Patents

Literature

31results about "Copper compounds preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

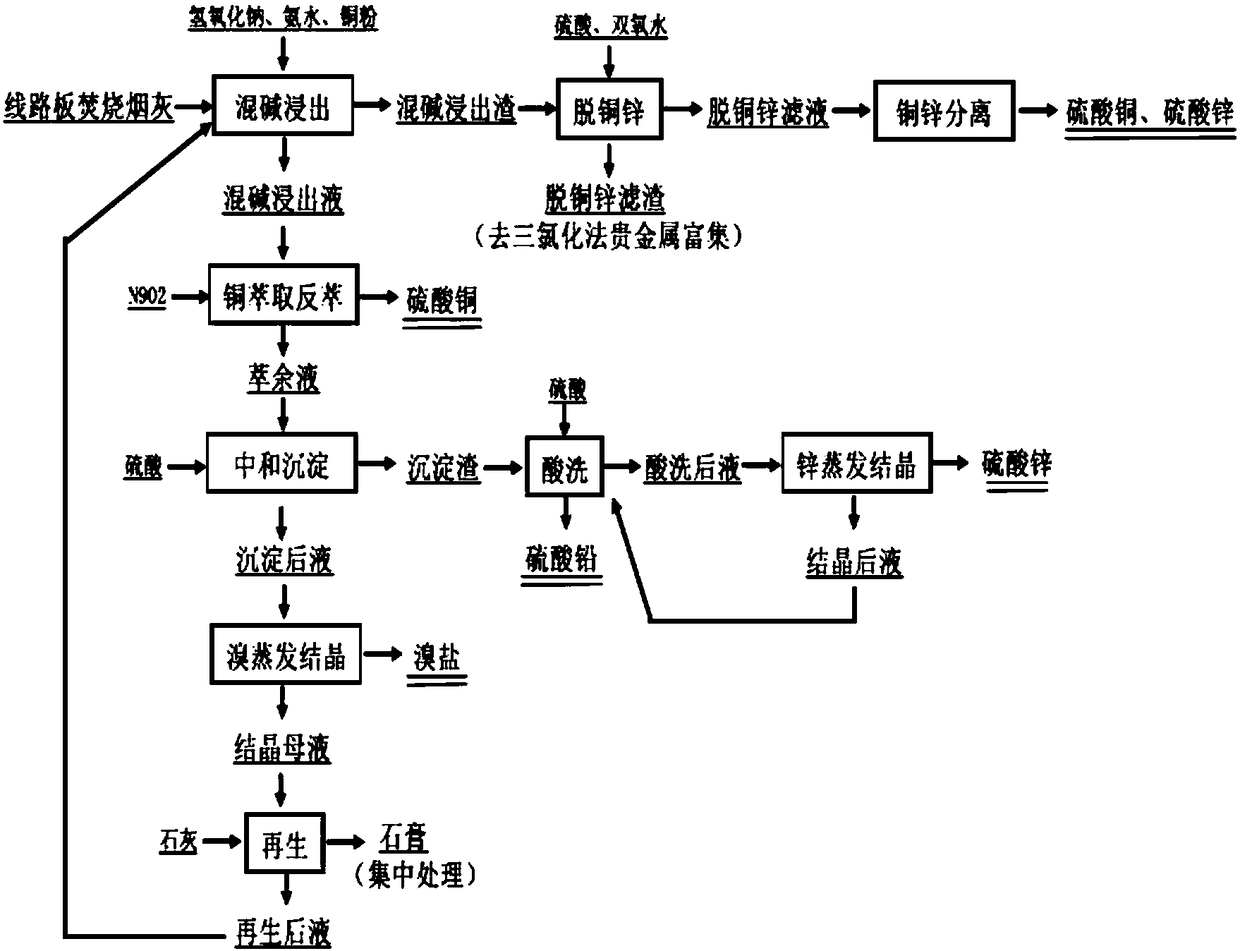

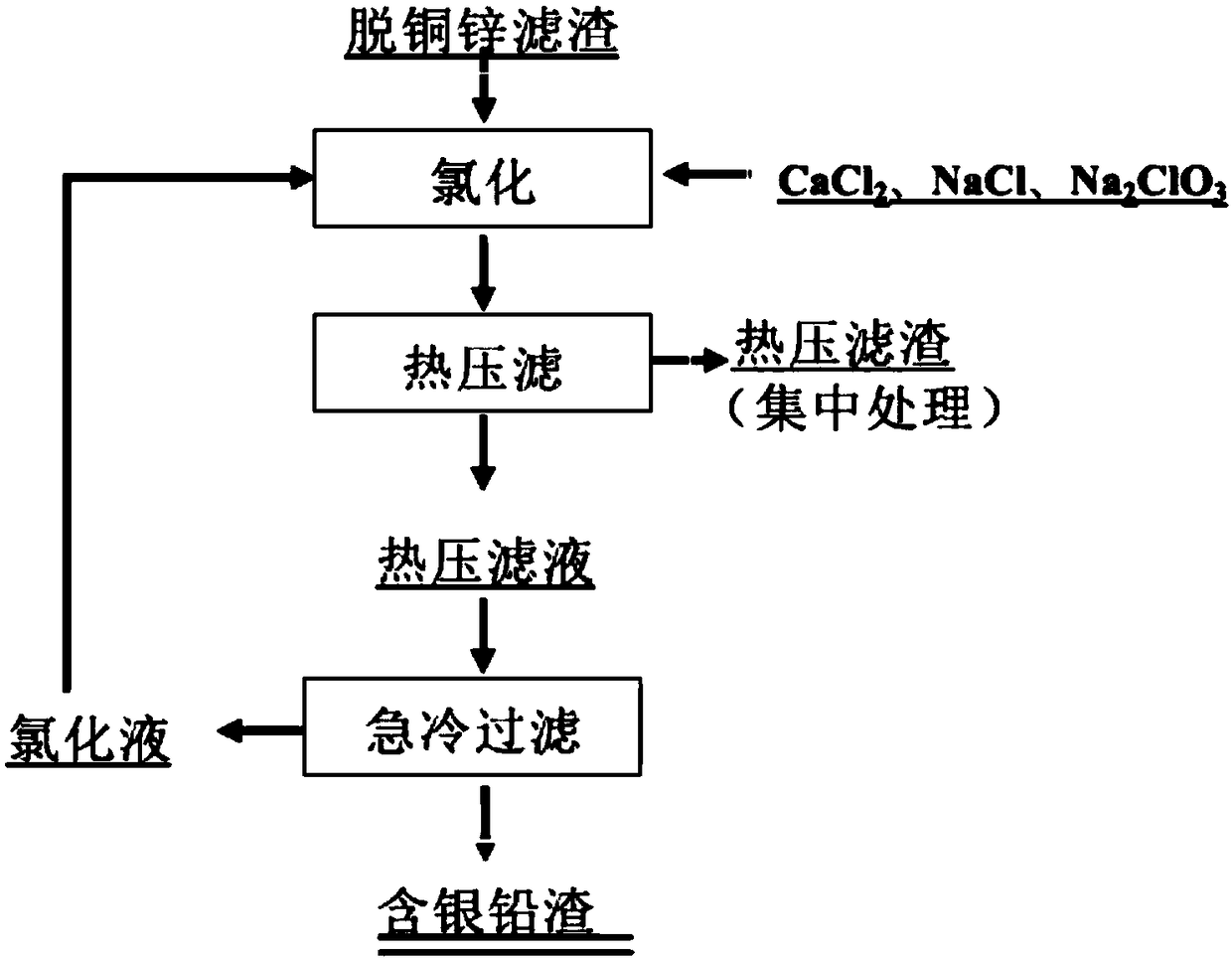

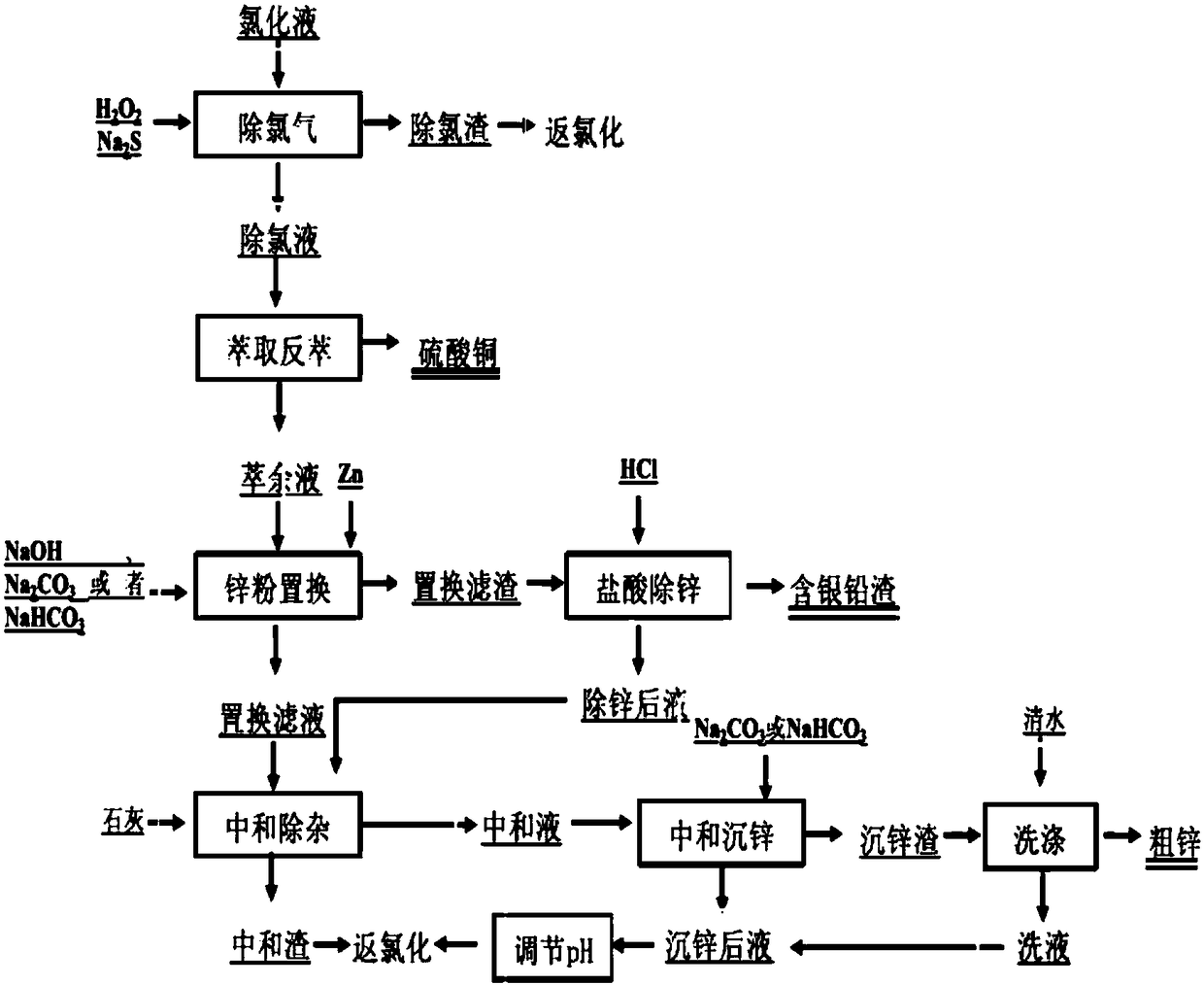

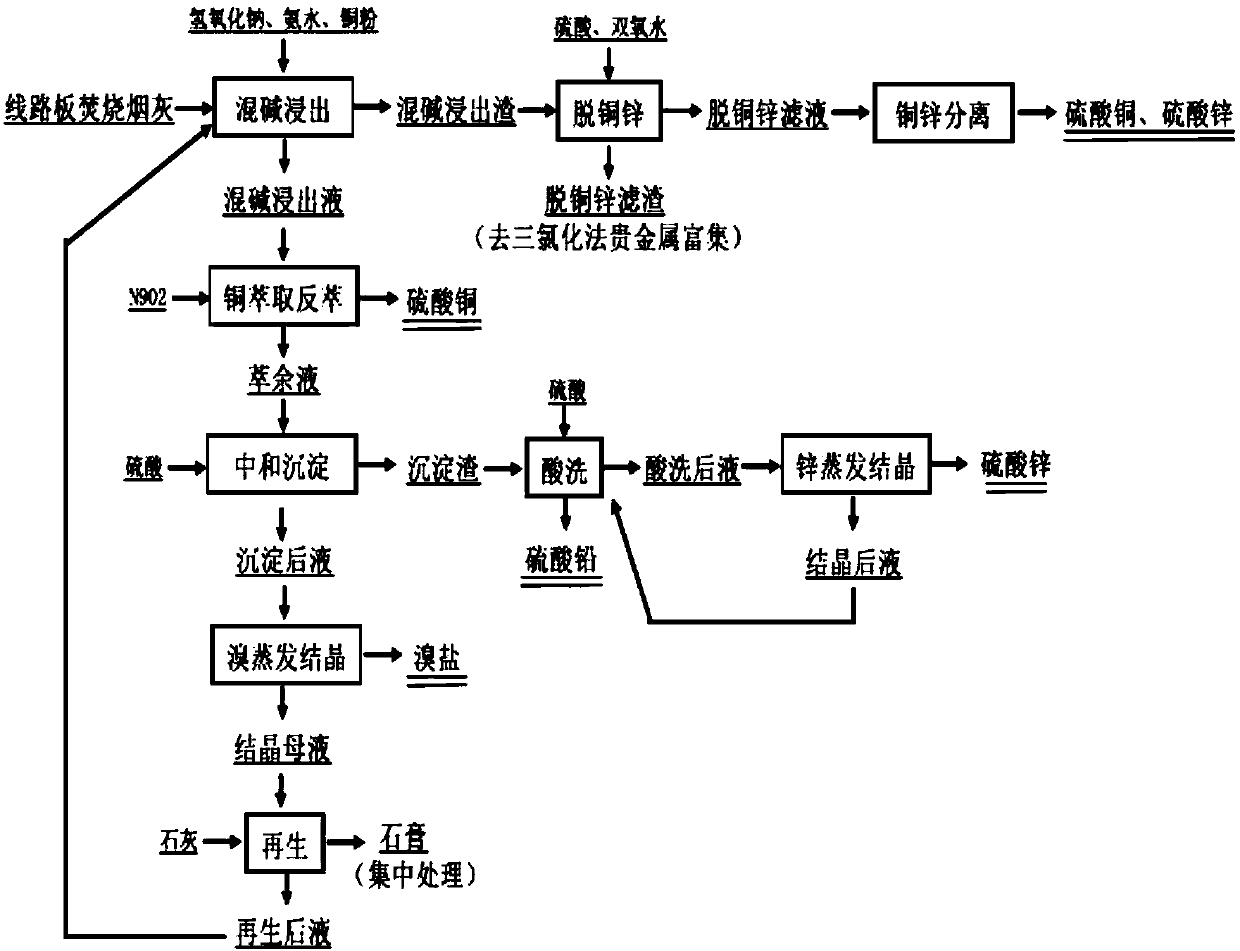

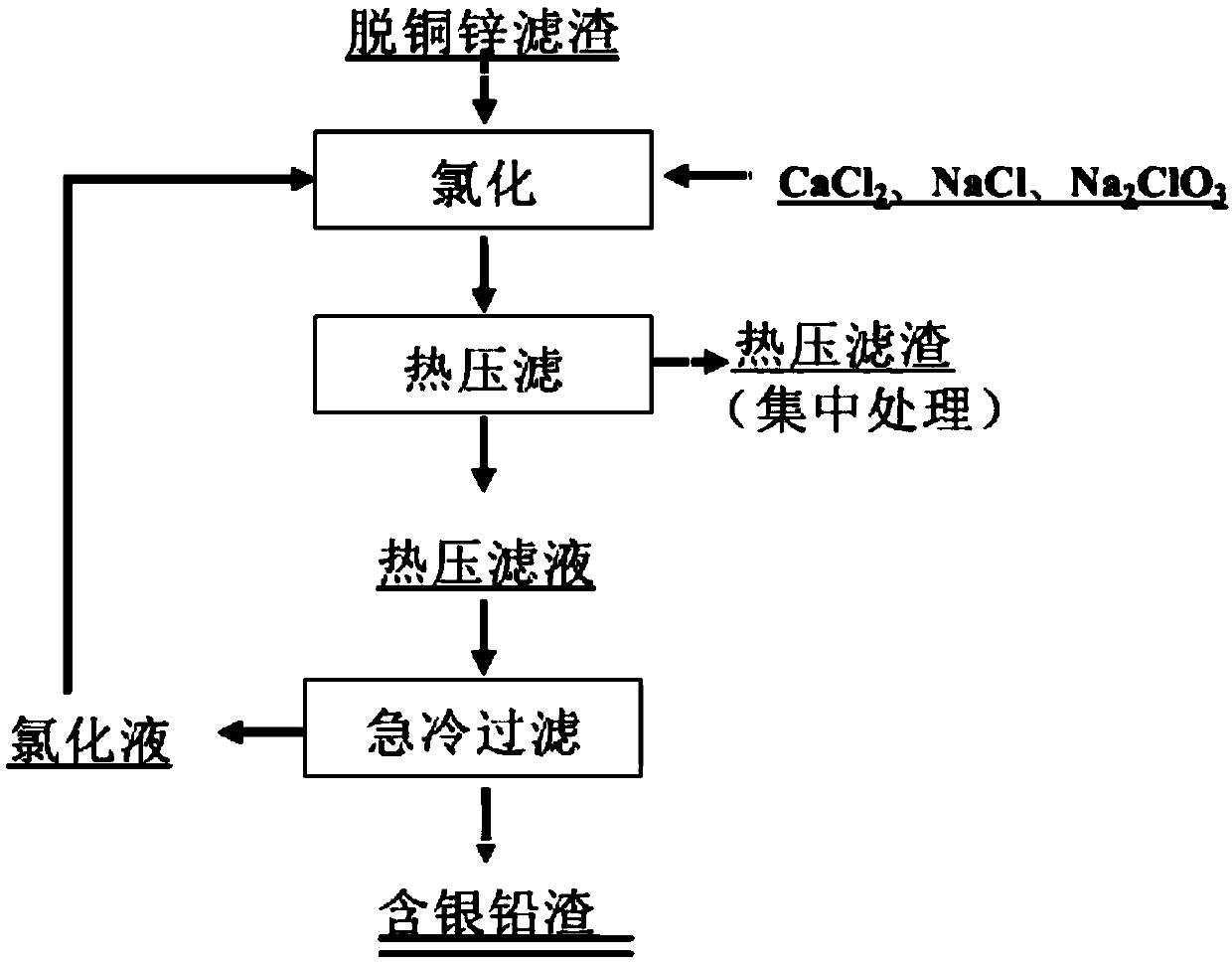

Method for pretreating incineration ash of circuit board and recovering bromine

ActiveCN108118157AEasy to recycleNo emissionsZinc sulatesCalcium/strontium/barium sulfatesRecovery methodBromine

The invention discloses a method for pretreating incineration ash of a circuit board and recovering bromine, belongs to the field of comprehensive recovery of ash whole-wet valuable metal and particularly relates to a method for recovering valuable metal, enriching precious metal and recovering bromine salt in the pretreatment process of incineration ash of the circuit board. The method mainly comprises the steps: extracting mixed alkali; recovering copper by copper extraction and back extraction; carrying out neutralization and precipitation to separate lead and zinc; evaporating and crystallizing bromine; regenerating mixed alkali extracting liquor; removing zinc by acid pickling; evaporating and crystallizing zinc; carrying out zinc and copper removal on mixed alkali extracting residuesand the like. Compared with a traditional ash comprehensive process, the technology disclosed by the invention has the advantages that recovery of valuable metals such as copper, zinc and lead and enrichment of precious metal such as silver in the pretreatment process of the ash is realized to the maximum extent; meanwhile, the bromine salt is separated and recovered; the method has the characteristics of high recovery added value, no tail liquid drainage and the like.

Owner:BEIJING UNIV OF TECH

Feed-level copper sulfate and production technology thereof

ActiveCN106348334ARealize comprehensive utilizationSimple production process and equipmentCopper compounds preparationCopper sulfatesEconomic benefitsIon exchange

The invention relates to the technical field of industrial wastewater treatment, in particular to feed-level copper sulfate and a production technology thereof. The production technology comprises the following steps of A, preparing rough purification etching waste liquid; B, neutralizing, pressing and filtering; C, extracting, and exchanging ions; D, acidifying and crystallizing. The production technology has the advantages that the environment-friendly and pollution-free effects are realized, the emission of waste gas and wastes is avoided, and the wastes are utilized; the mother liquor is recycled, and the subsidiary liquor is sold back to enterprises, so that the economic benefit is high; the equipment is simple, and the operation is simple and convenient; the content of copper ions in the prepared feed-level copper sulfate is 95%, and the prepared feed can improve digestion systems of livestock and poultry.

