Patents

Literature

196 results about "Sheet metal bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

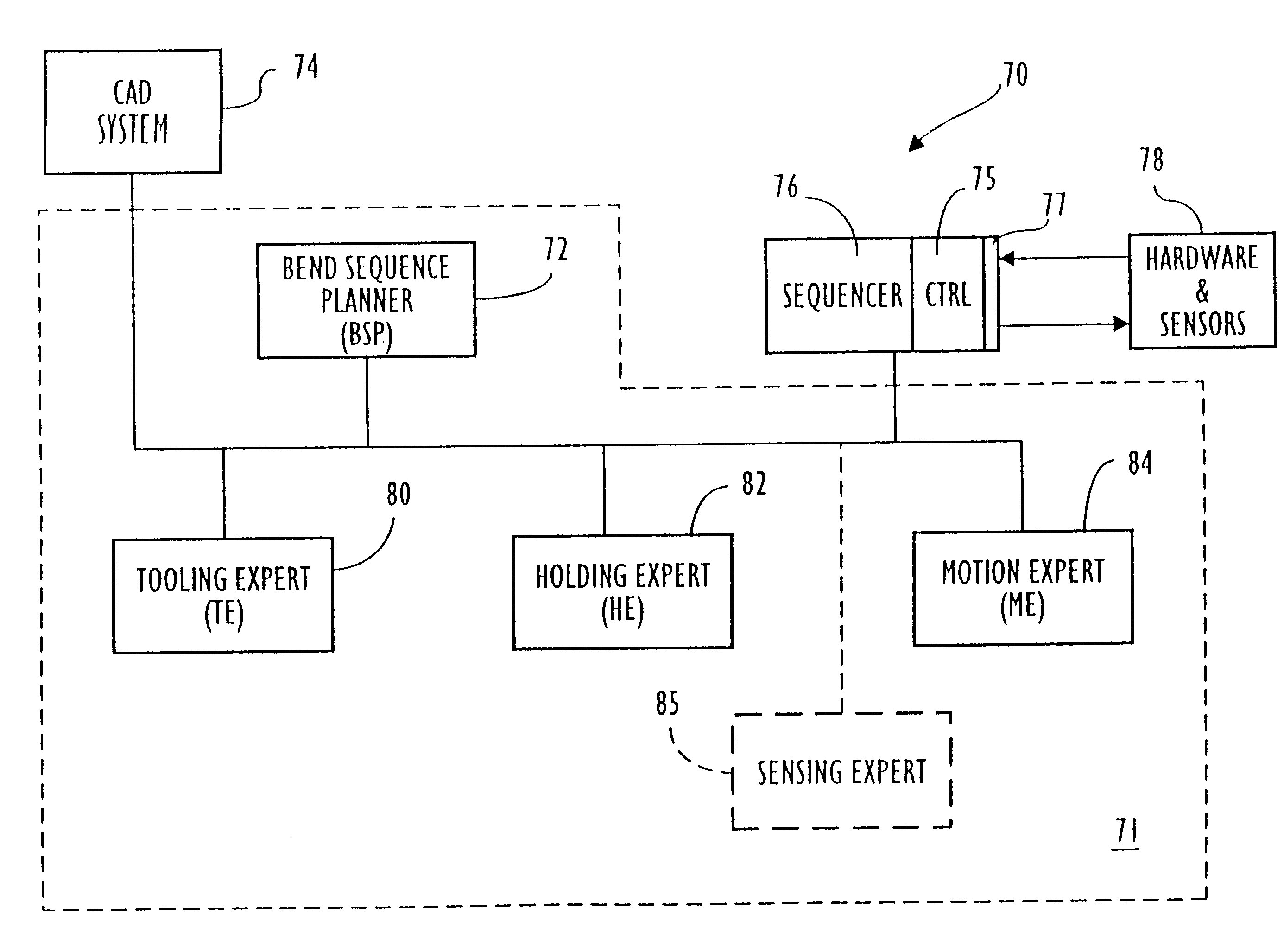

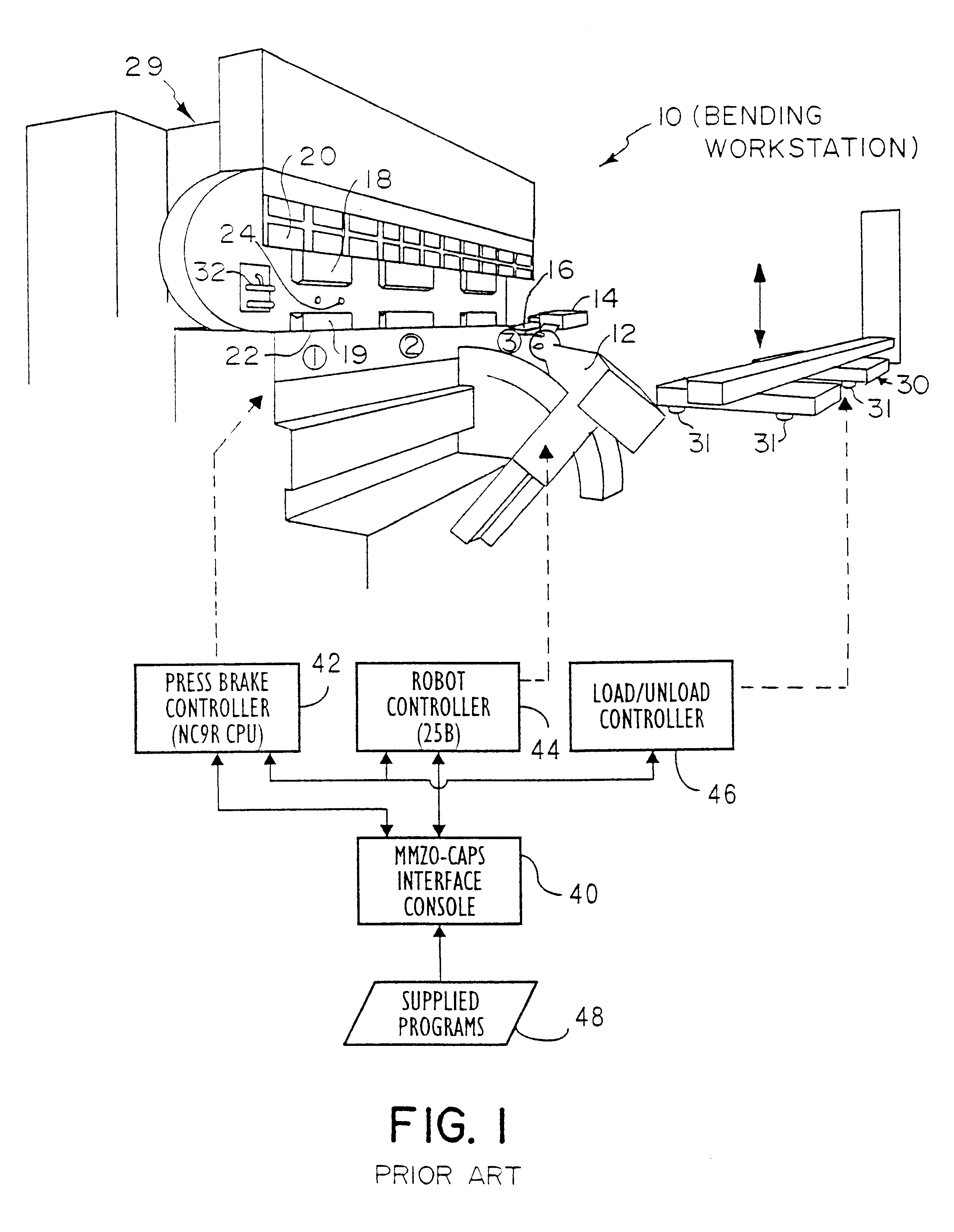

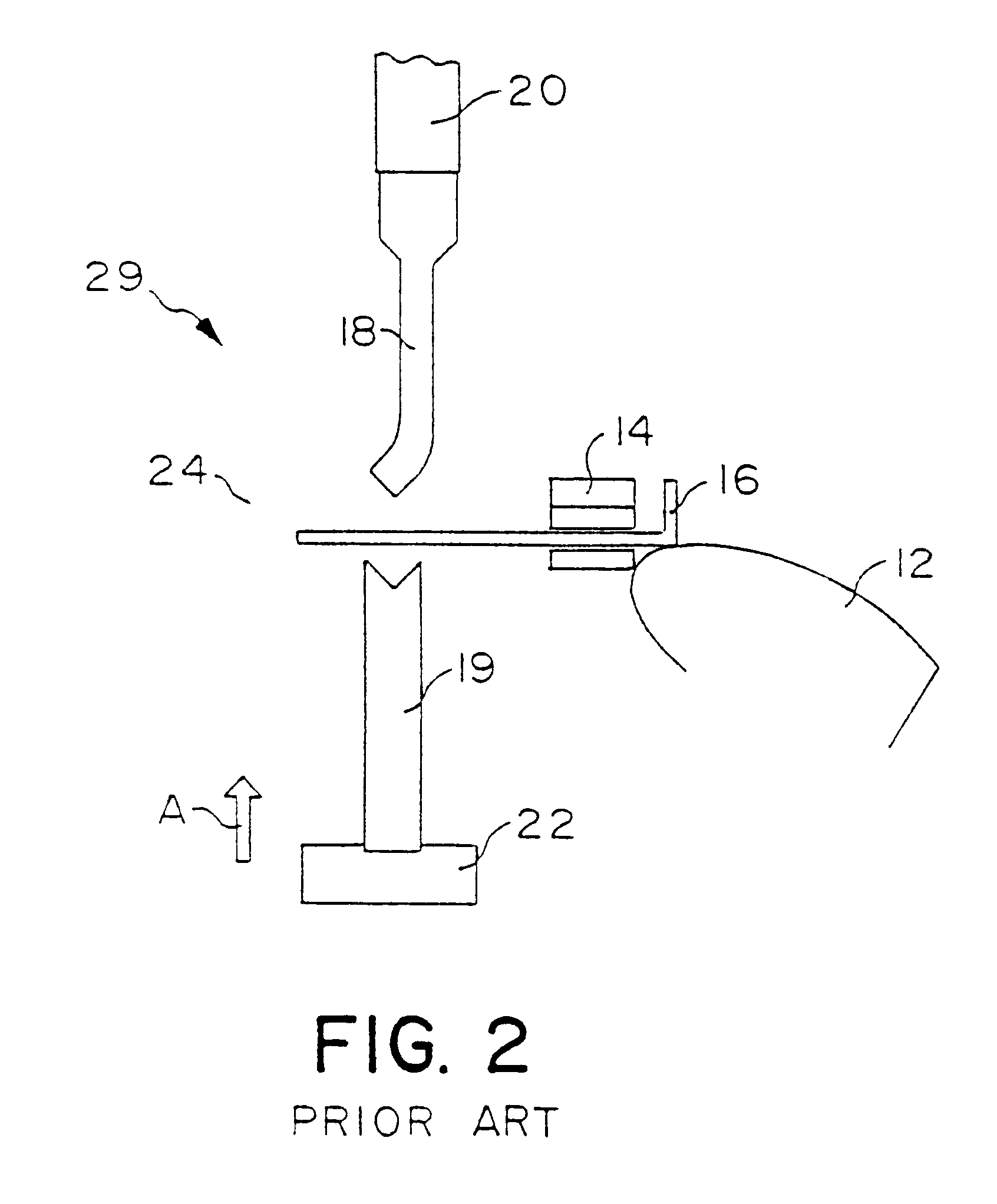

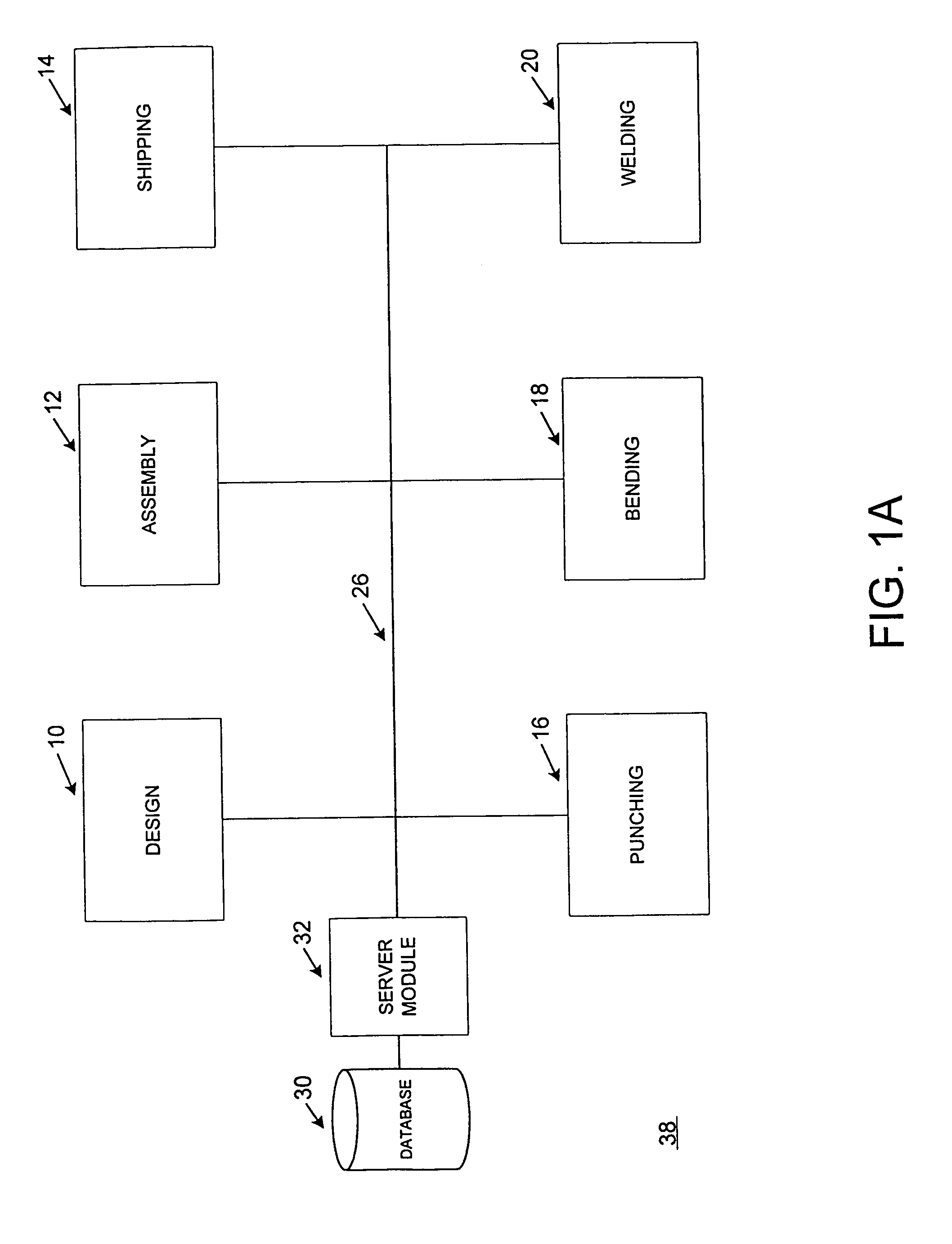

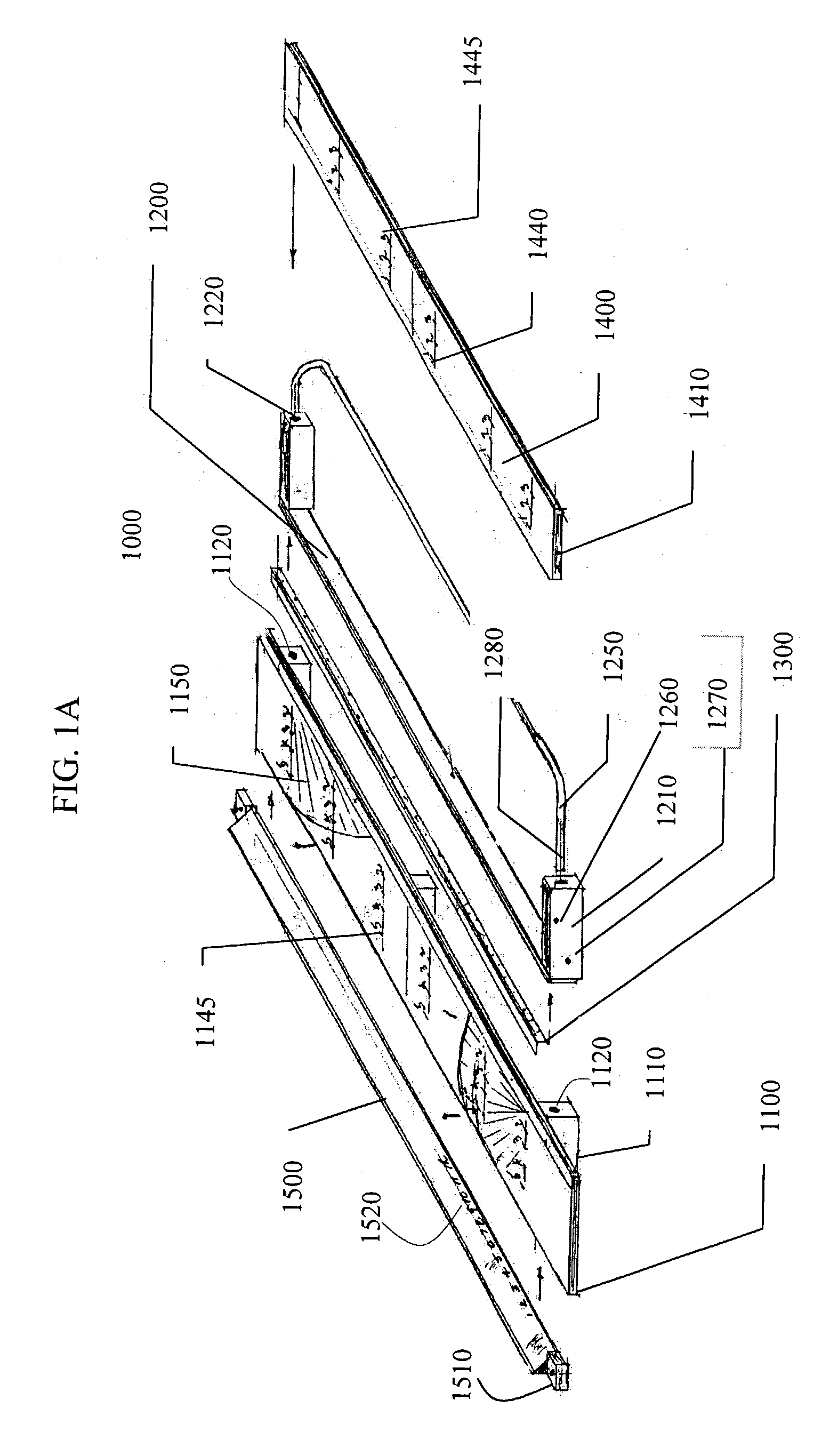

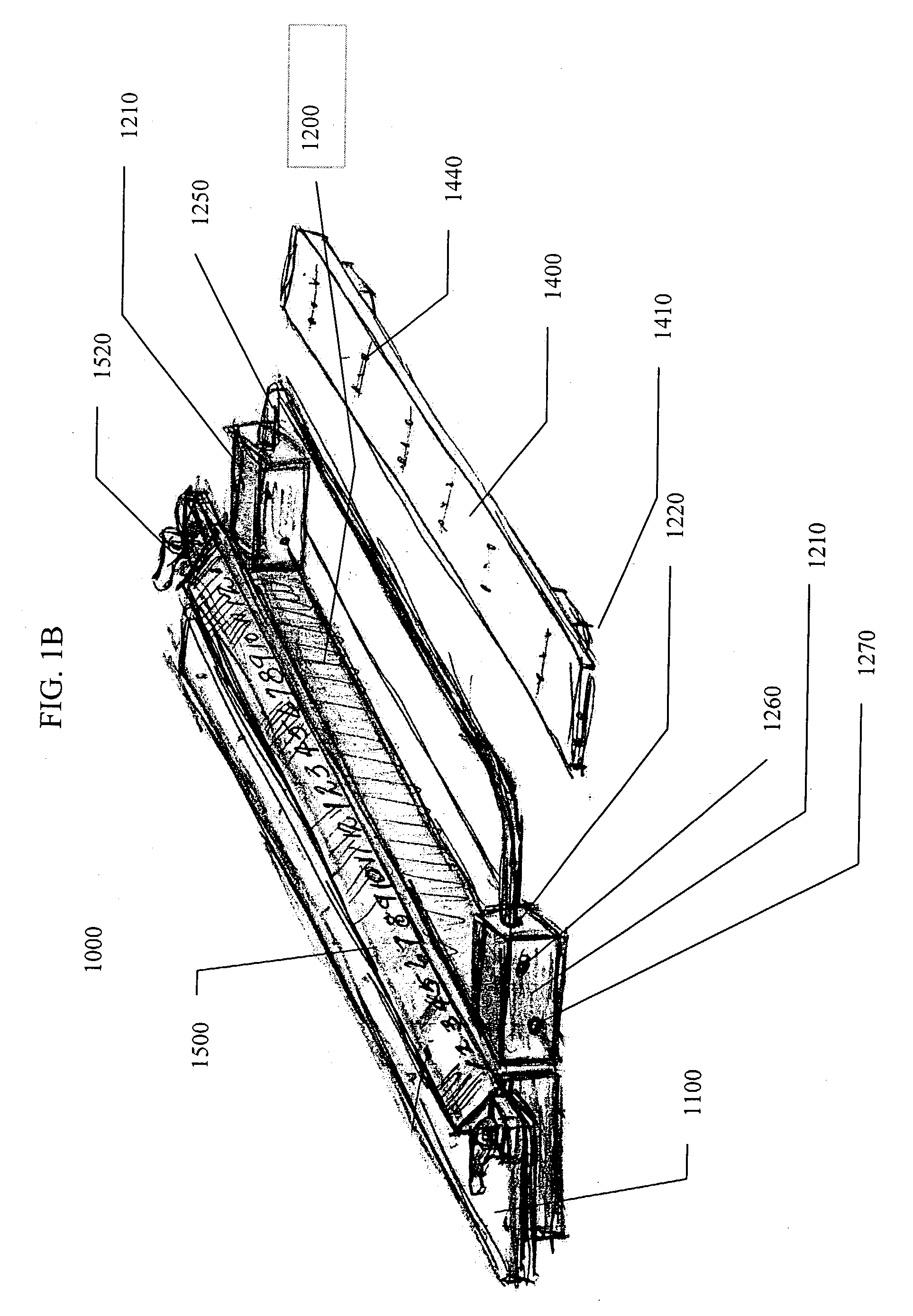

Intelligent system for generating and executing a sheet metal bending plan

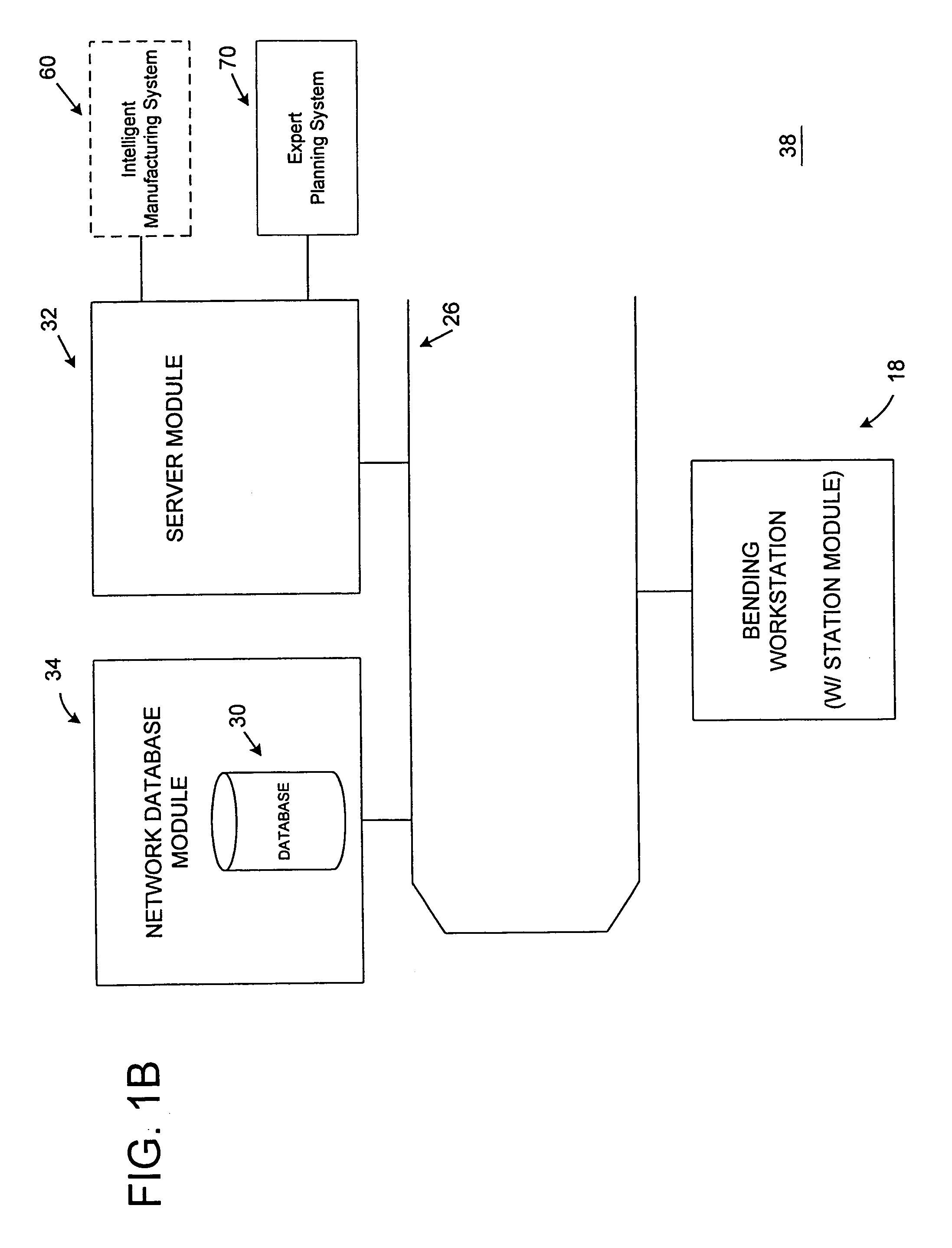

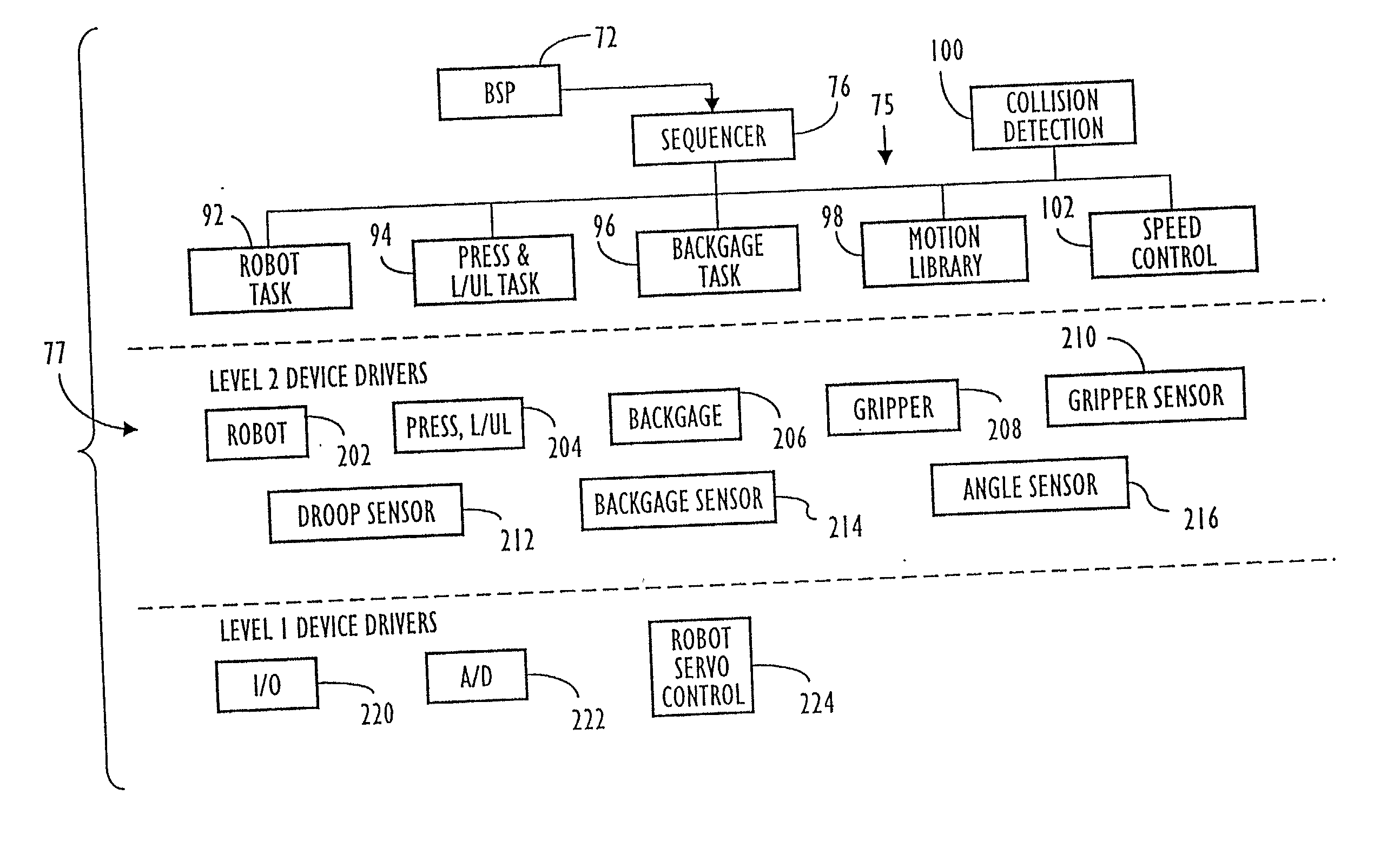

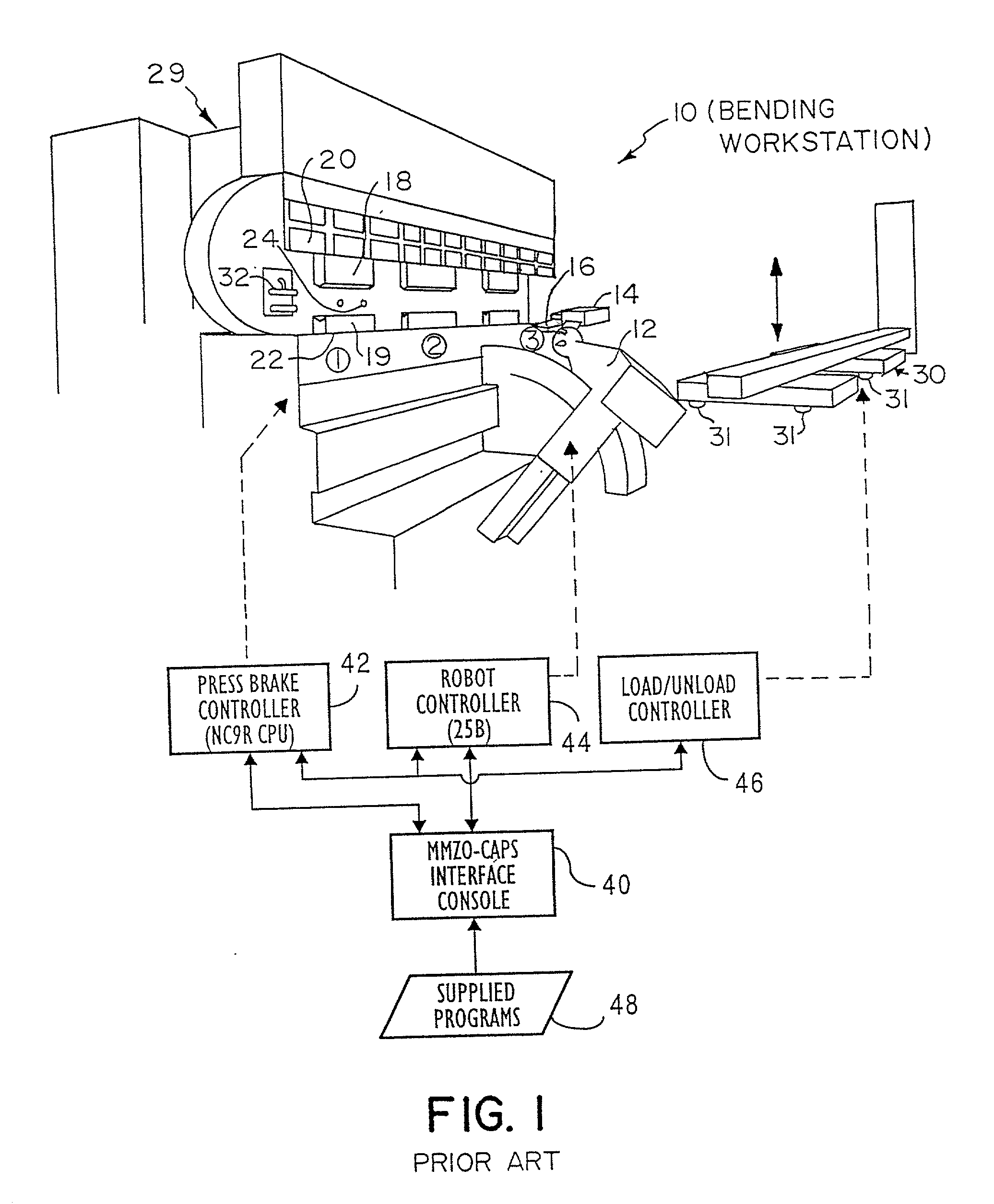

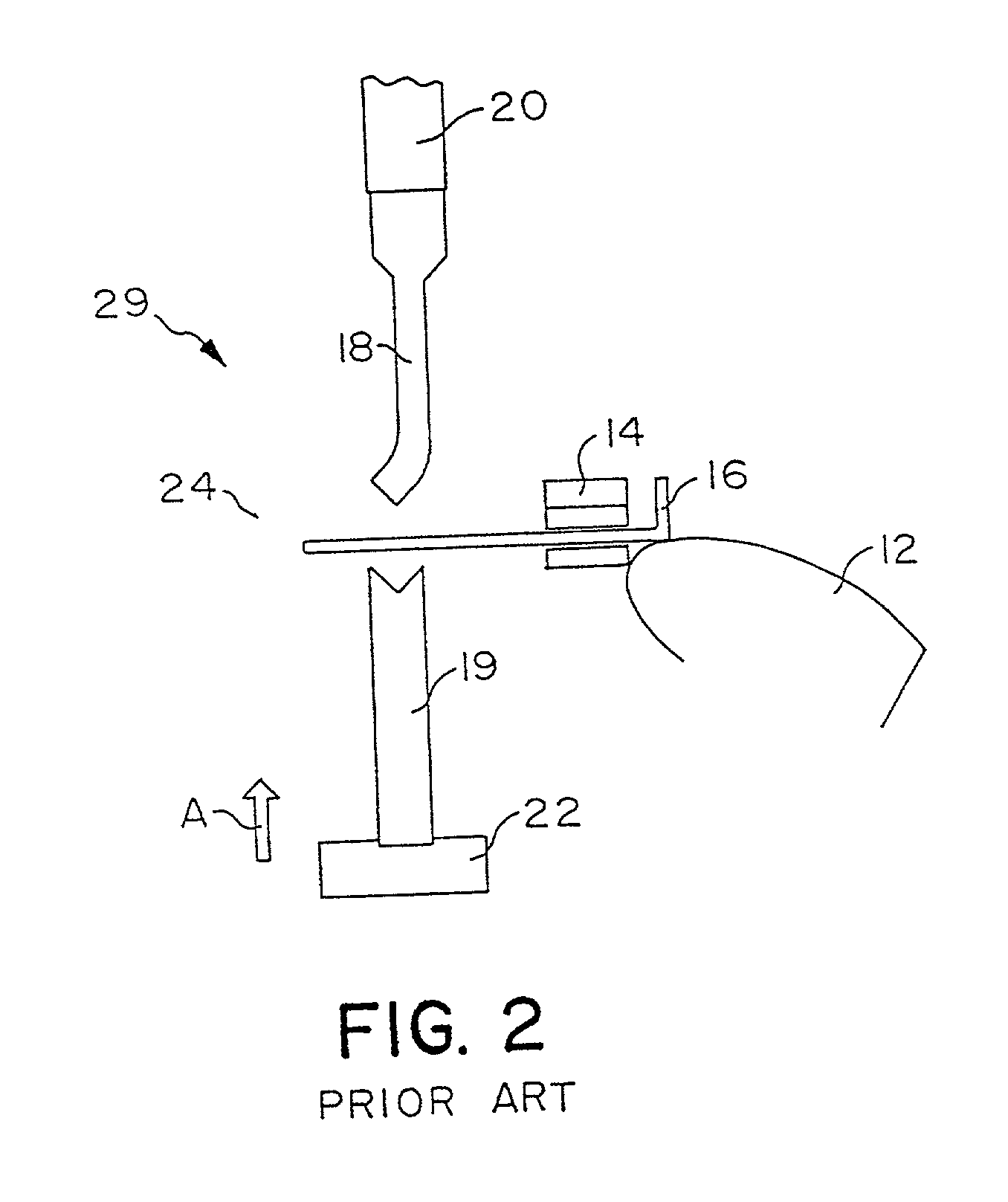

An intelligent sheet metal bending system is disclosed, having a cooperative generative planning system. A planning module interacts with several expert modules to develop a bending plan. The planning module utilizes a state-space search algorithm. Computerized methods are provided for selecting a robot gripper and a repo gripper, and for determining the optimal placement of such grippers as they are holding a workpiece being formed by the bending apparatus. Computerized methods are provided for selecting tooling to be used by the bending apparatus, and for determining a tooling stage layout. An operations planning method is provided which allows the bending apparatus to be set up concurrently while time-consuming calculations, such as motion planning, are performed. An additional method or system is provided for positioning tooling stages by using a backgage guide member which guides placement of a tooling stage along the die rail the bending apparatus. A method is provided for learning motion control offset values, and for eliminating the need for superfluous sensor-based control operations once the motion control offset values are known. The planning system may be used for facilitating functions such as design and assembly system, which may perform designing, costing, scheduling and / or manufacture and assembly.

Owner:U S AMADA +1

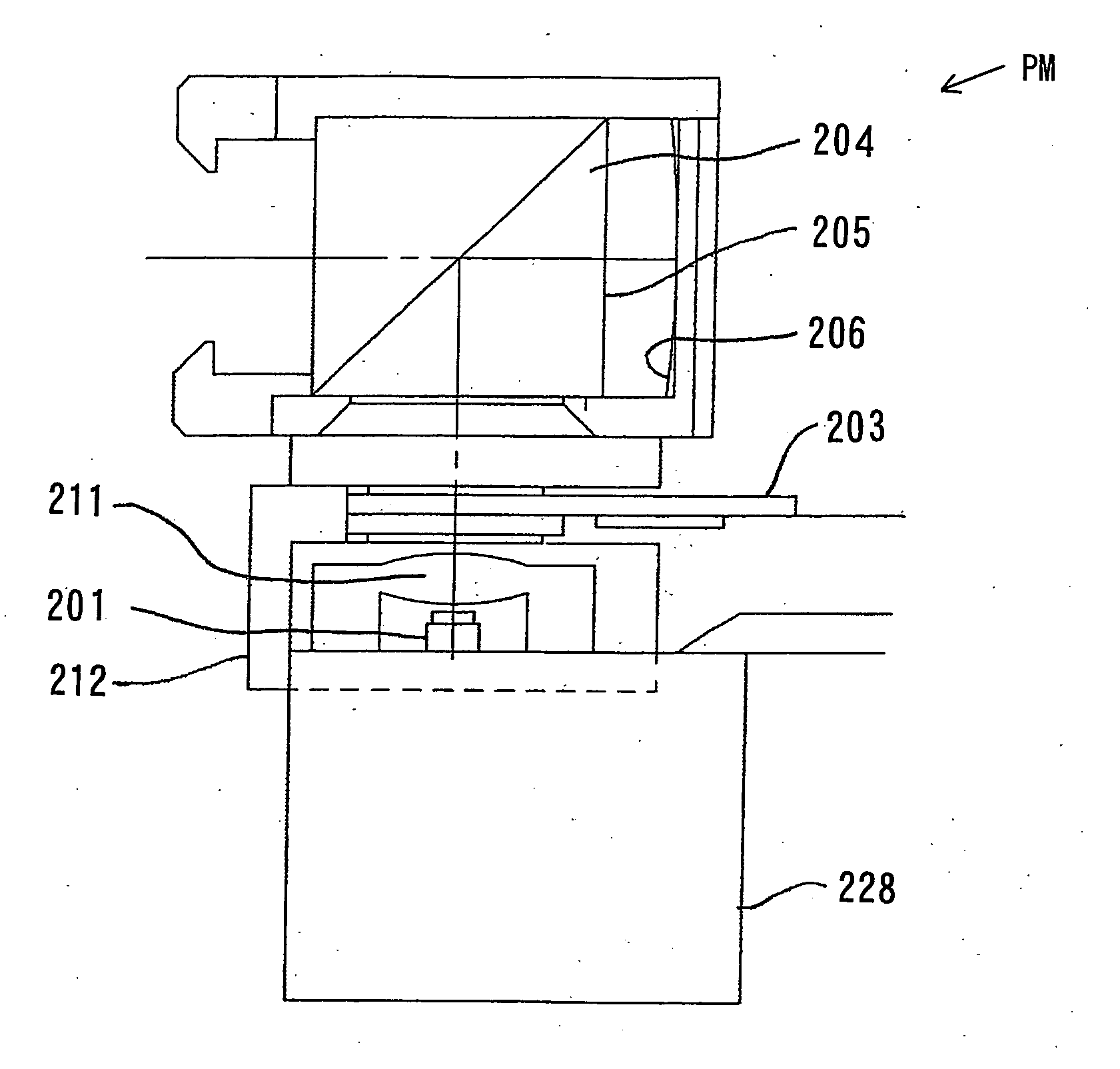

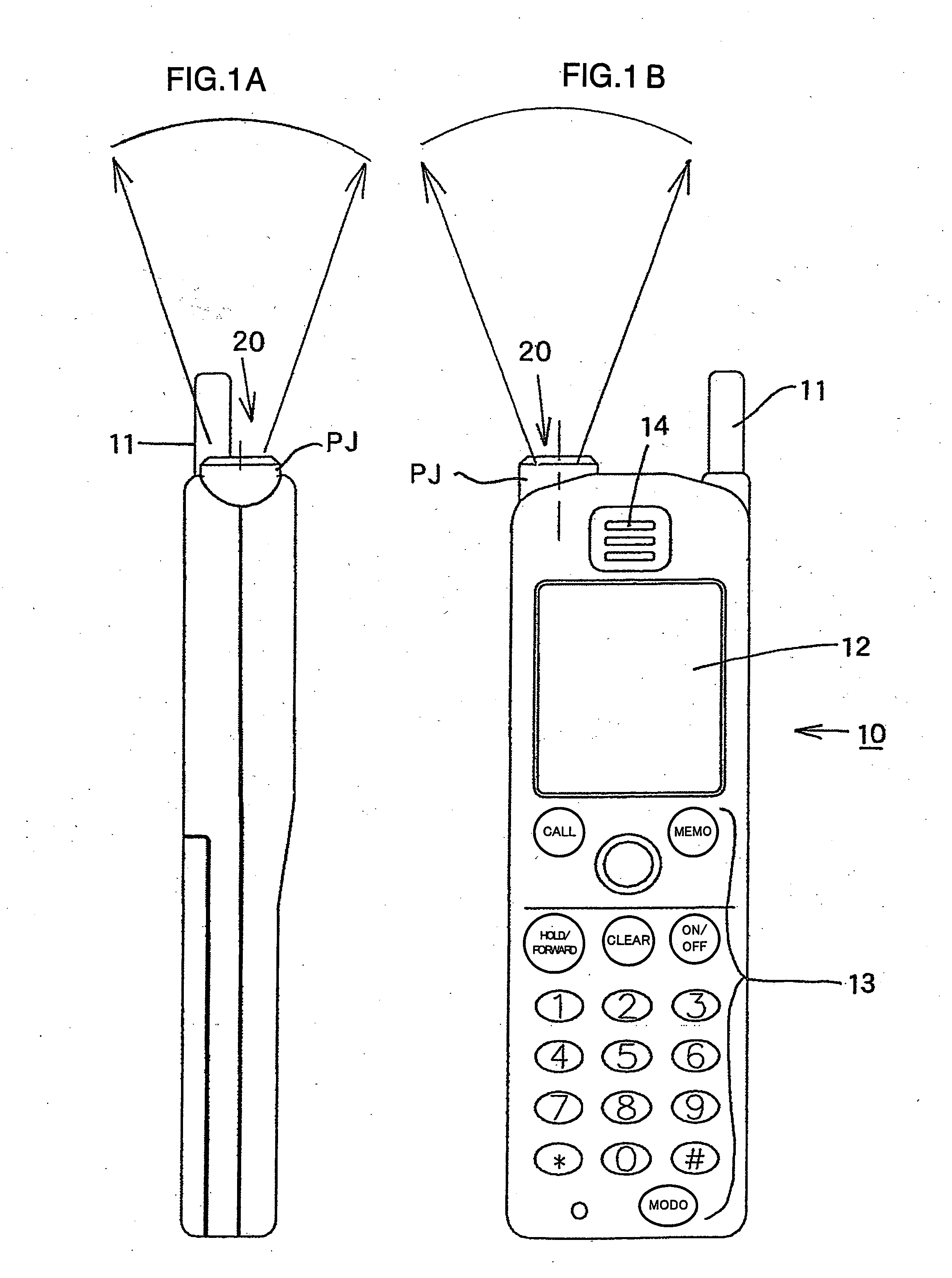

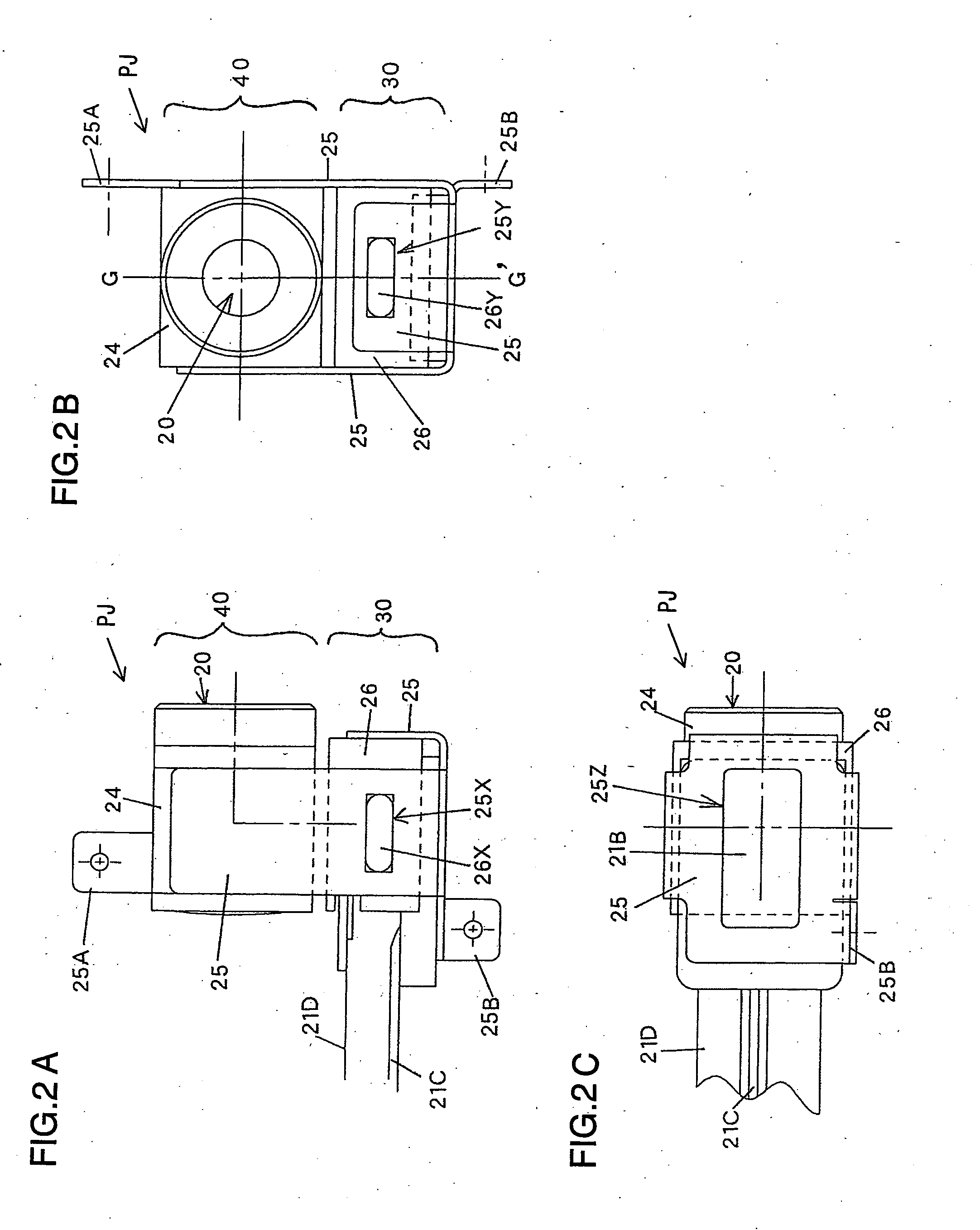

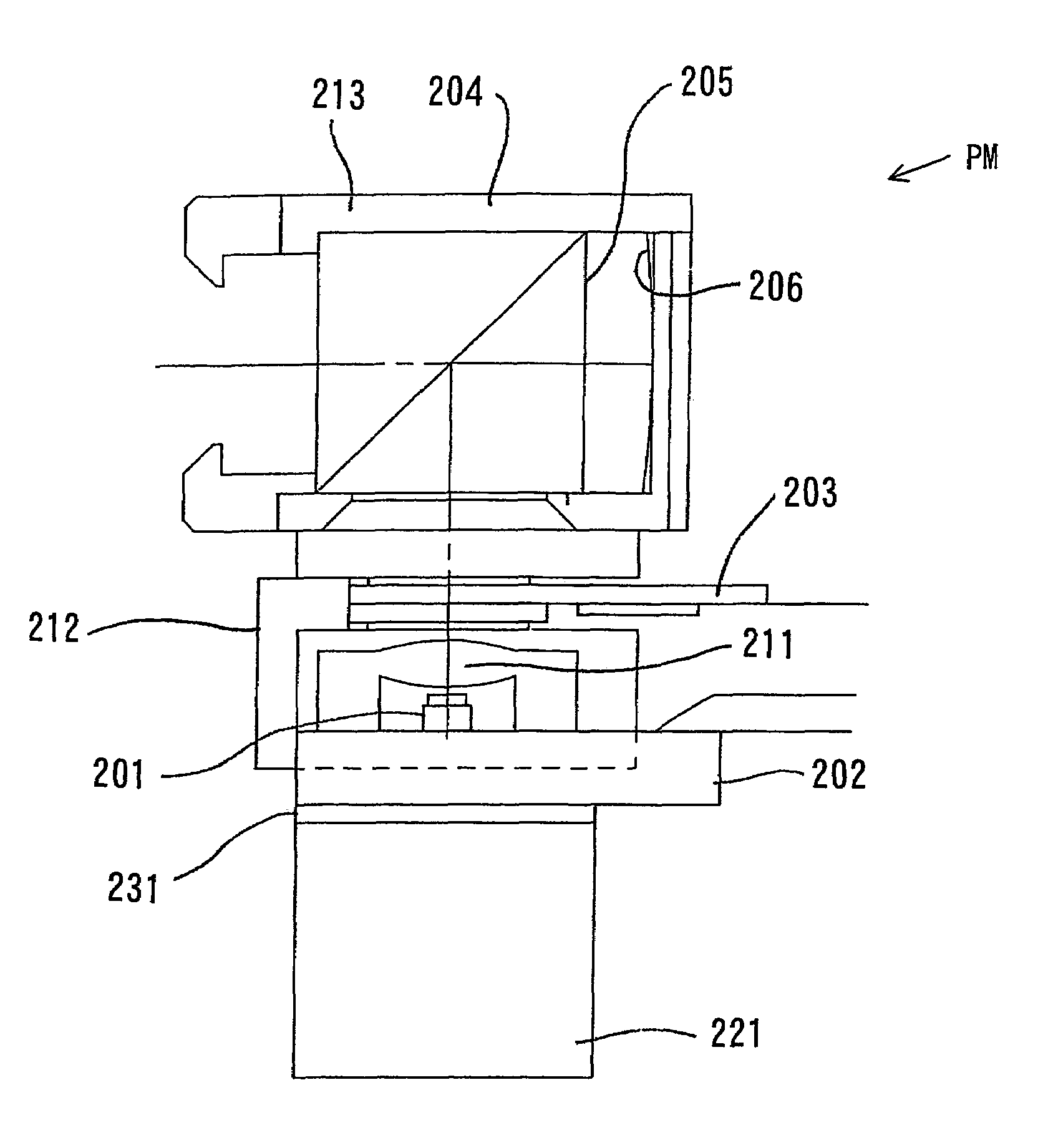

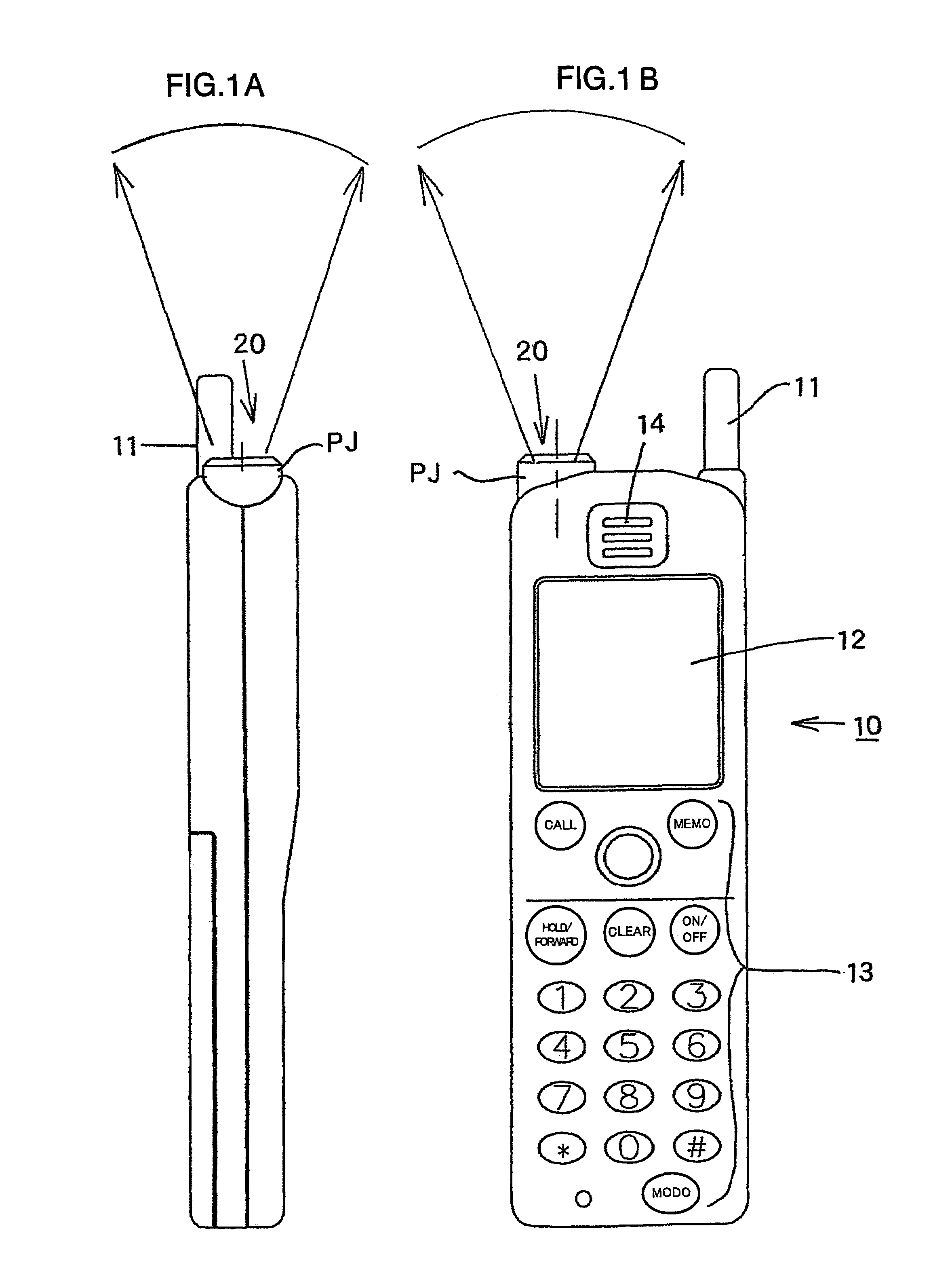

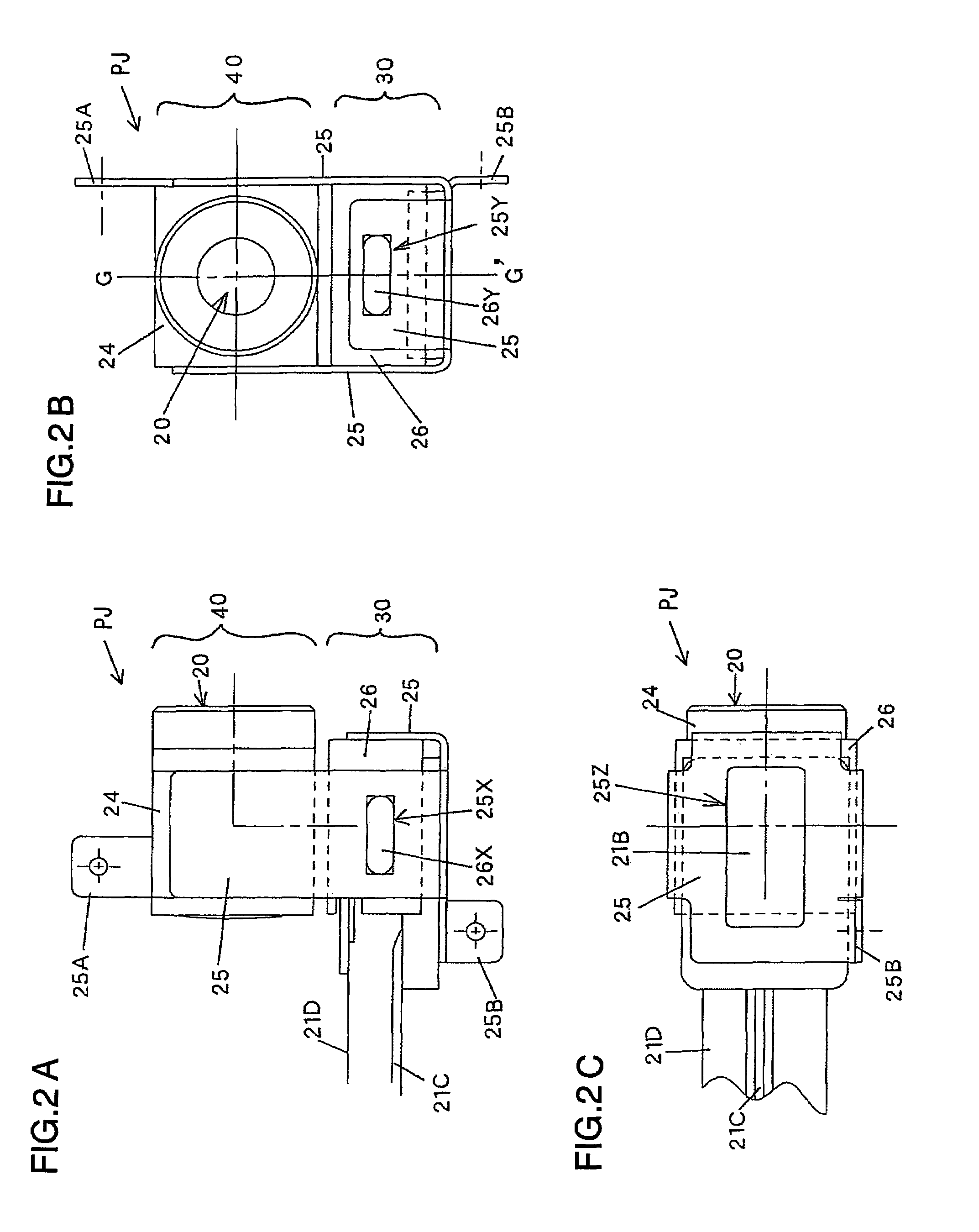

Illuminating device and projector device

