Patents

Literature

46results about How to "Speed up distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

After-sun repair serum containing dendrobium candidum

ActiveCN107669597AProtect collagenReduce harmCosmetic preparationsToilet preparationsDendrobium candidumPassionfruits

The invention provides after-sun repair serum containing dendrobium candidum. The after-sun repair serum is prepared from raw materials in parts by weight as follows: 0.2-0.9 parts of a dendrobium candidum extracting solution, 0.2-0.8 parts of passion fruit seed essential oil, 0.1-0.3 parts of shaddock peel essential oil, 0.1-0.5 parts of sodium hyaluronate, 0.5-1.0 part of trehalose, 0.1-0.3 parts of lecithin, 5-20 parts of a moisturizer, 0.5-2.5 parts of gel matrix and 95-120 parts of water. The after-sun repair serum is prepared from the dendrobium candidum extracting solution, the passionfruit seed essential oil and the shaddock peel essential oil as main functional components, thereby being capable of rapidly replenishing water, moisturizing skin, keeping skin elasticity, resisting free radicals and aging, reducing ultraviolet damage and the like.

Owner:GUANGXI SHUNCHANGLONG BIOTECH CO LTD

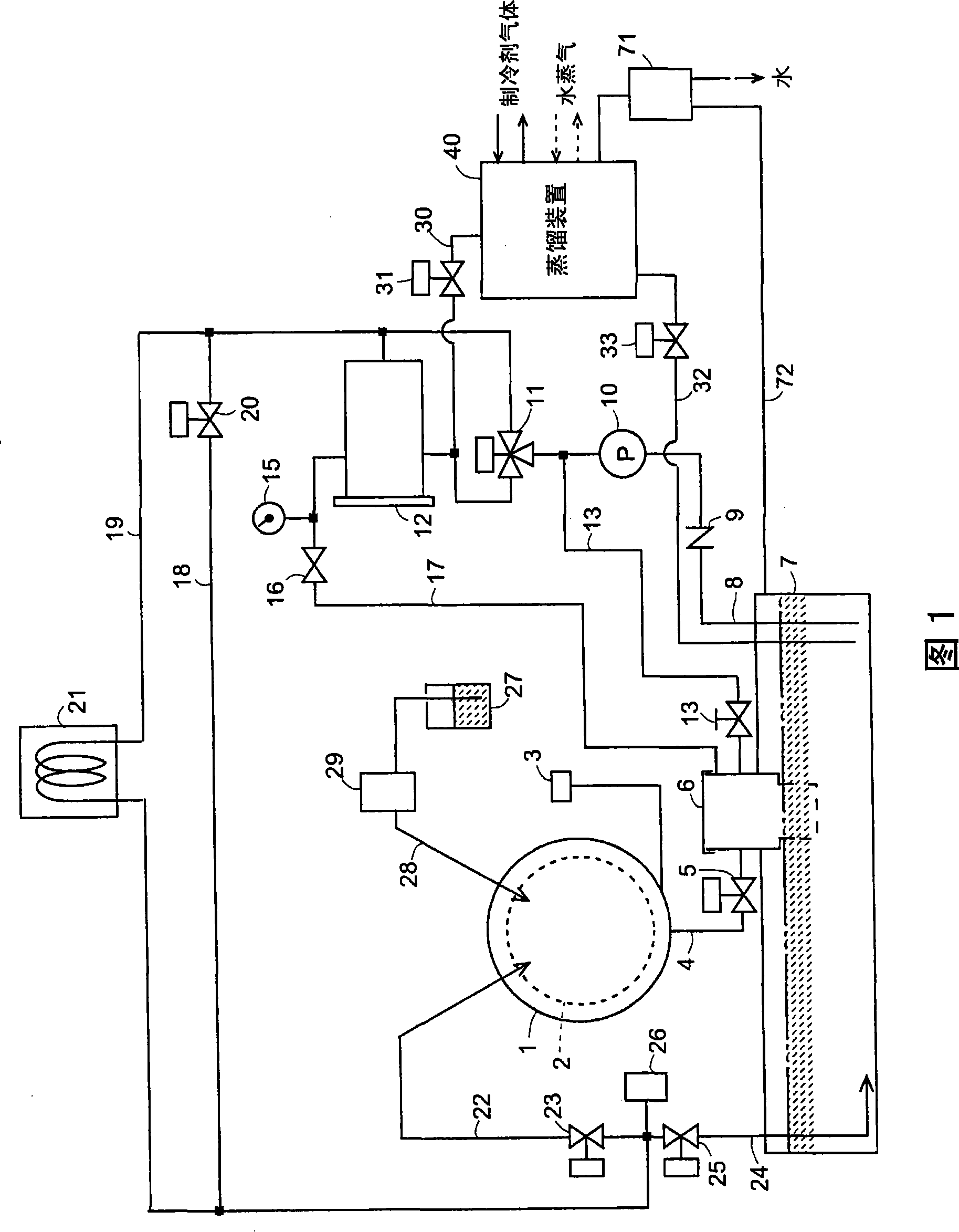

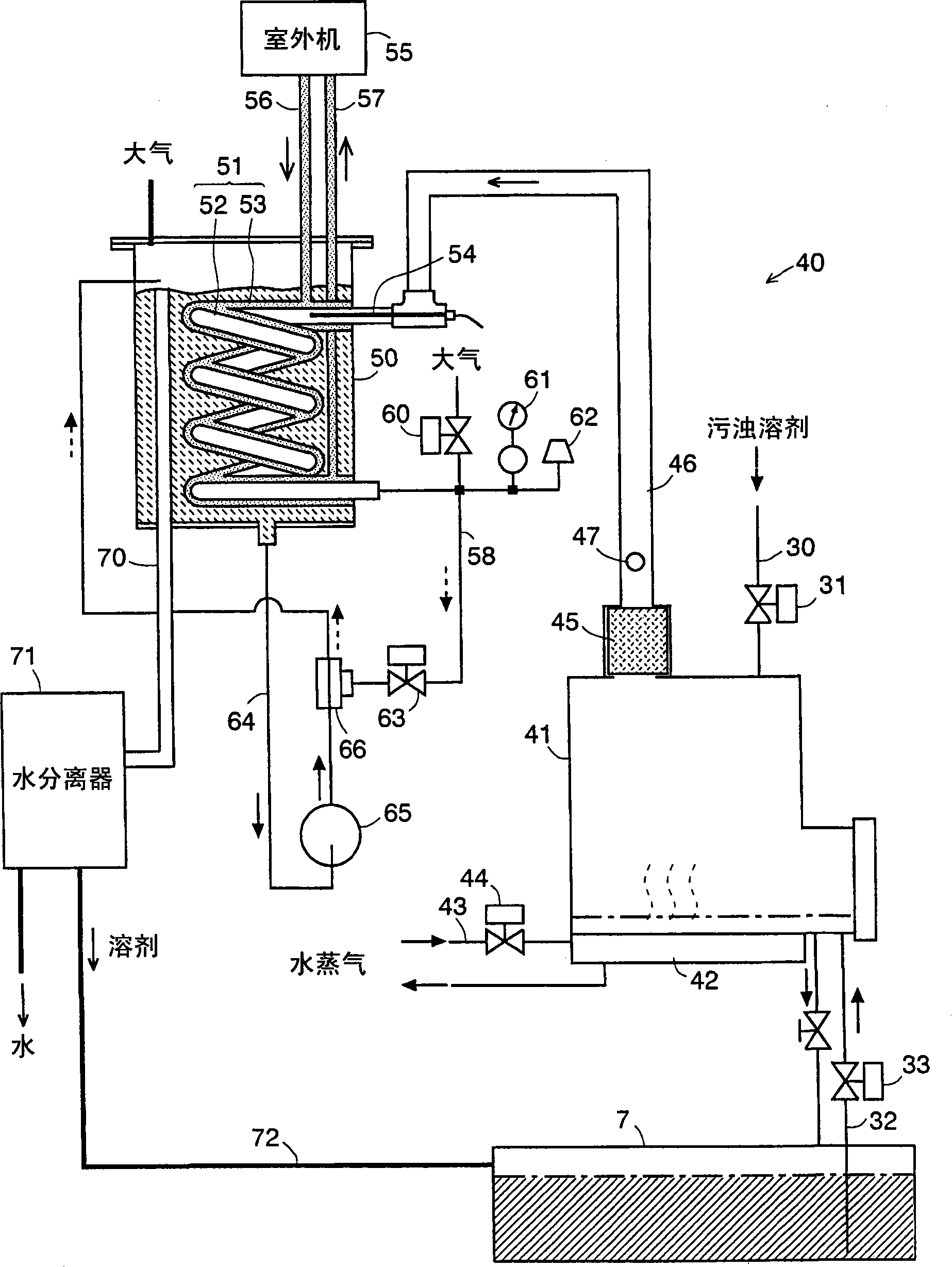

Distillation apparatus

InactiveCN101156994ASpeed up distillationImprove cooling effectVacuum condensationDry-cleaning apparatusSolvent vaporBuffer tank

Owner:SANYO ELECTRIC CO LTD +1

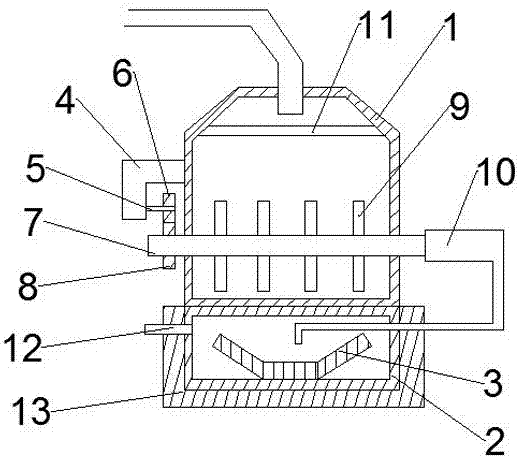

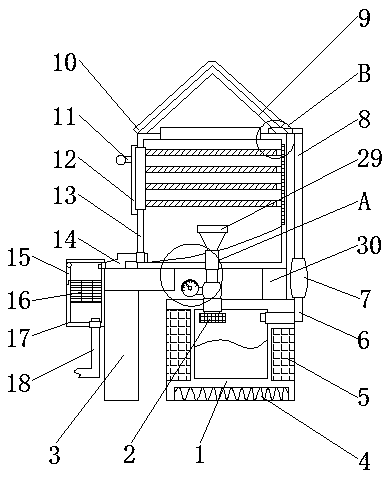

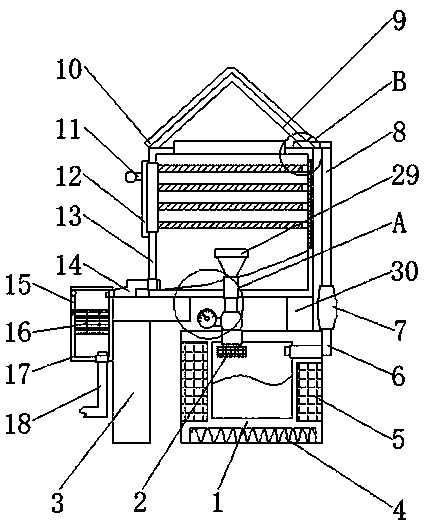

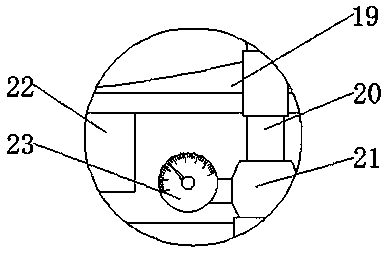

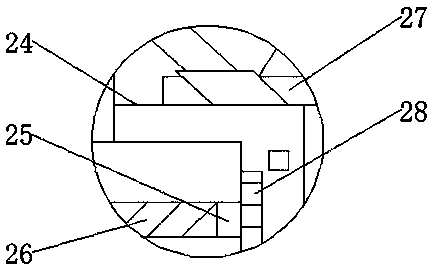

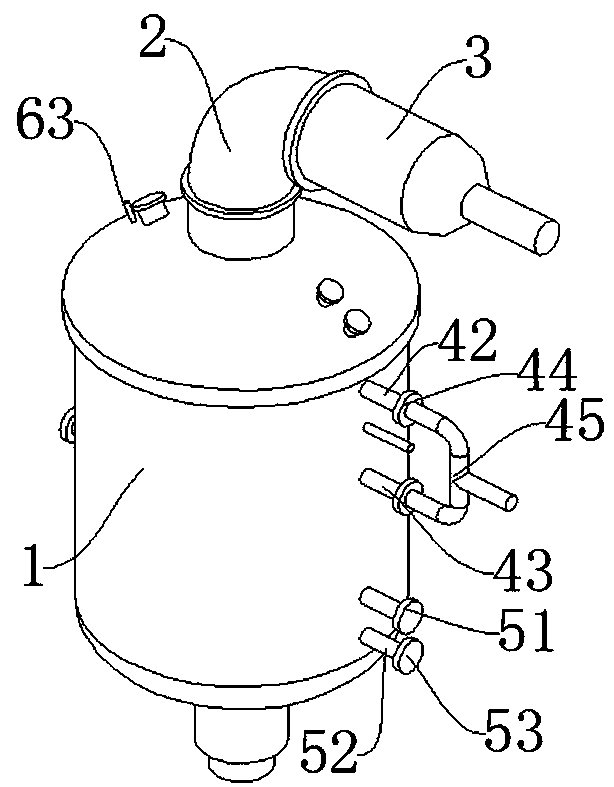

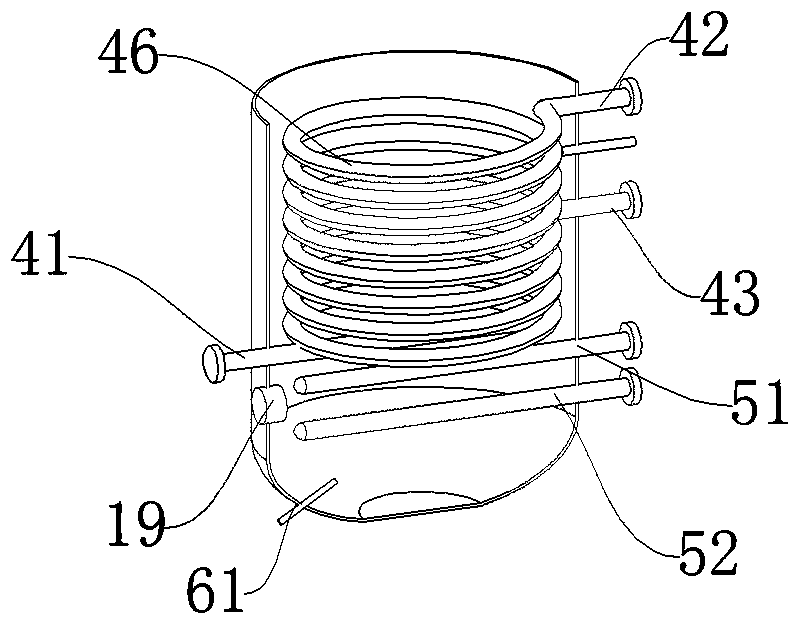

Distillation device for Baijiu

InactiveCN107418857AEvenly distributedFully distilledAlcoholic beverage preparationDistillationEngineering

The invention discloses a distillation device for Baijiu. The distillation device is characterized in that a steam disperser is fixed at the center of the bottom of a steam tank, a motor is arranged on the outer wall of a steamer, a rotary shaft is connected to the motor, a first gear is fixedly connected to one end of the rotary shaft, a first steam inlet pipe is horizontally rotatably connected into the steamer, two ends of the first steam inlet pipe penetrates the lateral walls of the steamer and extend out of the steamer, the first steam pipe is provided with a plurality of stainless-steel stirring shafts, the stirring shafts are in clearance fit with the bottom of the steamer, one end of the steam inlet pipe is fixedly connected with a second gear in a sleeved manner, the first gear meshes with the second gear, the other end of the first steam inlet pipe is communicated with a second steam inlet pipe, the first steam inlet pipe is rotatably connected with the second steam inlet pipe, one end of the second steam inlet pipe is located in the steam tank and located above the steam disperser, and the steam tank is provided with a steam outlet pipe. When the distillation device is used for brewing the Baijiu, raw materials in the steamer can be thoroughly distilled, and distillation efficiency is increased at the same time.

