Patents

Literature

105results about "Nickel compounds preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium metal oxide materials and methods of synthesis and use

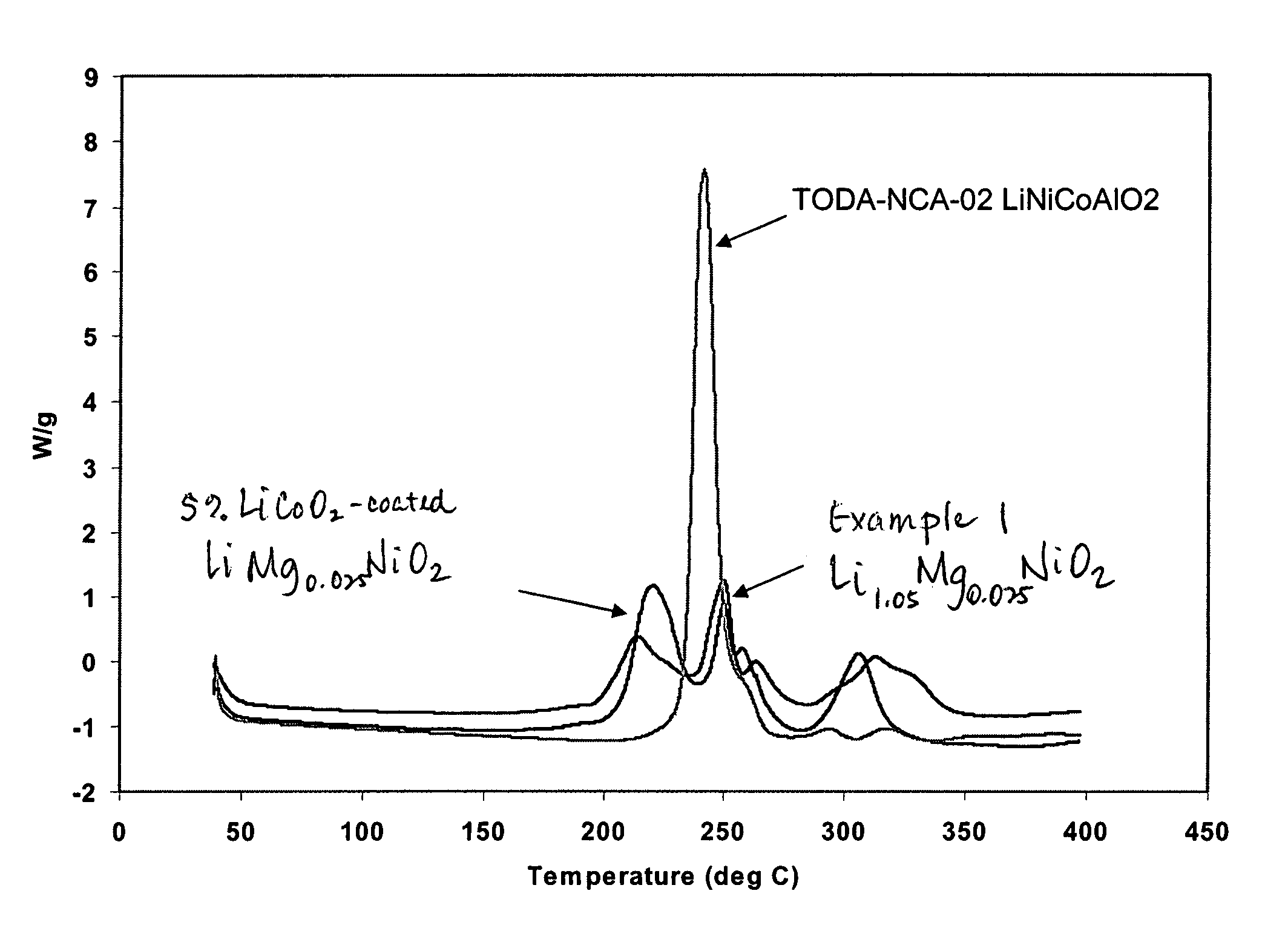

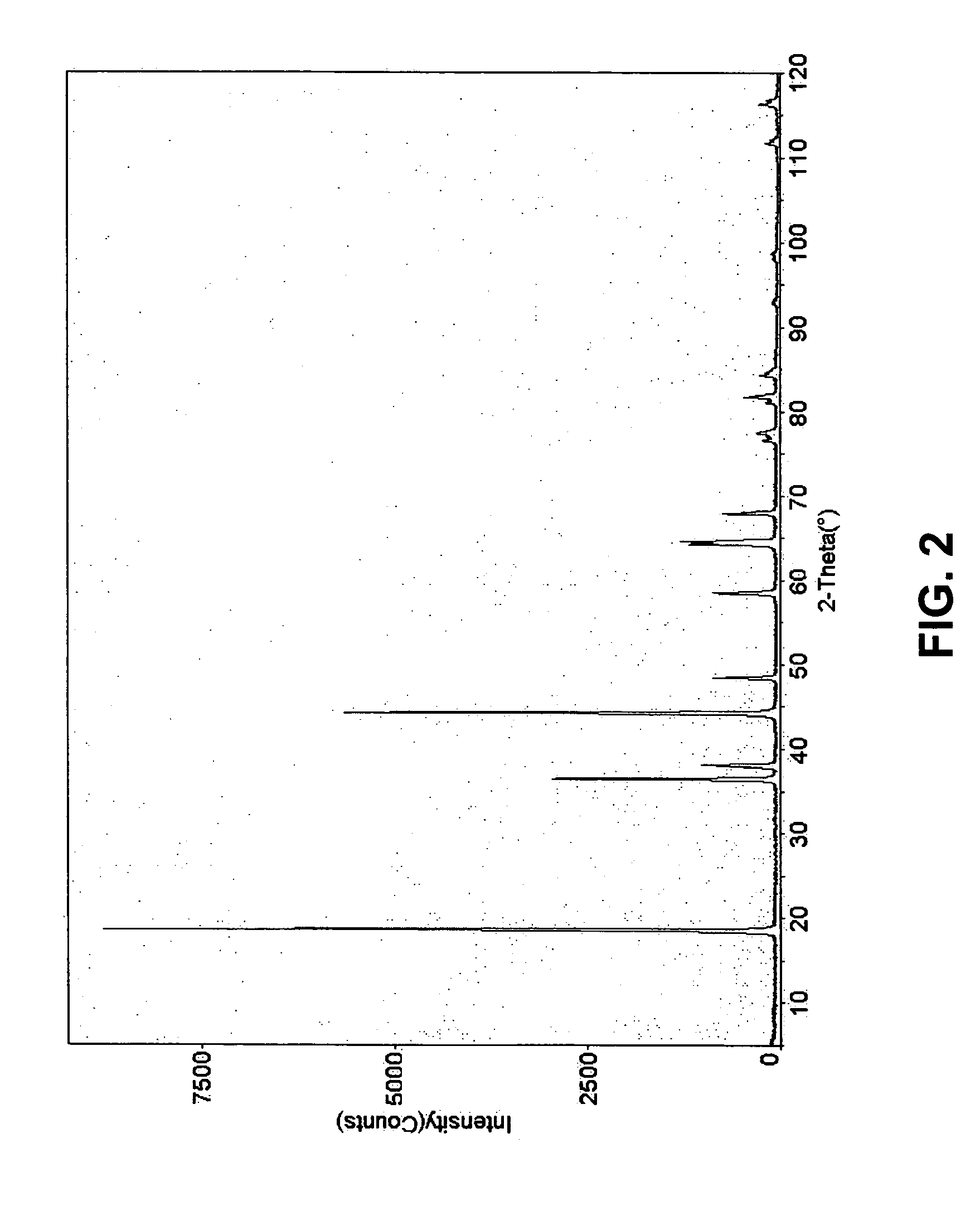

ActiveUS7381496B2Large capacityImprove cycle lifeOxide/hydroxide preparationNickel compounds preparationLithium metalElectrochemical cell

A composition having a formula LixMgyNiO2 wherein 0.9<x<1.3, 0.01<y<0.1, and 0.91<x+y<1.3 can be utilized as cathode materials in electrochemical cells. A composition having a core, having a formula LixMgyNiO2 wherein 0.9<x<1.3, 0.01<y<0.1, and 0.9<x+y<1.3, and a coating on the core, having a formula LiaCobO2 wherein 0.7<a<1.3, and 0.9<b<1.2, can also be utilized as cathode materials in electrochemical cells.

Owner:TIAX LLC

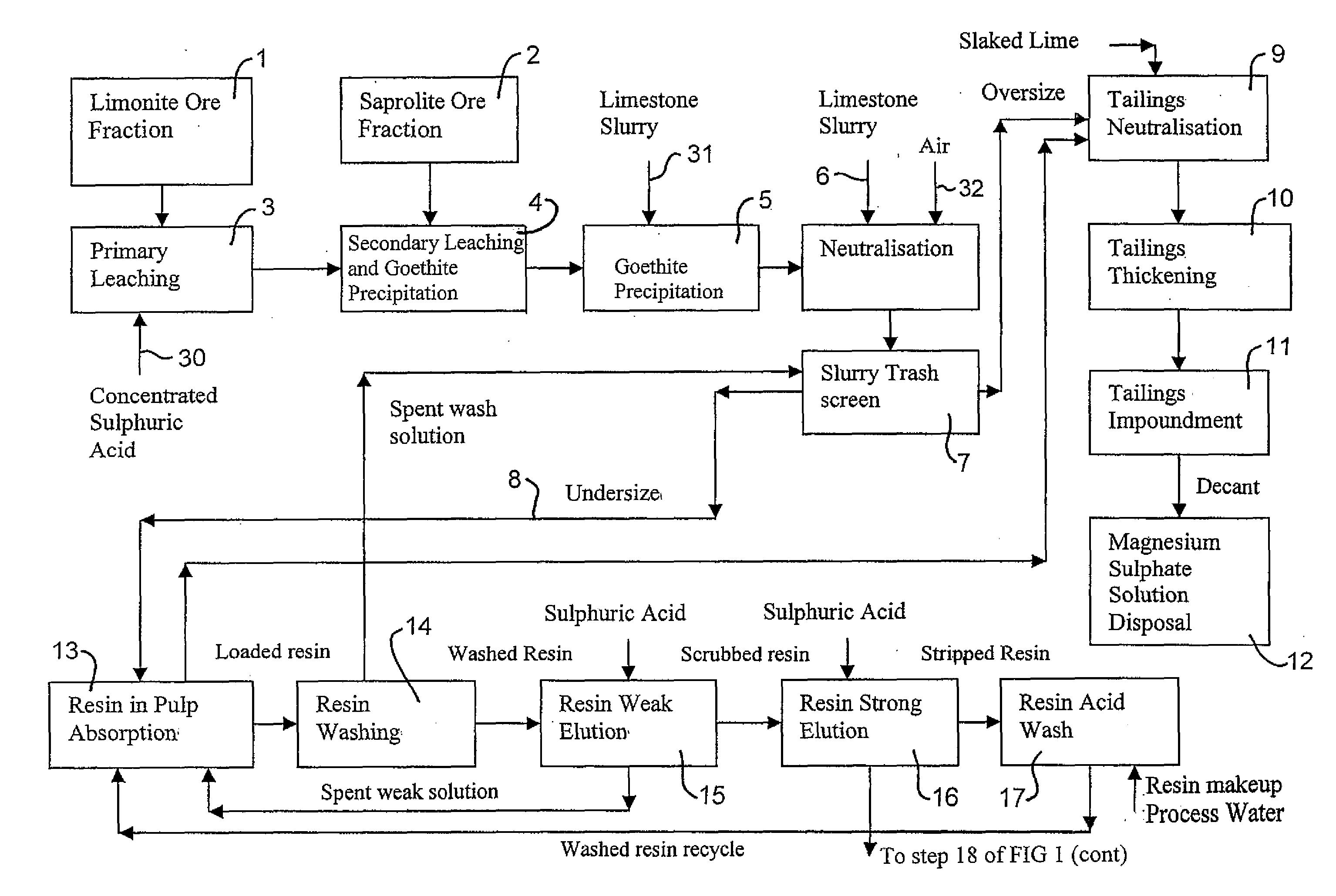

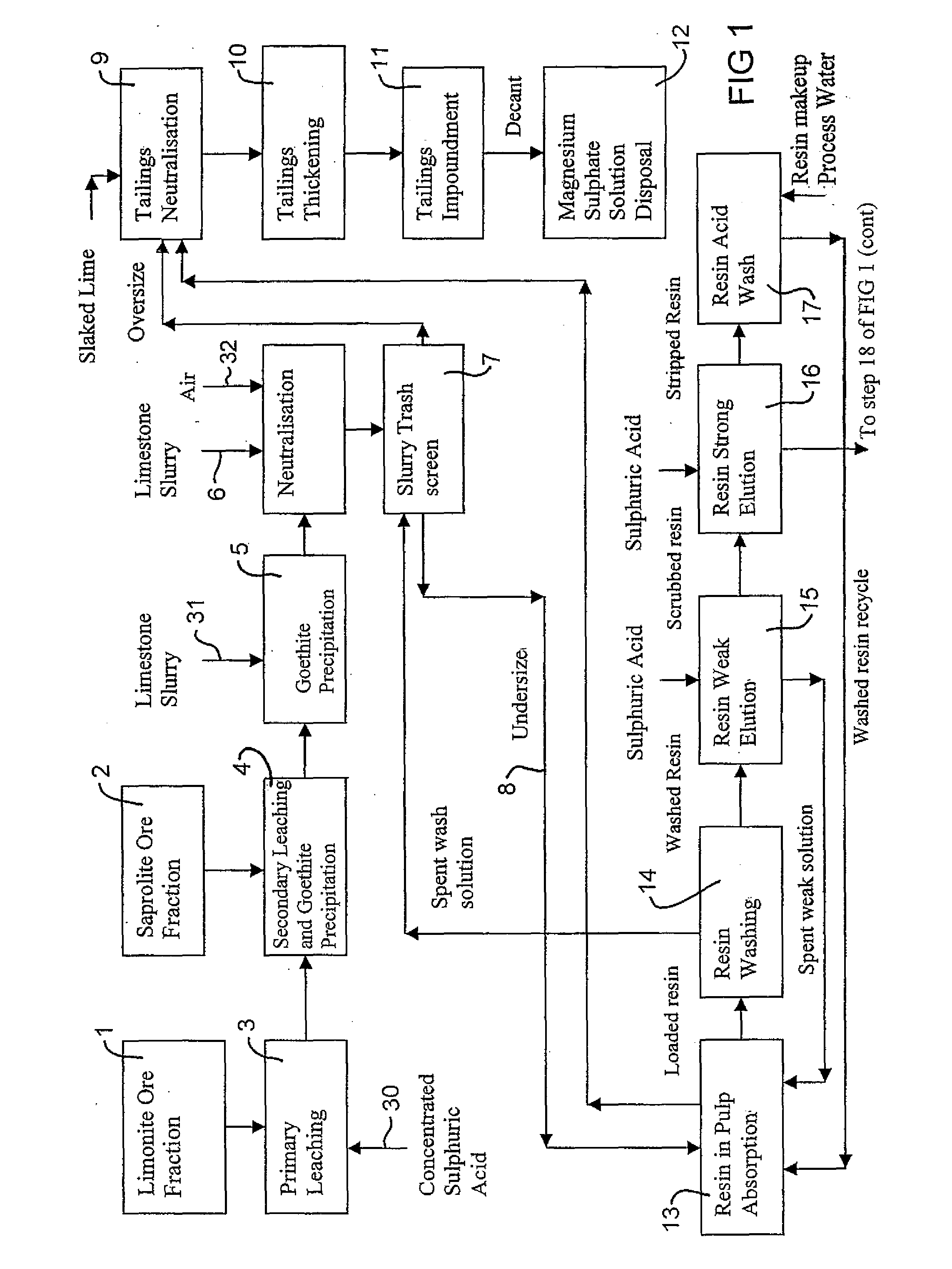

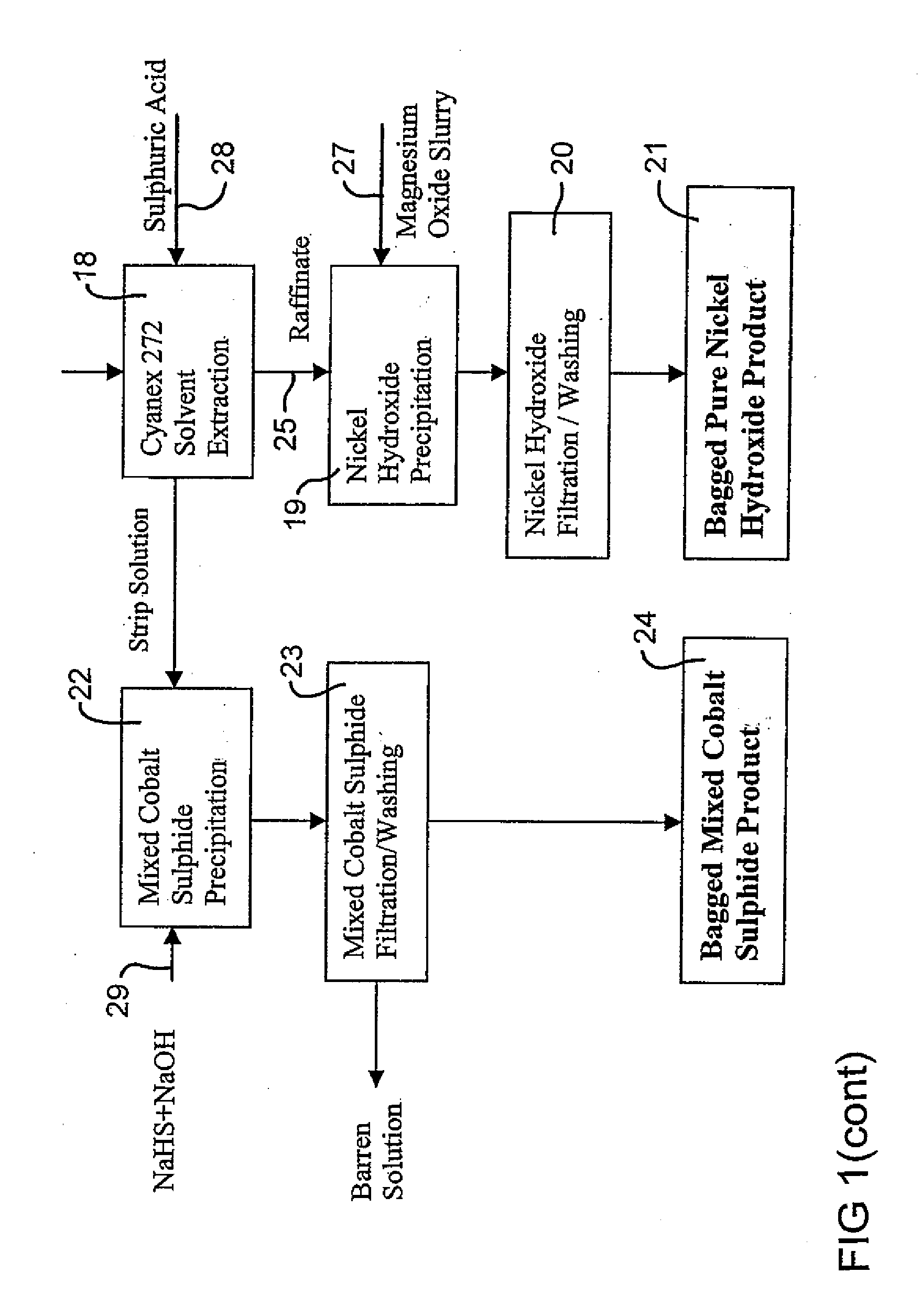

Extraction of Nickel and Cobalt from a Resin Eluate Stream

InactiveUS20070297960A1Easy to transportEasy to disassembleNickel compounds preparationIron compoundsManganeseCopper

A process for the recovery of nickel and cobalt from an acidic resin eluate containing at least nickel and cobalt, said process including the steps of: (a) treating the eluate with an immiscible organic reagent (18) to selectively absorb the majority of the cobalt, and a portion of any copper, zinc and manganese present in the eluate, leaving a raffinate containing the nickel and minor impurities; (b) neutralising the raffinate to precipitate the nickel as nickel hydroxide (19); (c) stripping the cobalt from the organic reagent (22); and (d) recovering the cobalt (23).

