Patents

Literature

51results about How to "Improve the efficiency of the reduction reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing iron ore concentrate by using microwave to deoxidize weak-magnetic iron minerals

InactiveCN101012497ANo consumptionLow costMagnetic separationProcess efficiency improvementIron powderMicrowave

The invention discloses a making method of concentrate iron ore, which comprises the following steps: (1) adding 5-25% ferric powder or ferric mud into disposed powder evenly; (2) placing material into reducing sintering furnace to sinter for 2-8 min through microwave; reducing weak magnetic ferric ore into magnetic ferric ore; (3) proceeding magnetic cobbing to obtain the product.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

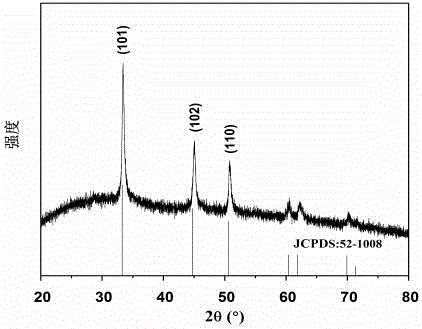

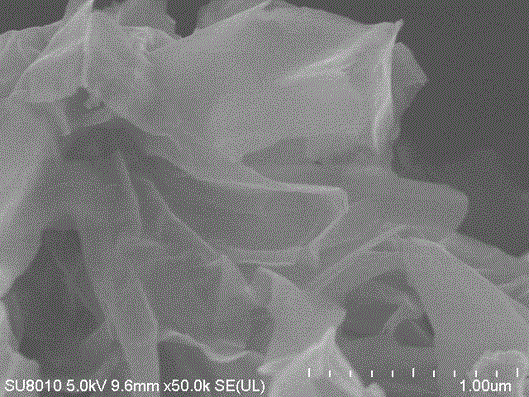

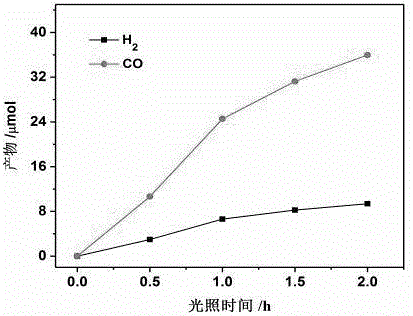

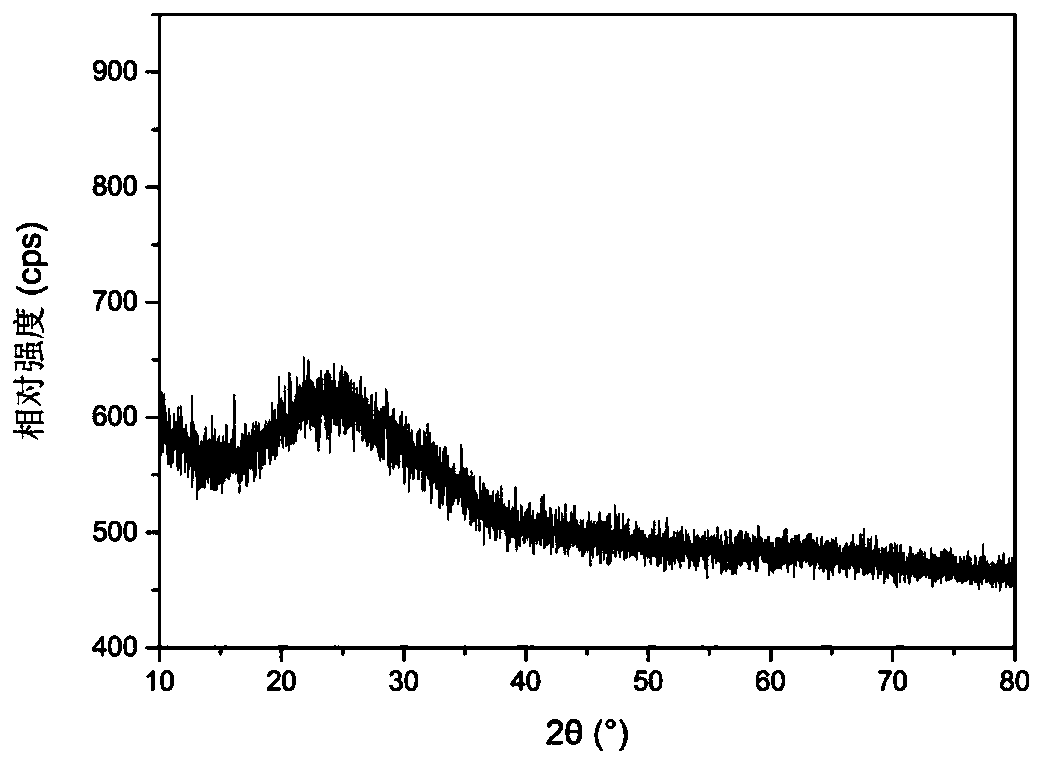

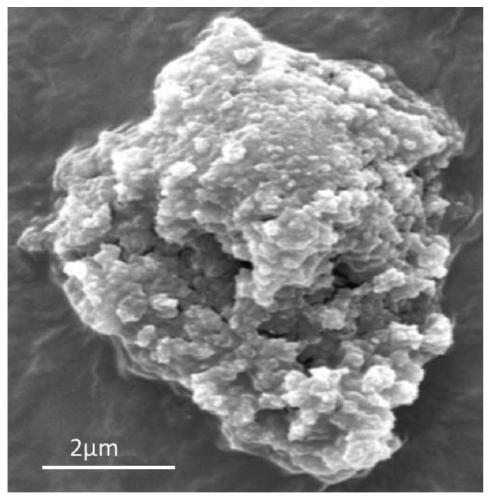

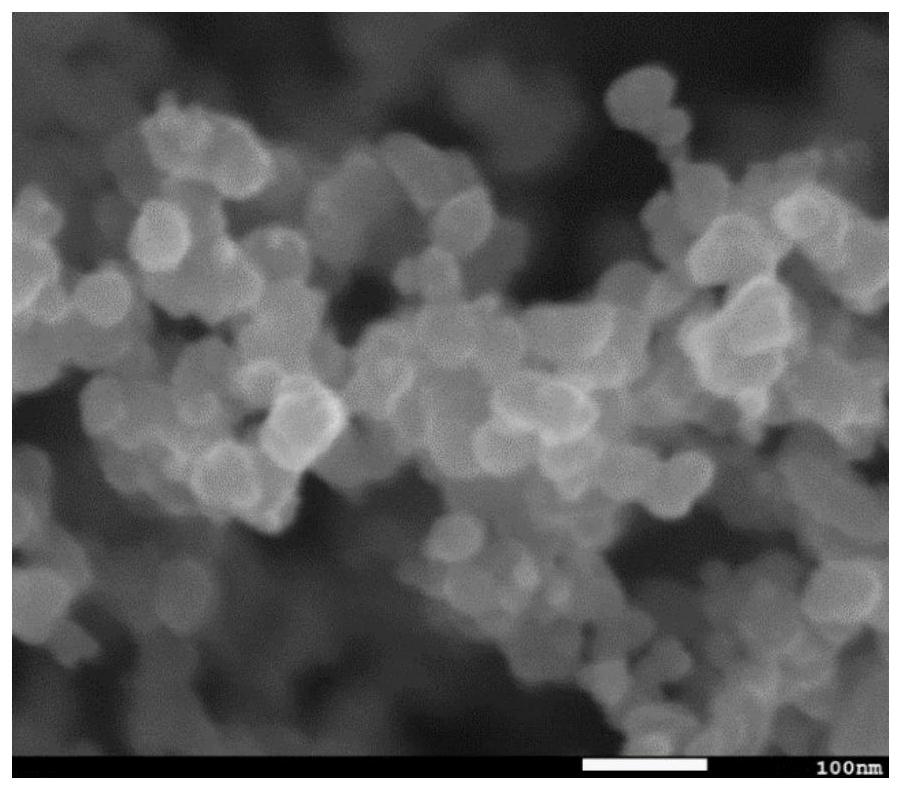

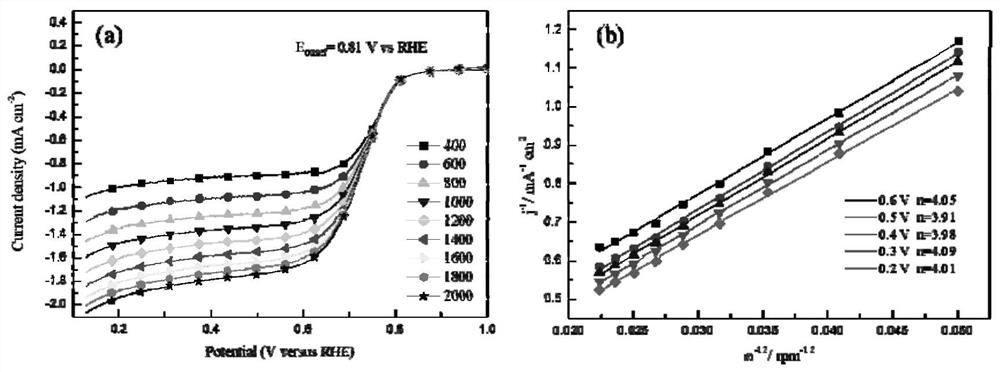

Cobaltous selenide promoter as well as preparation method and application thereof

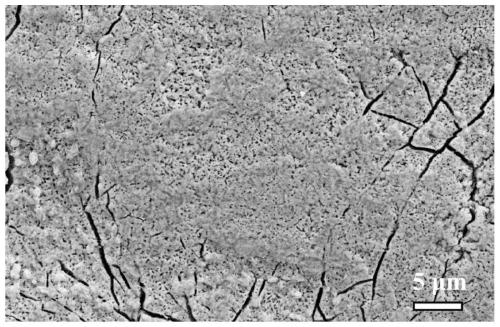

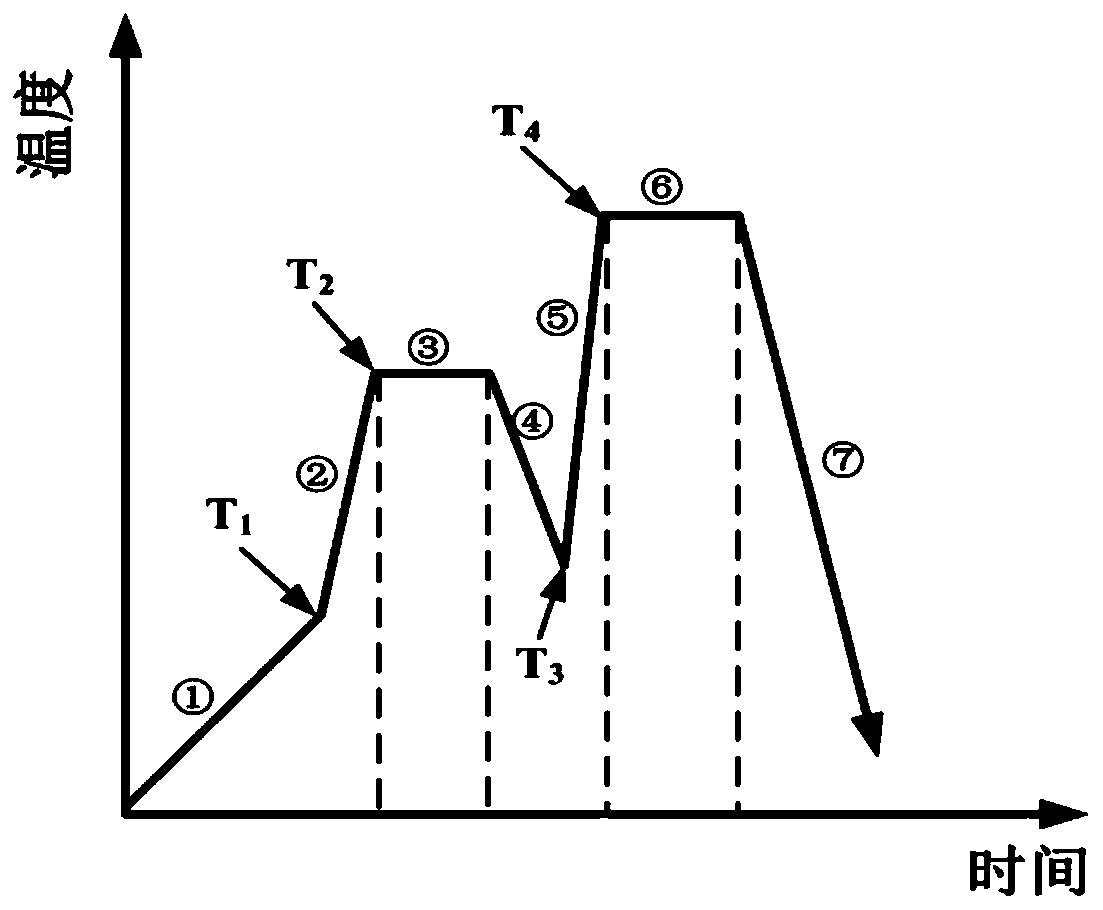

ActiveCN107519899AImprove the efficiency of the reduction reactionSimple manufacturing methodEnergy inputCatalyst activation/preparationSolventHigh activity

The invention provides a cobaltous selenide promoter Co0.85Se as well as a preparation method and application thereof and belongs to the field of photocatalysis. The promoter provided by the invention is a nano laminated material synthesized by using a solvothermal method. The material integrates advantages of electron transmission of transition metallic ions, large specific surface areas of two-dimensional materials, high activity exposure ratios, and the like, and performance of photocatalysis CO2 reduction reactions can be effectively improved. The cobaltous selenide promoter is simple and feasible in preparation method, gentle in reaction system condition and wide in application prospect in fields such as CO2 immobilization, conversion and the like with solar energy.

Owner:SHAANXI UNIV OF SCI & TECH

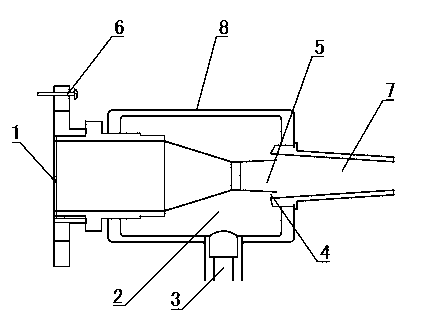

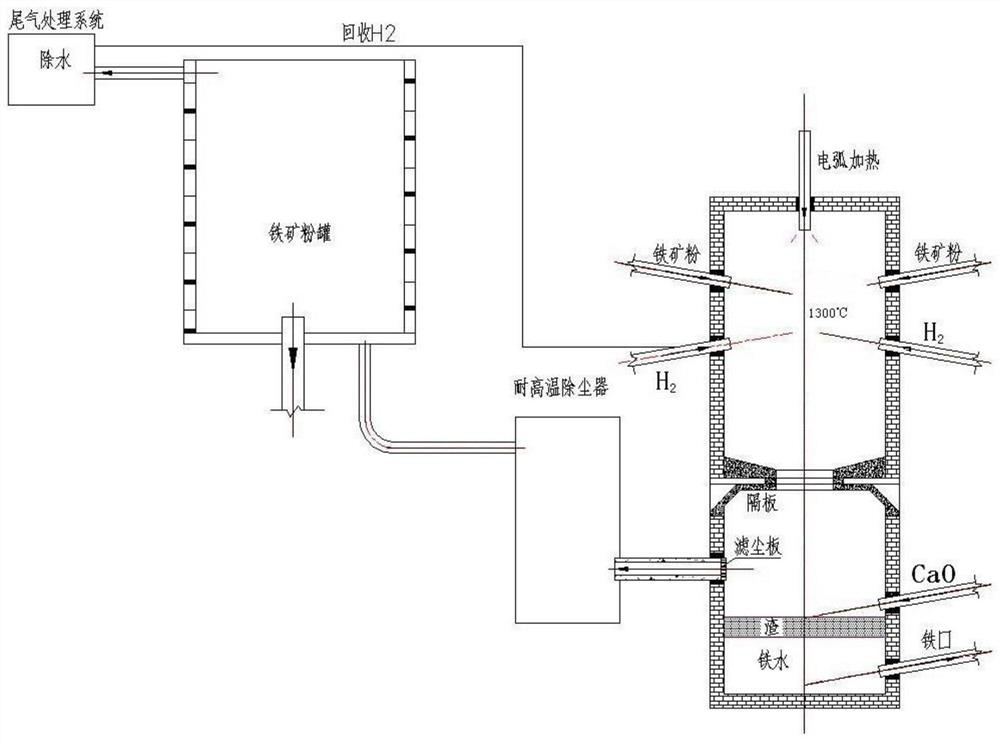

Iron-making method by utilizing flash iron-making furnace

InactiveCN104451015AQuick method of smelting ironEnergy saving ironmaking methodFluidised-bed furnacesMelting tankSlag

The invention provides an iron-making method by utilizing a flash iron-making furnace. The iron-making method comprises the following steps: spraying dry iron ore concentrate, a solvent and a fuel comprising coke, pulverized coal and oxygen in a cavity of a reduction tower of the flash iron-making furnace, and forming a high-temperature reducing atmosphere in the cavity of the reduction tower; carrying out an oxidation-reduction reaction inside the cavity of the reduction tower on the dry iron core concentrate and reducing gas to obtain molten iron, slag and smoke gas, and forming a coke layer, a slag layer and a molten iron layer from top to bottom inside a molten pool, wherein the oxidation-reduction reaction is carried out at 600-1200 DEG C, and 5-80% of carbon monoxide in volume is contained in the reducing atmosphere. The iron-making method by adopting the embodiment of the invention is simple in technology and low in cost, and the reduction reaction efficiency can be obviously improved.

Owner:邱江波

Recycling method of tail gas from pyrolusite reduction and sulfuric acid coproduction in fluidized bed furnace

InactiveCN102424365AGuaranteed normal boilingImprove the efficiency of the reduction reactionSulfur compoundsManganese sulfatesPyrolusiteFluidized bed

The invention provides a recycling method of tail gas from pyrolusite reduction in a fluidized bed furnace, belonging to the technical field of ore product processing. In order to improve the conversion of manganese peroxide to manganese monoxide in the fluidized bed furnace, the reduction reaction is necessarily carried out under a low-oxygen condition, and the mixed gas formed by air and tail gas of the fluidized bed furnace is blown from the lower segment of the fluidized bed furnace so as to guarantee that the oxygen content in the mixed gas is very low. The technique is simple and easy in operation, has high manganese peroxide conversion rate, recycles the tail gas, and reduces the environmental pollution.