Owner:东莞市德睿工业废品处理有限公司

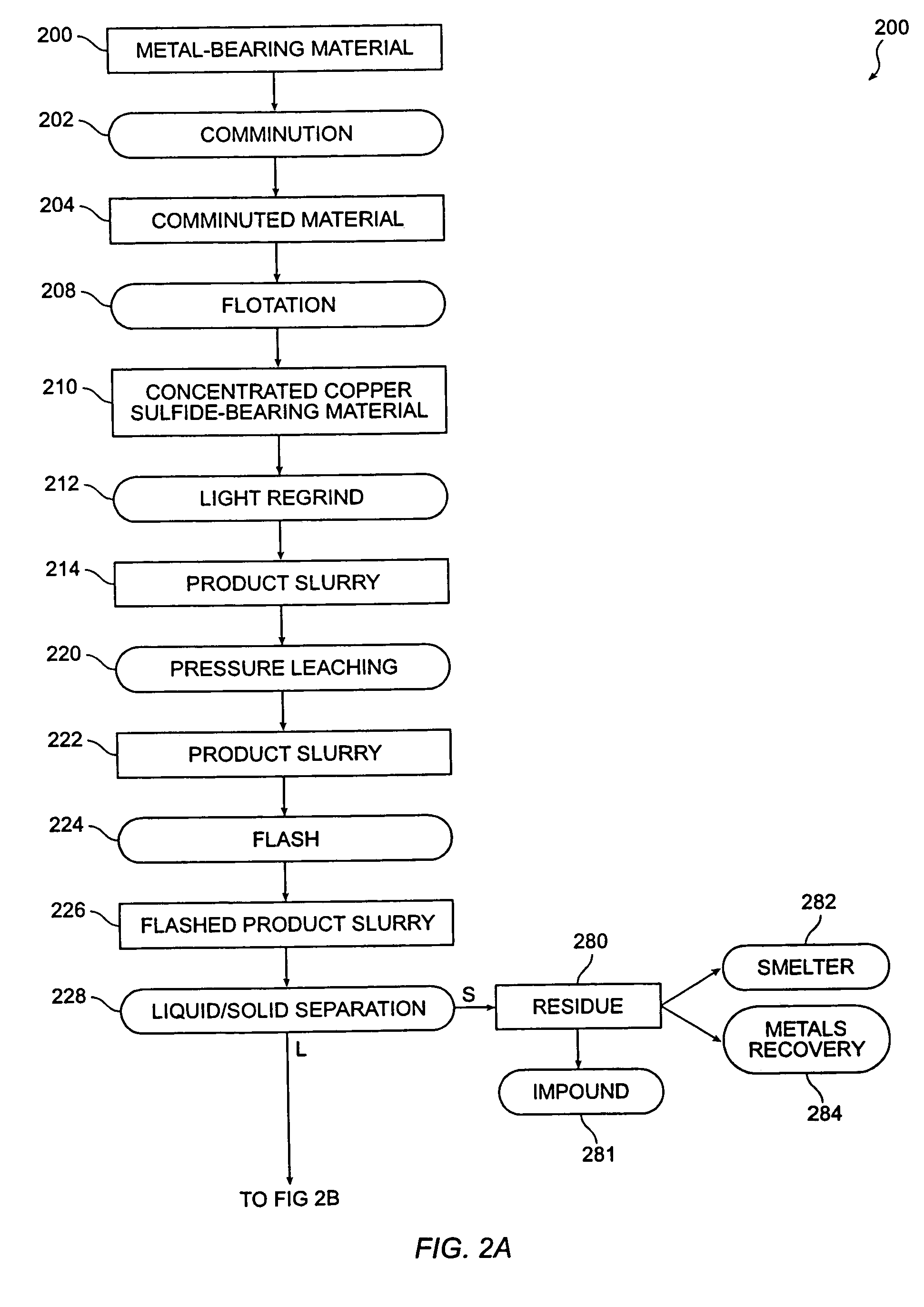

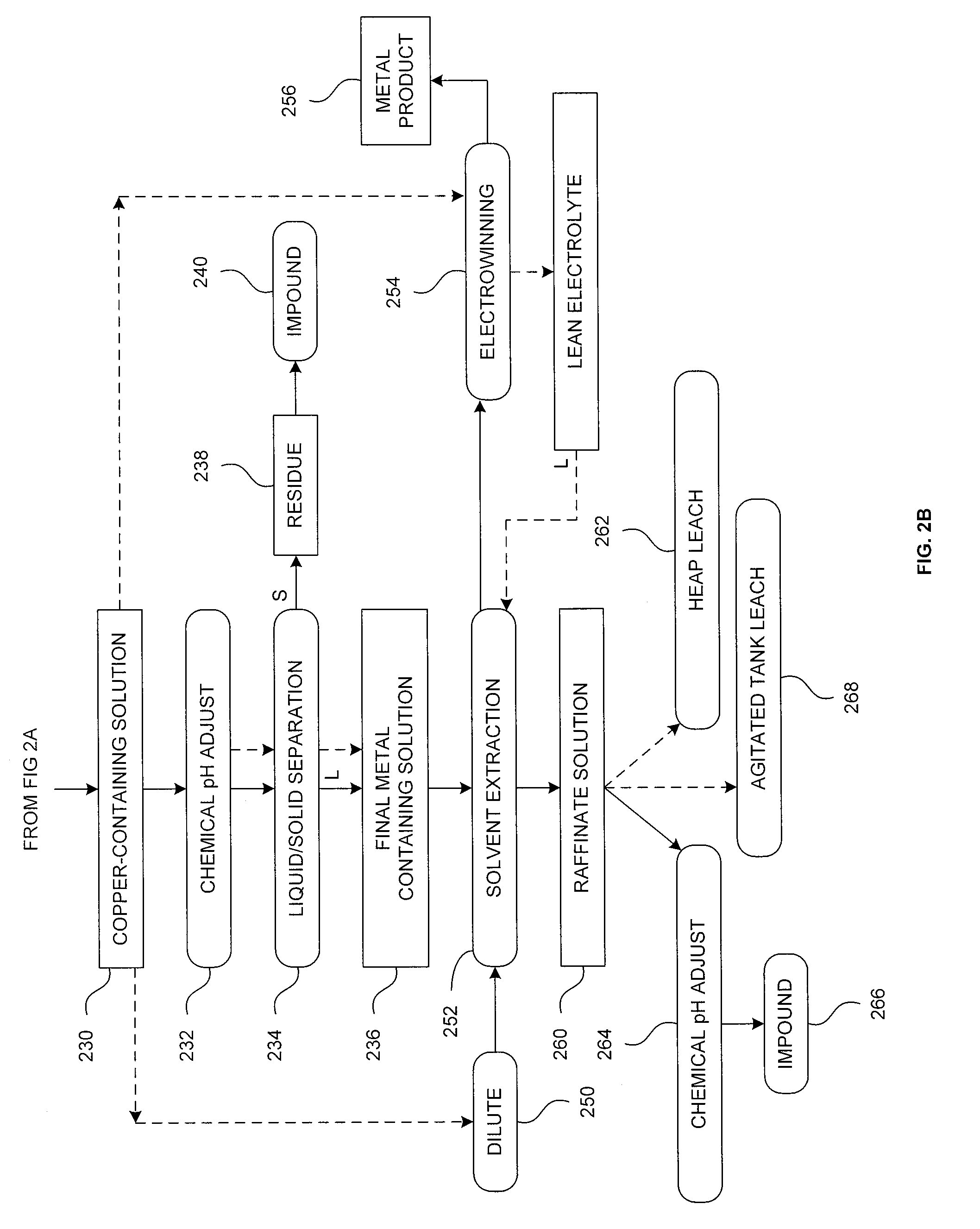

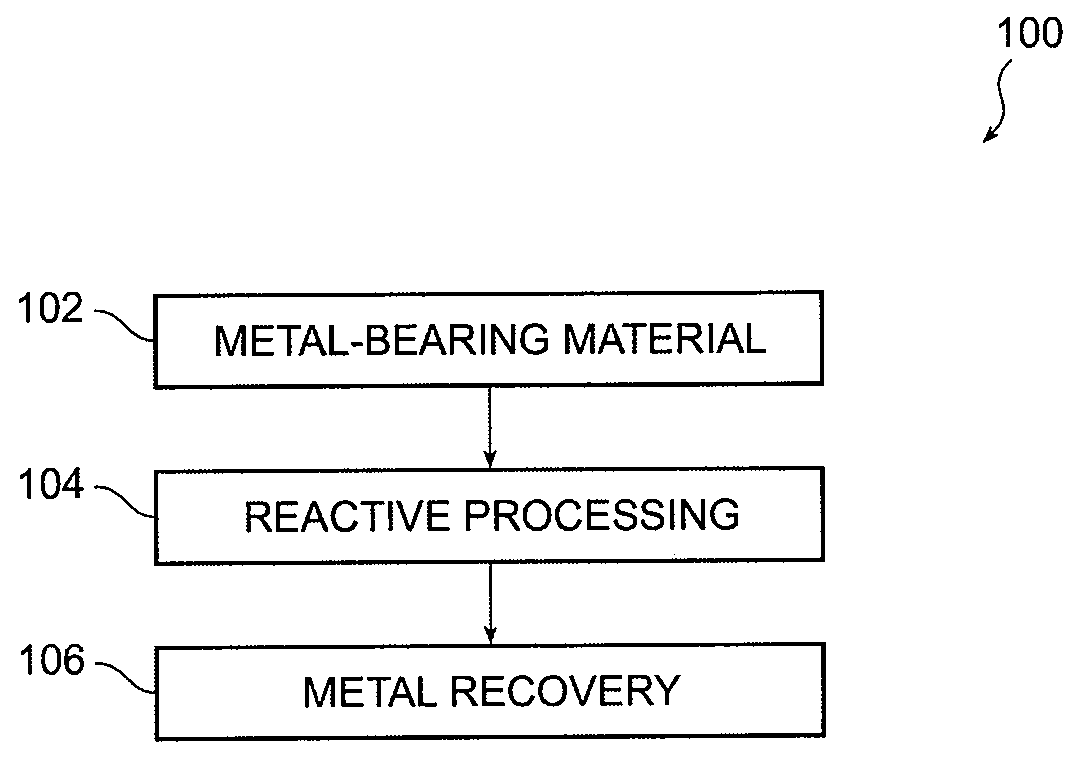

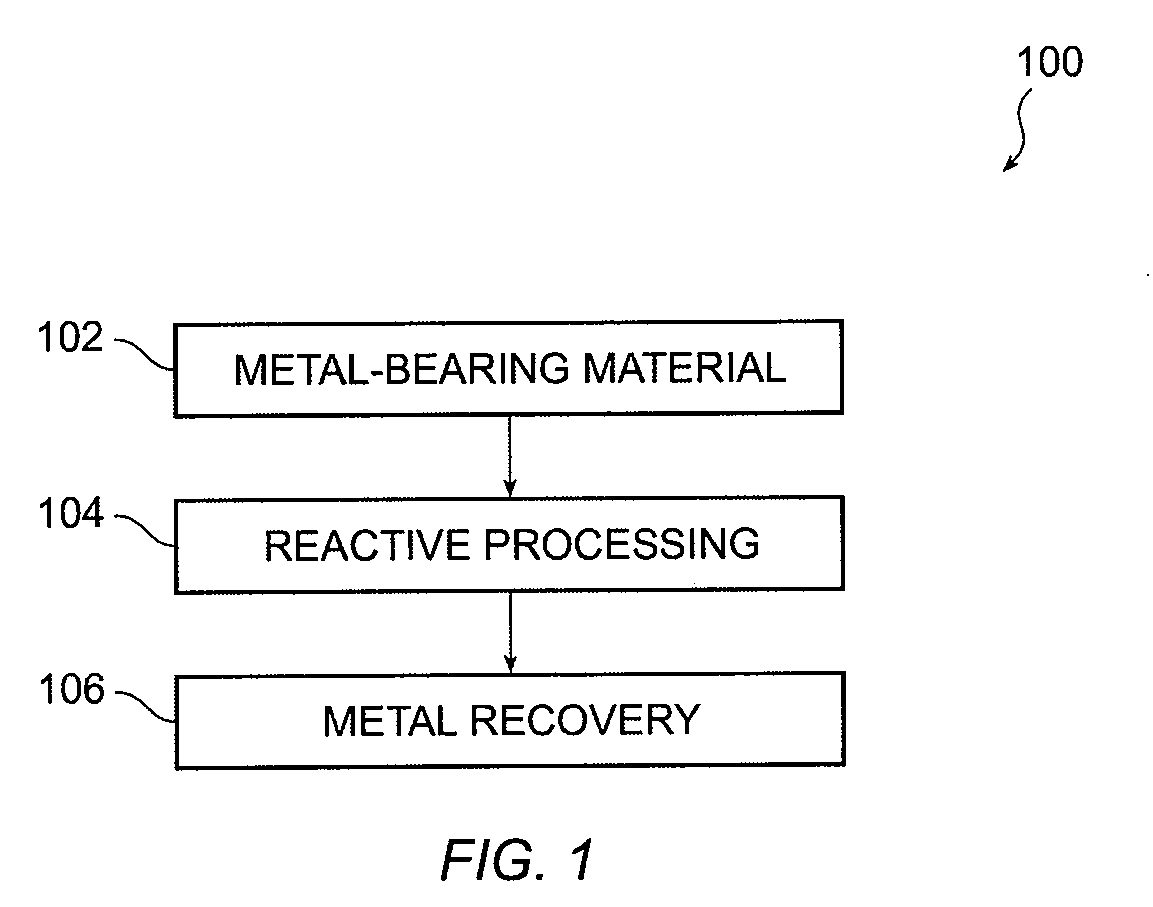

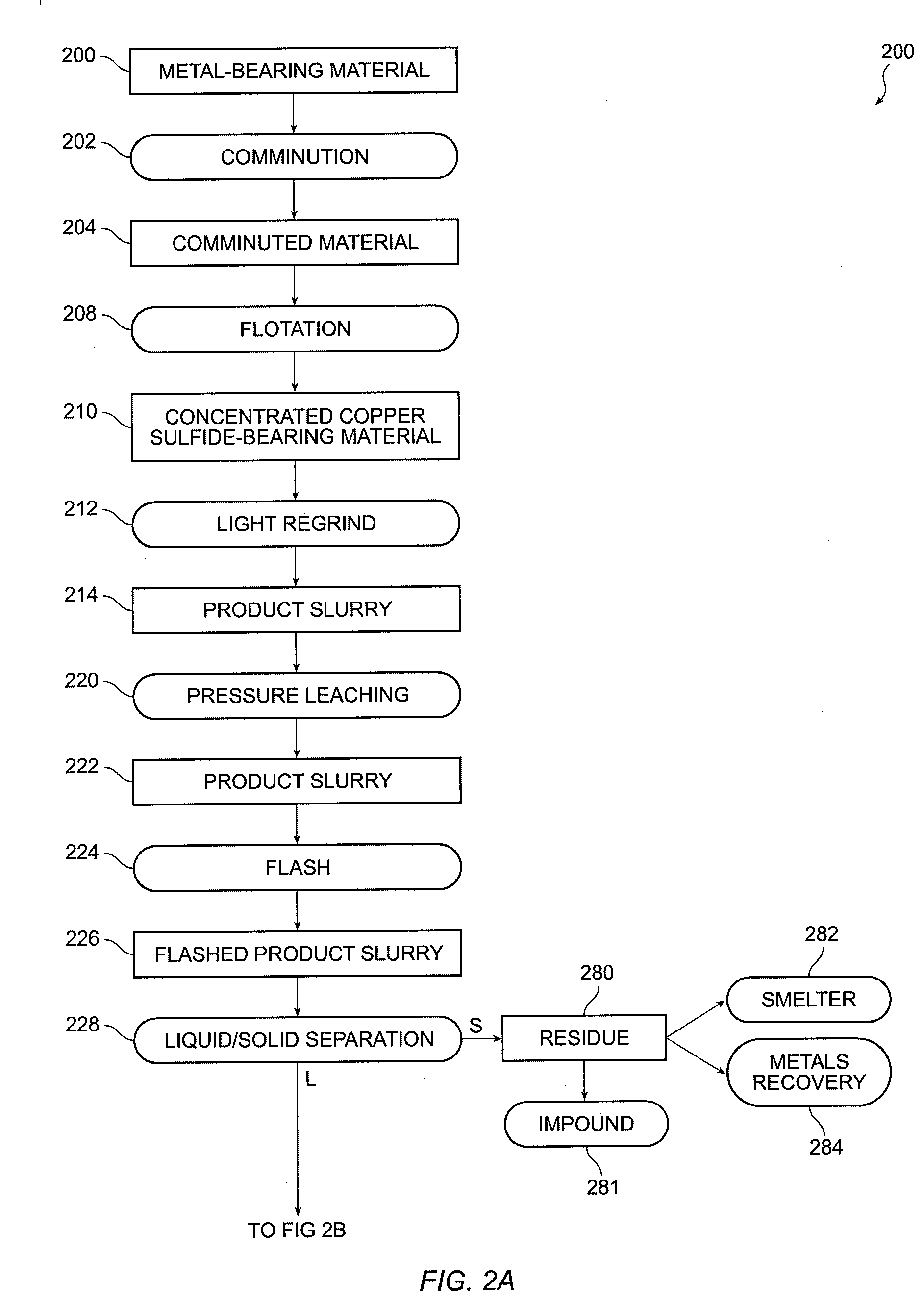

Method for recovering metal values from metal-containing materials using high temperature pressure leaching

InactiveUS7473413B2Low costHigh recovery rateSolvent extractionSolid sorbent liquid separationPregnant leach solutionElectrolysis

The present invention relates generally to a process for recovering copper and other metal values from metal-containing materials through pressure leaching operations. In accordance with the various aspects of the present invention, metal-containing pregnant leach solutions from pressure leaching operations need not be significantly diluted to facilitate effective metal recovery using solvent extraction and electrowinning.

Owner:FREEPORT MCMORAN COPPER & GOLD INC

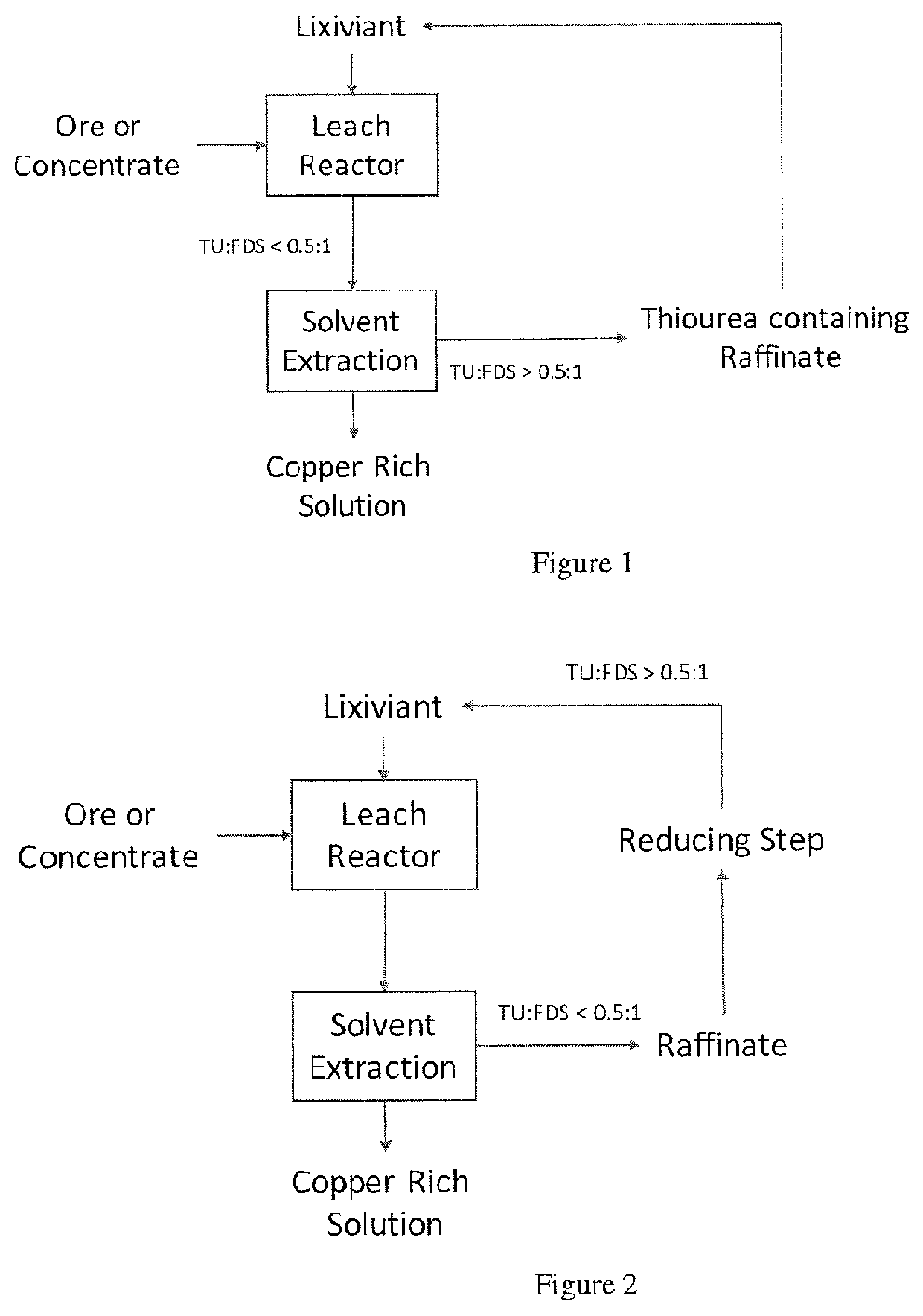

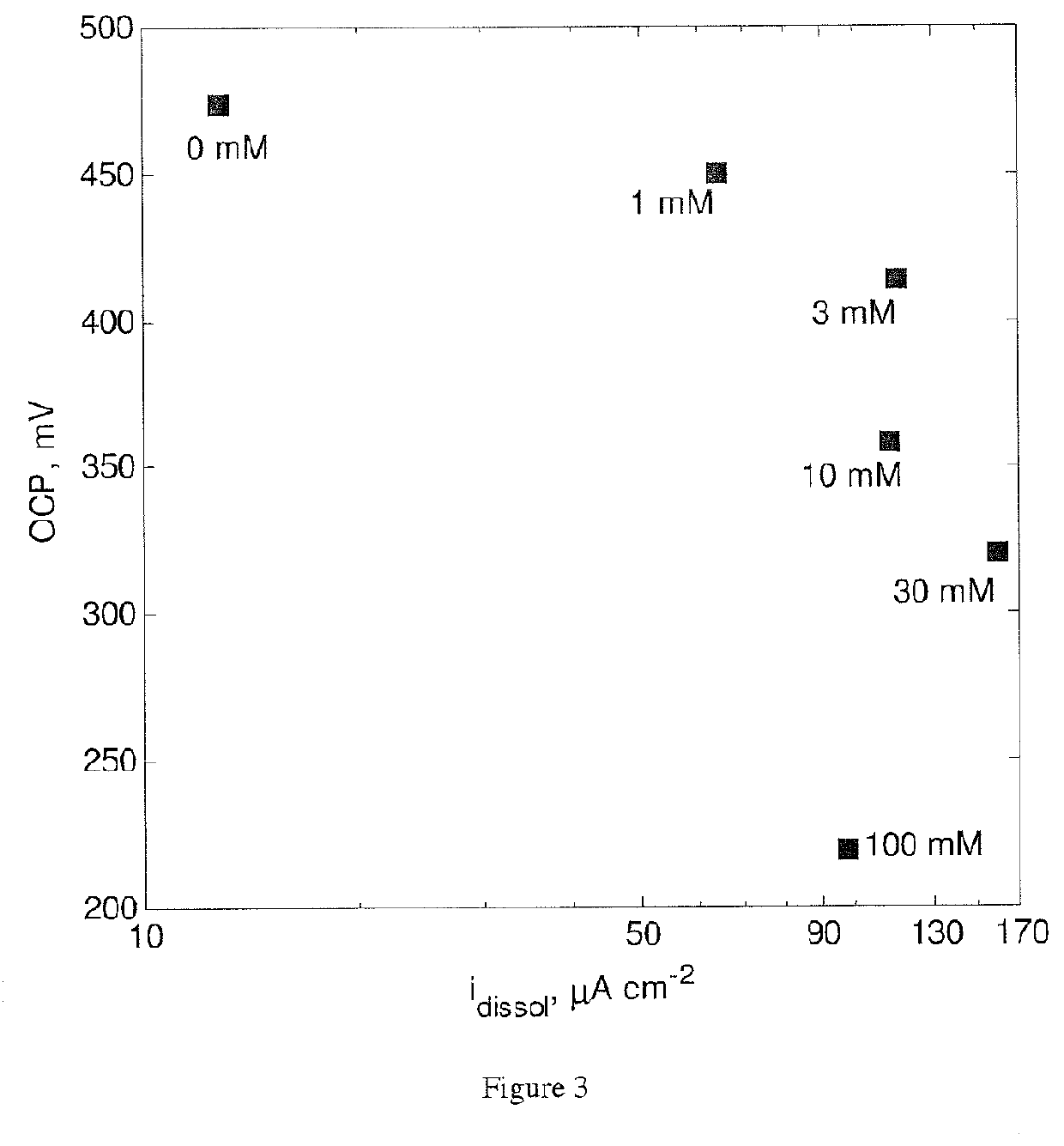

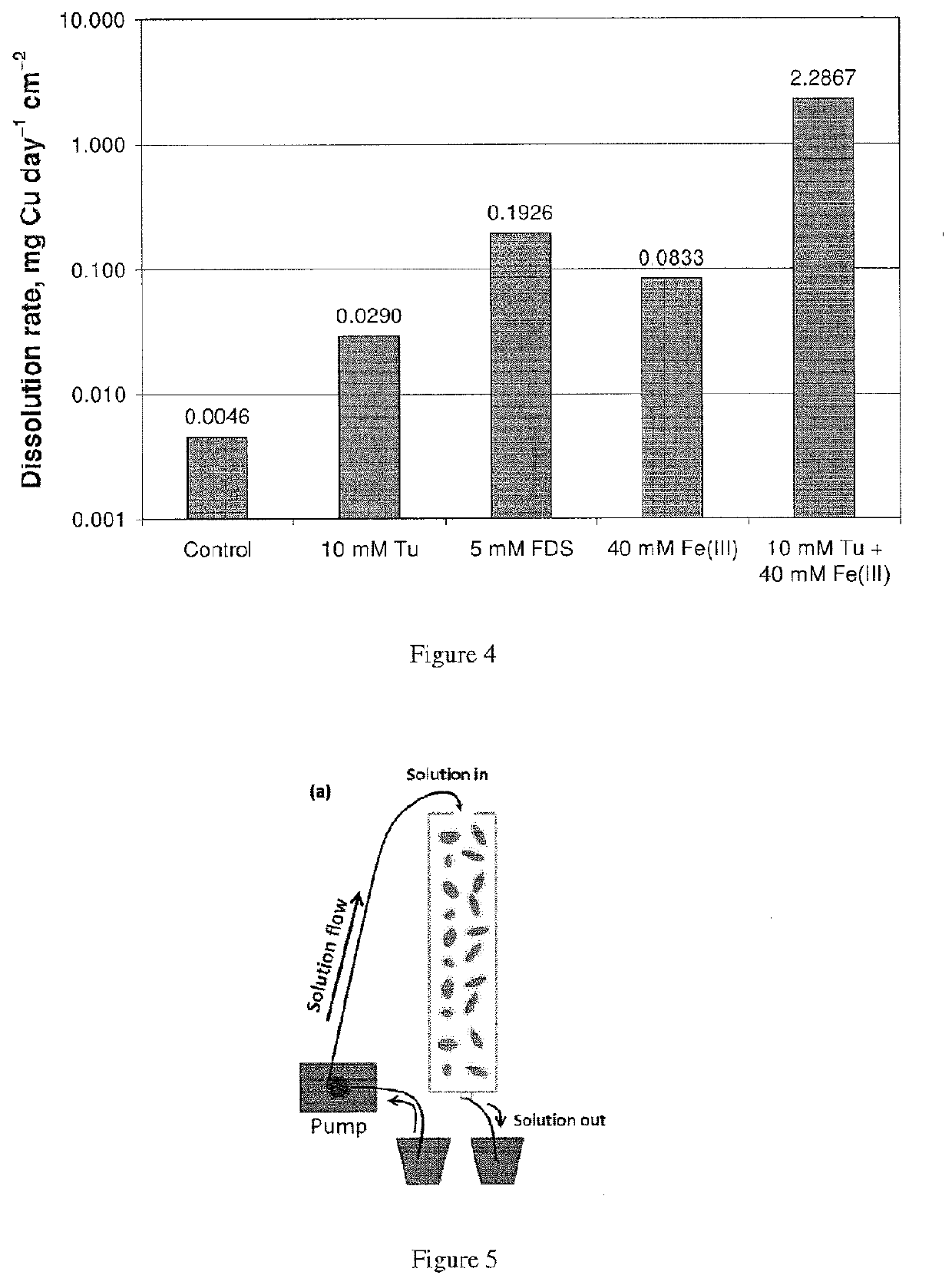

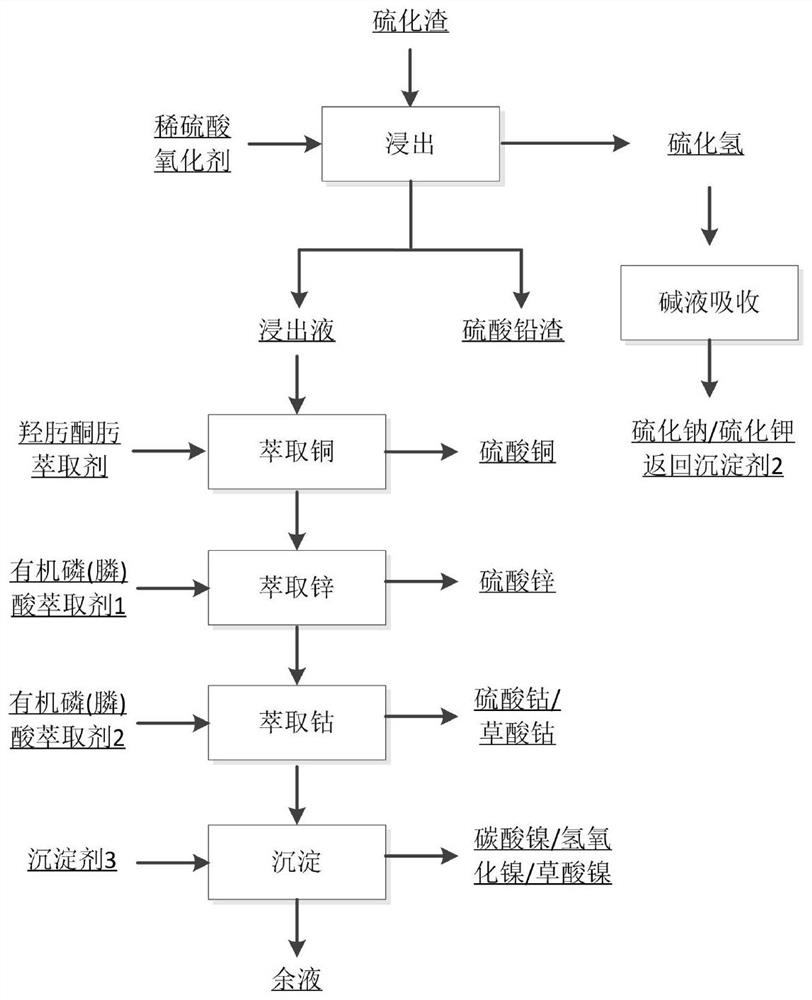

Process for leaching metal sulfides with reagents having thiocarbonyl functional groups

