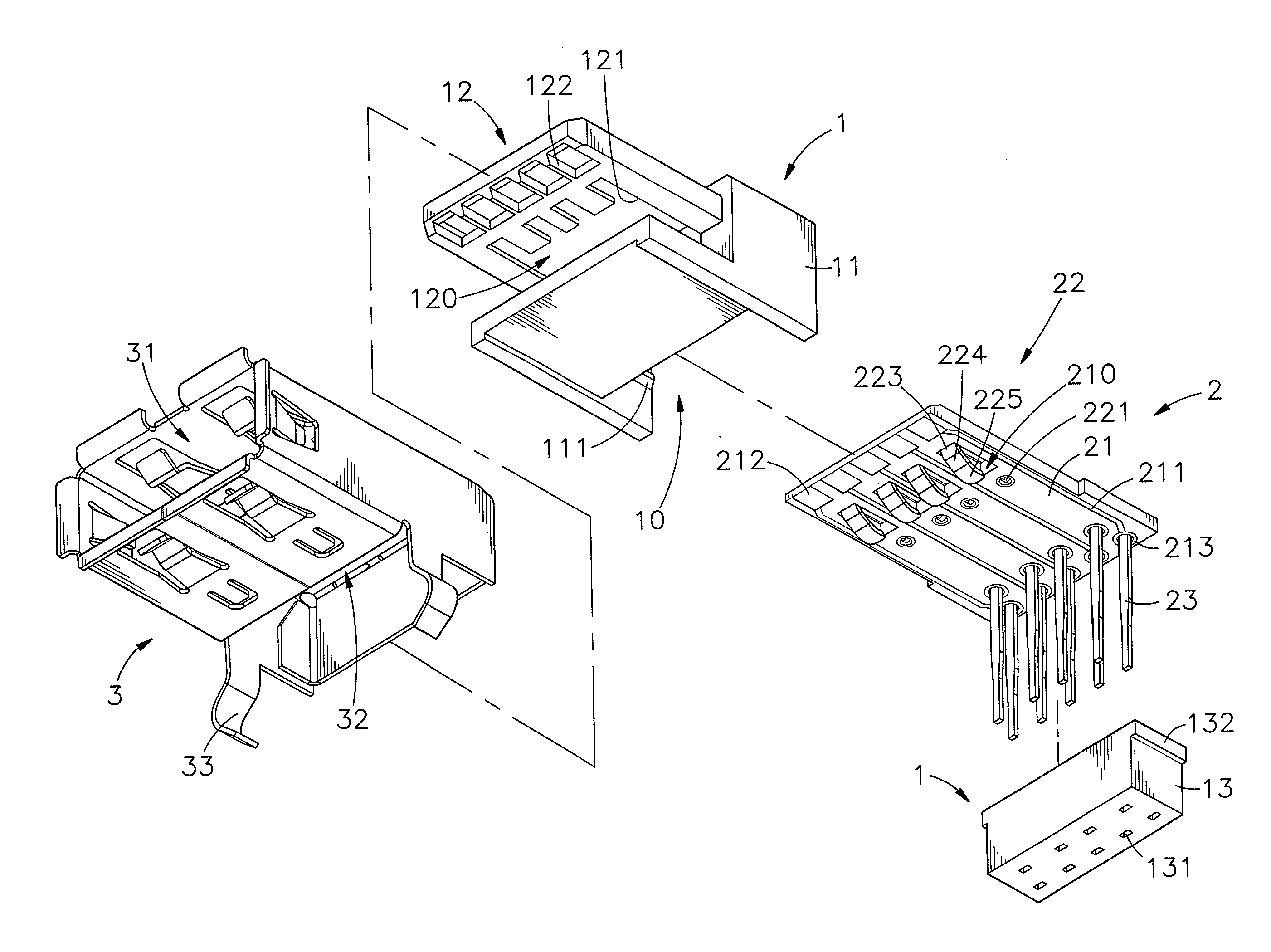

Panel mount cable connector assembly

InactiveUS6991494B1High speed signal transmitting effectPrevent excessive deformationComputer periphery connectorsPrinted circuitsAnti stressEngineering

A cable connector assembly (100) includes an electrical connector (1) including an insulative housing (10), a number of conductive contacts (12) received in the insulative housing and a conductive shield (11) enclosing the insulative housing, a cable (5) including a number of lines (520, 522), a printed circuit board (4) electrically connecting the conductive contacts of the electrical connector with the lines of the cable, and a shielding member (2) electrically connecting with the electrical connector and secured with the printed circuit board and the cable. The shielding member forms a number of deflecting members (212) for securing to a panel (3) and a number of anti-stress members for preventing the deflecting members from excessive deformation.