Owner:BHP BILLITON SSM TECH PTY LTD

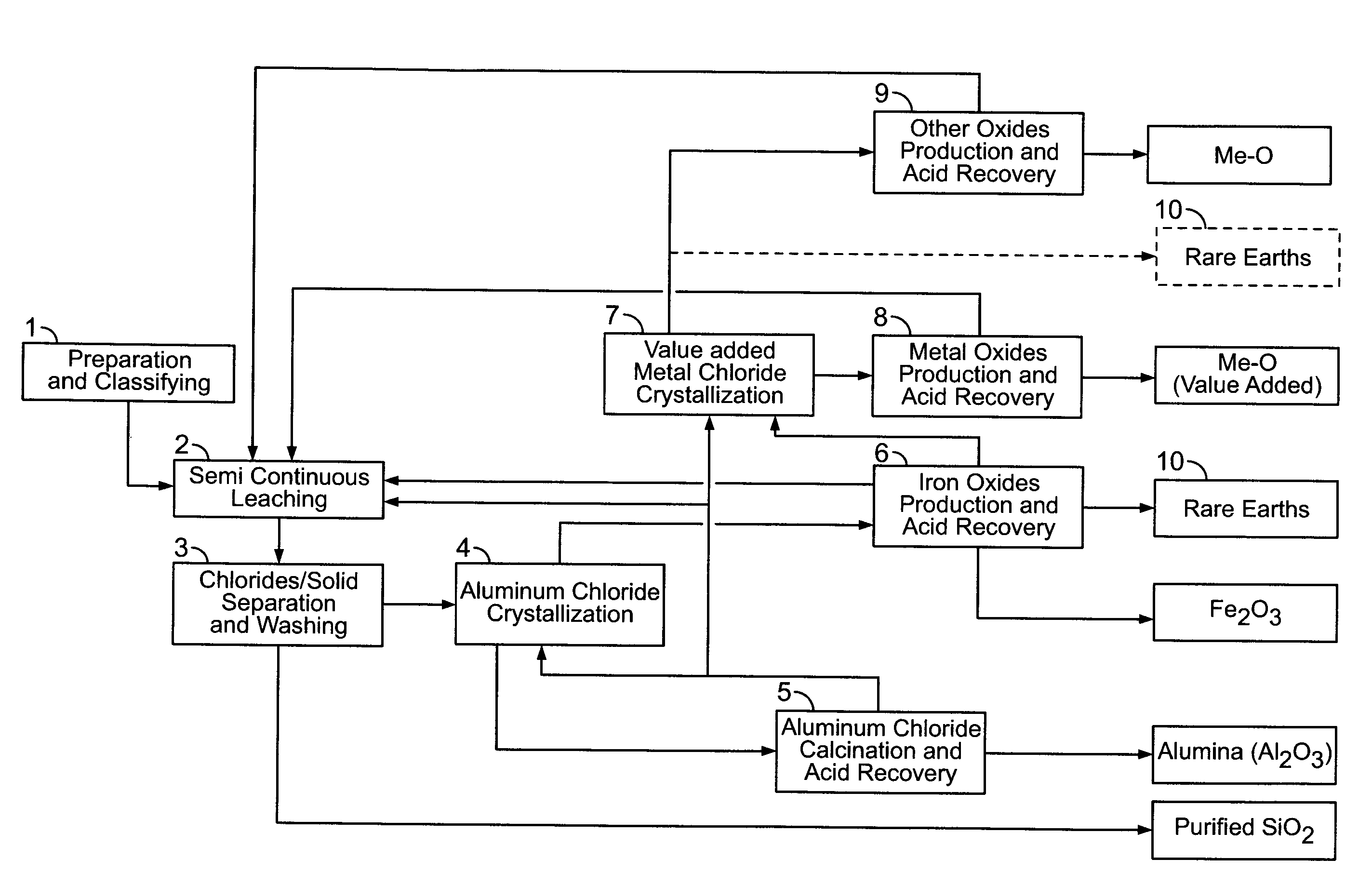

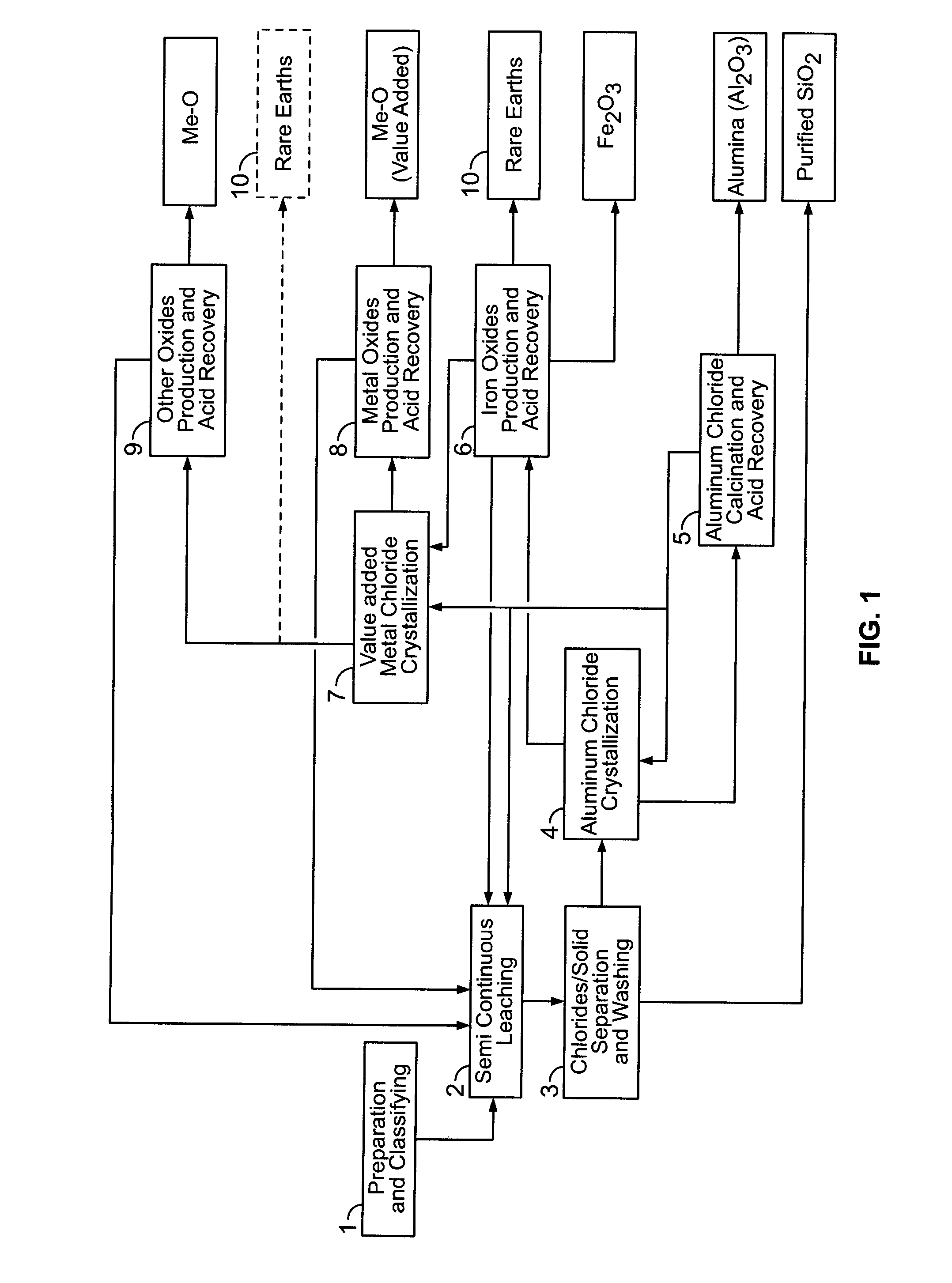

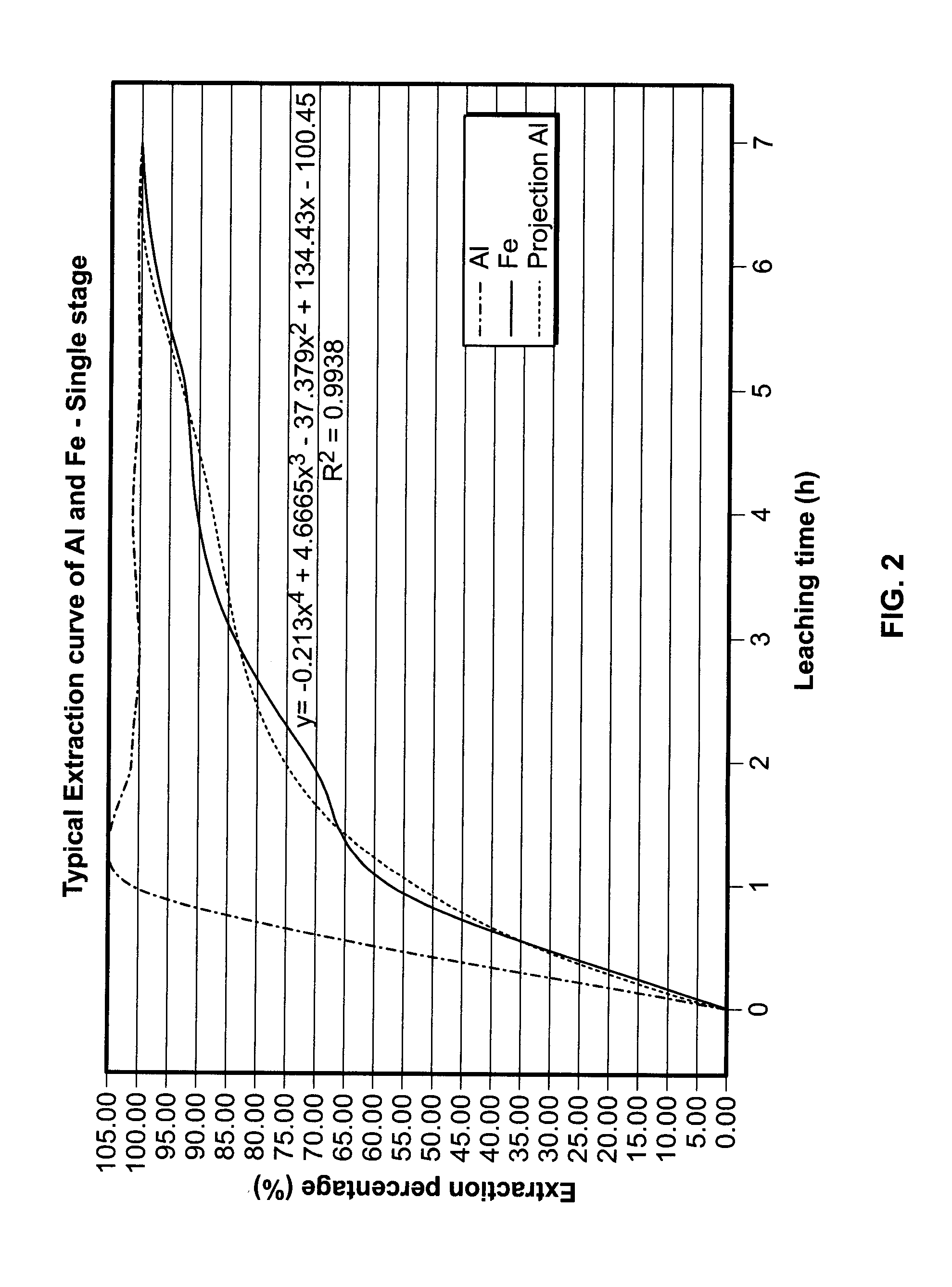

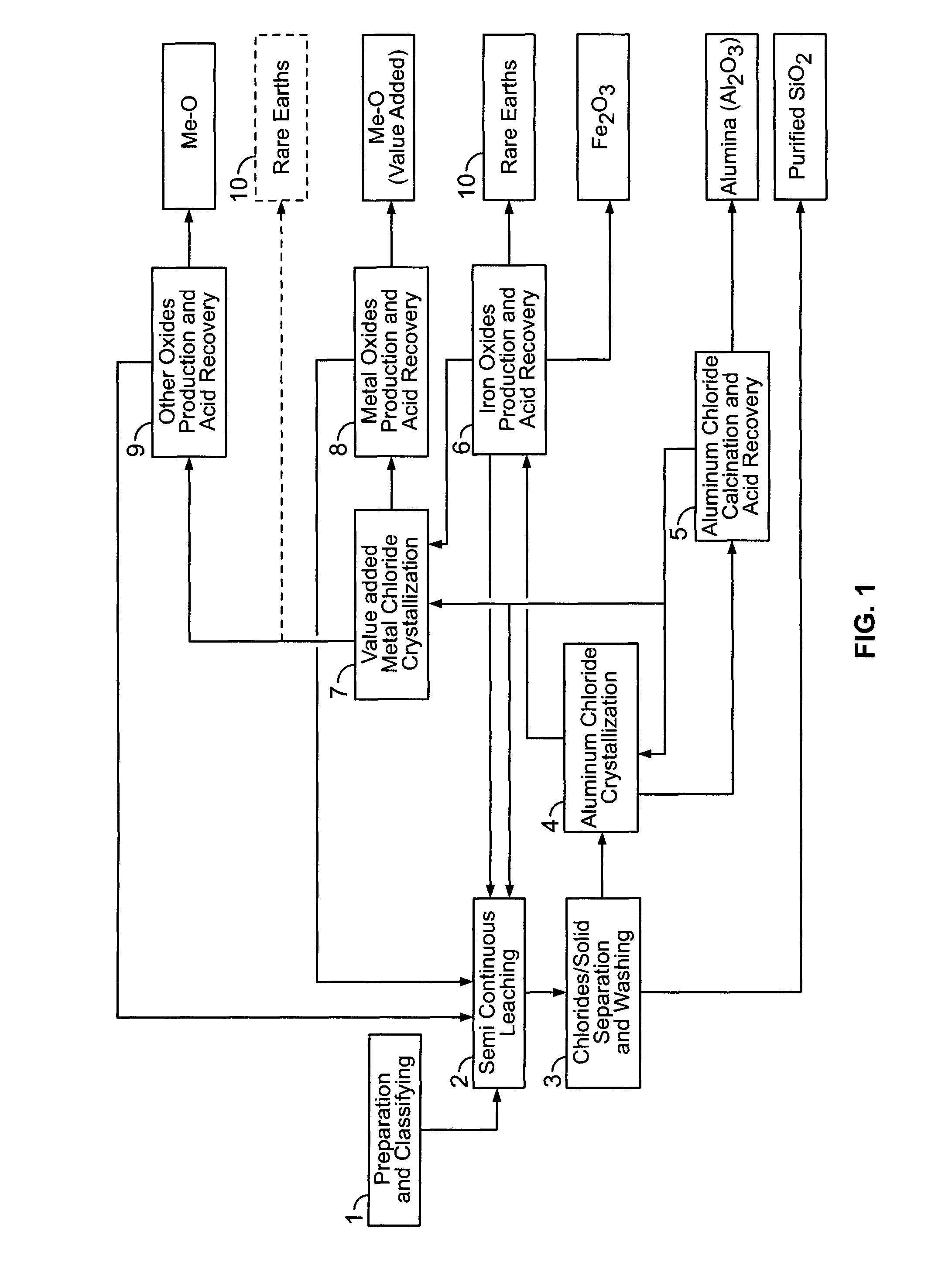

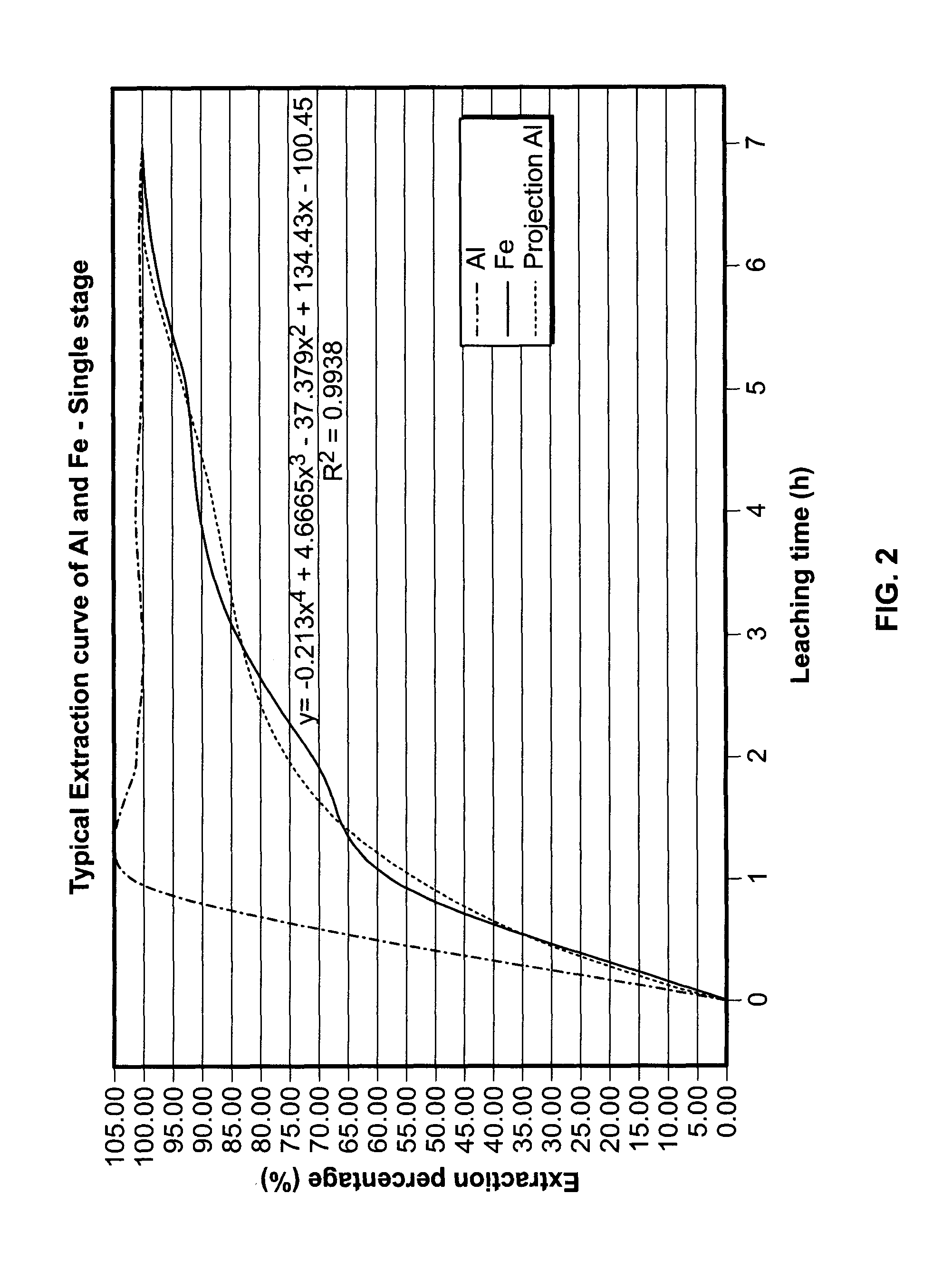

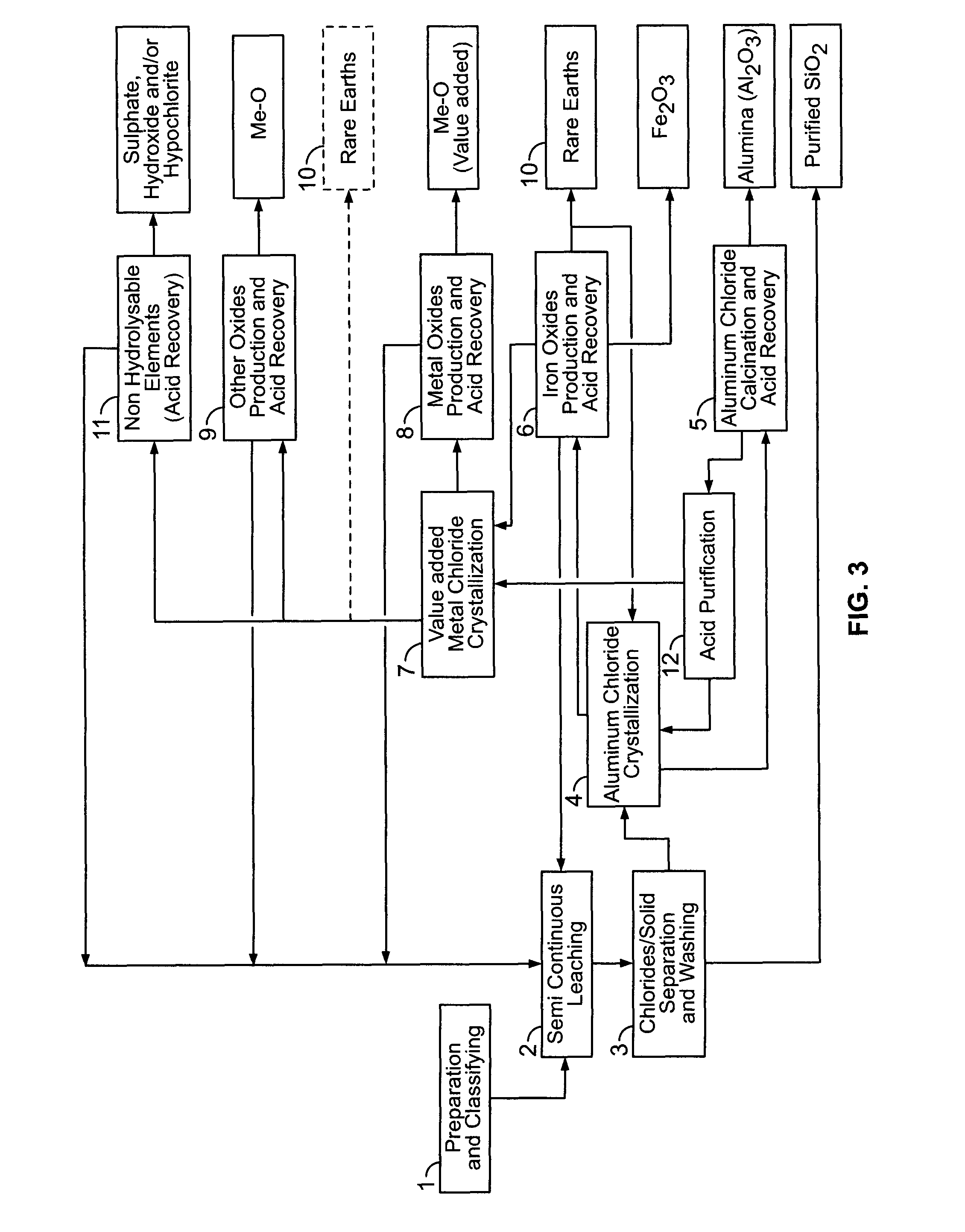

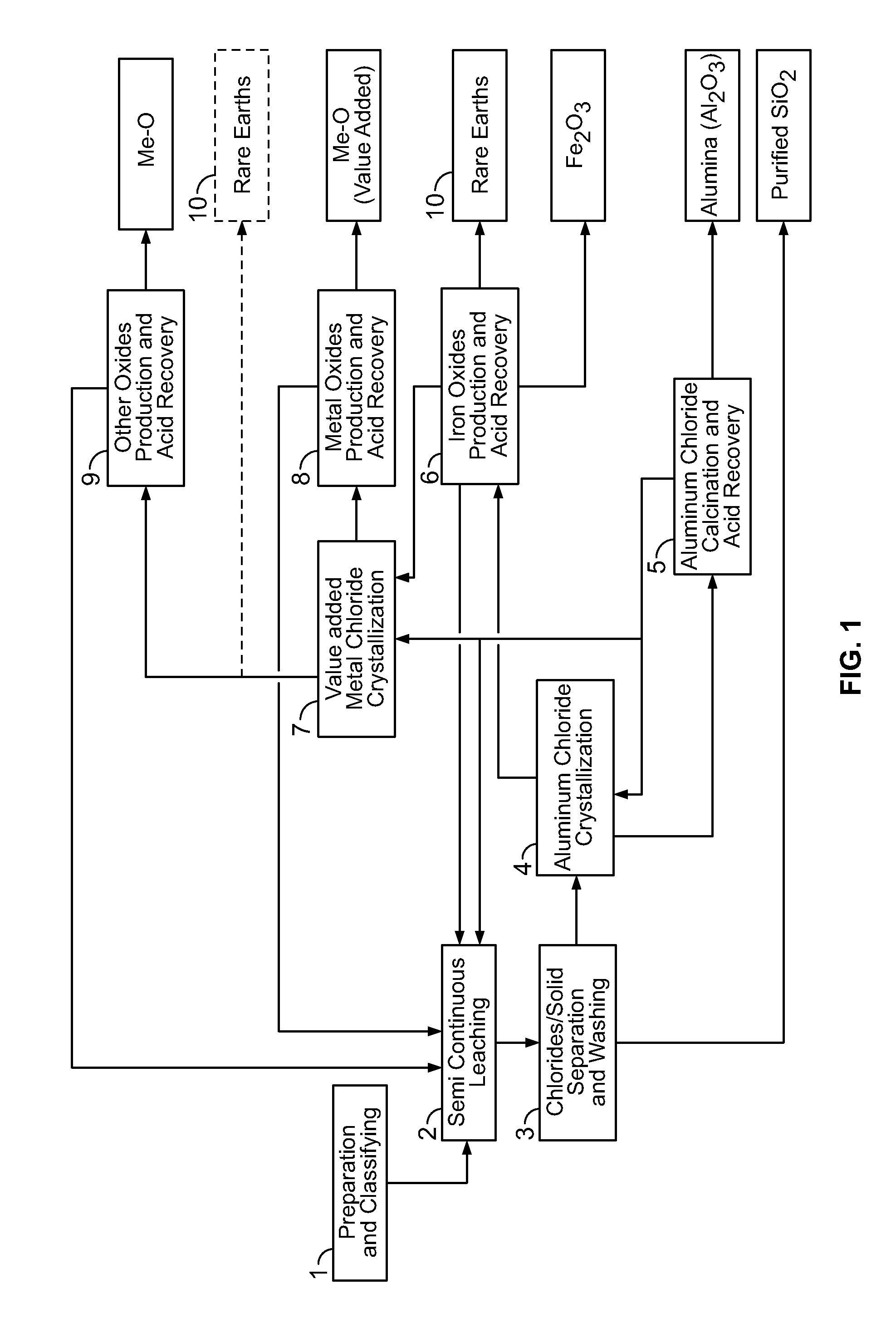

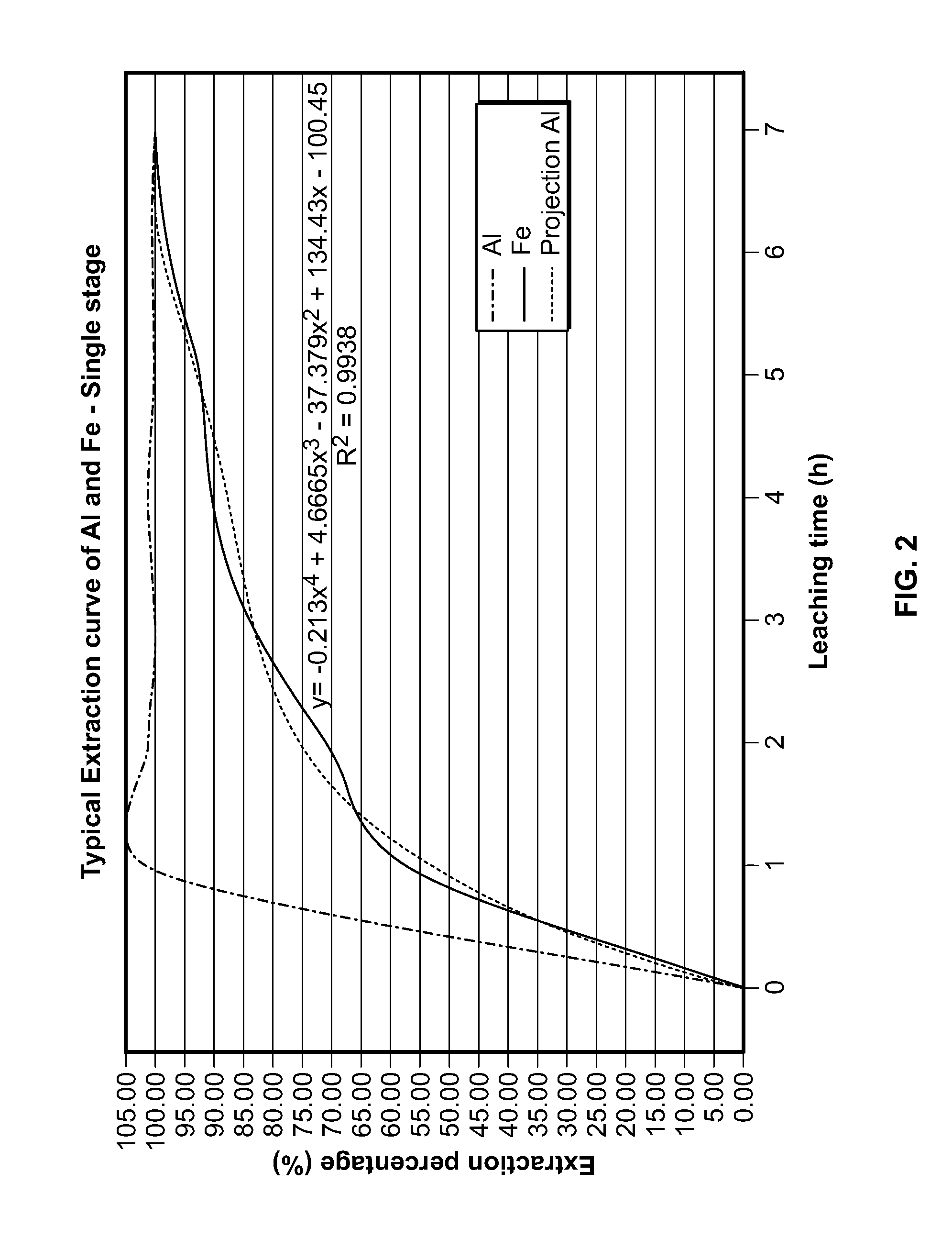

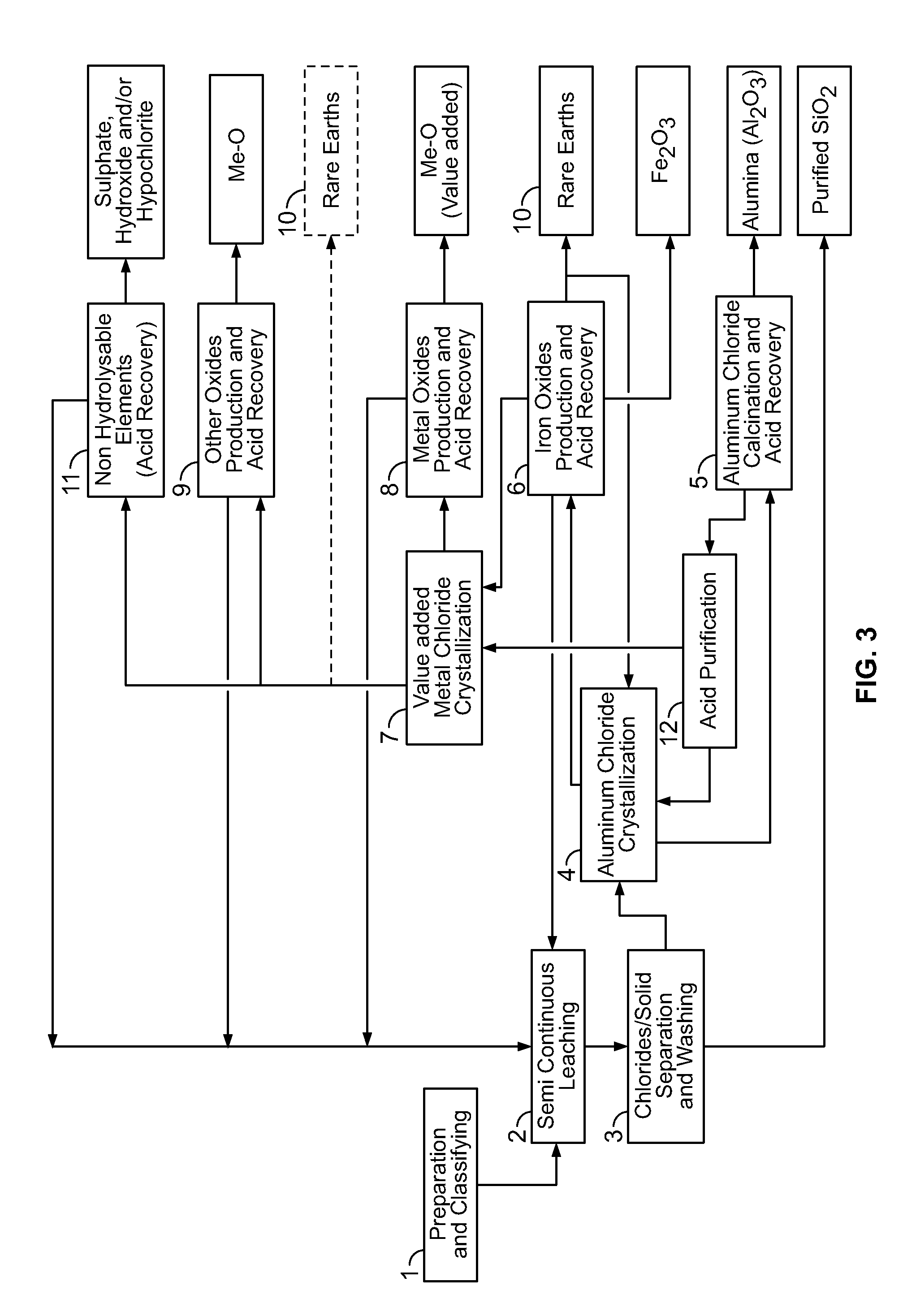

Processes for treating red mud

ActiveUS20140369907A1Simple and efficientLow costAluminium compoundsSolvent extractionPregnant leach solutionRare-earth element

There are provided processes for treating red mud. For example, the processes can comprise leaching red mud with HCl so as to obtain a leachate comprising ions of a first metal (for example aluminum) and a solid, and separating said solid from said leachate. Several other metals can be extracted from the leachate (Fe, Ni, Co, Mg, rare earth elements, rare metals, etc.). Various other components can be extracted from solid such as TiO2, SiO2 etc.

Owner:ORBITE ALUMINAE INC

Method for preparing nickel sulfate solution and battery grade ferric phosphate from nickel-containing pig iron

ActiveCN106829907AImprove use valueReduce processing costsNickel compounds preparationNickel sulfatesSulfatePhosphate

The invention discloses a method for preparing a nickel sulfate solution and battery grade ferric phosphate from nickel-containing pig iron. The method comprises the following steps of carrying out raw materials pretreatment, acid leaching treatment, sedimentation treatment, ferric phosphate drying treatment, nickel-containing filtrate extraction treatment and reverse extraction to obtain the nickel sulfate solution. The method for preparing the nickel sulfate solution and the battery grade ferric phosphate from the nickel-containing pig iron has the characteristics of simpleness in technology, high recovery rate of the nickel-containing pig iron, low cost and good performance of a product.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

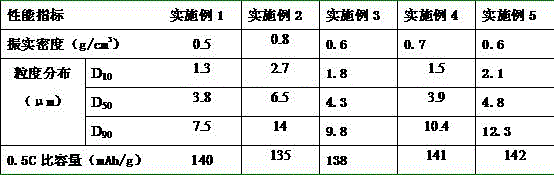

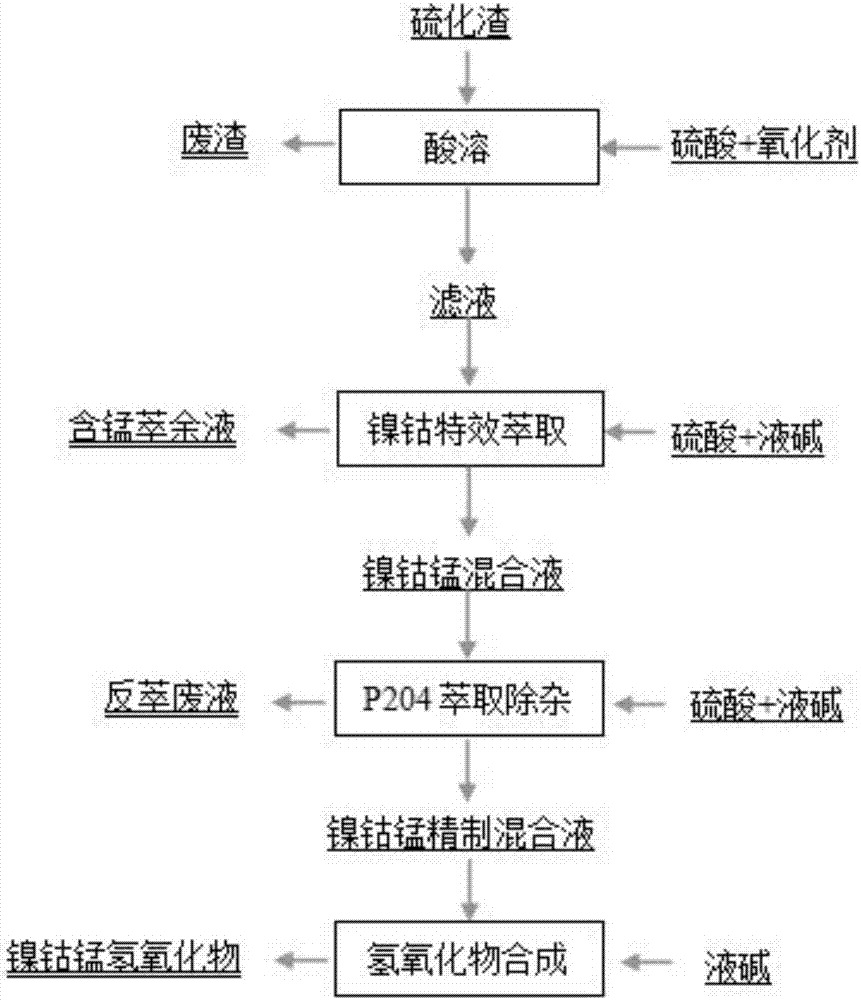

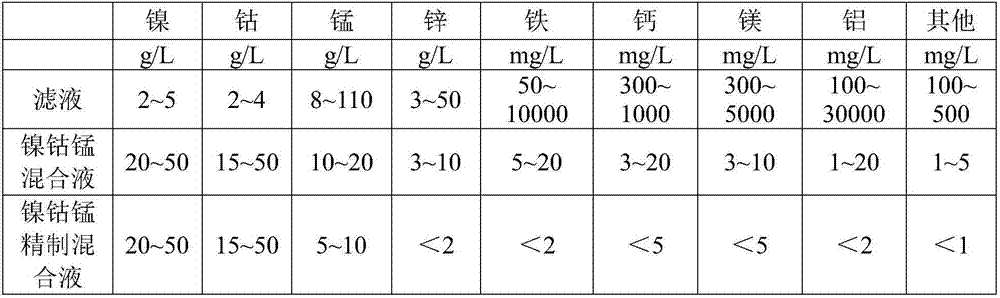