Owner:ZUNYI JINHONG METAL EQUIP

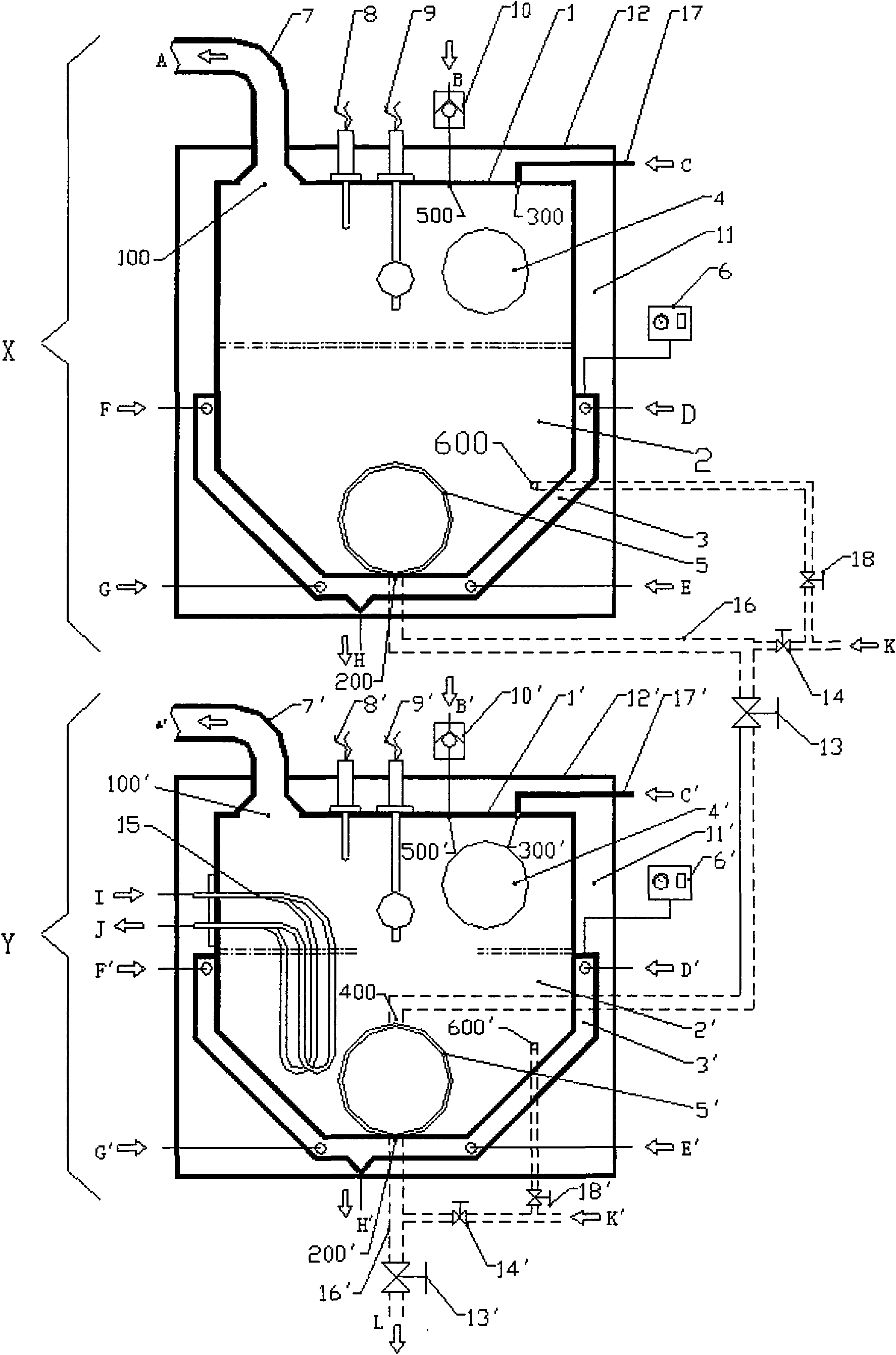

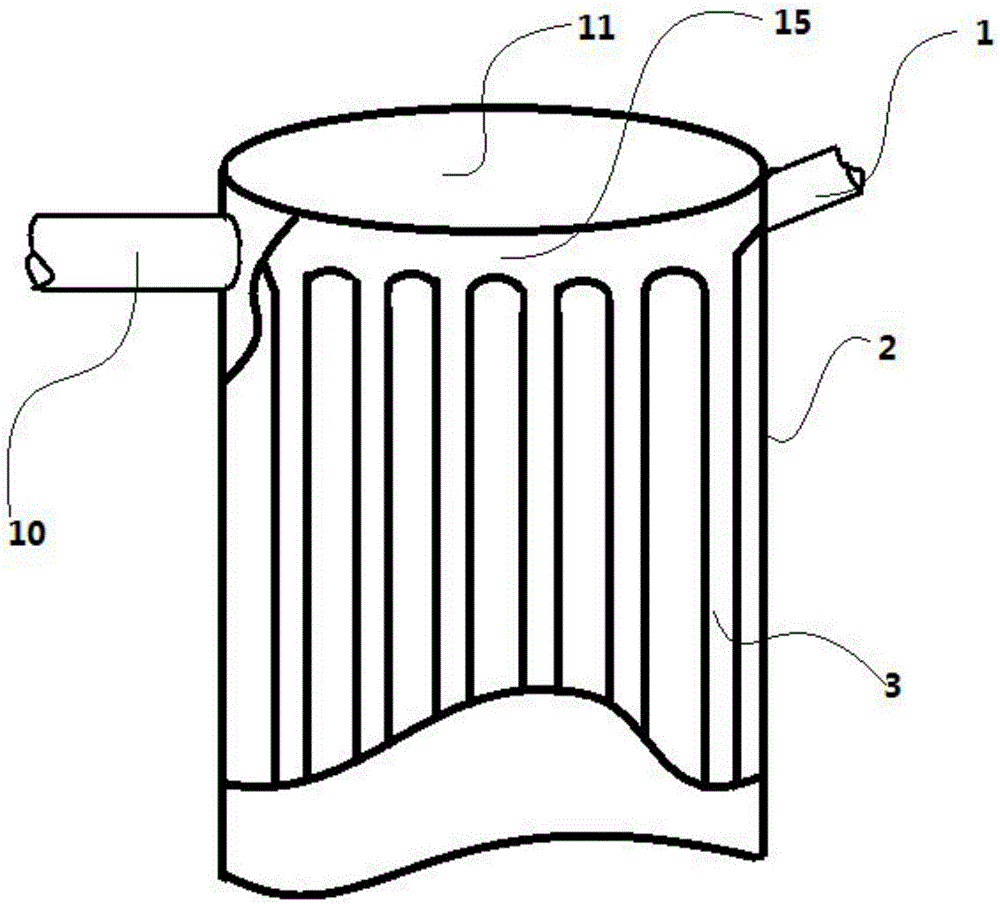

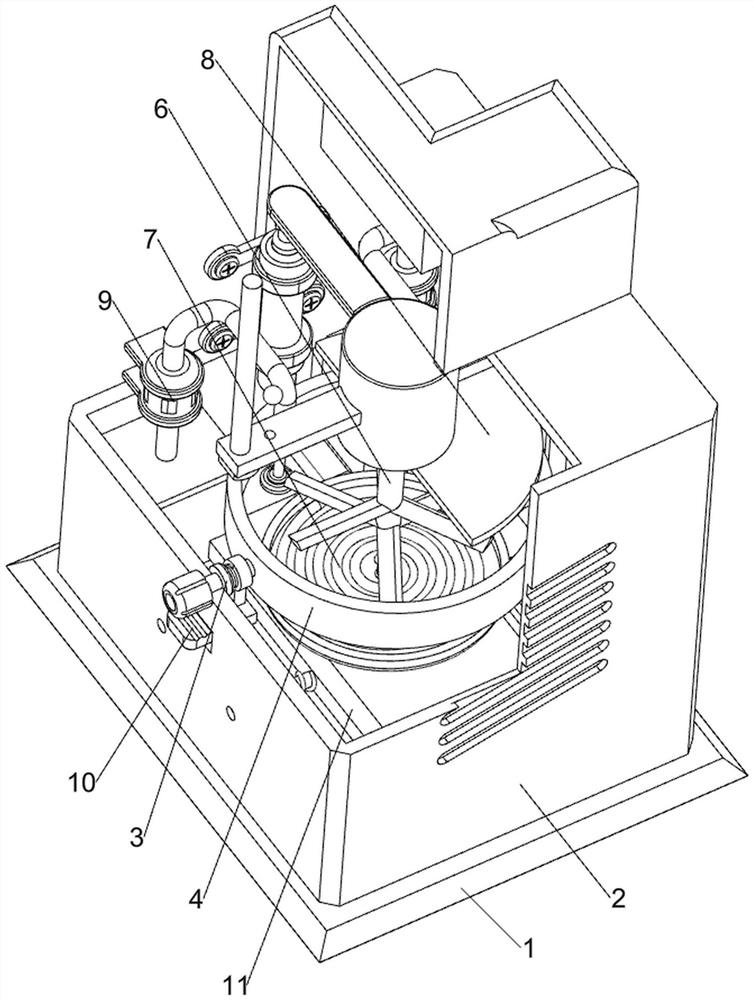

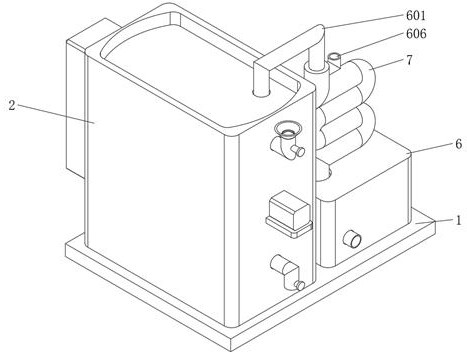

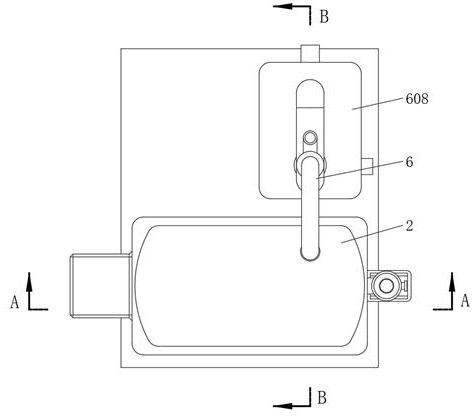

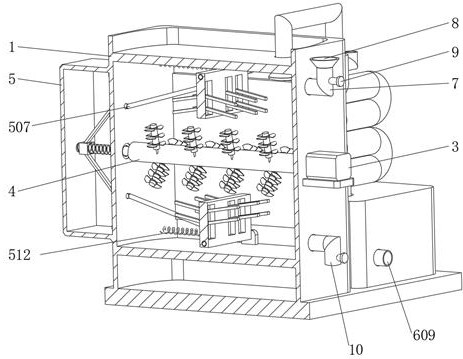

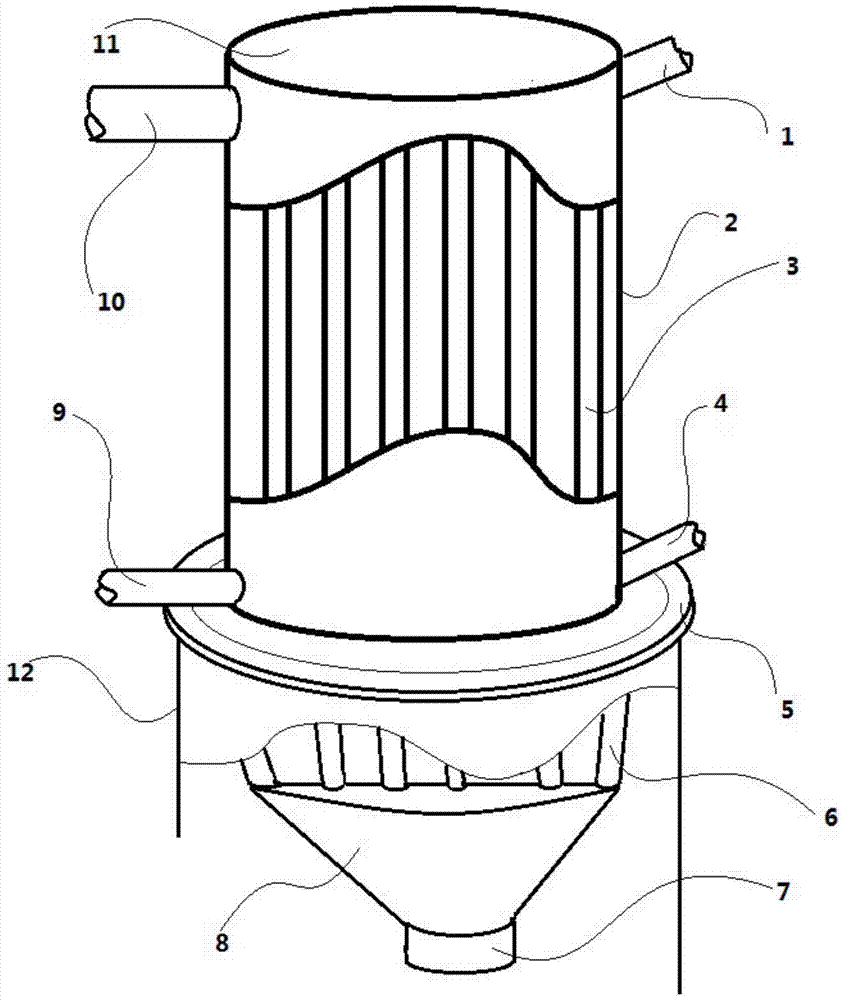

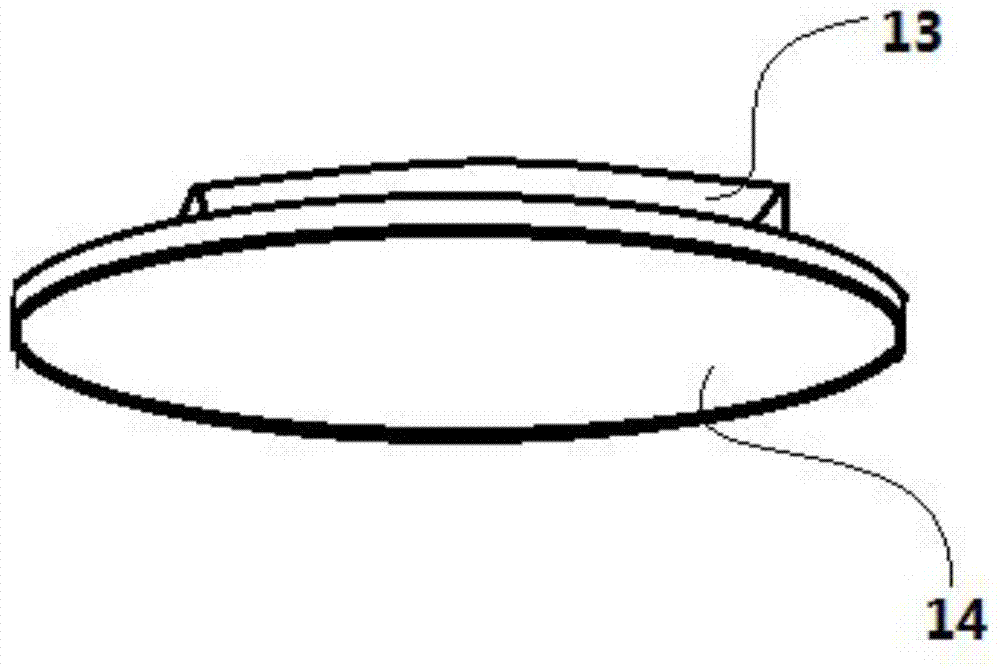

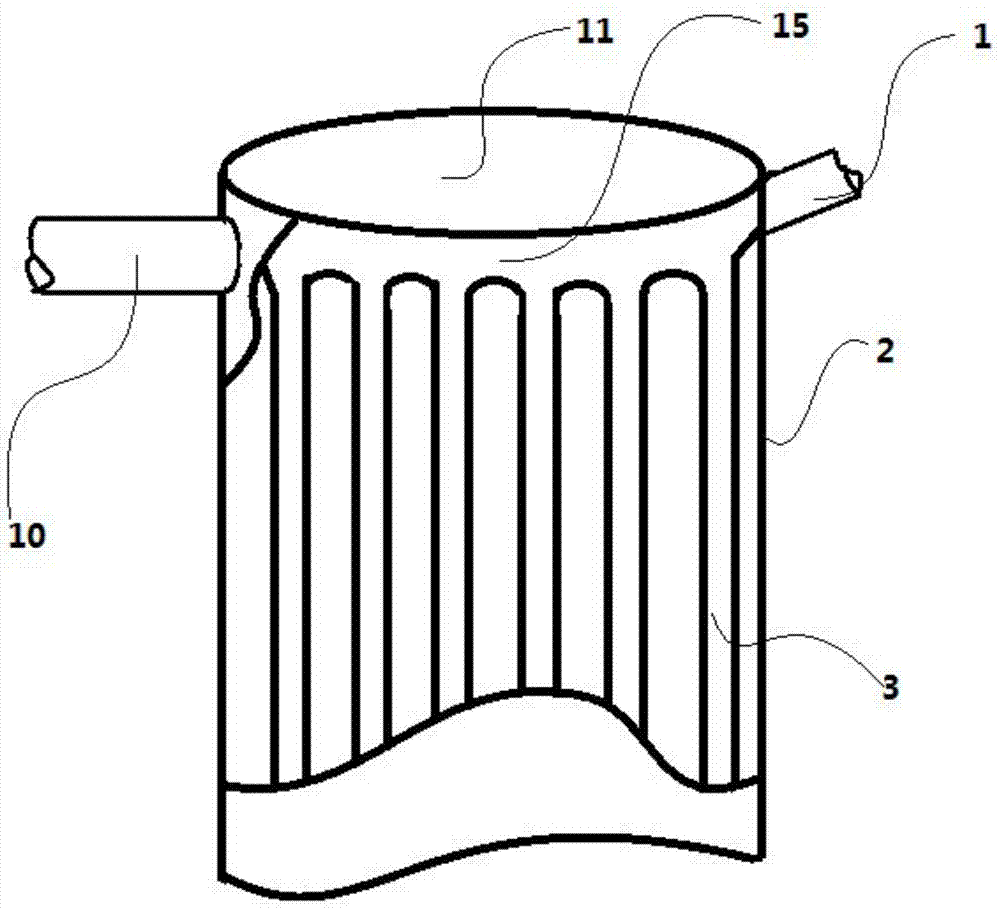

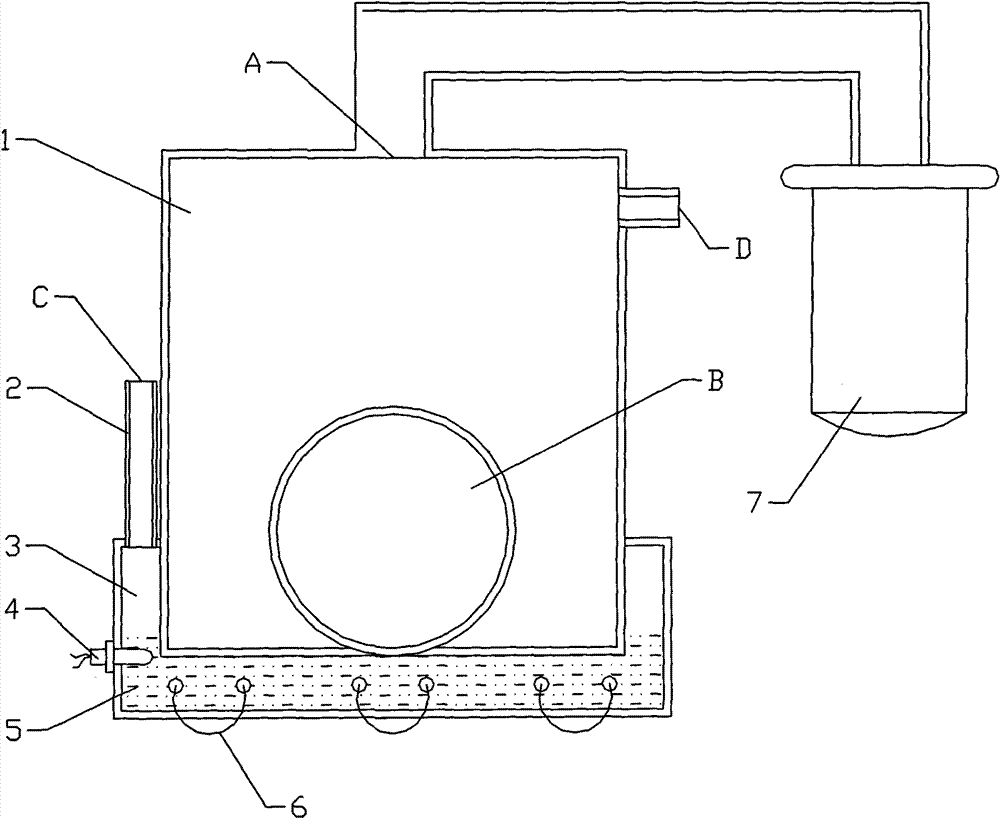

Interporosity flow double-distilled box structure in fur defatting machine

InactiveCN101642628AIncrease stiffnessAvoid deformationPre-tanning chemical treatmentLeather/skins/hides/pelt chemical treatment apparatusEngineeringSolvent

The invention relates to an interporosity flow double-distilled box structure in a fur defatting machine. A distilled box of the fur defatting machine is changed from an originally single-box structure into a double-box structure; the bottom plane of a solvent cavity of the distilled box is changed into a polygonal heating bottom plane; the top surface of the solvent cavity of the distilled box isadditionally provided with a balanced air suction port connected with a pressure one-way valve; the lower box structure is additionally provided with a lower box auxiliary heater; a connecting flangeof a cleaning door of the distilled box is provided with a discharge port of interporosity flow, the upper box and the lower box can be communicated by a pipe so that the liquid flows between the twoboxes, and the interporosity flow or discharge pipe is added with a steam cleaning function and the function of using steam to clean the solvent cavity.

Owner:上海雅森洗涤设备有限公司

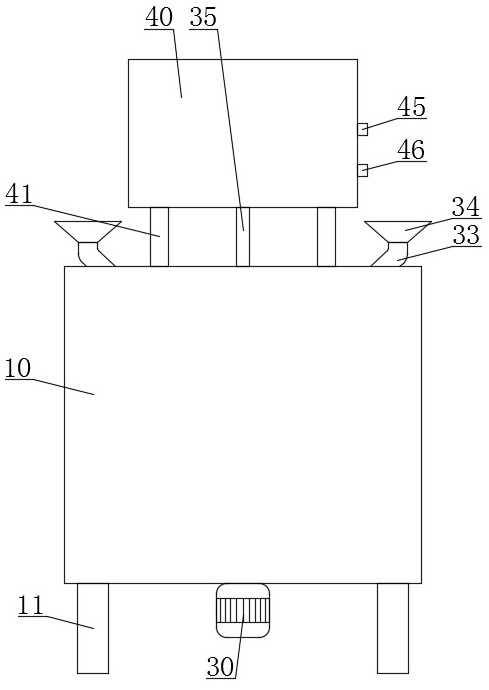

Rose essential oil hydrolat extraction device

PendingCN108485814AAffect extraction speedImprove stabilityEssential-oils/perfumesGrain treatmentsDistillationEngineering

The invention discloses a rose essential oil hydrolat extraction device. The rose essential oil hydrolat extraction device comprises a distillation bin, wherein a partition plate adapted to the distillation bin is fixedly connected to the inside of the distillation bin; heating pipes arranged at equal distances are arranged on the inner bottom wall of the distillation bin; water filling pipes areregularly communicated to the left side surface of the distillation bin; a crushing bin is fixedly connected to the upper surface of the partition plate; the upper surface of the crushing in is fixedly connected with the inner top wall of the distillation bin; a gas transmission pipe is fixedly communicated to the right side of the upper surface of the partition plate; one end of the gas transmission pipe far away from the partition plate penetrates through the crushing bin and extends to the inner side wall of the crushing bin; and a filter screen adapted to the gas transmission pipe is fixedly connected to the inside of the gas transmission pipe. According to the rose essential oil hydrolat extraction device, the extraction speed of the rose essential oil hydrolat as a whole is fast, andthe operation is simple, so that workers can move the extraction device through a lifting device, the labor cost of the workers to carry the extraction device can be reduced, the requirements of production enterprises can be met, and extensive promotion can be facilitated.