Owner:HON HAI PRECISION IND CO LTD

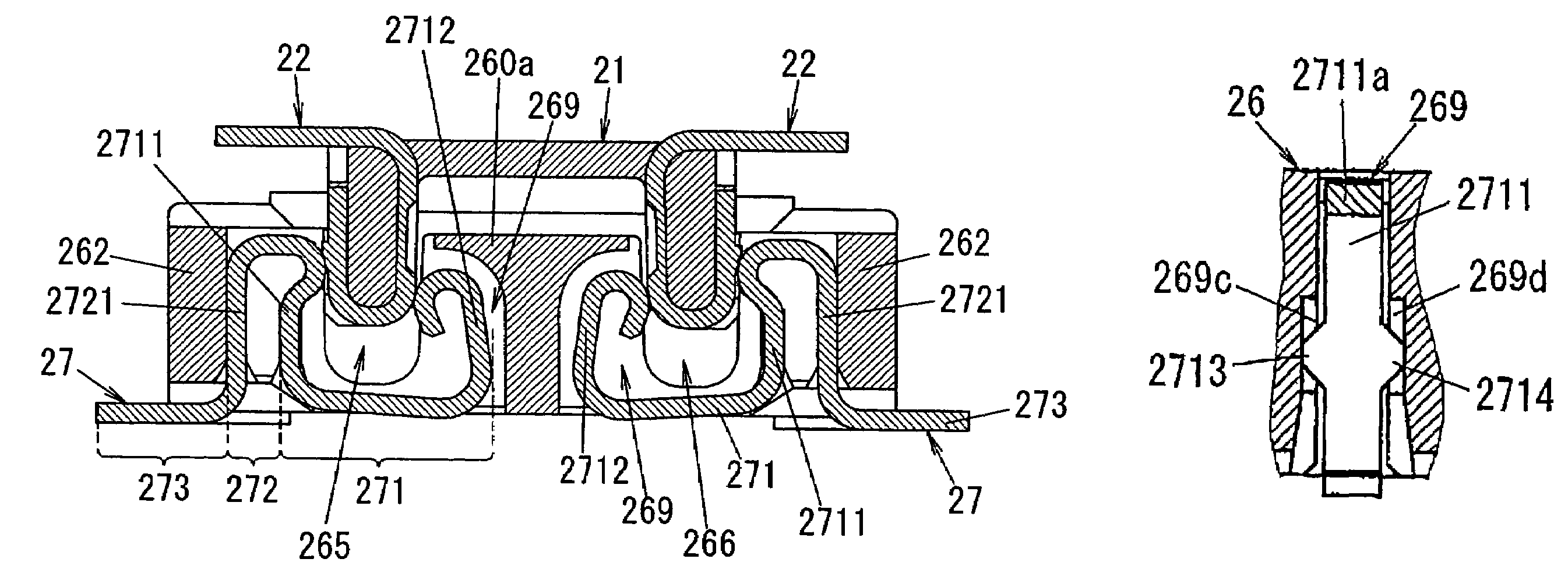

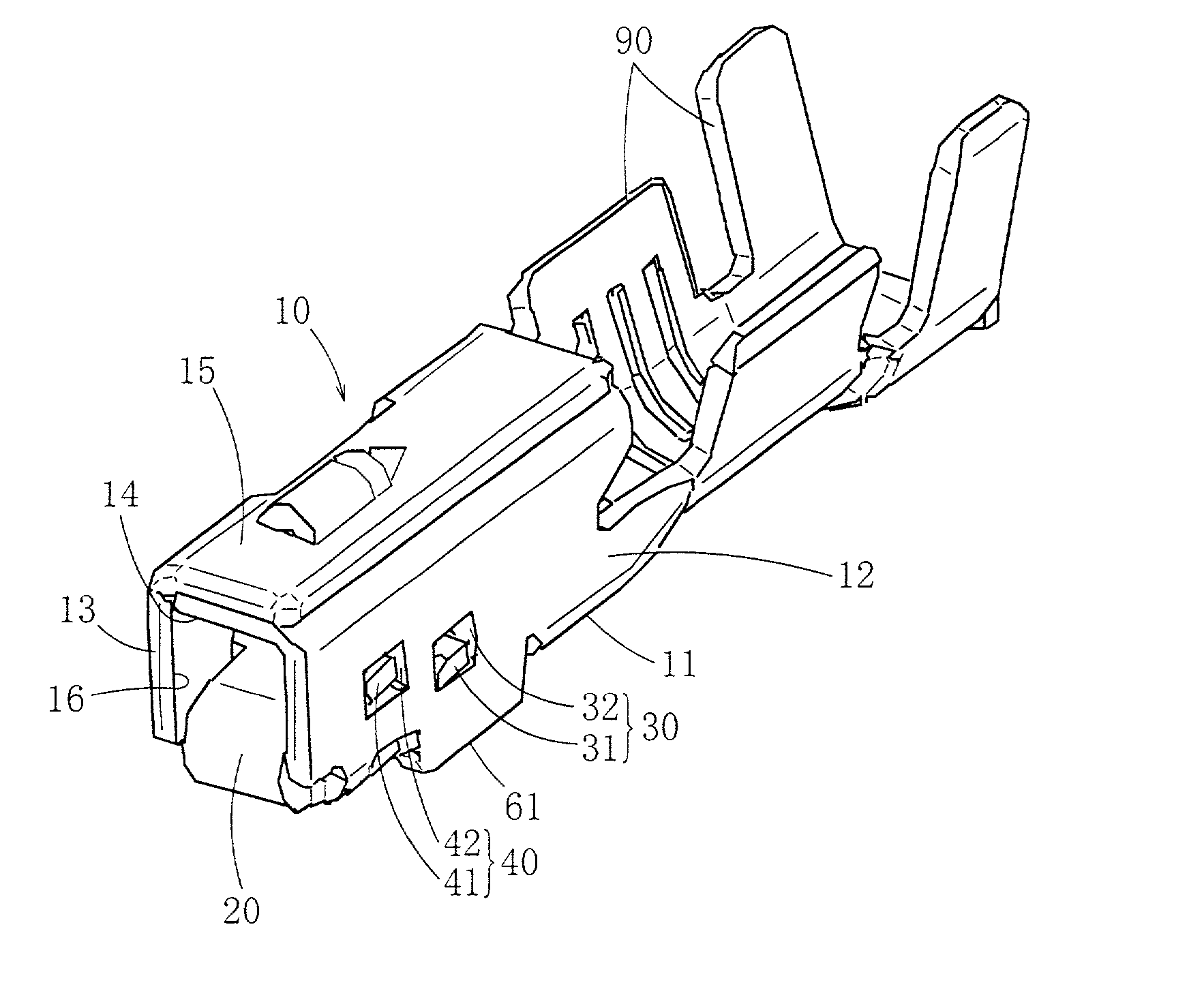

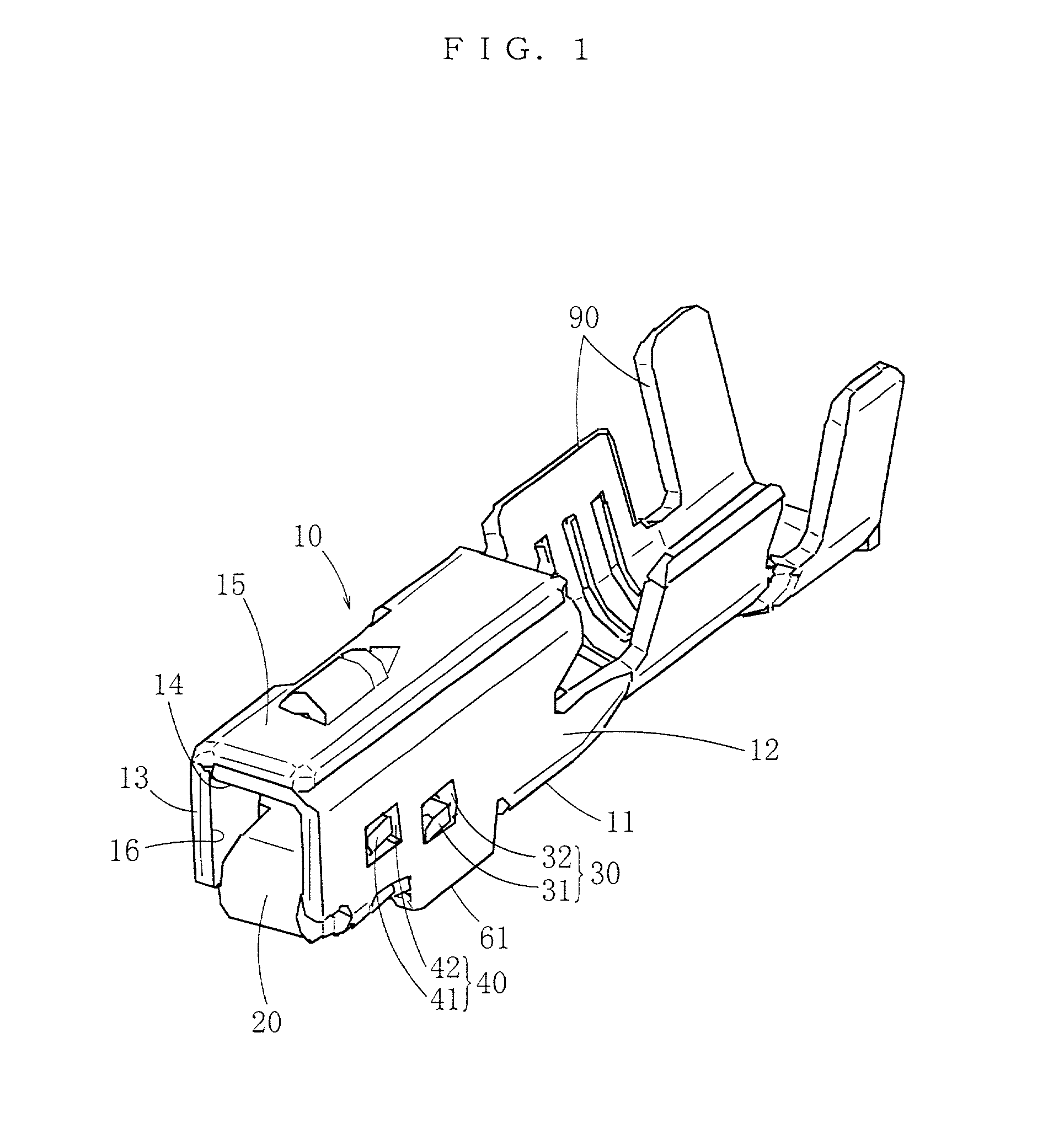

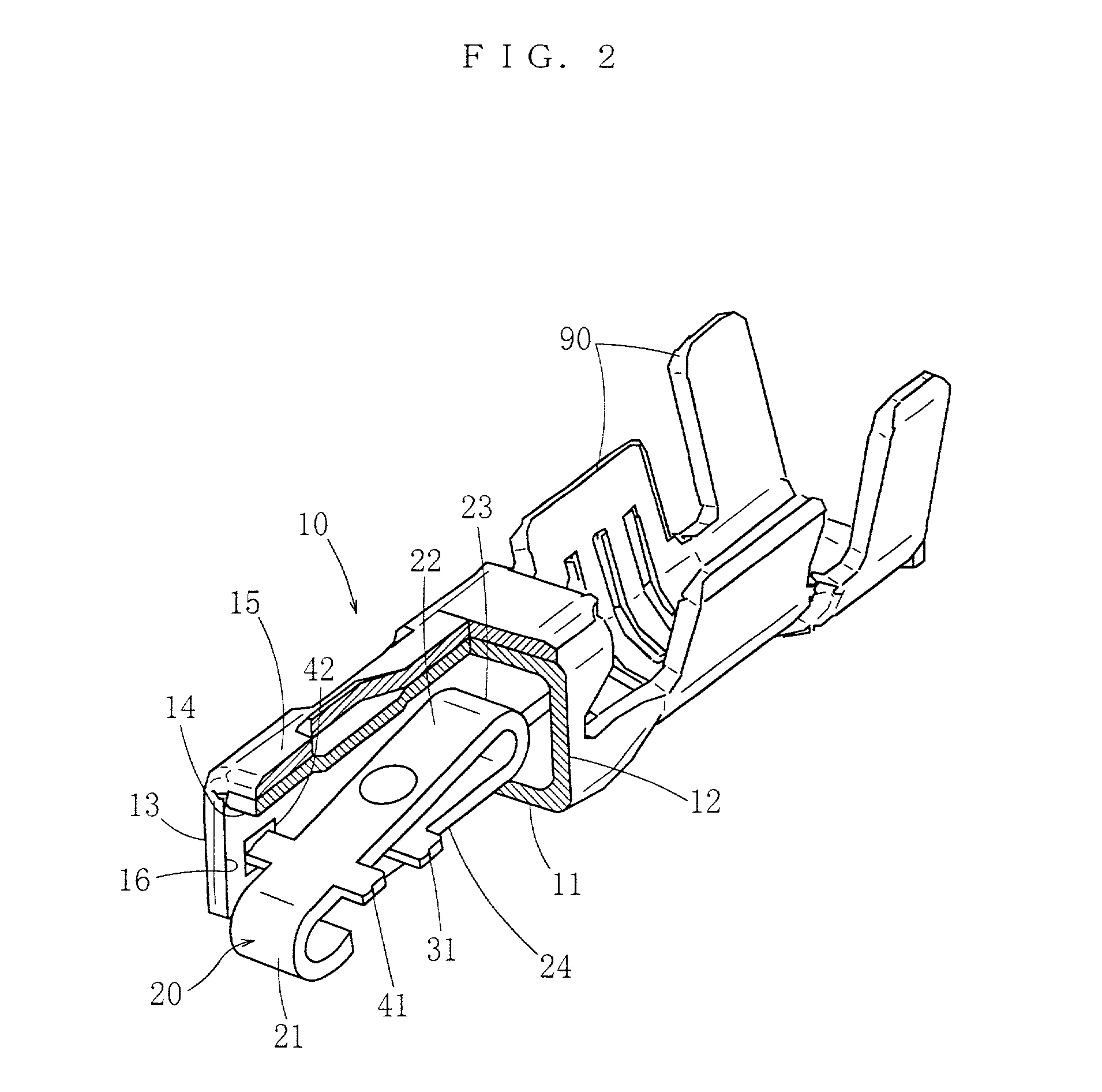

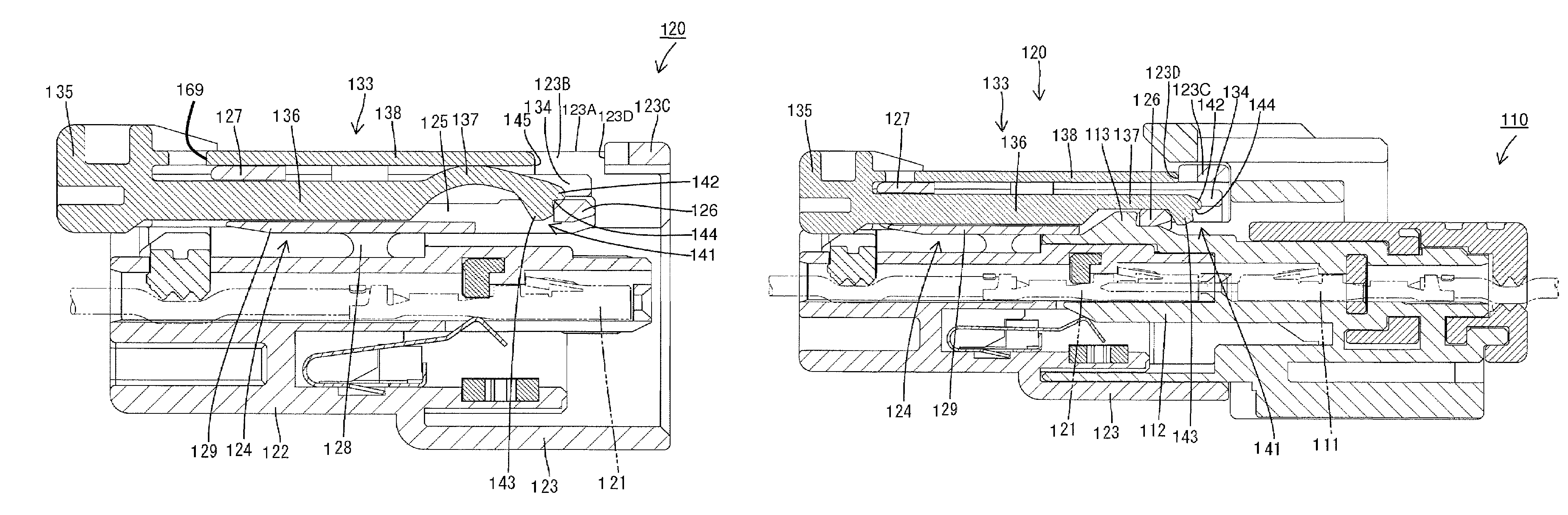

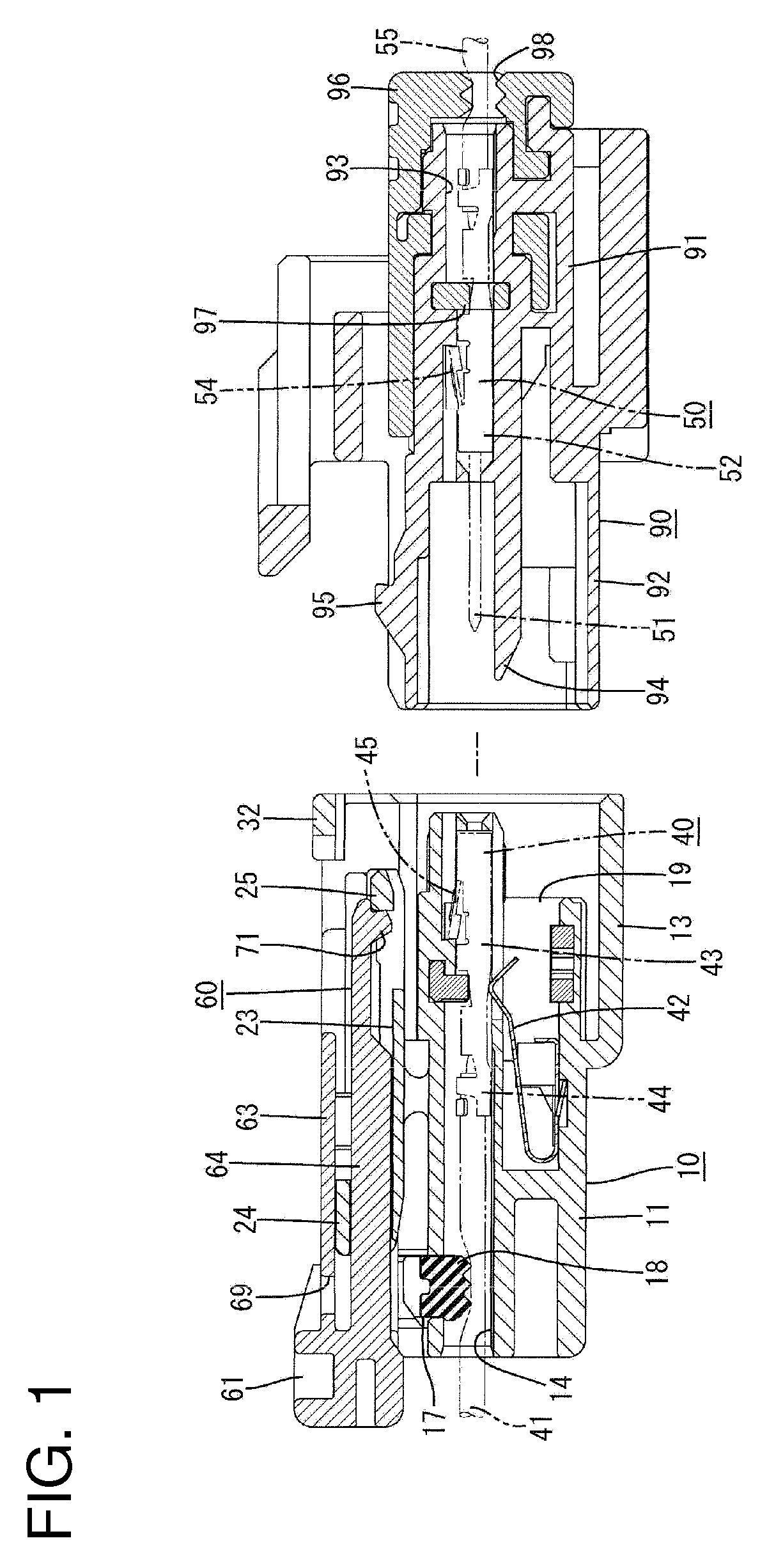

Connector and connector assembly

InactiveUS7591668B2Improve connection reliabilityPrevent movementElectrically conductive connectionsIncorrect coupling preventionMatingElectrical and Electronics engineering

A detector (60) is assembled with a lock arm (12) of a housing (10) to be movable between a standby position and a detection position. The detector (60) can move from the standby position to the detection position when the housing (10) is connected properly with a mating housing (90), and a movement thereof to the detection position is prevented when the housing (10) is connected partly with the mating housing (90). The detector (60) is formed with a window (69). A detecting main body (64) of the detector (60) is seen through the window (69) at the standby position, whereas an upper plate (24) of the lock arm (12) is seen therethrough at the detection position. The detector (60) is in a first color and the housing is in a second color different from the first color.

Owner:SUMITOMO WIRING SYST LTD

Substrate storage container

ActiveUS20050274645A1Damage can be suppressedPrevent particle generationSemiconductor/solid-state device manufacturingOther accessoriesGasketEngineering

A substrate storage container comprises: a container casing having an aperture through which a plurality of substrates are placed in or taken out; a cover adapted to fit into the aperture of the container casing; a sealing gasket capable of elastic deformation provided between the container casing and the cover, and a retainer, mounted on the cover, capable of retaining the periphery of the substrates. The retainer has: a supporting body mounted on the inside face of the cover; a plurality of elastic pieces provided in elastically deformable fashion on the supporting body; and a block provided on each of the elastic pieces, the block retaining the periphery of one of the substrates. A relation 10.8×w<y<34.3×w is satisfied when a substrate retaining force of each of the elastic pieces is y [unit: N] and a weight per the substrate is w [unit: kg].

Owner:SHIN-ETSU POLYMER CO LTD

Connector and connector assembly

InactiveUS20090035980A1Improve connection reliabilityPrevent movementElectrically conductive connectionsIncorrect coupling preventionMatingEngineering

A detector (60) is assembled with a lock arm (12) of a housing (10) to be movable between a standby position and a detection position. The detector (60) can move from the standby position to the detection position when the housing (10) is connected properly with a mating housing (90), and a movement thereof to the detection position is prevented when the housing (10) is connected partly with the mating housing (90). The detector (60) is formed with a window (69). A detecting main body (64) of the detector (60) is seen through the window (69) at the standby position, whereas an upper plate (24) of the lock arm (12) is seen therethrough at the detection position. The detector (60) is in a first color and the housing is in a second color different from the first color.

Owner:SUMITOMO WIRING SYST LTD

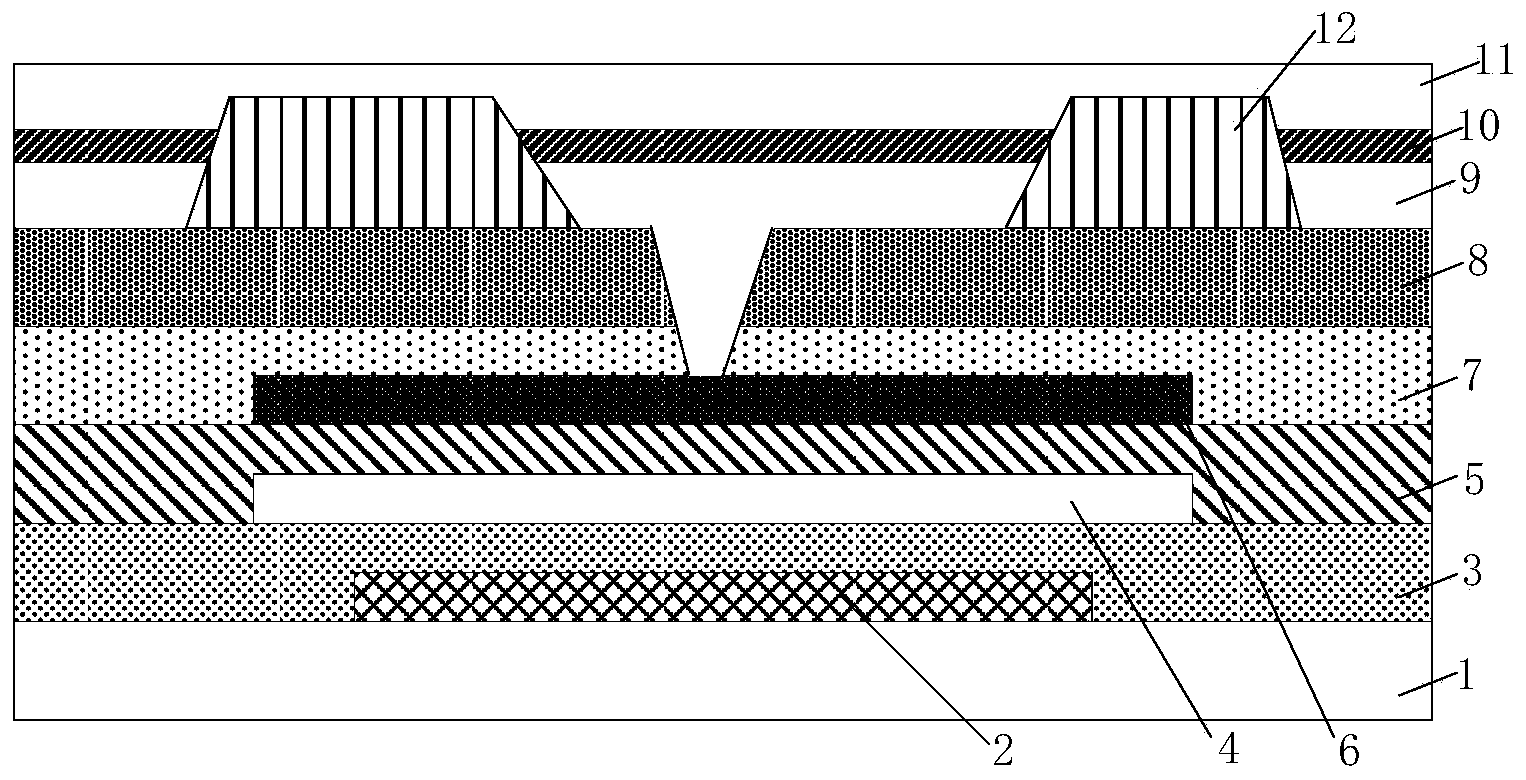

Color film substrate, manufacturing method thereof, display panel and display device

ActiveCN104078491APrevent excessive deformationAvoid using effectsSolid-state devicesNon-linear opticsInternal pressureElastic compression

The invention provides a color film substrate, a manufacturing method of the color film substrate, a display panel and a display device. The color film substrate comprises a substrate body, single-layer color film layers and a color folding film layer, wherein the single-layer color film layers are formed on one side of the substrate body and located in color sub-pixel areas, and the color folding film layer is located between one part of the color sub-pixel areas and formed by multiple single-layer color film layers in a laminated mode. The color film substrate further comprises a shock insulator located between the other part of the color sub-pixel areas and an auxiliary electrode layer with which the surface of the color folding film layer is covered. The top surface of the shock insulator is higher than that of the color folding film layer, and the shock insulator can be elastically compressed in the height direction. The situation that the color film substrate cannot be used normally due to uneven internal pressure when a screen is oversize is avoided, the color film substrate is applied to display of OLEDs, damage to ITO materials and cathode materials of the auxiliary electrode layer can be effectively reduced, and a good electric conduction effect can be guaranteed.

