Comprehensive treatment method of acidic etching waste liquid

An acid etching waste liquid, comprehensive treatment technology, applied in metallurgical wastewater treatment, chemical instruments and methods, heating water/sewage treatment and other directions, can solve the problems of high risk, troublesome treatment, increase the salt content of wastewater, etc. The effect of ensuring the discharge standard, improving the resource recovery rate, and increasing the distillation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

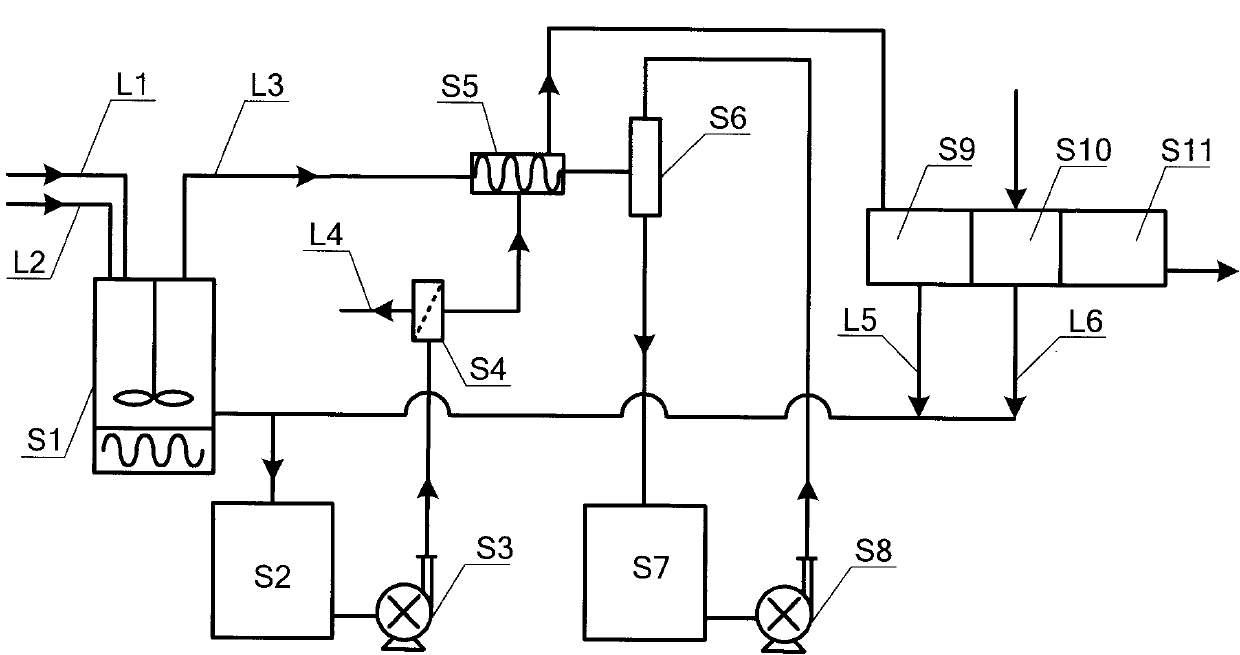

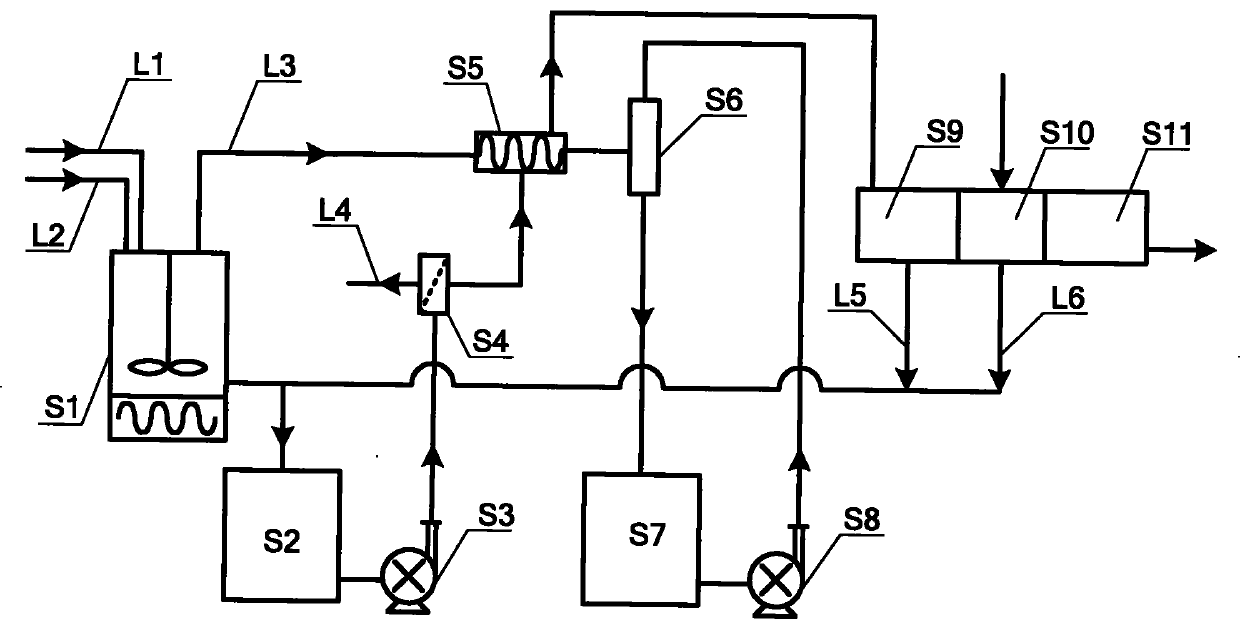

Image

Examples

Embodiment 1

[0024] will be 1m 3 The acidic etching waste liquid to be treated with a hydrochloric acid concentration of 2N and a copper ion concentration of 120g / L is pumped into the distillation kettle, 5L of hydrogen peroxide is added, and after stirring for 20 seconds, 80L of 98% concentrated sulfuric acid is added for heating and distillation, heated with saturated steam, and the temperature of the kettle is 100°C. until evaporated. Add 300L of clear water to the product storage tank in advance, and the distilled steam is absorbed by the water ejector. The vacuum pressure of the water ejector is 1kPa. After the distillation is completed, the volume of dilute hydrochloric acid becomes 1350L, and the concentration is 15%. Then add clear water to the distillation kettle while it is hot to dissolve the residue as a solution, use a high-pressure pump to inject the mother liquor into the nanofiltration membrane, concentrate and separate it under a pressure of 0.9MPa, and discharge 40L of th...

Embodiment 2

