Patents

Literature

189results about How to "The preparation process is short" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomass particle fuel and preparation method thereof

InactiveCN104927961AQuality improvementImprove qualitySolid fuelsWaste based fuelOrganic matterCow dung

The invention relates to the technical field of biomass fuel, in particular to biomass particle fuel and a preparation method thereof. The biomass particle fuel and the preparation method are characterized in that cow dung, biogas residues, sawdust, yellow mud and corn straw are pre-fermented to change the structure layer of the biomass raw materials and form a compact structure, high-content organic matter is formed, and organic matter components are increased; drainage oil is poured into the organic matter, high-speed stirring is used to allow microscopic biochemical reaction between the drainage oil and the fermented materials, and organic matter mass and quality are increased; the stirred mixture is fermented to further convert the organic matter so as to increase the combustible substances in the organic matter and improve the quality of the organic matter; combustion improver is added and extrusion forming is performed to allow the prepared biomass particle fuel to be good in quality.

Owner:广西稳德福能源科技有限公司

Al-Ti-Si alloy target material and preparation method thereof

InactiveCN102321833AThe preparation process is shortReduce manufacturing costVacuum evaporation coatingSputtering coatingTitaniumAlloy

The invention relates to an Al-Ti-Si alloy target and a preparation method thereof. The Al-Ti-Si alloy target is prepared from the following raw materials in percent by weight: 5-90% of aluminum, 5-90% of titanium and 1-30% of silicon. The invention also comprises a hot-pressing and sintering preparation method of the Al-Ti-Si alloy target. In the Al-Ti-Si alloy target and the hot-pressing and sintering preparation method thereof which are provided by the invention, components of the alloy are uniform, relative density of the alloy target is high, technological process is short, and production cost is low, thus the alloy and the preparation method thereof are beneficial to popularization and application.

Owner:余鹏

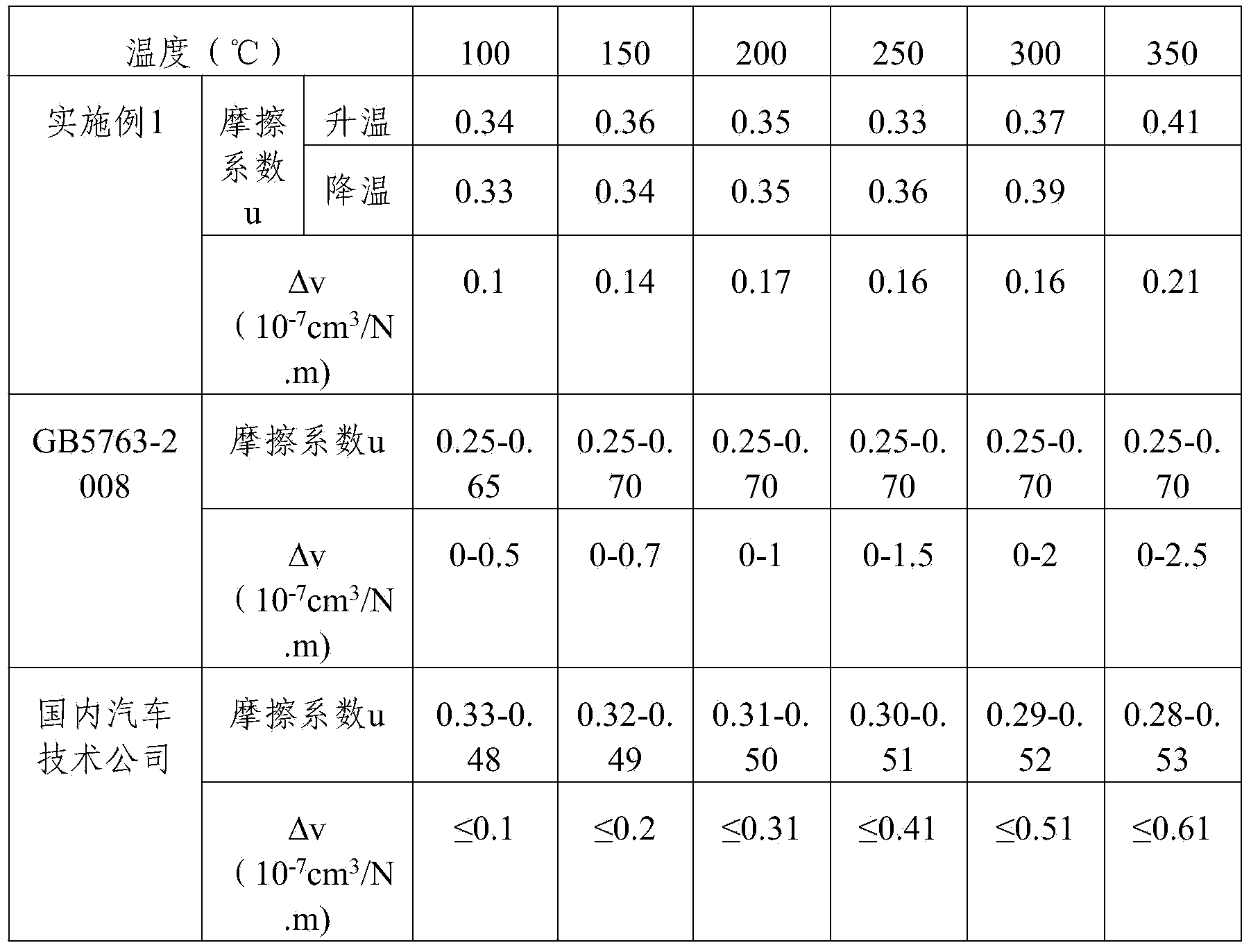

Carbon-based ceramic brake block and preparing method of carbon-based ceramic brake block

InactiveCN104235242AReasonable formulaMeet the requirements of braking standardsFriction liningCarbon fibersEconomic benefits

The invention relates to the technical field of friction materials, in particular to a carbon-based ceramic brake block and a preparing method of the carbon-based ceramic brake block. Through the proper proportioning and combination of raw materials such as carbon fiber, ceramic fiber, aramid fiber, phenolic resin, mineral fiber, blanc fixe, modified silicon carbide, friction modifying agents, inorganic lubricating agents, organic friction powder, tougheners and improving agents are properly mixed and combined, so that the raw material formula of the carbon-based ceramic brake block is reasonable, in addition, through the steps of raw material mixing, molding pressing forming, heat treatment and grinding in the preparing process, the manufacturing technical flow process of the carbon-based ceramic brake block is shorter, the production period is short, the production cost is low, and the obvious economic benefits are realized; in addition, the friction coefficient and the abrasion degree of the prepared carbon-based ceramic brake block are better through being compared with the brake block produced by manufacturers of products produced according to the GB5763-2008 standard and the domestic automobile brake technology.

Owner:WANSHAN SPECIAL ZONE HONG AN FRICTION MATERIAL

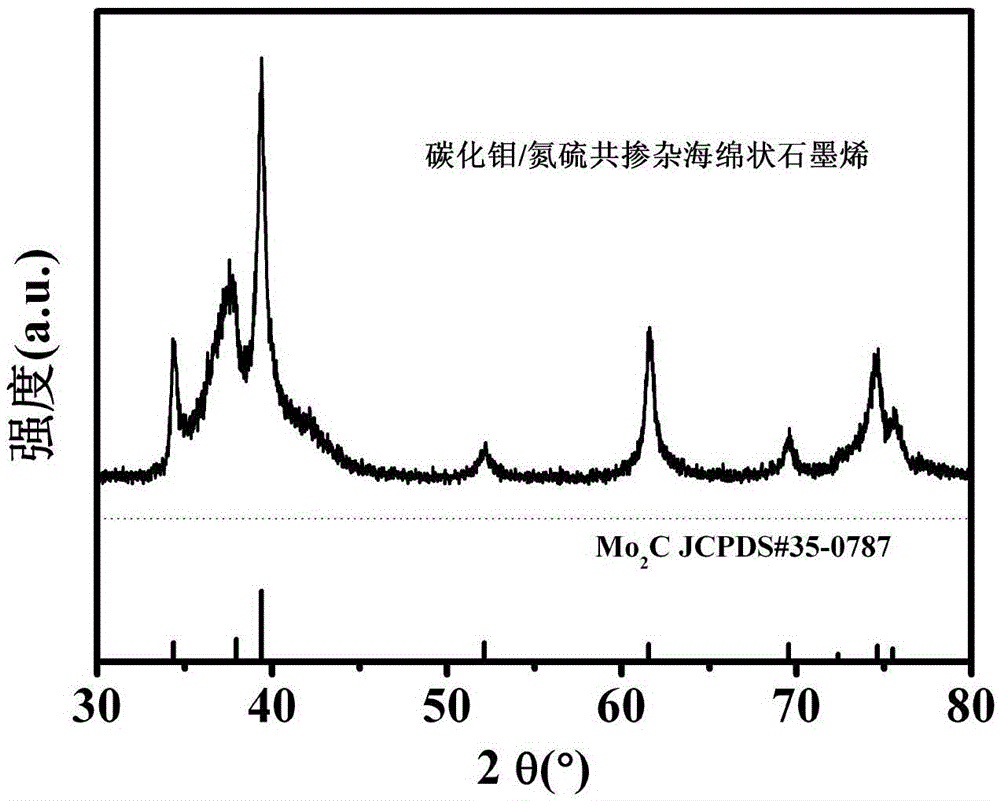

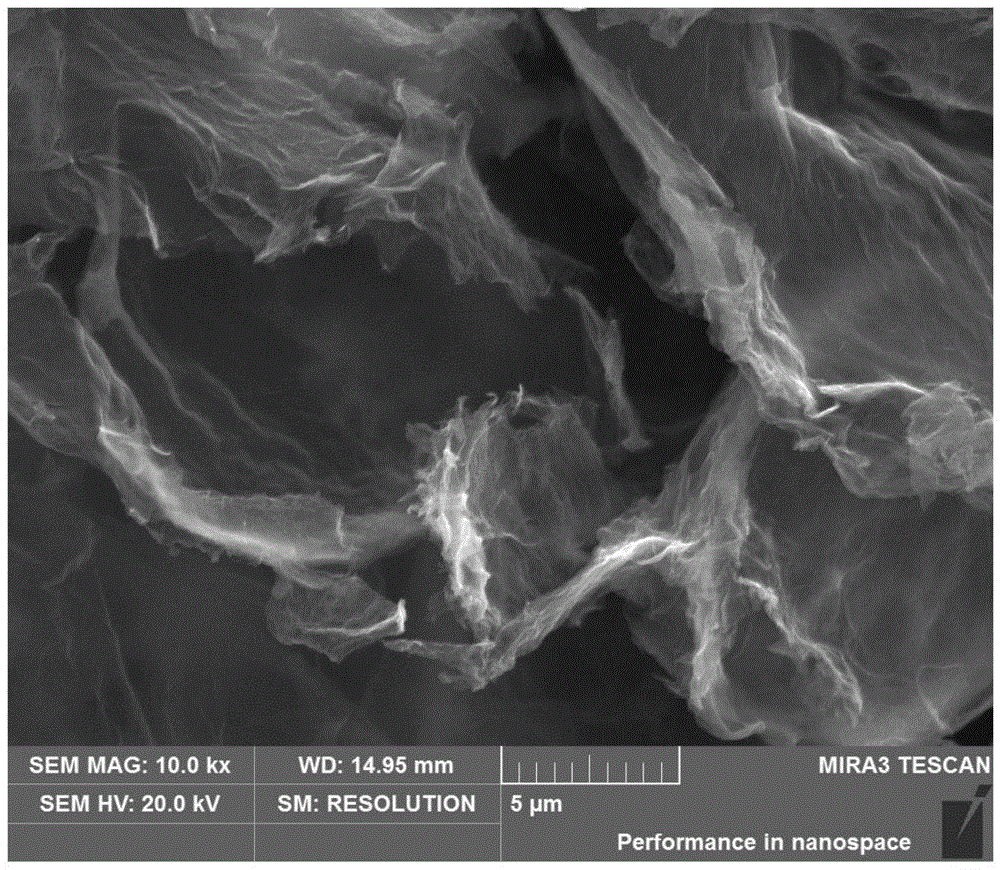

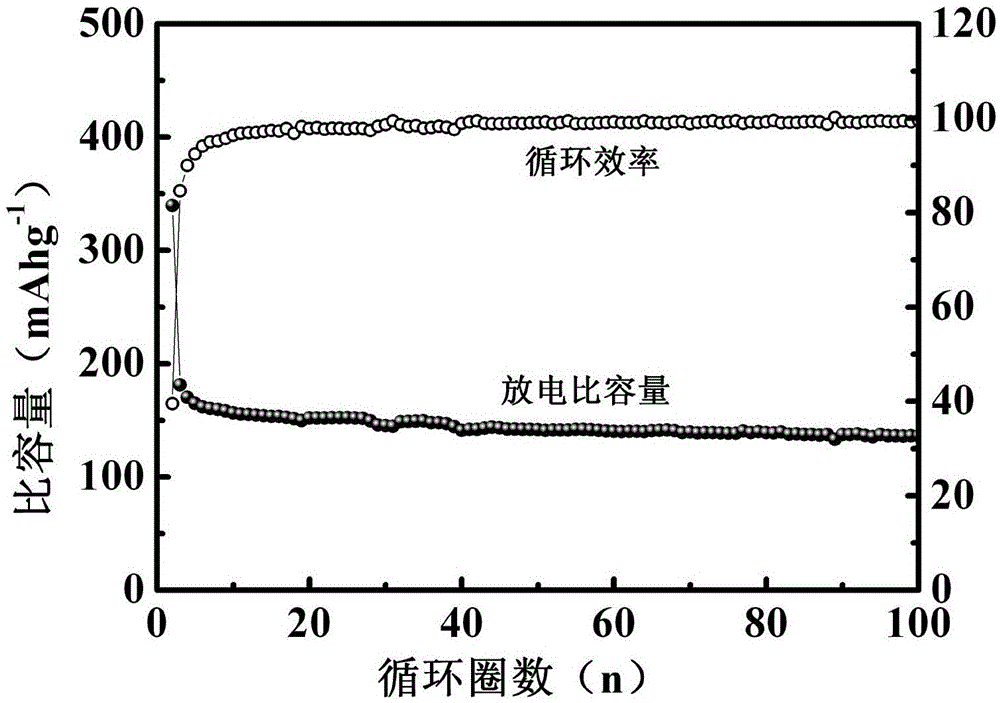

Preparation method of molybdenum carbide/nitrogen-sulfur codoped spongy graphene cathode composite for sodium-ion battery

ActiveCN105591077ASmall volume expansionImproved magnification performanceCell electrodesSecondary cellsDoped grapheneFreeze-drying

The invention discloses a preparation method of a molybdenum carbide / nitrogen-sulfur codoped spongy graphene cathode composite for a sodium-ion battery. According to the molybdenum carbide / nitrogen-sulfur codoped spongy graphene cathode composite prepared through the preparation method, molybdenum carbide particles are uniformly distributed in carbide / nitrogen-sulfur codoped spongy graphene which has a great number of surface folds, has a great number of active sites and is of a three-dimensional structure. The preparation method comprises the steps of dissolving a molybdenum source and a carbon source into a graphene oxide solution, adding a nitrogen source and a sulfur source, adjusting ph value, then conducting a hydrothermal reaction on an obtained mixed solution, conducting freeze-drying on a product, then putting the product in a quartz crucible for high temperature heat treatment, and conducting natural cooling after a reaction is ended, so that the composite is obtained. In the hydrothermal reaction process, graphene doping and reduction, formation of a precursor and composition of the precursor and doped graphene are conducted synchronously. The composite can be obtained by combining the hydrothermal method with the subsequent heat treatment process, and the preparation method is simple in process and low in cost and has good research prospect.

Owner:CENT SOUTH UNIV

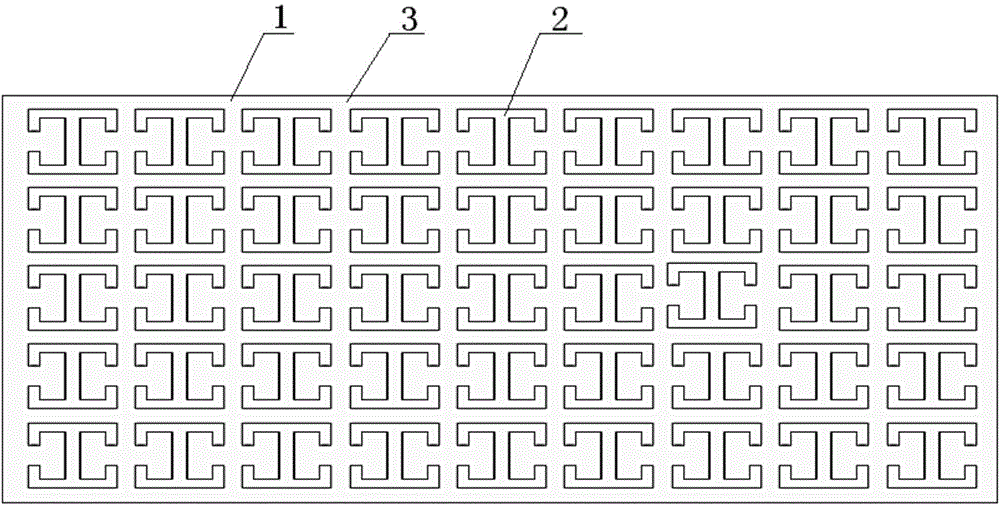

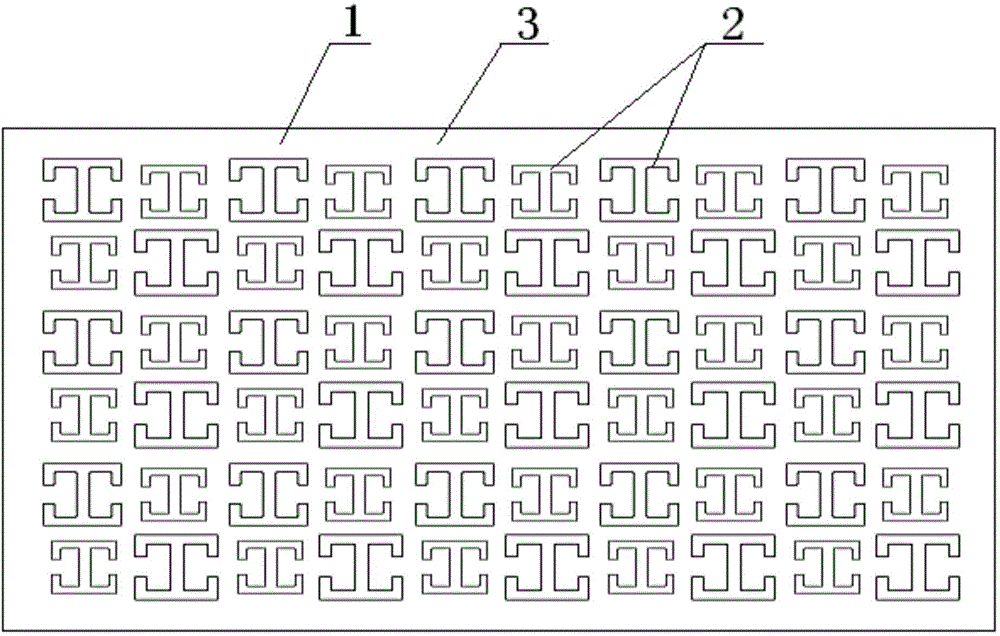

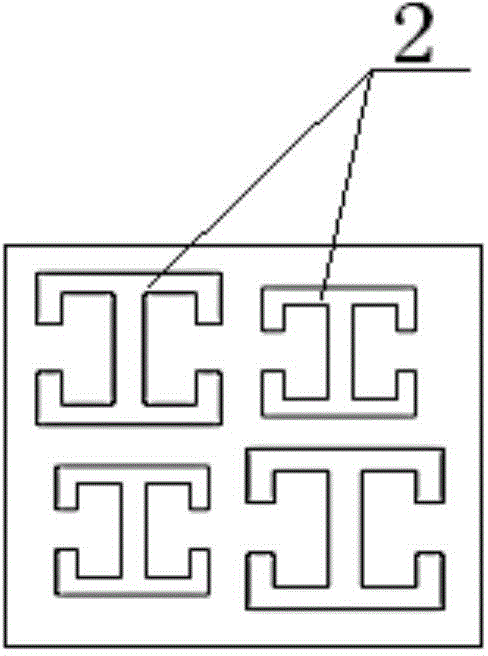

Multi-frequency response TeraHertz wave modulator

InactiveCN103984124ASimple structureThe preparation process is shortNon-linear opticsResonancePeriodic matrix

The invention discloses a multi-frequency response TeraHertz wave modulator, which comprises a semiconductor substrate capable of being transmitted by TeraHertz wave, metamaterial resonance units with more than two dimensions, and a metallic titanium film layer, wherein the metamaterial resonance units are arranged on the semiconductor substrate, the metallic titanium film layer is arranged on the metamaterial resonance units and the semiconductor substrate, all the metamaterial resonance units with the same dimension are arranged on the substrate in a periodic matrix manner, metamaterial resonance units with different dimensions are arranged in a staggered manner, and gaps exist among different metamaterial resonance units. According to the multi-frequency response TeraHertz wave modulator disclosed by the invention, a two-frequency TeraHertz wave modulator or a multi-frequency TeraHertz wave modulator is integrated on the substrate, and TeraHertz waves with two kinds and multiple kinds of frequencies are modulated according to needs, in such a way, the use cost is favorably reduced, and the multi-frequency response TeraHertz wave modulator has better practicability and convenience.

