Patents

Literature

30results about How to "Improve coagulation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-radiation concrete produced from slag aggregate, and production method thereof

InactiveCN103224369ATotal momentum downReduce the degree of stratificationSolid waste managementSlagTackifier

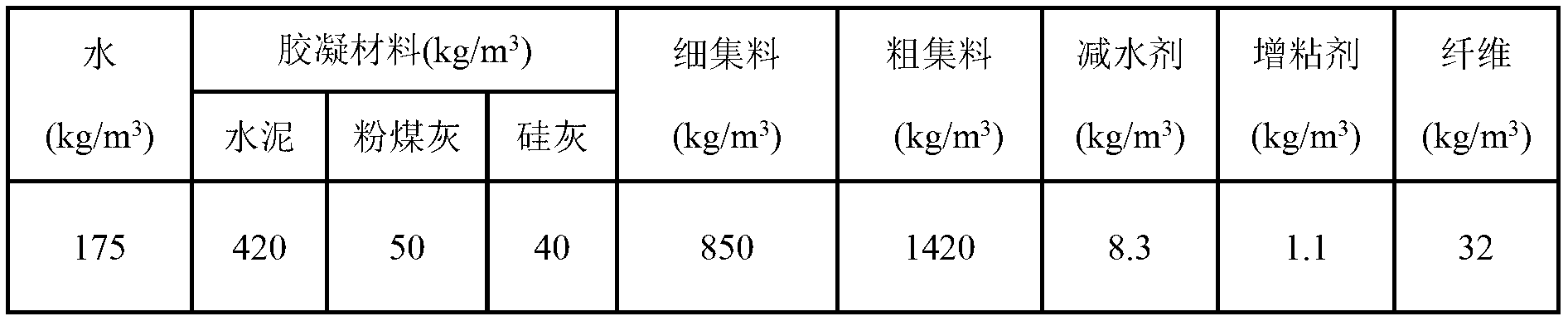

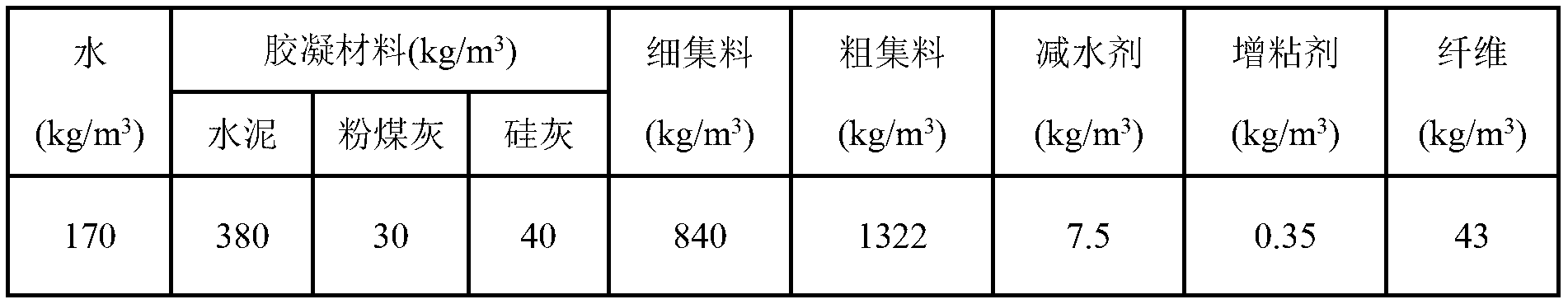

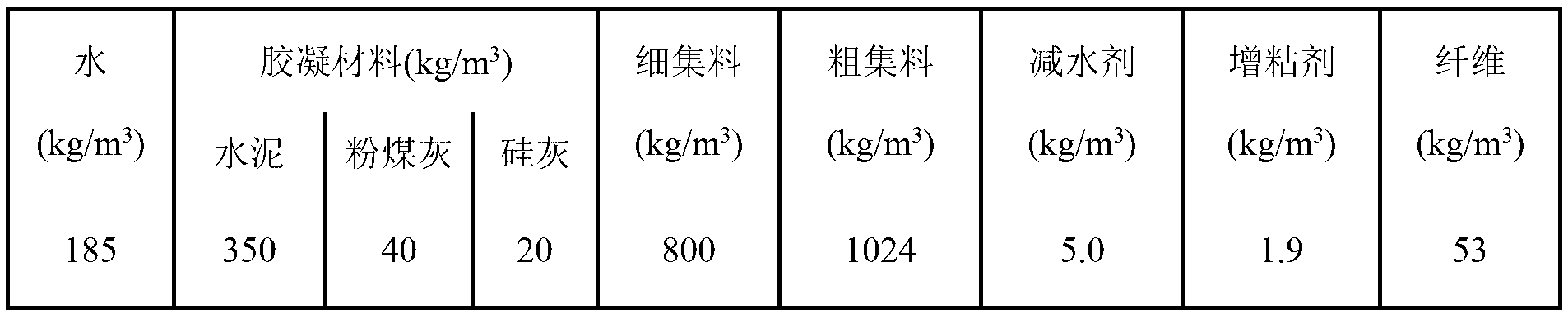

The invention relates to anti-radiation concrete produced from slag aggregate, and a production method thereof so as to effectively consume and utilize mineral waste, and improve an anti-radiation performance and durability of concrete. The anti-radiation concrete produced from slag aggregate comprises the following raw materials, by weight, 140-190 parts of water, 350-630 parts of a cementing material, 750-850 parts of a fine aggregate, 1000-1500 parts of a coarse aggregate, 0.35-1.9 parts of a tackifier, 2.1-7.5 parts of a water reducing agent, and 30-70 parts of fibers, wherein the cementing material comprises cement and a mineral admixture, the mineral admixture comprises silicon ash and fly ash, the cementing material comprises 300-500 parts by weight of the cement, 20-60 parts by weight of the silicon ash and 30-70 parts by weight of the fly ash, the coarse aggregate is a high titanium heavy slag coarse aggregate, the fine aggregate comprises high titanium heavy slag sand and lead powder according to a mass ratio of 1:0.2-3.0, the tackifier is methyl cellulose ether, and the fibers are one or a plurality of material selected from polypropylene fibers, steel fibers and lead fibers.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

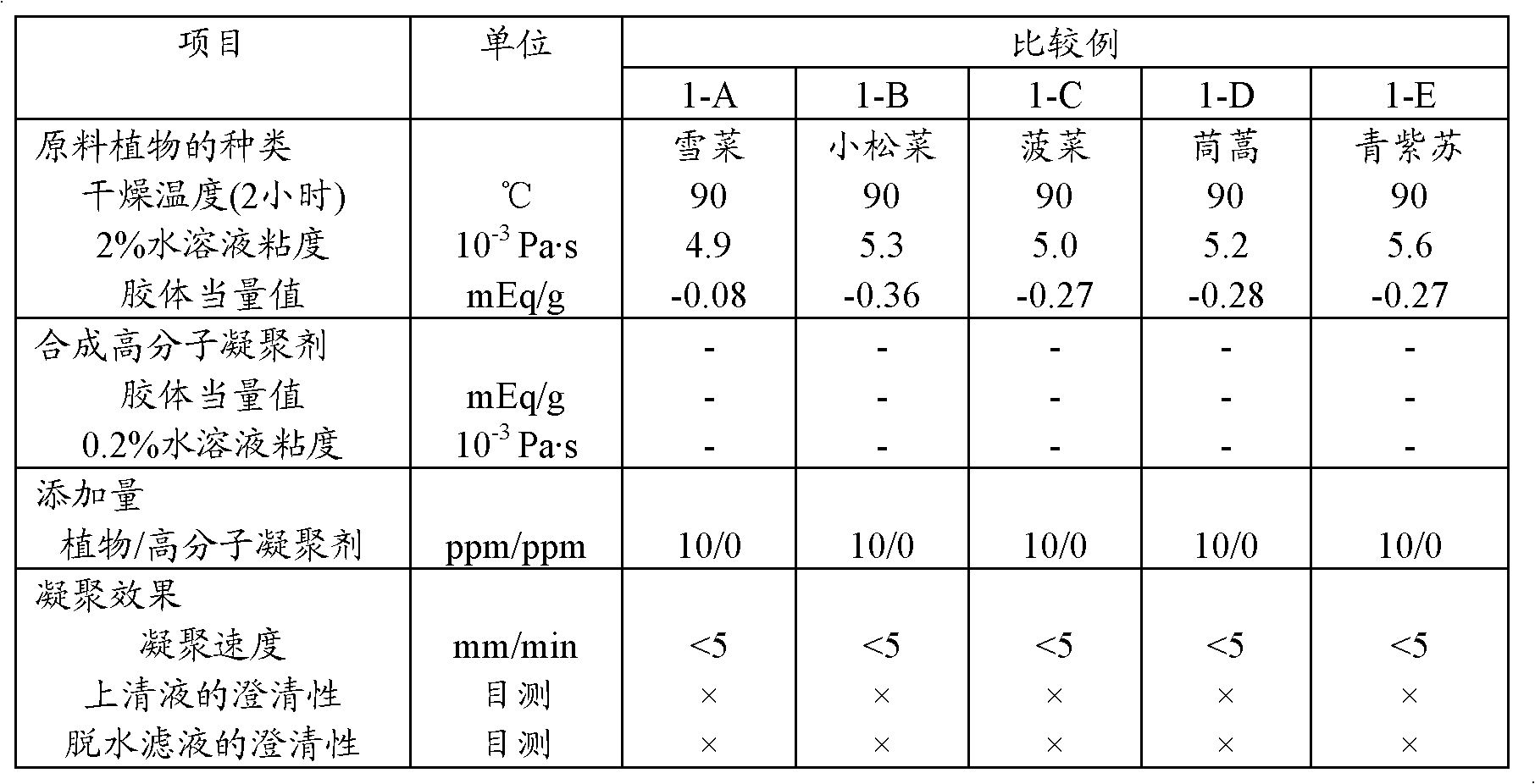

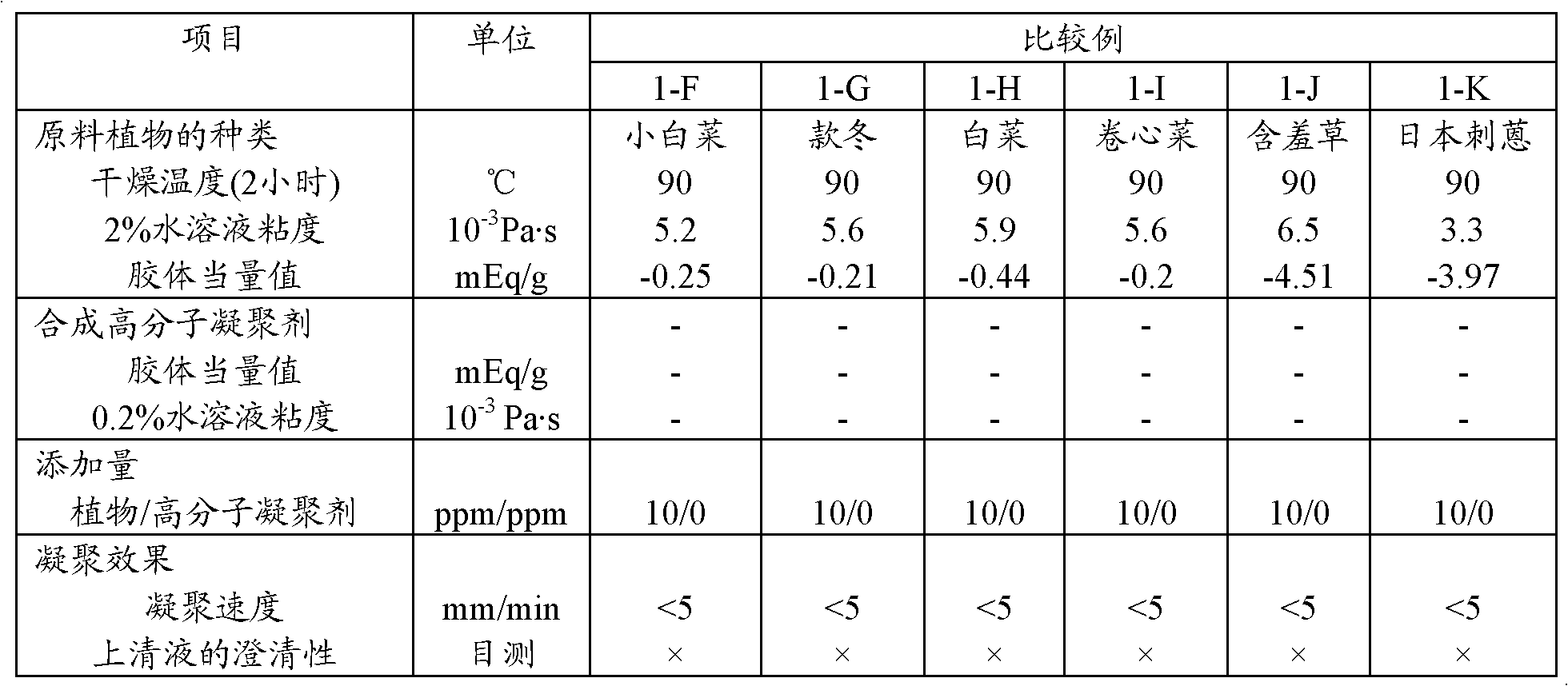

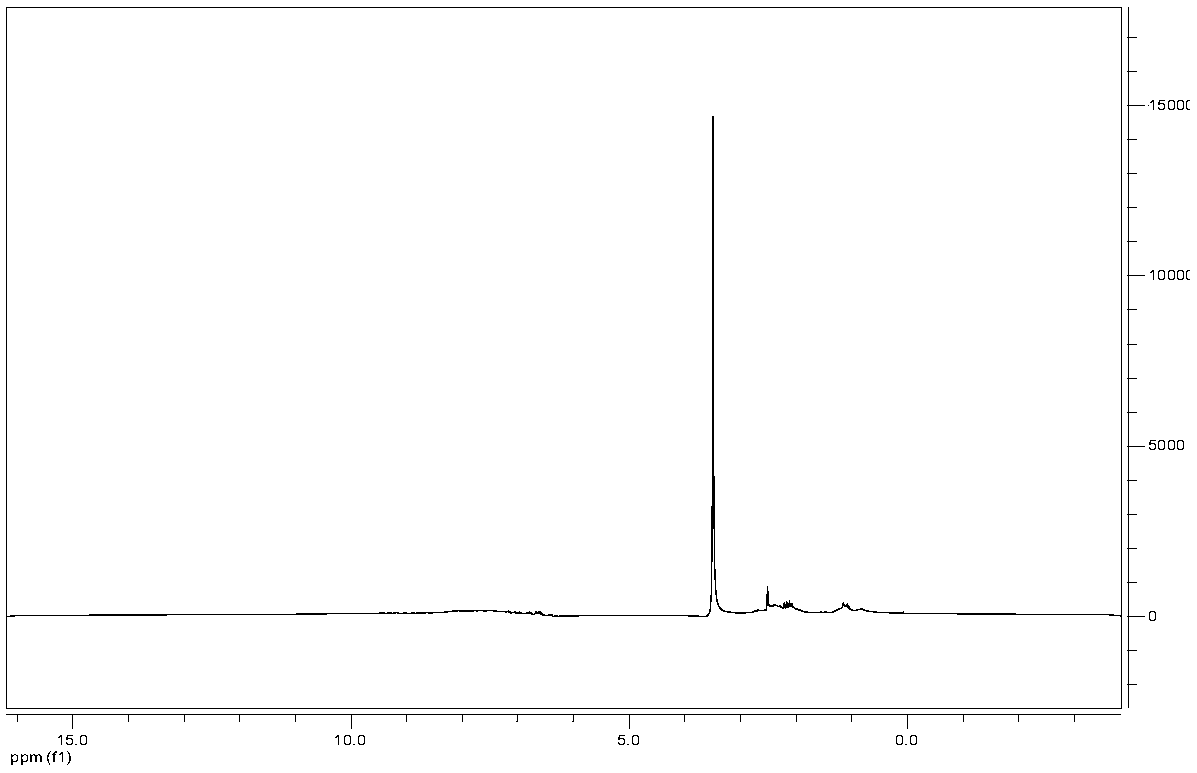

Plant-sourced flocculant, flocculant mixture, condensation method and method for preparing plant-sourced flocculant

