Carbon-based ceramic brake block and preparing method of carbon-based ceramic brake block

A carbon-based ceramic and brake pad technology, applied in friction linings, mechanical equipment, etc., can solve the problems of high cost, poor high temperature resistance, unreasonable formula, etc., and achieve excellent friction coefficient and wear degree, and the production process flow Short, significant economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

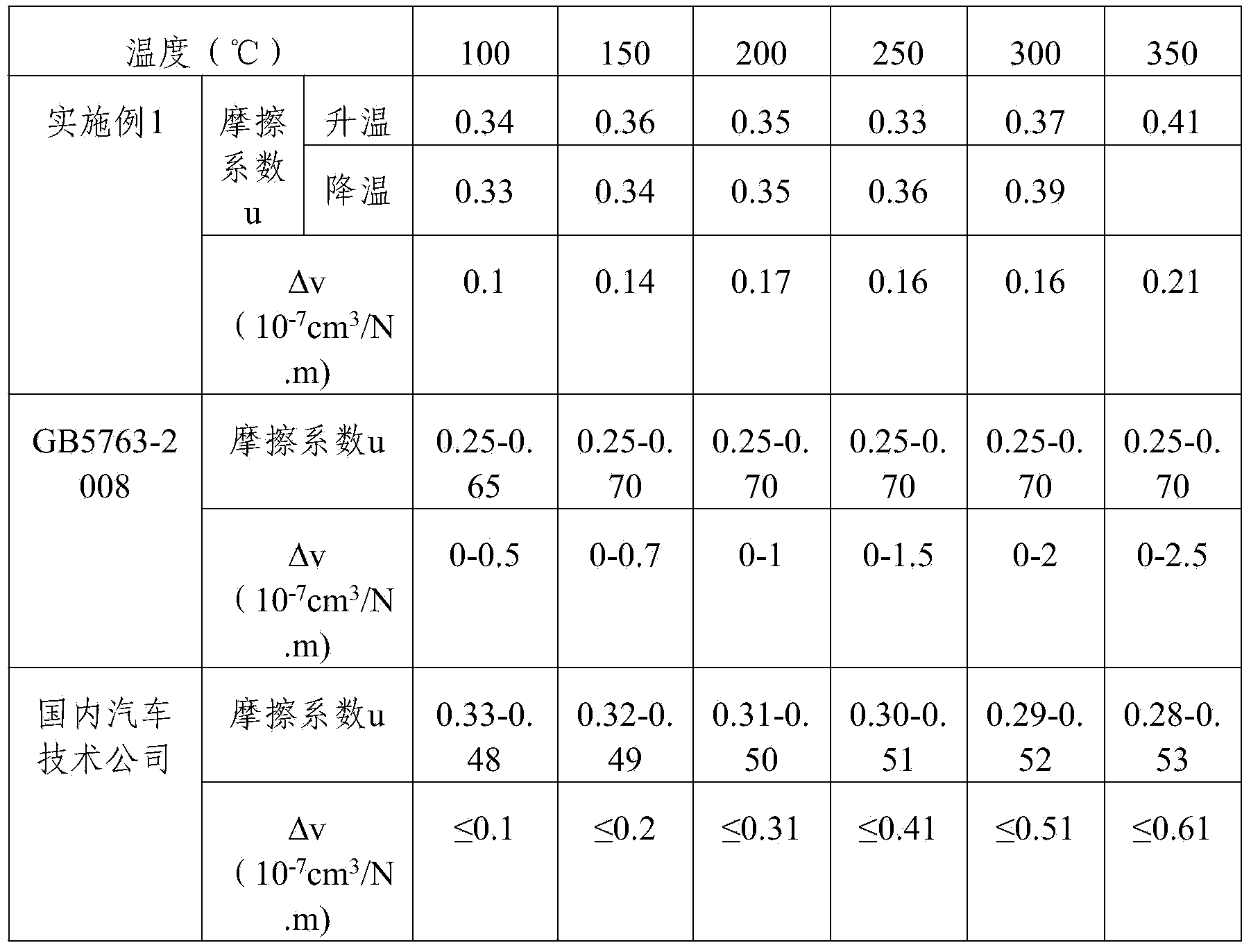

Examples

Embodiment 1

[0033] A carbon-based ceramic brake pad, the raw material ratio is 12kg of carbon fiber, 19kg of ceramic fiber, 1kg of aramid fiber, 8kg of phenolic resin, 8kg of mineral fiber, 15kg of barium sulfate powder, 2.5kg of modified silicon carbide, and 16kg of friction modifier , Inorganic lubricant 6.5kg, organic friction powder 4kg, toughening agent 7kg, improver 4kg.

[0034] Mineral fiber has a coefficient of thermal expansion of 0.1, a coefficient of refraction of 0.1, a melting point of 1750°C, a Mohs hardness of 2.4, a density of 300g / cm3, and a pH of 7.8.

[0035] The organic lubricant is a mixture of 54% calcium fluoride, 16% lithium fluoride, and 30% aluminum oxide, calculated by weight percentage.

[0036] The organic friction powder is graphite.

[0037] The toughening agent is an epoxy resin toughening agent.

[0038] The modifier is TORCO limited slip friction modifier.

[0039] Its preparation method comprises the following steps:

[0040] (1) Mixing of raw mater...

Embodiment 2

[0045] On the basis of Example 1, other steps are the same as Example 1, a carbon-based ceramic brake pad, its raw material components are 11kg of carbon fiber, 14kg of ceramic fiber, 0.5kg of aramid fiber, 7kg of phenolic resin, 7.5kg of mineral fiber, Barium sulfate powder 14kg, modified silicon carbide 2kg, friction modifier 15kg, inorganic lubricant 6kg, organic friction powder 3kg, toughening agent 6kg, modifier 3kg.

[0046] Mineral fiber has a coefficient of thermal expansion of 0.1, a coefficient of refraction of 0.1, a melting point of 1750°C, a Mohs hardness of 2.6, a density of 300g / cm3, and a pH of 7.8.

[0047] The organic friction powder is nano silicon dioxide.

[0048] Its preparation method comprises the following steps:

[0049] (1) Mixing of raw materials: Weigh the above raw materials according to parts by weight, and classify them into fiber materials, resins, light materials, and heavy materials, and mix the classified fiber materials according to parts ...

Embodiment 3

[0055] On the basis of Example 1, other steps are the same as Example 1, a carbon-based ceramic brake pad, its raw material components are 13kg of carbon fiber, 25kg of ceramic fiber, 1.5kg of aramid fiber, 9kg of phenolic resin, 8.5kg of mineral fiber, Barium sulfate powder 16kg, modified silicon carbide 3kg, friction modifier 17kg, inorganic lubricant 7kg, organic friction powder 5kg, toughening agent 8kg, modifier 5kg.

[0056] Mineral fiber has a coefficient of thermal expansion of 0.1, a coefficient of refraction of 0.1, a melting point of 1750°C, a Mohs hardness of 2.5, a density of 300g / cm3, and a pH of 7.8.

[0057] The organic friction powder is nano silicon dioxide.

[0058] Its preparation method comprises the following steps:

[0059] (1) Mixing of raw materials: Weigh the above raw materials according to parts by weight, and classify them into fiber materials, resins, light materials, and heavy materials, and mix the classified fiber materials according to parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com