Method for recovering and purifying nickel cobalt from manganese-containing waste material

ActiveCN106904667AReduce security risksLow costNickel compounds preparationManganese sulfatesManganeseSulfide

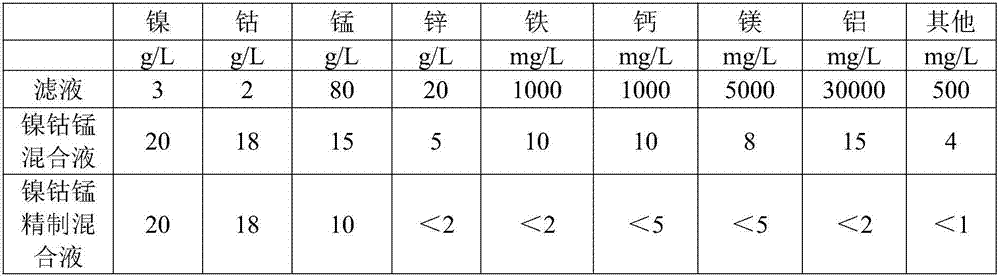

The invention relates to a method for recovering and purifying nickel cobalt from a manganese-containing waste material. The method comprises the following steps: the manganese-containing waste sulfide residues is subjected to slurrying, an acid solution and oxidant are added to the sulfide residues for being dissolved, and the acid-soluble waste residue and a filtrate are obtained; the filtrate is subjected to saponification by liquid caustic soda and then extraction by a nickel cobalt specific extractant to obtain a raffinate containing manganese; a nickel and cobalt-organic phase is extracted by dilute sulfuric acid to obtain a nickel cobalt manganese mixture; the nickel cobalt manganese mixture is subjected to impurities extraction with a dodecyl alkyl phosphate extraction agent after saponification and then is subjected to purification to obtain a nickel cobalt manganese refining mixture; according to the stoichiometric ratio of nickel cobalt manganese metals, the corresponding sulfate is supplemented, and a precursor nickel cobalt manganese hydroxide of lithium cobalt nickel manganese is synthesized by adding the liquid caustic soda. The method has the advantages of effective utilization of waste resources, low cost, good impurity removing effect, and small environmental risk.

Owner:GUIZHOU DALONG HUICHENG NEW MATERIAL CO LTD

Lithium metal oxide materials and methods of synthesis and use

ActiveUS20050260495A1Large capacityImprove cycle lifeOxide/hydroxide preparationNickel compounds preparationLithium metalElectrochemical cell

A composition having a formula LixMgyNiO2 wherein 0.9<x<1.3, 0.01<y<0.1, and 0.91<x+y<1.3 can be utilized as cathode materials in electrochemical cells. A composition having a core, having a formula LixMgyNiO2 wherein 0.9<x<1.3, 0.01<y<0.1, and 0.9<x+y<1.3, and a coating on the core, having a formula LiaCObO2 wherein 0.7<a<1.3, and 0.9<b<1.2, can also be utilized as cathode materials in electrochemical cells.