ActiveCN102583681AImprove coagulation performanceHigh clarityEnergy based wastewater treatmentWater/sewage treatment by flocculation/precipitationAqueous solutionPlant Sources

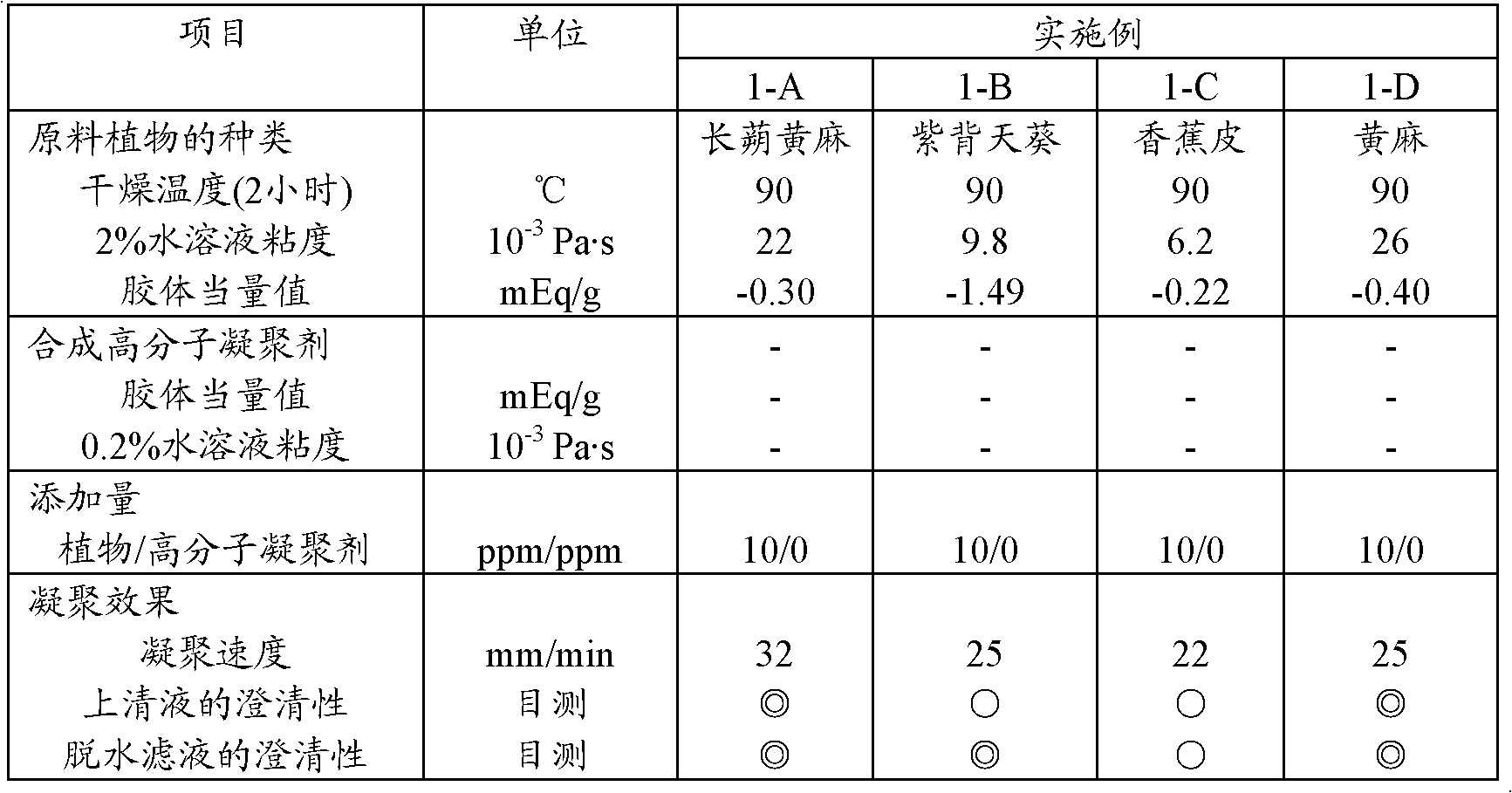

The invention provides plant-sourced flocculant with high condensation capacity and flocculant mixture. An equivalent value of colloid of the plant-sourced flocculant is minus 1.5mEq / g to minus 0.3mEq / g, viscosity of aqueous solution of 2 percent by weight is 6.0 *10<minus3> <Pa.s(6.0cP) or more. In addition, the flocculant mixture comprises the plant-sourced flocculant and synthesized polymer flocculant, and the equivalent value of the colloid of the synthesized polymer flocculant is minus 4.5mEq / g to minus 1.2mEq / g, and the viscosity of the aqueous solution of 0.2 percent by weight is 1.3 *10<minus1Pa.S> to 4*10 <minus1Pa.S> (130cP to 400cP).

Owner:SONY CORP +1

Ardealite substrate wood-like floor and preparation method thereof

The invention relates to the technical field of chemical construction materials, in particular to an ardealite substrate wood-like floor and a preparation method thereof. Due to appreciate preparation of ardealite, yellow phosphorus slag, quick lime, cement, a brine and magnesium oxide mixed liquid, fiber and a wood-like coating in a mixing ratio, ardealite is sufficiently activated, the activity of ardealite is improved, the content of soluble impurities in ardealite is further reduced, and the curing property of ardealite is improved; particularly due to addition of the brine and magnesium oxide mixed liquid, sodium in ardealite can form a product which is hard to dissolve, can be fixed in an ardealite crystal cavity, and then is prevented from being exposed on the surface of an ardealite product, so that the phenomenon that the surface of the ardealite product is powdered because of sodium is avoided, the strength and the quality of the ardealite product are improved, and the property of the ardealite product is improved.

