Patents

Literature

97 results about "COPPER SULFATE CRYSTALS" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

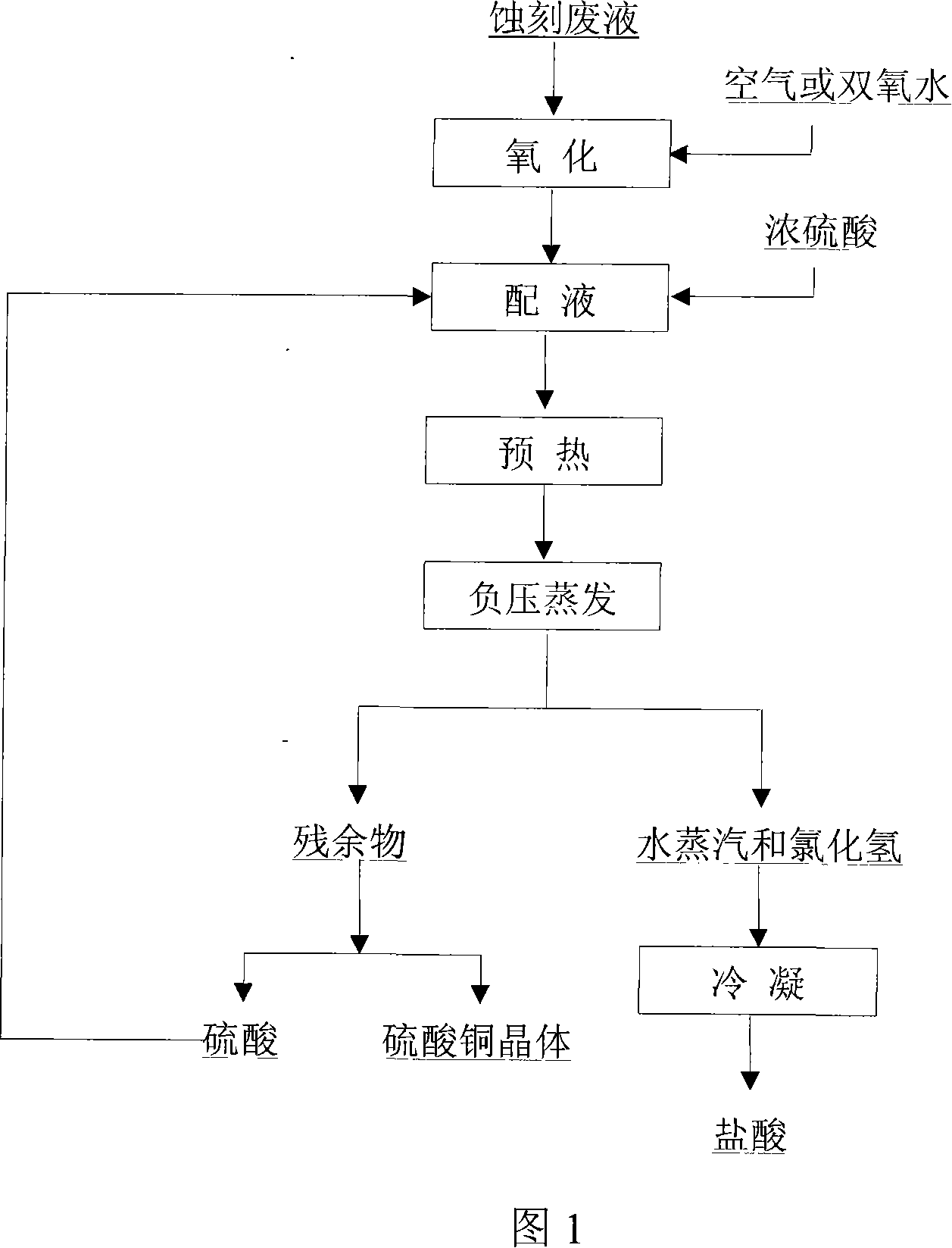

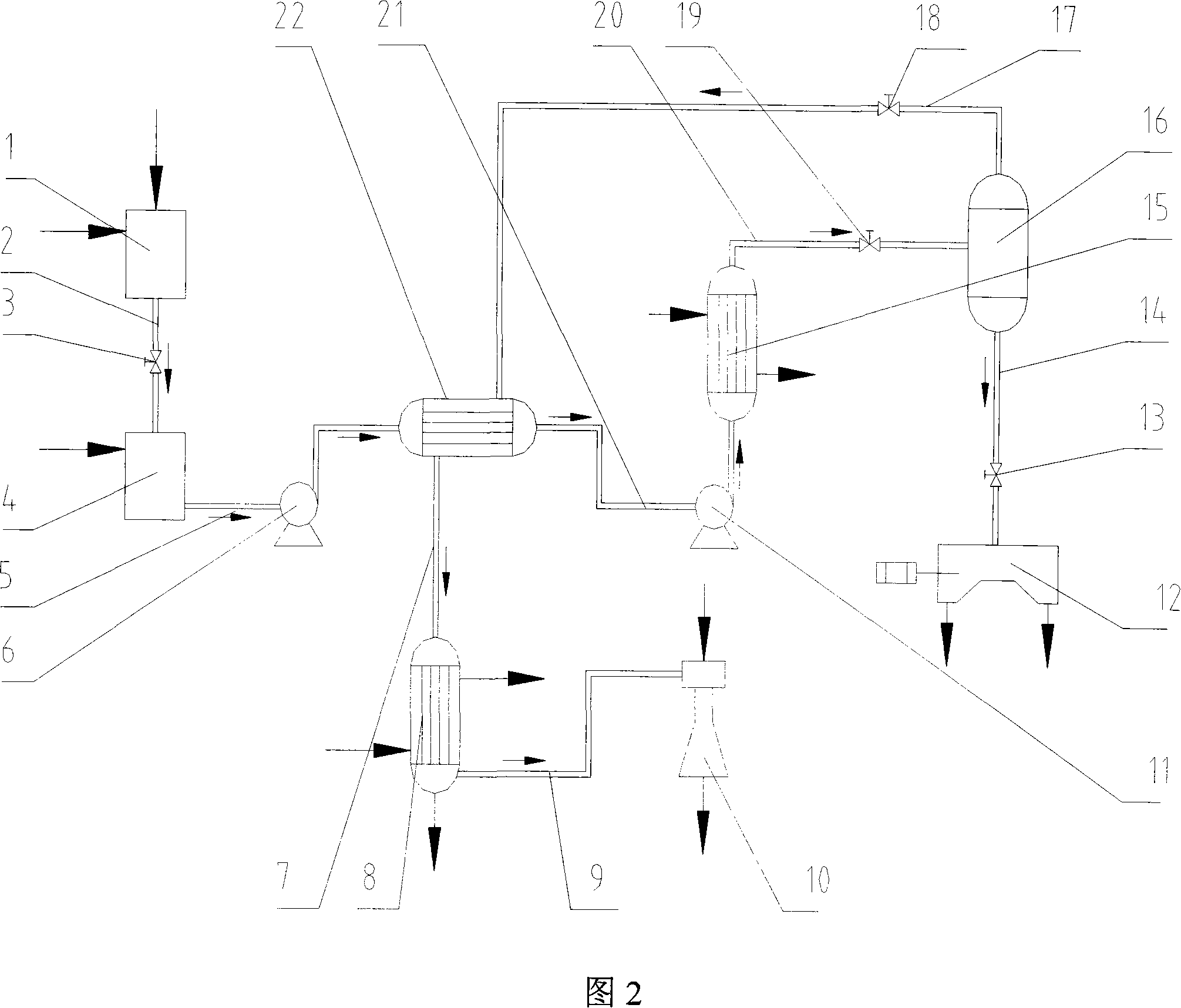

Method and system for reclaiming valuable resource in acidic etching waste liquid

InactiveCN101215062AImprove liquidityReduce cooling energy consumptionChlorine/hydrogen-chlorideMultistage water/sewage treatmentLiquid wasteWater vapor

Provided are system of value resource in acidic corrosion waste fluid and a recycling method. The recycling method of the invention includes the following steps that adding oxidation agent and concentrated sulfuric acid into the corrosion waste fluid, pre-heating and heating the corrosion waste fluid, evaporating out water vapor and hydrogen chloride under negative pressure and recycling hydrochloric acid, the residue separates hydric sulphate from blue copperas crystal via centrifugal filtration and recycle hydric sulphate, washing blue copperas crystal by blue copperas crystal solution and absolute ethyl alcohol and recycling blue copperas. The recycling system comprises an oxidation ditch, a dosage bunker, a pre-heater, a heat booster, an evaporation tank, a filter, a cooler, a spraying and absorbing device and the like. The recycling method of the invention increases the recovery rate of metal copper and hydrogen chloride, with both recovery rates more than 99%. The method can employ scheme of batch operation or continuous recycling, which is adapted for industry utilization.

Owner:郝屿

Technique for extracting copper ions from industrial wastewater

ActiveCN104355474AHigh extraction rateGood removal effectWater contaminantsWater/sewage treatment by ion-exchangeIon exchangeIon-exchange resin

The invention discloses a technique for extracting copper ions from industrial wastewater, which comprises the following steps: 1) respectively pretreating an acidic coppery etching waste liquid and an alkaline coppery etching waste liquid; 2) neutralization and precipitation: carrying out neutralization reaction on the acidic coppery etching waste liquid and alkaline coppery etching waste liquid in a neutralizing tank, and precipitating to obtain a basic copper chloride precipitate and a filtrate; 3) adding the basic copper chloride precipitate into a reaction tank, and adding sulfuric acid to obtain a copper sulfate crystal; 4) sending the filtrate into an ion exchange resin tower to adsorb the rest unrecovered copper ions, thereby obtaining ammonia nitrogen wastewater; and 5) carrying out evaporative concentration on the ammonia nitrogen wastewater by a vapor recompression technique, crystallizing the concentrate to produce an ammonium chloride product, treating the condensation water by an ion-exchange process, and discharging after reaching the standard. The technique can greatly enhance the extraction rate of copper ions, solves the problem of environmental pollution caused by heavy metal ions, and can produce other products from the waste liquid to implement cyclic utilization, thereby saving the resources and protecting the environment.

Owner:清远市中宇环保实业有限公司

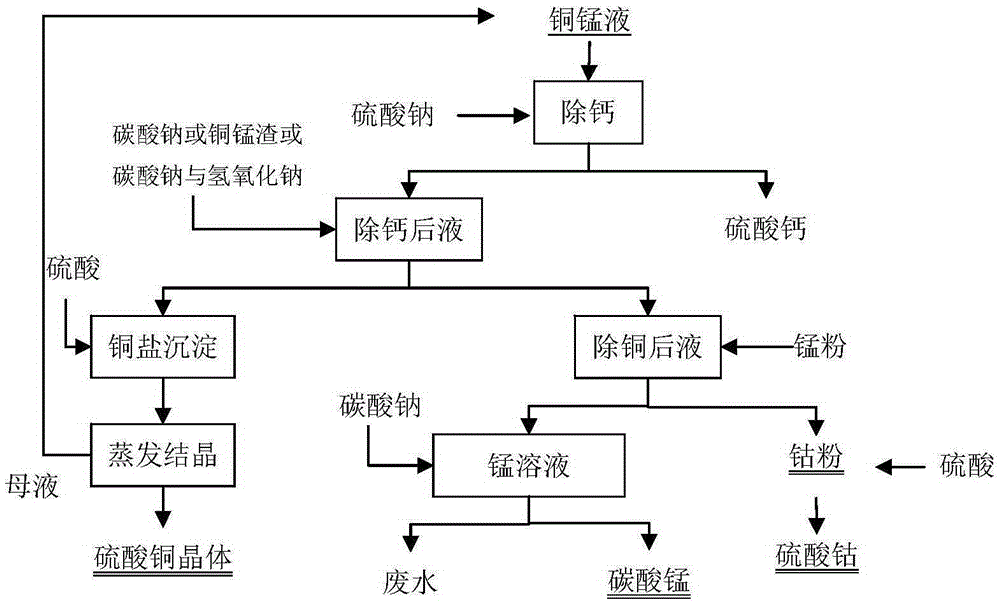

Method for separating copper, cobalt and manganese from cupric chloride manganese-cobalt-calcium-zinc impurity removal solution

ActiveCN105296754AShort processLow costRotary drum furnacesCrucible furnacesManganese(II) carbonateSulfate

The invention relates to a method for separating copper, cobalt and manganese from a cupric chloride manganese-cobalt-calcium-zinc impurity removal solution. The method comprises the steps that sodium sulfate is added to the cupric chloride manganese-cobalt-calcium-zinc solution, and calcium sulfate is removed by filtration; then sodium carbonate is added to a solution obtained in step one, a pH value is adjusted to 4.0-6.0 to allow copper ions in the solution to be precipitated, and copper precipitates are obtained by filtration separation; the copper precipitates are dissolved with sulfuric acid and are subjected to evaporation crystallization to form copper sulfate crystals; manganese powder is added to a solution after copper removal to allow cobalt ions to be reduced to cobalt powder to be precipitated, and cobalt powder is obtained after the filtration separation and is dissolved with acid to form a cobalt solution; and a solution after cobalt removal contains manganese and a little zinc and calcium, manganese is precipitated through the evaporation crystallization or by adding sodium carbonate, and manganese salts such as rough manganese carbonate are obtained. With the adoption of the method, three main valuable metals, namely copper, cobalt and manganese, can be separated and extracted economically and conveniently.

Owner:长沙百汇新材料科技有限公司

Comprehensive treatment method of acidic etching waste liquid

InactiveCN101792220AImprove resource recoveryGuaranteed emission standardsChlorine/hydrogen-chlorideWaste water treatment from metallurgical processLiquid wasteDistillation

The invention relates to a comprehensive treatment method of acidic etching waste water. Tail water treated by the existing treatment method can not conform to the standard. The method comprises the following steps: firstly adding oxydol to an acidic etching waste liquid to be treated for breaking and regeneration; then adding 98% concentrated sulfuric acid, distilling by heating, and absorbing the distilled steam with clean water to obtain dilute hydrochloric acid; dissolving residues after the distillation in a solution to generate a mother solution, throwing nano filter membranes and reverse osmosis membranes for concentration and separation, cooling and crystallizing the condensed mother solution, rinsing with water, and drying to obtain a copper sulfate crystal product. The method comprehensively uses the resources of the acidic etching waste liquid, produces the industrial dilute hydrochloric acid and copper sulfate products, ensures that the discharged waste water conform to the standard, improves the resource recovery rate of copper, and also raises the distillation speed.

Owner:HANGZHOU DIANZI UNIV

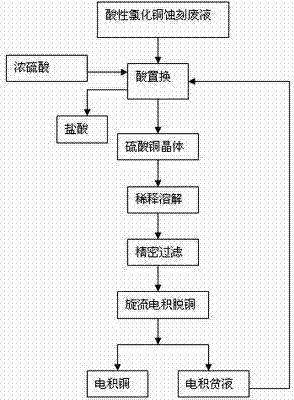

Process for recovering copper by processing acidic copper chloride etchant through rotational flow electrolysis

ActiveCN102418099AAvoid it happening againAvoid pollutionPhotography auxillary processesProcess efficiency improvementLiquid wasteHigh current density

The invention relates to a process for recovering copper by processing an acidic copper chloride etchant through rotational flow electrolysis, belonging to the technical field of copper-containing waste liquid treatment. The process comprises the following steps of: taking acidic copper chloride etching wastewater as a raw material; obtaining a copper sulfate crystal at a temperature of 120-180 DEG C through using an acid replacement conversion system; dissolving the copper sulfate crystal by diluting with distilled water to obtain a copper sulfate solution; filtering the copper sulfate solution through precise filtering equipment to obtain a filtrate; de-coppering the filtrate through the rotational flow electrolysis; and scalding an obtained copper pipe with little acid. According to the process provided by the invention, a rotational flow electrolytic cell and assorted equipment are convenient to mount, dismount and move through a portable or modular assembly; the solution is circulated in a closed loop without emission of harmful gases; electrolytic deposition is selectively carried out on metal, and the copper can be purified in a better manner by using the rotational flow electrolysis technology; due to higher current density and efficiency, the reagent consumption is reduced, the production cost is reduced and the enterprise benefit is improved; and an effective and highly-pure electroextraction is carried out on the solution, therefore, the recovered copper is standard cathode copper with a total recovery rate of more than 96%.

Owner:浙江科菲科技股份有限公司

Slow-release organic fertilizer for tea herb and preparation method thereof

InactiveCN102659475AHigh yieldIncrease profitSuperphosphatesCalcareous fertilisersEutrophicationNutrient deficiency

The invention provides a slow-release organic fertilizer for tea herb and a preparation method thereof. The slow-release organic fertilizer for tea herb is composed of lignin, kieselguhr, humic acid, calcium-based silicate mineral, nitrogenous fertilizer, phosphatic fertilizer, potash fertilizer, trace elements and water, wherein the trace elements contain calcium superphosphate, magnesium sulfate crystal, manganese sulfate crystal and copper sulfate crystal. The preparation method comprises the following steps: dissolving and stirring all the components, and then mixing and pelletizing, thereby obtaining the slow-release organic fertilizer for tea herb. The formula of the slow-release organic fertilizer for tea herb is reasonable; under the synergistic effect of all the components, the use ratio of organic fertilizer and the yield of tea herb are greatly increased; and meanwhile, the problem of eutrophication or nutrient deficiency symptom of the crops and the problem of water pollution caused by fertilizer loss are effectively solved, the soil is improved, the resource is saved and the cost is lowered; and the preparation method is simple and meets the requirement for large-scale industrial production.

Owner:TIANJIN FENGRUNYUAN FINE CHEM TECH

Method for preparing cupric sulphate by using cupric nitrate exhausted liquid

InactiveCN101113014ADoes not increase procurement costsAvoid destructionCopper sulfatesEconomic productionCupric nitrate

The invention relates to a method of preparation of copper sulfate with cupric nitrate waste solution, aiming at recycling cupric nitrate waste solution from manufacturing process of PCB and making the cupric nitrate waste solution as raw materials of solid copper sulfate. Concentrated sulfuric acid is first added into the cupric nitrate waste solution and forms a mixed solution of the sulfuric acid and the cupric nitrate and the sulfuric acid and the cupric nitrate react to each other chemically therein; then the mixed solution of the sulfuric acid and the cupric nitrate is heated to vaporize and separate HNO3 and the other solution is cooled then to generate copper sulfate crystal containing water or moisture; finally solid copper sulfate powder in a gain shape can be obtained after the crystal is dehydrated. The invention not only can completely recycle cupric nitrate solution and avoid secondary pollution, but also can directly get cheap or free raw material for preparing copper sulfate, thereby reducing economic production cost.