Owner:TIAX LLC

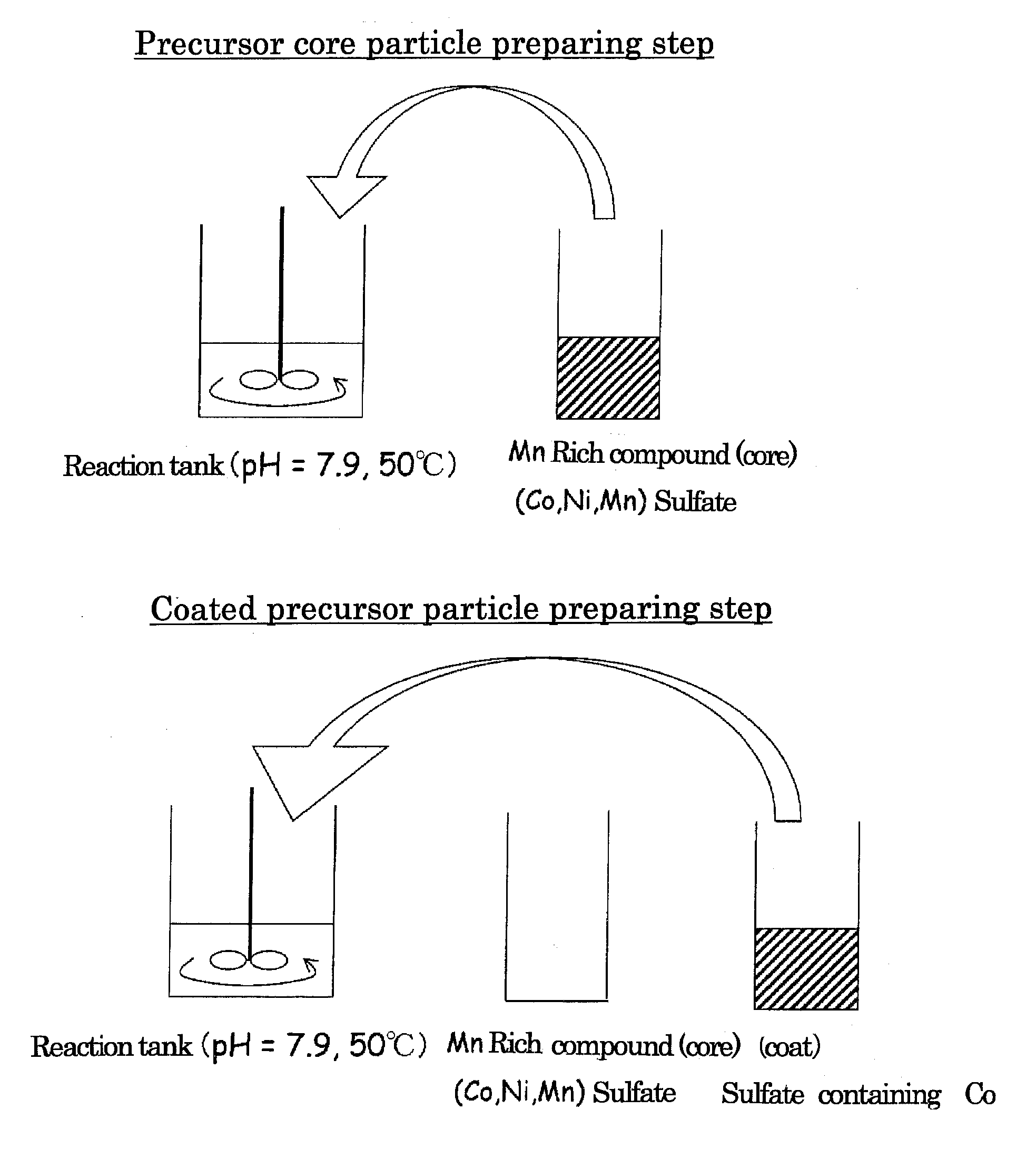

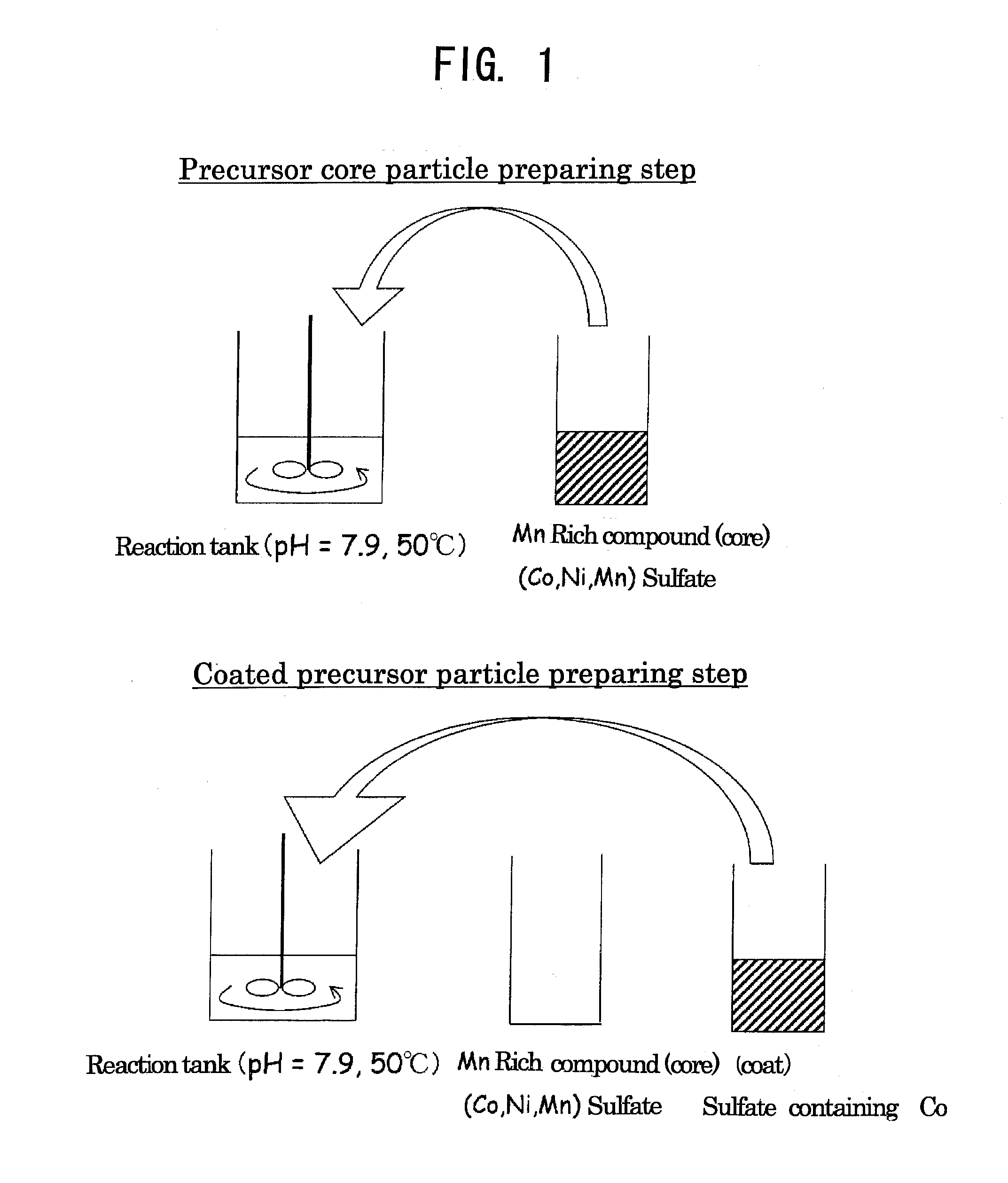

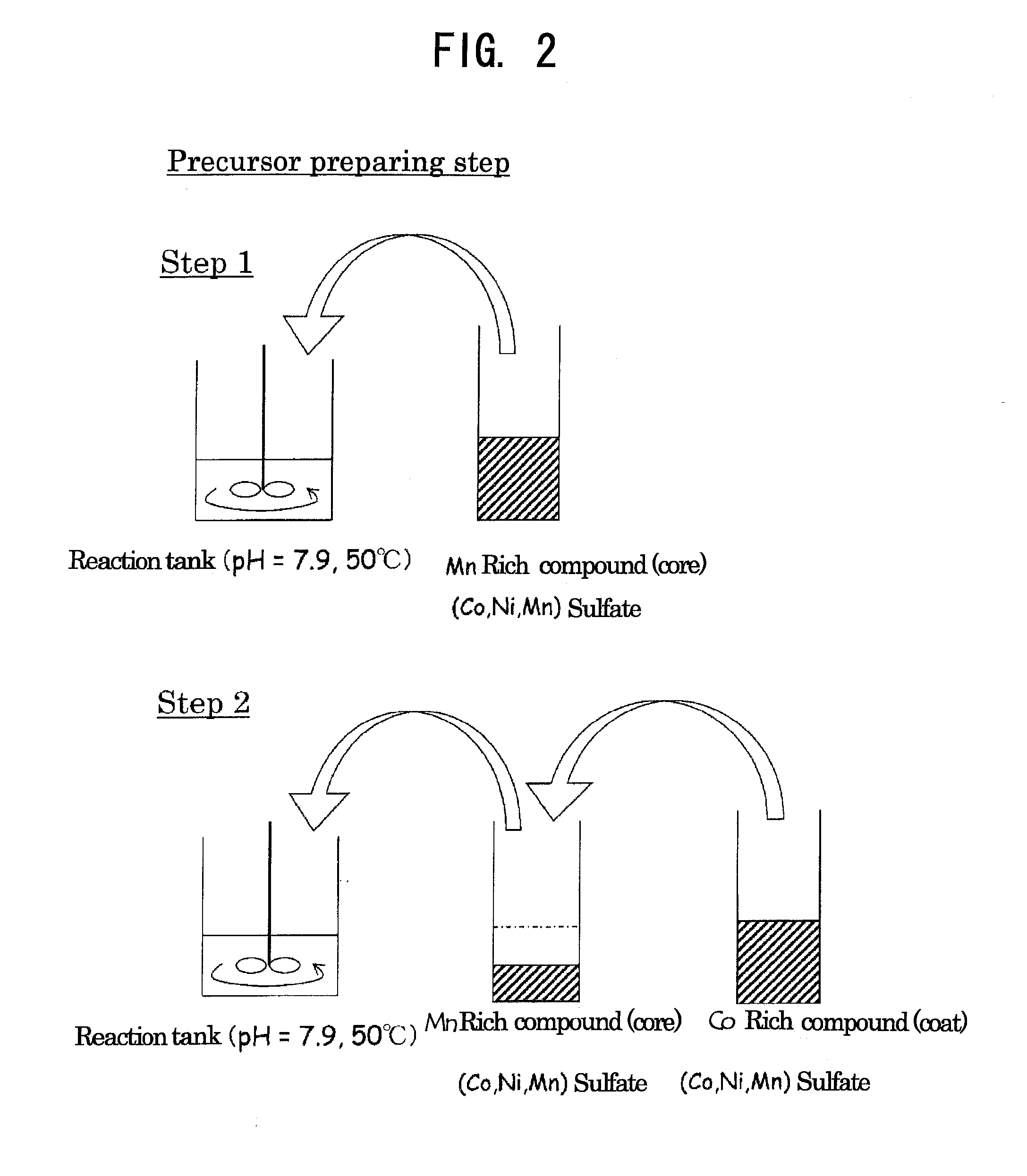

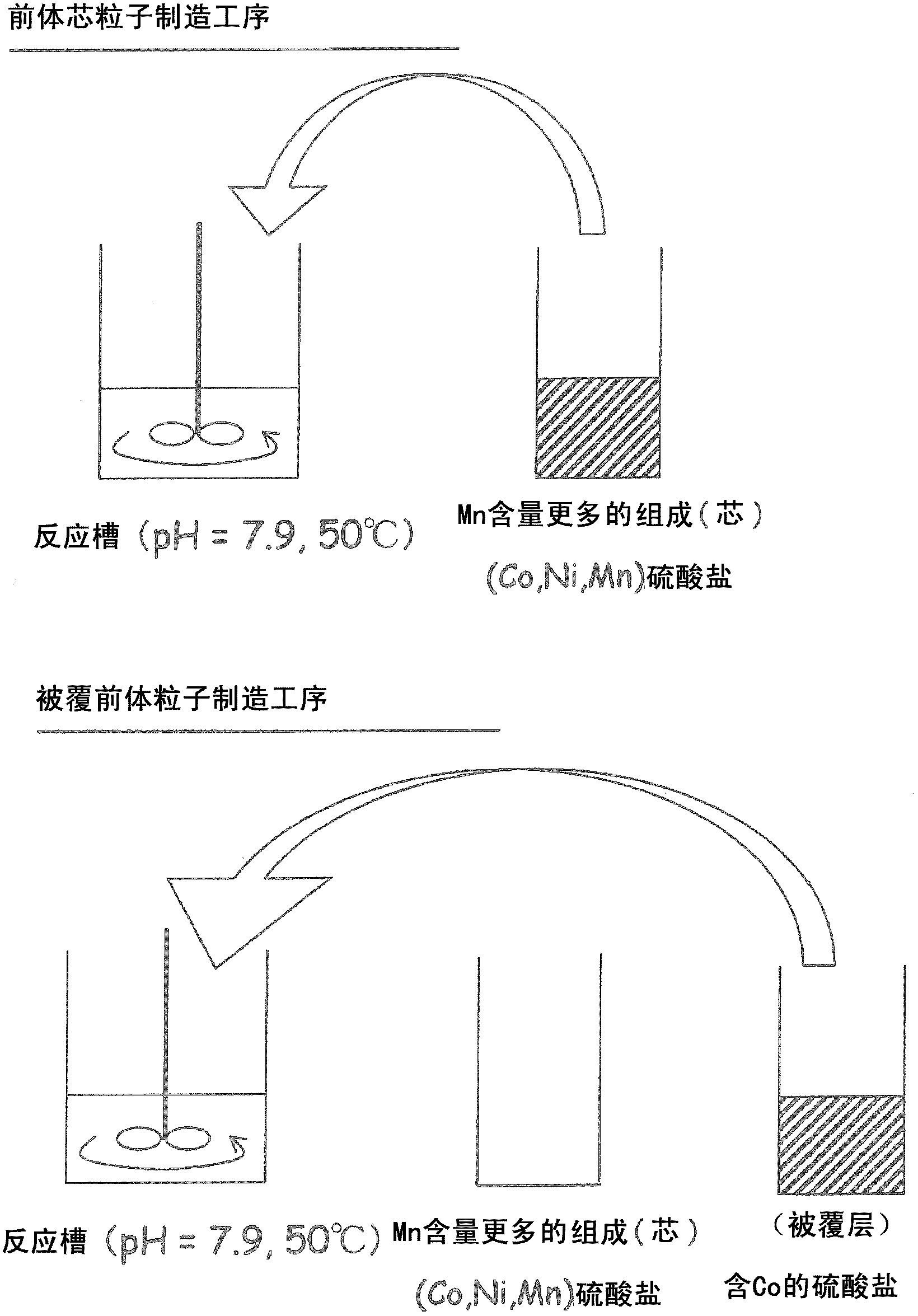

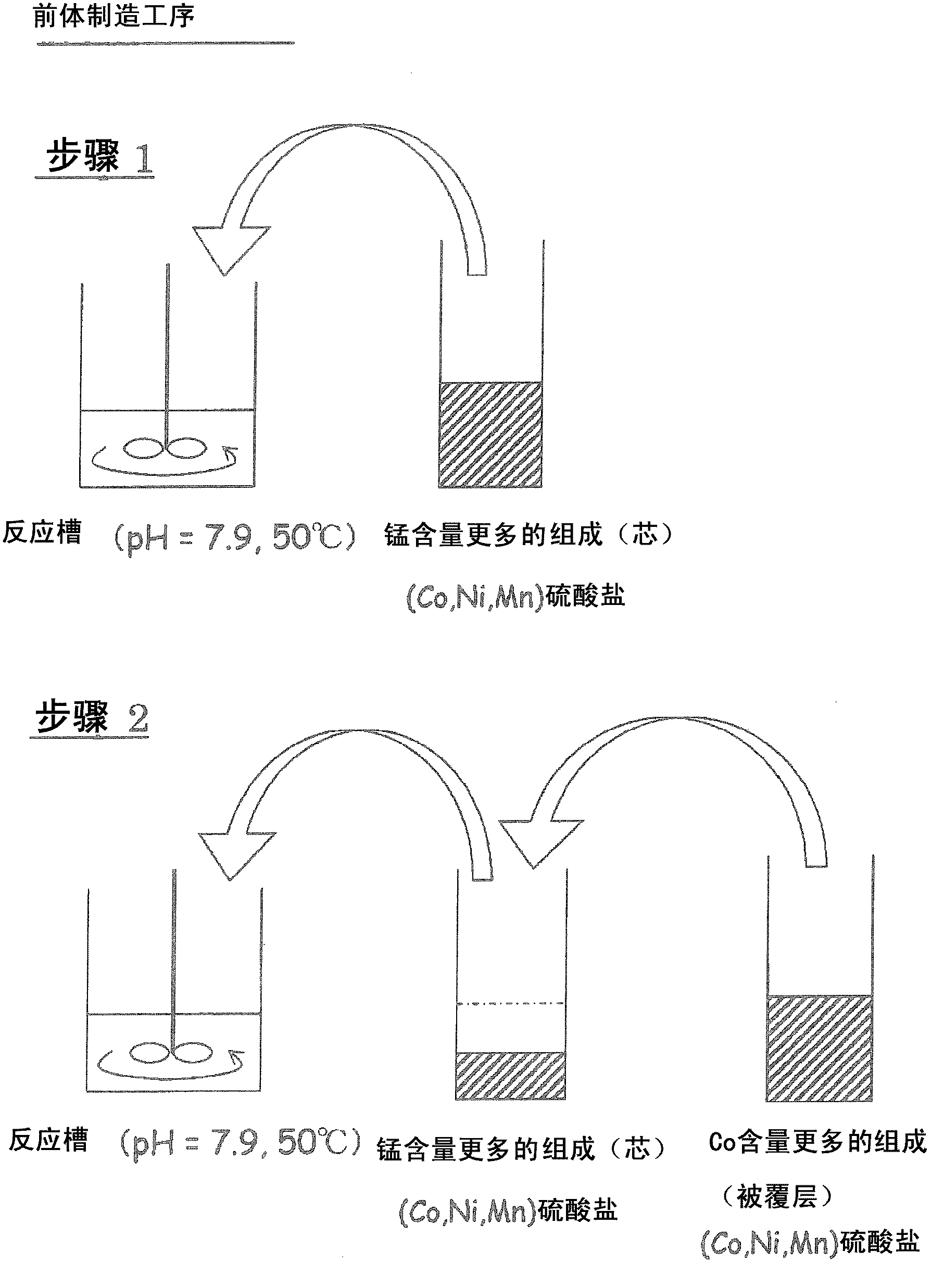

Active material for nonaqueous electrolyte secondary battery, method for production of the active material, electrode for nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery

InactiveUS20130230775A1Improve discharge characteristicsImprove power characteristicsNickel compounds preparationLi-accumulatorsManganeseCrystal structure

There is provided an active material for a nonaqueous electrolyte secondary battery, including a lithium-transition metal composite oxide which has an α-NaFeO2-type crystal structure and of which the average composition is represented by the composition formula of Li1+αMe1−αO2 (Me is a transition metal containing Co, Ni and Mn; and α>0), wherein the lithium-transition metal composite oxide is a particle having a core and a coated part, the cobalt concentration of the coated part is higher than the cobalt concentration of the core, the manganese concentration of the coated part is lower than the manganese concentration of the core, and the ratio of cobalt present in the coated part is 3 to 10% in terms of a molar ratio based on the amount of the transition metal present in the core.

Owner:GS YUASA INT LTD

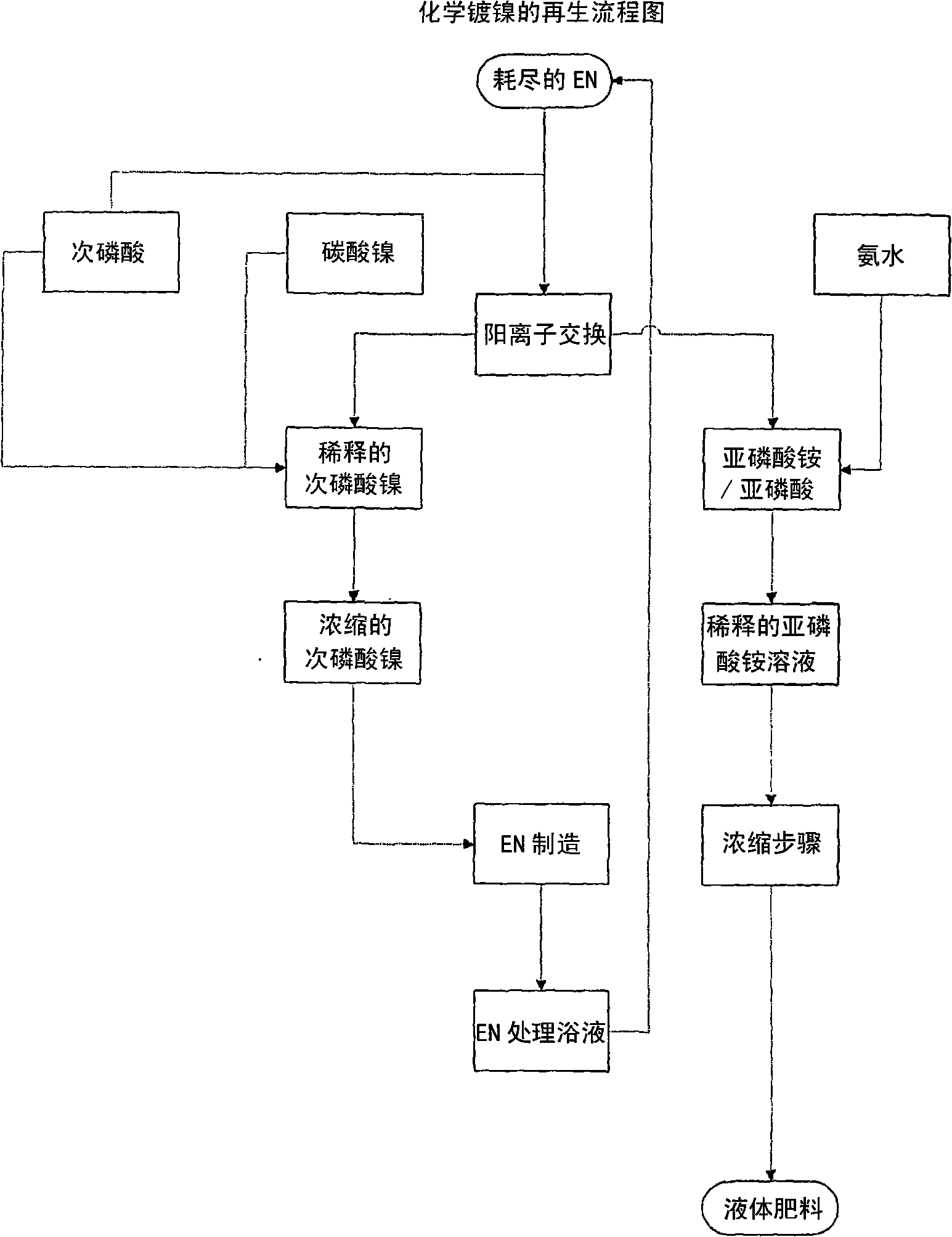

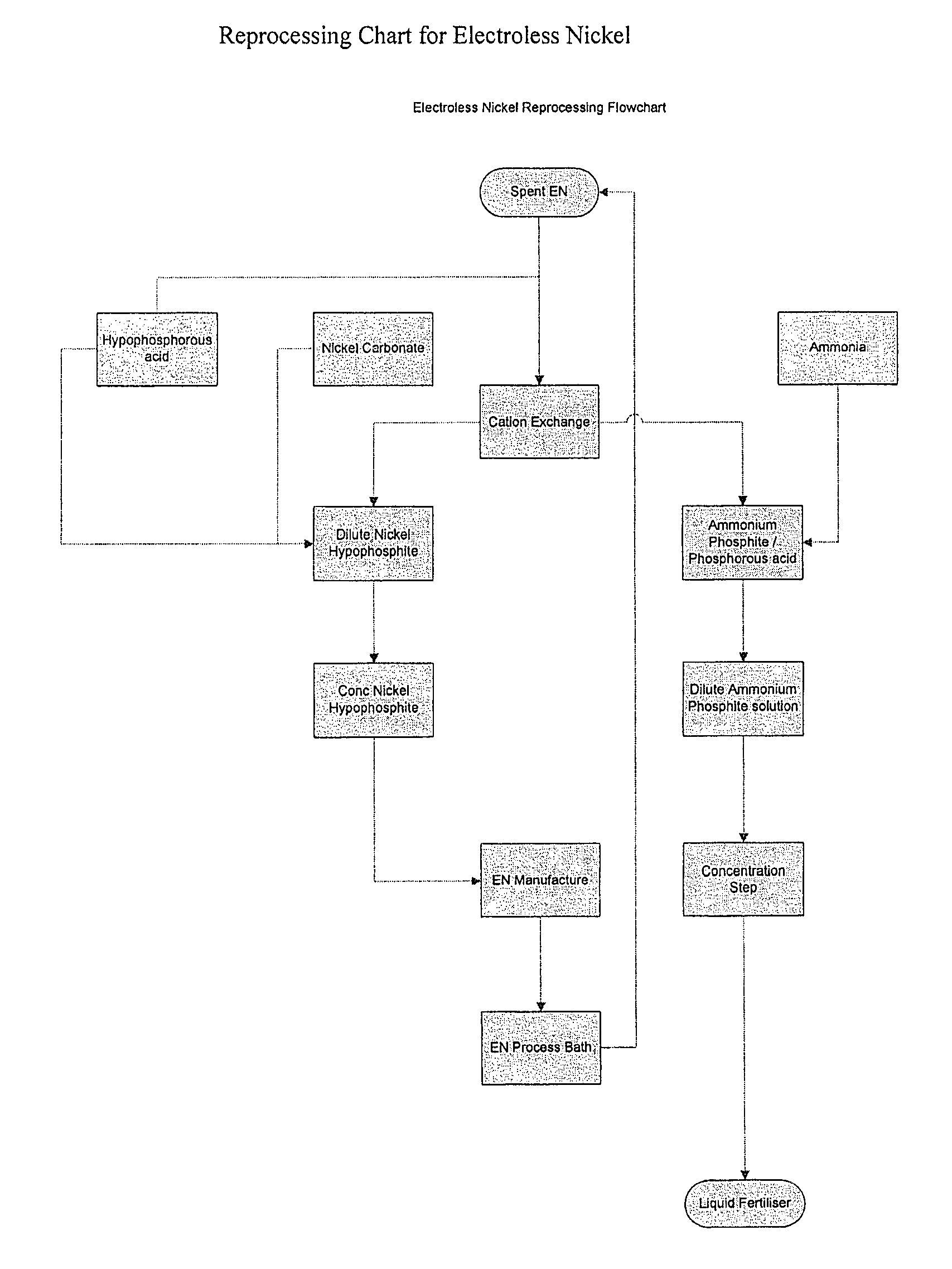

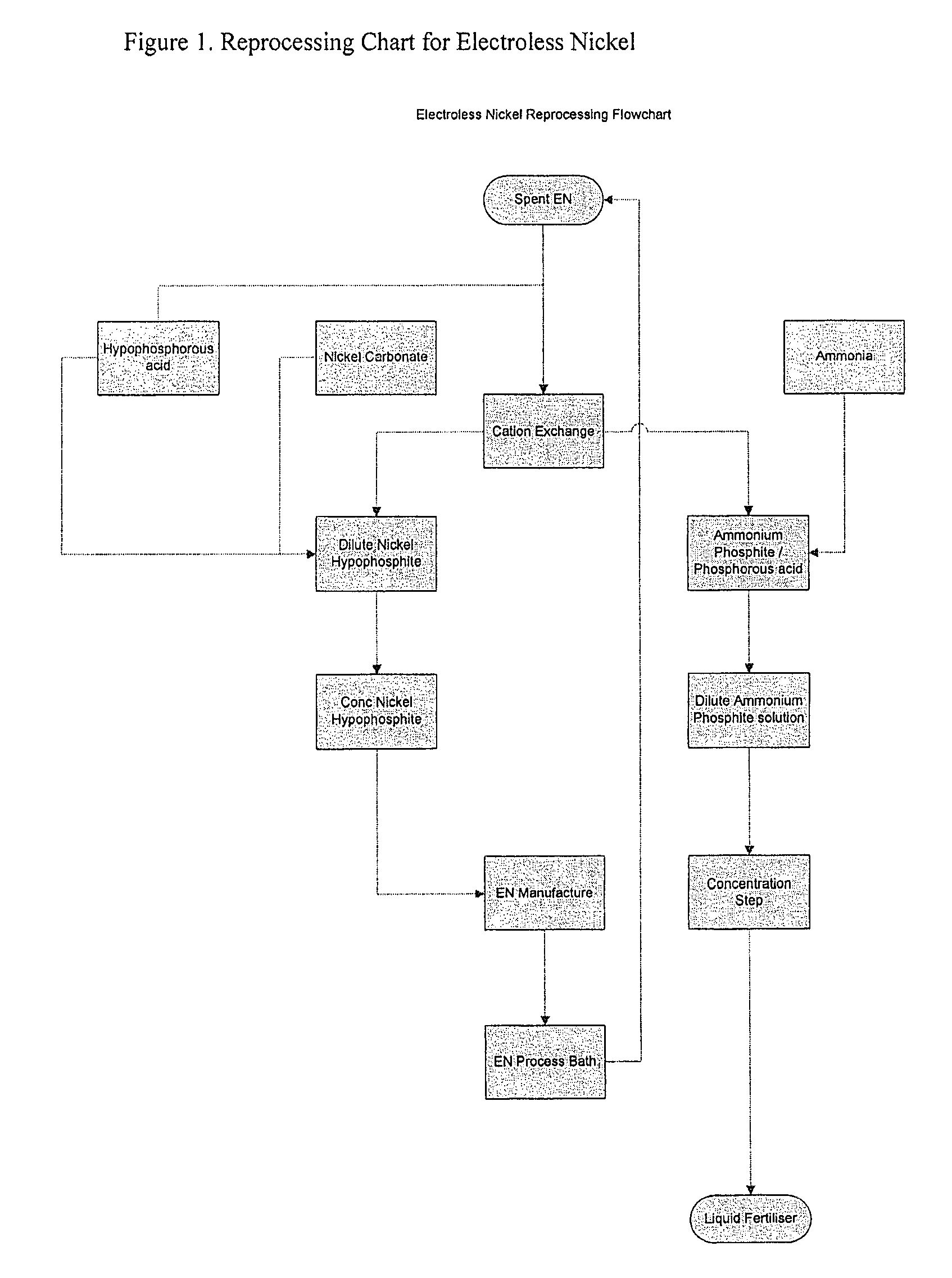

Method of recycling electroless nickel waste

InactiveCN101636353AEliminate processingAvoid it happening againNickel compounds preparationLiquid/solution decomposition chemical coatingElectroless nickelSULFATE ION

An electroless nickel plating bath is provided that utilizes hypophosphite ions as a reducing agent and is substantially free of sulphate and sodium ions. Spent nickel in the plating bath is removed using an ion exchange resin and the remaining effluent solution is usable for manufacturing fertilizer compositions. The nickel is processed for inclusion back into the plating bath. Thus, the process of the invention allows for the indefinite use of the solutions without discharging hazardous waste.