InactiveUS20060050515A1Low levelImprove the level ofPoint-like light sourceVehicle interior lightingLight equipmentPlastic materials

A projector module adopts a structure having an optical image forming block and an optical block integrated via a locking member. The optical image forming block adopts a structure achieved by disposing an aluminum substrate at which an LED is mounted and a liquid crystal panel in a casing constituted with a plastic material having low thermal conductivity. The locking member is formed by bending a metal sheet through a sheet metal bending process and the locking member is set in surface contact with the substrate. The optical block adopts a structure achieved by disposing a PBS and a reflecting member at the casing constituted with a plastic material having low thermal conductivity with a quarter-wave plate disposed at the boundary of the two members.

Owner:NIKON CORP

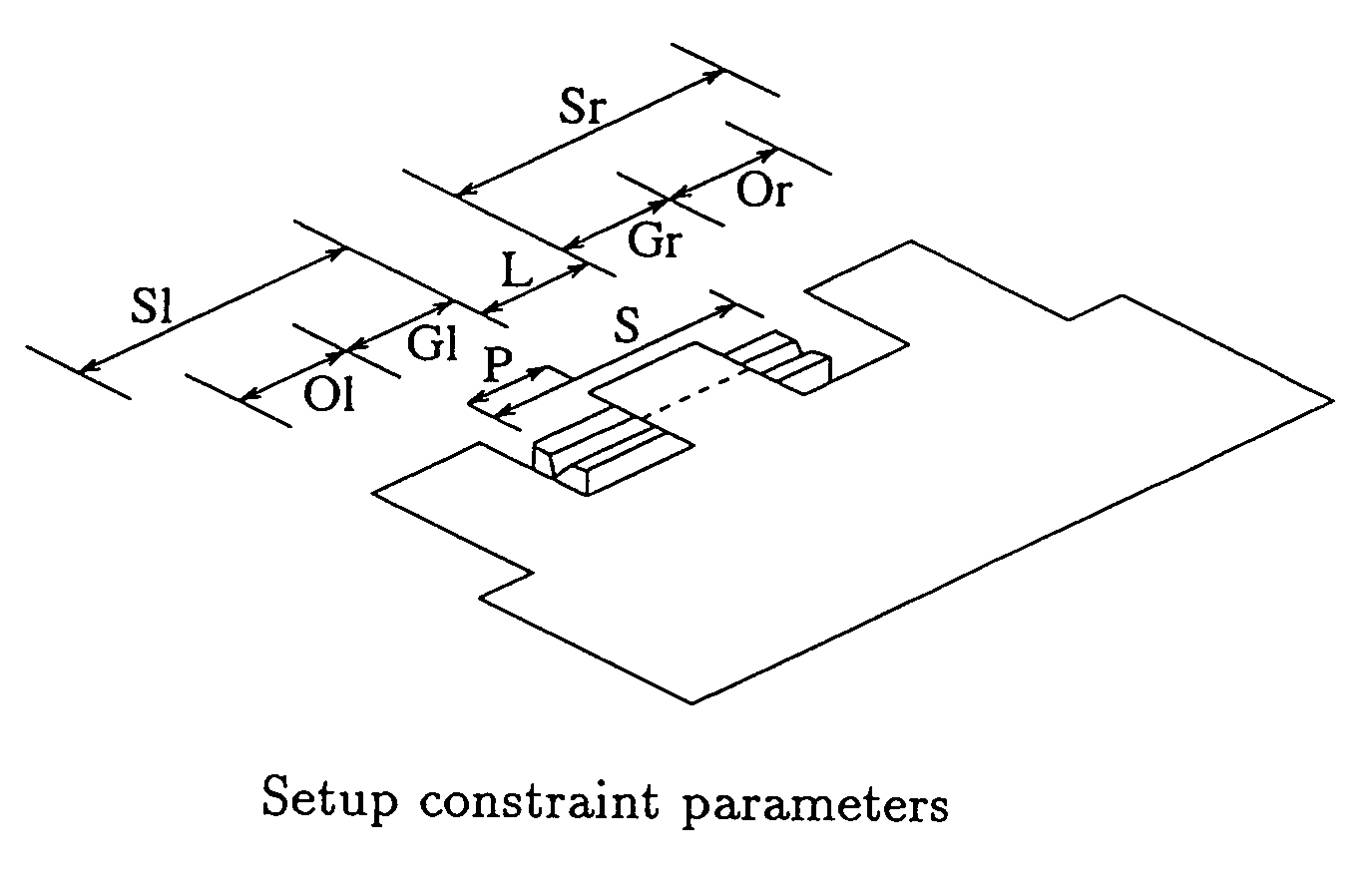

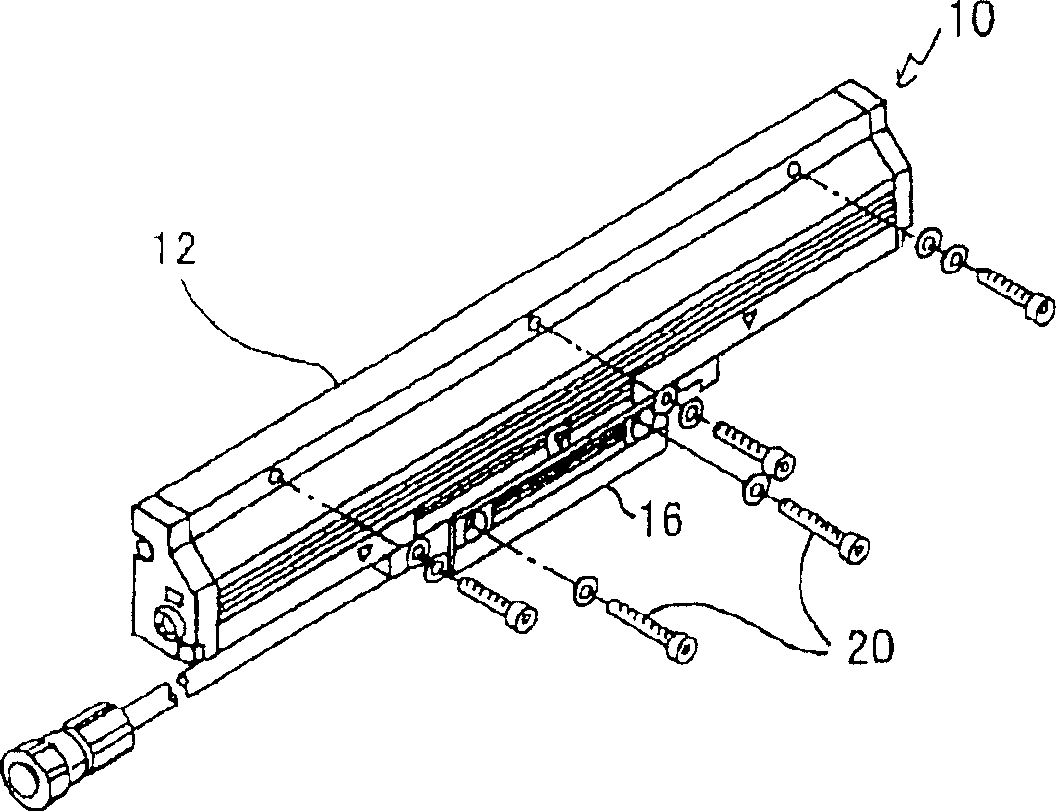

Apparatus and method for multi-part setup planning for sheet metal bending operations

InactiveUS7031893B2Improve efficiencyReduce in quantityProgramme controlProgramme-controlled manipulatorProgram planningEngineering

A setup planning technique is provided in which a family of parts to be manufactured is identified, and the setup constraints imposed by the various bending operations in the part family are determined. The setup constraints may define or describe spatial constraints on the sizes and locations of various tooling stages in the setup. After identifying setup constraints, setup plans are generated that satisfy all setup constraints. Any setup plan that satisfies all setup constraints may then be utilized to accommodate every part in the part family. Constraint propagation techniques may be utilized to identify compatible setup constraints and create setup plans. According to the various features and aspects of the invention, dissimilar sheet metal parts can share setups, and the need for extra tooling and fixturing may be minimized. Further, the present invention provides potential savings over state-of-the-art systems, and increases production capability and overall through-put of manufacturing facilities.