Owner:谢政龙

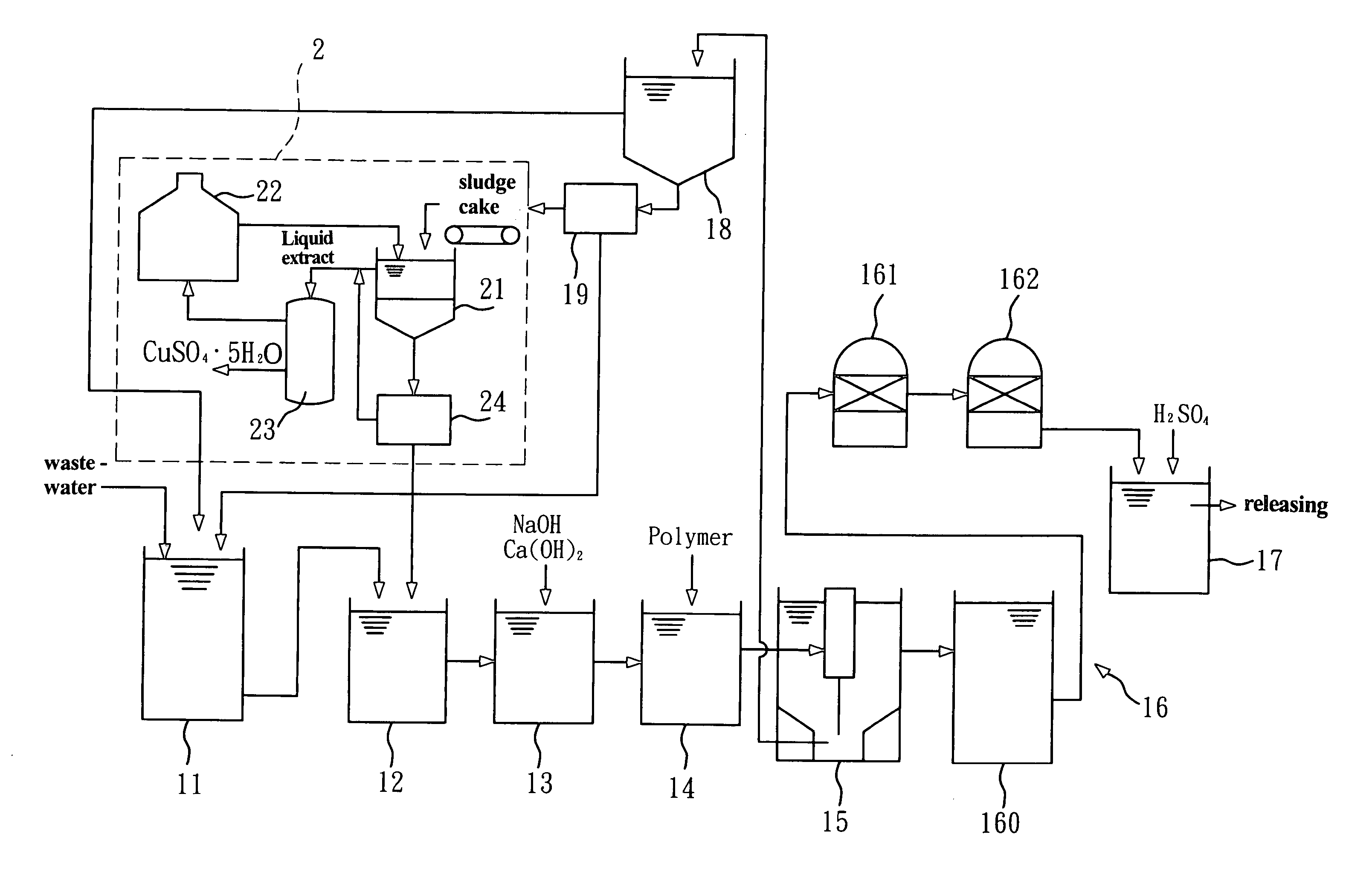

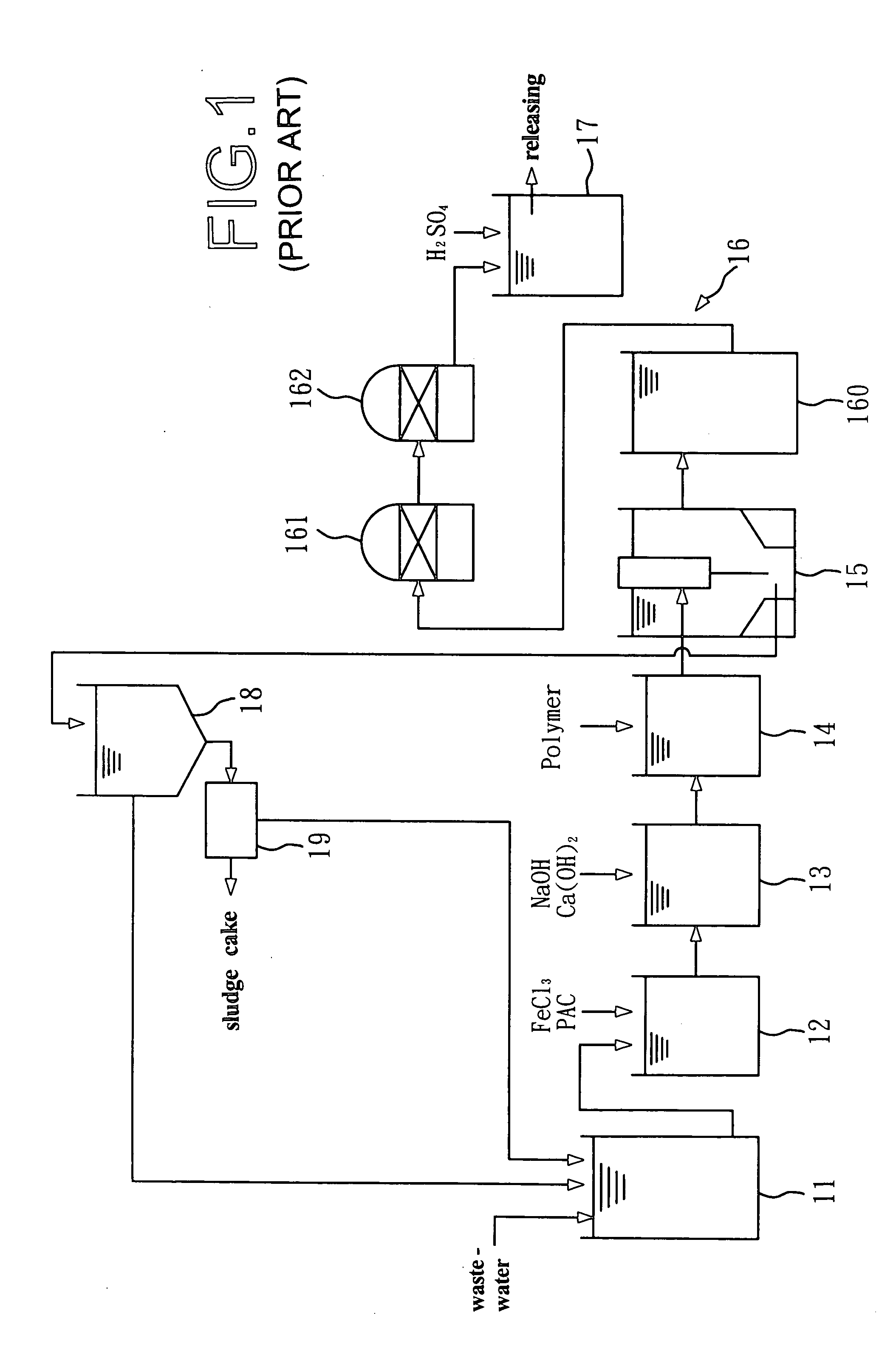

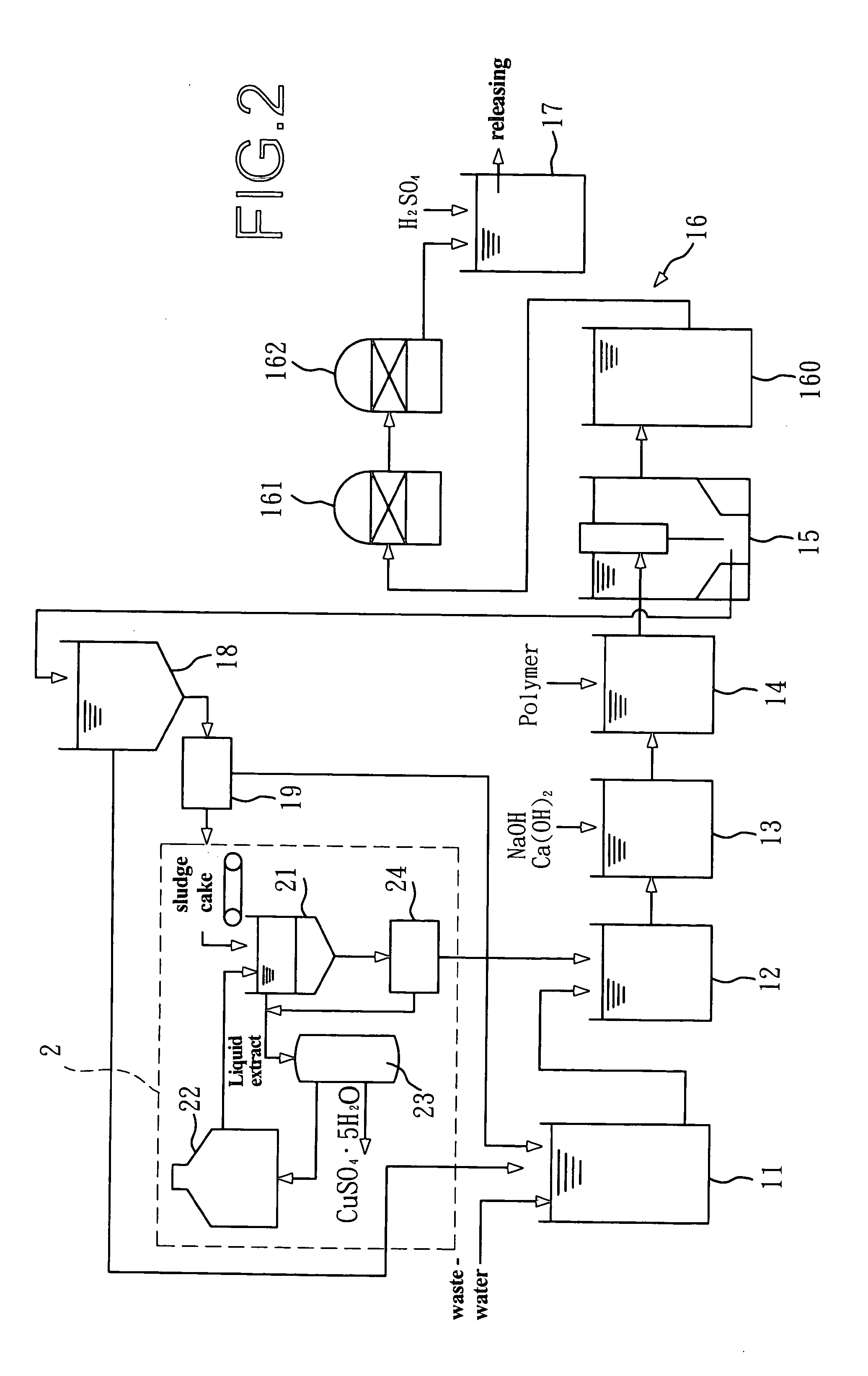

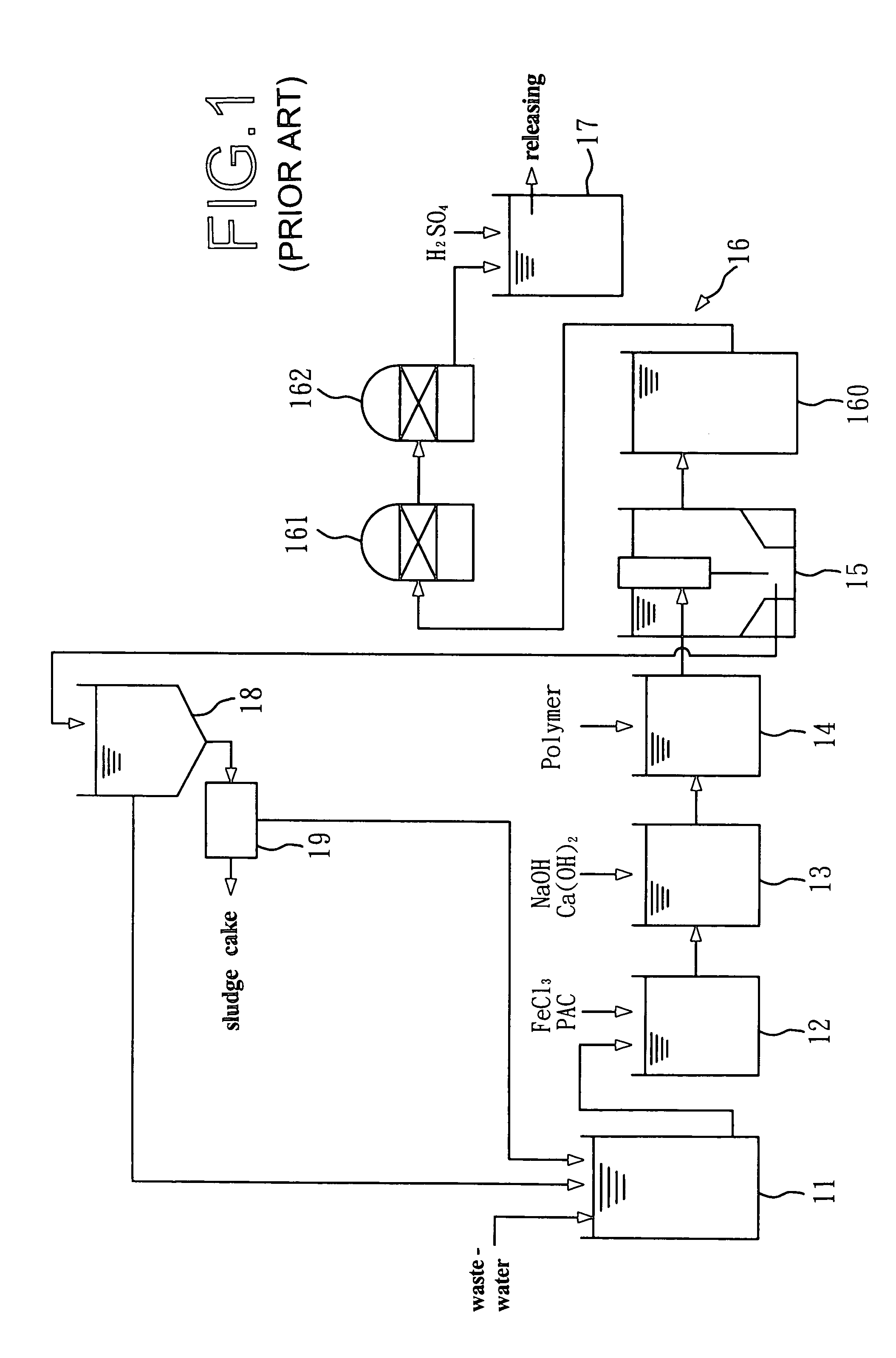

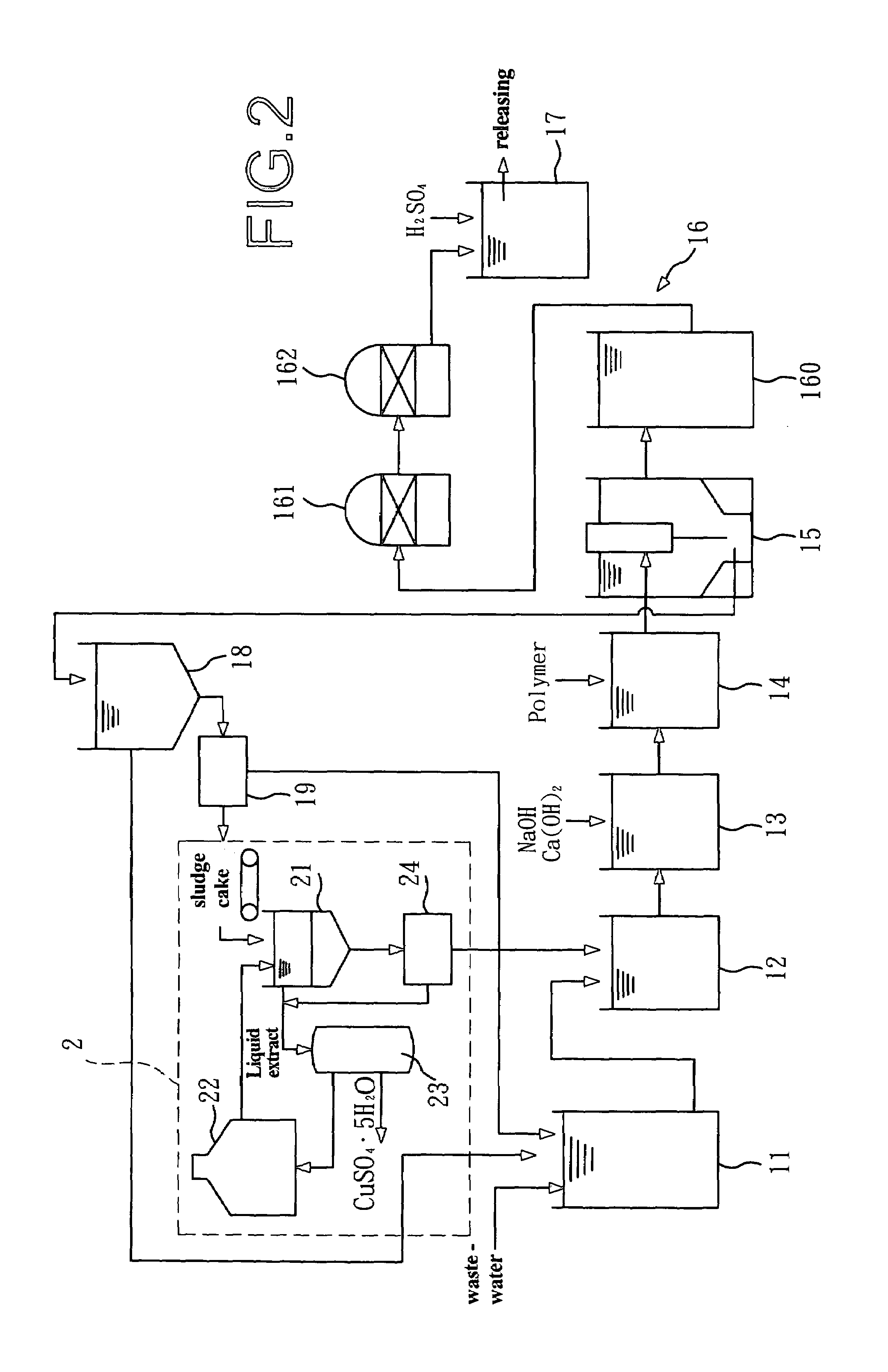

Method for recycling sludge during waste-water treatment

InactiveUS20060278583A1High economic valueEconomic valueSludge treatment by thermal conditioningWater contaminantsSludgeCopper

A method for recycling sludge during waste-water treatment firstly utilizes a process of chemical coagulation to produce sludge rich in copper ions. The sludge is then leached in a sulfuric acid storage tank with sulfuric acid of concentration 1-2N, whereby a extractive solution with copper enrichment 18-39 g / L and residues can be obtained. The extractive solution is then processed in a refrigeration crystallization tank to form copper sulfate crystals. Further, the residues produced are added into the coagulation tank as a coagulant in the process of chemical coagulation for wastewater treatment, thereby achieving a goal of zero sludge production.

