Feeding device applied to sheet metal bending machine

A technology of bending machine and sheet metal, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of manual feeding, time-consuming and laborious, and achieve the effect of increasing stability, reducing possibility and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

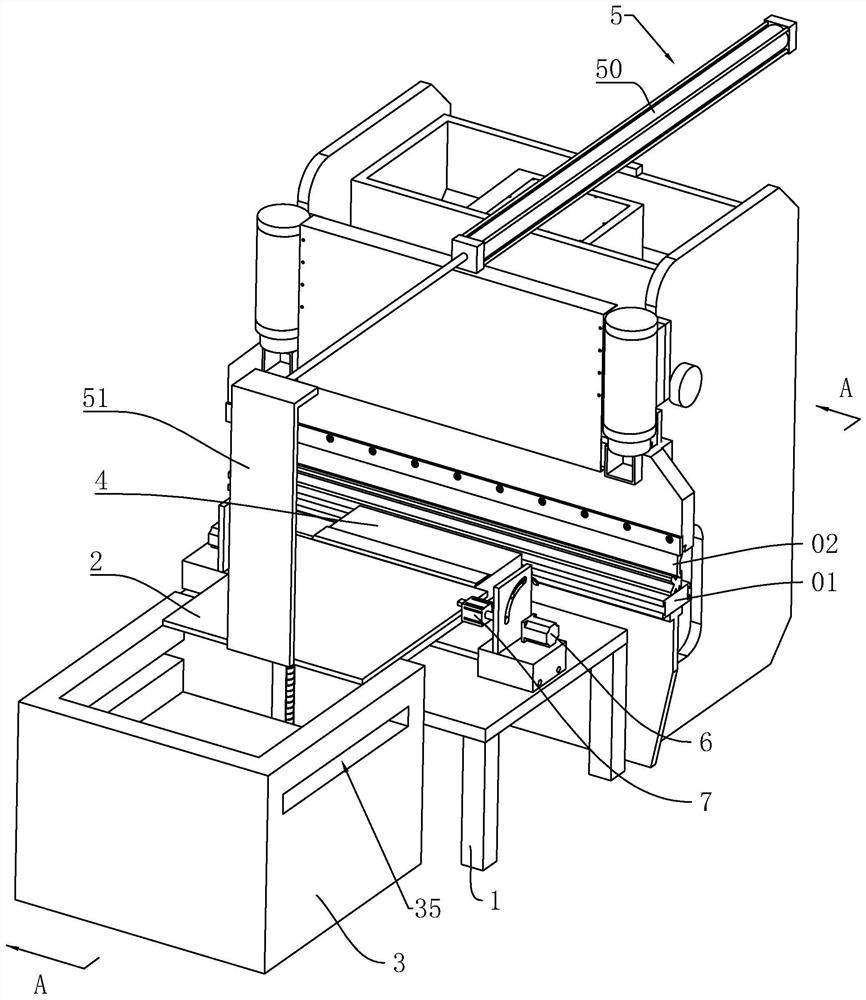

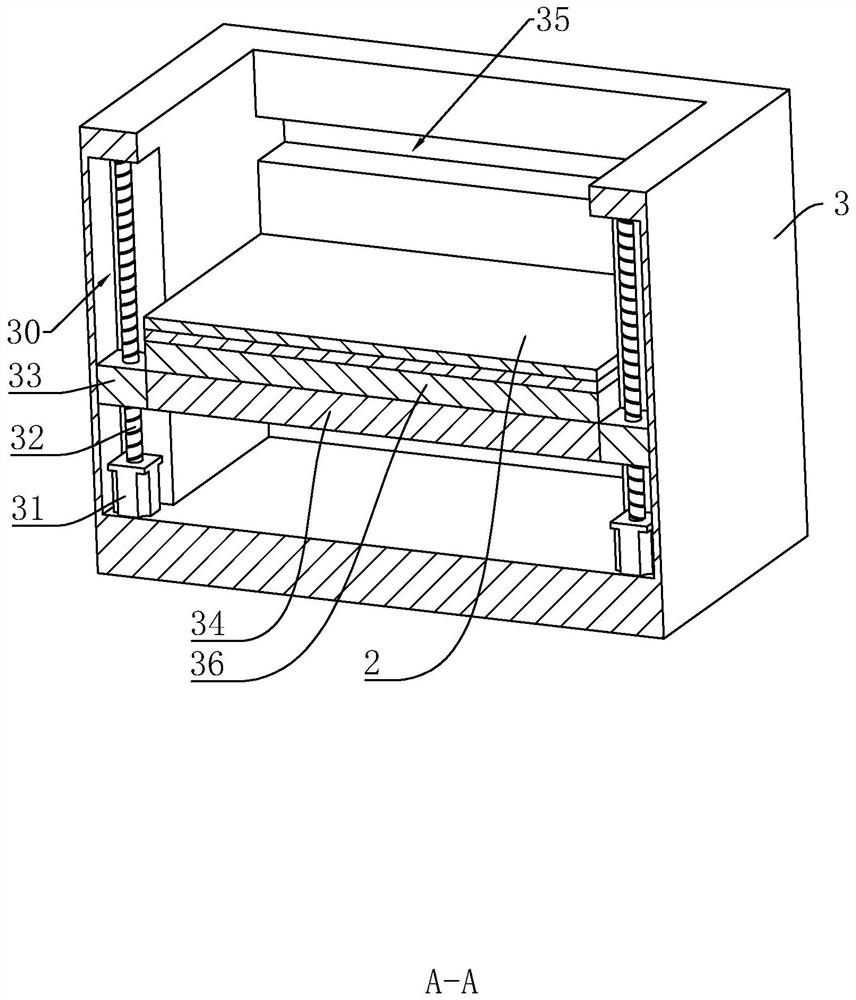

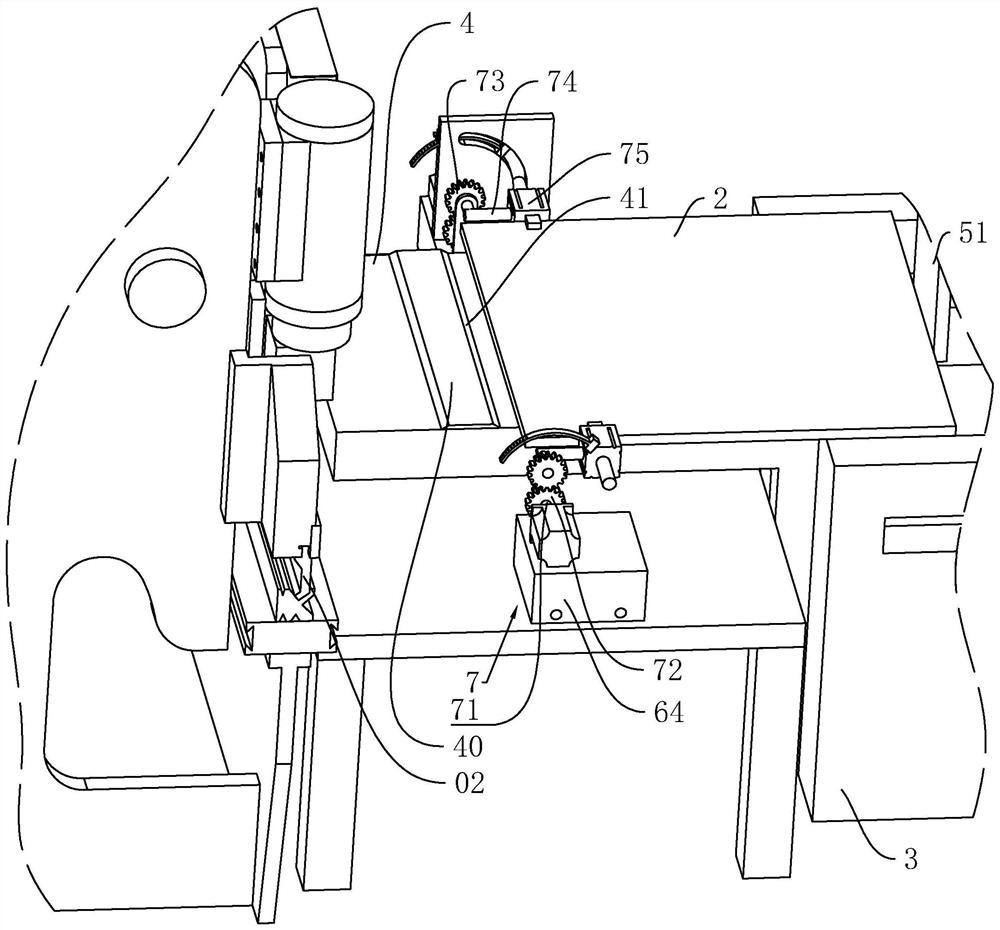

[0038] refer to figure 1 , a feeding device applied to a sheet metal bending machine, which includes a frame 1 and a stacking box 3 for storing sheets 2 and outputting the sheets 2 one by one, the stacking box 3 is open, and the frame 1 and the workbench 01 are provided with a material receiving table 4, and the frame 1 is provided with a driving member 5 for pushing the sheet 2 on the stacker 3 to the material receiving table 4 side, and the material receiving table 4 is provided with There is a power assembly 6 for moving the sheet 2 to the bottom of the processing plate 02, and the power assembly 6 is provided with a clamping member 7 for clamping the sheet 2; when the sheet 2 needs to be processed, the sheet 2 is first Put it into the stacking box 3, and then the stacking box 3 removes the sheets 2 one by one. Then the plate 2 is clamped, the power assembly 6 drives the clamping part 7 and the plate 2 to move to the side of the workbench 01, and the plate 2 is moved to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com