Flexible sheet metal bending and forming machine

A forming machine and sheet metal technology, applied in the field of sheet metal bending, can solve the problems of bending angle limitation, inaccurate positioning, time-consuming and labor-intensive problems, and achieve the effects of high utilization rate, improved production efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

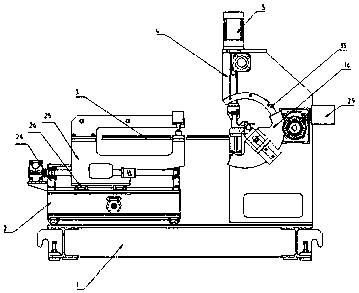

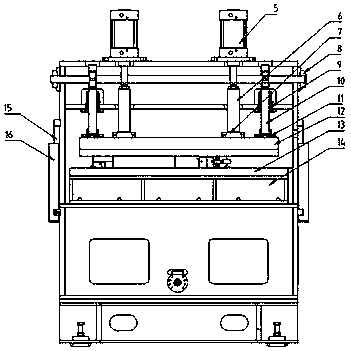

[0031] like Figure 1-5 As shown, a flexible sheet metal bending forming machine includes a machine base 1, a kinematic base 2 and a frame body 4. The top of the machine base 1 is provided with a frame body 4 and a kinematic base 2, and the frame body 4 is located at the side;

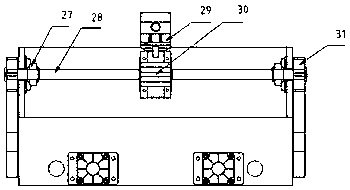

[0032] Wherein the top side of the motion seat 2 is fixed with a servo feed mechanism 24, and one side of the drive shaft 28 drives the robot hand 25 to move, and the bottom of the robot hand 25 is slidingly connected with the linear guide rail 26, and the linear guide rail 26 is arranged on the motion seat 2 , the inside of the kinematic seat 2 is fixed with a supporting mechanism 3 for fixing the sheet metal;

[0033] Wherein the interior of the frame body 4 is provided with an arc-shaped groove, and the two ends of the groove are provided with arc rails 15, and the outer side of the arc rail 15 is surrounded by an arc gear 16; the rear side of the frame body 4 is fixed with a bending servo. Motor ...

Embodiment 2

[0043] like Figure 1-6 As shown, a flexible sheet metal bending forming machine includes a machine base 1, a kinematic base 2 and a frame body 4. The top of the machine base 1 is provided with a frame body 4 and a kinematic base 2, and the frame body 4 is located at the side;

[0044] Wherein the top side of the motion seat 2 is fixed with a servo feed mechanism 24, and one side of the drive shaft 28 drives the robot hand 25 to move, and the bottom of the robot hand 25 is slidingly connected with the linear guide rail 26, and the linear guide rail 26 is arranged on the motion seat 2 , the inside of the kinematic seat 2 is fixed with a supporting mechanism 3 for fixing the sheet metal;

[0045] Wherein the interior of the frame body 4 is provided with an arc-shaped groove, and the two ends of the groove are provided with arc rails 15, and the outer side of the arc rail 15 is surrounded by an arc gear 16; the rear side of the frame body 4 is fixed with a bending servo. Motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com