Owner:无锡市鹅湖玫瑰园艺文化有限公司

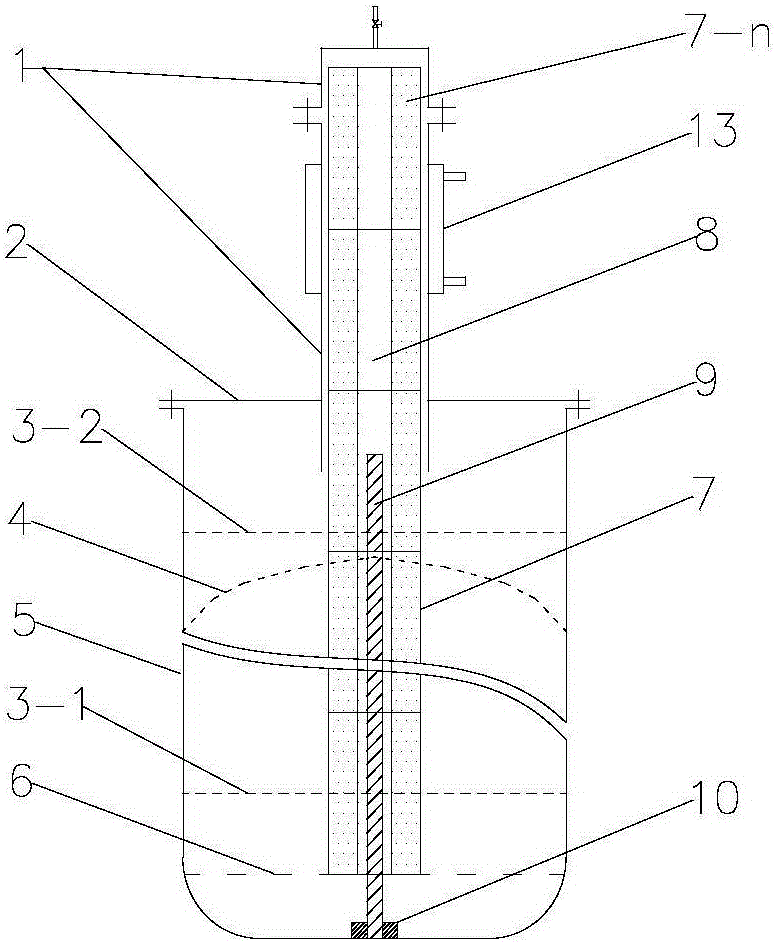

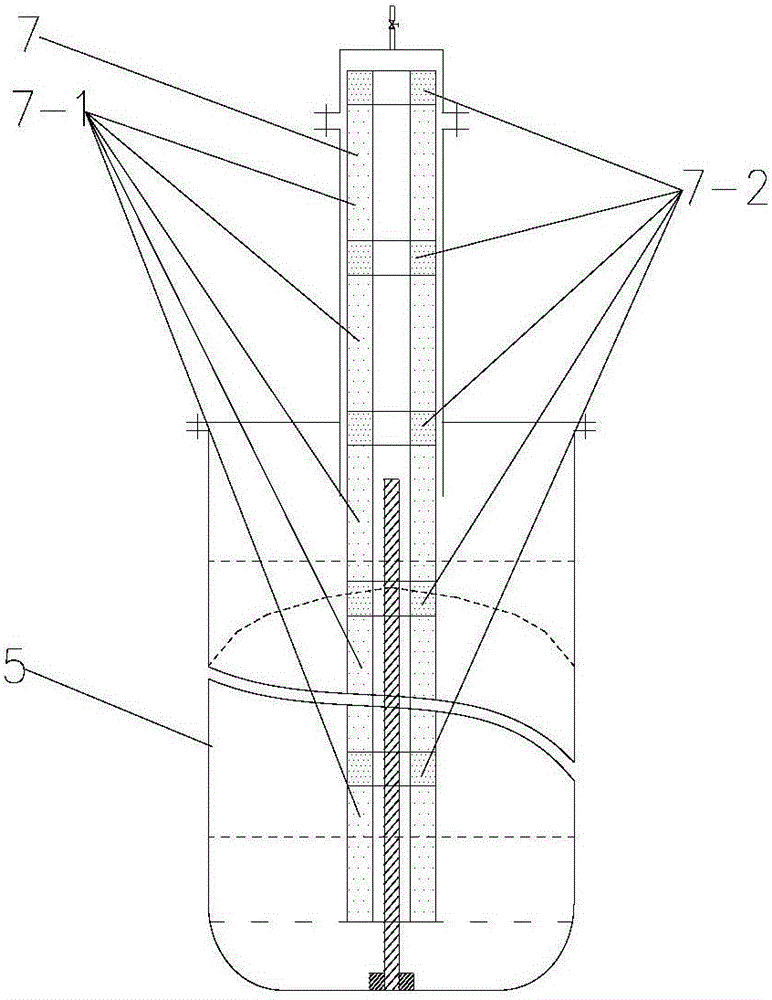

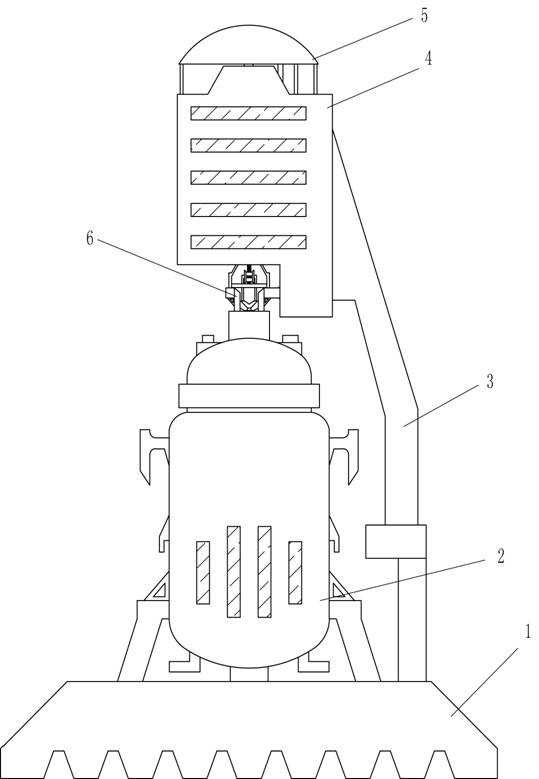

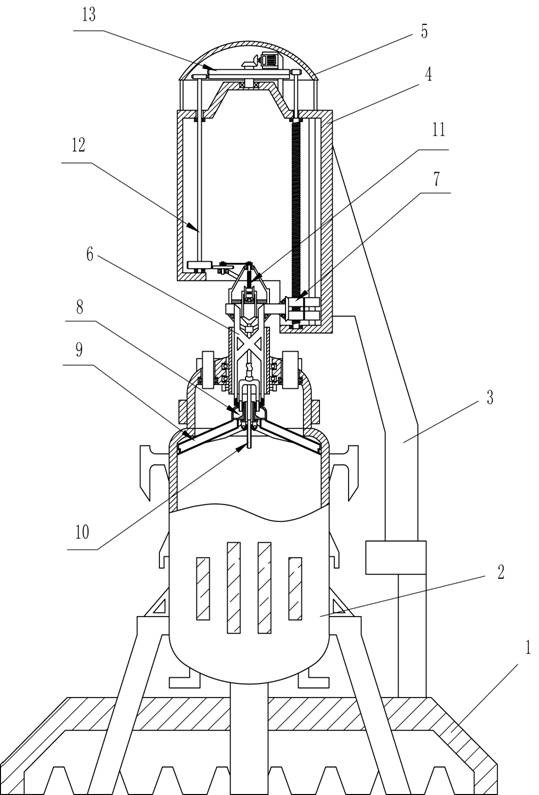

Device and method for improving production efficiency of titanium sponge and reducing energy consumption

InactiveCN105779791AIncrease the feeding speedImprove the efficiency of the reduction reactionDistillationTitanium

The invention discloses a device and method for improving the production efficiency of titanium sponge and reducing energy consumption. A device containing a fusibility column is arranged in the axis part of an existing reduction distillation furnace reactor and comprises two parts including the fusibility column and a reactor upper cover leading-out sleeve. The fusibility column (a metal magnesium ingot) located in the center part of liquid magnesium metal absorbs reaction heat and is gradually fused in the magnesium heat reduction process, and meanwhile a hole is formed in the axis of a titanium sponge mixing body. The device and method solve the problem that a large amount of heat gathered in the center area of the magnesium heat reduction reactor is dissipated, and meanwhile the heat released through the magnesium heat reduction reaction is utilized for fusing the reduction agent magnesium metal ingot. The hole can be formed in the axis position of the titanium sponge mixing body, the diffusion path of magnesium metal left in the mixing body and magnesium metal is shortened, the distillation speed is increased, and the distillation period is shortened. By means of the device and method, preconditions are provided for the large scale of titanium sponge reduction distillation furnaces.

Owner:王进民

Movable coal mine dust removing equipment with high-pressure nozzle

The invention discloses movable coal mine dust removing equipment with a high-pressure nozzle. The movable coal mine dust removing equipment includes a machine body, a dust absorption cavity, an annular pipe, a base, a distillation cavity and a first rotary shaft; the upper of the right side of the machine body is provided with a dust absorption head which is connected with the dust absorption cavity, and the dust absorption cavity is arranged at the upper left side of an inner cavity of the machine body; the lower of the dust absorption cavity is connected with a second fan which is connectedwith a dust absorption pipeline, and the lower left side of the dust absorption pipeline is provided with the distillation cavity; the upper of the distillation cavity is connected with an exhaust fan, the upper of the exhaust fan is connected with a draft tube, and the draft tube passes through the upper wall of the machine body; and the upper of the machine body is provided with the annular pipe. According to the movable coal mine dust removing equipment with the high-pressure nozzle, energy conservation and environment protection are achieved; the use is convenient, and the production costis low; dust in a coal mine can be efficiently and sufficiently removed; and the external environment and builders can be well protected.

Owner:TAIAN TAISHUO STRATUM CONTROL SCI & TECH CO LTD

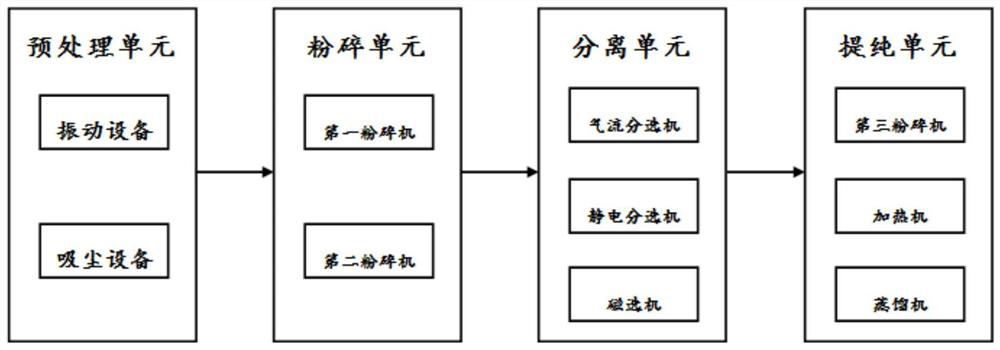

Waste treatment system for PCB

InactiveCN112813266AImprove crushing efficiencyEasy to operateProcess efficiency improvementGrain treatmentsHigh densityIron removal

The invention relates to the technical field of circuit board recovery treatment, in particular to a waste treatment system for a PCB. The system comprises a first crusher for crushing the PCB into waste fragments, a second crusher used for crushing the waste fragments into waste particles, an airflow sorting machine used for dividing the waste particles into metal particles with high density and non-metal particles with low density, an electrostatic separator used for separating the metal particles from the non-metal particles, a magnetic separator used for removing iron from the metal particles, a third crusher used for crushing the metal particles subjected to iron removal into metal powder, a heating machine and a distillation machine. The heating machine is used for heating the metal powder, so that soldering tin is melted, copper and zinc are not melted, and the soldering tin is separated; and the distillation machine is used for distilling the metal powder after the soldering tin is separated, so that zinc is evaporated and gasified, and pure copper is obtained. The technical problem that in the prior art, the purity of copper separated from the PCB waste is not high is solved through the system.

Owner:CHONGQING KAIGE ELECTRONICS CO LTD

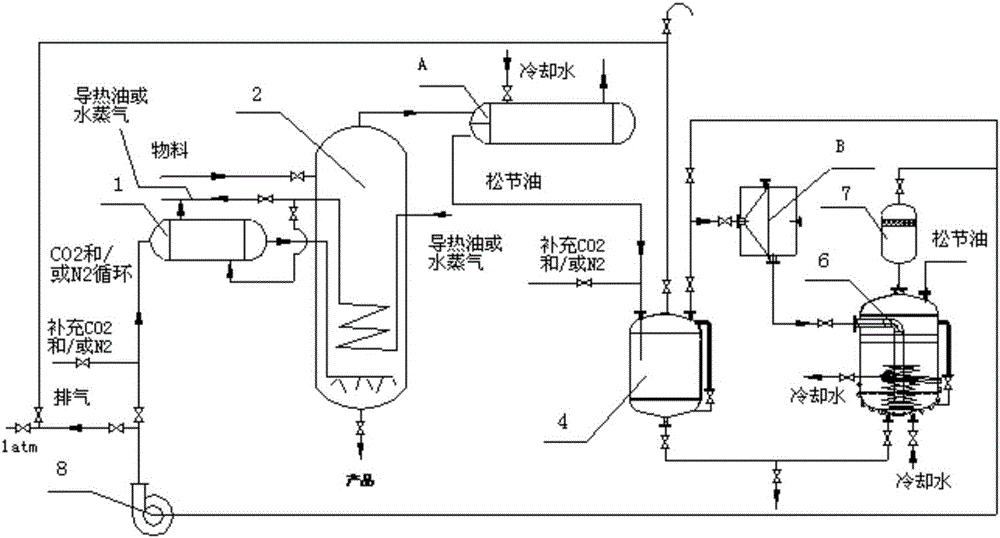

Energy-saving and clean production method for distilling rosin and process equipment

InactiveCN105820759AFacilitate desorptionAccelerate evaporationChemical industryTurpentine spiritsProcess equipmentDistillation

The invention discloses an energy-saving and clean production method for distilling rosin. The energy-saving and clean production method is a technique for distilling the rosin employing CO2 and / or N2 as a circulating activated gas. In the production process of separating the rosin and turpentine by rosin distillation, CO2 and / or N2 are introduced as the activated gases, so that partial pressure of the component in the turpentine of the distillation system is reduced; desorption of the turpentine is promoted to easily distill the rosin; meanwhile, the activated gas also plays a rosin stirring role; interphase heat transfer an mass transfer of the distillation system are intensified; the distillation speed and the product quality are improved. The energy-saving and clean production method has the advantages that the circulating activated gas does not generate a phase change in the rosin distillation process; phase change heat when super-heated steam is used as the activated gas is saved; the energy consumption is reduced, so that the investment cost on equipment is reduced; the obtained product does not contain moisture; the rosin is free of a crystallization phenomenon; the technique is transparent and not turbid. The CO2 and / or the N2 are used in cycle, so that the distillation process is fully sealed operation, is free of three wastes, and is the energy-saving and clean production method.