Owner:NAT CHENG KUNG UNIV

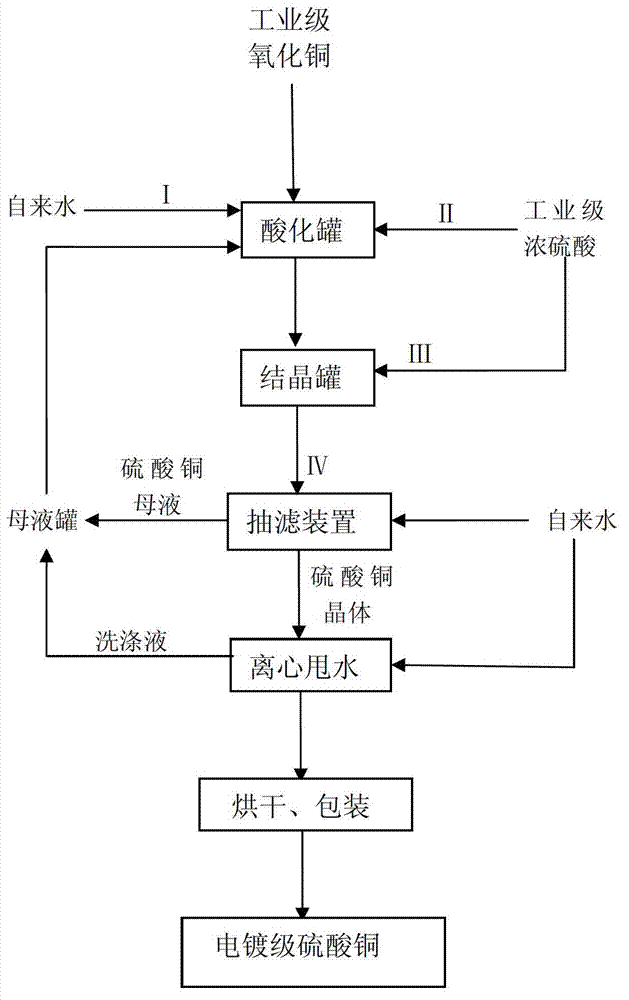

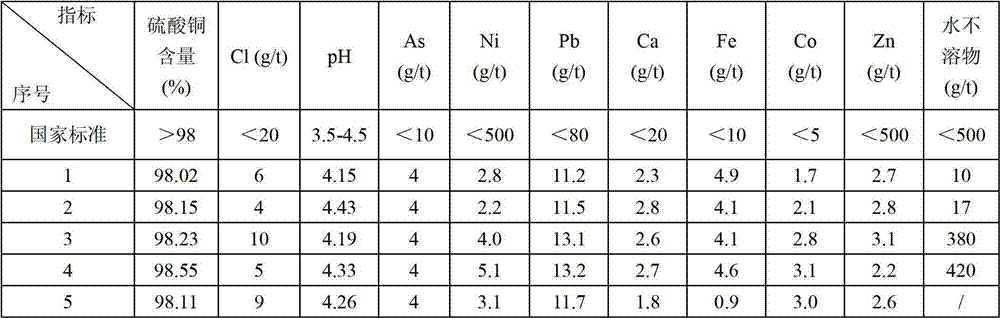

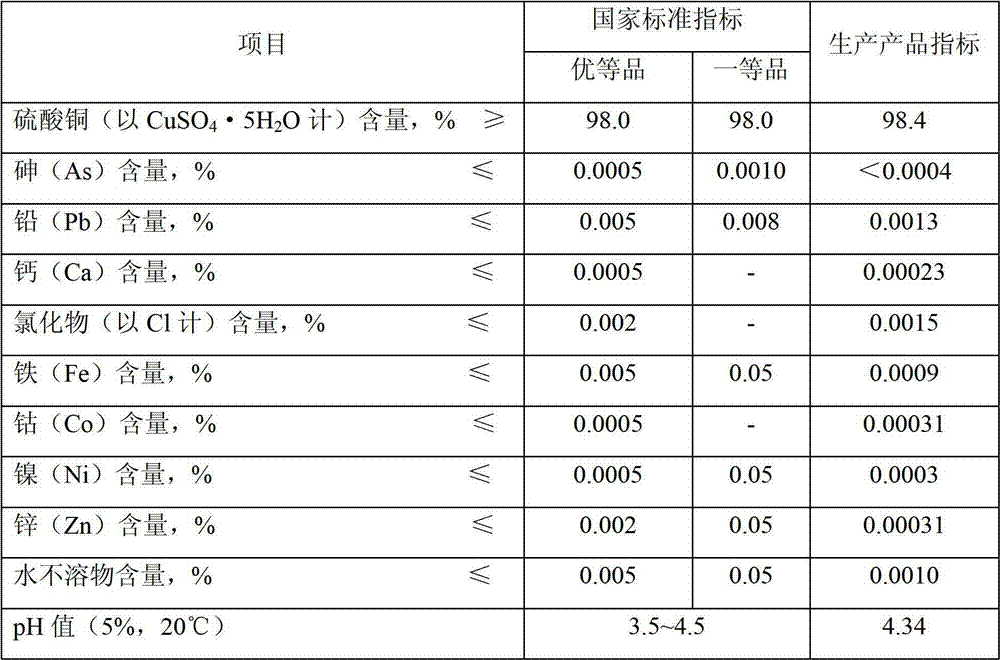

Preparation method of electroplating-grade copper sulfate

ActiveCN102963921ASimple manufacturing methodReduce processing costsCopper sulfatesEconomic benefitsSlurry

The invention relates to a preparation method of electroplating-grade copper sulfate. The preparation method comprises the following steps: step I: mixing water with industrial-grade copper oxide according to the weight ratio of 3.4-3.7: 1 and beating to form mixed slurry; step II: adding acid liquor into the mixed slurry for acidification; regulating the pH of the mixed slurry to 1-2, and stirring and reacting for 1.5-3h to form a mixed system; step III: adding the acid liquor to regulate the pH of the mixed system to below 1, and cooling and crystallizing the mixed system; and step IV: performing solid-liquid separation on the mixed system to get a copper sulfate crystal. The preparation method disclosed by the invention has the advantages of simplicity and easiness in operation and low treatment cost; and produced electroplating-grade copper sulfate is very low content of impurities, is completely in line with a national standard, can be suitable for market demands and further has higher economic benefits.

Owner:深圳市宝安东江环保技术有限公司

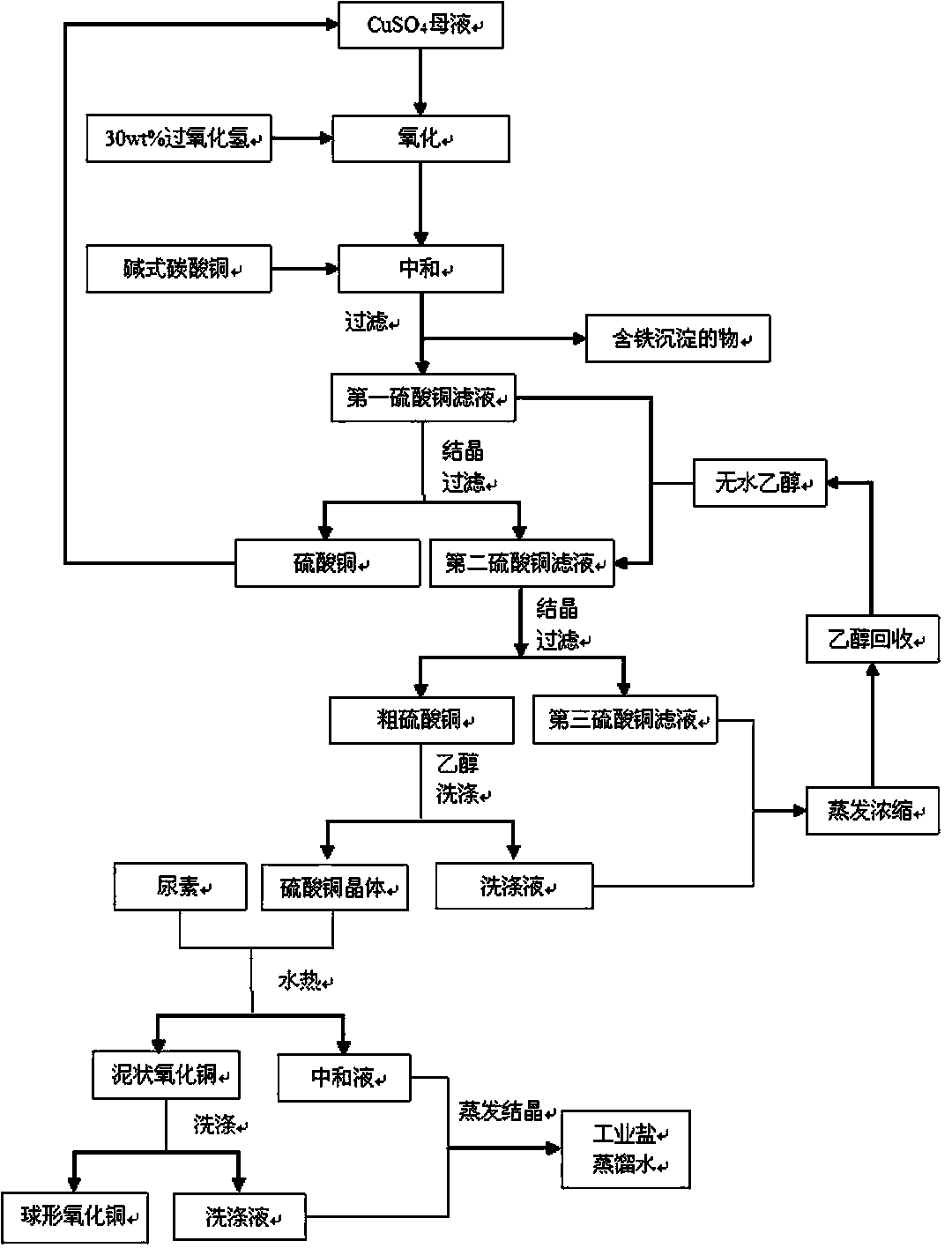

Method for using copper sulfate waste liquid to prepare high-purity spherical copper oxide

A disclosed method for using a copper sulfate waste liquid to prepare high-purity spherical copper oxide is characterized by comprising the following steps: a, injecting 25-35 wt% of hydrogen peroxide into the copper-sulfate-containing waste liquid to perform oxidation; b, adding basic copper carbonate powder into the copper sulfate solution until pH is about 3.5, standing and filtering; c, adding absolute ethanol into the copper sulfate filtrate obtained in the step b according to the volume ratio of 1:50, filtering, then adding absolute ethanol into the filtrate according to the volume ratio of 1:1, crystallizing, filtering, washing with an ethanol solution, and performing spin drying; d, dissolving copper sulfate crystal and urea in distilled water, putting in a hydro-thermal kettle to perform hydro-thermal reaction, so as to obtain copper oxide, and washing; e, drying, sintering, grinding and screening to obtain spherical copper oxide with the purity larger than 99.0%; and f, distilling an ethanol solution generated in the step c to recover ethanol. The method is less in generated wastewater, environment friendly and low in cost.

Owner:广东致卓环保科技有限公司

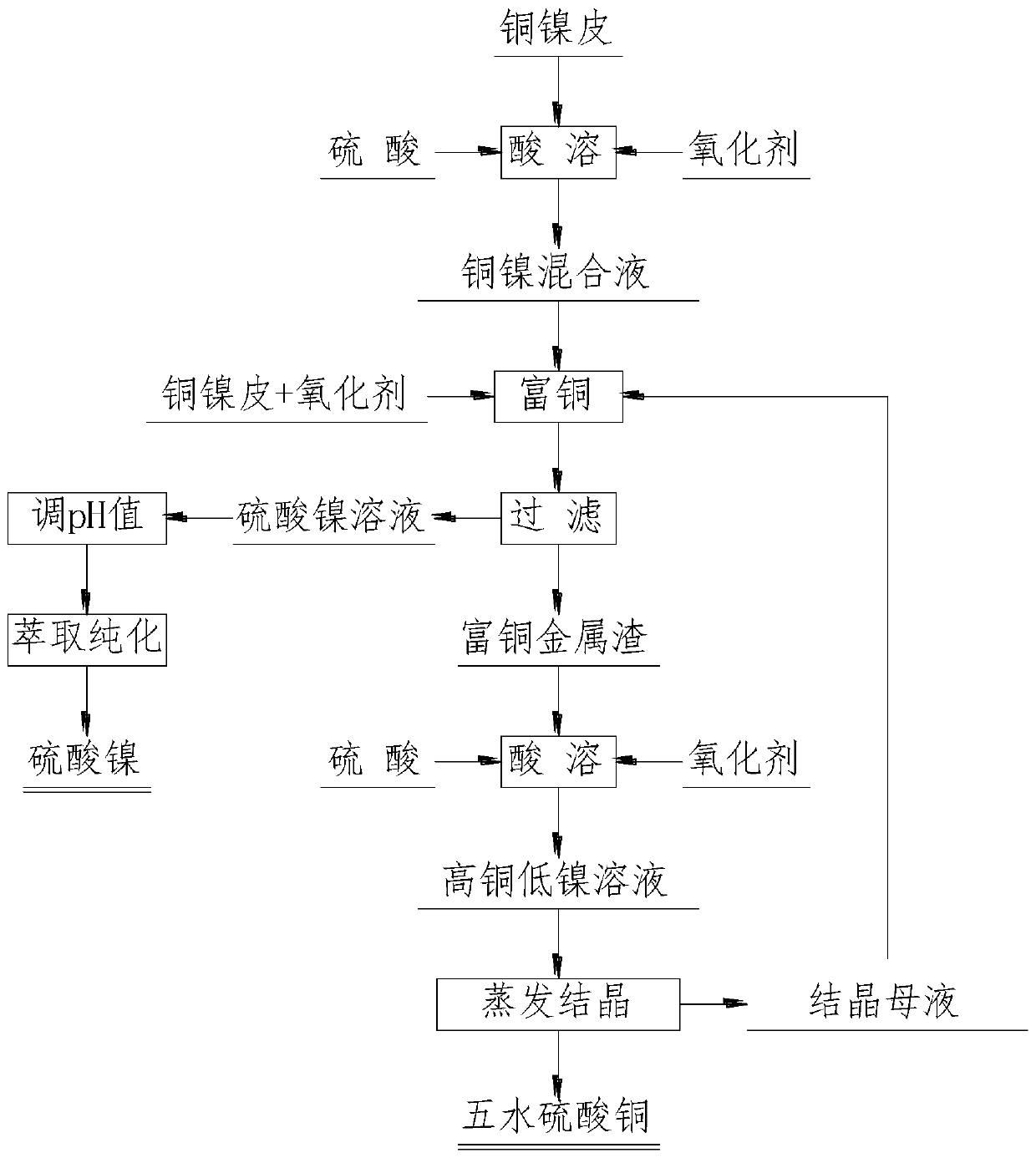

Method for comprehensively treating copper nickel scrap

InactiveCN110510659AShort processReduce energy consumptionNickel compounds preparationNickel sulfatesSlagSolvent

The invention provides a method for comprehensively treating copper-nickel scrap, and the method comprises the following steps: sequentially mixing the copper-nickel scrap with water and sulfuric acid, heating, stirring and adding an oxidant to obtain a mixed solution containing copper and nickel; adding the copper-nickel scrap and an oxidant into the mixed solution containing copper and nickel toobtain a nickel sulfate solution and copper-rich metal slag; adjusting the pH value of the nickel sulfate solution, and performing solvent extraction to obtain a battery-grade product; oxidizing anddissolving the copper-rich metal slag with an acid to obtain a high copper and low nickel mixed solution; evaporating and concentrating the high copper and low nickel mixed solution, crystallizing toseparate out copper sulfate crystals and crystallization mother liquor; reacting the crystallization mother liquor with the copper-nickel scrap; and finally obtaining copper sulfate crystals and a nickel sulfate solution from the copper-nickel scrap. Each index of the copper sulfate crystal product obtained by the method meets the standard level. The method has the advantages of short process flow, low energy consumption, simple industrialization, less impurity removal auxiliary materials and good economic benefits for treating the copper-nickel scrap.

