Method for preparing nanometer nickel oxide and application of method

A nano-nickel oxide, aging treatment technology, applied in nickel oxide/nickel hydroxide, electrochemical variables of materials, etc., can solve the problems of difficult mass production, harsh reaction conditions, complicated experimental process, etc., and achieve large-scale industrial production. , The effect of low product cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

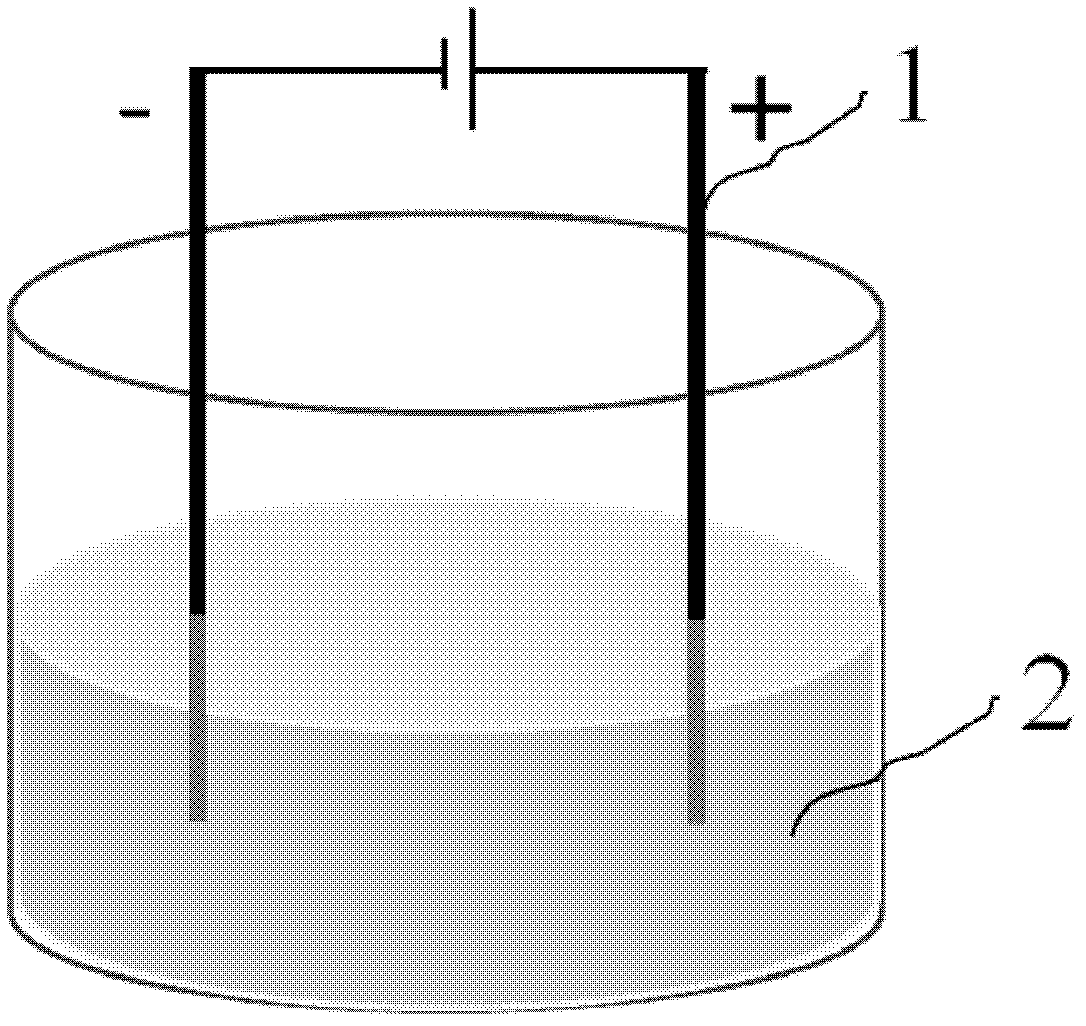

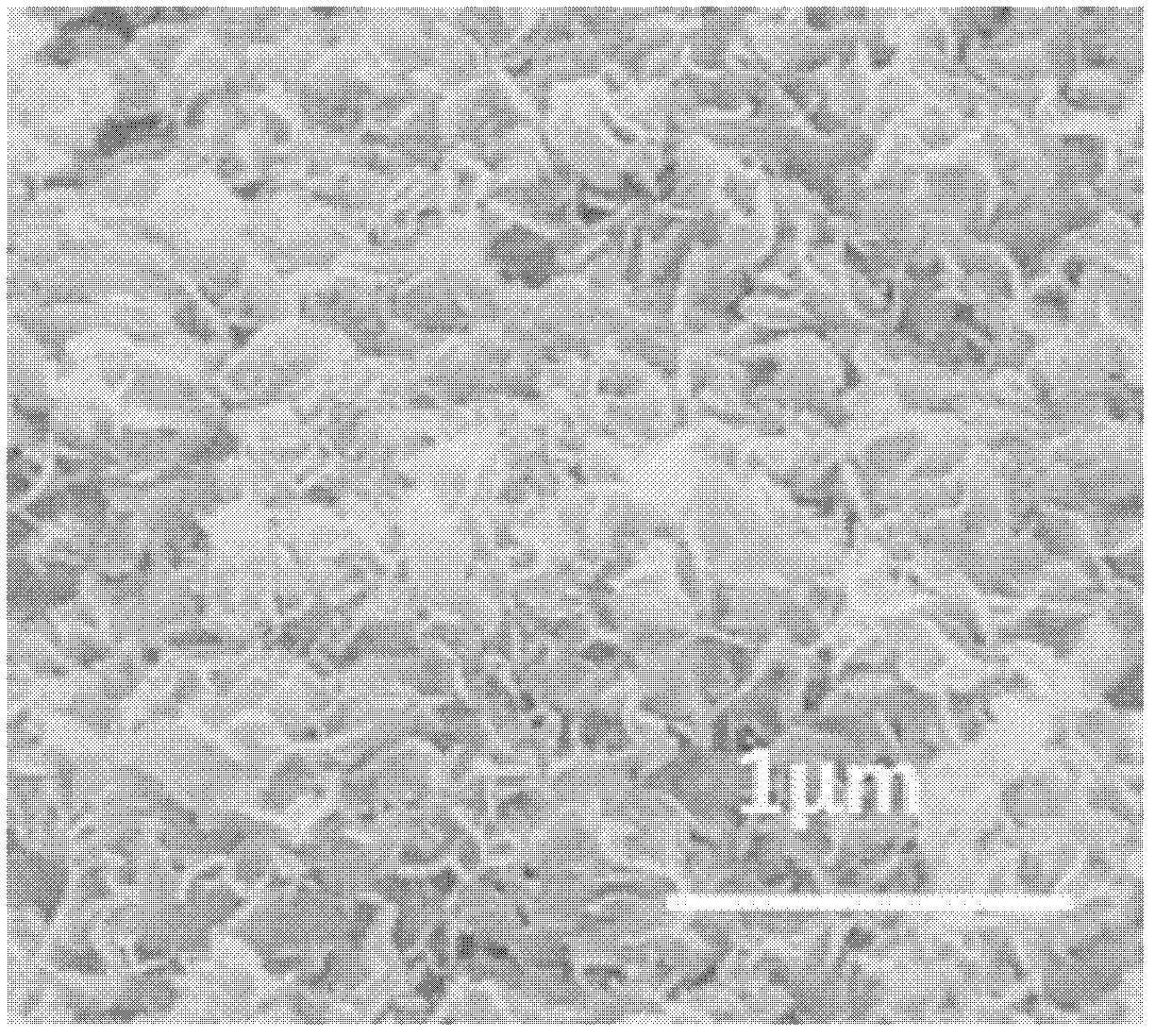

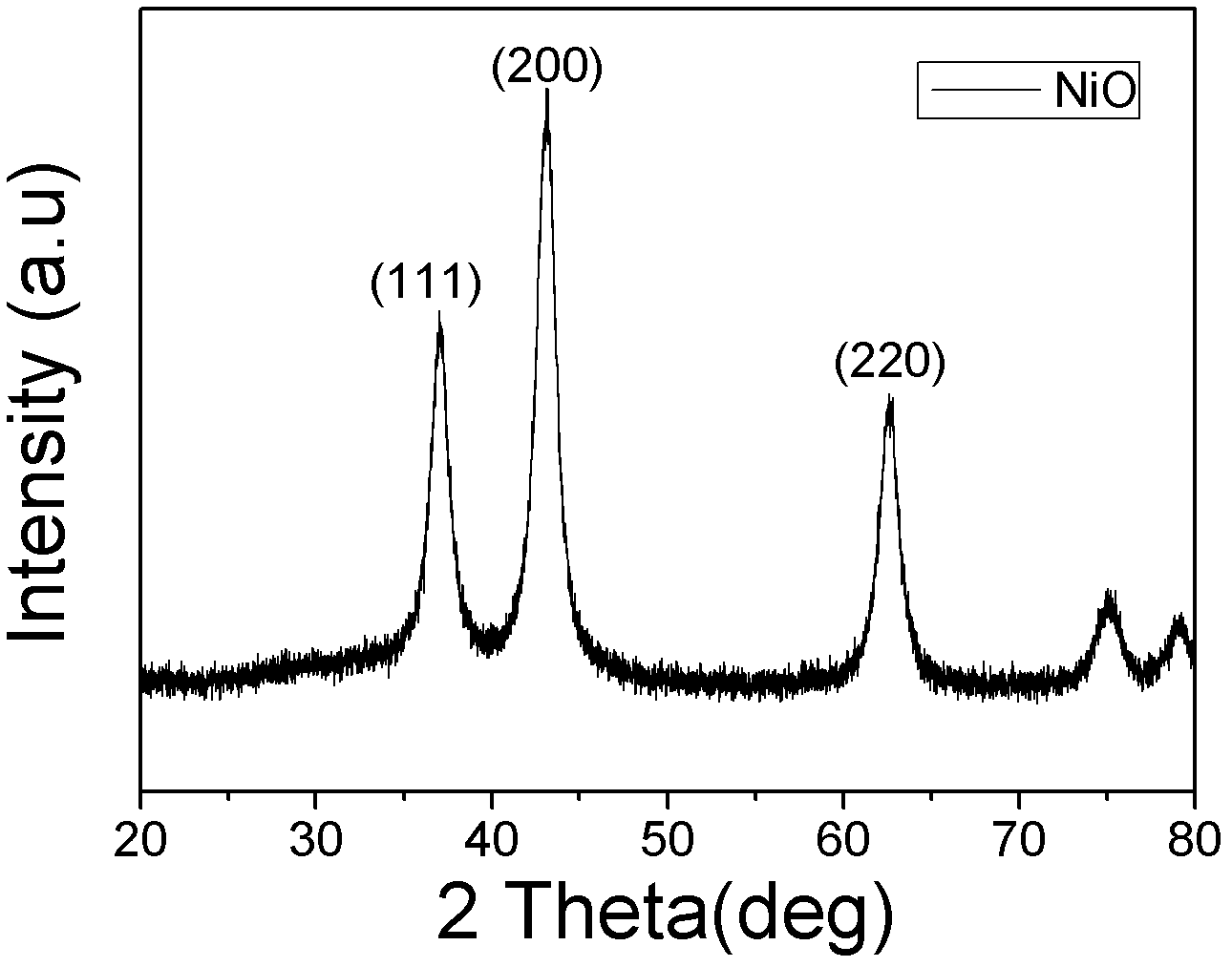

[0045] Example 1 Weigh 29.5 g of sodium chloride and 1.375 g of ammonium chloride. 0.2g of sodium hydroxide was dissolved in 250ml of deionized water to prepare a solution with PH=10. Then take out 80ml of the solution, insert two nickel wires at both ends of the electrode, the distance between the electrodes