Owner:GUANGXI UNIV

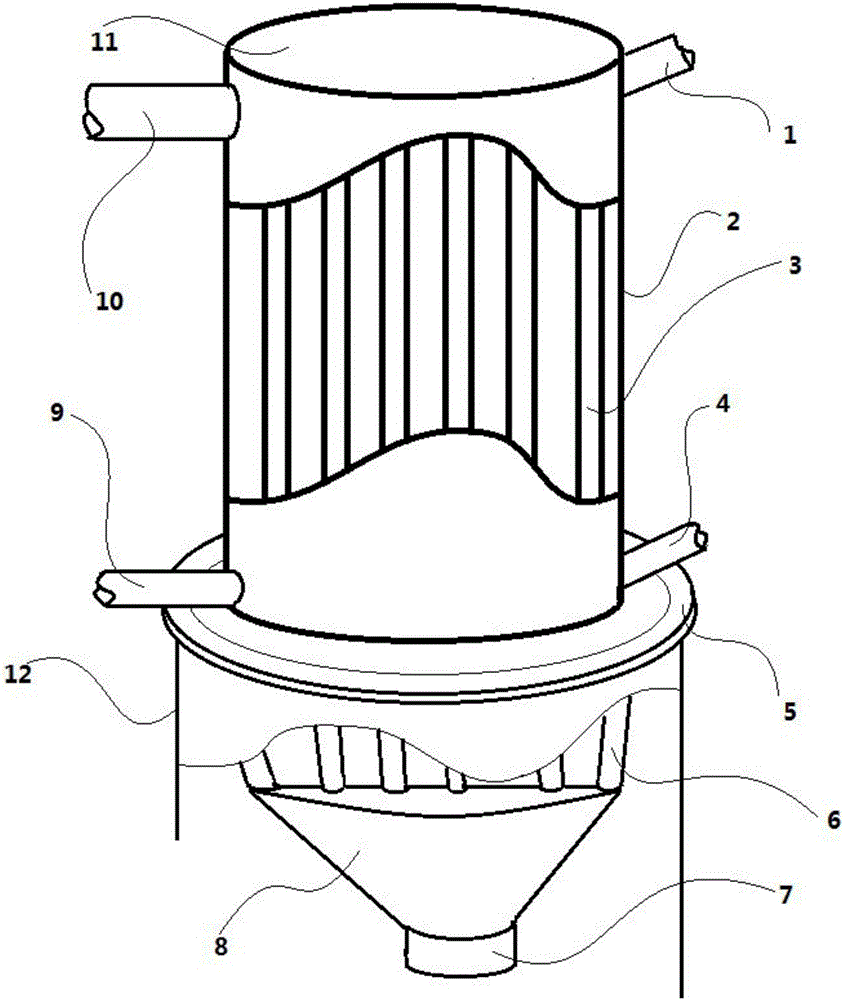

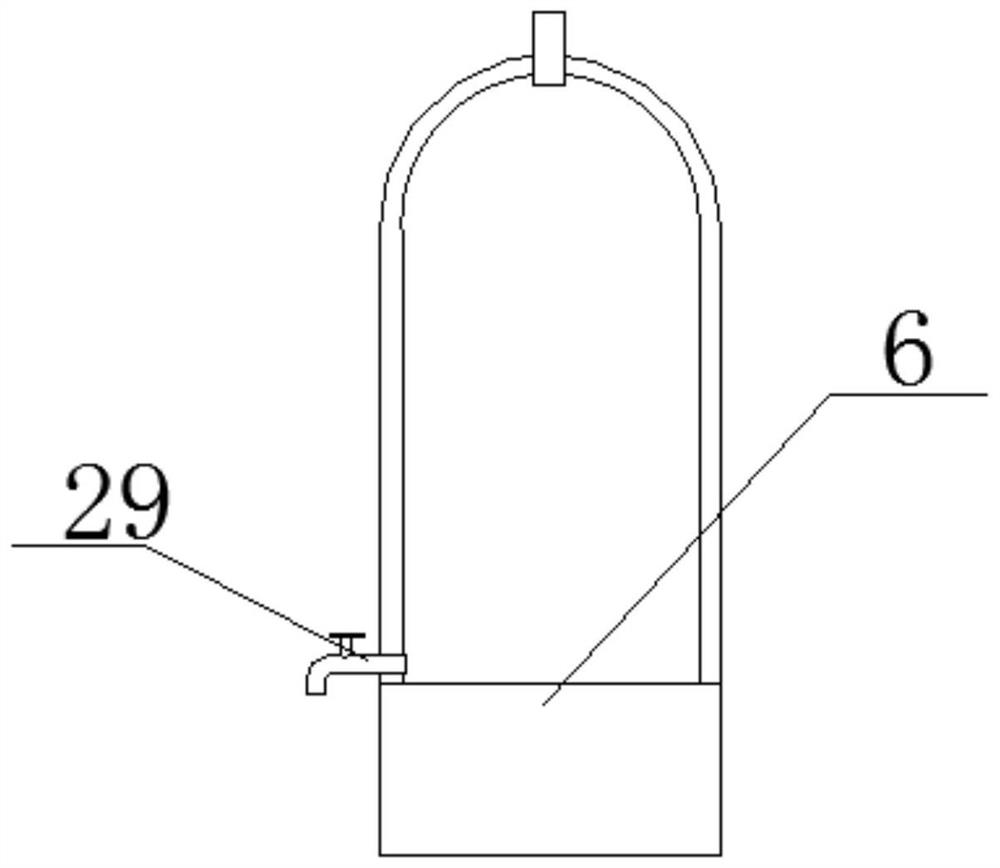

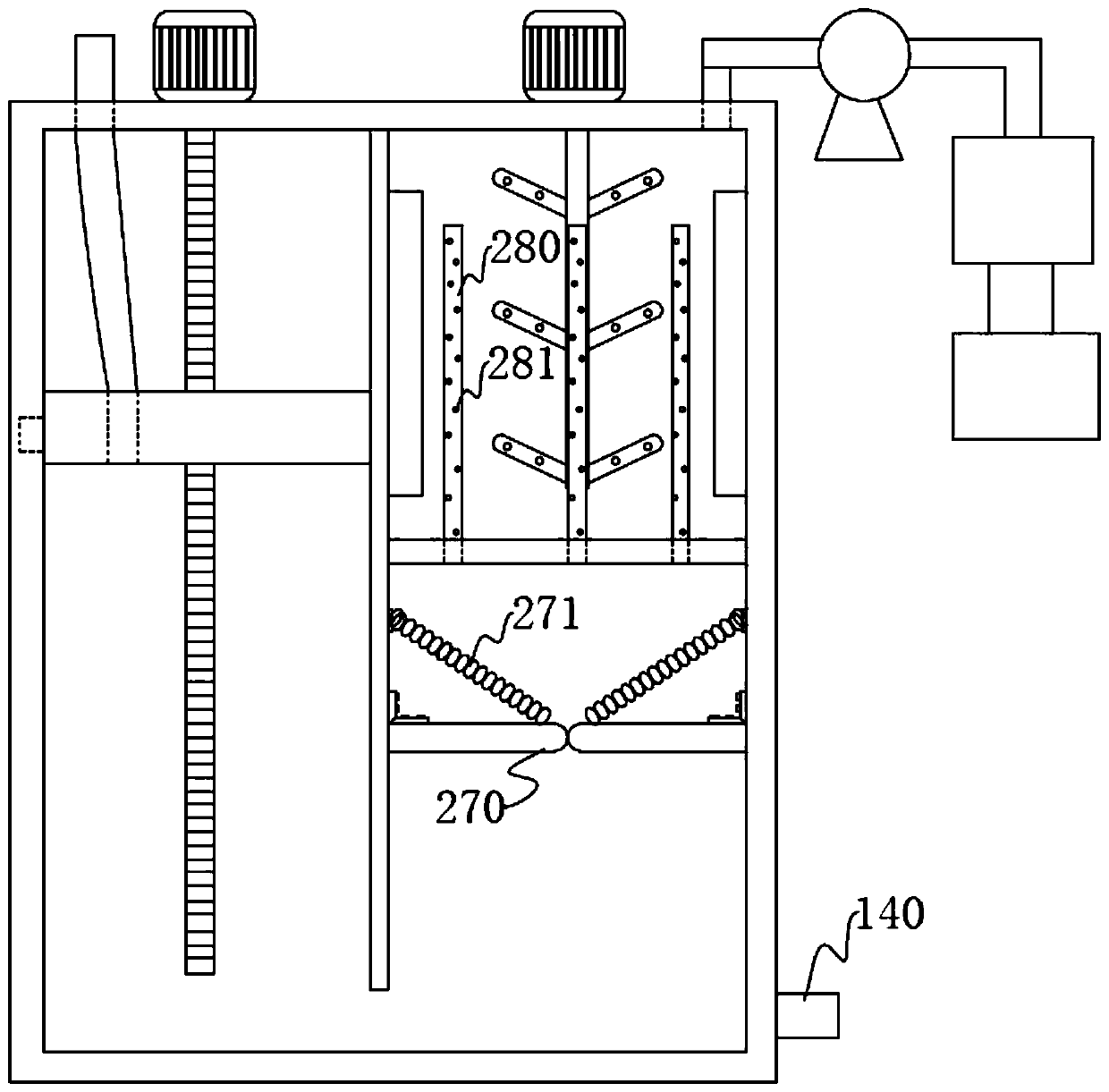

Automatic liquid separation type rose essential oil extraction device

PendingCN111961532ASpeed up distillationImprove extraction efficiencyEssential-oils/perfumesProcess engineeringEssence oil

The invention discloses an automatic liquid separation type rose essential oil extraction device. The device comprises a distillation tank, a distillation inner container and a liquid separation tank,a liquid guide pipe is fixedly mounted at the output end of a condenser through a bolt; one end, far away from the condenser, of the liquid guide pipe is fixedly connected with the input end of an oil-water separator through a bolt; the first output end of the oil-water separator is fixedly provided with an oil outlet pipe penetrating through the liquid separation tank through a bolt, and the second output end of the oil-water separator is fixedly provided with a water outlet pipe penetrating through the liquid separation tank through a bolt; steam generated by distillation of the distillation inner container is conveyed into the condenser through the air guide pipe; steam is condensed into liquid through the condenser, then the condensed liquid is conveyed into the oil-water separator through the liquid guide pipe, rose essential oil and water in the condensed liquid are separated through the oil-water separator, and therefore the rose essential oil is obtained, automatic liquid separation of the rose essential oil is achieved, and the extraction efficiency of the rose essential oil is improved.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

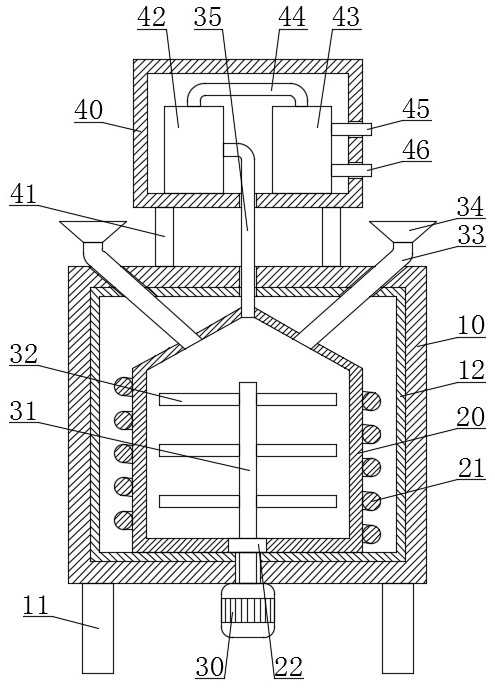

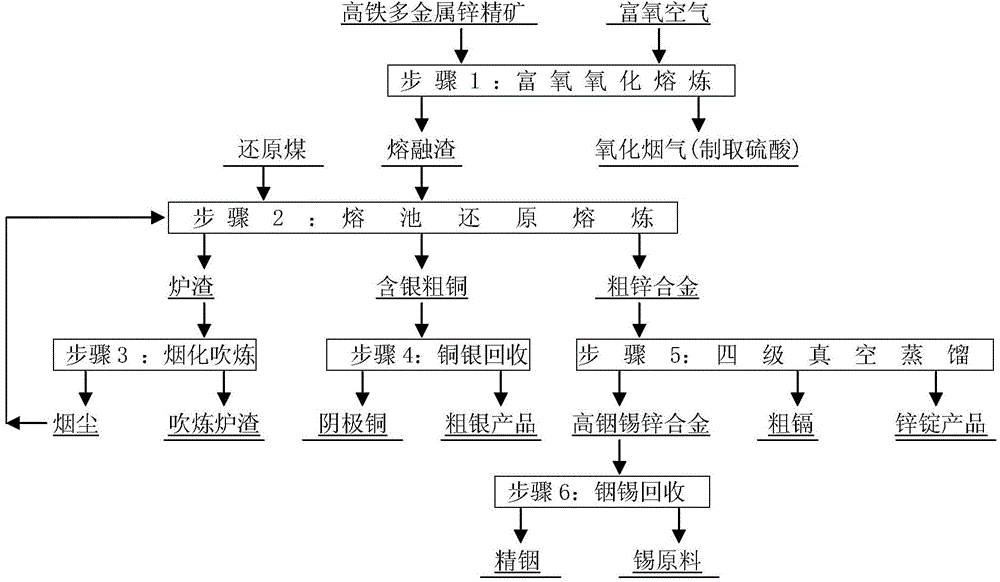

Smelting method of high-iron multi-metal zinc concentrate

ActiveCN103695663BReduce lossesEfficient recyclingPhotography auxillary processesProcess efficiency improvementIndiumDistillation

The invention relates to a smelting method of a high-iron multi-metal zinc concentrate. The method comprises the following steps: performing oxygen-enrichment oxidation melting on a zinc concentrate containing 14% to 20% of Fe, 0.03% to 0.10% of In, 0.2% to 0.6% of Cu, 0.2% to 0.6% of Cd, 0.005% to 0.02% of Ag, 0.1% to 0.2% of Sn and 40% to 50% of Zn so as to generate an oxidized flue gas and molten slags; preparing the oxidized flue gas into sulfuric acid; performing reduction smelting on the molten slags in a smelting pool so as to generate a crude zinc alloy, crude copper containing silver and slags; blowing the slags so as to obtain smoke dust and blown slags; returning the smoke dust to be subjected to reduction smelting; selling the blown slags in a market; extracting the copper and the silver from the crude copper containing silver; and performing four-stage distillation on the crude zinc alloy entering an electric-heating graphite vacuum furnace so as to generate a pyrogenic distilled zinc product, a crude cadmium product and a high-indium-tin zinc alloy which is used for extracting indium and tin. The method is reasonable in process, good in comprehensive recovery, high in production efficiency, low in production cost and clean and environmentally friendly in production process.

Owner:LAIBIN CHINA TIN SMELTING

Mercury catalyst processing device

The invention relates to the technical field of a device for mercury catalyst processing, in particular to a mercury catalyst processing device. The mercury catalyst processing device consists of a step, a distillation furnace cavity and a waste material collecting part, wherein the distillation furnace cavity is arranged at the step; the waste material collecting part is arranged under the step; the distillation furnace cavity consists of a furnace wall, a material inlet, a cover plate, an oxygen supply pipe, a coal gas inlet and a distillation pipe; the material inlet is formed in the top end of the distillation furnace cavity; the cover plate can be anastomotic with the material inlet; the oxygen support pipe and the coal gas inlet are arranged at the bottom of the furnace wall; the distillation pipe is vertically arranged inside the furnace wall; a combustion cavity is formed between the distillation pipe and the furnace wall; the oxygen supply pipe and the coal gas inlet are communicated with the combustion cavity; a tail gas outlet and a mercury vapor outlet are formed in positions, near the material inlet, of the furnace wall; the tail gas outlet is communicated with the combustion cavity; the top end of the distillation pipe is provided with a mercury vapor collecting cavity; and the mercury vapor collecting cavity is communicated with the mercury vapor outlet. Therefore mercury catalysts fall down under the gravity effect and perform heat exchange with the rising mercury vapor in the distillation pipe; the uniformly heated effect is achieved; the energy consumption is reduced; the mercury recovery rate is improved; and the mercury emission is lower than 0.3 percent.

Owner:贵州蓝天固废处置有限公司

Low-pressure spice distillation equipment

InactiveCN108219953AIncrease productionAvoid pollutionEssential-oils/perfumesDistillation separationInsulation layerWater vapor

The invention discloses low-pressure spice distillation equipment. The low-pressure spice distillation equipment comprises a steam cabin, wherein the right side of the top part of the steam cabin is fixedly connected with a balance bracket; the top part of the balance bracket is fixedly connected with a distillation cabin; the bottom part of the steam cabin is fixedly connected with an electric heating wire; asbestos heat insulation layers are arranged at two sides of the steam cabin; a decompression valve penetrates through the top part of the steam cabin; one end, located in the steam cabin,of the decompression valve is fixedly connected with a steam filtering screen. The low-pressure spice distillation equipment relates to the technical field of spice production. According to the low-pressure spice distillation equipment, atmospheric pressure in the steam cabin is reduced by the decompression valve so that the boiling point of water is reduced and the temperature of water steam isreduced; a process of gasifying the water into the water steam is more rapid, the distillation of the equipment is accelerated and the yield of spice extraction is effectively improved; a low-pressurewater steam evaporation processing principle can be used for preventing aromatic substances in raw materials from being coked by high temperature or hydrolyzed to lose effect, so that the extractionquality is higher.

Owner:张翔

Low-pressure distillation equipment for scallion oil production and use method

PendingCN112500922AProduction process cleaningPrevent heat lossFatty-oils/fats refiningDrying gas arrangementsOil productionProcess engineering

Disclosed low-pressure distillation equipment for scallion oil production comprises a distillation bin main body, a first door is arranged on the outer surface of the side end of the distillation binmain body, a first handle is arranged on the outer surface of the front end of the first door, and a first pipeline is arranged on the outer surface of the top end of the distillation bin main body; and a condenser is arranged on the outer surface of the side end of the first pipeline, a first extraction tank is arranged on the outer surface of one side of the first pipeline, and a workbench is arranged on the outer surface of the lower end of the distillation bin main body. The low-pressure distillation equipment for scallion oil production and the use method have the advantages that in the scallion oil production process, the equipment is provided with a working table, suitable for scallion oil production process, capable of collecting extracts in a graded mode and high in utilization rate, an electric heating structure can prevent waste gas generated by combustion of mineral fuel from polluting the atmospheric environment, and the production process is cleaner; and finally, a distilled tool can be subjected to concentrated high-temperature sterilization, and is convenient to use next time.