Owner:广西银亿新材料有限公司 +1

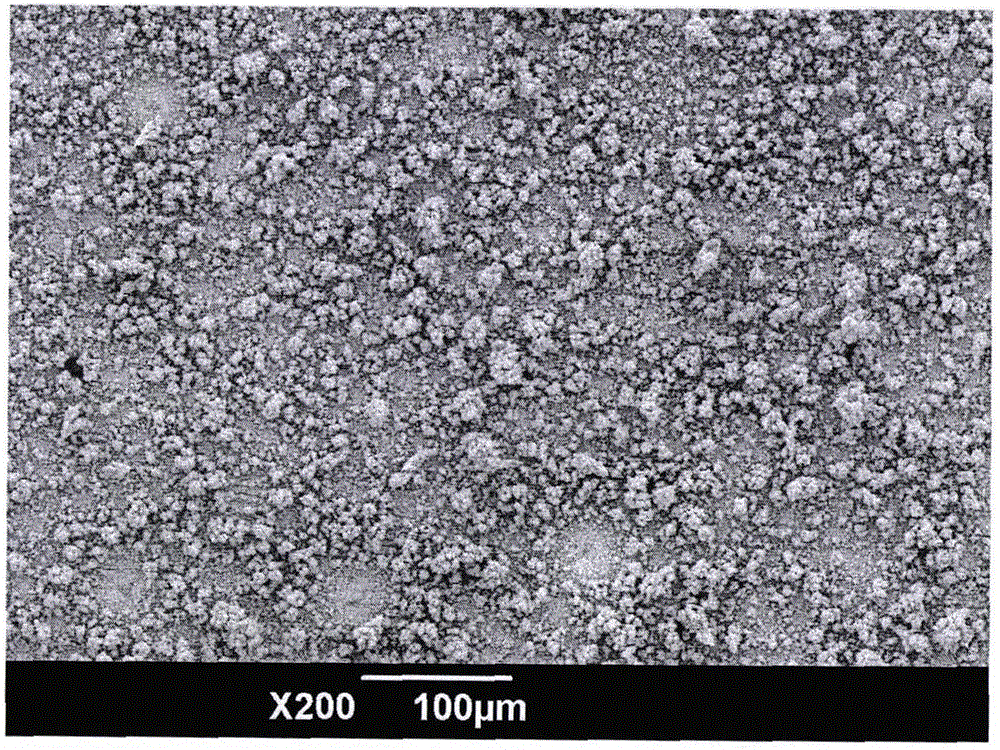

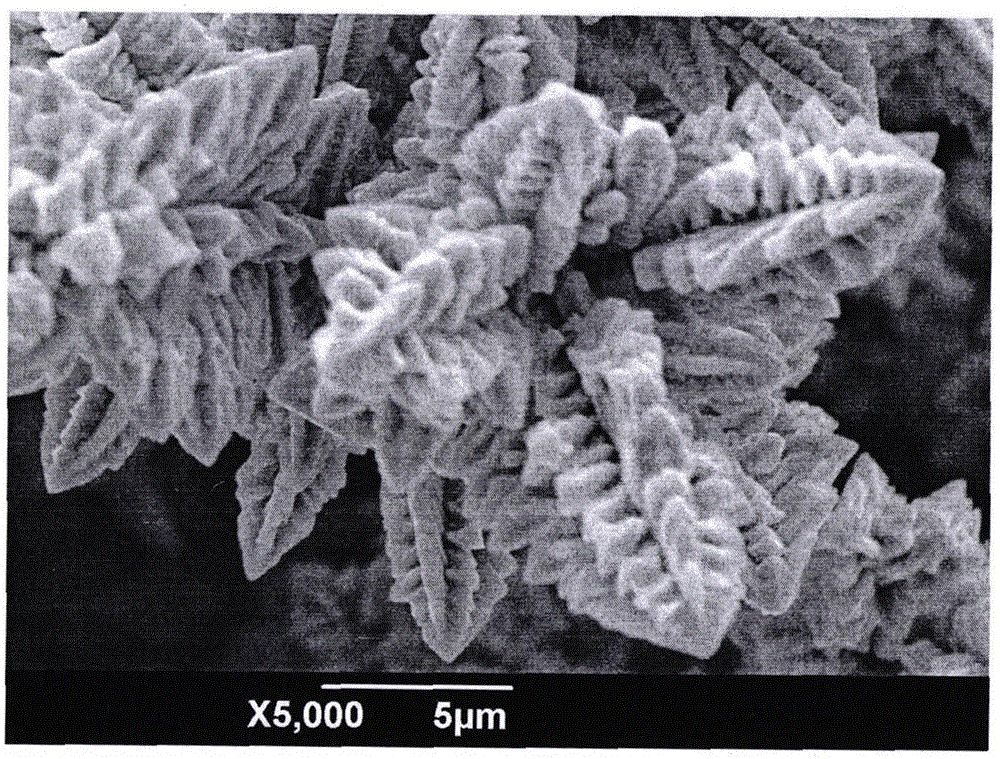

Electrochemical method for preparing super-hydrophobic surface of copper dendritic crystal

The invention discloses an electrochemical method for preparing a super-hydrophobic surface of a copper dendritic crystal. The method comprises the following steps: (1) concentrated sulfuric acid is slowly added in distilled water; and then, a copper sulfate crystal is dissolved in the solution for uniformly stirring to prepare solution A; (2) myristic acid is dissolved in anhydrous ethanol to obtain solution B; (3) oxide layers on the surfaces of two copper substrates are removed, are cleaned by distilled water and anhydrous ethanol in sequence, and are dried for future use; (4) the solution A is put in an electrolytic cell as electrolyte; and the dried two copper substrates are respectively used as an anode and a cathode for electrolysis; and (5) the electrolyzed cathode copper substrate is cleaned by the distilled water and the anhydrous ethanol in sequence; then, the surface of the cleaned cathode copper substrateis uniformly coated by the solution Bfor airing; and then, the surface is lightly wiped by sponge to obtain the super-hydrophobic surface. The super-hydrophobic surface, prepared on the copper substrate by the method, has a contact angle being 152 degrees or above, and keeps stable super-hydrophobic performance after one-year placement under conventional conditions.

Owner:XIAN UNIV OF SCI & TECH

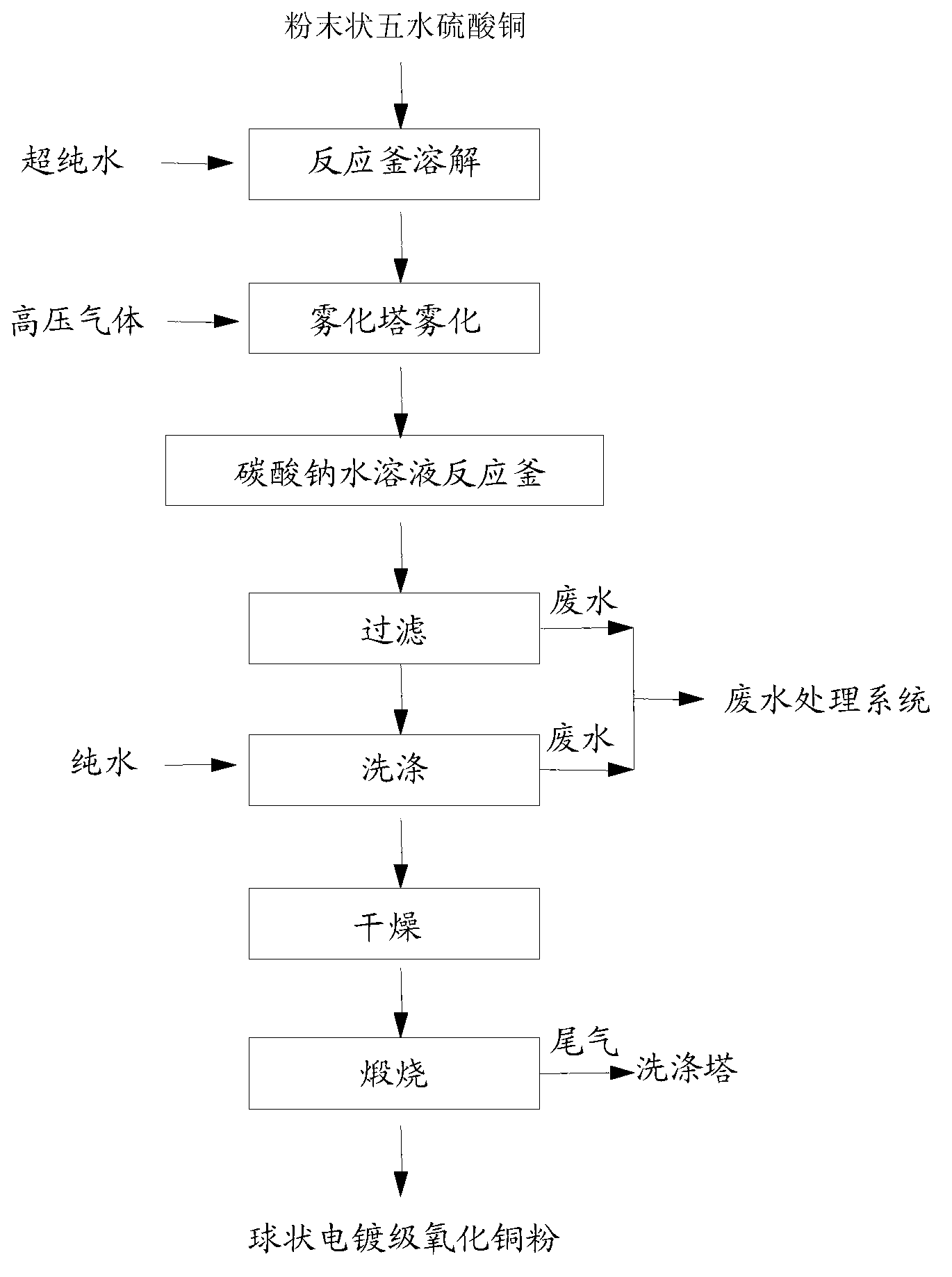

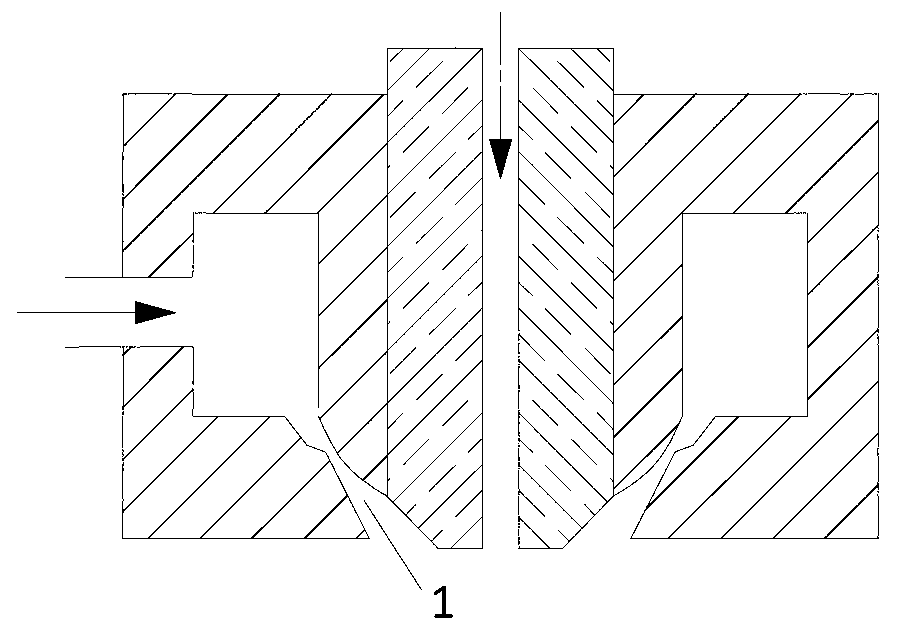

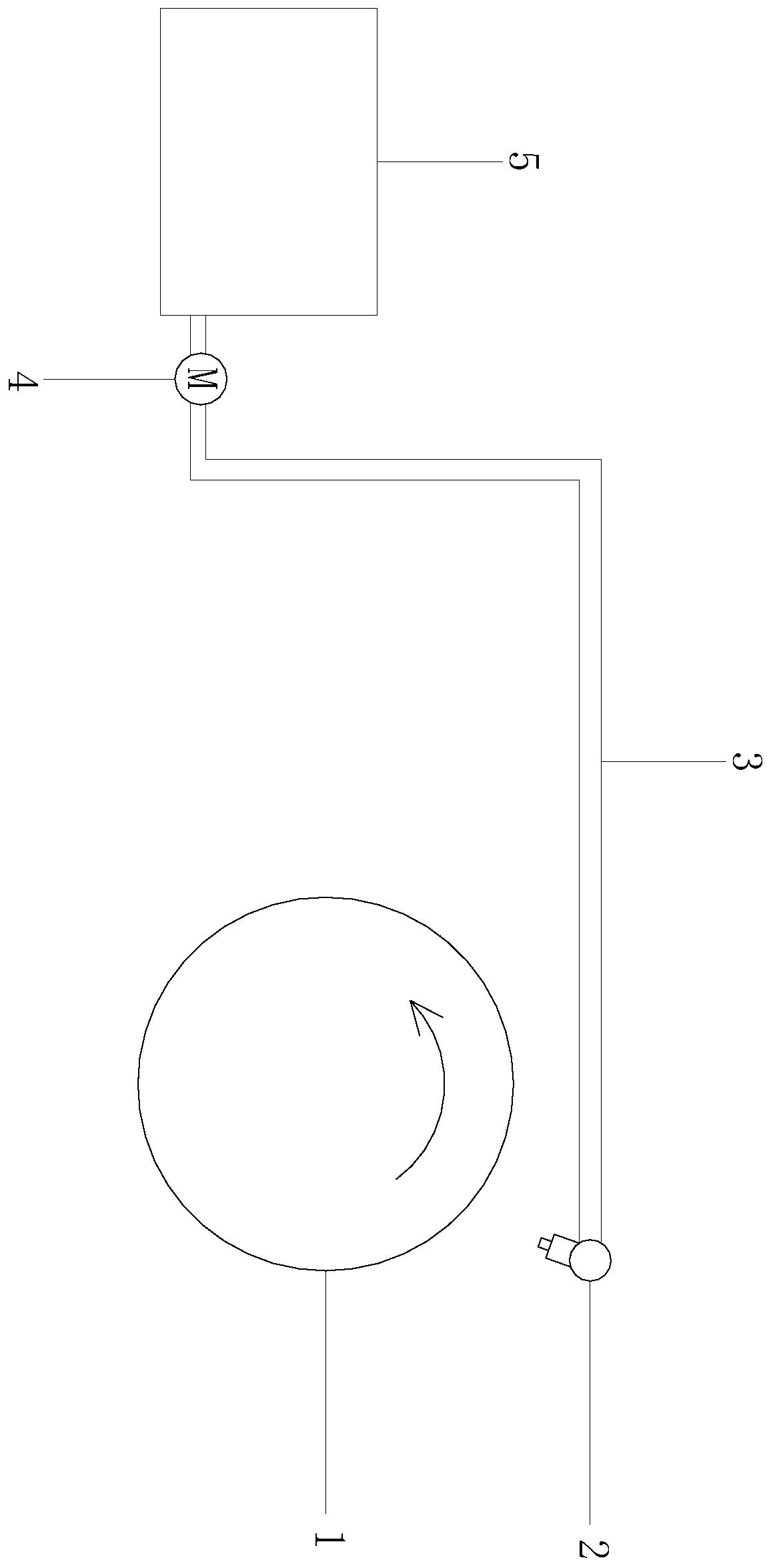

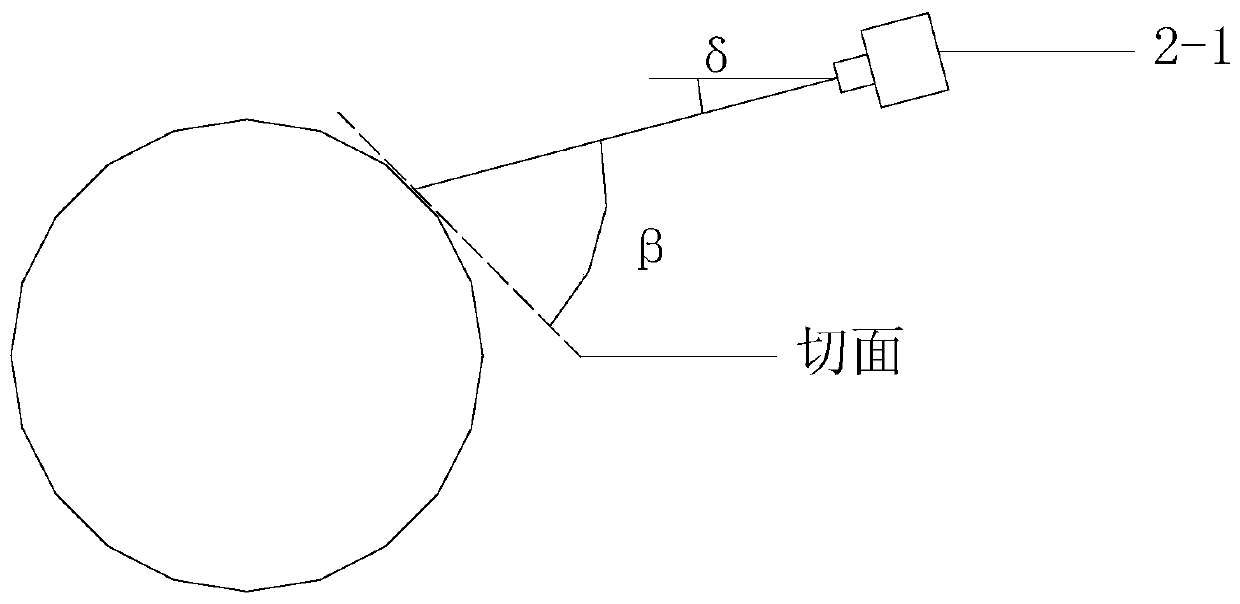

Preparation method of spherical electroplating-level copper oxide powder

InactiveCN103303961ALarge specific surface areaGood dispersionCopper oxides/halidesDispersityBasic copper carbonate

The invention relates to a preparation method of spherical electroplating-level copper oxide powder. The preparation method comprises the preparation steps of: (1) dissolving powdered copper sulfate pentahydrate into super-pure water to prepare a copper sulfate solution; (2) carrying out gas atomization on the copper sulfate solution to form spherical copper sulfate crystal drops; (3) naturally cooling the spherical copper sulfate crystal drops and then directly flowing in a reaction kettle containing a sodium carbonate aqueous solution, controlling the reaction temperature to range from 50 DEG C to 80 DEG C, and reacting for 10min to 20min under the stirring state; (4) filtering, washing and drying reacted materials to obtain spherical basic copper carbonate crystals; and (5) transferring the spherical basic copper carbonate crystals into a calcining furnace for calcining to prepare spherical electroplating-level copper oxide powder. The prepared copper oxide powder is irregularly spherical micro-fine powder, large in specific surface area, good in dispersity, and has the advantages of being high in purity and stable in product performance, and when being applied in electroplating technique, the copper oxide powder can be fast dissolved sufficiently in the electroplating dissolved solution.