Owner:HUNAN LUXI JINXU ZHIHUA CO LTD

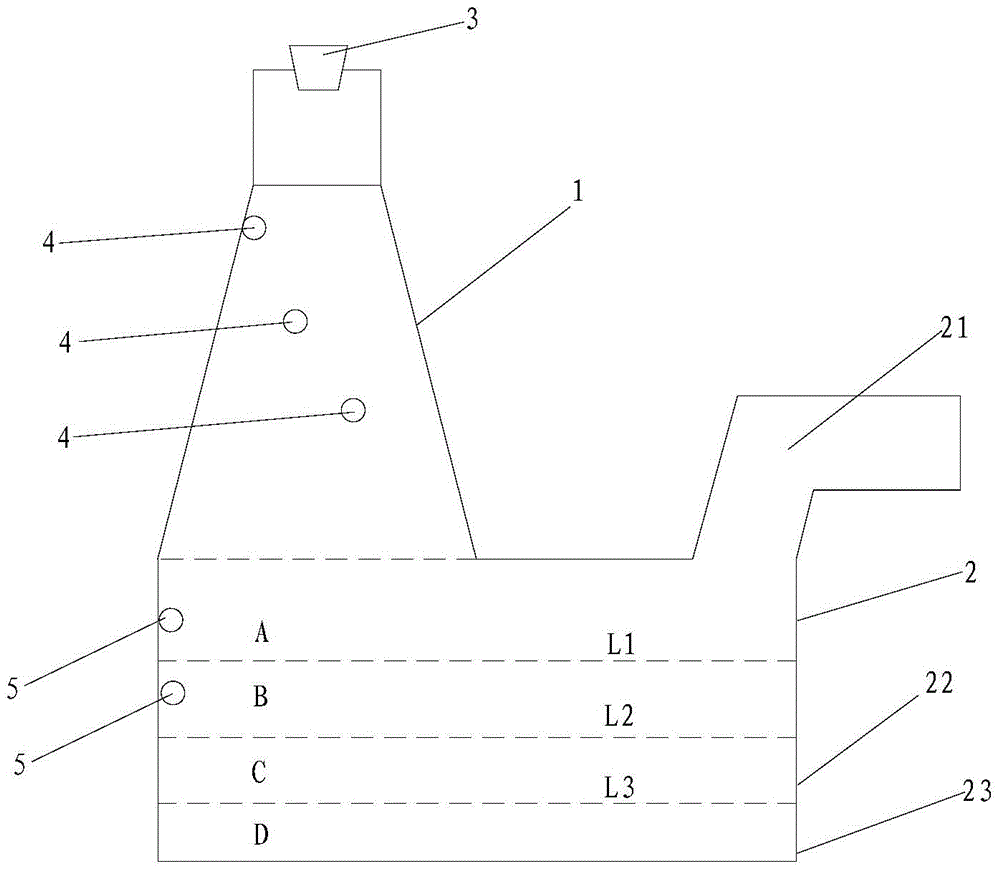

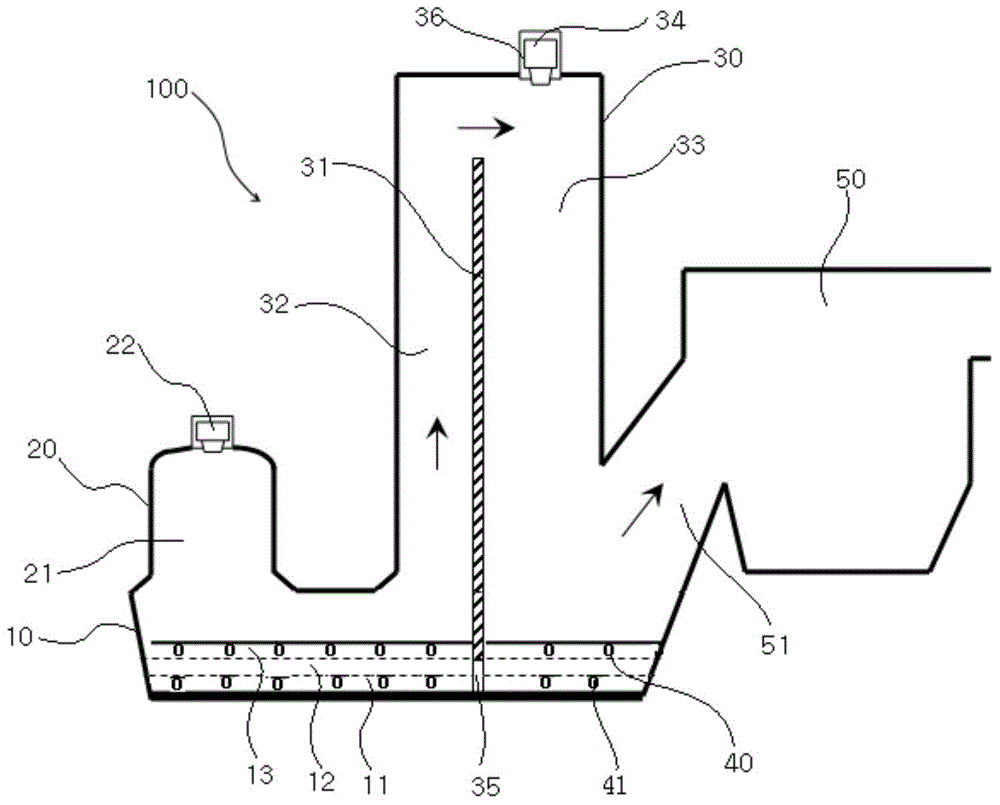

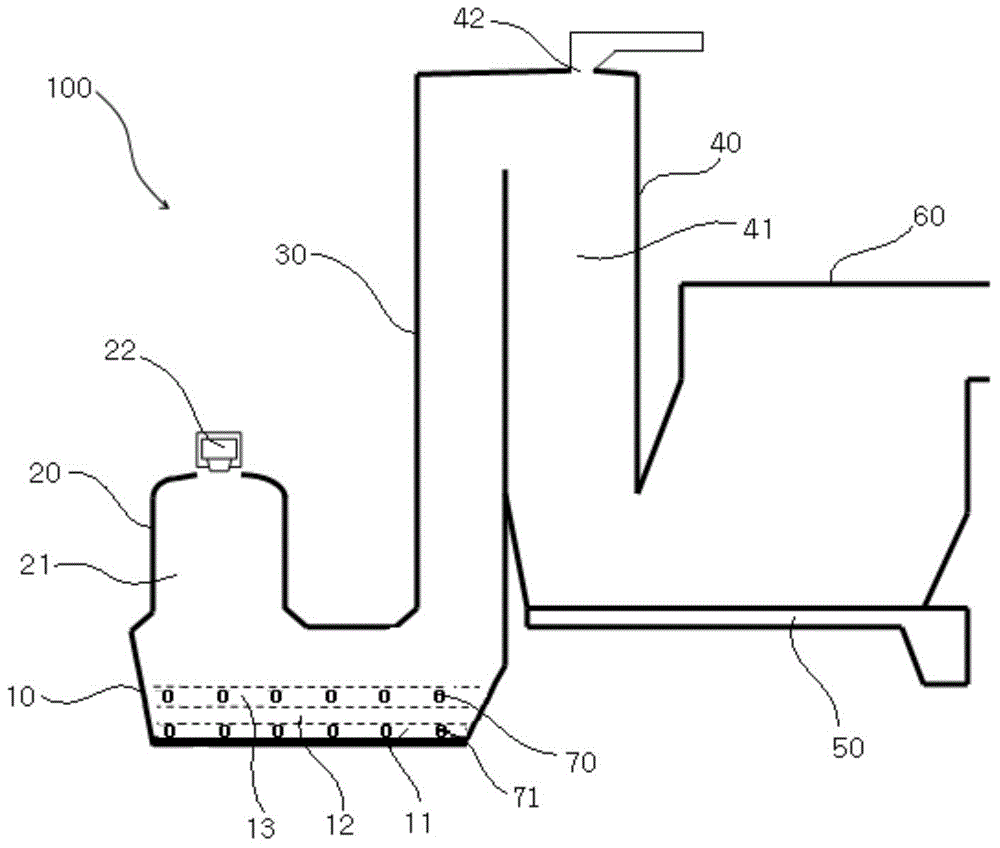

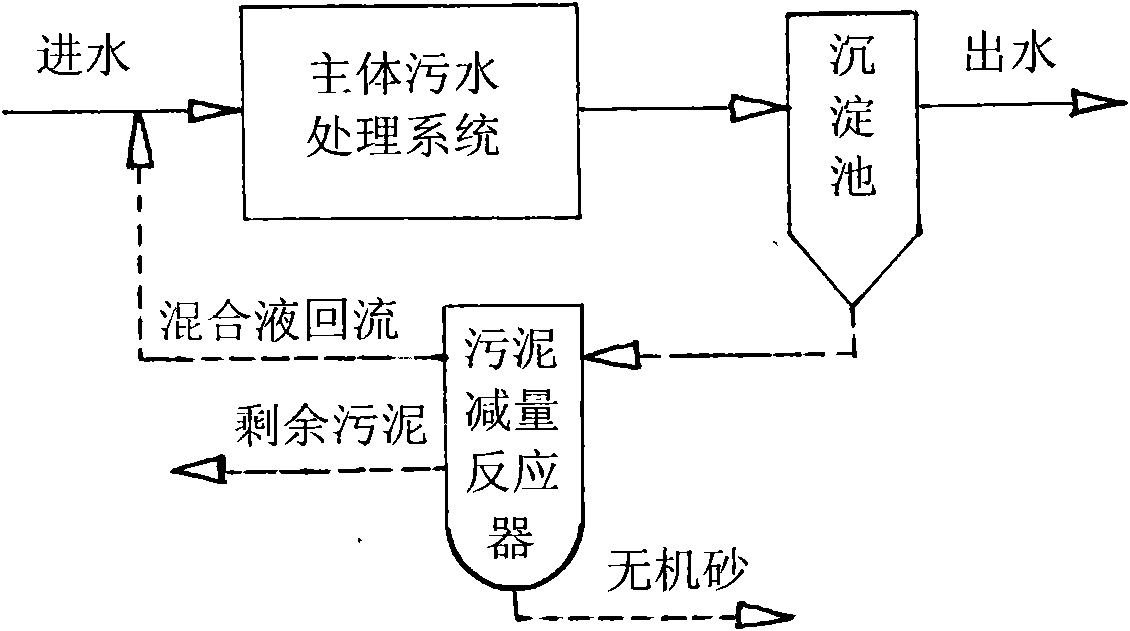

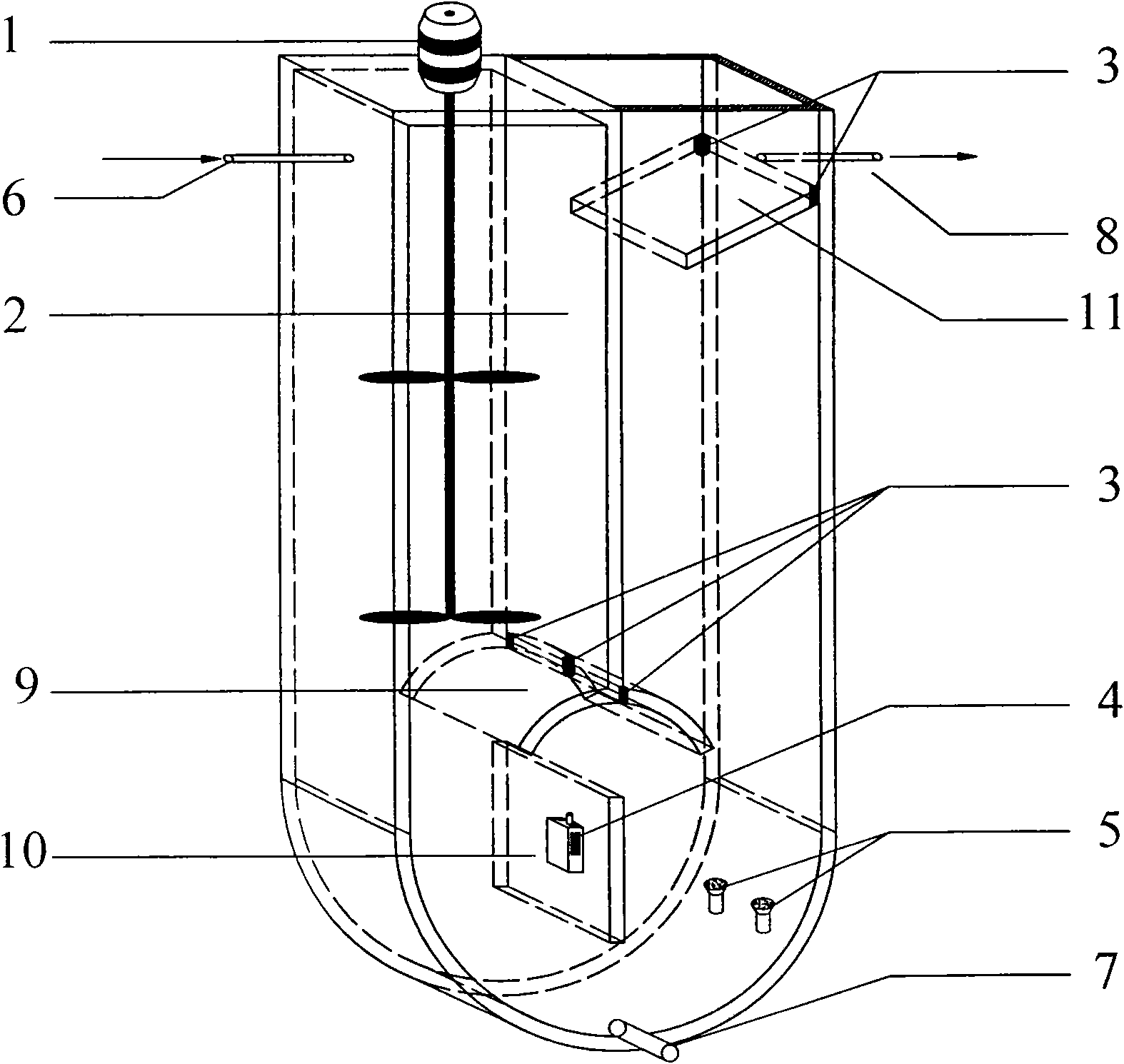

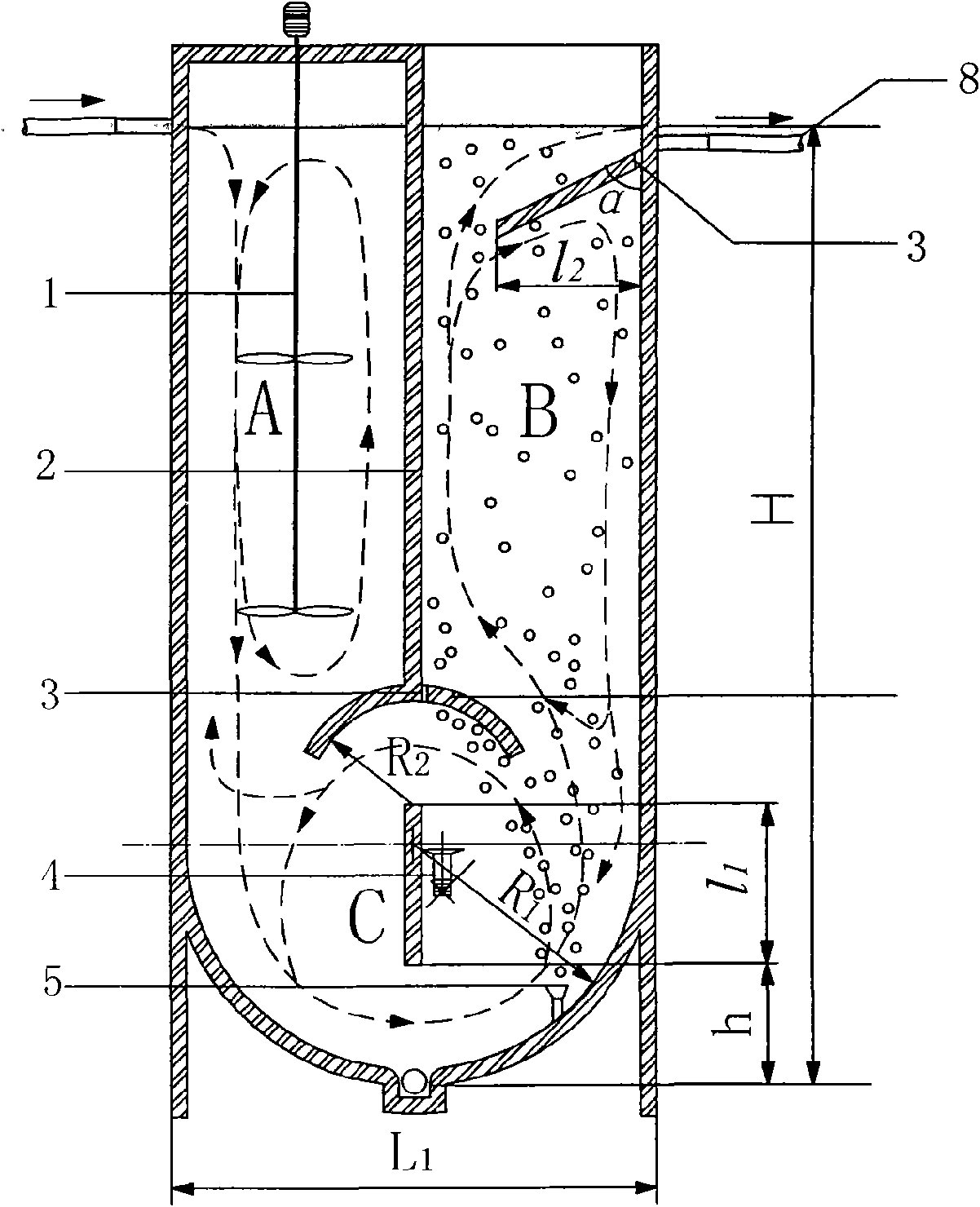

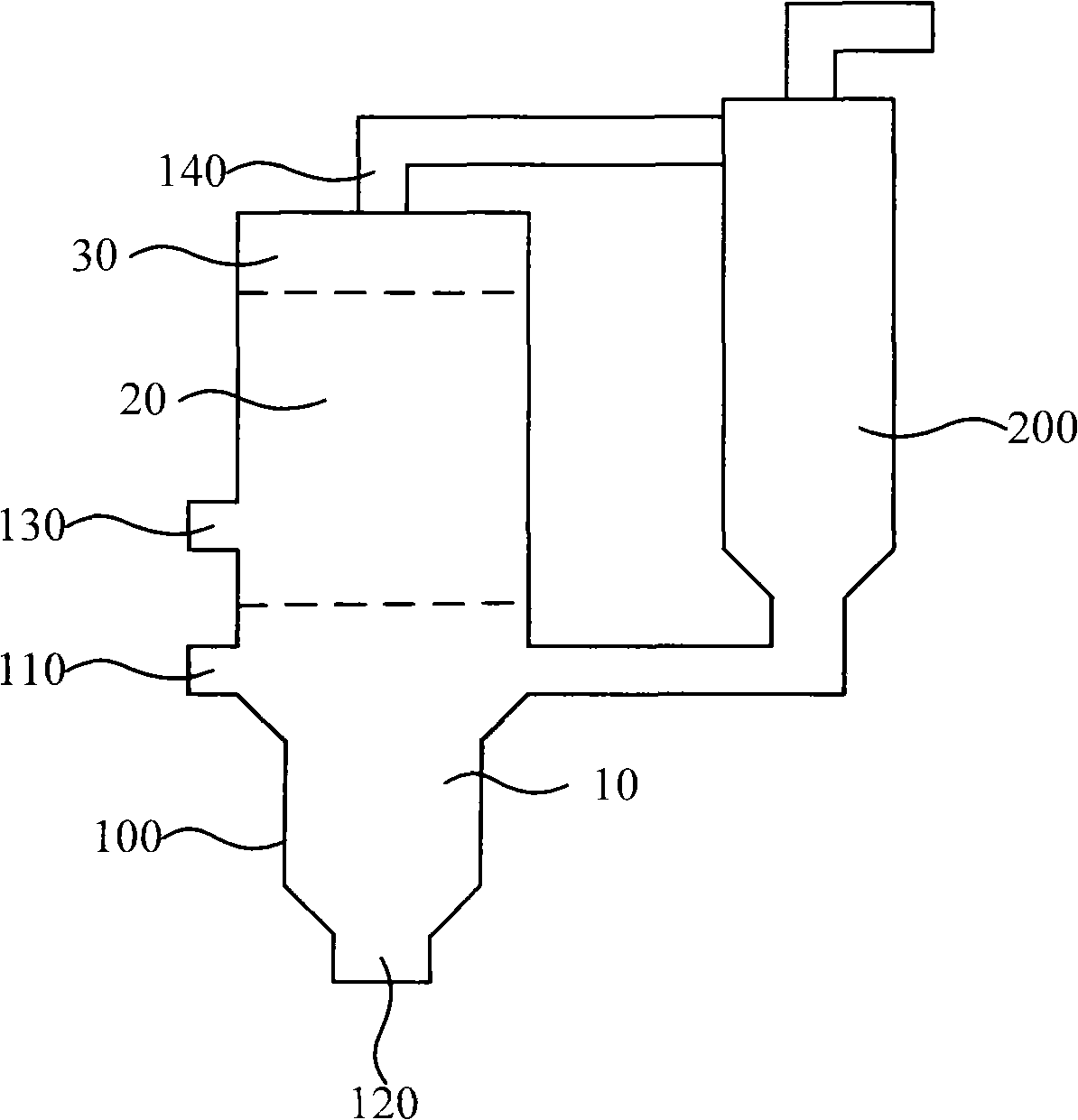

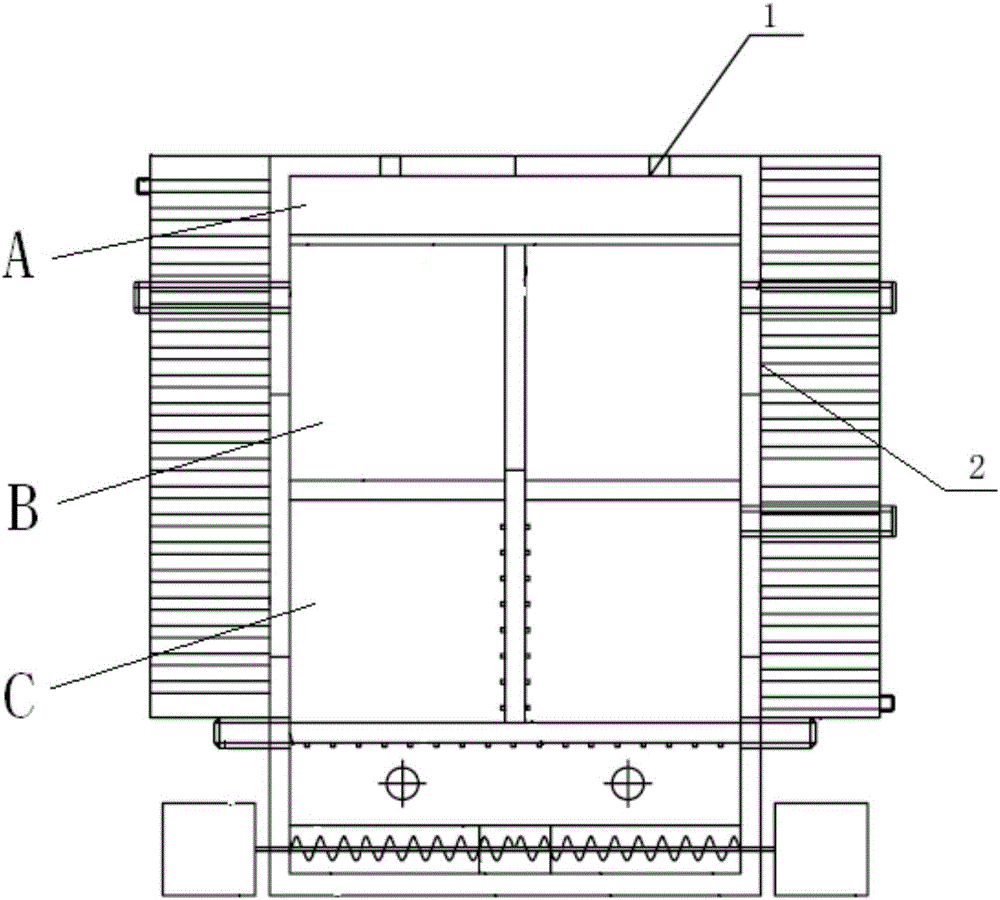

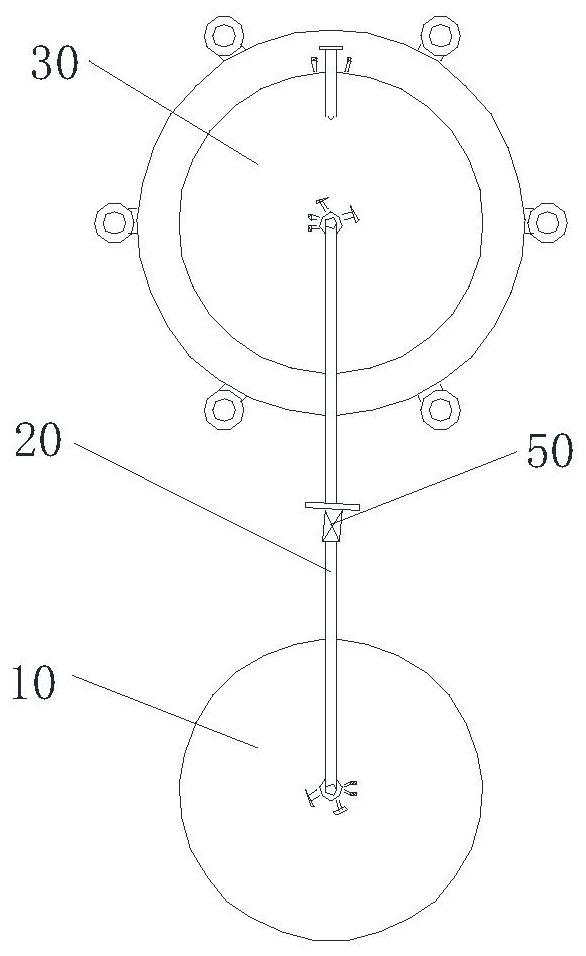

Method for controlling residual sludge reduction in activated sludge-sewage treatment system and reactor

InactiveCN101602548AFacilitate the hydrolysis effectIncrease consumptionTreatment with aerobic and anaerobic processesActivated sludgeWater treatment system

The invention provides a method for controlling residual sludge reduction in an activated sludge-sewage treatment system. The method sets three zones, namely an anaerobic zone, a circulating zone and a limited oxygen zone which are connected in turn from a sludge inlet to a sludge outlet in a sludge reduction reactor; the sludge enters the anaerobic zone from the sludge inlet at the upper part, is evenly mixed by stirring, and then downwards flows to the circulating zone; and the sludge circularly flows in the circulating zone under the action of an underwater mixer, then upwards enters the limited oxygen zone, and finally is discharged from the sludge outlet at the upper part of the limited oxygen zone. The invention further provides a reactor for realizing the method for anaerobic / limited oxygen hemicyclic sludge reduction with an arc guide plate. The residence time of the whole reactor is 6 hours, the dissolved oxygen concentration of the limited oxygen zone is 0.5 to 1.1 milligrams per liter, and the ratio of the practical anaerobic / limited oxygen residence time in the reactor is 1.10-1.25:1.0. The radius R1 of the circulating zone of the reactor is 0.5 L1, and the effective height H of the reactor is 4R1. The method has the advantages of good activated sludge reduction effect, low energy consumption, occupied place economy and the like, and can effectively separate inorganic granules in the activated sludge, ensure the effluent effect of the sewage treatment system, well improve the settling performance of the activated sludge, and the like.