Owner:湖南葱油哥农业发展有限公司

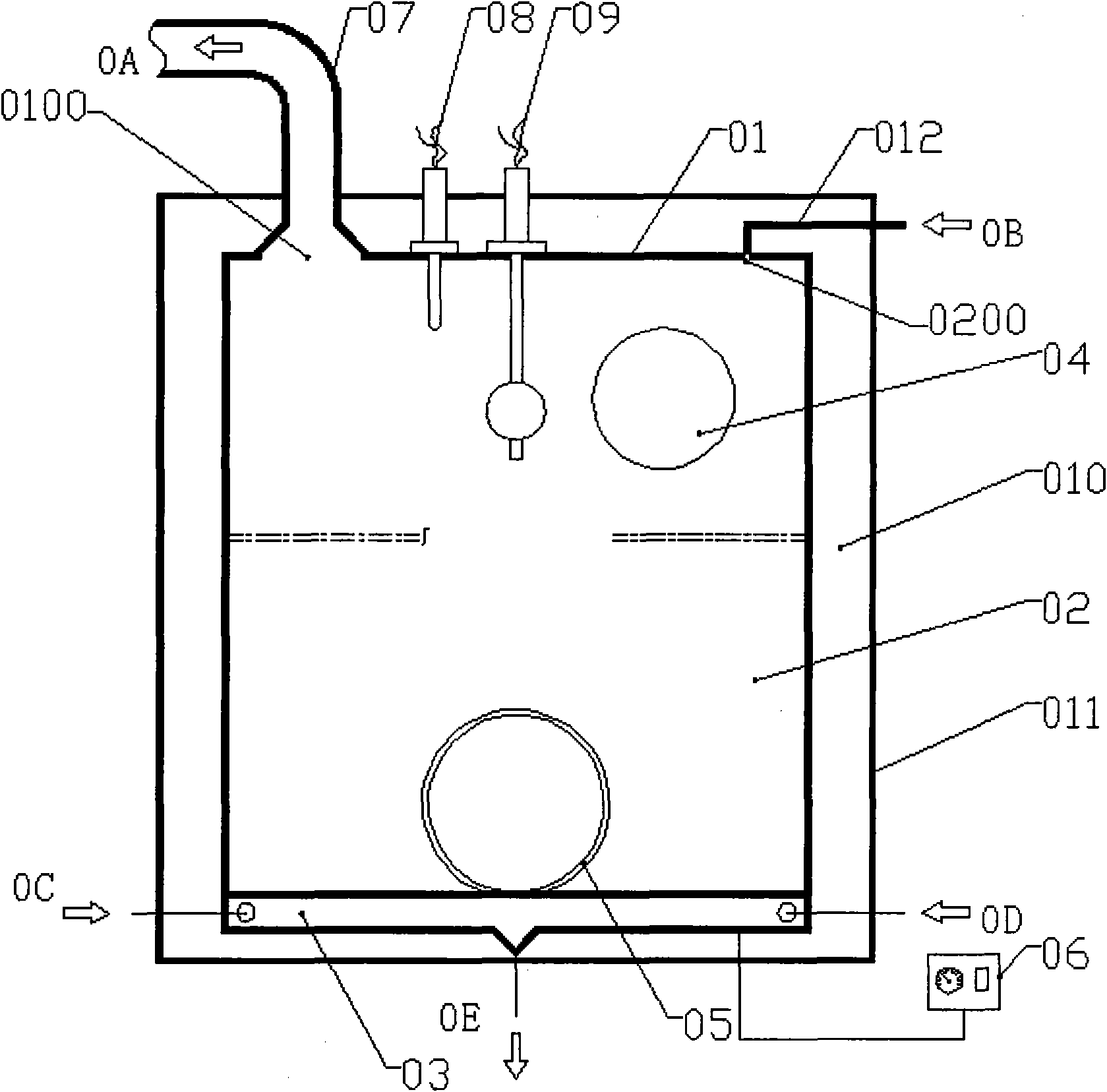

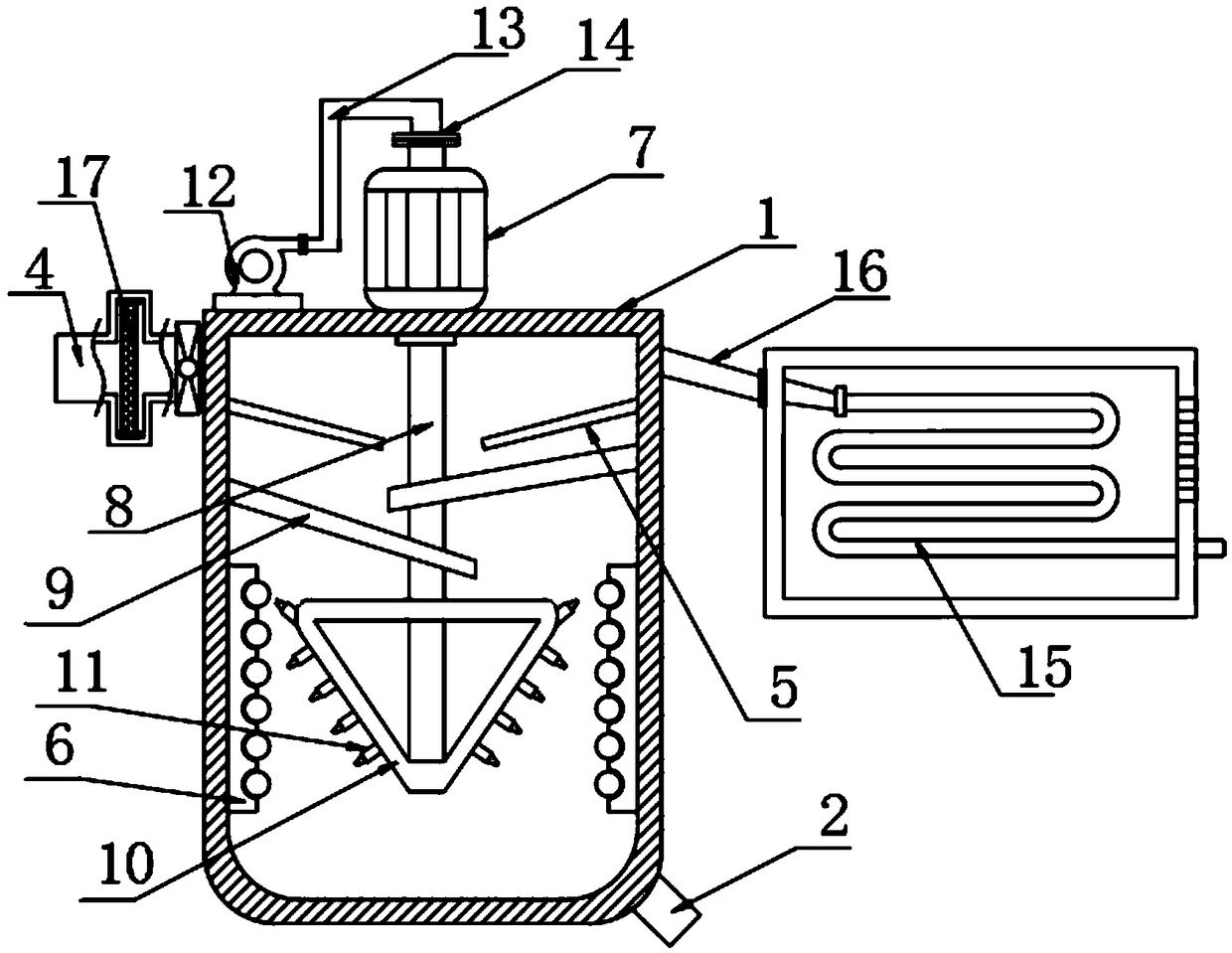

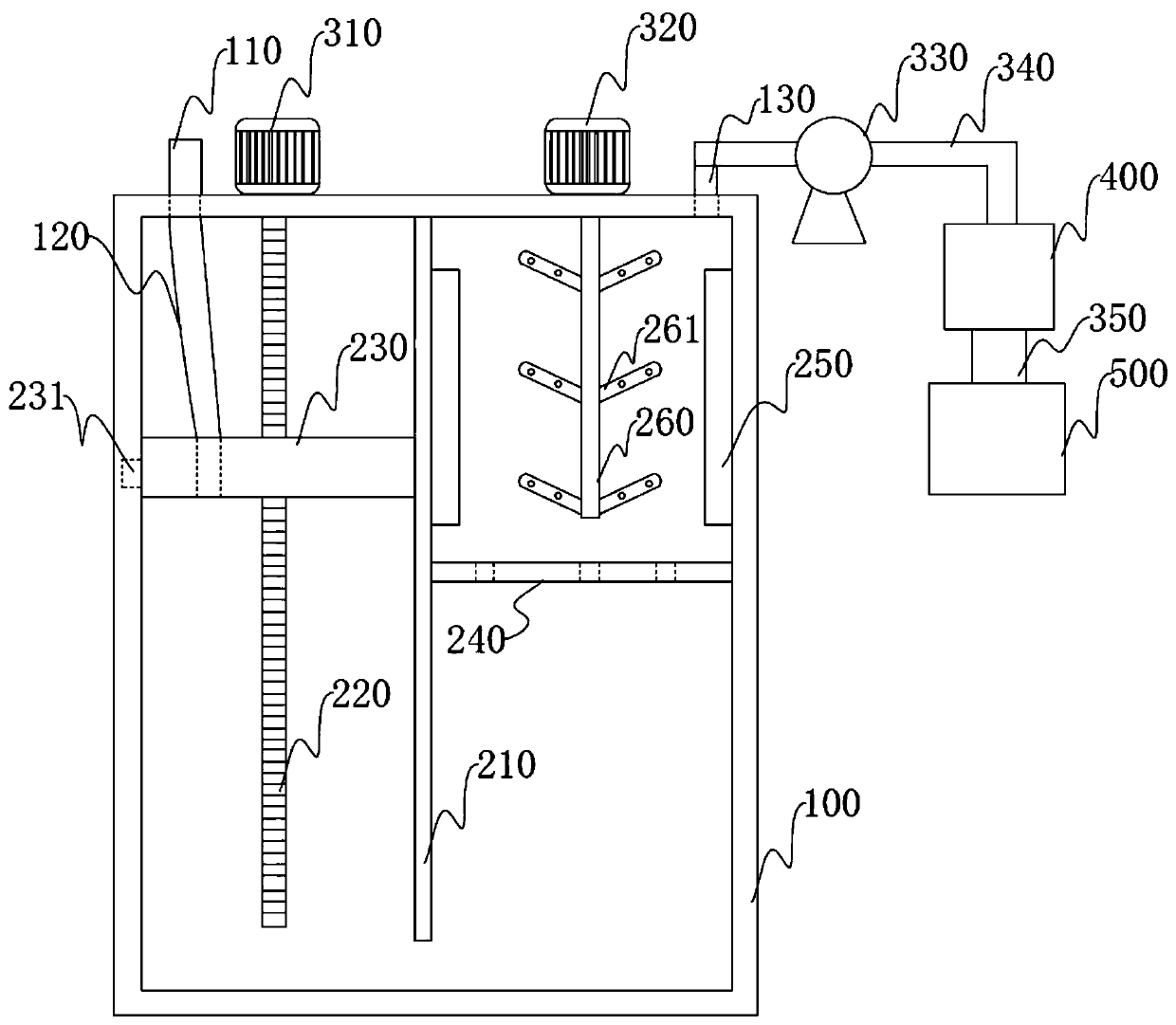

Seawater desalination device and method for ships

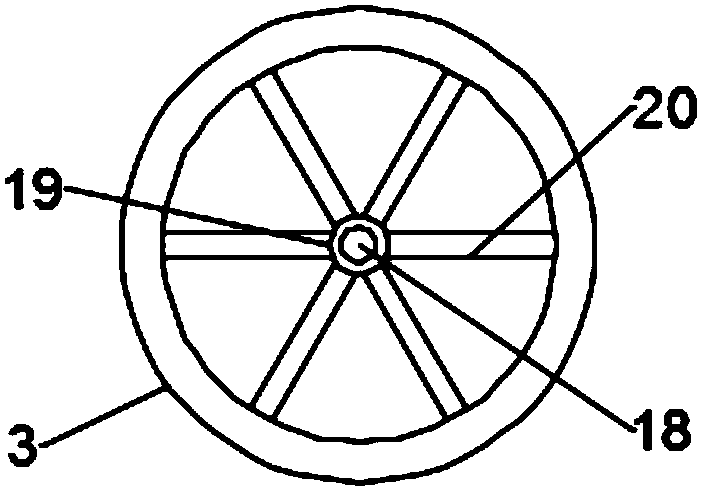

PendingCN109336204ASpeed up distillationFade fullyGeneral water supply conservationSeawater treatmentDistillationEngineering

The invention discloses a seawater desalination device and method for ships. The device comprises a box body; a liquid discharge port is formed in the bottom end of the outer wall on one side of the box body; an inlet is formed in the top end of the outer wall on the other side of the box body; two symmetrical guide plates are welded at the inner top end of the box body; the guide plates are inclined; heating plates are arranged at the bottom ends of the inner walls on two sides of the box body; a hollow shaft motor is fixed at the middle part of the top outer wall of the box body through a bolt; a hollow pipe is mounted at the output end of the hollow shaft motor; the hollow pipe is vertically disposed; the bottom end of the hollow pipe extends into the box body; and ring-shaped baffles are respectively on the inner walls on two sides of the box body. The device is simple in structural design; through starting the hollow shaft motor, the hollow pipe rotates under the driving of the hollow shaft motor, so that a triangle pipe is driven to stir slowly and the seawater flows inside the box body, thereby accelerating the seawater distillation and the seawater desalination.

Owner:DALIAN YING YUN TECH

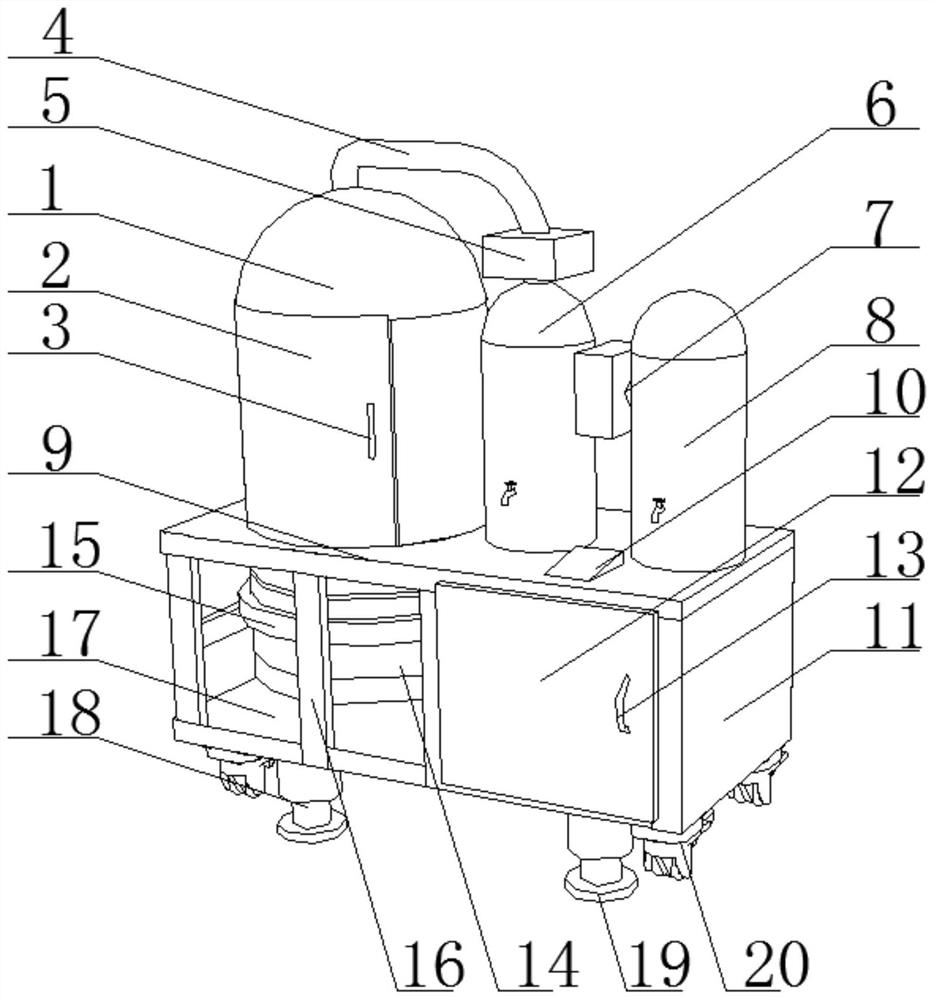

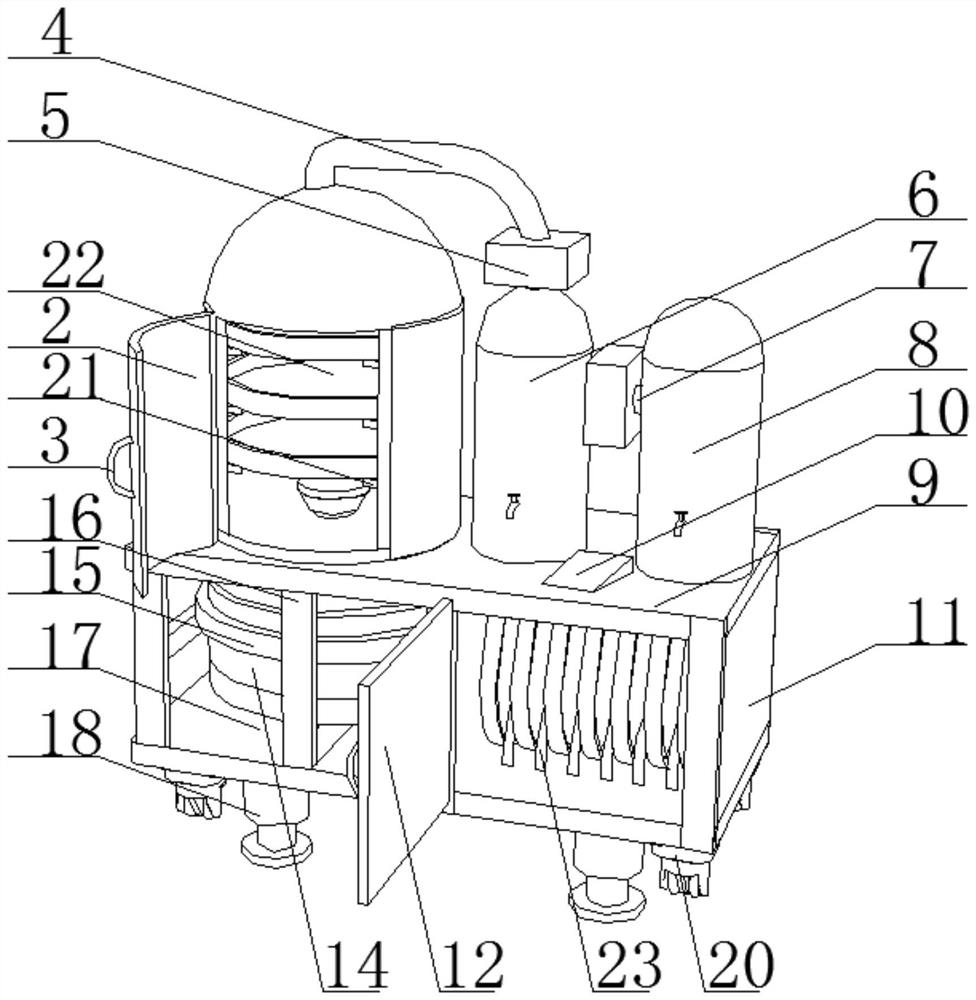

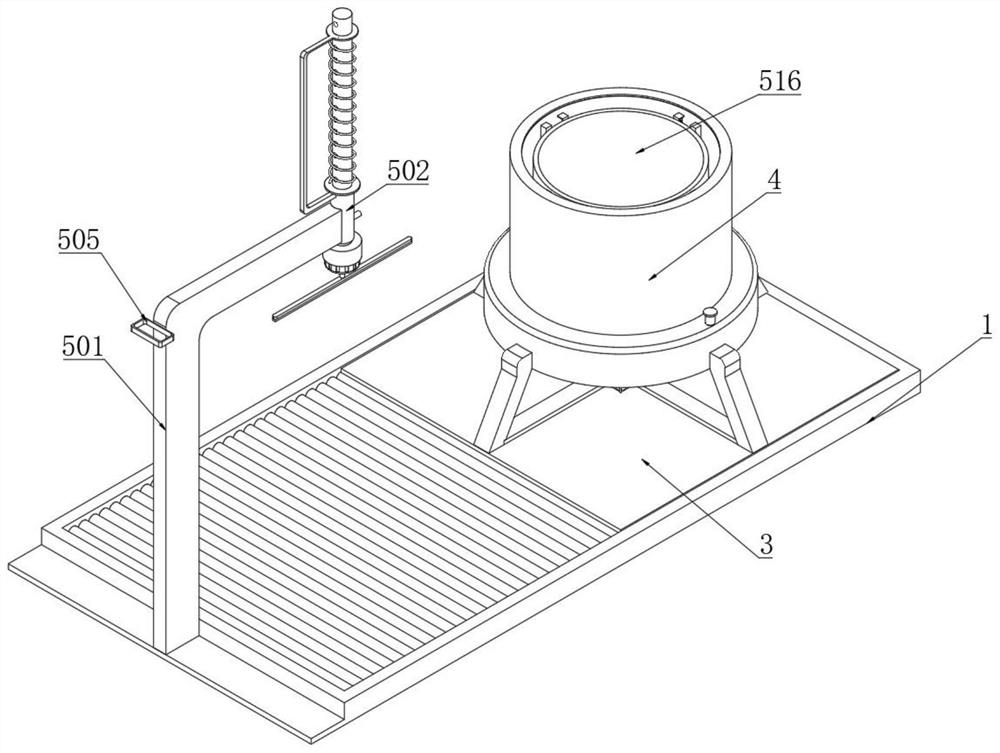

Integrated equipment for preparing living plant selenium skin nourishing liquid

InactiveCN113694550AQuick extractionImprove work efficiencyCosmetic preparationsToilet preparationsBiotechnologyAgricultural science

The invention relates to integrated equipment, in particular to integrated equipment for preparing living plant selenium skin nourishing liquid. The technical problem to be solved is to provide the integrated equipment for preparing the living plant selenium skin nourishing liquid, which has a dustproof effect and has supporting and limiting functions. According to the technical scheme, the integrated equipment for preparing the living plant selenium skin nourishing liquid comprises a bottom plate; a shell arranged at the top of the bottom plate; a first rotating seat arranged in the middle of one side in the shell; and a rotating ring rotationally arranged between the inner side of the first rotating seat and the shell. When a stirring rod rotates to mash plants, a clamping rod is clamped in a through hole of a pushing block, the situation that a discharging frame shakes is avoided, meanwhile, when a roller moves downwards to enable a supporting rod to move inwards, the supporting rod achieves the supporting and limiting effects, and the discharging frame can stably conduct mashing and distilling work.