Owner:东又悦(苏州)电子科技新材料有限公司

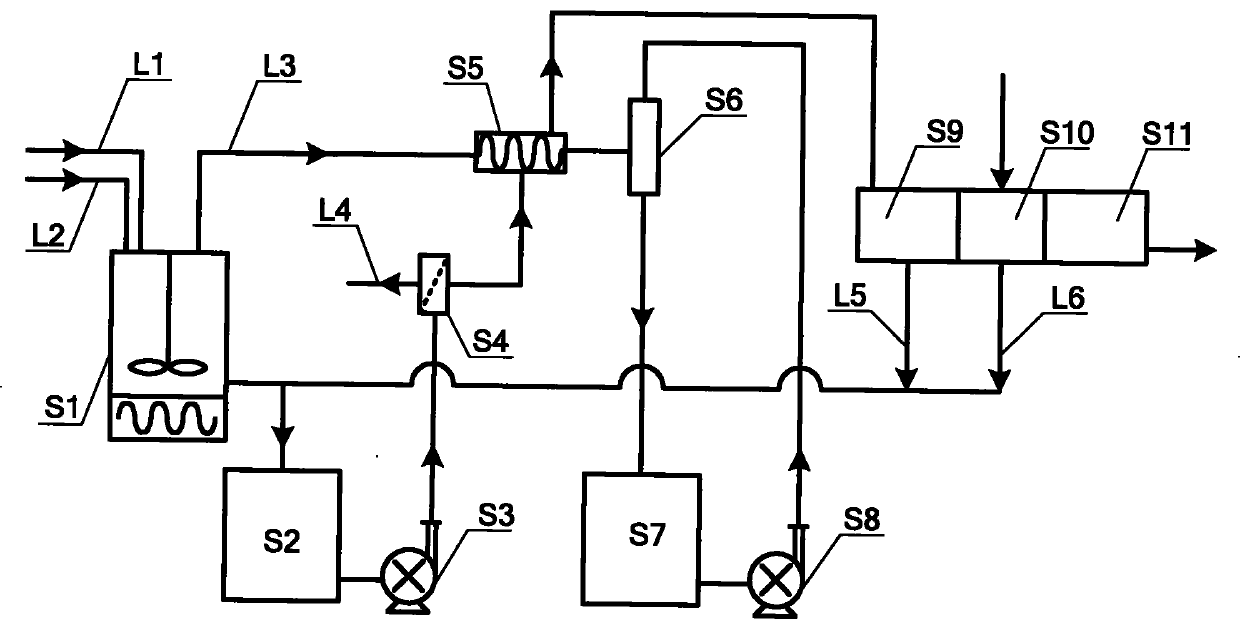

Micro-etching solution cyclic regeneration and copper reclamation device

InactiveCN101988199AReduce pressure on environmental protectionDoes not affect normal workPhotography auxillary processesProcess efficiency improvementElectrolysisEtching

The invention provides a micro-etching solution cyclic regeneration and copper reclamation device, and relates to a device for reclaiming copper from micro-etching waste solution and a regeneration technique for the waste solution in the printed circuit board industry. The micro-etching waste solution is generally repurchased for extracting copper sulfate crystals by a reclamation company in the current industry, and the discharge of the waste solution causes secondary pollution; and high-purity electrolytic copper is reclaimed by electrolysis technology, and the micro-etching solution can be recycled and does not need discharging so as to fulfill the aims of energy conservation, emission reduction and clean production.

Owner:章晓冬

Process for producing cathode copper by low-grade anode plates

ActiveCN109628954ARaise the gradeFlat surfacePhotography auxillary processesElectrolysis componentsElectrolysisEthyl acetate

The invention relates to a process for producing cathode copper by low-grade anode plates. Low-grade high-nickel tin black copper is used as raw materials for direct electrolysis refining to prepare qualified cathode copper; through such modes as adjustment of process conditions, selection of reasonable current density, flow and temperature, adjustment of the additive ratio and adding of modifiedpolyacrylamide, the obtained cathode copper is higher in grade, smooth in surface, clear and compact in grain, uniform in thickness and beautiful; meanwhile, the purification and replacement period ofelectrolyte is prolonged, so that the production cost is greatly reduced when the recovery rate is increased; anode mud is treated by adopting ethyl acetate and phenolic resins, so that the problem of difficult gold and silver separation of the anode mud due to adding of polyacrylamide is solved, and the daily treatment quantity of the anode mud is increased; and copper sulfate crystal seeds areintroduced to accelerate separation of copper sulfate crystals, so that the recycling rate of metal copper and nickel is improved.

Owner:江西新金叶实业有限公司

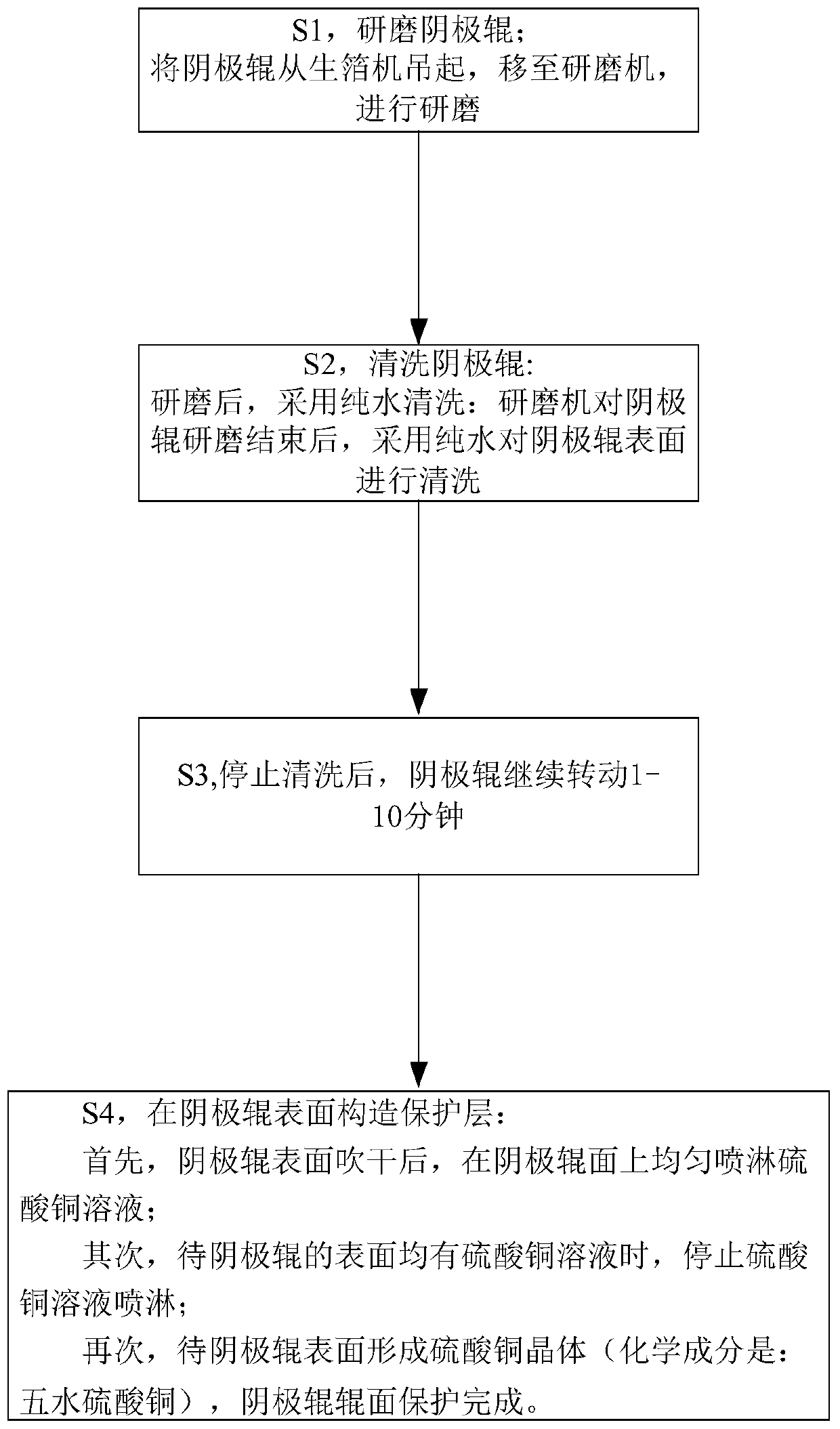

Protection method and device for cathode roller after grinding and application

ActiveCN111334849ASolve protection problemsInsulate the airPolycrystalline material growthFrom normal temperature solutionsElectrolysisCopper foil

The invention discloses a protection method and device for a cathode roller after grinding and application. The invention belongs to the technical field of electrolytic copper foil production. The method is technically characterized by comprising the following steps: S1, hoisting a cathode roller from a crude foil engine, and moving the cathode roller to a grinding machine for grinding; s2, aftergrinding, pure water is adopted for cleaning, specifically, after the grinding machine finishes grinding the cathode roller, pure water is adopted for cleaning the surface of the cathode roller; s3, after cleaning is stopped, the cathode roller continues to rotate for 1-10 min; s4, a protective layer is constructed on the surface of the cathode roller; S4, after the surface of the cathode roller is blow-dried, a copper sulfate solution is uniformly sprayed on the surface of the cathode roller; s4-2, stopping spraying the copper sulfate solution when the copper sulfate solution exists on the surface of the cathode roller; and S4-3, after copper sulfate crystals are formed on the surface of the cathode roller, the roller surface of the cathode roller is protected. According to the protectionmethod and device for the ground cathode roller and the application, the ground cathode roller surface is protected, and therefore various properties of the electrolytic copper foil are guaranteed.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

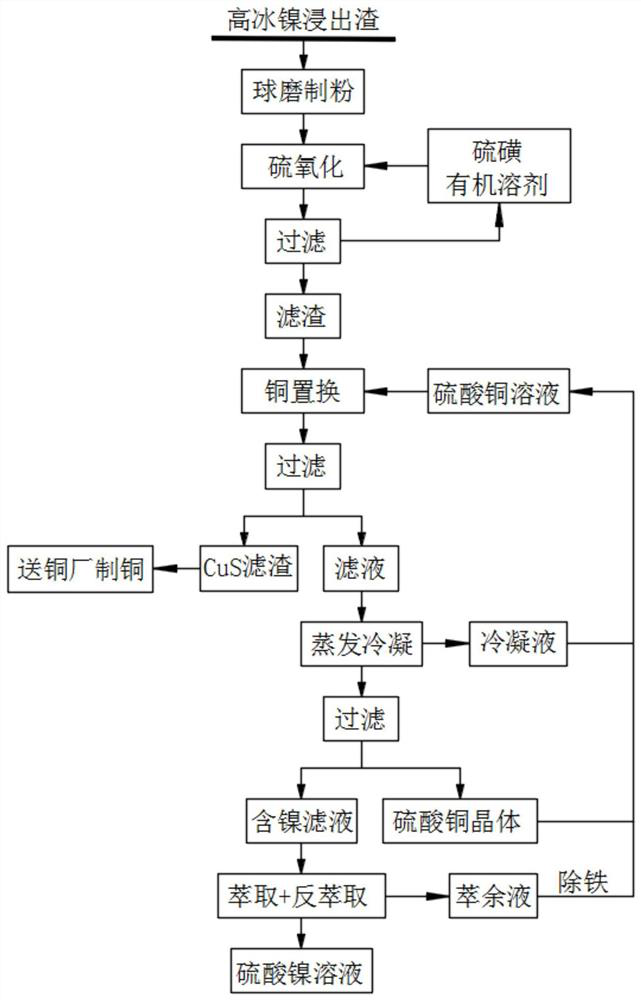

Method for extracting nickel from high-grade matte nickel leaching residues

ActiveCN113755698AIncreased copper contentConducive to smeltingProcess efficiency improvementCopper sulfatesOrganic solventPhysical chemistry

The invention discloses a method for extracting nickel from high-grade matte nickel leaching residues. The method comprises the following steps of firstly, adding a crushed material of the high-grade matte nickel leaching residues into an organic solvent dissolved with sulfur, heating for reaction, carrying out solid-liquid separation to obtain first filtrate and first filter residues, adding the first filter residues into a copper sulfate solution, heating for reaction, carrying out solid-liquid separation to obtain second filtrate and second filter residues, carrying out evaporation condensation concentration on the second filtrate, and filtering to obtain copper sulfate crystals and nickel-containing filtrate. According to the method, Cu2S, Ni3S2, CuFeS2, a nickel-iron-copper alloy and the like in the high-grade matte nickel leaching residues are oxidized into CuS, NiS and FeS by utilizing the oxidability of elemental sulfur in the organic solvent, the elemental sulfur in the high-grade matte nickel leaching residues is dissolved in the solvent in the presence of the organic solvent, then NiS and FeS are replaced by more insoluble CuS by adopting a copper sulfate solution, nickel ions and ferrous ions enter the solution, and the copper content in the leaching residues is further improved. Only a small amount of sulfur and copper sulfate are consumed in the whole reaction, and the organic solvent can be recycled.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Antibacterial-enhanced aqueous aluminum pigment with zinc oxide/silver compound powder

InactiveCN106221309AImprove corrosion resistanceGood dispersionAntifouling/underwater paintsInksTalc / Zinc OxideDibenzoyl Peroxide

The invention discloses an antibacterial-enhanced aqueous aluminum pigment with zinc oxide / silver compound powder. The antibacterial-enhanced aqueous aluminum pigment is characterized by being prepared from the following raw materials in parts by weight: 40 to 45 parts flaky aluminum powder, 100 to 110 parts of isopropyl alcohol, 0.3 to 0.35 part of copper sulfate crystal, a proper amount of deionized water, 4 to 4.5 parts of phenolic ether type phosphate, a proper amount of absolute ethyl alcohol, 9 to 10 parts of tetraethoxysilane, 6 to 7 parts of vinyltriethoxysilane, 9 to 10 parts of ammonia water with the weight concentration of 20 percent, 200 to 220 parts of butyl acetate, 5 to 6 parts of crylic acid, 5 to 6 parts of methacrylic acid, 0.6 to 0.65 part of dibenzoyl peroxide, 13 to 15 parts of propylene glycol monomethyl ether, 2 to 3 parts of zirconium phosphate, 4 to 5 parts of nano-zinc oxide, 2 to 3 parts of carboxymethylcellulose, 0.8 to 1 part of sodium polyacrylate, 2 to 3 parts of glycerinum and 4 to 5 parts of a silver nitrate solution with the weight concentration of 10 percent. The product disclosed by the invention can be well dispersed in finished products such as an aqueous coating and ink, and is high in antibacterial property.

Owner:HEFEI SUNRISE PIGMENTS

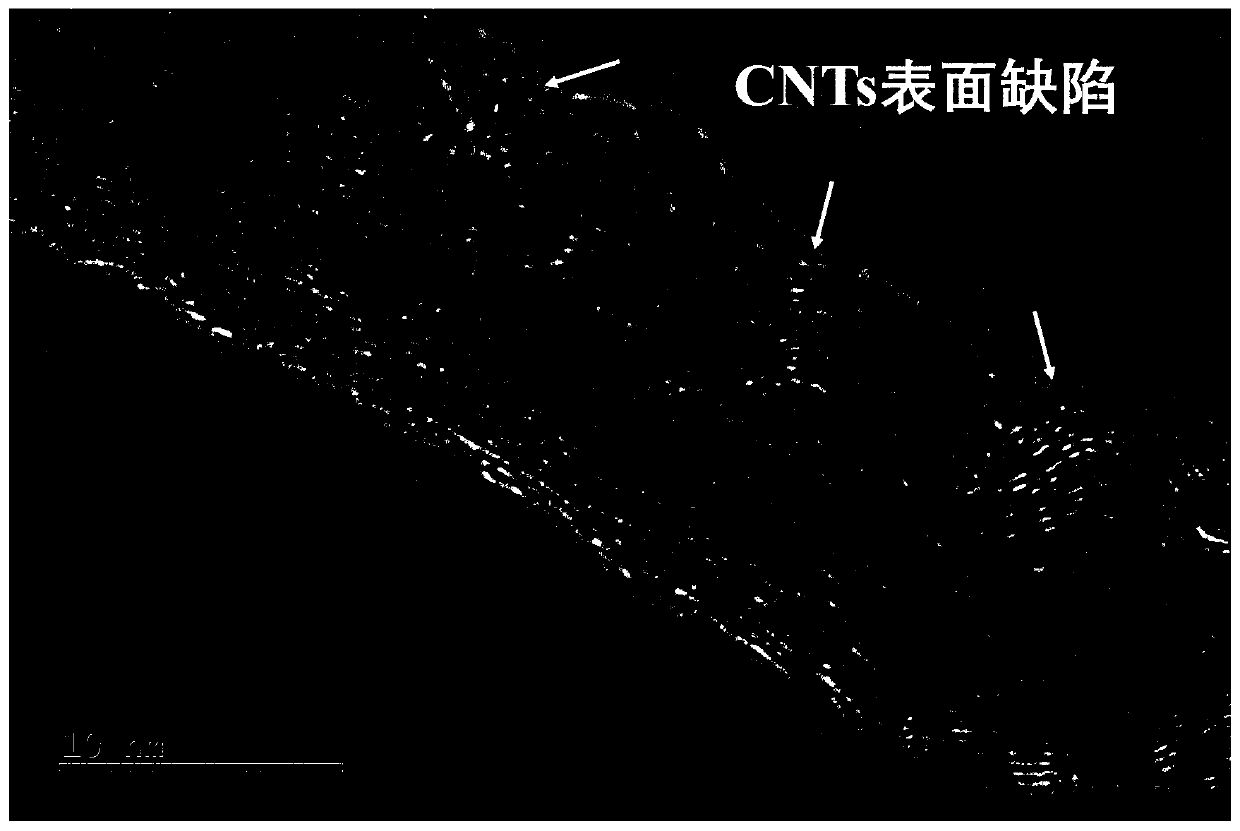

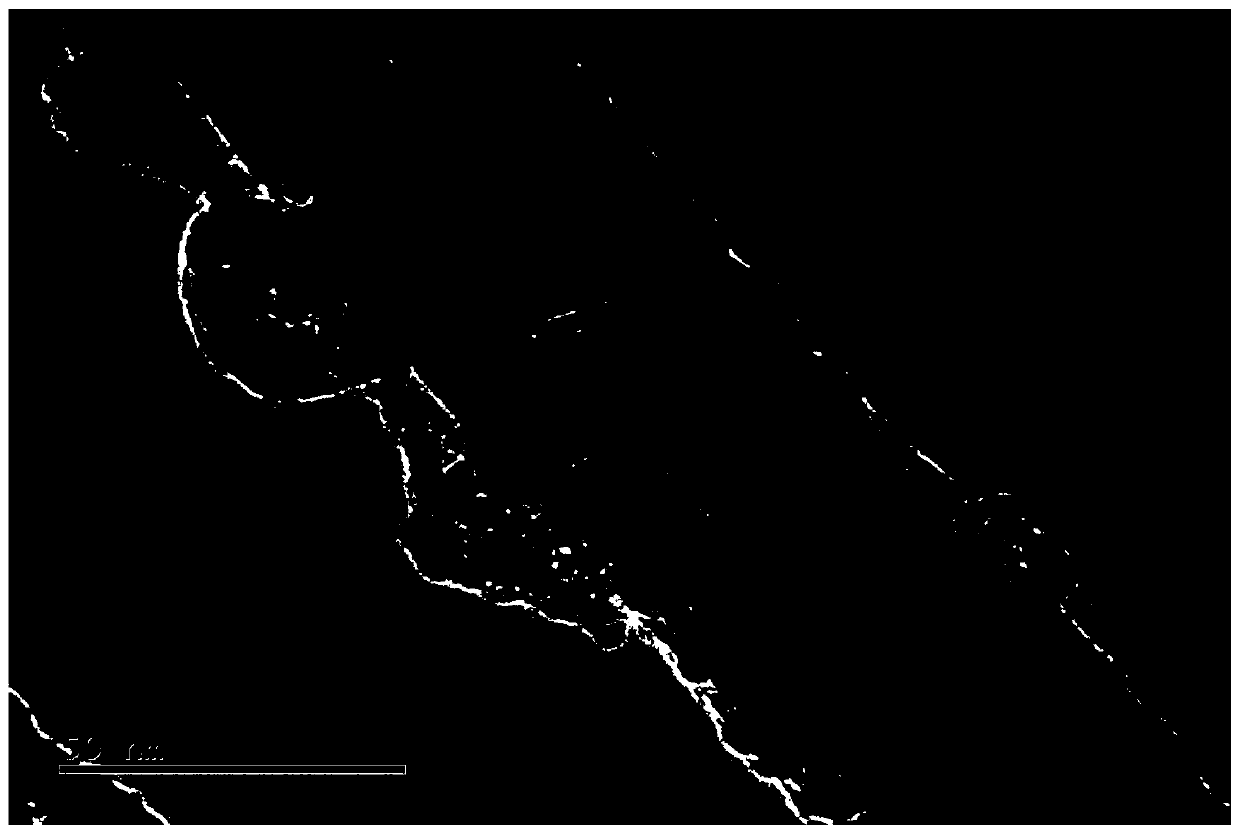

Preparation method for loading copper oxide nanoparticles on surface of in-situ synthesized carbon nanotube