Owner:CHONGQING UNIV

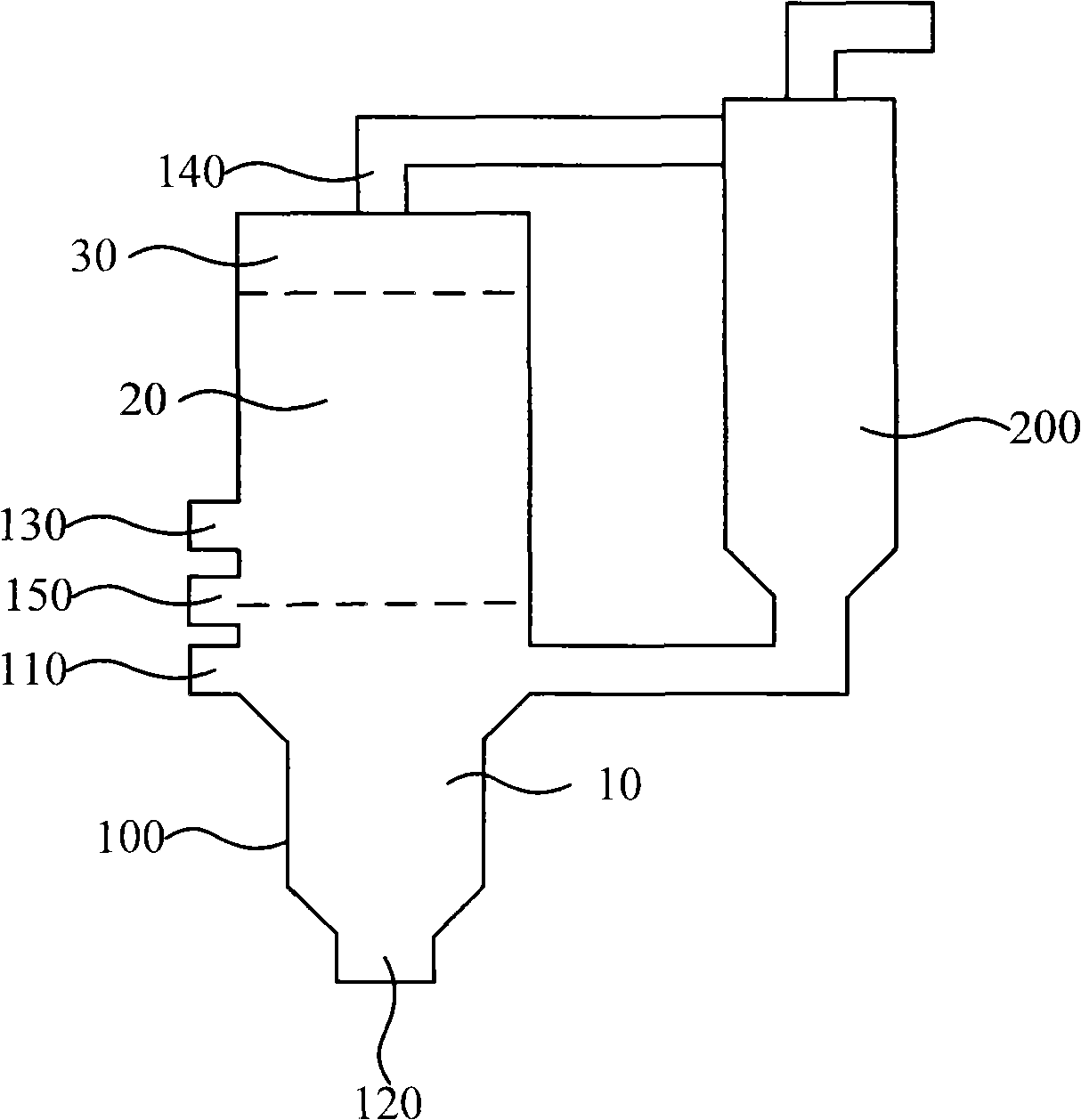

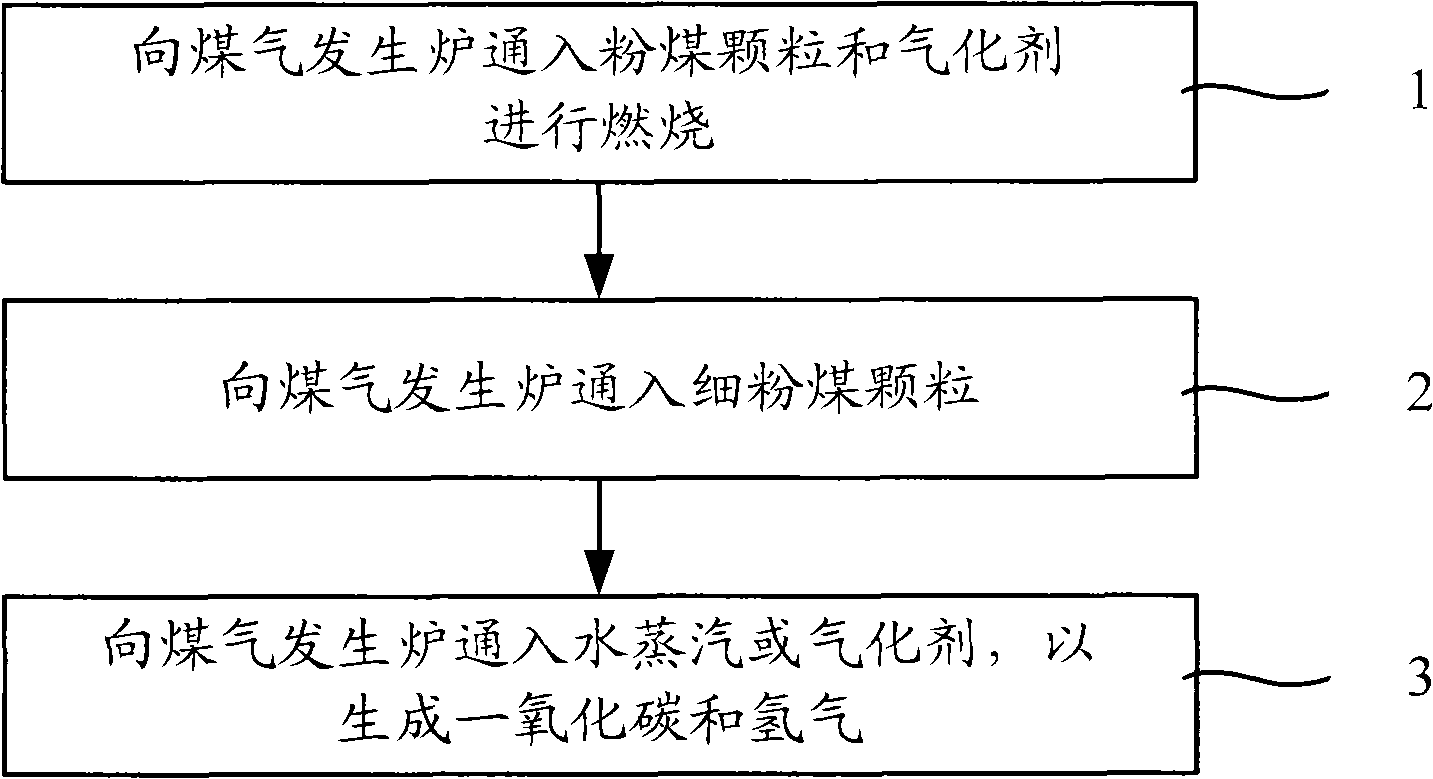

Gas producer and gas preparation method

ActiveCN101987975AImprove production efficiencyIncrease concentrationGranular/pulverulent flues gasificationHydrogenHearth

The invention relates to a gas producer and a gas preparation method. The gas producer comprises a hearth, a reducing zone and a gas guide zone which are sequentially arranged in a producer wall from top to bottom, wherein a pulverized coal inlet is formed on the wall face of the hearth; a second gas inlet is formed on the wall face of the reducing zone, and a fine pulverized coal inlet is also formed on the wall face of the reducing zone or a wall face at the intersection of the reducing zone and the hearth. The method comprises the following steps of: introducing pulverized coal particles and a gasification agent into the gas producer for burning; and introducing fine pulverized coal particles into the gas producer to ensure that the materials in the gas producer are reacted to form carbon monoxide and hydrogen gas. In the invention, the technical means of forming the fine pulverized coal inlet on the gas producer for leading the fine pulverized coal particles in a carbon monoxide preparing reaction through reduction is adopted, so that the concentration of materials in the reducing zone is improved; the reduction reaction efficiency in the reducing zone can be promoted; and then the preparation efficiency of gas can be improved.

Owner:KEDA MAS CLEAN ENERGY

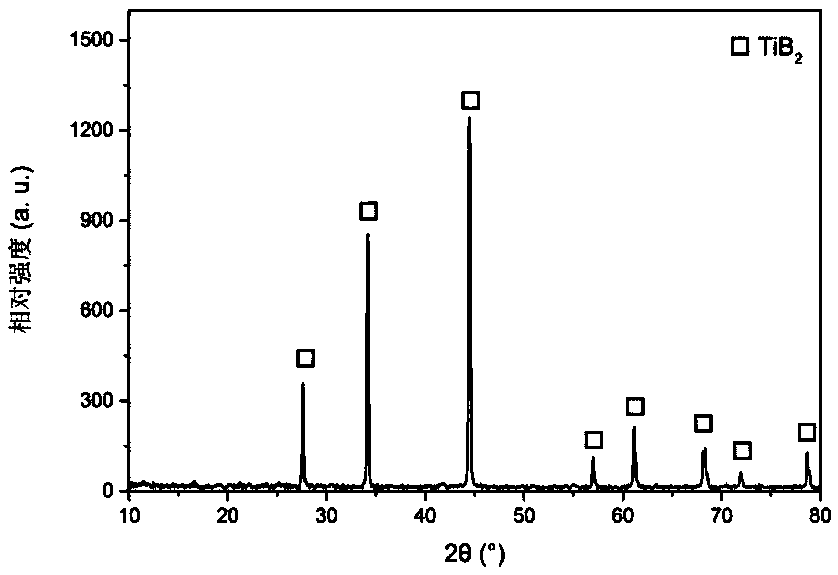

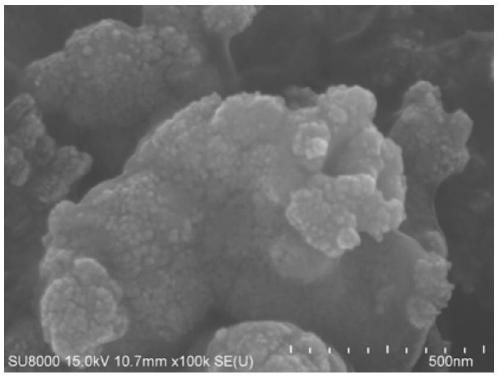

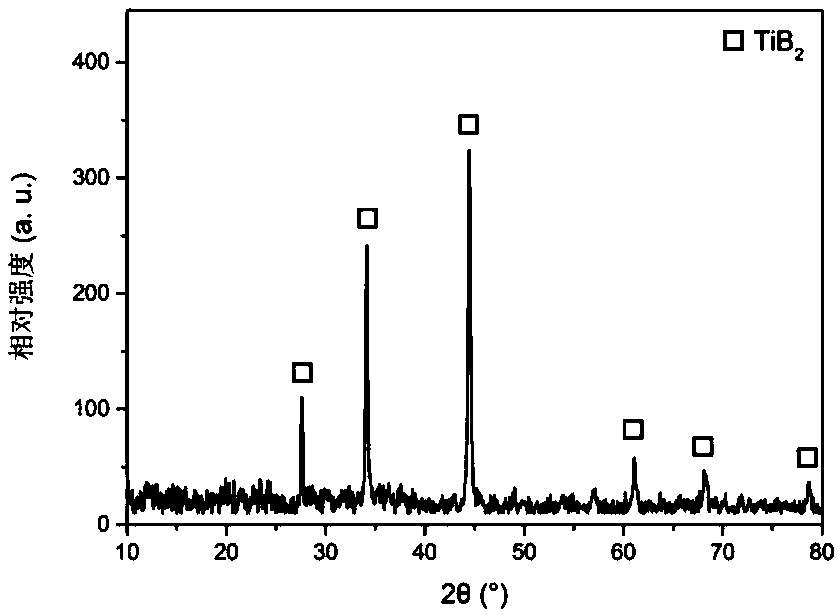

Preparation method of TiB2 ceramic powder

The invention relates to a preparation method of TiB2 ceramic powder. The preparation method comprises the steps: preparing materials according to the mass ratio of a reductant to a titanium source toa boron source to an alkali metal compound-containing molten salt of 1.0:(0.7-1.2):(0.7-4.0):(0.2-20.0), mixing evenly, carrying out heat treatment for 0.5-8 h under conditions of a protective atmosphere and the temperature of 600-1300 DEG C, dissolving in water or an alkali solution under a condition of room temperature-250 DEG C, washing, and drying, to prepare the TiB2 ceramic powder. The reductant is one or more of silicon powder and aluminum powder; the titanium source is one or more of Ti powder and TiO2 powder; the boron source is one or more of boron oxide, boric acid, sodium tetraborate, potassium tetraborate and lithium tetraborate; the alkali metal compound-containing molten salt is one or more of sodium hydroxide, sodium silicate, sodium carbonate, potassium hydroxide, potassium silicate, potassium carbonate, lithium hydroxide, lithium silicate, lithium carbonate and sodium aluminate. The preparation method has the advantages of low production cost, environmental friendliness and easy industrialized production, and the prepared product has small particle size and narrow particle size distribution.

Owner:WUHAN UNIV OF SCI & TECH

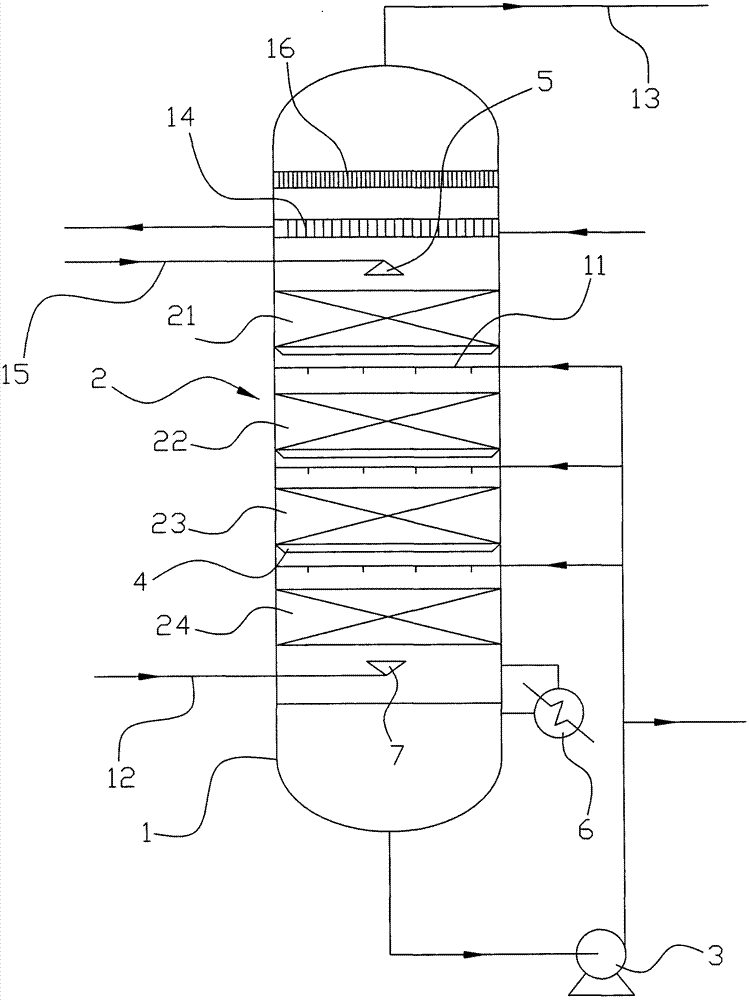

Nitric acid reduction device

InactiveCN106955649ASimple restore processImprove the efficiency of the reduction reactionLiquid-gas reaction processesNitrous acid preparation ester preparationEngineeringCirculating pump

The invention discloses a nitric acid reduction device, which comprises a shell, wherein a liquid inlet, a liquid outlet, an air inlet and an air outlet are formed in the shell; N packing layers are sequentially arranged in the shell up and down; a drop-leaching device is arranged in an inner cavity between two adjacent packing layers in the shell; the drop-leaching devices are connected with a circulating pump arranged outside the shell through pipes respectively; the air inlet is located in the lower part of the bottom packing layer; the air inlet is communicated with an NO gas inlet pipe; the air outlet is located in the top of the shell and is communicated with an exhaust pipe; a gas heat exchanger capable of cooling gas which passes through the packing layers is arranged in the inner cavity between the upper parts of the packaging layers and the air outlet; the liquid inlet is located in the shell between the gas heat exchanger and the packing layers; the liquid inlet is communicated with an inlet pipe capable of introducing mixed liquid of methanol and a nitric acid; the liquid outlet is located in the bottom of the shell and is communicated with the circulating pump through a pipe; and N is a natural number greater than 2. The nitric acid reduction device has the advantages of small occupied space and high nitric acid reduction efficiency, the reduced nitric acid can be utilized in cycle and a catalyst is not used.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH

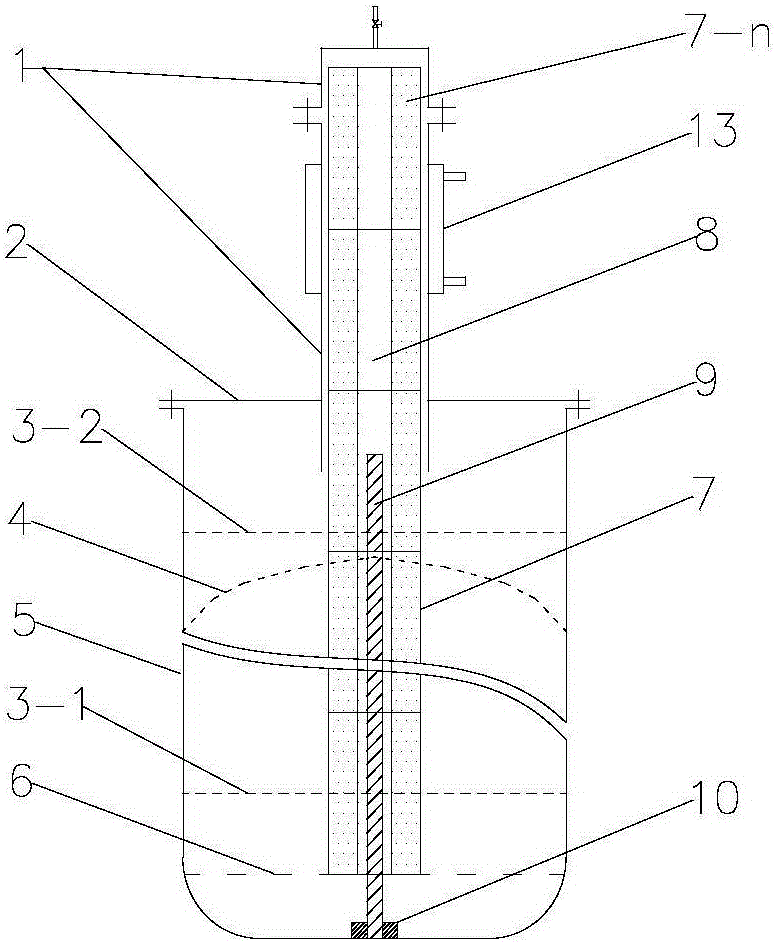

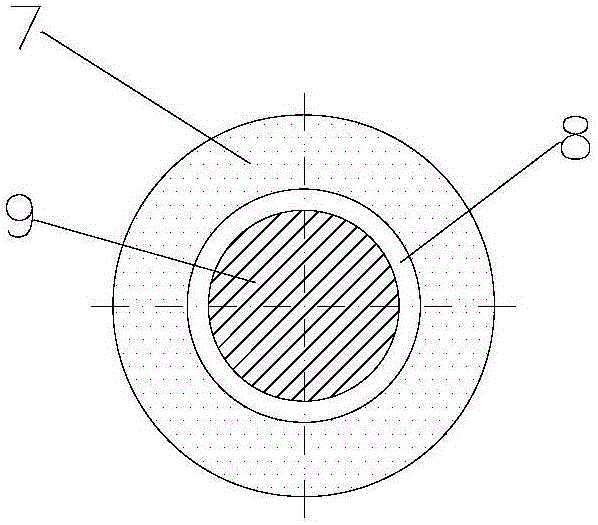

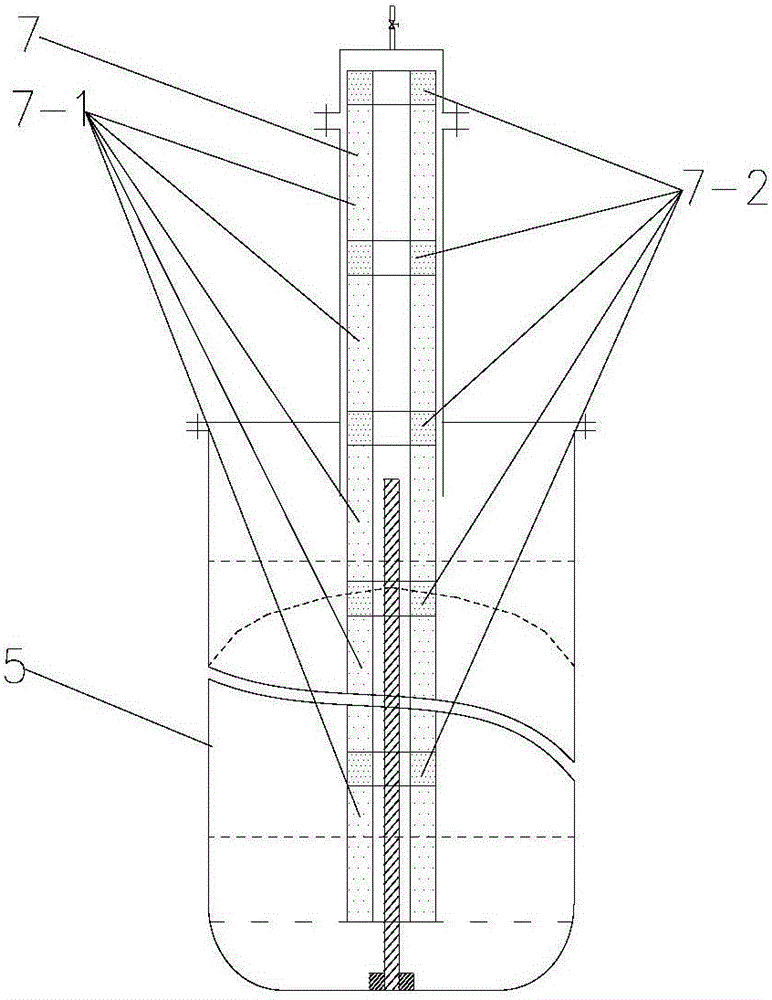

Device and method for improving production efficiency of titanium sponge and reducing energy consumption

InactiveCN105779791AIncrease the feeding speedImprove the efficiency of the reduction reactionDistillationTitanium

The invention discloses a device and method for improving the production efficiency of titanium sponge and reducing energy consumption. A device containing a fusibility column is arranged in the axis part of an existing reduction distillation furnace reactor and comprises two parts including the fusibility column and a reactor upper cover leading-out sleeve. The fusibility column (a metal magnesium ingot) located in the center part of liquid magnesium metal absorbs reaction heat and is gradually fused in the magnesium heat reduction process, and meanwhile a hole is formed in the axis of a titanium sponge mixing body. The device and method solve the problem that a large amount of heat gathered in the center area of the magnesium heat reduction reactor is dissipated, and meanwhile the heat released through the magnesium heat reduction reaction is utilized for fusing the reduction agent magnesium metal ingot. The hole can be formed in the axis position of the titanium sponge mixing body, the diffusion path of magnesium metal left in the mixing body and magnesium metal is shortened, the distillation speed is increased, and the distillation period is shortened. By means of the device and method, preconditions are provided for the large scale of titanium sponge reduction distillation furnaces.