Owner:SOUTHEAST UNIV

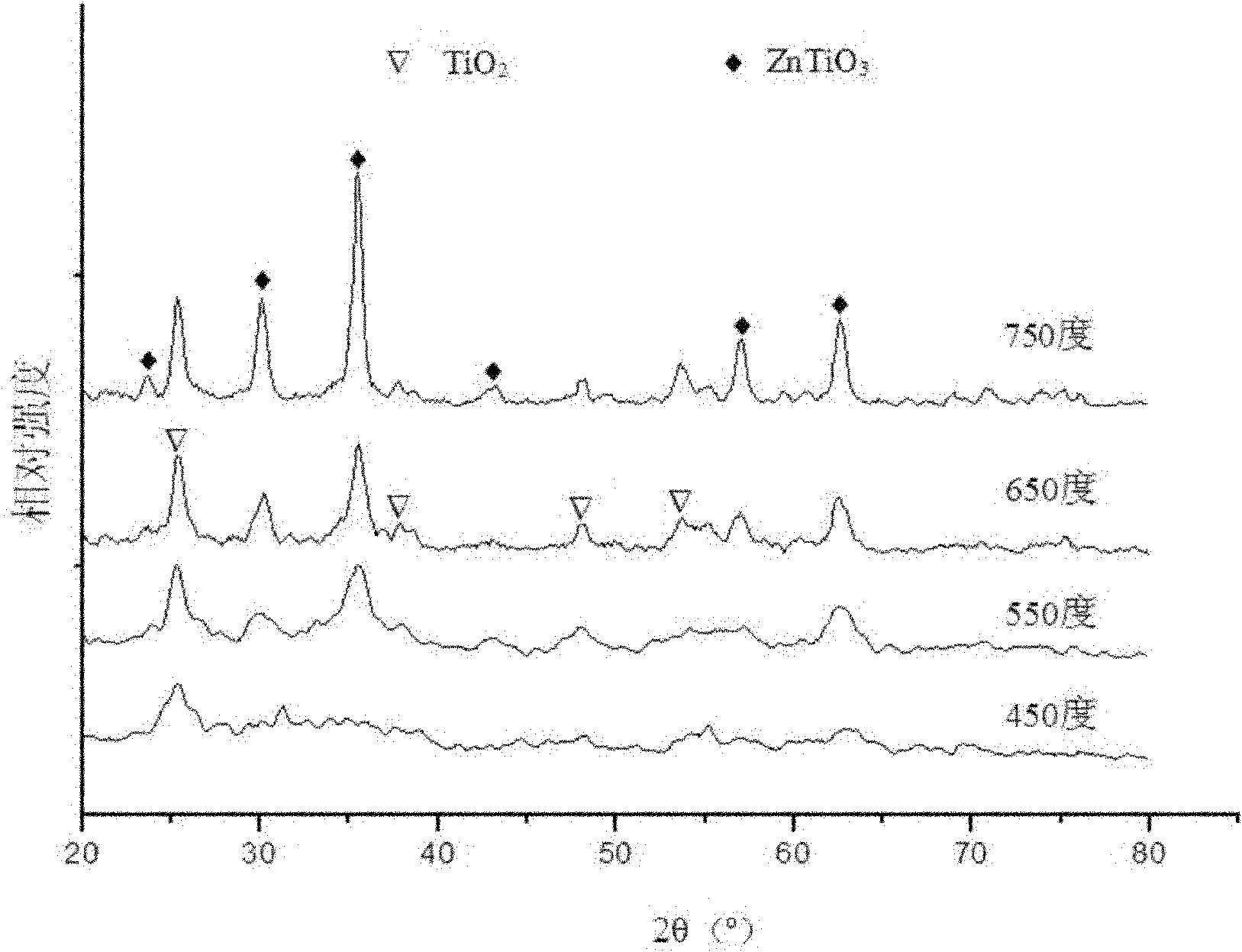

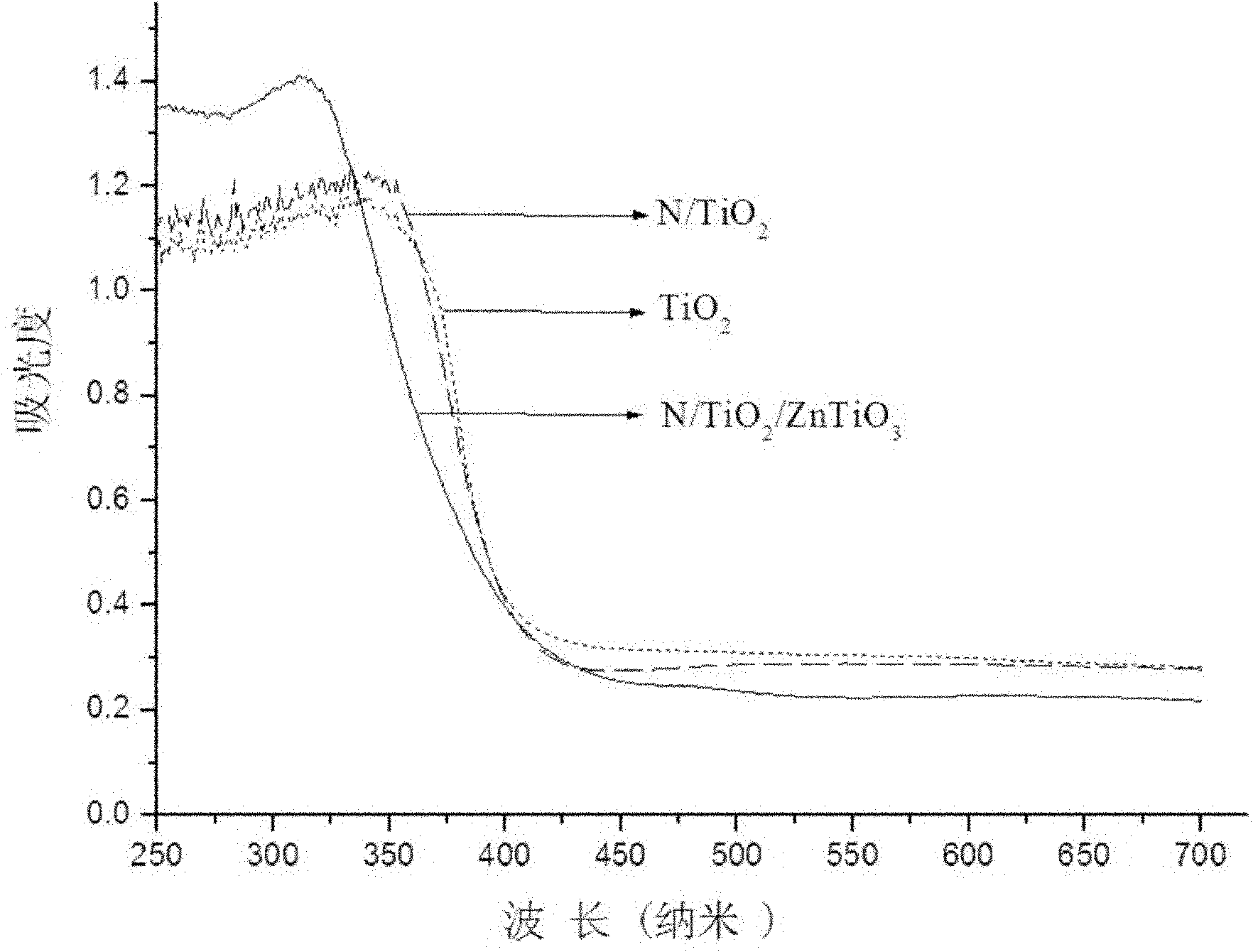

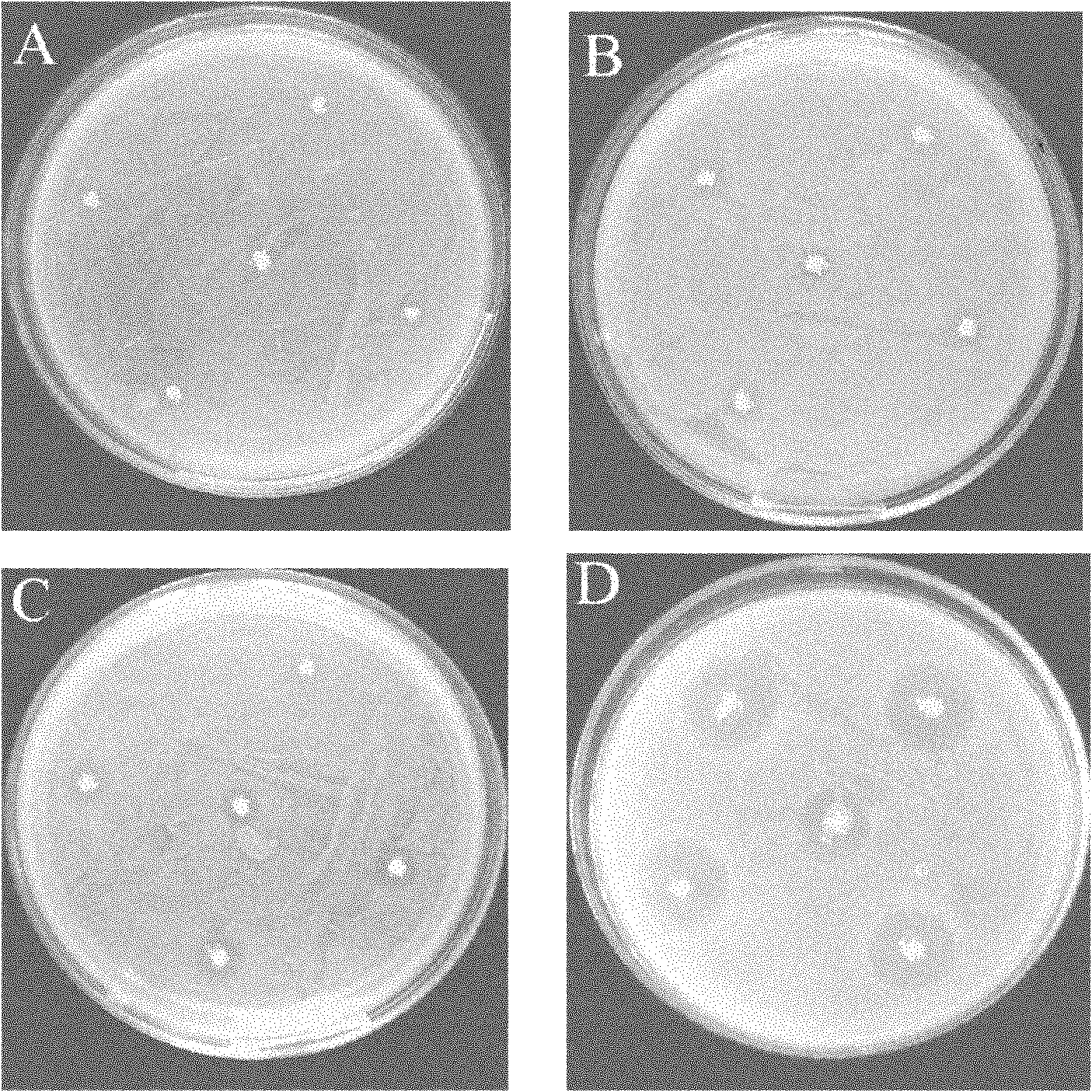

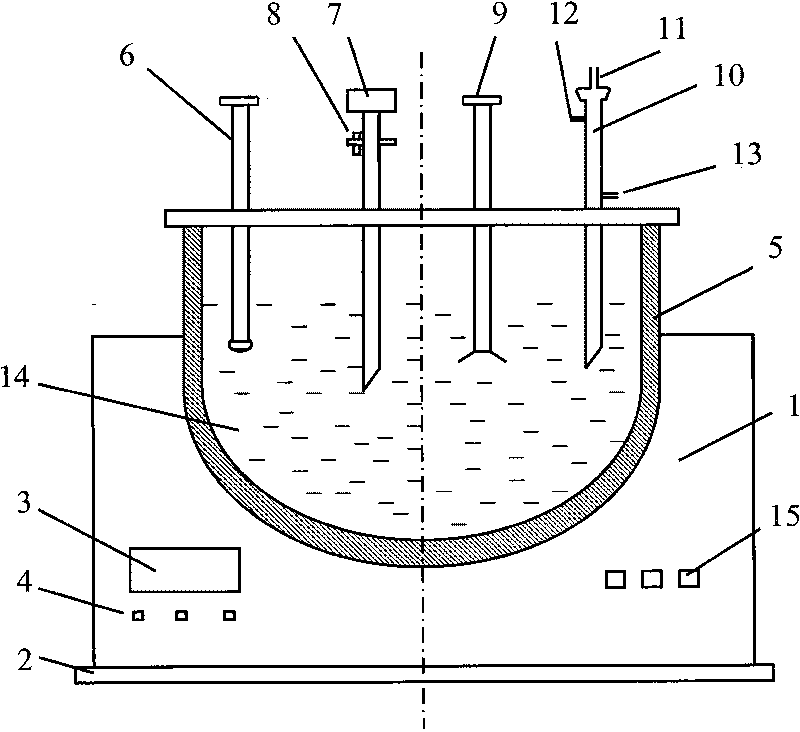

Preparation method of composite photocatalyst containing nitrogen-doped titanium dioxide and zinc titanate

InactiveCN102139206AImprove surface propertiesMild reaction conditionsBiocideWater/sewage treatment by irradiationWater bathsSpectral response

The invention relates to a preparation method of semiconductor composite antibacterial photocatalyst containing nitrogen-doped titanium dioxide and zinc titanate, and belongs to the technical field of the treatment of environmental pollution. The semiconductor composite antibacterial photocatalyst is prepared a uniform coprecipitation method which comprises the following steps of: preparing a mixed solution in the amount-of-substance ratio of titanium sulfate to urea to zinc ions of 1:10:0; continuously mixing the mixed solution; raising the temperature of a water bath to 60 DEG C; adding a surfactant (sodium dodecyl benzene sulfonate) into the mixed solution based on the concentration of 20mg / 150ml; keeping a constant temperature for 0.5h; raising the temperature to 90-100 DEG C again; keeping the temperature for 3-6h; adding ammonia water into the solution to regulate to pH (potential of hydrogen) to be 6-8; washing and drying the obtained product; and forging the product at the temperature of 400-800 DEG C. The preparation method has the advantages of short process flow, simple equipment, simple and convenient operation, and low price of raw materials. The prepared semiconductor composite has the advantages of having good dispersibility, visible spectral response and low energy consumption, and is an environment-friendly antibacterial purification material.

Owner:WUHAN UNIV OF TECH

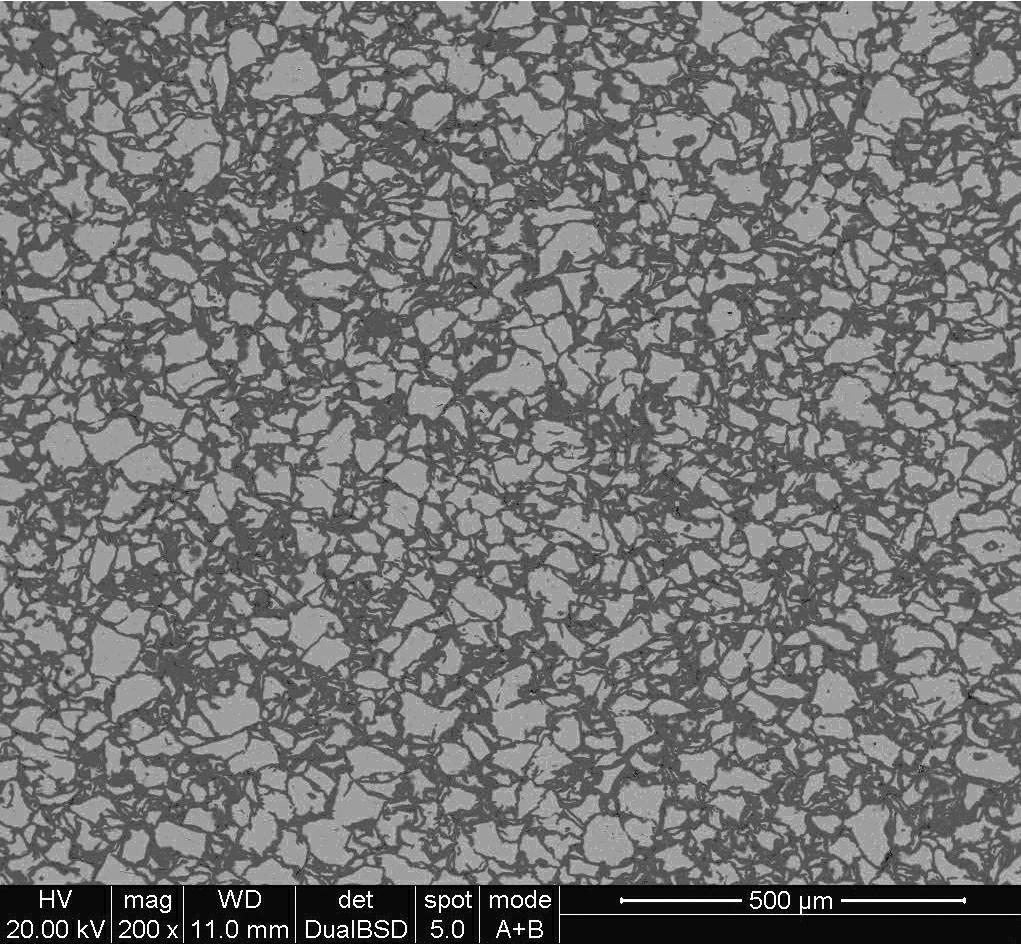

Preparation method of high carbon steel with good cold mouldability

The invention discloses a preparation method of high carbon steel with good cold mouldability. The preparation method sequentially comprises the following steps: molten iron desulphurization; bessemerizing; argon blowing; refining; continuous casting; soaking pit; finish rolling; laminar cooling; taking up; slow cooling of a coil yard; leveling; and annealing. By means of controlling the chemical components of a steel product as well as a hot rolling process, a laminar cooling process, a take-up temperature and annealing process and the like, fine and dispersed globular pearlites are formed in steel, wherein the rate of spheroidization of pearlites is greater than or equal to 60%, the pearlites with the diameter which is greater than or equal to 2 mu m are greater than or equal to 60%, the tensile strength is 400-800MPa, the ductility is greater than or equal to 25% and the hardness is 130-290 HV. The preparation method disclosed by the invention not only is short in process flow, but also the prepared high carbon steel plate material is good in cold mouldability. In the moulding processes of cold punching, cold bending and the like, the material is not cracking, so that the yield and the usability of the material are greatly improved.