Owner:BOE TECH GRP CO LTD

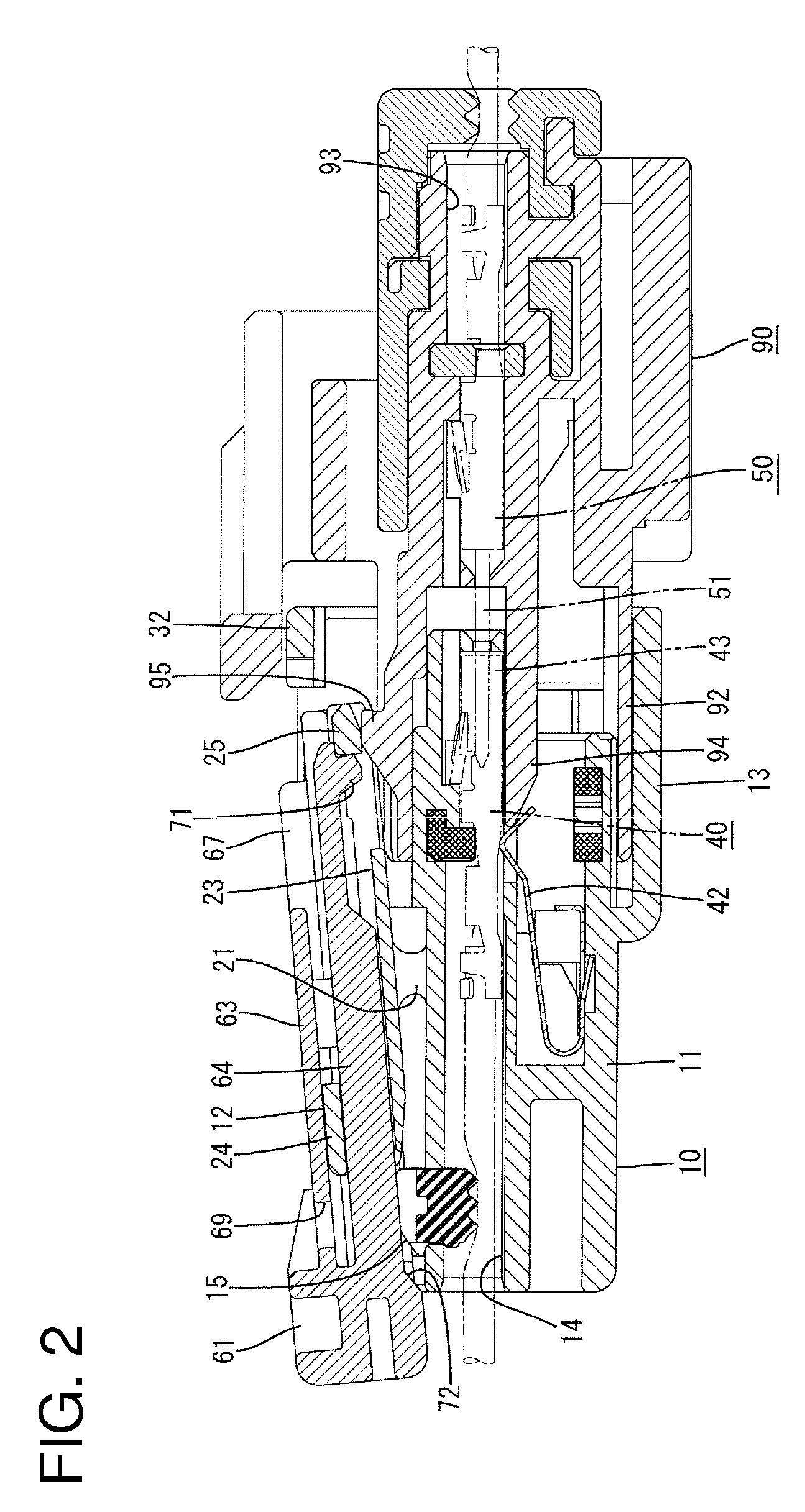

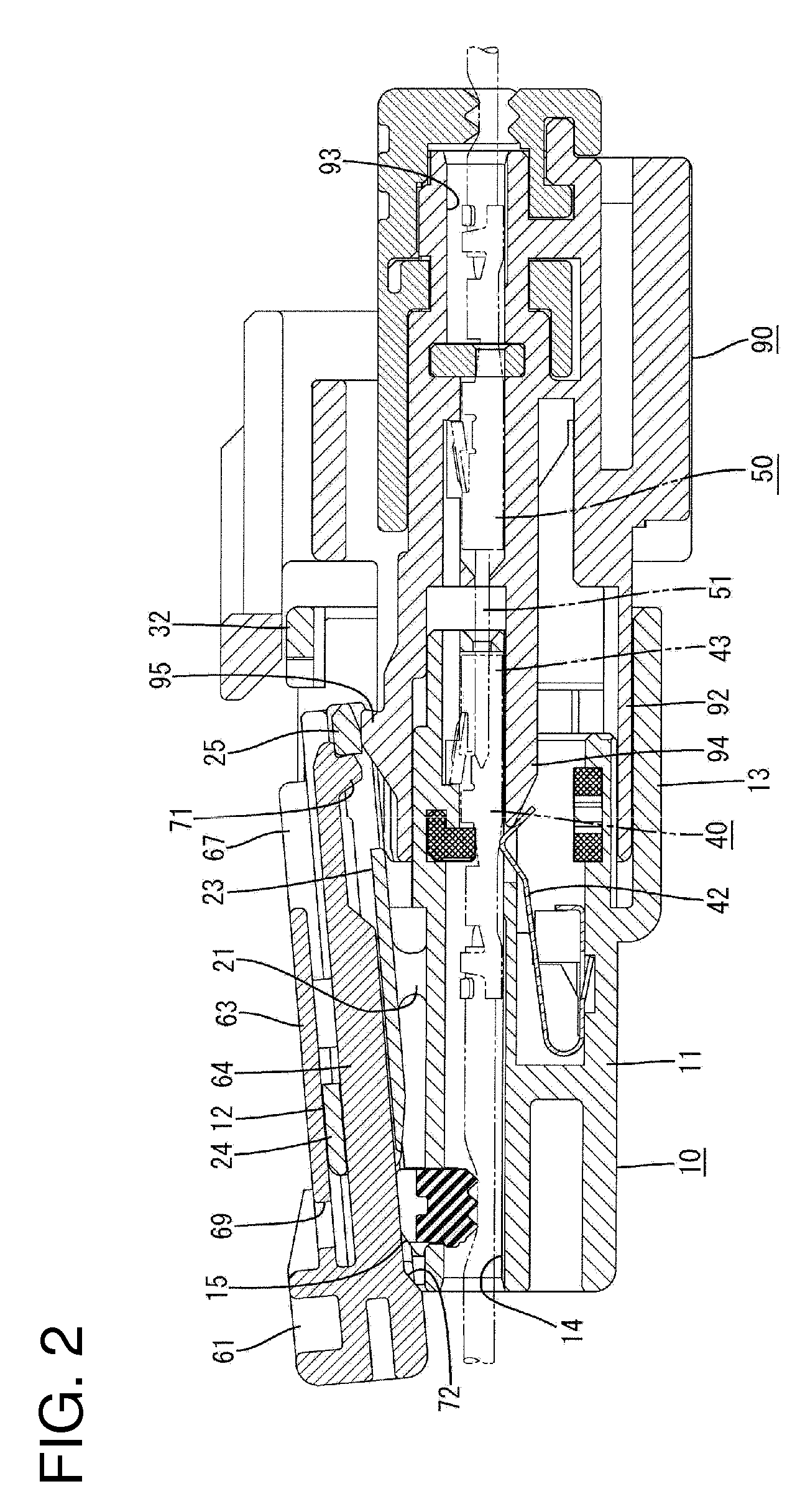

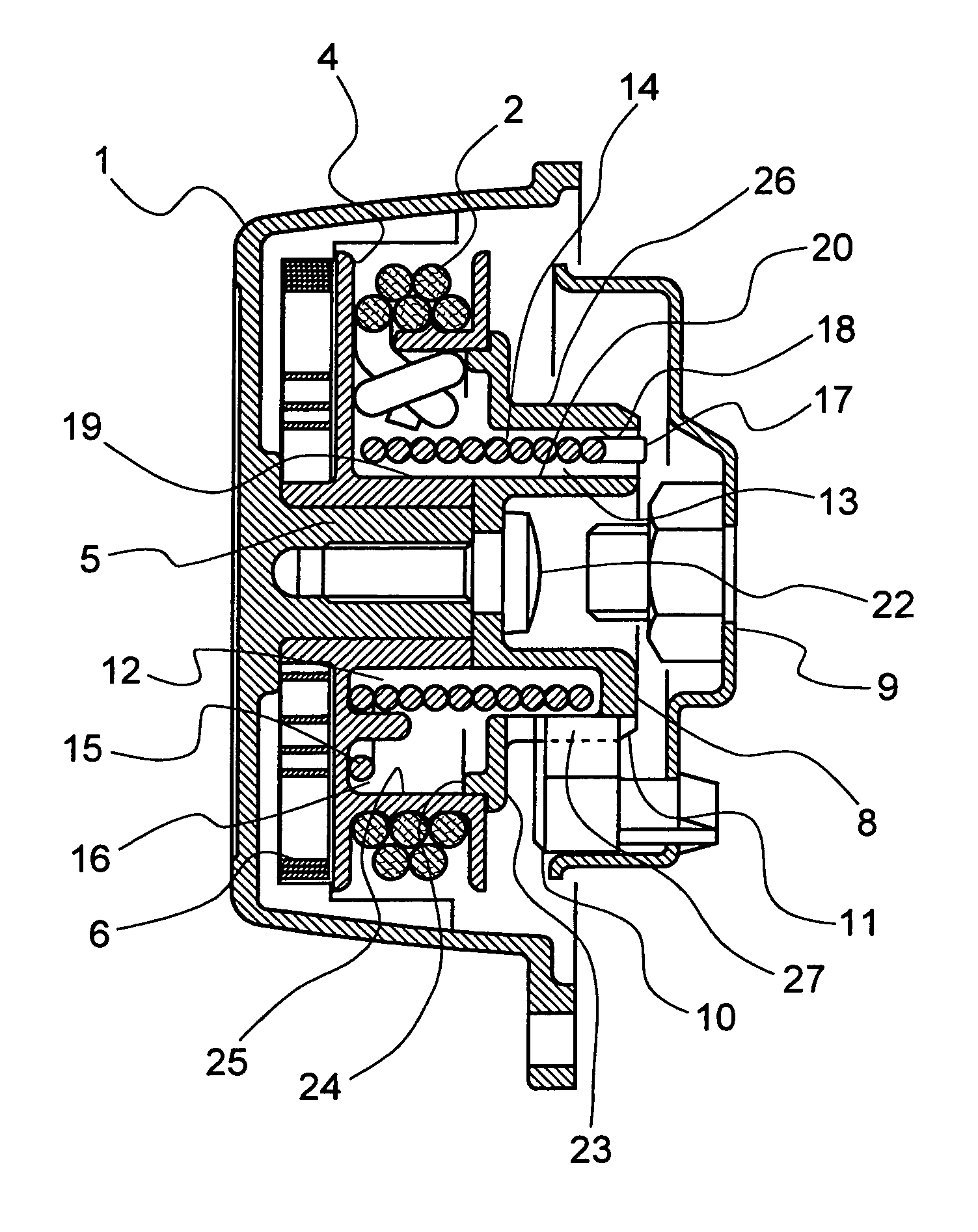

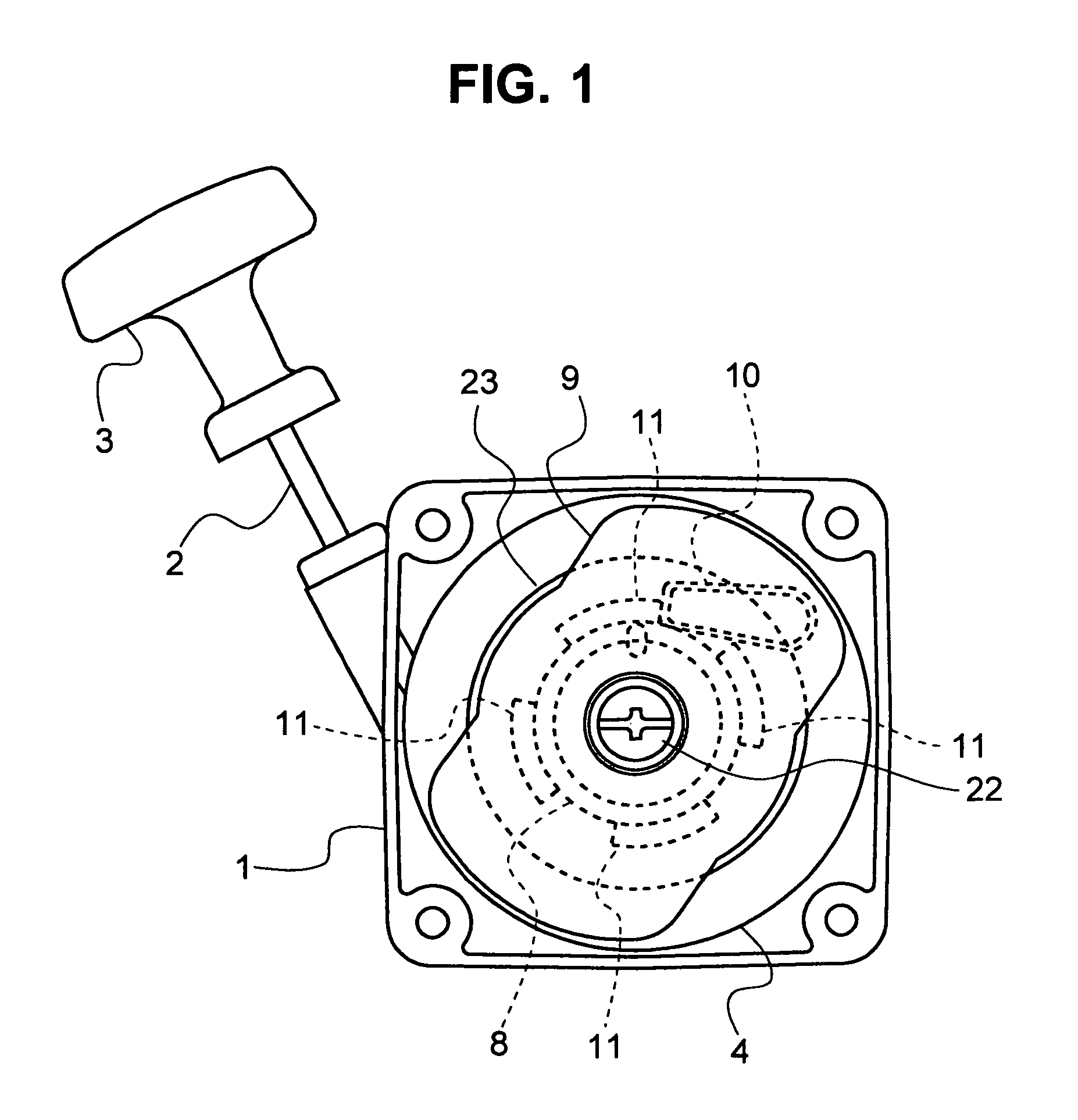

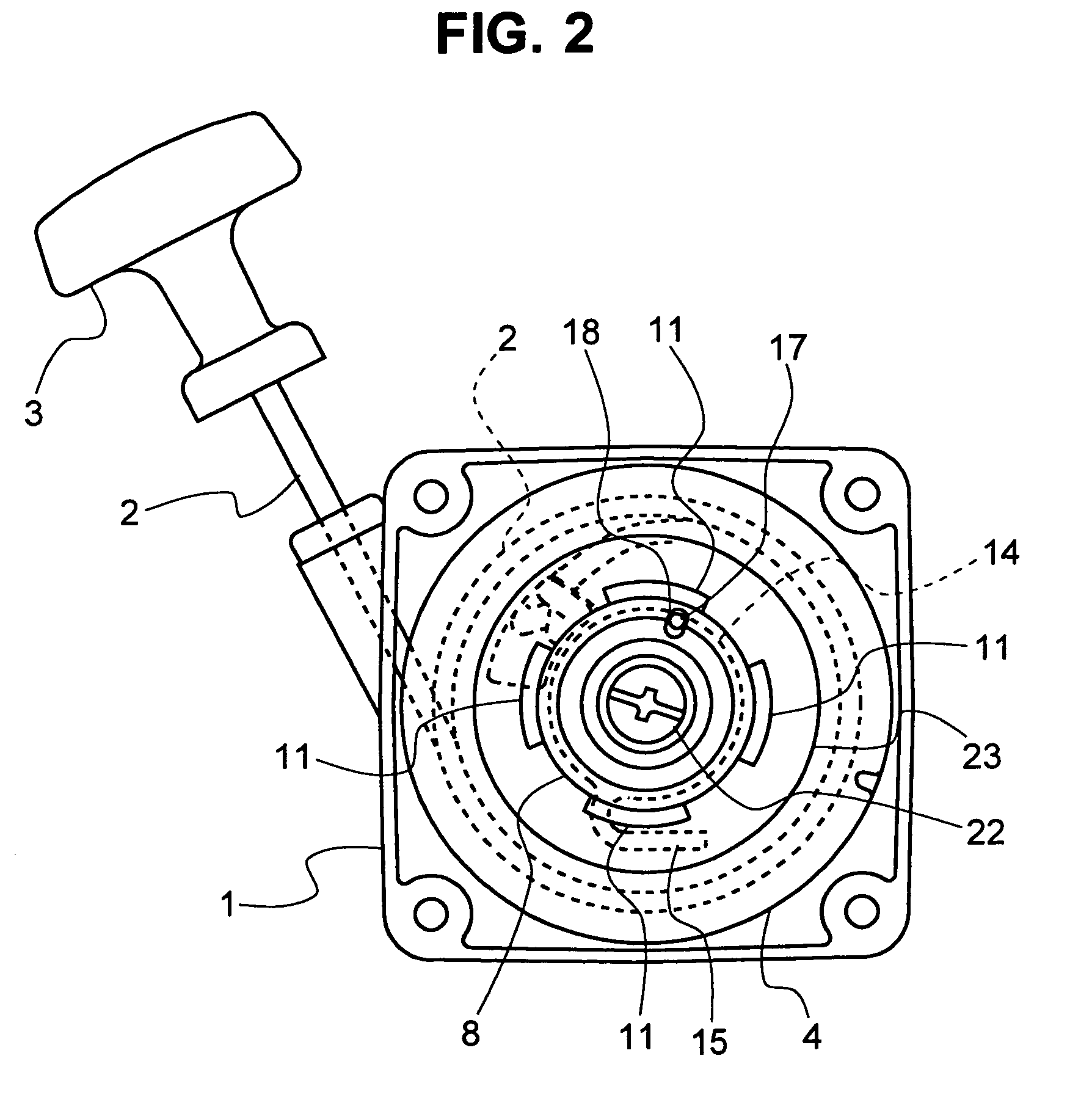

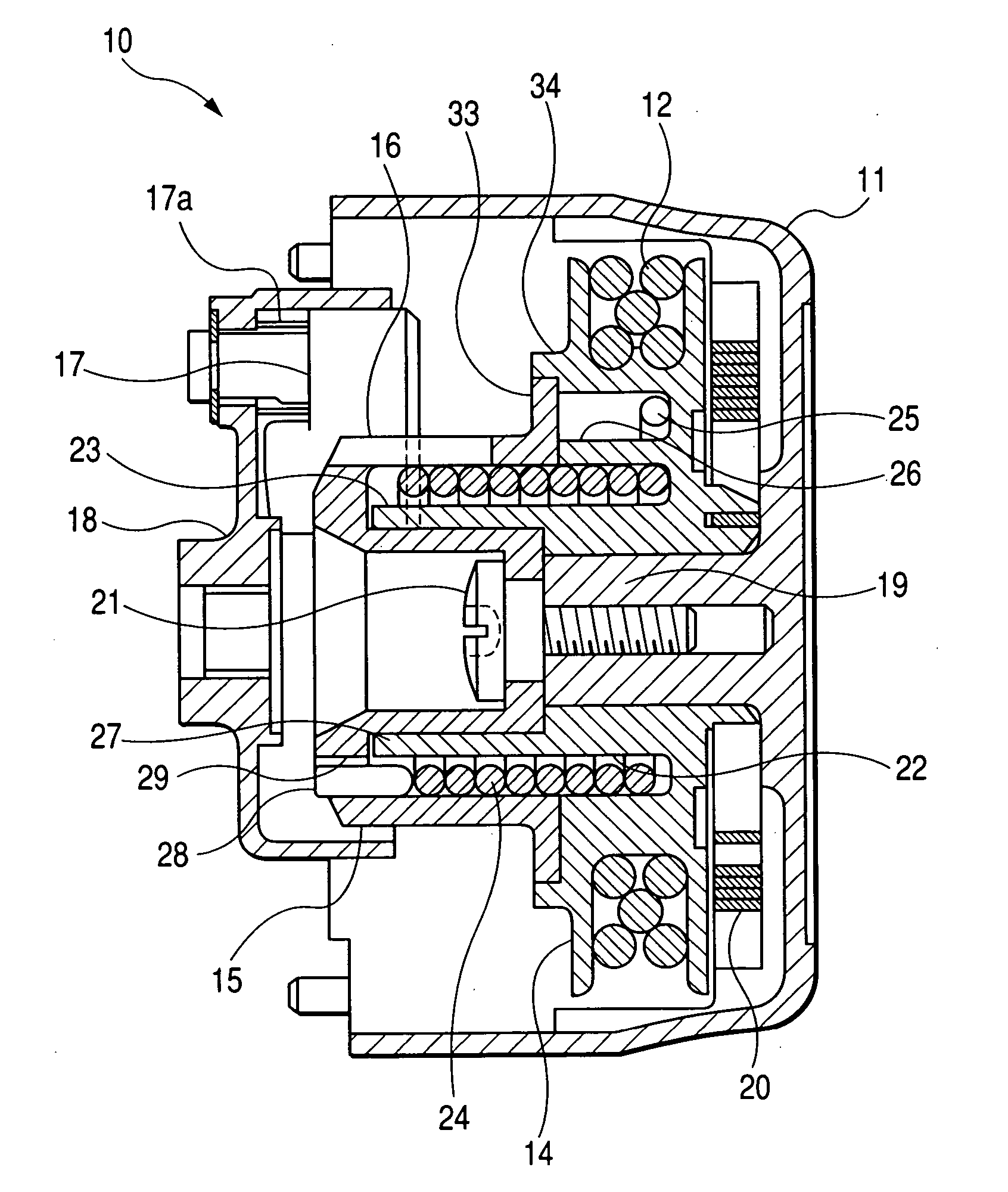

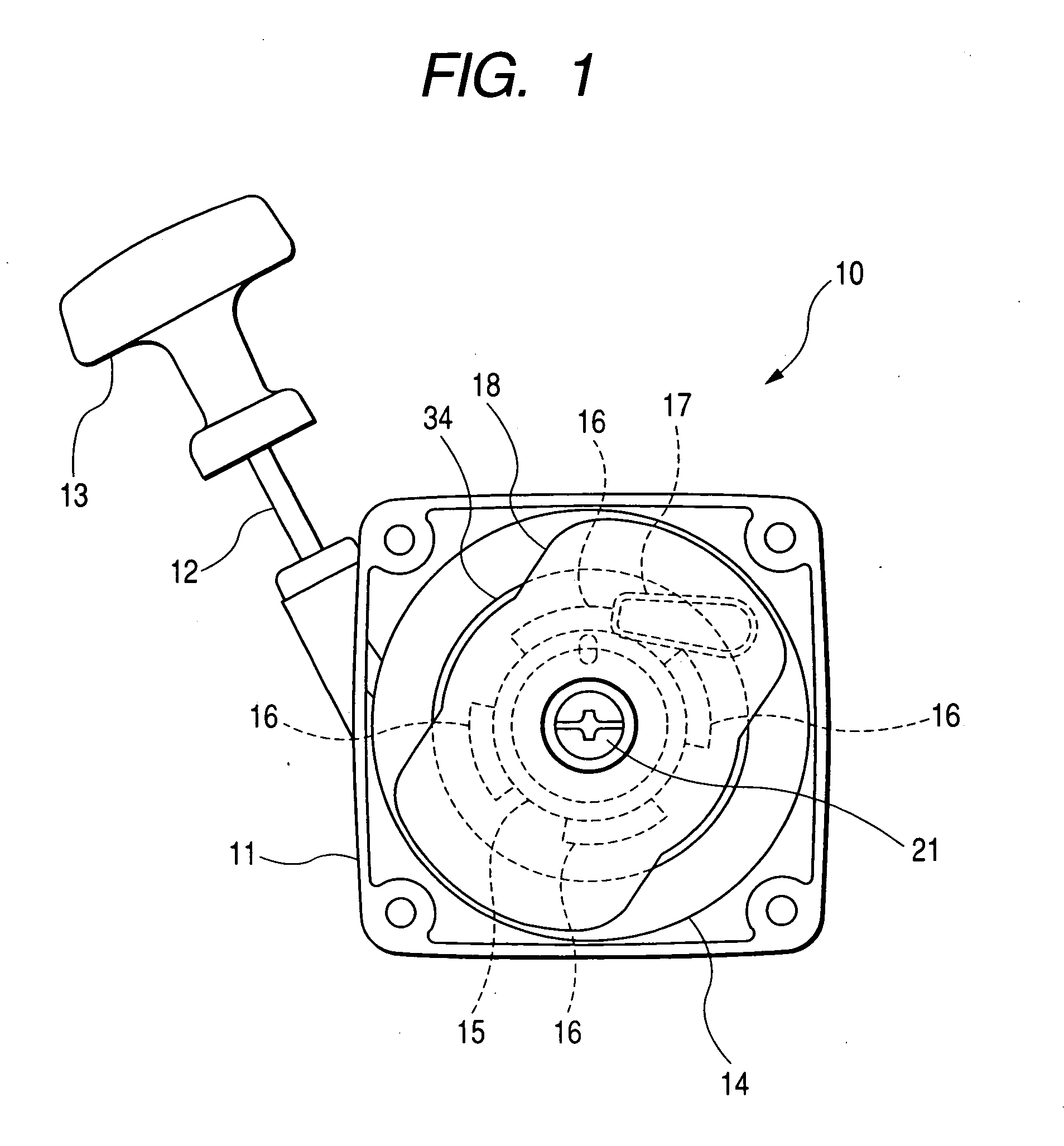

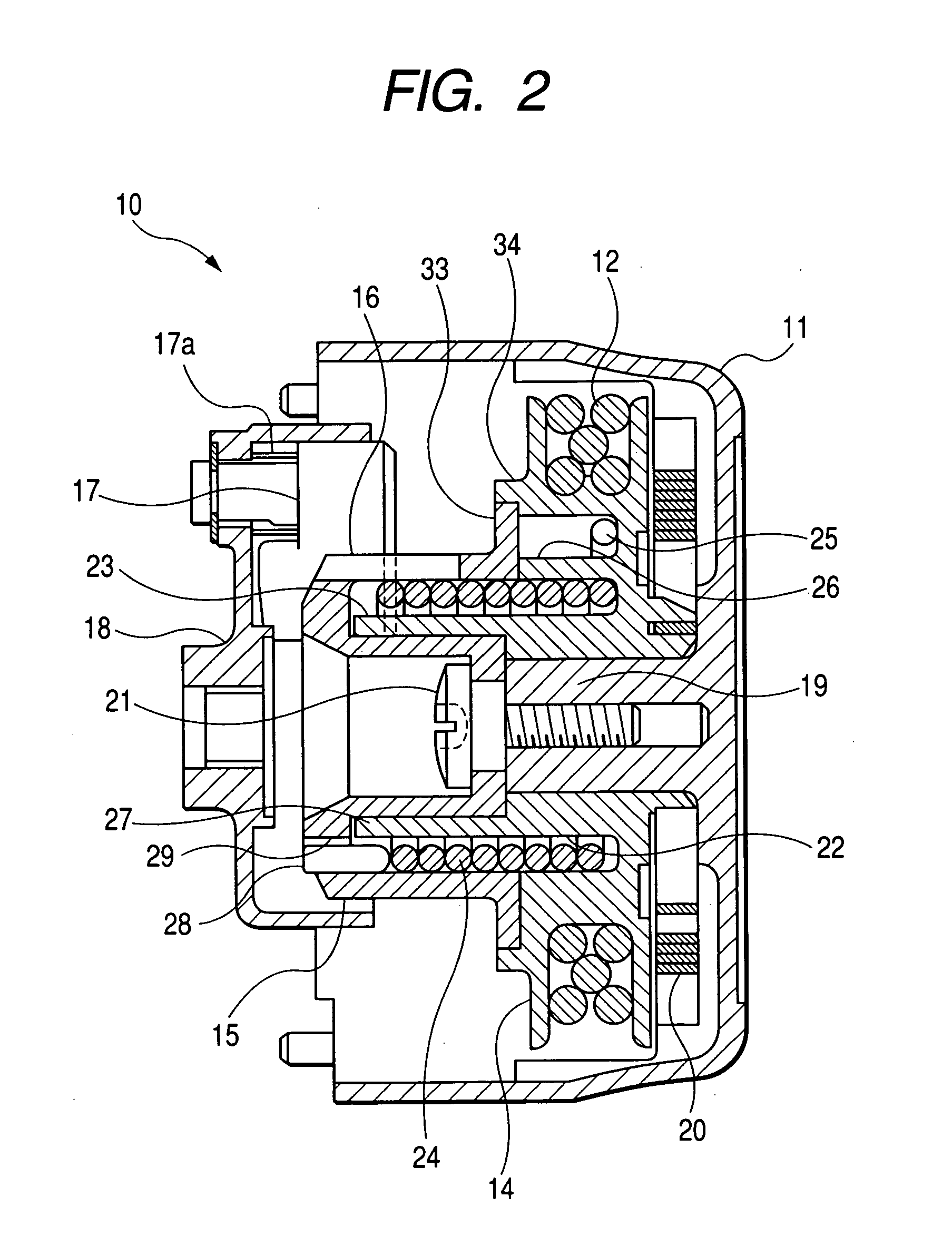

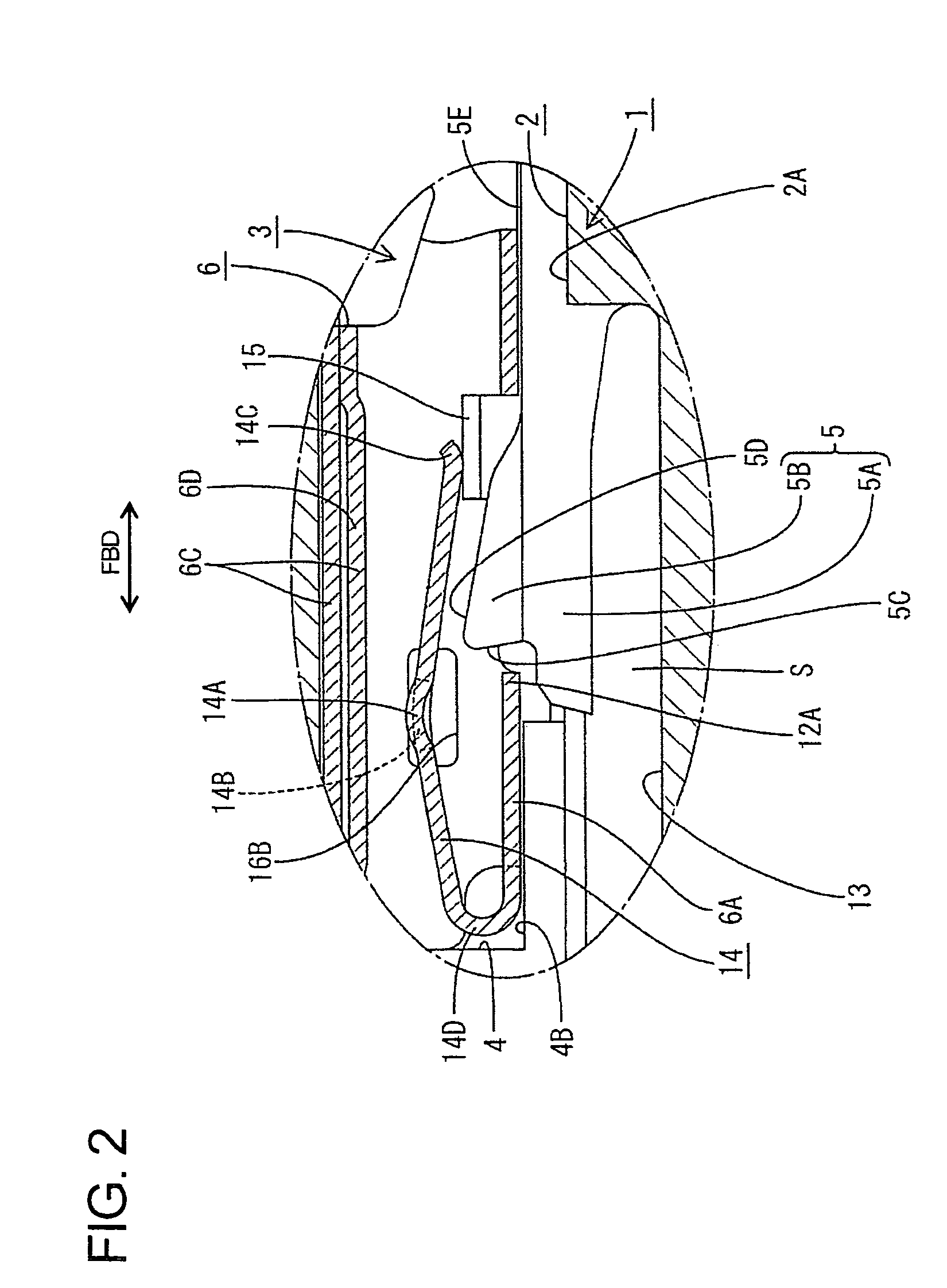

Recoil starter

InactiveUS6981482B2Increased durabilityPrevent excessive deformationPower operated startersMuscle operated startersSnubberCam

A recoil starter having improved durability by inhibiting excessive deformation of a damper spring, and capable of receiving a damper spring with high shock-absorbing and force-storing capabilities. The recoil starter includes a rope reel and a cam which are rotated by pulling a recoil rope, so that a rotation of the cam is transmitted to an engine