Owner:GUIZHOU KAILIN GRP CO LTD

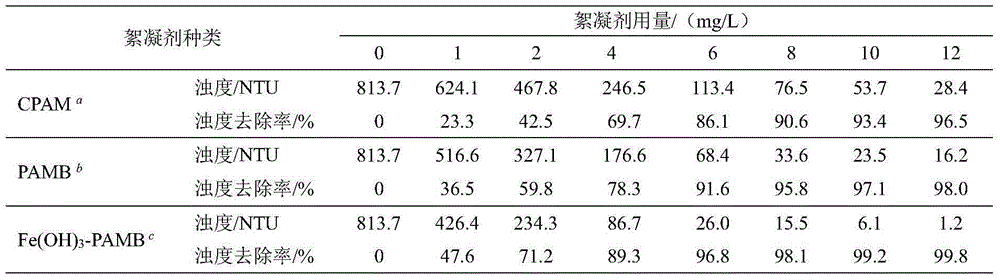

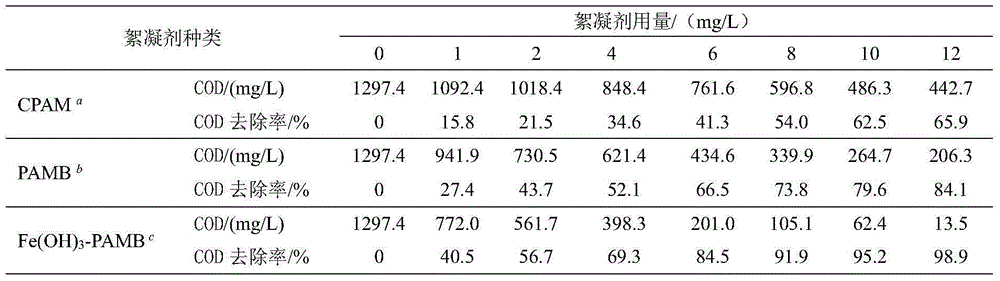

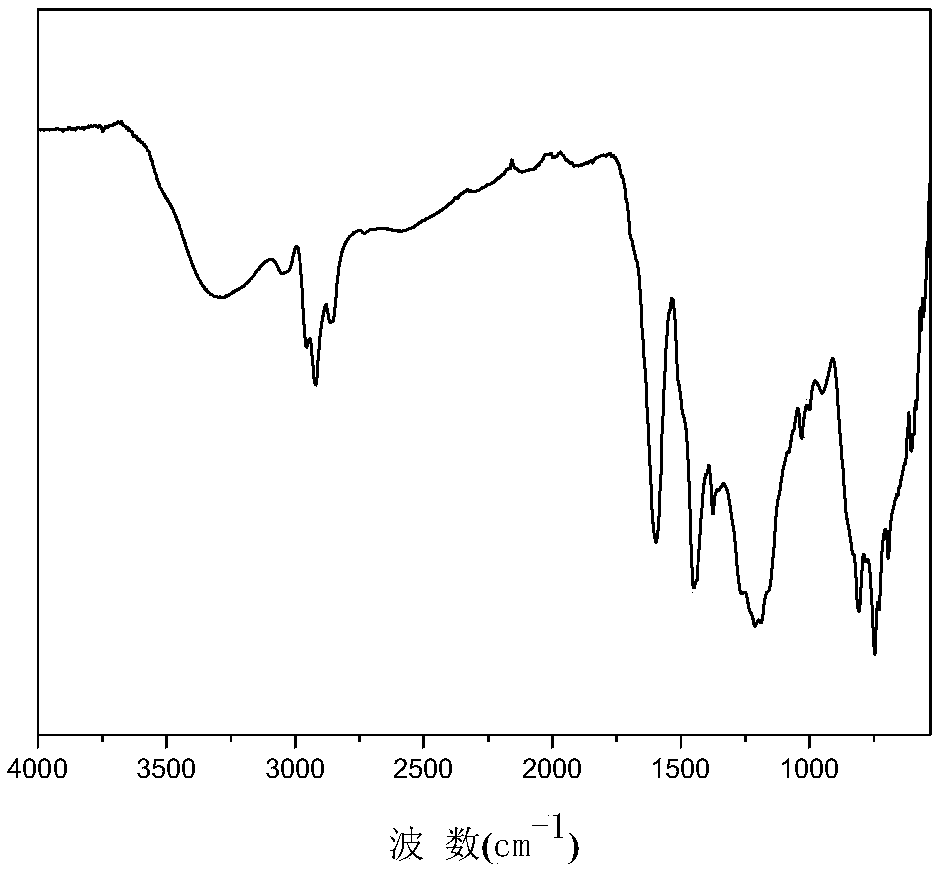

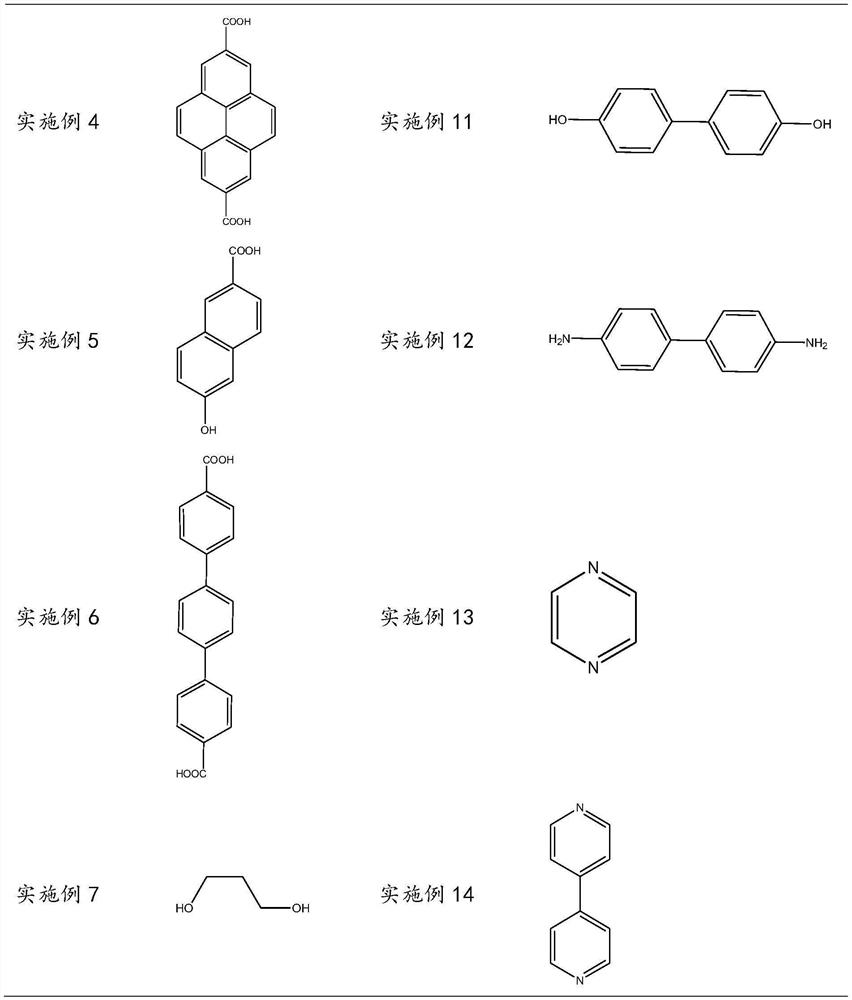

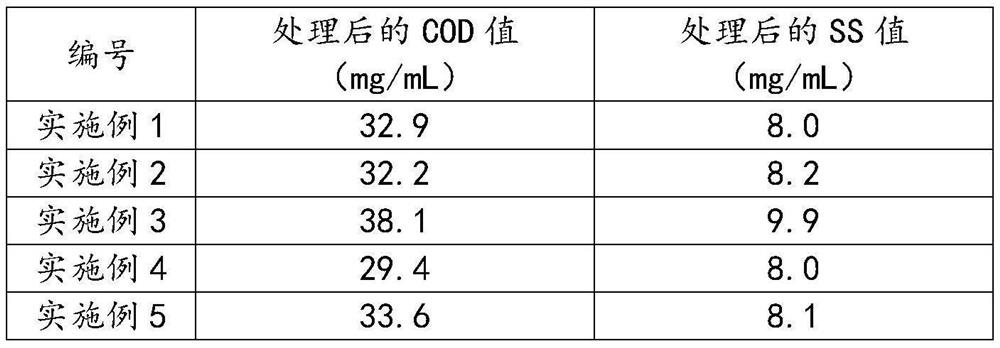

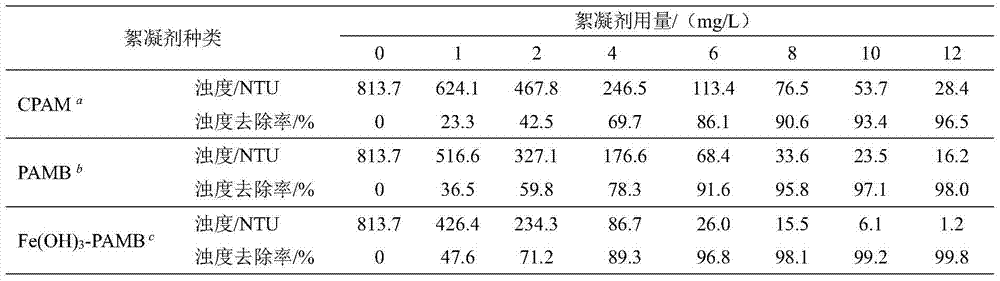

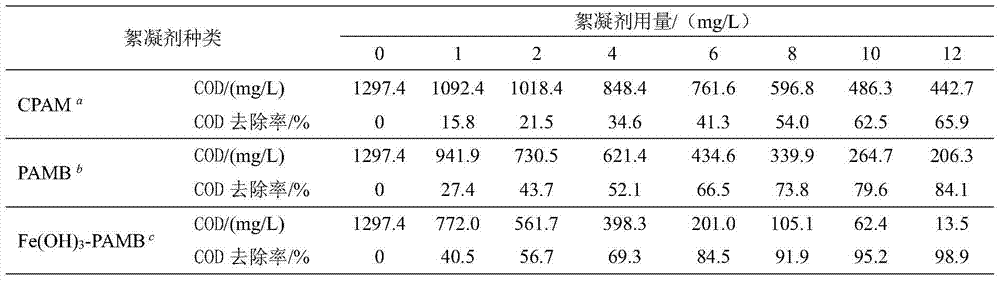

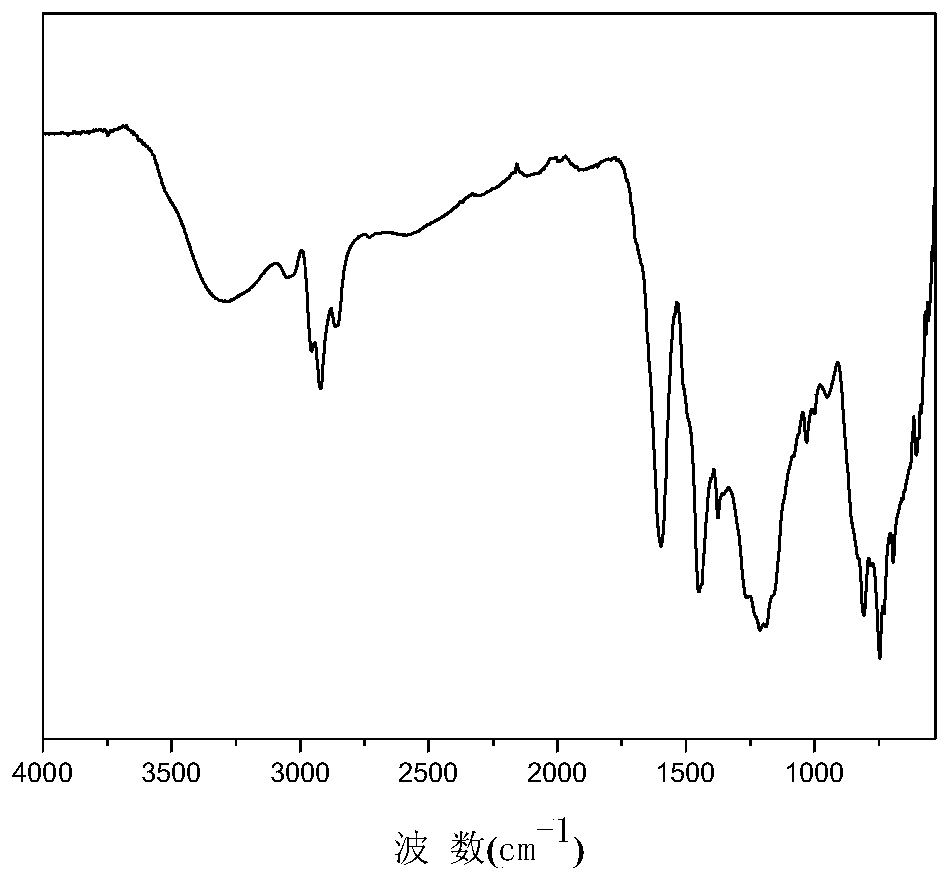

Preparation method of nano-Fe(OH)3-containing acrylamide-grafted copolymer flocculant

InactiveCN105218758AWill not cause secondary pollutionHigh molecular weightWater/sewage treatment by flocculation/precipitationPotassium persulfateReaction temperature

The invention discloses a preparation method of a nano-Fe(OH)3-containing acrylamide-grafted copolymer flocculant. The method is characterized in that 100 mL of a 100 g / L FeCl3 ethylene glycol solution is added to a three-neck reaction flask, 90-300 ml of a 40 g / L NaOH ethylene glycol solution is slowly added in the stirring state, the mixture reacts at the reaction temperature of 120-160 DEG C for 2-4 h in the rapid stirring state and then the product after reaction is cooled to the room temperature, reaction products are centrifugally separated and washed with deionized water, and nano-Fe(OH)3 is prepared; 20 parts of acrylamide are added to the three-neck reaction flask, then 150-600 parts of deionized water and 1.0-12 parts of trimethyl hexadecyl ammonium chloride are added, the mixture is stirred, 0.5-8 parts of the nano-Fe(OH)3 are added in the stirring state, 8-40 parts of cationic monomers and 0.8-10 parts of macromonomers are added, the mixture is stirred for 30 min, the pH value is 5-8, N2 is introduced for 30 min, 0.02-0.6 parts of an initiator, namely, potassium persulfate, is added at the temperature of 50-75 DEG C, the mixture reacts for 8-24 h, and the nano-Fe(OH)3-containing acrylamide-grafted copolymer flocculant Fe(OH)3-PAMB with excellent coagulation performance is prepared.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