Owner:MACDERMID ACUMEN INC

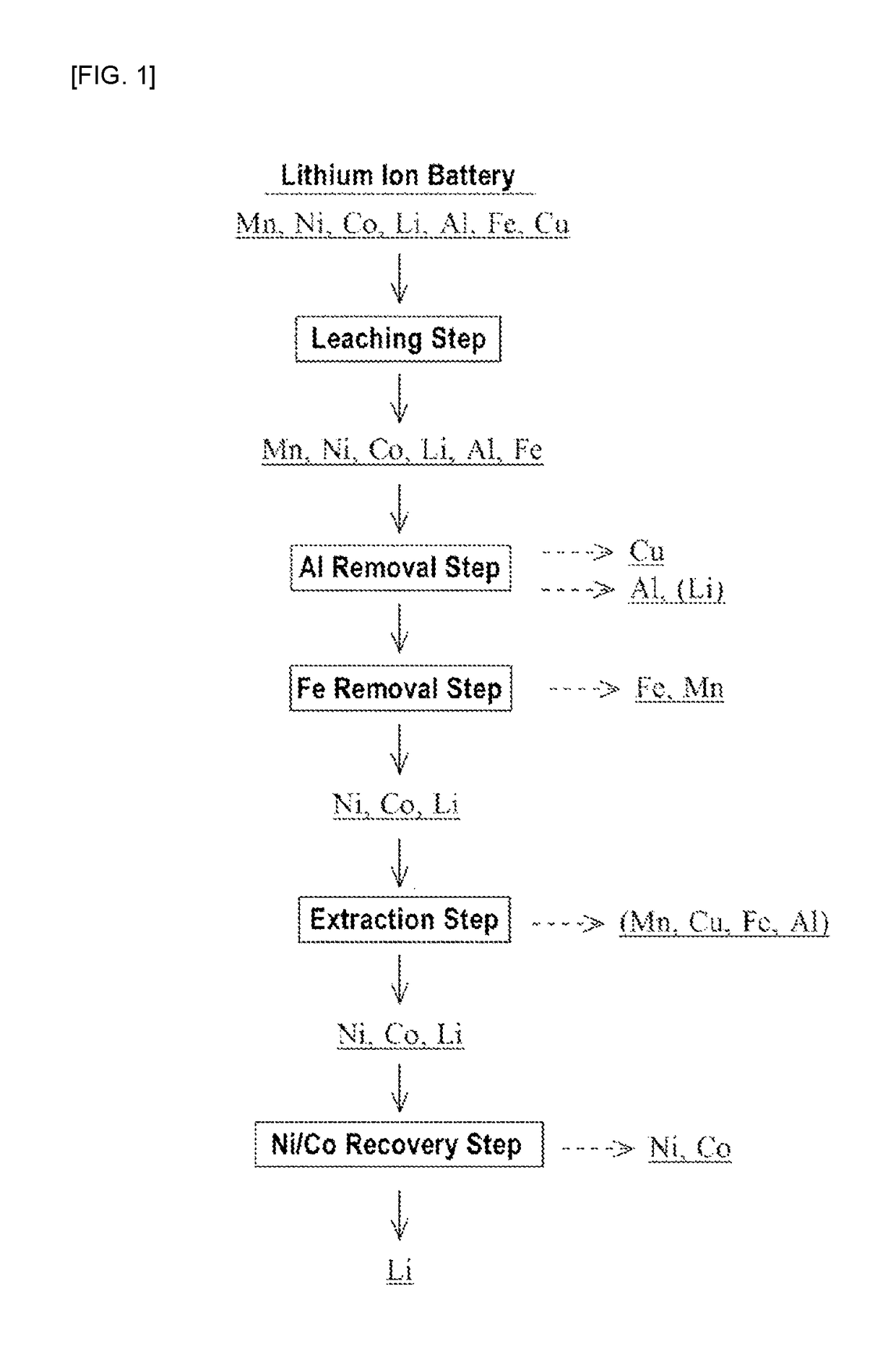

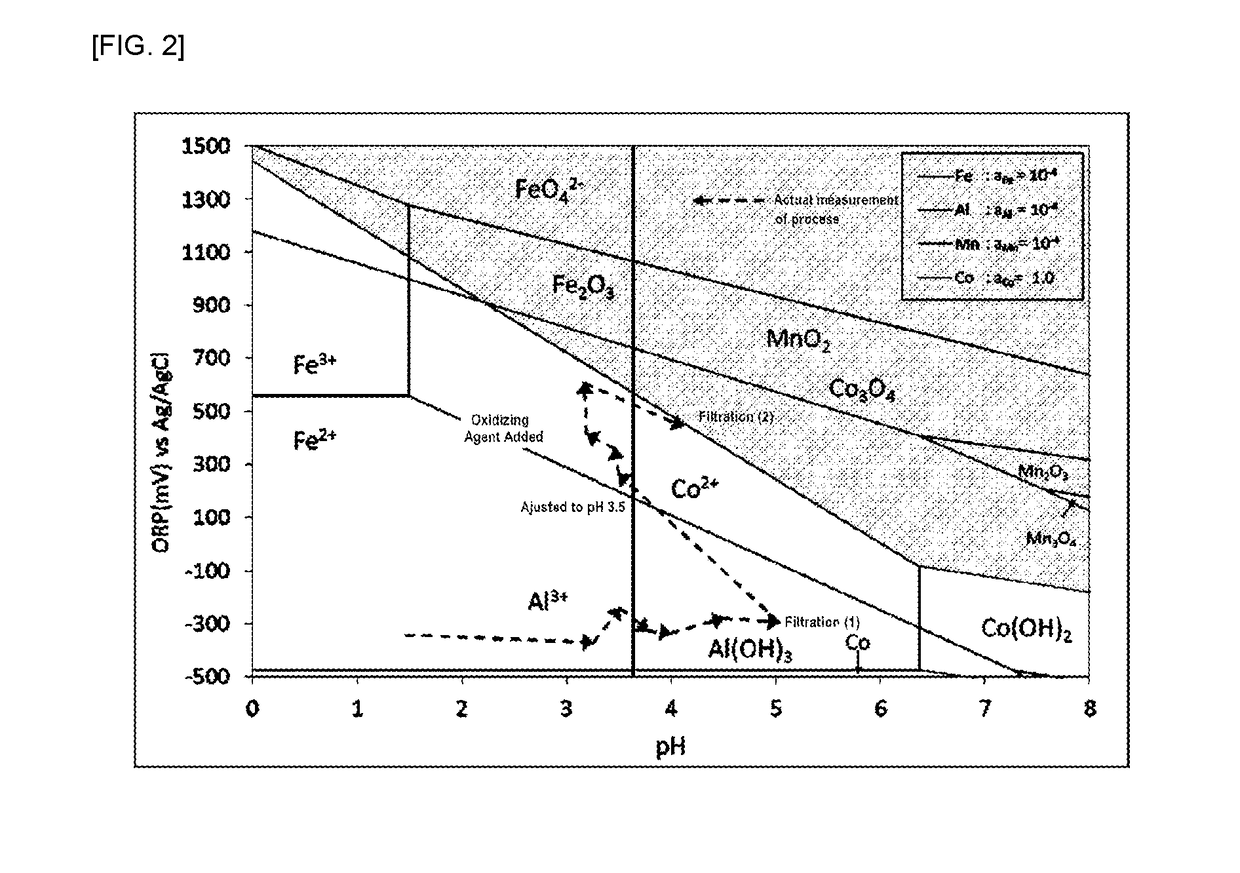

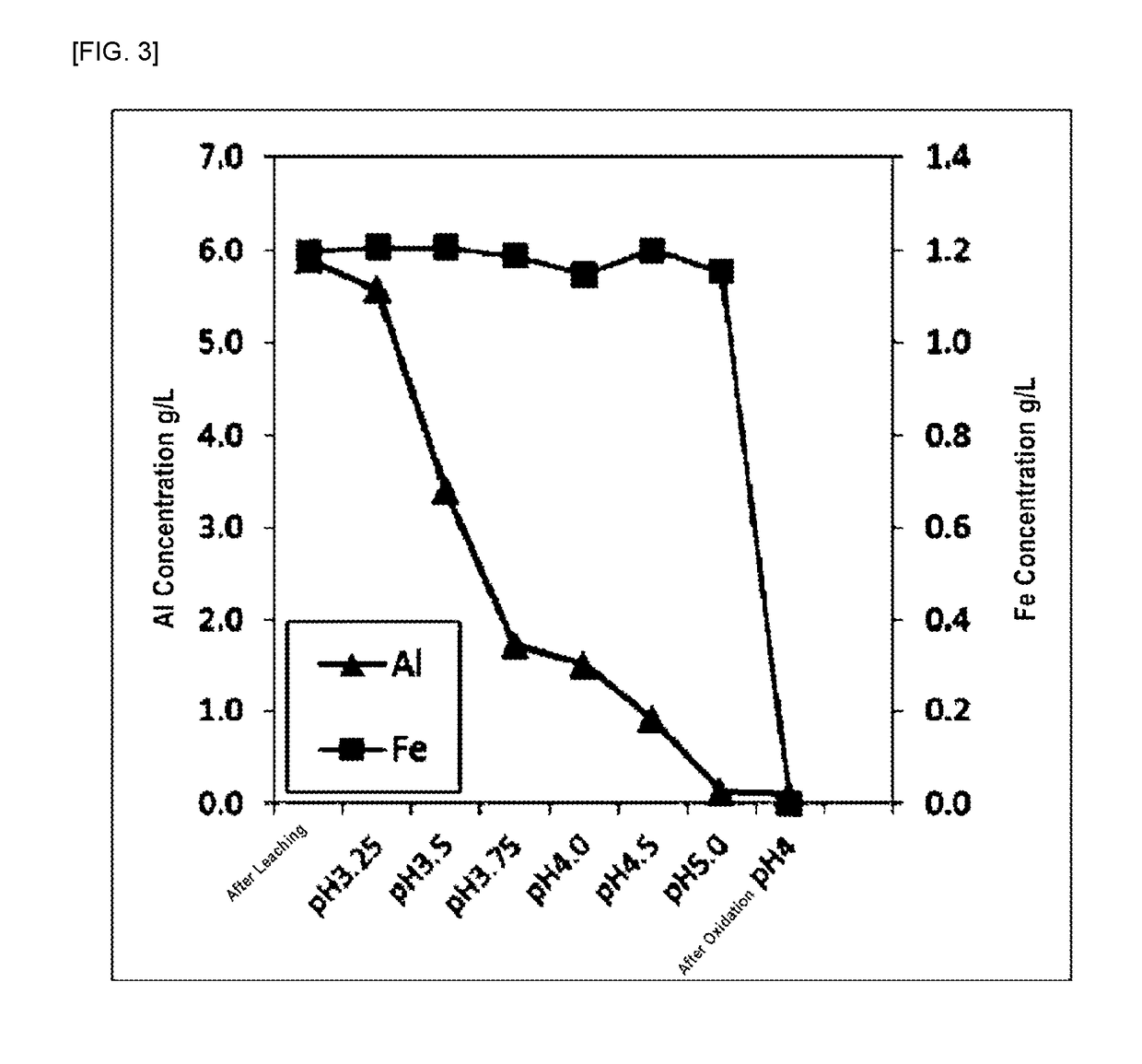

Processing method for lithium ion battery scrap

ActiveUS20190084839A1Transportation and packagingNickel compounds preparationElectrical batteryIron removal

A method for processing lithium ion battery scrap according to this invention includes a leaching step of leaching lithium ion battery scrap to obtain a leached solution; an aluminum removal step of neutralizing the leached solution to a pH range of from 4.0 to 6.0, then performing solid-liquid separation and removing aluminum in the leached solution to obtain a first separated solution; and an iron removal step of adding an oxidizing agent to the first separated solution and adjusting the pH in a range of from 3.0 to 5.0, then performing solid-liquid separation and removing iron in the first separated solution to obtain a second separated solution.

Owner:JX NIPPON MINING& METALS CORP

Method for recycling high-purity nickel sulfate from nickel-bearing waste batteries

InactiveCN107162067AReduce distractionsAchieve separationMagnesium carbonatesNickel compounds preparationSulfateChelating resin

The invention relates to the field of recycling of solid waste and particularly discloses a method for recycling high-purity nickel sulfate from nickel-bearing waste batteries; the method comprises the steps of disassembling the nickel-bearing waste batteries into battery powder; dissolving the battery powder with an acid to obtain dissolved solution, and adding alkali metal sulfate; removing iron by an oxidative precipitation process, and removing impurities from the dissolved solution with iron removed via an extraction process to obtain magnesium-bearing nickel liquid; passing the magnesium-bearing nickel liquid through chelate resin exchange columns, with nickel ions adsorbed by chelate resin, and magnesium-rich solution flowing out for treatment; desorbing the nickel ions to obtain nickel sulfate solution; evaporating the nickel sulfate solution, cooling, crystallizing, filtering, and drying to obtain finished nickel sulfate. By using the method, it is effectively guaranteed that the recycled finished nickel sulfate is a high-purity product having a content up to 99.5% and above, the impurity Mg content is less than 0.005% and below, and the product fully meets the standard for nickel sulfate products in HG / T2824-1997.

Owner:中矿(赣州)国际钴业有限公司

Processes for treating red mud

ActiveUS9023301B2Simple and efficientLow costAluminium compoundsNickel compounds preparationRare-earth elementRed mud

There are provided processes for treating red mud. For example, the processes can comprise leaching red mud with HCl so as to obtain a leachate comprising ions of a first metal (for example aluminum) and a solid, and separating said solid from said leachate. Several other metals can be extracted from the leachate (Fe, Ni, Co, Mg, rare earth elements, rare metals, etc.). Various other components can be extracted from solid such as TiO2, SiO2 etc.

Owner:ORBITE ALUMINAE INC

Method for producing battery grade nickel sulfate and cobalt sulfate by waste nickel cobalt alloy

ActiveCN108622943AMild responseReduce pollutionCobalt sulfatesNickel compounds preparationNew energyEvaporation

The invention discloses a method for producing battery grade nickel sulfate and cobalt sulfate by waste nickel cobalt alloy. The method comprises the following steps of performing pretreatment on nickel cobalt alloy waste materials; then, performing electrochemical dissolution; removing impurities such as iron, chromium and aluminum from the obtained solution step by step by a chemical method andan extraction method; firstly extracting cobalt from the solution subjected to impurity removal; then extracting nickel; thus respectively obtaining extraction liquid containing cobalt and nickel; after the reverse extraction, obtaining nickel sulfate and cobalt sulfate solution; then, respectively performing evaporation, cooling crystallization, and centrifugal dewatering on the solution to obtain a product of the battery grade nickel sulfate and cobalt sulfate. The problems of low nickel and cobalt leaching efficiency, low dissolution speed and the like in the waste nickel and cobalt alloy recovery process by a conventional wet process can be effectively solved; the battery grade nickel sulfate and cobalt sulfate conforming to the product quality standard requirement can be produced, andcan be used as a new energy source battery raw material to be applied to the field of new energy source battery manufacturing. The process is simple; the environment pollution is low; the metal recovery rate is high; good practical values and economic values are realized.

Owner:HOHAI UNIV

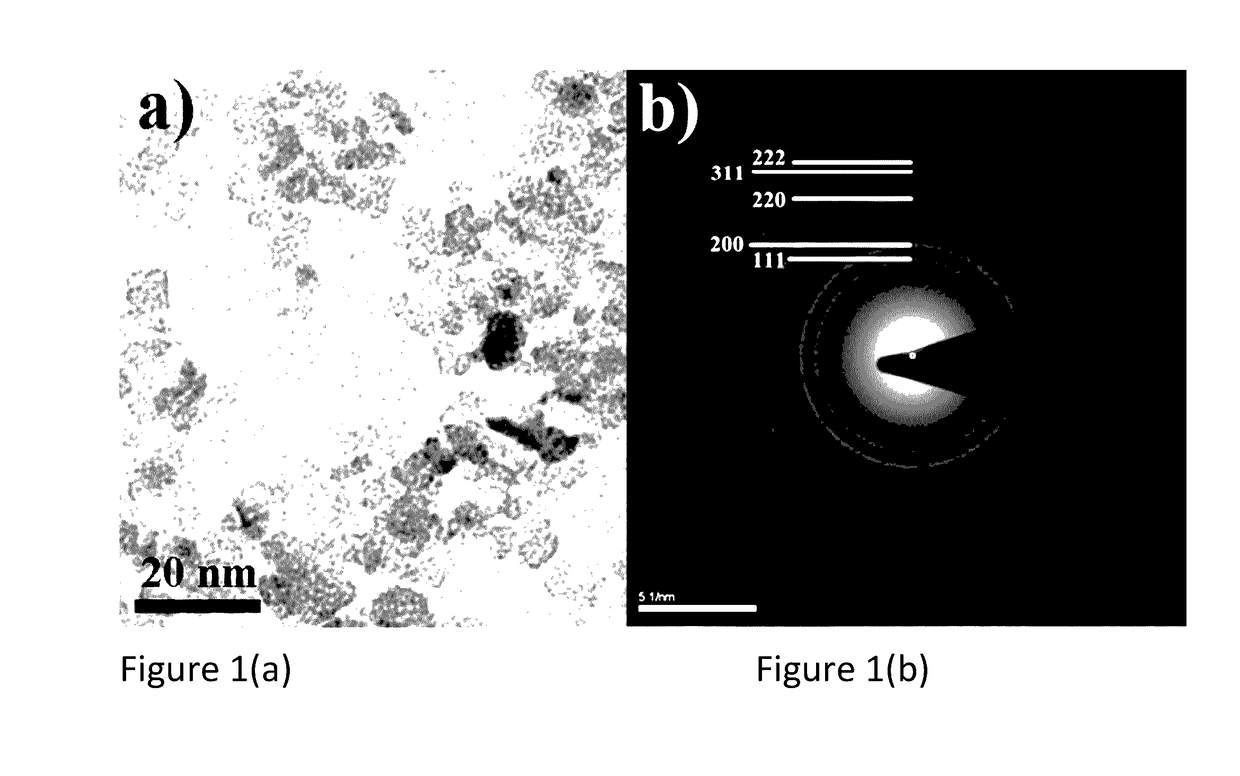

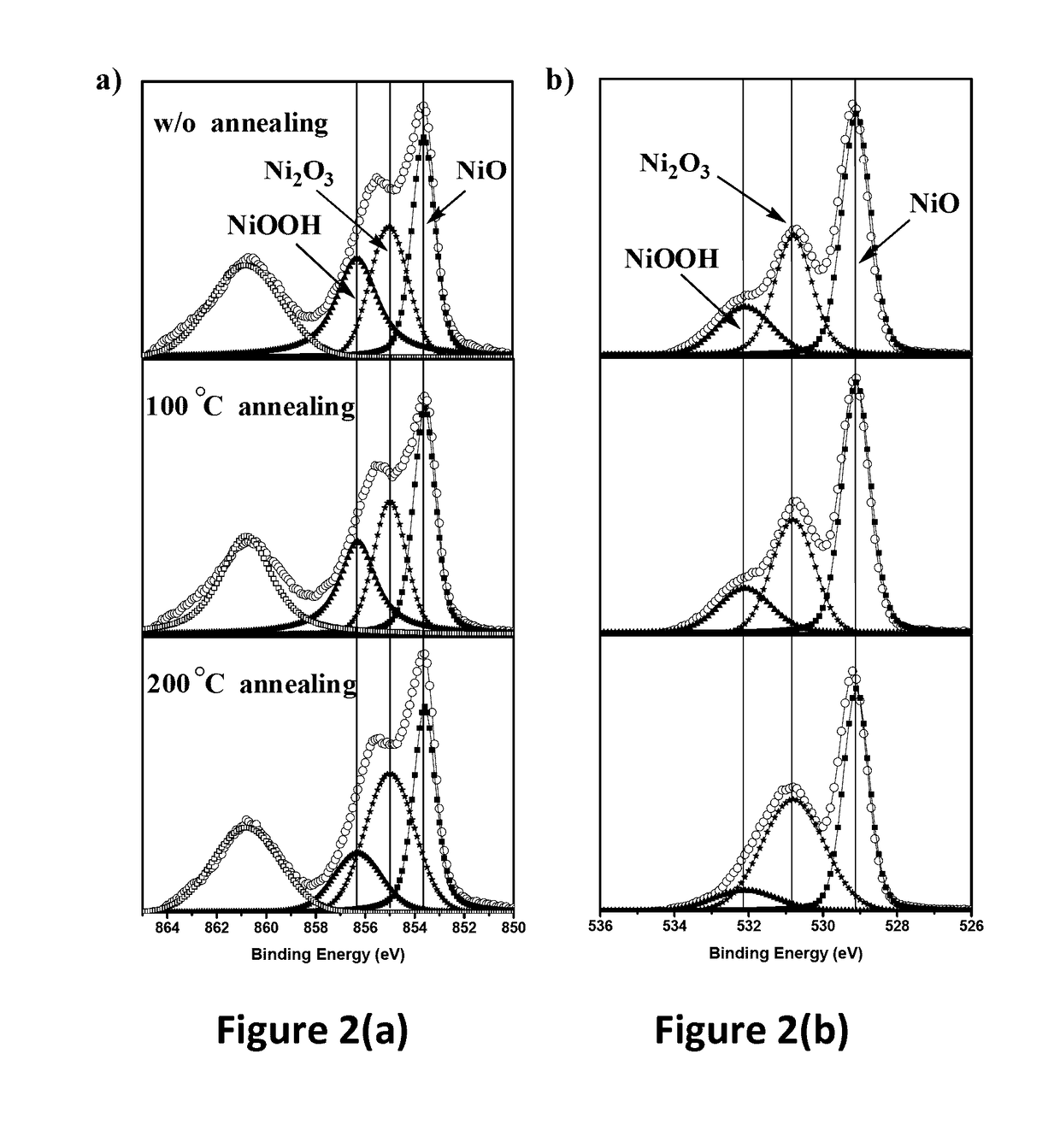

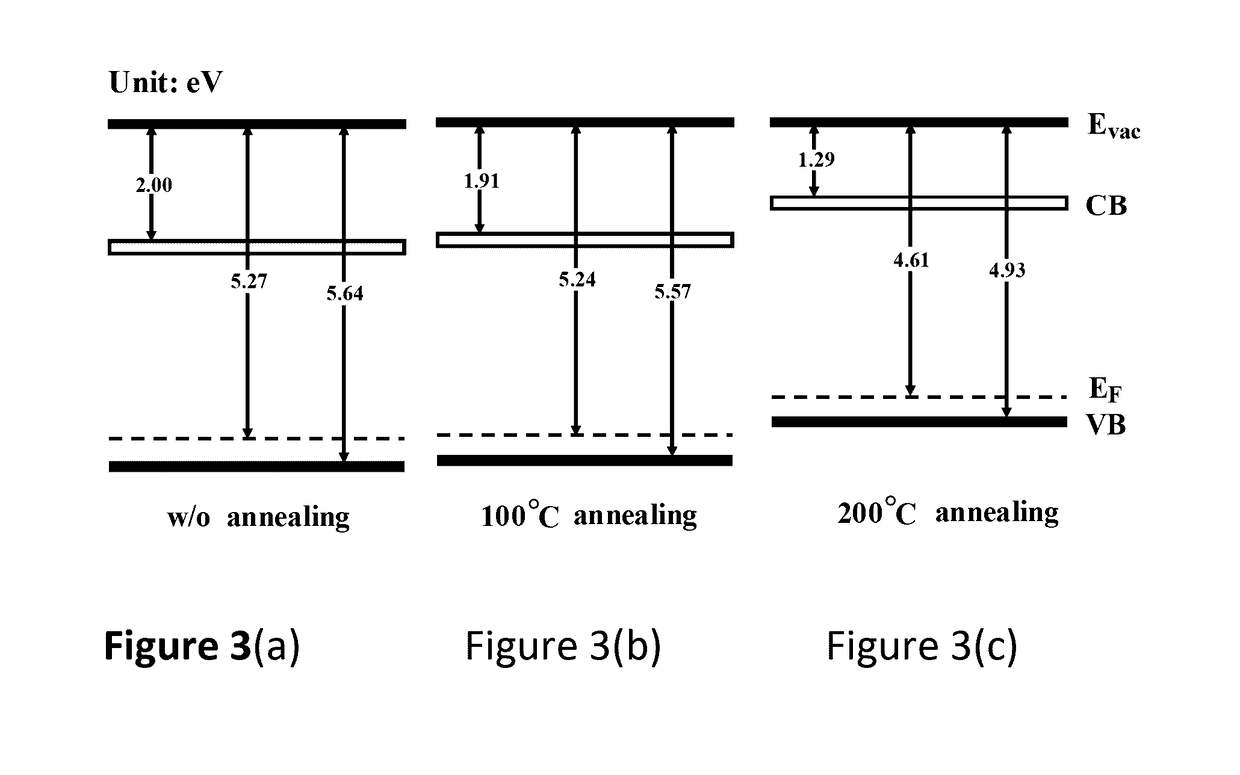

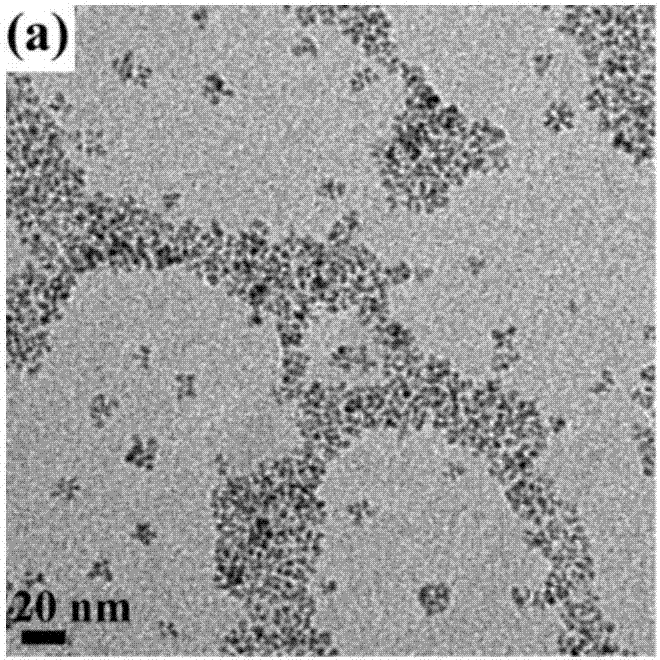

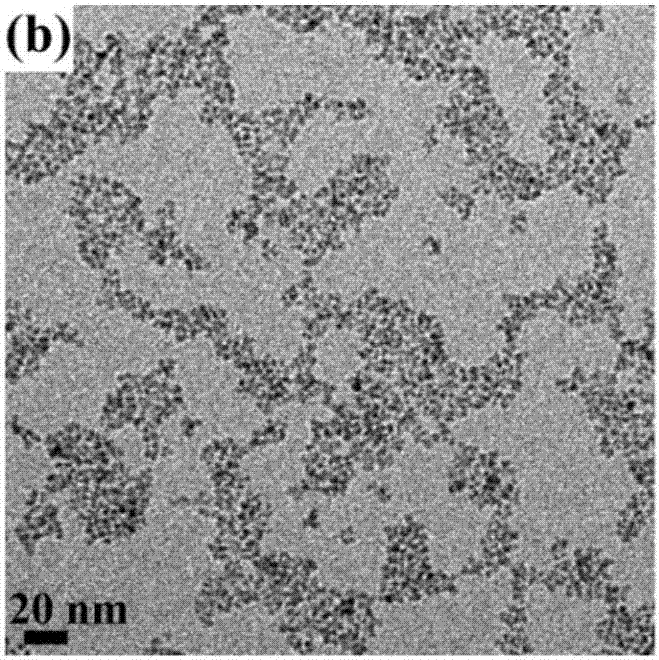

Simple Approach For Preparing Post-Treatment-Free Solution Processed Non-Stoichiometric Niox Nanoparticles As Conductive Hole Transport Materials

ActiveUS20170110679A1Improve surface propertiesLow costFinal product manufactureSolid-state devicesOrganic solar cellFree solution

High-quality non-stoichiometric NiOx nanoparticles are synthesized by a facile chemical precipitation method. The NiOx film can function as an effective p-type semiconductor or hole transport layer (HTL) without any post-treatments, while offering wide temperature applicability from room-temperature to 150° C. For demonstrating the potential applications, high efficiency is achieved in organic solar cells using NiOx HTL. Better performance in NiOx based organic light emitting diodes is obtained as compared to devices using PEDOT:PSS. The solution-processed NiOx semiconductors at room temperature can favor a wide-range of applications of large-area and flexible optoelectronics.

