Capacitor thickness detection and crack feedback plate bending machine based on PLC

A thickness detection and bending machine technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of excessive deformation of the clamping place, too large clamping force, and inability to adjust, so as to improve the processing quality, Reduction of bending cracks and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

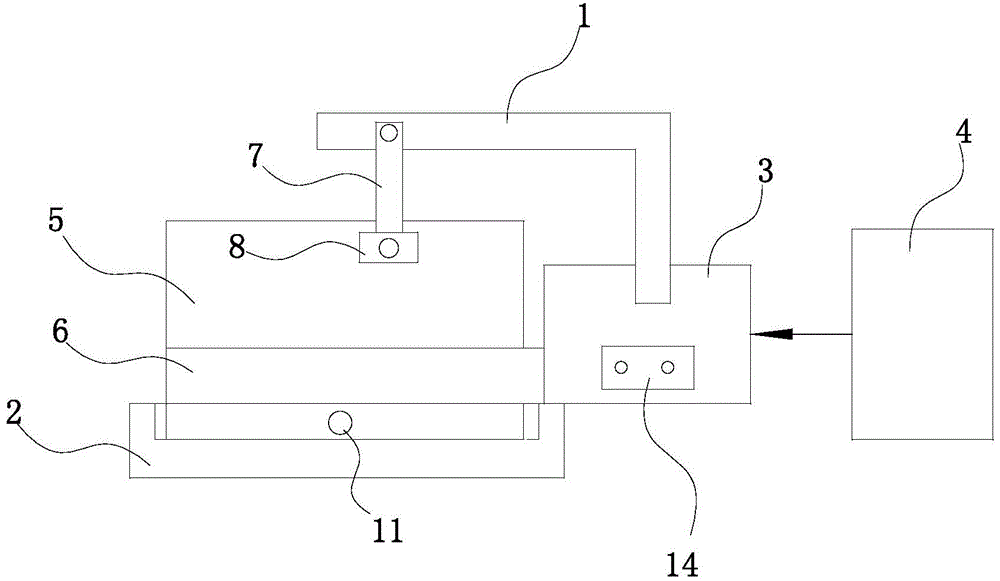

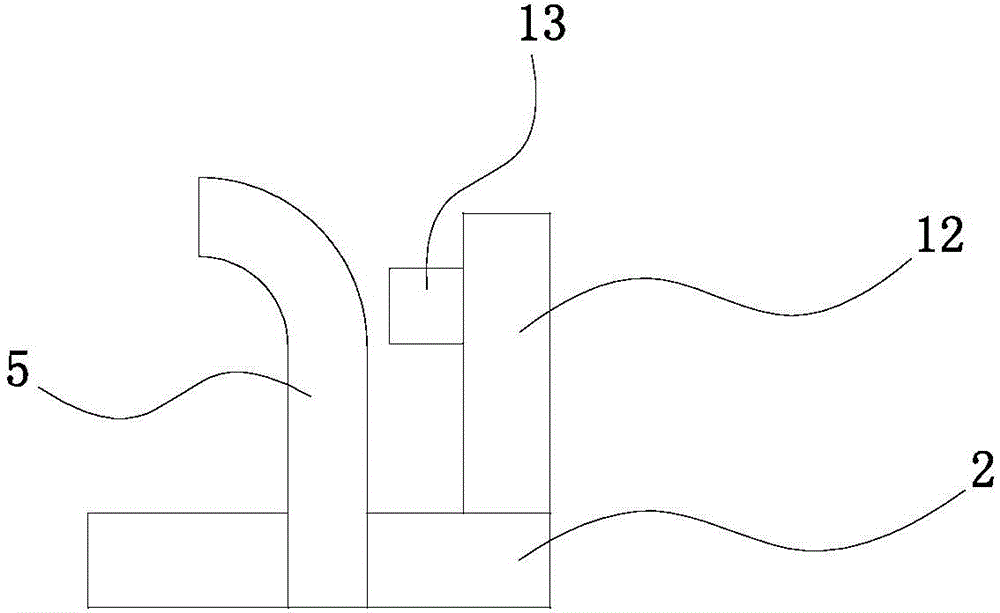

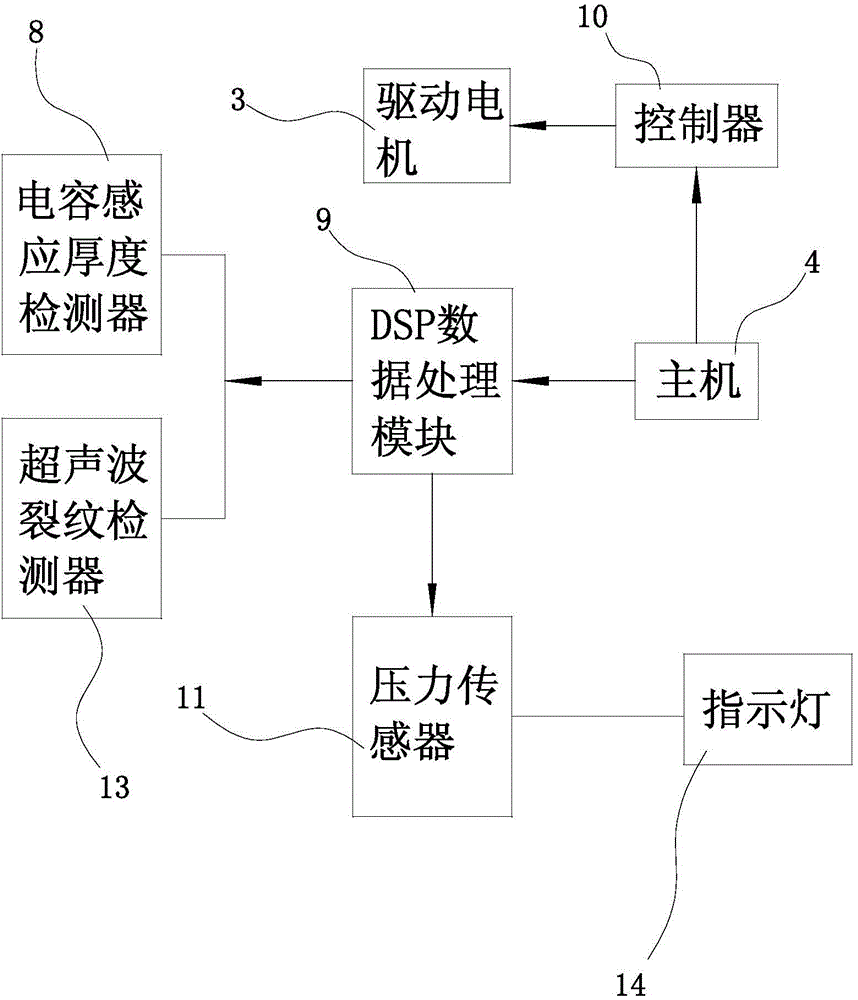

[0024] See figure 1 , figure 2 and image 3 The plate bending machine based on PLC capacitance thickness detection and crack feedback provided in this embodiment includes a drive motor 3 installed on the frame 1, a clamping and fixing seat 2 and a PLC host 4 for controlling the drive motor 3, the drive The bending shaft 6 is installed on the motor shaft of the motor 3, and the workpiece 5 is installed on the clamping seat 2;

[0025] It also includes a capacitive sensing thickness detector 8 installed on the frame 1 by means of the first bracket 7, a pressure sensor 11 installed on the side of the clamping groove of the clamping seat 2, a detection feedback device and a controller connected to the PLC host 4 10. The detection feedback device includes an ultrasonic crack detector 13 installed on the clamping and fixing seat 2 by means o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com