Owner:王进民

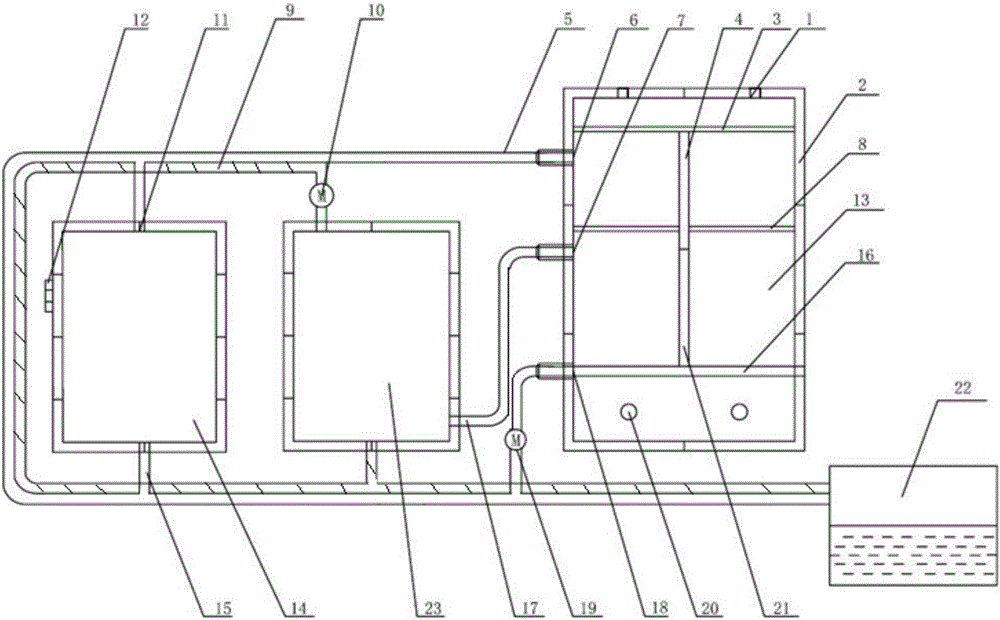

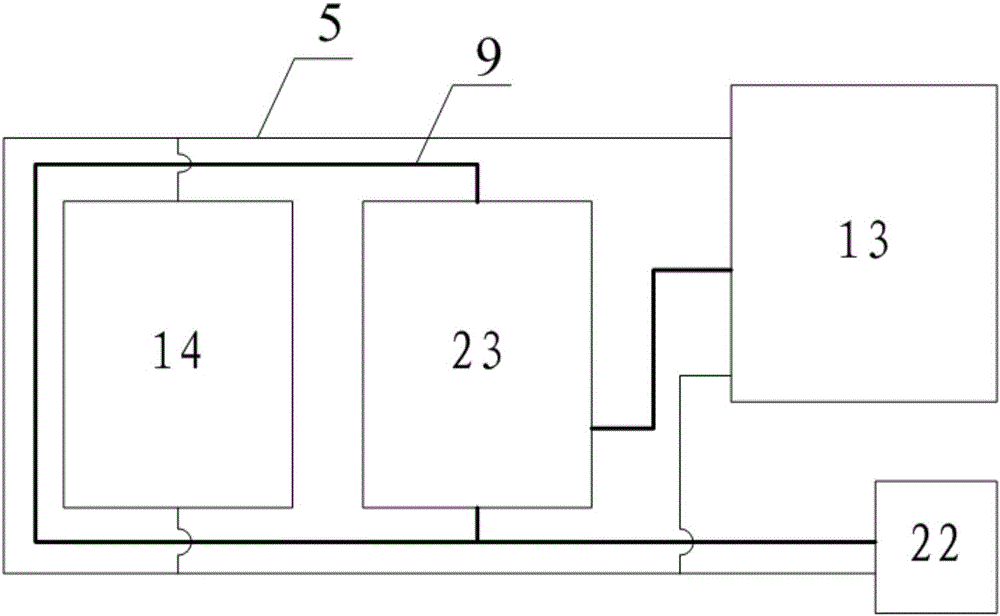

Garbage disposal device capable of utilizing self-circulation pyrolysis gas for preheating air

ActiveCN106439834AGuaranteed heat treatment efficiencyRealize heat conductionIndirect carbon-dioxide mitigationIncinerator apparatusDistribution systemPollutant emissions

The invention discloses a garbage disposal device capable of utilizing self-circulation pyrolysis gas for preheating air. The device comprises a feeding opening, a garbage pyrolysis furnace wall, a first horizontal heat conduction plate, a vertical heat conduction plate, a first smoke circular pipeline, a top smoke circular pipeline connection opening, a tail gas pipeline connection opening, a second horizontal heat conduction plate, a second smoke circular pipeline, a first induced draft fan, an air preheating cavity connection opening, a first air inlet, a garbage pyrolysis furnace, an air preheating cavity, an exhaust opening, a horizontal air distribution pipeline, a tail gas treatment pipeline, a bottom smoke circular pipeline connection opening, a second induced draft fan, an observation window, a vertical air distribution pipeline, a settling pond, a tail gas purification device, an air distribution system, a smoke circular system and other structures. According to the disposal device, the reduction reaction efficiency is improved, the garbage heat treatment efficiency is ensured; and meanwhile, the self-circulation pyrolysis gas can be used for preheating the air, it can be ensured that low-heat-value components such as aromatic alcohol and heavy oil can be sufficiently decomposed in the reaction, and pollutant emissions in the tail gas can be reduced.

Owner:湖南省环境保护科学研究院

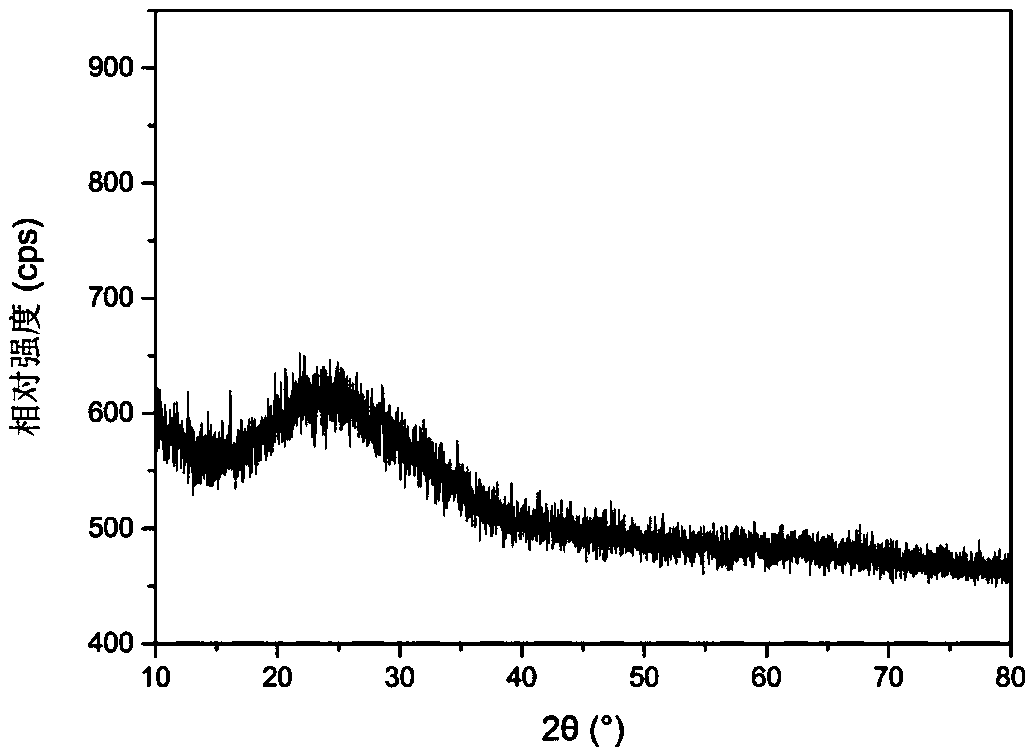

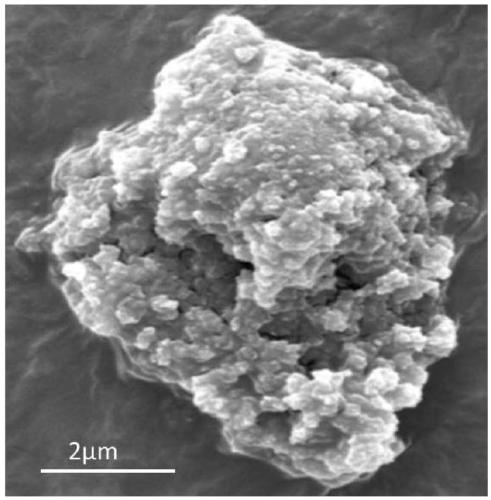

Preparation method of amorphous boron powder

The invention relates to a preparation method of amorphous boron powder. The preparation method comprises the following steps: uniformly mixing a reducing agent, a boron-containing compound and an alkali metal compound-containing molten salt according to a mass ratio of 1.0:(1.2-3.6):(0.2-16.0), carrying out heat treatment in a protective atmosphere at 600-1300 DEG C for 0.5-8 h, dissolving the obtained product in water or an alkali solution at a temperature of room temperature to 250 DEG C, and performing filtering, washing and drying to obtain the amorphous boron powder. The preparation method has the characteristics of low production cost, environmental protection, easiness in industrial production, recycling of reaction byproducts and high boron recovery rate, and the prepared amorphous boron powder has the advantages of small particle size, narrow particle size distribution and high purity.

Owner:WUHAN UNIV OF SCI & TECH

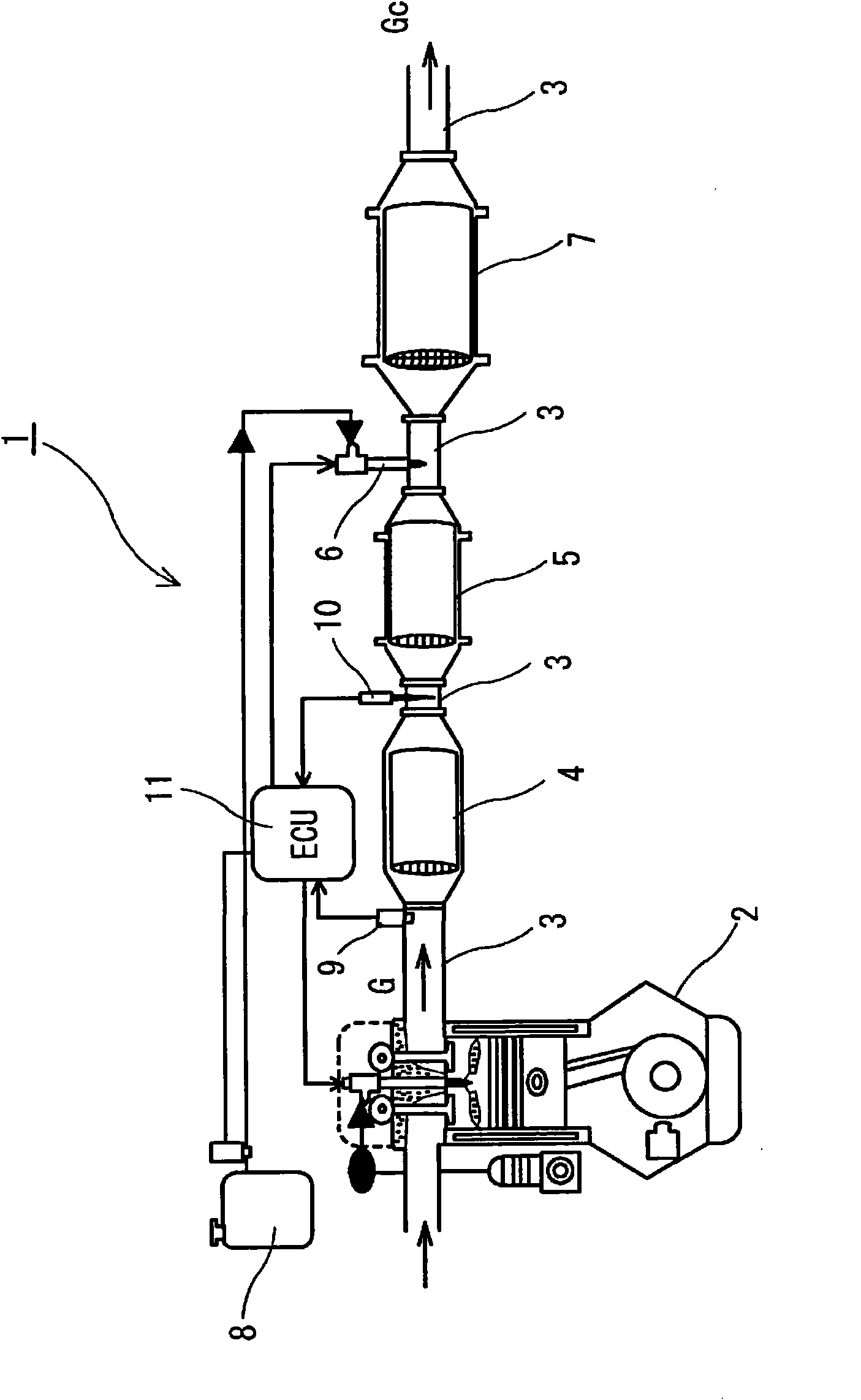

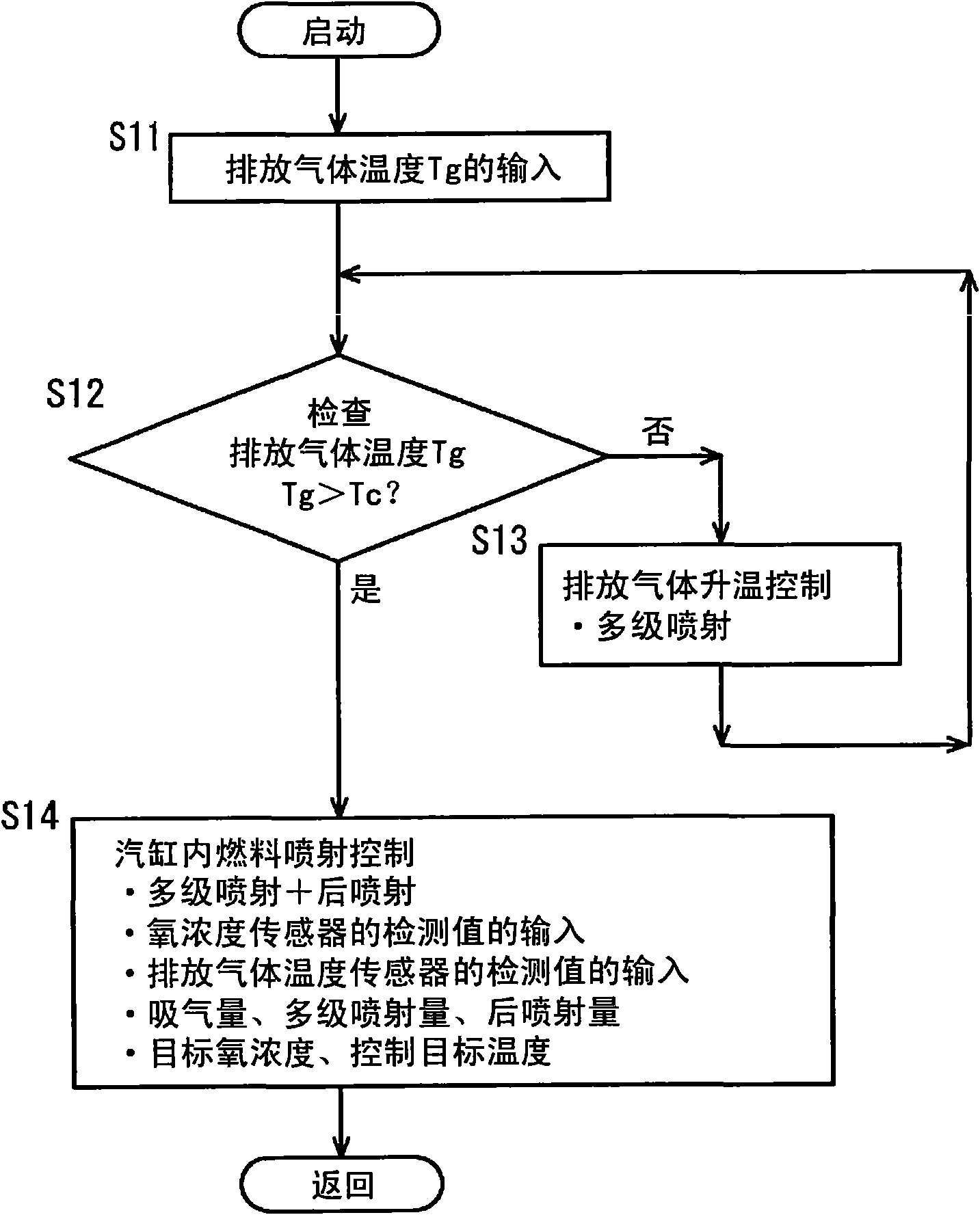

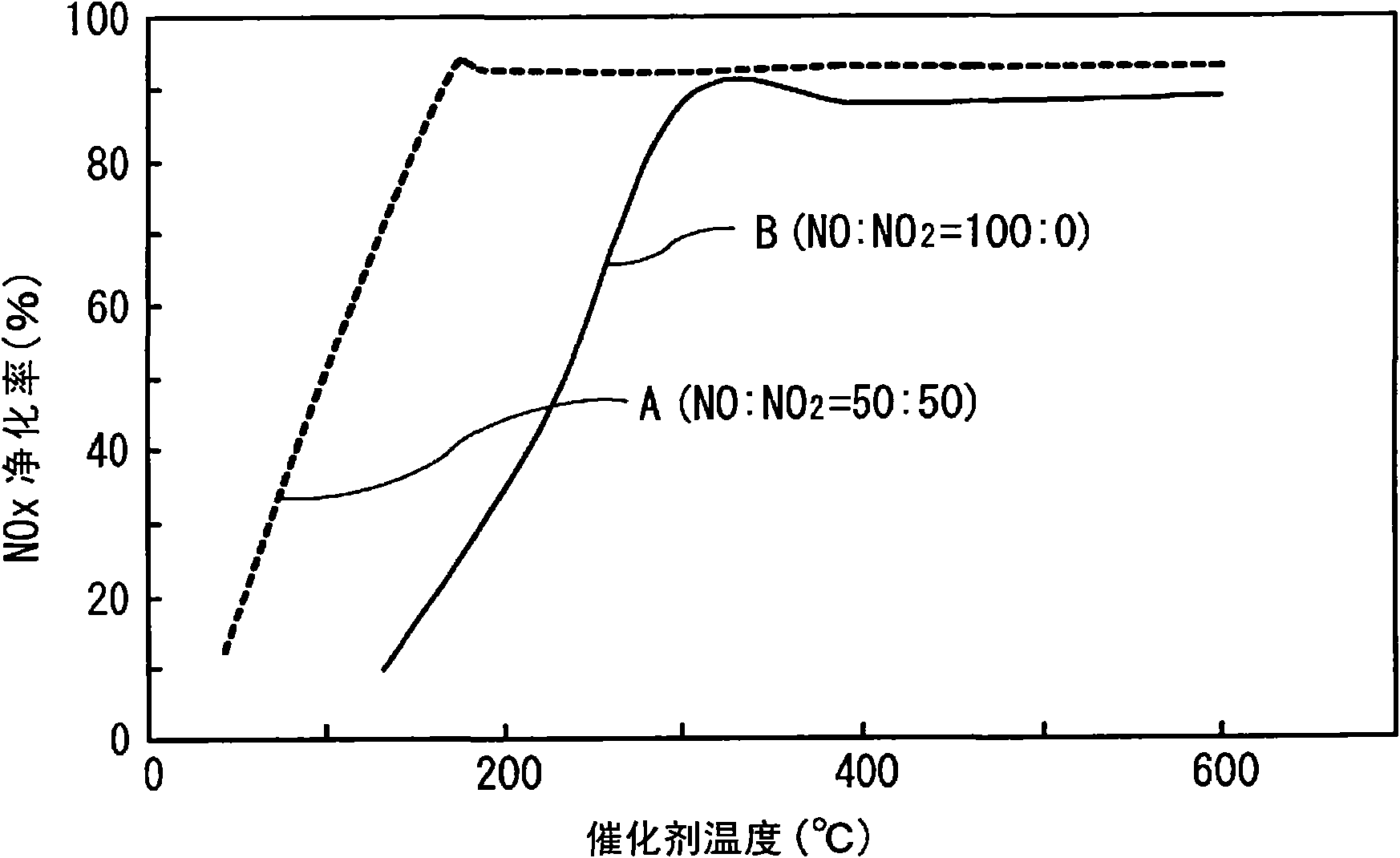

NOX purification system, and method for control of nox purification system

InactiveCN101680332AFacilitate the reduction reactionImprove purification effectElectrical controlInternal combustion piston enginesNitric oxideAmmonium hydroxide

In an NOx purification system and a method for control of the NOx purification system, two oxidation catalysts 4, 5 are provided upstream of an ammonia solution supply unit 6, and the in-cylinder fuelinjection is so controlled that hydrocarbon in exhaust gas is mainly oxidized by the upstream oxidation catalyst 4 and nitric oxide in the exhaust gas is mainly oxidized by the downstream oxidation catalyst 5. In the purification of NOx in the exhaust gas by feeding an ammonia solution for NOx reduction to a selective reduction NOx catalyst 6, this technique enables the system to adjust the concentrations of HC, NO and NO 2 in the exhaust gas flowing into the selective reduction NOx catalyst 6 to proper values so as to purify the NOx efficiently by the selective reduction NOx catalyst 6. TheNOx purification performance in a lower temperature range can be thus improved.