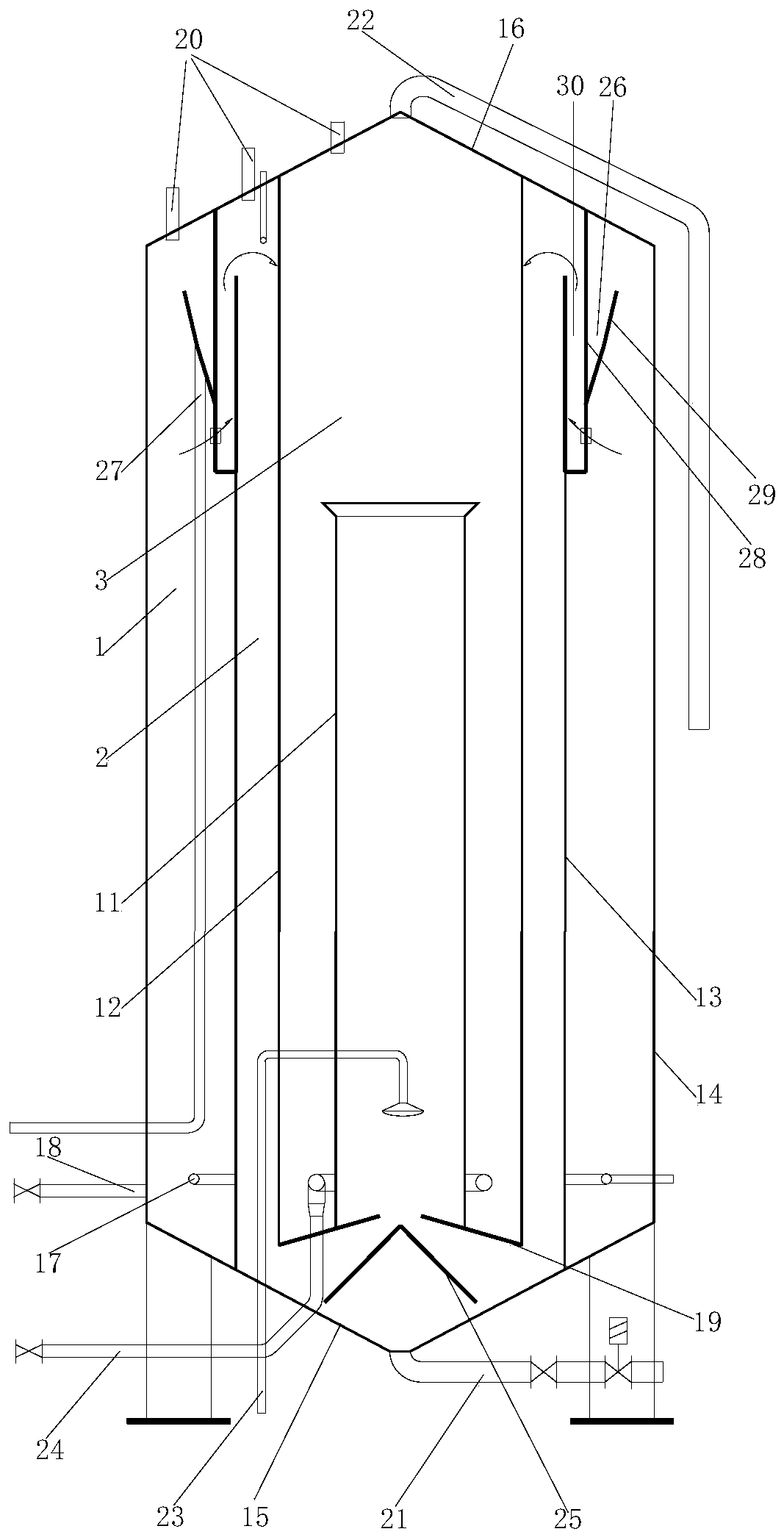

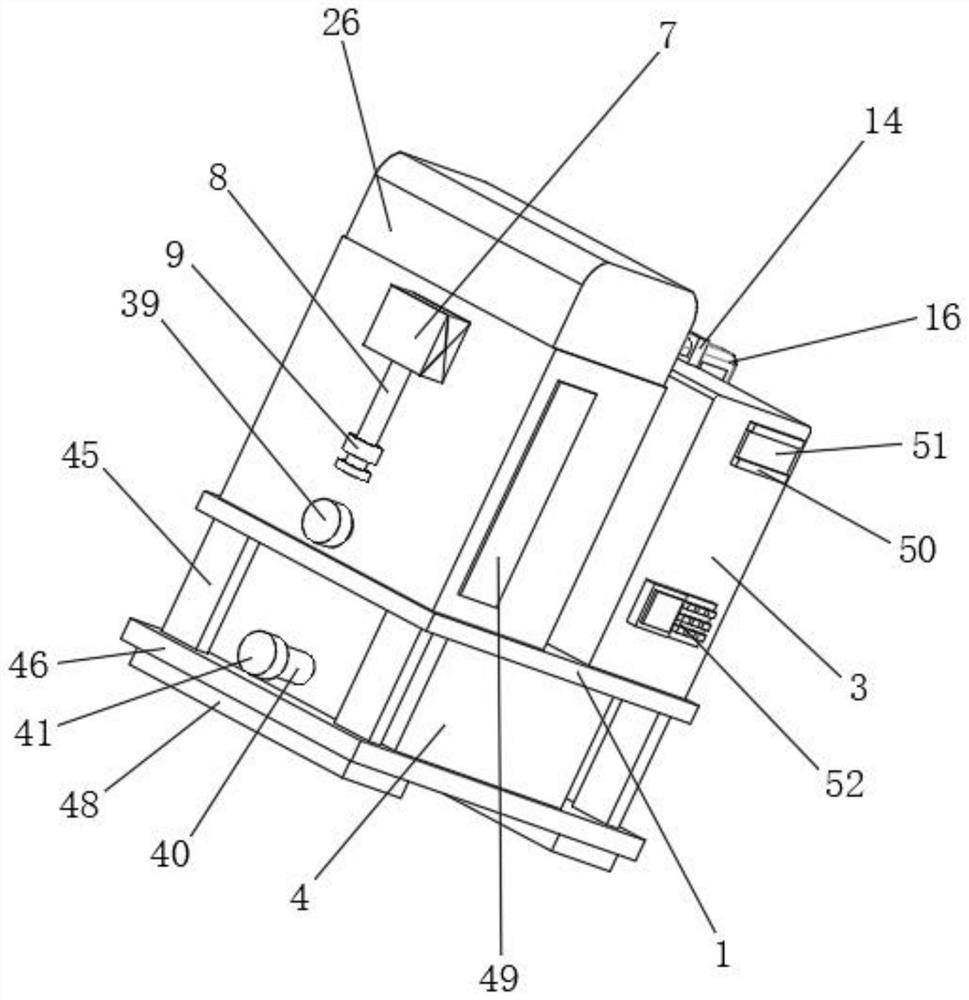

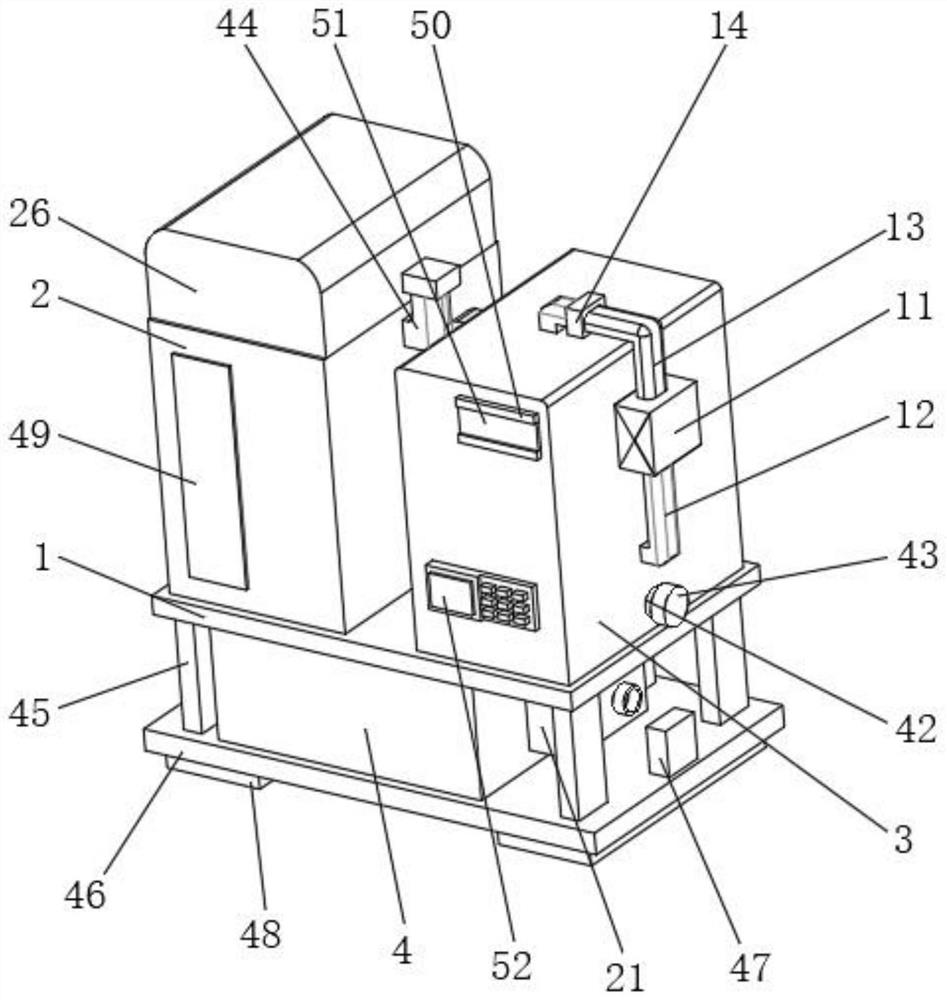

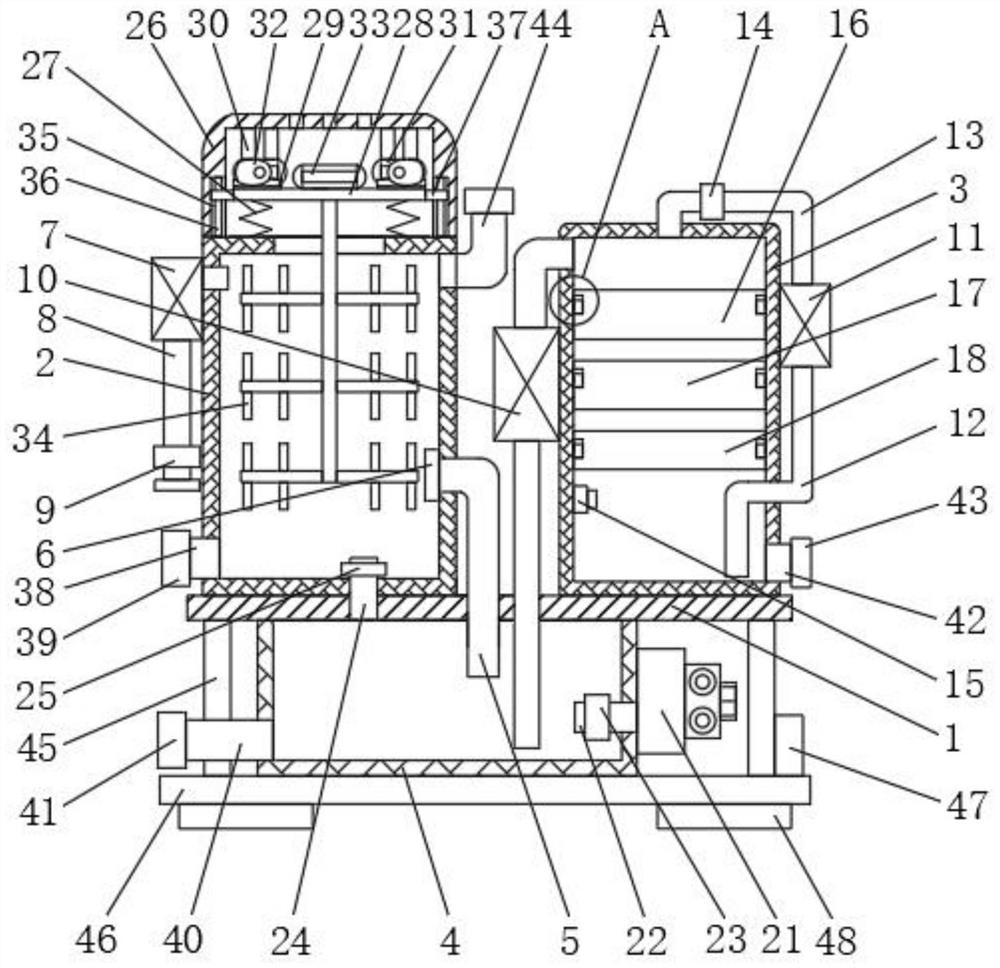

Air floating device having oil-water separation function

PendingCN110240324AImprove coagulation performanceImprove the effect of sewage treatmentFatty/oily/floating substances removal devicesWater treatment compoundsSewageSewage treatment

The invention relates to the technical field of sewage advanced treatment, and provides an air floating device having an oil-water separation function. The device comprises an inner cylinder body and an outer cylinder body which are arranged coaxially, and the inner cylinder body and the outer cylinder body constitute an air floating reaction zone; and the device further comprises an ozone oxidation zone, raw water and ozone are introduced into the ozone oxidation zone, the upper end opening of the ozone oxidation zone is provided with an oil collecting groove, and the oil collecting groove communicates with an oil discharging pipe; and dissolved ozone water is introduced into the lower end opening of the inner cylinder body, and the ozone oxidation zone communicates with the lower end opening of the inner cylinder body. According to the device provided by the invention, the ozone oxidation zone is arranged, ozone is utilized for oil-water separation, and ozone can also be utilized to improve cohesive properties of organic matter, so that wastewater after oil-water separation is conveniently subjected to a coagulation sedimentation reaction before being introduced into the inner cylinder body, and the sewage treatment effect is enhanced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Composite polyaluminum silicate chloride and preparation method thereof

InactiveCN102092827AStrong electrical neutralization abilityEnhanced adsorption and bridging abilityWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateAluminium chloride

The invention discloses composite polyaluminum silicate chloride and a preparation method thereof, belonging to the technical field of preparation of inorganic composite macromolecular flocculants. The composite polyaluminum silicate chloride is prepared by the steps of curing traditional polymeric aluminium chloride at high temperature and compositing with active silica sol, and has the nano Al30 content between 10% and 40%, wherein the proportion of silicon to aluminum is between 0.02-0.5. The composite polyaluminum silicate chloride can exert the high-efficiency electrical neutralization capability of the Al30 and exert a better flocculation effect due to the enhanced adsorption bridging capability, and is beneficial to broadening of application range of flocculants.

Owner:TSINGHUA UNIV

Method for removing heteroatom from coal tar

ActiveCN107739627AReduced stabilityImprove removal effectTar working-up by chemical refiningHeteroatomAsphalt

The invention relates to a method for removing heteroatom from coal tar. The method comprises the following steps: fully mixing coal tar with a multifunctional complexing agent A at a certain temperature, and reacting the mixture; injecting a multifunctional complexing agent B into the mixture to perform oil and water separation, wherein the multifunctional complexing agent A is prepared from 70 to 100mug / g of acid ionic denitrfying agent, 50 to 80mug / g of metal removing agent, 50 to 70mug / g of demulsifying agent, 20 to 40mug / g of synergist and 3 to 10 percent by weight of water; the multifunctional complexing agent B is prepared from 60 to 80mumg / g of asphalt fluctuating agent, 10 to 30mug / g of accelerant and 50 to 70mug / g of dispersing agent. Counted by the total weight of the coal tar,non-metal nitride and heavy asphaltene can be removed from the coal tar specially, and the removing rates are 75 percent and 21 percent respectively; moreover, metal ion iron calcium and ash can be removed effectively, the removing rate is 95 percent or more basically, and the treated coal tar can meet the requirement on subsequent deep processing.

Owner:NORTHWEST UNIV(CN)

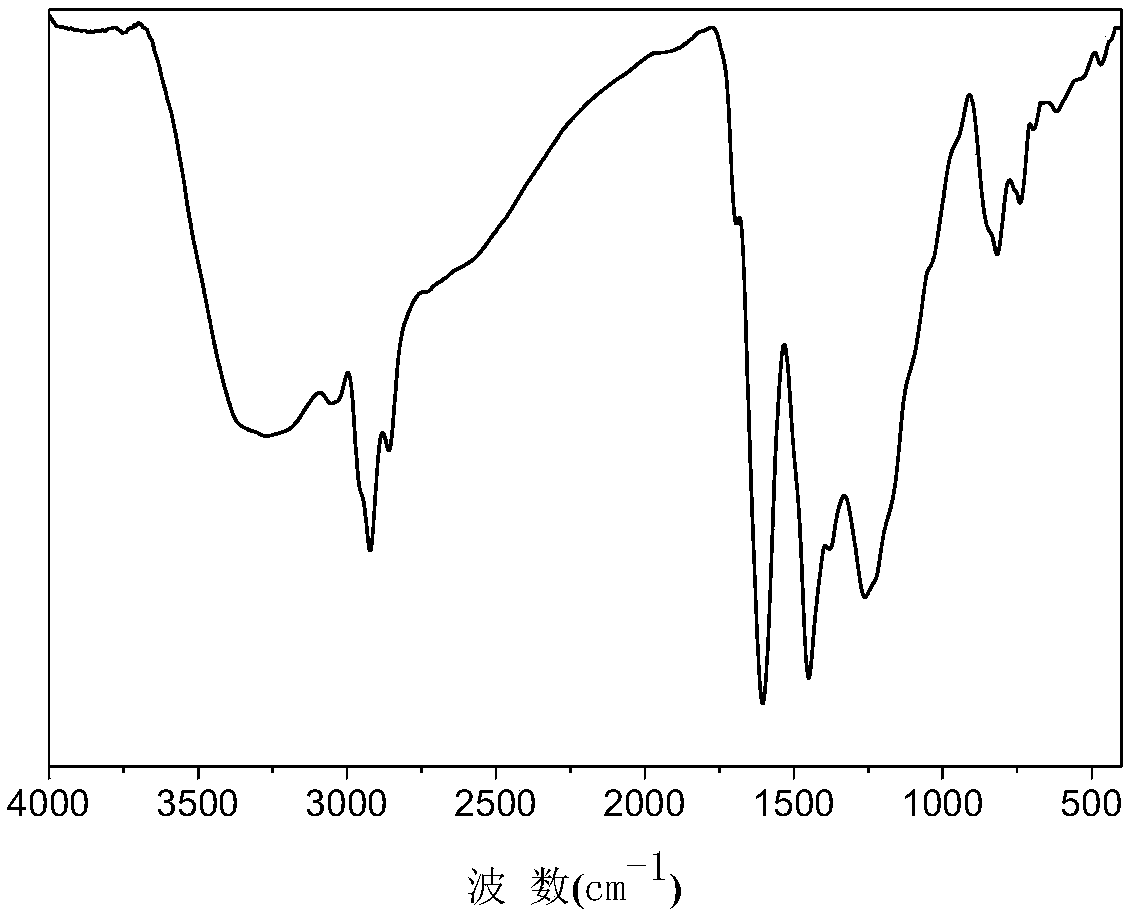

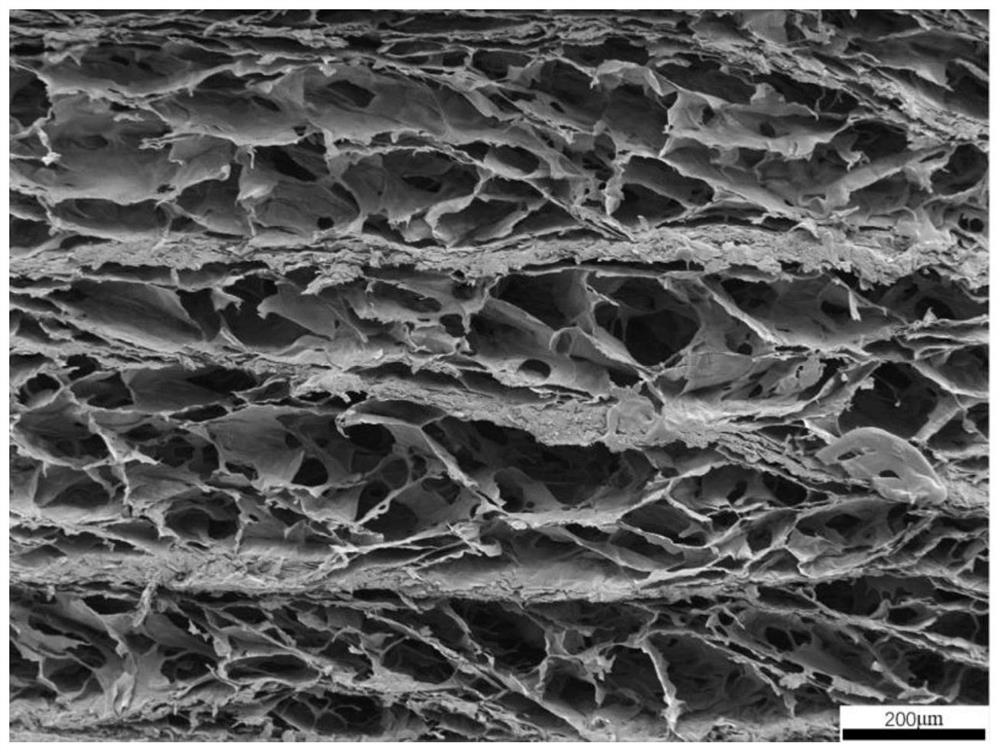

Preparation method and application of porous material assembled by graphene oxide and chitosan molecules

ActiveCN112321885AImprove coagulation performanceGood antibacterial propertiesSurgical adhesivesAbsorbent padsPolymer chemistryGraphite oxide

The invention discloses a porous material based on graphene oxide and chitosan molecule assembly, and also discloses a preparation method of the porous material based on graphene oxide and chitosan molecule assembly, which comprises the following steps: adding a graphene oxide aqueous solution into a chitosan aqueous dispersion, carrying out interface self-assembly, adding a cross-linking agent, adding an acid solution for treatment, and performing freeze drying to obtain the porous material of the cross-linked graphene oxide chitosan. The hemostatic material is prepared by crosslinking and compounding the graphene and the chitosan by using the crosslinking agent, so that the mechanical strength of chitosan macromolecules is improved, and the hemostatic performance and the antibacterial effect of the hemostatic material are also improved.

Owner:FANGDA CARBON NEW MATERIAL CO LTD +1

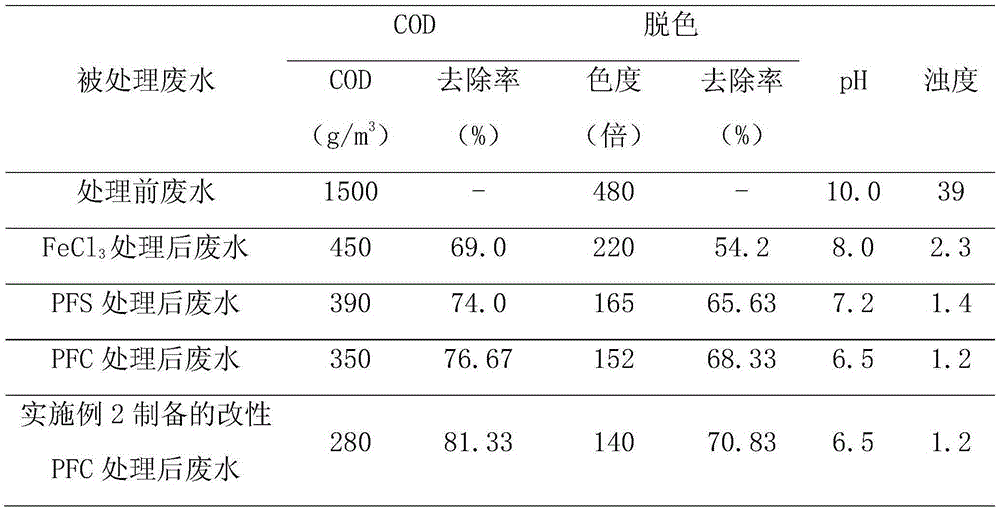

Preparation method of modified poly(iron chloride)

InactiveCN105236544ASolve pollutionRaw materials are easy to getWater/sewage treatment by flocculation/precipitationChemical oxygen demandPhosphate

The invention relates to a preparation method of modified poly(iron chloride). The preparation method is characterized by comprising the following steps: adding iron-containing waste hydrochloric acid and phosphate into a reactor, stirring, adding an oxidizing agent to carry out oxidation polymerization reactions for half hour, then adding a stabilizing retarder, and carrying on reactions for another half hour to obtain the modified poly(iron chloride) coagulant. The preparation method has the advantages that the resources are recycled, the raw materials are easily-available, the operation is simple, the production is safe and environment-friendly, the coagulation performance is excellent, and the modified poly(iron chloride) coagulant can be widely applied to sewage treatment, effectively remove soluble phosphor and phosphor in other forms in water, and reduce the chemical oxygen demand (COD) and chroma.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

Multi-core aluminium-poly (silicon-phosphorus) aluminum chloride and production method thereof

ActiveCN101538081AImprove performanceMass storageWater/sewage treatment by flocculation/precipitationLiquid productAluminium hydroxide

The invention relates to a water treatment agent, in particular to a surface water treatment agent used for drinking water, which adopts multi-core aluminium-poly (silicon-phosphorus) aluminum chloride. The water treatment agent is prepared by taking industrial synthetic hydrochloric acid, aluminium hydroxide, calcium aluminate powder, phosphate rock powder or phosphorus pentoxide, silicon oxide and water as raw materials, and becomes liquid product after liquid residue reparation. As the molecular weight, the quantity of electric charge and the intensity of multi-core aluminium are all larger than those of poly-aluminum chloride, the coagulation property thereof is much better than that of the common poly-aluminum chloride, and the adding amount can be saved by 30 to 50 percent. The water treatment agent has good fluidity, stable performance and long-term storage. As the technology is simple and the cost performance is high, the water treatment agent can be industrially produced in larger scale.

