Liquor brewing process

A process and liquor technology, applied in the field of liquor brewing technology, can solve the problems of reducing the taste of liquor, difficult to make high-quality liquor, and different liquor concentrations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

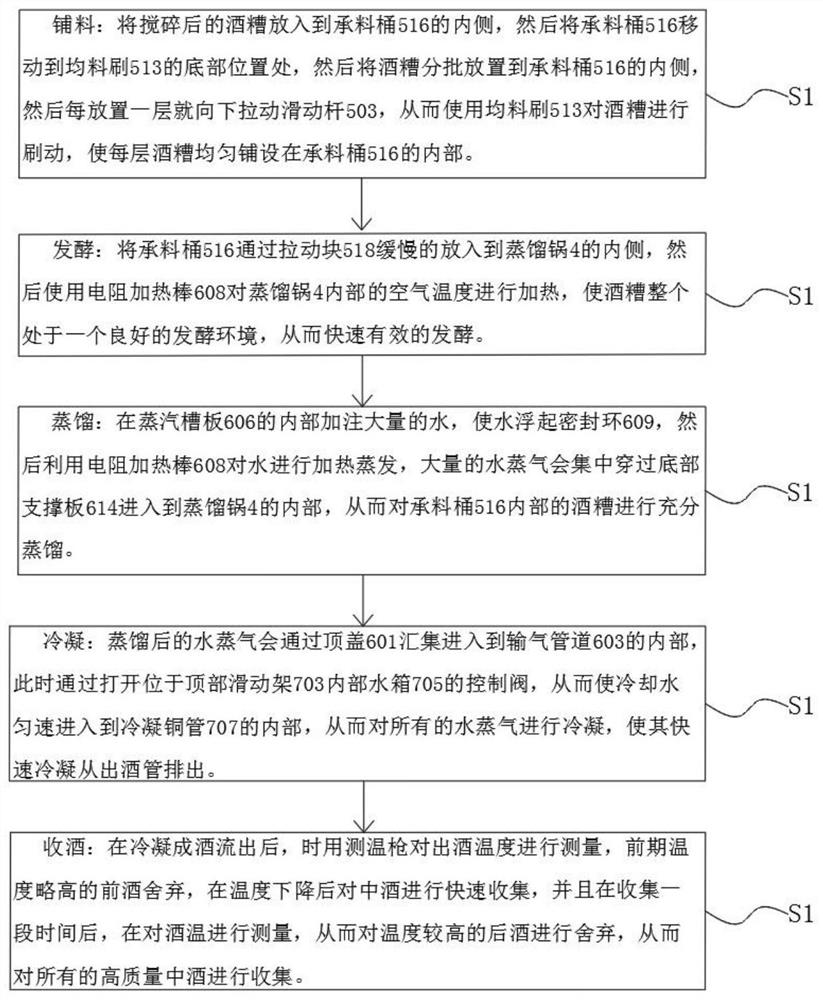

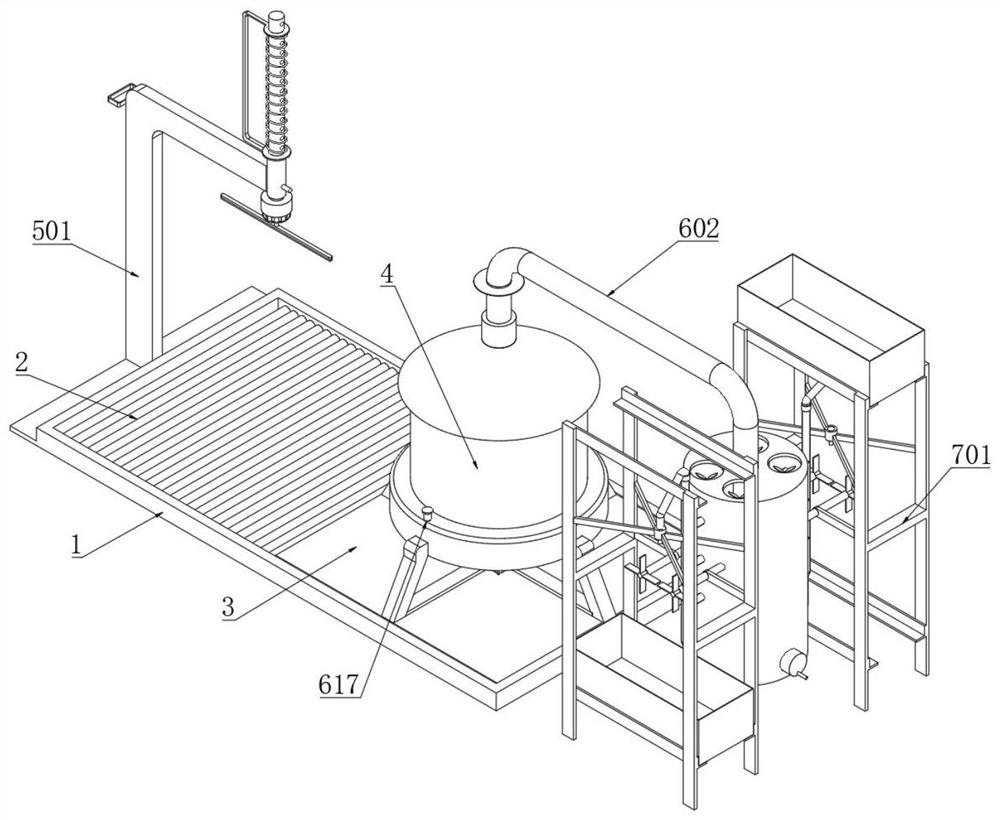

[0034] Example: such as figure 1 As shown, the present invention provides a kind of technical scheme, a kind of liquor brewing process, comprises the steps:

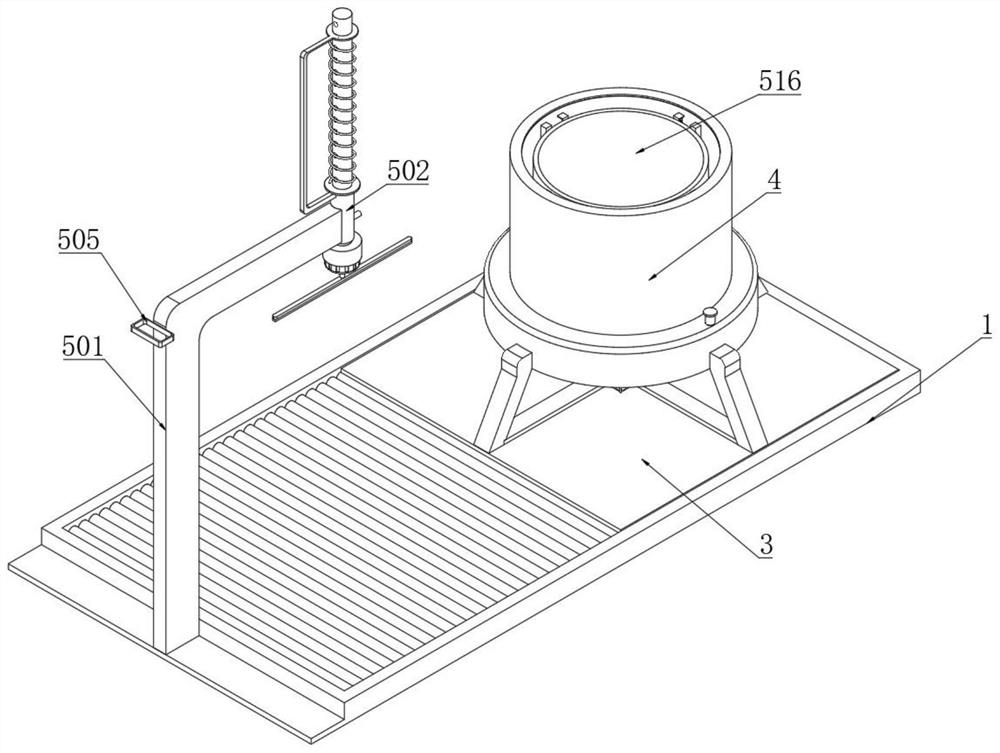

[0035] S1: Spreading material: Put the crushed distiller's grains into the inner side of the material receiving bucket 516, then move the material receiving bucket 516 to the bottom position of the equalizing brush 513, and then place the distiller's grains in batches on the inside of the material receiving bucket 516 Inside, then pull down the sliding bar 503 every time a layer is placed, so that the distiller's grains are brushed with the uniform material brush 513, so that each layer of distiller's grains is evenly laid on the inside of the material receiving barrel 516;

[0036] S2: Fermentation: Slowly put the material barrel 516 into the inner side of the stilling pot 4 by pulling the block 518, and then use the resistance heating rod 608 to heat the air temperature inside the stilling pot 4, so that the whole dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com