Owner:ISUZU MOTORS LTD

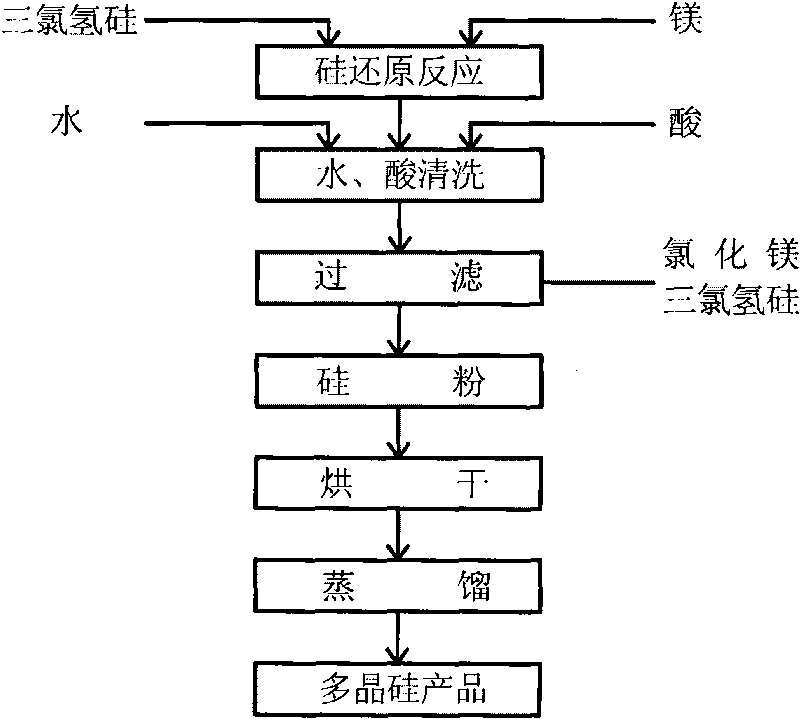

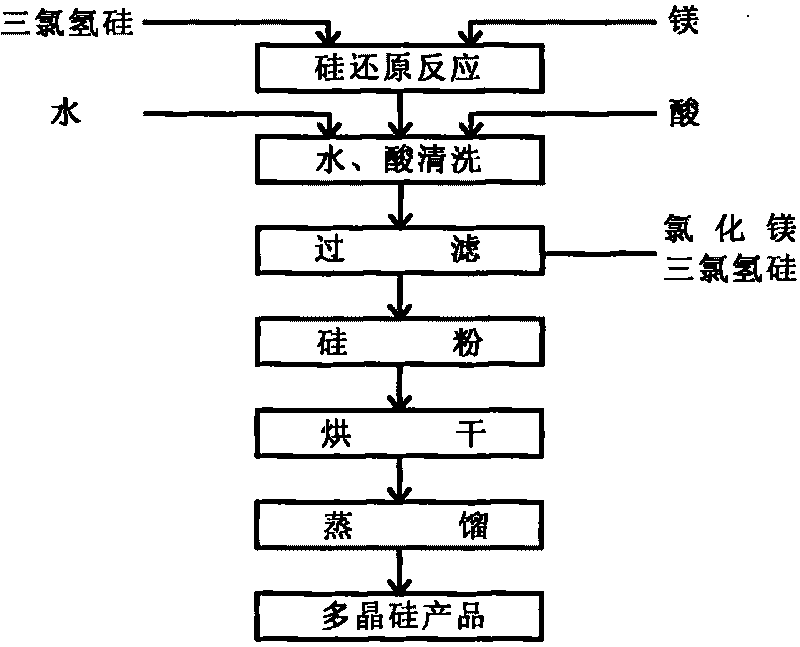

Method for manufacturing polycrystalline silicon by reducing silicon chloride with active metal

The invention discloses a method for manufacturing polycrystalline silicon by reducing silicon chloride with an active metal. The invention aims to overcome the defects of the prior art and provides a method for manufacturing the polycrystalline silicon by reducing the silicon chloride with the active metal, wherein the method has less energy consumption, simple process and low cost. The method comprises the following steps of: reducing the silicon chloride with the active metal, separating and washing reactants to obtain silicon powder, distilling and purifying the obtained silicon powder in vacuum, and separating silicon from the active metal and other impurities in the silicon through vacuum distillation to enable the purity of the silicon to reach the silicon purity requirement of a solar battery or an electronic industry. The method is used for manufacturing a polycrystalline silicon raw material for the solar battery or the electronic industry.

Owner:SHANGHAI QIMOU ENERGY SOURCE TECH DEV

Car tail gas purifying device

InactiveCN106150624AImprove purification efficiencyIncrease contact timeExhaust apparatusSilencing apparatusExhaust gasInjector

The invention discloses a car tail gas purifying device, and belongs to the field of automotive exhaust emission reduction. The car tail gas purifying device comprises a purifying ejector, a purifying room and a purifying tank for providing purifying matter for the purifying room. The purifying tank communicates with an adsorption cavity of the purifying ejector. The input end of the purifying ejector is connected with an engine exhaust pipe. The output end of the purifying ejector is connected with a gas inlet channel of the purifying room. The interior of the purifying room is divided into a plurality of purifying chambers through separation plates. The purifying chambers communicate through inner cavity channels. Tail gas enters the purifying room through the gas inlet channel, and the tail gas is exhausted out of a gas outlet channel after circularly flowing in all the purifying chambers to be purified. The car tail gas purifying device has the beneficial effects that zero emission of harmful mater of tail gas is achieved, engine power is further improved, combustion efficiency and fuel economy are improved, and cost is low.

Owner:桐城市宇洁机动车尾气检测有限公司

Technology for removing acidic high-concentration mercury-containing waste water

ActiveCN105565559AEasy to handleEfficient removalWater/sewage treatment by irradiationWater contaminantsChemical reactionWater chlorination

The invention discloses a method for removing acidic high-concentration mercury-containing waste water. The method includes the following steps that firstly, waste water containing divalent mercury is collected to a reaction vessel which is resistant to acid and alkali and good in ultraviolet permeability, sodium chloride is added into the waste water, a complexation reaction is performed under the stirring condition, fulvic acid is added after the complexation reaction ends, then the vessel is placed in a photo-chemical reaction device, a photo-chemical reduction reaction is performed under the stirring condition, the divalent mercury in the waste water is reduced into mercury protochloride to be recycled, and supernatant obtained after solid and liquid separation is treated effluent. The method solves the problem that the acidic high-concentration mercury-containing waste water pollutes the environment and has the advantages that the technology is simple, implementation is easy and the technology take effect fast, mercury in waste water can be economically and efficiently removed under the acidic condition, mercury in waste water can also be recycled, it is also possible that acid is recycled in the treated effluent, and economic benefits and environmental protection benefits are good.

Owner:四川深蓝环保科技有限公司

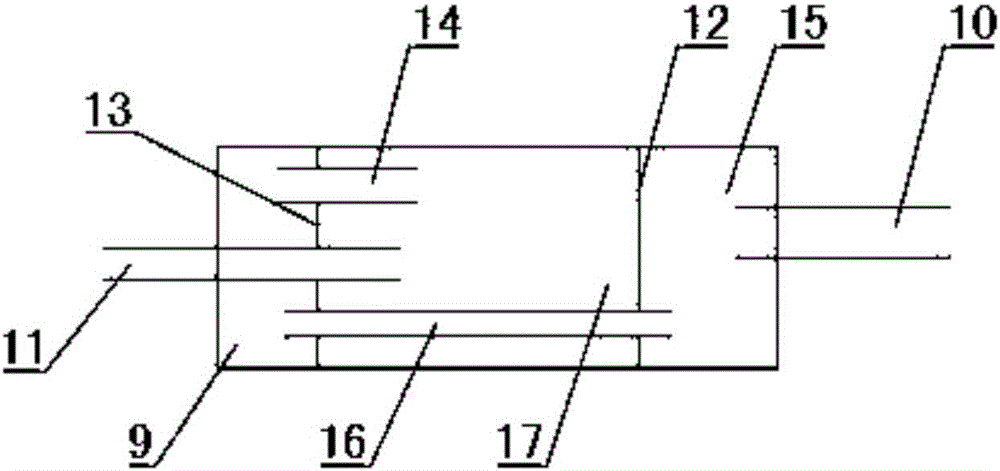

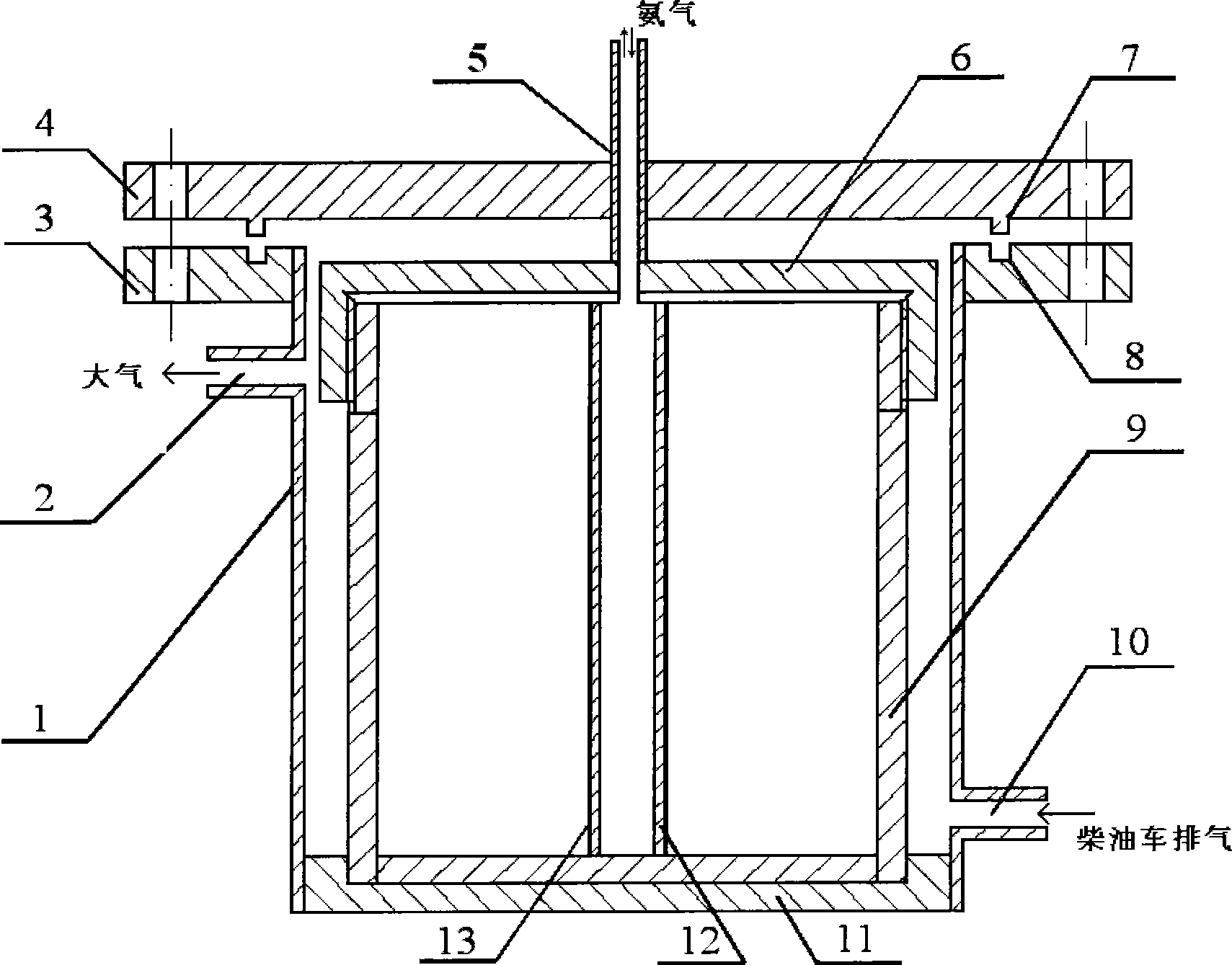

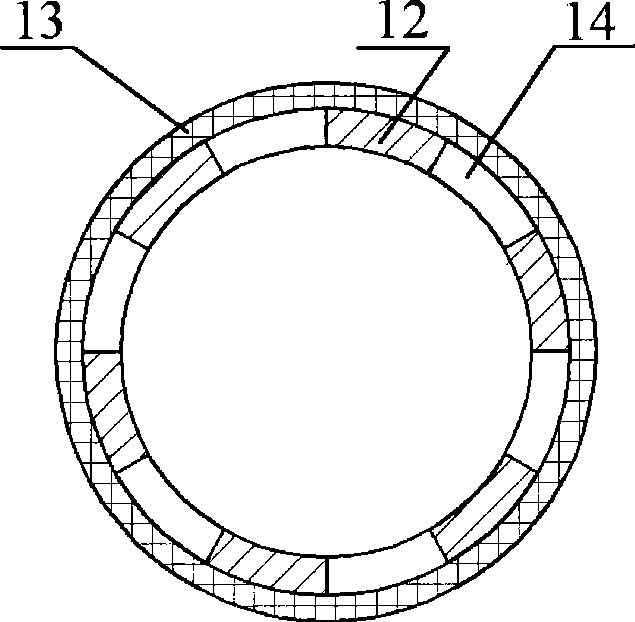

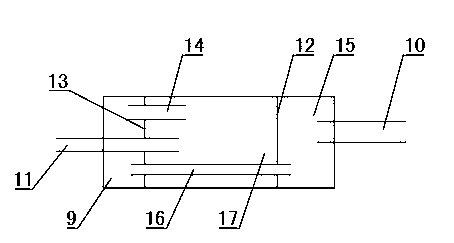

Ammine reducing reagent storing device in NH3-SCR system of diesel vehicle

InactiveCN101363351AImprove the efficiency of the reduction reactionAvoid efficiencyExhaust apparatusDispersed particle separationSorbentService condition

The invention relates to an ammonia reducing agent storage device in an NH3-SCR system of a diesel powered car, belonging to the technical field of controlling the pollutant emission of diesel engine tail gas. The device is composed of an inner barrel and an outer barrel, a stainless steel mass transfer tube is arranged at the axle center of the inner barrel, an annular space between the stainless steel mass transfer tube and the inner barrel functions as an adsorbent bed for placing CaCl2 adsorption working medium and NH3 is adsorbed on CaCl2. After being hermetically connected with an inner barrel cover, the inner barrel is placed in an outer barrel. An annular space between the inner barrel and the outer barrel serves as the place where exhaust gas of the diesel engine heats the inner barrel, the exhaust gas enters the barrel from an air inlet at the bottom of the outer barrel to heat the inner barrel and then is discharged from an air outlet at the upper part of the outer barrel, and after adsorption stripping, NH3 is discharged from an air duct through the stainless steel mass transfer tube. The ammonia reducing agent storage device can directly provide NH3 reducing agent for the SCR system and solves the problem of low utilization rate of ammonia reducing agent; the storage device is simple in structure, safe and reliable; by adopting the exhaust gas of the diesel powered car as a heating source, energy can be saved; as the inner and outer barrels are convenient to dismantle, the service condition monitoring and replacement of adsorbents can be realized.

Owner:SHANGHAI JIAO TONG UNIV

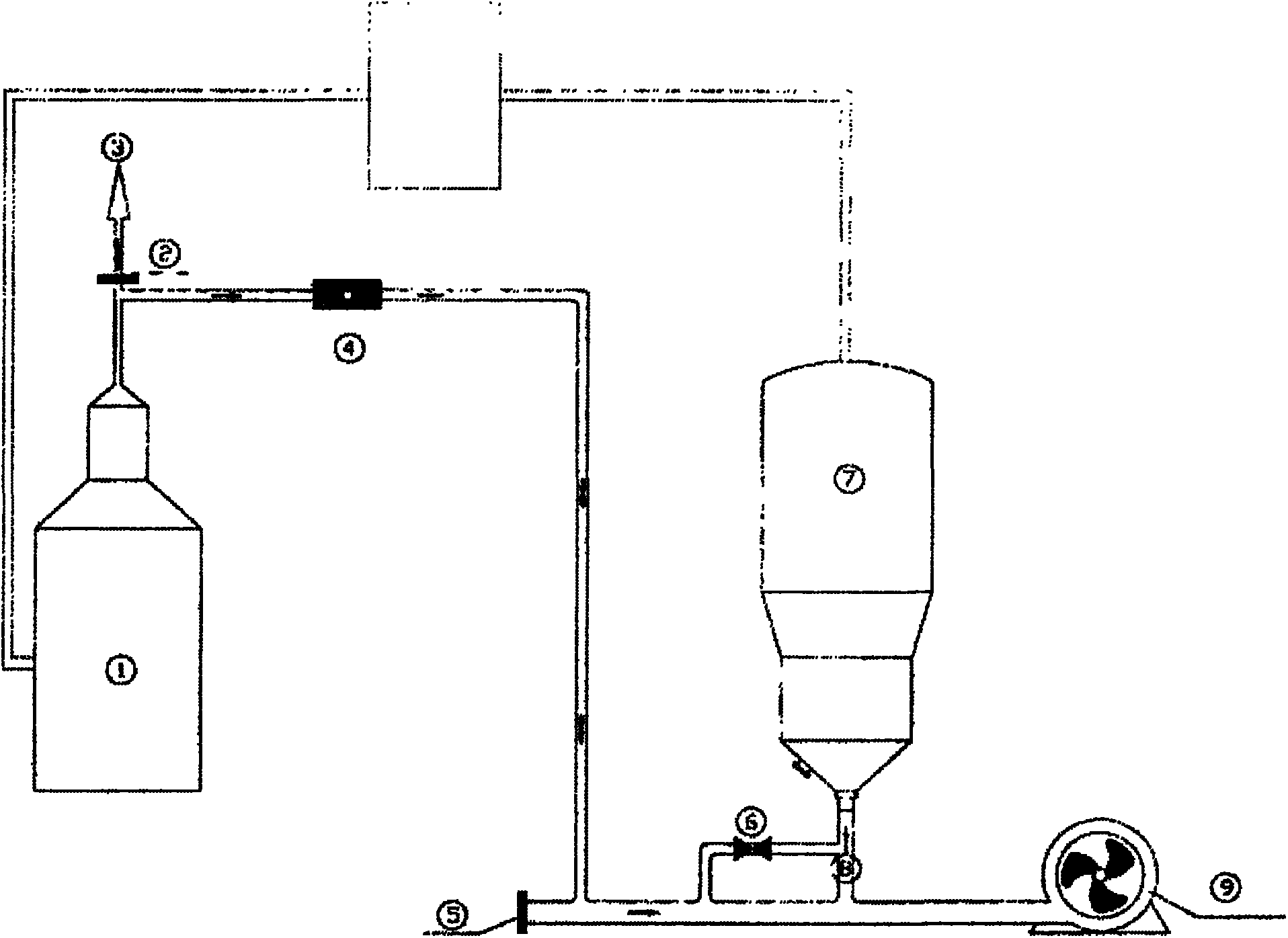

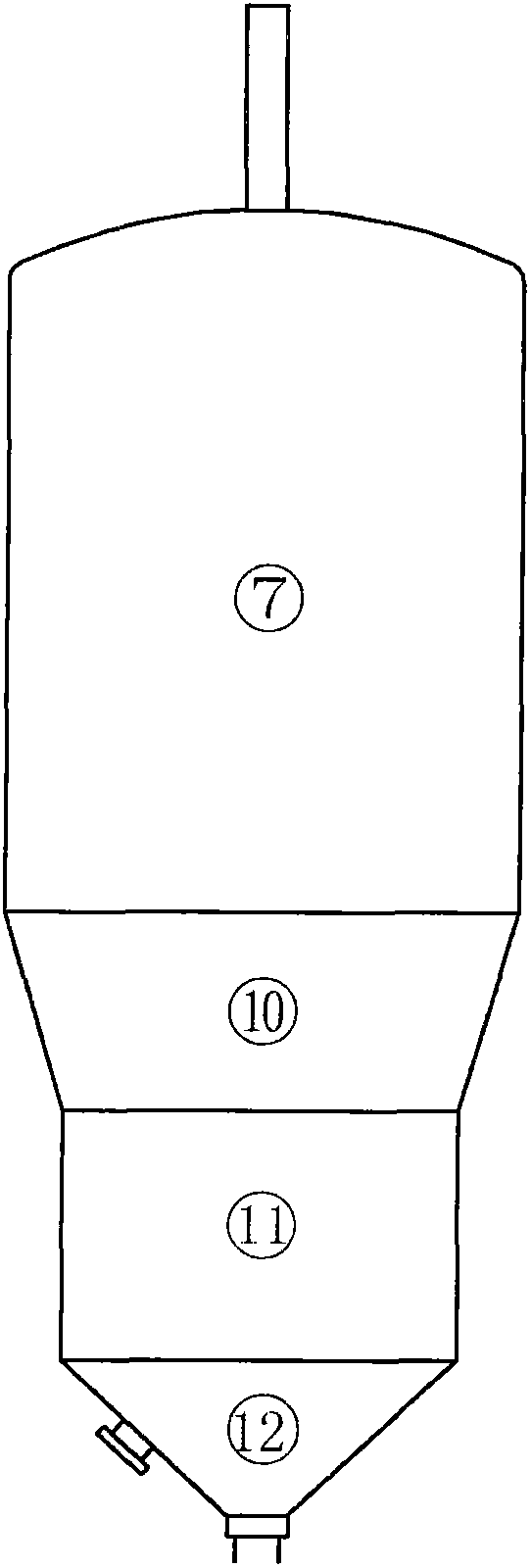

Desulfurization waste liquid treatment and reuse system and method

The invention relates to a desulfurization waste liquid treatment and reuse system. The desulfurization waste liquid treatment and reuse system includes a desulfurizing tower, a filter pressing device, a reduction tower, a desulfurization waste liquid distributing device, an aeration device, a heating device, a flocculant charging device, a sedimentation basin, a desulfurization waste liquid waterpump and a reduction liquid water pump, wherein the desulfurizing tower is provided with a flue gas inlet, a desulfurizing agent inlet, a desulfurization waste liquid outlet and an exhaust port, a tower body of the reduction tower is provided with a flocculant inlet, the desulfurization waste liquid distributing device is arranged in the tower body, the aeration device is provided with an aeration nozzle group located on the lower side of the desulfurization waste liquid distributing device, the sedimentation basin is provided with a reduction liquid cleaning water pump, an inlet of the desulfurization waste liquid water pump communicates with the desulfurization waste liquid outlet, and an inlet of the reduction liquid water pump communicates with an inner cavity of the reduction tower;and a waste residue outlet of the sedimentation basin communicates with the filter pressing device, an outlet of the desulfurization waste liquid water pump communicates with the desulfurization wasteliquid distributing device, an outlet of the reduction liquid water pump communicates with a reduction liquid inlet of the sedimentation basin, and an outlet of the reduction liquid cleaning water pump communicates with the desulfurizing agent inlet. According to the desulfurization waste liquid treatment and reuse system, treatment and reuse of desulfurization waste liquid are convenient, the amount of a desulfurizing agent is small, and the desulfurization effect is good.