[0026] will be 1m 3 The acidic etching waste liquid to be treated with a hydrochloric acid concentration of 3N and a copper ion concentration of 140g / L is pumped into the still, and 6.5L of hydrogen peroxide is added. After stirring for 30 seconds, 100L of 98% concentrated sulfuric acid is added for heating and distillation. Electric heating is used, and the temperature of the kettle is 110°C. until evaporated. Add 250L of clean water to the product storage tank in advance, and the distilled steam is absorbed by the water ejector. The vacuum pressure of the water ejector is 2kPa. After the distillation is completed, the volume of dilute hydrochloric acid becomes 1360L, and the concentration is 17%. Then add clear water to the distillation kettle while it is hot, as a solution to dissolve the residue, select a combination of nanofiltration membrane and reverse osmosis membrane, and discharge 70L of filtrate at an operating pressure of 1.9MPa. Use distilled steam to heat, cool a...

Embodiment 3

[0028] will be 1m 3 The acidic etching waste liquid to be treated with a hydrochloric acid concentration of 4N and a copper ion concentration of 160g / L is pumped into the distillation kettle, 8L of hydrogen peroxide is added, and after stirring for 40s, 130L of 98% concentrated sulfuric acid is added for heating and distillation. Evaporate to dryness. 200L of clean water is added to the product storage tank in advance, and the distilled steam is absorbed by the water ejector. The vacuum pressure of the water ejector is 3kPa. After the distillation is completed, the volume of dilute hydrochloric acid becomes 1380L, and the concentration is 20%. Then add clear water to the distillation kettle while it is hot, as a solution to dissolve the residue, select a combination of nanofiltration membrane and reverse osmosis membrane, and discharge 100L of filtrate at an operating pressure of 1.5MPa. Use distilled steam to heat, cool and crystallize, and drench the crystal with water Wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com