Owner:THE UNIVERSITY OF HONG KONG

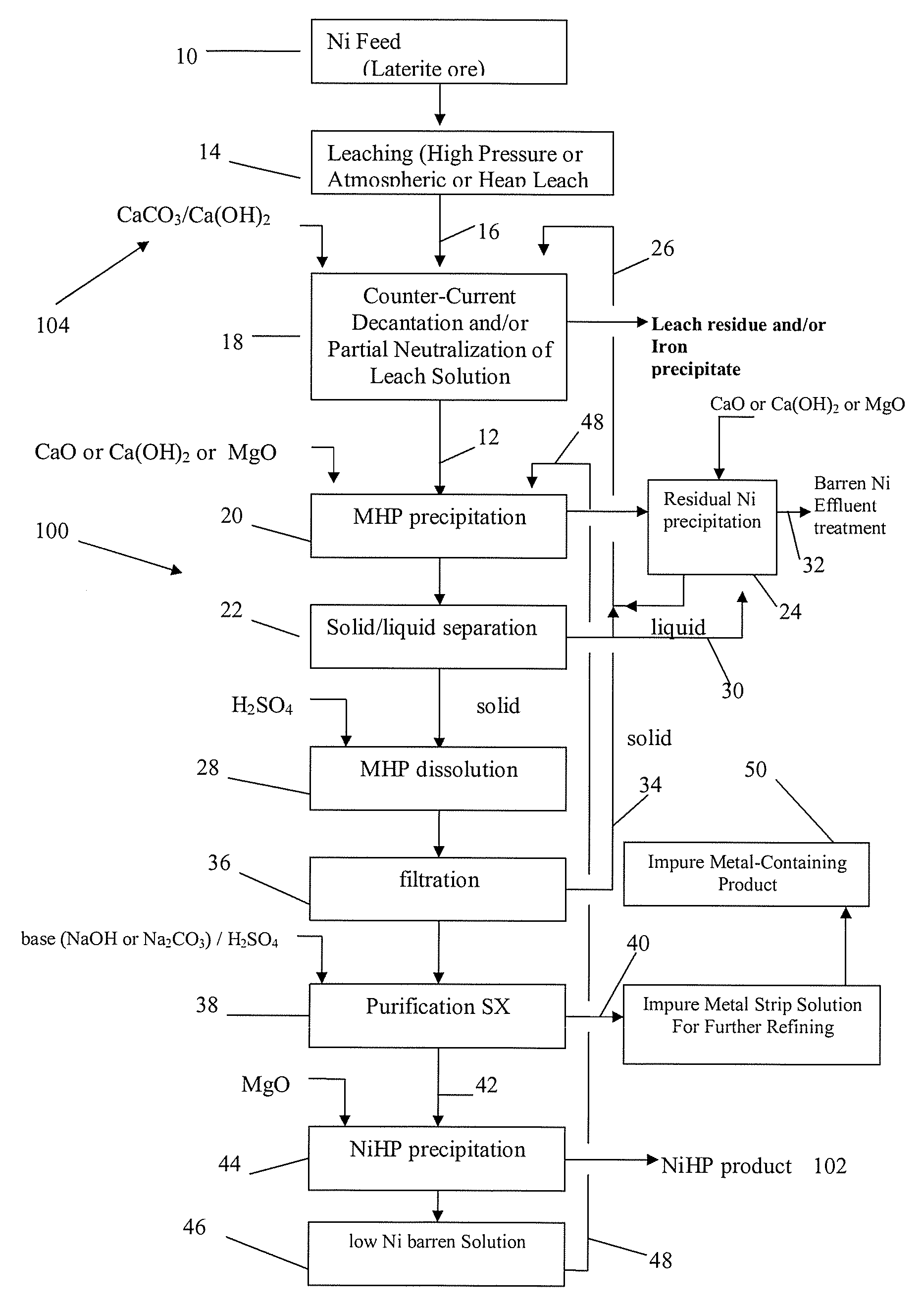

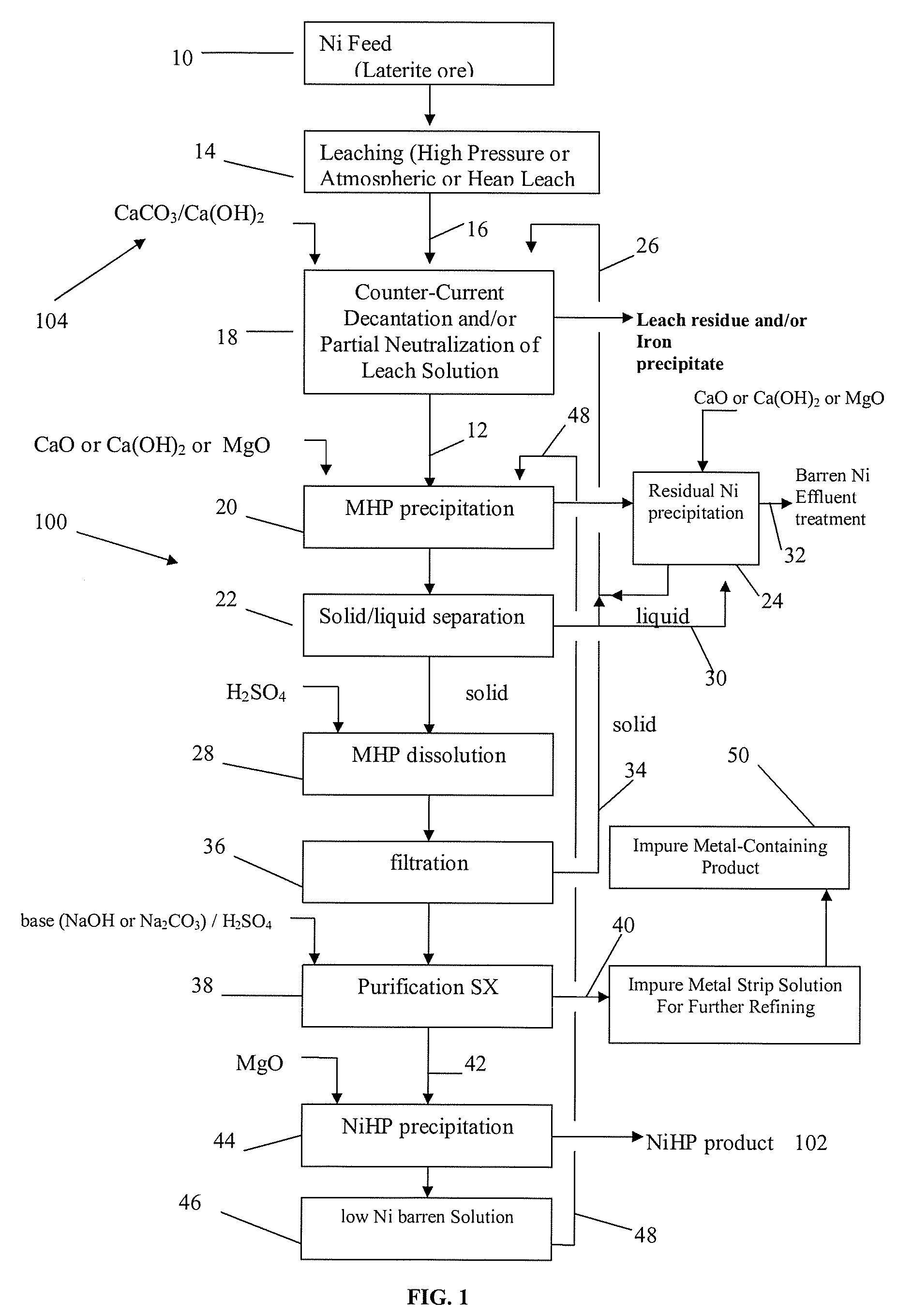

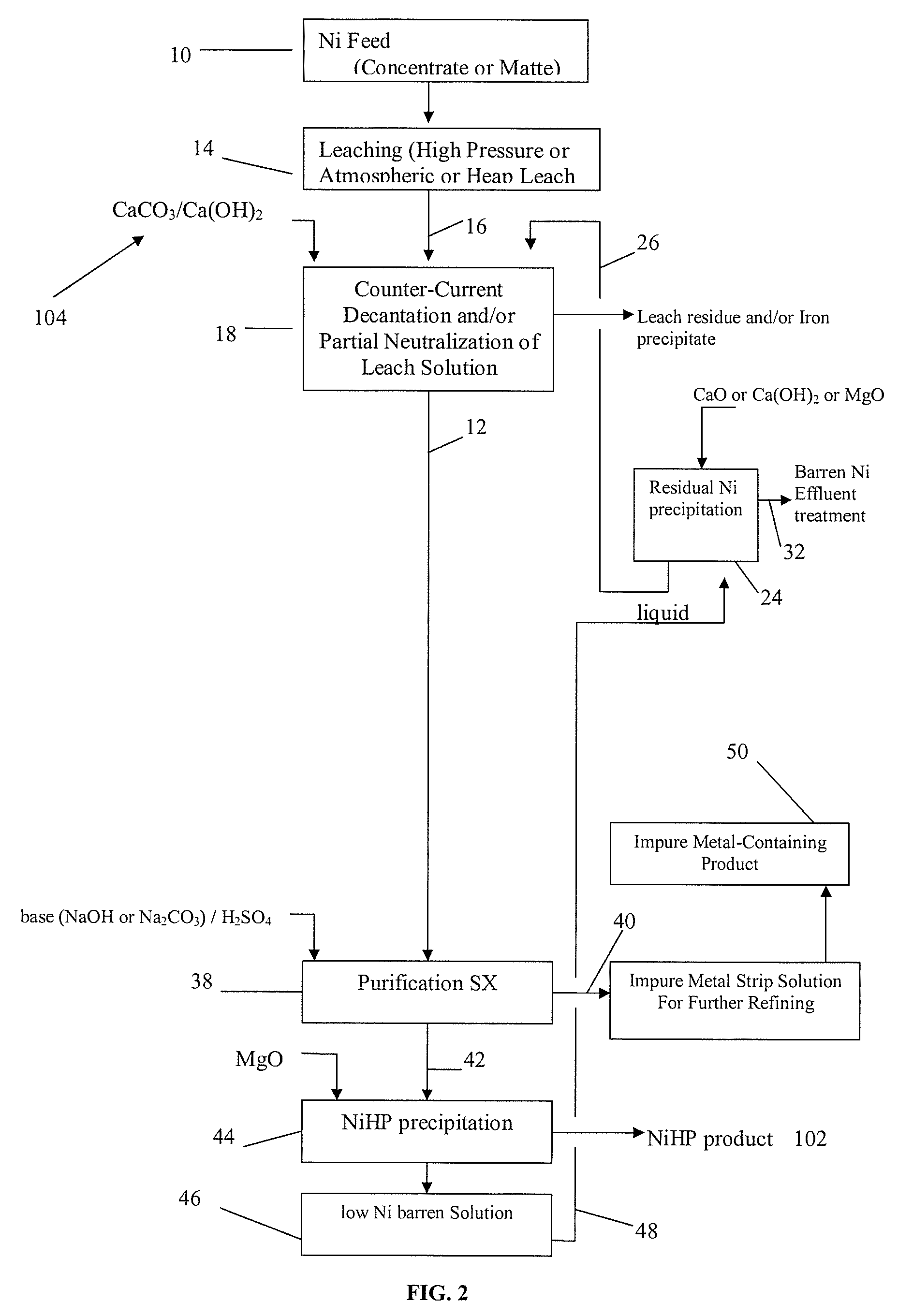

Producing nickel hydroxide suitable for pelletization with iron-containing ore and for stainless steel manufacture

ActiveUS20090087361A1Increased nickel concentrationNickel compounds preparationSolid sorbent liquid separationManganeseSlurry

A process for producing a purified nickel hydroxide precipitate from a nickel-containing leach solution with impurities including one or more of the following: manganese, copper, zinc, iron and / or cobalt, so that the purified nickel hydroxide is suitable for pelletization with iron-containing ores and / or stainless steel production, includes treating the leach solution with a base to form a slurry of mixed hydroxide precipitate and low-nickel barren solution, thickening the slurry to form filter cake, washing the filter cake and contacting it with acid to dissolve nickel and other metals to produce a concentrated nickel-containing solution, subjecting the concentrated nickel-containing solution to solvent extraction with an organic acid extractant to remove metals other than nickel from the nickel-containing solution and form a solvent extraction raffinate of purified nickel solution and treating the solvent extraction raffinate with a base to precipitate the purified nickel hydroxide precipitate.

Owner:VALE CANADA

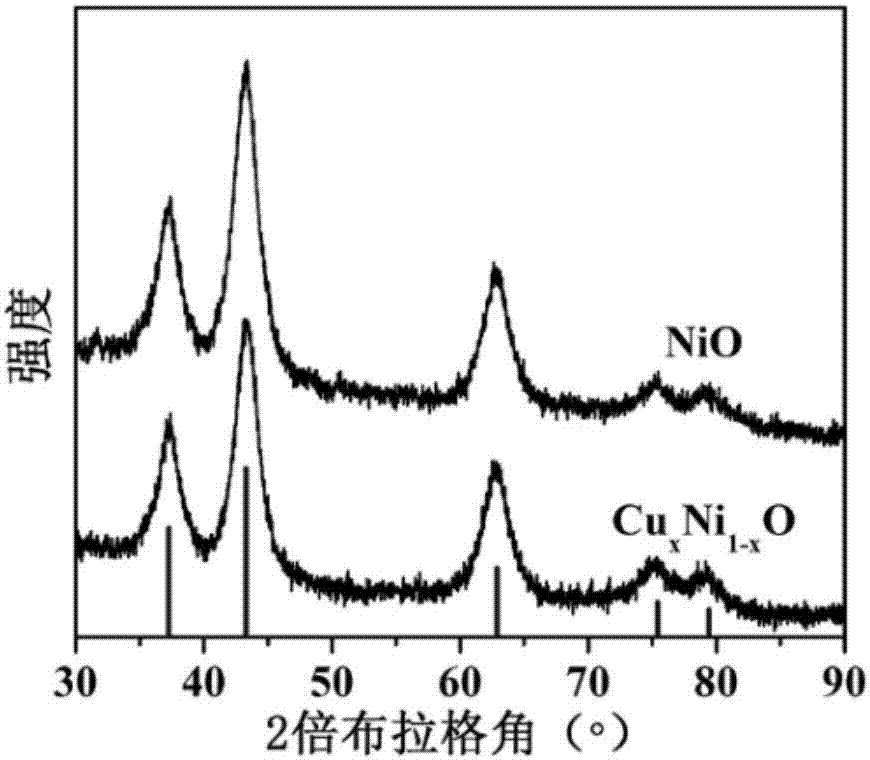

Copper ion-doped nickel oxide colloidal nano-crystal preparation method and product thereof, and applications of copper ion-doped nickel oxide colloidal nano-crystal

ActiveCN106966441ALow annealing temperatureLow temperature resistanceMaterial nanotechnologyNickel compounds preparationThermal insulationCarboxylic salt

The invention discloses a copper ion-doped nickel oxide colloidal nano-crystal preparation method and a product thereof, and applications of the copper ion-doped nickel oxide colloidal nano-crystal. The preparation method comprises: preparing a nickel oxide nano-crystal solution by using nickel carboxylate as a precursor; heating a copper precursor and a non-coordination organic solvent under an inert protective atmosphere to a temperature of 60-200 DEG C; and injecting the copper precursor and the non-coordination organic solvent into the nickel oxide nano-crystal solution with a temperature of 60-200 DEF C, and carrying out thermal insulation for 20 min-6 h, and purifying to obtain a CuxNi1-xO colloidal nano-crystal, wherein the copper precursor is copper carboxylate or a carbon anion copper salt. According to the present invention, the crystallization process of the CuxNi1-xO colloidal nano-crystal is separated from the crystallization film forming process of the existing CuxNi1-xO film, and the crystallization process and the film forming process are independent from each other, such that the film can be prepared through the conventional film forming method, and the film annealing temperature can be significantly reduced to 50-200 DEG C so as to be compatible with the substrate having the low high-temperature resistance.

Owner:ZHEJIANG UNIV

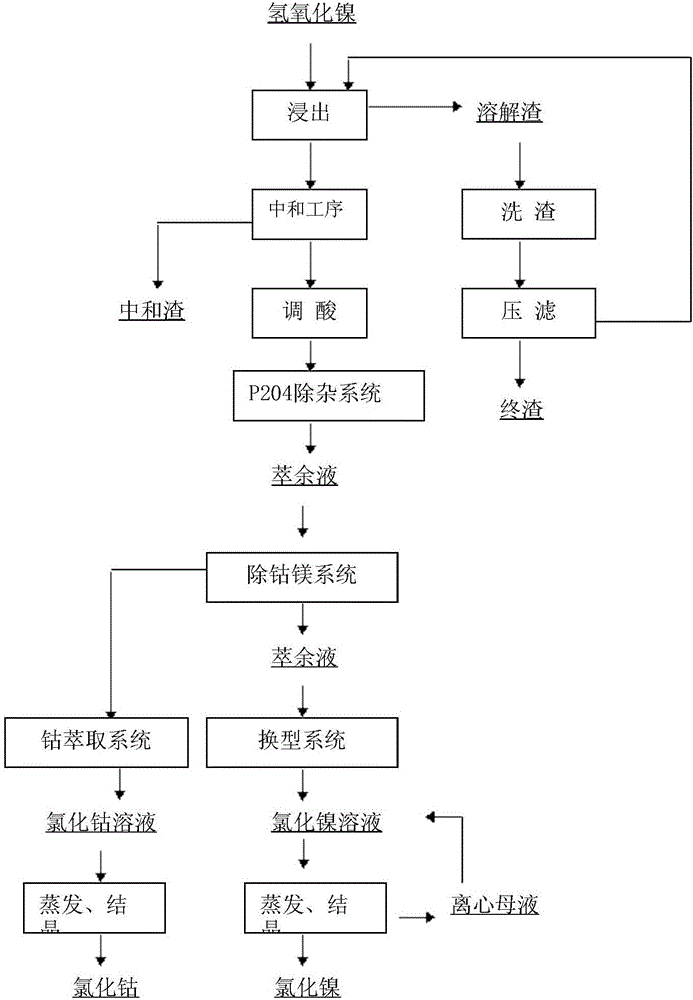

Method for preparing nickel chloride through sulfuric acid leaching of crude nickel hydroxide

ActiveCN106745342AReduce usageAvoid pollutionNickel compounds preparationNickel halidesNickel oxide hydroxideSulfate

The invention provides a method for preparing nickel chloride through sulfuric acid leaching of crude nickel hydroxide, and belongs to the technical field of hydrometallurgy. The method comprises the following steps: carrying out concentrated sulfuric acid leaching on the crude nickel hydroxide to obtain a nickel sulfate solution, removing silicon and iron from the nickel sulfate solution, and allowing the obtained solution to enter an extraction system; carrying out extraction to remove Mn, Zn, Ca, Mg and other impurities from the nickel sulfate solution and recover Co, wherein the content of Mn, Zn, Ca and Co is reduced to 0.001 g / L or below, and the content of Mg is reduced to 0.05 g / L or below; carrying out extraction to convert the nickel sulfate solution into a nickel chloride solution; and carrying out evaporation, crystallization and centrifuge packaging to obtain the nickel chloride product. The method has the advantages of simplicity, effective control of the content of the impurities in the nickel chloride, obtaining of the high-quality nickel chloride product, and wide application.

Owner:JILIN JIEN NICKEL IND

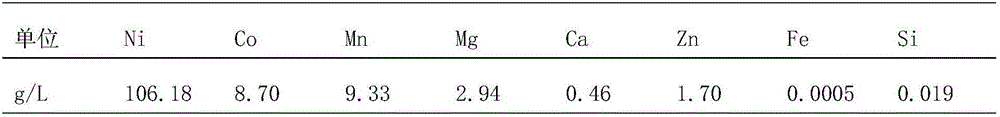

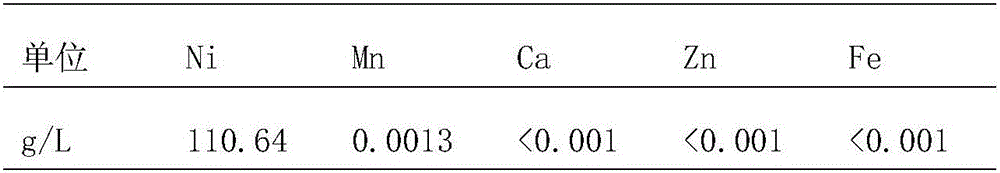

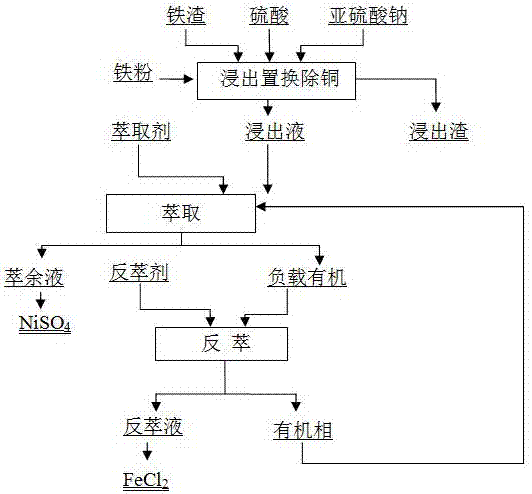

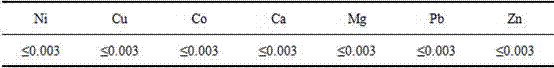

Extraction decontamination method for industrial iron slag sulfuric acid leaching

InactiveCN107200364AHigh removal rateSimple processIron compounds preparationNickel compounds preparationSlagKerosene

The invention discloses an extraction decontamination method for industrial iron slag sulfuric acid leaching. The extraction decontamination method comprises five procedures of sodium saponification, nickel saponification, extraction, washing and back extraction. P507 is adopted as an extraction agent, solvent oil or sulfonated kerosene is adopted as a diluent, on the basis of different combination properties of different metal ion extraction agents and the principle that the combination property of one metal with the extraction agents can be damaged by hydrochloric acid of different concentrations, target metals of Ni and Fe ions can be separated, metal ions such as Co, Cu, Pb, Zn, Ca and Mg in the leaching can be further removed, then the industrial iron slag sulfuric acid leaching can be deeply purified, and a nickel sulfate solution and a ferrous chloride solution with low impurity contents can be prepared. The extraction decontamination method disclosed by the invention is simple and convenient in process procedure and high in impurity removal rate, and the quality of the produced nickel sulfate solution and ferrous chloride solution meets quality requirements for producing nickel sulfate and ferric oxide products.