via a ratchet mechanism to start the engine. A damper spring which couples the rope reel and the cam to each other has, at opposite ends thereof, engaging portions radially movably supported by holding portions of the rope reel and the cam, respectively, so that substantially the overall length of the damper spring winds and tightens uniformly around outer peripheral surfaces of both bosses of the rope reel and the cam due to a startup resistance of the engine.

Owner:STARTING IND CO LTD

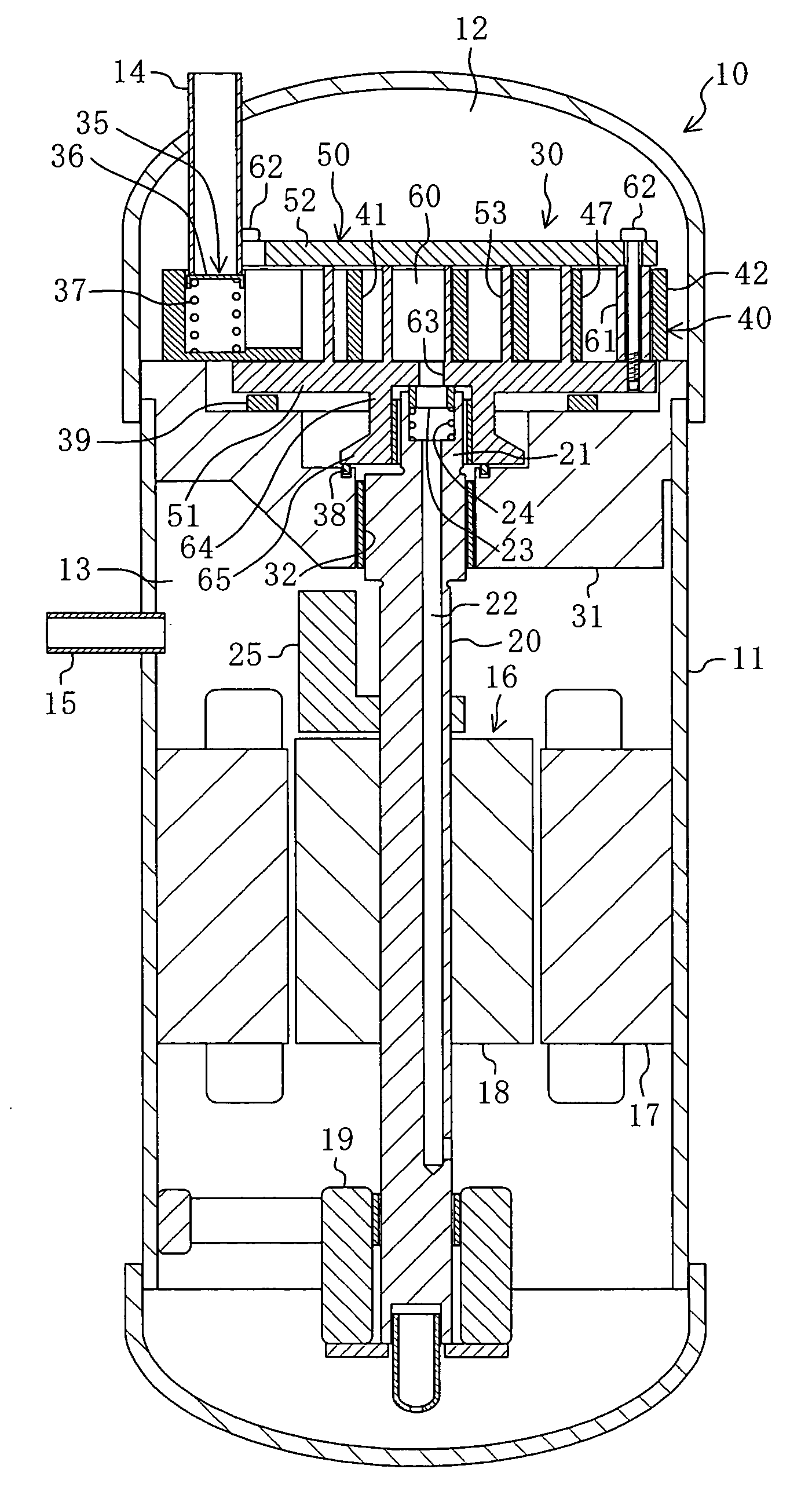

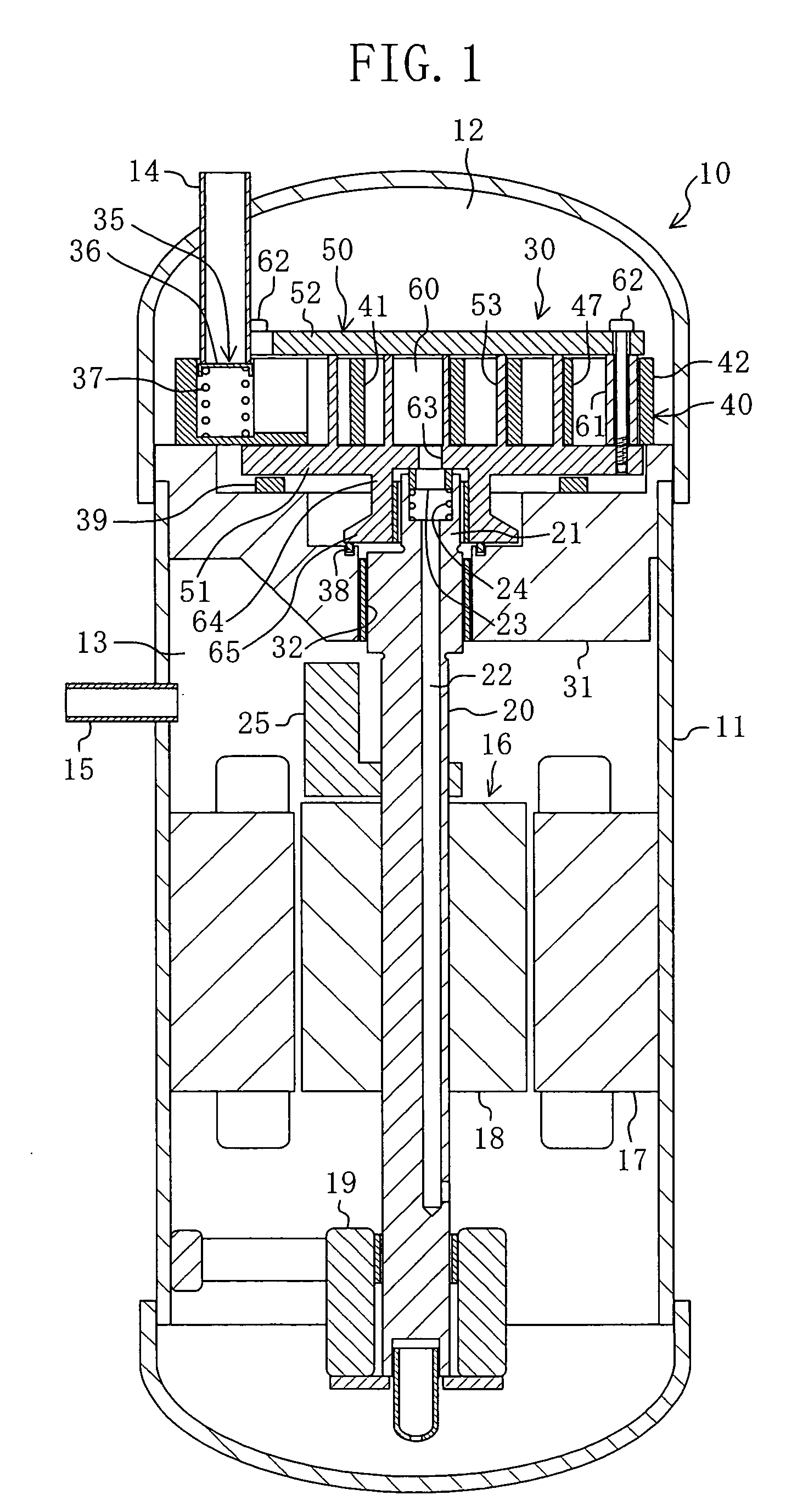

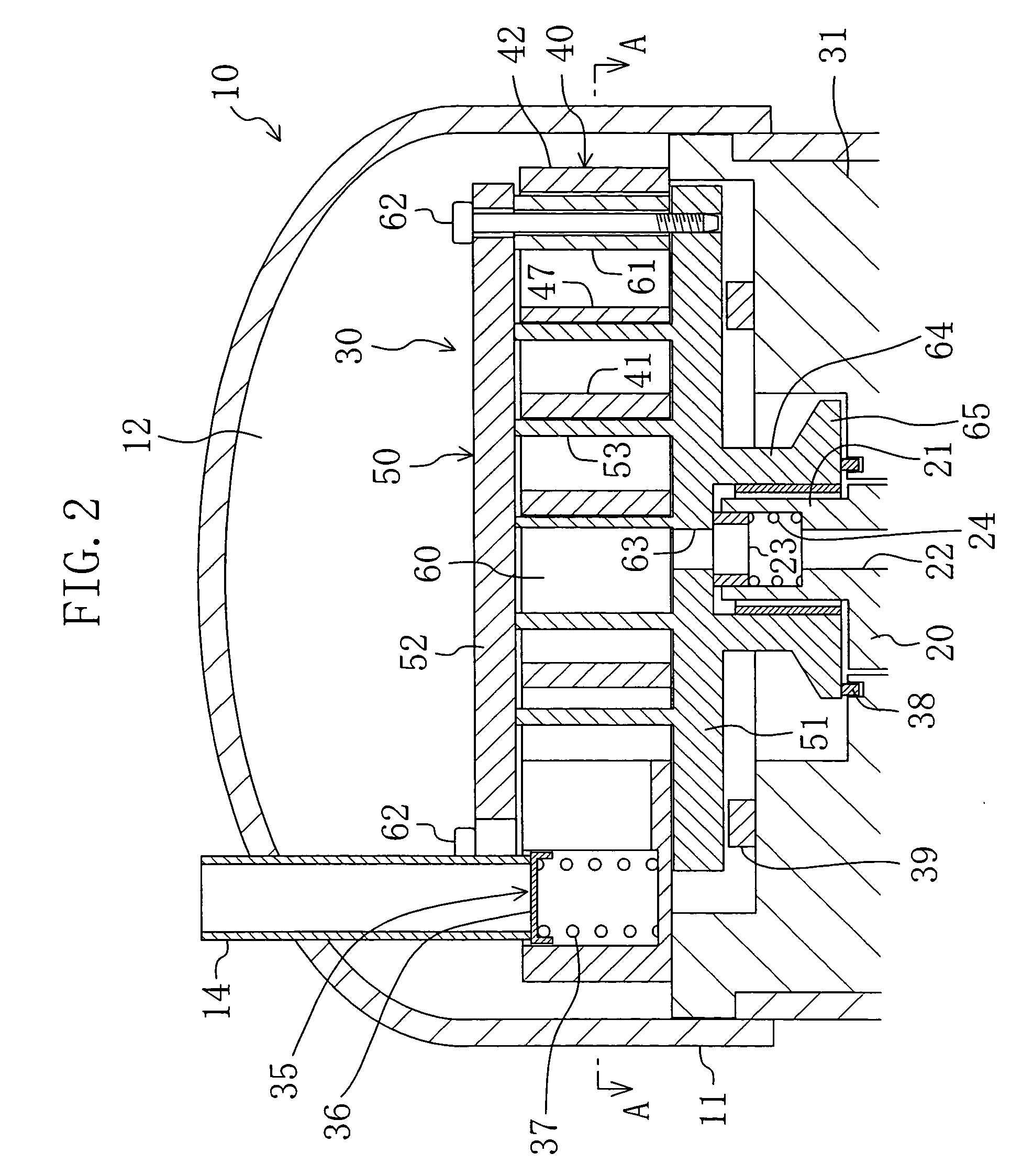

Scroll type fluid machine

InactiveUS20040101428A1Improve reliabilityIncrease frictional resistanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringMechanical engineering

A stationary scroll (40) is provided with a stationary side wrap (41) and an outer peripheral portion (42). The stationary side wrap (41) is formed into a spiral wall shape. The outer peripheral portion (42) is formed into a ring-like shape enclosing the periphery of the stationary side wrap (41). The movable scroll (50) is provided with a first flat plate (51), a movable side wrap (53), and a second flat plate (52). The movable side wrap (53) is formed into a spiral wall shape. Additionally, the movable side wrap (53) is caught between the first flat plate (51) and the second flat plate (52), with the movable side wrap (53) in mating engagement with the stationary side wrap (41). In the movable side wrap (53), the first flat plate (51) is formed integrally with the movable side wrap (53). Additionally, the second flat plate portion (52) is formed as a separate body from the first flat plate (51) and the movable side wrap (53) and is coupled to the first flat plate (51) with a bolt (62).