PendingUS20200048736A1Promote leachingIncrease ratingsNickel compounds preparationCopper compounds preparationIron sulfateThio-

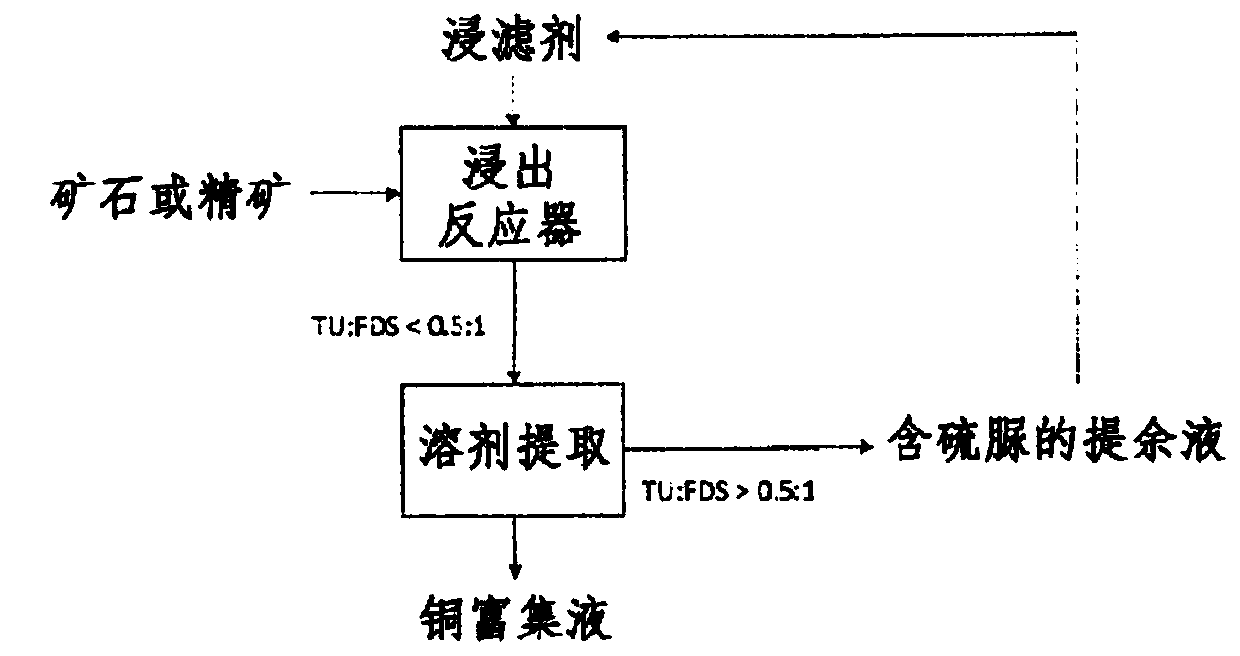

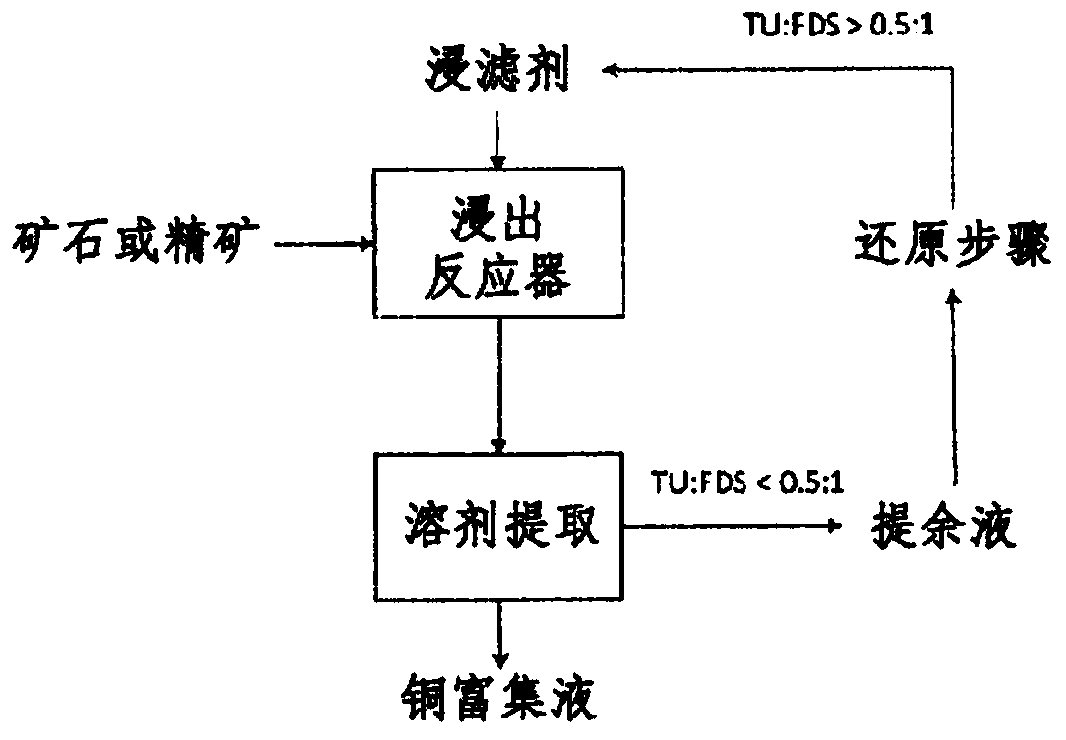

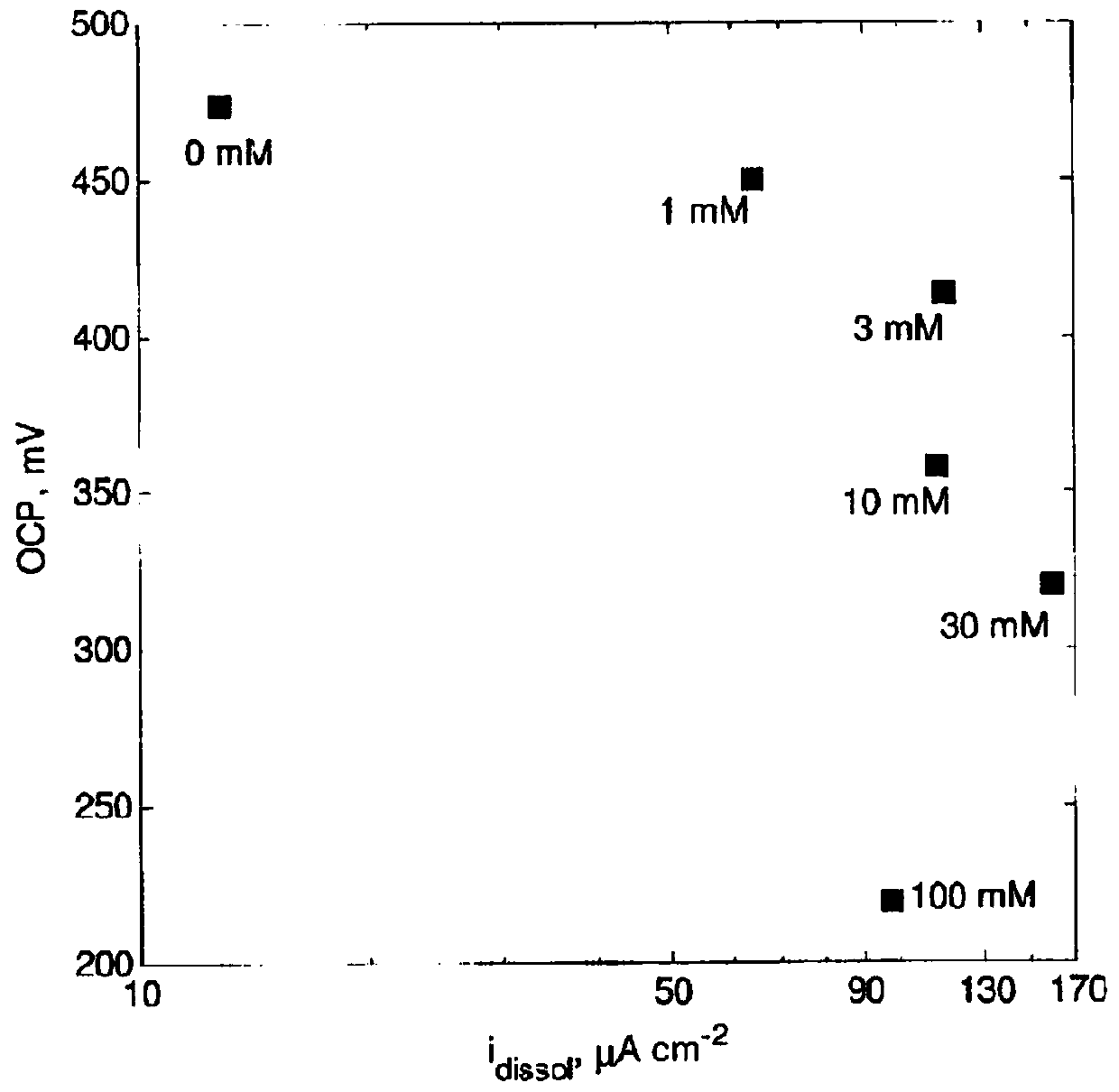

This application pertains to methods of recovering metals from metal sulfides that involve contacting the metal sulfide with an acidic sulfate solution containing ferric sulfate and a reagent that has a thiocarbonyl functional group, wherein the concentration of reagent in the acidic sulfate solution is sufficient to increase the rate of metal ion extraction relative to an acidic sulfate solution that does not contain the reagent, to produce a pregnant solution containing the metal ions.

Owner:JETTI RESOURCES LLC

Electroplating-grade copper sulfate and production process thereof

ActiveCN106495205ARealize comprehensive utilizationSimple production process and equipmentCopper compounds preparationCopper sulfatesEnvironmental resistanceIon exchange

The invention relates to the technical field of industrial wastewater and particularly relates to electroplating-grade copper sulfate and a production process thereof. The production process comprises the following steps: (A) preparation of roughly purified etching waste liquid; (B) neutralization and filter pressing; (C) extraction and ion exchange; (D) acidification and crystallization; and (E) purification and crystallization. The production process is environmentally friendly and pollution-free, the waste gas and the waste are not discharged, the utilization of the waste is realized, the cyclic utilization of mother liquid is realized, and the child liquid is sold to enterprises, so that the economic benefit is high, the equipment is simple, and the operation is simple and convenient. The content of copper ions in prepared electroplating-grade copper sulfate reaches up to 98%, so that the digestive systems of livestock are beneficially improved.