Owner:台州临港热电有限公司

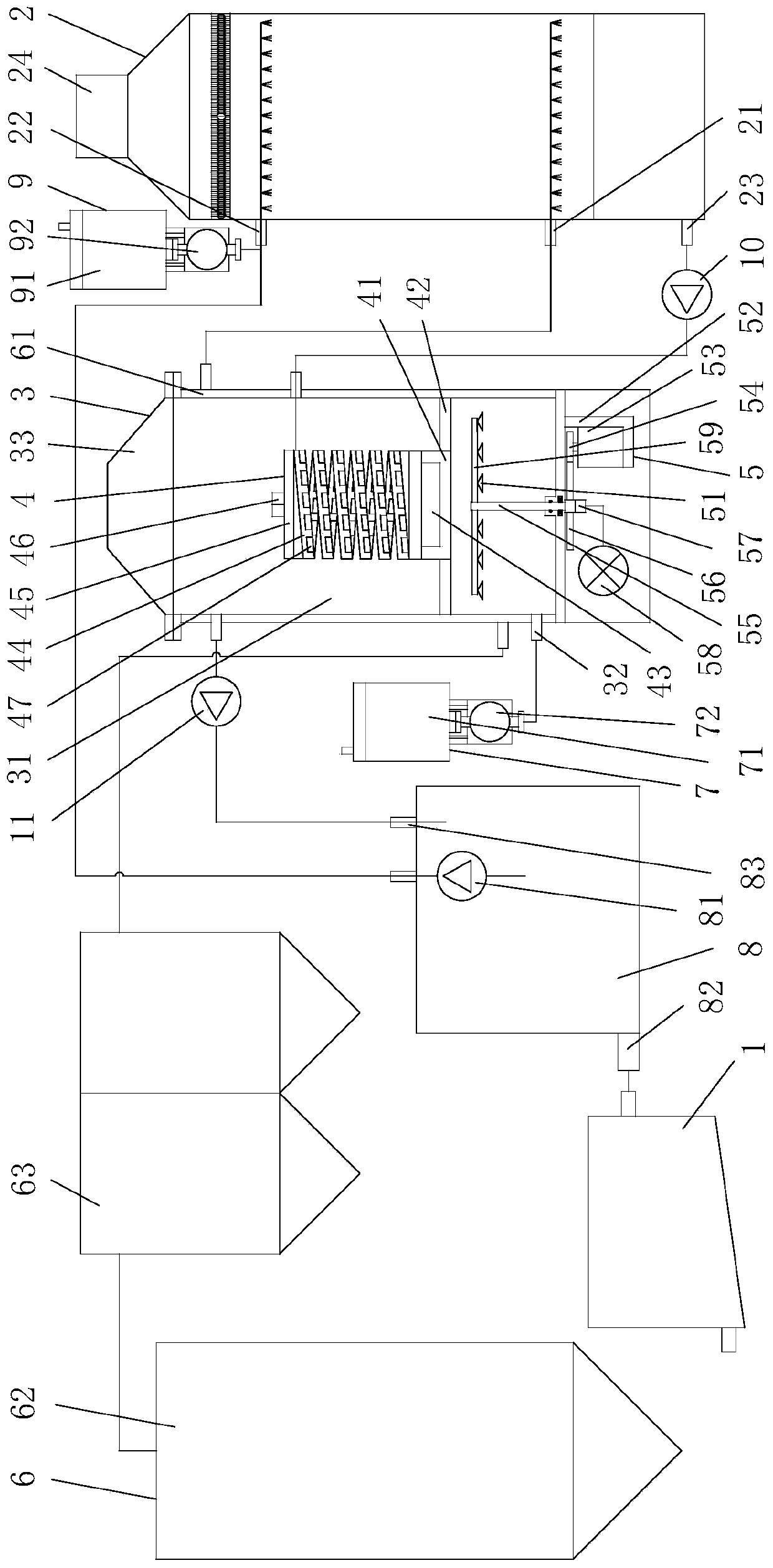

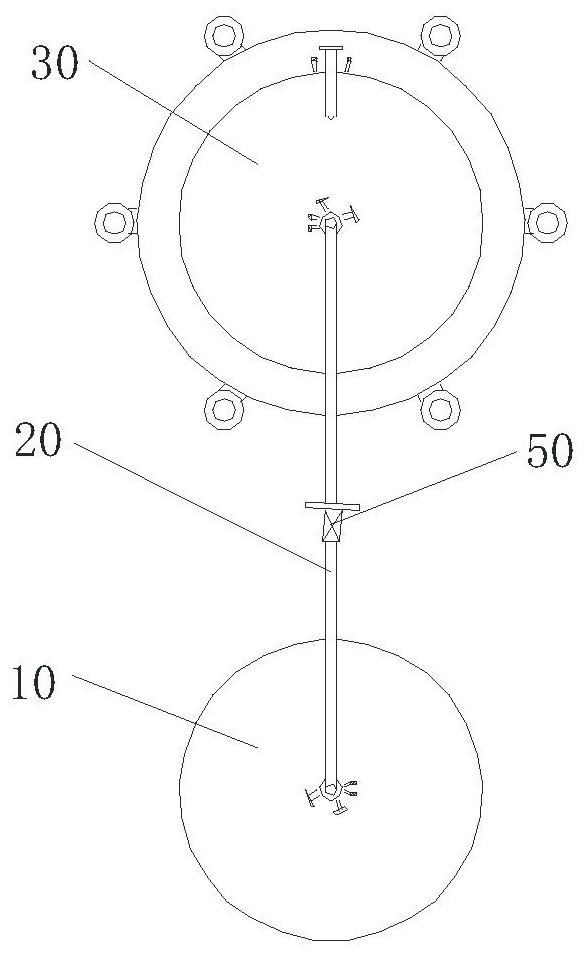

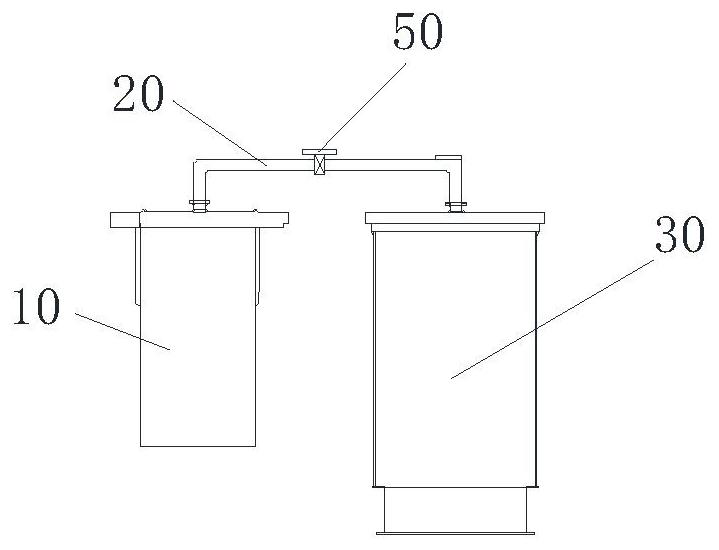

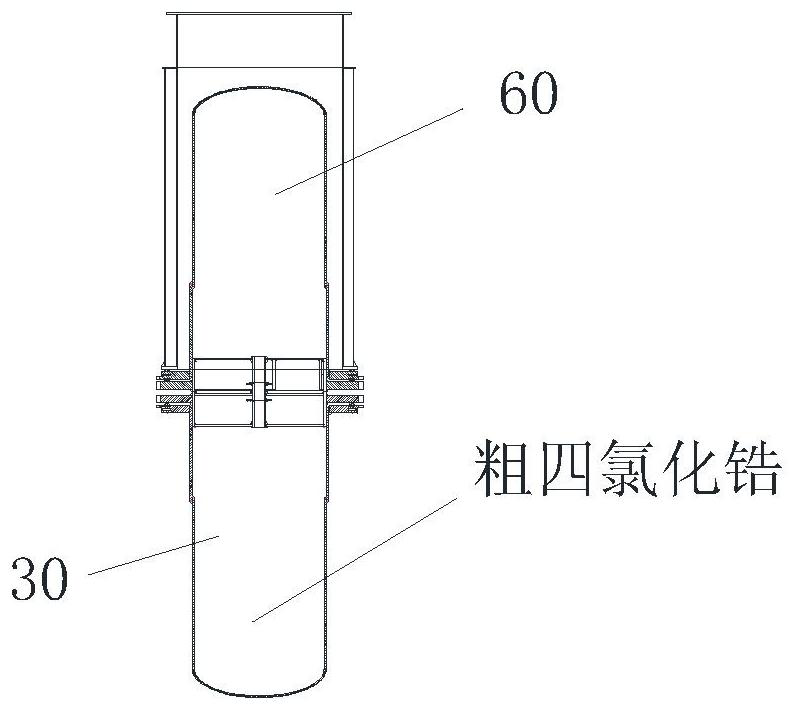

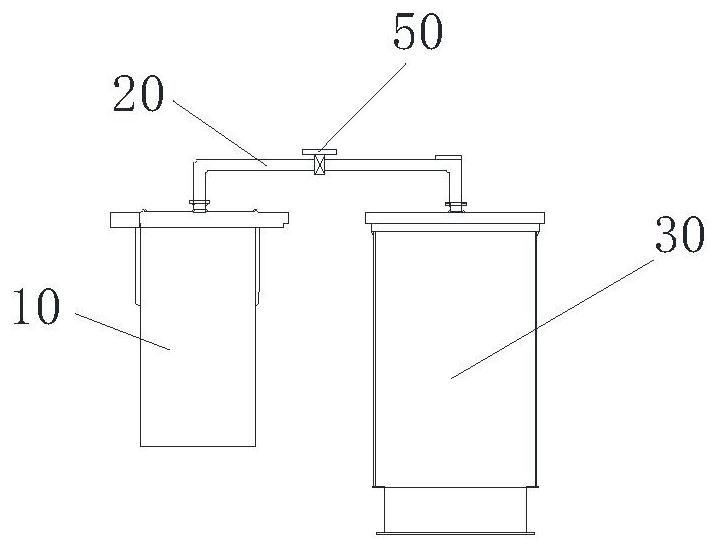

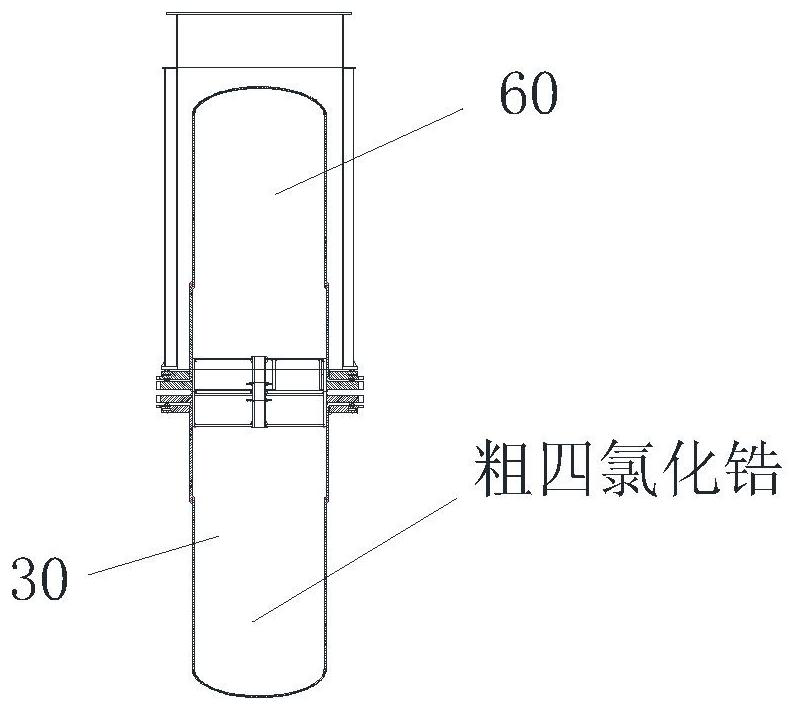

Production equipment and process of zirconium sponge

ActiveCN112430753AImprove the efficiency of the reduction reactionImprove qualitySocial benefitsAir pump

The invention relates to the technical field of metal smelting, in particular to production equipment and process of zirconium sponge. The production equipment of zirconium sponge comprises a channelfor connecting a sublimation furnace with a first reduction furnace, wherein molten liquid magnesium is placed in a furnace pipe, a furnace cover is provided with a magnesium feeding port, a liquid magnesium outlet, a temperature and pressure measuring device, inert gas supply equipment and a gas inlet pipe connected in a sealed mode, the gas inlet pipe is provided with a gas pump and a second one-way valve, a gas explosion pipe is arranged on the lower side of the gas inlet pipe, a gas pipe branch is arranged between the gas inlet pipe and the second one-way valve, a third one-way valve and astorage box for providing an explosion body are arranged on the gas pipe branch, and the explosion body is ejected out from the bottom of the gas explosion pipe by pressure of inert gas and explodesin magnesium liquid in the furnace pipe to accelerate reduction reaction. The production efficiency and quality of the zirconium sponge are improved, and good economic benefits and social benefits areachieved.

Owner:宝钛华神钛业有限公司

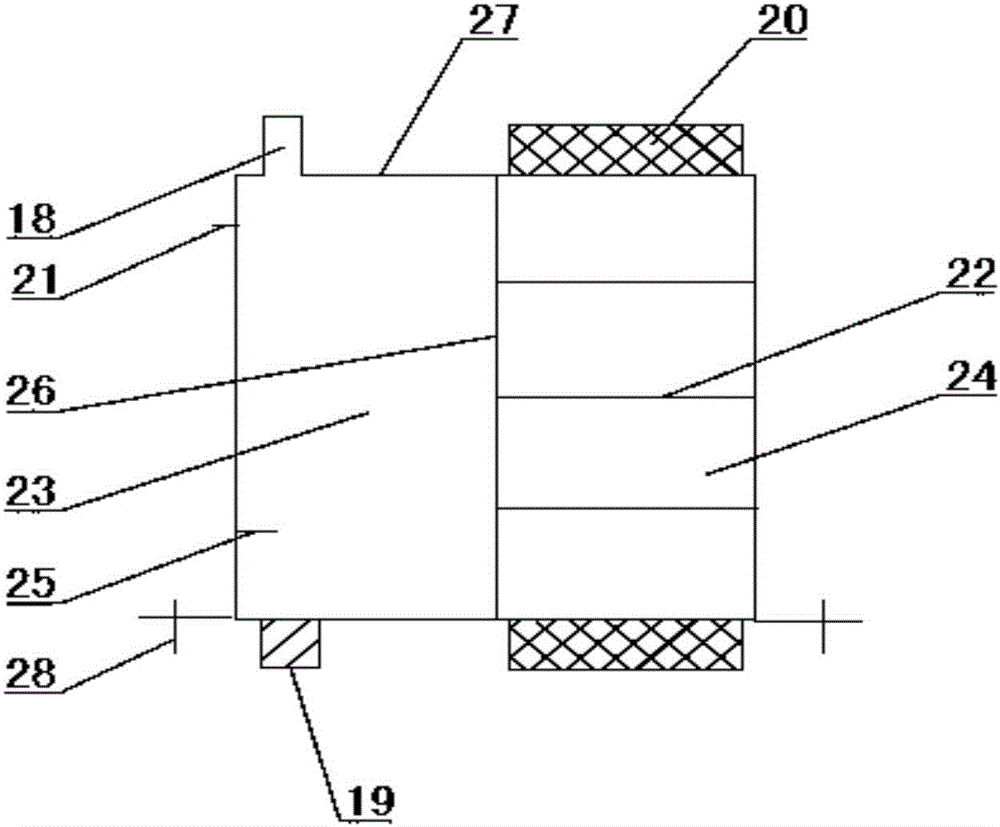

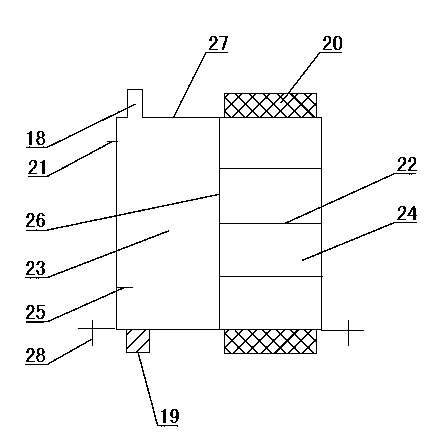

Motor vehicle exhaust purifying device

InactiveCN103758616AImprove the efficiency of the reduction reactionImprove combustion efficiencyExhaust apparatusSilencing apparatusExhaust gasInjector

The invention discloses a motor vehicle exhaust purifying device, and belongs to the field of motor vehicle exhaust emission reduction. The motor vehicle exhaust purifying device comprises a purifying ejector, a purifying chamber and a purifying tank (27) for providing purifying matter for the purifying chamber. The purifying tank (27) is communicated with an adsorption cavity (2) of the purifying ejector, the input end of the purifying ejector is connected with an engine exhaust pipe, the output end of the purifying ejector is connected with a gas inlet channel (10) of the purifying chamber, the interior of the purifying chamber is divided by partition plates into a plurality of purifying cavities, the purifying cavities are communicated through inner cavity channels, and exhaust enters the purifying chamber through the gas inlet channel (10) and circularly flows in the purifying cavities to be purified to be emitted out through a gas outlet channel (11). The motor vehicle exhaust purifying device has the advantages that zero emission of exhaust harmful substance is achieved, the power of an engine is further improved, the combustion efficiency and the fuel economy are improved, and cost is low.

Owner:赵金博

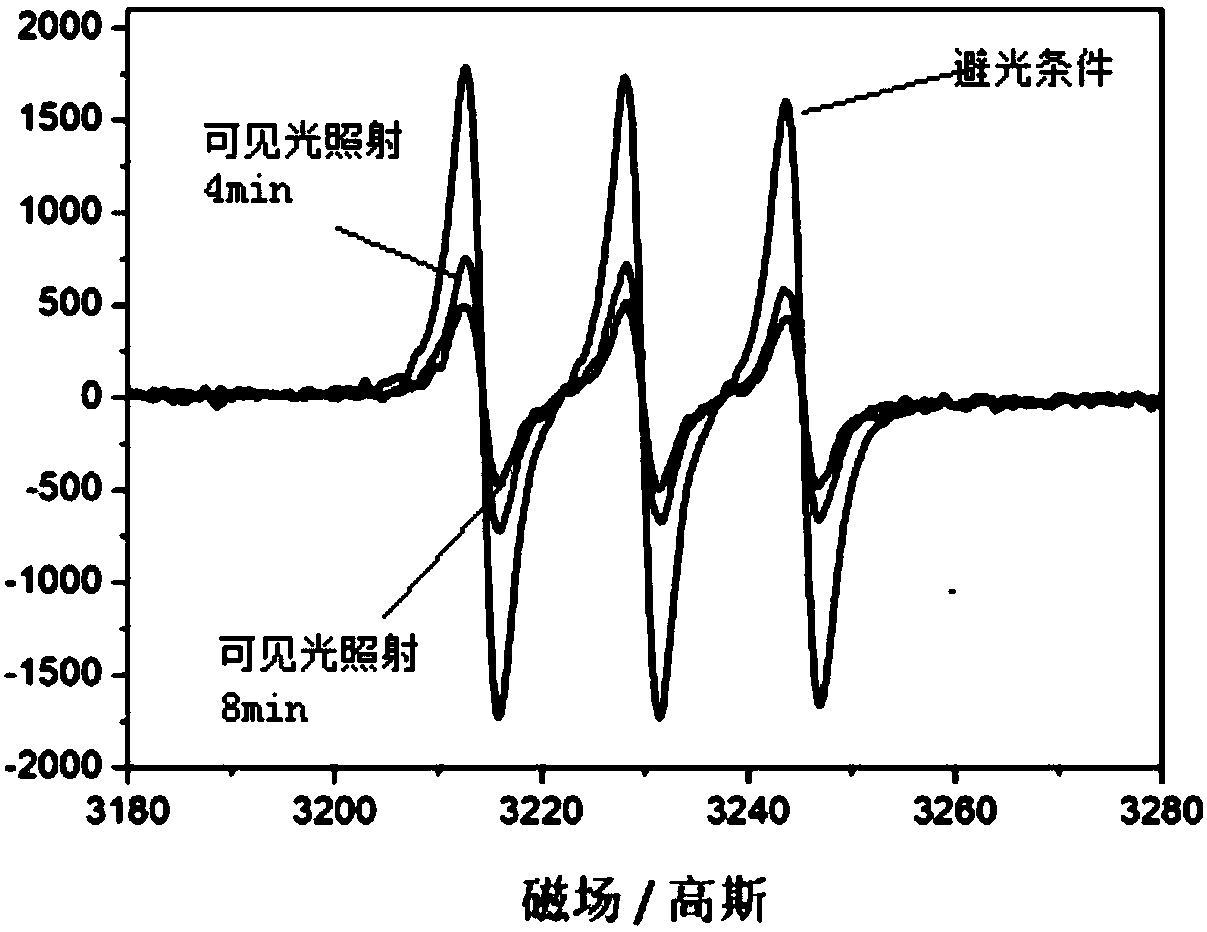

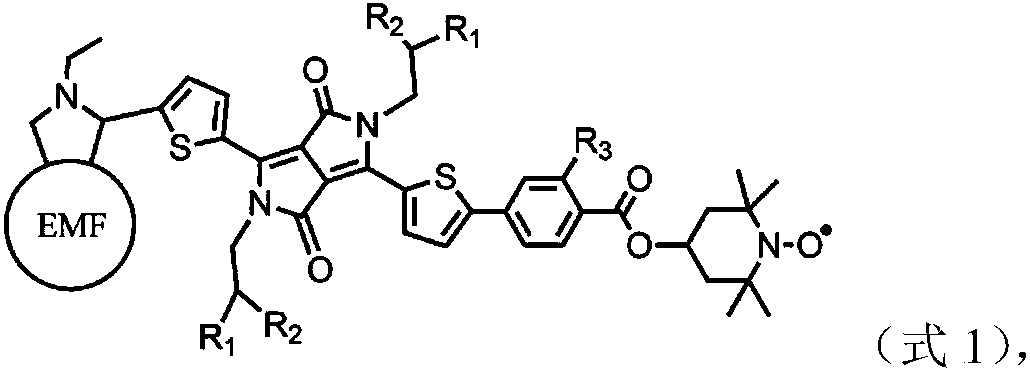

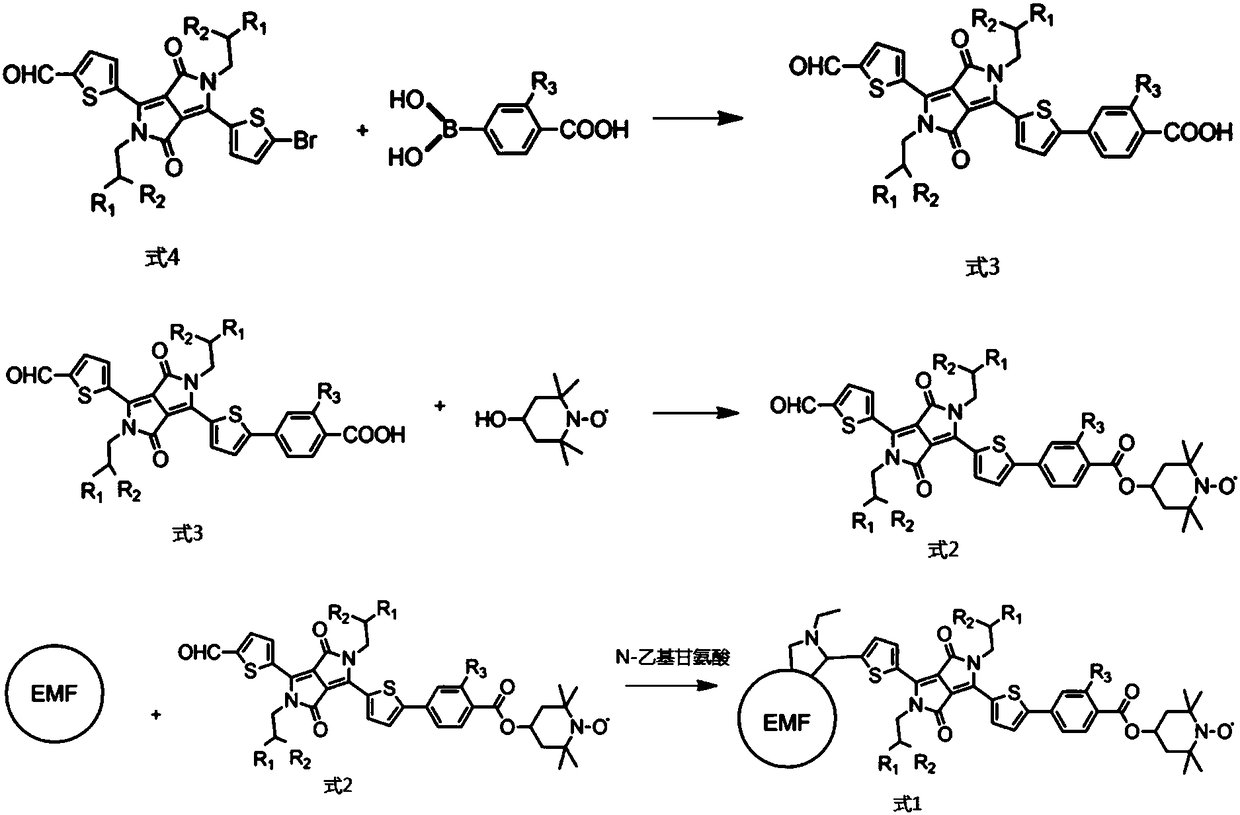

Metallofullerene nitroxide free radical derivative as well as preparation method and application thereof