Owner:武汉钢铁有限公司

Biomass fuel and production method thereof

The invention relates to the technical field of biomass fuels, in particular to biomass fuel and a production method thereof. According to the production method, the materials, such as biogas residue, crop stalks, marshal sludge and sawdust, are mixed prior to being treated via a fermentation process; thus, organics are biologically react microscopically, the materials act with one another, the structure of biomass is enhanced, crushing and compressing treatment of the materials is easier, the difficulty and energy consumption of the biomass fuel is lowered, and the cost of biomass fuel production is lowered. In addition, pulverized coal is subjected to crushing treatment and added with illegal cooking oil and gasoline; thus, the waste, the illegal cooking oil and the gasoline are made full use, the ignition point of the biomass fuel is lowered, and the ignition cost of the biomass fuel in applications is lowered.

Owner:玉林市新滔环保科技有限公司

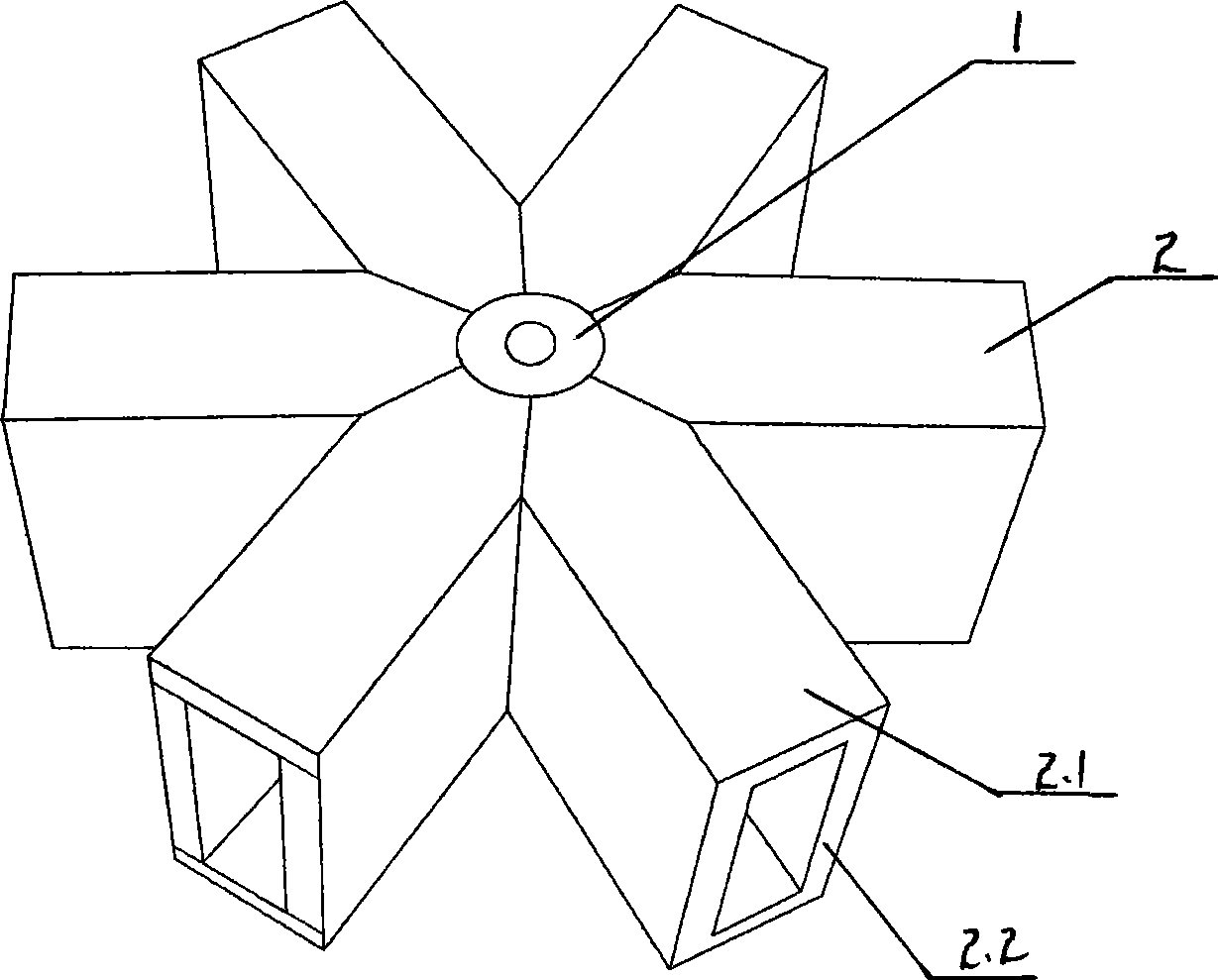

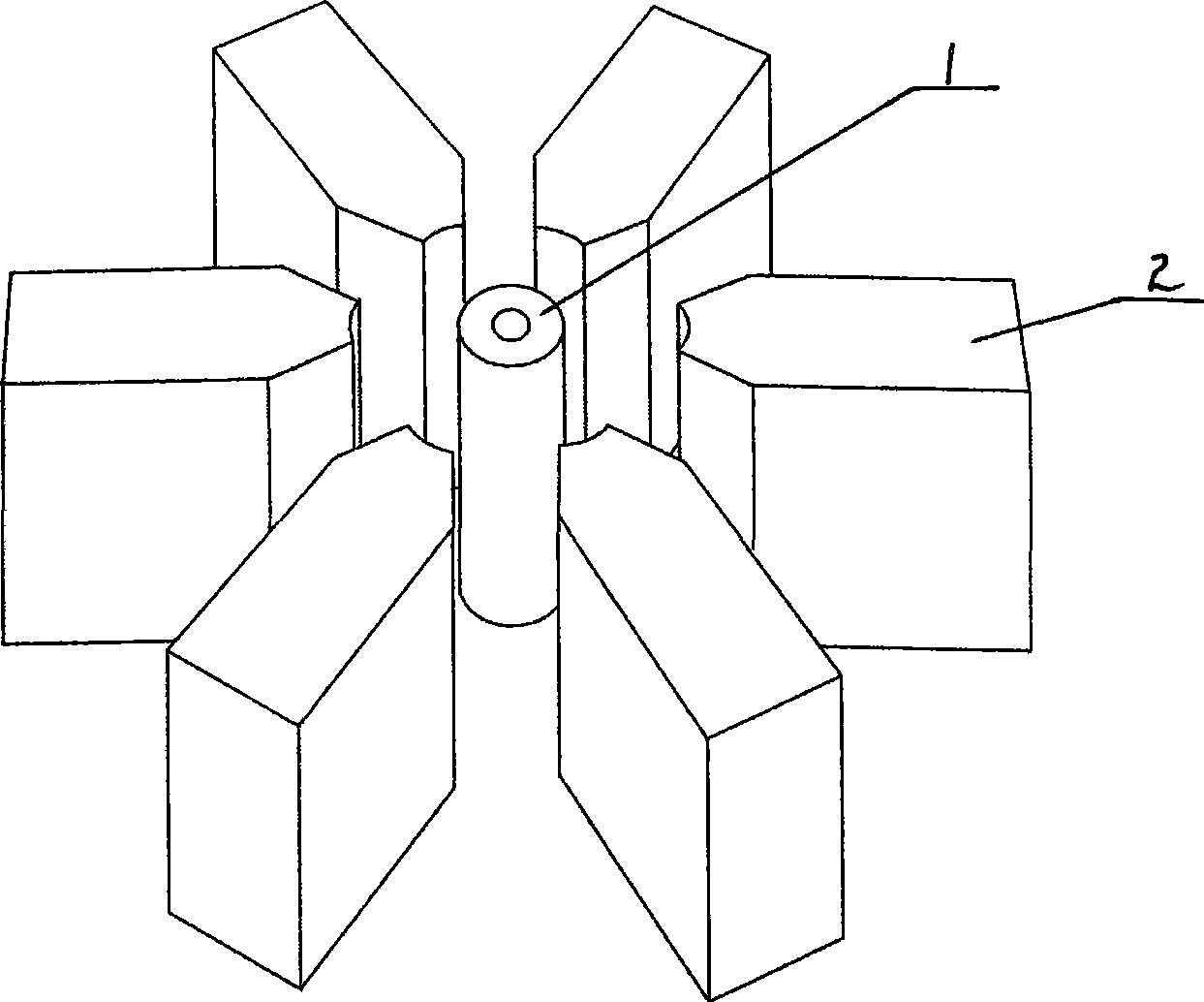

Method for manufacturing multi-rod converging valve type space net shell node

InactiveCN101519893AThe amount of processing is smallThe preparation process is shortBuilding constructionsComputer moduleEngineering

The invention relates to a method for manufacturing a multi-rod converging valve type space net shell node. The method comprises the following steps that: each converging valve type space net shell node is decomposed into several independent structure units, wherein the structure unit comprises a plurality of node valves and a central cylinder; a steel structure blank of the structure unit is manufactured according to geometric data of the structure unit; the node valve blank is processed according to geometric intersecting information of each structure unit so as to form a node valve module with a welding groove, a datum hole and a datum plane are processed for the central cylinder so as to form a central cylinder module; the structure unit modules formed in the same group are positioned and spliced on a tooling workbench, and adjacent node valves, the node valve module and the central cylinder module are subjected to spot welding in sequence so as to form nodes; the nodes are welded; the nodes are subjected to thermal treatment; and the nodes are subjected to treatment and surface treatment. The method has the advantages of short manufacture process flow, high automatic degree, high production efficiency and low manufacturing cost.

Owner:江阴纳尔捷机器人有限公司

Method for preparing rare earth europium ternary complex

InactiveCN101704829AImprove luminosityHigh color purityGroup 3/13 element organic compoundsChemical reactionFiltration

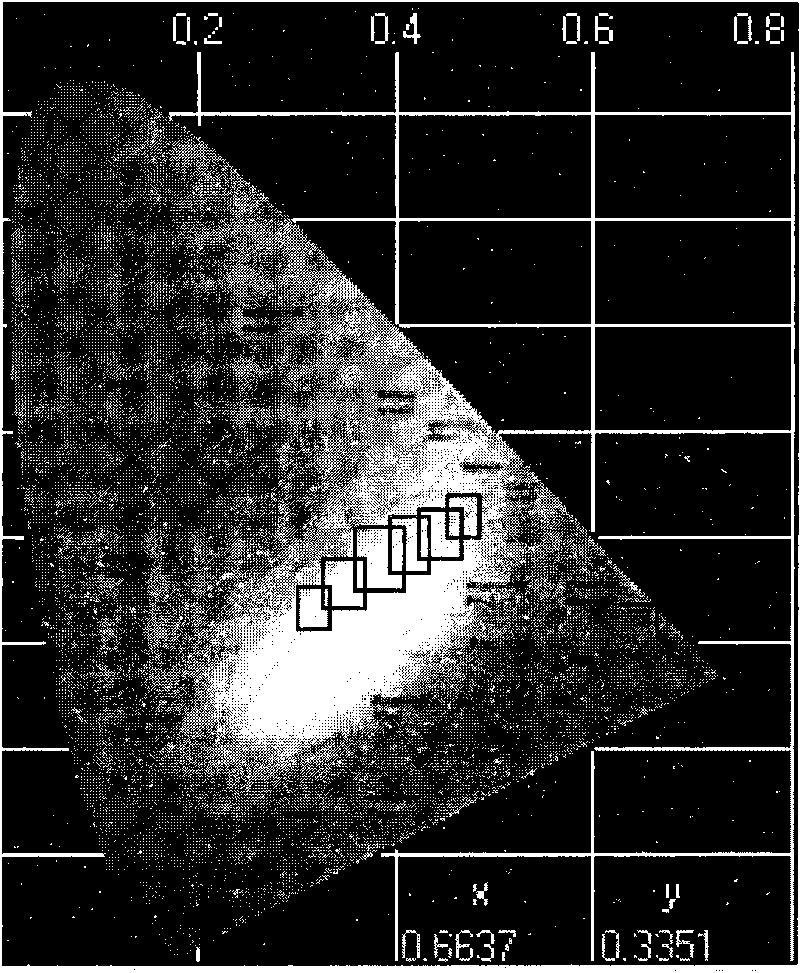

The invention relates to a method for preparing a rare earth europium ternary complex, which comprises the following steps of: using europium chloride hexahydrate, benzoyl acetone and triphenylphosphine oxide as raw materials, using absolute ethyl alcohol as a solvent and a detergent, using deionized water as a solvent and a cleaning agent, and using sodium hydrate as an acidity-basicity pH value conditioning agent; preparing a solution added with the benzoyl acetone, the triphenylphosphine oxide and ethanol first, and then preparing an europium chloride hexahydrate ethanol solution and a sodium hydrate aqueous solution; dropping the europium chloride hexahydrate ethanol solution and the sodium hydrate aqueous solution into a four-hole boiling flask under a condition with heating, stirring and water circulation condensation to perform chemical reactions so as to prepare a ternary mixed solution; performing vacuum suction filtration, washing, recrystallization purification and vacuum drying on the ternary mixed solution to prepare white powder of the rare earth europium ternary complex, wherein the chromaticity coordinates are that X is equal to 0.6637 and Y is equal to 0.3351, and the rare earth europium ternary complex glows. The preparation method has the advantages of short process flow, fewer used devices, high yield up to 90 percent, good product purity up to 98 percent, good luminous performance and high luminous efficiency.

Owner:TAIYUAN UNIV OF TECH

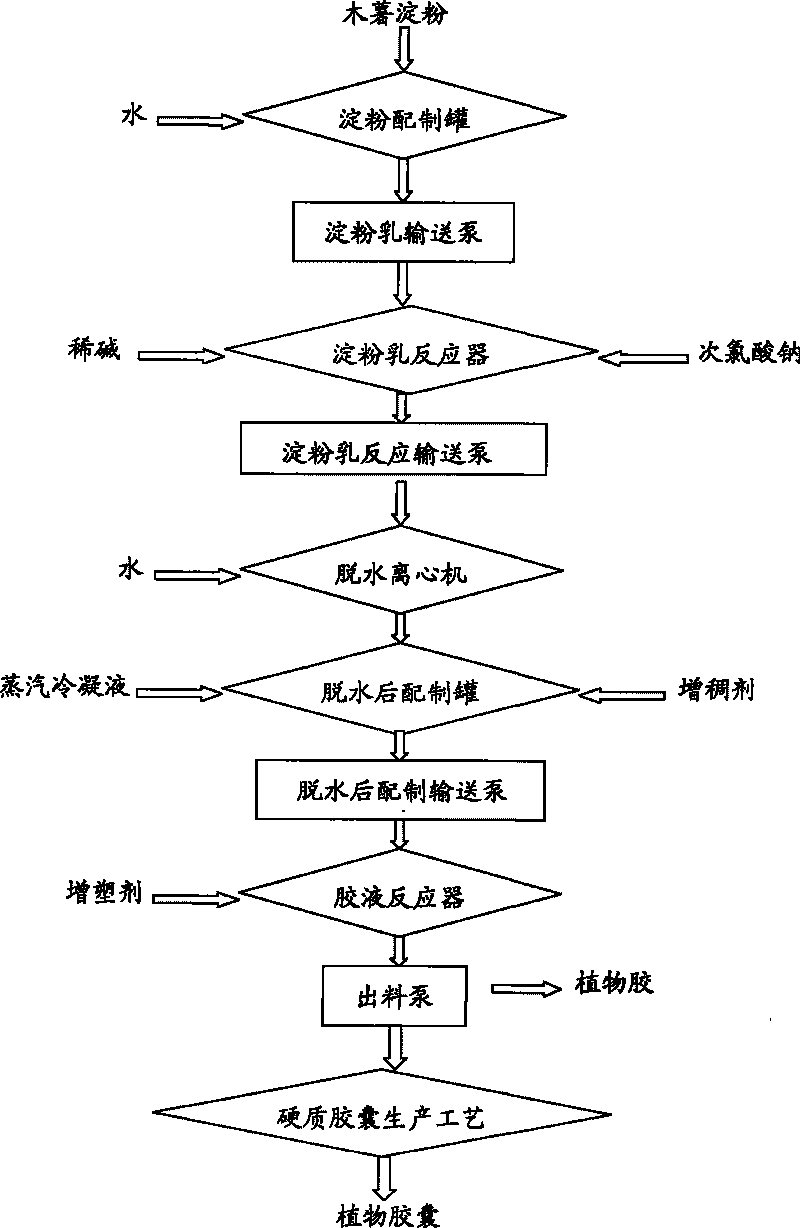

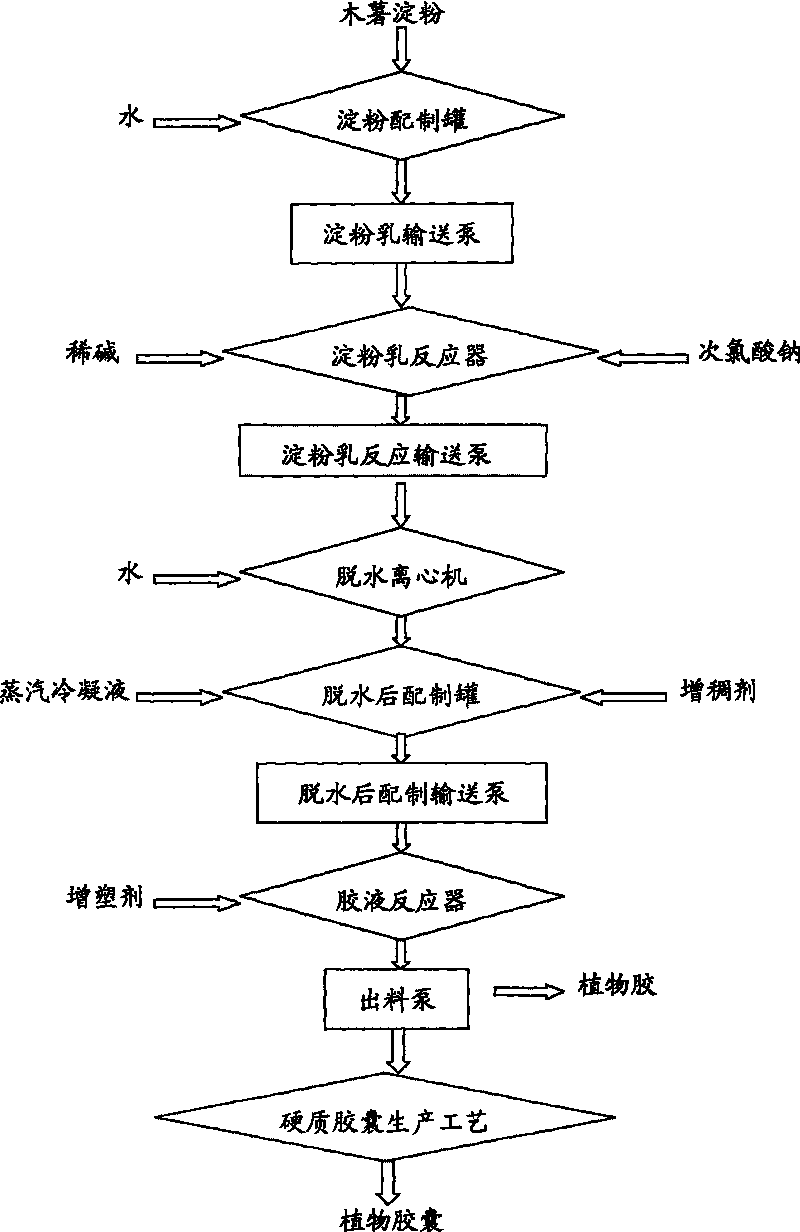

Technique of preparing cassava starch plant gum, the plant gum prepared thereby and plant capsules

ActiveCN101338045BIncrease planting areaReduce consumptionPharmaceutical non-active ingredientsCapsule deliveryBiotechnologyPlant Gums

The invention relates to a preparation method for cassava starch vegetable gum and vegetable gum and a vegetable capsule which are prepared by the preparation method. The preparation method mainly comprises the following steps: preparing starch milk, gelatinization reaction, dehydration, washing, preparation after dehydration and obtaining gel solution. The preparation method for cassava starch vegetable gum and the vegetable gum and the vegetable capsule which are prepared by the preparation method of the invention have stable product performance, low water content, wide application range, easy storage, no contamination, green environmental protection, wide raw material resources, simple preparation method and easy control.