Owner:AMADA CO LTD +1

Sheet metal bending brake

A bending brake assembly for manually bending pieces of sheet metal material including a base supporting a plurality of c-shaped members presenting opposing clamping surfaces for receiving the sheet metal material. An extension extends away from the clamping surfaces with a socket connection rotatably supporting a bending member on the base for bending the sheet metal material disposed between the clamping surfaces. The socket connection includes a mate portion and a female portion in sliding engagement with one another as the bending member moves between a pre-bending position, a first operating position, and a second operating position. A finger extends from the male portion and defines a gap between the finger and the extension when in the pre-bending position with the finger maintaining the gap as the finger moves from the pre-bending position to the first operating position and the finger engaging the extension when in the second operating position.

Owner:WESTLAKE ROYAL BUILDING PROD INC

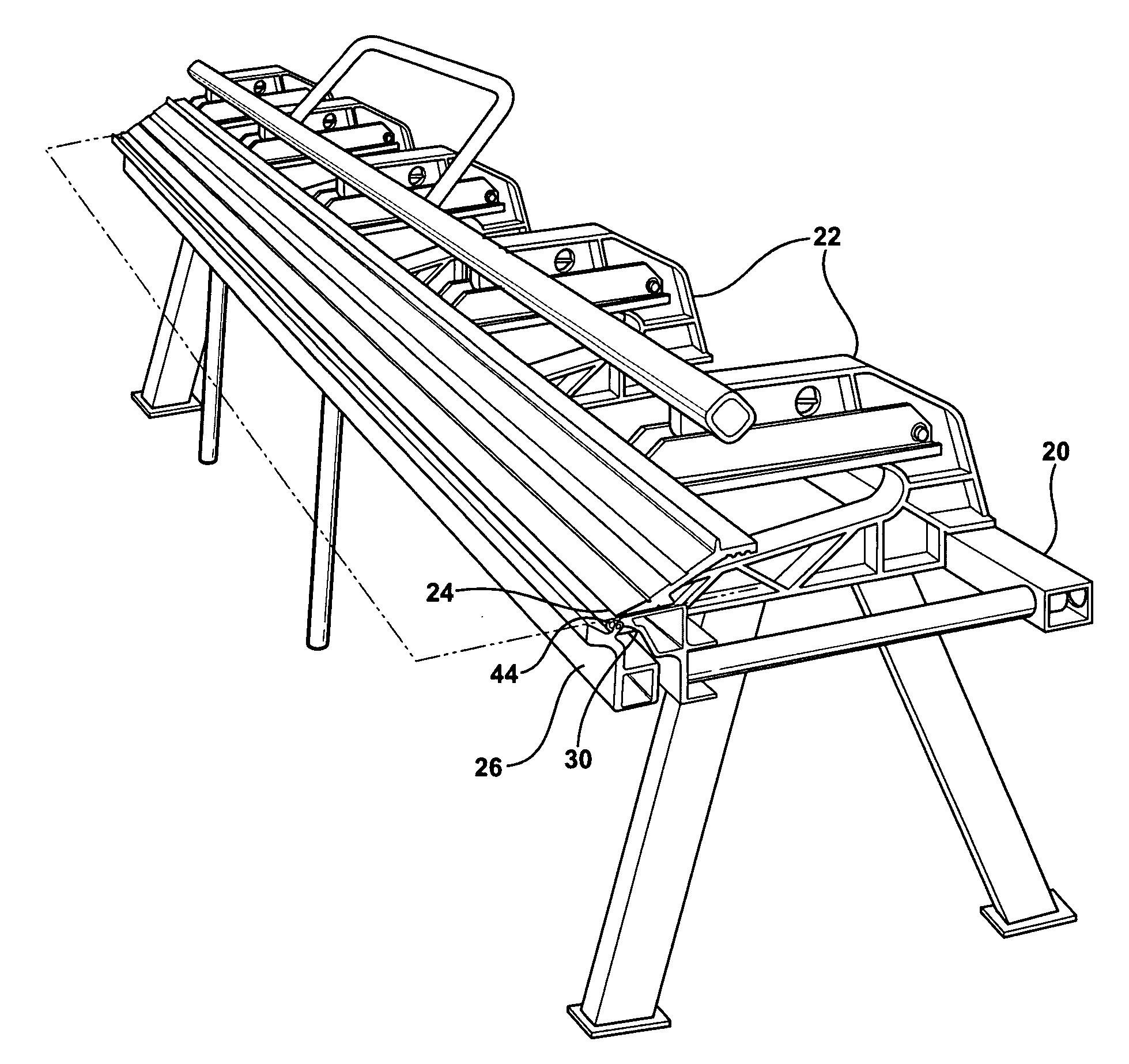

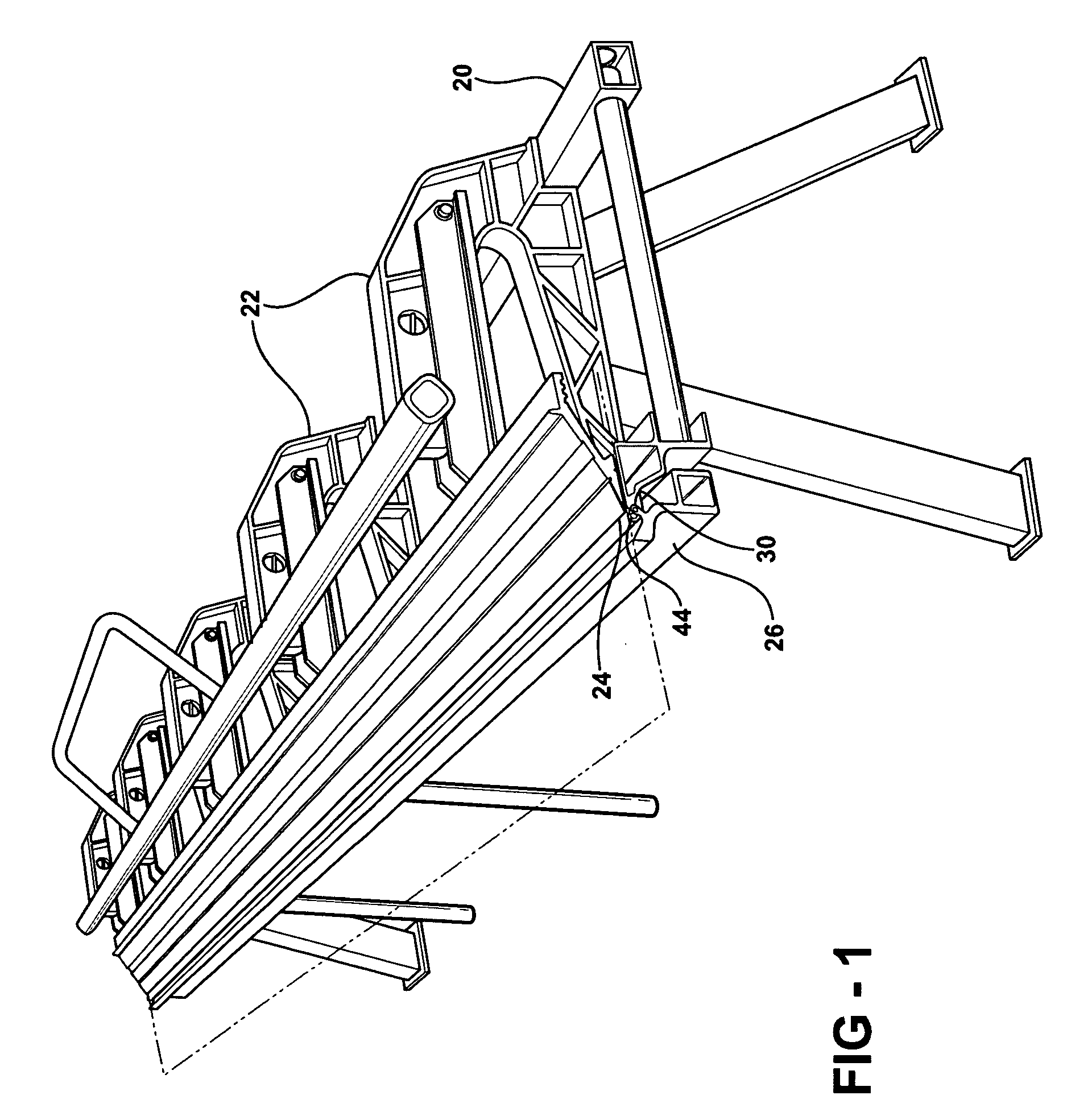

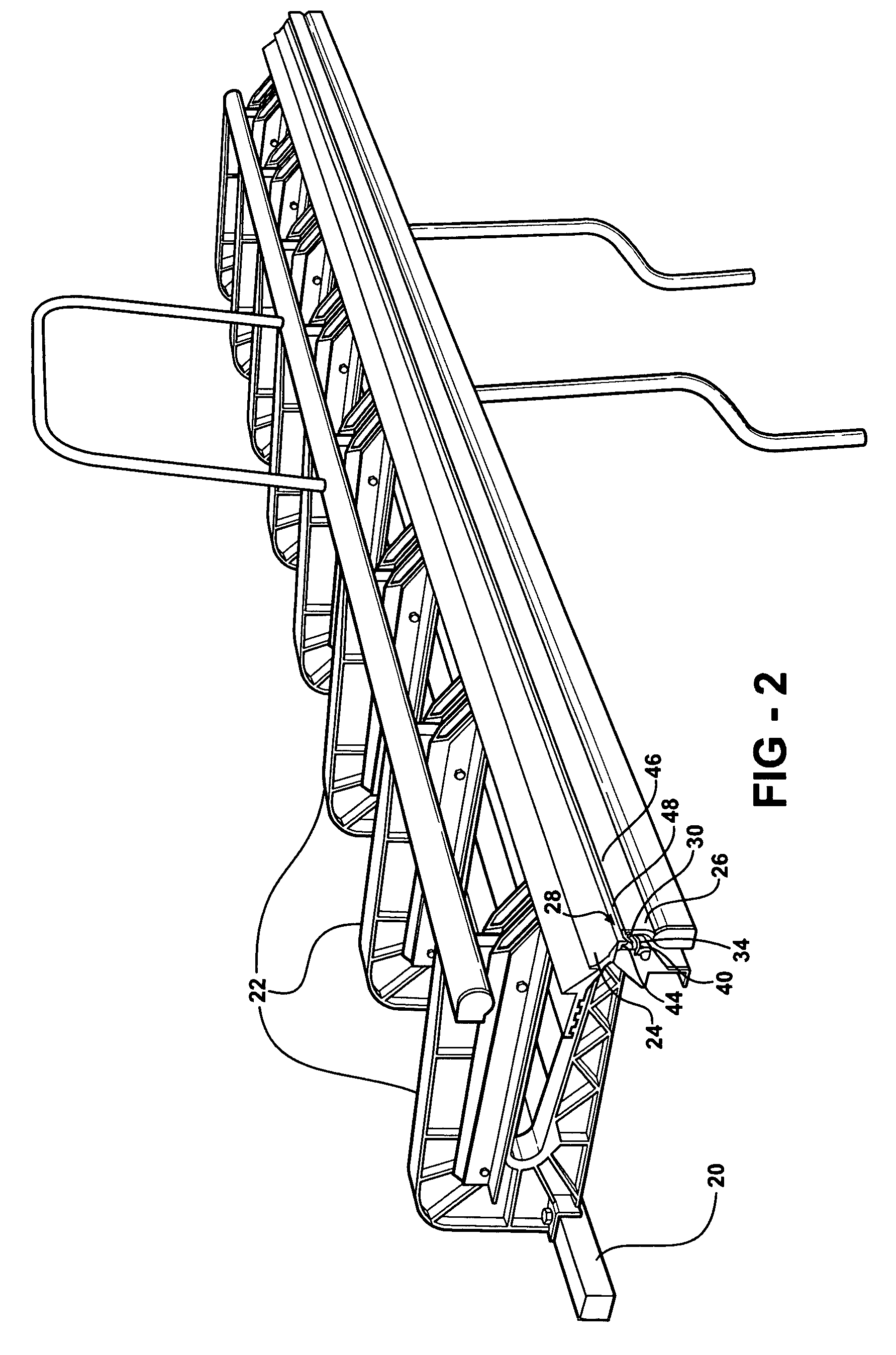

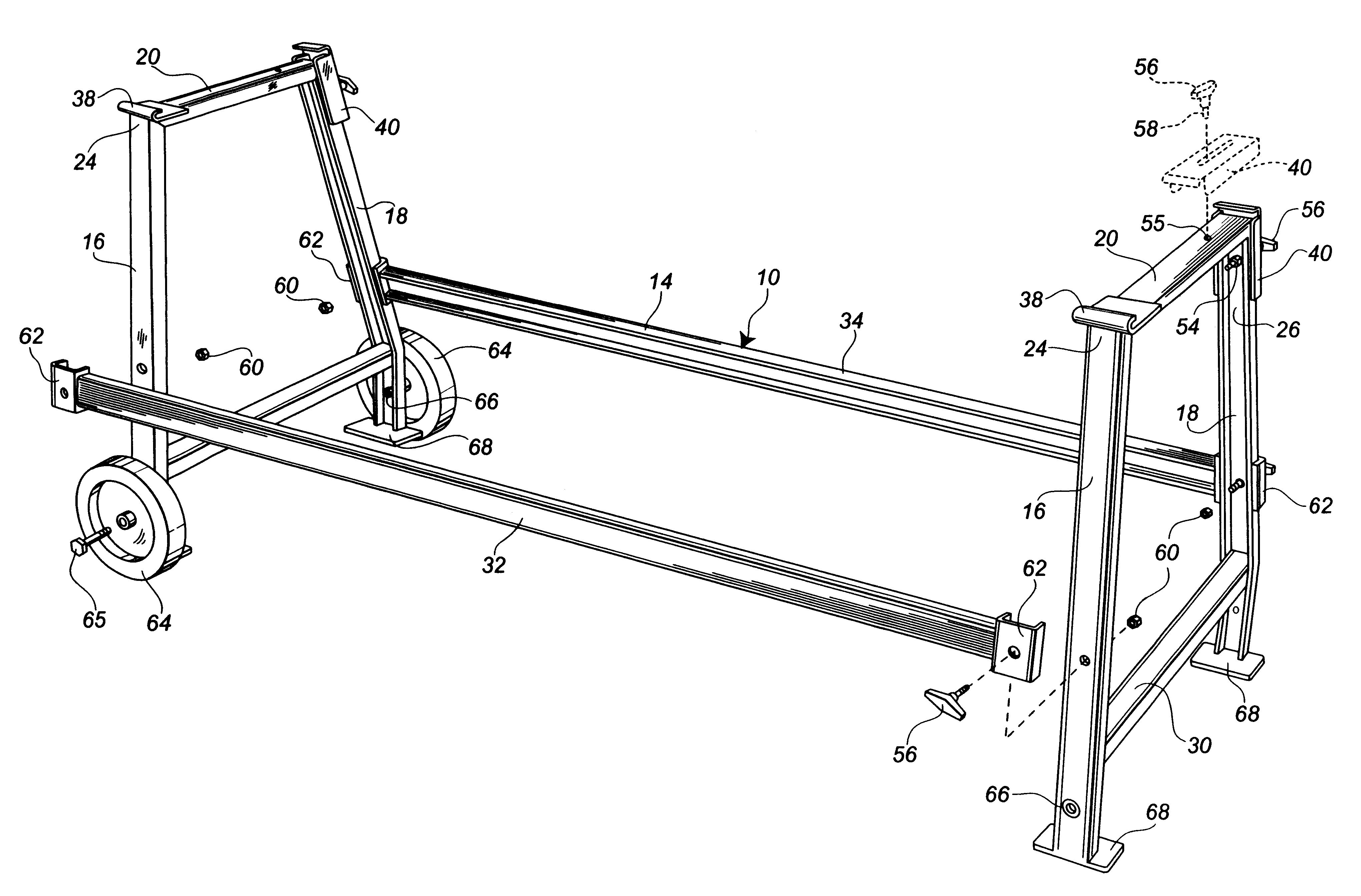

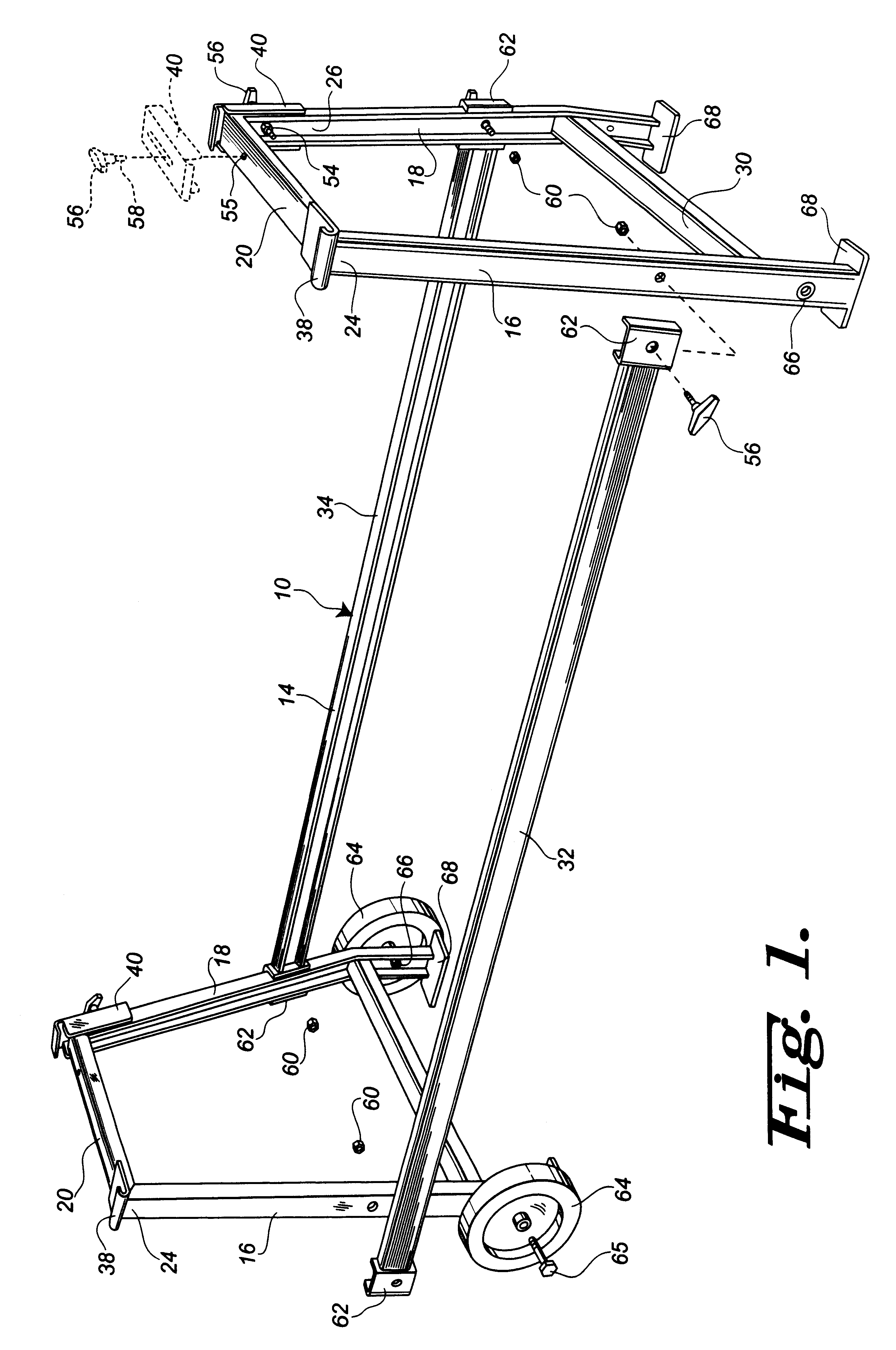

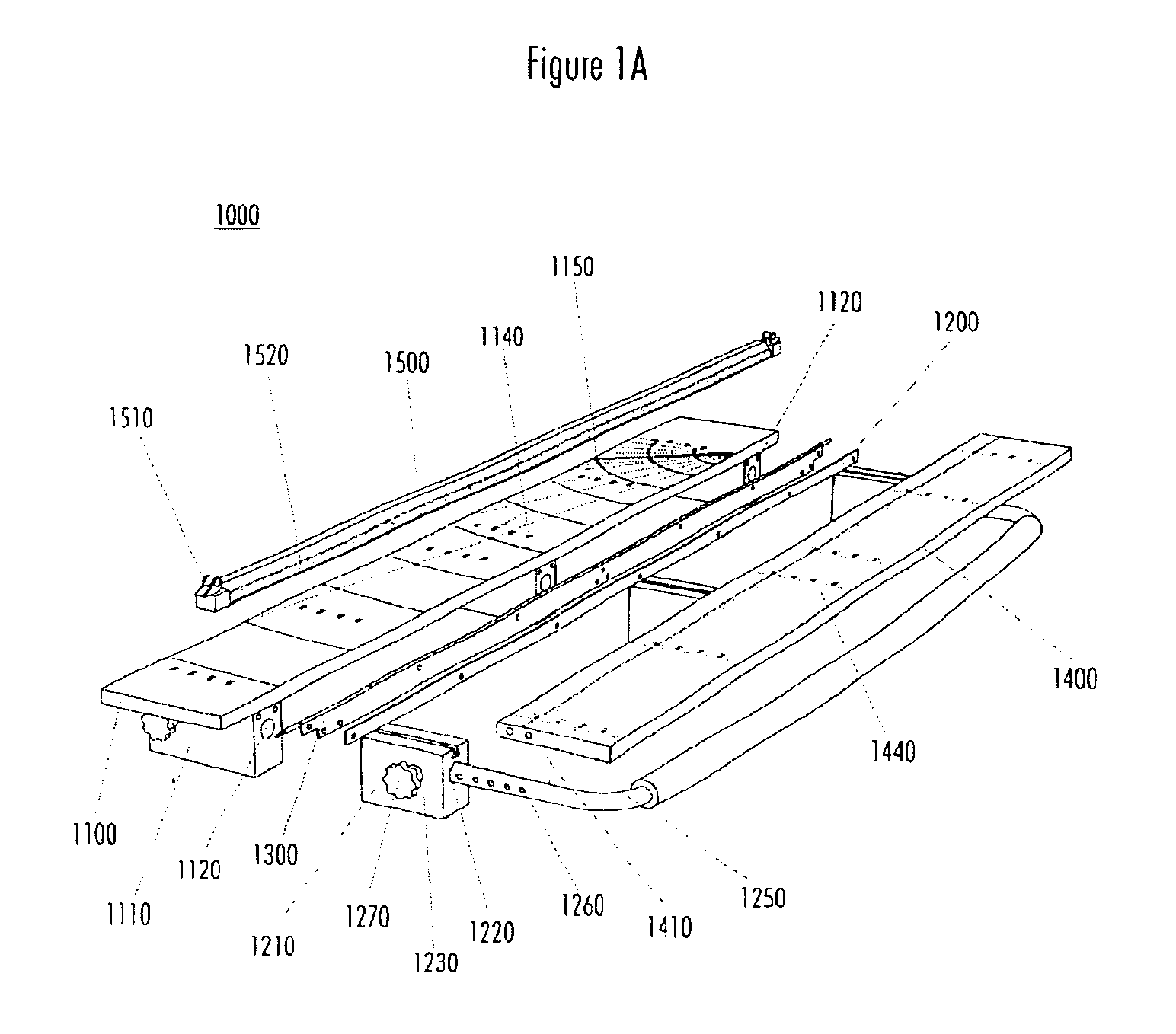

Sheet metal tool stand

InactiveUS6854314B2Promote sportsImprove stabilityPortable framesGang saw millsMechanical engineeringMetal

A stand for sheet metal tools is provided that may accommodate different types and sizes of sheet metal tools. The stand is intended to be used with portable sheet metal bending brakes, saw tables, coil slitters and coil holders. The stand has a versatile clamping system utilizing detachable anchor plates that may be secured in different locations and positions on the stand. A longitudinal extension may be incorporated as part of the stand or part of the support structure for sheet metal tools and a rear mounted roller table may also be provided in conjunction with the stand.