InactiveCN110577209AEnhanced interface bindingNo large-scale shedding occurredCarbon compoundsCopper oxides/halidesFiltrationCopper oxide nanoparticles

The invention relates to a preparation method for loading copper oxide nanoparticles on the surface of an in-situ synthesized carbon nanotube. The preparation method comprises the following steps: (1)preparation of a mixed solution of a carbon nanotube and a copper sulfate crystal; (2) chemical precipitation on the surface of the carbon nanotube to obtain a copper oxide / copper hydroxide mixture:heating the mixed solution of carbon nanotube and copper sulfate to 90-100 DEG C, dropwise adding a sodium hydroxide solution with the concentration of 1-2 mol / L after the mixed solution is heated to90-100 DEG C, carrying out suction filtration and washing on the mixed solution after the reaction is completed, and carrying out drying treatment on mixed powder obtained after suction filtration; and (3) annealing treatment of the mixed powder: putting the dried powder in a muffle furnace for annealing treatment at a temperature of 300 DEG C to 400 DEG C, carrying out heat preservation for 2 h to 3 h, then carrying out cooling to room temperature with the furnace cooling after heat preservation is completed so as to obtain the CuO@CNTs composite material.

Owner:TIANJIN UNIV

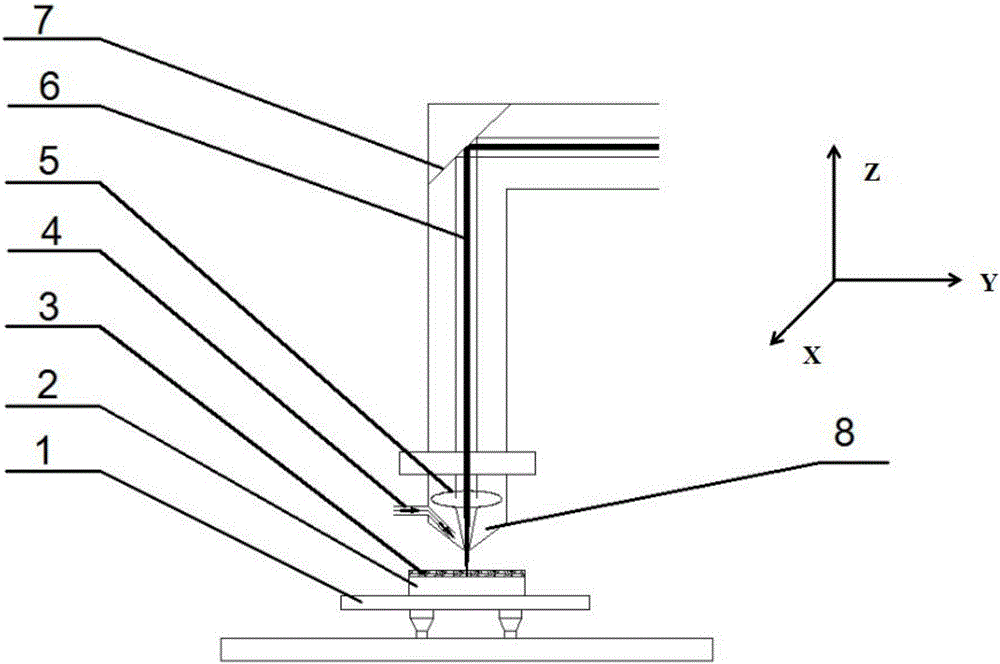

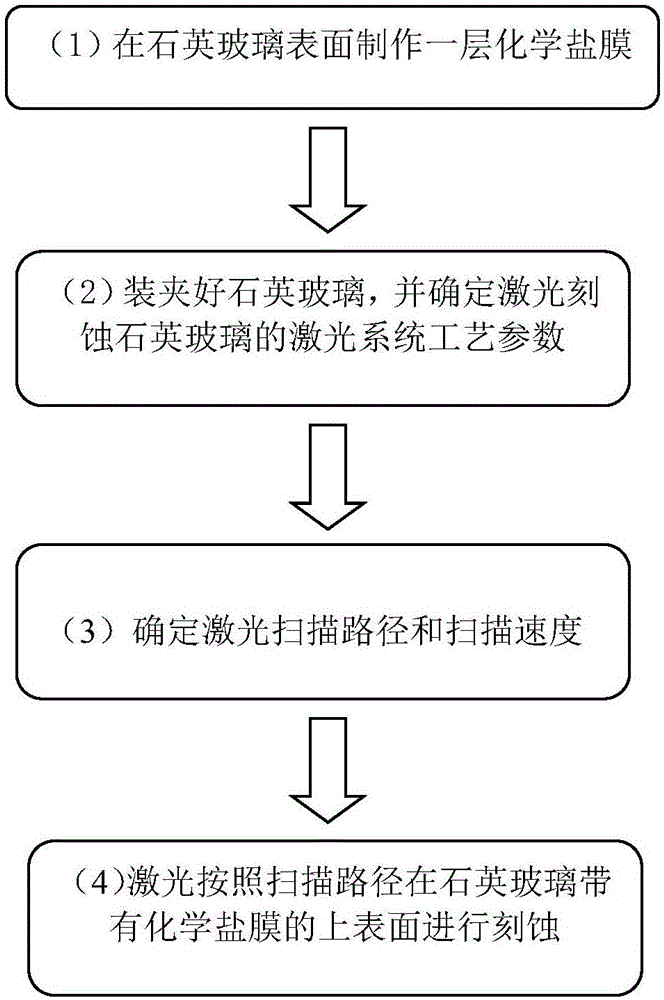

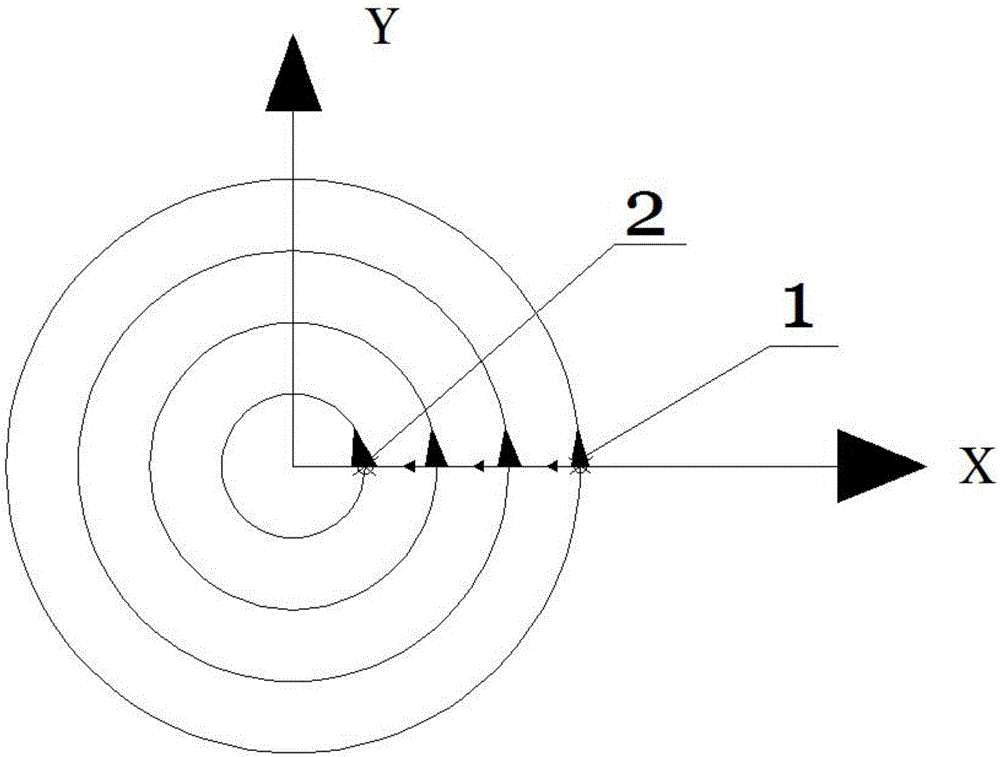

Machining method for etching front surface of silica glass through laser with assistance of chemical salt film

InactiveCN106271091AImprove absorption rateDirect etchLaser beam welding apparatusSlagLaser scanning

The invention provides a method for etching the front surface of silica glass with the assistance of a chemical salt film, belonging to the field of non-traditional machining. The machining method provided by the invention mainly comprises the four steps that (1), the silica glass is heated by an electric heating wire; a saturated copper sulfate solution is slowly added to the surface of the silica glass; copper sulfate crystals are continuously precipitated in the solution on the surface of the silica glass until a layer of very thin and uniform chemical salt film is formed on the surface of the silica glass; (2), the silica glass is clamped on a laser worktable, and laser system technological parameters of laser for etching the silica glass are determined; (3), a laser scanning path and laser scanning speed are determined; and (4), the silica glass of which the surface is provided with the chemical salt film is etched through the laser according to the scanning path. According to the method, laser energy is mainly absorbed by the chemical salt film in an assistant manner, so that a laser beam is prevented from being transmitted through the silica glass, and the laser beam emitted by a solid laser can perform etching on the surface of the silica glass. By adopting the method provided by the invention, obvious slags and edge breakage do not exist on the surfaces of grooves etched on the surface of the silica glass, and the surfaces are smooth and clean; and a good machining effect is reached.

Owner:JIANGNAN UNIV

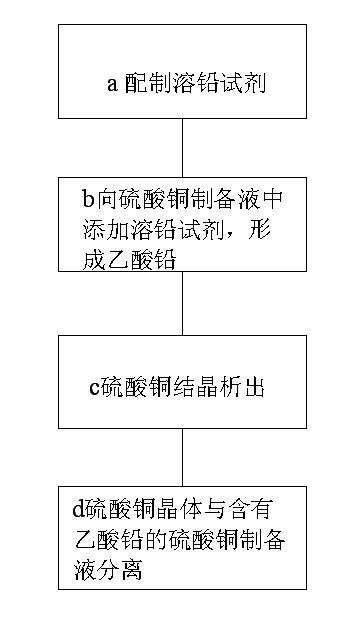

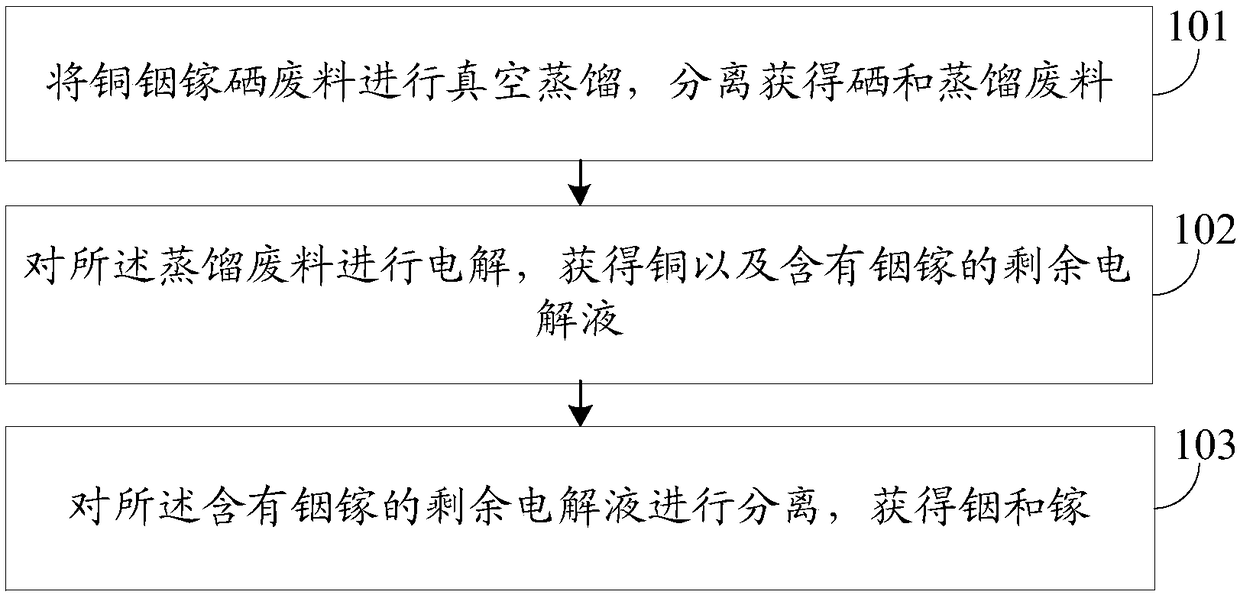

Method for removing lead in cupper sulfate preparation process

The invention discloses a method for removing lead in a cupper sulfate preparation process. The method is characterized by comprising the following steps: a, preparing a lead-dissolving reagent by utilizing acetic acid or one or more water-soluble acetates, wherein the molar weight of acetate in the lead-dissolving reagent is 2 times larger than that of lead in a cupper sulfate preparation solution to be treated; b, adding the lead-dissolving reagent into the lead-containing cupper sulfate preparation solution to be treated so that acetate in the lead-dissolving reagent and lead form soluble lead acetate; c, crystallizing and precipitating out cupper sulfate in the cupper sulfate preparation solution; and d, separating cupper sulfate crystal obtained by crystallization and precipitation from the treated cupper sulfate preparation solution. The method disclosed by the invention has the beneficial effects that the lead-removing process is wide in application range, the lead-removing cost is low, a deep lead-removing effect is good, the quality is stable, the efficiency is high, and equipment dose not need to be added and changed.

