Liquefied petroleum gas recycling and refining device

A technology of liquefied petroleum gas and refining equipment, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrocarbon distillation, etc., can solve the problems of low utilization rate of vacuum residue oil and decrease in value of vacuum residue oil, and achieve the effect of speeding up the distillation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

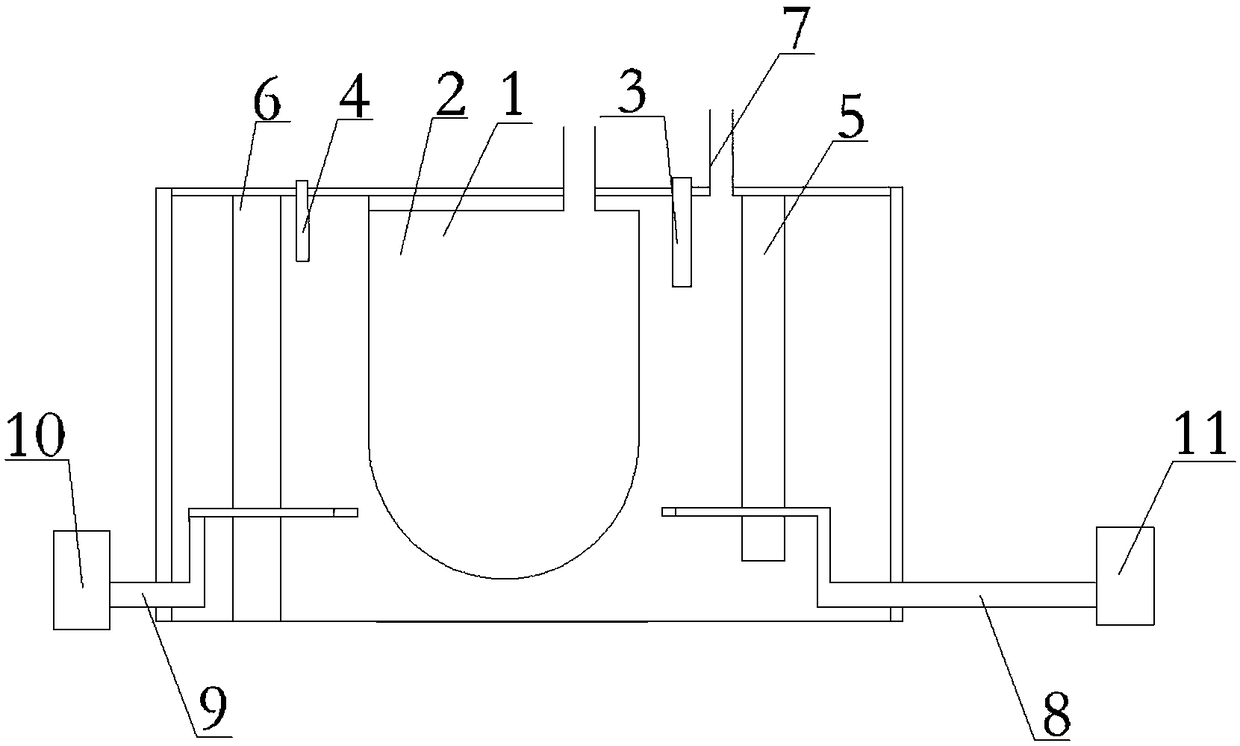

[0020] Such as figure 1 As shown, a recovery and refining device for liquefied petroleum gas comprises a box-type furnace body 1 and a furnace body body 2. One fire-retaining wall 5, the second fire-retaining wall 6, the upper end of the first fire-retaining wall 5 is fixed on the top of box-type furnace body 1, the bottom end of one end box-type furnace body 1 of the second fire-retaining wall 6, the second fire-retaining wall 6 The other end is a free end; one end of the box-type furnace body 1 is provided with a first gas pipeline 8, and one end of the first gas pipeline 8 passes through the first fire wall 5 and extends to the outer surface of the furnace body 2, and the first gas pipeline 8 The other end of gas pipeline 8 is positioned at the outside of chamber furnace body 1;

[0021] The other end of the box-type furnace body 1 is provided with a second gas pipeline 9, and one end of the second gas pipeline 9 passes through the second fire wall 6 and extends to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com