Owner:VAN MARK PRODS

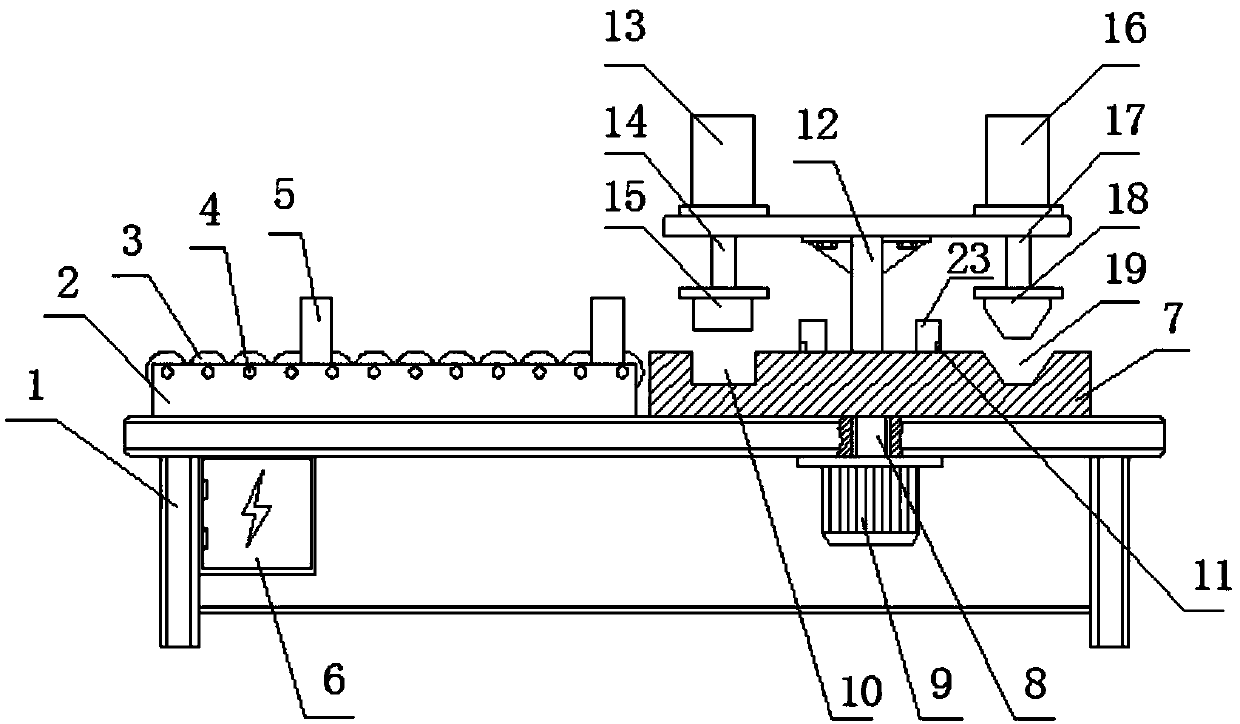

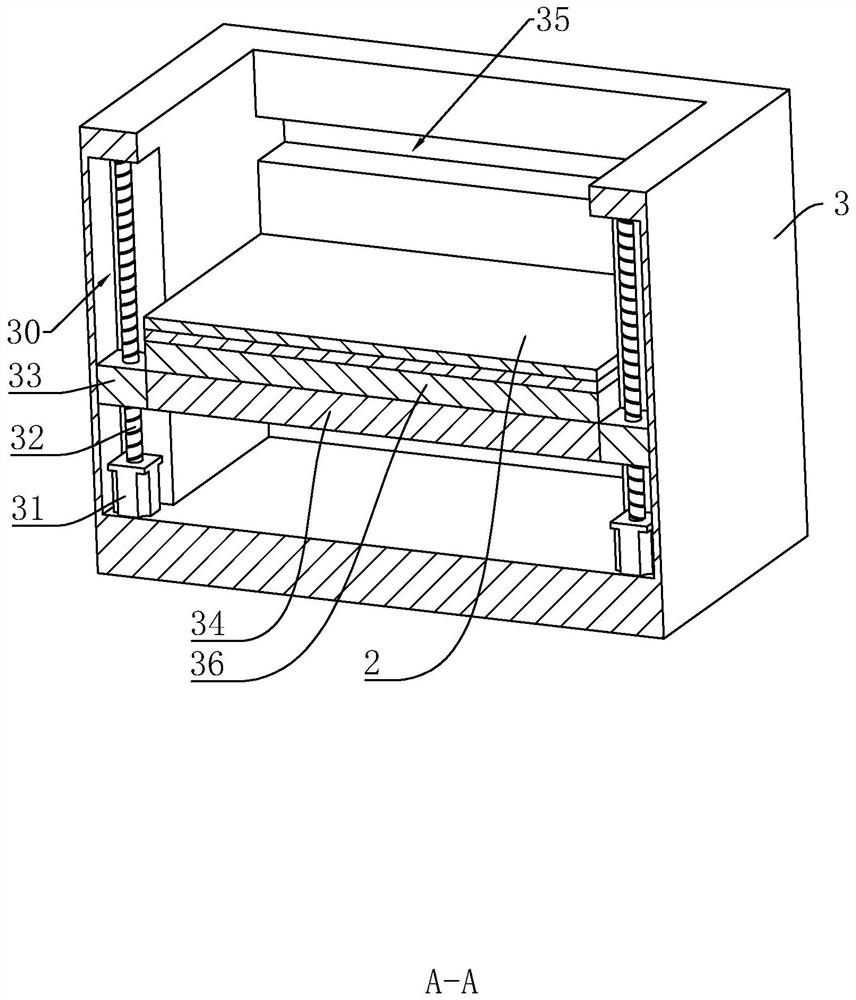

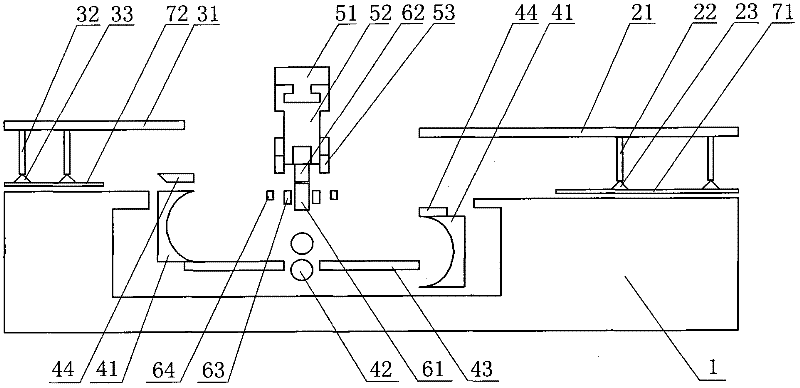

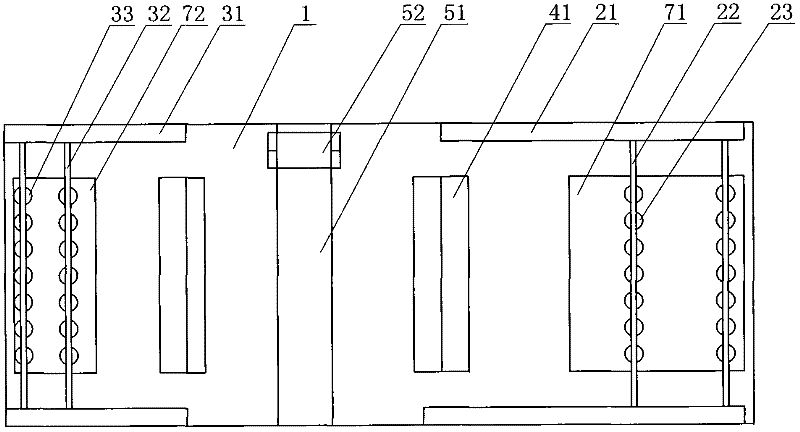

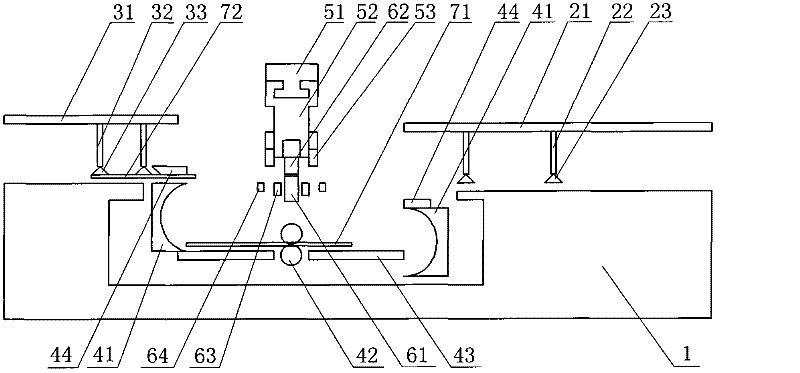

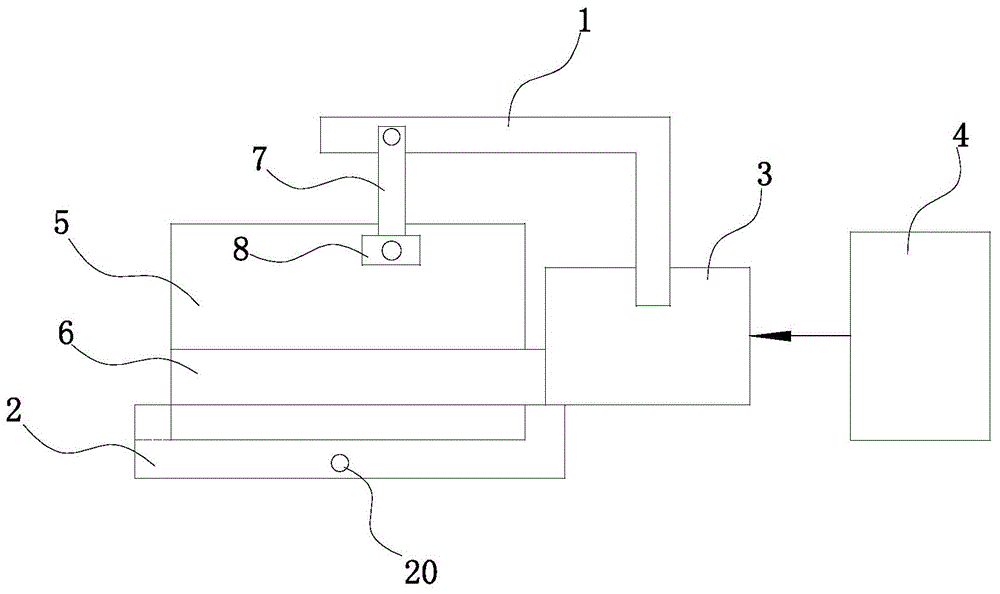

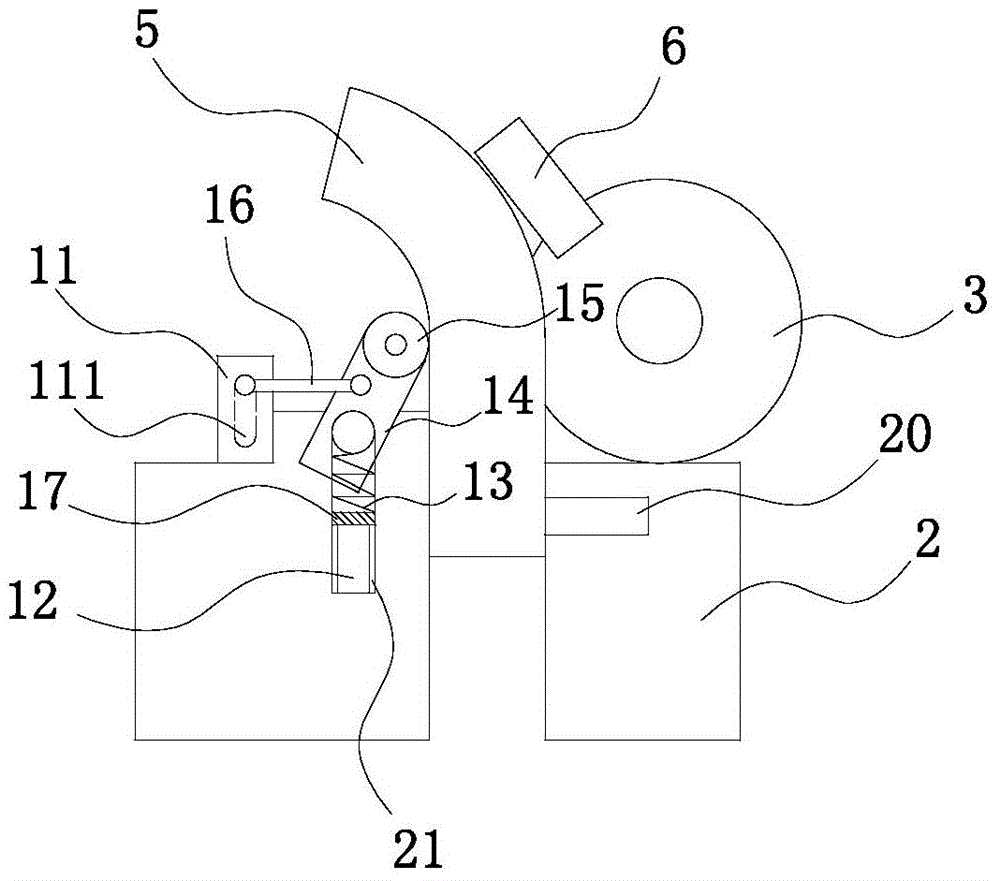

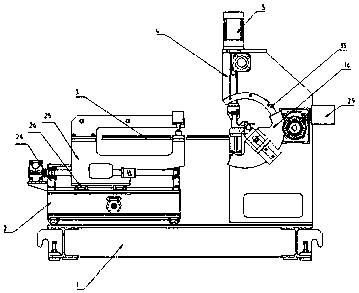

Automatic sheet metal bending production line

ActiveCN109550818AImprove bending work efficiencyMetal-working feeding devicesPositioning devicesProduction lineHydraulic cylinder

The invention discloses an automatic sheet metal bending production line. The production line comprises a bending machine base, a bending die base and a material pressing mechanism. A conveying support arm is installed on the upper side of one end of the bending machine base, the upper side of the conveying support arm is provided with a feeding roller through a conveying rotary shaft, the two sides of the upper end of the conveying support arm are provided with a material pressing mechanism, and the bending die base is rotationally installed on the upper side of one end of the bending machinebase. The lower side of the bending die base is in transmission connection with a motor through a die changing rotating shaft, a square bending groove and a trapezoid bending groove are formed in thetwo ends of the upper side of the bending die base respectively, a bending support is arranged in the middle of the upper side of the bending die base, a first hydraulic cylinder and a second hydraulic cylinder are installed on the two sides of the upper end of the bending support, and the lower side of the first hydraulic cylinder is provided with a square bent head through a first telescopic rod. According to the automatic sheet metal bending production line, the bending effect of different shapes can be completed by switching different stations, and the function of automatic feeding can berealized.

Owner:佛山市镭戈斯数控设备有限公司

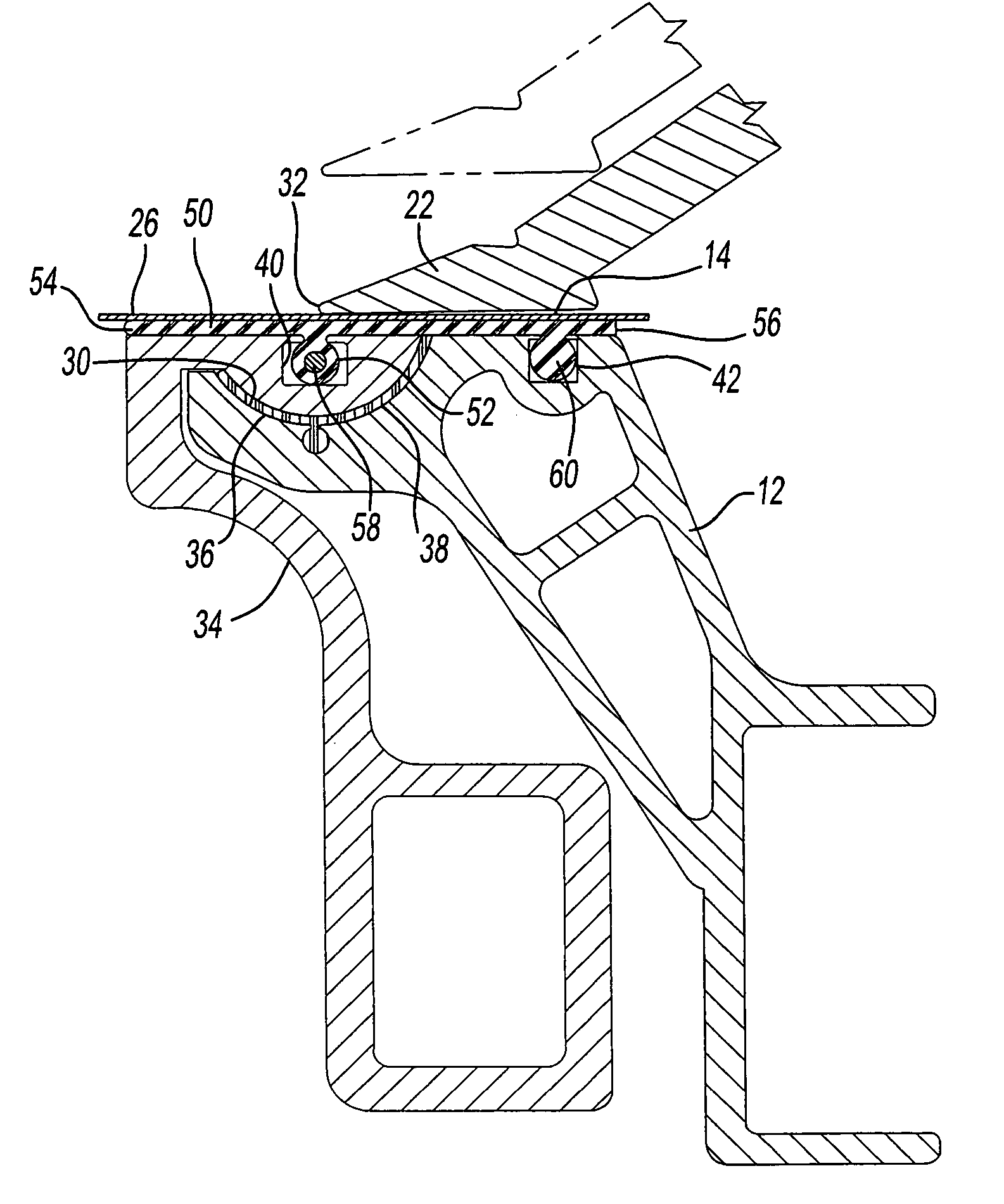

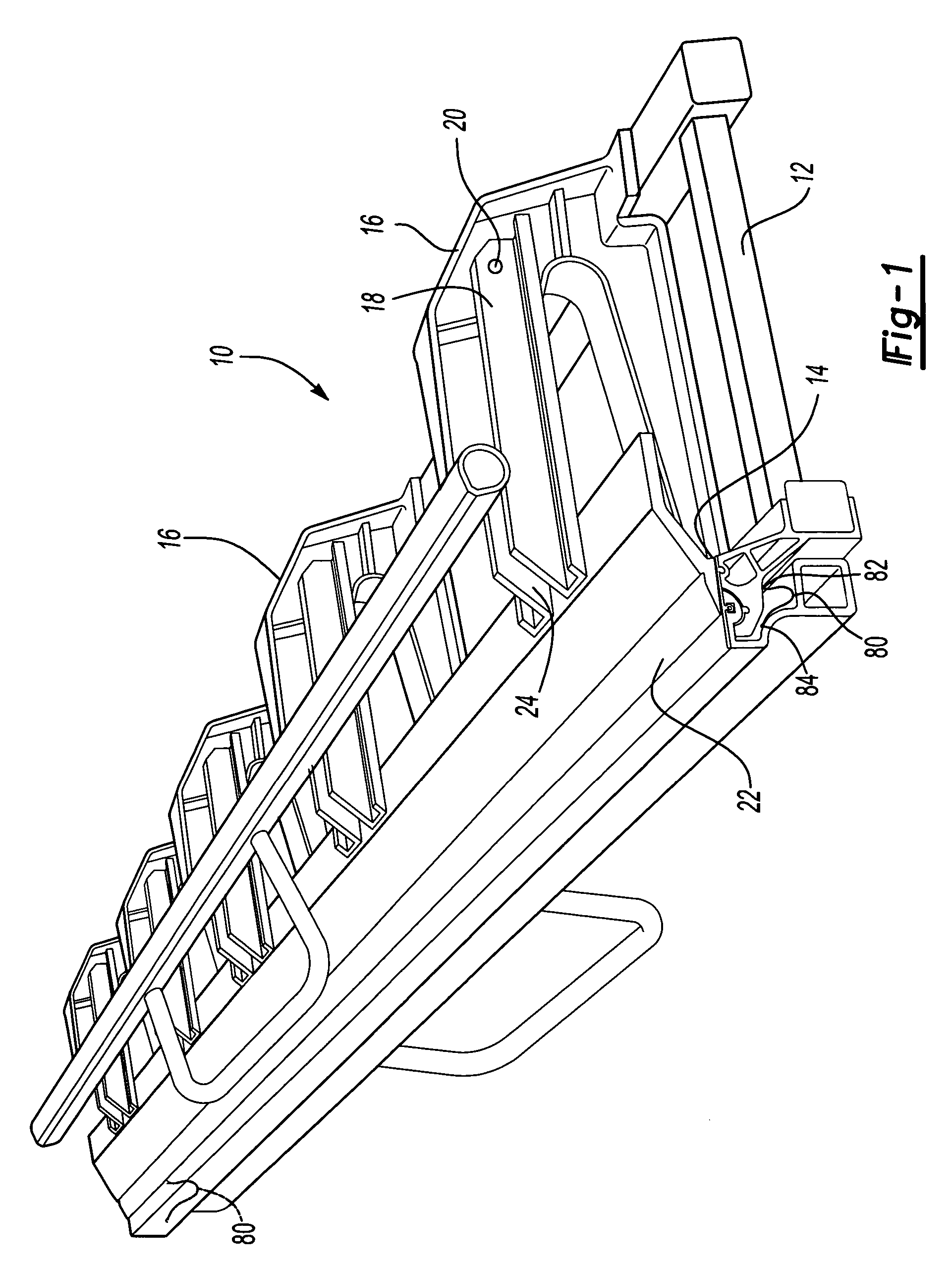

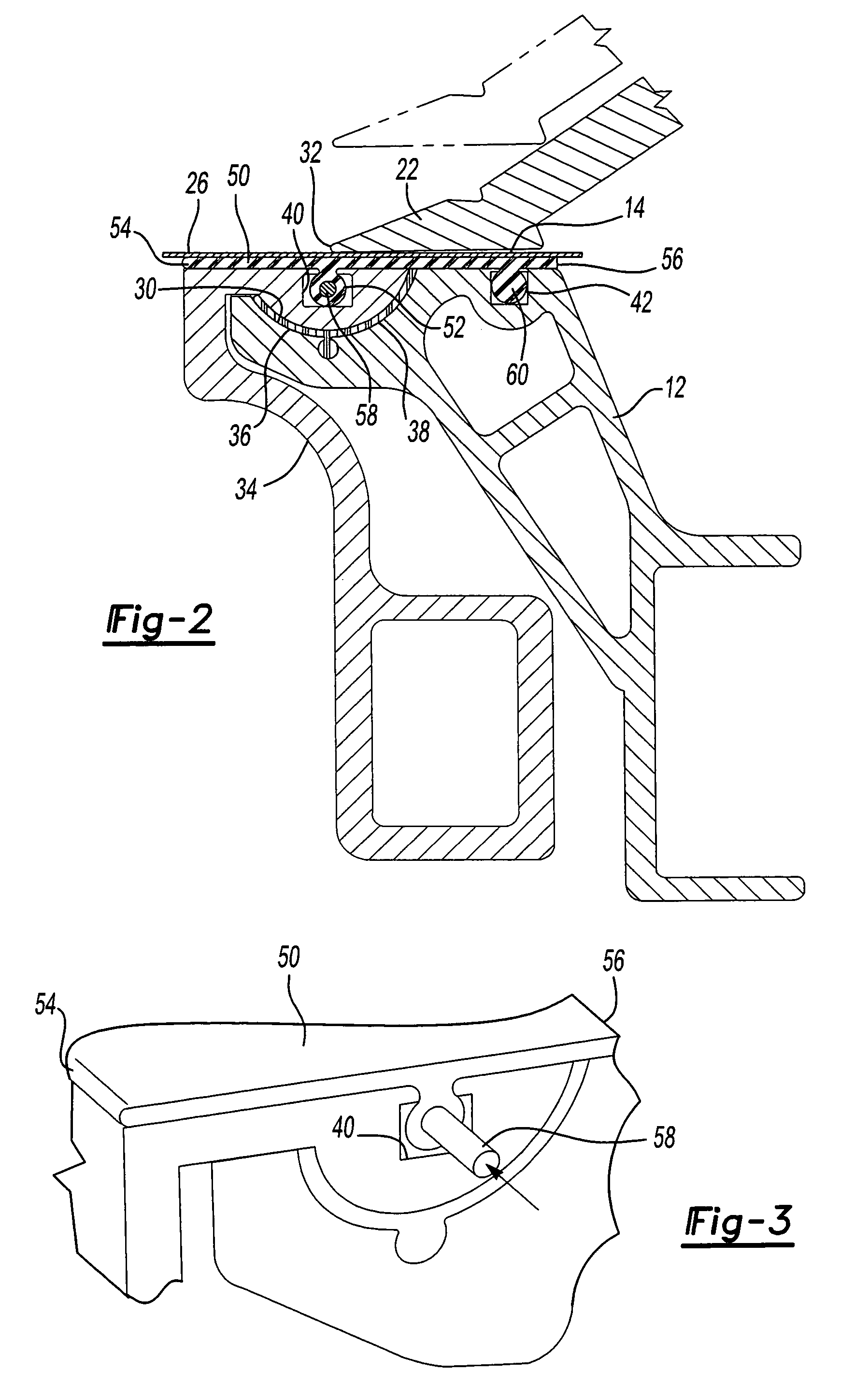

Sheet metal bending brake with improved hinge

A sheet metal bending brake having a frame with a sheet metal support surface. A clamping jaw is movable relative to the frame support surface to clamp the sheet metal between the clamping jaw and the frame. The clamping jaw has a linear front edge. An elongated bending arm is pivotally mounted to the frame by an elongated flexible strap having spaced apart edges. One edge of the strap is secured to the bending arm while the other edge of the strap is secured to the frame such that the bending arm extends parallel to and closely adjacent the clamping jaw front edge.

Owner:TAPCO INTERNATIONAL CORPORATON

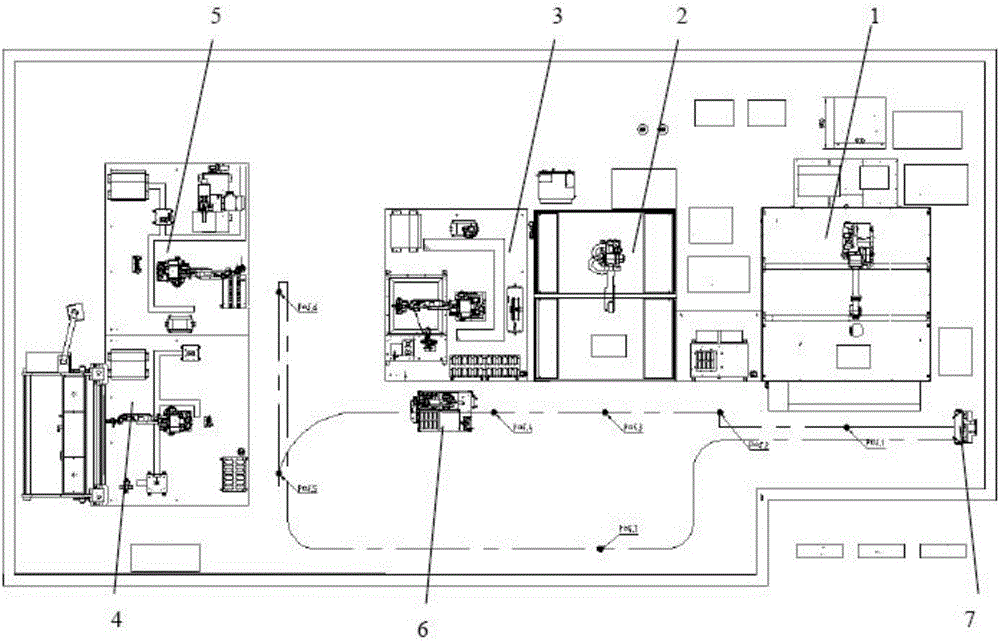

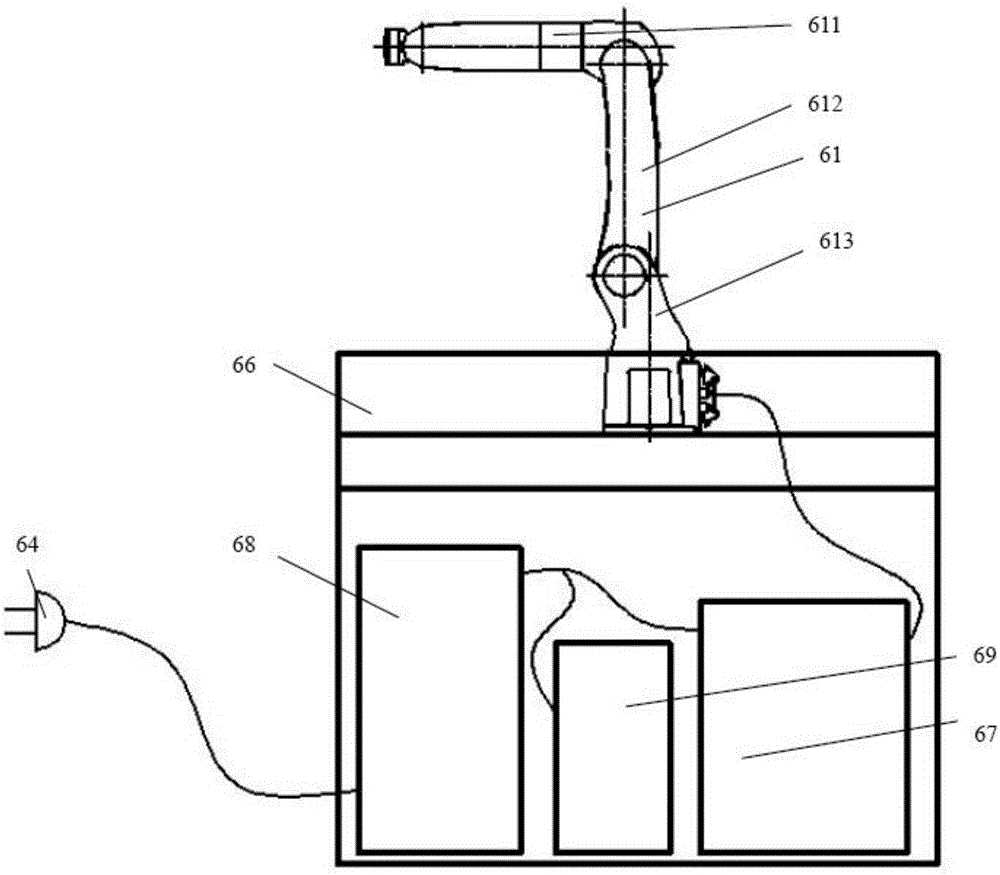

Sheet metal processing system and working process thereof

ActiveCN106493579AOther manufacturing equipments/toolsMetal working apparatusProduction lineMan machine

The invention discloses a sheet metal processing system and a working process thereof. An arrangement scheme of a workshop and a sheet metal processing production line process are included; a laser engraving unit, a laser cutting unit, a burr grinding unit, a sheet metal bending unit, a polishing and cleaning unit and an automated guided vehicle (AGV) carrying unit are arranged in the workshop; and an AGV carrying robot carries a raw material, is electrified by a socket structure, starts from the socket structure, advances to the various units sequentially, cooperates with the various units for feeding, working and discharging, carries the processed material to return to the socket structure for discharging and electrification after all procedures are completed. According to the system, a man-machine collaborating robot is combined with an AGV modularly, so that the robot is not limited by a certain unit, a certain area and a certain work type and can be deployed to any working station to participate in production according to production expansion requirements.

Owner:SHANGHAI FANUC ROBOTICS

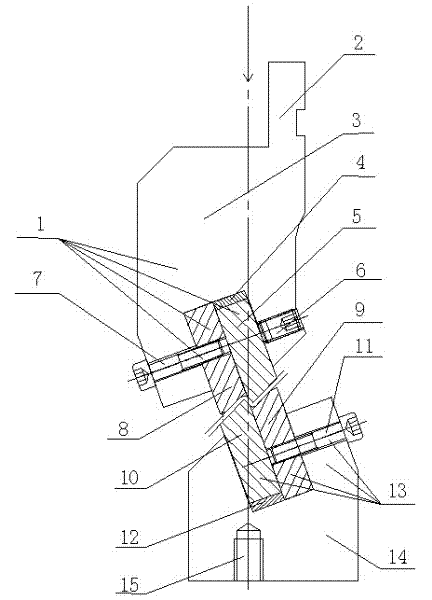

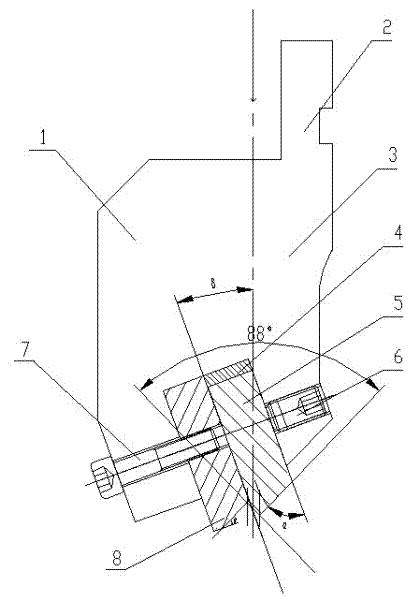

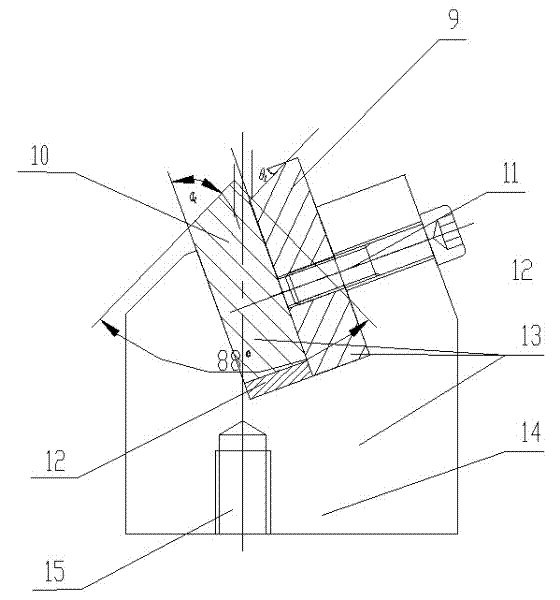

Adjustable Z-shaped offset bending mold

InactiveCN102284616AReasonable structureEasy to useShaping toolsMaterials scienceSheet metal bending

The invention discloses an adjustable Z-shaped offset bending mold and belongs to a sheet metal bending mold. The adjustable Z-shaped offset bending mold is characterized by mainly comprising an upper mold and a lower mold, wherein the upper mold mainly comprises an upper mold seat, an upper fixed press mold, an upper adjustable press mold, an upper combined gasket and an upper fixed bolt; the lower mold mainly comprises a lower mold seat, a lower fixed press mold, a lower adjustable press mold and a lower fixed bolt; the lower part of the upper mold seat is provided with a right-angled upperinclined through groove which forms a delta included angle with the pressure line of a bending machine; the upper inclined through groove is internally and correspondingly provided with the upper fixed press mold, the upper adjustable press mold and the upper combined gasket; the upper part of the lower mold seat is provided with a right-angled lower inclined through groove which also form a delta included angle with a vertical central line; the lower inclined through groove is internally and correspondingly provided with the lower fixed press mold, the lower adjustable press mold and the lower combined gasket; all the bottom surfaces or top surfaces of the upper fixed press mold, the lower fixed press mold, the upper adjustable press mold and the lower adjustable press mold are inclined surfaces which form theta included angles with the bottom surfaces or top surfaces of the upper mold seat and the lower mold seat correspondingly; and the upper mold and the lower mold are combined, and then the Z-shaped workpiece is formed. The adjustable Z-shaped offset bending mold has the advantages that the cost is low and the quality is good.

Owner:MAANSHAN CHENXING MACHINERY MFG

Sheet metal bending technology

The invention discloses a sheet metal bending technology which comprises the following steps: 1, before a bending production process, preparing to calculate the unfold size and positions of all hole sites and notches of a component; according to the principle that the length of a bent neutral layer is not changed, calculating the unfold size of a component sheet matal; the unfold length of the part sheet matal is sum of length of a straight part and length of the neutral layer of a bent part; 2, according to the size and material thickness on a drawing, determining a cutter and a cutter groove during bending, wherein avoidance of deformation caused by collision between a product and the cutter is key to selection of an upper die, and selection of a lower die is determined according to the thickness of a sheet material; and 3, determining the bending sequence, wherein the bending rule is as follows: internal first and external second, small first and big second, and special first and common second; for a workpiece to be tightly pressed, firstly, the workpiece is bended by 30-40 degrees, and then the workpiece is tightly pressed by a leveling die. The sheet metal bending technology ensures that all machined hole sites, notches and the boundary dimension of the bended component meet the expected requirements.