Owner:刘雨微

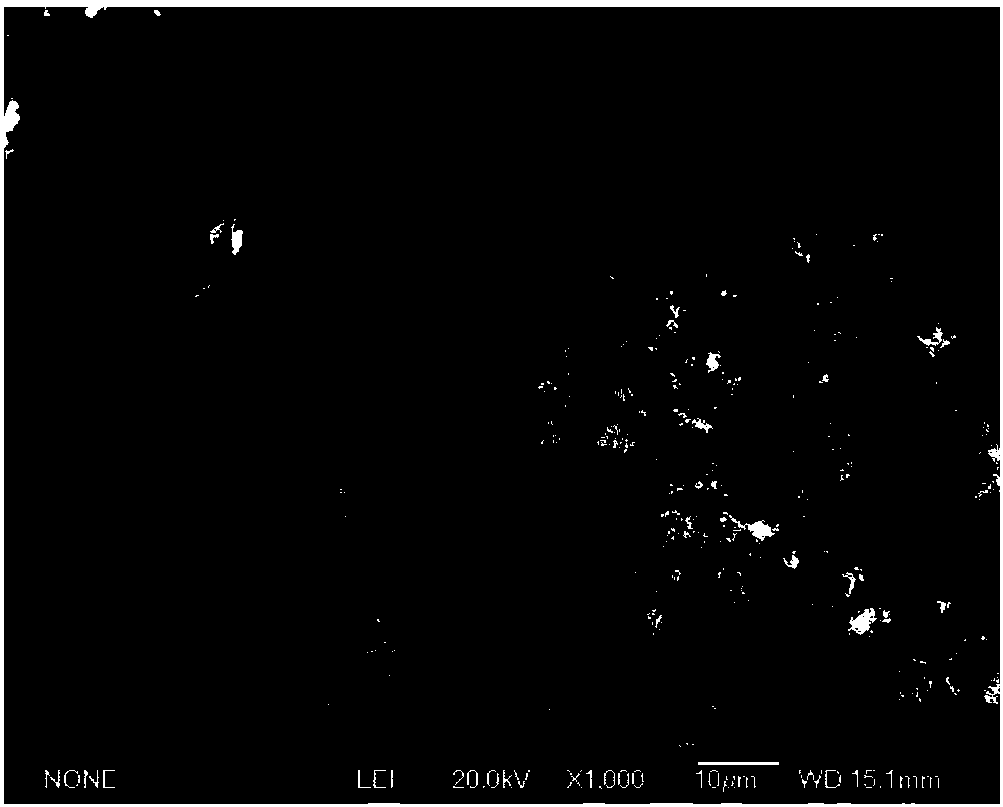

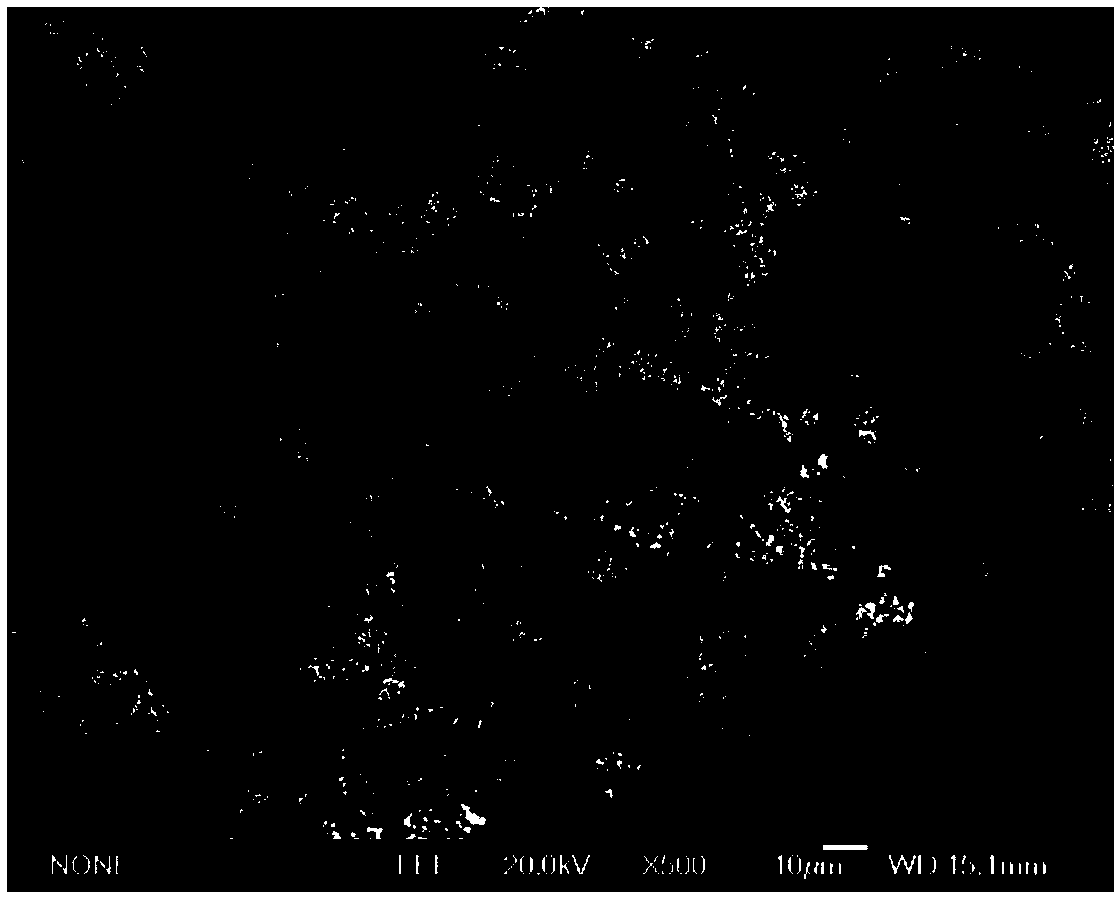

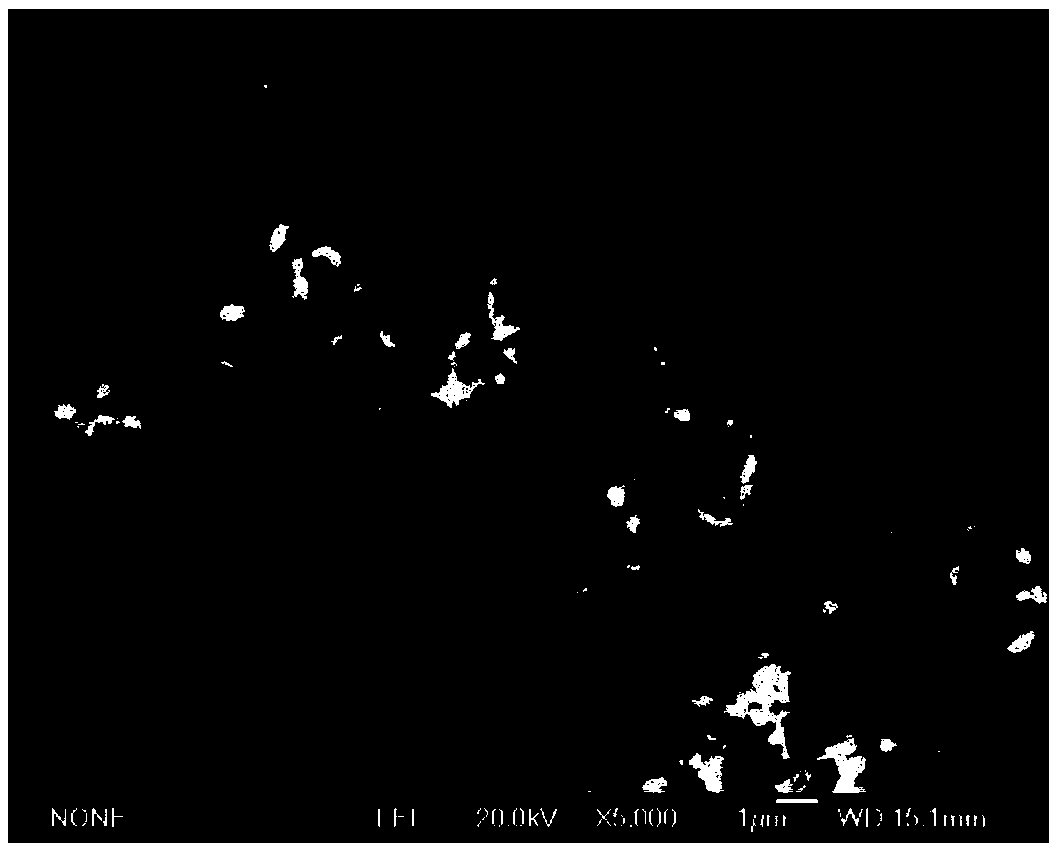

Micro-nano dual-stage porous copper and preparing method thereof

InactiveCN108188400AUniform distribution of poresUniform three-dimensional bicontinuous ligament/tunnel structureDual stageMicrometer

The invention discloses micro-nano dual-stage porous copper. The copper is characterized in that a sintered porous Cu framework serves as a base body, a bicontinuous nano porous structure is formed onthe framework, the average hole diameter of a micro hole ranges from 2.2 micrometers to 3.7 micrometers, the average hole diameter of a nano hole ranges from 60 nm to 113 nm. The preparing method comprises the specific steps that firstly, Cu powder and Mn powder with a certain proportion are evenly mixed and then are pressed into a blank, and are placed in an atmosphere tubular furnace to be subject to temperature rise to a certain temperature, heat preservation is carried out for a certain time, cooling to the room temperature is achieved, and a precursor CuMn alloy is obtained; secondly, the precursor is placed in hydrochloric acid to be subject to dealloying until no obvious bubbles are escaped, and the micro-nano dual-stage porous copper is prepared. The prepared micro-nano dual-stageporous copper has the uniform micro hole / nano hole composite hole structure, a three-dimensional bicontinuous tough belt / hole way structure and the like, the preparing process is short in flow, the method is simple, the structure is controllable, and the functionization production prospect is achieved.

Owner:XIAN UNIV OF TECH

Low-temperature shearing rheological die casting technology

The present invention relates to a low-temperature shearing rheopectic die-casting process. It is characterized by that said process includes the following steps: (1), making alloy melt be passed through feeding device and be fed into turning conveying pipe, and adopting conveying pipe with low rotating speed to control cooling and implement splat cooling of molten metal and stirring of primary stage of coagulation; (2), making the melt with lots of crystal nucleus be flowed into a crystallization furnace, utilizing slurry microstructure on-line detection technique to control and detect growth form of nascent phase and solid-phase rate of slurry; and (3), making the slurry be injected into pressure chamber of die-casting machine to make directly-forming.

Owner:NANCHANG UNIV

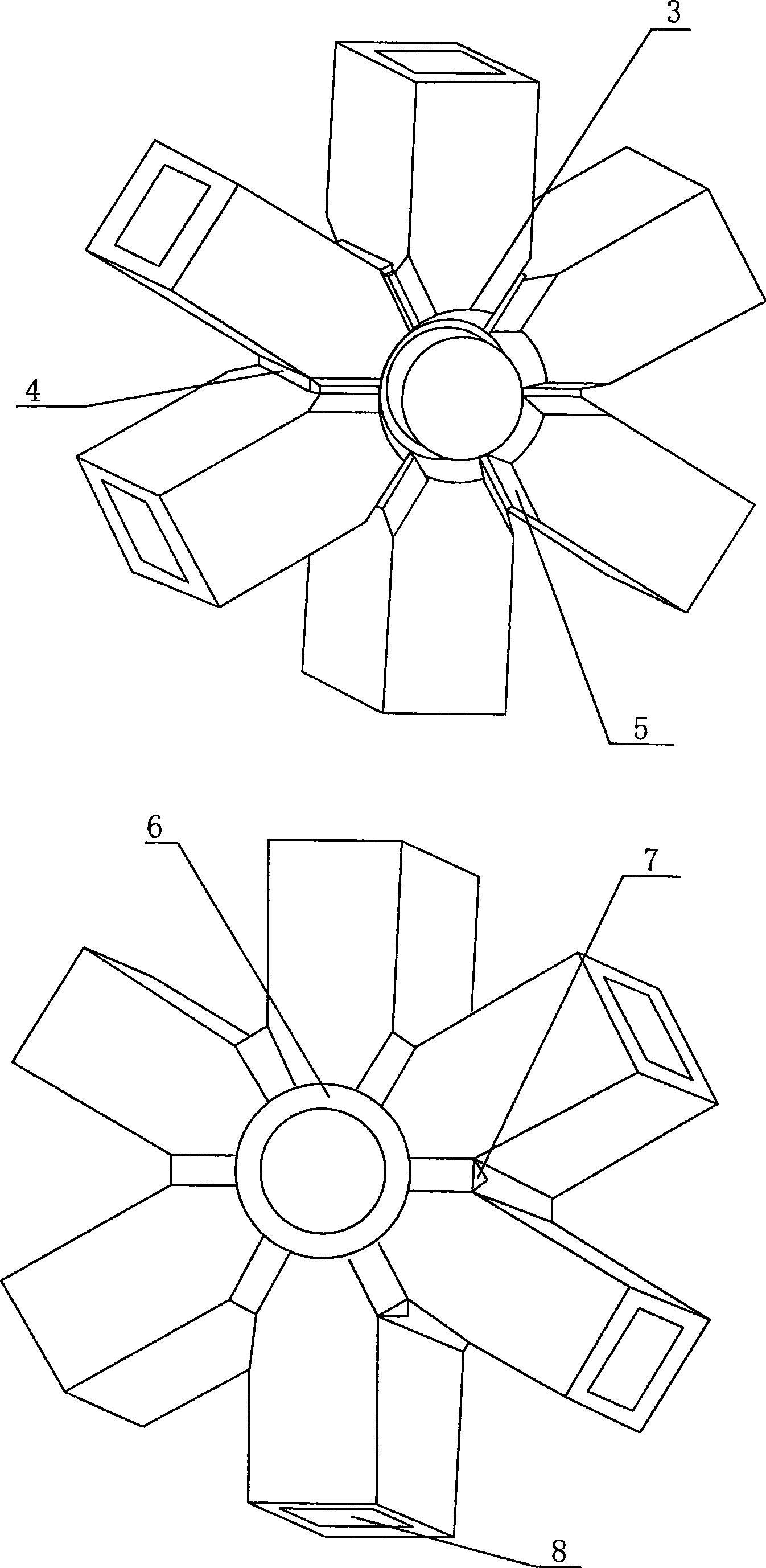

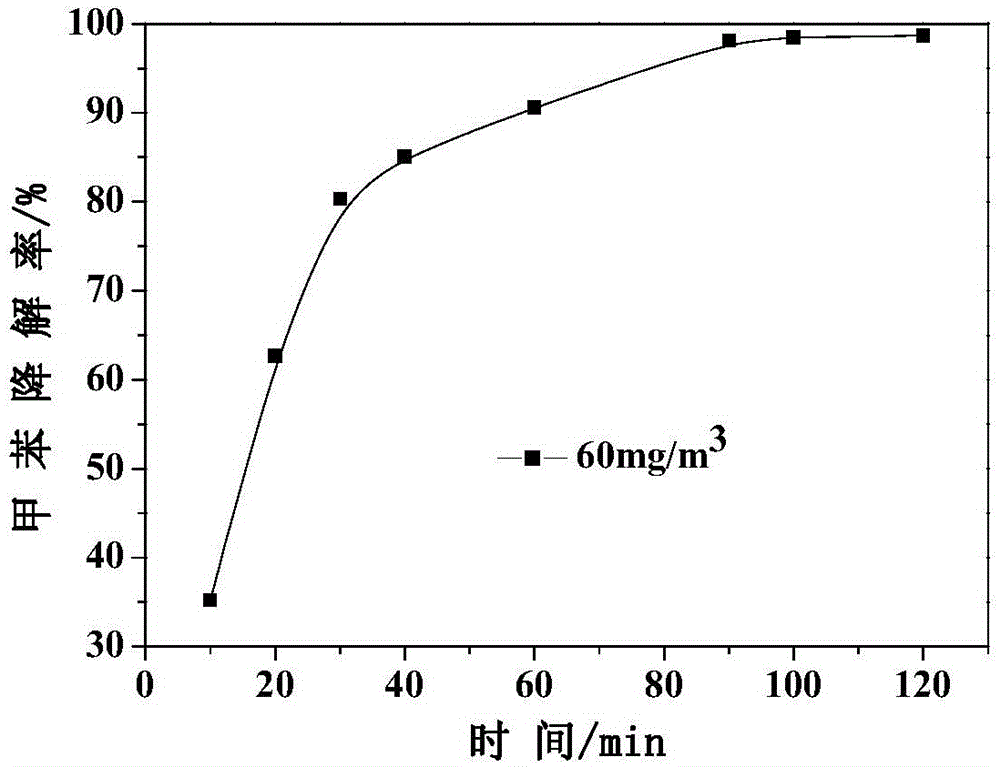

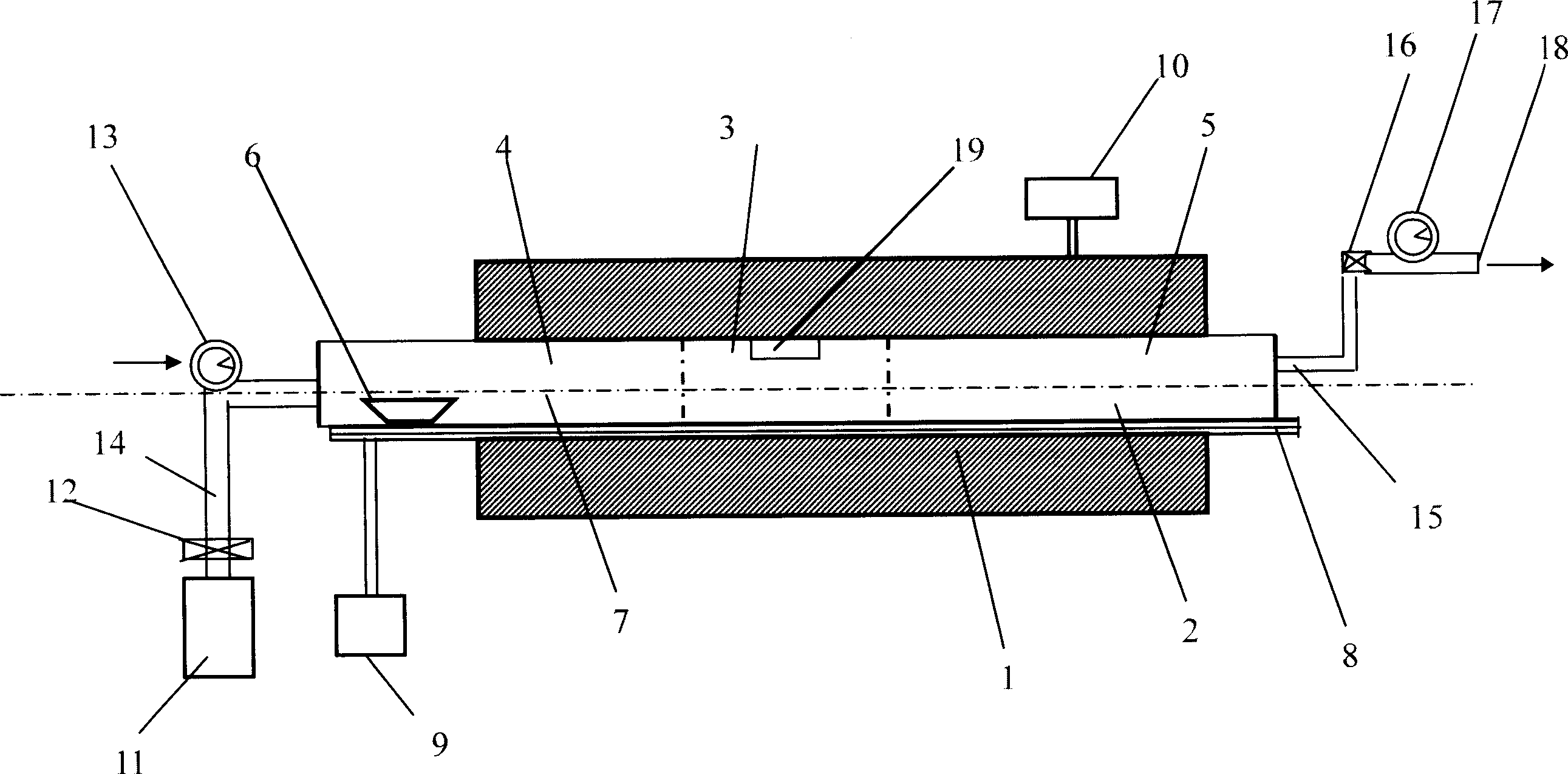

Activated carbon based nano TiO2 composite MnO2 catalytic material and preparation method therefor

InactiveCN105107494AHigh catalytic activityThe preparation process is shortDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiberHigh concentration

The invention discloses an activated carbon based nano TiO2 composite MnO2 catalytic material. The material comprises honeycomb rectangular blocks, honeycomb circular blocks, honeycomb hexagonal blocks, honeycomb holes, triangular strips, semi-circular strips, Ti / Mn coatings and honeycomb fiber meshes. A preparation method for the catalytic material comprises: substrate activation; nano titanium preparation; titanium spraying; manganese spraying; chemical deposition ; and post-treatment. By taking honeycomb activated carbon as a carrier, manganese dioxide and nano titanium dioxide as a compound catalyst is loaded on the honeycomb activated carbon to prepare a catalytic block or a fiber mesh for air purification and treatment; manganese dioxide is attached to the surfaces of nano TiO2 particles by virtue of a chemical deposition method to form a composite material. The preparation process disclosed by the invention is short in flow and easy to control. The obtained composite catalytic material has high catalytic activity, can be used for treating total volatile organic compounds (TVOC) in low concentration indoor air at normal temperature and can be used for treating high concentration industrial organic waste gas in a temperature range of 70-120 DEG C.