Owner:苏州长湖纳米科技有限公司

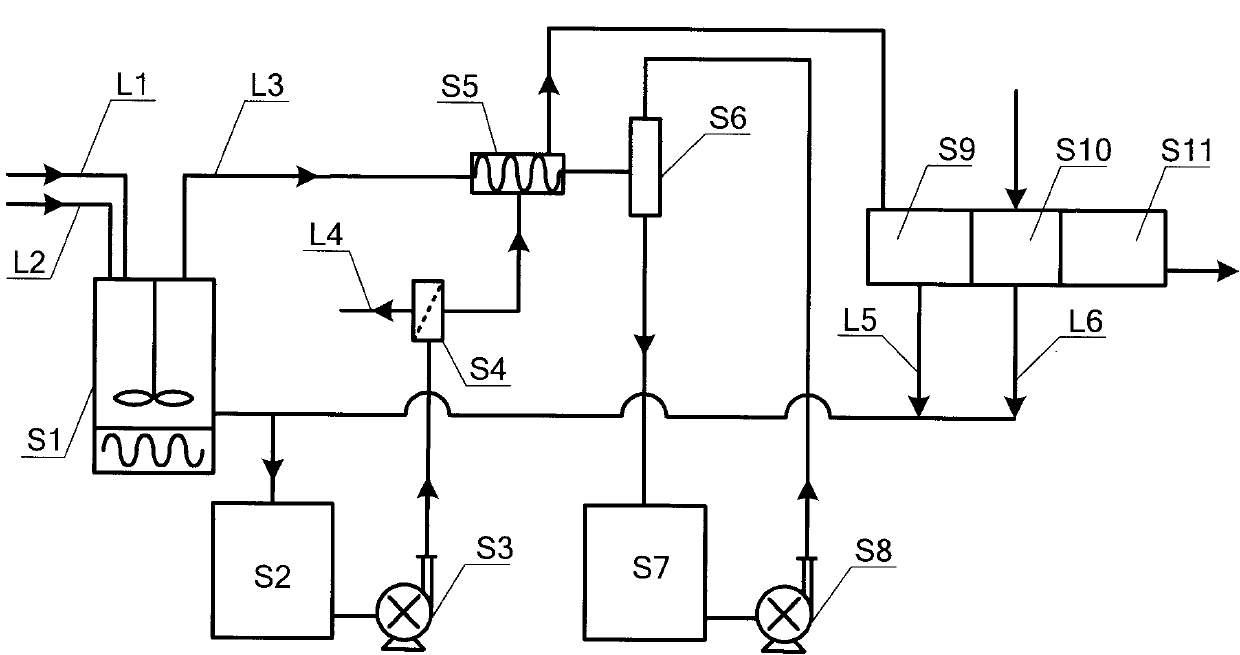

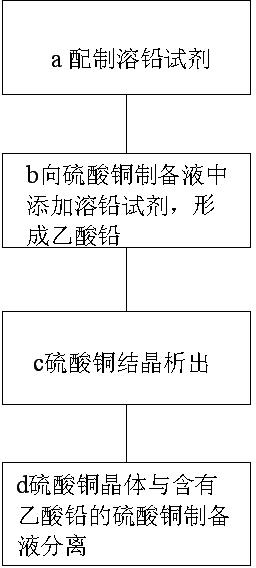

Recycling method and system of PCB (printed circuit board) etching waste liquid

ActiveCN105540975AAvoid secondary pollutionSolve the real problemWaste water treatment from metallurgical processWater/sewage treatment by ion-exchangeCatalytic oxidationProcess engineering

The invention discloses a recycling method and system of a PCB (printed circuit board) etching waste liquid. The method adopts a technical process of diffusion dialysis, catalytic oxidation, bipolar membrane, evaporative crystallization and recrystallization, and comprises the following steps: sequentially passing the acidic chlorine-type copper etching waste liquid through a treatment system composed of a diffusion dialyzer, a catalytic oxidation device, a bipolar membrane dialyzer and an evaporative crystallizer to finally obtain crude copper sulfate crystals, and recrystallizing the crude copper sulfate crystals to obtain the commercially available high-purity copper sulfate. In the meanwhile, the hydrochloric acid separated from the diffusion dialyzer and bipolar membrane dialyzer can be concentrated through a rectification tower or graphite evaporator to obtain the industrial-grade concentrated hydrochloric acid. The technical process can ensure that the acidic etching waste liquid can be converted into the industrial-grade high-purity concentrated hydrochloric acid and high-purity copper sulfate after adding acid once, thereby implementing complete recycling of valuable resources in the waste liquid, achieving the environmental-economical dual benefits, and having favorable application prospects.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

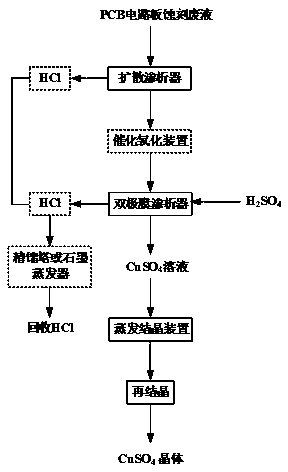

Recovery method of copper-indium-gallium-selenium waste materials

InactiveCN108642290AReduce pollutionEmission reductionPhotography auxillary processesFinal product manufactureRecovery methodIndium

The embodiment of the invention provides a recovery method of copper-indium-gallium-selenium waste materials. The method comprises the steps of performing vacuum distillation on the copper-indium-gallium-selenium waste materials, and separating so as to obtain selenium and distillation waste materials; electrolyzing the distillation waste materials so as to obtain copper and residual electrolyte containing indium and gallium; and separating the residual electrolyte containing indium and gallium so as to obtain indium and gallium. The invention provides a novel recovery idea of the copper-indium-gallium-selenium waste materials, the process is simple, and the environmental pollution of the copper-indium-gallium-selenium waste materials is reduced; a proper amount of copper sulfate crystal and sulfuric acid are added to raffinate so as to prepare copper sulfate electrolyte to continue to be used for electrolyzing and distilling the waste materials so as to obtain copper, so that the flowof the copper sulfate electrolyte forms a closed cycle, the discharge of waste water is reduced, and the environmental pollution is reduced.

Owner:HANERGY NEW MATERIAL TECH CO LTD

Corrosion inhibiting modified double coated thermal-stabilized water-based aluminum pigment

InactiveCN106221310AImprove corrosion resistanceGood dispersionAnti-corrosive paintsPigment treatment with macromolecular organic compoundsWater basedPhosphate

The invention discloses a corrosion inhibiting modified double coated thermal-stabilized water-based aluminum pigment. The corrosion inhibiting modified double coated thermal-stabilized water-based aluminum pigment is prepared from, by weight, 40-45 parts of flaky aluminum powder, 100-110 parts of isopropanol, 0.3-0.35 part of copper sulfate crystals, a proper amount of deionized water, 4-4.5 parts of phenolic ether type phosphate, a proper amount of absolute ethyl alcohol, 9-10 parts of tetraethoxysilane, 6-7 parts of vinyltriethoxysilane, 9-10 parts of ammonium hydroxide with the concentration being 20 wt%, 200-220 parts of butyl acetate, 5-6 parts of crylic acid, 5-6 parts of methacrylic acid, 0.6-0.65 part of dibenzoyl peroxide, 13-15 parts of propylene glycol monomethyl ether, 4-5 parts of aluminum hydroxide, 3-4 parts of antimonous oxide, 0.8-1 part of silane coupling agent KH-550, 1.2-1.5 parts of alkylphenol ethoxylates, 0.5-0.6 part of span-80 and 0.8-1 part of polyethylene wax. A product prepared from the corrosion inhibiting modified double coated thermal-stabilized water-based aluminum pigment can be evenly dispersed in a coating, and high stability is achieved.

Owner:HEFEI SUNRISE PIGMENTS

Environment friendly acid solution for removing copper sheets on titanium and titanium alloy extruded tube blanks

The invention relates to an environment friendly acid solution for removing copper sheets on titanium and titanium alloy extruded tube blanks. The environment friendly acid solution for removing the copper sheets on the titanium and titanium alloy extruded tube blanks is characterized by comprising the following raw materials in percentage by mass: 15-20% of H2SO4, 5-10% of HNO3, 5-10% of H2O2 and the balance of water. By using the environment friendly acid solution for removing the copper sheets on the titanium and titanium alloy extruded tube blanks, provided by the invention, the using amount of the nitric acid is reduced, the using amount of the hydrogen peroxide is increased, brownish red nitric oxide (NO2) as a poisonous gas is prevented from being generated, and excessive cupric ions and nitrate ions are prevented from being generated, and waste gases and waste solutions can meet environment friendliness requirements, so that the environment friendly acid solution has a practical application value; and meanwhile, the economic benefit is increased by recovery of copper sulfate crystal substances, so that the environment friendly acid solution can be widely used by enterprises adopting the conventional technique (sulfuric acid and nitric acid, water or nitric acid and water) through slightly changing the conventional technique and equipment.

Owner:NINGXIA ORIENT TANTALUM IND

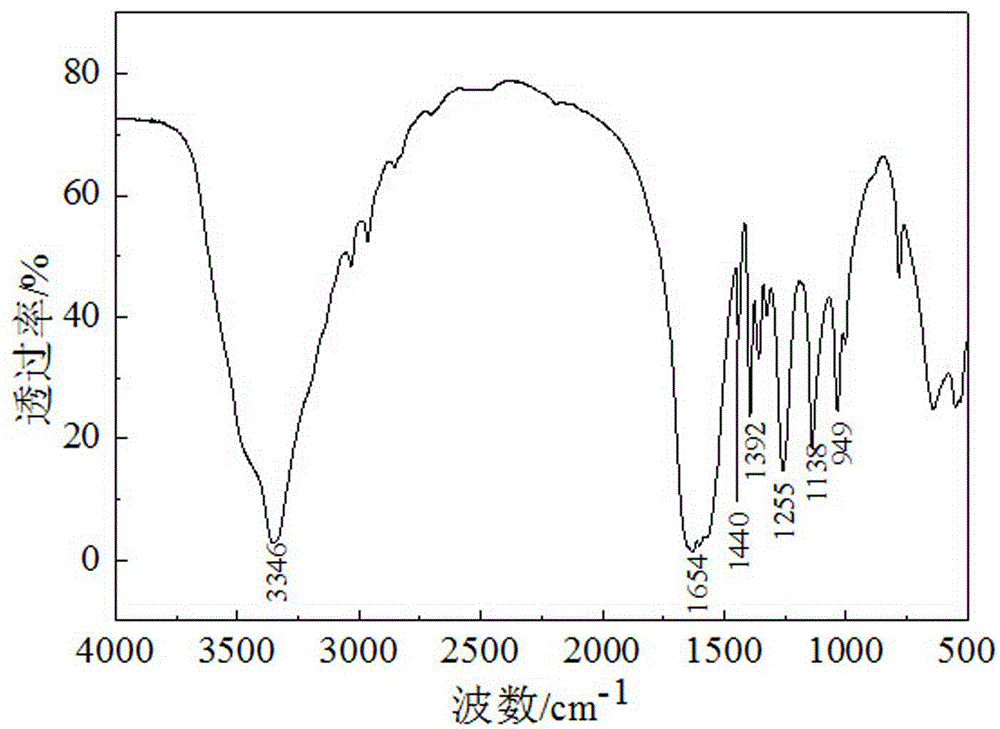

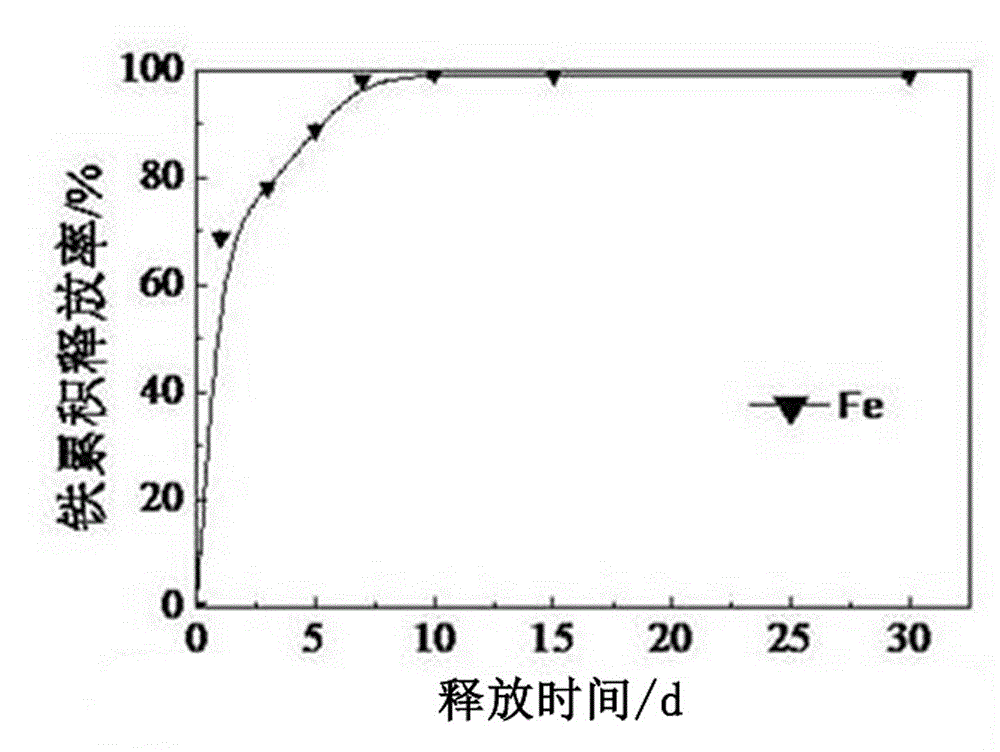

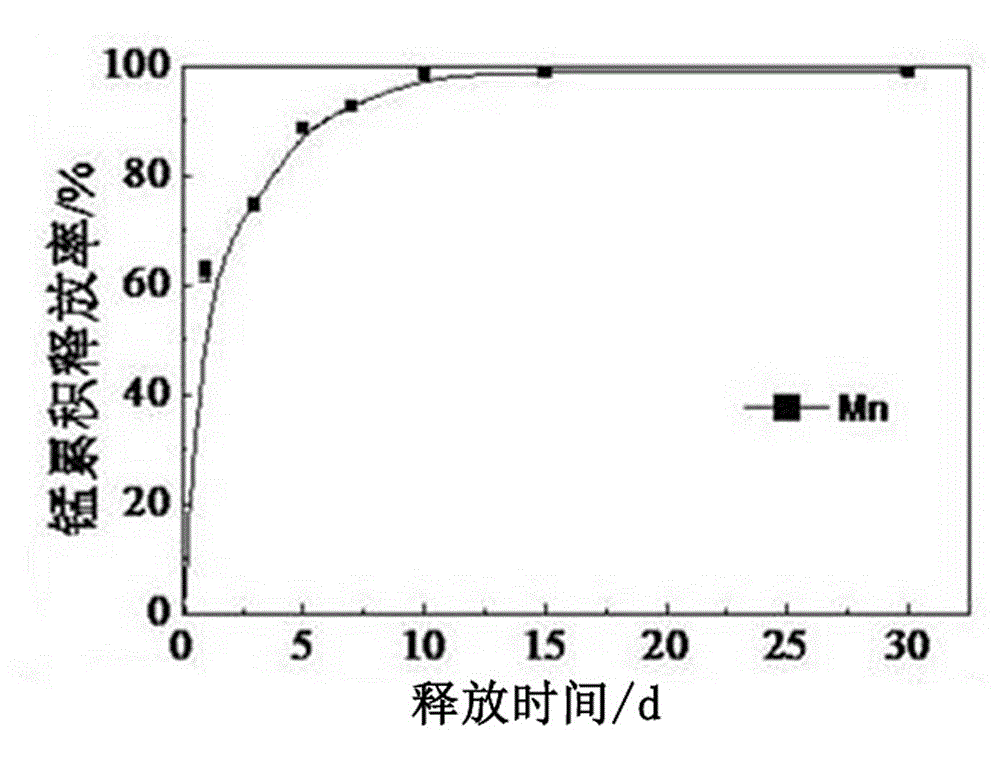

Organic polymer slow-controlled release nitrogen and phosphorus fertilizer containing iron, manganese, copper and zinc microelements and preparation method of organic polymer slow-controlled release nitrogen and phosphorus fertilizer

InactiveCN104557317AIncrease profitGood slow releaseUrea compound fertilisersFertilizer mixturesManganese sulphateO-Phosphoric Acid

The invention discloses an organic polymer slow-controlled release nitrogen and phosphorus fertilizer containing iron, manganese, copper and zinc microelements. The organic polymer slow-controlled release nitrogen and phosphorus fertilizer is prepared by the following steps: stirring and dissolving phosphoric acid and zinc powder in the molar ratio of 27 to 1 to prepare a component A; adding ferrous sulfate, manganese sulfate and copper sulfate crystal to 50mL of distilled water in the molar ratio of 1.9 to 1 to 0.18; adjusting pH to be 8-10, standing and filtering to prepare a component B; adding the component B to the component A to prepare a product C; enabling urea and formaldehyde to react at 30-35 DEG C in the molar ratio of (5:4) to (2:1) for 40-200 minutes when the pH value is 8-10, then heating to 50-60 DEG C, and further reacting for 30-90 minutes; and adding the product C, adjusting the temperature to be 70-100 DEG C, and further reacting for 30-40 minutes, wherein the reaction solution is in a viscous state; pelletizing and drying to obtain the organic polymer slow-controlled release nitrogen and phosphorus fertilizer containing iron, manganese, copper and zinc microelements.

Owner:ZHONGBEI UNIV

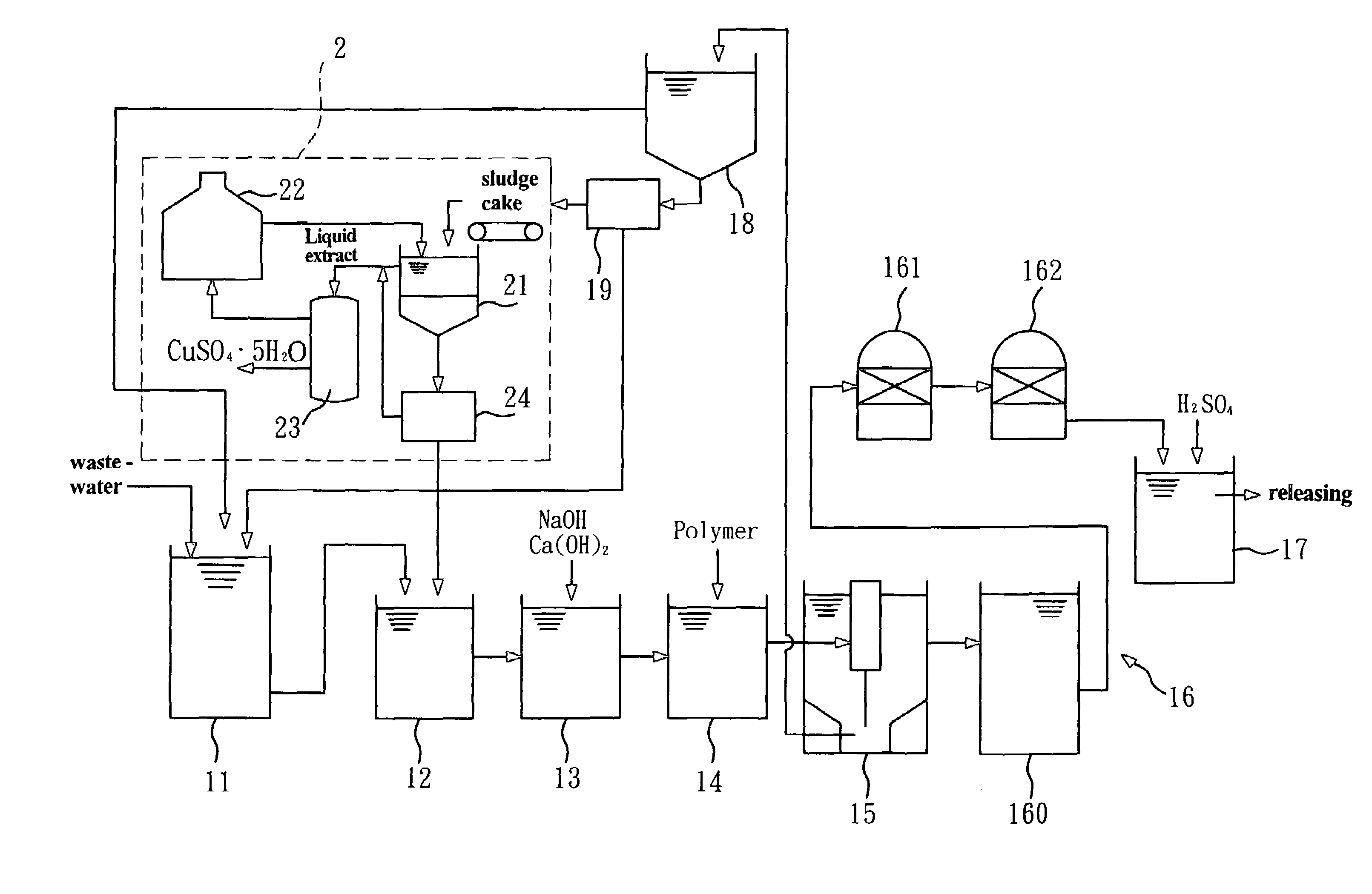

Method for recycling sludge during waste-water treatment

InactiveUS7285222B2High economic valueEconomic valueSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeCopper

A method for recycling sludge during waste-water treatment firstly utilizes a process of chemical coagulation to produce sludge rich in copper ions. The sludge is then leached in a sulfuric acid storage tank with sulfuric acid of concentration 1-2N, whereby a extractive solution with copper enrichment 18-39 g / L and residues can be obtained. The extractive solution is then processed in a refrigeration crystallization tank to form copper sulfate crystals. Further, the residues produced are added into the coagulation tank as a coagulant in the process of chemical coagulation for wastewater treatment, thereby achieving a goal of zero sludge production.