Owner:东莞市德睿工业废品处理有限公司

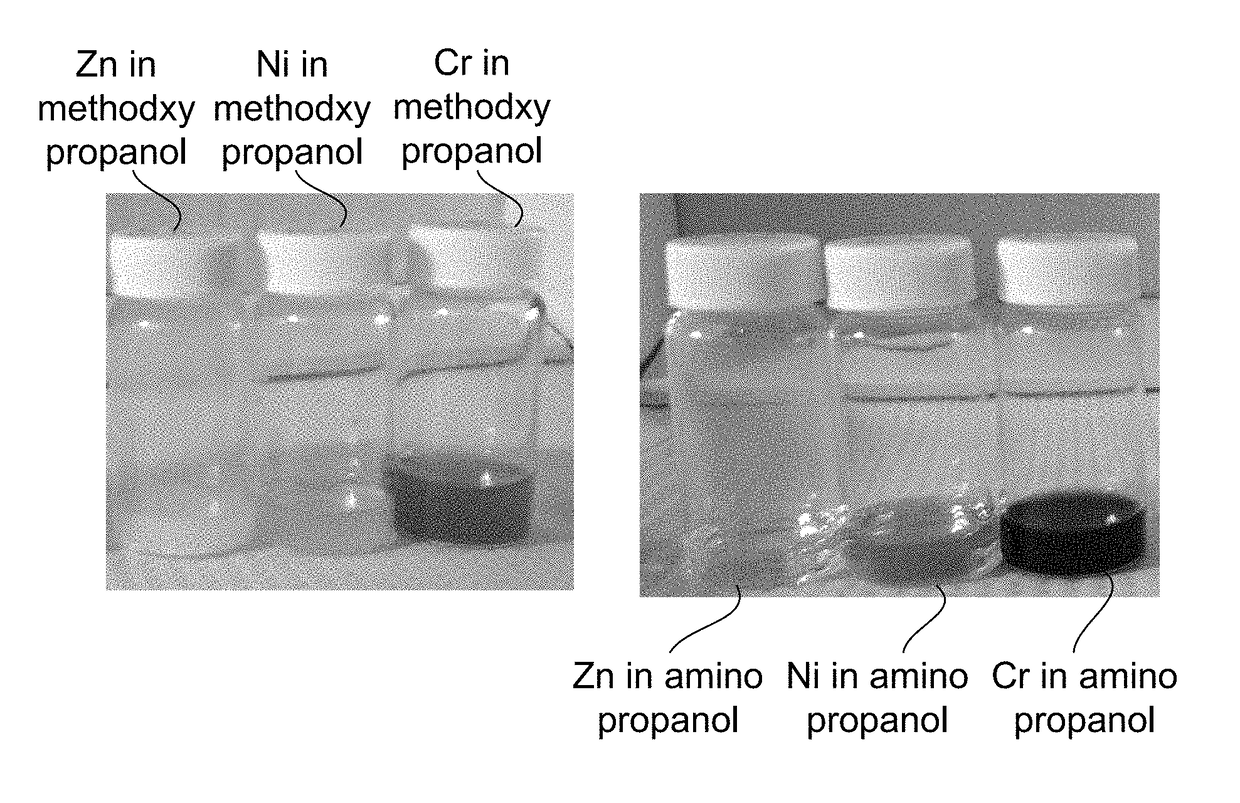

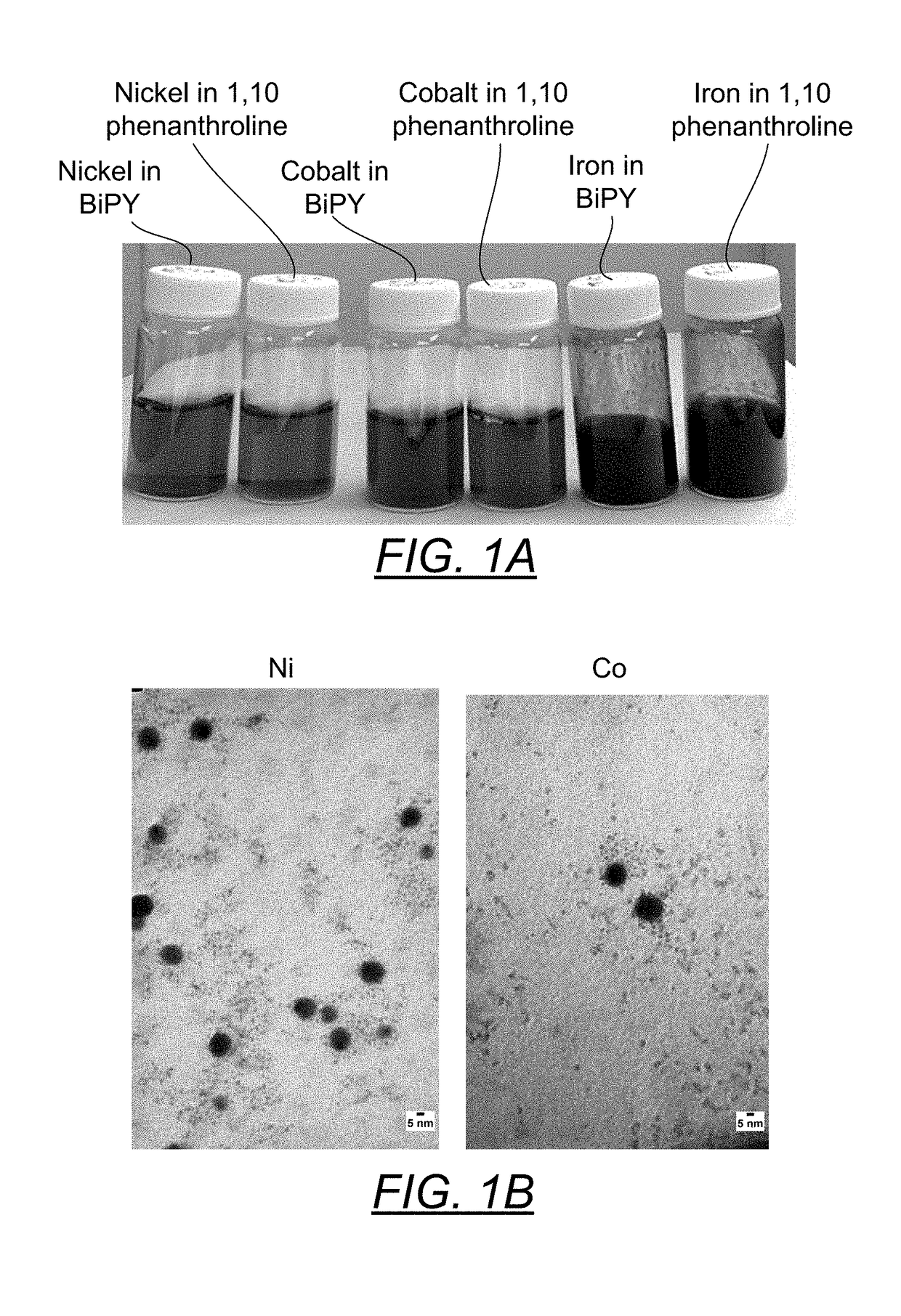

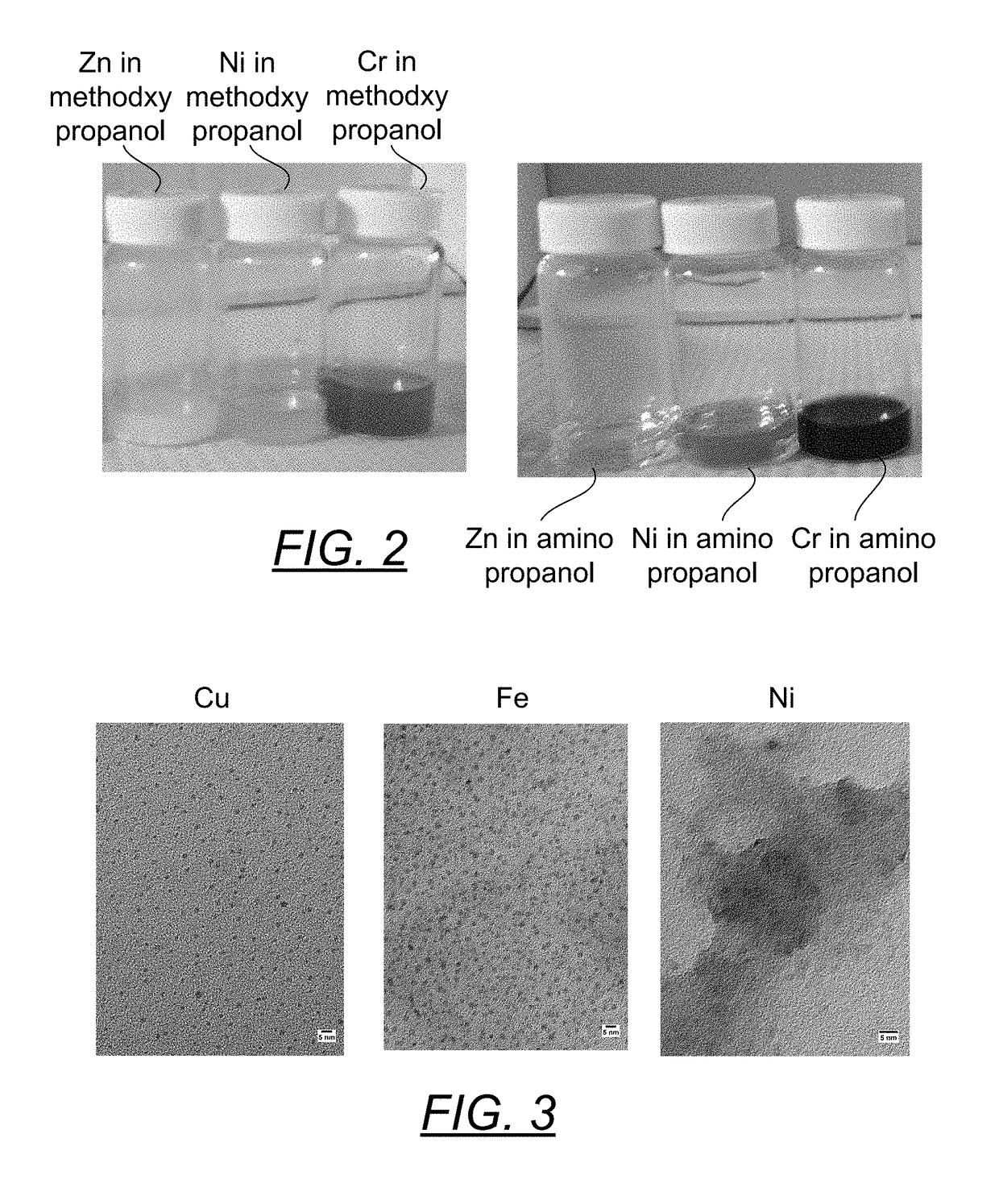

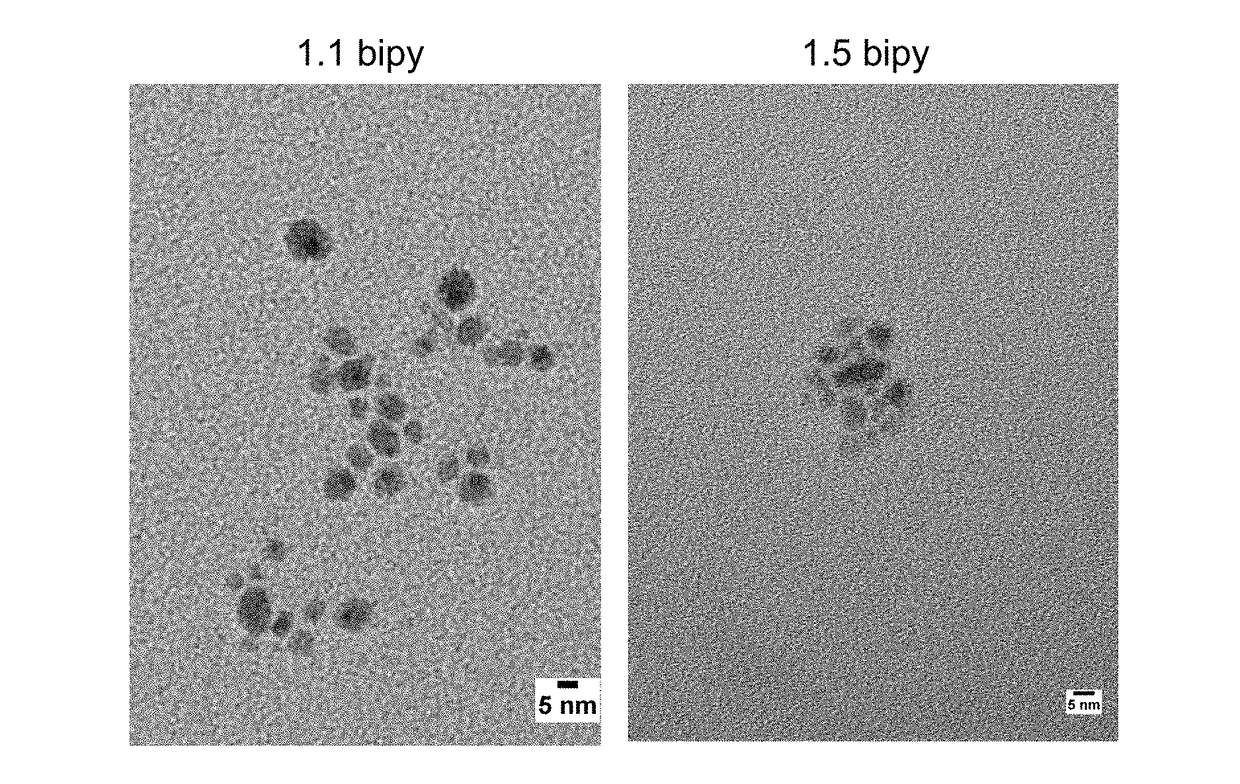

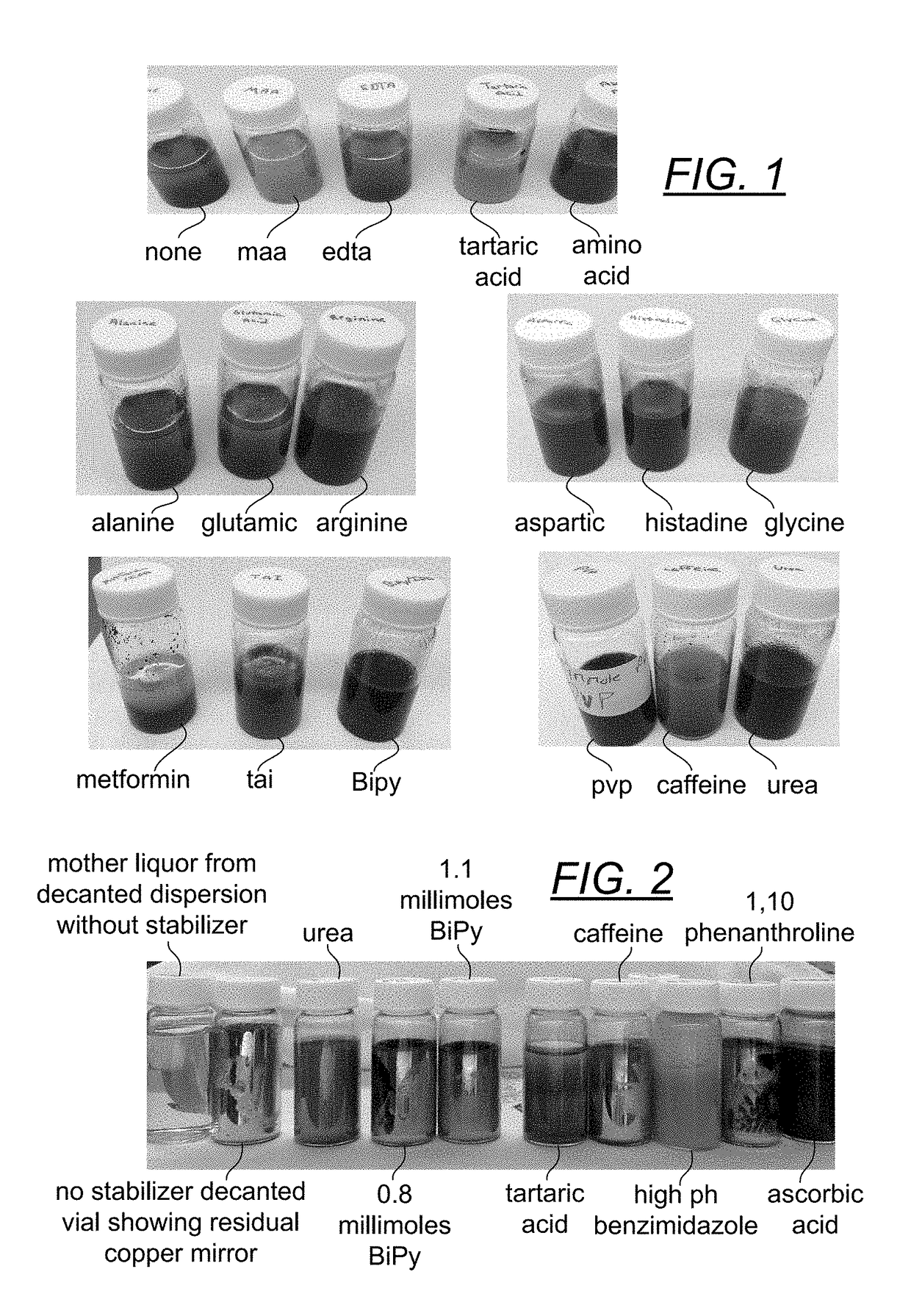

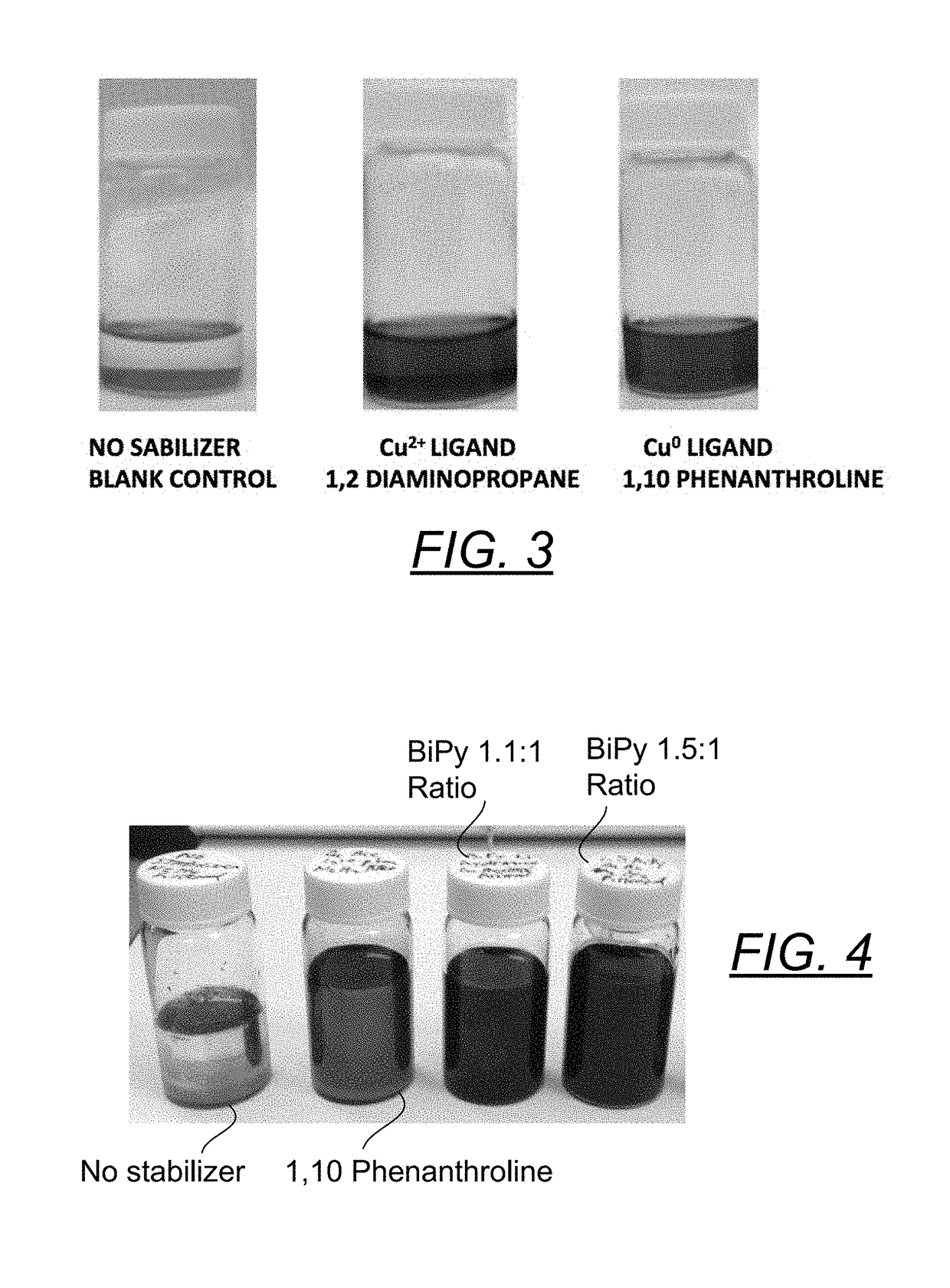

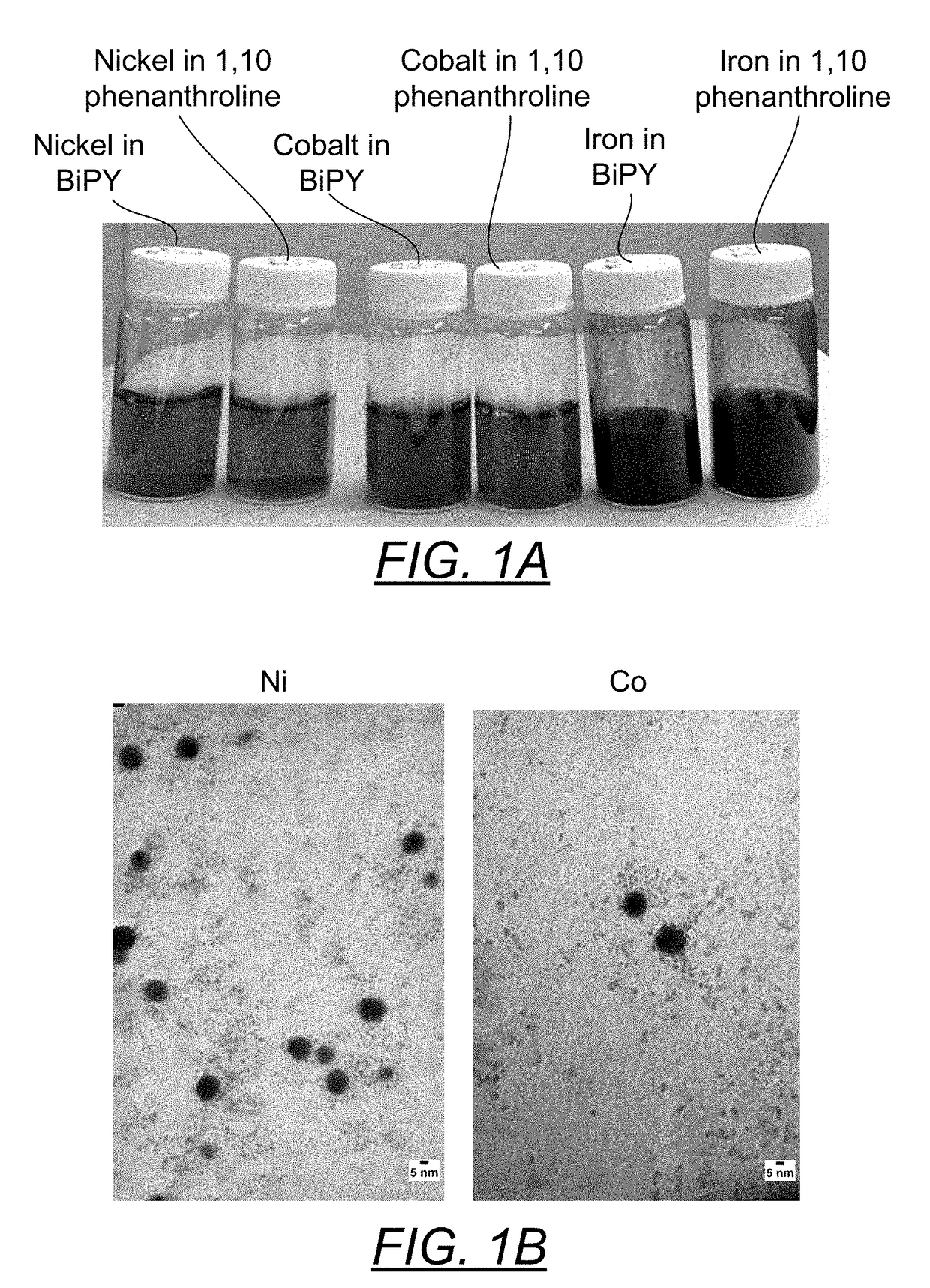

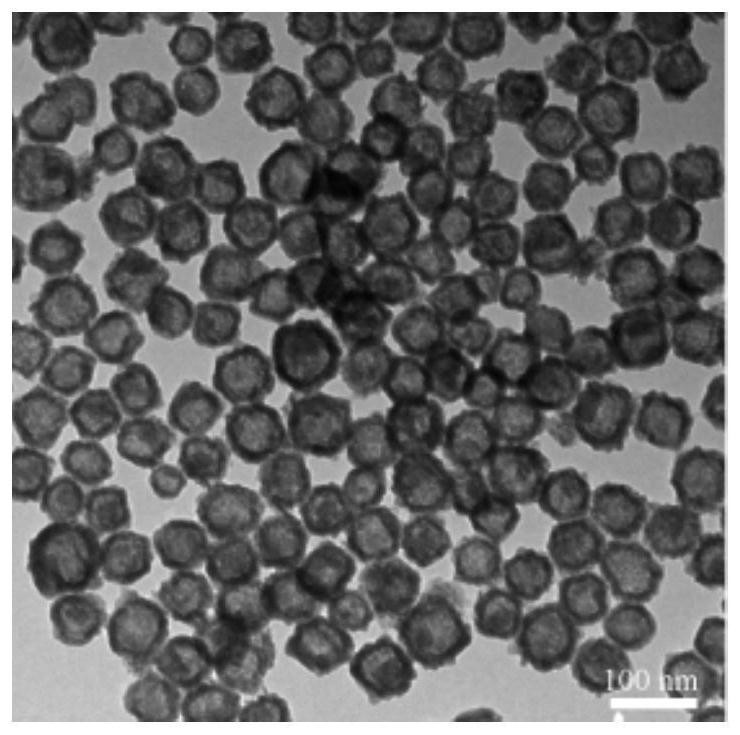

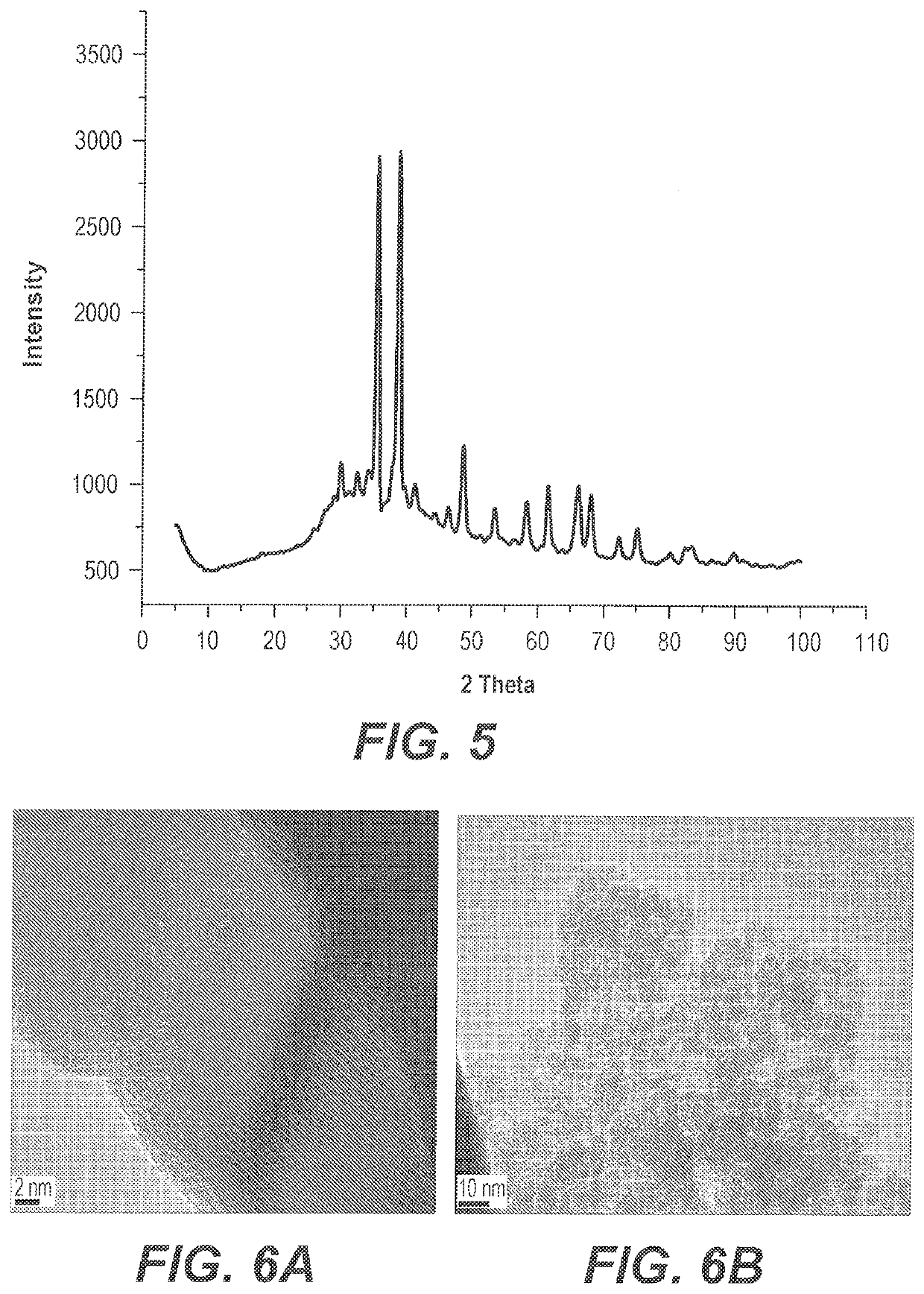

Method of producing metallic NANO particle colloidal dispersions

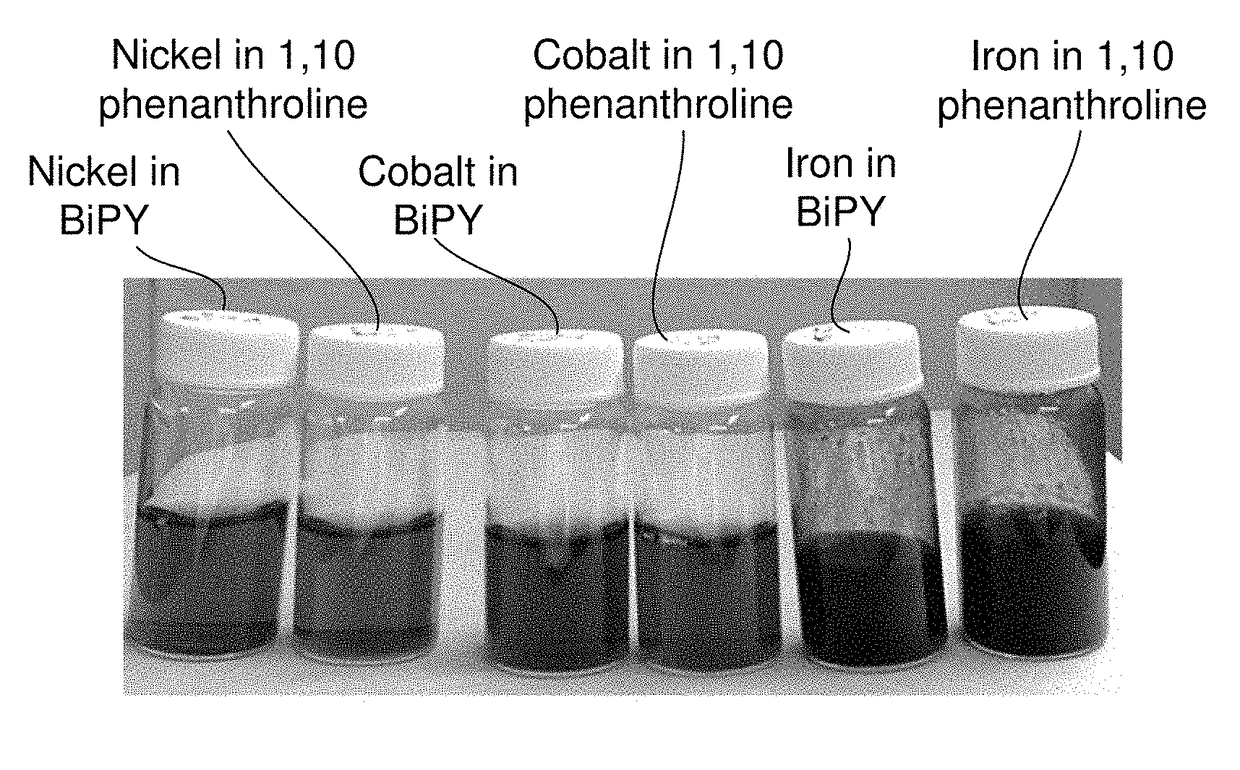

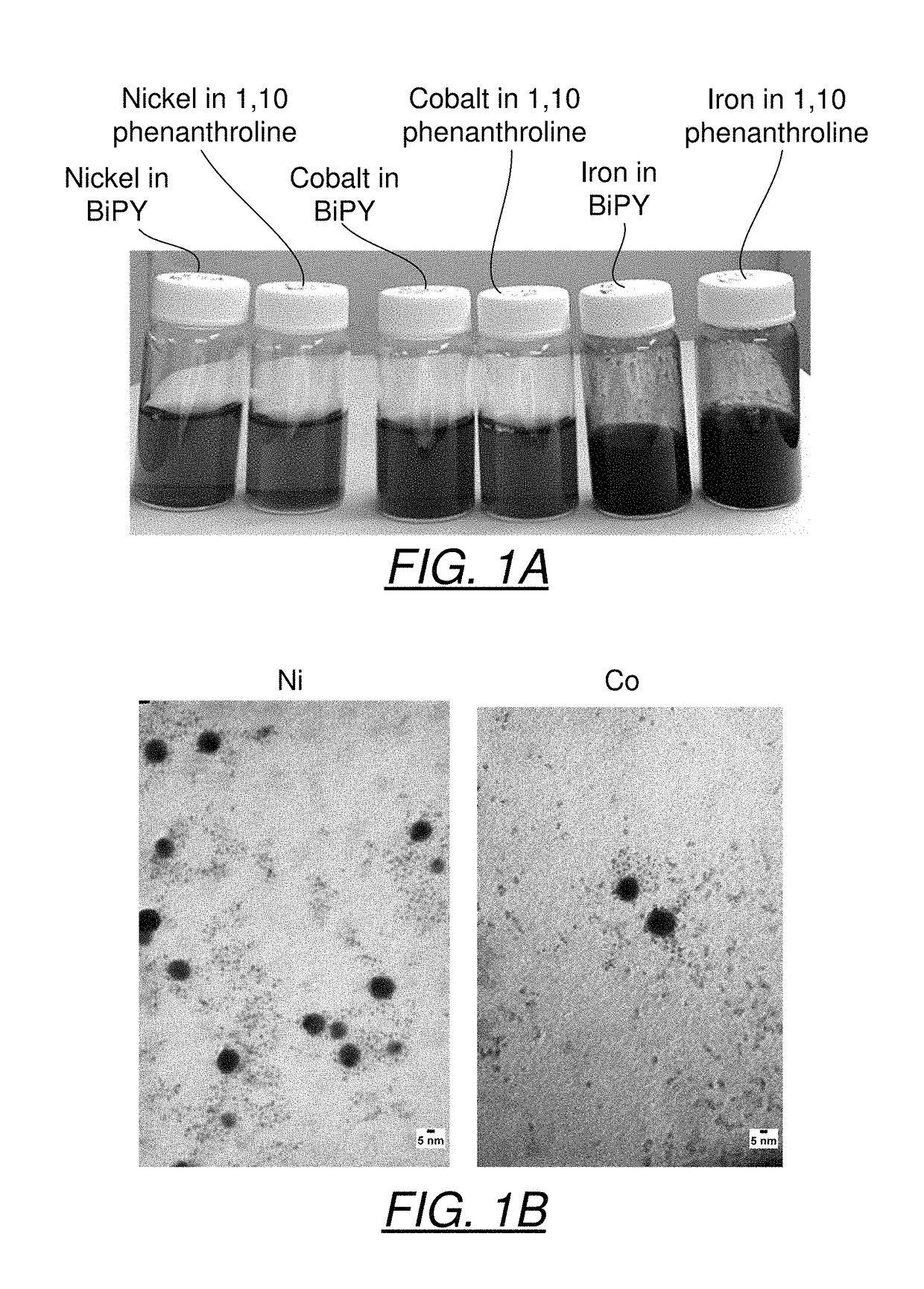

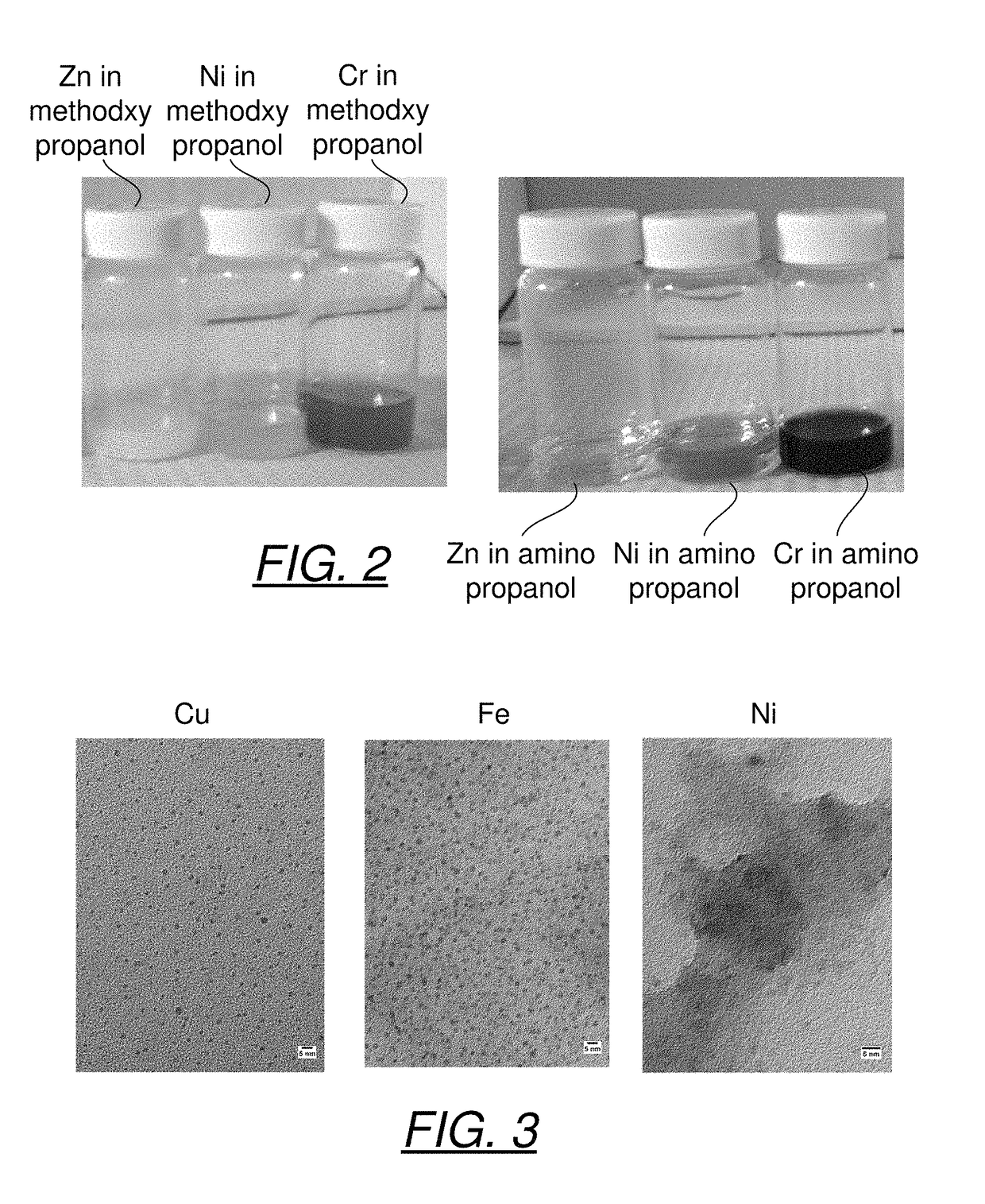

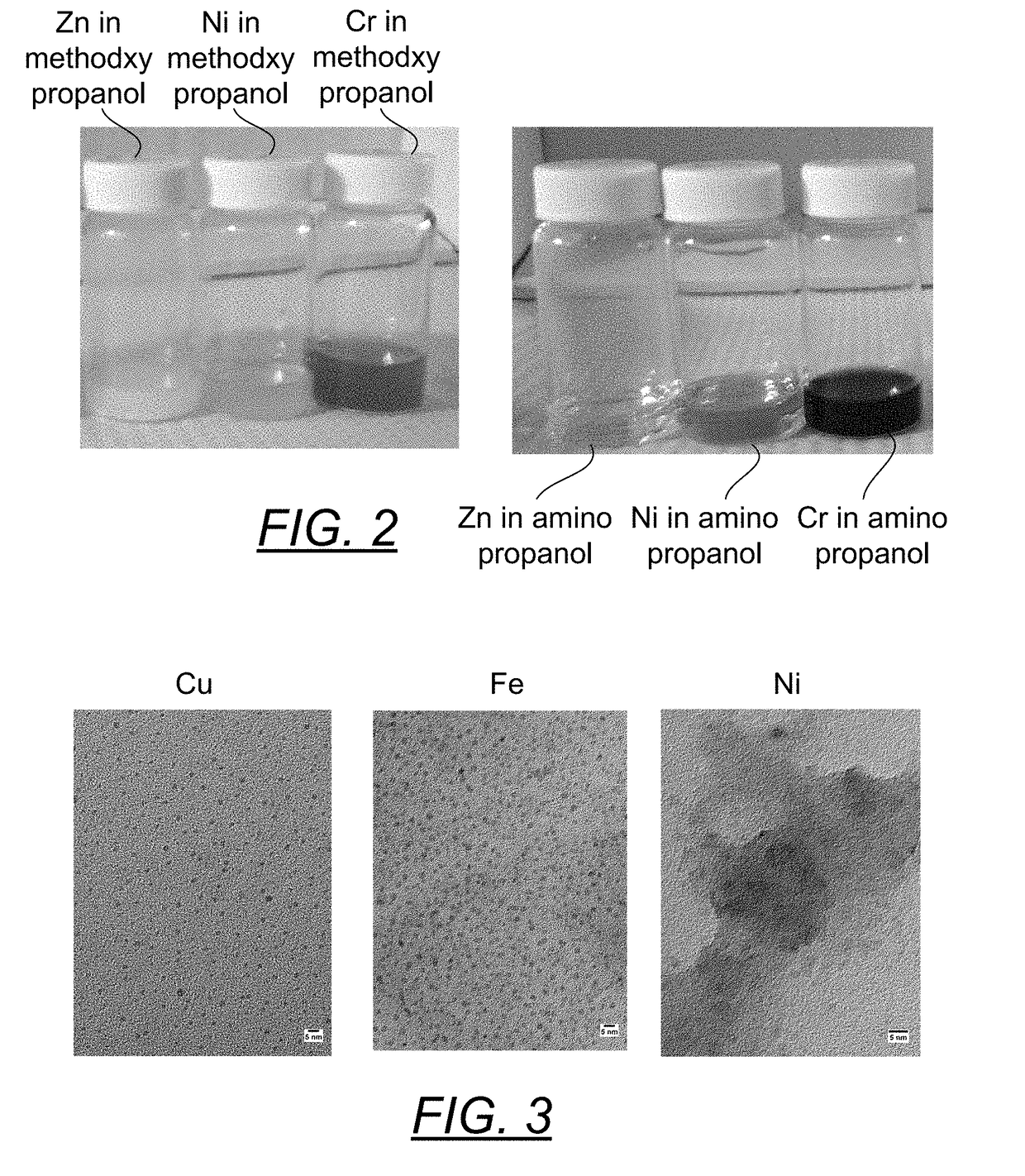

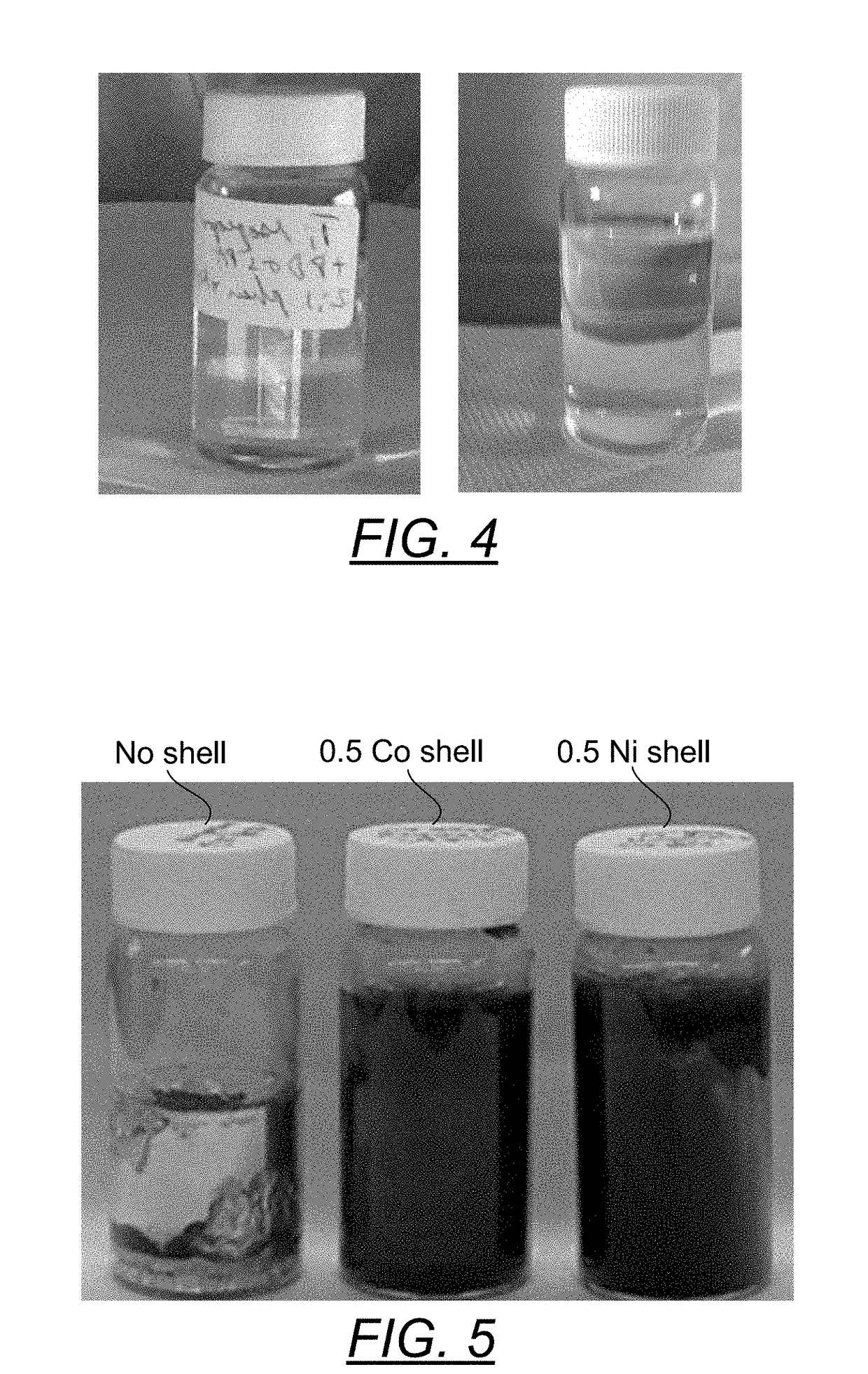

ActiveUS20180015537A1High densityEliminate needMaterial nanotechnologyFrom normal temperature solutionsAlloySolvent

The present process provides a method for synthesizing difficult to make oxide-free nanometals and such as Zn, Sn and Ti and alloys of the period 4 and 5 transition metal elements in a free and reduced state using a solution phase synthesis process. Also provided is a method for stabilizing their associated colloidal metal and alloy dispersions under kinetic control at modest temperatures (<80 degrees Celsius). A solution of an organic reducing agent containing at least two proximal nitrogen atoms is reacted with a separate solution containing one or more metal-organic salts dissolved in the same or different low molecular weight solvent as the reducing agent. The reaction products are stabilized with Lewis bases and Lewis acids and optionally can be concentrated by removing a portion of the volatile low molecular weight solvent by either the use of a partial vacuum or by chemical extraction into another phase.

Owner:ZEROVALENT NANOMETALS INC

Method of producing metallic nano particle colloidal dispersions

The present process provides a method for synthesizing difficult to make oxide-free nanometals and such as Zn, Sn and Ti and alloys of the period 4 and 5 transition metal elements in a free and reduced state using a solution phase synthesis process. Also provided is a method for stabilizing their associated colloidal metal and alloy dispersions under kinetic control at modest temperatures (<80 degrees Celsius). A solution of an organic reducing agent containing at least two proximal nitrogen atoms is reacted with a separate solution containing one or more metal-organic salts dissolved in the same or different low molecular weight solvent as the reducing agent. The reaction products are stabilized with Lewis bases and Lewis acids and optionally can be concentrated by removing a portion of the volatile low molecular weight solvent by either the use of a partial vacuum or by chemical extraction into another phase.

Owner:ZEROVALENT NANOMETALS INC

Copper sulfate pentahydrate crystal and preparation method thereof

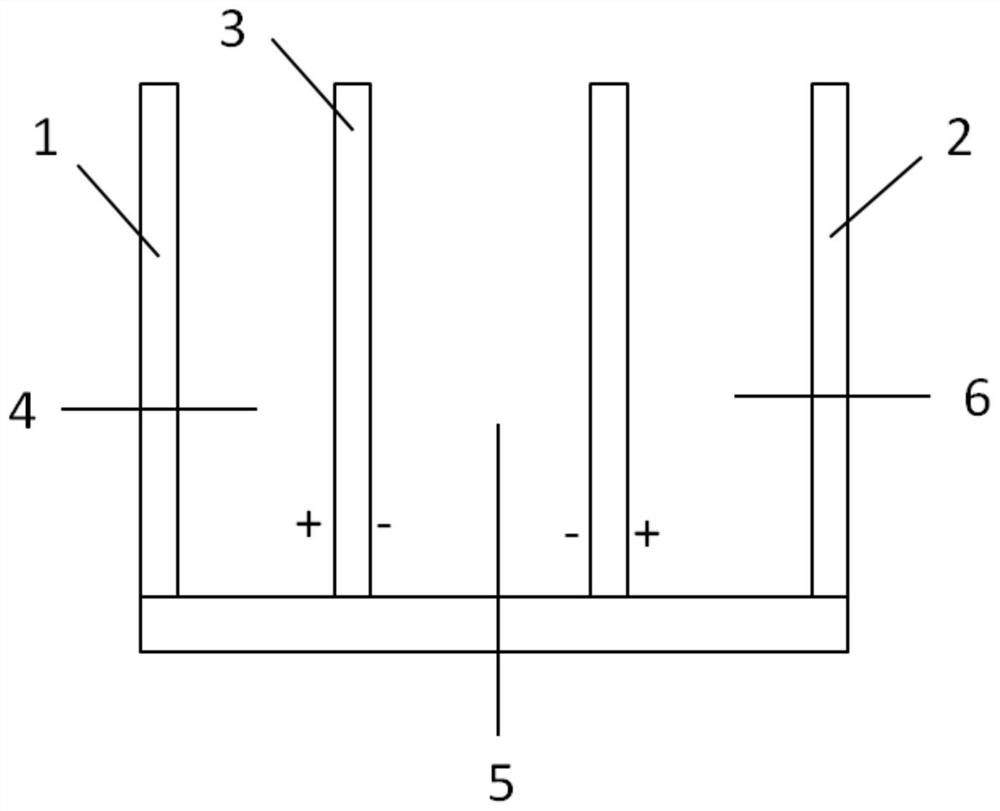

InactiveCN114016047ASimple processContinuous preparationCellsCopper compounds preparationElectrolysisAqueous solution

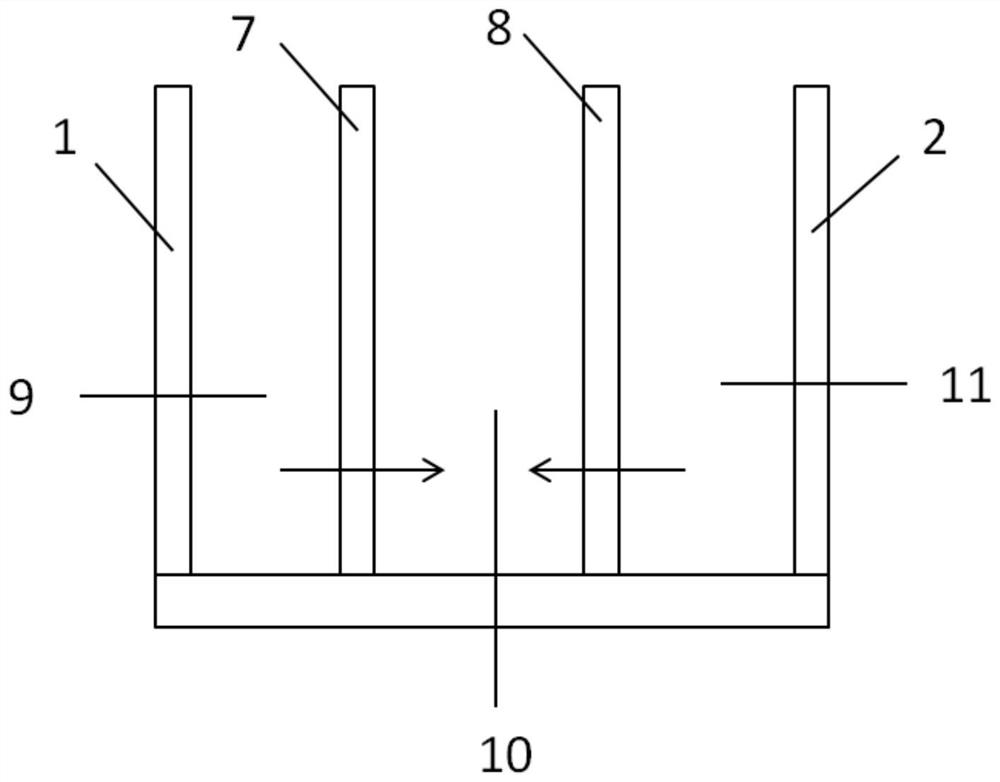

The invention relates to a copper sulfate pentahydrate crystal and a preparation method thereof. The preparation method comprises the following steps of: 1, arranging a one-way ionic membrane only allowing positive ions to pass through on the side, close to an anode, in an electrolytic bath, and arranging a one-way ionic membrane only allowing negative ions to pass through on the side, close to a cathode, in the electrolytic bath; adding a sulfuric acid aqueous solution into the electrolytic bath, and electrifying for electrolyzing by taking an electrolytic copper plate as an anode to obtain a copper sulfate solution; 2, alternately arranging at least one group of cationic membranes and anionic membranes in an electrodialyzer, the cationic membranes being adjacent to the anode, and the anionic membranes being adjacent to the cathode; introducing the copper sulfate solution in the step 1 into an electrodialyzer, and electrifying for electrodialysis to obtain a further purified copper sulfate solution; and 3, carrying out evaporation, concentration and crystallization treatment on the copper sulfate solution obtained in the step 2, and centrifuging to obtain the copper sulfate pentahydrate crystal. The preparation method is simple in process, and the prepared copper sulfate crystal is high in purity and stable in quality.

Owner:JIANGSU AISEN SEMICON MATERIAL CO LTD

Preparation method of electroplating copper sulfate

ActiveCN107986317AAchieve recyclingAvoid emissionsCopper compounds preparationCopper sulfatesElectrolysisDesorption