Owner:浙江嘉灵环保科技有限公司

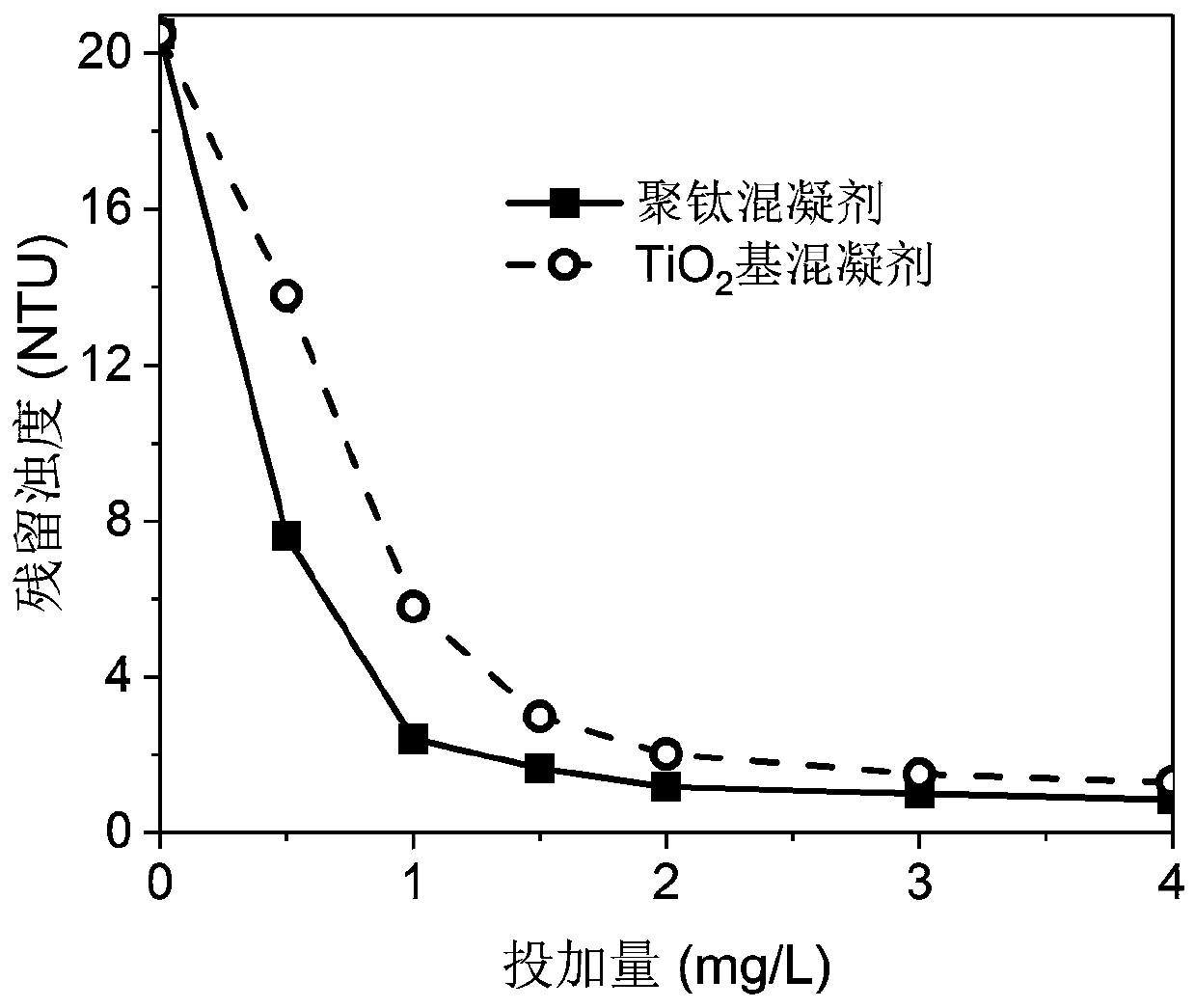

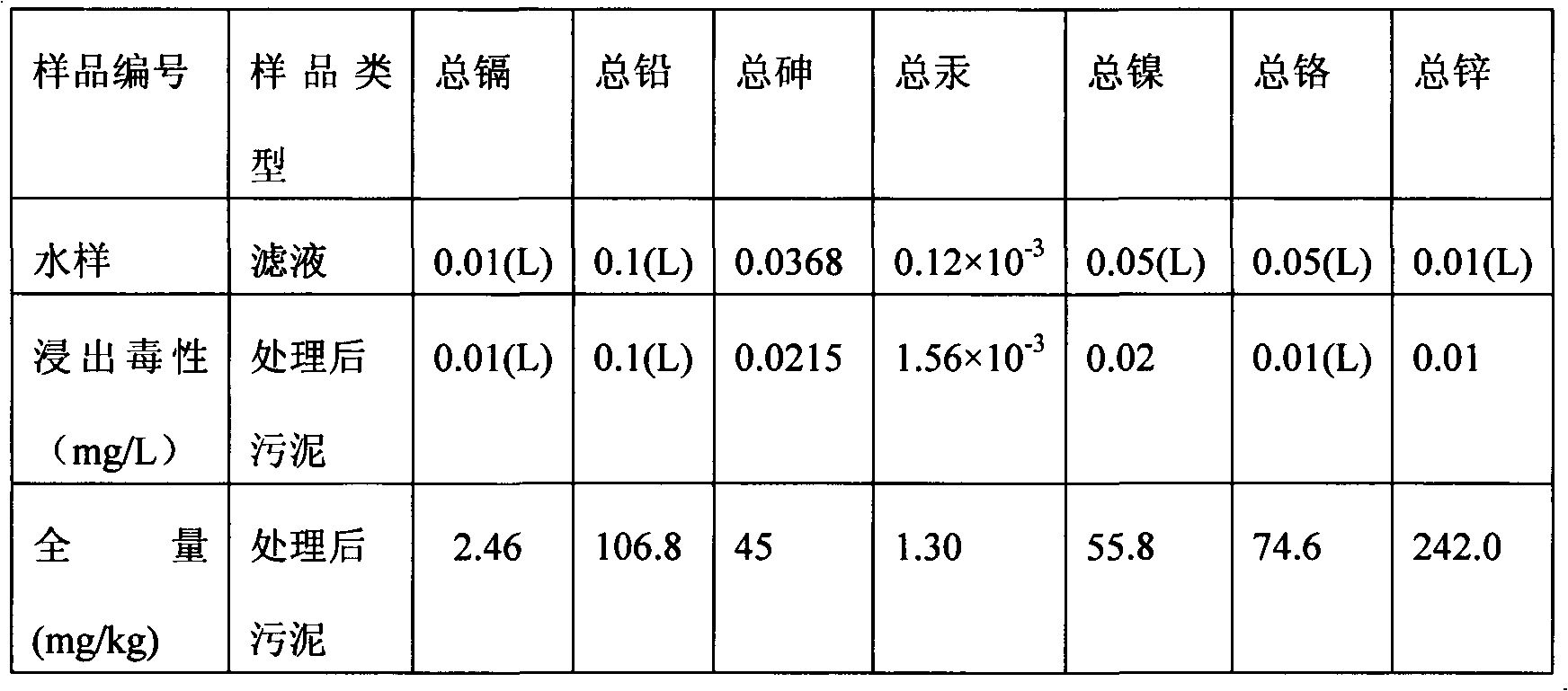

Method for preparing polytitanium coagulant and application thereof

InactiveCN111115783AStable manufacturingImprove solubilityWater contaminantsWater/sewage treatment by flocculation/precipitationAlcoholPhysical chemistry

The invention discloses a method for preparing a polytitanium coagulant and application thereof. The method comprises the following specific steps: (1) uniformly mixing alcohol and an organic chelating agent, and adding organic titanium alkoxide; (2) mixing deionized water, acid and alcohol, adding the mixed liquid into (1), and performing stirring to obtain a mixed solution; and (3) drying the mixed solution in the step (2) to obtain the polytitanium coagulant. The preparation method of the polytitanium coagulant provided by the invention is mild and controllable in process, and the problem that the polytitanium coagulant is difficult to quickly and stably prepare is solved; besides, the polytitanium coagulant obtained by adopting the method has the excellent coagulation performance, canbe applied to removal of turbidity and heavy metals in wastewater, especially low-temperature low-turbidity water, high-salt wastewater, arsenic-containing and antimony-containing wastewater and the like, has low concentration of residual metals after coagulation and mild pH value of effluent, and is beneficial to operation of subsequent treatment units.

Owner:NANJING UNIV

Double-formulation polysilicate coagulant preparation method

InactiveCN1800015AGood coagulation effectStrong adsorption and bridging abilitySilicon compoundsWater/sewage treatment by flocculation/precipitationChemistryDosage form

The invention discloses a making method of two-agent typed polysilicate coagulant, which comprises the following steps: diluting one or more metal salt and or polymeric metal salt solution by water to produce 5-15 percent weight density at metal elemental unit; adjusting the pH value through inorganic acid as agent A; diluting the solution with silicon material by water to produce 2-10 percent weight density at SiO2 unit as agent B; packing agent A and B separately; mixing agent A and B evenly to produce the molar rate at 1:0.5-5.0 for silica dioxide and metal; obtaining the final polysilicate coagulant. The invention can produce excellent property of polysilicate coagulant with impurity-removing and high decolouring efficiency, which forms rapid and dense floccules.

Owner:WUYI UNIV

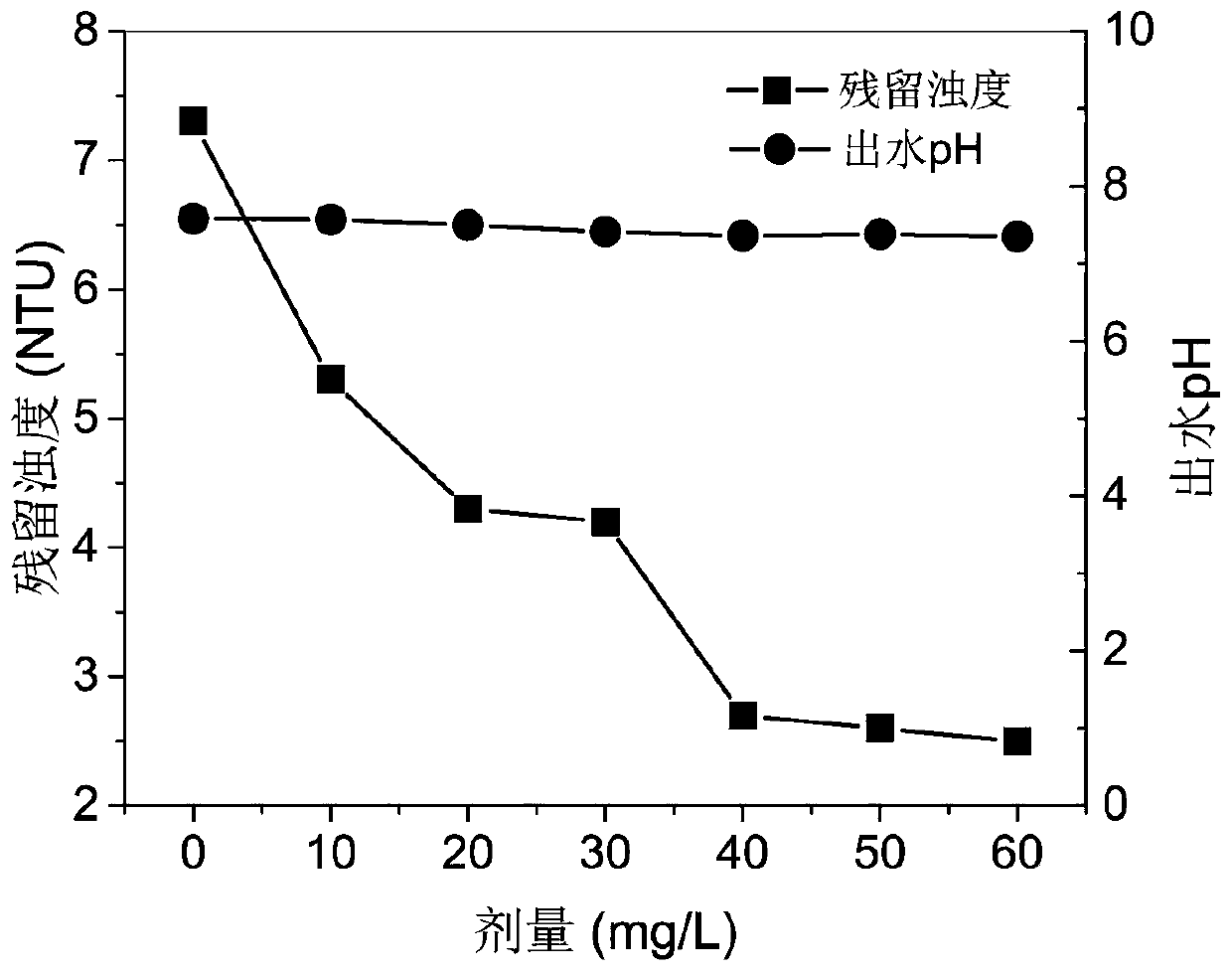

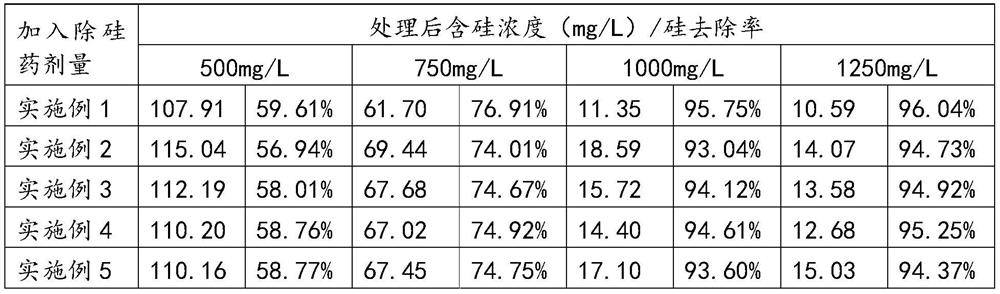

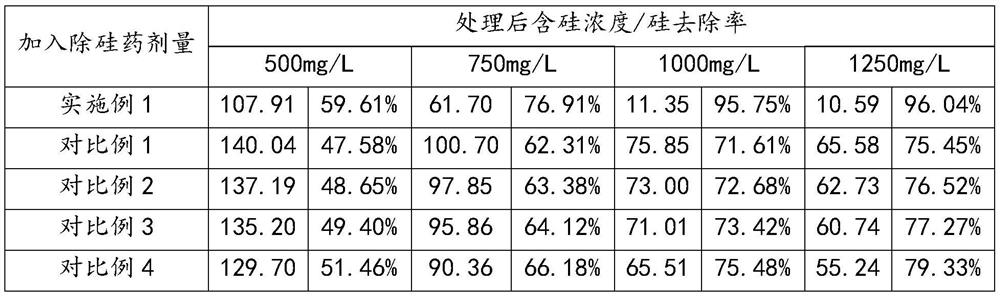

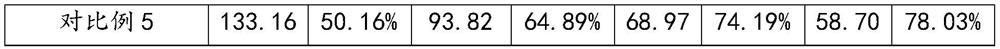

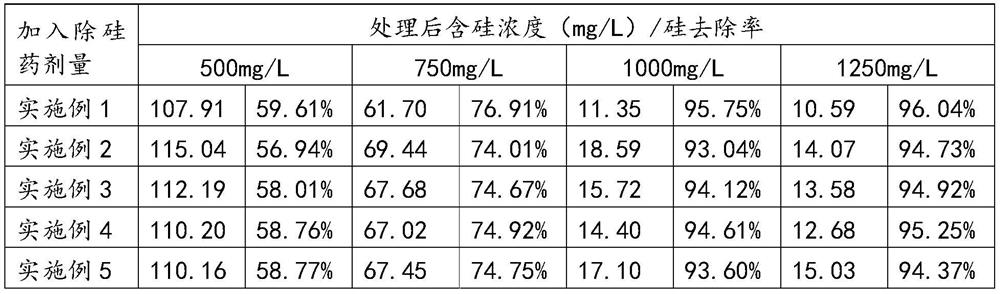

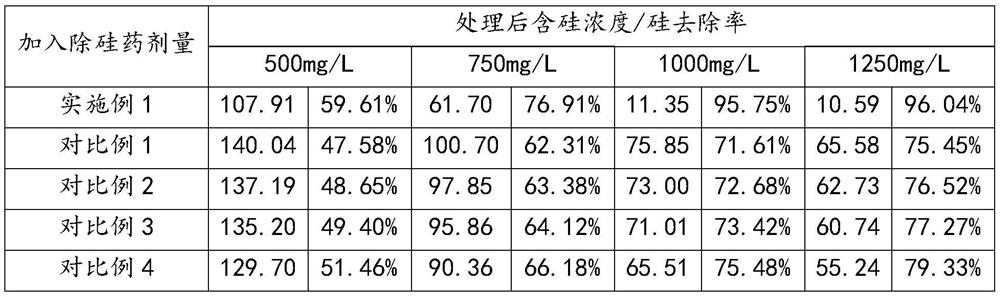

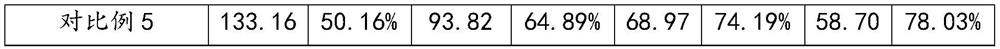

Silicon removal agent and preparation method and application thereof

ActiveCN112062249AGood removal effectImprove coagulation performanceWater/sewage treatment by flocculation/precipitationAluminium chlorideIron sulfate