is 3cm. A voltage of 5V was added to the two ends of the electrode, the voltage was applied for 12 minutes, and then centrifuged, dried, and then annealed in the air at 300°C for 2 hours to finally obtain nano-nickel oxide. Refer to figure 2 As shown, the obtained product is a nickel oxide nanosheet with regular morphology and uniform size. Refer to image 3 The XRD pattern of the sample shows that the product obtained is cubic nickel oxide with higher purity and better crystallinity. Refer to Figure 4 The HRTEM results of the sample show that the obtained nickel oxide nanosheets are polycrystalline nickel oxide nanosheets composed of crystal grains with a size range ...

Embodiment 2

[0046] Example 2 Dissolve 29.5 g of sodium chloride, 1.375 g of ammonium chloride, 0.2 g of sodium hydroxide, and 0.1 g of sodium oxalate in 250 ml of deionized water. Using the method of Example 1 to prepare nano-nickel hydroxide, nickel hydroxide nano-sheets of uniform size are formed. Then, an annealing treatment is carried out at 500°C in the air for 2 hours, and finally nickel oxide nanosheets are obtained.

Embodiment 3

[0047] Example 3 Add 29.5g of sodium chloride, 1.375g of ammonium chloride, 2.0625ml of ammonia, 0.2g of sodium hydroxide to 250ml of deionized water, and then stir them to prepare nanohydroxide by the method of Example 1. Nickel forms spherical nickel hydroxide particles. It is annealed to prepare spherical nano-nickel oxide (see Image 6 ), mix the nano-nickel oxide with water at 0.5-2g / ml, and coat it on the surface of the sensor substrate, and then age it at 200-400℃ to make a formaldehyde sensor, and then detect the formaldehyde. It can realize highly sensitive detection of 1-1000 ppm formaldehyde gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com