Silica sol-silane emulsion capillary crystalline waterproof material and preparation method thereof

A technology of silane emulsion and osmotic crystallization, applied in the direction of coating, etc., to achieve the effect of preventing intrusion, environmental friendliness and good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

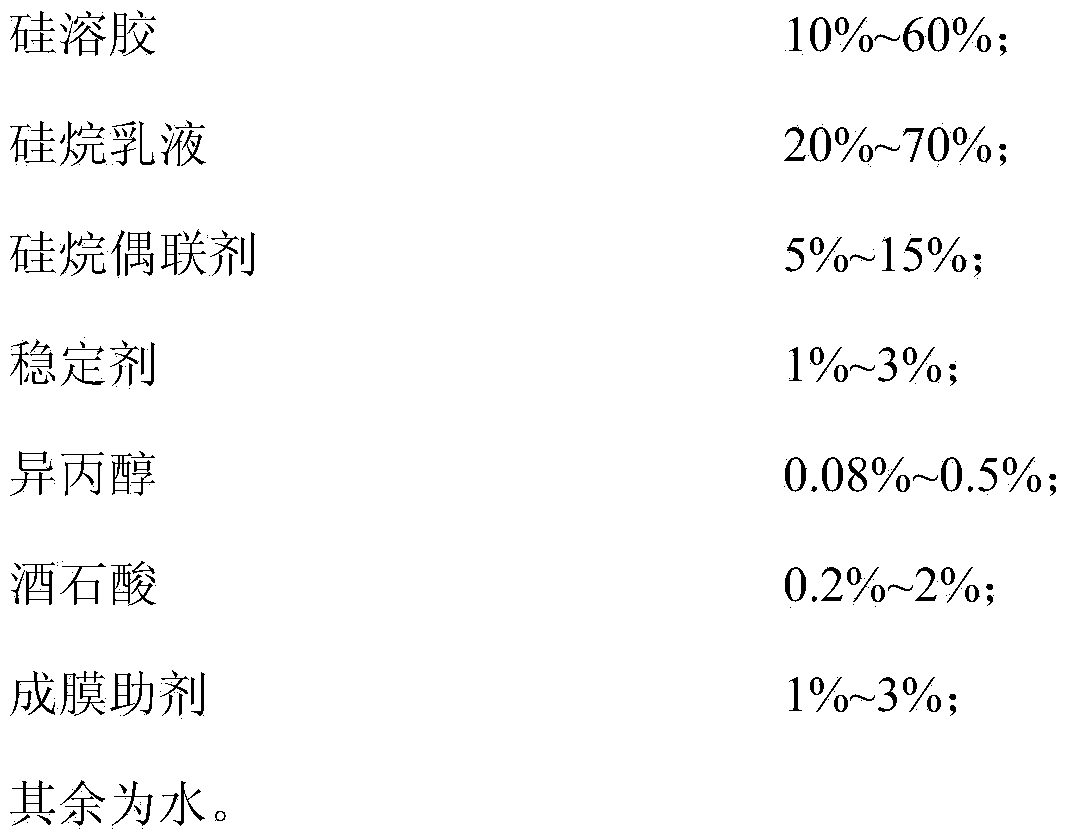

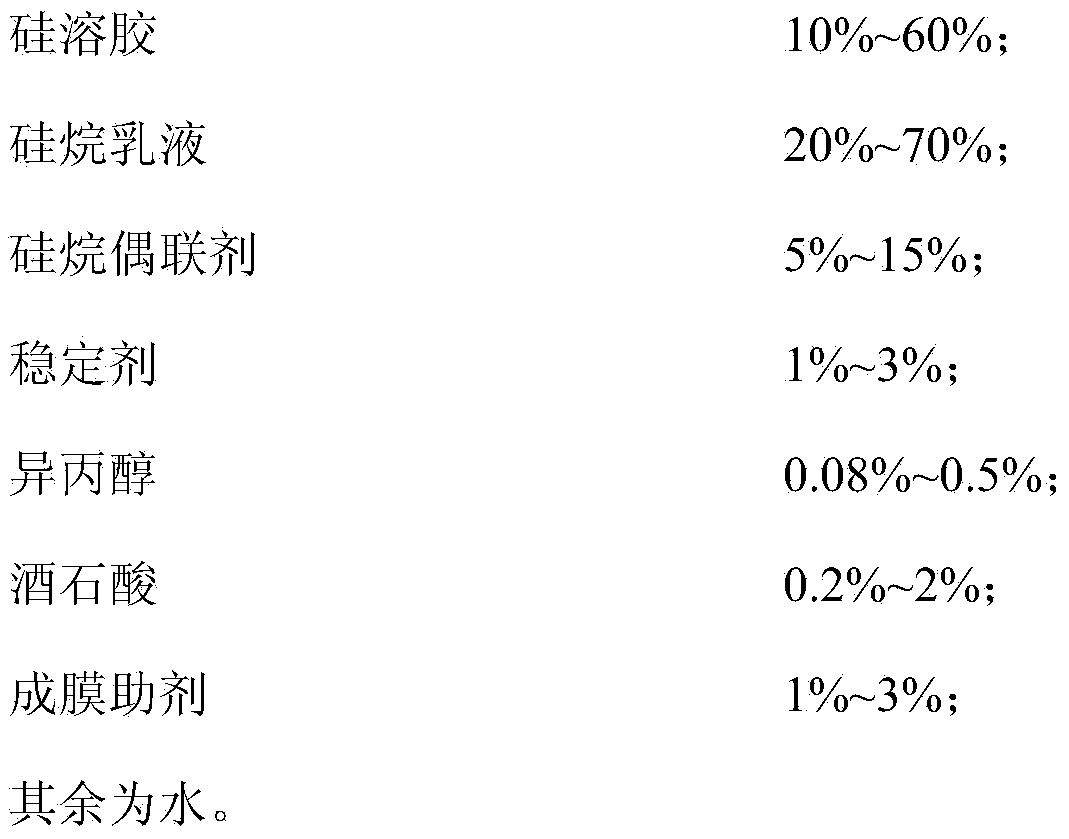

Method used

Image

Examples

Embodiment 1

[0019] In this example, 1 kg of silica sol-silane emulsion permeated crystalline waterproof material was prepared. The raw materials used and the preparation process are as follows:

[0020] Mix 100g of silica sol and 30g of γ-glycidyl triethoxysilane, and add 700g of methyl triethoxysilane emulsion and 15g of fatty alcohol polyoxyethylene ether succinate half ester in sequence under stirring at 800r / min Sulfonate, 1.2g isopropanol, 3g tartaric acid, 15g polyvinyl alcohol, then adjust the pH value to 4.0 with phosphoric acid, react at 55°C for 5h, and finally add water to make up to 1kg.

[0021] In this example, the prepared silica sol-silane emulsion infiltrating crystalline waterproof material is painted on the surface of dry mortar test block and concrete at room temperature, and the amount of coating film is 0.5kg / m 2 , The water absorption rate of the mortar is reduced by 55.2%, the penetration depth of the waterproof material on the concrete surface reaches 5.2mm, the w...

Embodiment 2

[0023] In this example, 1 kg of silica sol-silane emulsion permeated crystalline waterproof material was prepared. The raw materials used and the preparation process are as follows:

[0024] Mix 200g of silica sol and 80g of γ-glycidyl triethoxysilane, and add 600g of methyltriethoxysilane emulsion and 13.5g of alkylphenol polyoxyethylene ether succinic acid in sequence under stirring at 800r / min Half ester sulfonate, 1.0g isopropanol, 3g tartaric acid, 18g polyvinyl alcohol, then adjust the pH value to 4.5 with phosphoric acid, react at 55°C for 6h, and finally add water to make up to 1kg.

[0025] In this example, the prepared silica sol-silane emulsion infiltrating crystalline waterproof material is painted on the surface of dry mortar test block and concrete at room temperature, and the amount of coating film is 0.5kg / m 2 , The water absorption rate of the mortar is reduced by 52.7%, the penetration depth of the waterproof material on the concrete surface reaches 4.7mm, th...

Embodiment 3

[0027] In this example, 1 kg of silica sol-silane emulsion permeated crystalline waterproof material was prepared. The raw materials used and the preparation process are as follows:

[0028] Mix 300g of silica sol and 100g of γ-aminopropyltriethoxysilane, and add 500g of methyltriethoxysilane and 15g of fatty alcohol polyoxyethylene ether succinate half-ester sulfonic acid in sequence under stirring at 800r / min Salt, 1.2g isopropanol, 3g tartaric acid, 20g polyvinyl alcohol, then adjust the pH value to 4.5 with phosphoric acid, react at 55°C for 6h, and finally add water to make up to 1kg.

[0029] In this example, the prepared silica sol-silane emulsion infiltrating crystalline waterproof material is painted on the surface of the dry mortar test block and concrete at room temperature, and the amount of coating film is 0.6kg / m 2 , The water absorption rate of the mortar is reduced by 61.6%, the penetration depth of the waterproof material on the concrete surface reaches 5.0mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com