The invention provides a silicon removal agent and a preparation method and application thereof, and belongs to the technical field of silicon-containing sewage treatment. The silicon removal agent comprises the following components in parts by weight: 73-77 parts of polyaluminum chloride, 10-14 parts of sodium metaaluminate, 4-8 parts of polyaluminum sulfate, 3-7 parts of polyferric sulfate and 1-3 parts of activated aluminum oxide. After the silicon-containing sewage is treated by adopting the silicon removal agent, the soluble silicon in the sewage is reduced to a certain degree, the recycling of the sewage is not influenced, near-zero emission is achieved, and the silicon removal agent has multiple effects of silicon removal, coagulation, turbidity removal and the like. The silicon removal agent is high in purity, less in impurity, less in dosage, low in sludge amount, high in silicon removal efficiency, free from influence of water quality change of sewage, very high in operationstability, low in operation cost and safe and convenient to operate.

Owner:神美科技有限公司

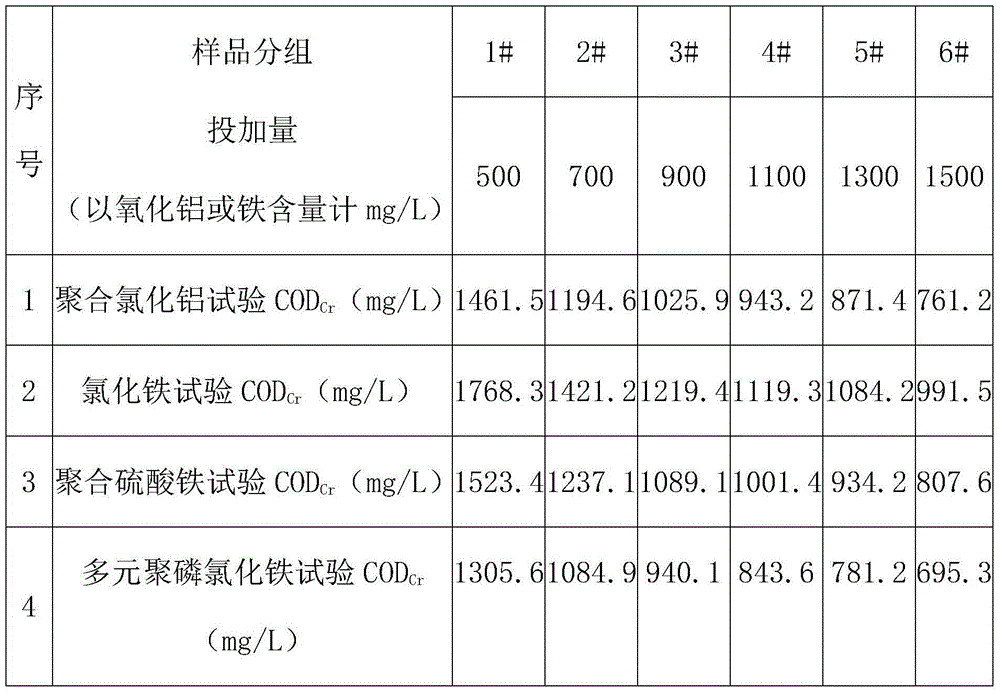

Multielement polyphosphate ferric chloride coagulant and preparation method thereof

InactiveCN103951022AHigh removal rateIncreased effective active ingredientsWater/sewage treatment by flocculation/precipitationChemistryHigh concentration

The invention discloses a multielement polyphosphate ferric chloride coagulant and a preparation method thereof. The coagulant consists of the following raw materials by weight: 180 parts of steel hydrochloric acid washing liquid, 100 parts of iron powder, 300 parts of hydrochloric acid, 395 parts of water, 10 parts of a sodium chlorate oxidation agent and 5 parts of an auxiliary agent, 5 parts of trisodium phosphate and 5 parts of yam glue. The invention has the following advantages: a novel product added with the organic natural flocculant has water purification capacity increased by 5-10% than usual poly ferric chloride; and the novel product added with phosphate delays hydrolysis reaction of Fe<3+>, prevents generation of sediment, and solves the weakness of unstable storage of a high-concentration old product, so as to ensure the stability of the product.

Owner:JIASHAN LVYE ENVIRONMENTAL PROTECTION MATERIAL FACTORY

Composite polyaluminum silicate chloride and preparation method thereof

InactiveCN102092827BImprove adsorption bridging effectImprove coagulation performanceWater/sewage treatment by flocculation/precipitationAluminium chlorideFlocculation

The invention discloses composite polyaluminum silicate chloride and a preparation method thereof, belonging to the technical field of preparation of inorganic composite macromolecular flocculants. The composite polyaluminum silicate chloride is prepared by the steps of curing traditional polymeric aluminium chloride at high temperature and compositing with active silica sol, and has the nano Al30 content between 10% and 40%, wherein the proportion of silicon to aluminum is between 0.02-0.5. The composite polyaluminum silicate chloride can exert the high-efficiency electrical neutralization capability of the Al30 and exert a better flocculation effect due to the enhanced adsorption bridging capability, and is beneficial to broadening of application range of flocculants.

Owner:TSINGHUA UNIV

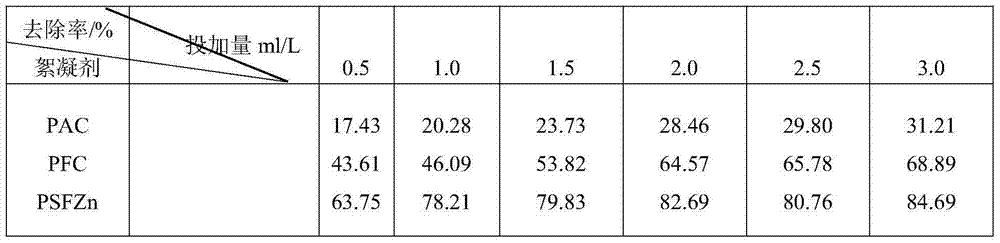

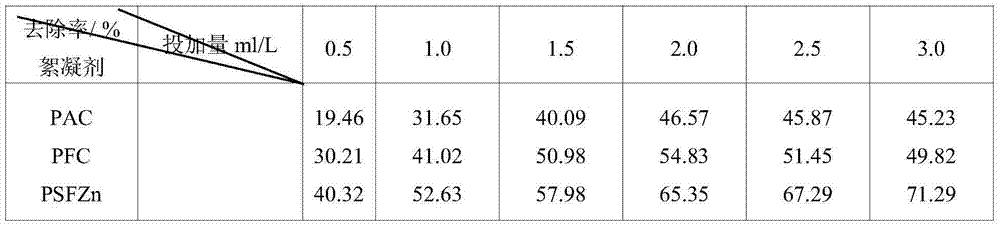

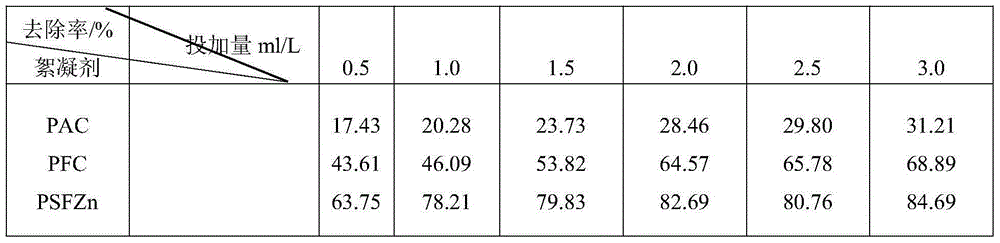

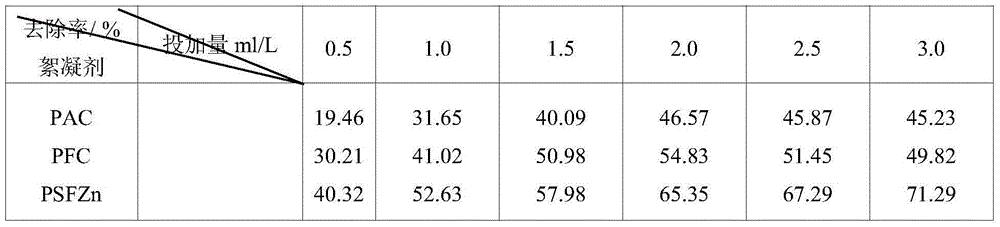

Flocculant for purifying landscape water and preparation method of flocculant

InactiveCN103936118AImprove stabilityEasy to storeWater/sewage treatment by flocculation/precipitationSodium bicarbonateSulfate

The invention provides a flocculant for purifying landscape water and a preparation method of the flocculant. The flocculant is used for improving the quality of landscape water in cities, parks, residential districts and the like, and the flocculant disclosed by the invention is a flocculant PSFZn which is low in preparation raw material, simple in process, safe and efficient. The flocculant is prepared from the following raw materials in percentage by weight: 15-30% of sodium silicate, 1-8% of ferric chloride, 2-4% of zinc sulfate, 10-20% of a dilute hydrochloric acid, 1-10% of sodium bicarbonate and the balance of deionized water, wherein the mass concentration of the dilute hydrochloric acid is 10%, and the silica content of sodium silicate is 21-25%.

Owner:江苏立能环保水处理工程有限公司

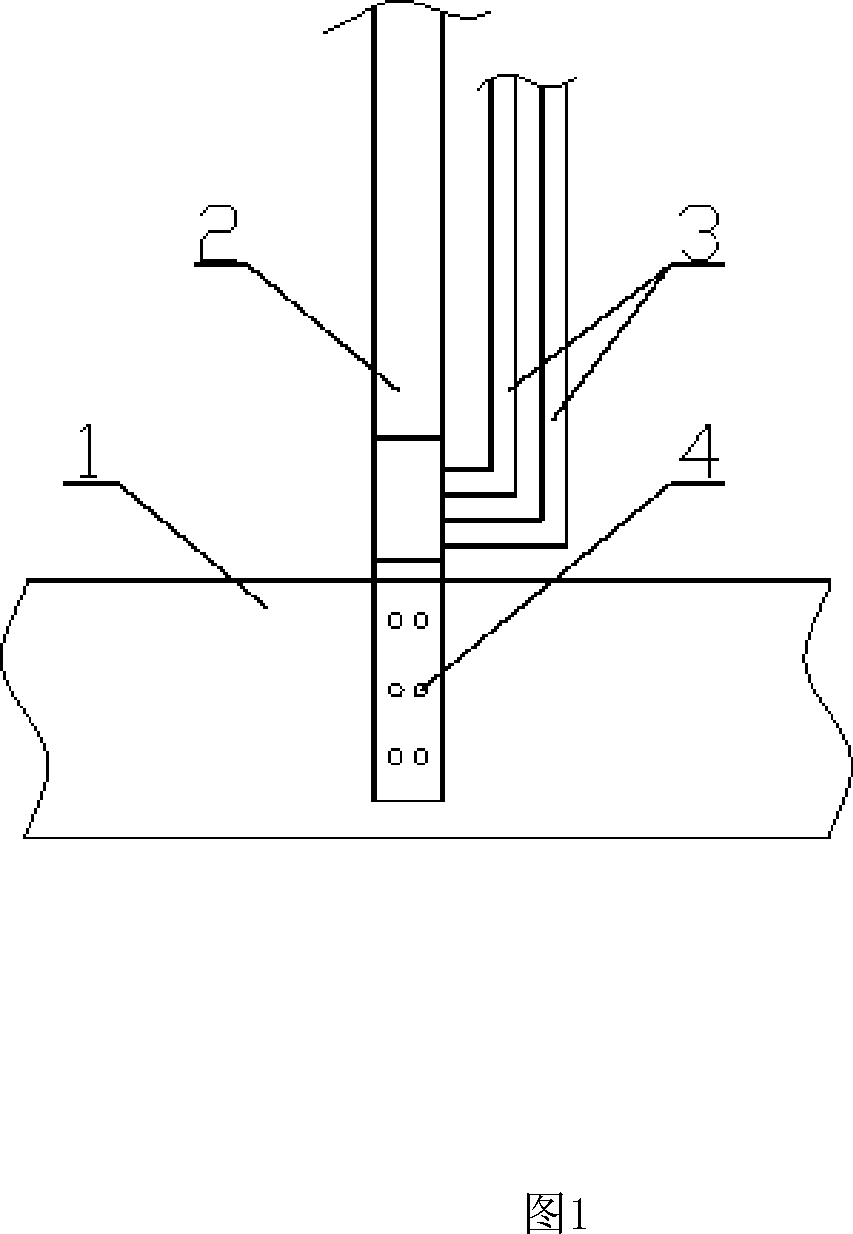

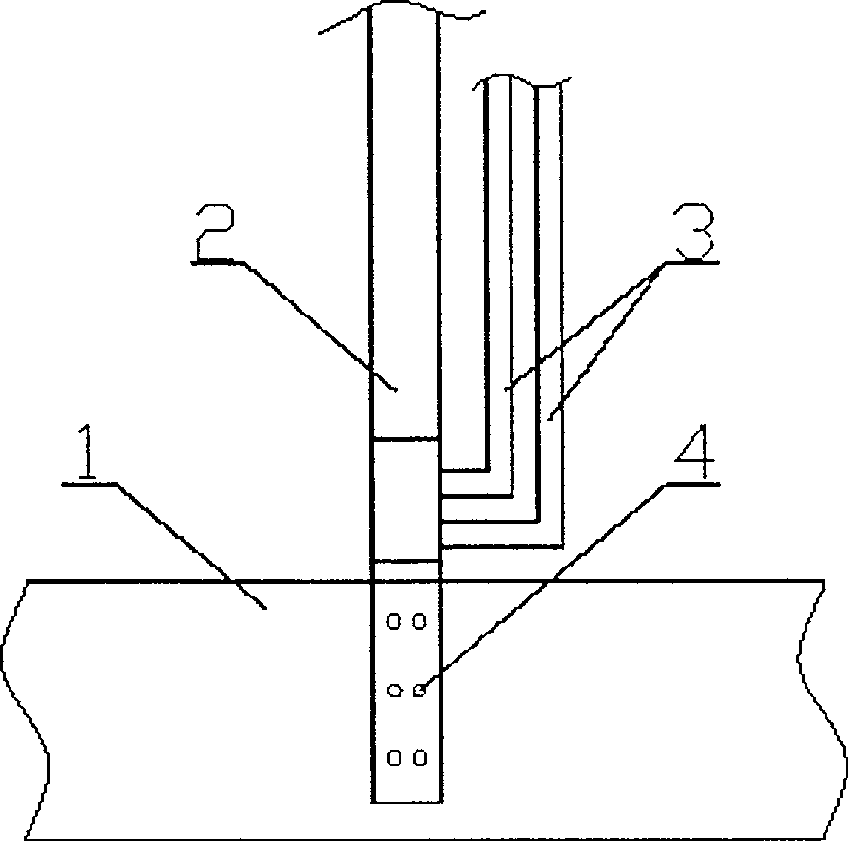

Method and device for adding coagulant in sewage

InactiveCN1970465AImprove coagulant effectExcellent coagulant effectWater/sewage treatment by flocculation/precipitationWater qualityEngineering

The invention discloses a coagulant adding method and device in the effluent, which is characterized by the following: connecting at least one additional pipe on the drug injecting pipe; adding composite element in the additional pipe to improve coagulant efficiency; blending composite element and coagulant into effluent pipe or outlet effluent; possessing optimal coagulating property; avoiding secondary pollution for water.