Owner:DAIKIN IND LTD

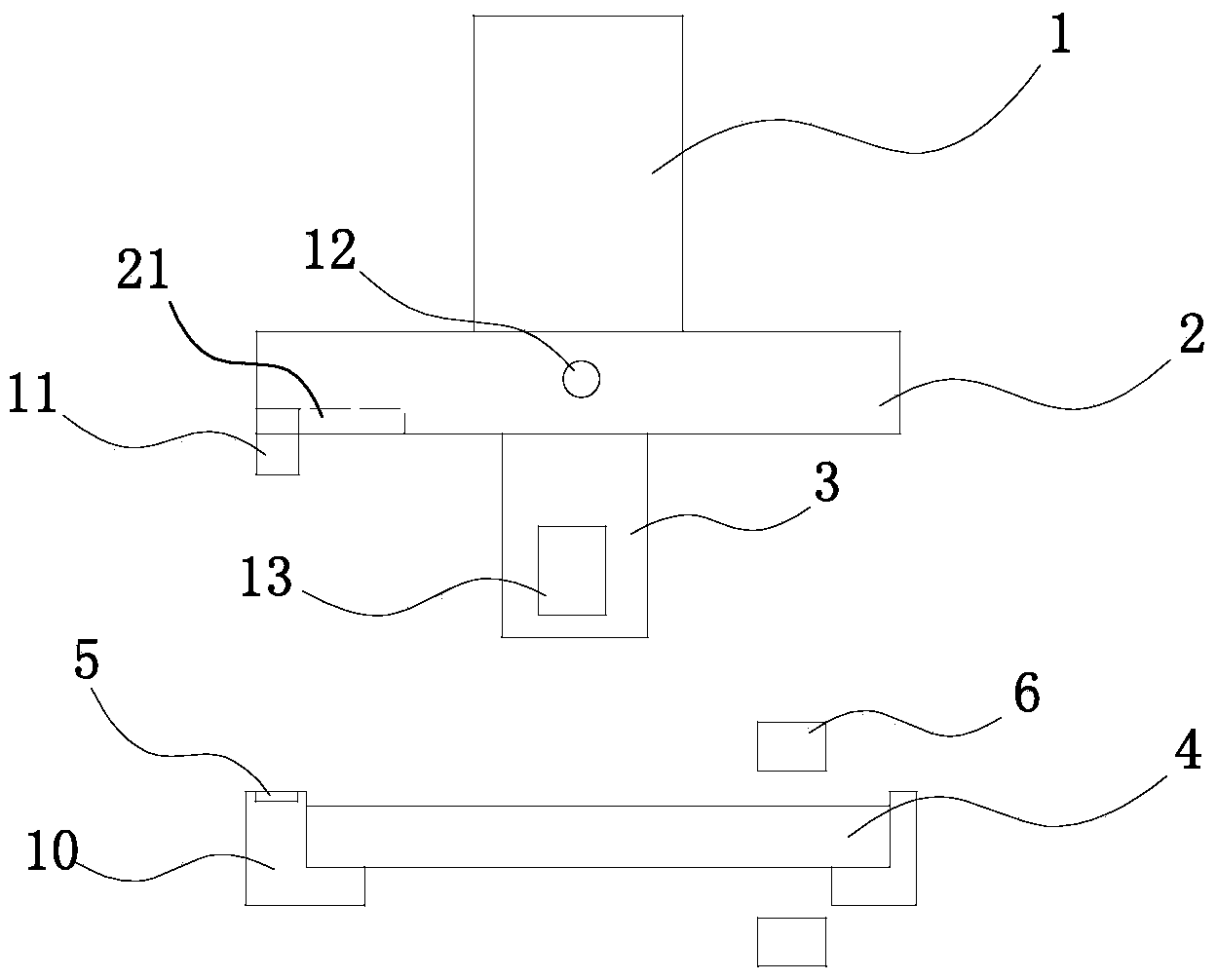

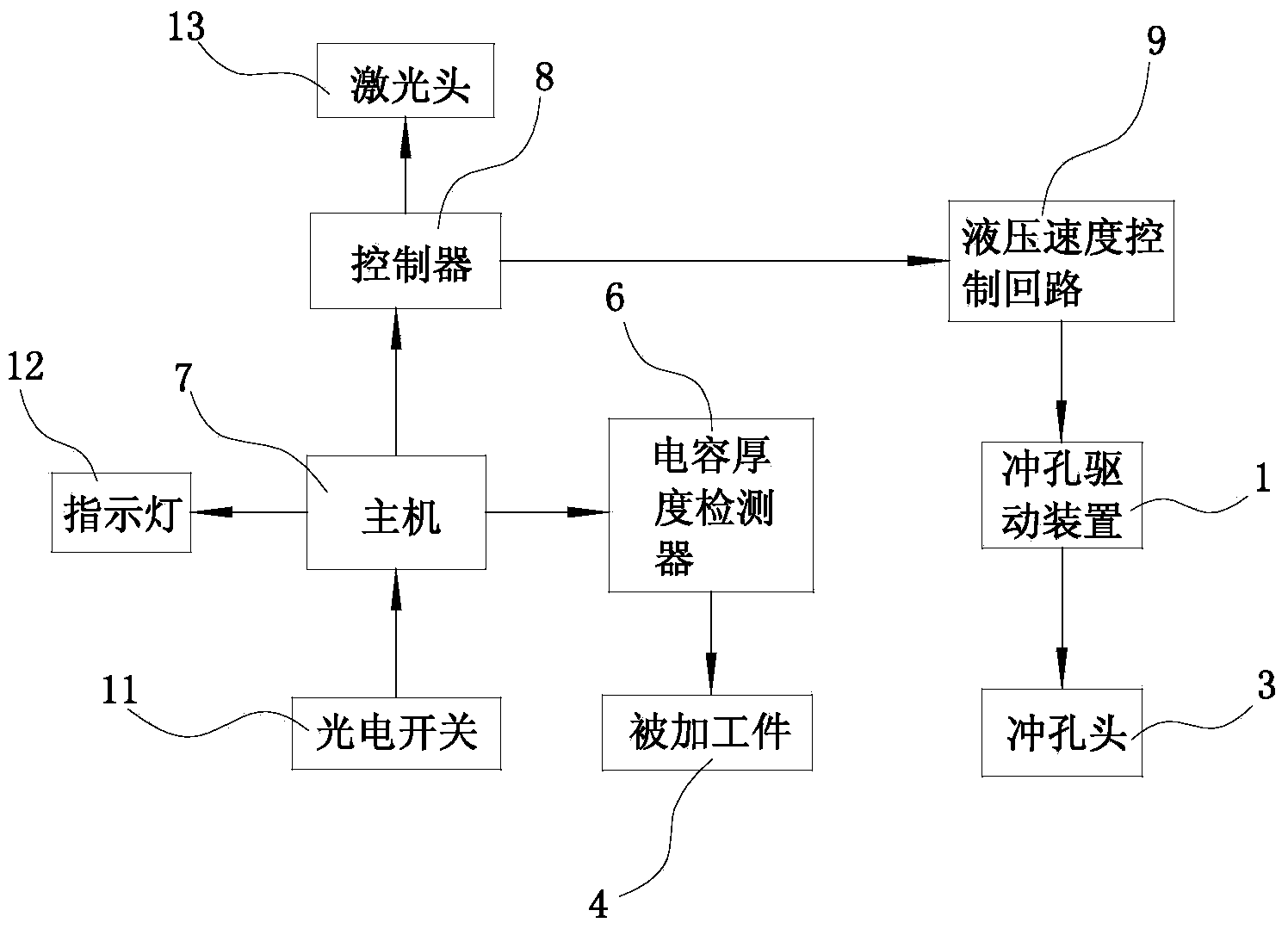

Punching device based on capacitance detection and photoelectric induction positioning

InactiveCN104162585APrecise positioningPrevent excessive deformationMetal-working feeding devicesMetal working apparatusPhotoswitchPunching

The invention relates to a punching device based on capacitance detection and photoelectric induction positioning. The punching device based on capacitance detection and photoelectric induction positioning comprises a punching driving device, an upper die plate, a punching head and a clamping device located below the punching head, and a machined workpiece is mounted in the clamping device. The punching device comprises a mainframe, a controller, a hydraulic speed control loop, a capacitance thickness detector and a photoelectric switch. A color code for detecting the photoelectric switch is mounted on the clamping device, the output end of the mainframe is connected with the controller and the capacitance thickness detector, and a laser head is arranged in the punching head. According to the punching device, laser hole cutting and punching are combined, and machining efficiency is improved; the machined workpiece is accurately positioned through the photoelectric switch, and the punching device is accurate in positioning and convenient to operate. The thickness of the machined workpiece is detected, the punching speed and the laser energy are controlled through thickness, the defects of excessive deformation of plates due to the too high punching speed and burrs of the plates due to the too low punching speed are overcome, and machining quality is improved.

Owner:SUZHOU JINGYU AUTOMATION TECH

Recoil starter

ActiveUS20060070596A1Increased durabilityIncrease the number ofPower operated startersMuscle operated startersCoil springEngineering

A coil starter formed so that the rotation of a rope reel is transmitted to a cam member via a coil spring-like damper spring both ends of which are engaged with the rope reel and cam member respectively, wherein the rope reel or cam member is provided with a boss portion the length of which is substantially equal to that of a wound portion of the damper spring, the inner circumferential side of substantially the whole length of the damper spring being supported on the boss portion, the wound portion of substantially the whole length of the damper spring being thereby wound uniformly and tightly around the outer circumferential surface of the boss portion when the damper spring is elastically deformed due to the engine starting resistance.