Owner:甘肃有色冶金职业技术学院

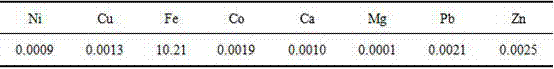

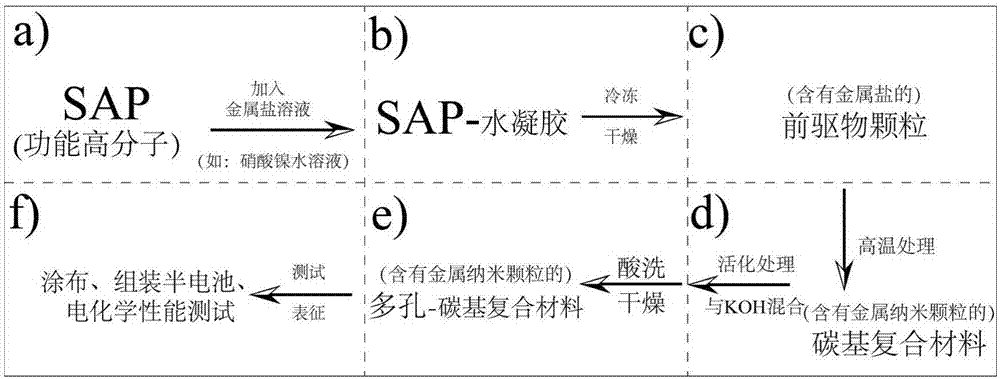

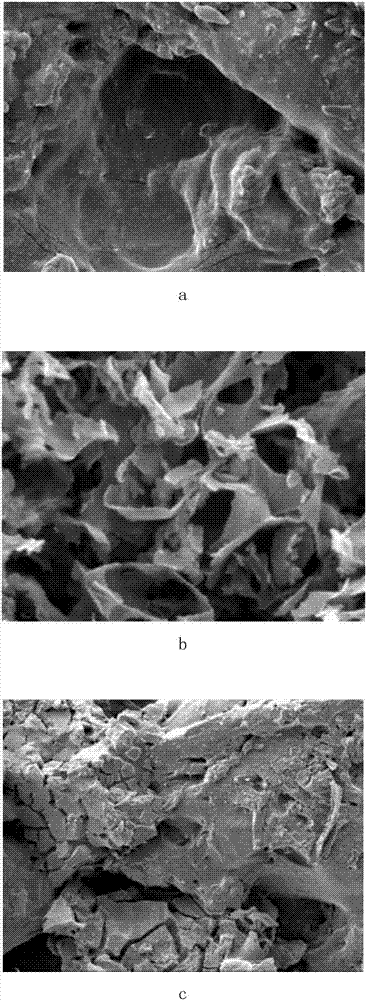

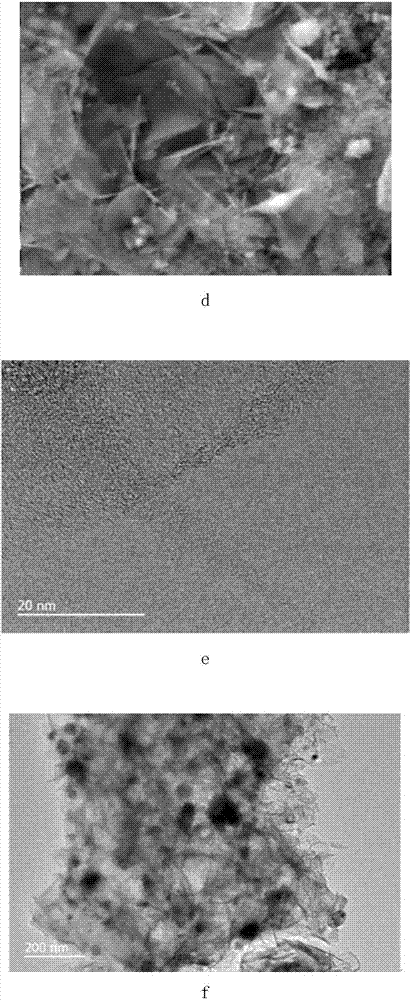

Preparation method of high-cycle and high-rate carbon-based negative electrode energy storage composite material

ActiveCN106920950AImprove cycle stabilityStable applicationMaterial nanotechnologyCell electrodesHigh rateNickel salt

The invention relates to a preparation method of a high-cycle and high-rate carbon-based negative electrode energy storage composite material. The preparation method comprises the following steps: preparing nickel salt hydrogel; preparing a dry gel precursor; transferring xerogel precursor particles into a tubular furnace, carrying out high temperature calcination, and cooling the obtained calcined product; taking out the preliminarily calcined product, grinding the preliminarily calcined product in a dry environment, pickling the ground product, and drying the pickled product; activating the dried calcined product under KOH grinding and mixing; transferring the potassium hydroxide ground and mixed product into the tubular furnace, and calcining the mixed product; naturally cooling the calcined mixed product to room temperature; and pickling the cooled product, washing the pickled product with distilled water or ethanol until the washed product is neutral, and drying the neutral product to obtain the high-cycle and high-rate carbon-based negative electrode energy storage composite material. Compared with other negative electrode energy storage composite materials, the carbon-based negative electrode energy storage composite material has the advantages of extremely high initial capacity, excellent cycle stability and good rate performance. The preparation method has the advantages of simplicity, low cost, excellent performances, and suitableness for producing large-scale commercial batteries.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Processes for treating red mud

ActiveUS20150275330A1Simple and efficientLow costAluminium compoundsNickel compounds preparationPregnant leach solutionRare-earth element

Owner:AEM TECH INC

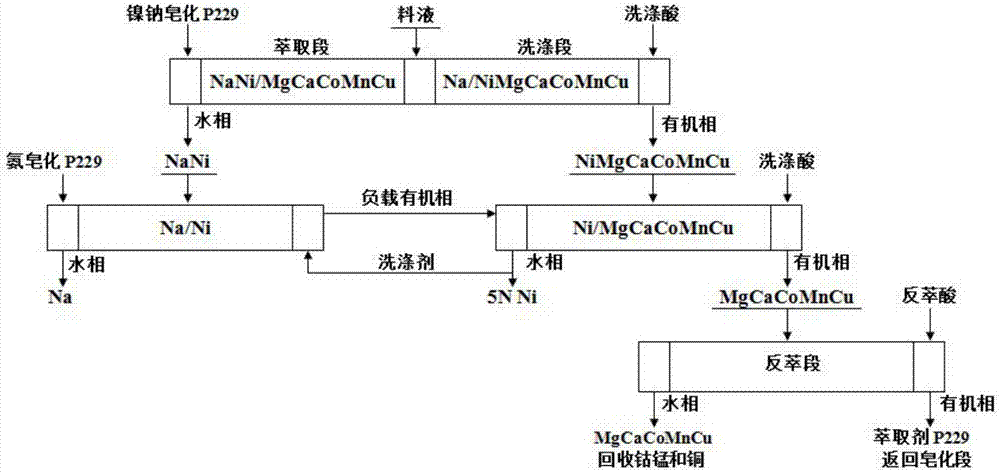

Method for preparing 6N-grade nickel sulfate by fractionally extracting P229 (bis(2-ethylhexyl)phosphonic acid)

InactiveCN107188244AHigh purityHigh yieldNickel compounds preparationNickel sulfatesSulfateAqueous solution

The invention discloses a method for preparing 6N-grade nickel sulfate by fractionally extracting P229 (bis(2-ethylhexyl)phosphonic acid), and belongs to the technical field of preparing high-purity nickel sulfate. 2N to 3N industrial-grade nickel sulfate is used as feed liquid, and bis(2-ethylhexyl)phosphonic acid (P229 for short) is used as an extraction agent. The method comprises the following steps: a NaNi / NiMgCaCoMnCu fractional extraction and a separation step, a Na / Ni fractional extraction and separation step and a Ni / MgCaCoMnCu fractional extraction and separation step, wherein the Na / Ni fractional extraction and separation step and the Ni / MgCaCoMnCu fractional extraction and separation step are connected in series; separation of Ni from metal elements of Cu, Mn, Co, Ca, Na and the like is successfully realized, and the 6N-grade nickel sulfate is directly prepared; the yield of the Ni is up to 94 to 96 percent. The method disclosed by the invention has the advantages of high purity of a separation product-nickel sulfate, high yield of valuable metal elements, less reagent consumption, short technological process, low production cost and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

Method of recycling electroless nickel waste

InactiveUS7833583B2Eliminate the problemInhibit productionNickel compounds preparationPretreated surfacesElectroless nickelIon-exchange resin

An electroless nickel plating bath is provided that utilizes hypophosphite ions as a reducing agent and is substantially free of sulphate and sodium ions. Spent nickel in the plating bath is removed using an ion exchange resin and the remaining effluent solution is usable for manufacturing fertilizer compositions. The nickel is processed for inclusion back into the plating bath. Thus, the process of the invention allows for the indefinite use of the solutions without discharging hazardous waste.

Owner:MACDERMID ACUMEN INC

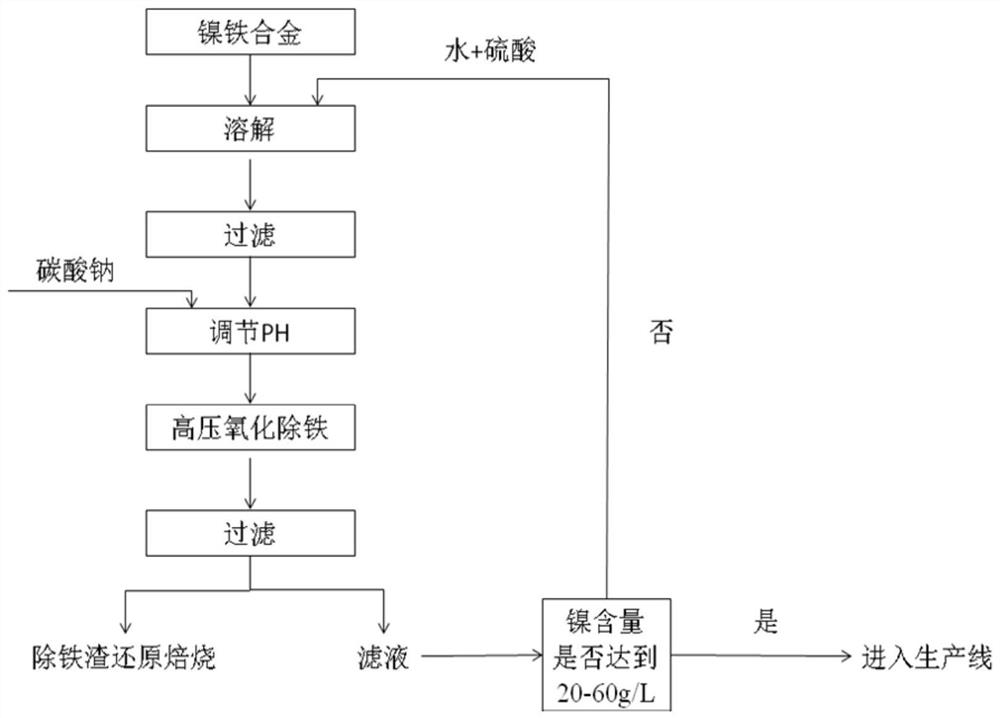

Method for producing battery-grade nickel sulfate by taking ferro-nickel alloy as raw material

PendingCN113620356AFully recycleSimple technical solutionNickel compounds preparationNickel sulfatesIron sulfateSteelmaking

The invention discloses a method for producing battery-grade nickel sulfate by taking a ferro-nickel alloy as a raw material, and belongs to the technical field of metallurgy and chemical industry. The method comprises the following steps of: firstly, carrying out high-temperature static dissolution on ferro-nickel alloy to enable nickel and iron in the ferro-nickel alloy to react with dilute sulphuric acid to generate corresponding nickel sulfate and ferric sulfate which enter a solution, then filtering, adjusting the pH value of filtrate, then removing iron through high-temperature oxygen pressure, and taking rich iron oxide resources contained in filter residues after iron removal as raw materials for steelmaking; and circularly leaching the filtrate, enriching nickel sulfate, purifying and removing impurities after the content of nickel in the solution reaches a certain requirement, and extracting to produce battery-grade nickel sulfate. The method disclosed by the invention is simple in process, low in equipment requirement, low in production cost, green and environment-friendly, wide in application range of raw material ferro-nickel alloy components and capable of treating various ferro-nickel alloys with the nickel content of 10-90% and the iron content of 10-90%, and meanwhile, the produced nickel sulfate product is high in quality and can be directly used for preparing a battery material.

Owner:MEISHAN SHUNYING POWER BATTERY MATERIALS CO LTD

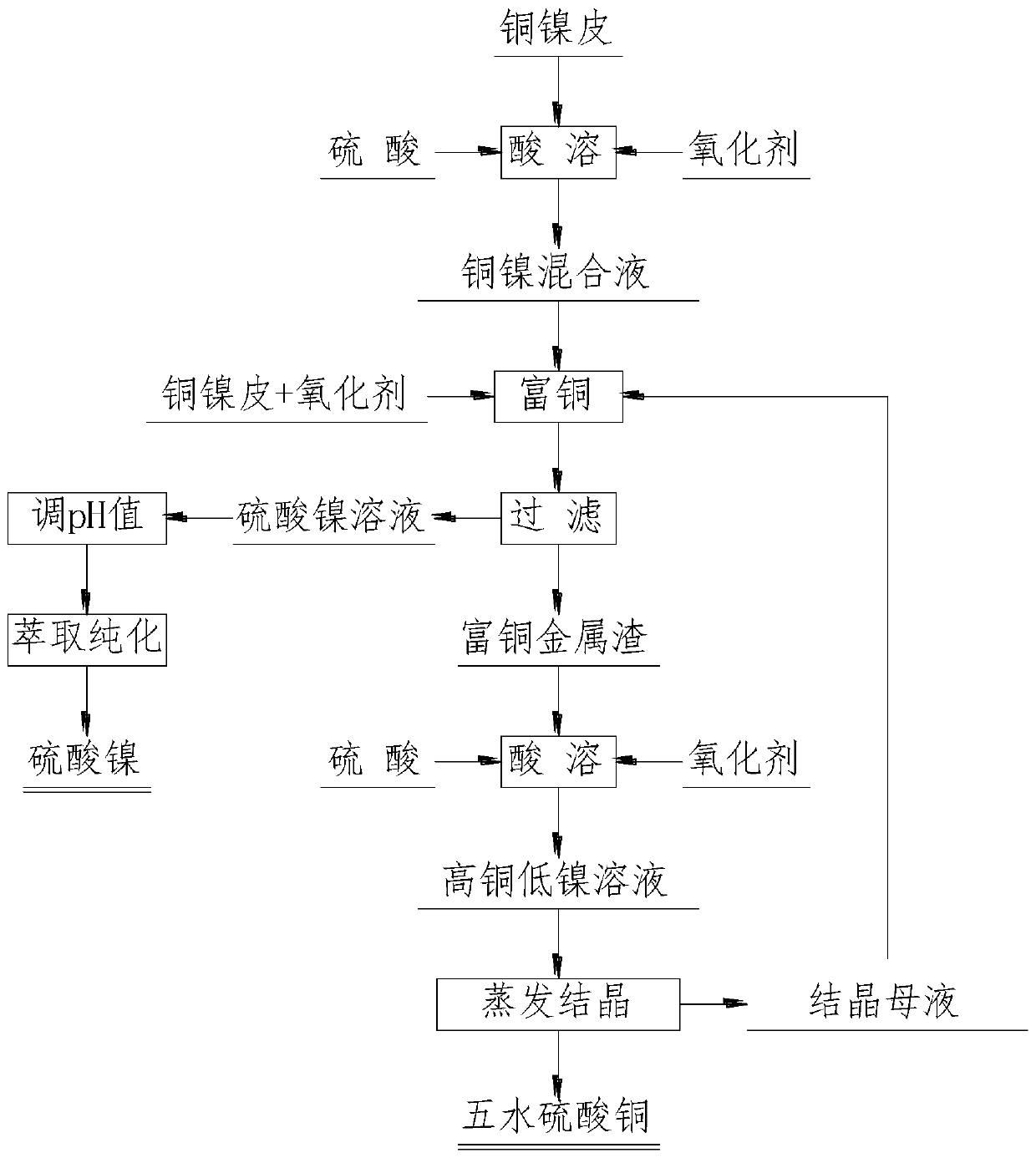

Method for comprehensively treating copper nickel scrap

InactiveCN110510659AShort processReduce energy consumptionNickel compounds preparationNickel sulfatesSlagSolvent

The invention provides a method for comprehensively treating copper-nickel scrap, and the method comprises the following steps: sequentially mixing the copper-nickel scrap with water and sulfuric acid, heating, stirring and adding an oxidant to obtain a mixed solution containing copper and nickel; adding the copper-nickel scrap and an oxidant into the mixed solution containing copper and nickel toobtain a nickel sulfate solution and copper-rich metal slag; adjusting the pH value of the nickel sulfate solution, and performing solvent extraction to obtain a battery-grade product; oxidizing anddissolving the copper-rich metal slag with an acid to obtain a high copper and low nickel mixed solution; evaporating and concentrating the high copper and low nickel mixed solution, crystallizing toseparate out copper sulfate crystals and crystallization mother liquor; reacting the crystallization mother liquor with the copper-nickel scrap; and finally obtaining copper sulfate crystals and a nickel sulfate solution from the copper-nickel scrap. Each index of the copper sulfate crystal product obtained by the method meets the standard level. The method has the advantages of short process flow, low energy consumption, simple industrialization, less impurity removal auxiliary materials and good economic benefits for treating the copper-nickel scrap.

Owner:广西银亿新材料有限公司 +1

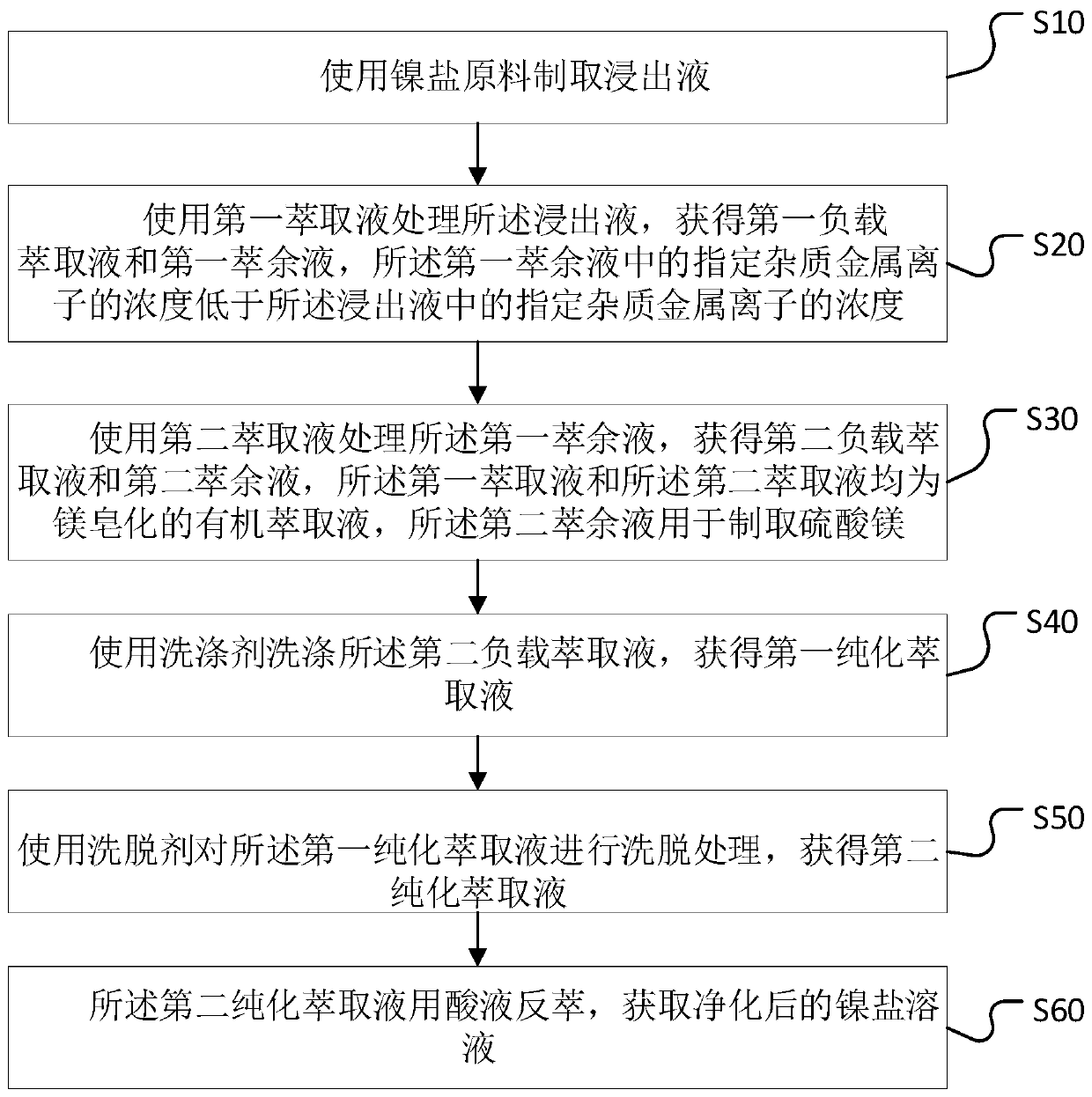

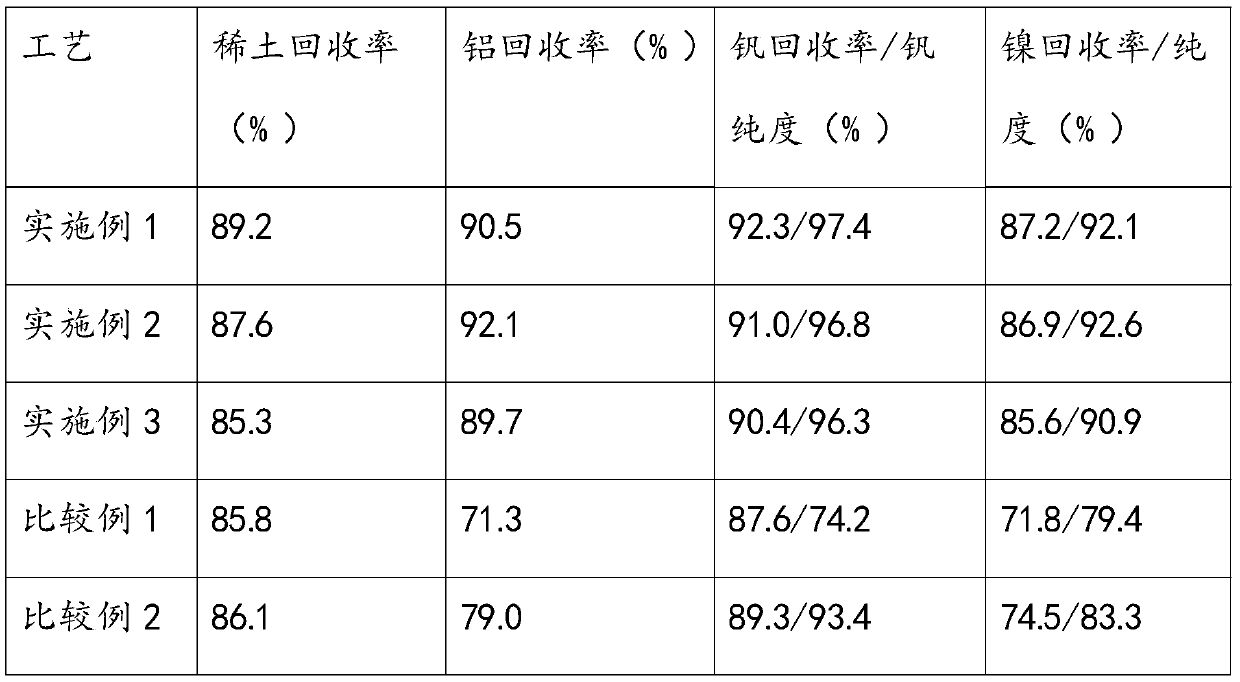

Nickel salt production method

ActiveCN111268750AEfficient separationHigh purityNickel compounds preparationMagnesium sulfatesPregnant leach solutionNickel salt

The invention relates to the field of hydrometallurgy, and discloses a nickel salt production method, which comprises the following steps: preparing leachate from a nickel salt raw material; treatingthe leachate by using a first extraction solution to obtain a first loaded extraction solution and a first raffinate, the concentration of specified impurity metal ions in the first raffinate being lower than the concentration of specified impurity metal ions in the leachate; treating the first raffinate with a second extraction liquid to obtain a second loaded extraction liquid and a second raffinate, both the first extraction liquid and the second extraction liquid being magnesium saponified organic extraction liquid, and the second raffinate being used for preparing magnesium sulfate; washing the second loaded extracting solution with a detergent to obtain a first purified extracting solution; carrying out elution treatment on the first purified extracting solution by using an eluent toobtain a second purified extracting solution; and reversely extracting the second purified extracting solution by using an acid solution to obtain a purified nickel salt solution. The nickel salt prepared by the method is high in purity, low in production cost, small in discharge amount of discharge liquid generated in the production process, low in salinity and environment-friendly.

