Preparation method and application of flocculant for water treatment

A flocculant and water body technology, which is applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of high production cost of titanium salt flocculants and the inability to use them in large quantities in production and life, and achieve Easy to quantify production, excellent coagulation performance, simple and quick preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

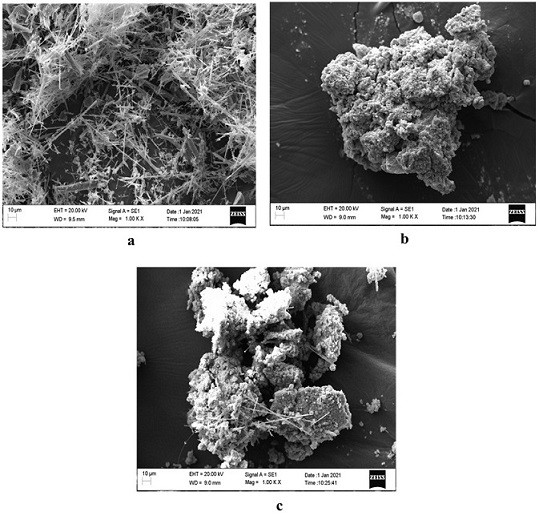

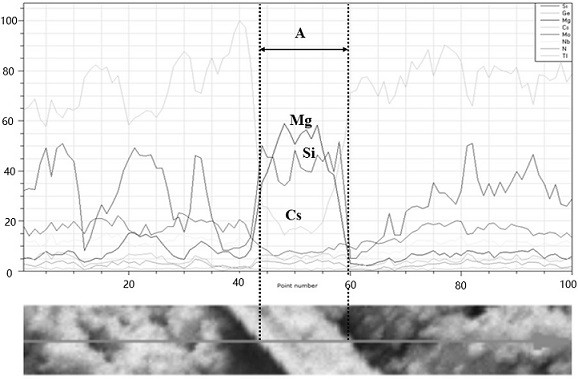

[0034] Preparation of composite flocculant: first prepare titanium tetrachloride solution, ethanol and acetylacetone mixed solution, take 1kg of titanium tetrachloride with a solution volume ratio of 99%, 1.6kg of ethanol with a solution volume ratio of 95%; the solution volume ratio is 99.5 % acetic acid 0.09kg, stirred at a rate of 500rpm / min for 30min to obtain a mixed solution A. Get solution volume ratio and be 95% ethanol 1kg, sepiolite 0.1kg, resistivity 18.25MΩ deionized water 0.5kg, solution volume ratio is 99.5% acetic acid or solution volume ratio 36%-38% hydrochloric acid 0.2kg , mix ethanol, sepiolite, deionized water, and acetic acid evenly to obtain a mixed solution B. Mixed solution B was dropped into mixed solution A, and then stirred at a rate of 500 rpm / min for 90 min to obtain mixed solution C. Dry the mixed solution C at 70-80°C to constant weight to obtain the natural clay composite flocculant, namely TXC-SE.

[0035] The product of titanium tetrachlori...

Embodiment 2

[0039] (1) Preparation of simulated experiment water sample: the humic acid-kaolin mixed water sample was used as the simulated water sample for the experiment, and was prepared according to the following method: First, weigh 1 g of humic acid, set the volume to 1 L, and configure the concentration to be 1g / l humic acid stock solution. Accurately weigh 5g of kaolin, add appropriate amount of deionized water and 50ml of humic acid stock solution in sequence, and dilute to 1L to obtain humic acid-kaolin simulated water sample. The initial water quality indicators of the simulated water samples are as follows: turbidity=40±0.5NTU, UV254=0.2±0.01cm-1, pH=7.85-8.24.

[0040] (2) Flocculation experiment procedure: put six beakers containing 1L of experimental water samples on the stirrer, add a known amount of flocculant, stir rapidly at 250rpm / min for 5min; then change the stirring speed to 50rpm / min, After continuing to stir for 15 minutes, let stand for 30 minutes. Samples were...

experiment example 2

[0045] Experimental example 2 result analysis:

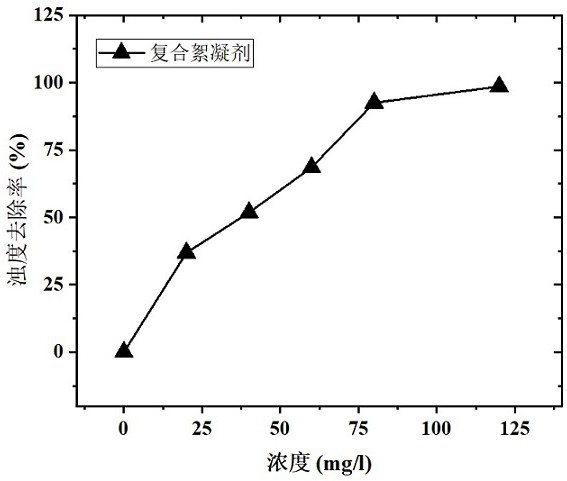

[0046] Adopt turbidimeter, ultraviolet spectrophotometer and portable hand-held pH meter to detect the various indicators of the water sample after adding different flocculant treatment in embodiment 2, the flocculation effect sees image 3 , Figure 4 and Figure 5 shown.

[0047] Depend on image 3 , Figure 4 and Figure 5 It can be seen that under the same dosage of flocculant, the composite flocculant prepared according to the method of the present application has the best effect of removing turbidity and reducing organic matter, and the pH value of the effluent is stable. The removal rate of turbidity is as high as 98.52%, and the removal rate of UV254 is as high as 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com