Waste treatment system for PCB

A technology for PCB circuit board and waste treatment, applied in the field of waste treatment system, can solve the problem of low copper purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

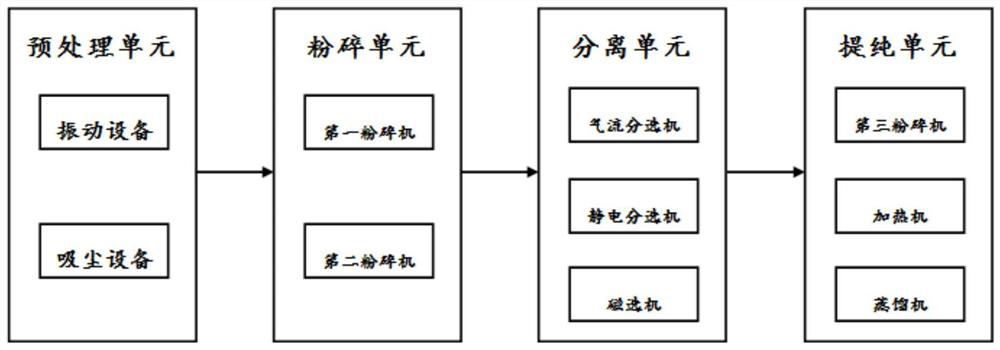

[0027] The embodiment of the waste treatment system for PCB circuit boards of the present invention is basically as attached figure 1 shown, including:

[0028] Pretreatment unit, the pretreatment unit includes vibration equipment and dust collection equipment; vibration equipment, used to vibrate the PCB circuit board; dust suction equipment, used to absorb dust generated in the vibration equipment;

[0029] The pulverizing unit includes a first pulverizer and a second pulverizer; the first pulverizer is used to pulverize the PCB circuit board into waste pieces in a first size range; the second pulverizer is used to pulverize the waste pieces into waste particles in a second size range;

[0030] Separation unit, the separation unit includes airflow separator, electrostatic separator and magnetic separator; airflow separator is used to divide waste particles into metal particles with high density and non-metallic particles with low density according to the characteristics of ...

Embodiment 2

[0046] The only difference from Example 1 is that

[0047] The purification unit also includes a first motor, a second motor and a condenser, and the first motor and the second motor are respectively connected to a heating machine and a distillation machine. During the process of heating the metal powder by the heating machine at a temperature of 250 ° C, the first motor drives the heating machine to rotate, and the molten solder will sink to the bottom of the heating machine with the help of centrifugal force, which is conducive to the separation of solder; in the distillation machine In the process of distilling the metal powder after the separation of solder at a temperature of 1000 ° C, the second motor drives the distillation machine to rotate, and the zinc and copper are dispersed with the help of centrifugal force to increase the heating area of zinc, thereby speeding up the distillation speed. The condenser is located above the distillation machine, and converts the ...

Embodiment 3

[0050] The only difference from Embodiment 2 is that before the PCB circuit board is shredded, it is first judged whether the shredding can be started. That is, blow and dust the PCB circuit board first, then detect the concentration of dust near the surface of the PCB circuit board, and judge whether it is lower than the concentration threshold: if the concentration of dust near the surface of the PCB circuit board is lower than the concentration threshold, the crushing can be started; If the concentration of dust near the surface of the PCB is not lower than the concentration threshold, crushing cannot be started.

[0051] In this embodiment, after the PCB circuit board is blown and dust removed, parallel monochromatic light is used to irradiate the vicinity of the PCB circuit board surface, and the relative attenuation rate of the incident light near the PCB circuit board surface is detected. Since the dust will produce light scattering phenomenon under the irradiation of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com