Methods and means for coating paper by film coating

A paper and coating technology, applied in paper, biochemical equipment and methods, papermaking, etc., can solve problems such as the negative impact of paper whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0090] Preparation of coating formulation

[0091] The pigment slurry (1000 g dry weight) was added to a 2000 mL beaker and dispersed with a diluent. Add water if needed. Under stirring, add starch (if it is cold water soluble, add in dry state) or starch solution. Under stirring, the synthetic binder is added to the dispersion. Finally, other additives are added to the coating formulation. The formulation was adjusted to the desired pH using diluted sodium hydroxide solution (16w / w%). Use a water bath to adjust the temperature of the coating formulation. The coating composition is diluted with water to the desired amount of dry solids.

[0092] Rheology of coating formulation

[0093] Brookfield viscosity: Brookfield RVDVII, 100rpm, 25°C. The coating was measured in a 500 mL beaker.

[0094] Medium viscosity: Hercules DV-10 high shear at 100rpm and 1000rpm, 25°C. Use Bob / cup method, use Bob type A.

[0095] High shear viscosity: at 1×10 6 s -1 ACAV A2 Ultra High Shear Capill...

Embodiment 1

[0108] Example 1: Stability of coating formulation

[0109] This example shows that compared with other coated starches, it has excellent stability at high concentrations of HBS. Dissolve starch in hot water to measure stability and color. The cold water solubility is determined as described above.

[0110] Compared with other ingredients tested, HBS solutions with a solid content of 50% or 35% are very stable at 50°C and have a very low viscosity. Except for the very clear, colorless and transparent HBS solution, all solutions are yellow to brown.

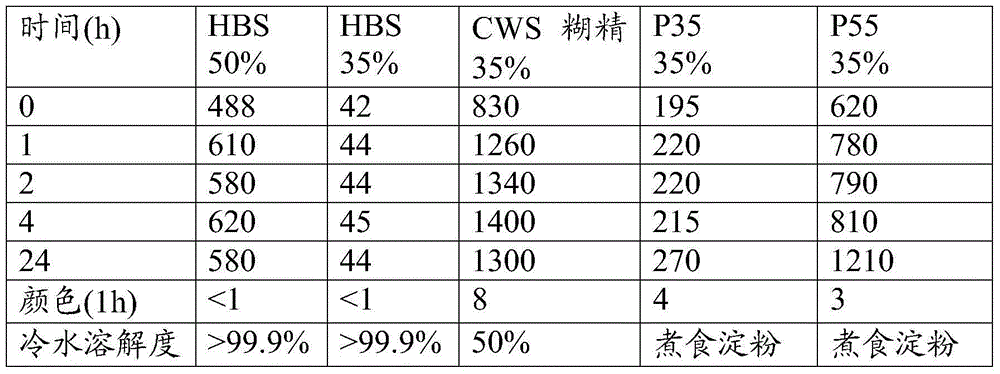

[0111] Table 1. Brookfield viscosity (mPas) at 50℃ for a certain period of time

[0112]

[0113] CWS = cold water soluble dextrin (= C*Icoat from Cargill)

Embodiment 2

[0114] Example 2: Rheology

[0115] This example shows that HBS imparts excellent rheological properties to the coating composition for film coating application, wherein HBS can be used as the sole binder or can be combined with SB latex. This example also shows that the coating composition prepared according to Example 2 of EP060170B2 does not have rheological properties suitable for coating on a film coater.

[0116] HBS was used to prepare coating compositions for film coating applications and tested for their rheological behavior. At least 50% of the binder is starch.

[0117] Reference paint 1 (R1) is a coating composition including 100 parts of calcium carbonate pigment, 7.5 parts of Perfectacote 45 and 7 parts of latex.

[0118] Reference coating 2 (R2) is a coating composition according to EP0690170B2 including 100 parts of kaolin pigment (SPS clay) and 12.5 parts of HBS.

[0119] The coating 1 (C1) of the present invention is a coating composition comprising 100 parts of calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com