Owner:SUZHOU INDAL PARK HESHUN ENTERPRISE ENVIRONMENTAL PROTECTION SERVICE

Flocculation adsorption treatment method of waste liquid of nuclear power plant and flocculating agent

ActiveCN102915783BImprove decontamination abilityEfficient removalRadioactive decontaminationLiquid wastePotassium

The invention provides a flocculation adsorption treatment method of waste liquid of a nuclear power plant and a flocculating agent. The flocculation adsorption treatment method includes the steps of adding flocculating agent into the waste liquid of the nuclear power plant, keeping a pH (potential of hydrogen) value within 7-9, performing mixed reaction to obtain colloid flocculation; and subjecting the colloid flocculation to activated carbon adsorption column for adsorption, wherein Fe, Co, Mn and Ag nuclides are absorbed and intercepted by the activated carbon adsorption column. The flocculating agent comprises a component A including NaOH or KOH, a component B which is polyacrylamide, a component C which is sodium polyacrylate or potassium polyacrylate. Coagulation capacity of corrosion product colloids is improved by adding the flocculating agent, and decontamination factor of activated carbon to Fe, Co, Mn, Ag is increased by 5 times. The flocculation adsorption treatment method is stable in eliminating effect, good in repeatability, low in running energy consumption and less in secondary pollution output.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

Desiliconization agent, preparation method and application thereof

ActiveCN112062249BPromotes bridging adsorptionPlay the role of adsorption and flocculationWater/sewage treatment by flocculation/precipitationIron sulfateAluminium sulfate

Owner:神美科技有限公司

Multi-core aluminium-poly (silicon-phosphorus) aluminum chloride and production method thereof

ActiveCN101538081BImprove performanceMass storageWater/sewage treatment by flocculation/precipitationLiquid productAluminium hydroxide

The invention relates to a water treatment agent, in particular to a surface water treatment agent used for drinking water, which adopts multi-core aluminium-poly (silicon-phosphorus) aluminum chloride. The water treatment agent is prepared by taking industrial synthetic hydrochloric acid, aluminium hydroxide, calcium aluminate powder, phosphate rock powder or phosphorus pentoxide, silicon oxide and water as raw materials, and becomes liquid product after liquid residue reparation. As the molecular weight, the quantity of electric charge and the intensity of multi-core aluminium are all larger than those of poly-aluminum chloride, the coagulation property thereof is much better than that of the common poly-aluminum chloride, and the adding amount can be saved by 30 to 50 percent. The water treatment agent has good fluidity, stable performance and long-term storage. As the technology is simple and the cost performance is high, the water treatment agent can be industrially produced in larger scale.

Owner:浙江嘉灵环保科技有限公司

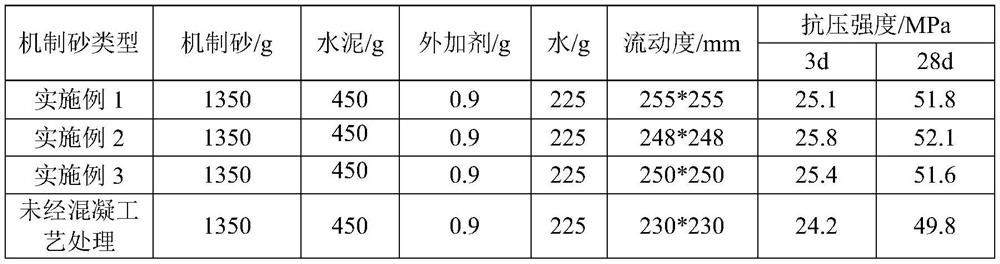

Coagulation process treatment method for machine-made sand cleaning water

ActiveCN112794427AIncrease polarityHigh affinitySolid waste managementWater/sewage treatment by flocculation/precipitationDimethyldiazeneProcess engineering

The invention relates to a coagulation process treatment method for machine-made sand cleaning water. The coagulation process treatment method comprises the following steps that: S1, a coagulant aid is prepared; S2, a cleaning solution is prepared, wherein the cleaning solution comprises an organic coagulant dimethyl diallyl ammonium salt solution and an inorganic coagulant aid polysilicate metal salt solution; S3, mud-water separation is carried out, namely, turbid wastewater generated by cleaning the machine-made sand is collected, the cleaning solution is uniformly added into the turbid wastewater through a material distributor, and large floc particles formed after reaction are fed into a spiral filtering and conveying device to realize rapid solid-liquid separation of the mud-water; and S4, the water is cyclically utilized, namely, the separated water is pumped into a machine-made sand cleaning tank to realize cyclic utilization of the water for cleaning the machine-made sand. The machine-made sand cleaning water is recycled, and the working performance and the mechanical performance of the machine-made sand concrete are improved. According to the coagulation process treatment method for machine-made sand cleaning water, the machine-made sand cleaning water is recycled, and the working performance and the mechanical performance of machine-made sand concrete are improved.

Owner:HUAXIN CEMENT

A flocculant for purifying landscape water and its preparation method

InactiveCN103936118BImprove stabilityEasy to storeWater/sewage treatment by flocculation/precipitationSodium bicarbonateSulfate

The invention provides a flocculant for purifying landscape water and a preparation method of the flocculant. The flocculant is used for improving the quality of landscape water in cities, parks, residential districts and the like, and the flocculant disclosed by the invention is a flocculant PSFZn which is low in preparation raw material, simple in process, safe and efficient. The flocculant is prepared from the following raw materials in percentage by weight: 15-30% of sodium silicate, 1-8% of ferric chloride, 2-4% of zinc sulfate, 10-20% of a dilute hydrochloric acid, 1-10% of sodium bicarbonate and the balance of deionized water, wherein the mass concentration of the dilute hydrochloric acid is 10%, and the silica content of sodium silicate is 21-25%.

Owner:江苏立能环保水处理工程有限公司

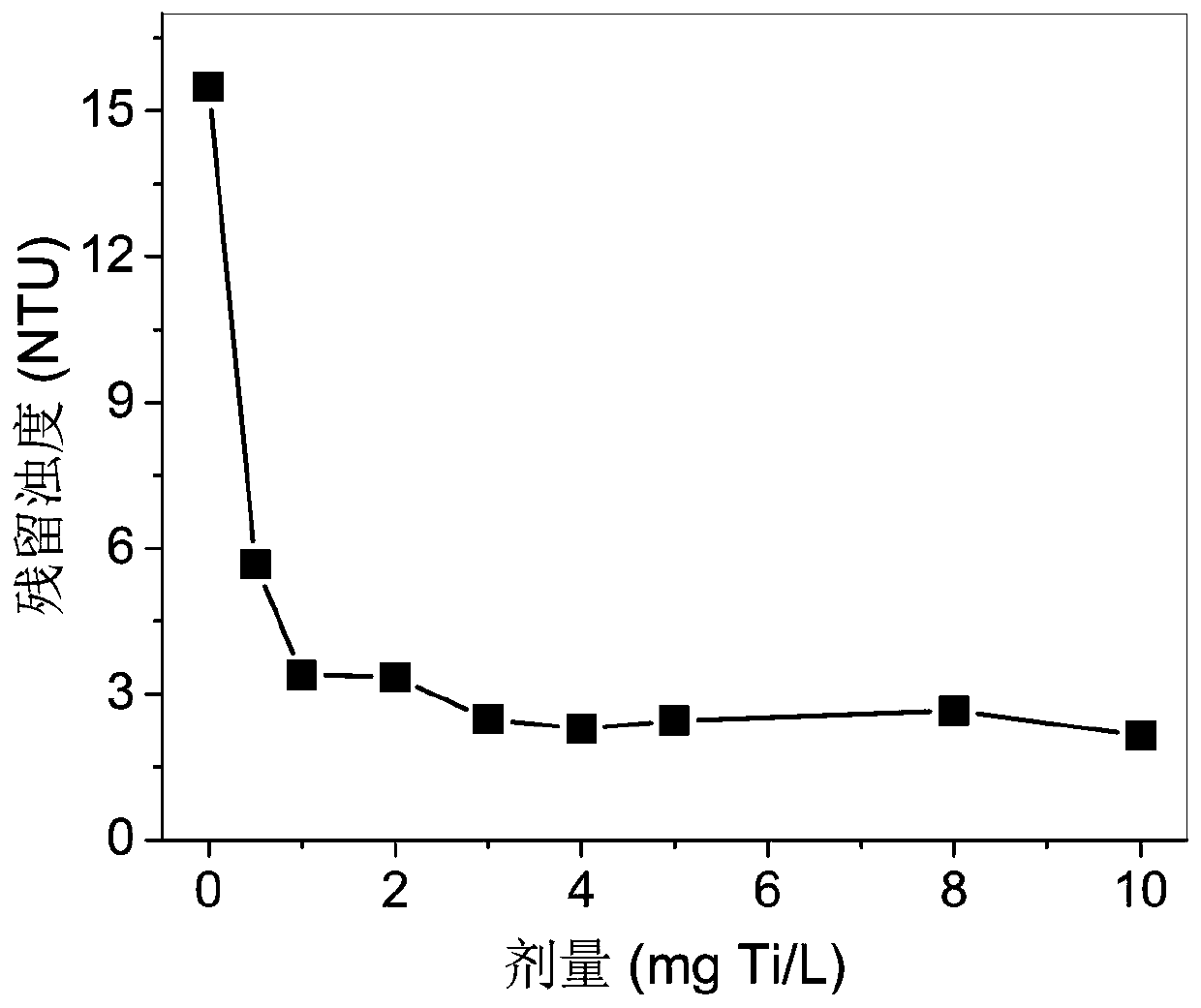

Preparation method and application of flocculant for water treatment

PendingCN113603197AEasy and quick to makeGood repeatabilityWater/sewage treatment by flocculation/precipitationTitanium tetrachlorideSuspended solids

The invention relates to a preparation method and application of a flocculant for water treatment. Raw materials such as titanium tetrachloride, ethanol, acetylacetone, sepiolite, deionized water and acetic acid or hydrochloric acid are blended to obtain a mixed solution A and a mixed solution B according to respective formulas; the obtained mixed solution B is dropwise added into the mixed solution A at a dropwise adding rate of 1 mL / min, and stirring is conducted at a rate of 500 rpm / min to obtain a mixed solution C; and the mixed solution C is dried until the weight does not change any more to obtain the composite flocculant. The flocculant has good turbidity removal and pollutant reduction effects in flocculation treatment of a water body, and can realize rapid destabilization and coagulation of suspended solids in the water body and improve the transparency of the water body. The flocculant can be widely applied to turbidity removal and pollutant removal in feed water and wastewater, and is simple and rapid to prepare, good in repeatability, easy to produce in a quantitative manner, excellent in coagulation performance, low in residual metal content and good in precipitation performance.

Owner:中科智感(南京)环境科技有限公司 +1

A kind of synthetic method of polyferric sulfate and polyferric sulfate

ActiveCN112694136BImprove coagulation performanceImprove water purification effectIron sulfatesWater/sewage treatment by flocculation/precipitationIron sulfateFerrous sulfate iron

Owner:杭州金丰环保科技有限公司

Contains nano fe(oh) 3 Preparation method of grafted acrylamide copolymer flocculant

InactiveCN105218758BWill not cause secondary pollutionHigh molecular weightWater/sewage treatment by flocculation/precipitationPotassium persulfateReaction temperature

The invention discloses a preparation method of a nano-Fe(OH)3-containing acrylamide-grafted copolymer flocculant. The method is characterized in that 100 mL of a 100 g / L FeCl3 ethylene glycol solution is added to a three-neck reaction flask, 90-300 ml of a 40 g / L NaOH ethylene glycol solution is slowly added in the stirring state, the mixture reacts at the reaction temperature of 120-160 DEG C for 2-4 h in the rapid stirring state and then the product after reaction is cooled to the room temperature, reaction products are centrifugally separated and washed with deionized water, and nano-Fe(OH)3 is prepared; 20 parts of acrylamide are added to the three-neck reaction flask, then 150-600 parts of deionized water and 1.0-12 parts of trimethyl hexadecyl ammonium chloride are added, the mixture is stirred, 0.5-8 parts of the nano-Fe(OH)3 are added in the stirring state, 8-40 parts of cationic monomers and 0.8-10 parts of macromonomers are added, the mixture is stirred for 30 min, the pH value is 5-8, N2 is introduced for 30 min, 0.02-0.6 parts of an initiator, namely, potassium persulfate, is added at the temperature of 50-75 DEG C, the mixture reacts for 8-24 h, and the nano-Fe(OH)3-containing acrylamide-grafted copolymer flocculant Fe(OH)3-PAMB with excellent coagulation performance is prepared.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Intelligent water changing device for aquarium

InactiveCN113880294AImprove experienceImprove practicalityWater treatment parameter controlSpecific water treatment objectivesBiologyMechanical engineering

The invention discloses an intelligent water changing device for an aquarium, wherein the intelligent water changing device comprises a transverse plate; the left side of the top of the transverse plate is fixedly connected with a sediment box, the right side of the top of the transverse plate is fixedly connected with a filter box, the bottom of the transverse plate is fixedly connected with a sterilization box, and the bottom of the right side of the sediment box communicates with a first water conveying pipe; and one end of the first water conveying pipe communicates with a first one-way valve, the bottom of the first water conveying pipe communicates with the top of the transverse plate, and the top of the left side of the sediment box is fixedly connected with a first water pump. According to the intelligent water changing device for the aquarium, the purposes of circulating purification, energy conservation and environmental protection are achieved, water can be circularly purified and reused, and thus the intelligent water changing device for the aquarium conforms to the time trend of energy conservation and environmental protection, the experience feeling of a user on the intelligent water changing device for the aquarium is improved, the current market requirement is met, the practicability and usability of the intelligent water changing device for the aquarium are improved, and the problem that an existing aquarium intelligent water changing device is poor in using effect is solved.