Owner:苏州弗莱希智能科技有限公司

Ceramic tile produced by pottery clay and preparation method thereof

The invention relates to the technical field of comprehensive utilization of mineral resources and in particular to a ceramic tile produced by pottery clay and a preparation method thereof. The preparation method is characterized in that by controlling and adjusting the raw material formula of the ceramic tile prepared from high-calcium pottery clay, combining the preparation process to grind high-calcium pottery clay raw materials and controlling and adjusting the granularity, active ingredients in the high-calcium pottery clay are improved and the performance of the high-calcium pottery clay raw materials is optimized; by combining treatment of initial bodies and semi-finished products after the compression molding process, each performance index of the green body before firing molding is optimized and controlled; after firing the semi-finished products in a kiln and controlling the firing temperature, low-energy-consumption firing is realized, and by combining control of the firing time, the strength and other mechanical properties of the prepared ceramic tiles are optimized. Therefore, the flexural and compressive strength of the obtained ceramic tile is 35.77-64.75 MPa, the water absorption rate of the ceramic tile is less than 1 percent, and ceramic tiles with excellent architectural decoration properties are further obtained.

Owner:ZUNYI ENERGY & MINERAL INVESTMENT CO LTD +1

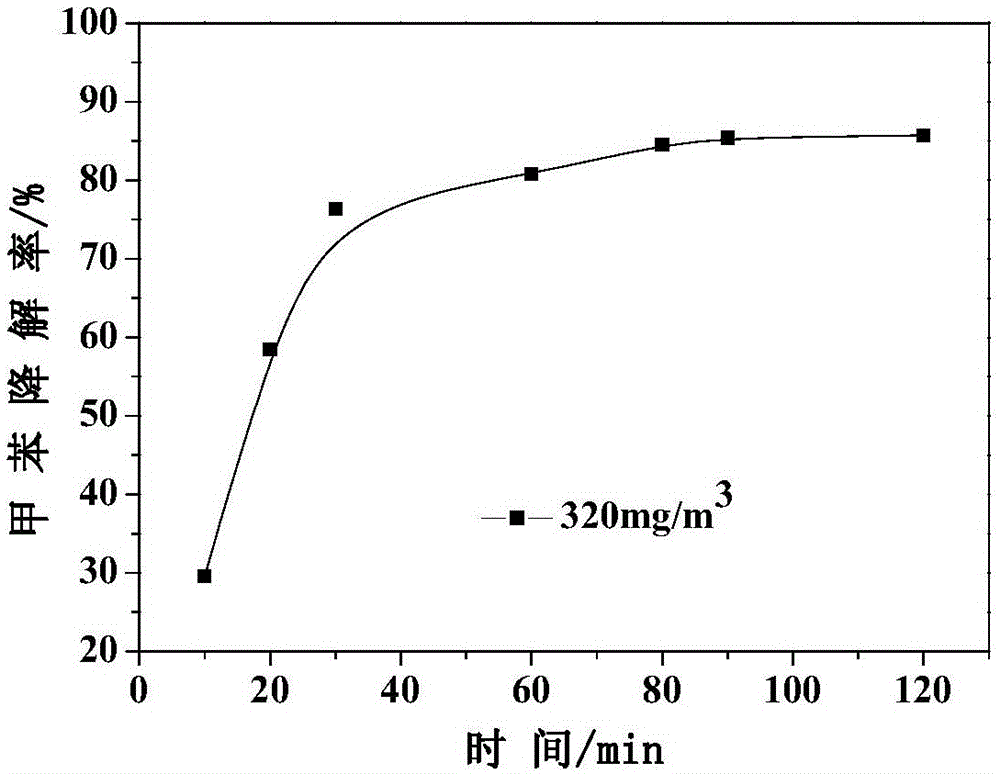

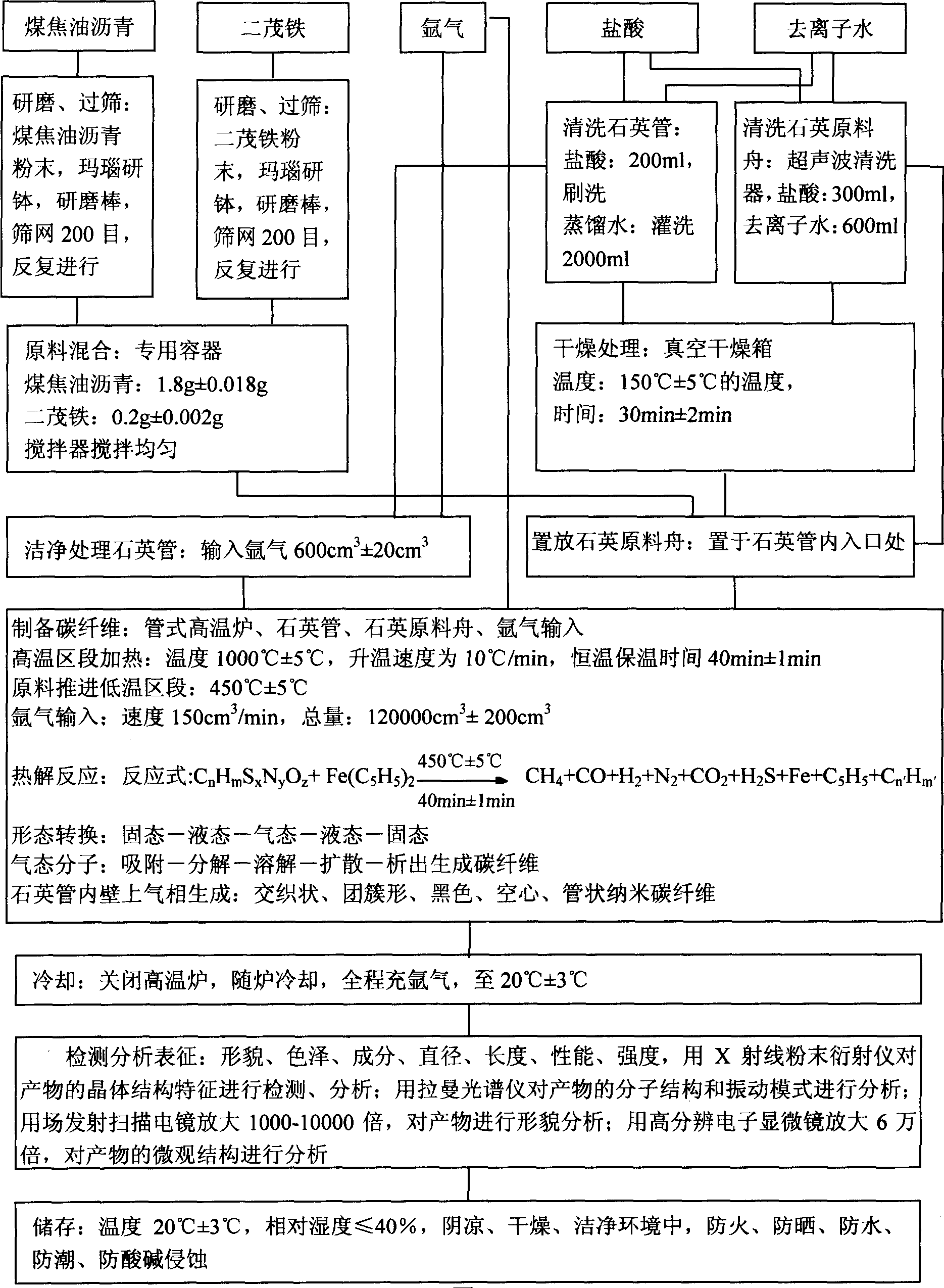

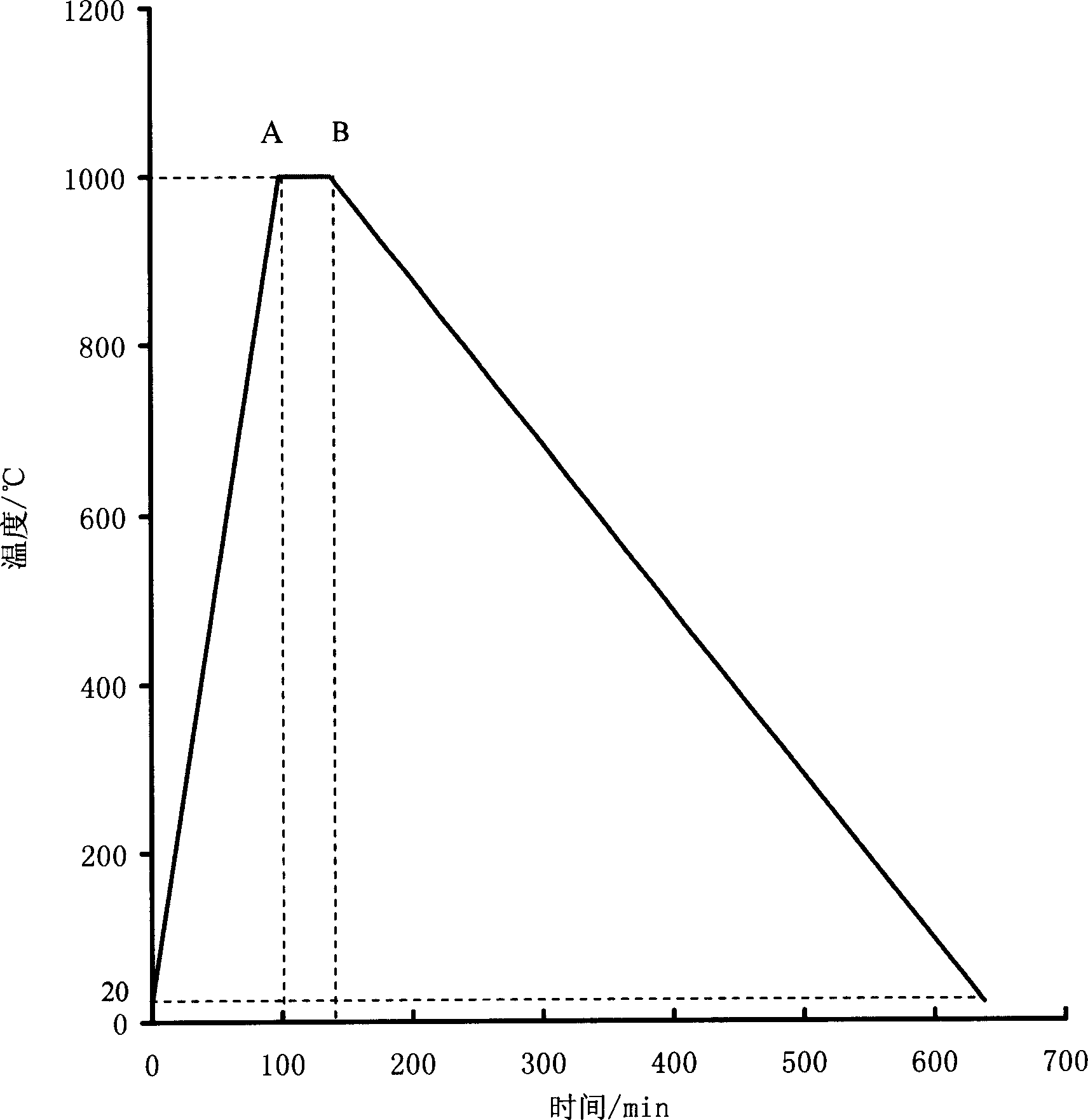

Method of preparing nano-carbon fiber using coal tar asphalt as raw material

The present invention relates to a method for preparing nano carbon fibre by using coal-tar pitch as raw material. It is characterized by that said method includes the following steps: using coal-tar pitch as raw material, using organic metal compound ferrocene as catalyst, using hydrochloric acid and deionized water as cleaning agent and using inert gas-argon gas as protective gas, in the tubular high-temperature furnal pyrolyzing chemical substance raw materials to make conversion from solid state to liquid state to gaseous state to liquid state to solid state form, make gaseous state molecular adsorption, decomposition, dissolution, diffusion and precipitation so as to obtain the nano carbon fibre product formed on the inner wall of quartz tube of tubular high-temperature furnace.