Owner:江西中科硒谷功能农业发展有限公司

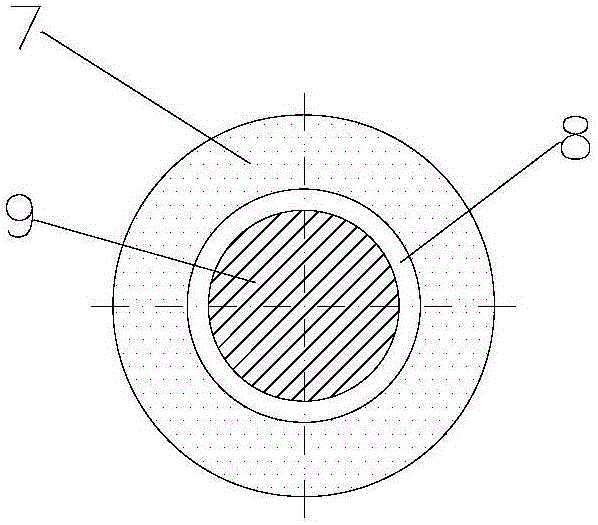

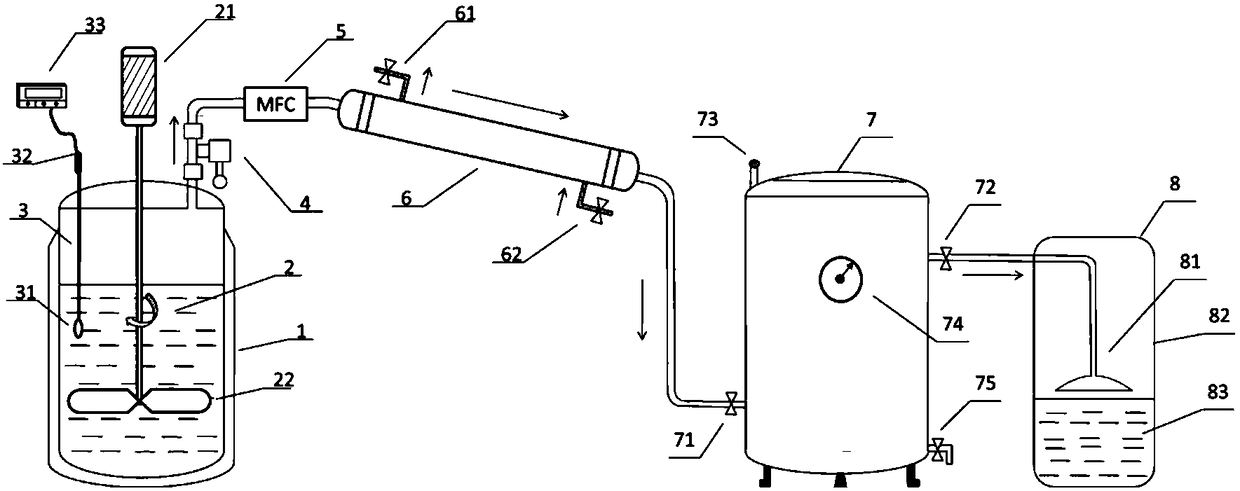

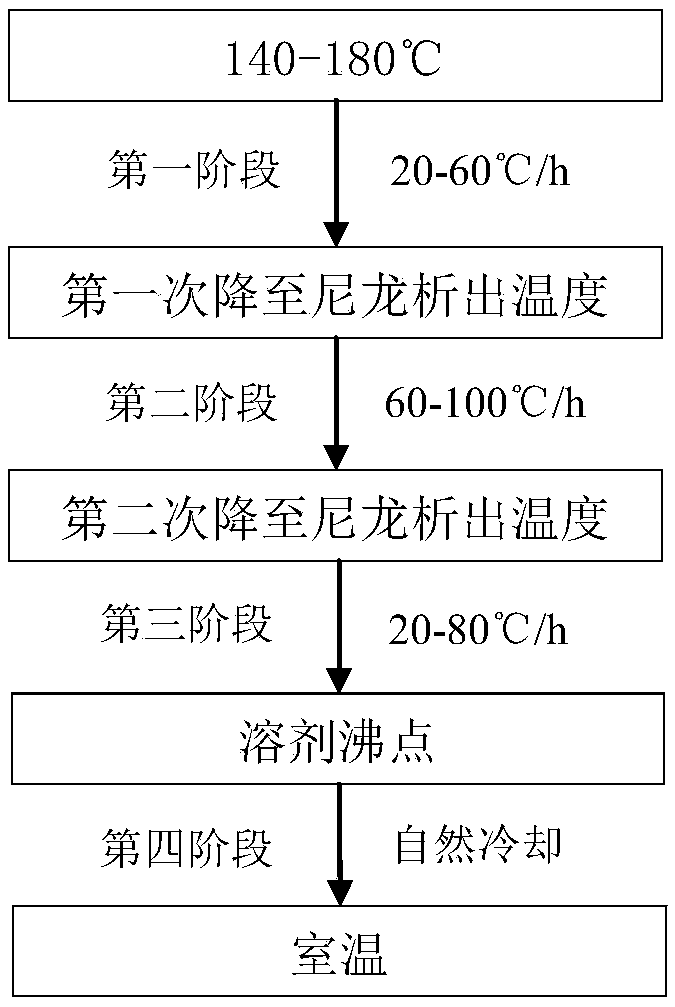

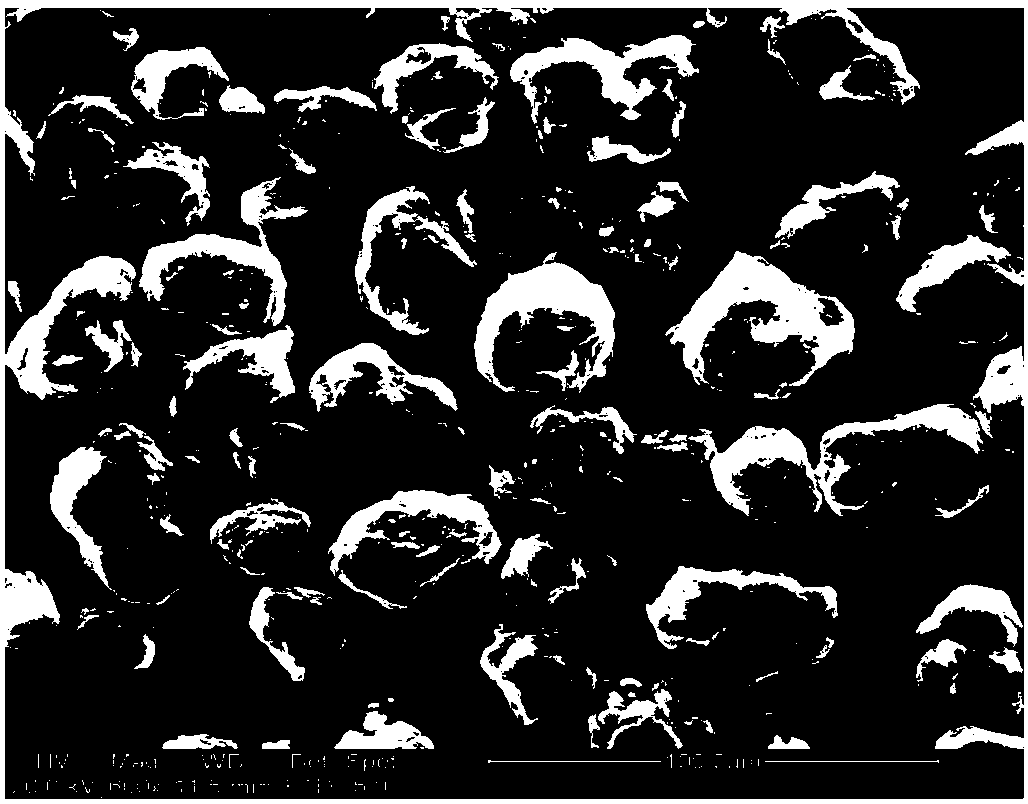

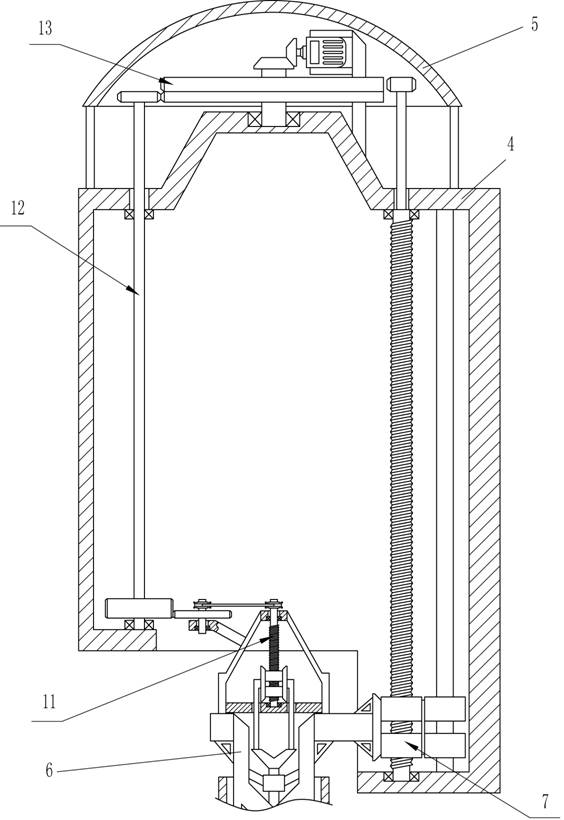

A kind of distillation cooling device and cooling method of nylon powder for sls

ActiveCN106671416BEnsure controllabilityGuaranteed RegularityAdditive manufacturing apparatusAdditive manufacturing with solidsDistillationEvaporation

The invention discloses a distillation cooling device and method for preparing nylon powder for SLS through a solvent deposition method. The distillation cooling device comprises an autoclave body, a stirring device, an online temperature monitoring device, a control valve, an MFC, a condenser and a receiving device. According to the distillation cooling method, through the arrangement of the MFC, the evaporation gas flow control manner is adopted for controlling the cooling temperature of the system, crystallized enthalpy generated during nylon deposition can be brought away in time, the temperature rise range in the autoclave body is reduced, the system temperature uniformity is guaranteed, and the sphere-like nylon powder controllable in particle size, regular in shape and appearance and good in fluidity can be prepared.

Owner:HUAZHONG UNIV OF SCI & TECH

Recovery technology of tetrahydrofuran

InactiveCN106674158AHigh recovery rateImprove condensation recoveryOrganic chemistryVacuum pumpingDistillation

The invention relates to a recovery technology of tetrahydrofuran. The technology comprises the following steps: firstly testing concentration of prepared tetrahydrofuran, and pouring tetrahydrofuran into an oilless vacuum pump when water content is greater than 10% and carrying out vacuum-pumping treatment; adding potassium permanganate into the oilless vacuum pump, stirring while carrying out oxidation treatment; adding a catalyst into the solution obtained after oxidization, reacting at the temperature of 50-65 DEG C for 30-50 min; and finally pouring the solution into a reduced pressure distiller and carrying out reduced pressure distillation, collecting 0-90% of a fraction, and finally obtaining tetrahydrofuran with water content being less than 5%. The invention has the following advantages: by adding a special oxidizing agent, oxidizability index of tetrahydrofuran meets the quality standard, distillation frequency is reduced, and energy consumption is decreased; by the use of the oilless vacuum pump for vacuum-pumping, clean exhausted gas is obtained; by additionally arranging an exhausted gas recovery system for condensation and recovery of tetrahydrofuran, pollutant discharge is reduced; and through cooperation of the above operations, recovery yield of tetrahydrofuran is increased.

Owner:南通德益化工有限公司

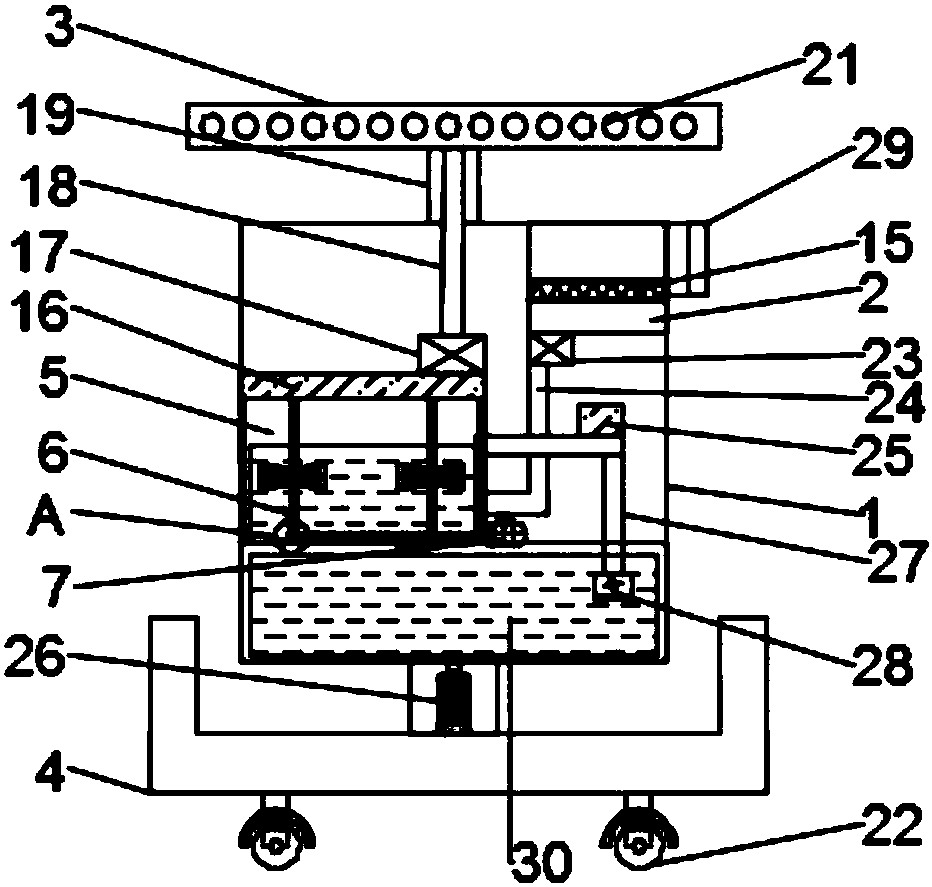

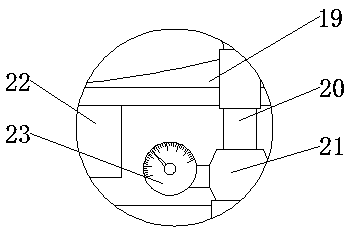

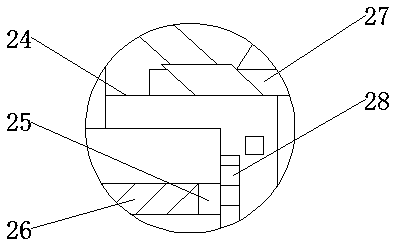

Perfume low-pressure distillation method

InactiveCN108587787AIncrease productionAvoid pollutionEssential-oils/perfumesWater vaporDistillation method

The invention discloses a perfume low-pressure distillation method. A plant perfume material is placed inside a distillation support 26, a holding rod 11 is used to push or pull a baffle plate 12; thedistillation support is pushed into a distillation cabin 13; a permanent magnet at the right side of the distillation support 26 and a powerful magnetic stripe fixed at the right side of the inner wall of the distillation cabin 13 adsorb each other to complete fixation of the distillation support 26 inside the distillation cabin 13; a heating wire 4 at the bottom of a steam cabin 1 operates to emit heat, and then water in the steam cabin 1 is heated to boiling; steam generated by boiling enters a reducing valve 21 through a steam strainer 2; hot steam in the reducing valve 21 enters an atomization nozzle 29 in the distillation cabin 13 through a distillation tube 20; the hot steam is further refined and diffused into the distillation cabin 13 through the atomization nozzle 29 for high-temperature distillation operation; and the plant perfume material in the distillation support 26 is heated, and aromatic molecules in the plant perfume material moves from the inside of the plant perfume material out of the surface of the plant perfume material; and the obtained aromatic molecular liquid slides by gravity and is collected by a tunnel pedestal 19 to enter a collecting pipe 14.

Owner:张翔

Terpene resin distillation pot and distillation method

InactiveCN111035951AIncrease outflow speedAvoid bringing outDistillation regulation/controlDistillation in boilers/stillsTemperature controlProcess engineering

The invention discloses a terpene resin distillation pot and a distillation method. The terpene resin distillation pot comprises a distillation mechanism and an electronic mechanism, wherein the electronic mechanism is mounted on the distillation mechanism, the terpene resin distillation pot further comprises an external temperature control mechanism for guaranteeing the temperature of distilled gas, and a condensation mechanism for condensing distilled mixed gas, a heating mechanism for heating distillate in a sectional mode and a nitrogen inlet mechanism for improving the distillation speedand the safety of a to-be-distilled matter are further arranged in the distillation mechanism, the external temperature control mechanism is connected with the upper end of the distillation mechanism,the condensation mechanism is connected with one end of the external temperature control mechanism, the sectional heating mechanism is connected to the interior of the distillation mechanism, and thenitrogen inlet mechanism is connected to the bottom of the distillation mechanism. According to the invention, the terpene resin distillation pot is reasonable in structure, adopts a sectional type heat conduction oil mode to heat so as to improve the heating effect, avoids product burning so as to ensure the quality, avoids fire disaster caused by dry burning so as to improve the safety, adoptsnitrogen inflation stirring and inert gas stirring so as to avoid fire accidents, and improves the product quality and the heat transfer speed so as to improve the production efficiency.

Owner:黎月清

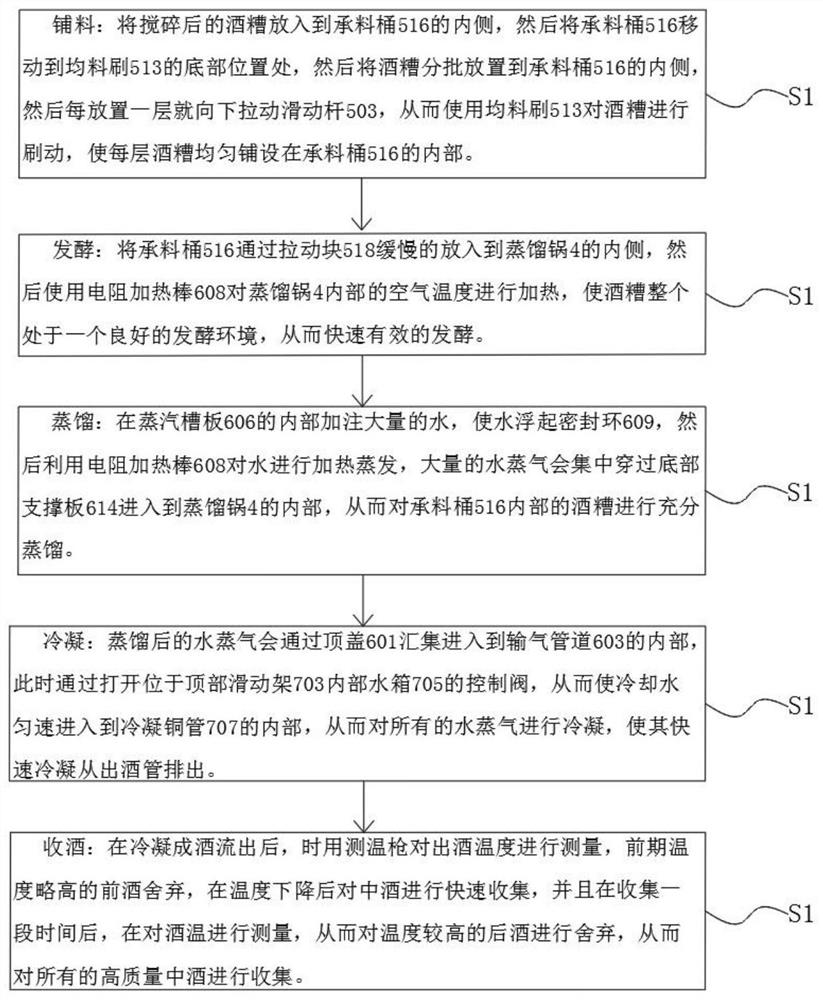

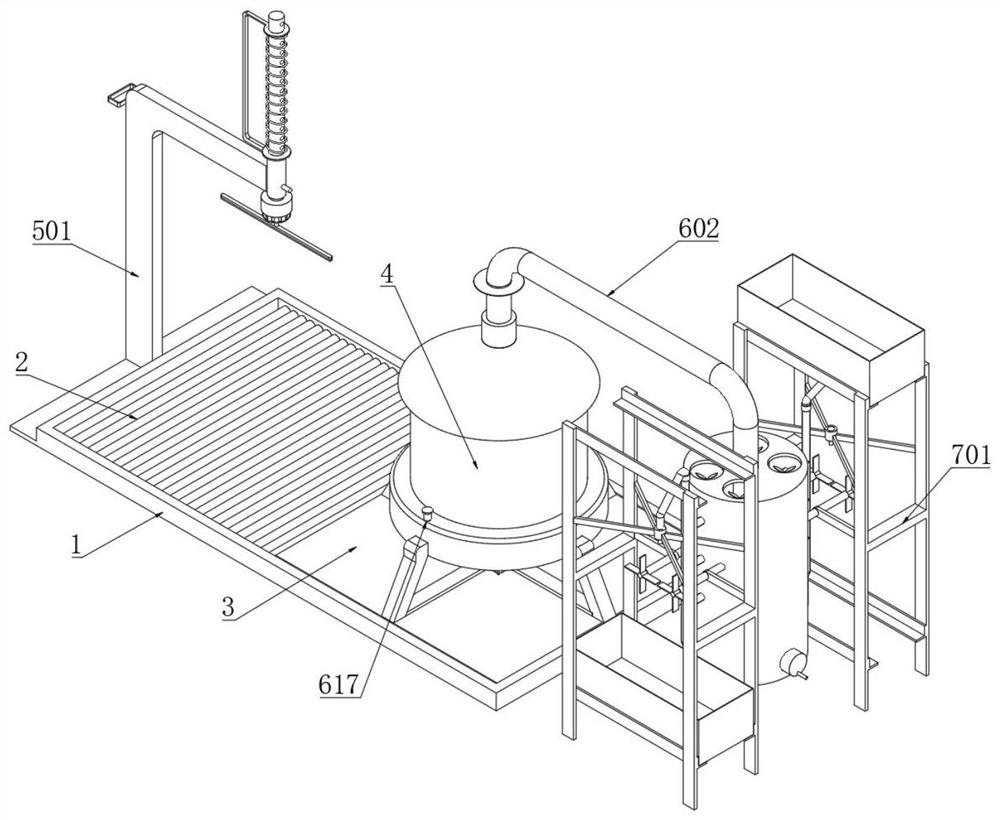

Liquor brewing process

InactiveCN113388466APrevent uneven pavingImprove qualityAlcoholic beverage preparationAlcoholEngineering

The invention discloses a liquor brewing process. A material uniformizing supporting rod is mounted at one side of the top end of a base, limiting holes are formed in the outer side of a sliding rod at equal intervals, a limiting rod is slidably connected to the inner side of the material uniformizing supporting rod, a connecting rod is welded to the outer side of a sliding sleeve, a reset supporting plate is welded to one end of the connecting rod, a mounting groove is formed in the bottom end of the sliding rod, a servomotor is mounted at the inner side of the mounting groove, a rotating transverse rod is connected to a power output end of the servomotor, and a material uniformizing brush is bonded to the bottom end of the rotating transverse rod. According to the liquor brewing process, the structure is scientific and reasonable, and the use is safe and convenient; all distiller's grain crushed materials are evenly laid through uniform-speed rotation of the material uniformizing brush and then uniformly laying all crushed materials layer by layer, and it is guaranteed that all distiller's grains can be evenly cooked by steam in a distillation process, so that alcohol concentrations of all distilled wine can be improved and guaranteed to be the same, and thus, the quality and taste of liquor are improved.