Owner:NAT CHENG KUNG UNIV

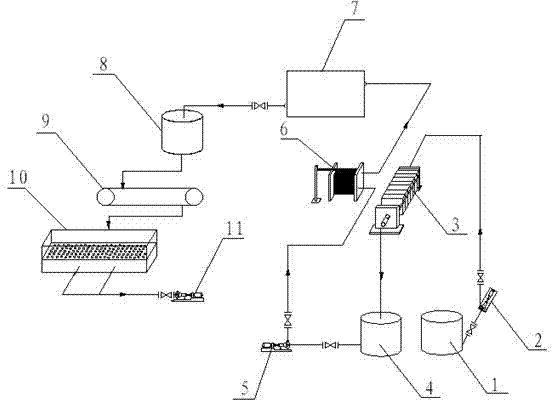

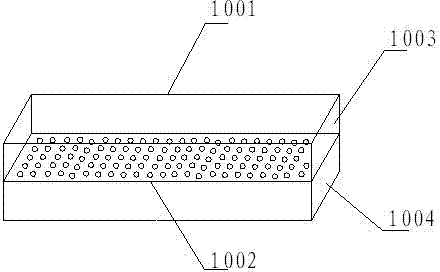

Waste copper sulfate electrolyte purification system and method

InactiveCN103710732ALow impurity contentHigh purityElectrolysis componentsMultistage water/sewage treatmentPurification methodsFiltration

The invention provides a waste copper sulfate electrolyte purification system and a waste copper sulfate electrolyte purification method realized by using the system. The system comprises a waste electrolyte storage tank, a waste electrolyte pump, a plate filter, a waste filtrate storage tank, a waste filtrate pump, a plate heat exchanger, a vacuum evaporator set, a copper sulfate water cooling crystallization tank, a belt filter and a suction filtration tank which are sequentially connected, wherein the suction filtration tank comprises a tank body; the upper part of the tank body is opened; the middle of the tank body is provided with a pore plate; the tank body is partitioned into a material chamber and a suction filtration chamber by the pore plate; filter cloth covers on the pore plate; the suction filtration chamber is connected with a vacuum pump. According to the invention, devices such as the plate heat exchanger and the like are not easy to scale, so that the safety use of the equipment is ensured; meanwhile, waste electrolyte entering the vacuum evaporator set is low in impurity content, so that the purity of a final product is improved; secondary suction filtration is realized by the suction filtration tank, so that the water and acid contents of a copper sulfate crystal product are effectively reduced, and the quality of the product is improved.

Owner:BAIYIN NONFERROUS GROUP

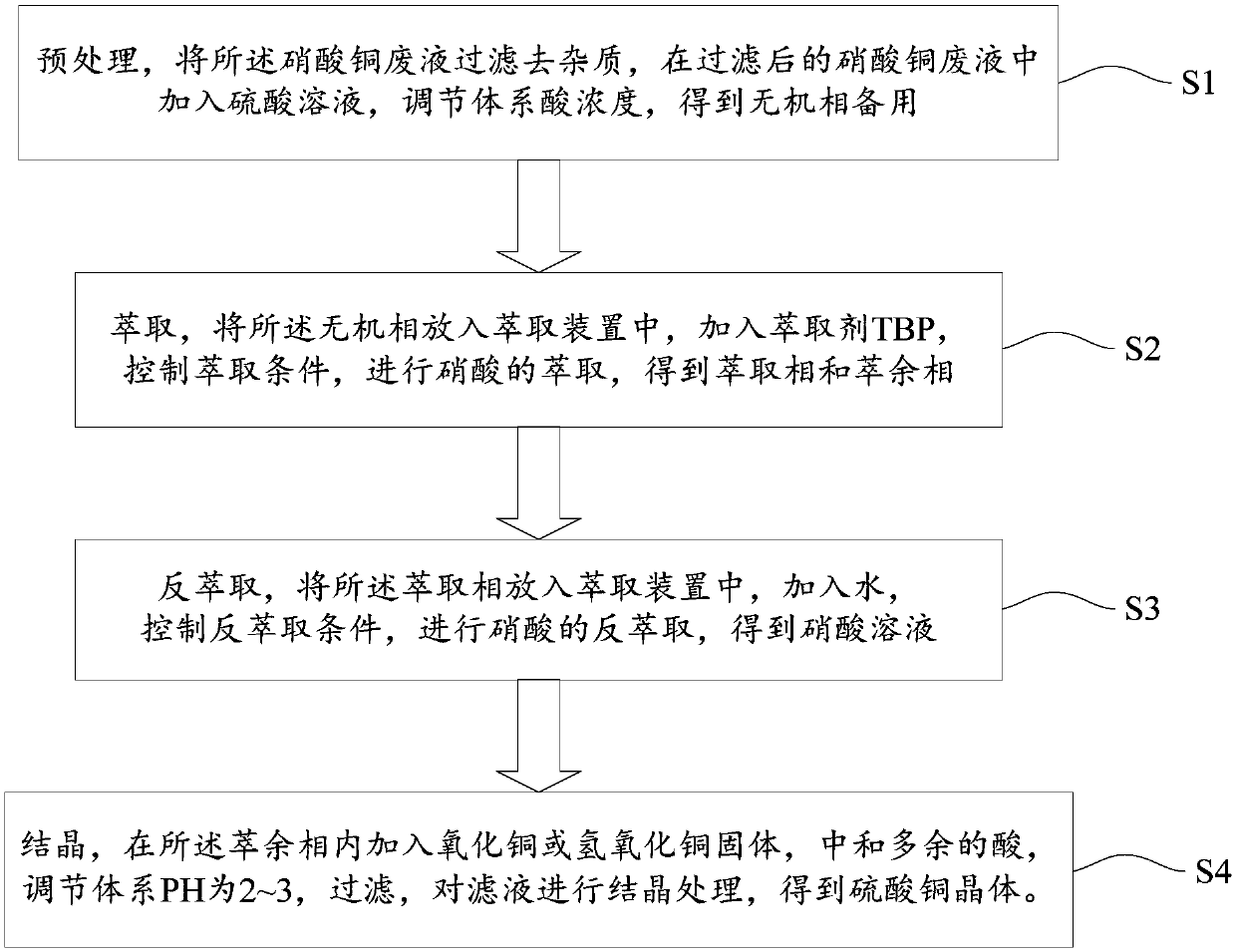

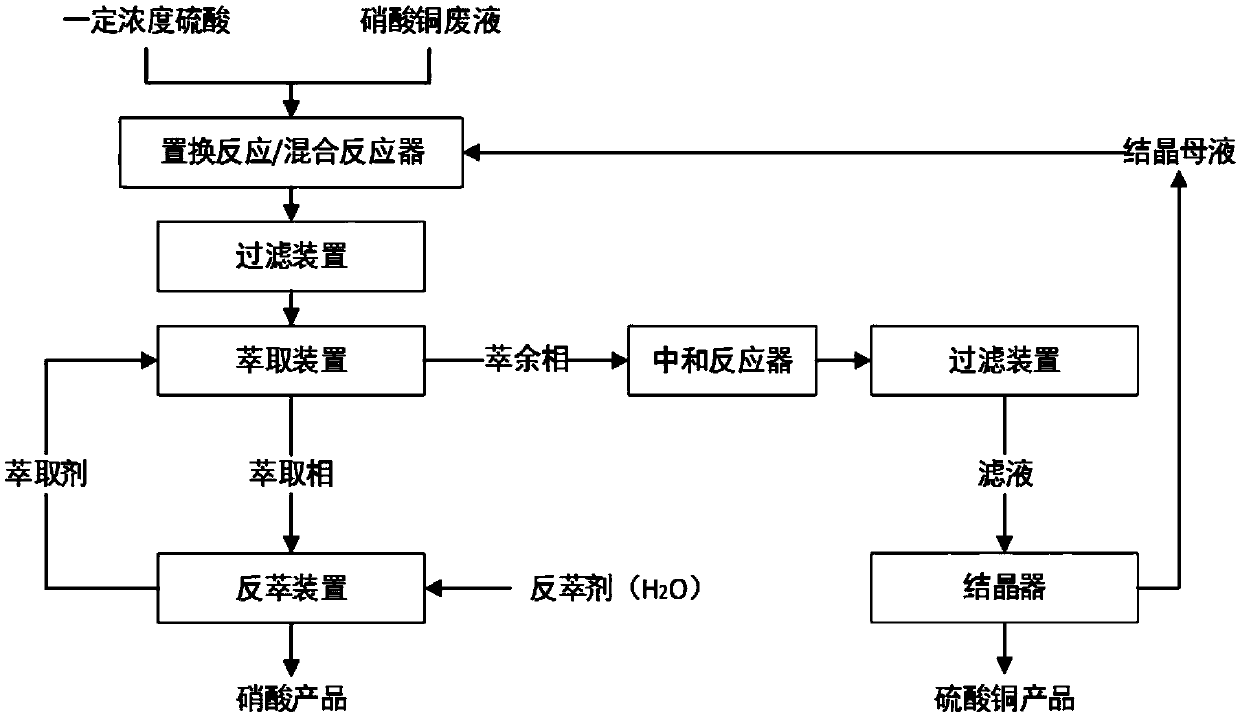

Resource utilization method suitable for PCB deplating waste liquor

ActiveCN109626344AAchieve recyclingIncrease profitCopper sulfatesNitric acidResource utilizationAcid concentration

The invention discloses a resource utilization method suitable for PCB deplating waste liquor. The deplating waste liquor is copper nitrate waste liquor. The method comprises the following steps of pretreatment, wherein the copper nitrate waste liquor is filtered to remove impurities, a sulfuric acid solution is added into the filtered copper nitrate waste liquor, and the acid concentration of thesystem is adjusted to obtain an inorganic phase for use; extraction, wherein the inorganic phase is put into an extraction device, an extraction agent TBP is added, and the extraction condition is controlled for extracting nitric acid to obtain an extract phase and a raffinate phase; back extraction, wherein the extract phase is put into the extraction device, water is added, and the back extraction condition is controlled for back-extracting nitric acid to obtain a nitric acid solution; crystallization, wherein a copper oxide or copper hydroxide solid is added into the raffinate phase to neutralize redundant acid, the pH of the system is adjusted to 2-3, filtering is conducted, a filtrate is crystallized, and then a copper sulfate crystal is obtained. According to the resource utilization method, copper and waste liquor are recycled under normal temperature and normal pressure, the energy consumption is lowered, the waste of resources is avoided, the environmental pollution is prevented, and the production cost is lowered.

Owner:深圳星河环境股份有限公司

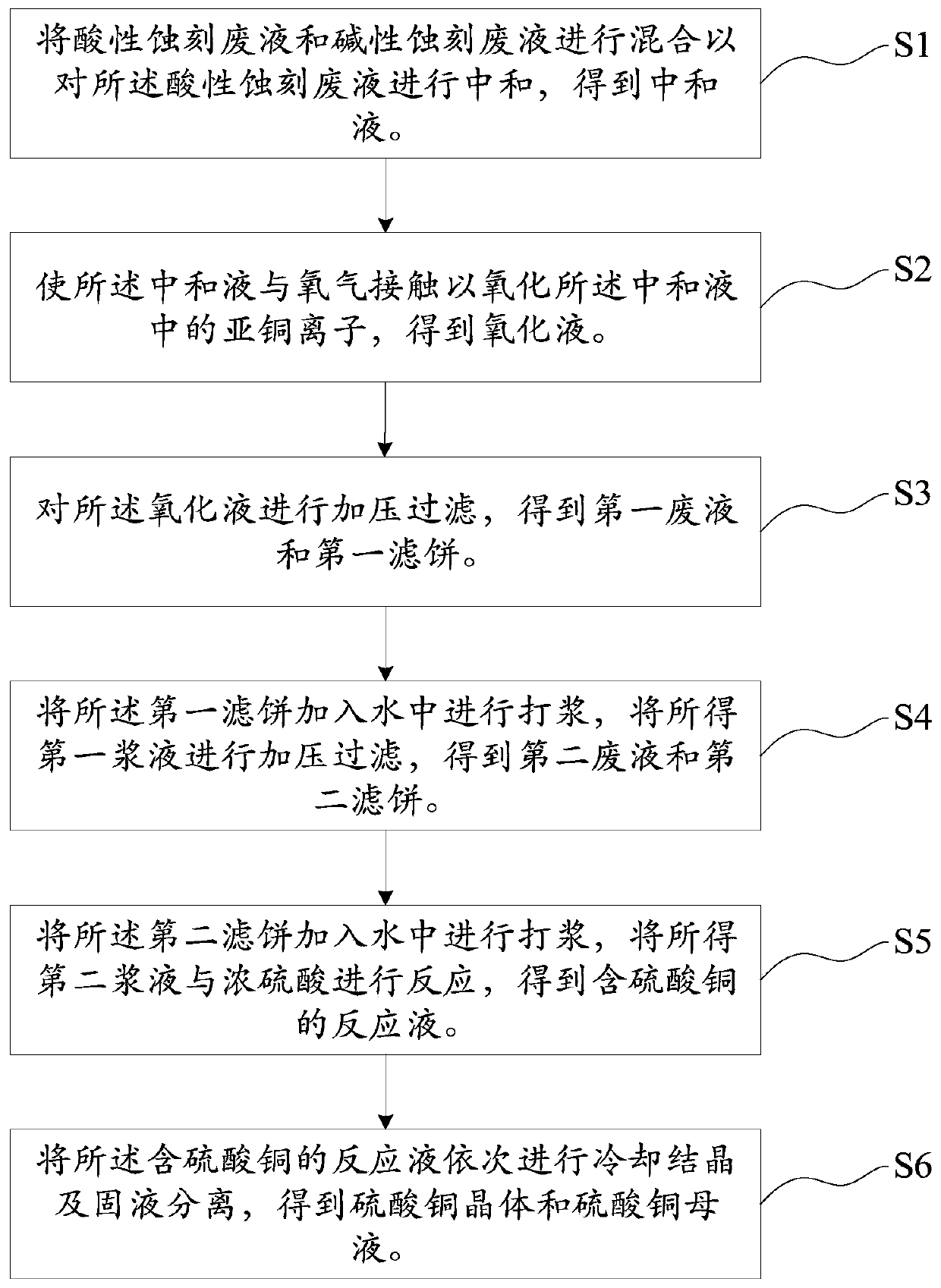

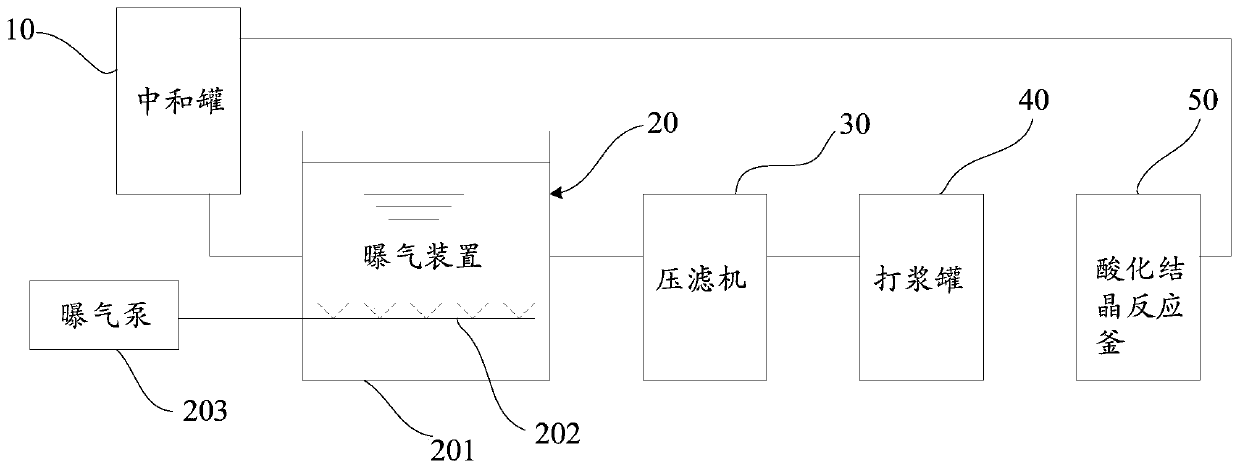

Method and system for treating copper-containing etching waste liquid

ActiveCN110357142AHigh recovery rateReduce concentrationCopper sulfatesCopper chloridePhysical chemistry

The invention relates to the technical field of wastewater treatment, and provides a method and system for treating a copper-containing etching waste liquid. The method comprises the following steps:mixing an acidic etching waste liquid with an alkaline etching waste liquid to obtain a neutralized liquid; contacting the neutralized liquid with oxygen to obtain an oxidizing liquid; performing pressure filtration on the oxidizing liquid; beating the above obtained first filter cake, and carrying out pressure filtration on the above obtained first slurry; beating the obtained second filter cake,and reacting the obtained second slurry with concentrated sulfuric acid; and sequentially carrying out cooling crystallization and solid-liquid separation on the obtained copper sulfate-containing reaction liquid to obtain copper sulfate crystals and a copper sulfate mother liquor. The copper-containing acidic etching waste liquid is neutralized, then the neutralized liquid is aerated, cuprous ions in the neutralized liquid and chloride ions form a complex, cuprous ions are rapidly oxidized in an aeration state to form copper ions in order to form a basic copper chloride precipitate, and thebasic copper chloride precipitate is recovered by pressure filtration and used to prepare copper sulfate, so the copper concentration of the wastewater is reduced, and the copper recovery rate is increased.

Owner:广东海文环保技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com