The invention provides a preparation method of electroplating copper sulfate. The method comprises the following steps: taking acid copper waste water as a raw material, adsorbing organic matters in the acid copper waste water by chelating resin, adopting selective copper cation resin to adsorb copper ions in the acid copper waste water, adding strong acid to perform desorption for the selective copper cation resin, regenerating to obtain a concentrated copper sulfate solution, adding hydrogen peroxide into the concentrated copper sulfate solution, successively performing weak electrolysis, filtering, pH value adjustment and crystallization for the concentrated copper sulfate solution with hydrogen peroxide, and obtaining copper sulfate crystals. By adopting the preparation method of the electroplating copper sulfate of the invention, the prepared copper sulfate crystals are exquisite, the water content is little, the purity is high and can reach 99.9 percent or higher, the waste wateremission and treatment cost can be reduced, and environmental protection and emission reduction can be realized.

Owner:XIAMEN RUNNER IND CORP

Process for leaching metal sulfides with reagents having thiocarbonyl functional groups

This application pertains to methods of recovering metals from metal sulfides that involve contacting the metal sulfide with an acidic sulfate solution containing ferric sulfate and a reagent that hasa thiocarbonyl functional group, wherein the concentration of reagent in the acidic sulfate solution is sufficient to increase the rate of metal ion extraction relative to an acidic sulfate solutionthat does not contain the reagent, to produce a pregnant solution containing the metal ions.

Owner:捷迪资源有限责任公司

Pretreatment of circuit board incineration soot and recovery method of bromine

ActiveCN108118157BEasy to recycleNo emissionsZinc sulatesCalcium/strontium/barium sulfatesRecovery methodSlag

The invention relates to the pretreatment of circuit board incineration soot and the recovery method of bromine, which belongs to the field of comprehensive recovery of valuable metals by soot full wet method, and particularly relates to the recovery of valuable metals, the enrichment of precious metals and the recovery of bromine salts in the pretreatment process of circuit board incineration soot. It mainly includes mixed alkali leaching, copper extraction and stripping to recover copper, neutralization and precipitation to separate lead and zinc, bromine evaporation and crystallization, mixed alkali leaching solution regeneration, pickling to remove zinc, zinc evaporation and crystallization, mixed alkali leaching slag dezincification of copper and other steps. Compared with the traditional soot comprehensive recovery process, the invented technology maximizes the recovery of valuable metals such as copper, zinc, lead and the enrichment of silver and other precious metals in the soot pretreatment process, and at the same time separates and recovers bromine salts, which has the advantages of recovery High added value, no tail liquid discharge and other characteristics.

Owner:BEIJING UNIV OF TECH

Method of producing copper NANO particle colloidal dispersions

ActiveUS20180016154A1Reduce needHigh suspension densityMaterial nanotechnologyFrom normal temperature solutionsSolution phase synthesisCharge-transfer complex

The present process provides a method for synthesizing oxide-free copper nanometal dispersion in a free and reduced state using a solution phase synthesis process. A solution of an organic reducing agent containing at least two proximal nitrogen atoms is reacted with a separate solution containing a copper salt reformulated into a charge transfer complex. The reaction products are stabilized with Lewis bases and Lewis acids and optionally can be concentrated by removing a portion of the volatile low molecular weight solvent by either the use of a partial vacuum or by chemical extraction into another phase.

Owner:ZEROVALENT NANOMETALS INC

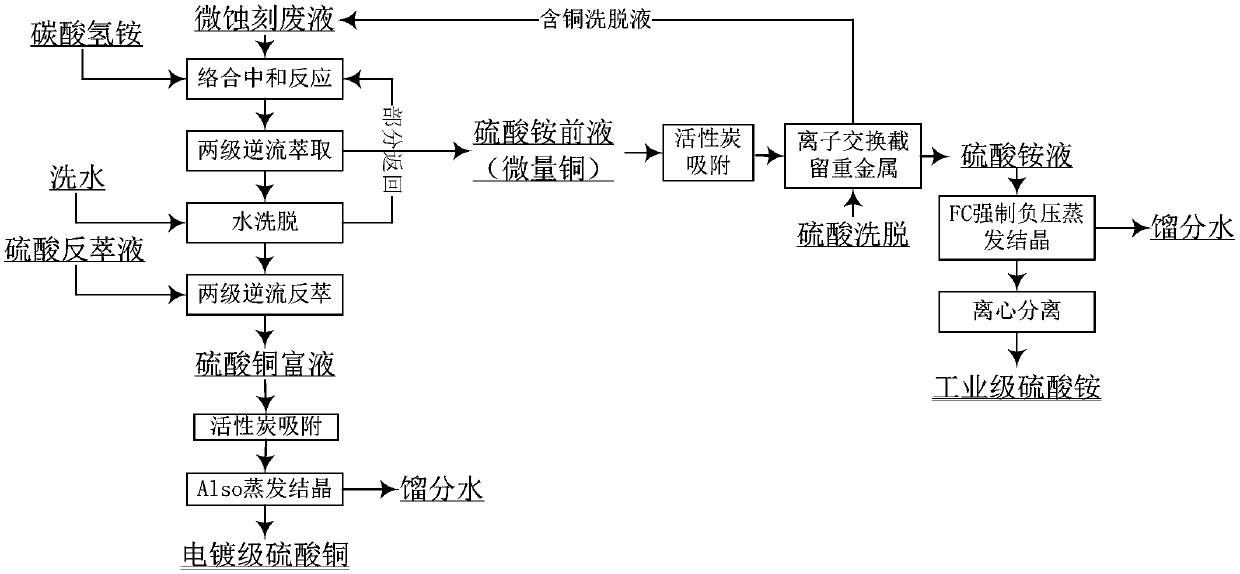

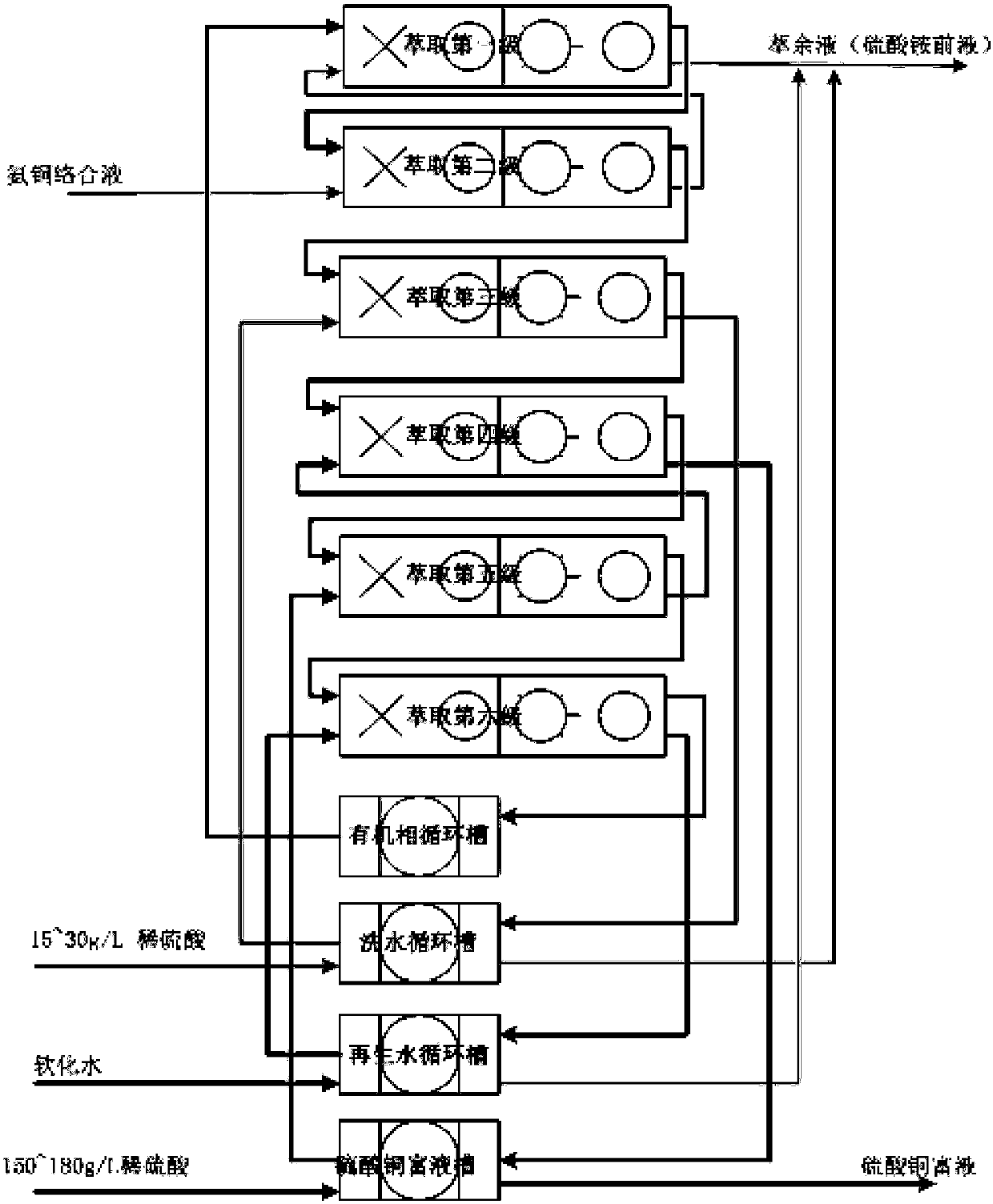

Method for fully recycling anions and cations from microetching waste liquid

ActiveCN109678196ANo worries about disposalMeet needsCopper compounds preparationAmmonium sulfatesFiltrationActivated carbon filtration

Owner:SHANGHAI TIANHAN ENVIRONMENTAL RESOURCES CO LTD

Method of producing metallic NANO particle colloidal dispersions

The present process provides a method for synthesizing difficult to make oxide-free nanometals and such as Zn, Sn and Ti and alloys of the period 4 and 5 transition metal elements in a free and reduced state using a solution phase synthesis process. Also provided is a method for stabilizing their associated colloidal metal and alloy dispersions under kinetic control at modest temperatures (<95 degrees Celsius). A solution of an organic reducing agent containing at least two proximal nitrogen atoms is reacted with a separate solution containing one or more metal-organic salts dissolved in the same or different low molecular weight solvent as the reducing agent. The reaction products are stabilized with Lewis bases and Lewis acids and optionally can be concentrated by removing a portion of the volatile low molecular weight solvent by either the use of a partial vacuum or by chemical extraction into another phase.

