Method and system for extracting natural gas hydrate through thermal jet flow

A technology for natural gas and hydrates, used in the production of fluids, earth-moving drilling, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

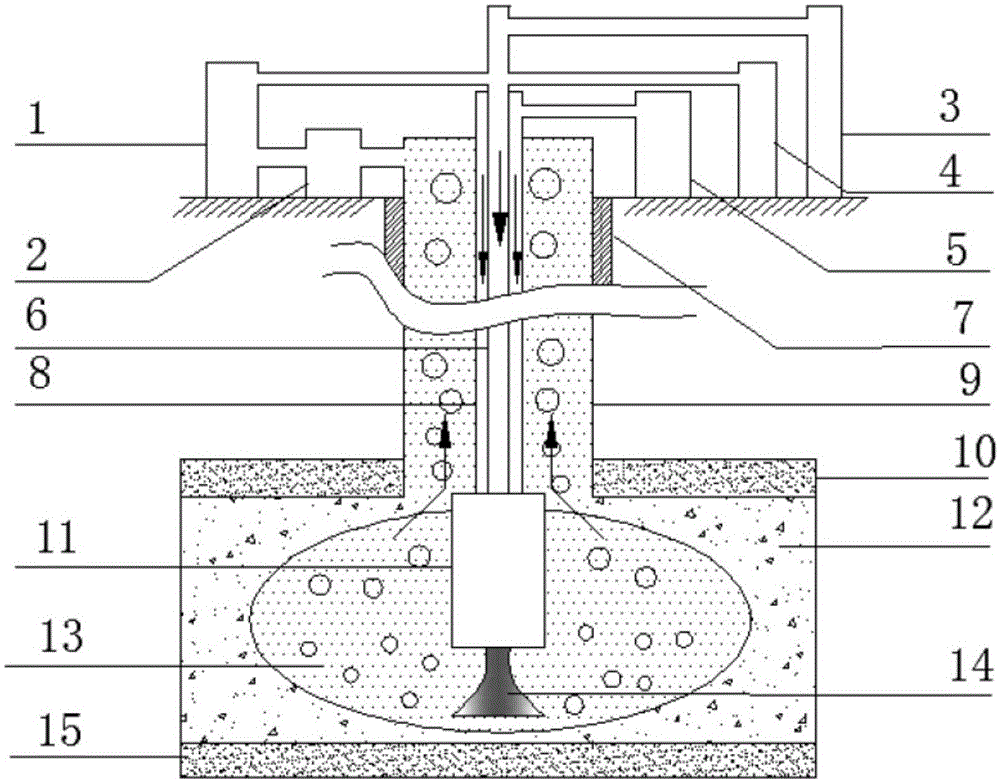

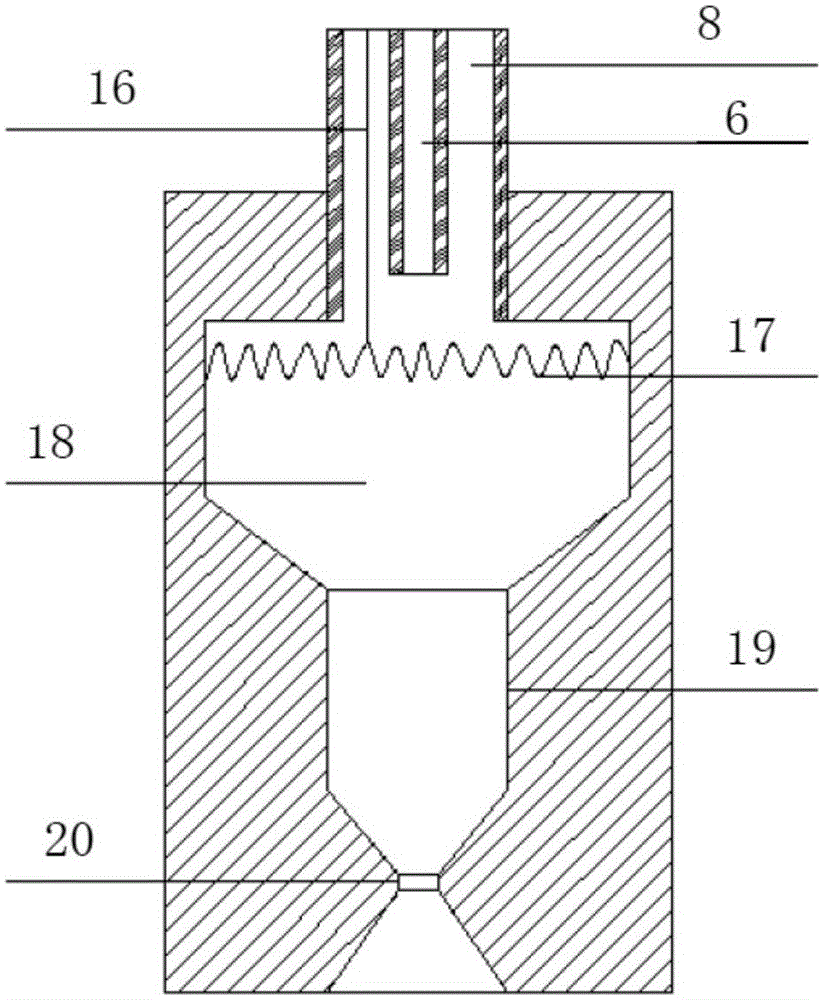

[0052] This embodiment provides a system for exploiting natural gas hydrates using thermal jets, such as figure 1 and figure 2 As shown, the system includes: combustion reaction device 11, coiled tubing inner tube 6, coiled tubing outer tube 8, cable 16, production casing 9, water supply device 3, fuel supply device 4, oxygen supply device 5, natural gas storage With the supply device 1, the gas-liquid separation device 2 and the pump set;

[0053] The combustion reaction device 11 is set at the target position in the well of the natural gas hydrate reservoir 12, the overlying formation 10 is above the natural gas hydrate reservoir 12, and the underburden formation 15 is below, and the combustion reaction device 11 includes a combustion reaction Chamber 18, the resistance wire 17 positioned in the combustion reaction chamber 18, the nozzle pipeline 19 positioned at the bottom of the combustion reaction chamber 18, and the nozzle outlet 20, the nozzle outlet 20 is a gradually...

Embodiment 2

[0058] This embodiment provides a method for exploiting natural gas hydrates using thermal jetting. The method uses the system provided in Embodiment 1, which includes the following steps:

[0059] Use thermal jet to drill multi-branch wells to different layers of natural gas hydrate reservoir 12. Above the natural gas hydrate reservoir 12 is the overlying stratum 10, and below it is the underlying stratum 15. For drilling through thermal jet, please refer to CN103790516A The drilling method disclosed in;

[0060] The combustion reaction device 11 is placed under the target position of each branch well, and the combustion reaction device 11 comprises a combustion reaction 18, a resistance wire 17 positioned in the combustion reaction chamber 18, a nozzle pipeline 19 positioned at the bottom of the combustion reaction chamber 18 and a nozzle outlet 20, the nozzle outlet 20 is a tapered outlet with gradual divergence;

[0061] Lower the production casing 9 from the ground to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com