Owner:李成文 +1

Method for comprehensively recovering waste FCC catalyst by using hydrochloric acid system

ActiveCN111378842AAchieve recyclingHigh recovery rateNickel compounds preparationAluminium hydroxide preparationOXALIC ACID DIHYDRATEPtru catalyst

The invention discloses a method for comprehensively recovering a waste FCC catalyst by using a hydrochloric acid system. The method comprises the following steps that the waste FCC catalyst is reacted with a hydrochloric acid solution; hydrogen peroxide is added into a hydrochloric acid leaching solution for reaction; extracting is conducted by using an extracting agent; the pH value is adjustedby using a sodium hydroxide solution; oxalic acid is added for precipitation reaction; and sodium sulfide is added into filtrate for precipitation reaction. According to the method for comprehensivelyrecovering the waste FCC catalyst by using the hydrochloric acid system, recovery of macroelements such as rare earth and aluminum can be achieved, recovery of elements such as vanadium and nickel isinvolved as well, the high recovery rate can be achieved, and the impurity content of vanadium and nickel is lower.

Owner:河北天蓝环保科技有限公司

Treatment method of laterite-nickel ore

ActiveCN111498917ALow costNickel compounds preparationProcess efficiency improvementPhysical chemistryManganese

The invention provides a treatment method of laterite-nickel ore. The treatment method of the laterite-nickel ore comprises the steps of: S1, enabling the laterite-nickel ore to be sequentially subjected to acid leaching, pre-neutralization, iron and aluminum removal and neutralization treatment, and obtaining an intermediate product containing cobalt nickel hydroxide; S2, dissolving the intermediate product with sulfuric acid to obtain a scandium-containing iron mixed solution; S3, adsorbing the scandium-iron-containing mixed solution by using cationic resin to remove scandium and iron to obtain adsorbed resin and an adsorbed solution; S4, performing desorption treatment on the adsorbed resin by using alkali liquor, and separating desorption resin from the adsorbed solution containing scandium-iron precipitate to obtain desorption resin and desorption slurry containing scandium-iron precipitate; S5, carrying out solid-liquid separation on the desorption slurry containing the scandium-iron precipitate to obtain the scandium-iron precipitate and the adsorbed solution, and returning the adsorbed solution to the desorption treatment step for reuse; and S6, extracting the adsorbed solution to remove manganese. The process of precipitating the metal desorbed from the adsorbed solution does not exist, so that the cost is low.

Owner:CHINA ENFI ENGINEERING CORPORATION

Active material for nonaqueous electrolyte secondary battery, method for production of the active material, electrode for nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery

ActiveCN103296268AHigh rate discharge characteristicsExcellent cycle characteristicsCell electrodesNickel compounds preparationHigh rateElectrical battery

The invention provides an active material for a nonaqueous electrolyte secondary battery, a method for production of the active material and the nonaqueous electrolyte secondary battery using the active material, the active material excellent high-rate discharge characteristics. The active material for a nonaqueous electrolyte secondary battery includes a lithium-transition metal composite oxide which has an alpha-NaFeO2 -type crystal structure and of which the average composition is represented by the composition formula of Li1+[alpha]Me1-[alpha]O2 (Me is a transition metal containing Co, Ni and Mn; and alpha > 0), wherein the lithium-transition metal composite oxide is a particle having a core and a coated part, the cobalt concentration of the coated part is higher than the cobalt concentration of the core, the manganese concentration of the coated part is lower than the manganese concentration of the core, and the ratio of cobalt present in the coated part is 3 to 10% in terms of a molar ratio based on the amount of the transition metal present in the core. In addition, the method for production of the active material of the nonaqueous electrolyte secondary battery is characterized by enabling cobalt-containing compounds, cobalt-nickel-containing compounds and cobalt-nickel-manganese-containing compounds with more cobalt than manganese in a molar ratio to coat co-precipitated precursor core particles of transition metal compounds containing cobalt, nickel and manganese and being with more manganese than cobalt in the molar ratio, mixing the co-precipitated precursor core particles and lithium compounds, and then firing.

Owner:GS YUASA INT LTD

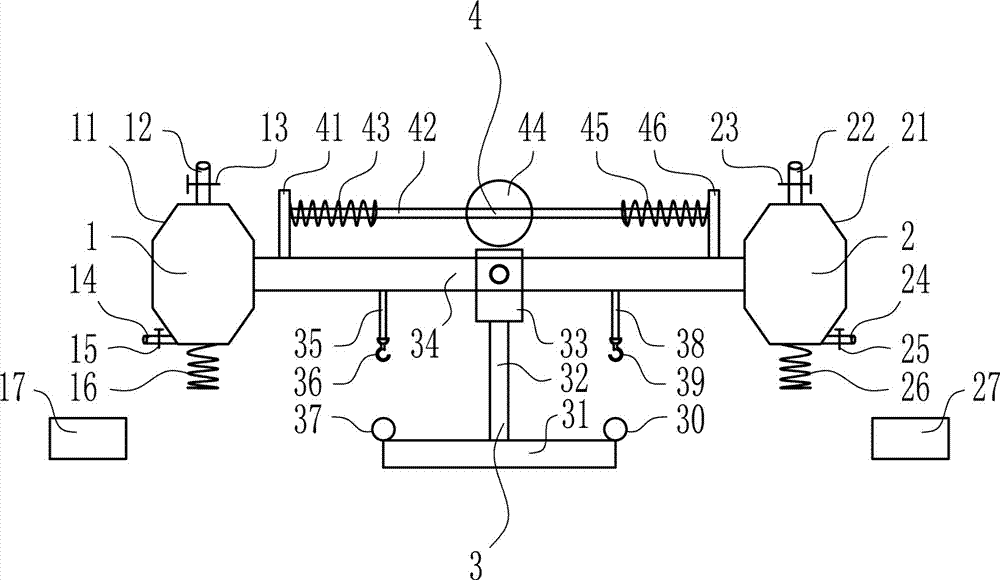

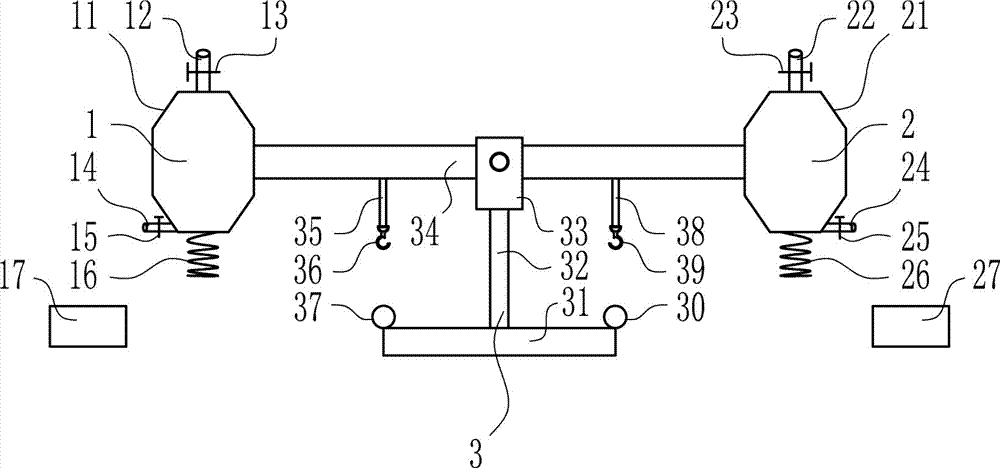

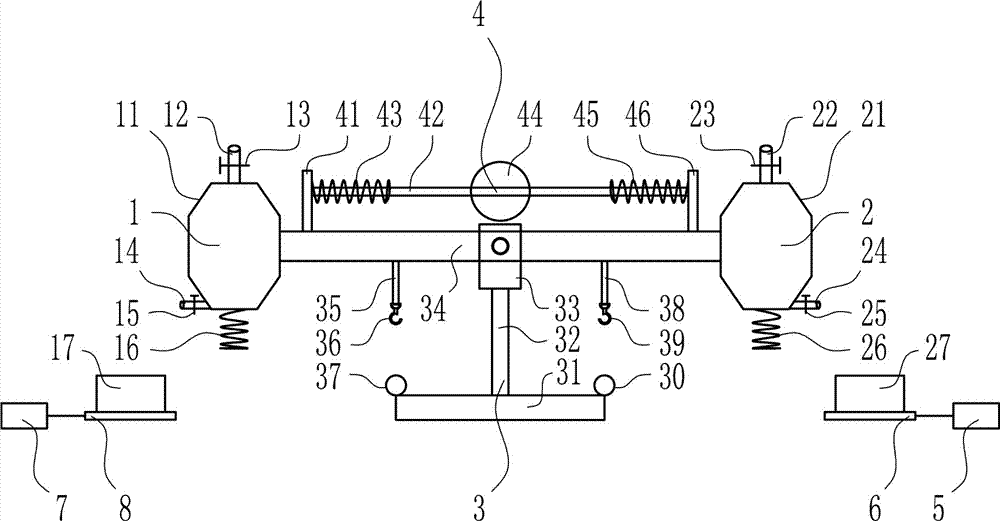

New energy-saving extraction device for extracting nickel sulfate from waste batteries

ActiveCN106902547AWill not polluteUnique structureNickel compounds preparationLiquid solutions solvent extractionSulfateNew energy

The invention relates to an extraction device, and in particular relates to a new energy-saving extraction device for extracting nickel sulfate from waste batteries. The technical problem to be solved by the invention is to provide the new energy-saving extraction device for extracting the nickel sulfate from the waste batteries. The new energy-saving extraction device for extracting the nickel sulfate from the waste batteries comprises a left extraction device, a right extraction device, a shaking mixing device and the like, the right extraction device is arranged at the right side of the shaking mixing device, and the right extraction device and the left extraction device are symmetrically arranged. The new energy-saving extraction device for extracting the nickel sulfate from the waste batteries has a unique structure and can mix and stir a liquid mixture through relative motion of the two extraction devices.

Owner:全南县瑞隆科技有限公司

Method for refining nickel sulfate

InactiveCN108751267AReduce intensityAvoid pollutionNickel compounds preparationNickel sulfatesSulfideImpurity

The invention discloses a method for refining nickel sulfate. The method specifically comprises the following steps: step 1, dissolving and oxidizing crude nickle sulphate; step 2, preparing a nickelsoap; step 3, extracting and removing iron; step 4, extracting and removing copper; step 5, extracting and removing zinc; step 6, removing organic impurities; and step 7, carrying out a series of steps in a post treatment process. According to the method for refining nickel sulfate, provided by the invention, a tradition method for refining nickel sulfate is changed, the labor intensity is lowered, that environment is polluted by hydrogen sulfide can be well avoided, and that part of Ni2+ is carried away due to hydroxide and sulfide precipitation produced can be prevented, and further the purification yield is increased greatly, and is increased to 95 percent from the 85 percent in the previous. Therefore, the yield of refined products meets market requirements, and the quality also meetschemical reagent grade requirements.

Owner:贵州中伟资源循环产业发展有限公司

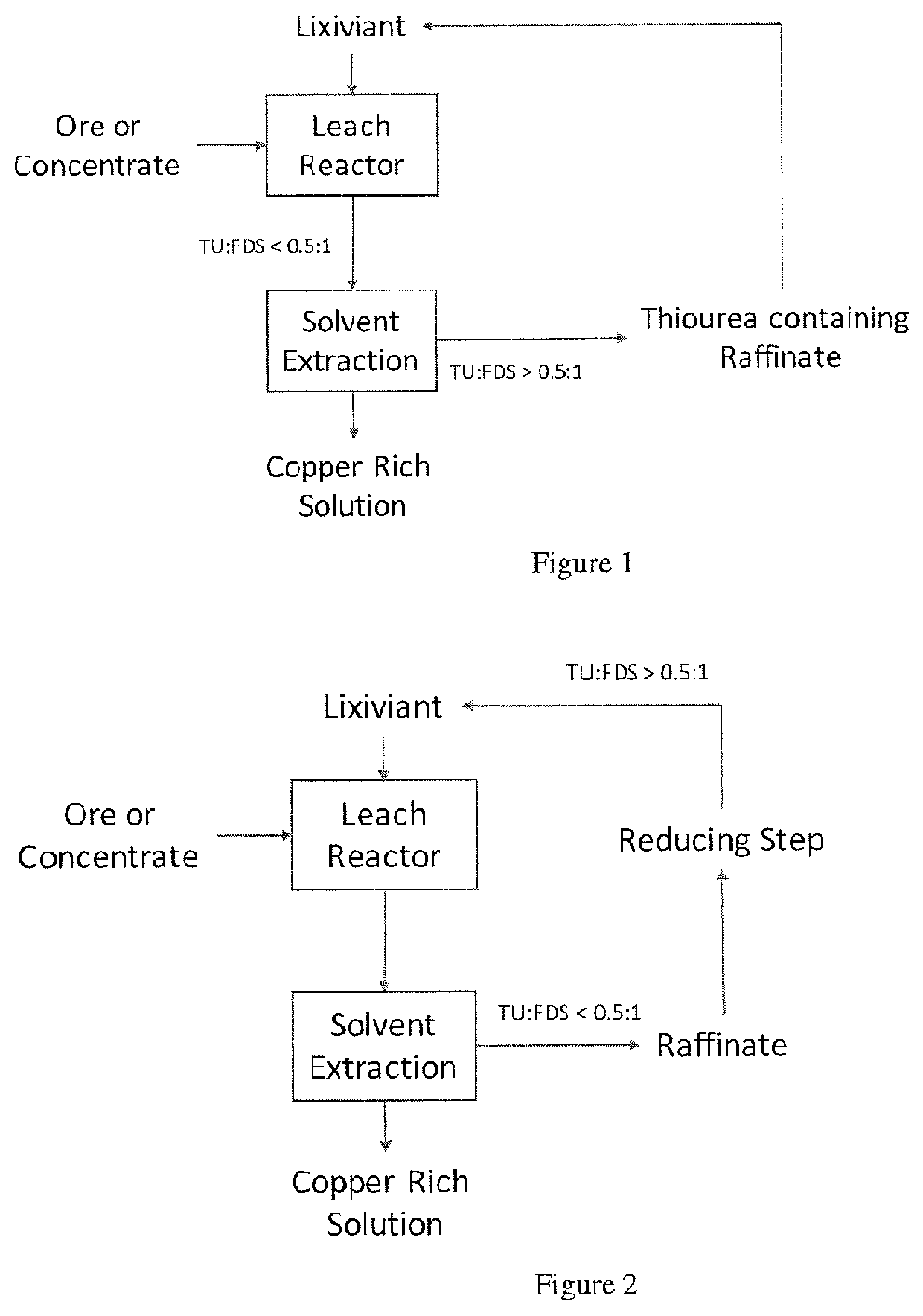

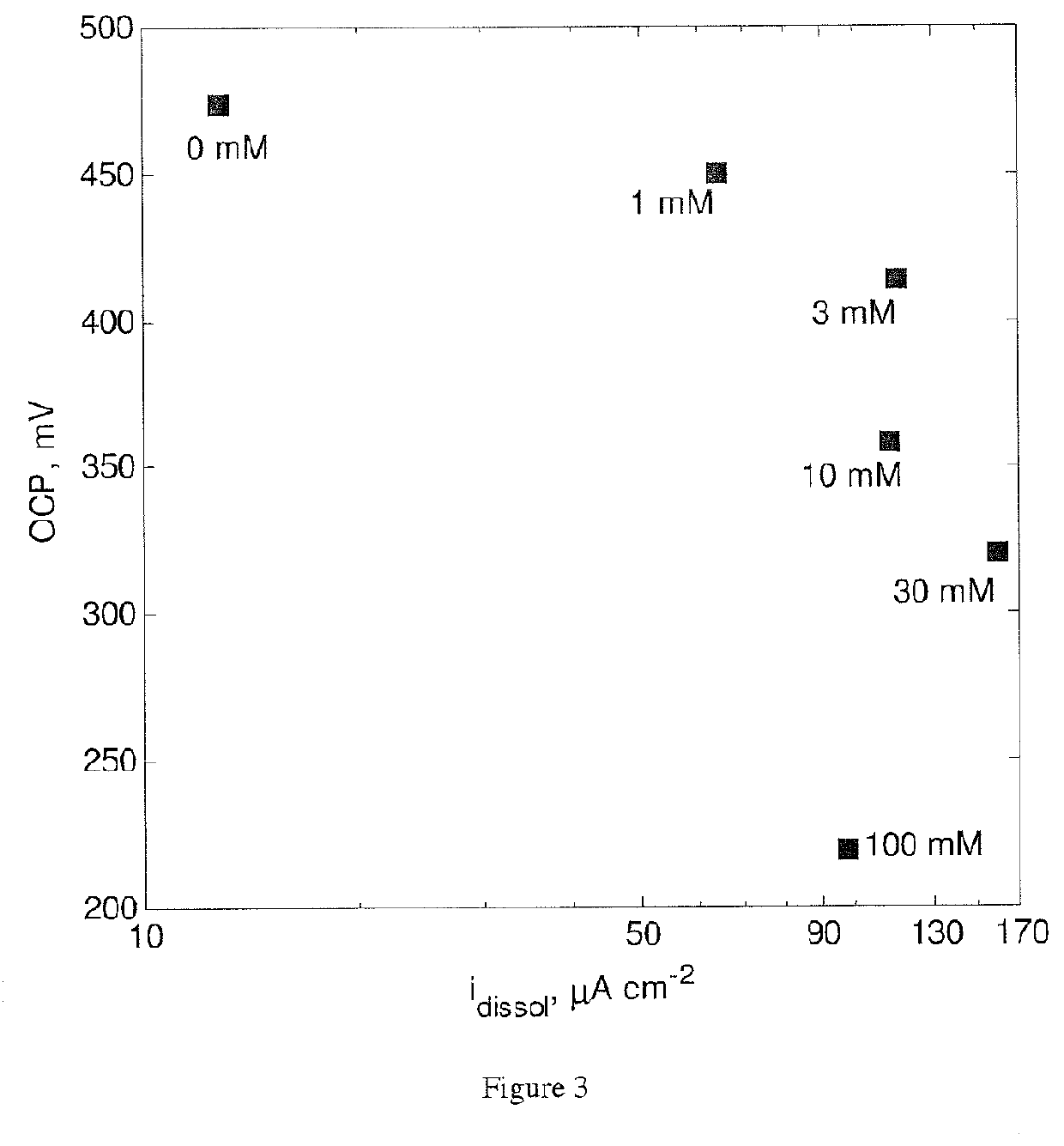

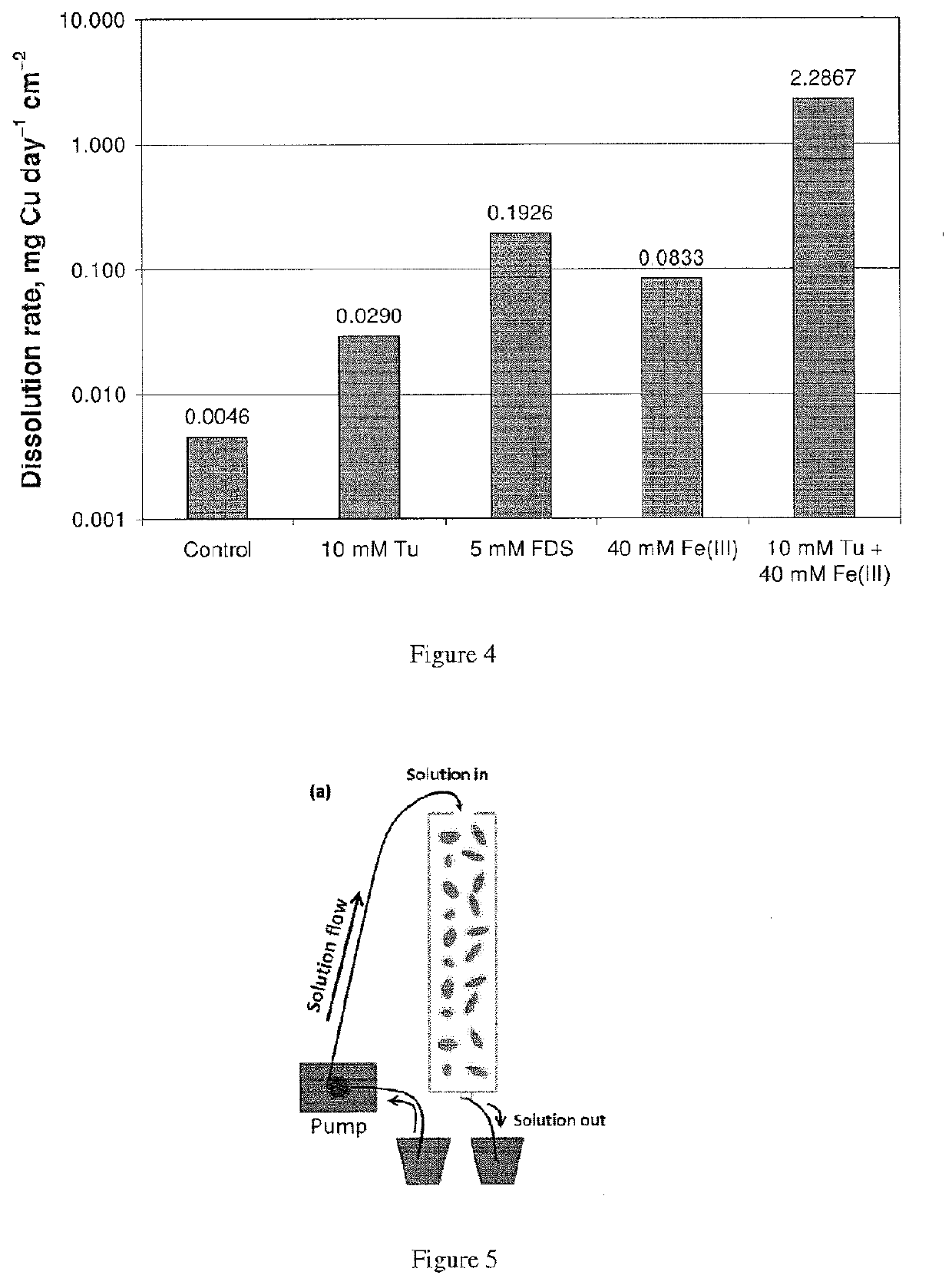

Process for leaching metal sulfides with reagents having thiocarbonyl functional groups

PendingUS20200048736A1Promote leachingIncrease ratingsNickel compounds preparationCopper compounds preparationIron sulfateThio-

This application pertains to methods of recovering metals from metal sulfides that involve contacting the metal sulfide with an acidic sulfate solution containing ferric sulfate and a reagent that has a thiocarbonyl functional group, wherein the concentration of reagent in the acidic sulfate solution is sufficient to increase the rate of metal ion extraction relative to an acidic sulfate solution that does not contain the reagent, to produce a pregnant solution containing the metal ions.

Owner:JETTI RESOURCES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com