Owner:南京奕巴巴智能科技有限公司

A method for removing heteroatoms in coal tar

ActiveCN107739627BReduced stabilityImprove removal effectTar working-up by chemical refiningDemulsifierPhysical chemistry

Owner:NORTHWEST UNIV

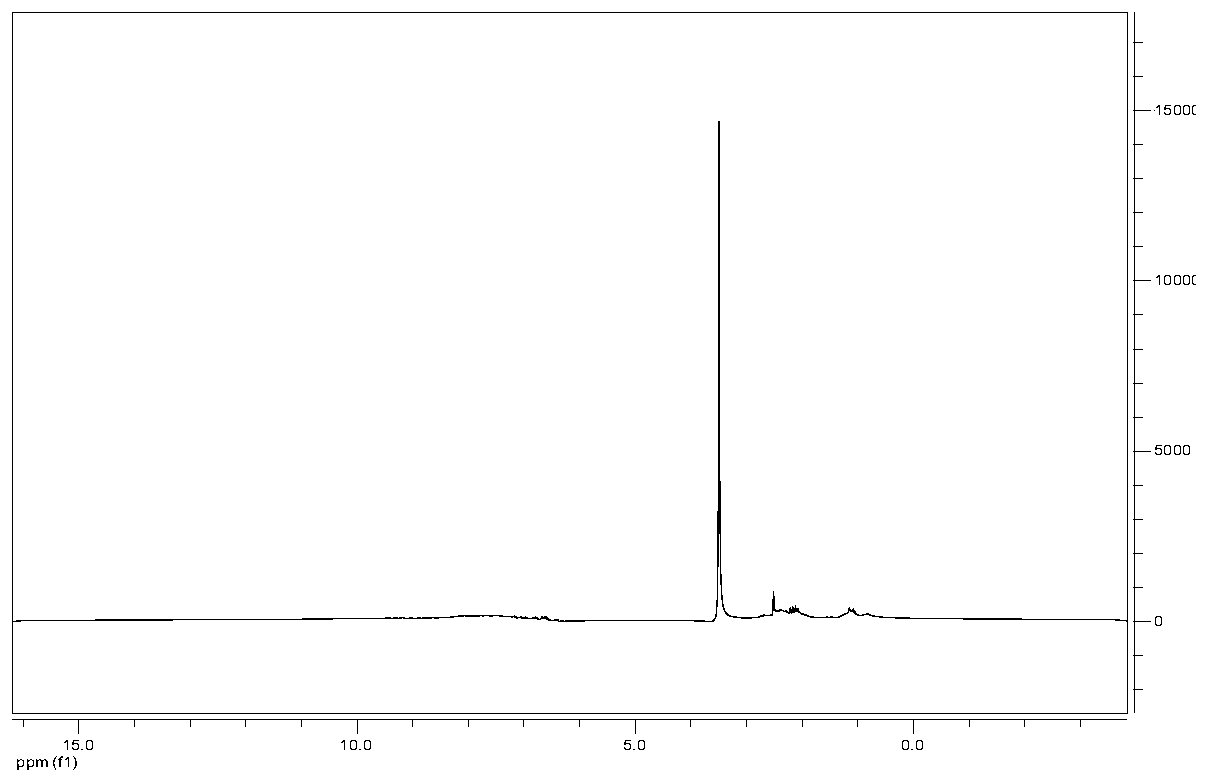

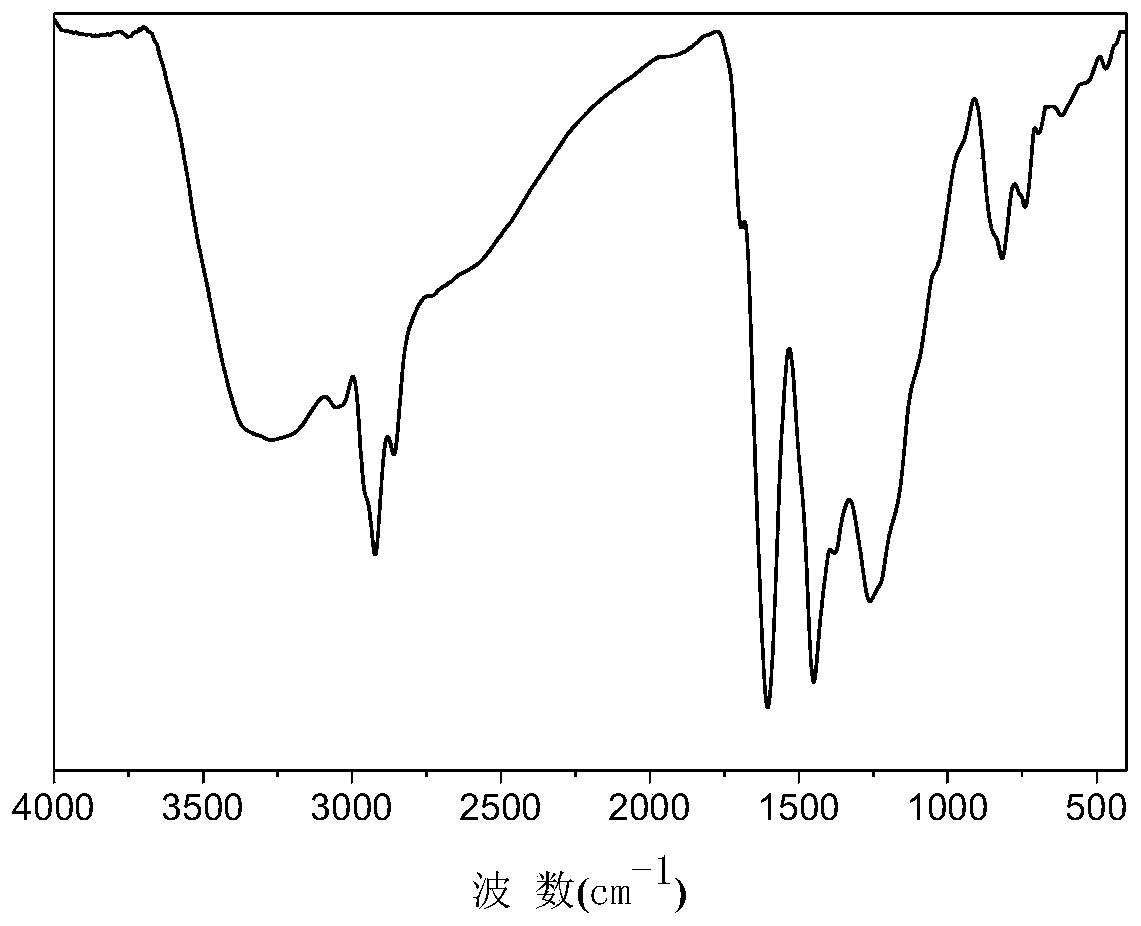

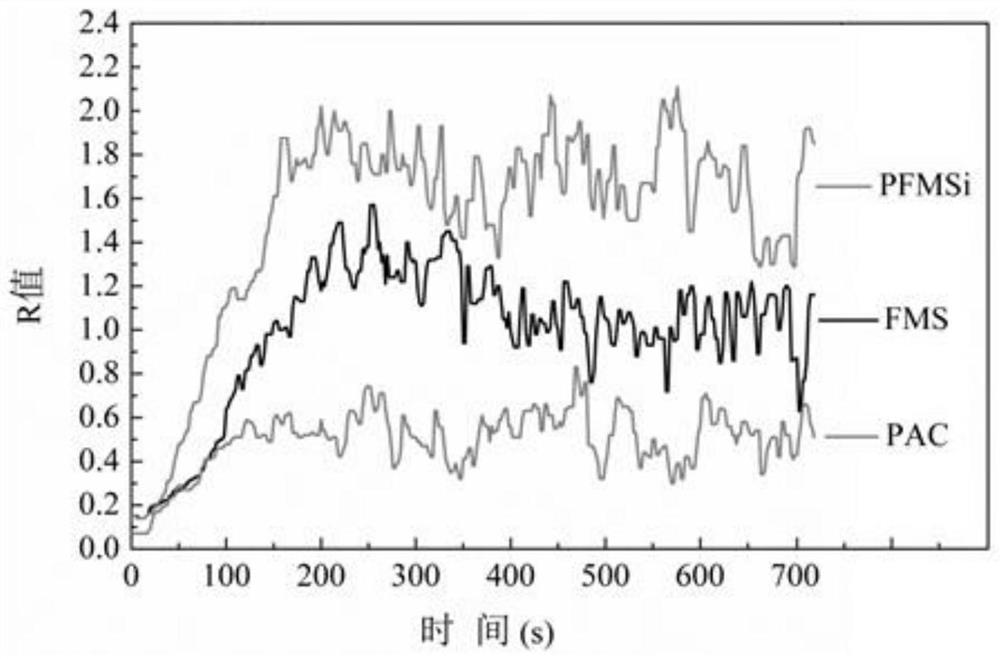

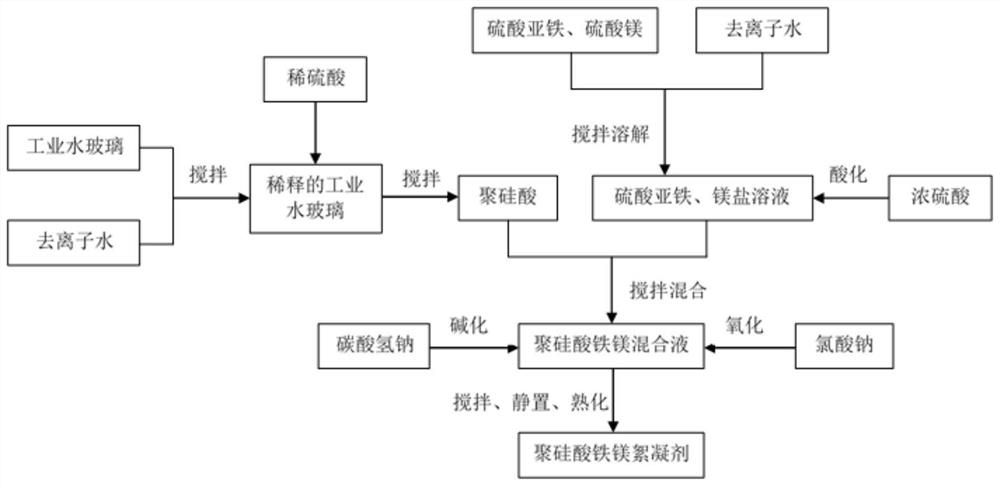

Novel polysilicate ferric magnesium flocculant

PendingCN114506913AHigh removal rateImprove adsorption capacityEnergy based wastewater treatmentWater/sewage treatment by flocculation/precipitationSodium bicarbonateFerrous salts

A preparation method of the novel polysilicate ferric magnesium flocculant comprises the following steps: diluting industrial water glass with deionized water, adding the diluted industrial water glass into dilute sulphuric acid with a certain concentration, and preparing polysilicic acid under the condition of rapid stirring; dissolving ferrous salt and magnesium salt in deionized water, adding concentrated sulfuric acid to obtain a ferrous salt and magnesium salt acidified solution, adding the ferrous salt and magnesium salt acidified solution into rapidly stirred polysilicic acid, and adding an oxidizing agent to completely oxidize ferrous ions into ferric ions; adding a certain amount of sodium bicarbonate solution, hydrolyzing ferric ions and magnesium ions, and polymerizing the hydrolyzed ferric ions and magnesium ions with polysilicic acid; and finally, standing and curing for a certain time at room temperature to obtain the polysilicate ferric magnesium flocculant. Compared with the prior art, the flocculating agent has the advantages that the operation is simple, the cost is low, the flocculating agent adsorption bridging and net repairing and sweeping capabilities are improved, the formed floc is larger and denser, the sedimentation rate is high, the turbidity, chromaticity and organic matter removal rate are high, and the coagulation performance is superior to that of a conventional flocculating agent in the market.

Owner:江西省水利科学院

Method and device for adding coagulant in sewage

InactiveCN100500587CImprove coagulant effectExcellent coagulant effectWater/sewage treatment by flocculation/precipitationSewageSanitary sewer

The invention discloses a coagulant adding method and device in the effluent, which is characterized by the following: connecting at least one additional pipe on the drug injecting pipe; adding composite element in the additional pipe to improve coagulant efficiency; blending composite element and coagulant into effluent pipe or outlet effluent; possessing optimal coagulating property; avoiding secondary pollution for water.

Owner:SUZHOU INDAL PARK HESHUN ENTERPRISE ENVIRONMENTAL PROTECTION SERVICE

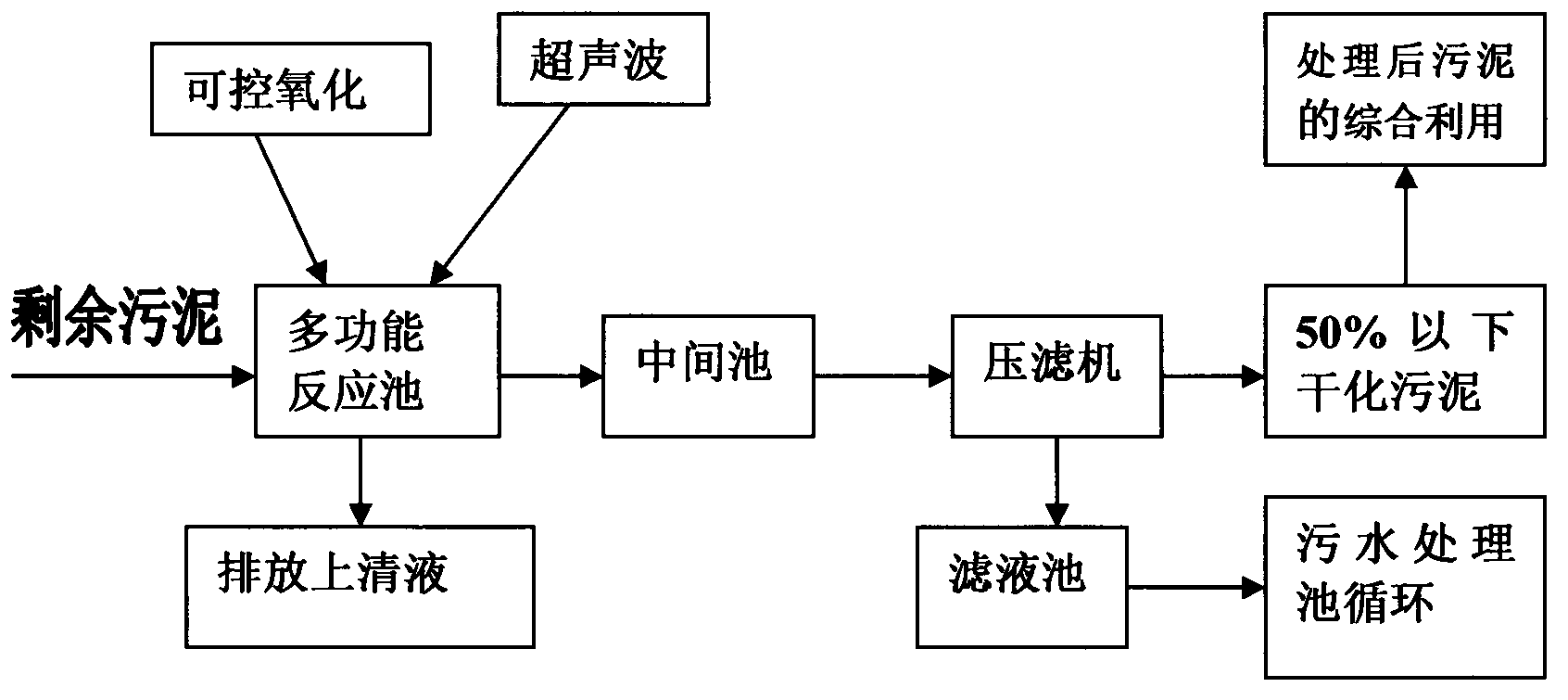

Immobilized catalyst for deep sludge treatment

InactiveCN103721728ALow costImprove oxidation effectSludge treatment by de-watering/drying/thickeningPhysical/chemical process catalystsWater contentChemistry

The invention discloses an immobilized catalyst for deep sludge treatment. The immobilized catalyst consists of FeCl<3>, titanium dioxide, coal ash and kieselguhr. The invention further discloses a method for deep treatment on sludge by using the immobilized catalyst. Through the adoption of the method, the water content of the sludge can be controlled to be less than 50%, the cost is low, the effect is good, and the treated sludge can meet the national standard.

Owner:何小东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com