Owner:昆山市力勋达精密机械有限公司

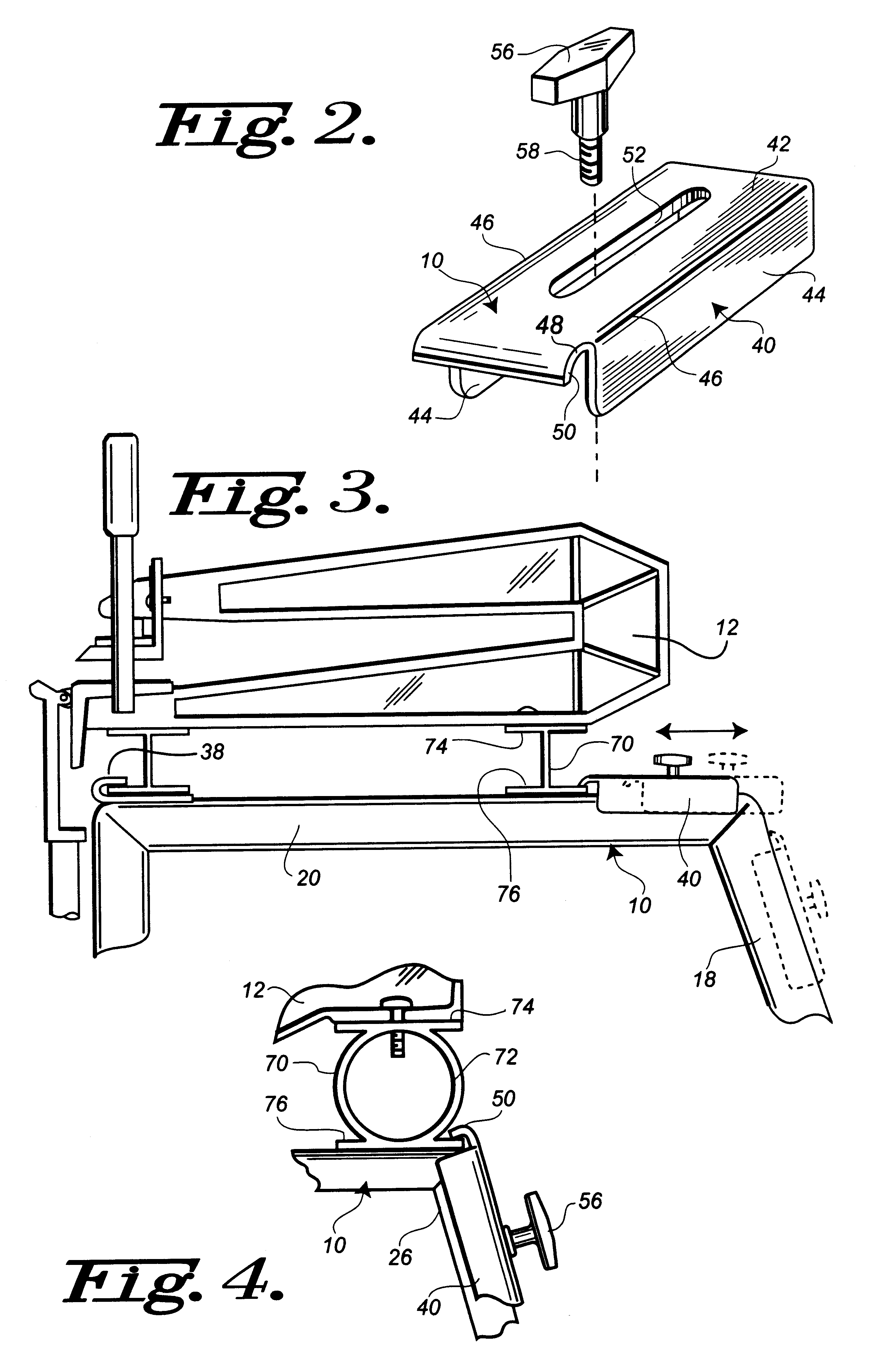

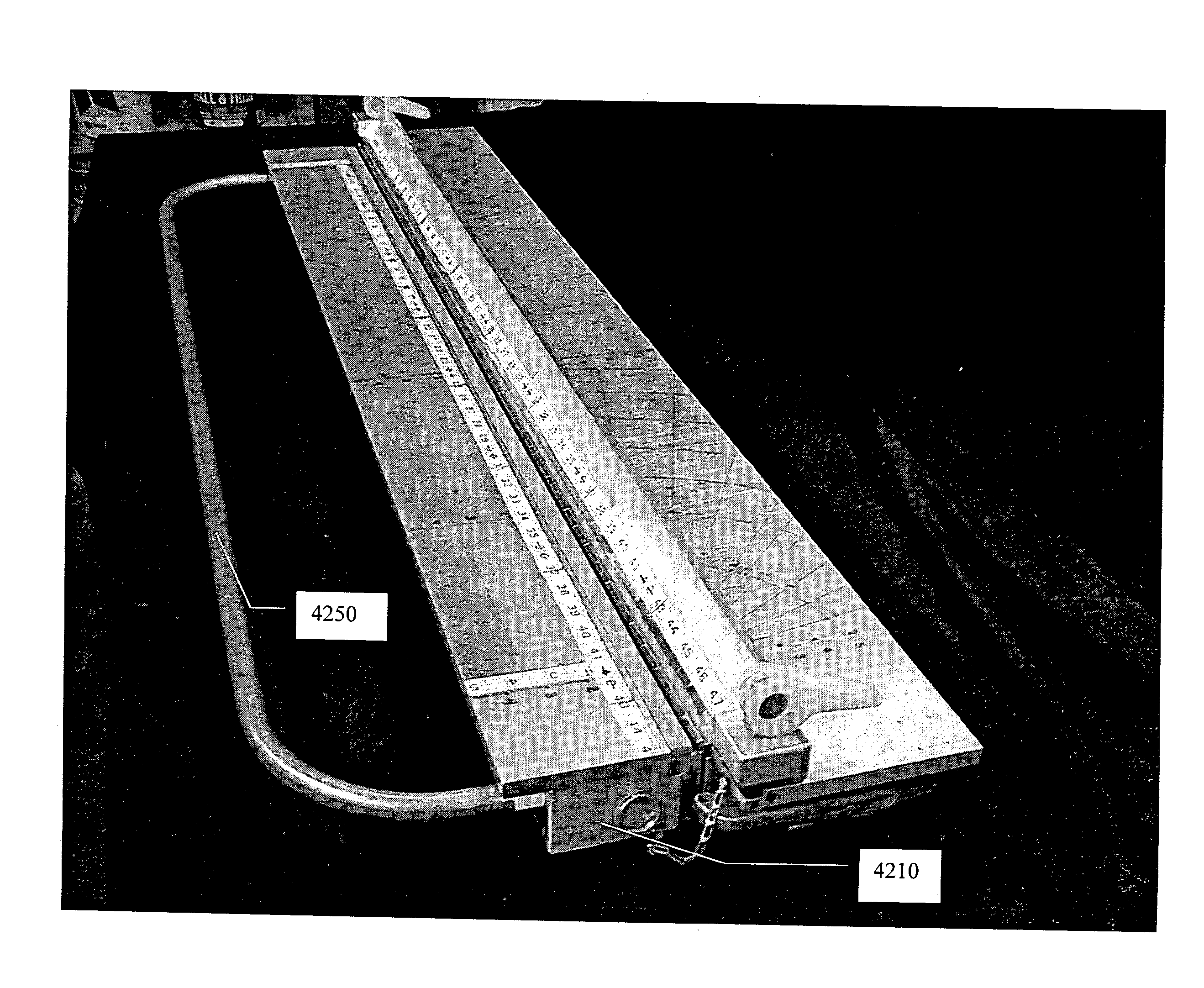

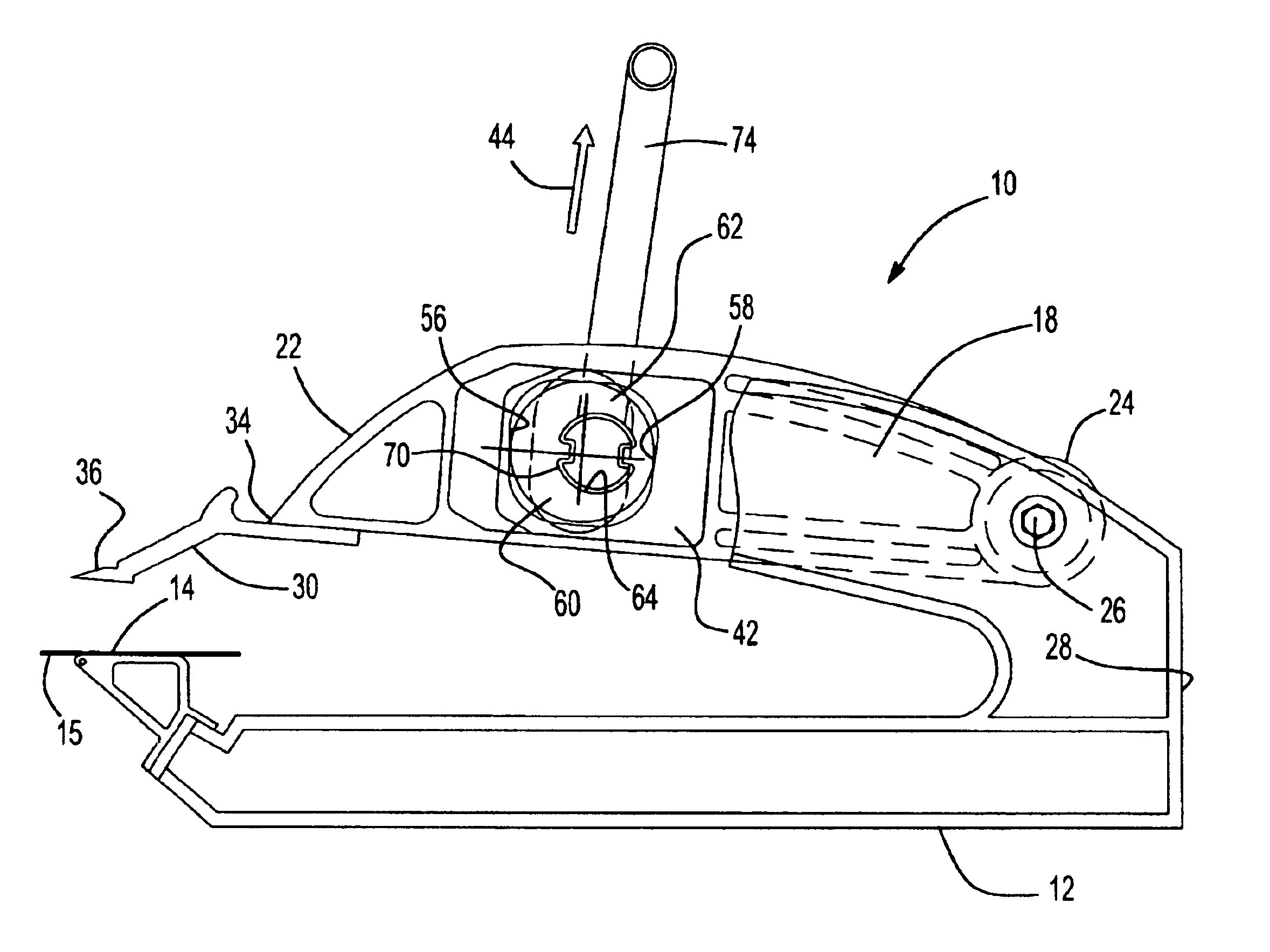

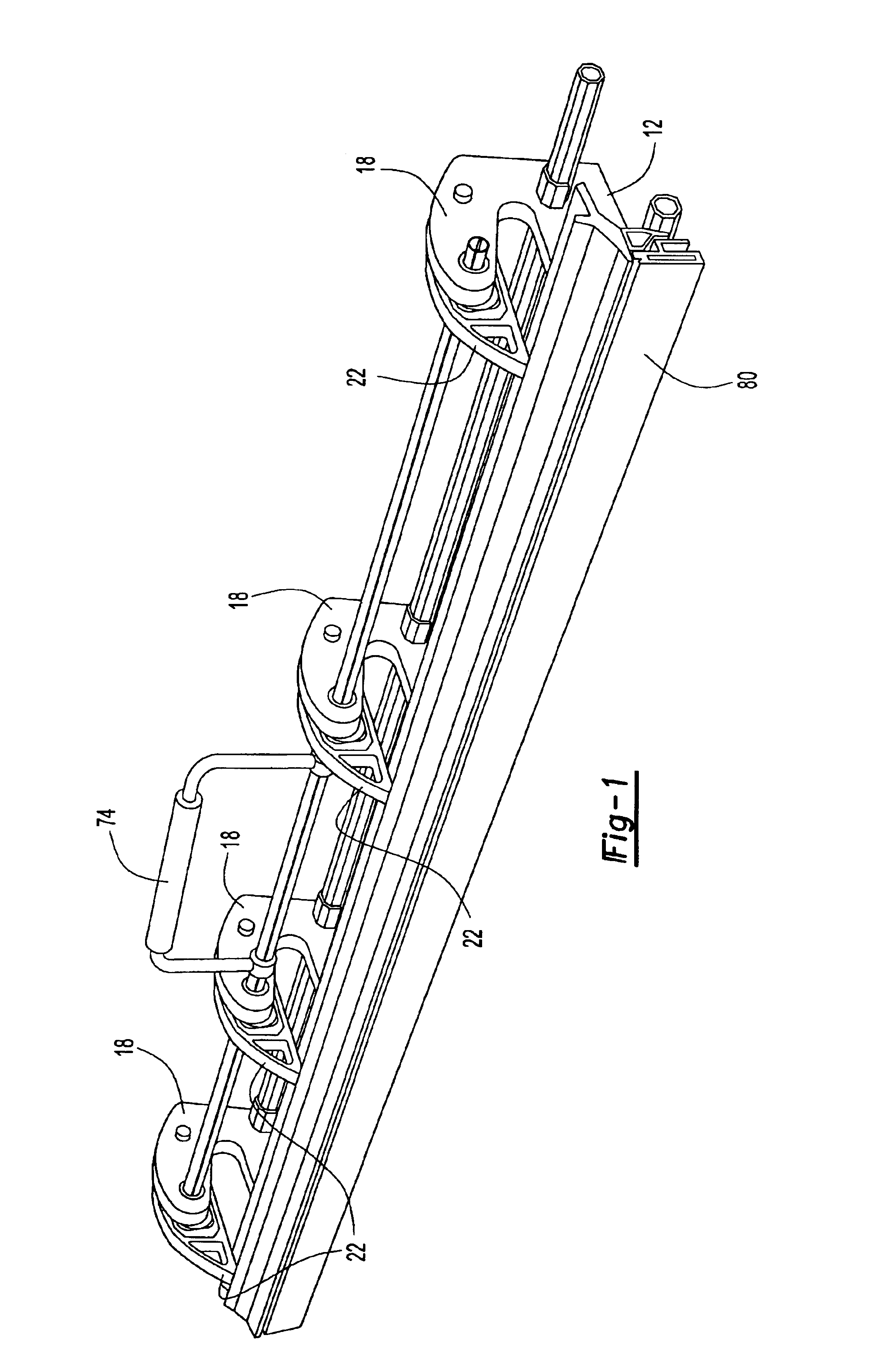

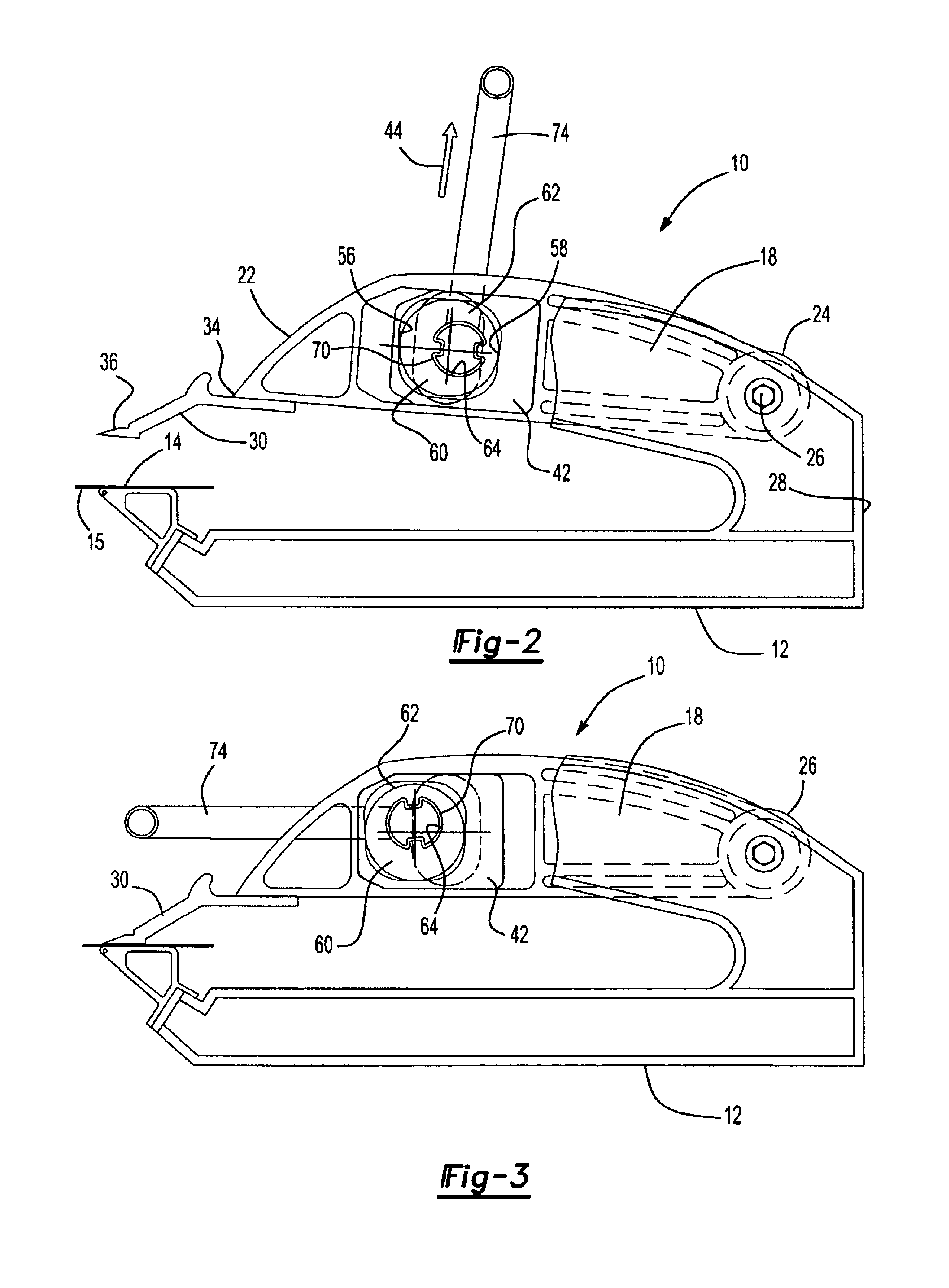

Portable mini-break

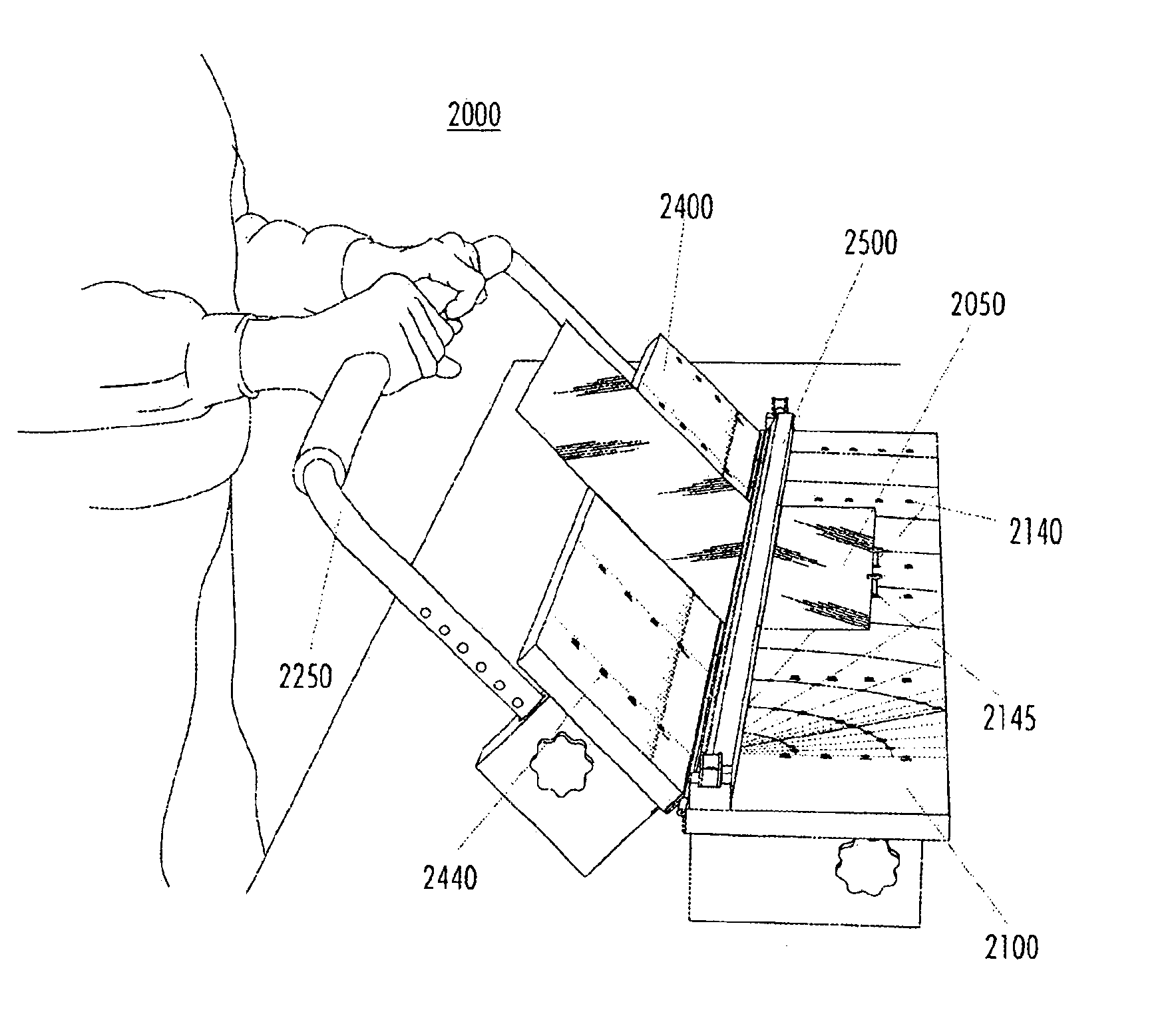

A sheet metal bending tool for bending materials, such as flat metal sheets is disclosed. The tool has a restraining base for receiving and cooperatively holding a sheet metal workpiece and the tool has a bending component that is rotatably mounted to the restraining base, the workpiece is held, cooperating with the restraining base component, and the clamp bar for stabilizing the workpiece while the workpiece is held and bent by the rotating action of the bending component. In the preferred embodiment, the workpiece is restrained by a template comprising a pattern of holes drilled, a hole receiving a peg or means of stop, the stops (pegs) constraining the workpiece from movement while being bent act like a jig for measuring and predetermined incumbents. Holes are also drilled in restraining base and in the bending component at spaced intervals along lines that are run parallel to the line defined by the intersection of the bending component and the restraining base. There is a pull back bar that is used for the process of cutting. The Unit can be clamped down also. Rulers are installed on the clamp bar, and the slide table. The apparatus is designed so that two or more may be joined together to form a larger apparatus for the purpose of bending larger workpieces.

Owner:PERRUCCIO DANIEL

Sheet metal bending machine and production line incorporating a machine of this type

A roll bender machine for bending metal sheets which includes a roller driven in rotation and about which the sheet metal is rolled and at least two backing rollers adapted to receive and bear against a sheet while it is being bent around the roller. The backing rollers are mounted to rotate on a support that is adjustable. The bending roller and backing rollers are each associated with at least one set of devices for compensating their deflection. An arm is mounted on the machine for receiving coiled sheet metal and is provided with a housing in which the bending roller is at least partially received.

Owner:CONCEPTION MACHINES FAVEYRIAL

Portable mini-break

A sheet metal bending tool for bending materials, such as flat metal sheets is disclosed. The tool has a restraining base for receiving and cooperatively holding a sheet metal workpiece and the tool has a bending component that is rotatably mounted to the restraining base, the workpiece is held, cooperating with the restraining base component, and the clamp bar for stabilizing the workpiece while the workpiece is held and bent by the rotating action of the bending component. In the preferred embodiment, the workpiece is restrained by a template comprising a pattern of holes drilled, a hole receiving a peg or means of stop, the stops (pegs) constraining the workpiece from movement while being bent act like a jig for measuring and predetermined incumbents. Holes are also drilled in restraining base and in the bending component at spaced intervals along lines that are run parallel to the line defined by the intersection of the bending component and the restraining base. There is a pull back bar that is used for the process of cutting. The Unit can be clamped down also. Rulers are installed on the clamp bar, and the slide table. The apparatus is designed so that two or more may be joined together to form a larger apparatus for the purpose of bending larger workpieces.

Owner:PERRUCCIO DANIEL

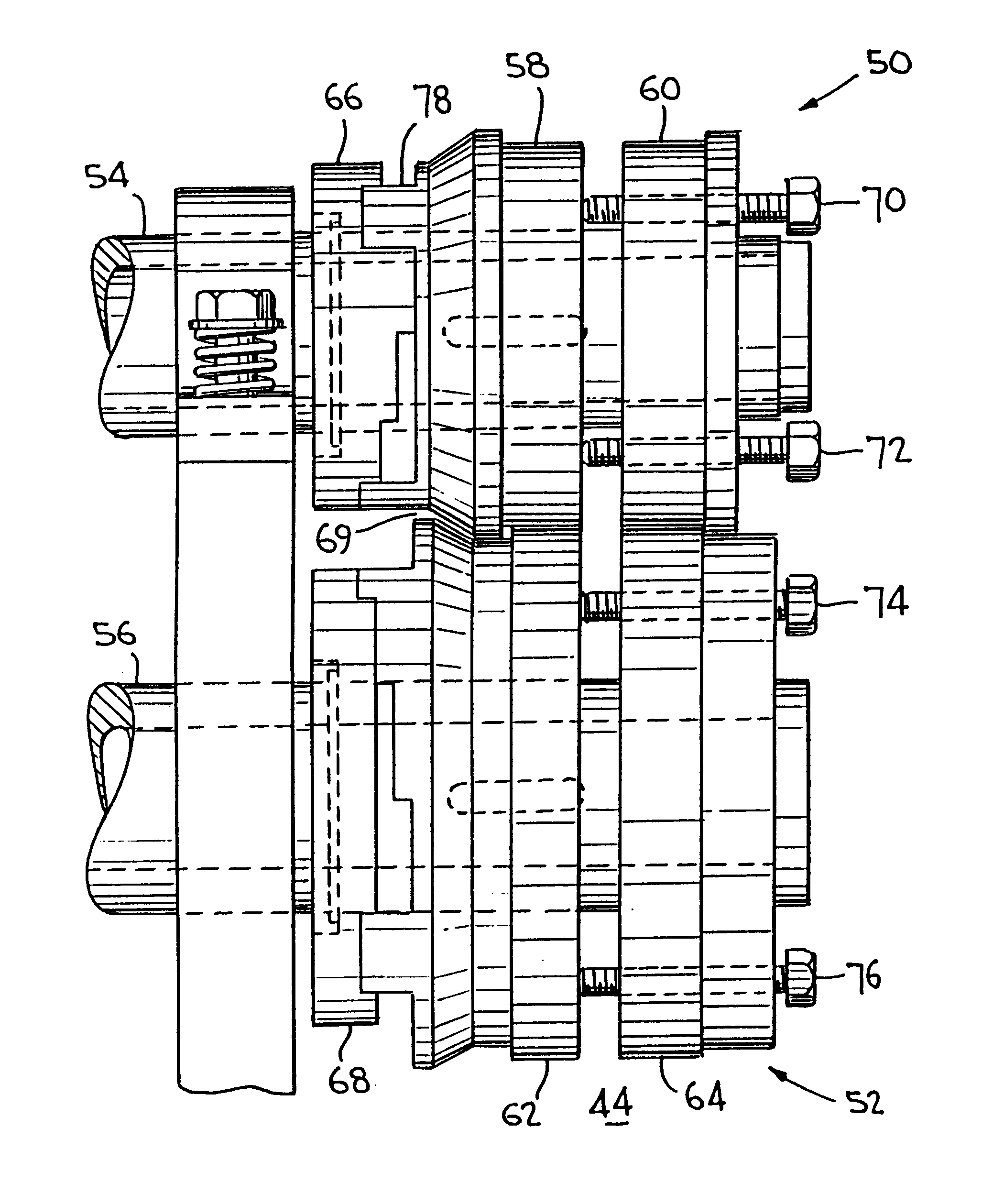

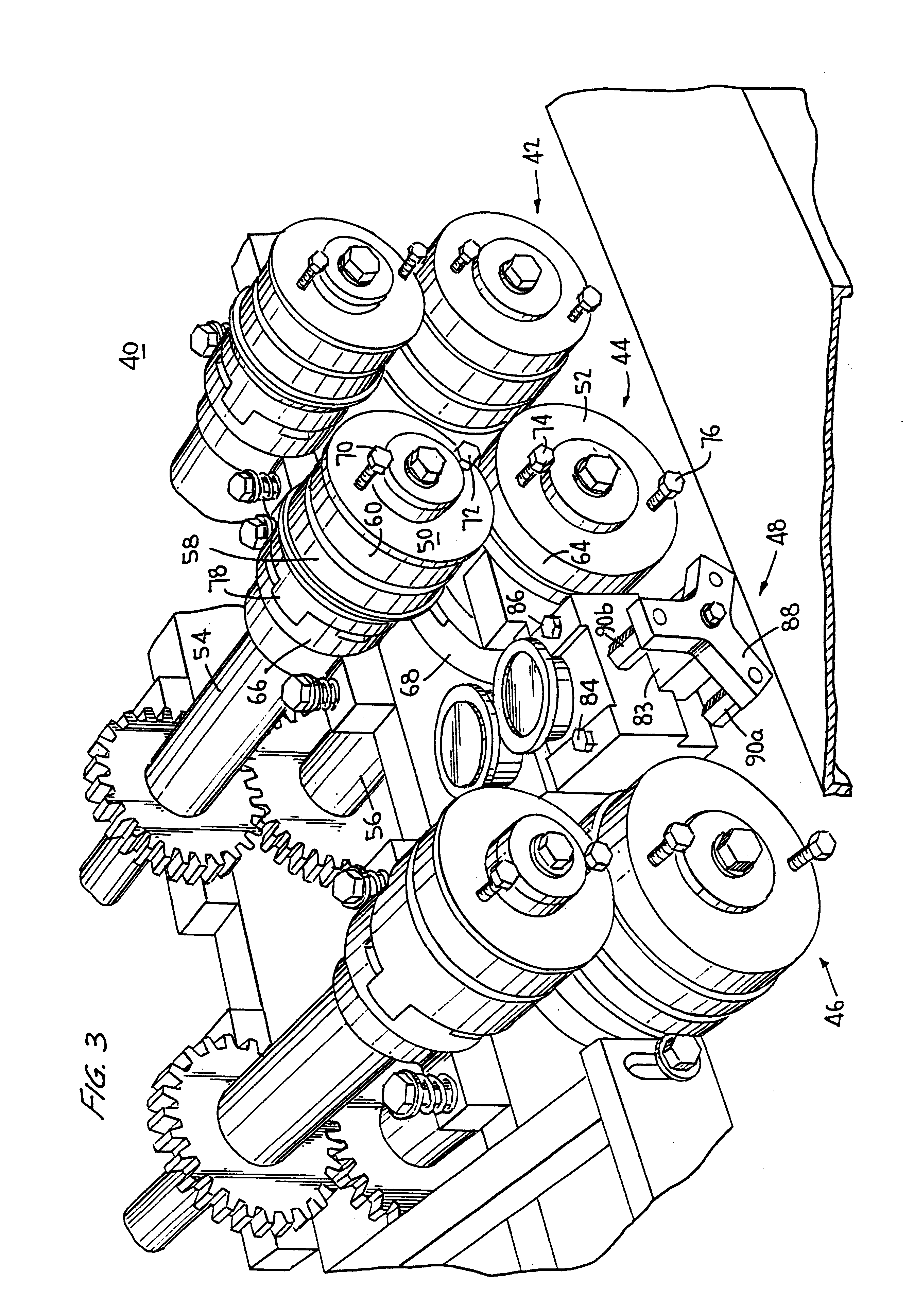

Sheet metal bending apparatus

InactiveUS6311534B1Avoid the needAdjustable positionMetal rolling stand detailsMetal rolling arrangementsRoll formingEngineering

A roll forming apparatus is provided having a plurality of roll forming stations arranged in an advancing path and having at least one roll forming station including adjustable top and bottom rolls. The adjustable forming rolls include separate inner and outer sections. The inner roll sections are adjustable transverse to the advancing path in order to shift the position of bend introduction to a workpiece. In a preferred embodiment, each inner roll section cooperates with a backing collar which has preset stops of different heights to quickly and precisely adjust the apparatus to predetermined settings. The apparatus is particularly useful for forming flanges on duct sections where duct sections having different flange heights are desired. The at least one adjustable roll forming station can be used to retrofit existing non-adjustable roll forming apparatus.