Owner:ZEROVALENT NANOMETALS INC

Preparation method of high-purity copper chloride dihydrate

InactiveCN106379928AOvercoming technical difficultiesImprove reliabilityCopper compounds preparationCopper chloridesCopper chlorideChloride

The invention discloses a preparation method of high-purity copper chloride dehydrate. According to the method, hydrochloric acid is added into a basic copper chloride solution for regulating the pH to be 2 to 4; hydrogen peroxide is added; reaction liquid is heated and boiled; chlorides of Al, Bi and Fe are added; basic copper chloride and / or copper oxide are / is used for regulating the pH to be 6.5 to 7.5; filtering is performed; activated charcoal is added into filtrate; heat insulation stirring is performed at 90 to 100 DEG C for 0.5 to 5h; then, filtering is performed; hydrochloric acid is used for regulating the filtrate until the pH is 2 to 3; concentration and crystallization are performed to obtain the high-purity copper chloride dehydrate. The preparation method has the advantages that the operation is simple; the cost is low; the environment-friendly effect is achieved; the purity of the prepared copper chloride dehydrate is high; the impurity metal ion content reaches to ppb grade.

Owner:XILONG SCI CO LTD

Decontamination of radioactive metals

The present invention relates to a method for the volumetric decontamination of radioactive metals. The method includes the step of precipitating out radioactive gamma and beta emitting nucleotides and then recovering non-radioactive metal compounds.

Owner:RETRIEV TECH

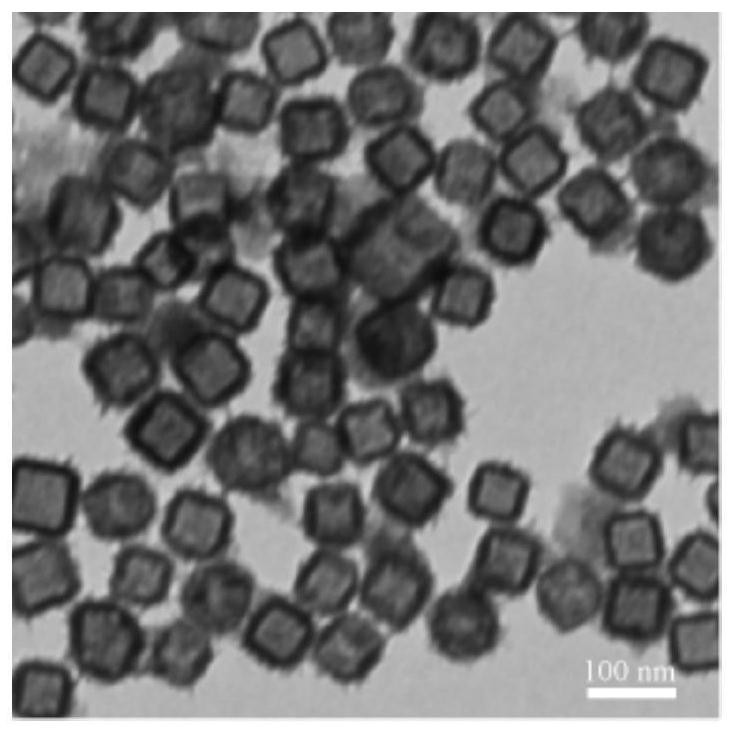

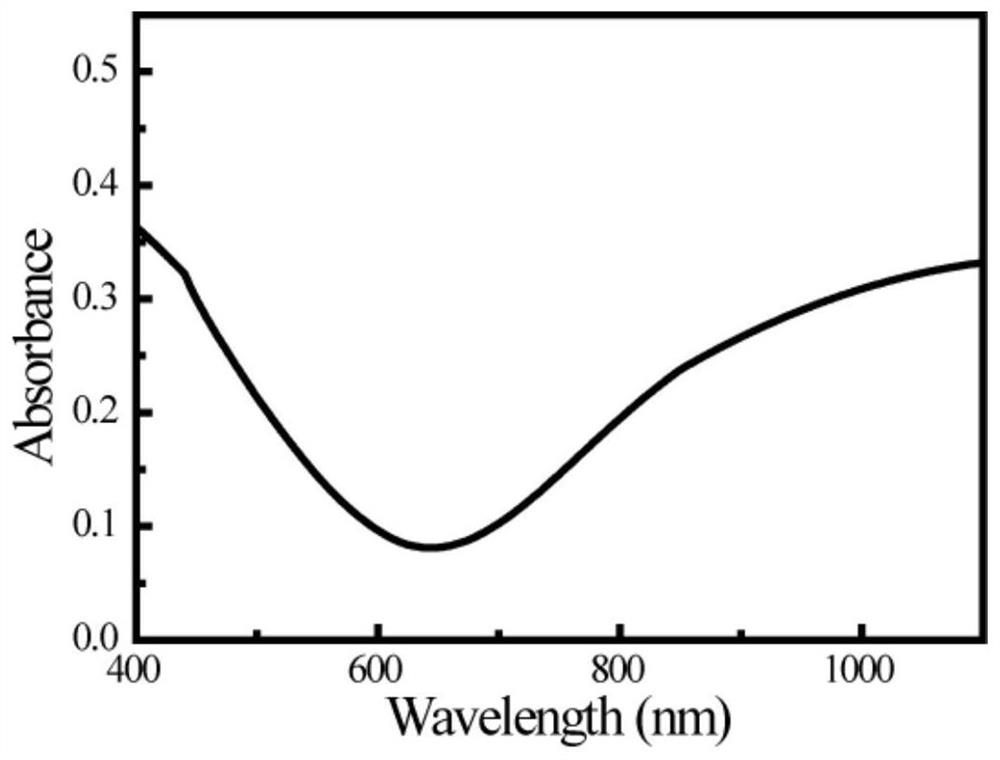

Hollow Cu7S4 nano cubic structure and preparation method and application thereof

PendingCN112850779ADeep penetrationPromote absorptionOrganic active ingredientsEnergy modified materialsPyrrolidinonesBiocompatibility

The invention discloses a hollow Cu7S4 nano cubic structure and a preparation method and application thereof. The side length of the hollow Cu7S4 nano cubic structure is about 70-80 nm, and the shape of the hollow Cu7S4 nano cubic structure is a hollow nano cubic structure. The preparation method comprises the following steps: dissolving polyvinylpyrrolidone in water, then adding cupric acetate, sodium hydroxide and ascorbic acid, performing stirring, performing heating in an oil bath, adding sodium sulfide for continuous reaction, and after the reaction is completed, centrifugally washing and dispersing the product. The prepared hollow Cu7S4 nano cubic structure has good stability and biocompatibility, has large absorption in a near-infrared region 900-1100 nm, is high in photothermal conversion efficiency, provides conditions for photothermal therapy of tumor cells, and is simple in preparation method, mild in conditions, environmentally friendly and suitable for industrial production. Meanwhile, due to the fact that large holes exist in the surface of the material, the material can be more efficiently applied to preparation of photothermal therapy reagents for treating cancers.

Owner:NANJING NORMAL UNIVERSITY

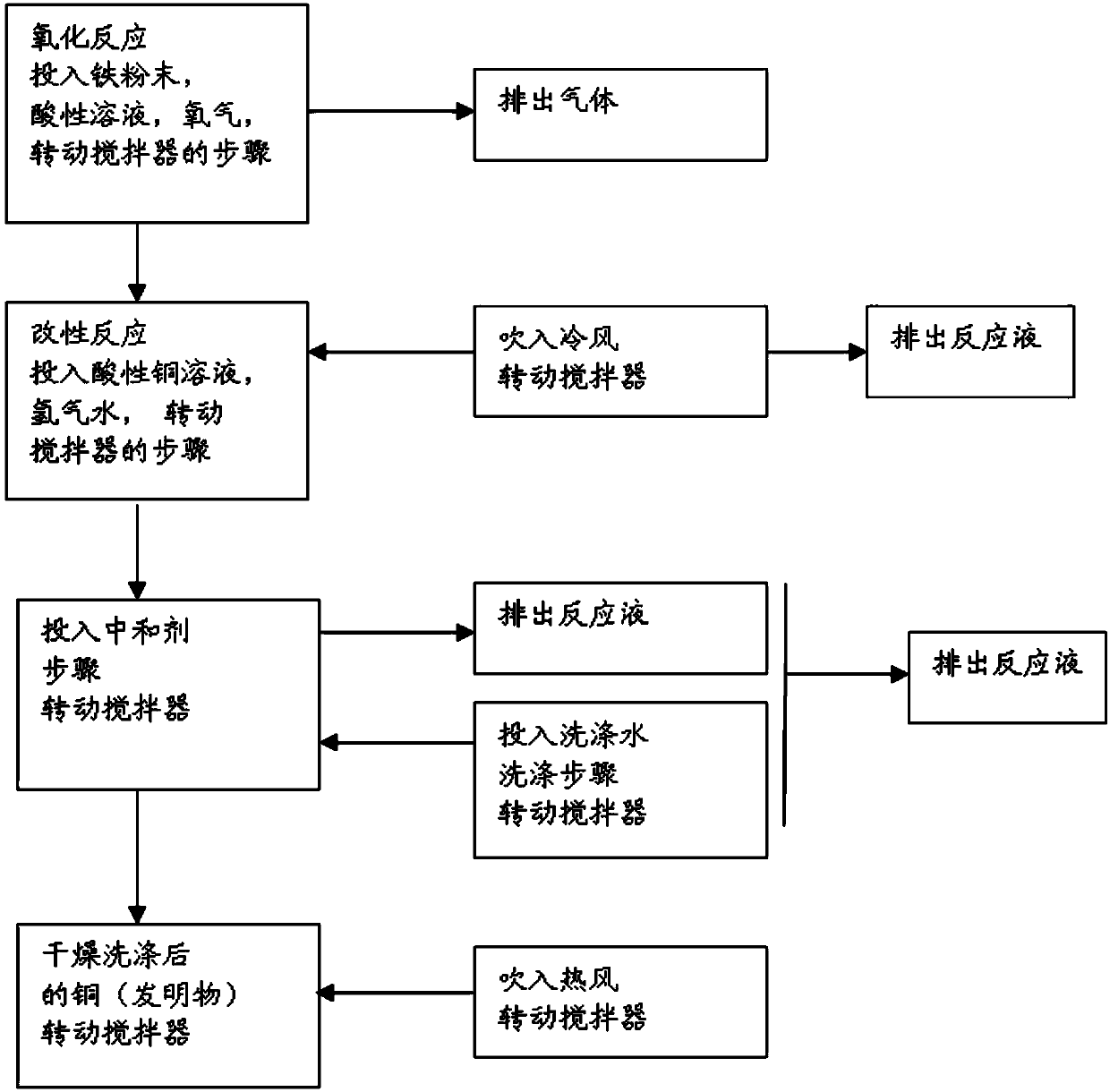

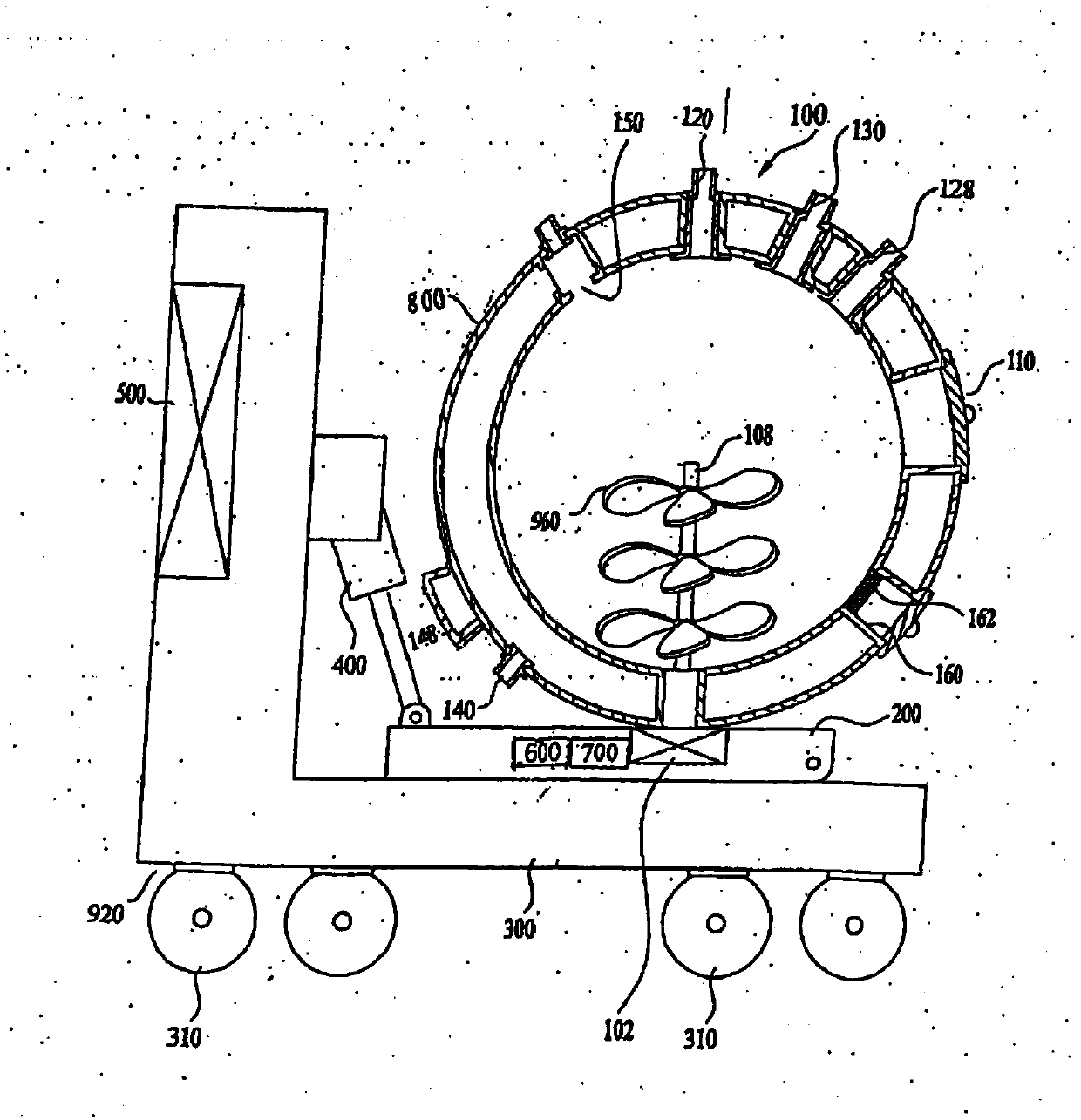

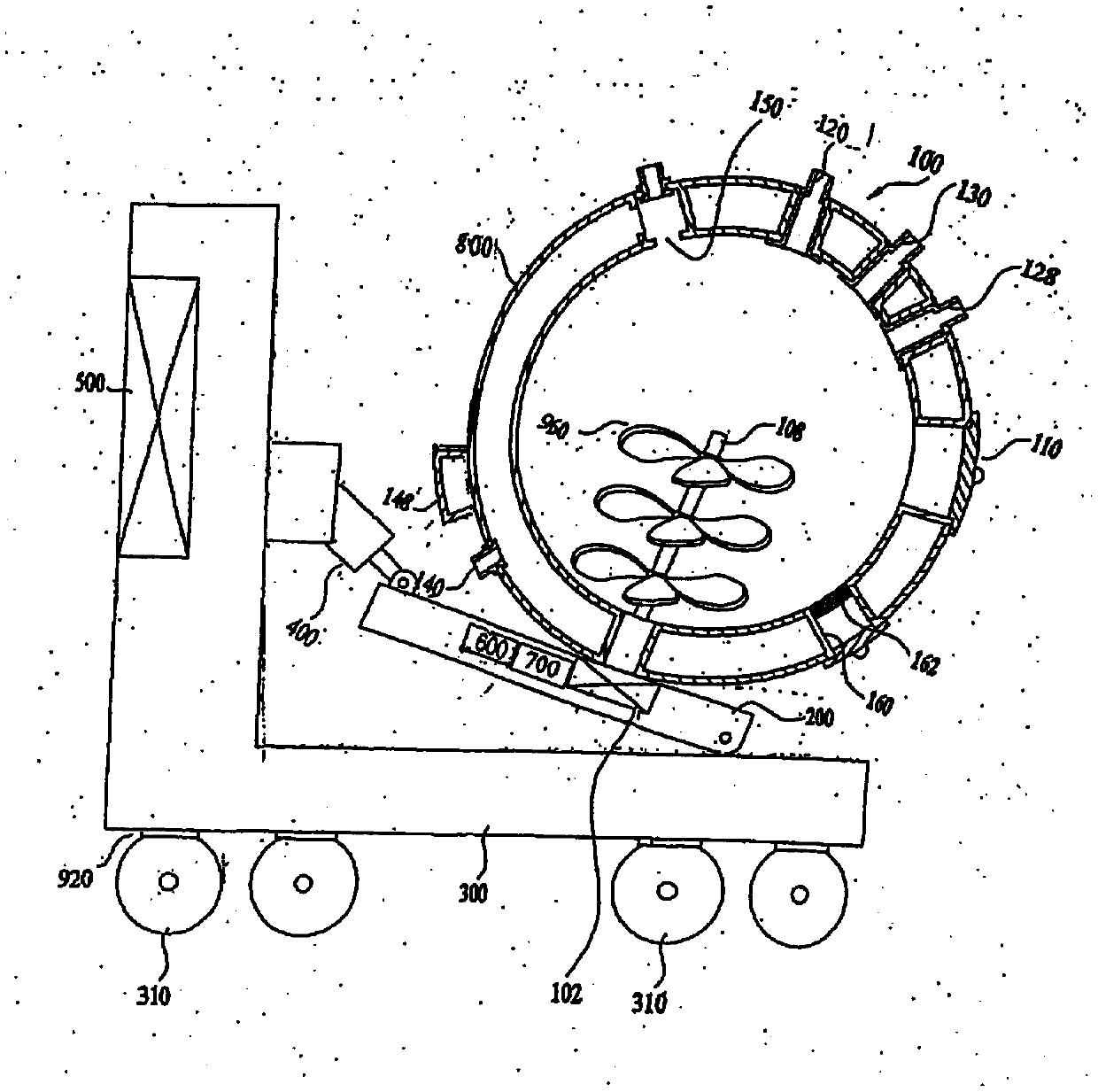

Copper precipitation method by iron modification and copper precipitation and preparation apparatus used therefor

InactiveCN109642267AReduce precipitation costImprove economyWater/sewage treatmentCopper compounds preparationHydrogenCopper mine

The present invention relates to a copper precipitation method by iron modification and to a copper precipitation and preparation apparatus used for the method, wherein in the copper precipitation method, iron is put into an acidic solution to attain iron ionization, and then a copper-containing acidic solution is put thereinto and hydrogen as an accelerator is added thereto, thereby artificiallymodifying iron elements into copper elements, and herein, a large amount of copper can be precipitated using iron, thereby obtaining the same economic effect as obtaining copper mines.

Owner:韩京玉

Method for inhibiting extractant degradation by diluent and extractant input method

ActiveUS20210024368A1Inhibiting extractant degradationPrevent degradationZinc compounds preparationComponent separationSolventEnvironmental chemistry