Owner:STARTING IND CO LTD

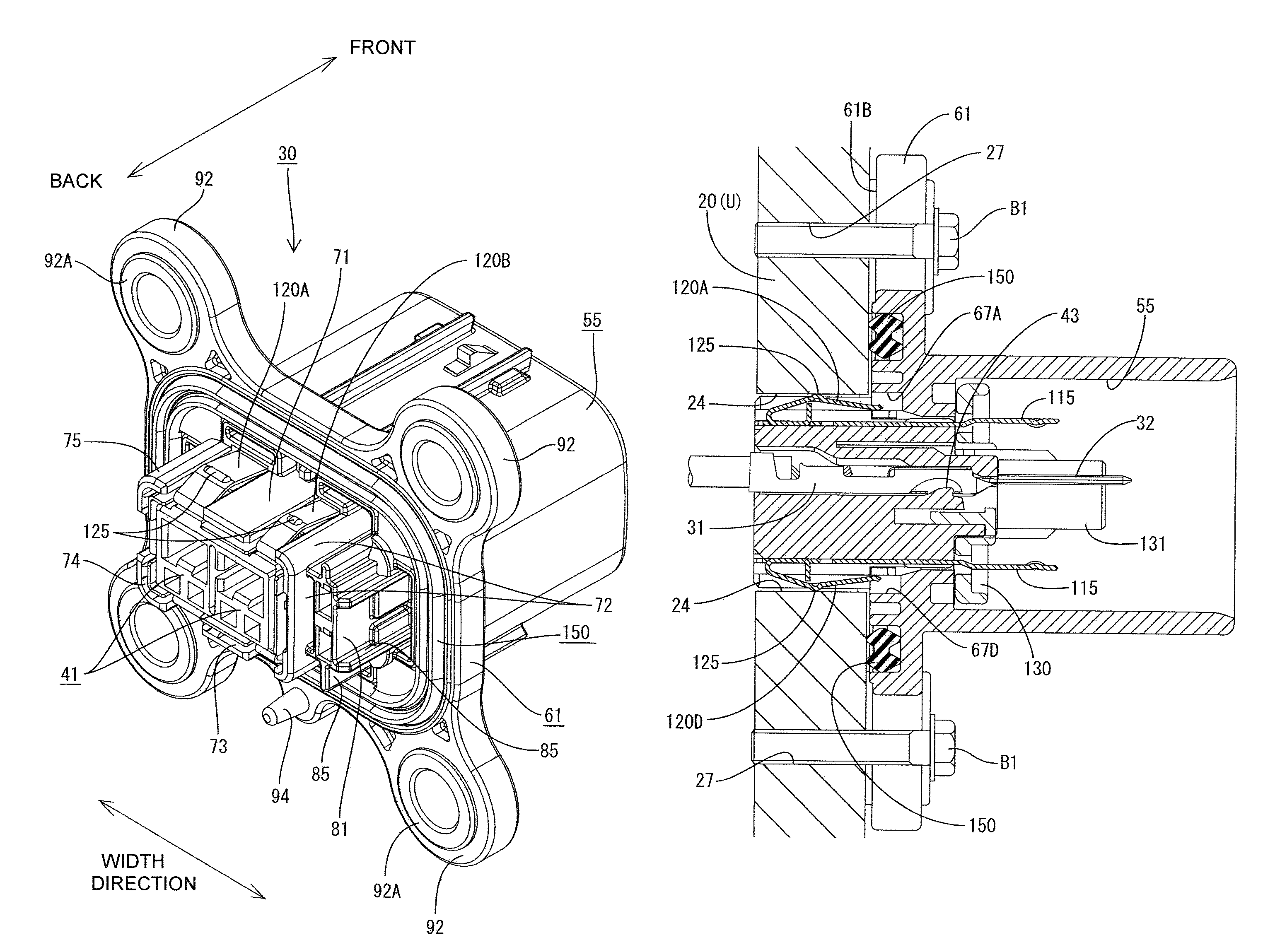

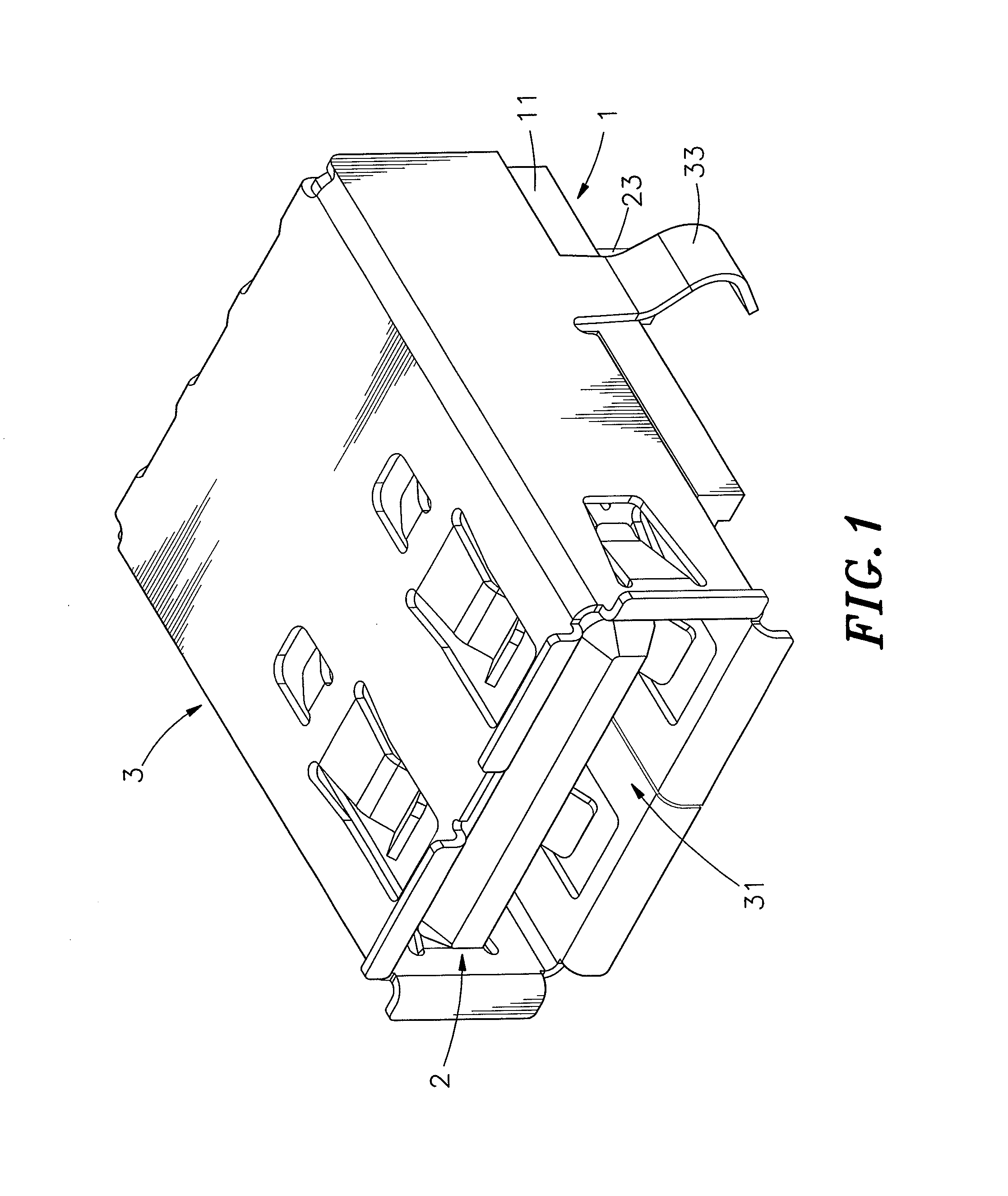

Shield connector

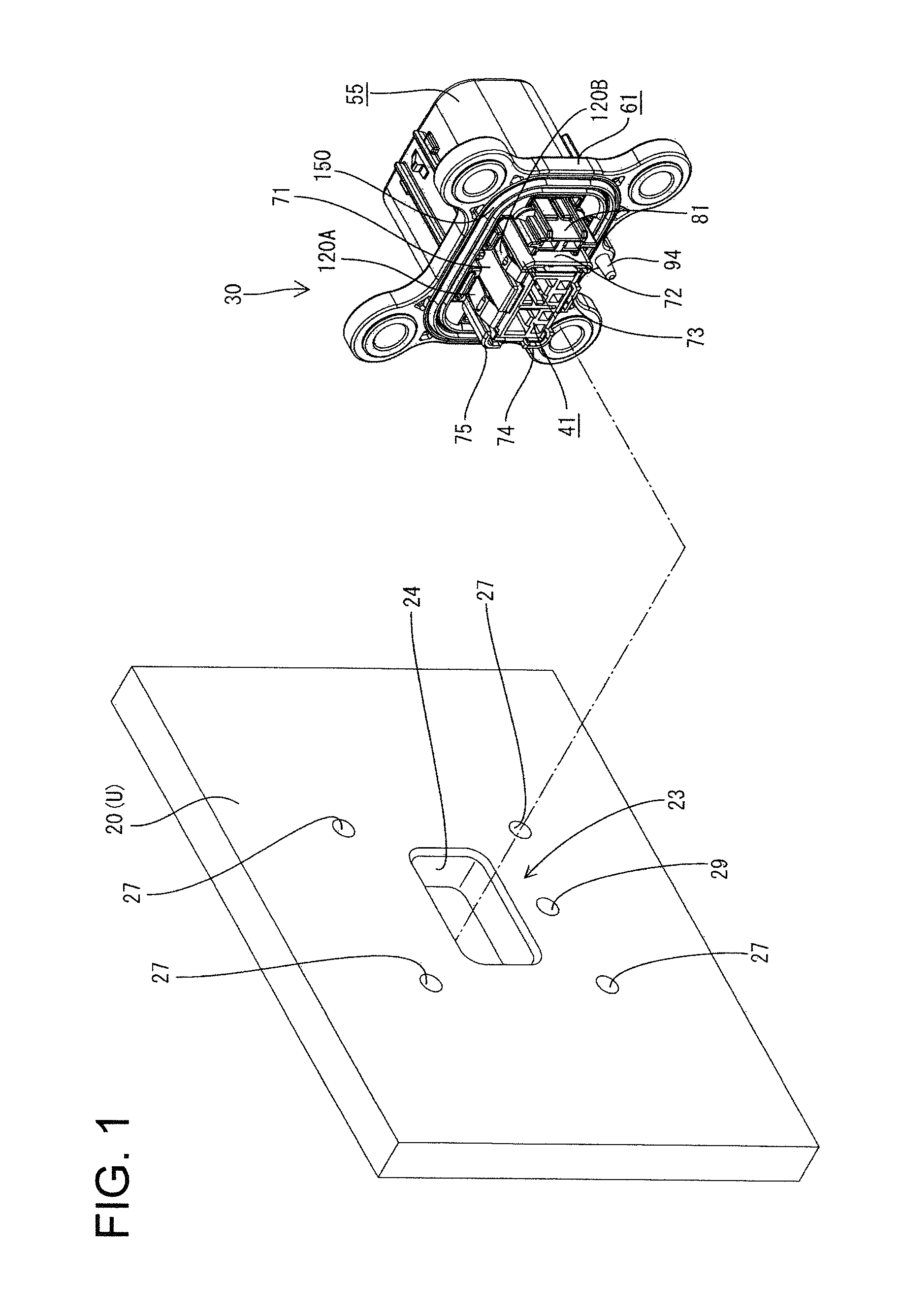

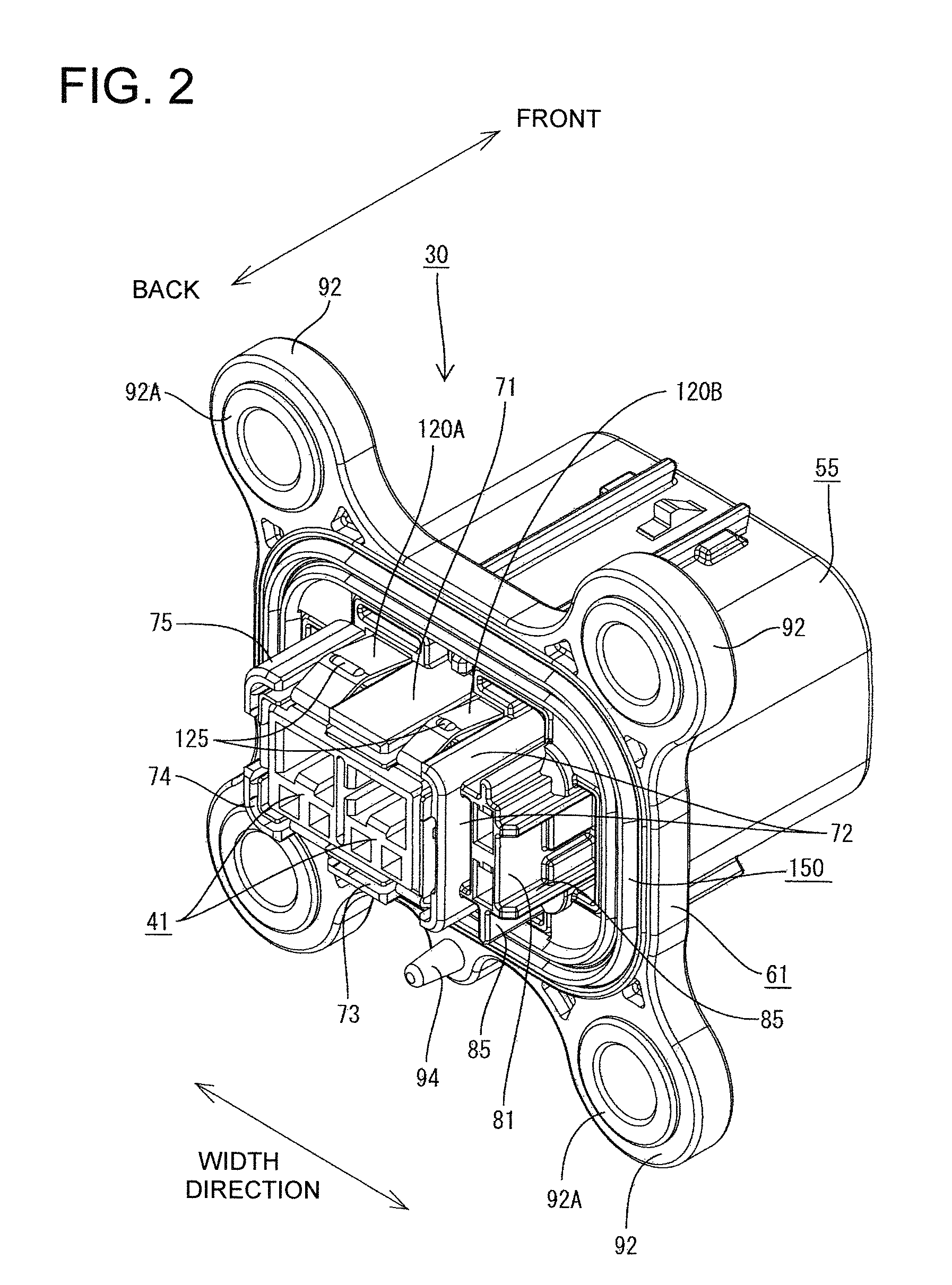

ActiveUS8262413B2Avoid leaningIncrease contact pressureVehicle connectorsCoupling protective earth/shielding arrangementsFlangeEngineering

A shield connector (30) has a housing (40) with a terminal mounting portion (41), a receptacle (55) and a mounting flange (61). Male terminals (31) are mounted in the terminal mounting portion (41) and have tabs that project into the receptacle (55). A shield shell (100) including a shell main body (110) and resilient contact pieces (120) for grounding the shell main body (110) to a mounting member. The resilient contact pieces (120) have leading ends (121) accommodated in accommodating portions (67) formed in the mounting flange (61), and the housing (40) includes protection walls (70) located lateral to the resilient contact pieces (120).

Owner:SUMITOMO WIRING SYST LTD

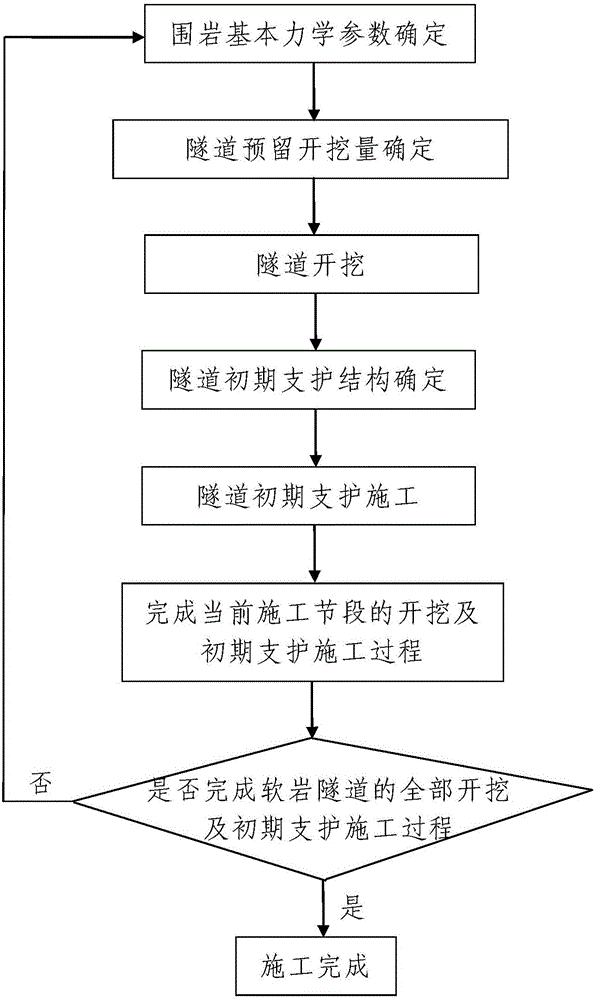

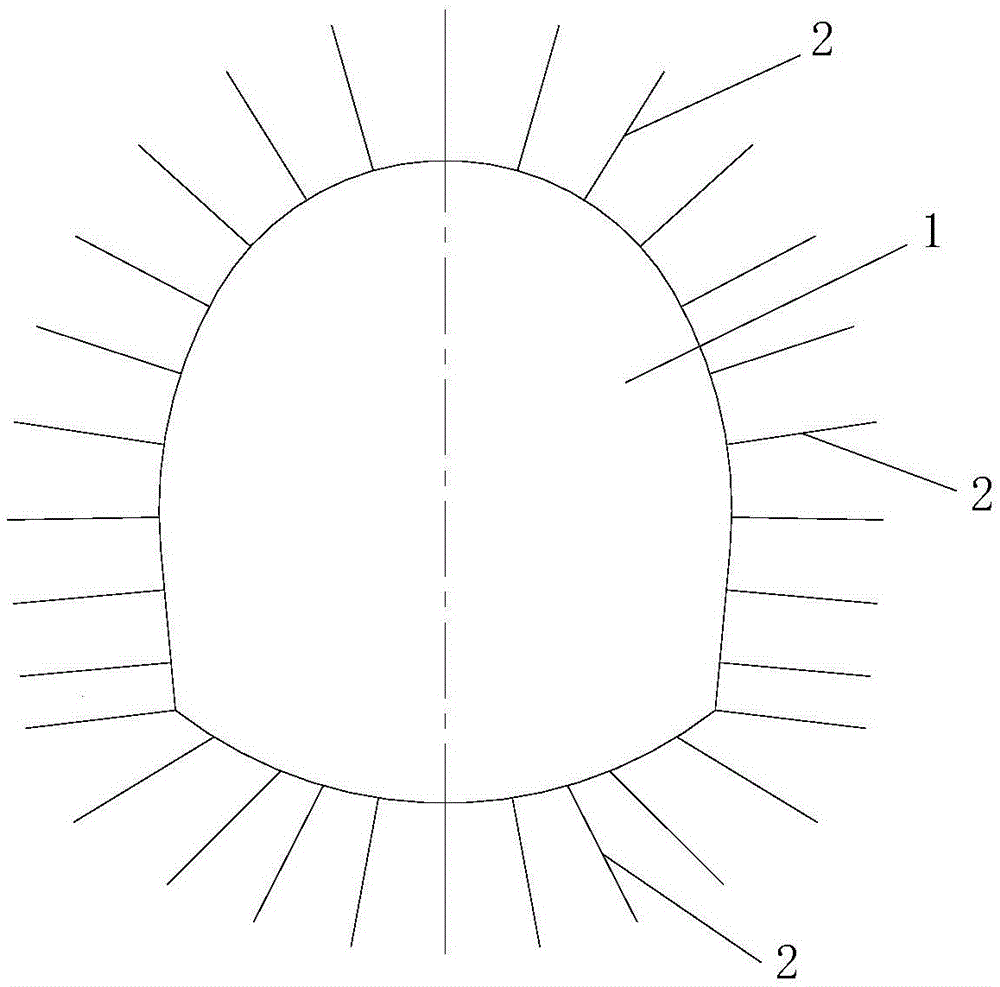

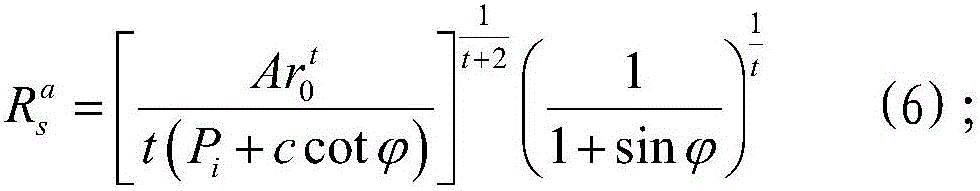

Excavation and preliminary bracing method for soft rock tunnel

InactiveCN106481343AThe method steps are simpleEasy to implementUnderground chambersTunnel liningRock tunnelWall rock

The invention discloses an excavation and preliminary bracing method for a soft rock tunnel. The excavation and preliminary bracing construction for the soft rock tunnel are performed in sections from back to front. When any section is subjected to excavation and preliminary bracing construction, the method comprises the following steps: 1) confirming basic mechanical parameters of the surrounding rock; 2) confirming the reserved excavated volume of the tunnel: confirming the reserved excavated volume of the currently constructed section according to a theoretical value of inward displacement of the surrounding rock of the soft rock tunnel after being braced; 3) excavating the tunnel; 4) confirming a preliminary bracing structure of the tunnel; 5) constructing the preliminary bracing of the tunnel; 6) performing the excavation and preliminary bracing construction of the next section; and 7) repeating the step 6) till all the processes of the excavation and preliminary bracing construction of the soft rock tunnel are completed. The method disclosed by the invention has the advantages of simple steps, reasonable design, convenience in realization and good use effect; the reserved excavated volume is confirmed according to the surrounding rock deformation condition of the soft rock tunnel; and the steel bracket and the anchoring net sprayed preliminary bracing structure are coordinated for performing all-section preliminary bracing on the tunnel.