Owner:MET COIL SYST

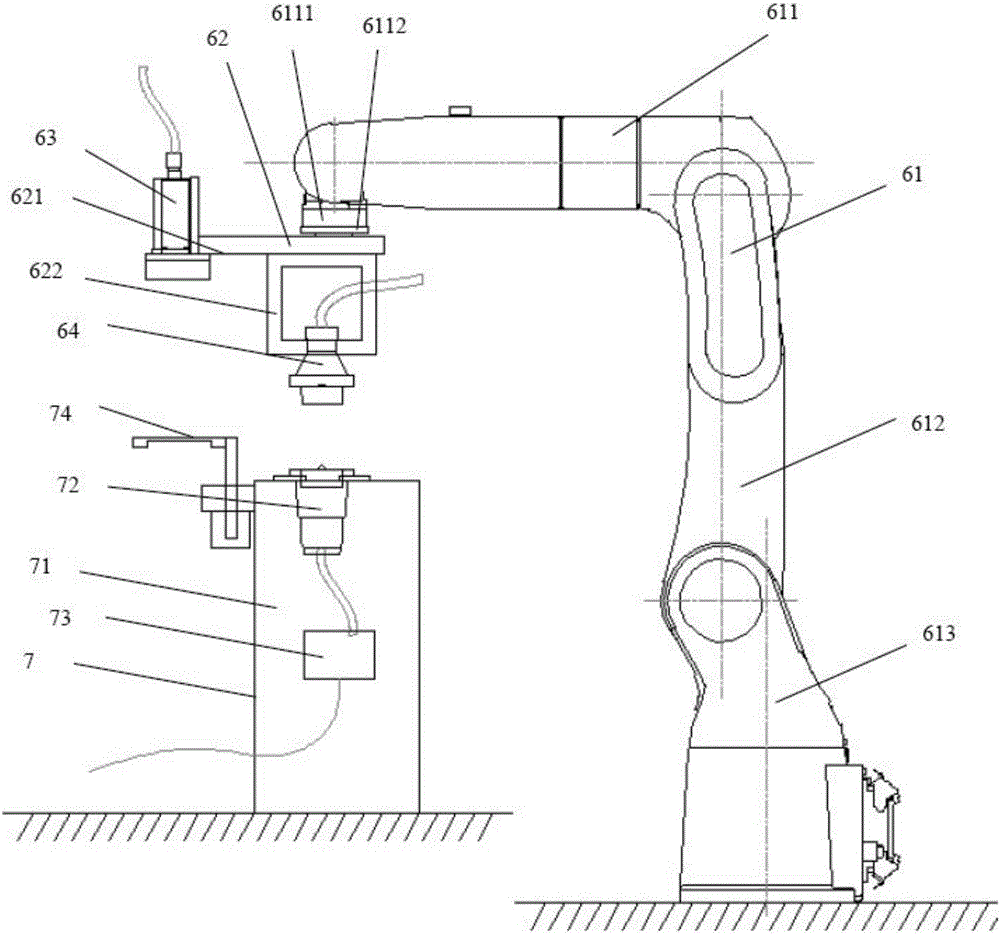

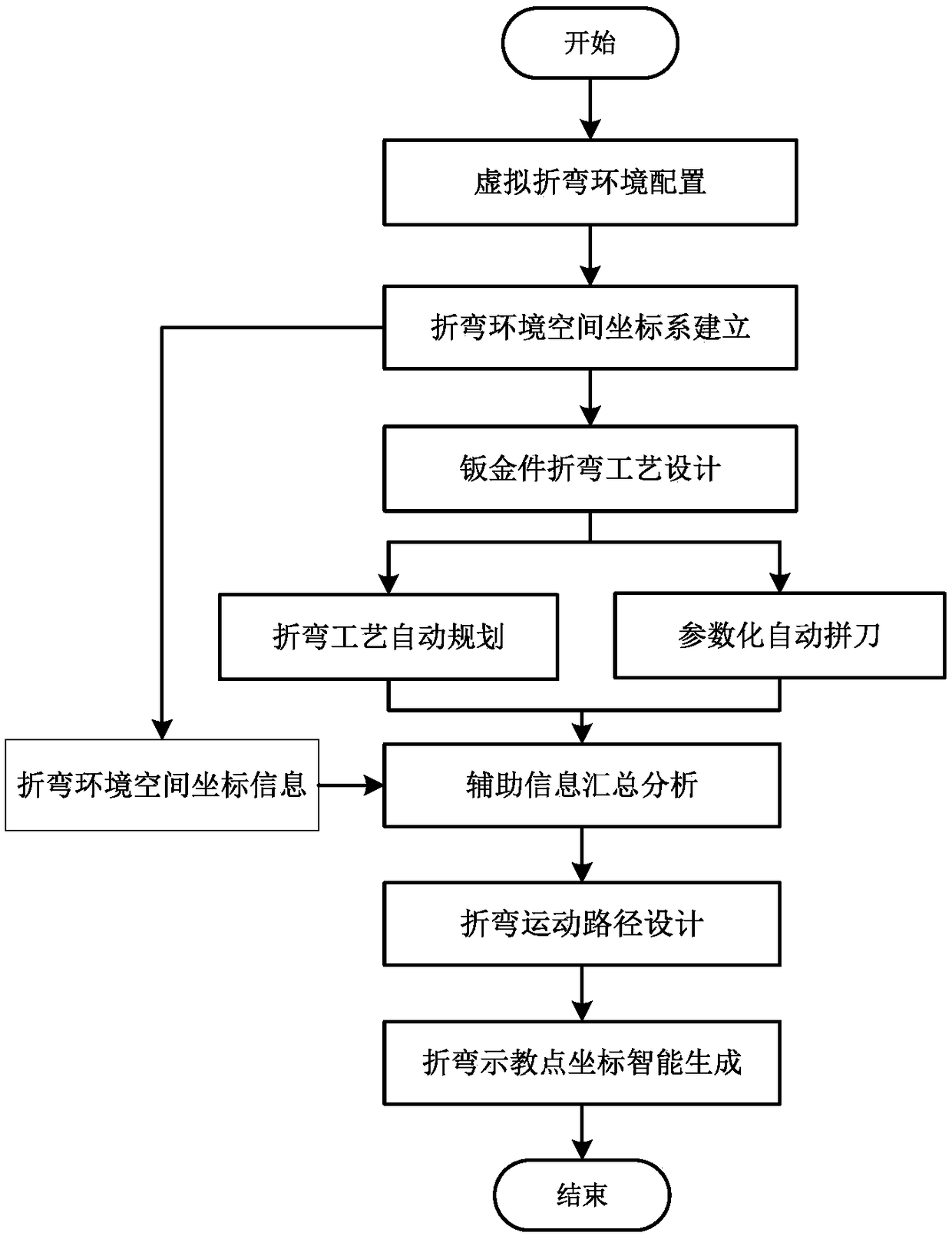

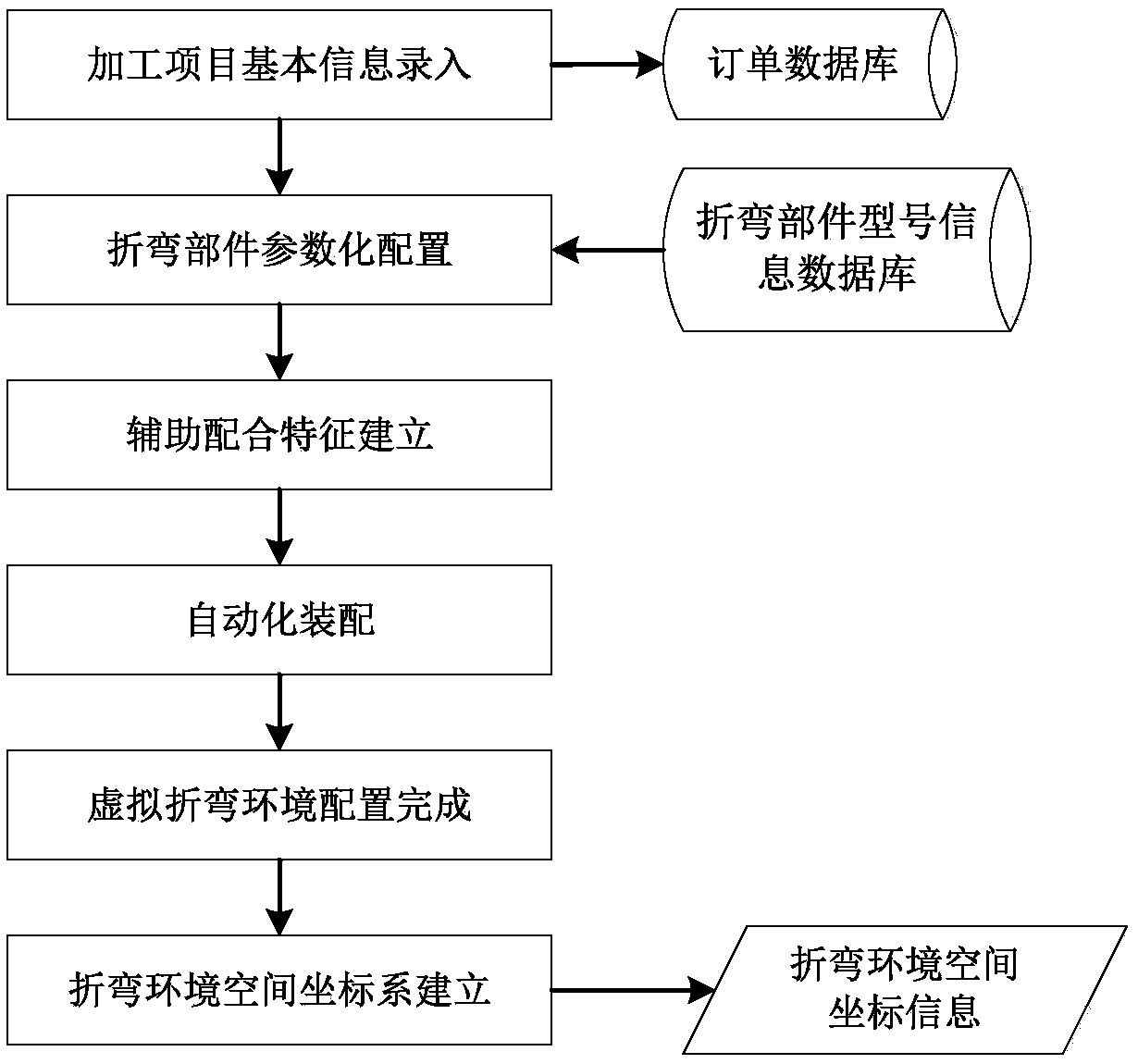

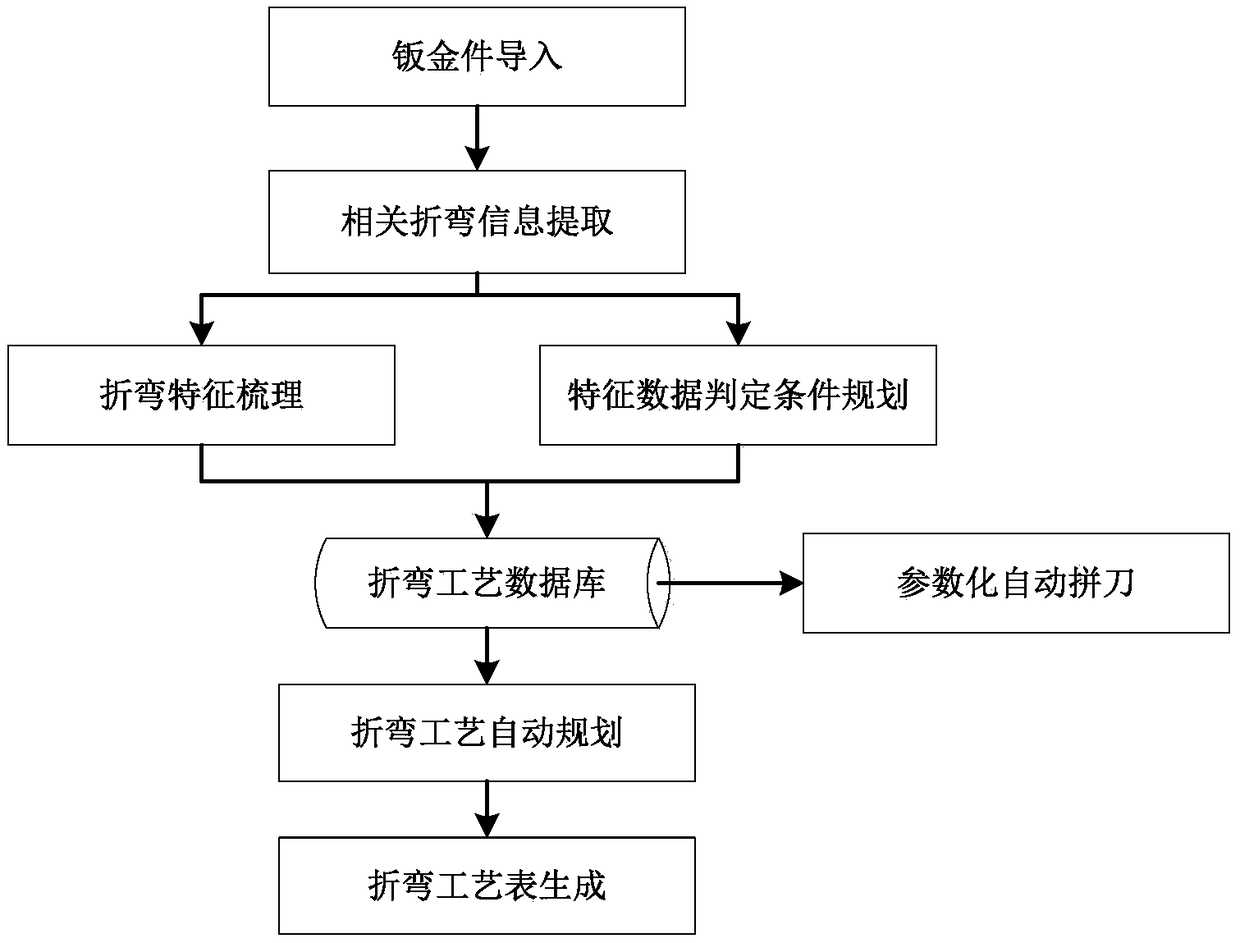

Method for intelligently generating coordinates of bending teaching points of sheet metal bending robot

ActiveCN109333521ARealize intelligent generationLow experience requirementProgramme-controlled manipulatorTotal factory controlDesign cycleSoftware engineering

The invention discloses a method for intelligently generating coordinates of bending teaching points of a sheet metal bending robot. The method includes the steps that first a virtual sheet metal bending machining environment which is the same as an actual machining environment is constructed by using parametric design and the automatic assembly technology; secondly, through the sheet metal part bending process planning technology, automatic acquisition of sheet metal part bending process information and automatic planning of a corresponding bending process are realized; then through the automatic tool assembly technology, automatic planning and tool assembly of a machine tool lower die bending tool are realized in the bending machining process; and finally, through the intelligent bendingmovement teaching point coordinate generation technology, intelligent generation of the bending teaching point coordinates of the sheet metal bending robot is realized. According to the method for intelligently generating the coordinates of the bending teaching points of the sheet metal bending robot, manual intervention in the sheet metal bending process is fundamentally reduced, the shortcomings of obtaining the bending teaching points by traditional manual online teaching are overcome, the design cycle of sheet metal bending machining is shortened, repetitive labor is avoided, and the product quality is guaranteed.

Owner:JIANGSU UNIV OF SCI & TECH

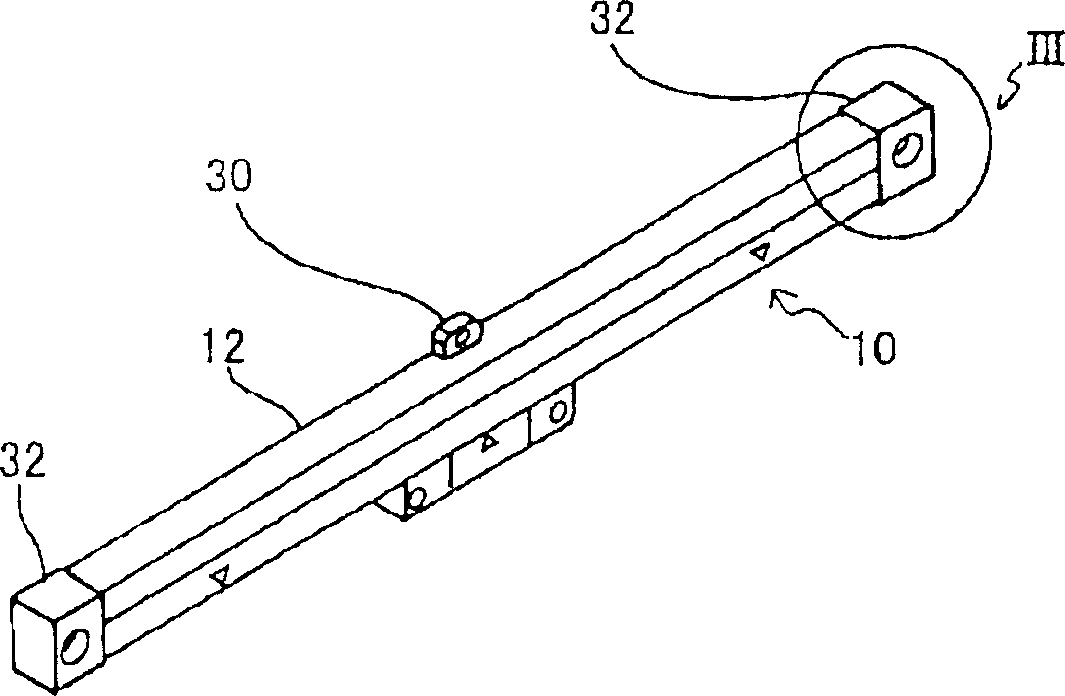

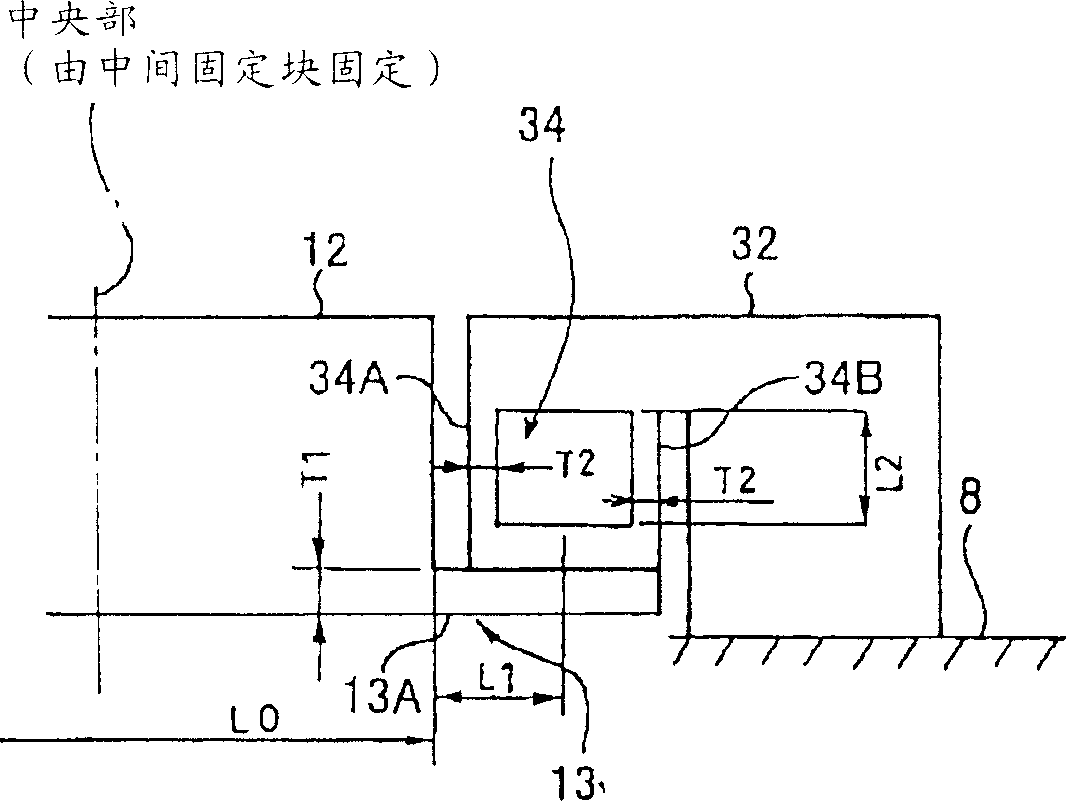

Elastic fixture and attachment method for length measuring apparatus

InactiveCN1724972AReduce sizeReduce restrictionsMeasurement apparatus componentsConverting sensor outputMeasurement deviceParallel plate

The invention provides a flexible fixing piece of a length measuring device, which is used to install the length measuring device on a device of different expansion coefficient to be measured and capable of flexible deforming in the lengthwise direction of the device to be measured. One end of the flexible fixing piece is fixed on the length measuring device, while the other end is fixed on the device to be measured, and the flexible fixing piece is provided with a sheet metal bending beam. Therefore, the restrictions on the size and accuracy of processing are fewer, and the device is easily manufactured, and can be used in more stringent environmental temperatures like hand operating mechanism, etc. Compared with the parallel plate spring mechanism, the device is smaller and has lower price.

Owner:MITUTOYO CORP

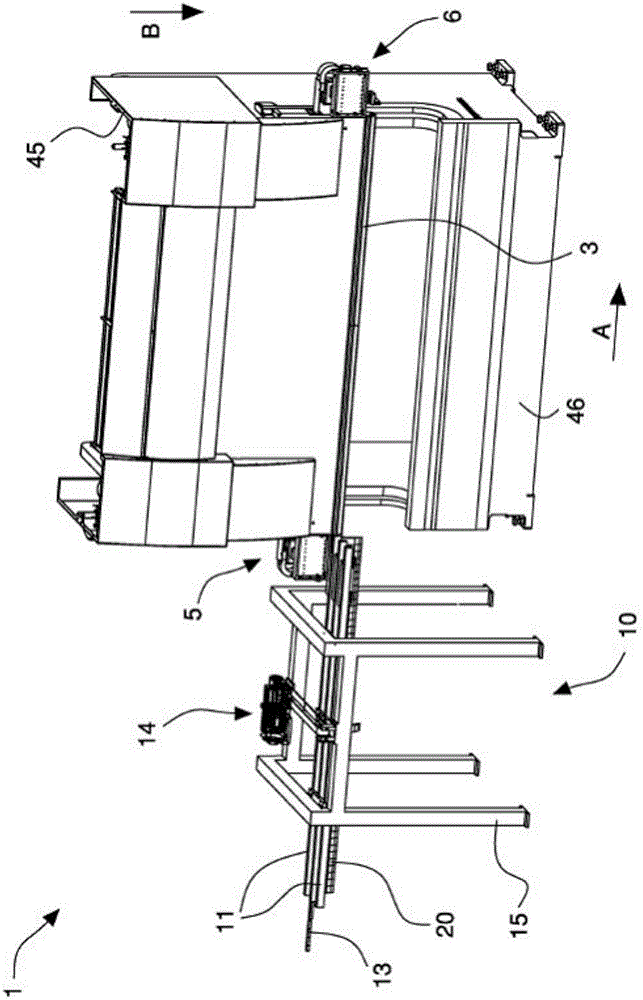

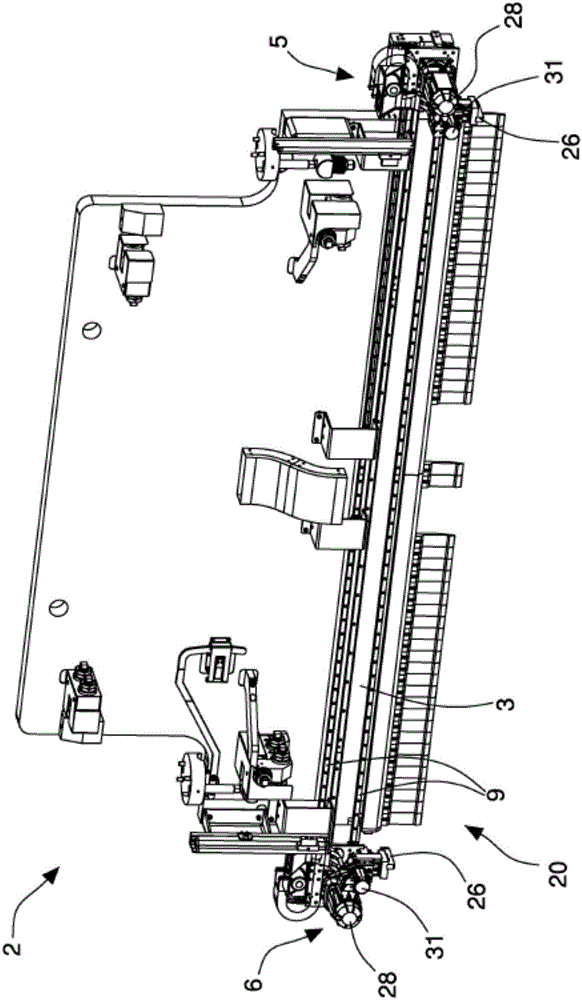

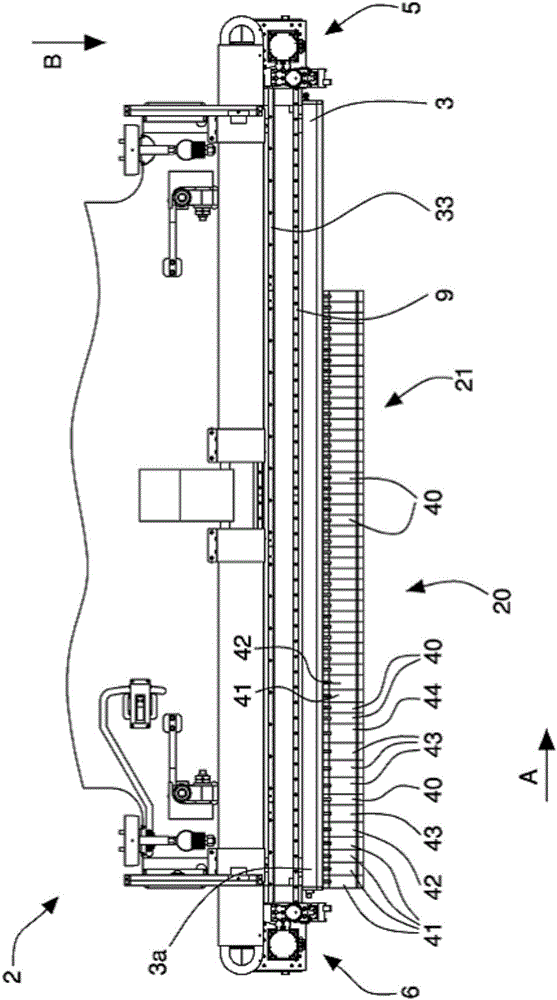

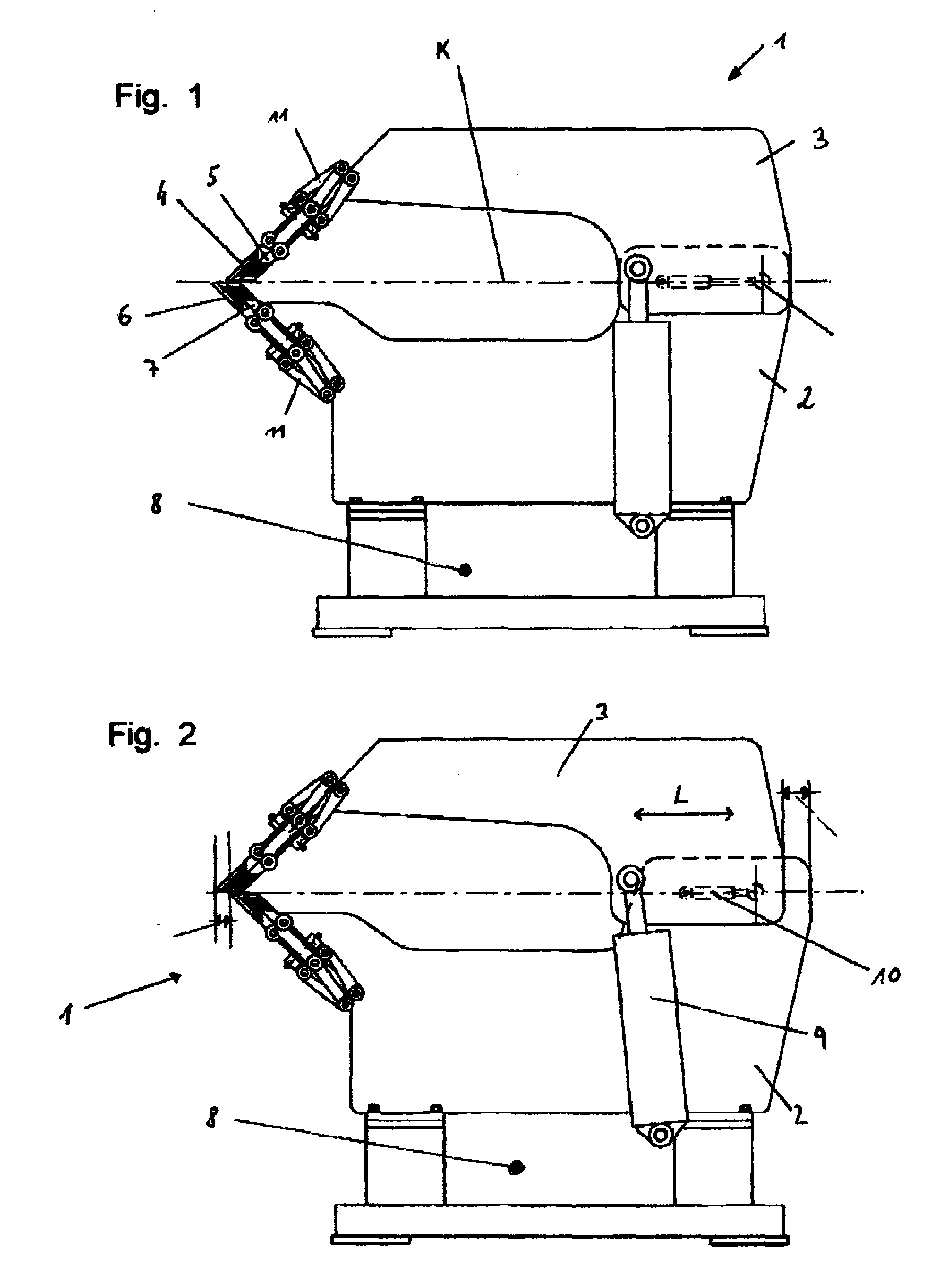

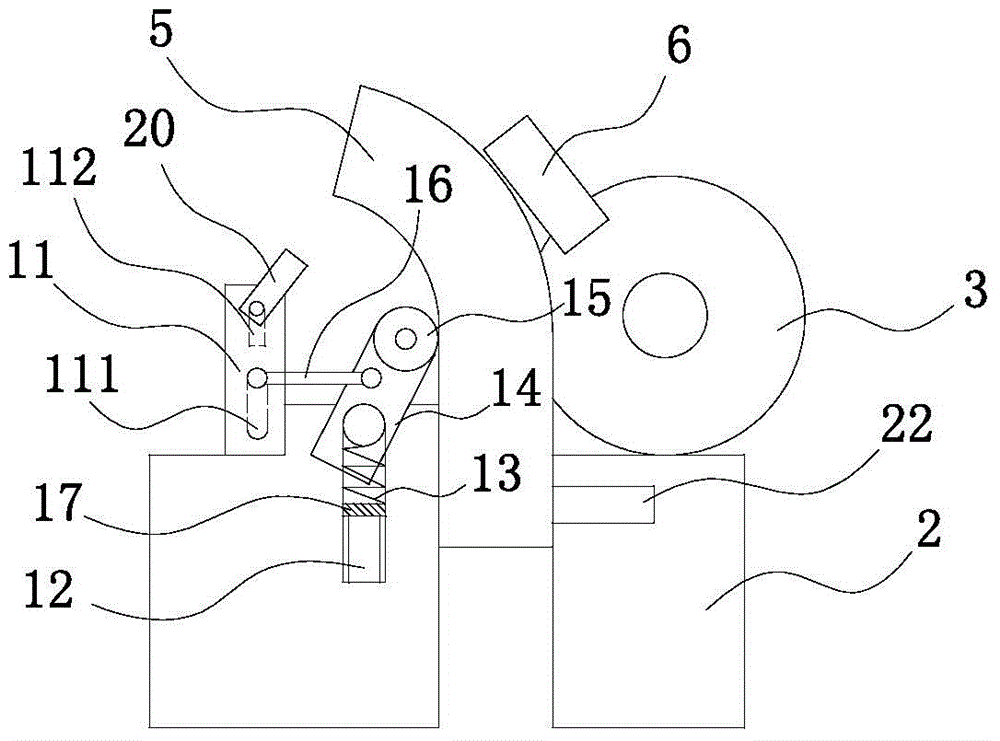

Sheet metal bending machine

ActiveCN105992658AAvoid replacementDoes not increase cycle durationShaping toolsForging/hammering/pressing machinesEngineeringMetal

A bending machine for sheet metal comprises a bending assembly (2) provided with a tool holder crosspiece (3) which is mobile and supports a set (20) of bending tools (40, 41, 42, 43, 44) which are aligned, and mutually positionable, along a first longitudinal direction (A) so as to form predetermined compositions (CI, C2, C3, C4) of bending tools suitable to bend a workpiece (50) according to respective defined bending lines; the bending assembly (2) comprises moving means (5, 6) to move the bending tools (40, 41, 42, 43, 44) along the crosspiece (3), the set (20) of bending tools comprises, arranged adjacent and in sequence starting from an end (3a) of said crosspiece (3): four first bending tools (41) having a width of X+ p, one second bending tool (42) having a width of X+2-p, one third bending tool (43) having a width of X+3-p, one basic bending tool (40) having a width of X, three third bending tools (43), one fourth bending tool (44) having a width of X+4-p, two basic bending tools (40), one first bending tool (41), one second bending tool (42), a further set (21) of basic bending tools (40), wherein X is a basic width in mm of said basic bending tool (40) comprised between 30 and 70 mm, and p is a step between two lengths of subsequent tool compositions (CI, C2, C3, C4), comprised between 5 and 20 mm; the combination of one or adjacent more tools (40, 41, 42, 43, 44) of said set (20) of bending tools allowing obtaining bends having all the lengths starting from a minimum bending length equal to said basic width (X) with said step (p).