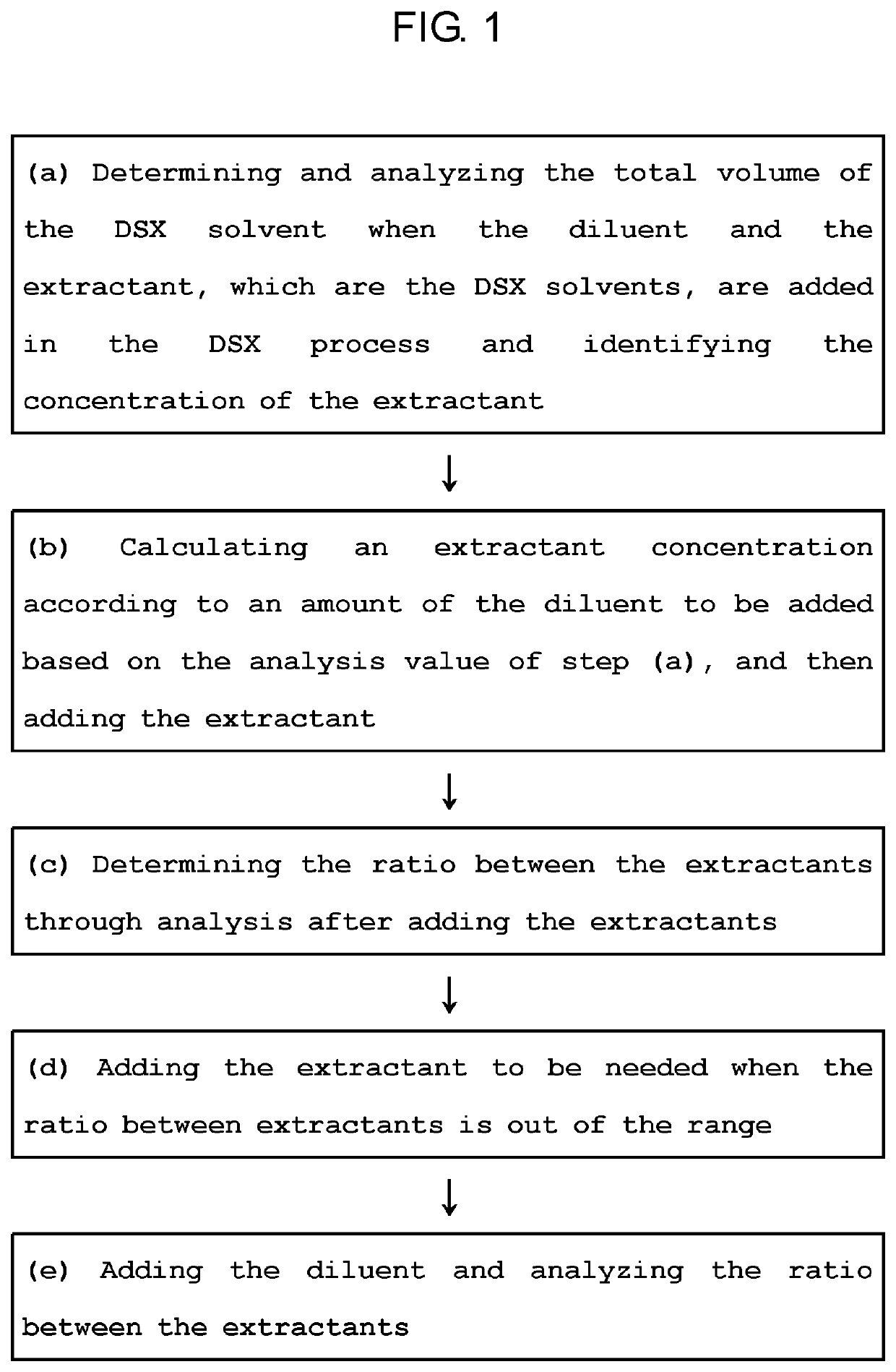

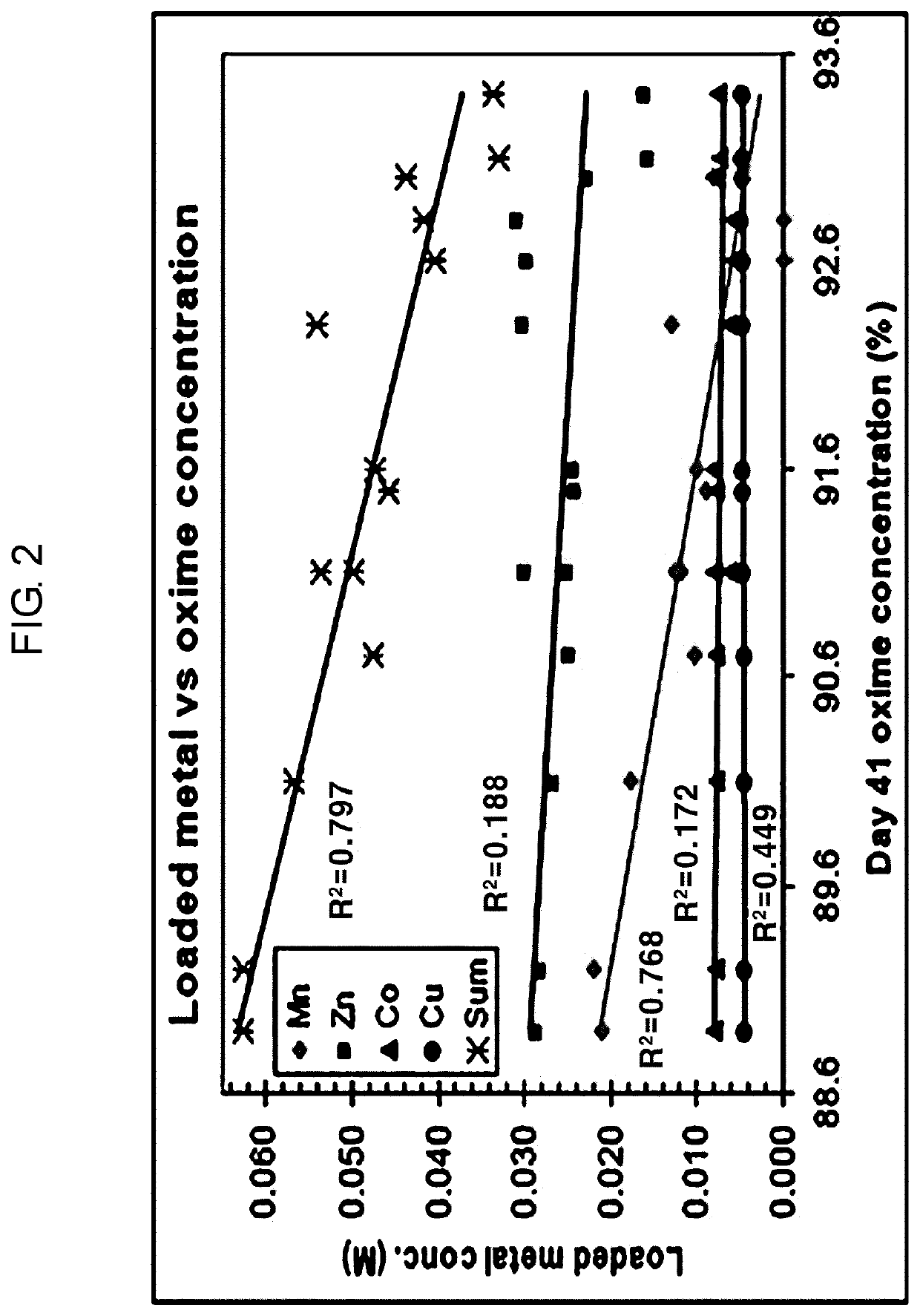

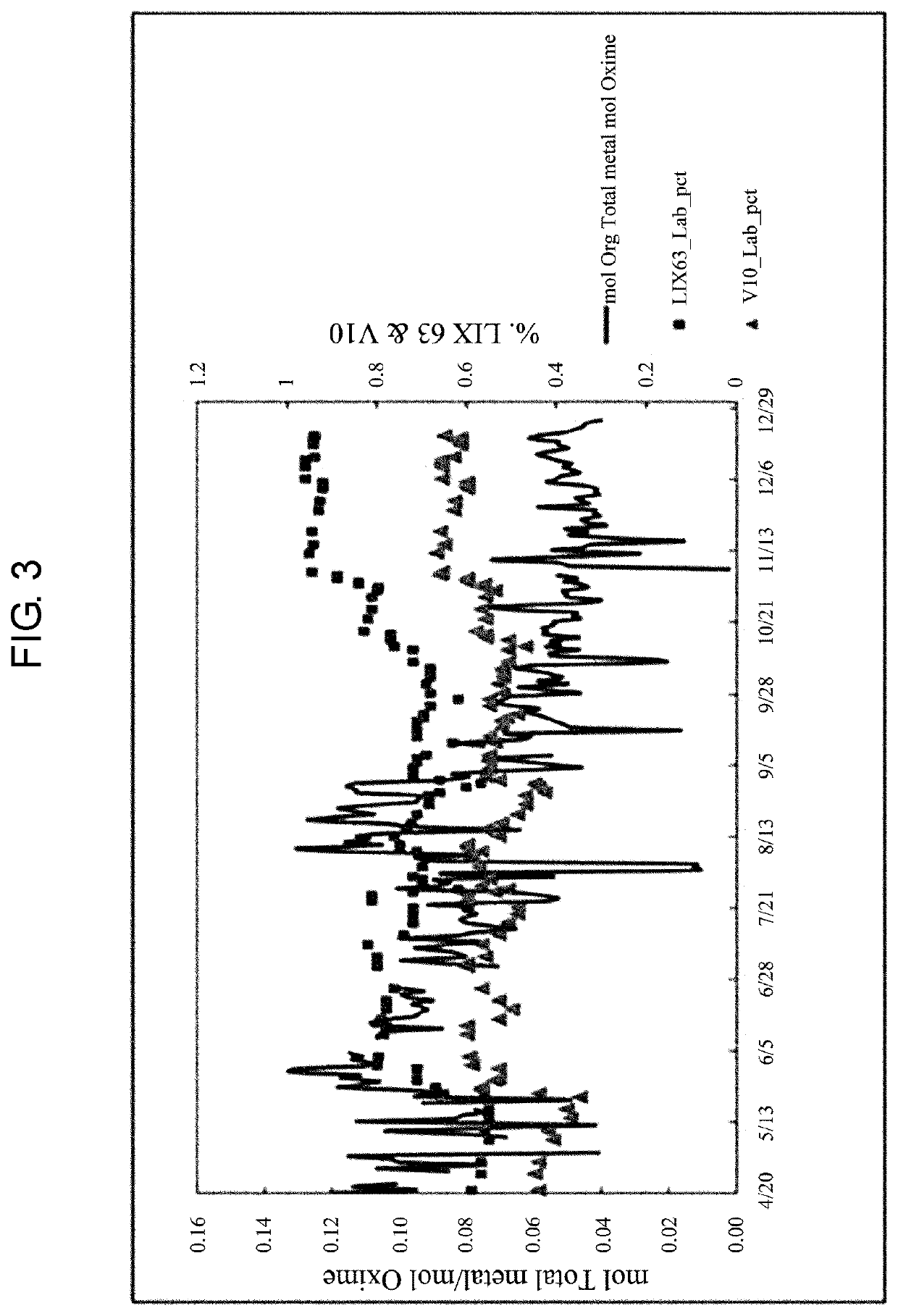

Provided is a method for inhibiting extractant degradation by a diluent and an extractant input manner, the method including steps of: (a) determining and analyzing the total volume of the DSX solvent when the diluent and the extractant, which are the DSX solvents, are added in the DSX process and identifying the concentration of the extractant; (b) calculating an extractant concentration according to an amount of the diluent to be added based on the analysis value of step (a), and then adding the extractant; (c) determining the ratio between the extractants through analysis after adding the extractants; (d) adding the extractant to be needed when the ratio between extractants is out of the range; and (e) adding the diluent and analyzing the ratio between the extractants.

Owner:KOREA MINE REHABILITATION & MINERAL RESOURCES CORP

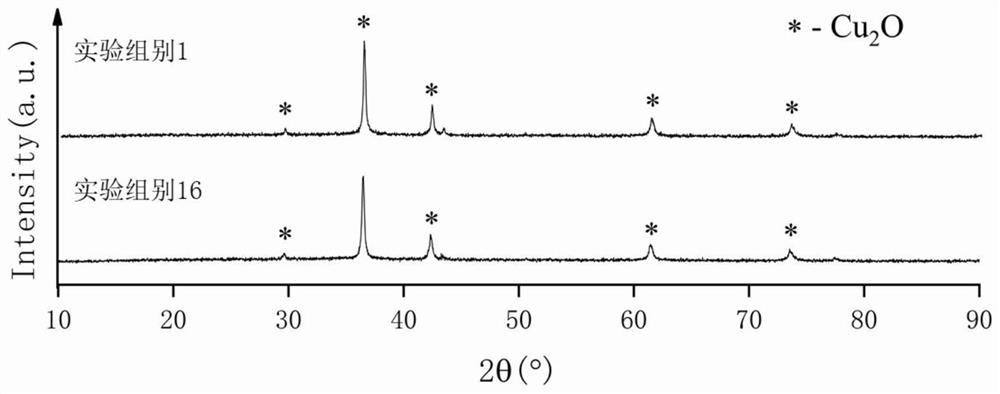

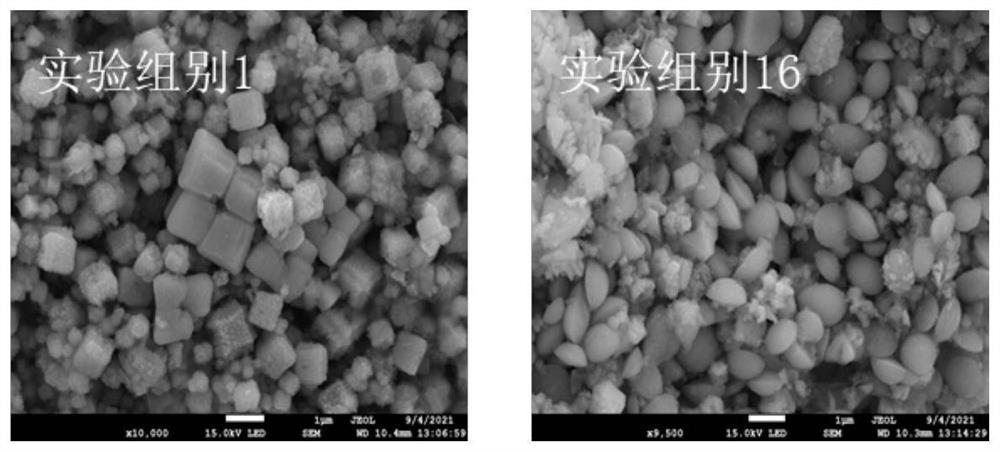

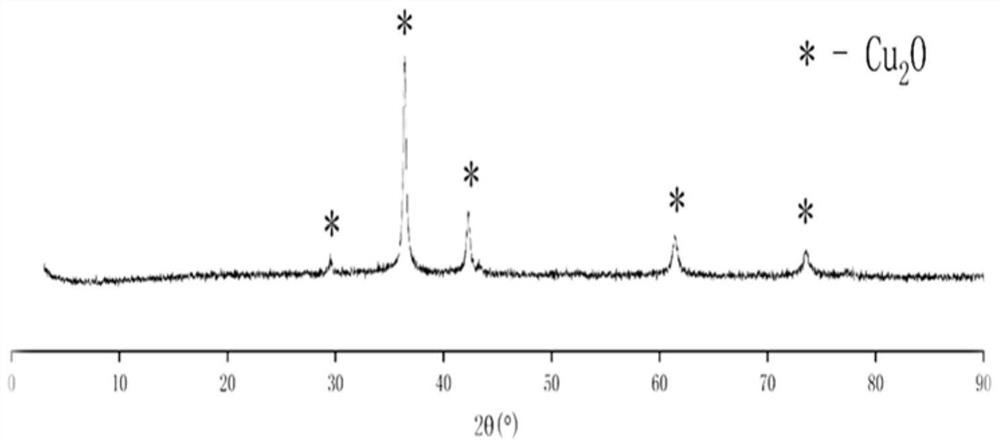

Method for preparing nano cuprous oxide by using copper-containing waste mobile phone circuit board as raw material

PendingCN114804185ALow costLow purity requirementCopper compounds preparationNanotechnologyActive agentKerosene

The invention relates to a method for preparing nano cuprous oxide by taking a copper-containing waste mobile phone circuit board as a raw material. The method comprises the following steps: 1) heating, stirring and dissolving crushed and ground powder of the waste mobile phone circuit board by using dilute nitric acid, and filtering to obtain an acid leaching solution; (2) uniformly mixing an oil-phase component surfactant Span80, a carrier Lix984, liquid paraffin and a membrane solvent kerosene, and then adding an isometric ascorbic acid solution while stirring at a high speed to obtain an emulsion; and 3) diluting the acid leaching solution with water, adjusting the pH value to 7-9, adding the emulsified liquid, stirring, then transferring into a separating funnel, separating, and standing. And 4) transferring the upper-layer emulsion to a centrifuge tube, adding absolute ethyl alcohol, centrifuging, washing, evaporating ethyl alcohol from a solid containing a small amount of ethyl alcohol to obtain the product nano cuprous oxide, and recovering the ethyl alcohol. The method is simple in process, low in recovery cost, environmentally friendly and reliable in quality.

Owner:NANKAI UNIV

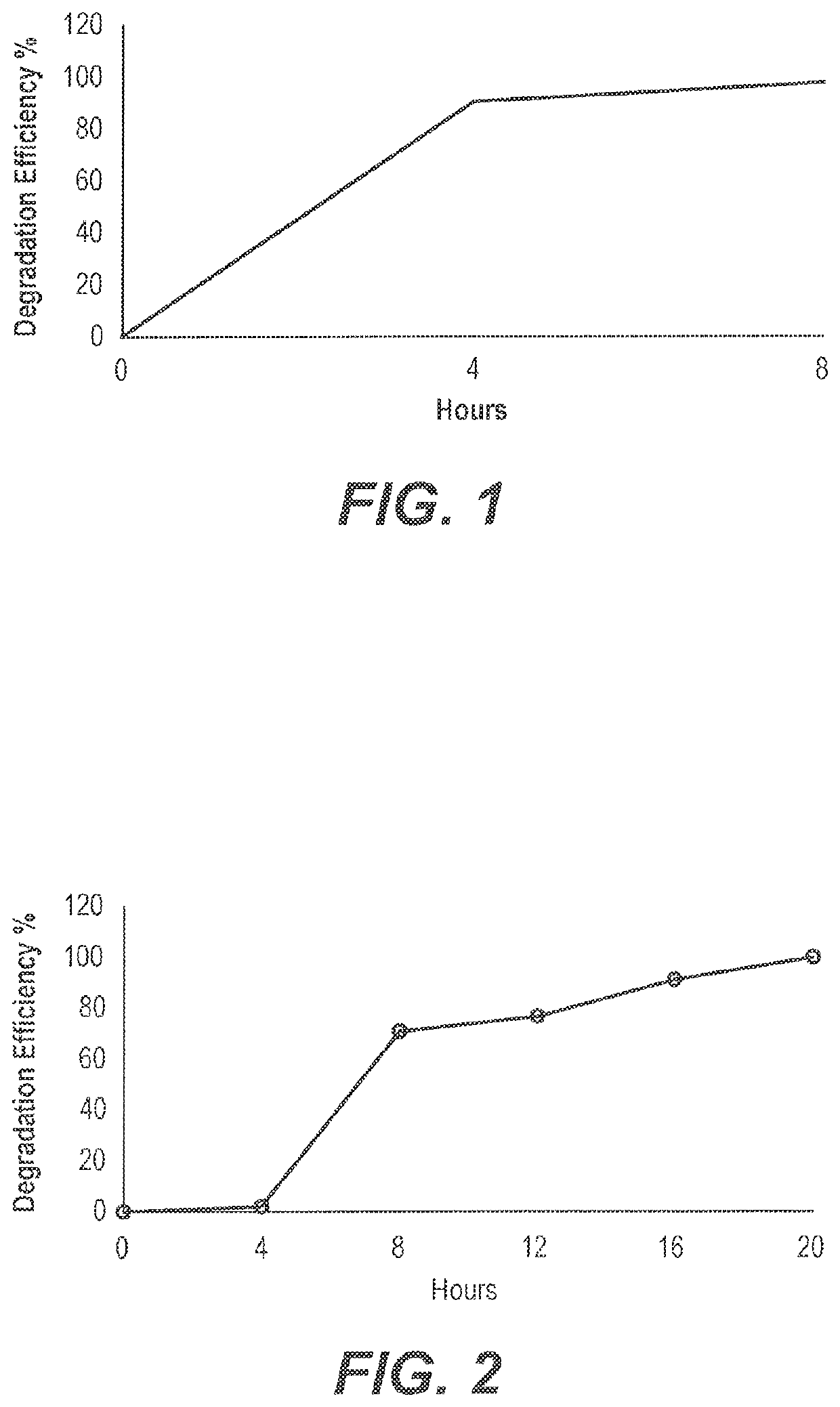

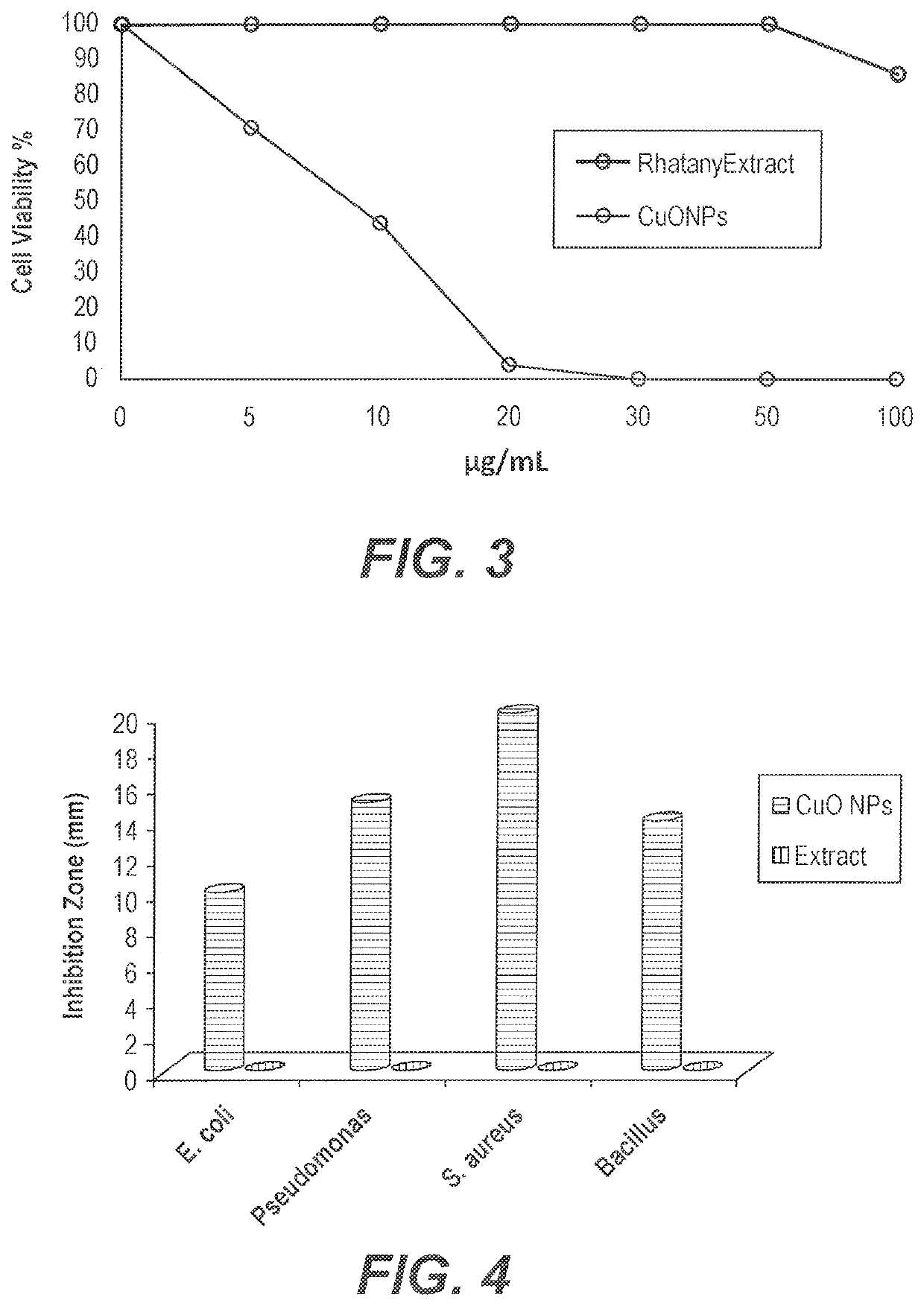

Copper oxide nanoparticles synthesized using rhatany root extract

ActiveUS20210387862A1Catalyst activation/preparationCopper compounds preparationBiotechnologyAntibacterial activity

