Preparation method for large-grained spherical cobalt oxyhydroxide

A technology of cobalt oxyhydroxide and sodium hydroxide, applied in chemical instruments and methods, cobalt oxide/cobalt hydroxide, cobalt compounds, etc., can solve problems such as poor product stability, reduced mixing efficiency and effect, uneven reaction, etc. Achieve the effect of strong product stability, increase effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Cobalt liquid configuration: Weigh 1.5 kg of cobalt chloride crystals, add deionized water to dissolve, and set the volume to 5 liters. In order to configure enough cobalt liquid, the above steps can be repeated;

[0028] 2. Alkaline preparation: Weigh 1 kg of sodium hydroxide crystals, add deionized water to dissolve, set the volume to 3 liters, then add 0.7 L of ammonia water with 25% ammonia content and 20 ml of hydrazine hydrate solution with 80% content, and finally Set the volume to 5L, in order to configure enough lye, the above steps can be repeated;

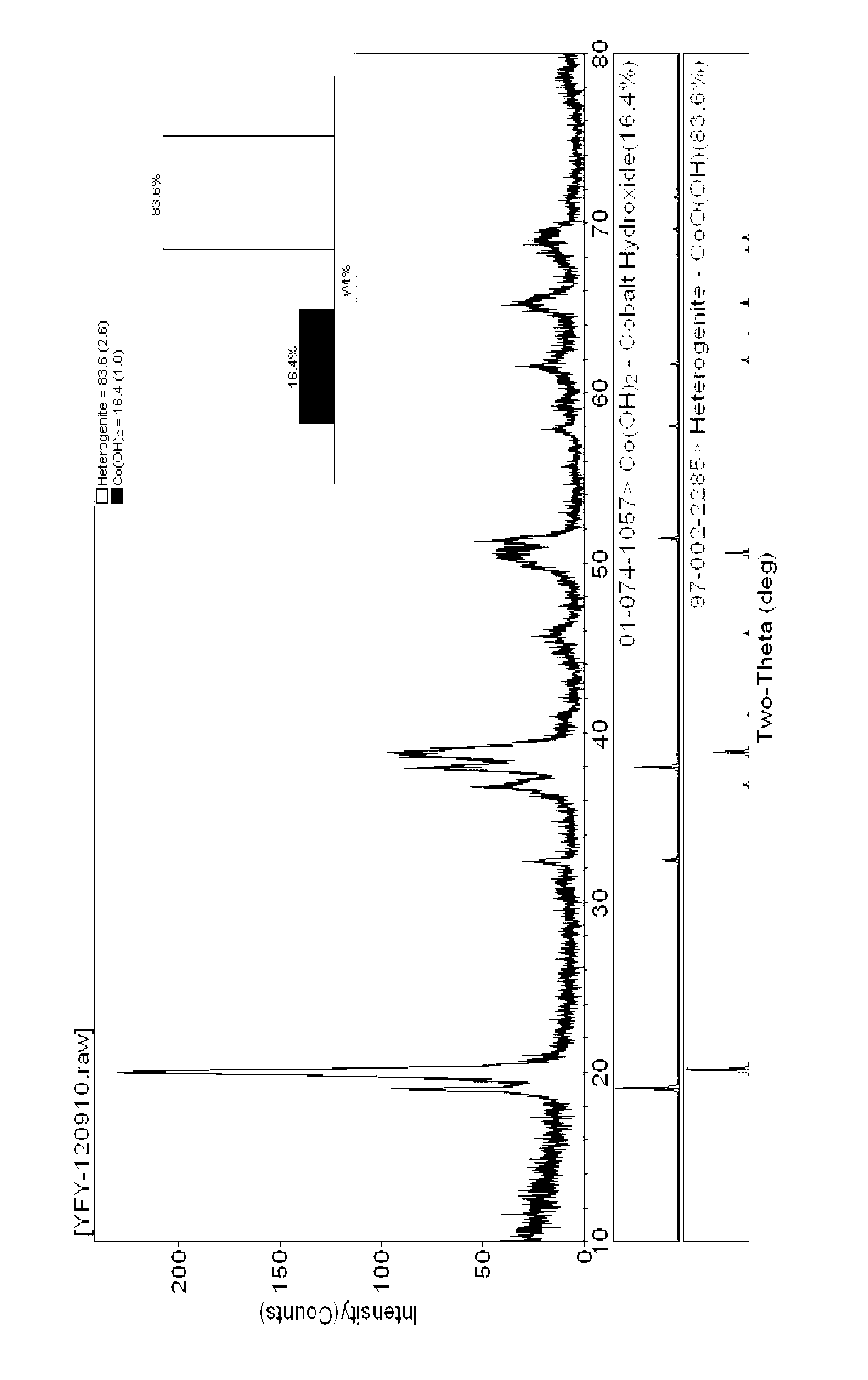

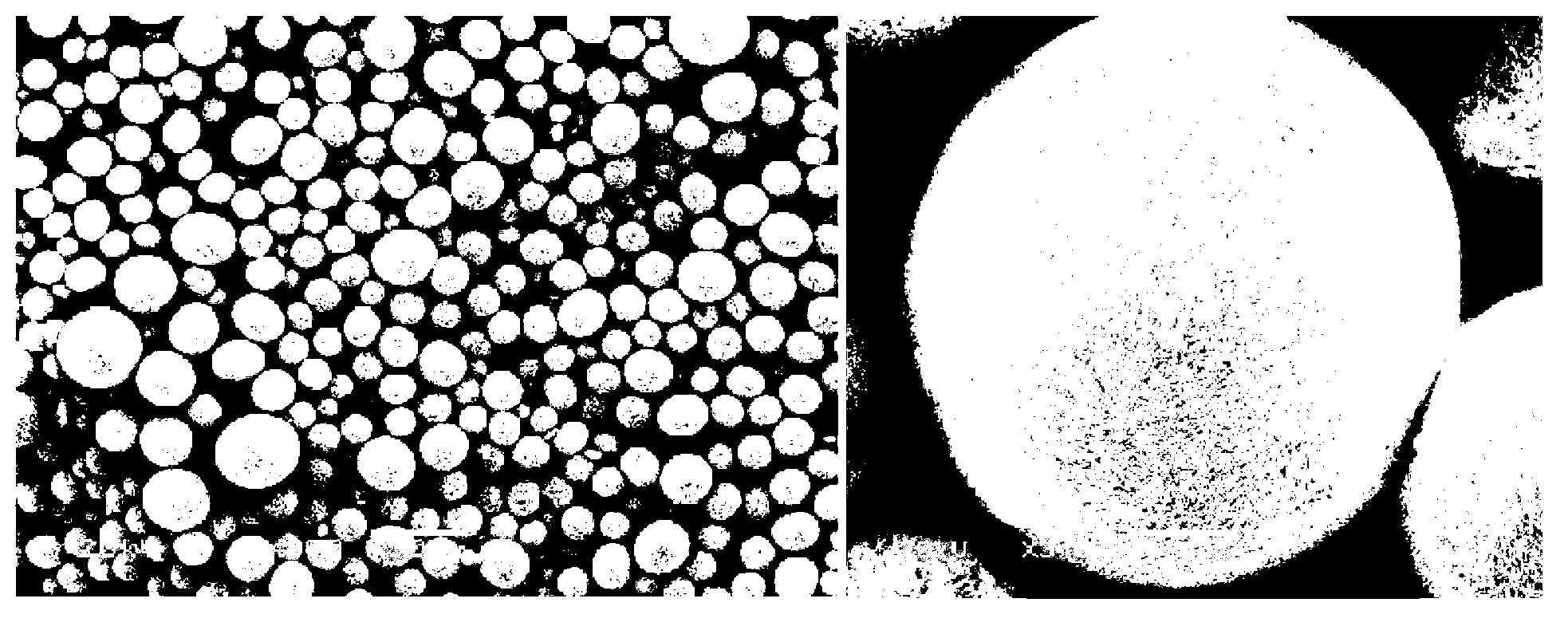

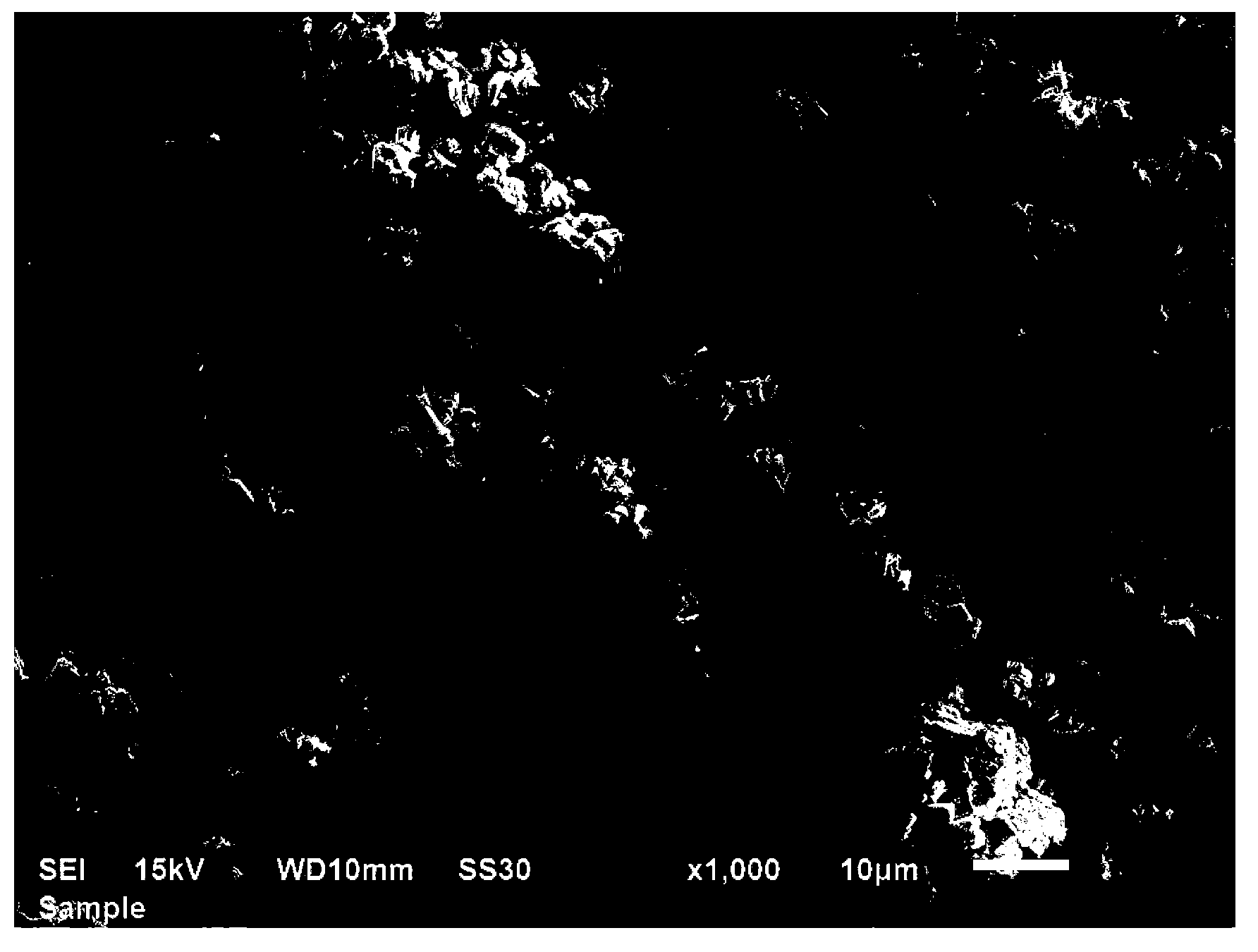