ActiveCN108440535AGood visible light absorption propertiesNo pollution in the processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholCatalytic oxidation

An embodiment of the invention relates to a metallofullerene nitroxide free radical derivative as well as a preparation method and an application thereof. The metallofullerene nitroxide free radical derivative in the embodiment can efficiently produce electron transfer under irradiation of visible light, so that a NO free radical turns into NO+ with certain catalytic oxidation activity, and efficient and high-selectivity catalytic conversion of alcohol compounds into aldehyde compounds is realized under the mild condition. Meanwhile, the metallofullerene nitroxide free radical derivative catalyst can replace functions of multiple reported catalysts in a catalyst system taking the nitroxide free radical as one of catalysts; besides, the dose of the metallofullerene nitroxide free radical derivative catalyst is basically 1 / 10 of that of NO free radical catalysts in the prior art, but similar or better effects can be realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

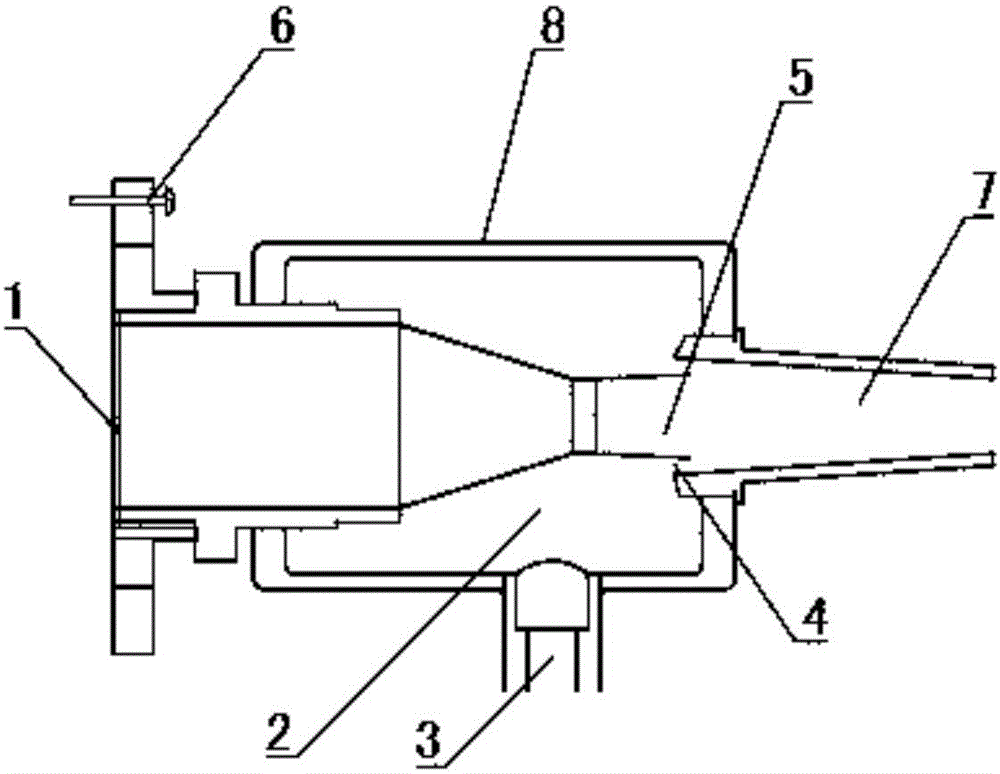

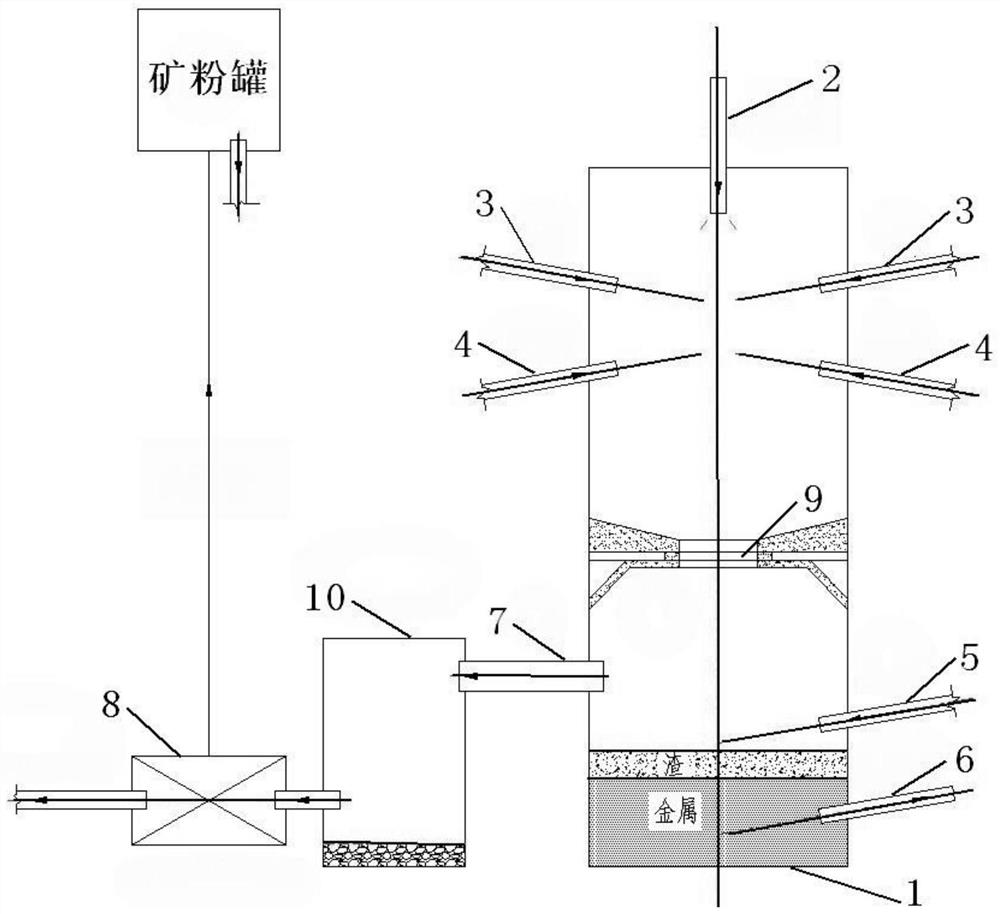

Device and method for smelting metal through thermal reduction method

PendingCN112985057AQuick restoreIncrease contact areaCharge manipulationCrucible furnacesSlagPowder injection

The invention relates to a device and method for smelting metal through a thermal reduction method, and belongs to the technical field of metal smelting. The device and method for smelting the metal through the thermal reduction method are provided, and the device comprises a smelting furnace 1, a heating device 2, a mineral powder injection device 3, a reducing agent injection device 4, a slag former injection device 5, a metal discharging device 6 and a tail gas guiding device 7. The device can directly spray mineral powder and a reducing agent into a smelting furnace, heating is quickly conducted in the furnace to the reduction temperature, the reducing agent and the mineral powder are sufficiently contacted to produce reduction reaction, and reducing metal and slag fall into the bottom of the furnace to be layered and are discharged out of the furnace at regular time. When the device is used for smelting the metal by the thermal reduction method, the process energy consumption can be reduced, the contact area of the reducing agent and the mineral powder can be increased, the dynamic conditions of reduction reaction are greatly improved, the metal is quickly reduced, and the efficiency of the reduction reaction is improved.

Owner:CISDI ENG CO LTD +1

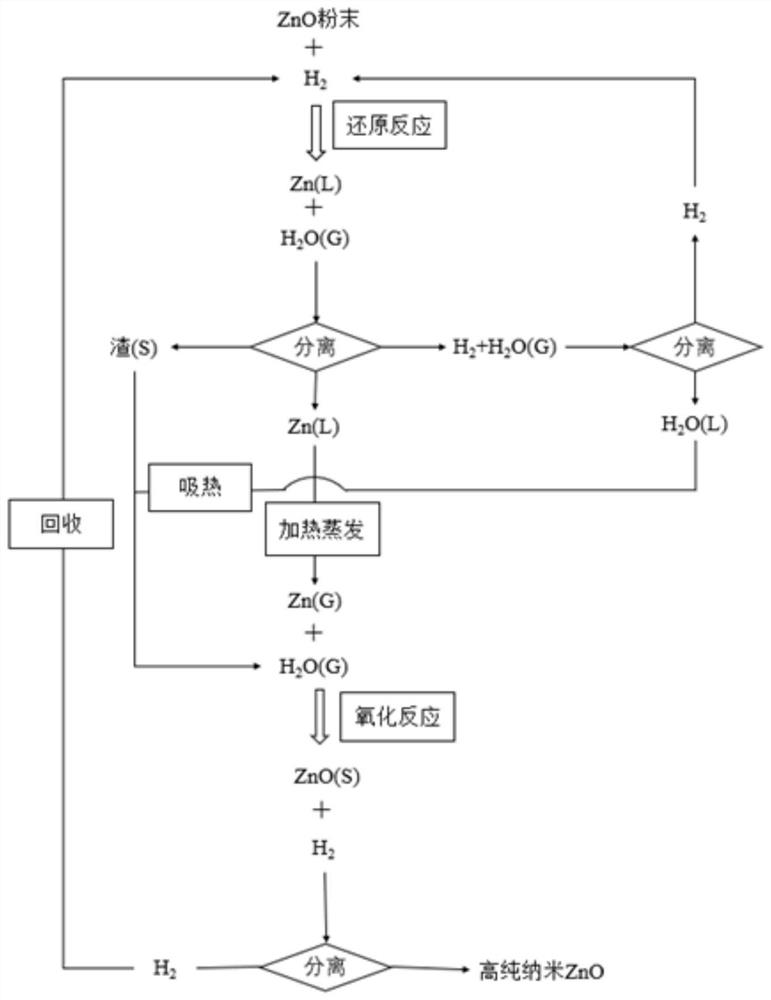

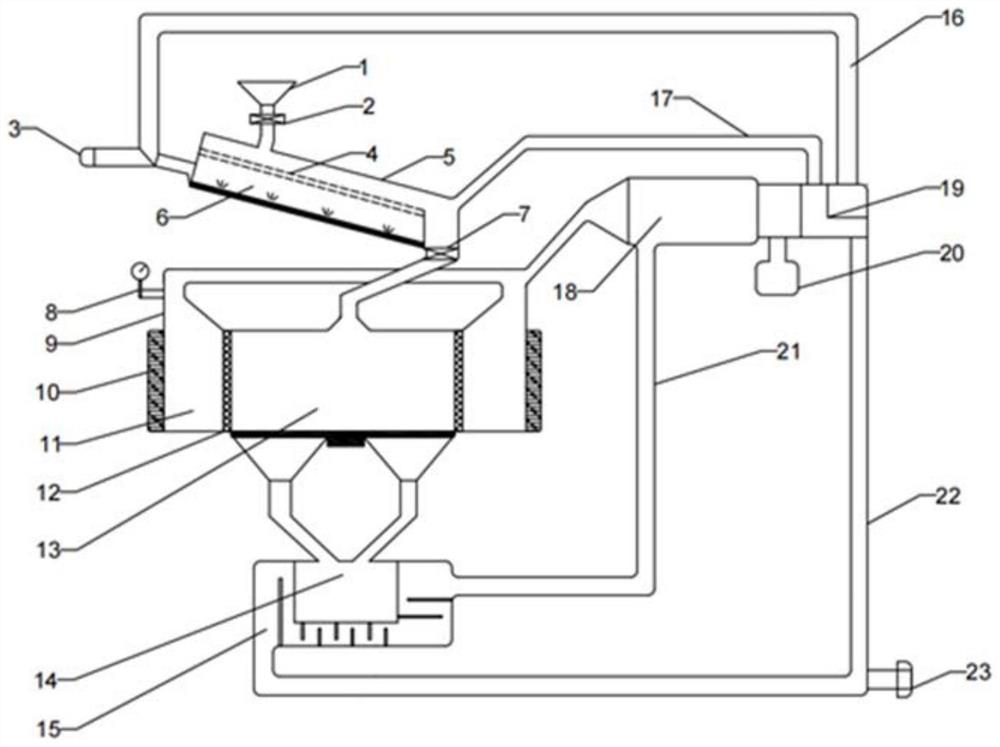

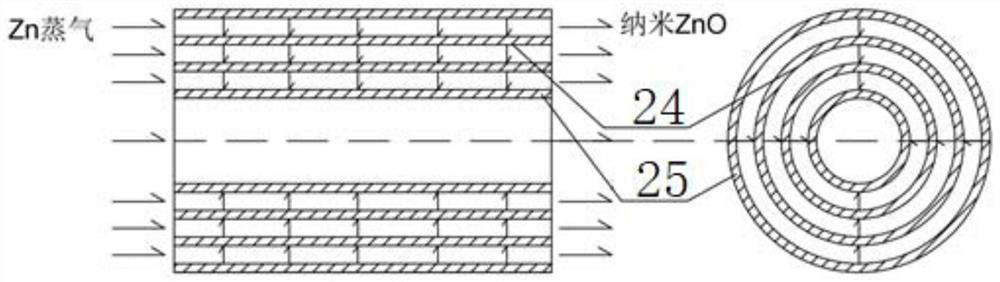

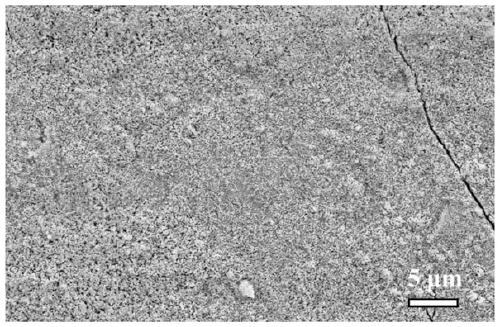

Device and method for preparing high-purity nano ZnO through hydrogen cycle reduction

The invention discloses a device and a method for preparing high-purity nano ZnO through hydrogen circulation reduction. The device comprises a reduction furnace, a solid-liquid separation and vaporization furnace, a waste heat recoverer and an oxidation bin, wherein a bottom plate of the reduction furnace is a first porous plate; a heater is arranged on the outer side of the solid-liquid separation and vaporization furnace; the reduction furnace is connected with a feeding bin; a hydrogen bin is arranged at the lower part of the first perforated plate; the solid-liquid separation and vaporization furnace comprises an internal rotary drum which is connected with the reduction furnace, and the side wall of the internal rotary drum is a second perforated plate; an interlayer is formed between the inner wall of the solid-liquid separation and vaporization furnace and the second perforated plate; a waste heat recovery bin connected with the internal rotary drum is arranged in the waste heat recoverer; the oxidation bin is respectively connected with the interlayer, the nano zinc oxide condensation collector and the water vapor condenser; the water vapor condenser is connected with a condensed water reheating pipeline connected with the waste heat recoverer, a hydrogen recovery pipeline connected with the hydrogen bin and a hydrogen water vapor conveying pipeline connected with the reduction furnace; and the waste heat recoverer is connected with a water vapor regeneration and recovery pipeline. The method is short in process and low in energy consumption, and the prepared nano ZnO is high in purity.

Owner:XI AN JIAOTONG UNIV

A method for reducing iron scale of hot-rolled strip steel based on reduction pretreatment process

ActiveCN109554529BImprove the efficiency of the reduction reactionControl dew pointFurnace typesProcess efficiency improvementStrip steelContinuous annealing

Owner:NORTHEASTERN UNIV LIAONING

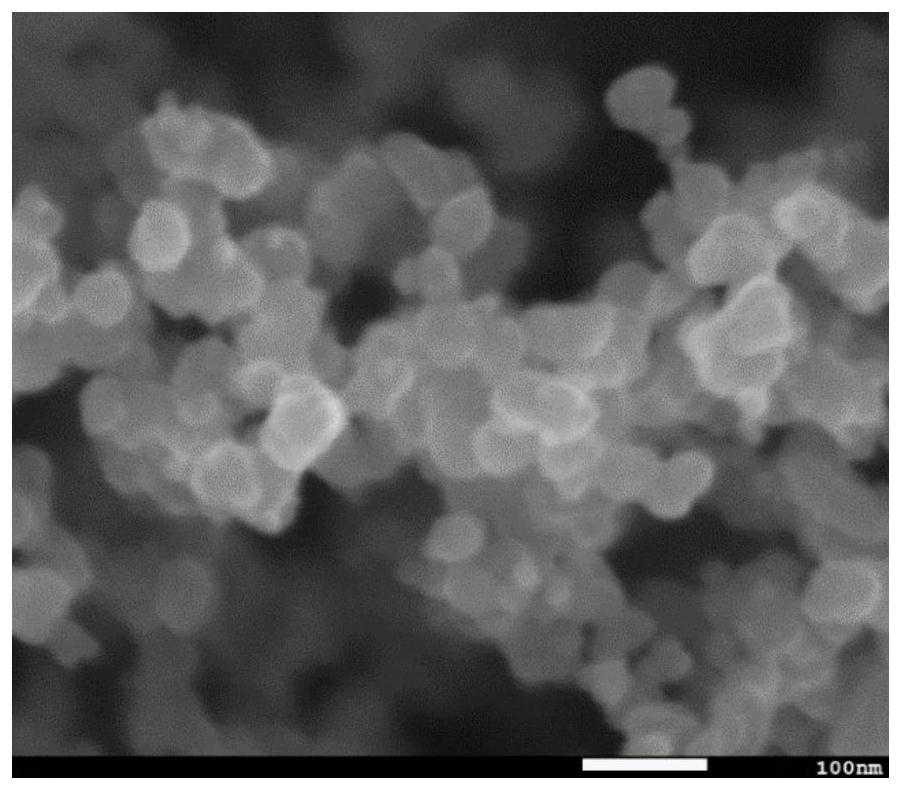

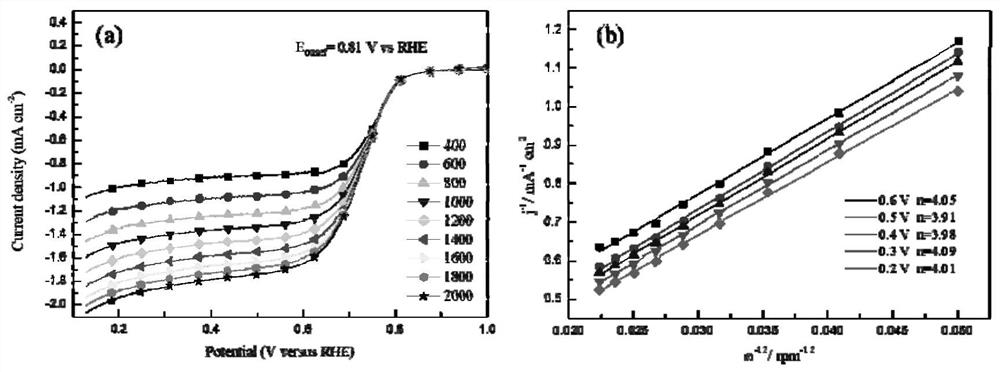

A kind of electrode catalyst, composite electrode and preparation process thereof

ActiveCN113270599BImprove catalytic performanceSimple manufacturing methodCell electrodesPtru catalystOrganometallic chemistry

The invention discloses an electrode catalyst and a preparation process thereof. The composite electrode uses foamed metal or alloy materials such as foamed titanium, foamed nickel and foamed stainless steel sheets as the electrode substrate, and after processing, an air diffusion layer is prepared on one side of the substrate and the other is One side is conductive, and on the surface of the conductive side, the flame smoke particles generated by the combustion of fuel such as paraffin, gasoline, diesel or kerosene mixed with organometallic chemicals are smoked, and the catalytic layer is prepared on the conductive side of the electrode substrate. The surface of the layer is impregnated with fuel and burned and calcined to obtain a composite electrode with the catalytic layer firmly attached. The composite electrode prepared by the invention has the advantages of simple preparation process, uniform loading of the electrode catalyst, no need to use any binder and current collector, higher mechanical strength and electrical conductivity, and better practical application.

Owner:XI AN JIAOTONG UNIV +1

A kind of preparation method of amorphous boron powder

Provided is a method for preparing the amorphous boron powder, comprising uniformly mixing a reducing agent, a boron-containing compound, and an alkali metal compound-containing molten salt which have the mass ratio of 1.0:(1.2-3.6):(0.2-16.0), performing thermal treatment on same for 0.5-8 h at the temperature of 600-1,300ºC in a protective atmosphere, resolving a thermal treatment product with water or the alkali solution at the temperature of 195-250ºC, filtering same, washing same, and drying same to prepare the amorphous boron powder. The method is low in production costs, is environment-friendly, is easily applied to industrial production, makes it possible to recycle a reaction byproduct, and has a high recovery rate of boron. The amorphous boron powder prepared by the method has a small particle size, a narrow granularity distribution, and a high purity.