Owner:XIAN UNIV OF SCI & TECH

Connector

ActiveUS20070141866A1Increase in sizeLengthen insert lengthSubstation/switching arrangement detailsElectric discharge tubesMechanical engineering

Owner:MATSUSHITA ELECTRIC WORKS LTD

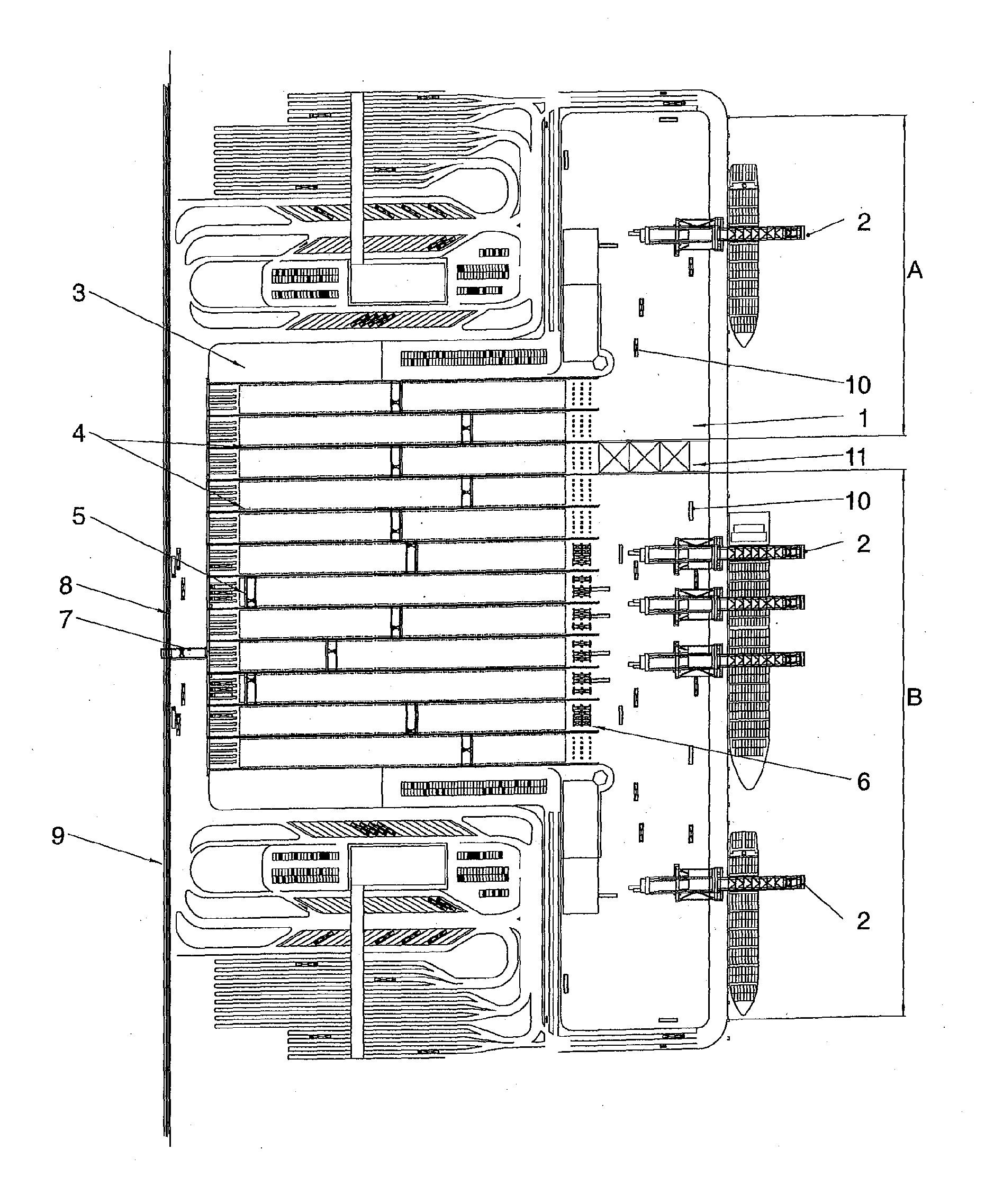

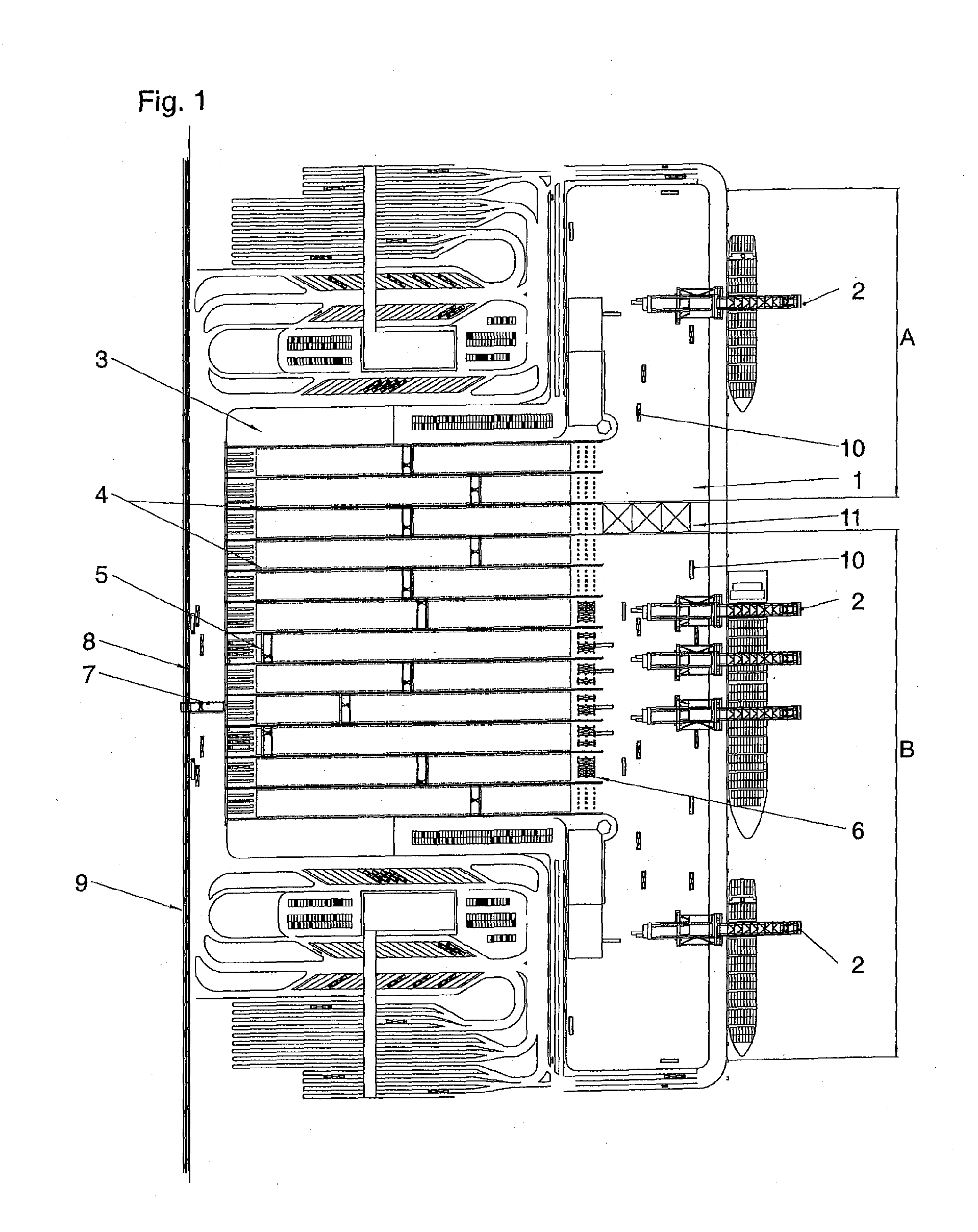

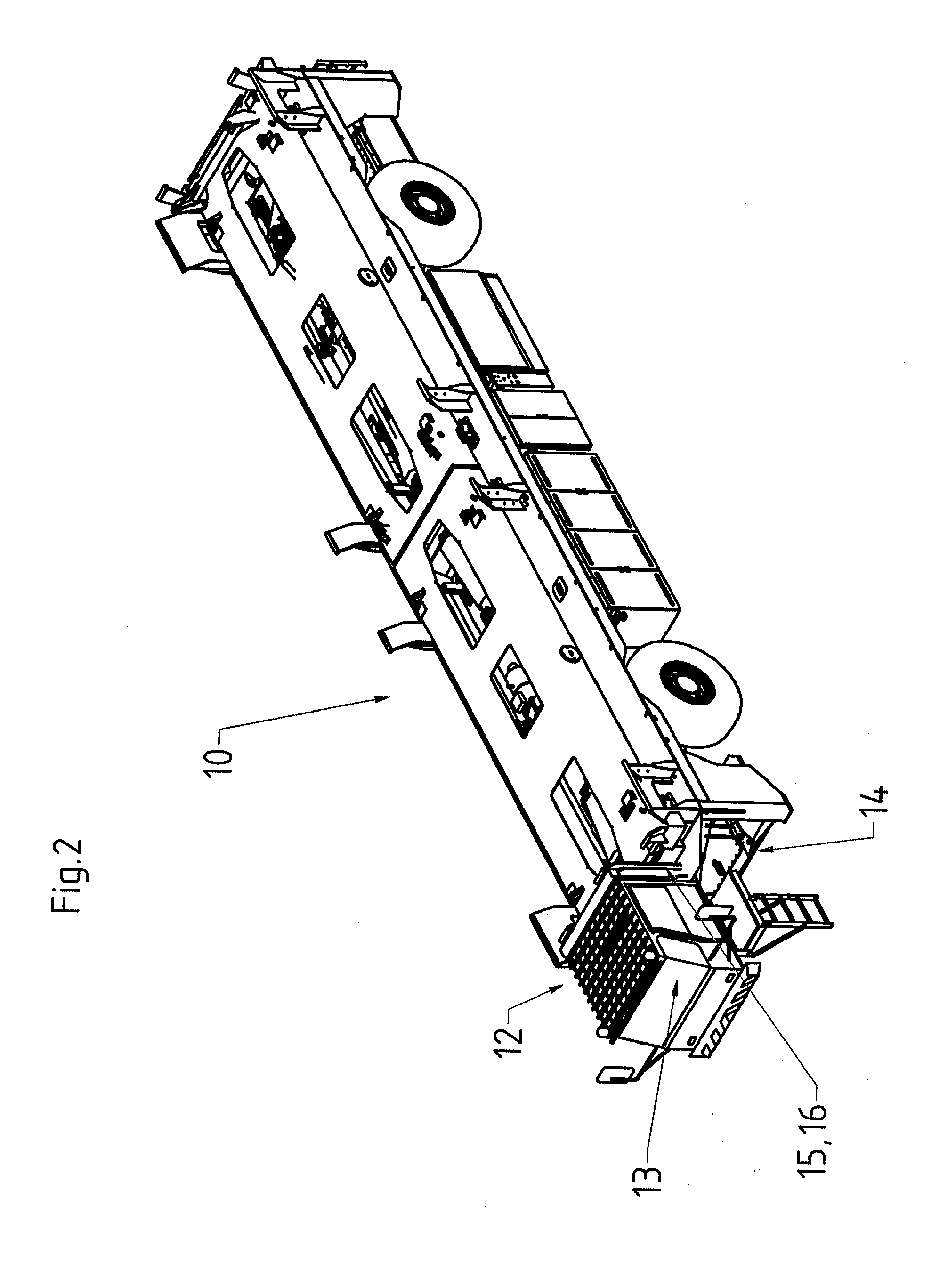

Handling system for containers

InactiveUS20130236279A1Prevent excessive deformationProtect from harmVehicle with removable loadingAutomatic initiationsControl systemHandling system

A handling system for containers includes an automated zone in which floor-bound, rubber-tired and driverless container transport vehicles are used which transport containers between container bridges and a container storage facility. A non-automated zone is provided in which floor-bound, rubber-tired and manned container transport vehicles are used, the container transport vehicles being optionally operable in a driverless or manned mode and thus being optionally transportable in the automated zone or the non-automated zone. A corresponding container transport vehicle which can be connected to an auxiliary device for control in the manned mode is characterized in that the auxiliary device comprises a driver's cab that is equipped with a control system for steering, motion control and braking in the manned mode, the container transport vehicle having a detachable fastening possibility for the driver's cab at the front face of the vehicle.

Owner:KONECRANES GLOBAL +1

Connector

InactiveUS7374465B2Avoid interferenceIncrease contact pressureSecuring/insulating coupling contact membersCoupling contact membersEngineeringFront edge

A connector has a housing (1) with a cavity (2) for receiving a terminal fitting (3). The terminal fitting (3) has a tubular main portion (6) and a locking hole (12) is formed in the main portion (6) for receiving locking projection (5B) of a lock (5). A tongue (14) extends from the front end of the main portion (6) and is folded back into the main portion (6). The front end of the locking projection (5B) is located before an extending end (14C) of the tongue (14) and the rear end thereof is located behind the extending end (14C) of the tongue (14). Accordingly, the locking projection (5B) is long at a position where a front end surface (5C) of the locking projection (5B) receives a shear force from a front edge (12A) of the locking hole (12), thereby enlarging a sectional area against the shear force.

Owner:SUMITOMO WIRING SYST LTD +1

Electrical connector with specially designed metal contact terminals to avoid solder-off

InactiveUS8602825B2Prevent permanent deformationControl deformationElectric discharge tubesCoupling contact membersElectricityComputer module

An electrical connector includes an electrically insulative holder member, a signal module formed of a circuit board with longitudinal terminal holes, circuit lines, electrical contacts and via-holes, metal contact terminals and metal mounting terminals, and a metal shield. The metal contact terminals have rear soldering end portions thereof soldered to respective circuit lines, an extension arm forwardly extended from the rear soldering end portion along one longitudinal terminal hole, a turn portion extended from the extension arm and curved into the associating longitudinal terminal hole to enhance vertical deformation stroke of the respective metal contact terminal, a front contact portion suspending below the associating longitudinal terminal hole, and an oblique spring arm connected between the turn portion and the front contact portion to flexibly support the front contact portion.

Owner:U D ELECTRONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com