[0029] 3. Clean the reaction kettle, and pump the cobalt solution in step 1 and the lye solution in step 2 at the same time under the conditions of pH 11.1, temperature 65°C, rotation speed (300-rpm) and nitrogen protection, and adjust the hydrogen The flow rate of sodium oxide is stable and the pH value is controlled at 11.1, and the reaction is continuous. After 12 hours of feeding, the particle size of the s...

Embodiment 2

[0033] 1. Cobalt liquid configuration: Weigh 2.2 kg of cobalt chloride crystals, add deionized water to dissolve, and set the volume to 5 liters. In order to configure enough cobalt liquid, the above steps can be repeated;

[0034] 2. Alkaline preparation: Weigh 1 kg of sodium hydroxide crystals, add deionized water to dissolve, and set the volume to 3 liters, then add 0.9L ammonia water with 25% ammonia content and 20 ml hydrazine hydrate solution with 80% content, and finally Set the volume to 5L, in order to configure enough lye, the above steps can be repeated;

[0035] 3. Clean the reaction kettle, and pump the cobalt liquid in step 1 and the lye in step 2 at the same time under the protection conditions of pH value 10.9, temperature 50°C, rotation speed (350-rpm) and nitrogen gas, and adjust the hydrogen The flow rate of sodium oxide is stable and the pH value is controlled at 10.9, and the reaction is continuous. After 12 hours of feeding, the particle size of the slurr...

Embodiment 3

[0039] 1. Cobalt liquid configuration: Weigh 1.9 kg of cobalt sulfate crystals, add deionized water to dissolve, and set the volume to 5 liters. In order to configure enough cobalt liquid, the above steps can be repeated;

[0040]2. Alkaline preparation: Weigh 1 kg of sodium hydroxide crystals, add deionized water to dissolve, and set the volume to 3 liters, then add 0.9L ammonia water with 25% ammonia content and 20 ml hydrazine hydrate solution with 80% content, and finally Set the volume to 5L, in order to configure enough lye, the above steps can be repeated;

[0041] 3. Clean the reaction kettle, and pump the cobalt solution in step 1 and the lye solution in step 2 at the same time under the conditions of pH 11.5, temperature 40°C, rotation speed (400-rpm) and nitrogen protection, and adjust the hydrogen The flow rate of sodium oxide is stable and the pH value is controlled at 11.5, and the reaction is continuous. After 12 hours of feeding, the particle size of the slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com