Owner:霍爱华

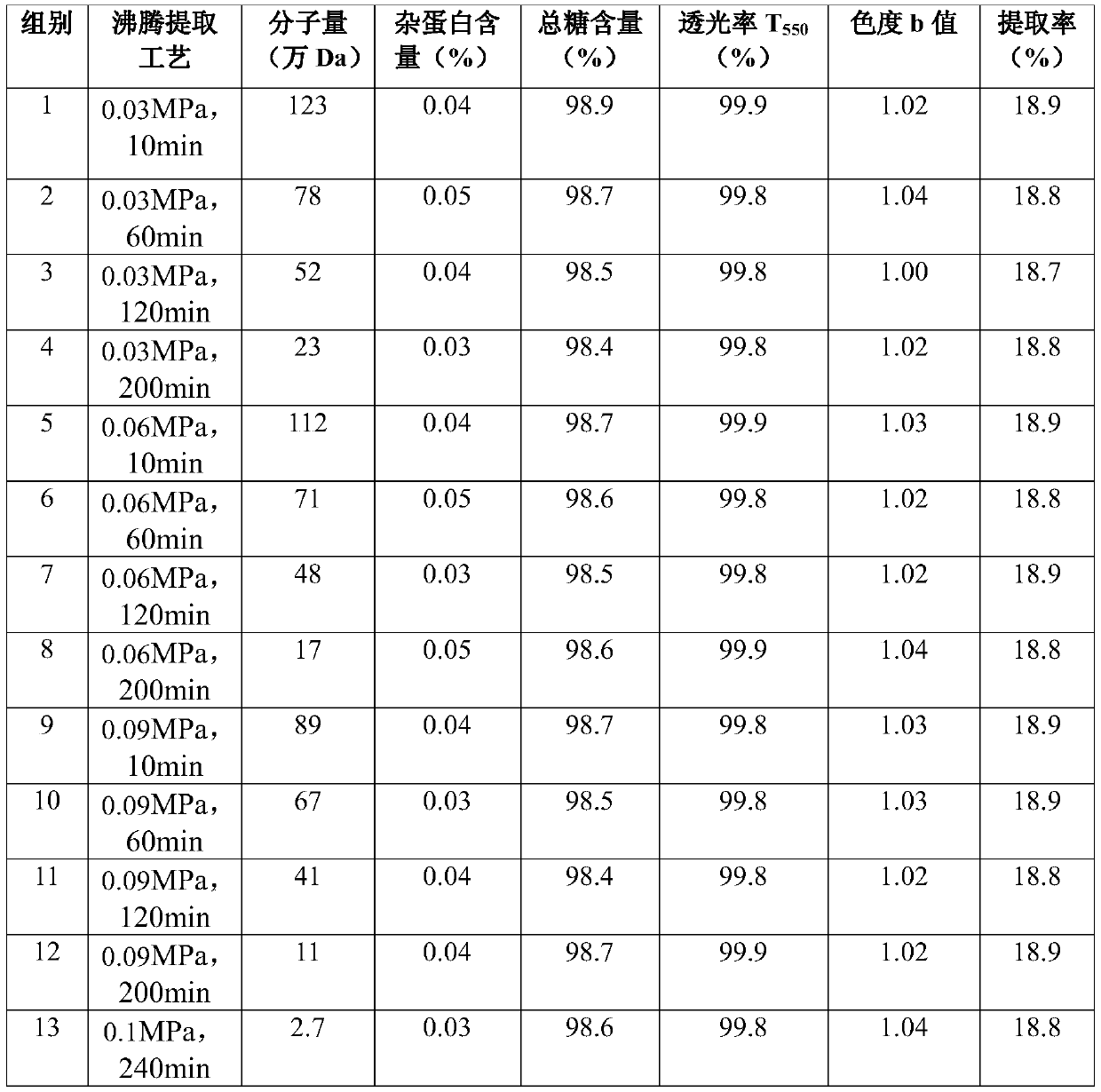

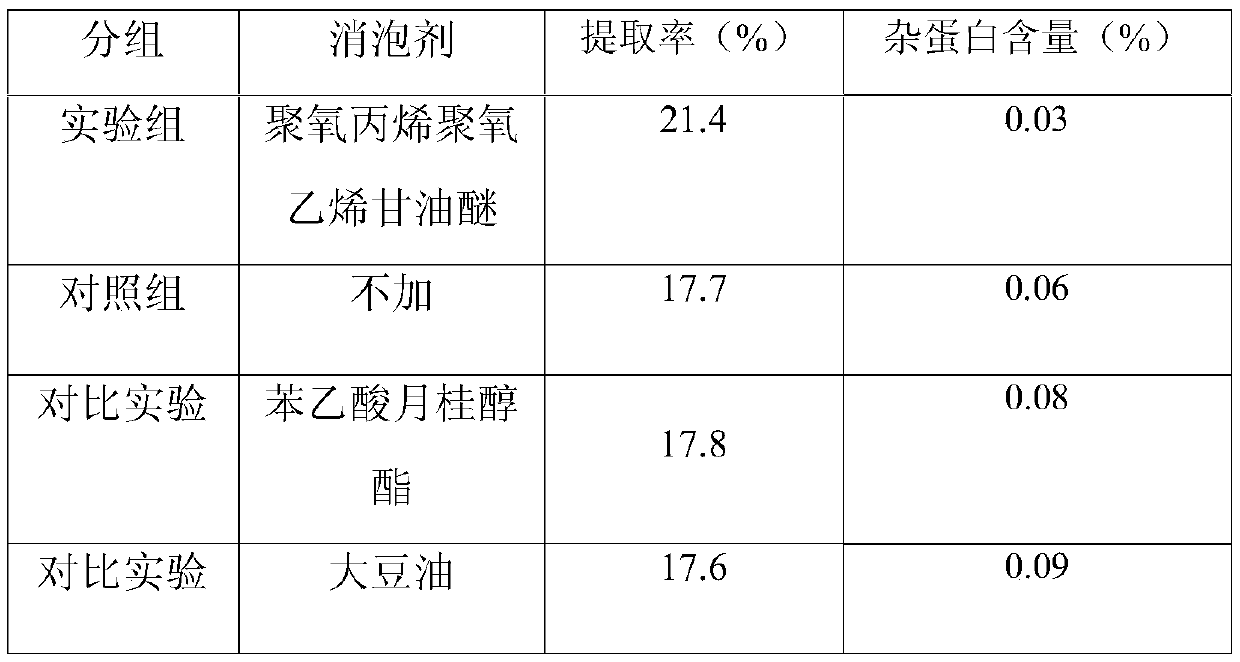

A kind of preparation technology of tremella polysaccharide of whole series molecular weight

The invention discloses a preparation process of tremella polysaccharides with a full range of molecular weight, including extraction, impurity removal and decolorization, coarse filtration, fine filtration, concentration, precipitation, suction filtration and drying processes, characterized in that the extraction process includes steam pressure holding The two-step extraction steps of boiling extraction and high-efficiency enzyme activity accelerator combined with compound enzyme extraction have the beneficial effect of the present invention: the polyoxypropylene polyoxyethylene glyceryl ether added in the steam pressure-preserved boiling extraction effectively solves the problem of foaming and at the same time , which can significantly promote the enzymatic hydrolysis efficiency of subsequent acid protease, cellulase and pectinase. A high-efficiency enzyme activity accelerator was unexpectedly found in the compound enzyme extraction. The auxiliary agent in the coarse filtration process can not only improve the state of the precipitated material , so that the precipitated material is uniformly dispersed fine particles, and it also improves the distillation speed in the next membrane distillation process.

Owner:SHANDONG FOCUSFREDA BIOTECH CO LTD

Liquefied petroleum gas recycling and refining device

InactiveCN108102685AImprove the heating effectSufficient heat exchangeHydrocarbon distillationHydrocarbon oils treatmentEngineeringLiquefied petroleum gas

The invention discloses a liquefied petroleum gas recycling and refining device which comprises a box type furnace body and a furnace body, wherein the furnace body is arranged in the center of the box type furnace body, a first fire barrier wall and a second fire barrier wall are respectively arranged at the two ends of the furnace body, the upper end of the first fire barrier wall is fixed to the top end of the box type furnace body, one end of the second fire barrier wall is fixed to the bottom end of the box type furnace body, and the other end of the second fire barrier wall is the free end, a first gas transmission pipeline is arranged at one end of the box type furnace body, one end of the first gas transmission pipeline penetrates through the first fire barrier wall and extends tothe outer surface of the furnace body, and the other end of the first gas transmission pipeline is arranged outside the box type furnace body. According to the liquefied petroleum gas recycling and refining device disclosed by the technical scheme of the invention, a first through hole and a second through hole are respectively formed in the first fire barrier wall and the second fire barrier wall; furthermore, the first through hole and the second through hole are mainly used for bring convenience to the first gas transmission pipeline and the second gas transmission pipeline, and high temperature gas can reach any position on the surface of the furnace body through the first gas transmission pipeline and the second gas transmission pipeline to fully exchange heat with the furnace body.

Owner:CHENGDU LAIBAO PETROLEUM EQUIP

Distillation furnace device for drug intermediates

PendingCN113476876AEvenly heatedImprove the mixing effectRotary stirring mixersDistillation in boilers/stillsThermodynamicsPharmaceutical drug

The invention relates to the technical field of medicine production, in particular to a distillation furnace device for drug intermediates. The distillation furnace device comprises a bottom plate, wherein a distillation furnace main body is mounted on one side of the upper surface of the bottom plate, a driving motor is fixedly mounted on the surface of one end of the distillation furnace main body, a first stirring mechanism is arranged at the output end of the driving motor and located in the distillation furnace main body, a second stirring mechanism is arranged at the other end of the first stirring mechanism and located at the end, which is away from the driving motor, of the distillation furnace main body, and a cooling mechanism is arranged on the upper surface of the bottom plate and located on one side of the distillation furnace main body. By arranging the first stirring mechanism and the second stirring mechanism, internal materials can be longitudinally and transversely stirred at the same time, so that the mobility of the materials in the distillation furnace is higher, the materials are heated more uniformly, distillation is more sufficient, and the distillation efficiency is further improved.

Owner:南通辉正医药科技有限公司

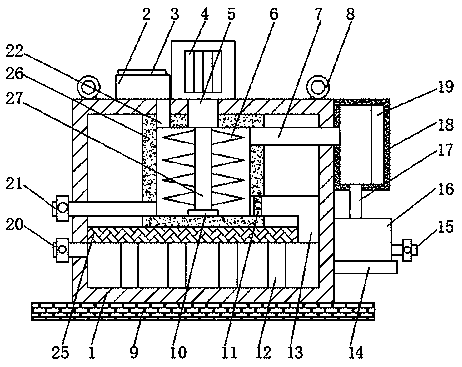

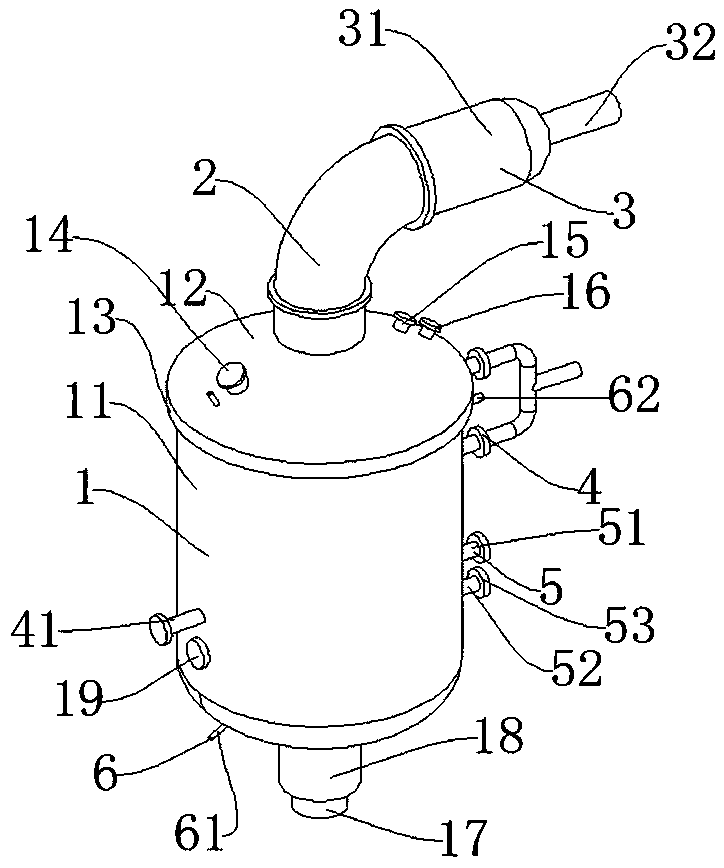

Distillation kettle with buffering function

InactiveCN112386933ALiquid filling process directlySpeed up distillationDistillation in boilers/stillsProcess engineeringBolt connection

The invention discloses a distillation kettle with a buffer function, which comprises a bottom frame and a kettle body, and the bottom frame and the still body are provided with a lifting device, a liquid supply device, a shunting device, a displacement device, a transmission device, a connecting device and a driving device; the kettle body is connected to the bottom frame through bolts, a supporting frame is fixedly connected to one side of the bottom frame, a mounting box is fixedly connected to one side of the supporting frame, and a protective ceiling is fixedly connected to the position,away from one side of the kettle body, of the mounting box. Through cooperation of the lifting device, the liquid supply device, the flow dividing device, the displacement device, the transmission device, the connecting device and the driving device, the automation degree of the distillationkettle in the working process is improved, distillation components in the distillationkettle can be protected, the distillation components in the distillation kettle cannot be directly impacted by liquid, and corrosion and impact damage of the distillation components are avoided; meanwhile, the problem thatthe liquid leaks when being injected into the distillation kettle can be avoided.

Owner:潍坊惠米农业科技发展有限公司

Distillation recovery device for producing lubricating oil

InactiveCN110404286AChange gap sizeThe amount of changeLubricant compositionFractional distillationCurrent limitingLiquid state

The application provides a distillation recovery device for producing lubricating oil, the distillation recovery device comprises a distillation tank, wherein a first partition plate which divides thedistillation tank into a first chamber and a second chamber is arranged in the distillation tank, a first screw rod is arranged in the first chamber, and a movable baffle plate sleeves an upper thread of the first screw rod; a second partition plate perpendicular to the first partition plate is arranged in the second chamber, the second partition plate divides the second chamber into a reaction chamber and a current limiting chamber, an electric heating plate is arranged in the reaction chamber, a stirring rod is arranged in the reaction chamber, and stirring blades are arranged on the stirring rod; the second partition plate is provided with an inflow port which is communicated with the reaction chamber and the current limiting chamber, a condensation tank is arranged outside the distillation tank, and steam in the reaction chamber flows into a recovery tank after passing through the condensation tank. The distillation recovery device has the beneficial effects that feed liquid entering the distillation tank is stirred, heated and evaporated into a gaseous state and then discharged out of the distillation tank, and the steam is condensed into a liquid state after passing throughthe condensation tank and then flows to the recovery tank.

Owner:TOILX TIANJIN

A kind of coal gas energy-saving mercury distillation furnace and preparation method thereof

InactiveCN105154688BEvenly heatedPrevent leakageDistillation in pipe stillsProcess efficiency improvementDistillationPollution