Owner:TAIYUAN UNIV OF TECH

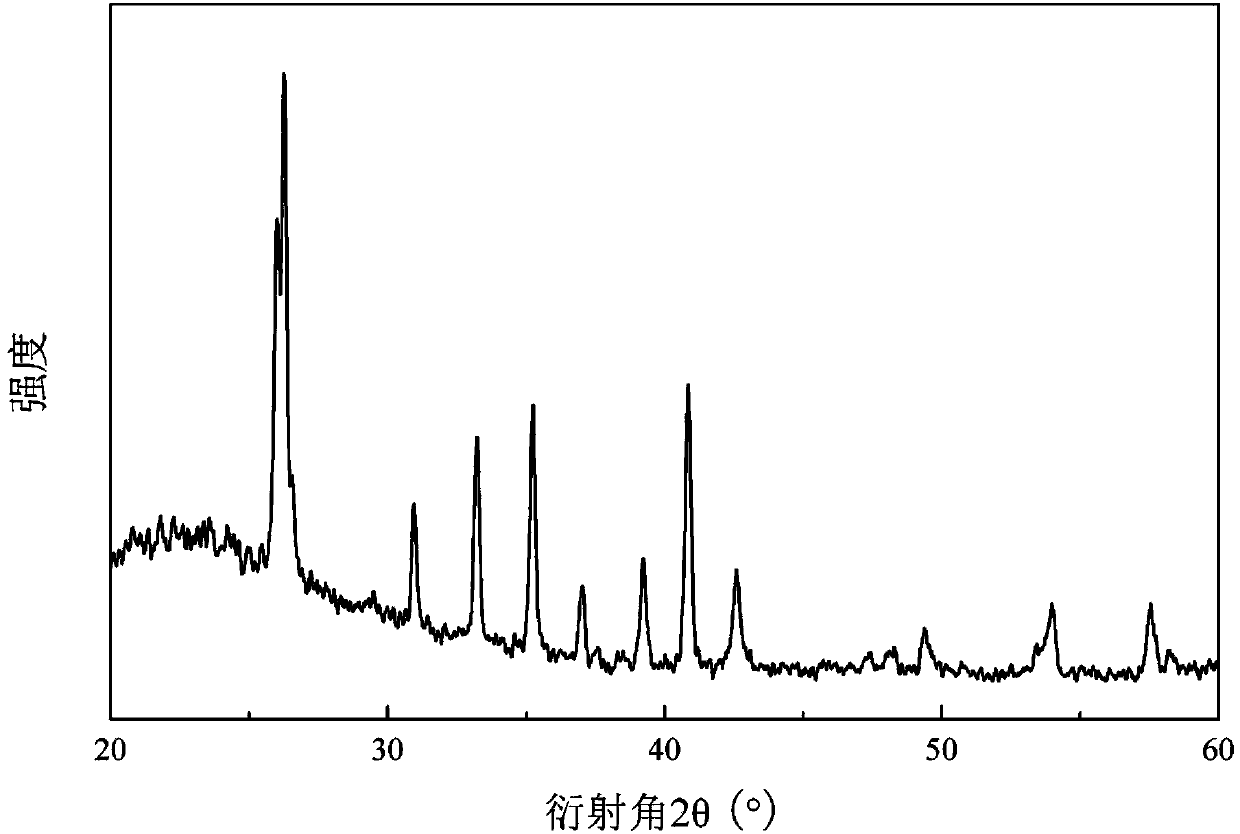

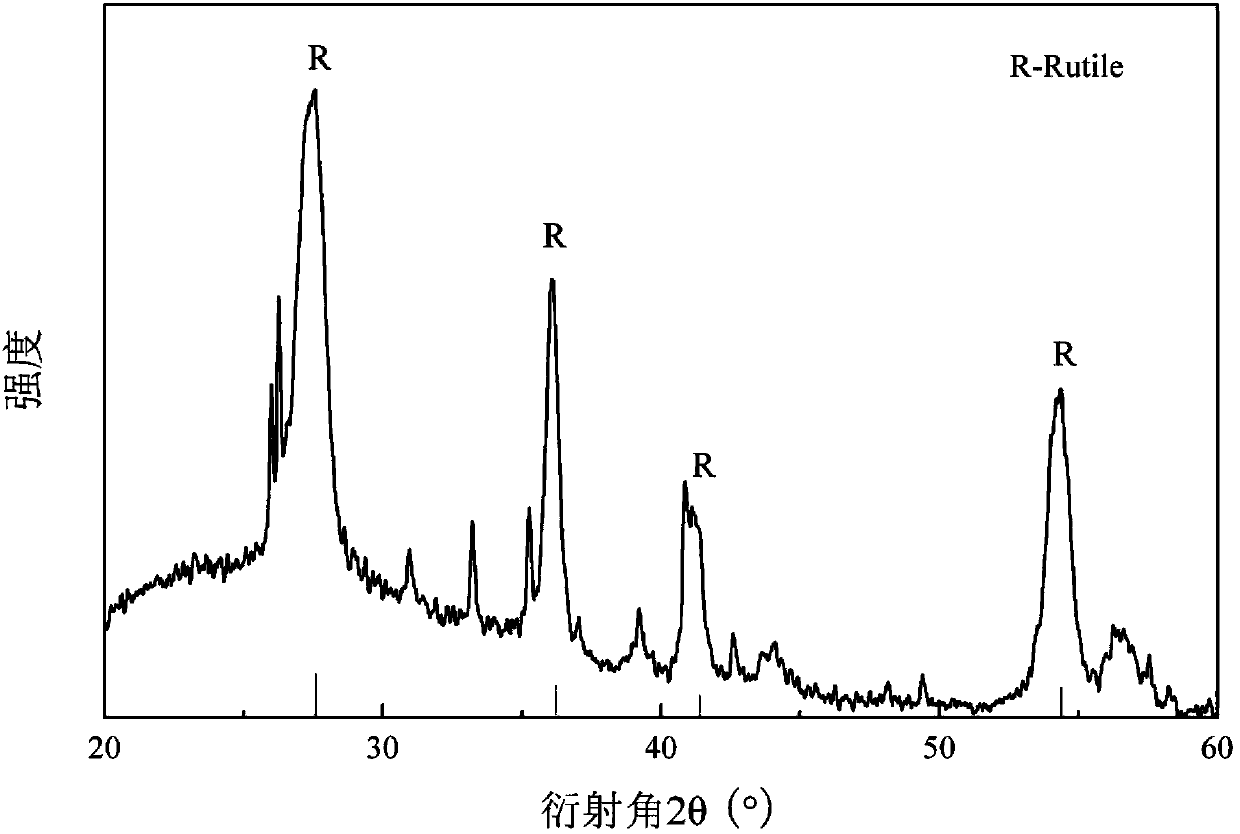

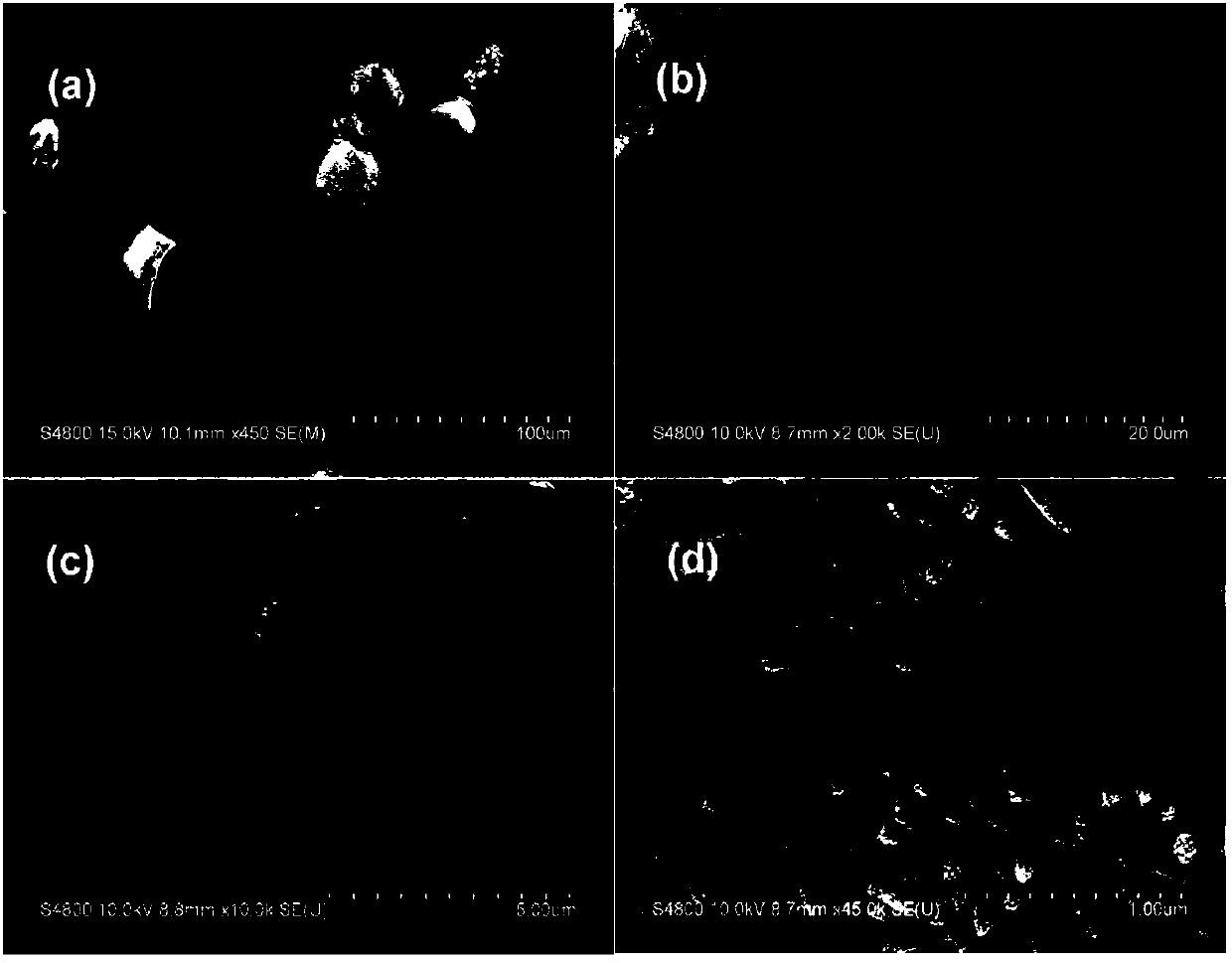

Photocatalytic composite material taking coal ash hollow microspheres as substrate and preparation method of photocatalytic composite material

InactiveCN103386309AThe preparation process is shortEasy to controlMetal/metal-oxides/metal-hydroxide catalystsPollutantCoal

The invention provides a photocatalytic composite material taking coal ash hollow microspheres as a substrate and a preparation method of the photocatalytic composite material. The photocatalytic composite material taking the coal ash hollow microspheres as the substrate consists of the coal ash hollow microspheres and TiO2 nanorods growing on the surface of the coal ash hollow microspheres; the grain diameter of the coal ash hollow microspheres is 30-60Mum; the TiO2 nanorods are in the type of rutile, the length of the TiO2 nanorods is 0.1-1.5Mum, and the diameter of the TiO2 nanorods is 20-100nm. According to the invention, the preparation process flow is short and easy to control, and the photocatalytic composite material taking coal ash hollow microspheres has the characteristics of being large in specific surface area, high in photocatalytic activity, light in weight, floatable, dispersable, easy to recycle and the like, and can be used for effectively treating organic pollutants in water when being used as a photocatalytic material.

Owner:SHANGHAI HUAMING HI TECH GRP

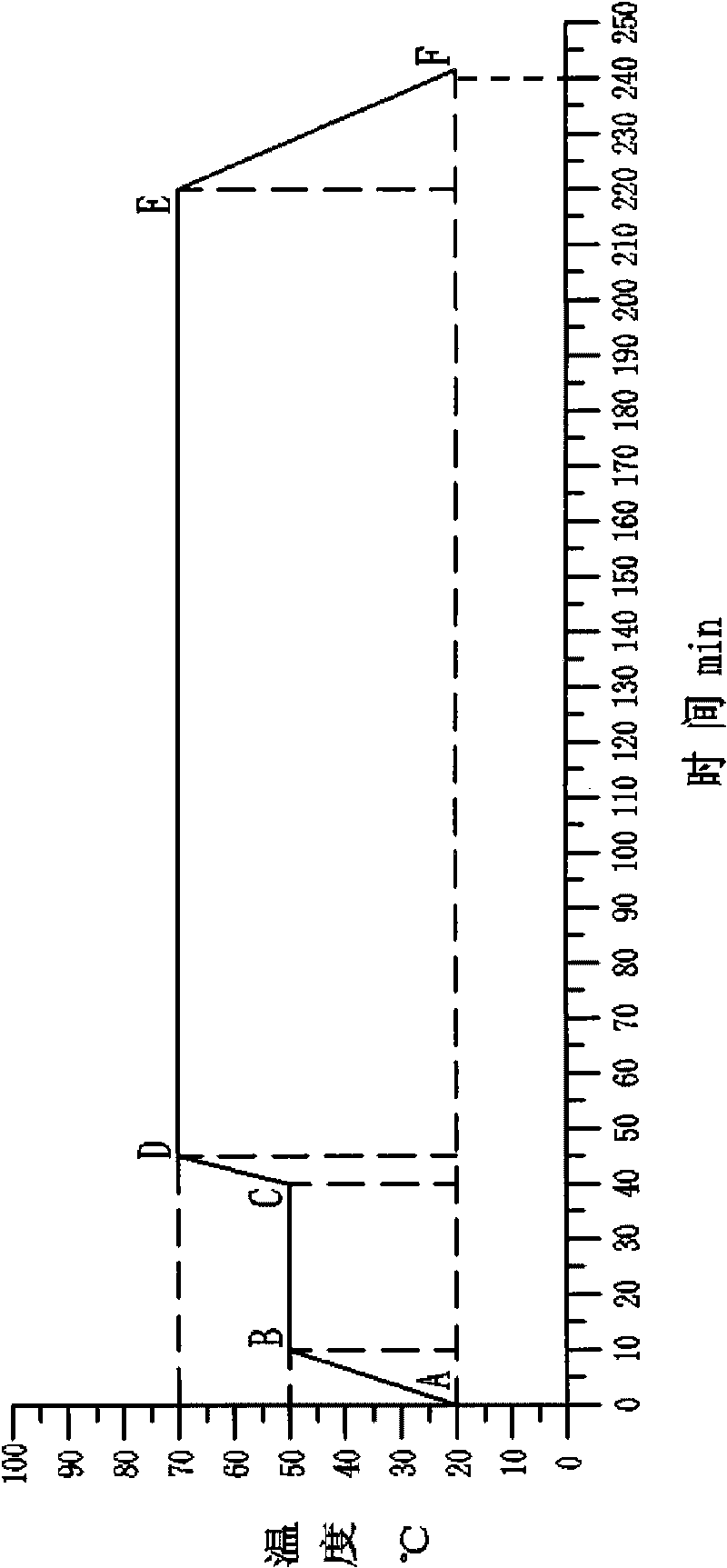

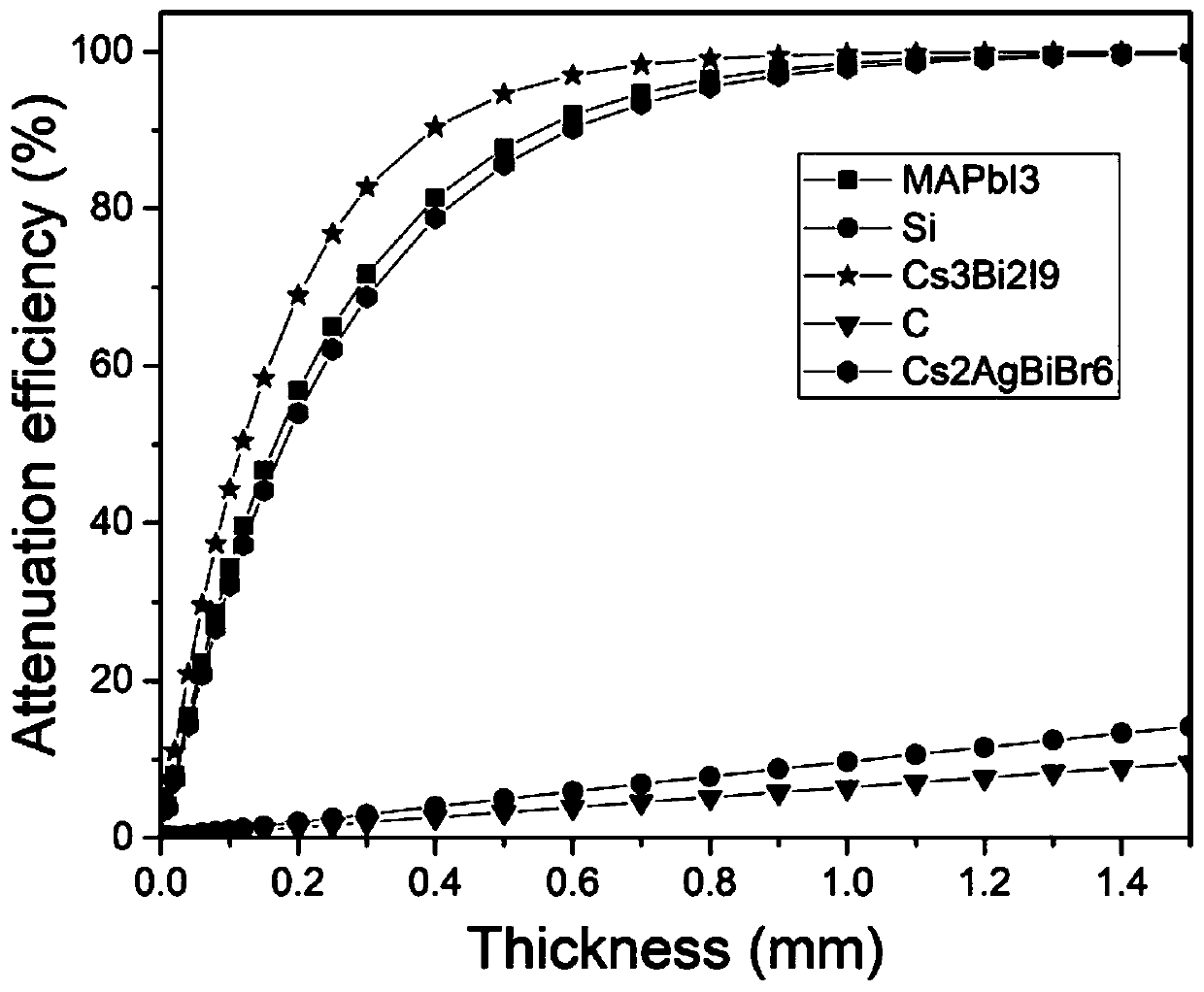

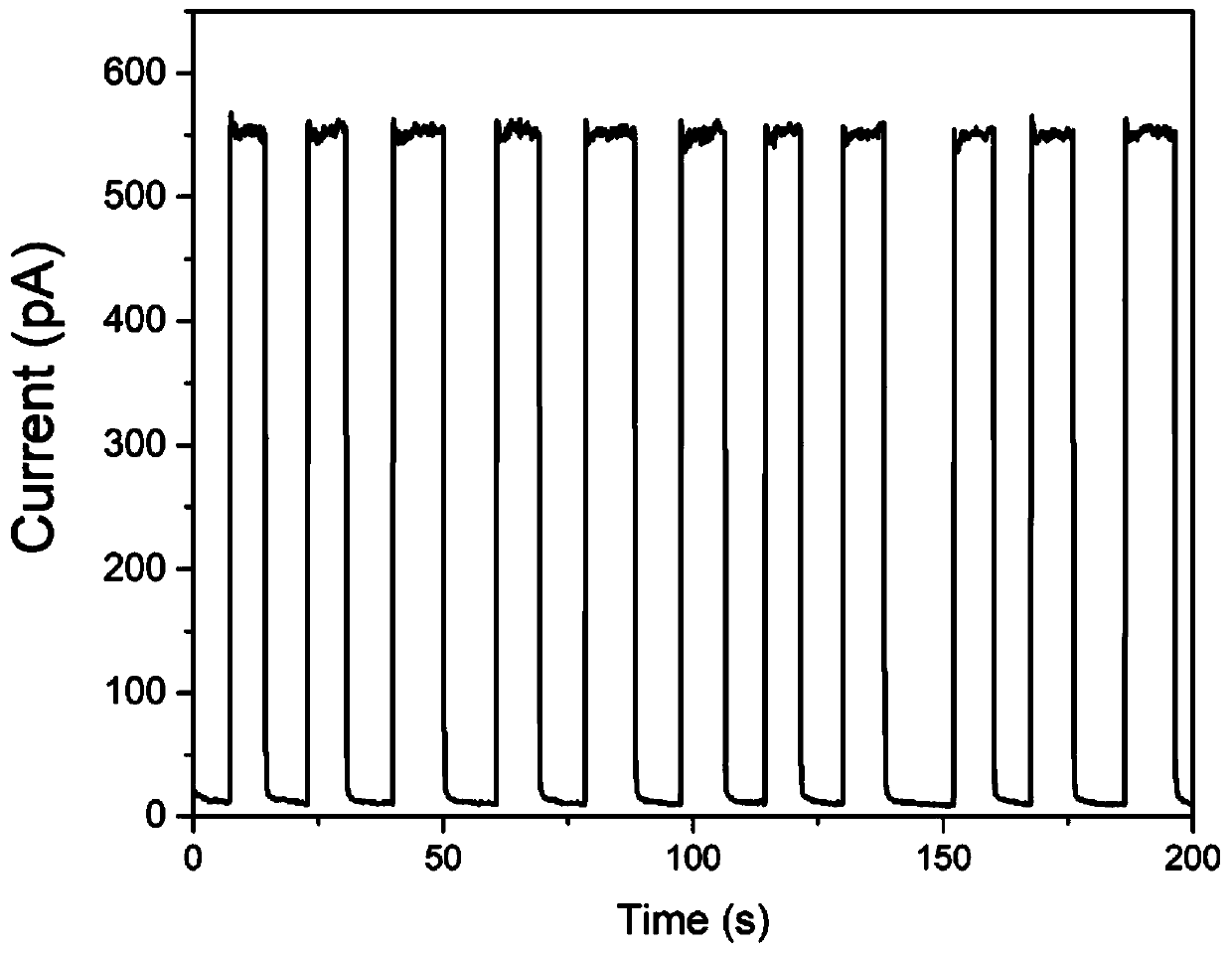

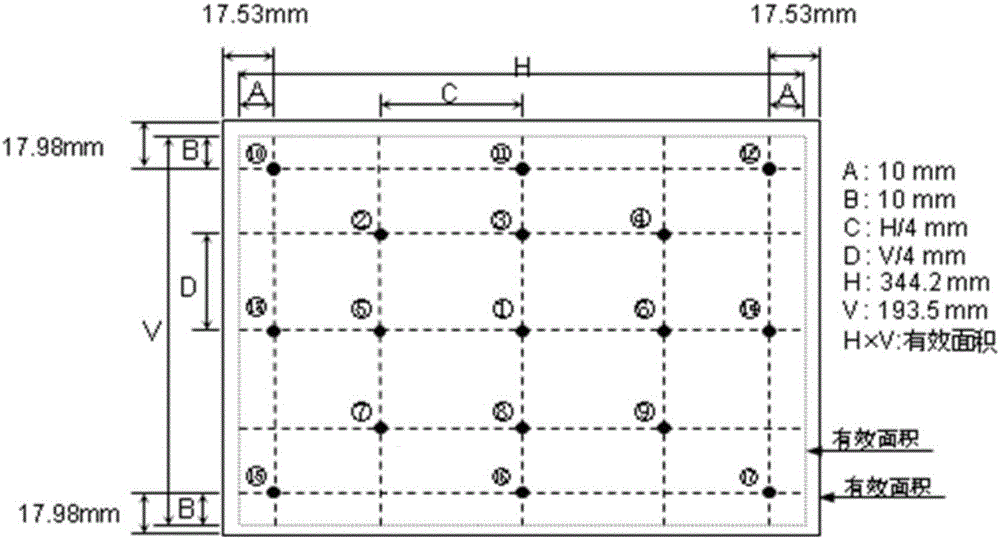

X-ray detector based on perovskite material and preparation method thereof

ActiveCN110676342ALarge atomic numberImprove mobilityFinal product manufactureSemiconductor devicesMetallic electrodeOrganic solvent

The invention discloses an X-ray detector based on a perovskite material and a preparation method of the X-ray detector. The method comprises the steps: 1, weighing AI and BI3 raw materials accordingto a molar ratio of 3: 2, and dissolving the AI and BI3 raw materials in an organic solvent to obtain a mixed precursor solution, wherein AI is CsI, CH3NH3I or RbI, and BI3 is BiI3 or SbI3; 2, sealingthe mixed precursor solution, heating the solution to 60-100 DEG C and maintaining the temperature for 2-48 hours to achieve full dissolution equilibrium, and then, taking supernate to obtain a completely saturated solution of the precursor; 3, placing the completely saturated solution of the precursor at an environment temperature lower than the heating termination temperature in the step 2, then, gradually carrying out heating at a speed of less than 5 DEG C / day until crystallization, and stopping heating until the temperature is continuously increased by at most 10 DEG C to obtain an A3B2I9 perovskite single crystal; 4, taking out the single crystal and carrying out drying; and 5, evaporating an interdigital metal electrode on the surface of the single crystal.

Owner:SHAANXI NORMAL UNIV

Ardealite substrate wood-like floor and preparation method thereof

The invention relates to the technical field of chemical construction materials, in particular to an ardealite substrate wood-like floor and a preparation method thereof. Due to appreciate preparation of ardealite, yellow phosphorus slag, quick lime, cement, a brine and magnesium oxide mixed liquid, fiber and a wood-like coating in a mixing ratio, ardealite is sufficiently activated, the activity of ardealite is improved, the content of soluble impurities in ardealite is further reduced, and the curing property of ardealite is improved; particularly due to addition of the brine and magnesium oxide mixed liquid, sodium in ardealite can form a product which is hard to dissolve, can be fixed in an ardealite crystal cavity, and then is prevented from being exposed on the surface of an ardealite product, so that the phenomenon that the surface of the ardealite product is powdered because of sodium is avoided, the strength and the quality of the ardealite product are improved, and the property of the ardealite product is improved.

