Sheet metal bending machine and production line incorporating a machine of this type

A metal sheet and production line technology, which is applied in the field of roll bending presses and roll bending presses, and can solve the problems of inability to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

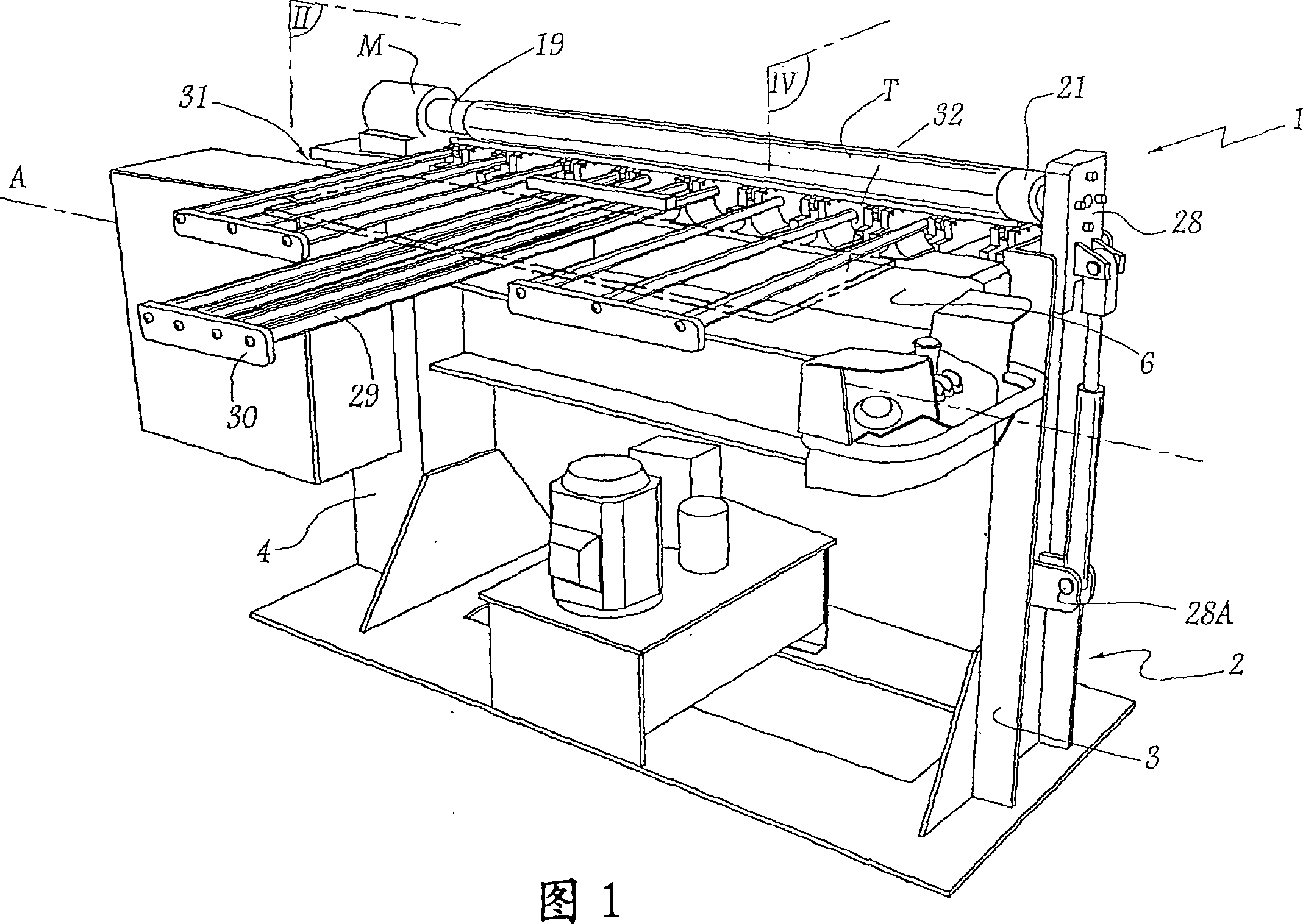

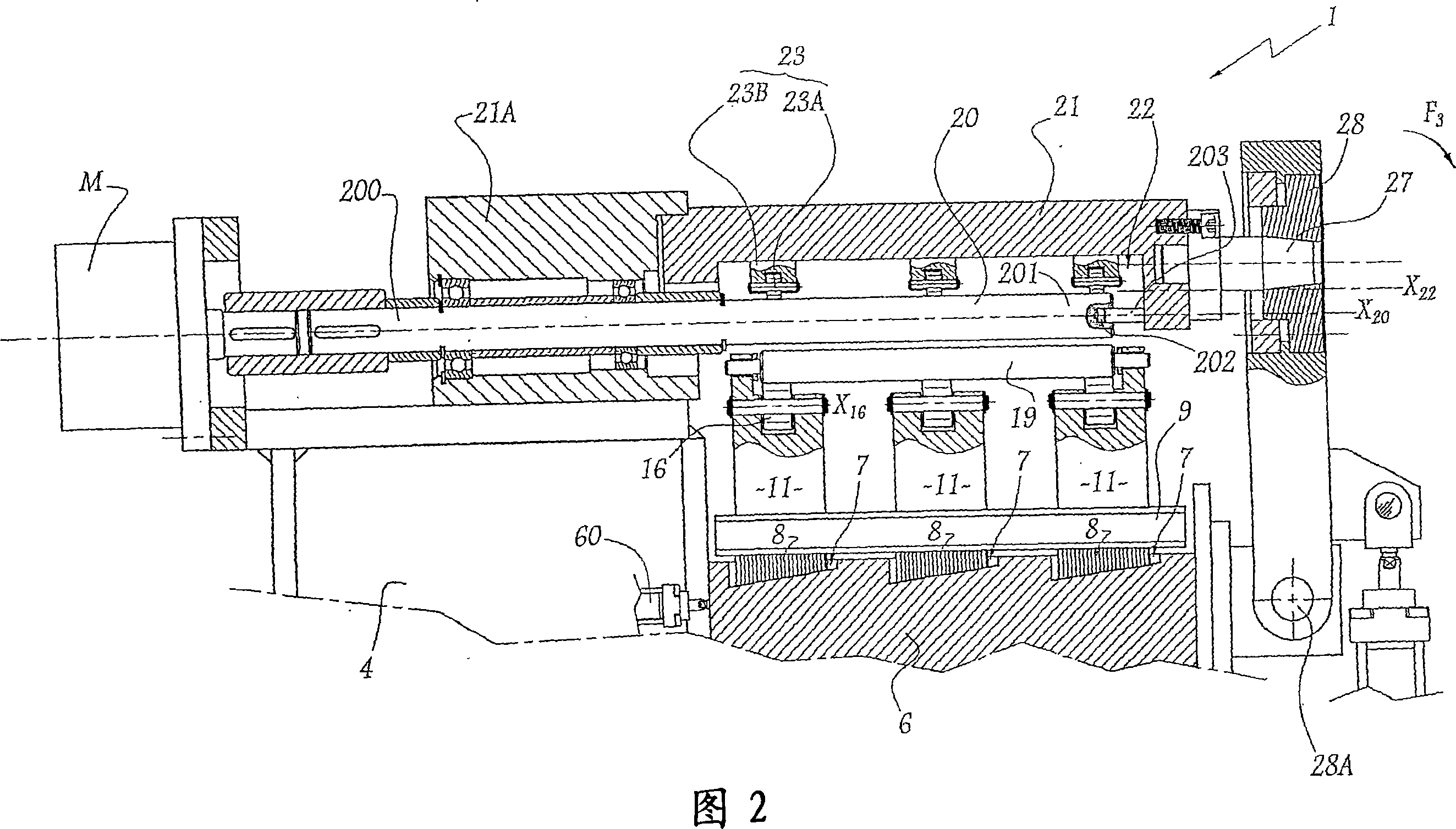

[0028] A sheet metal bending machine 1 called a "roll bending press" shown in FIG. 1 includes a substantially H-shaped main body portion 2 . The spacing between the H-shaped uprights 3 and 4 is adapted to the desired final length of the tube T to be produced. The transverse bar 5 of the body 2 of the machine supports a stationary transverse bar 6 which is kept substantially horizontal. The crossbar 6 has on its top face three notches 7 inclined at approximately 45° with respect to the longitudinal axis A-A' of the crossbar 5 . The crossbar 6 is movable longitudinally by a hydraulic device 60 in a direction parallel to the axis A-A'.

[0029] A second crossbar 9 , which is equipped on its bottom face with at least two partitions 8 , rests on the crossbar 6 . Therefore when the cross bar 6 and the partition plate 8 move from left to right or from right to left in Fig. 2 at the same time, the cross bar 6 and the partition plate 8 are on the slope of the notch 7-the partition pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com