Owner:SALVAGNINI ITAL

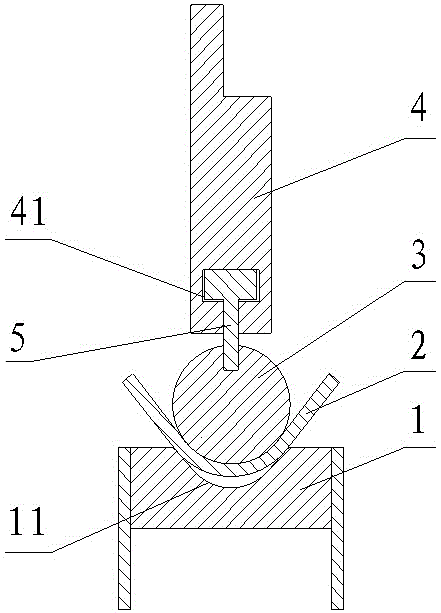

Sheet metal processing method for conical pipe

The invention discloses a sheet metal processing method for a conical pipe. The sheet metal processing method for the conical pipe comprises a to-be-processed workpiece and further comprises a bottom die, wherein the bottom die is mounted on an externally connected sheet metal bending machine; a tool holder capable of moving up and down and a pressure head connected with the tool holder are arranged above the bottom die respectively; the workpiece is placed on the bottom die; and the pressure head is arranged over against the bottom die and presses downwards the workpiece through the tool holder. According to the sheet metal processing method for the conical pipe, the bottom die of the sheet metal bending machine and the tool holder connected with the pressure head are used in a matching manner, so as to provide convenience for processing the workpiece and reduce the intensity of manual manufacture. Meanwhile, a welding procedure for manufacturing the workpiece is omitted, so as to improve the attractiveness of the workpiece and eliminate potential safety hazards caused by welding in manual manufacture. Moreover, compared with the manual manufacture, the method effectively improves the accuracy of the workpiece by the use of the bottom die of the sheet metal bending machine and the tool holder connected with the pressure head.

Owner:SHANGHAI QIYUAN GAS DEV

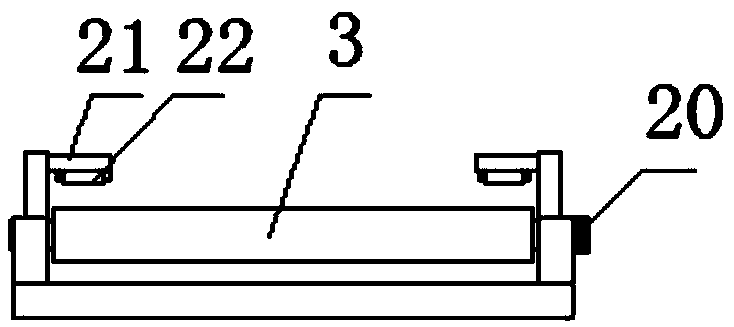

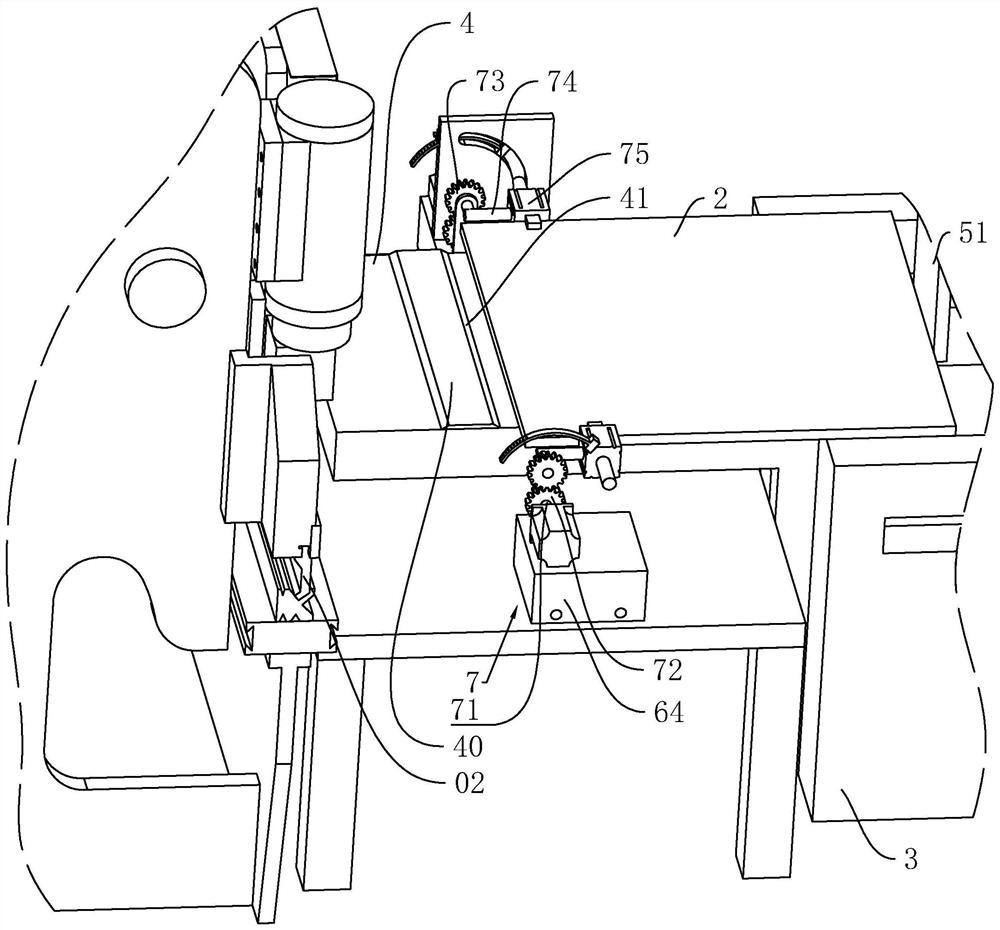

Feeding device applied to sheet metal bending machine

ActiveCN111618196AImprove work efficiencyReduce workloadMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a feeding device applied to a sheet metal bending machine, and relates to an auxiliary device of the sheet metal bending machine. The device aims to solve the technical problemof manual feeding by workers in the prior art. The device comprise a rack, a stacking box and a receiving table arranged close to one side of a workbench, the rack is provided with a drive part usedfor moving sheet metals on the stacking box to one side of the receiving table, a power assembly is arranged on the rack, the power assembly is provided with a clamping part used for clamping the sheet metals; and when the sheet metals need to be processed, the sheet metals are stacked in the stacking box, the stacking box outputs the sheet metals one by one, the drive part is used for moving thesheet metals from the stacking box to the receiving table, then the clamping part is used for clamping the sheet metals, the power assembly drives the clamping part and the sheet metals to move a position below a processing plate, the sheet metal bending machine can smoothly process the sheet metals, a manual feeding method of the workers can be replaced, the work efficiency is improved, and the work burden is reduced.

Owner:杭州富阳海翔机械有限公司

Manufacturing method of metal composite plate

InactiveCN107199441AGuaranteed bonding strengthGuaranteed mechanical propertiesPolyurethane adhesiveComposite plate

The invention discloses a method for manufacturing a metal composite panel. The manufacturing method includes the following steps: taking out the upper metal sheet and the lower metal sheet, cutting and blanking, and processing to obtain the upper sheet metal and the lower sheet metal with at least three bending edges. Sheet metal parts; bonding the PVC film suitable for the upper sheet metal part and the lower sheet metal part, folding the PVC film on the bending edge inward; evenly coating polyurethane adhesive, heating and rolling to form a composite Sheet metal parts; secondary bending and forming of composite sheet metal parts; drilling of bent parts with auxiliary processing parts; drilling holes in the auxiliary processing piece and the area to be drilled with a drill bit; The bent piece is cured and cured to obtain a metal composite panel. The metal composite board of the present invention guarantees excellent bonding strength and mechanical properties, is firm and stable, is smooth polished, is convenient to process, saves costs, is suitable for large-scale production, and can be widely used in building curtain walls, interior decoration, light industry manufacturing, furniture manufacturing, etc. field.

Owner:HEFEI HUIZHI NEW MACHINERY TECH CO LTD

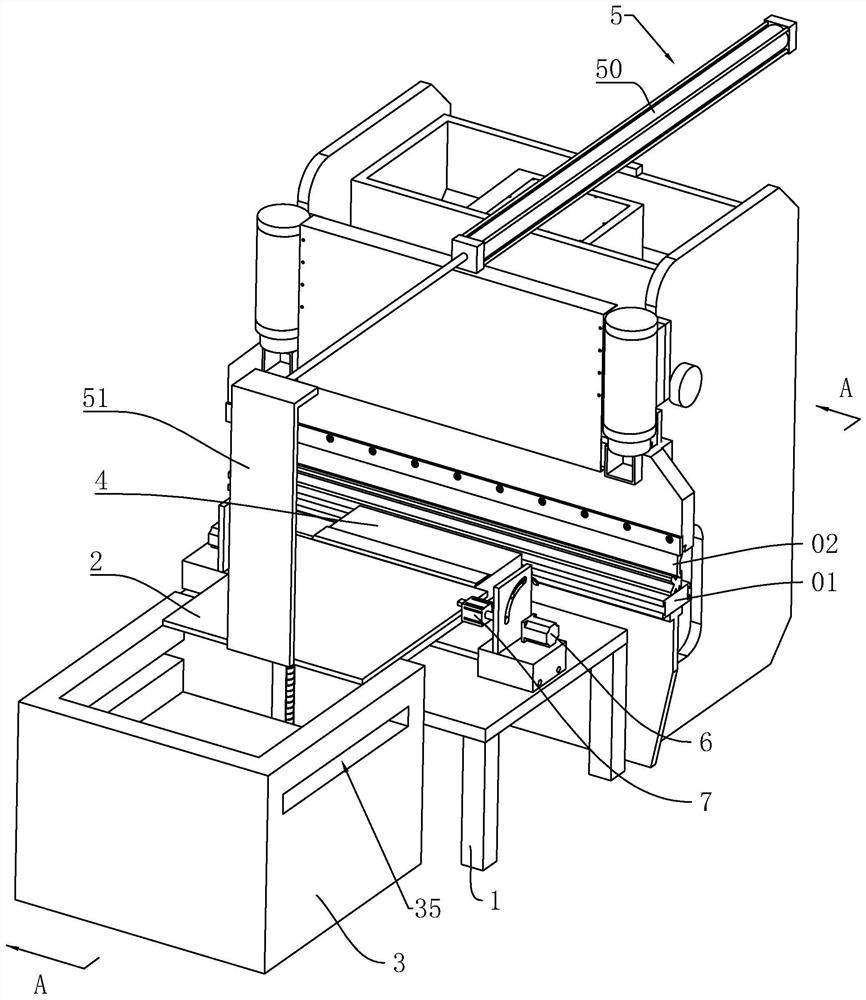

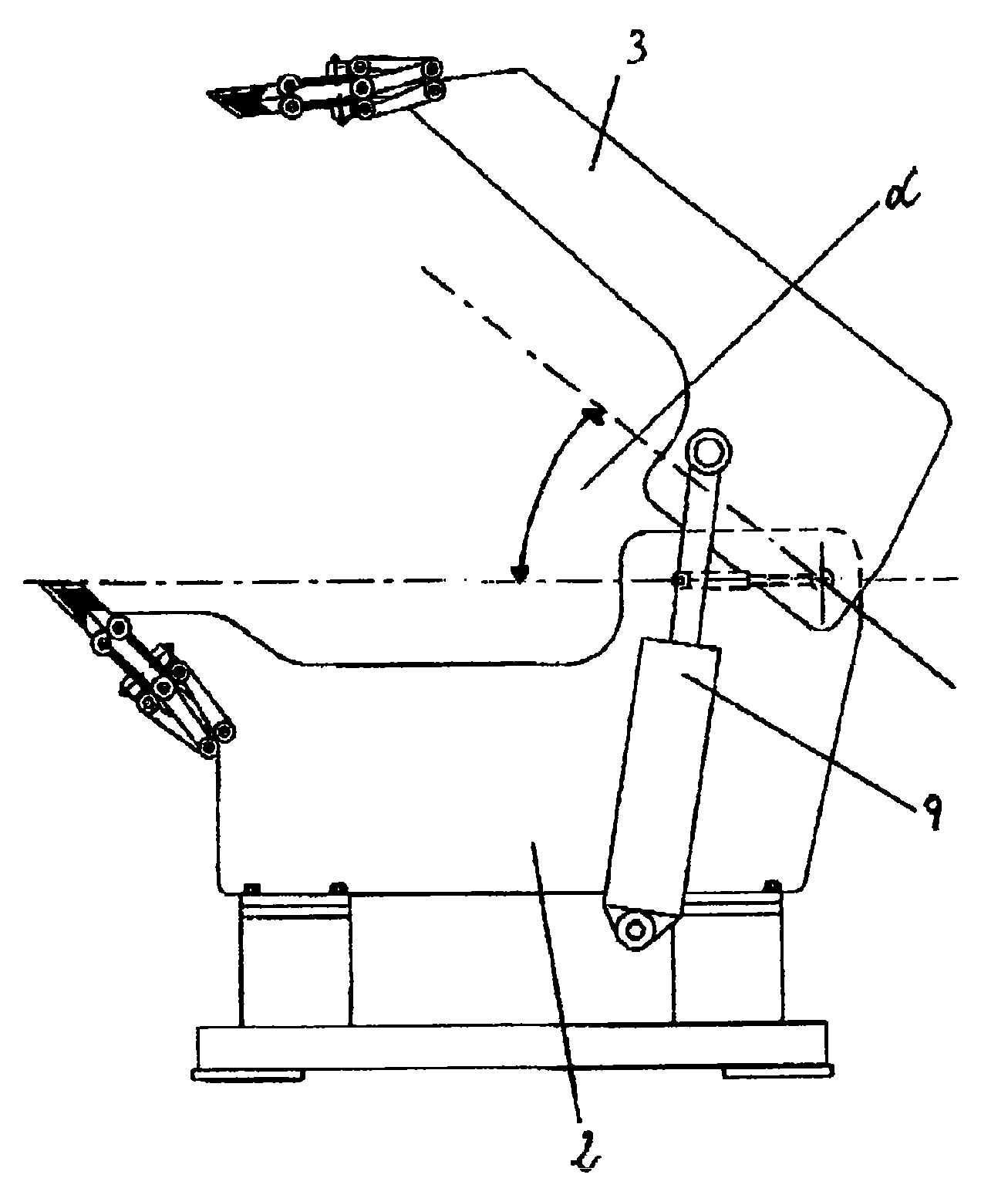

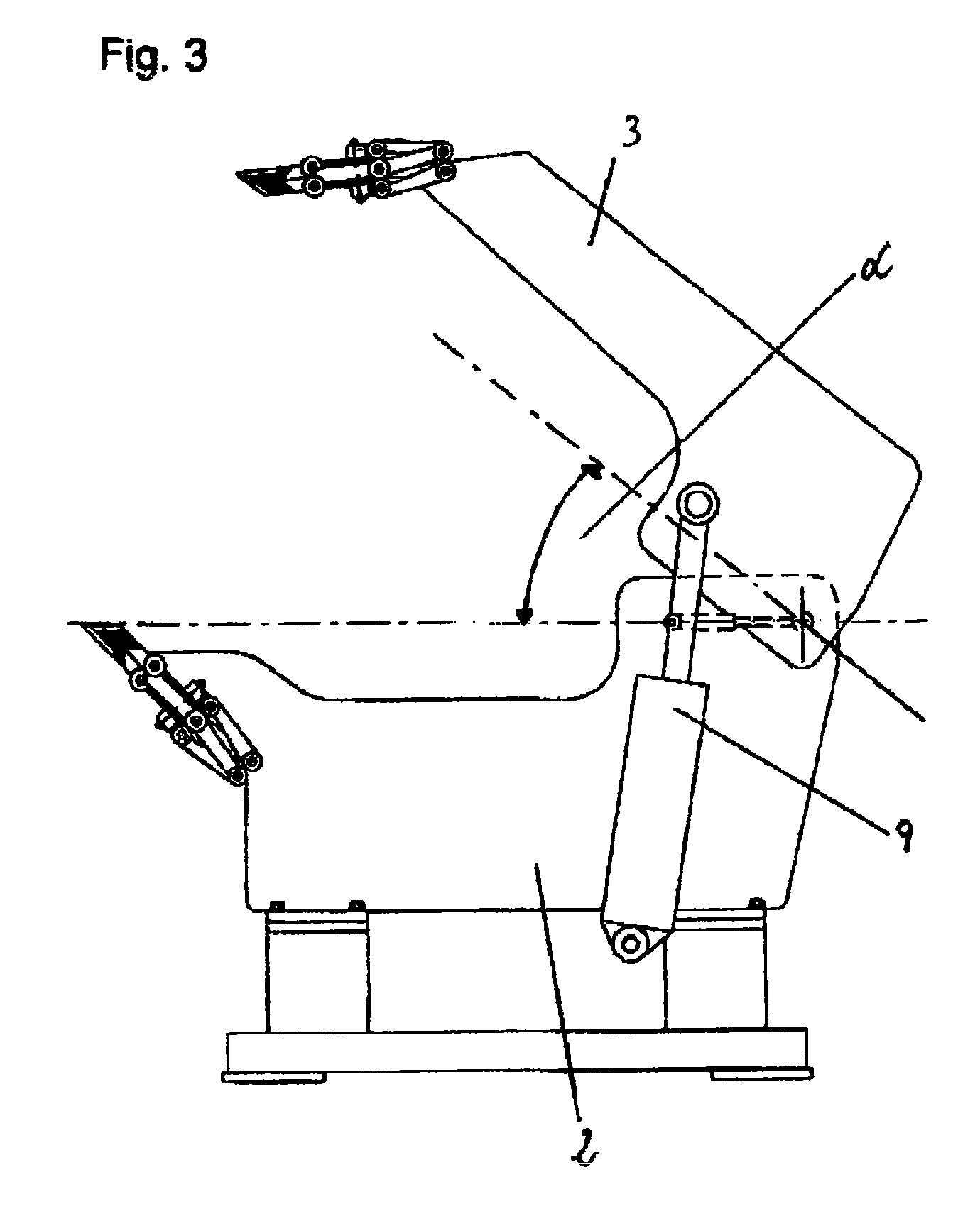

Sheet-metal bending machine, preferentially hydro-powered machine, and a method of its operation

ActiveUS20090013748A1Wide range of anglesGood handling of sheetShaping toolsForging/hammering/pressing machinesEngineeringMetal sheet

The invention deals with a sheet-metal bending machine containing a lower machine part and an upper machine part mounted on it in a movable way where on either of the upper and lower machine part there is a pair of working tools designed as a bending arm and a holding arm where the principle is that the upper machine part (3), or at least the pair of the working tools connected to it, is, in relation to the lower machine part (2), or at least in relation to the pair of the working tools connected to it in the feeding direction (L) of the processed metal sheet (14), mounted in a mutually horizontally sliding bond.

Owner:HIRSCHEWALD LLC +1

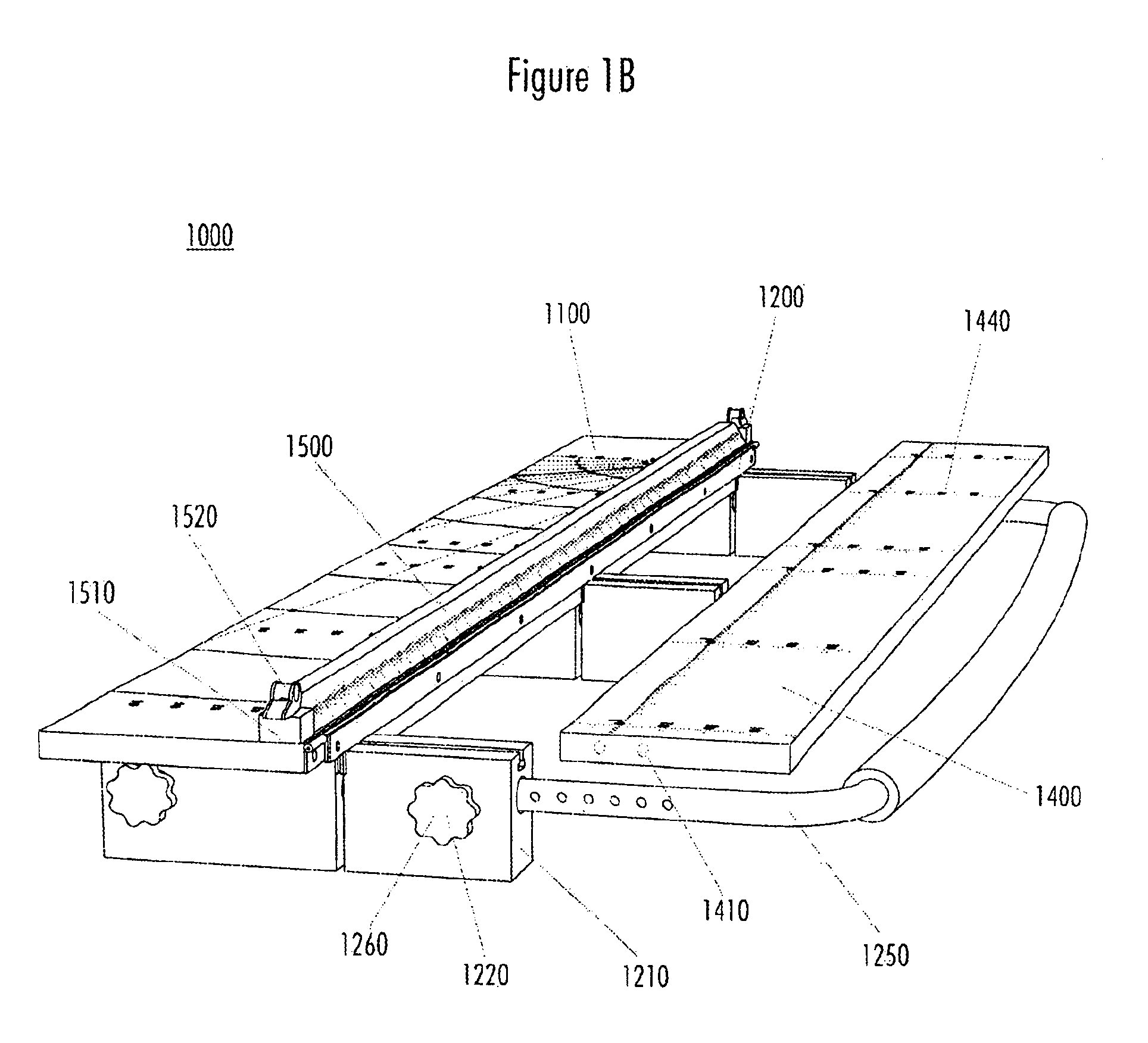

Sheet metal bending brake

A sheet metal bending brake having a frame with a planar work supporting surface and a plurality of spaced frame members extending over the work support surface. Each frame member has a throughbore and these throughbores are aligned with each other. A plurality of elongated pivot arms are pivotally secured at one end to the frame for movement toward and away from the work supporting surface. Each pivot arm also includes a generally rectangular opening aligned with the frame member throughbores. A block is longitudinally slidably mounted in each pivot arm opening and this slide block is constrained against movement in a direction perpendicular to the work support surface. Each block furthermore includes a trapezoidal opening with spaced apart and parallel top and bottom surfaces and outwardly flared side surfaces. An elongated shaft extends through and is rotatably mounted to the frame member throughbores and this shaft also extends through the trapezoidal openings in the pivot arms. A plurality of eccentric cams are secured to the shaft so that one cam is associated with and positioned within each trapezoidal opening. This cam is dimensioned so that the cam contacts the outwardly flared side surfaces of its associated slide block regardless of the rotational position. Pivotal movement of the shaft thus displaces the pivot arms in a direction generally perpendicular to the work support surface due to the coaction of the eccentric cams with the side surfaces of the slide blocks.

Owner:BREAK DOUGLAS G

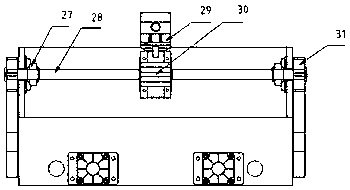

Fully automatic solar barrel processing machine

InactiveCN102259140AReduce manufacturing costOvercome disadvantagesMetal-working feeding devicesPositioning devicesLeaking waterButt joint

The invention discloses a full-automatic external solar energy barrel processing machine which is jointed into a cylinder shape after a sheet metal is bent. The full-automatic external solar energy barrel processing machine comprises a rack, wherein one end of the rack is provided with a main sheet metal supplying device; the other end of the rack is provided with an assistant sheet metal supplying device; the rack on the stroke tail ends of the main sheet metal supplying device and the assistant sheet metal supplying device is provided with a sheet metal bending device; the rack above the sheet metal bending device is provided with a sheet metal edge folding device and a sheet metal butt joint pressing device; and the rack is also provided with an automatic barrel discharging device. According to the full-automatic external solar energy barrel processing machine, the defect of the traditional external barrel processing equipment is overcome, and the processing machine is flow operation equipment integrating the steps of splicing sheet metals, blank pressing for coiling barrels and jointing a cylinder. The machining process is free from drilling and is not provided with rivets, and a joining seam is free from leaking water. The full-automatic external solar energy barrel processing machine has the advantages of high degree of automation, high machining precision and low external barrel production cost in batches and is simple to operate and use.

Owner:日照光慧机械设备有限公司

Illuminating device and projector device

Owner:NIKON CORP

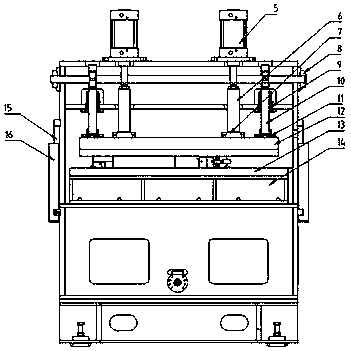

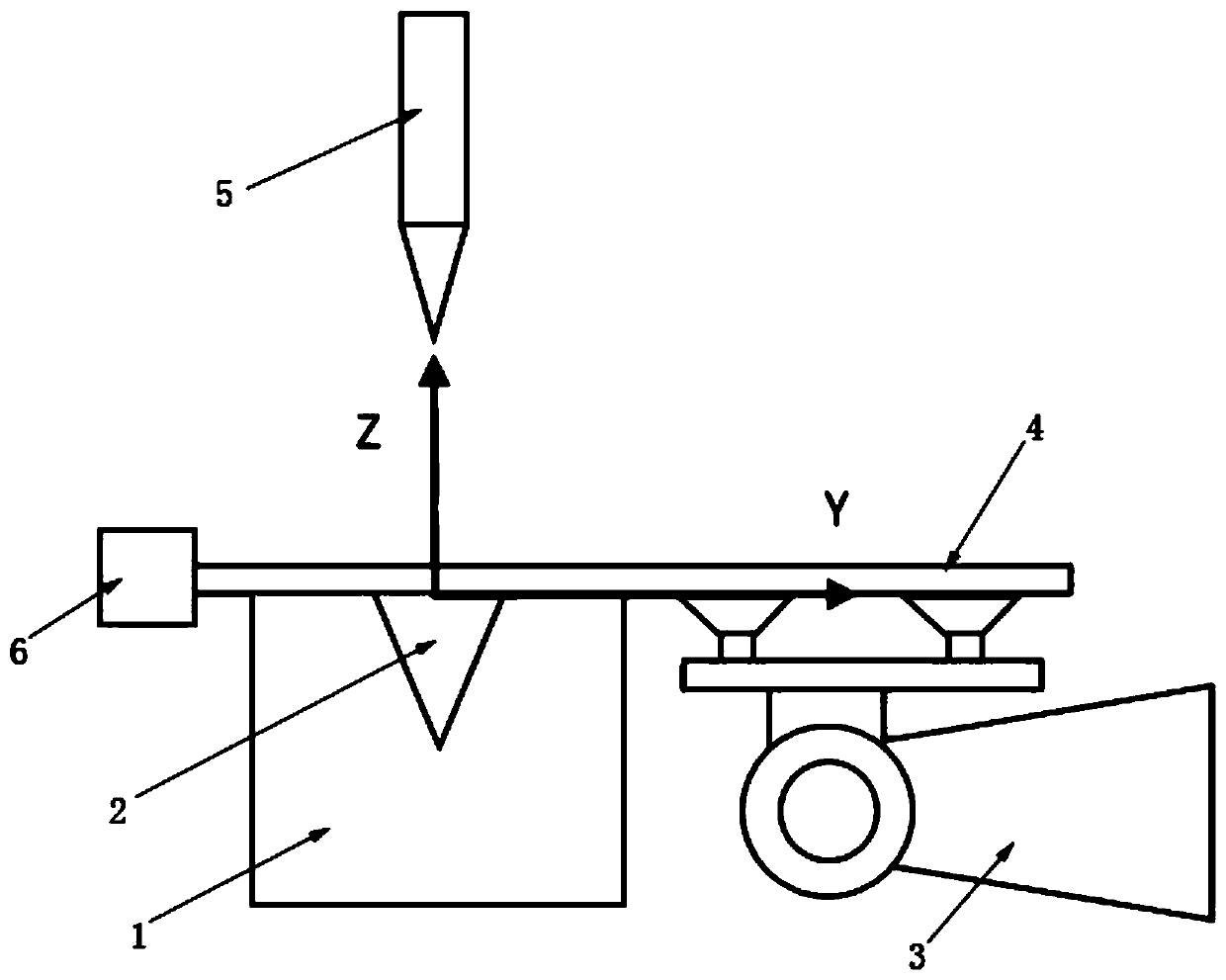

Sheet metal bending system and method based on clamping controlling and staged bending

InactiveCN104942084AAvoid influenceEfficient removalMetal-working feeding devicesBurnishing machinesEngineeringDrive motor

The invention relates to a sheet metal bending system and method based on clamping controlling and staged bending. The sheet metal bending system comprises a driving motor, a clamping fixing seat and a host which are installed on a rack, the driving motor is provided with a bending shaft, and a work piece is arranged on the clamping fixing seat; the sheet metal bending system further comprises an ultrasonic wave thickness detector, an ultrasonic wave crack detector, pressure sensors, a roller and a controller which is connected with the host; the ultrasonic wave thickness detector, the ultrasonic wave crack detector and the pressure sensors are connected with the host through a DSP data processing module. According to the sheet metal bending system and method, through the combination of staged type bending and feedback controlling, the crack number is greatly decreased, and the machining quality is improved; the roller is arranged to perform extrusion friction on the inner concave face of the work piece, protrusive burrs and cracks are effectively removed, the subsequent machining process is omitted, and the machining cycle is shortened; the camping pressure is controlled by the pressure sensors, and therefore sheet metal deformation or disengagement is avoided, and the machining reliability is improved.