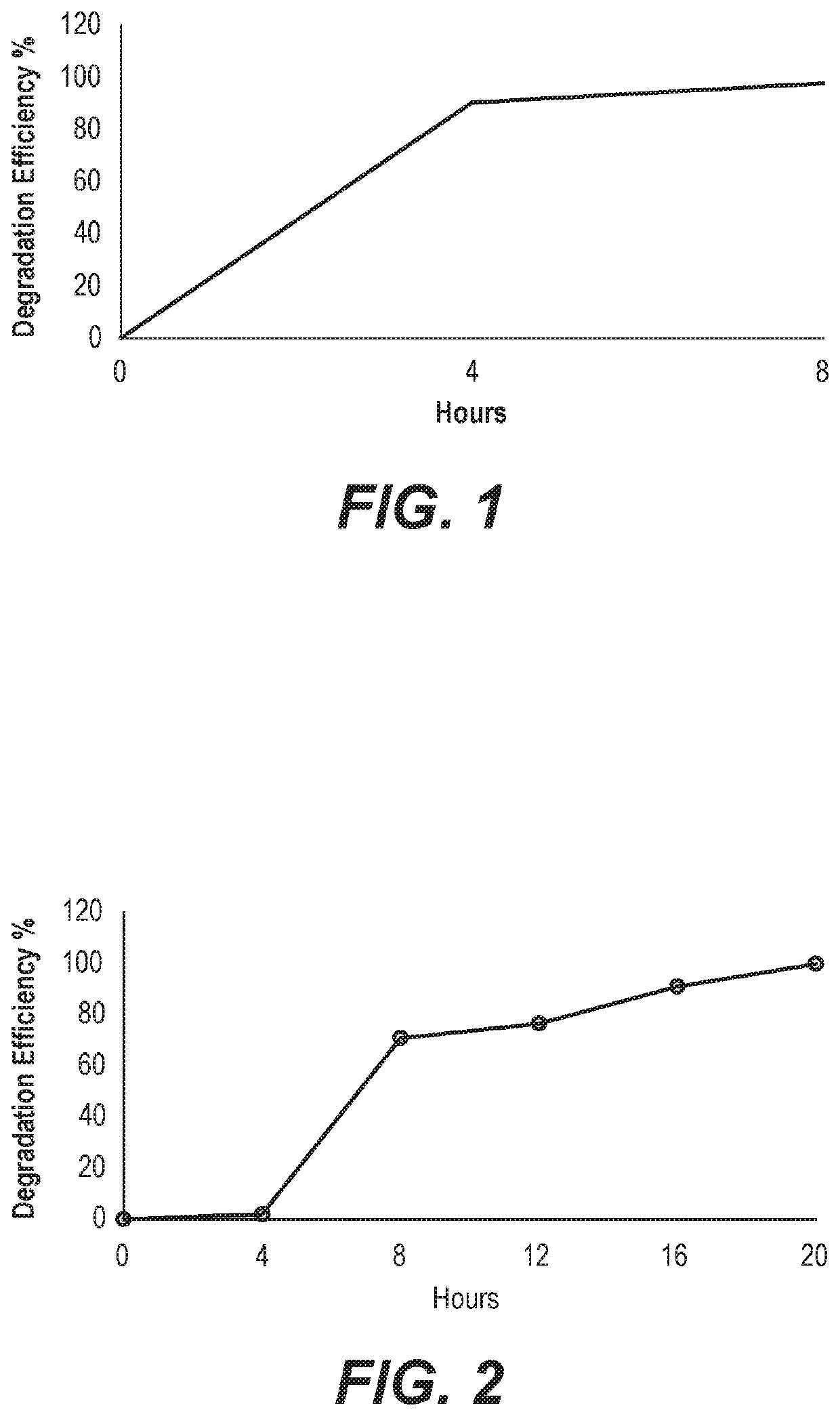

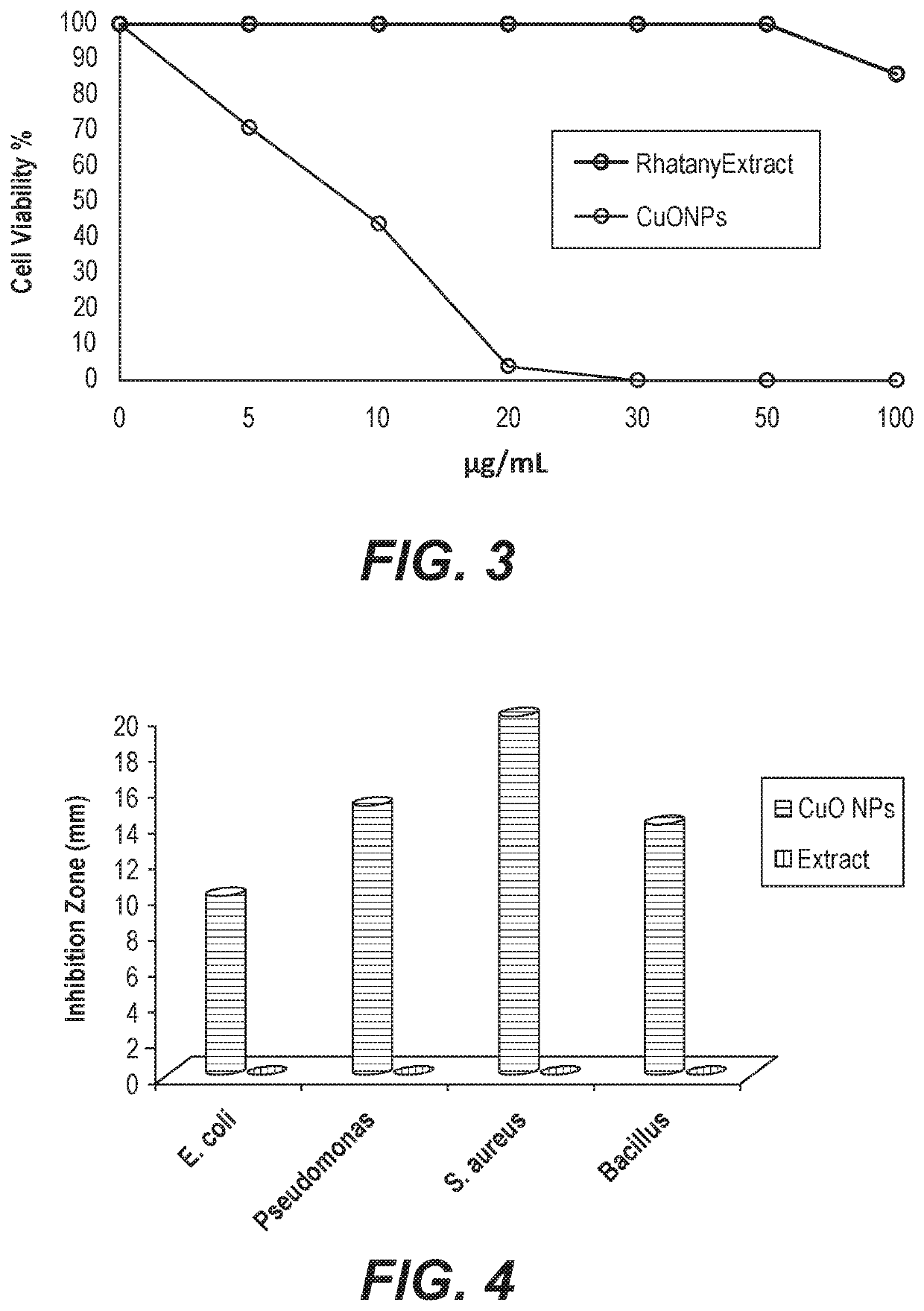

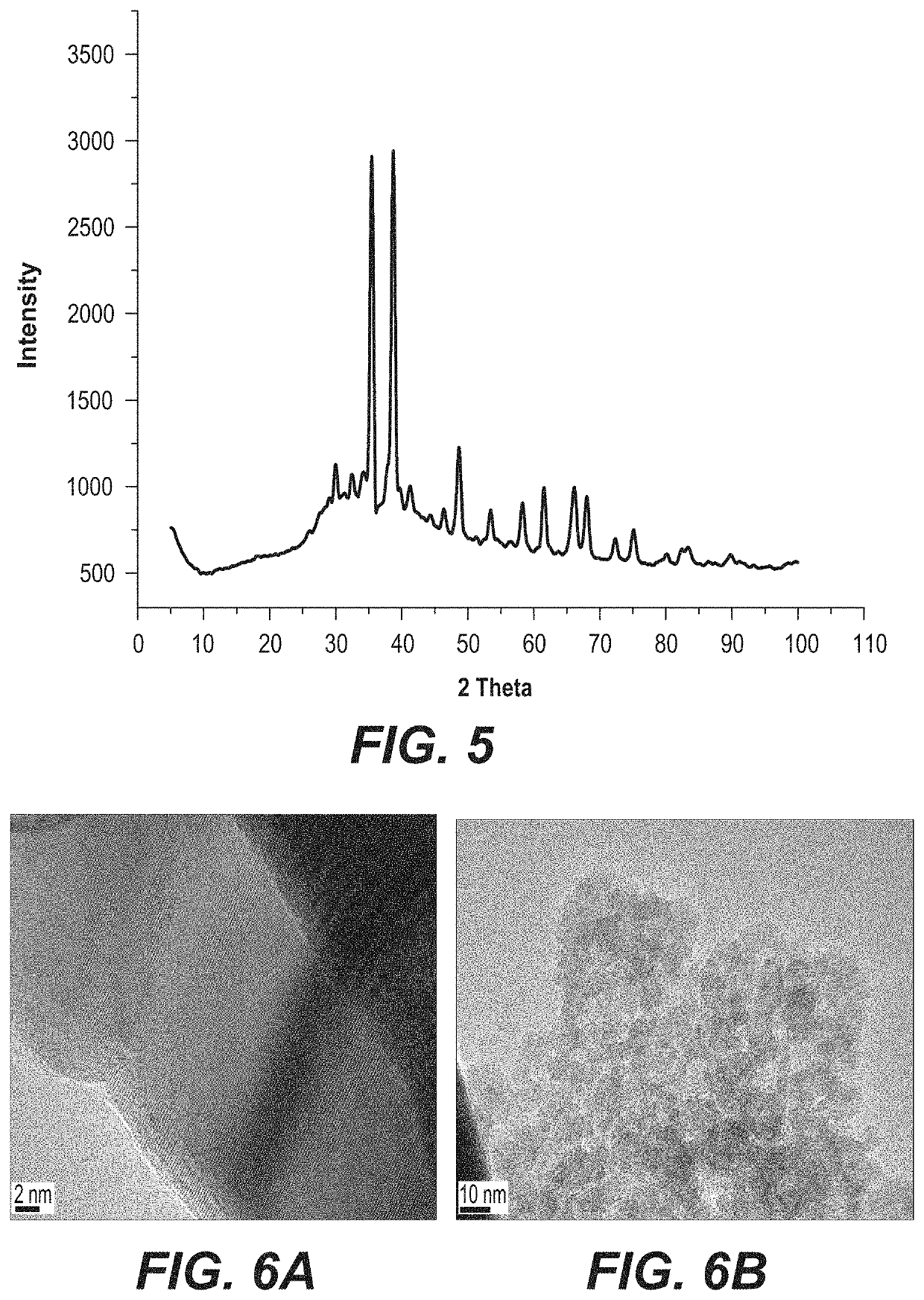

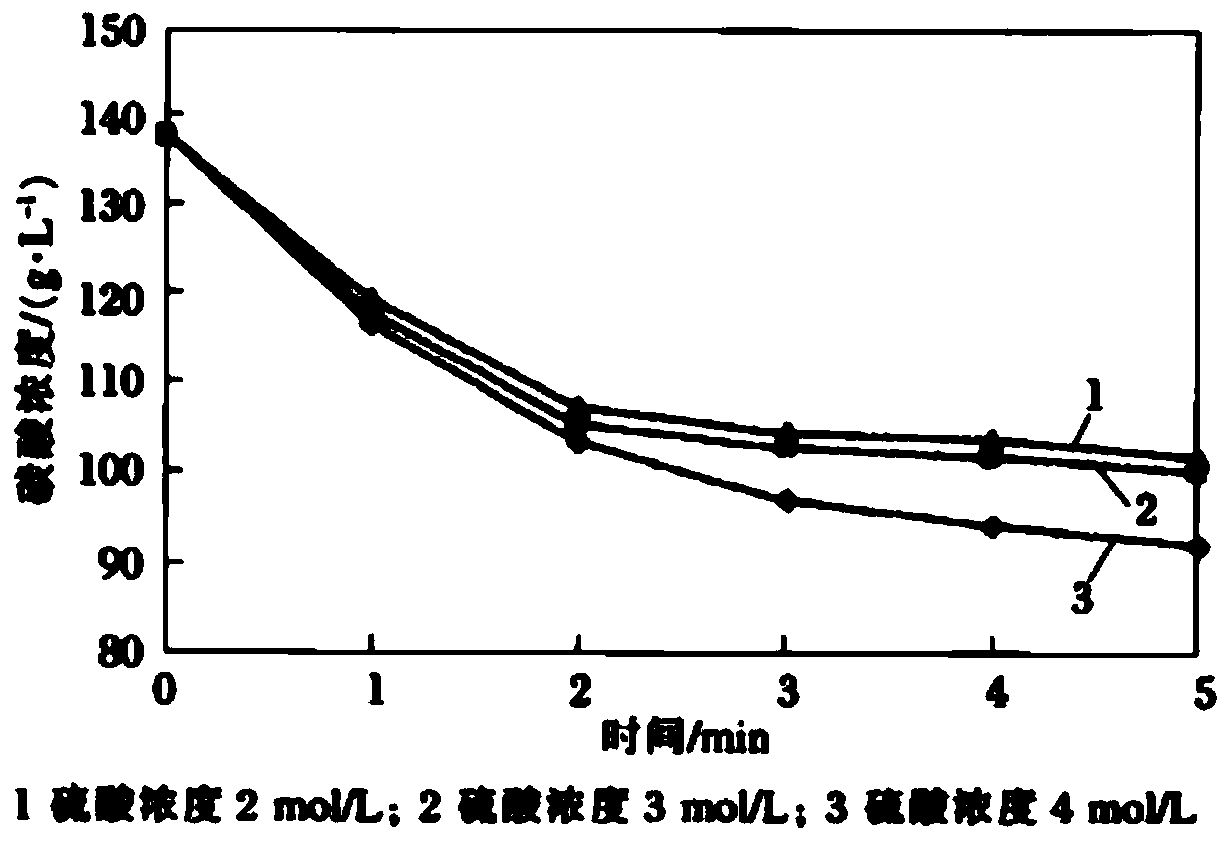

The copper oxide nanoparticles synthesized using Rhatany root extract involves preparing the Rhatany root extract by adding powdered Rhatany roots to boiling water, allowing the mixture to soak overnight, and removing any solid residue by filtering to obtain the aqueous extract. The copper oxide nanoparticles are prepared by mixing equal volumes of the aqueous Rhatany root extract and 0.1 M aqueous copper sulfate, heating the mixture at 80° C. for 40 minutes, and adding 1 M sodium hydroxide dropwise to the mixture to precipitate CuO. The precipitate is removed by centrifuge, washed with ethanol, dried, and calcined at 400° C. for 4 hours to obtain the copper oxide nanoparticles. The resulting nanoparticles proved effective in degrading wastewater dyes, showed anticancer activity against human cervical cancer by cell viability assay, and showed antibacterial activity against various strains of bacteria by agar diffusion.

Owner:KING SAUD UNIVERSITY

A kind of feed grade copper sulfate and production technology thereof

ActiveCN106348334BRealize comprehensive utilizationSimple production process and equipmentCopper compounds preparationCopper sulfatesSulfateEconomic benefits

The invention relates to the technical field of industrial wastewater treatment, in particular to feed-level copper sulfate and a production technology thereof. The production technology comprises the following steps of A, preparing rough purification etching waste liquid; B, neutralizing, pressing and filtering; C, extracting, and exchanging ions; D, acidifying and crystallizing. The production technology has the advantages that the environment-friendly and pollution-free effects are realized, the emission of waste gas and wastes is avoided, and the wastes are utilized; the mother liquor is recycled, and the subsidiary liquor is sold back to enterprises, so that the economic benefit is high; the equipment is simple, and the operation is simple and convenient; the content of copper ions in the prepared feed-level copper sulfate is 95%, and the prepared feed can improve digestion systems of livestock and poultry.

Owner:东莞市德睿工业废品处理有限公司

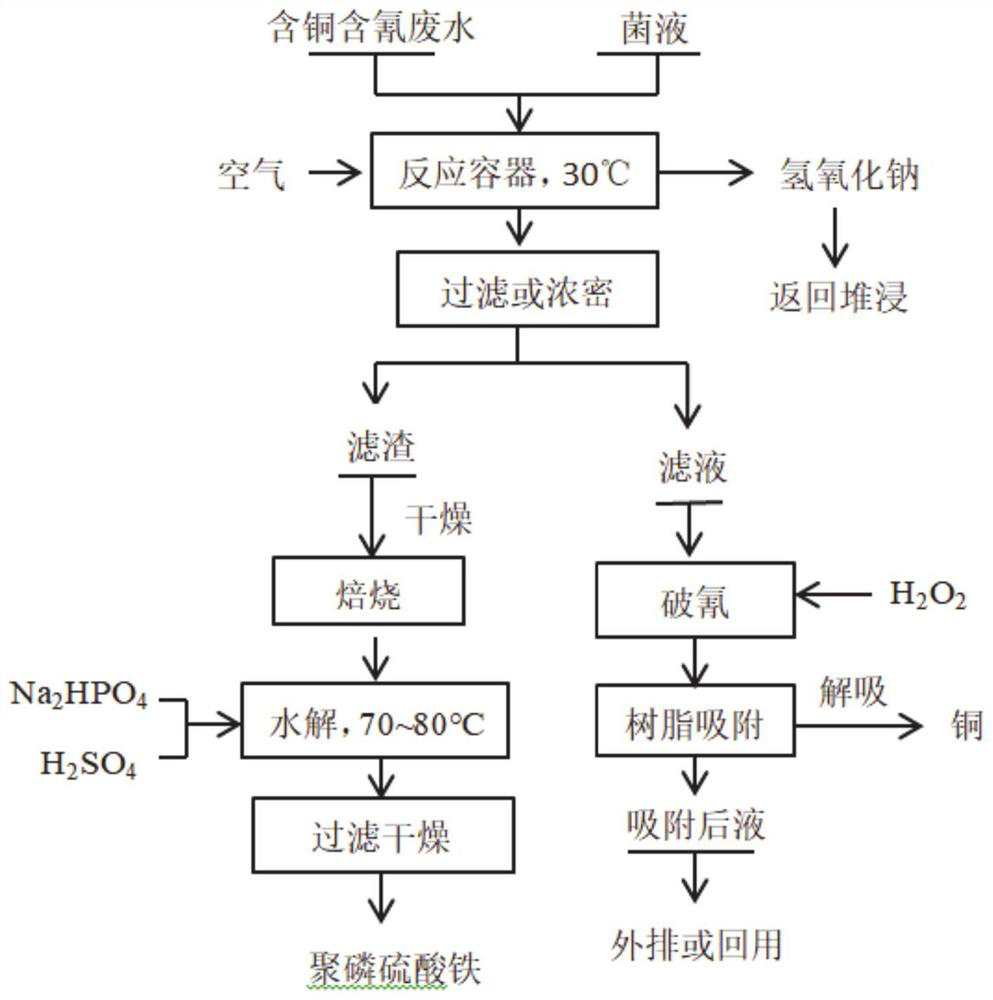

Method for removing cyanogen and recycling copper by mixing bacterial liquid and copper-containing and cyanogen-containing wastewater

ActiveCN113105067AReduce dosageTake advantage ofWater treatment parameter controlSpecific water treatment objectivesCyanidePolymeric adsorbent

The invention discloses a method for removing cyanogen and recycling copper by mixing bacterial liquid and copper-containing and cyanogen-containing wastewater. The method comprises the following steps: mixing a bacterial solution with a potential of 600 mV or more with the copper-containing and cyanide-containing wastewater, conducting heating to 30 DEG C, performing inflating for 2 hours, controlling a pH value to be 3-4.5, carrying out dense filtration, adding hydrogen peroxide into a filtrate to allow a total cyanide content to be reduced from 0.5-5 mg / L to 0.5 mg / L or below, carrying out resin copper adsorption on cyanogen-removed liquid, performing desorbing, recycling a desorption product as copper sulfate, and discharging or recycling the copper-removed liquid. The new method has the main advantages that existing resources can be fully utilized, the dosage of chemicals is reduced, income is increased, and the process is economically feasible and is an economical and effective treatment and recovery process.

Owner:内蒙古金中矿业有限公司

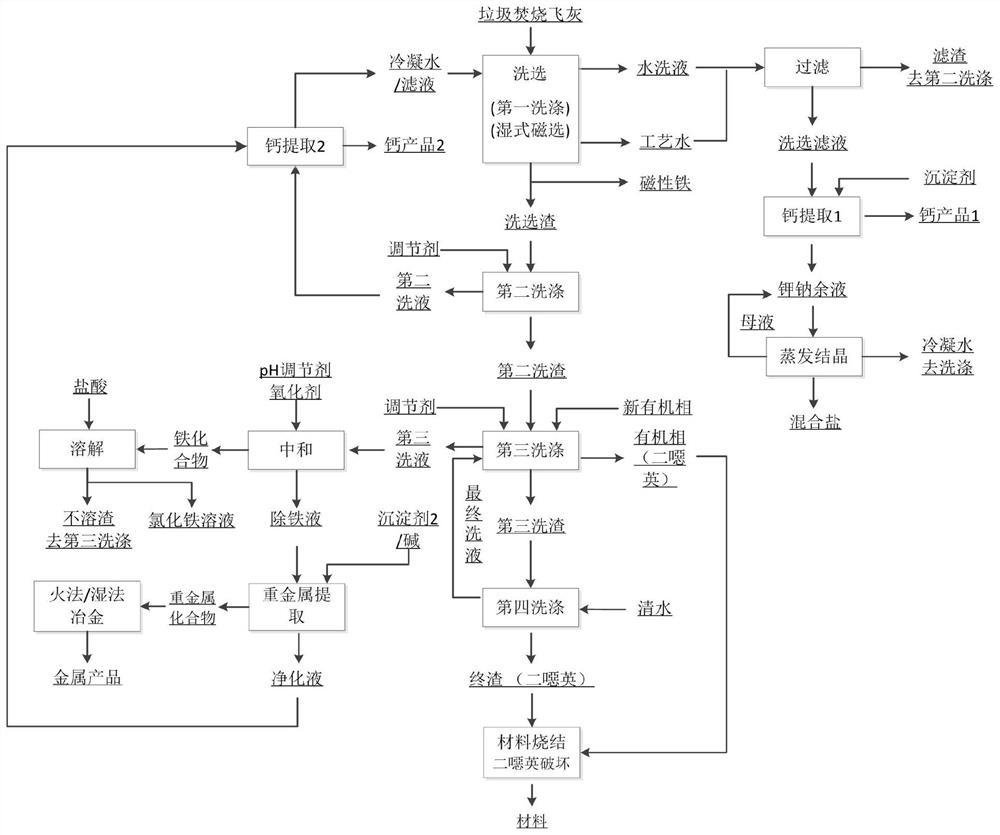

Resource utilization method of waste incineration fly ash

PendingCN114455623AImplement resourcesRealize comprehensive utilizationCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesMaterials preparationSlag

The invention belongs to the technical field of waste incineration fly ash treatment, and particularly relates to a resource utilization method of waste incineration fly ash. According to the method provided by the invention, soluble salt and magnetic substances in the waste incineration fly ash can be synchronously separated through washing, washing slag is subjected to second washing when the pH value is 6.5-8.0, and second washing slag is subjected to third washing when the pH value is 0.6-1.5. And step-by-step washing is carried out by controlling different pH values, and all extractable components in the garbage fly ash are respectively concentrated in different sections of washing liquid. According to the method, calcium salt and industrial salt extraction is carried out on the washing filtrate, calcium and heavy metal extraction is carried out on the second washing liquid and the third washing liquid, the final slag is used as a substitute raw material for building material preparation after high-temperature sintering or is directly prepared into building materials, and meanwhile dioxin is thoroughly decomposed during high-temperature treatment. According to the method provided by the invention, the garbage fly ash is completely recycled.

Owner:陈彤 +1

Method for recovering metal values from metal-containing materials using high temperature pressure leaching

InactiveUS20080156656A1Lower cost of capitalReduce operating costsPhotography auxillary processesSolvent extractionPregnant leach solutionElectrolysis

The present invention relates generally to a process for recovering copper and other metal values from metal-containing materials through pressure leaching operations. In accordance with the various aspects of the present invention, metal-containing pregnant leach solutions from pressure leaching operations need not be significantly diluted to facilitate effective metal recovery using solvent extraction and electrowinning.

Owner:FREEPORT MCMORAN COPPER & GOLD INC

Copper oxide nanoparticles synthesized using Rhatany root extract

ActiveUS11001505B1Showed anticancer activityShowed antibacterial activityCatalyst activation/preparationCopper compounds preparationBiotechnologyAntibacterial activity

The copper oxide nanoparticles synthesized using Rhatany root extract involves preparing the Rhatany root extract by adding powdered Rhatany roots to boiling water, allowing the mixture to soak overnight, and removing any solid residue by filtering to obtain the aqueous extract. The copper oxide nanoparticles are prepared by mixing equal volumes of the aqueous Rhatany root extract and 0.1 M aqueous copper sulfate, heating the mixture at 80° C. for 40 minutes, and adding 1 M sodium hydroxide dropwise to the mixture to precipitate CuO. The precipitate is removed by centrifuge, washed with ethanol, dried, and calcined at 400° C. for 4 hours to obtain the copper oxide nanoparticles. The resulting nanoparticles proved effective in degrading wastewater dyes, showed anticancer activity against human cervical cancer by cell viability assay, and showed antibacterial activity against various strains of bacteria by agar diffusion.

Owner:KING SAUD UNIVERSITY

A kind of preparation method of electroplating grade copper sulfate

ActiveCN107986317BAchieve recyclingAvoid emissionsCopper compounds preparationCopper sulfatesCu2 ionsStrong acids

The invention provides a method for preparing electroplating-grade copper sulfate. The method comprises: using acid copper wastewater as a raw material, absorbing organic matter in acid copper wastewater through chelating resin, and using selective copper ion cation resin to adsorb organic matter in acid copper wastewater Add strong acid to desorb and regenerate the selective copper ion cation resin to obtain a concentrated copper sulfate solution, add hydrogen peroxide to the concentrated copper sulfate solution, and perform weak electrolysis, filtration and adjustment to the concentrated copper sulfate solution after adding hydrogen peroxide. pH and crystallization, copper sulfate crystals were obtained. According to the preparation method of electroplating grade copper sulfate of the present invention, the copper sulfate crystal prepared by it is delicate, has little water content, and high purity, which can reach more than 99.9%, and the method can reduce waste water discharge and treatment cost, environmental protection and emission reduction.

Owner:XIAMEN RUNNER IND CORP

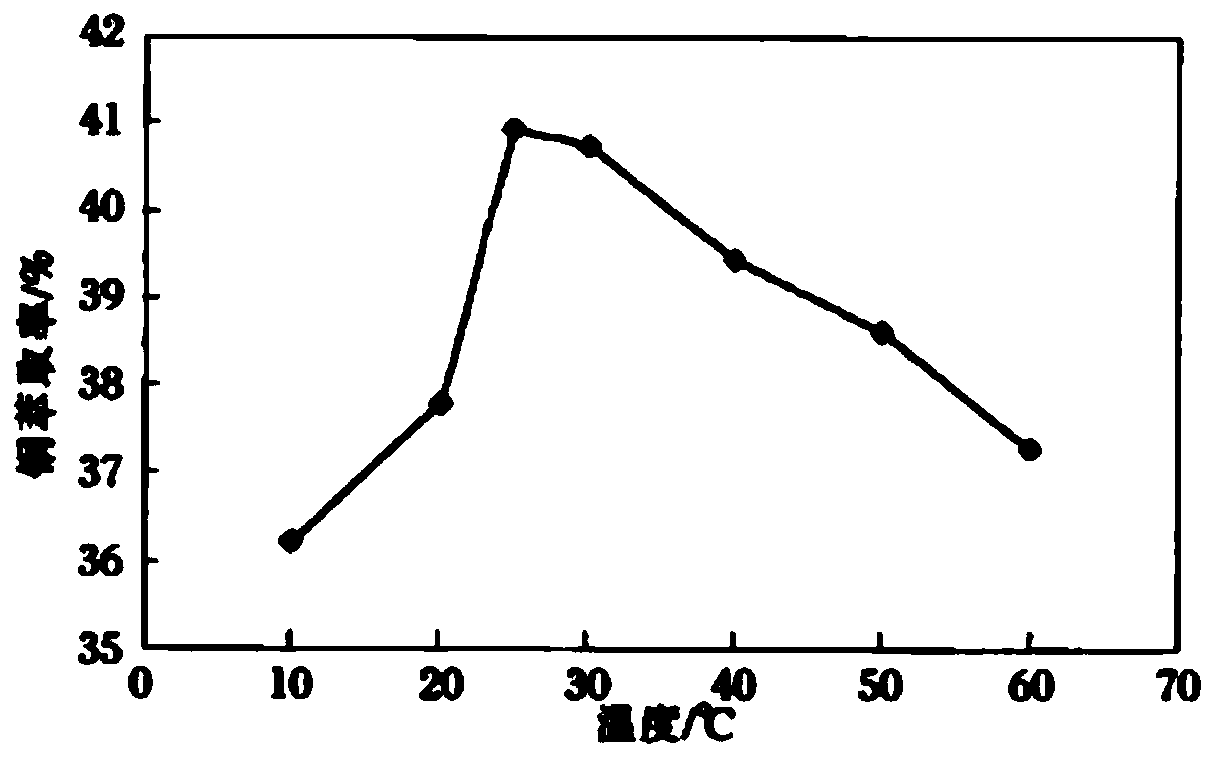

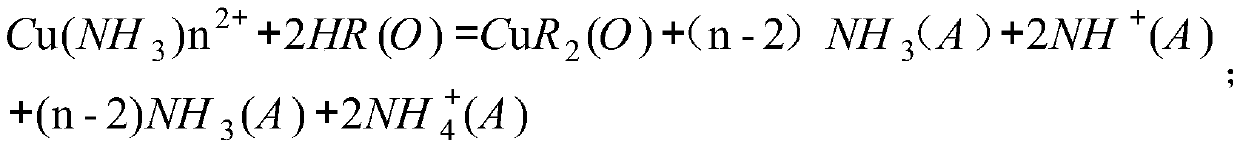

Alkaline etching ammonia recycling system

InactiveCN110408937AReach recoveryAchieve recyclingCopper compounds preparationCopper sulfatesReaction temperatureWastewater

The invention provides an alkaline etching ammonia recycling system. The system comprises the following steps of adding sulfuric acid solutions of different concentrations as reverse extraction agentsinto three containers; performing reaction on alkali-phase solutions added with the sulfuric acid solutions of different concentrations to obtain a copper sulfate solution at the reaction temperatureof 10 DEG C-60 DEG C; leaving the copper sulfate solution subjected to cooling at room temperature to obtain a solution containing crystalline copper sulfate; and adding ammonia and ammonium chlorideinto a reaction kettle, and then heating the temperature and stirring the mixer so as to obtain an alkaline etching liquid. According to the alkaline etching ammonia recycling system, a method of extraction is adopted to divide the alkaline etching liquid into an aqueous phase and an alkali phase for separated treatment; and while the aqueous phase is used as a regeneration resource of a new etching liquid, the alkaline liquid is subjected to effects of extraction and reverse extraction, copper resource within is recycled, and during the process of recycling, all waste liquid is regenerated,no wastewater is discharged, and therefore the purpose of saving through resource recycling and re-utilization is achieved, and energy consumption is reduced as well.

Owner:安徽绿洲危险废物综合利用有限公司

A kind of electroplating grade copper sulfate and production technology thereof

ActiveCN106495205BRealize comprehensive utilizationSimple production process and equipmentCopper compounds preparationCopper sulfatesLiquid wasteIon exchange

The invention relates to the technical field of industrial wastewater and particularly relates to electroplating-grade copper sulfate and a production process thereof. The production process comprises the following steps: (A) preparation of roughly purified etching waste liquid; (B) neutralization and filter pressing; (C) extraction and ion exchange; (D) acidification and crystallization; and (E) purification and crystallization. The production process is environmentally friendly and pollution-free, the waste gas and the waste are not discharged, the utilization of the waste is realized, the cyclic utilization of mother liquid is realized, and the child liquid is sold to enterprises, so that the economic benefit is high, the equipment is simple, and the operation is simple and convenient. The content of copper ions in prepared electroplating-grade copper sulfate reaches up to 98%, so that the digestive systems of livestock are beneficially improved.

Owner:东莞市德睿工业废品处理有限公司

Improved copper sulphate production technology

ActiveCN106745181AAchieve contentReduce contentCopper compounds preparationCopper sulfatesFiberMicrosphere

The invention relates to an improved copper sulphate production technology. The production technology comprises the following steps: grinding copper sponge to 50-70 meshes, reacting the copper sponge and a high acid solution at temperature of 50 DEG C to prepare a solution containing 95-100 g / L of copper ions; adding a sulfuric acid solution in the solution, diluting the materials to the copper ion content of 55-59 g / L, then employing an organic extractant for extracting the solution, wherein the volume ratio of the organic reagent to a water phase is 5:1; adding hydrochloric acid in the extract for washing, adjusting the pH value to 2.5-3.5; using industrial diluted sulfuric acid for performing back extraction on an organic phase, controlling the copper content in strip liquor to no greater than 80 g / L; splitting the phase, using fiber microspheres to remove oil of the strip liquor, concentrating the strip liquor to obtain concentrated liquid with copper content of 230 g / L, and performing concentrate and crystallization on the solution to obtain the copper sulphate product. The production technology can greatly reduce the content of other impurity in the final product, can repeatedly reuse the used reagent, and reduces the production cost.

Owner:HENGYANG YISHUN CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com