Titanium dioxide-aluminum oxide composite carrier and preparation method thereof

A technology of alumina carrier and composite carrier, applied in catalyst activation/preparation, catalyst carrier, chemical instrument and method, etc., can solve problems such as unfavorable macromolecular diffusion, affecting reaction rate, small average pore size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

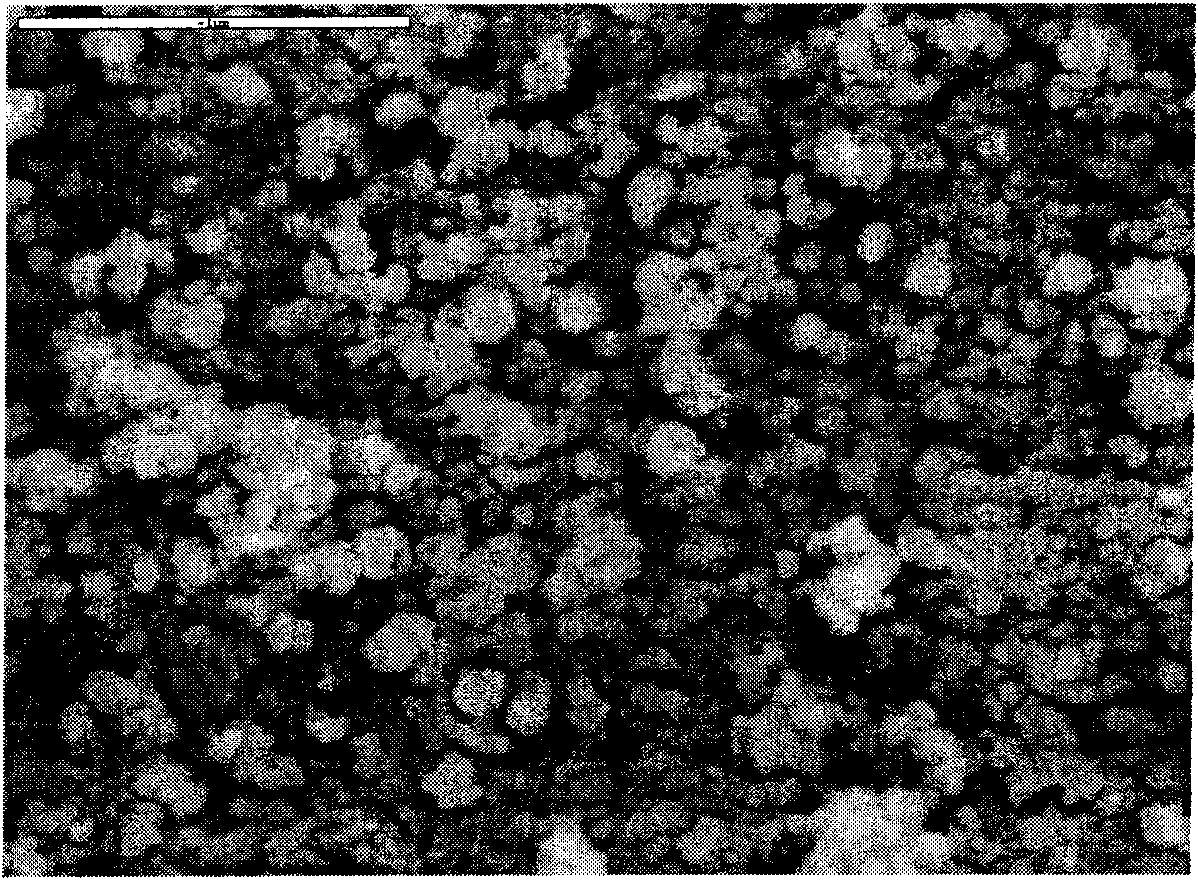

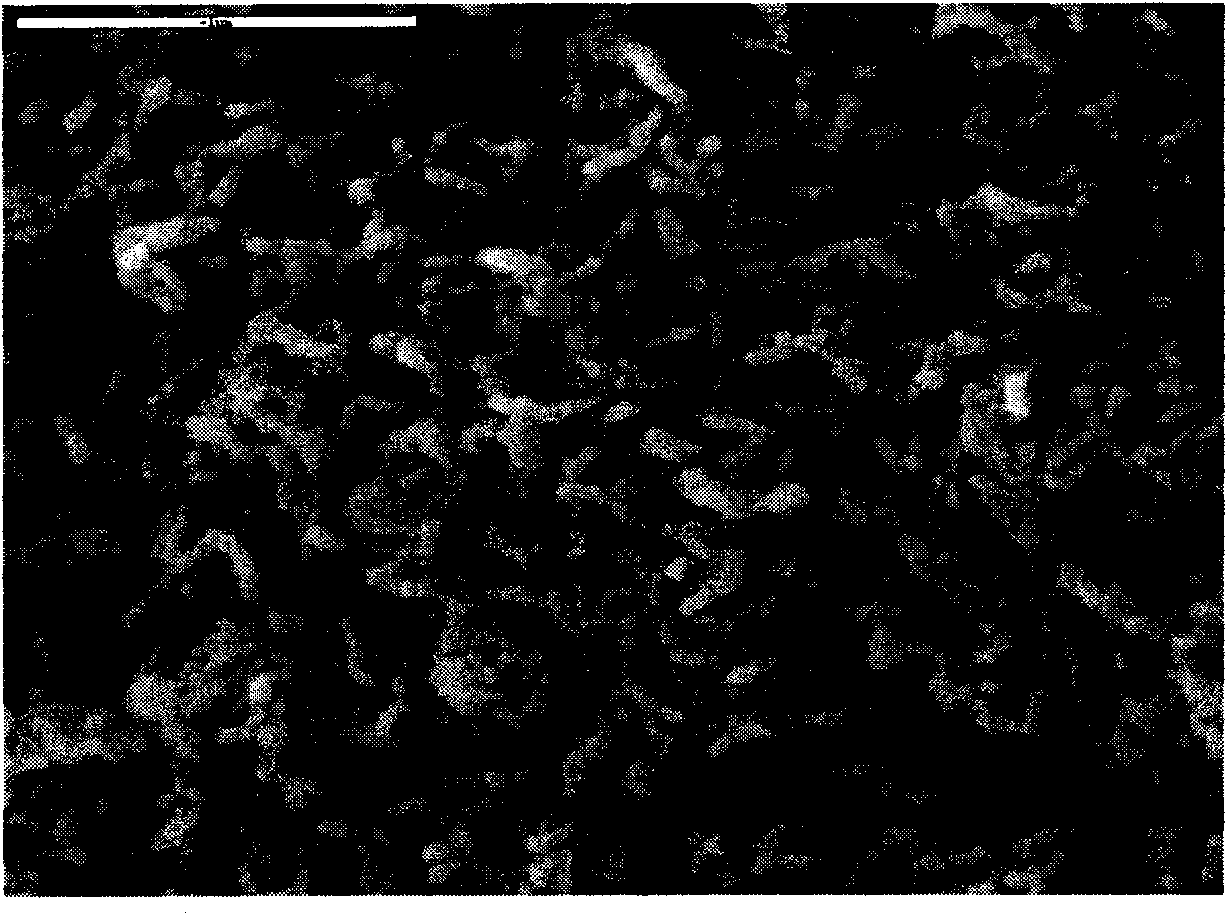

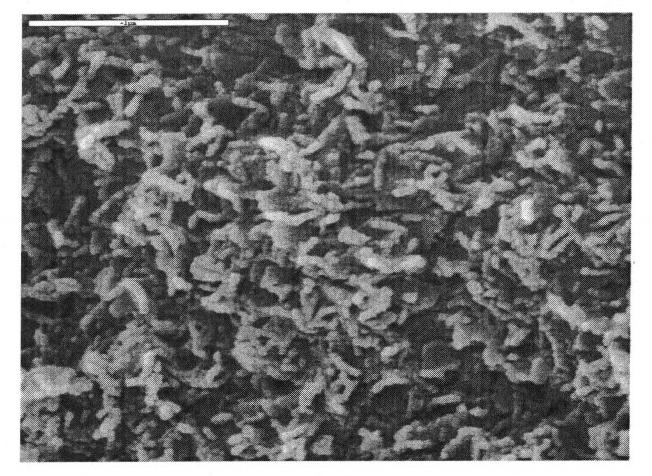

Embodiment 1

[0052]Under stirring conditions, 375g of aluminum nitrate nonahydrate and 90g of urea were mixed and heated to 100°C, and added to a mixture of 32g of polyisobutylene maleate triethanolamine maleate and 88g of 150HVI neutral oil at the same temperature to form supersolubilizing micelles . 96g of titanium tetrachloride was added to 200g of ethanol, added dropwise to the micelles, and then reacted in a closed manner at 100°C for 3 hours to obtain nanometer titanium hydroxide-aluminum hydroxide gel. Wash three times with 200ml of distilled water, and dry at 120°C for 10 hours. Mix 160g of nano-titanium hydroxide-aluminum hydroxide gel dry powder with 40g of binder pseudo-boehmite; mix 2.6g of dilute nitric acid (mass concentration 17%), 60g of water and 10g of cosolvent ethanol, and stir Evenly, mix evenly on the mixer, and then shape it in the extruder, and control the pressure at 10MPa. The formed product was dried at 100°C for 10 hours, calcined at 240°C for 3 hours, and cal...

Embodiment 2

[0054] The titania-alumina carrier TA1 obtained in Example 1 is impregnated with active metals, and the resulting residue hydrodesulfurization catalyst HDS-1 contains 14% (mass fraction) MoO 3 , 4% (mass fraction) NiO.

[0055] The residual oil hydrodesulfurization catalyst HDS-1 was used in the hydrodesulfurization experiment of residual oil raw material (properties are shown in Table 2). The test conditions are shown in Table 3 and the test results are shown in Table 4.

Embodiment 3

[0061] Change the forming method of Example 1 to the tableting method, and the process is as follows: put the dry powder of nano-titanium hydroxide-aluminum hydroxide gel and 12 g of carbon black into the tablet press, and press the tablet under the condition of a pressure of 0.08 MPa. forming. The molded product was dried at 120°C for 8 hours, calcined at 260°C for 3 hours, and calcined at 750°C for 4 hours, wherein the heating rate was 4°C / min to obtain the titania-alumina carrier TA2 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com