Owner:贵州蓝天固废处置有限公司

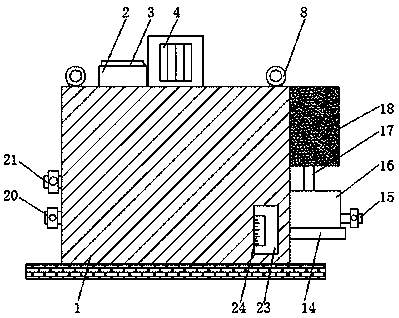

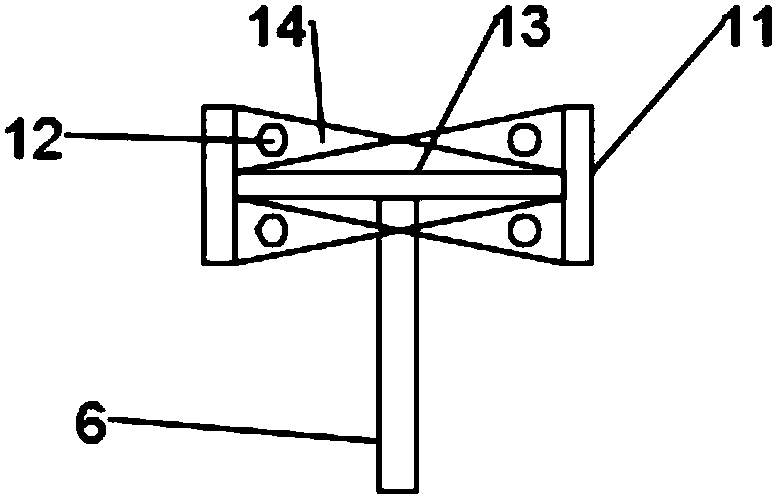

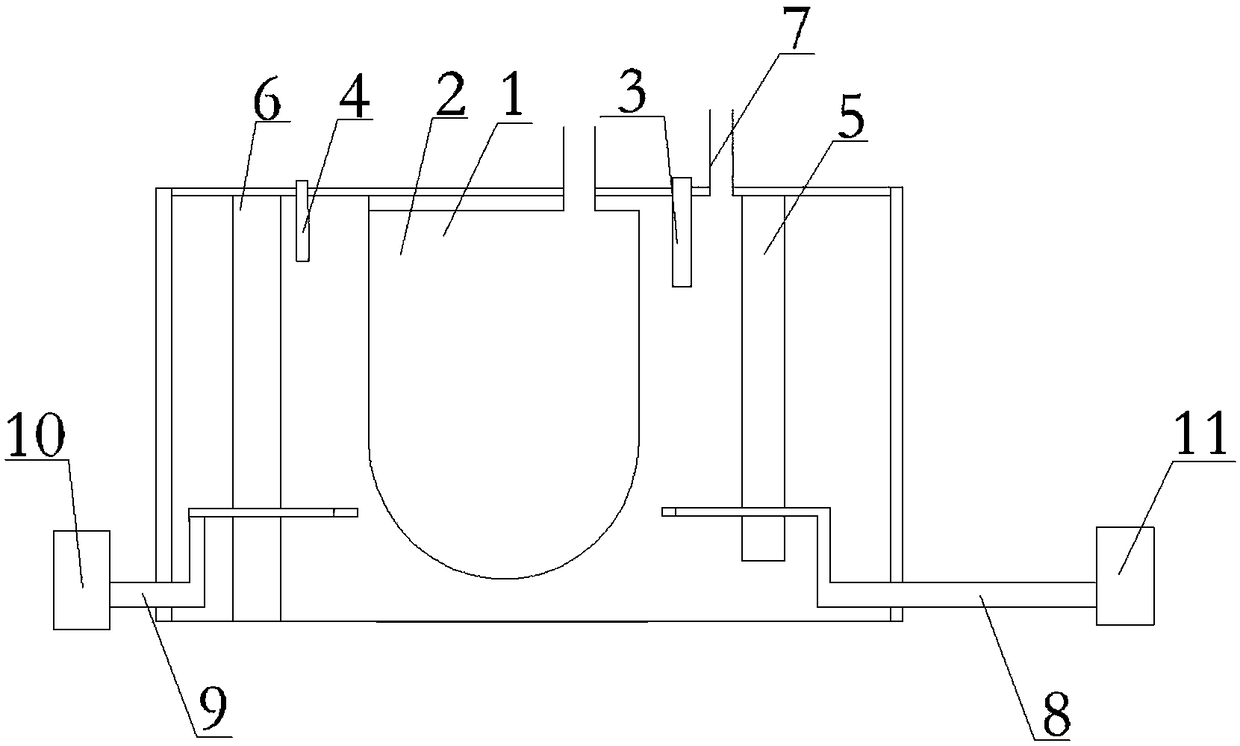

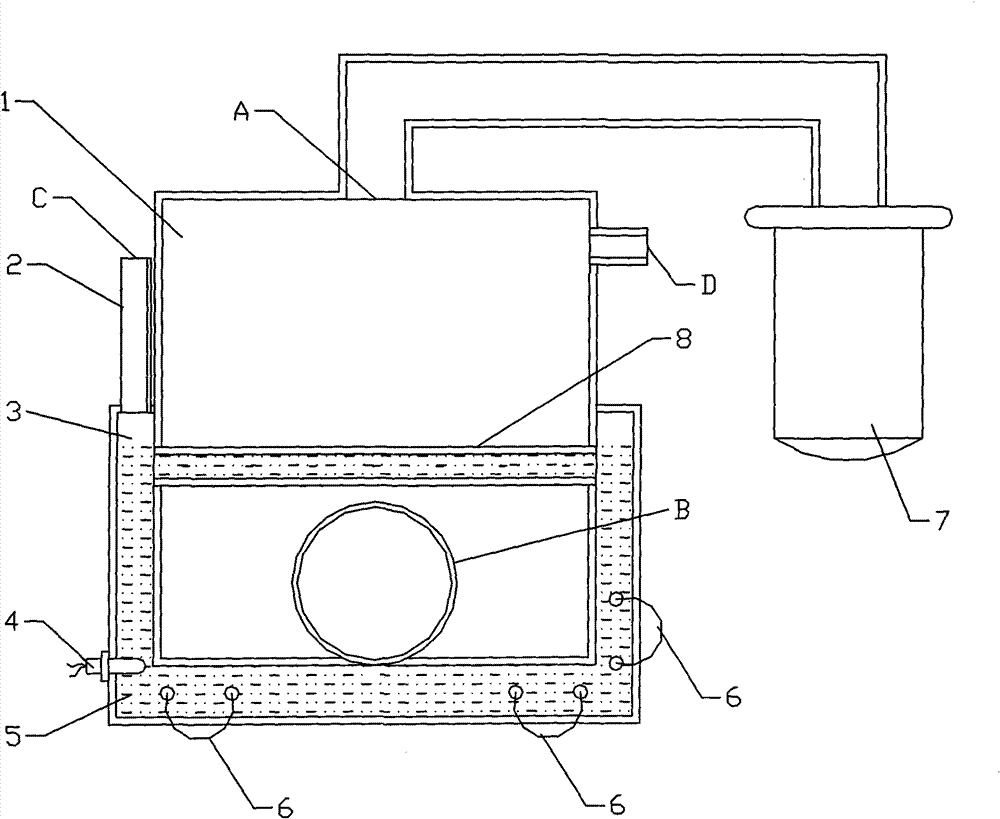

Distillation kettle provided with automatic overflowing device

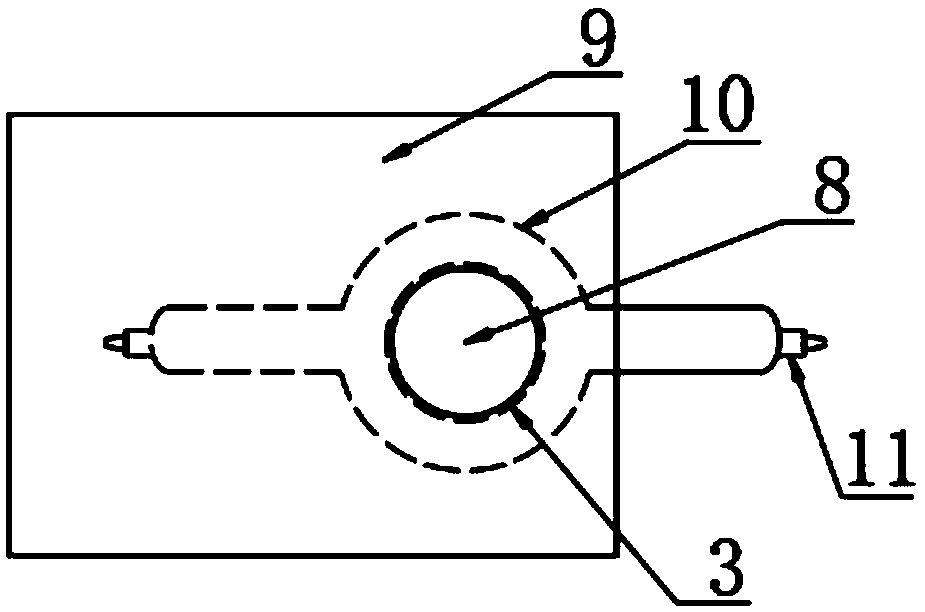

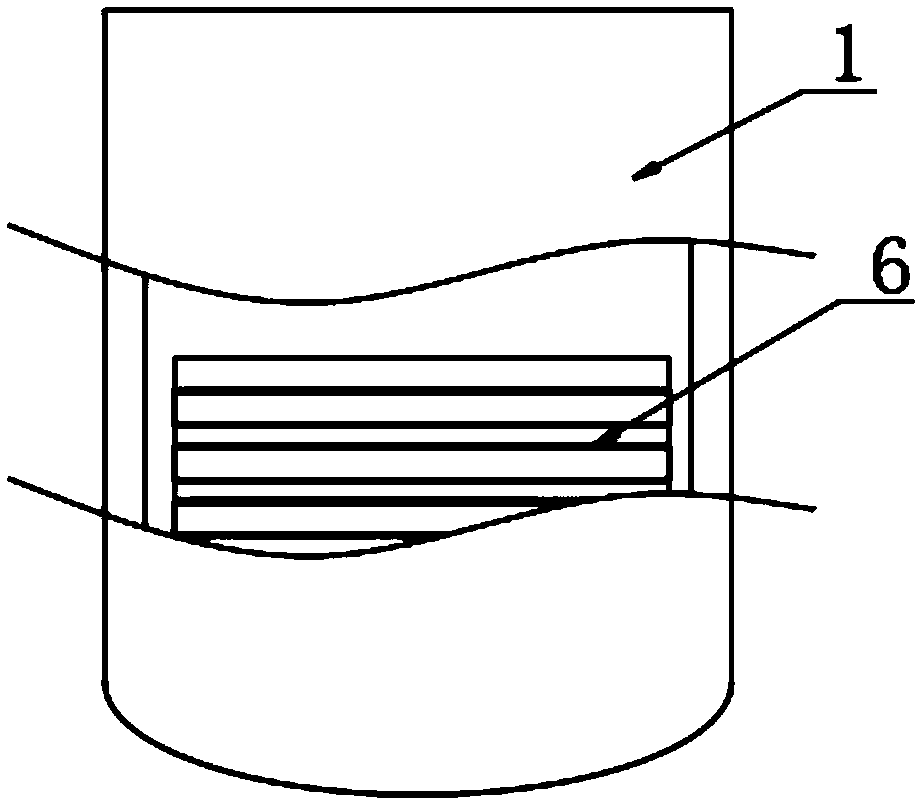

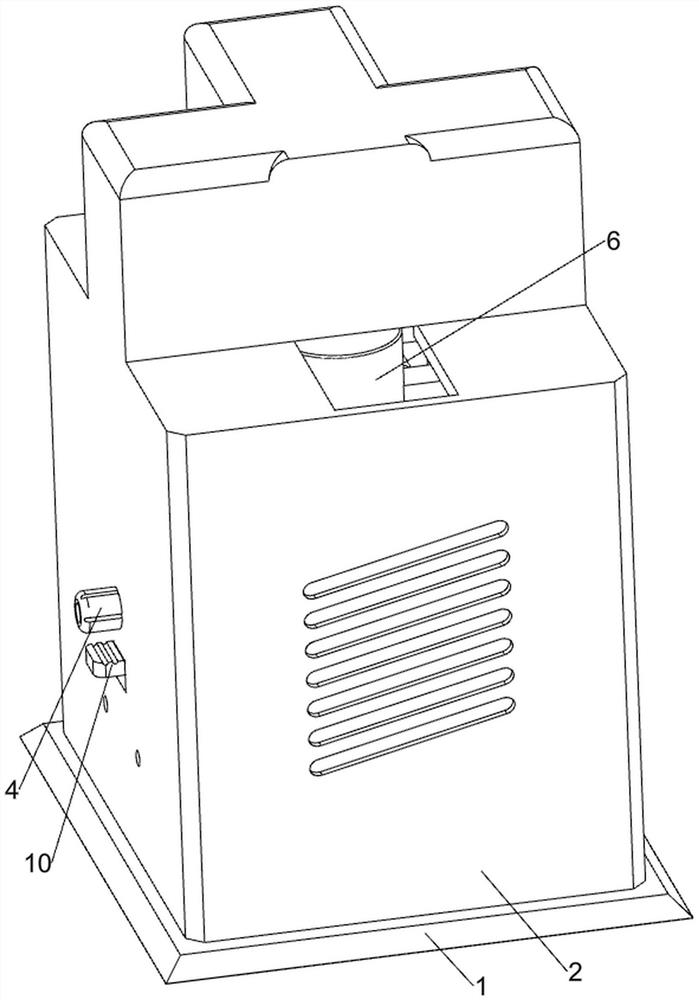

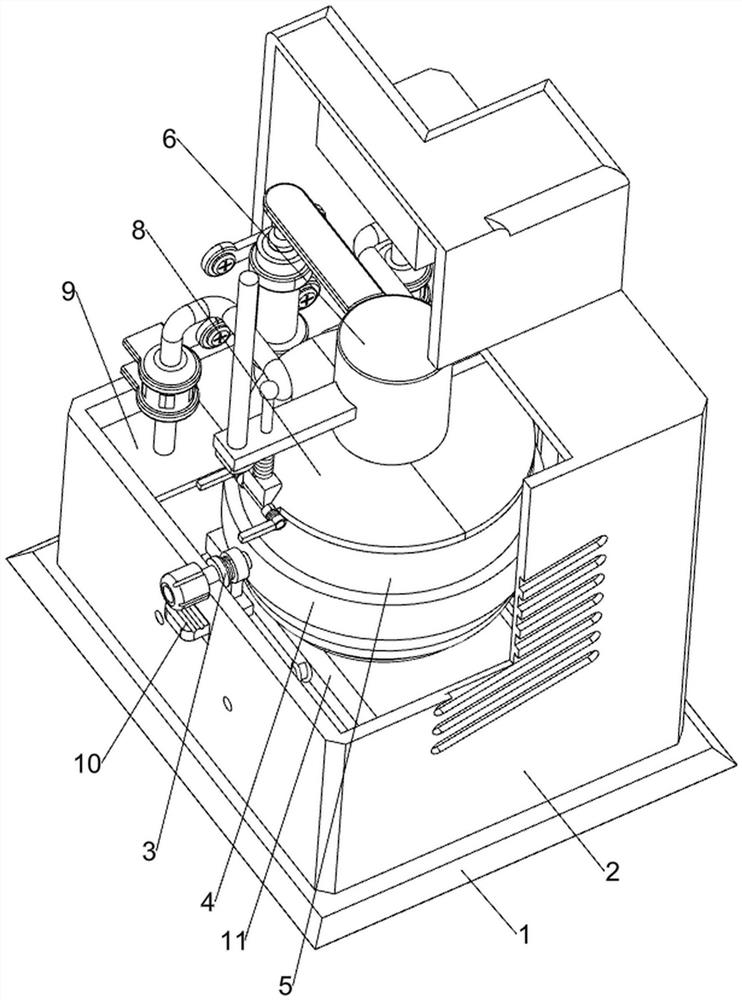

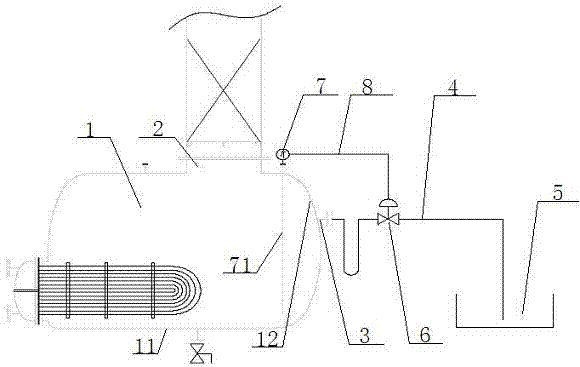

InactiveCN103203114AReduce labor intensitySpeed up distillationDistillation in boilers/stillsProcess engineeringEnvironmental geology

The invention discloses a distillation kettle provided with an automatic overflowing device. The distillation kettle comprises a distillation kettle body (1), wherein the distillation kettle body (1) is provided with a material feeding opening (2) and a material overflowing opening (3). The distillation kettle is characterized in that the material overflowing opening (3) is located at a rear end socket (12) of the distillation kettle body (1); the material overflowing opening (3) is connected with a collection box (5) through an overflowing pipe (4); a valve (6) is arranged on the overflowing pipe (4); the valve (6) is a temperature control valve; the distillation kettle body (1) is internally provided with a temperature measuring set (7); and the temperature measuring set (7) is connected with the valve (6) through a data line (8). According to the distillation kettle disclosed by the invention, the problems of a traditional distillation kettle that a manual manner is used for controlling the discharging of materials so that not only can solvents be wasted, but also the load of subsequent wastewater treatment is increased can be solved.

Owner:HUAIAN WAN BANG SPICE IND CO LTD

Distillation box of dry washer heated by using conduction oil

InactiveCN101899773BImprove heat transfer efficiencySpeed up distillationDry-cleaning apparatusTextiles and paperElectricityDistillation

Owner:上海雅森洗涤设备有限公司

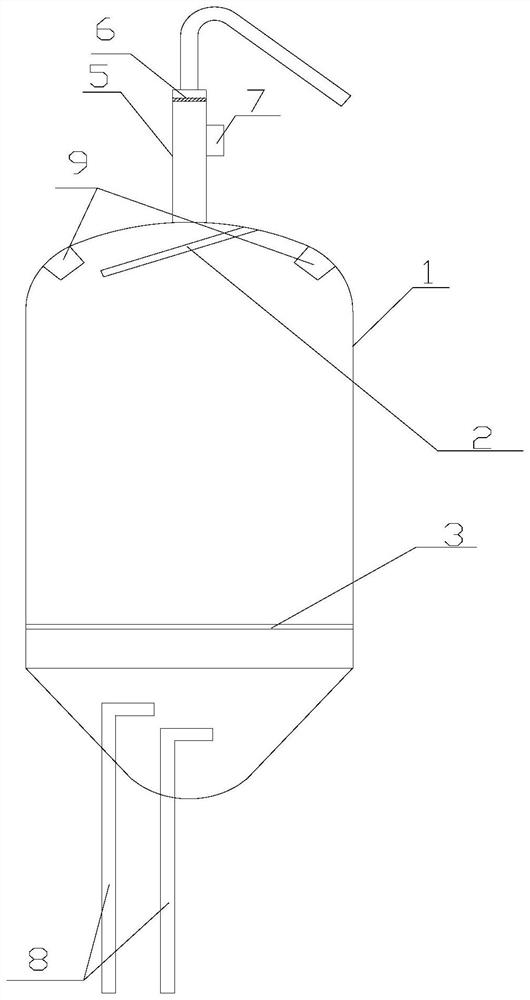

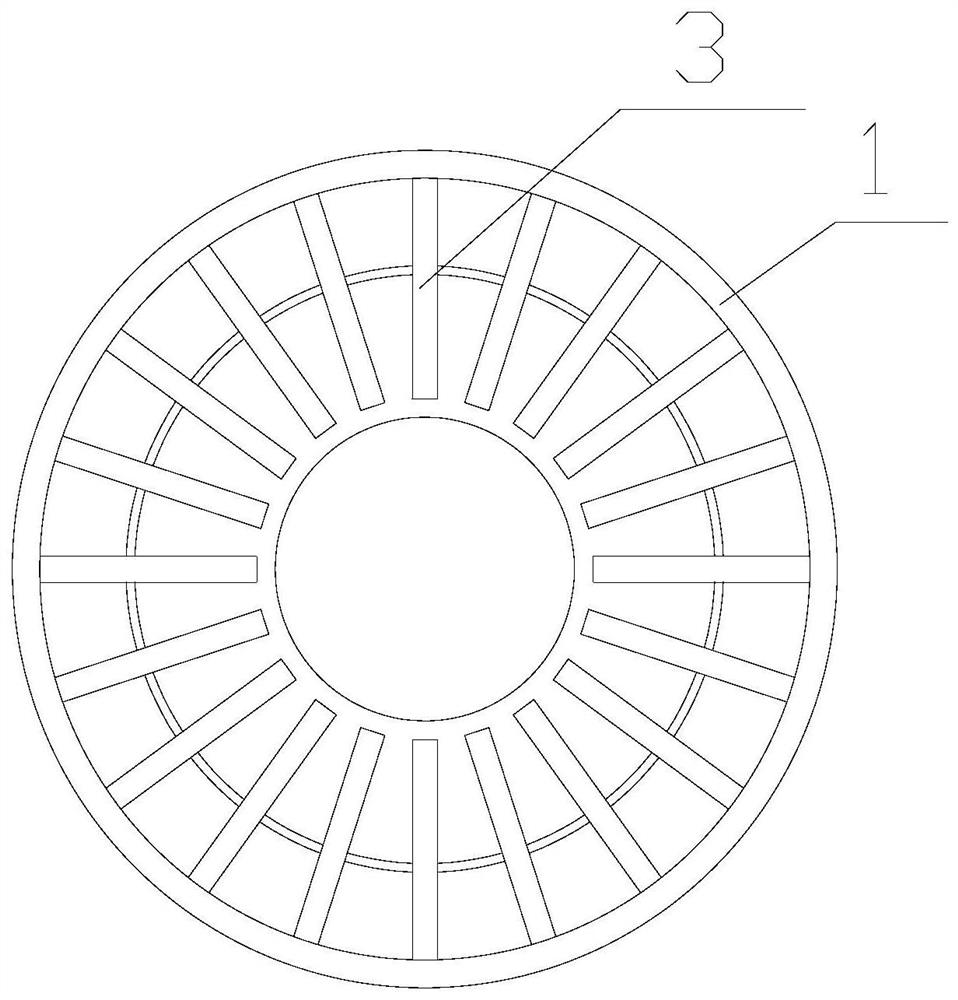

Novel litsea cubeba distillation kettle

PendingCN113512468AEnhance breaking powerIncrease frictionEssential-oils/perfumesThermodynamicsAlembic

The invention discloses a novel litsea cubeba distillation kettle. The distillation kettle comprises a distillation barrel body, a pot top baffle, friction plates, a rising column, a filter screen, a pressure alarm and a steam spraying pipe, the multiple friction plates which are connected with one another and placed at 45 degrees are fixedly arranged at the position, close to the bottom, in the distillation barrel body, the rising column is arranged at the top of the distillation barrel body and communicates with the distillation barrel body, and the filter screen is arranged in the rising column. The pressure alarm is arranged on the rising column. The pot top baffle is arranged in the center of the upper end of the distillation barrel body, and the center of the pot top baffle is aligned with the center of the rising column. The mixture of litsea cubeba and water collides with the wall of the distillation barrel body and the pot top baffle, the upward throwing formation of litsea cubeba is shortened, energy consumption is reduced, the friction effect is improved through friction of the friction plates, and the oil yield and the production efficiency are improved; litsea cubeba can be prevented from entering a condenser to cause pipe blockage; and heat can be heated from the inside of litsea cubeba, escape of litsea cubeba oil molecules from the inside is accelerated, and the distillation speed and the oil yield are increased.

Owner:HUNAN ACAD OF FORESTRY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com