Owner:GUIZHOU KAILIN GRP CO LTD

Dual-curing light guide glue for display screen backlight modules and preparation method of dual-curing light guide glue

InactiveCN106497498AHigh peel strengthImprove dispersion uniformityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyMethacrylate

The invention discloses dual-curing light guide glue for display screen backlight modules. The dual-curing light guide glue comprises a component A and a component B, wherein the component A is prepared from a light-curing monomer, polybutadiene dimethacrylate, aliphatic polyurethane acrylate, epoxy resin, a activated diluent, a crosslinker, a leveling agent, a dispersant, a coupling agent and light guide powder by means of mixing and reacting; the component B is prepared from a light initiator, epoxy resin-modified aliphatic amine, a defoaming agent, light guide powder and a rheological agent by means of reaction. The invention further relates to a preparation method of the dual-curing light guide glue for the display screen backlight modules. The preparation method has the advantages of short process flow and low cost. The dual-curing light guide glue prepared by the method has the advantages of excellent peel strength, storage stability, impact resistance, high luminance and uniformity and the like.

Owner:NANJING NUOBANG NEW MATERIAL CO LTD

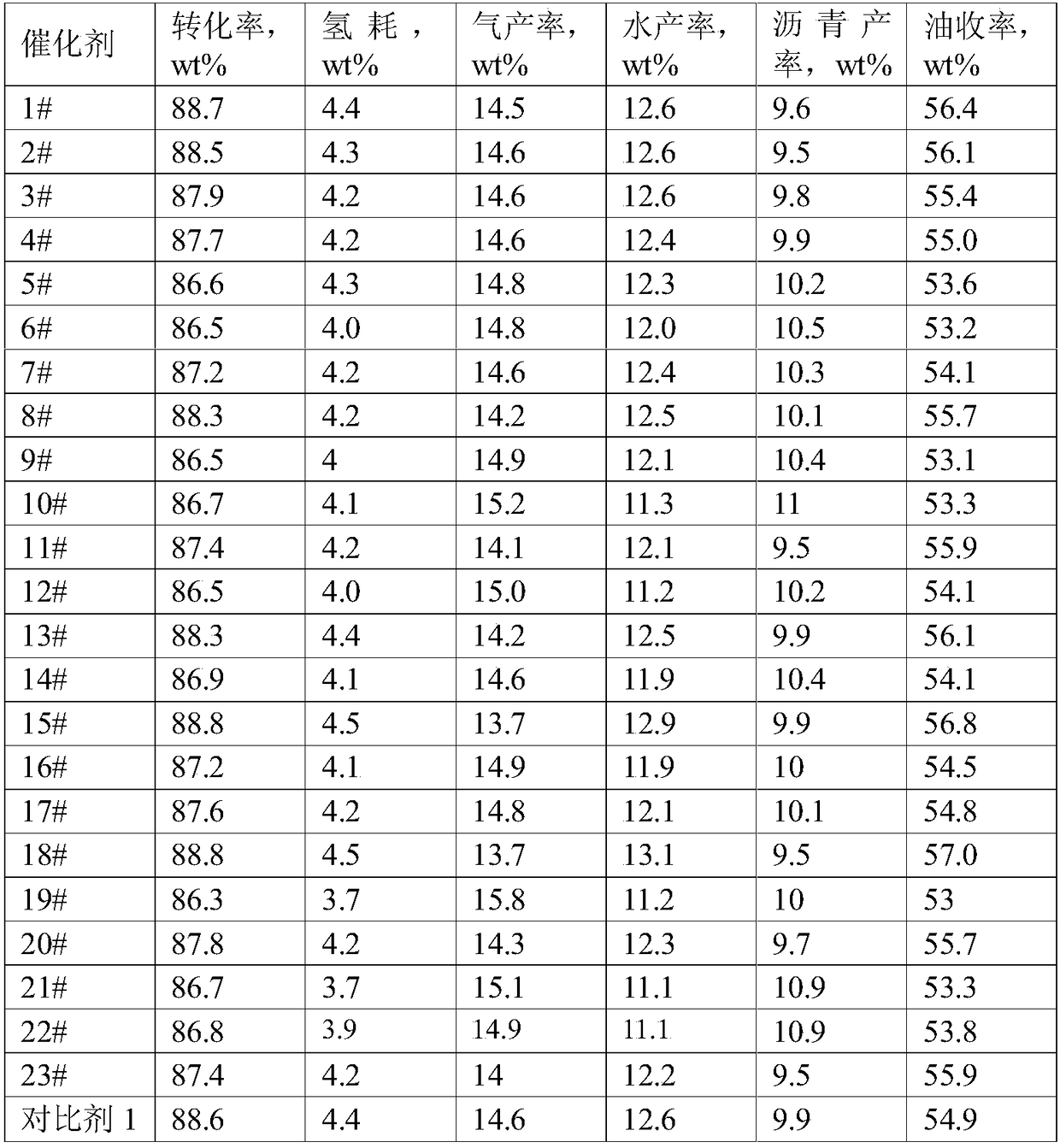

A preparing method for an iron based catalyst

ActiveCN108772064AReduce the amount of waterReduce water consumptionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAlkaline waterPtru catalyst

The invention provides a preparing method for an iron based catalyst. An active component of the iron based catalyst is FeOOH. The preparing method includes the following steps: a soluble salt solution containing iron is supported catalyst on a catalyst carrier in a spray mode to obtain an initial product; an alkaline aqueous solution is reacted with the head product to obtain a secondary product;oxidation is optionally performed on the secondary product according to a valent state of iron ion in the soluble salt solution containing iron, and the iron based catalyst is obtained through crystal phase transition. Adopting the provided preparing method for the iron based catalyst is beneficial to reduce water consumption, waste water is not generated or less waste water is generated, and investment of the whole technology and the preparing cost are low.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Preparation method for tungsten disulfide

ActiveCN103420423AThe preparation process is shortEasy to useTungsten compoundsTungstic acidTungsten disulfide

The invention relates to the technical field of compound preparation and in particular to a preparation method for tungsten disulfide. The preparation method comprises the following steps: uniformly mixing tungstic acid with an ammonium trisulfide solution to obtain a mixture; putting the mixture into vulcanization equipment, vacuumizing, and heating in the vulcanization equipment at first stage for 50-70 minutes at the temperature of 650-750 DEG C; heating at second stage for 110-130 minutes at the temperature of 1350-1400 DEG C to obtain tungsten disulfide. According to the preparation method, the process is short, the used equipment is simple, and the environmental pollution is alleviated at the same time.

Owner:深圳市威勒科技股份有限公司

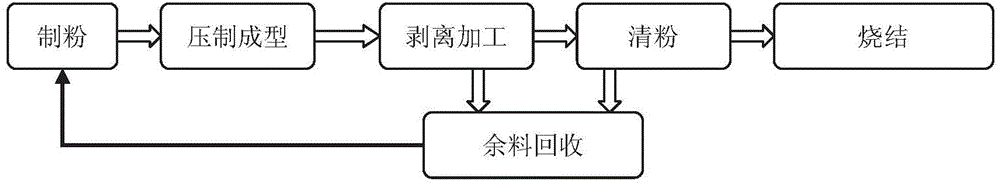

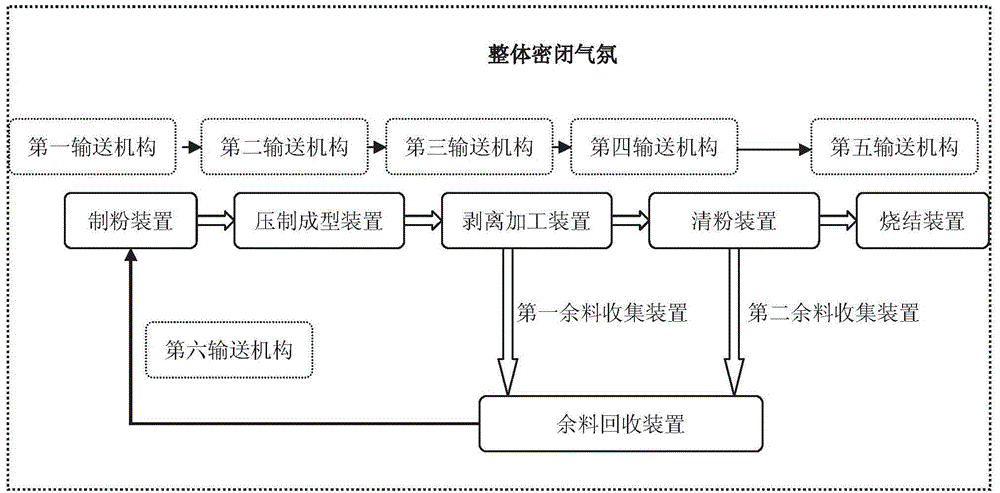

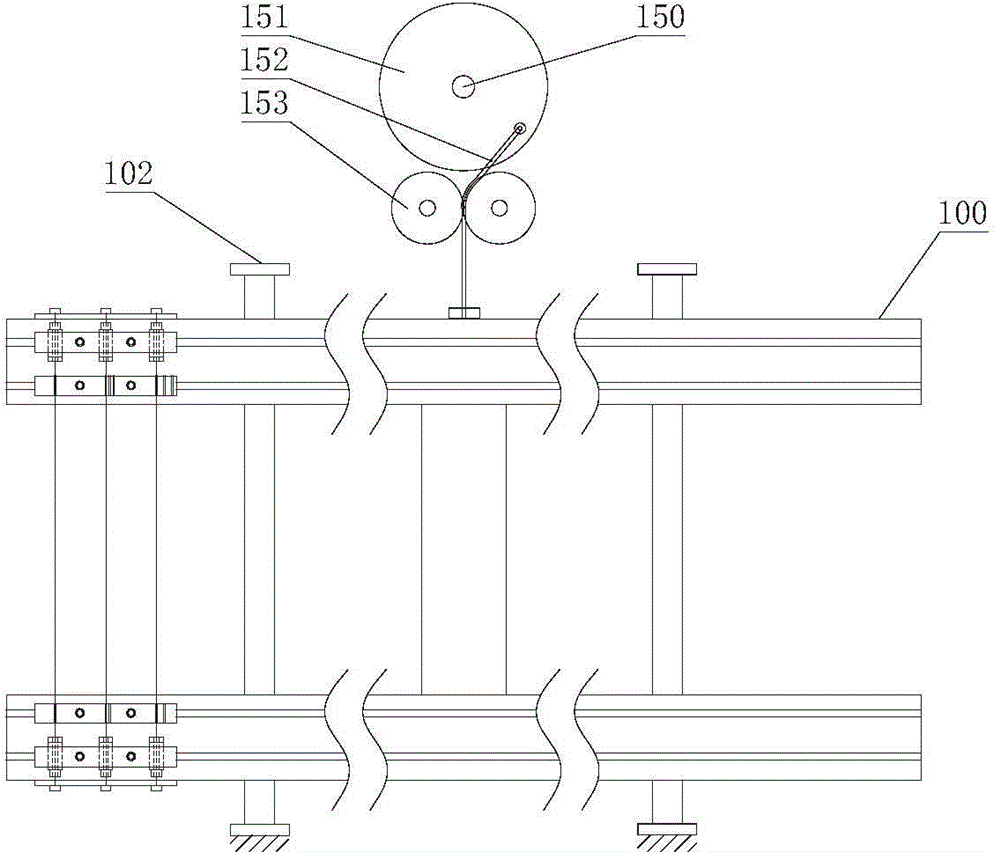

A rare earth permanent magnetic material preparing method

ActiveCN104907558AReduce lossEliminate finishing processMagnetic materialsRare earthSintered magnets

The invention relates to a rare earth permanent magnetic material preparing method comprising the steps of preparing a press blank of powder of sintered magnets, using row wires to machine the press blank and then performing sintering. All the steps are performed in a wholly sealed atmosphere. The row wire machining means line machining for the press blank formed by pressing; after the press blank is clamped and located, a driving mechanism drives the row wires to move back and forth linearly; the press blank is machined according to a preset path along with the rotation of a locating clamp and finally forms a block body or a sheet body with a preset shape and size, an arched body or other specially-shaped bodies; the final forming size contains the sintering shrinkage allowance. The rare earth permanent magnetic material preparing method has the advantages of short preparation technological process, high machining efficiency, low magnetic powder loss, and high rare earth utilization rate. The machining is near net machining, so that a finish machining procedure performed after sintering is saved.

Owner:浙江三环康盈磁业有限公司

Method for preparing nickel cobalt lithium manganate ternary system anode material of lithium ion battery

The invention discloses a method for preparing a nickel cobalt lithium manganate ternary system anode material of a lithium ion battery. Sulfates of Ni, Co and Mn are used as raw materials. The method comprises the following steps of: dissolving the three sulfates into water in a certain molar ratio to form solution, then evaporating the solution with stirring, heating and decomposing the powder obtained by evaporating to obtain LiNi1-x-yCoxMnyO2 precursor composite oxide, then mixing the precursor composite oxide and lithium carbonate or lithium hydrate in a certain molar ratio, and heating the mixture at a high temperature to obtain LiNi1-x-yCoxMnyO2. The method overcomes the defect that Li+ is difficultly mixed with Co2+, Ni2+ and Mn2+ uniformly in a solid phase method, and meanwhile avoids the disadvantages of harsh condition control requirements such as pH of the solution, concentration, temperature, stirring speed and the like in a co-precipitation method during preparing the precursor. The gas generated by high-temperature heating is absorbed by using mixed slurry of manganese dioxide and manganese carbonate so as to obtain manganese sulfate serving as one of synthesis raw materials.

Owner:湖南昊宏新材料科技有限公司

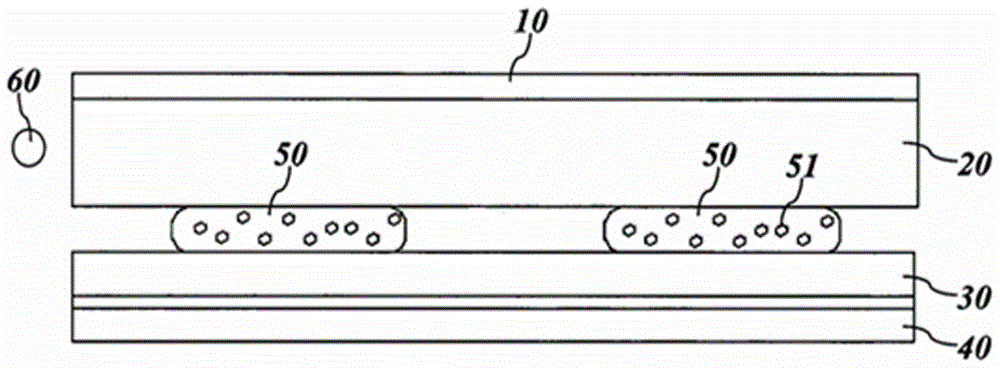

Compact ultrathin liquid crystal display backlight module structure and manufacturing method thereof

InactiveCN106353850AImprove consistencyImprove protectionOptical light guidesNon-linear opticsLiquid-crystal displayLight guide

The invention discloses a compact and ultra-thin liquid crystal display backlight module structure, which includes a light guide and reflection structure, the light guide and reflection structure includes a light guide plate and a reflection sheet, and the reflection sheet is attached to the backlight surface of the light guide plate through light guide glue. Combined to form an integrated structure, the light guide glue is distributed on the printing dots of the light guide plate or reflector, the light guide glue is doped with reflective particles, there is a gap between the light guide plate and the reflector, and the gap is filled with air; thus, in ensuring On the premise that the rigidity of the module is not reduced, the purpose of reducing the thickness of the liquid crystal display is achieved. The invention completes the printing of the light guide adhesive and the lamination of the light guide plate and the emitting sheet in one step, simplifies the manufacturing process of the light guide plate, reduces the loss of raw materials, improves the production efficiency, and saves the production cost.

Owner:NANJING NUOBANG NEW MATERIAL CO LTD

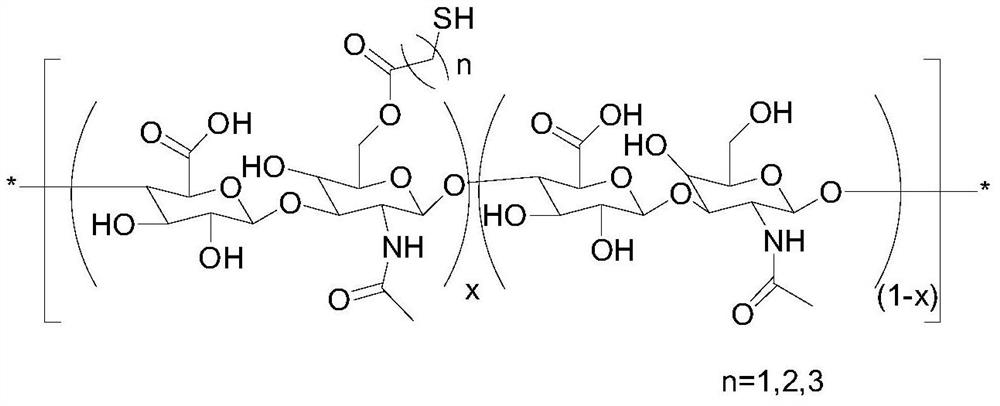

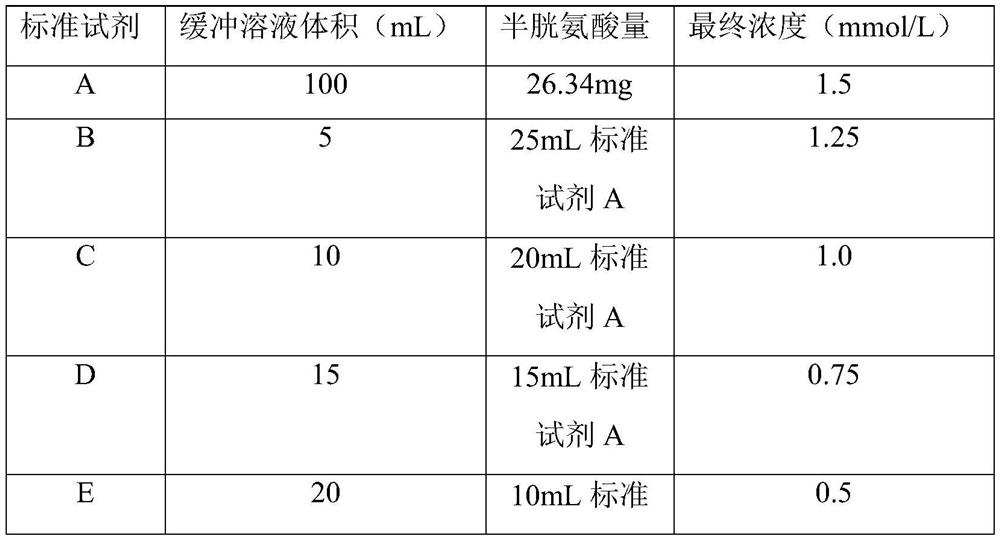

Sulfhydrylated hyaluronic acid as well as preparation method and application thereof

PendingCN112842929AThe degree of substitution is controllableDissolve fastCosmetic preparationsToilet preparationsDisulfide bondingDisulfide bond reduction

The invention discloses sulfhydrylated hyaluronic acid as well as a preparation method and application thereof. The sulfhydrylated hyaluronic acid is obtained by sulfhydrylation modification of hydroxyl sites of hyaluronic acid or salt thereof. According to the invention, the hyaluronic acid or salt thereof reacts with a disulfide compound to generate a hyaluronic acid disulfide compound, and then a reducing agent is added to reduce disulfide bonds into a sulfydryl group, so the sulfhydrylated hyaluronic acid is obtained. The sulfhydrylated hyaluronic acid has the characteristics of controllable sulfydryl substitution degree, fast dissolution, fast gelling and good biocompatibility, and can be applied to the fields of skin care products, joint injection, tissue filling, cell culture and the like.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

Micro-nano double-stage porous copper and preparation method thereof

ActiveCN108149048ATo achieve an organic combinationThe preparation process is shortMicro nanoRoom temperature

The invention discloses micro-nano double-stage porous copper. By using a sintered porous Cu framework as a substrate, double continuous micro-nano porous structures are formed on the substrate, wherein the average aperture of micro-holes is 2.18 microns to 3.68 microns, and the average aperture of nano-holes is 153nm to 234nm, so that organic combination of sintering preparation of the micro-holes and de-alloying preparation of the nano-holes in a copper matrix is realized, and the micro-nano double-stage porous copper has the characteristics of a micro-hole / nano-hole composite hole structureand a three-dimensional double continuous ligament / pore canal structure. A preparation method of the micro-nano double-stage porous copper comprises the following specific steps: 1, uniformly mixingpowder Cu with powder Zn in a certain proportion to obtain mixed powder and compressing the mixed powder into a blank, putting the blank into an atmosphere tube type furnace, heating the blank to a certain temperature, and cooling the blank to a room temperature after heat insulation is carried out for a certain time so as to obtain a precursor CuZn alloy; and 2, putting the precursor into a hydrochloric acid solution and performing de-alloying until air bubbles are not obviously effused so as to obtain the micro-nano double-stage porous copper. The preparation process of the micro-nano double-stage porous copper is simple and convenient, and is easy for realization.