Owner:SUZHOU BIANTONG SENSING TECH

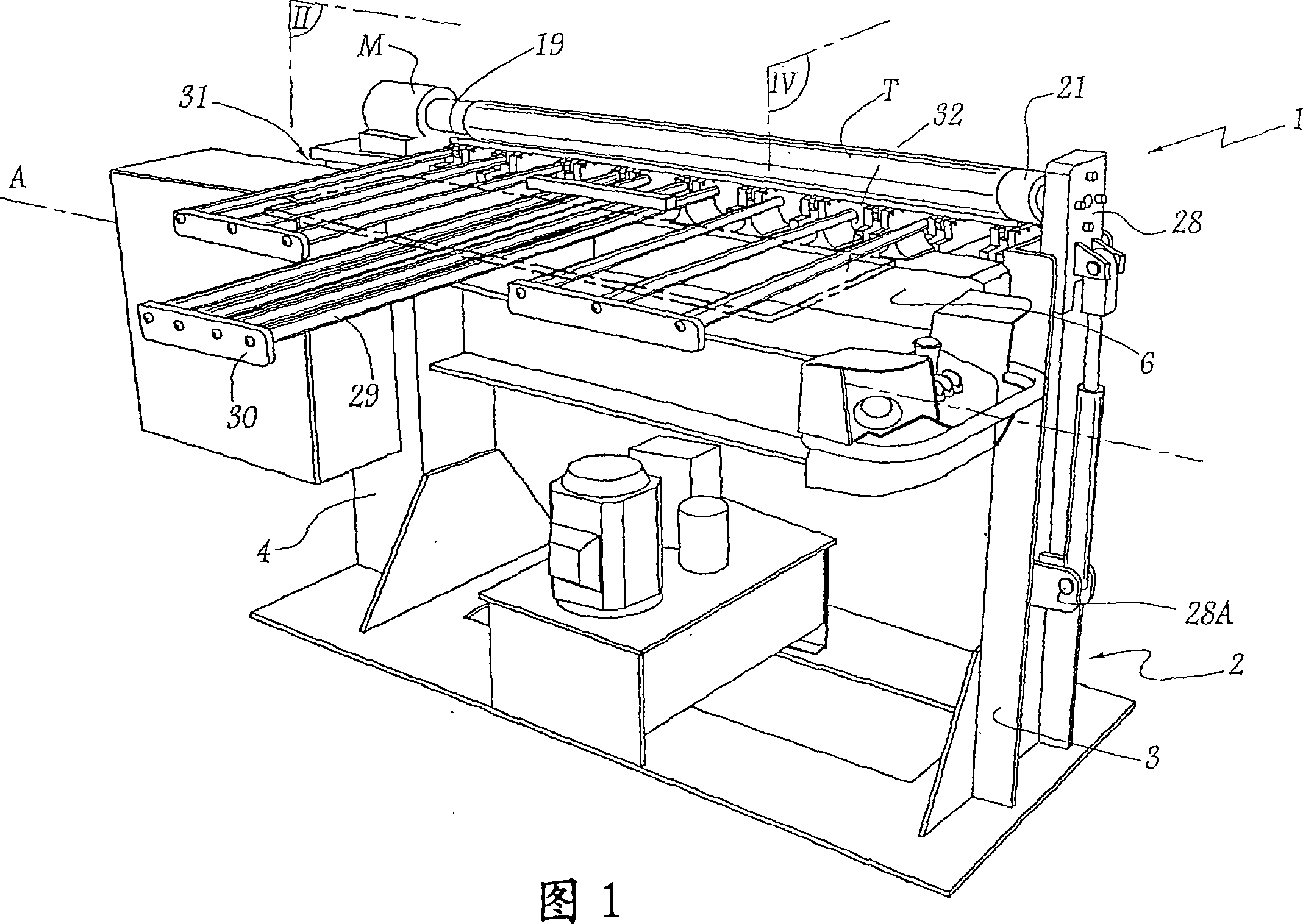

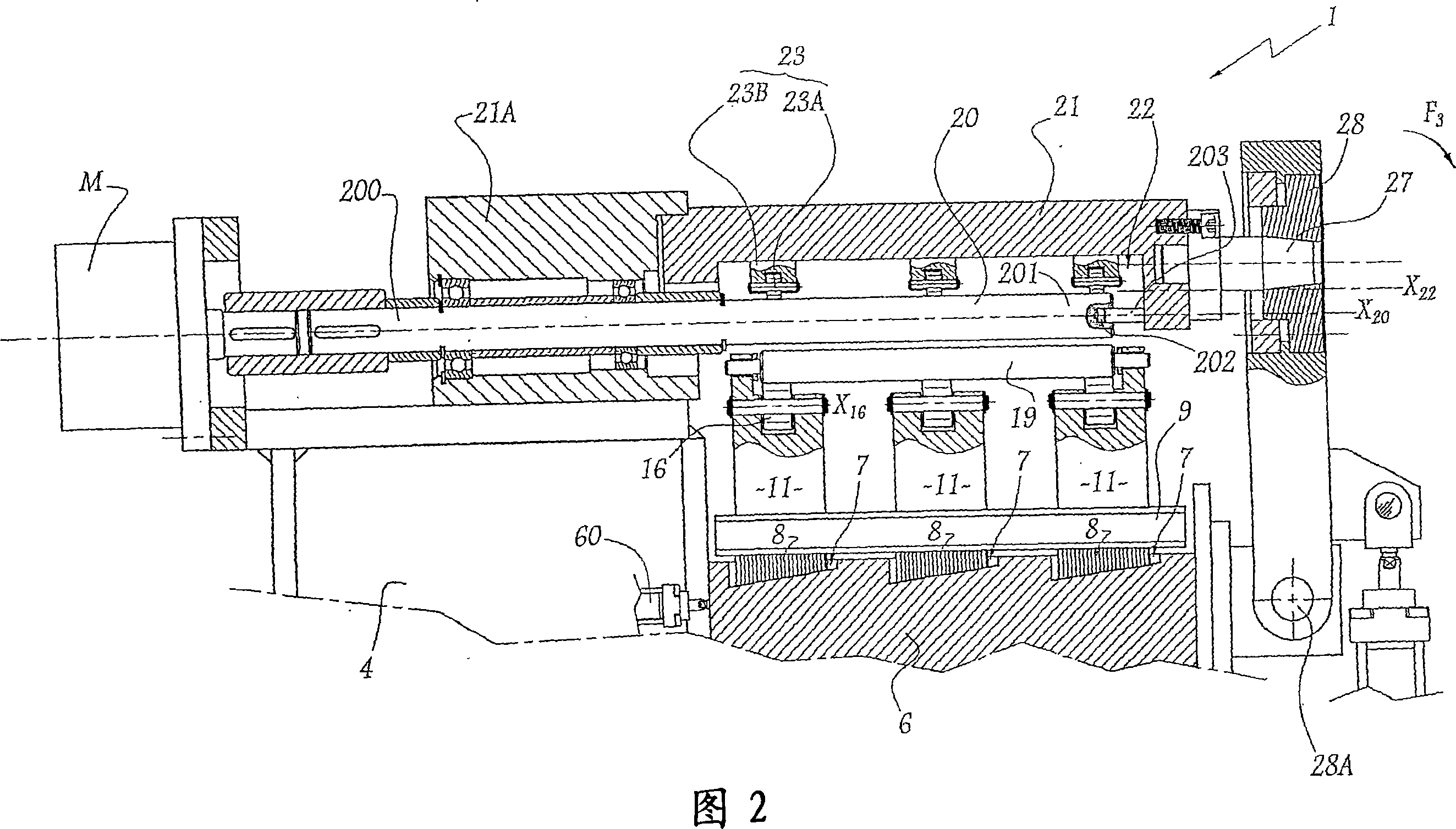

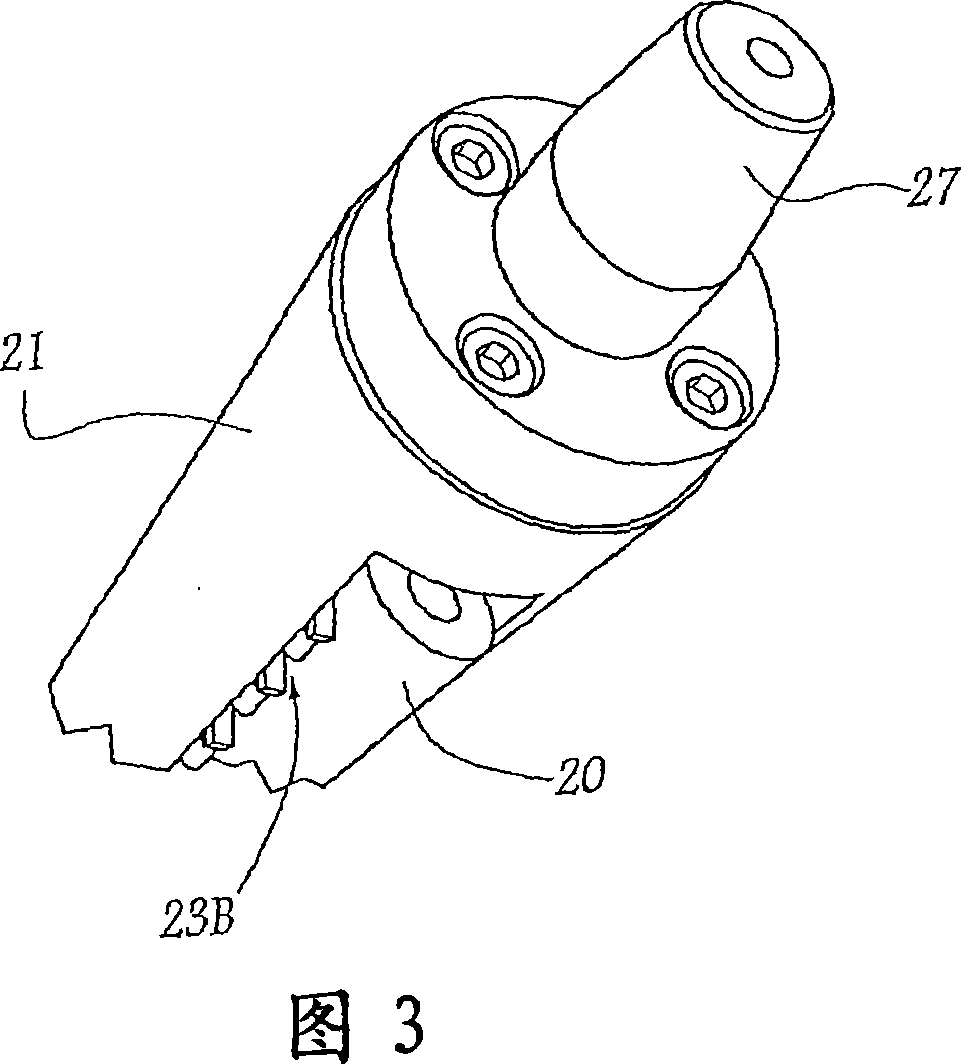

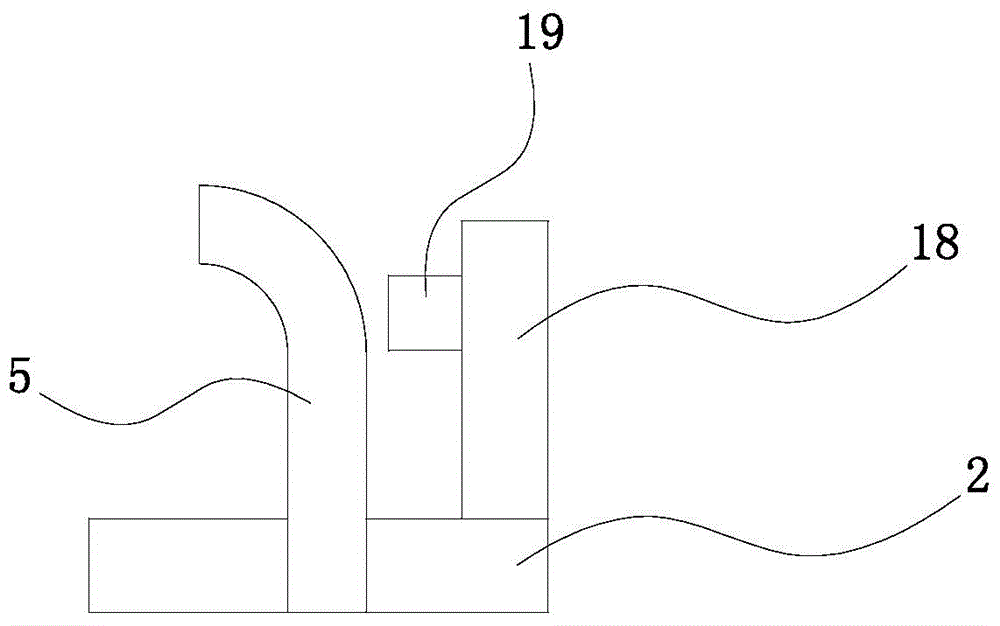

Sheet metal bending machine and production line incorporating a machine of this type

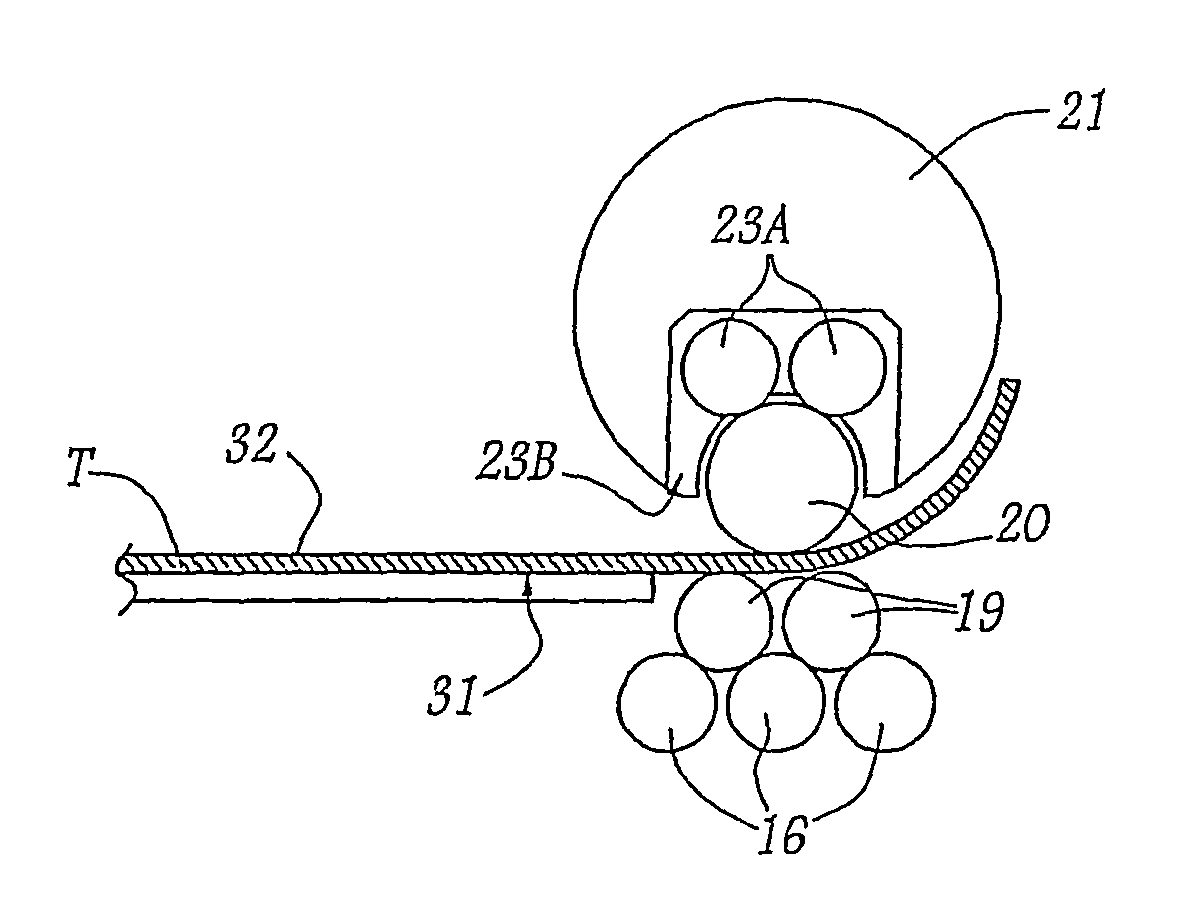

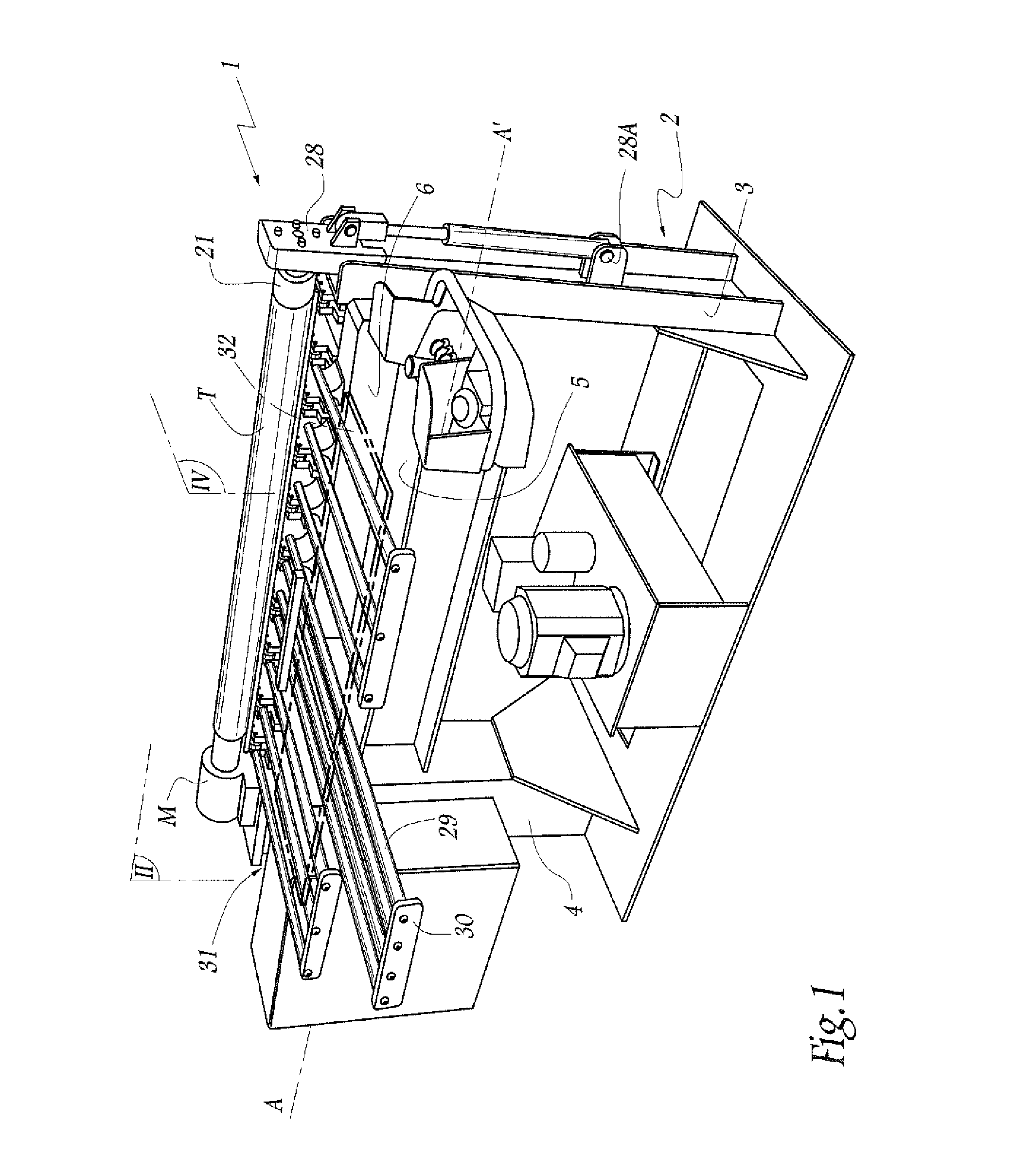

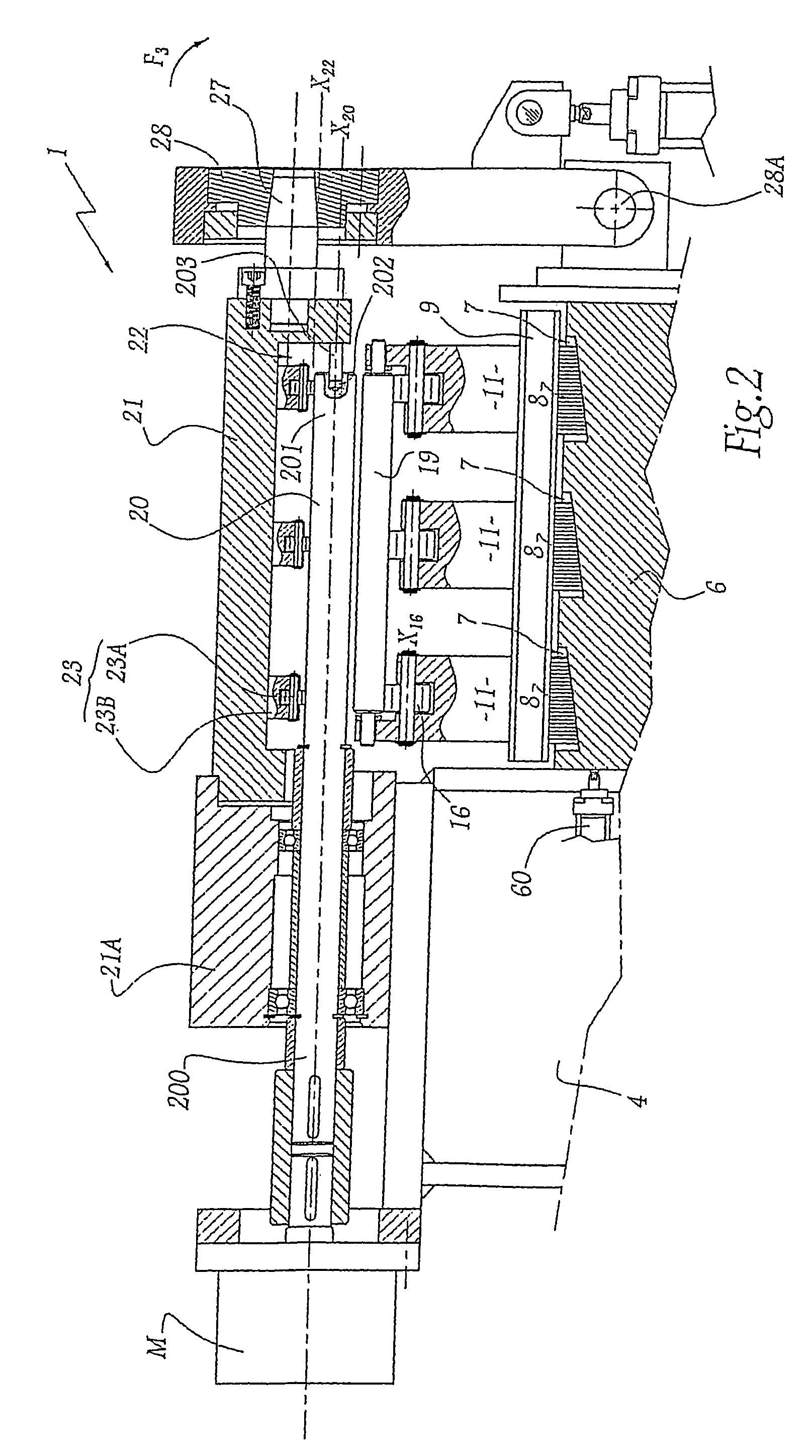

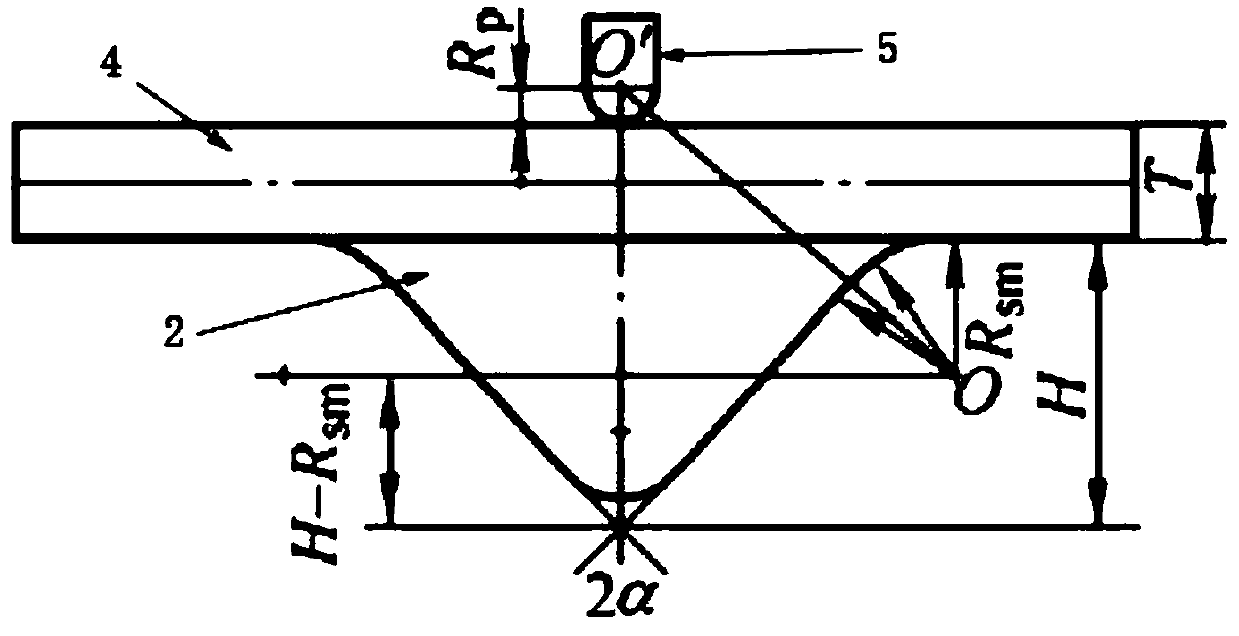

The invention relates to a roller-type sheet metal bending machine comprising a so-called bending roller (20), which is rotationally driven and around which the sheet metal winds, and comprising at least two supporting rollers (19) designed for receiving, while being pressed against by, a sheet metal that is being bent around the bending roller (20). The supporting rollers (19) are mounted so they can freely rotate on a support (11) and can be adjusted in the height thereof whereby adapting the clearance between the bending roller (20) and the supporting rollers (19) to the thickness of the sheet metal. The bending roller (20) is associated with at least one set of means (21, 23) for compensating for, at least in part, its deflection. The supporting rollers (19) are associated with at least one set of means (11) for compensating for their deflection, this set being able to be adjusted according to the potential residual deflection of the bending roller (20). The set of means (21, 23) for compensating for the deflection of the bending roller (20) comprises an arm (21) provided with a housing (22) inside of which the roller (20) is partially accommodated, as well as means (23A, 23B) for holding the roller (20) inside the housing (22). The invention particularly serves to produce tubes with a high ratio of length to diameter.

Owner:JAMES IND INC

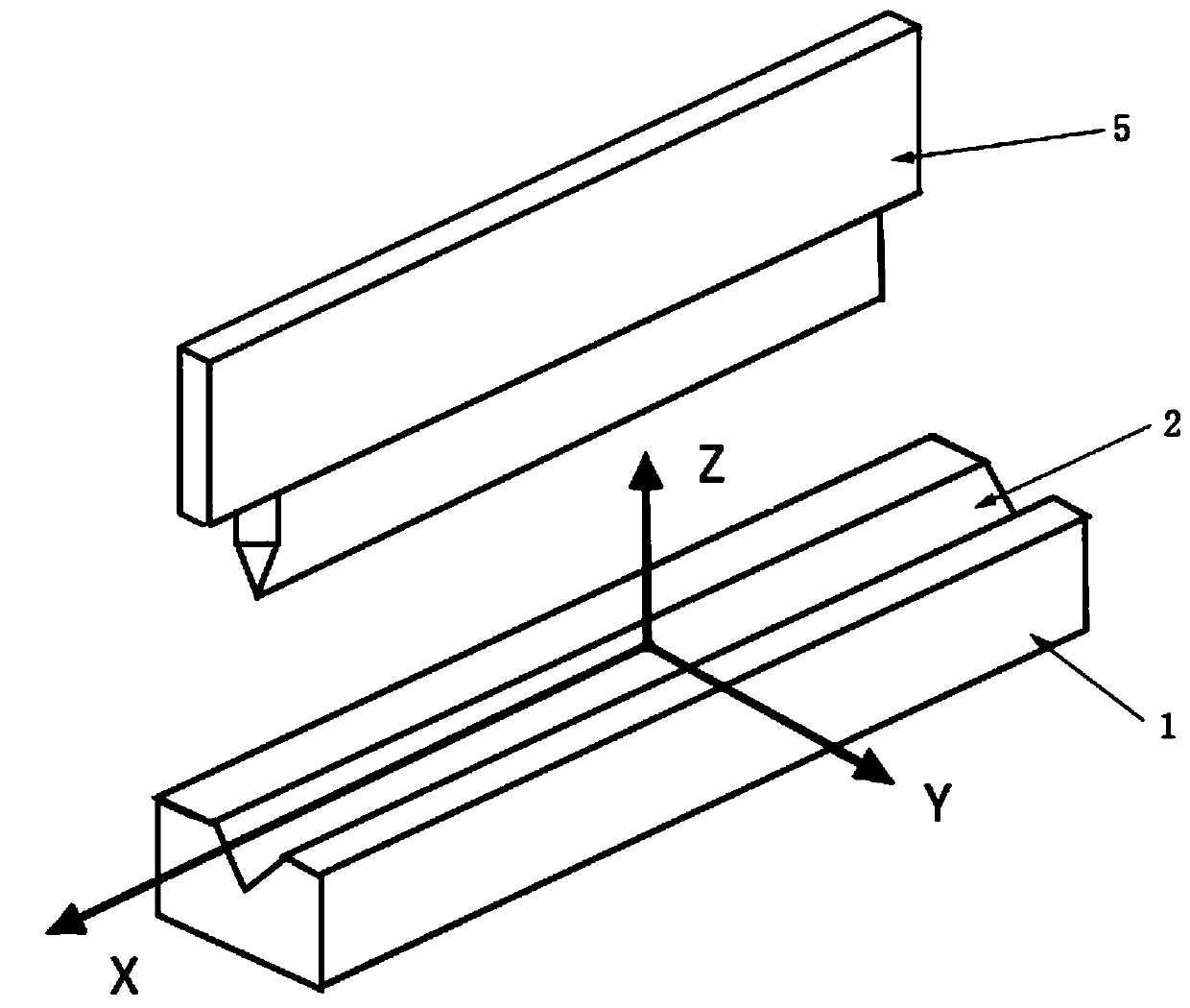

Flexible sheet metal bending and forming machine

The invention provides a flexible sheet metal bending and forming machine and relates to the field of sheet metal bending. The flexible sheet metal bending and forming machine comprises a machine base, a moving seat and a frame body, wherein the frame body and the moving seat are arranged at the top of the machine base; in addition, the frame body is positioned on one side of the moving seat; a servo feed mechanism is fixed on one side of the top of the moving seat; in addition, one side of a driving shaft drives a manipulator to move; the bottom of the manipulator is connected with a linear guide rail in a sliding manner; the linear guide rail is arranged on the moving seat; and a material supporting mechanism for fixing sheet metal is fixed inside the moving seat. The flexible sheet metal bending and forming machine is arranged for one-time positioning of sheet metal and multi-time accurate bending; a required bending angle is controlled by a servo motor; the upper part and the lowerpart of the sheet metal can be simultaneously bent; and arc bending with any size within certain range is realized, the cost of equipment and a mold is reduced, the mold change time is shortened, labor intensity of an operator is reduced and the production efficiency is improved.

Owner:ANHUI KECHANG MACHINERY MFG

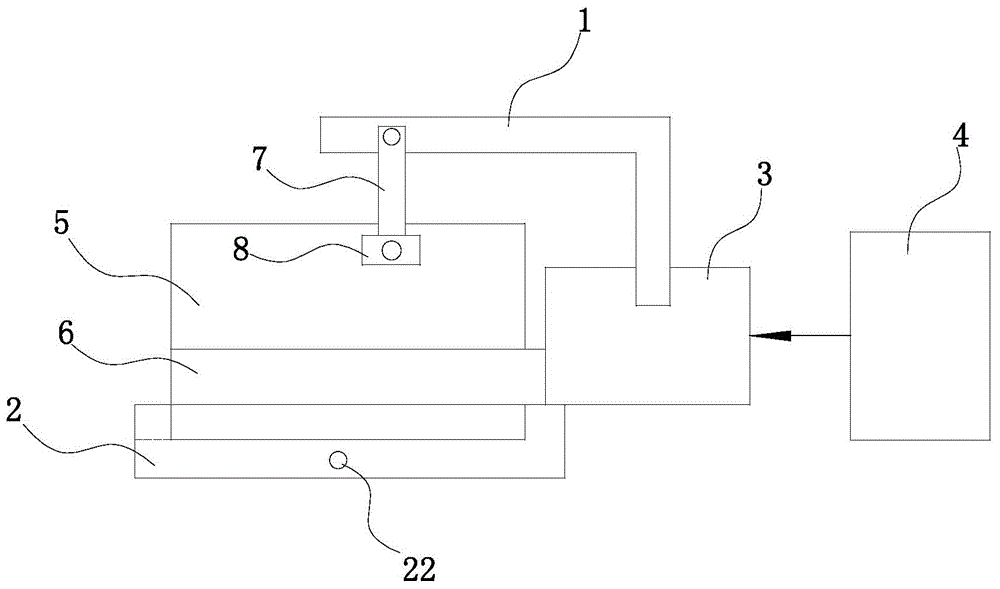

Sheet metal bending system and method with angle regulating and controlling function and phased bending function

InactiveCN104942076APrevent looseningAvoid influenceMetal-working feeding devicesMetal working apparatusDrive motorEngineering

The invention relates to a sheet metal bending system and method with the angle regulating and controlling function and the phased bending function. The system comprises a driving motor arranged on a rack, a clamping and fixing base and a main machine. A bending shaft is installed on the driving motor. A machined workpiece is installed on the clamping and fixing base. The system further comprises an ultrasonic thickness detector, an ultrasonic crack detector, a pressure sensor, a rolling shaft, a proximity switch and a controller connected with the main machine. The ultrasonic thickness detector, the ultrasonic crack detector, the pressure sensor and the proximity switch all connected with the main machine through a DSP data processing module. According to the system, the quantity of cracks is greatly reduced through combination of phased bending and feedback control. The rolling shaft is arranged to perform extrusion and friction on the inwards-concave face of the machined workpiece, and protruding burrs and the cracks are effectively removed. The proximity switch is used for controlling the bending angle so that excessive bending can be avoided. The clamping force is controlled through the pressure sensor, a plate is prevented from deforming or falling off, and machining reliability is improved.

Owner:SUZHOU BIANTONG SENSING TECH

Bending following method and sheet metal bending process based on robot additional shaft

InactiveCN110153239AUnreachable solutionResolve interferenceMetal-working feeding devicesPositioning devicesEngineeringAccessibility

The invention discloses a bending following method and a sheet metal bending process based on a robot additional shaft. The bending following method comprises the following steps: S1, establishing a user coordinate system; S2, adopting a robot to grab a sheet metal to put the sheet metal on the upper surface of a die flatwise, and coinciding a tool coordinate system with the user coordinate system; S3, establishing the geometrical relationship between the distance from the bending part of the lower surface of the sheet metal to the upper surface of the die and the single-side bending angle ofthe sheet metal, and calculating bending following dynamic points to generate the bending following action program of the robot; S4, carrying out inverse solution on the point location position of themoving process of the robot, judging whether the robot meets the accessibility requirement, if yes, finishing the bending action, otherwise, carrying out step 5; and S5, according to the robot angleconfiguration, calculating the following drawing pace of the additional shaft, and if the additional shaft moves to a new position with the drawing pace multiplying the adjusting times of the drawingpace, returning to S3. With adoption of the bending following method, efficient and reliable automatic bending of the sheet metal is realized.

Owner:SHANGHAI FANUC ROBOTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com