Owner:WUHAN UNIV OF SCI & TECH

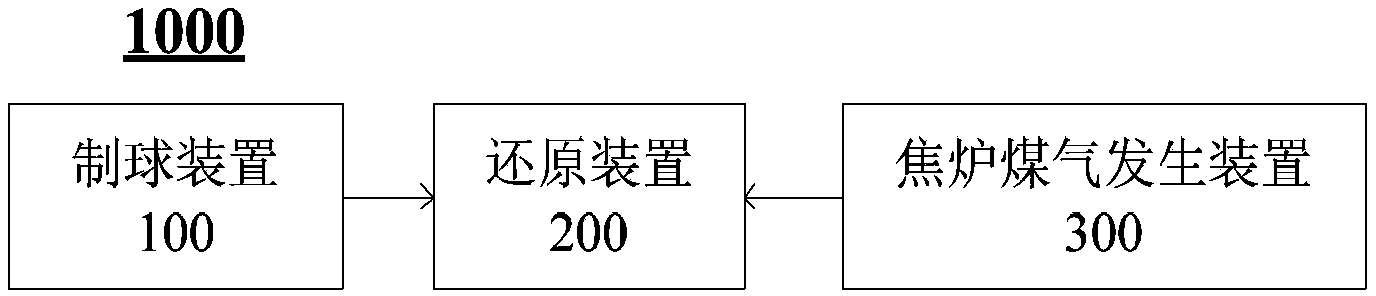

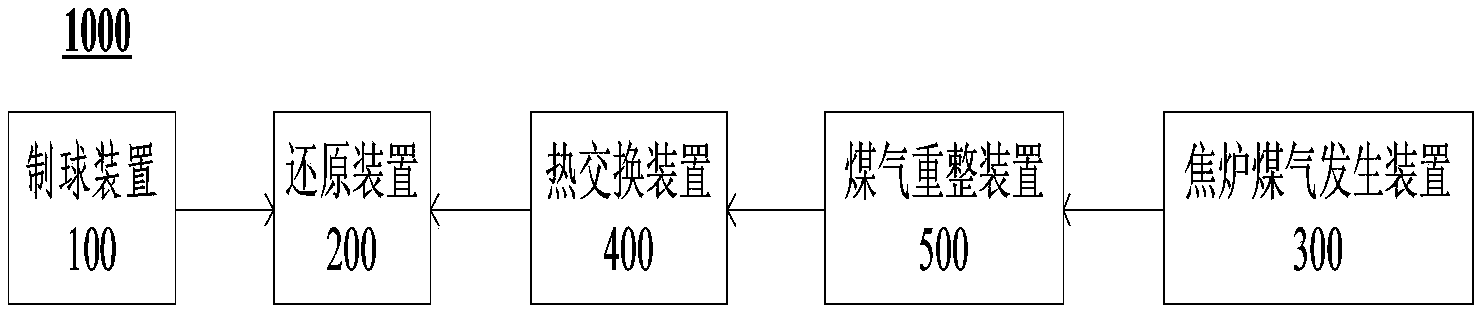

Laterite gas gas reduction apparatus

The invention discloses a laterite gas base reduction apparatus which comprises a pelletizing device, a reduction device and a coke furnace raw gas generator, wherein the pelletizing device is used for pelletizing laterite-nickel ore, binding agent, reduction coal and regulator; the reduction device is connected with the pelletizing device, and a reduction reaction chamber is defined in the reduction device so as to receive pellets from the pelletizing device; and the coke furnace raw gas generator is connected with the reduction device, and used for introducing coke furnace raw gas into the reduction reaction chamber. The laterite-nickel ore smelting apparatus disclosed by the embodiment of the invention can effectively smelt laterite-nickel ore to obtain ferronickel alloy by utilizing the coke furnace raw gas.

Owner:CHINA ENFI ENGINEERING CORPORATION

Electrode catalyst, composite electrode and preparation process of electrode catalyst

ActiveCN113270599AImprove catalytic performanceSimple manufacturing methodCell electrodesComposite electrodePtru catalyst

The present invention discloses an electrode catalyst and a preparation process of the electrode catalyst. A composite electrode takes a foamed metal or alloy material, such as foamed titanium, foamed nickel and a foamed stainless steel sheet, etc., as an electrode substrate, an air diffusion layer is prepared at one side of the substrate after treatment, and the other side of the substrate is conductive. Flame smoke particles generated by the combustion of the fuels, such as paraffin, gasoline, diesel oil or kerosene mixed with organic metal chemicals, etc., are mixed on the conductive side surface by roasting, the catalytic layer is prepared at the conductive side of the electrode substrate, and the composite electrode with the catalytic layer firmly attached is prepared through the procedures of fuel dipping combustion and calcination on the surface of the catalytic layer. The prepared composite electrode has the advantages that the preparation process is simple, the electrode catalyst is uniformly loaded, no binder or current collector is needed, and the composite electrode has higher mechanical strength and conductivity and can be better applied in practice.

Owner:XI AN JIAOTONG UNIV +1

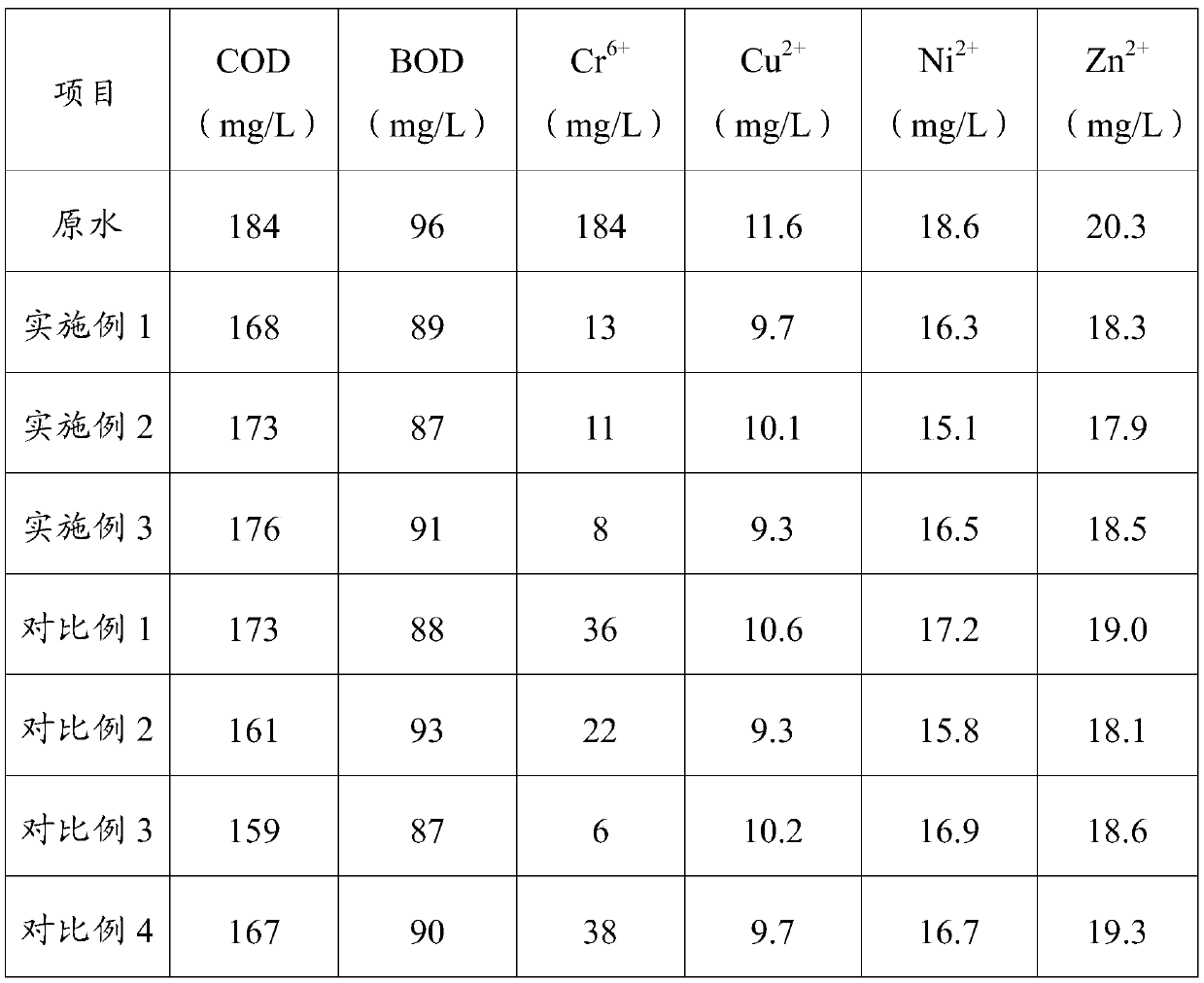

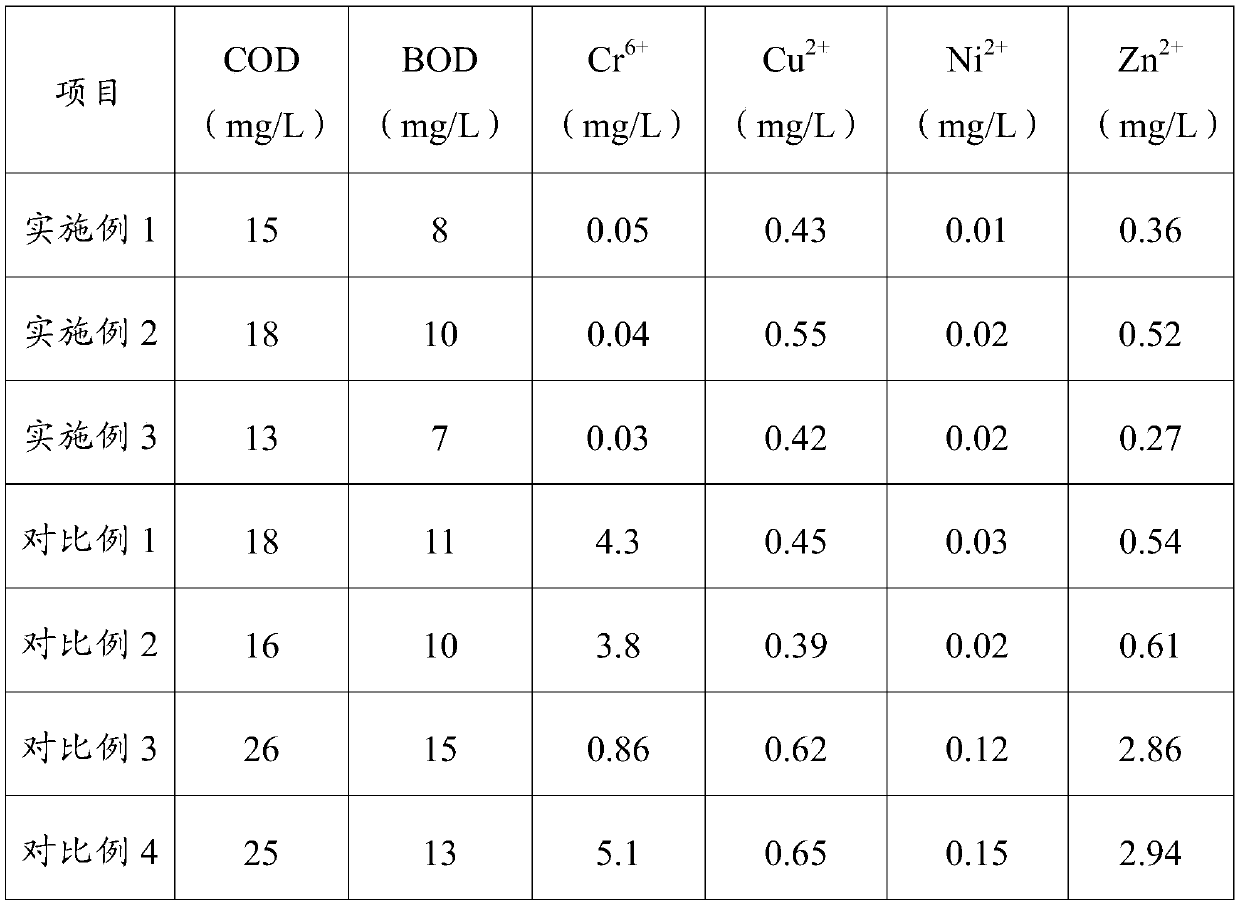

A method for treating hexavalent chromium pollution in water

ActiveCN109081518BAchieve emission standardsReduce dosageTreatment using aerobic processesWater treatment compoundsActivated sludgeReducing agent

The invention discloses a method for treating hexavalent chromium pollution in water. The method includes following steps: homogenizing and acidifying wastewater containing hexavalent chromium, and adding a reducing agent composed of ferrous sulfate, polyphosphorus ferric chloride and urea for redox reaction; adding alkali to redox reaction liquid for flocculation precipitation reaction, and allowing supernate after flocculation precipitation to enter a biological reaction tank for biological reaction under action of medical stone powder, lignin powder and activated sludge in the biological reaction tank to obtain wastewater after being treated. By the method, various physiochemical indexes of the wastewater after being treated can reach discharging standards, COD, BOD, SS and hexavalent chromium ion content is lowered effectively. The method is simple in treatment process, low in agent consumption, good in treatment effect, stable in performance and good in outgoing water quality andhas great application prospect.

Owner:XIAN AERONAUTICAL UNIV

A kind of production equipment and technology of zirconium sponge

ActiveCN112430753BImprove qualityImprove the efficiency of the reduction reactionSocial benefitsAir pump

The invention relates to the technical field of metal smelting, in particular to a production equipment and process of zirconium sponge. The production equipment of a kind of sponge zirconium provided by the present invention comprises the channel that connects the sublimation furnace and the first reduction furnace; The temperature and pressure device, the equipment for supplying inert gas, and the airtightly connected air inlet pipe. The air pump and the second one-way valve are arranged on the air inlet pipe, and the gas explosion pipe is arranged on the lower side of the air inlet pipe. Between the air inlet pipe and the second one-way valve There is a trachea branch, the trachea branch is equipped with a third one-way valve and a storage box for providing explosives, and the explosives are ejected from the bottom of the gas explosion tube by the pressure of inert gas and explode in the magnesium liquid in the furnace speed up the reduction reaction. The invention improves the production efficiency and quality of the zirconium sponge, and achieves good economic and social benefits.

Owner:宝钛华神钛业有限公司

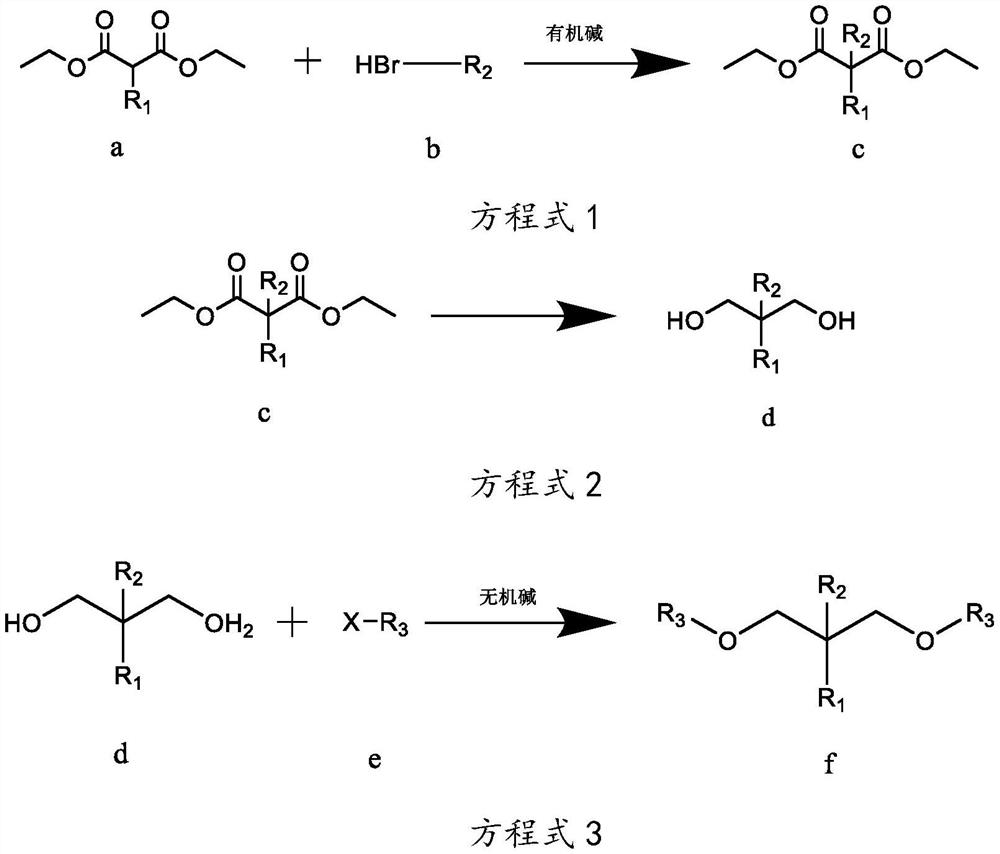

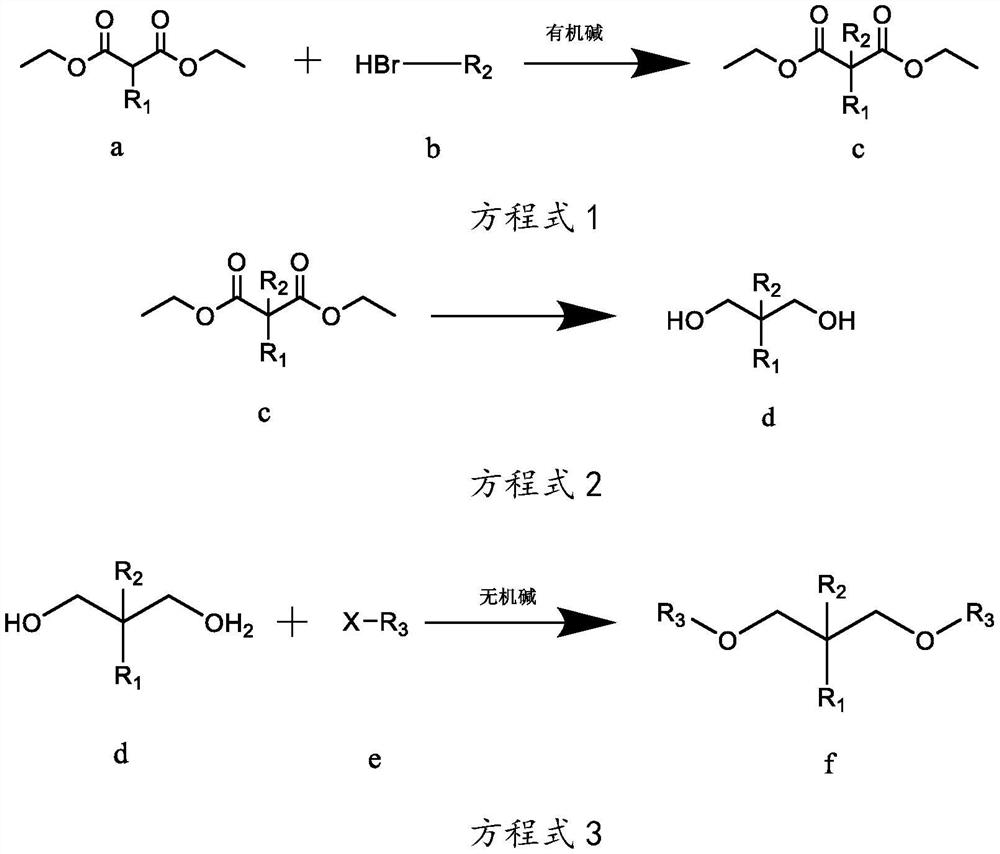

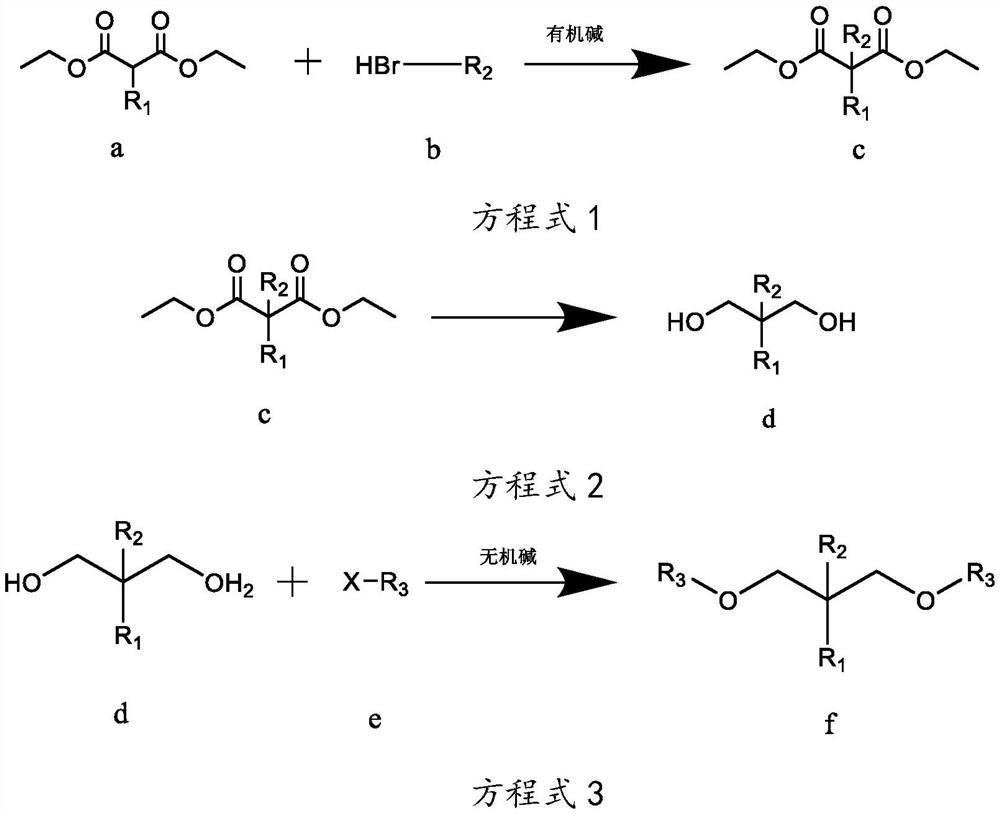

Preparation method of alkyl-substituted diether type electron donor

PendingCN114276221AHigh yieldThe preparation process is shortOrganic compound preparationCarboxylic acid esters preparationPtru catalystElectron donor

The invention relates to the technical field of diether type organic compounds, in particular to a preparation method of an alkyl-substituted diether type electron donor. The method comprises the following specific reaction steps: under the catalytic action of organic alkali, adding a compound b into a compound a, and carrying out an alkylation reaction of carbonyl alpha-carbon to obtain a compound c; carrying out ester reduction reaction on the compound c to obtain a compound d; and carrying out etherification reaction on the compound d and a compound e under the action of inorganic alkali to obtain a diether compound f. According to the invention, the alkyl diethyl malonate is adopted as a raw material and can be used for various alkyl-substituted diether electron donors, the intermediate treatment process is simple, other noble metal catalysts are not used, the product yield is high, the reaction route is short, and the preparation cost is low.

Owner:山东研峰新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com