Owner:XIAN UNIV OF TECH

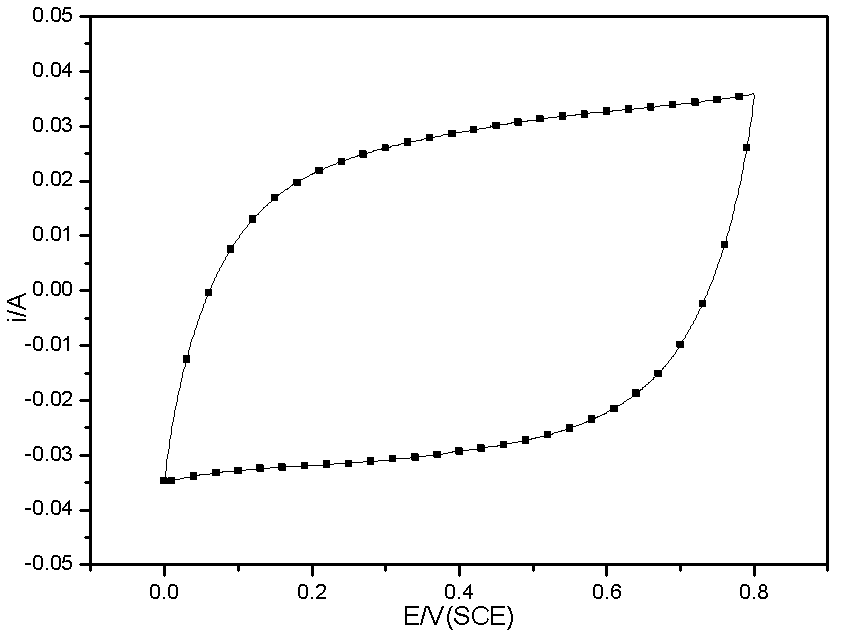

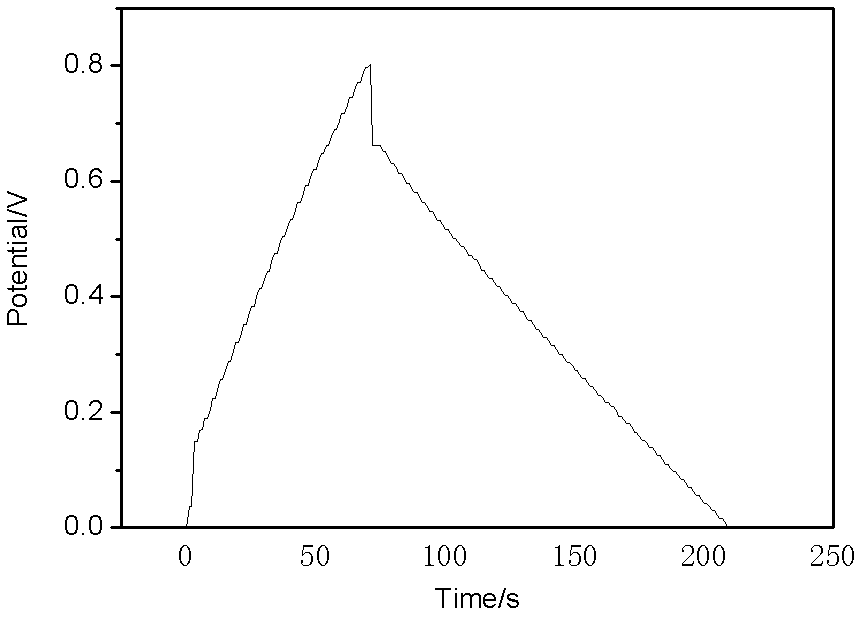

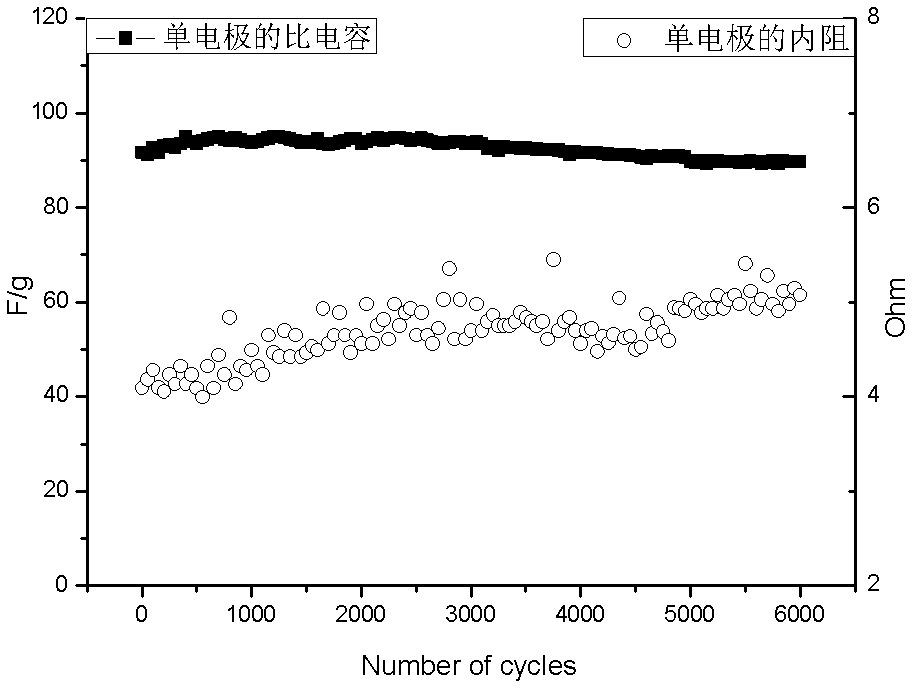

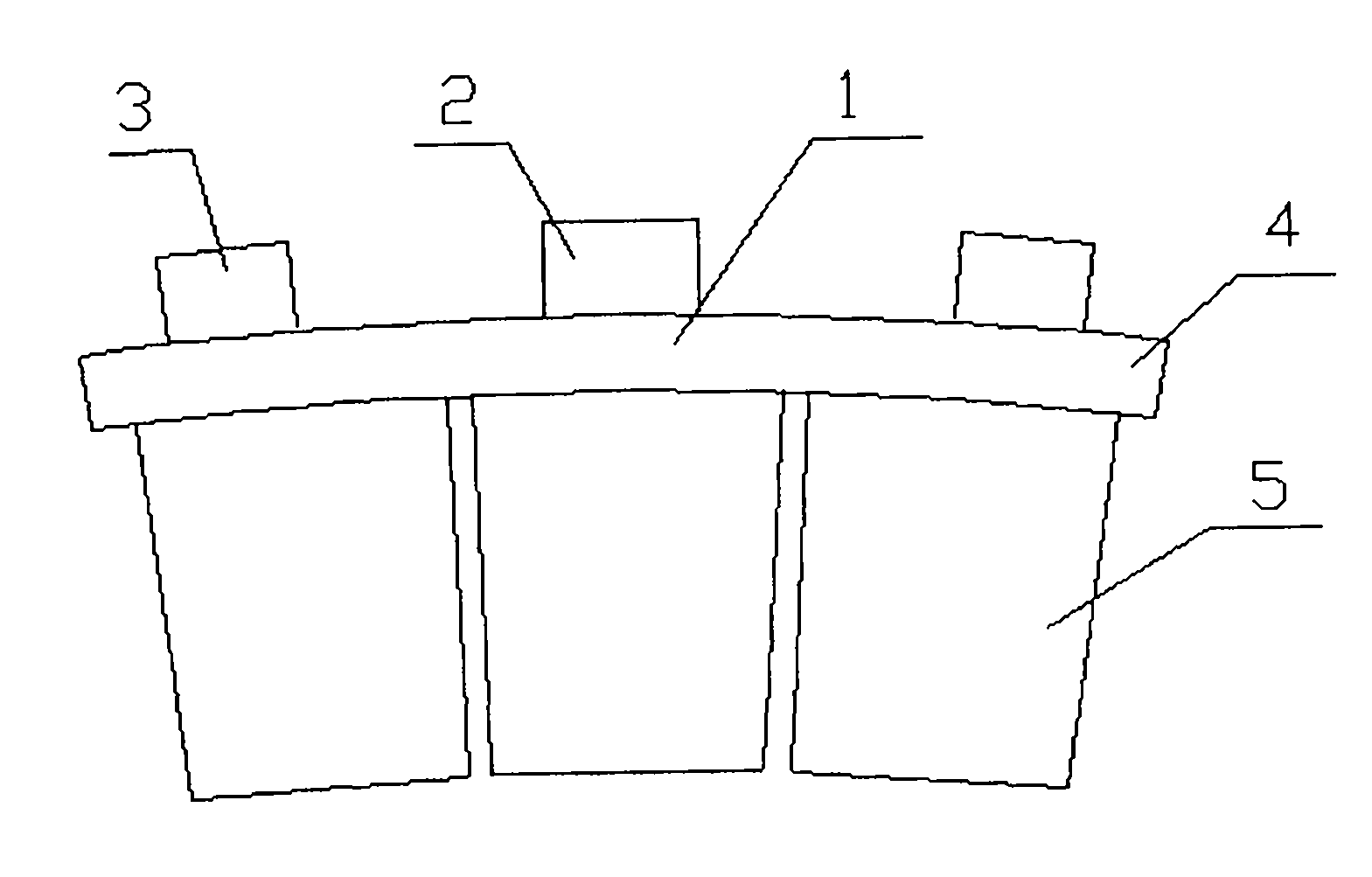

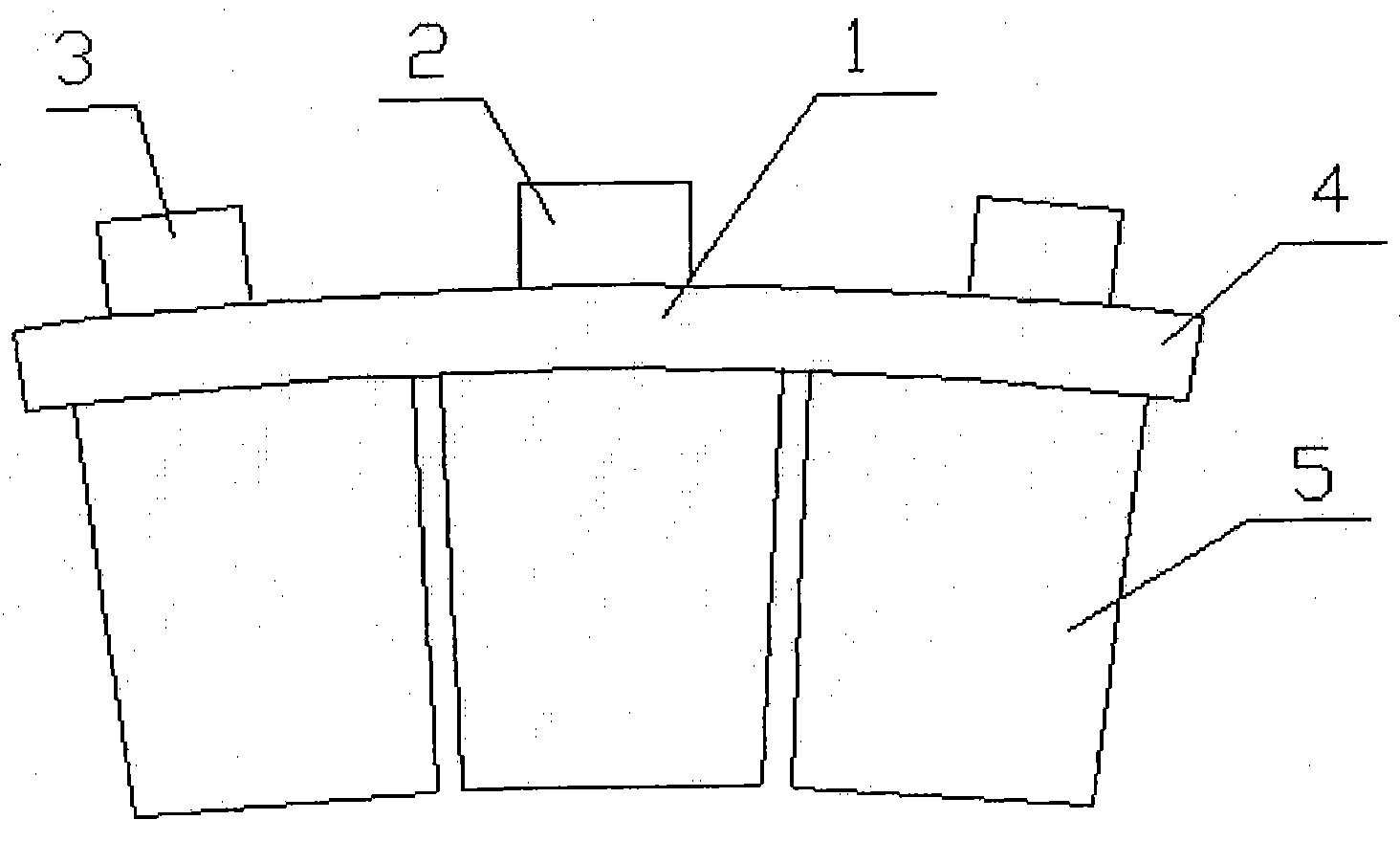

Low inner resistance manganese dioxide electrode for water system supercapacitor and preparation method thereof

ActiveCN102543470ALower internal resistanceImprove performanceElectrolytic capacitorsCapacitanceCarbon nanotube

The invention provides a low inner resistance manganese dioxide electrode for a water system supercapacitor and a preparation method thereof, solving the problem that inner resistance of a manganese dioxide electrode is high. The manganese dioxide electrode comprises the following components in parts by weight: 65-91 parts of manganese dioxide, 2-15 parts of acetylene black, 2-15 parts of carbon nano tube and 4-6 parts of polytetrafluoroethylene. The preparation method comprises mixing, stirring, coating, rolling, drying and cutting, wherein multiple variable-step rolling is adopted in the rolling process, the total compression amount is controlled in each rolling process, and the step is gradually reduced. The low inner resistance manganese dioxide electrode for the water system supercapacitor provided by the invention has the advantages of low inner resistance, good electrochemical stability, high specific capacitance and the like, has a work window with high specific energy sum in solution such as Na2SO4, K2SO4, Li2SO4 and the like and can be applied to a power supply occasion with high power density. By adopting the low inner resistance manganese dioxide electrode provided by the invention, production process is simple, production period is short, equipment cost is low, and industrialization is easy to realize.

Owner:CHINA ELECTRIC POWER RES INST +1

Preparation method of high carbon steel with good cold formability

The invention discloses a preparation method of high carbon steel with good cold mouldability. The preparation method sequentially comprises the following steps: molten iron desulphurization; bessemerizing; argon blowing; refining; continuous casting; soaking pit; finish rolling; laminar cooling; taking up; slow cooling of a coil yard; leveling; and annealing. By means of controlling the chemical components of a steel product as well as a hot rolling process, a laminar cooling process, a take-up temperature and annealing process and the like, fine and dispersed globular pearlites are formed in steel, wherein the rate of spheroidization of pearlites is greater than or equal to 60%, the pearlites with the diameter which is greater than or equal to 2 mu m are greater than or equal to 60%, the tensile strength is 400-800MPa, the ductility is greater than or equal to 25% and the hardness is 130-290 HV. The preparation method disclosed by the invention not only is short in process flow, but also the prepared high carbon steel plate material is good in cold mouldability. In the moulding processes of cold punching, cold bending and the like, the material is not cracking, so that the yield and the usability of the material are greatly improved.

Owner:武汉钢铁有限公司

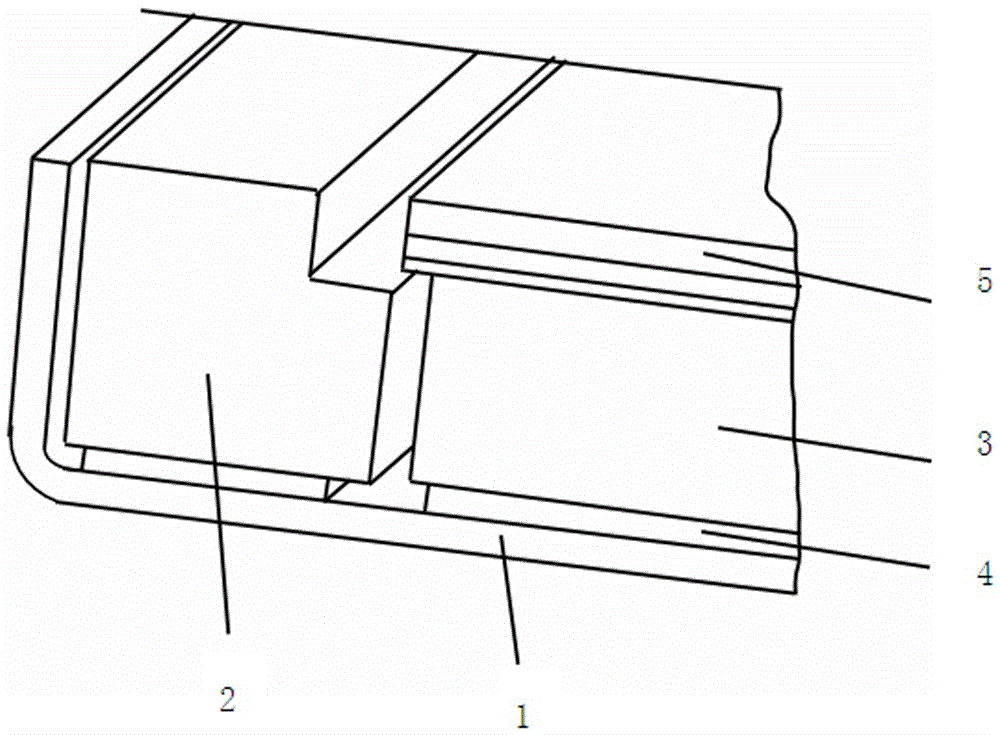

Powder metallurgical brake shoe for railway locomotive

The invention relates to a powder metallurgical brake shoe for a railway locomotive. The brake shoe comprises a brake shoe back and a frictional material block, wherein the brake shoe back comprises a brake shoe nose and a positioning groove; the frictional material block is manufactured by a powder metallurgical process; and the frictional material block and the brake shoe back are directly sintered together at the pressure sintering stage of the powder metallurgical process. The brake shoe is characterized in that: the frictional material block consists of the following components in percentage by weight: 12 to 14 percent of graphite, 3 to 5 percent of copper, 1 to 3 percent of manganese, 1 to 3 percent of chromium, 1 to 3 percent of nickel, 1 to 2 percent of aluminum, 2 to 5 percent of molybdenum disulfide, 2 to 5 percent of mullite, 2 to 4 percent of molybdenum trioxide and the balance of iron. The brake shoe has the advantages of simple structure, short manufacturing process flow and low manufacturing cost. The powder metallurgical brake shoe has a stable friction coefficient, little abrasion and long service life.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com