Equipment matching method for solid-filling coal face of coal mine

A technology for coal mining face and solid backfill, which is used in mining equipment, backfill, earthwork drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

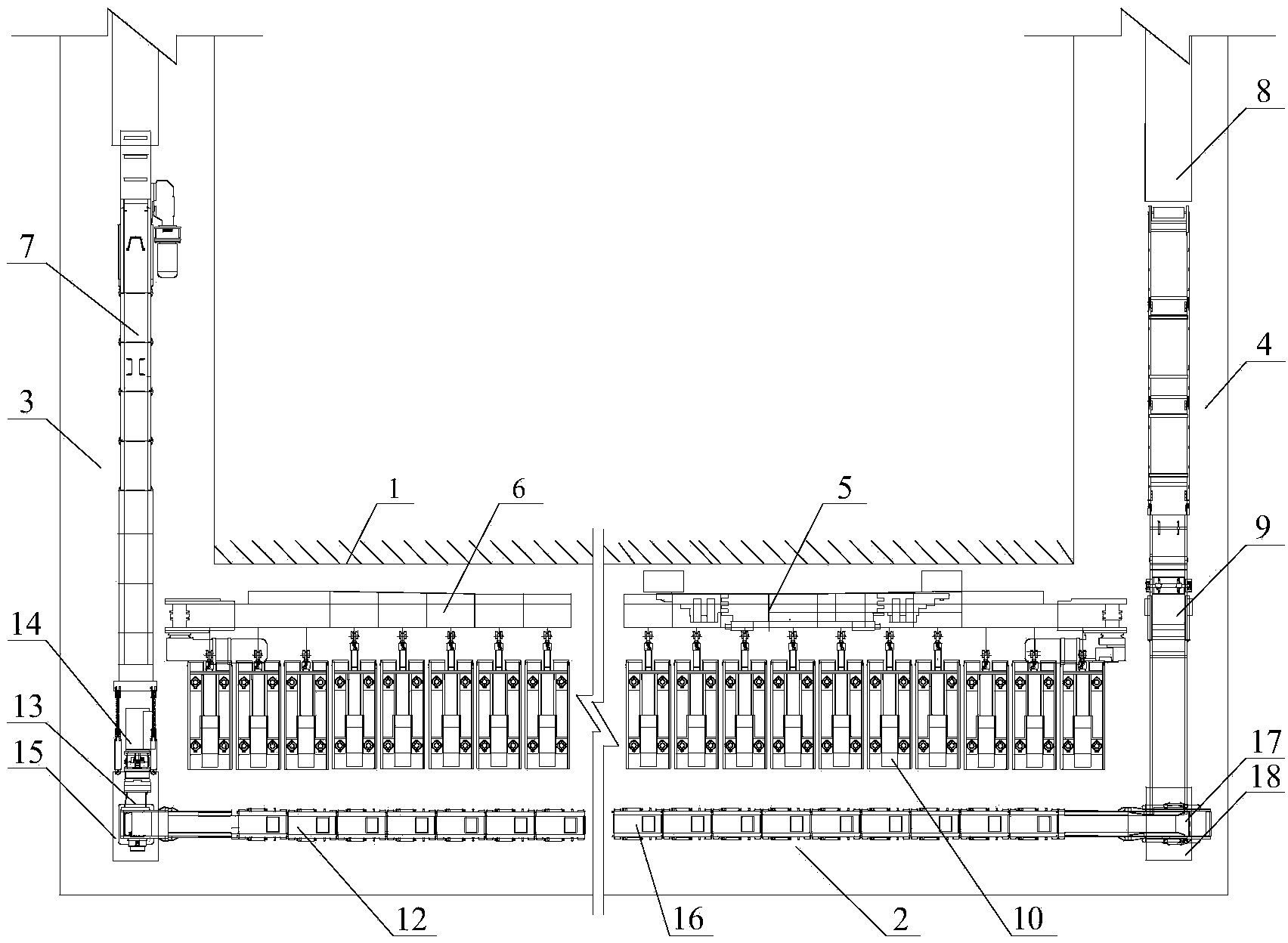

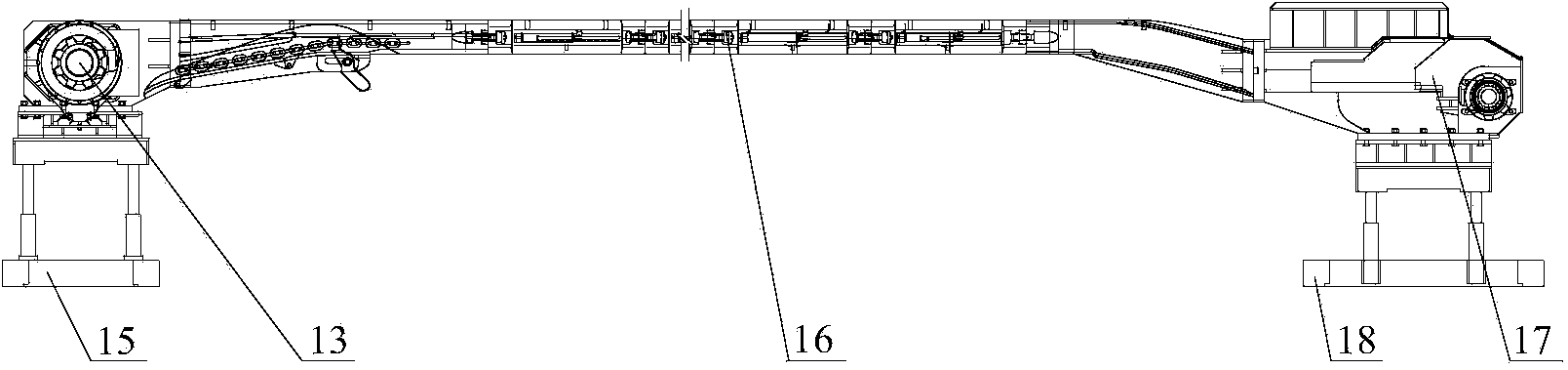

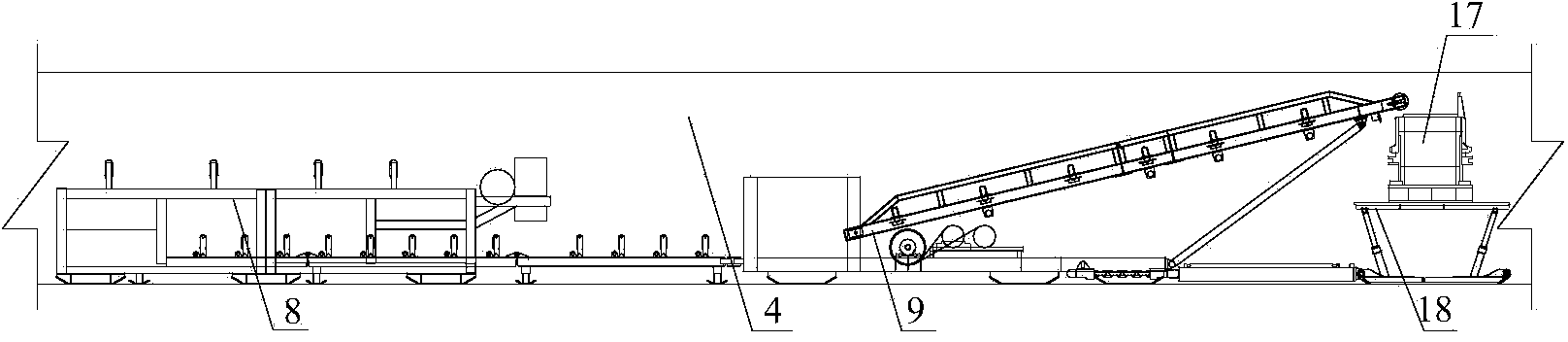

Embodiment 1

[0014] Embodiment 1: The equipment operation cooperation method in the solid filling coal mining face is as follows: the coal cut by the shearer 5 is transported to the coal transport roadway 3 through the scraper conveyor 6 in the coal mining face 1 and transferred to the coal transport The equipment 7 is transported out of the coal mining face 1 by the coal transporting equipment 7; Transferred to the tail 17 of the porous bottom unloading conveyor 12, the gangue is unloaded to the goaf below the porous bottom unloading conveyor 12 through the middle section 16 of the porous bottom unloading conveyor 12 and repeatedly tamped by the compacting mechanism 11.

[0015] exist figure 1 Among them, the coal mining face 1 is covered by the front roof beam of the filling coal mining hydraulic support, the filling face 2 is covered by the back roof beam of the filling coal mining hydraulic support, and the coal transportation lane 3 and gangue transportation lane 4 are set up on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com